Page 1

● Thank you for purchasing “Constant Temperature

Precision Oven DF832/1032 and DH832/1032” of

Yamato Scientific Co., Ltd.

● This product has not been designed for medical

applications. Use this as a laboratory drying

sterilizer only.

● In order to use this Equipment properly, please read

this Instruction Manual and Warranty Card

thoroughly before use. Keep them in safe place

close to this Equipment so that you can refer to

them any time.

Warning: Please read the important warning

notes in this Manual carefully and

thoroughly, and get the good

understanding of their contents

before using this Equipment.

Constant Temperature Precision Oven

(Fine Oven)

DF832/1032

DH832/1032

Instruction Manual

First Edition

Yamato Scientific Co., Ltd.

Printed on recycled paper

Page 2

Contents

1. Safety Precautions ................................................................ 1

Explanation of symbols .................................................................1

List of symbols .........................................................................2

Warning and Cautions ..................................................................3

2. Before operating the Equipment .................................................... 4

Precautions when installing the Equipment ................................................4

3. Names and functions of each part .................................................. 7

Main unit ..............................................................................7

Control Panel ..........................................................................8

4. Operating procedure .............................................................. 9

Prior confirmation ......................................................................9

Date & Time setting ...................................................................10

Buzzer function selection ...............................................................11

Fixed temperature operation ............................................................13

Auto stop operation....................................................................17

Auto start operation ...................................................................20

Using and setting of the variable wind speed function ......................................23

Program operation ....................................................................25

How to copy or delete programs .........................................................35

About the wait function .................................................................37

Setting key lock mode .................................................................38

Calibration offset ......................................................................39

Setting the recovery mode ..............................................................40

Resetting integrated CO2 volume and CO2 emission factor .................................41

Backup data saving / reading out / resetting...............................................43

Monitoring data .......................................................................44

Independent Overheat Prevention Device ................................................46

5. Handling precautions ............................................................ 47

Warning ............................................................................47

Caution .............................................................................48

6. Maintenance method ............................................................. 53

Daily inspection/maintenance ...........................................................53

7. Long storage and scrap .......................................................... 54

When not using the Equipment for a long time / when scrapping ...................................54

Matters to consider when scrapping the Equipment ........................................54

8. When a trouble occurs ........................................................... 55

Message error table ...................................................................55

Troubleshooting ......................................................................57

9. After sales service and warranty .................................................. 58

Request to repair parts .................................................................58

10. Specifications .................................................................. 59

Page 3

Specifications ........................................................................59

12. Wiring diagram ................................................................. 61

DF/DH832 Wiring diagram ............................................................61

DF/DH1032 wiring diagram ..........................................................62

Wiring diagram part symbols ............................................................63

13. List of dangerous substances .................................................... 64

Page 4

1

About symbols

Various symbols are provided in this Instruction Manual and on the

product to ensure safe operation. Improper handling of this Equipment

without understanding their contents will lead to the results classified

below. Be sure to fully understand the description of symbols below

before proceeding to the text of this Manual.

Warning

Caution

Indicates a situation which may result in minor injury (Note 2)

and property damages (Note 3.)

( Note 1) Serious injury means a wound, an electrical shock, a bone fracture or

intoxication that may leave after effects or require hospitalization or

outpatient visits for a long time

( Note 2) Minor injury means a wound or an electrical shock that does not require

hospitalization or outpatient visits for a long time.

( Note 3) Property damage means damage to facilities, devices and buildings or other

properties.

Meanings of symbols

This symbol indicates a matter urging user to follow the warning

(“caution” included).

Specific description of warning is indicated near this symbol.

This symbol indicates prohibitions.

Specific prohibition is indicated near this symbol.

This symbol indicates matters that the user must perform.

Specific instruction is indicated near this symbol.

Indicates a situation which may result in death

or serious injury (Note 1.)

1. Safety Precautions

Explanation of symbols

Page 5

General

Warnings

Danger!: High

Voltage

Danger!: High

Temperature

Danger!: Moving

Part

Danger!:

Explosion Hazard

General Cautions

Caution:

Electrical Shock!

Caution: Burns!

Caution: Heating

Container without

water!

Caution: Water

Leak!

Caution: For

water only

Caution: Toxic

Chemicals

General

Prohibited

Actions

No open flame

Do not

disassemble

Do not touch

General

Mandatory

Actions

Connect

grounding wire

Leveled

Installation

Disconnect Power

Regular

Inspection

Warning

Caution

1. Safety Precautions

List of symbols

Prohibitions

Compulsions

2

Page 6

Warning

Never operate the Equipment in an atmosphere where flammable or explosive gas is

present.

Never operate this Equipment in an atmosphere where flammable or explosive gas is

present.

This Equipment is not explosion-proof. It will cause fire/explosion. (Refer to “Chapter 13. List

of Dangerous Substances” on P.64).

Ground always the Equipment.

Ground always this Equipment properly in order to avoid electric shock due to electrical

leakage.

Turn the power of the controller and the ELB off immediately when you notice any

abnormality.

Turn the power of the controller and the ELB off immediately and unplug Power Cord from

outlet or disconnect the breaker of switch board of facilities, If smoke or strange smell is

generated from this Equipment by chance. It may cause fire or electrical shock.

Do not operate at Power Cord/Power Cable bundled state.

Do not operate at Power Cord/Power Cable bundled state. If it is operated in such a manner,

it will overheat, and then cause fire.

Do not damage Power Cord/Power Cable.

Do not damage Power Cord/Power Cable by bending, pulling, or twisting with force. It may

cause fire or electric shock.

Never use an explosive or a combustible substance.

Never use an explosive or a combustible substance or any substances that contain such a

substance. Otherwise an explosion or a fire may result.

Never disassemble nor modify the Equipment.

Never disassemble nor modify this Equipment. Those actions may cause malfunction, fire

or electric shock.

Never touch high temperature sections.

Never touch high temperature sections. Some sections of this Equipment are heated during

and right after operation. Watch out for getting burned.

Caution

Turn immediately the power of the controller and the ELB off at thundering.

Turn immediately the power of the controller and the ELB off at thundering. If not, it may

cause fire or electric shock.

1. Safety Precautions

Warning and Cautions

3

Page 7

Do not install this Equipment in the place where:

・the location is rough, dirty or un-leveled.

・flammable gas, explosive gas or corrosive gas will be generated.

・ambient temperature will be more than 35℃ or less than 5℃.

・ambient temperature will fluctuate. ・Liquid may splash

・there is excessive humidity and dusty. ・there is direct sunlight.

・there is constant vibration. ・outside the building.

・power supply is instable.

Install the Equipment(s) at the place with sufficient space as specified as below.

There is an exhaust port on the back of the unit. When an exhaust duct is not installed on the

premises, take care to assure sufficient space on the rear side and for flammable substances.

When you are going to operate the unit with ventilation (with the damper open), take

appropriate measures to assure sufficient ventilation around the installation site. Insufficient

ventilation around the unit may cause rise in the temperature of the room from hot air from the

exhaust port or allow smoke or gas from specimen to fill the room. Be sure to connect an

exhaust duct to the exhaust port so that hot air will be discharged outside.

Install this Equipment on leveled floor. If it is installed on rough and/or slope floor, vibration or

noise will be occurred, and unexpected trouble and malfunction may be happened.

Weight of this Equipment is as follows:

DF/DH832:approx. 320㎏ DF/DH1032:approx.420kg ( Do not include a shelf board)

Handle this Equipment carefully by Four people at least at the transportation and the installation

1m 以上

60㎝以上 60㎝以上

1m 以上

Min 60cm

Min 60cm

Min1m

Min1m

2. Before operating the Equipment

1. Choose proper place for installation

Precautions when installing the Equipment

2. When operating with ventilation

3. Install the Equipment on leveled location.

4

Page 8

May be injured by moved and/or fallen this Equipment down by earthquake and/or unexpected

impact. Recommend to install this Equipment at the place away from the access door and to take

other safety steps.

May be injured by moved and/or fallen this Equipment down by earthquake and/or unexpected

impact.

Implement appropriate measures against falling down for safety.

Do not operate the Equipment blocked in the radiating slit holes-Louver on its side and back

panels and top panel. Refer to 3. “Name and Functions of each part” on page 8 for the location

of Louvers.

Internal temperature will rise, causing a malfunction of the controller to compromise the

performance as well as to cause a possible accident or a fire.

Do not operate this Equipment at the location of liquid splashing. If Controller of this Equipment

will be wetted by splashing any kind of liquid, it may cause accident, controller malfunction,

electrical shock and/or fire.

Never operate this Equipment in an atmosphere where flammable or explosive gas is present.

This Equipment is not explosion-proof. Spark may be discharged by switching Earth Leakage

Breaker (ELB) “ON(|)” and “OFF(○)” and also relay during operation, and then it may cause

fire or explosion. See Chapter 13. “List of Dangerous Substances” for flammable and explosive

gases on page .64

Connect Power Cord/Power Cable to suitable receptacle/switch board of facilities according to

electrical requirements as follows.

Electrical

requirements:

DF832 AC220V 3 phase 50/60Hz 13.5A or more (ELB capacity;20A)

DF1032 AC220V 3 phase 50/60Hz 17A or more(ELB capacity;30A)

DH832 AC220V 3 phase 50/60Hz 20A or more(ELB capacity;30A)

DH1032 AC220V 3 phase 50/60Hz 28Av(ELB capacity;40A)

The operational voltage range is ±10%, the voltage range where the specified performance is

guaranteed is rating±5%, the frequency is rating±1%.

※ Check line voltage of its receptacle/switch board of facilities and/or whether utilize the same

line with other equipments or not, if this Equipment does not start up/operate even to turn

Earth Leakage Breaker(ELB) On(|). Take correct action for the solution, such as changing

its power source away from other equipment.

These models are designed to operate at 3-phase AC200V. Ask your dealer or an electrical

technician for connection work of the power cord.

Connection requires professional knowledge and skills. A fire or an electrical shock may result if

an unqualified person performs this work.

Wire Color

Facility Supply

Red

Phase R

White

Phase S

Black

Phase T

Green

Ground

G

2. Before operating the Equipment

Precautions when installing the Equipment

4. Implement safety measures when installing the unit.

5. Implement appropriate safety measures after installation.

6. Ventilate sufficiently for the Equipment

7. Do not operate at the location of liquid splashing.

8. Never operate in an atmosphere where flammable or explosive gas is present.

9. Connect Power Cord/Power Cable to receptacle or switch board of facilities.

10. Take care when connecting the power cord.

5

Page 9

・ Require to ground by Electrical Equipment Technical Standards Section 19-calss

D(Grounding Resistance Max. 100Ω) in Japan, if grounding terminal is not provided. Please

contact with local dealer, local electrician, or Yamato Customer Service Center.

・ Connect the terminals firmly to switch board of facilities or appropriate power plug.

・ Power plug itself will not be included as an accessory of this Equipment. Connect to the

power supply facilities that meet the electric capacity.

Wire Color

Facility Supply

Red

Phase R

White

Phase S

Black

Phase T

Green

Ground

Never connect grounding wire to gas line pipe, water line pipe or telephone grounding wire due

to fire or electric shock.

Never operate this Equipment at bundled Power Cord/Power Cable. May heat its Cord/Cable and

then cause fire, if operate at bundled it.

Do not modify, bend forcibly, twist or pull Power Cord/Power Cable. Otherwise, may cause fire

and/or electrical shock.

Do not damage Power Cord/Power Cable by setting under any desk and/or chairs, or by pinching

it between objects. Otherwise, may cause fire and/or electrical shock.

Do not place Power Cord/Power Cable close to kerosene heater, electric heater, or other heatgenerating devices.

Insulation of Power Cord/Power Cable may burn and cause fire or electrical shock.

Turn immediately off Earth Leakage Breaker (ELB) and also disconnect Power Plug/breaker of

switch board of facilities, if it is damaged such as exposure of core wire or disconnection.

May cause fire or electrical shock, if this Equipment is operated with damaged Power Cord/Power

Cable.

Ask local dealer to replace Power Cord/Power Cable.

Connect Power Cord/Power Cable to appropriate receptacle or switch board of facilities.

Never disassemble nor modify this Equipment. Those actions may cause this Equipment

malfunction, fire or electric shock.

Set shelf pegs to places you want in the chamber before using the unit for the first time.

A heater is installed below the bottom plate inside the bath and the plate temperature is higher

than the set temperature. Therefore, placing a specimen directly on the bottom in the bath may

damage it or may cause an accident from a high temperature.

Never attempt to place specimens directly on the bottom in the bath. Otherwise air blow

circulation may be disturbed making proper temperature control hard resulting in burning of the

specimen or a fire from a temperature error.

G

2. Before operating the Equipment

Precautions when installing the Equipment

11. Must connect grounding wire properly.

12. Handle Power Cord/Power Cable carefully.

13. Never disassembly nor modify the Equipment.

14. Installation of shelf boards and samples (Do not put samples directly on the

bottom of the chamber.)

6

Page 10

Control panel

Handle

Door

Exhaust damper

Cable port

Exhaust port

Circuit

breaker

3. Names and functions of each part

Main unit

7

Page 11

No

Name

Description

1

Top screen

Display read temperature in Chamber and error numbers.

2

Bottom screen

Display target temperature and various information.

3

Program setting item display

Illuminate one of lamps selected from different settings.

4

Comes on during

duration/time setting and in

the Monitoring mode

Illuminate one of lamps selected from 3(three) different settings.

5

REMOTE Lamp

Illuminate during control via communication

6

ERROR Lamp

Illuminate this Lamp at each error occurred.

7

OPERATE Lamp

lluminate this Lamp during oepration, and flash it during operation standby

mode.

8

HEATER Lamp

Flashes or lights while the heater is live according to the operation amount.

9

EVENT Lamp

lluminate this Lamp at Event Output setting(option).

10

FIXED TEMP Lamp

lluminate while the fixed temperature operation mode is selected.

11

PROGRAM Lamp

lluminate in the Program operation mode.

12

AUTO START Lamp

lluminate in the Auto start mode.

13

AUTO STOP Lamp

lluminate in the Auto stop mode.

14

MODE key

Use at changing Operation Mode among No. 10 thru. No.13(⑩~⑬ on the

Panel).

15

Controller POWER key

Turn “Idle State”-(Controller is sleeping) or “Standby State”-(Controller is

awaking) of Keys(except ⑱MENU Key) by pressing and holding this key.

16

DISP key

Keep this key pressed longer to execute the Monitoring function.

This key functions as the back key for setting items while any of setting

menusis displayed.

17

START/STOP key

Use to start sellected operation or to stop working operation.

18

MENU key

Use to set target program, click on/off, output temperature range(option), and

etc.

19

Esc key

Use to abort or get out of working menu without entering and/or editing set

value and items.

20

▲(Up) key

Use to change set value up.

21

▼(Down) key

Use to change set value down.

22

key

Used as the Left key for the setting digits (cursor) during setting.

23

ENTER key

Use to enter set value and items.

▼

3. Names and functions of each part

Control Panel

8

Page 12

Make sure to connect with this Equipment Power Cord/Power Cable to appropriate power source

and to ground definitely.

Check if the ELB functions properly.

See “Maintenance method” on P.54 Chapter 6.

Check ELB performance once a month or before continuous long-term operation.

Tick current time on Bottom Screen of Control Panel at ELB ON(|).

Make sure to set IOPD temperature more than 20℃ higher of Target Temperature in Chamber.

Check IOPD performance before continuous long-term operation. Refer to “Independent

Overheat Prevention Device” on page 46.

Check that the damper openness is set correctly. Close the exhaust damper if you do not require

ventilation.

4. Operating procedure

1. Check the power supply and the ground wire.

2. Check the ELB.

3. Check the Independent Overheat Preventive device.

4. Check the openness of the exhaust damper.

Prior confirmation

9

Page 13

The controller of this product keeps backup memory for customer settings including the calendar,

timer settings, or operation programs using the built-in battery. This battery will hold data for about

five years even if you turn power of the unit off. (Battery life will change depending on specific

operating conditions.)

※ Contact with Yamato local dealer or Yamato Customer Service Center in case of replacing this

battery. Make backup data file of the existing program data in case of being processed program

mode. See “Backup data saving/reading out/resetting” on page 43.

Set up date & time properly in accordance with local time after replacing with new battery.

1

Turn on power.

Turn on(|) Earth Leakage Breaker(ELB) on the right

side of this Equipment.

Bottom Screen of the controller indicate clock time.

This is “Idle State” of this Equipment.

Press and hold key to display standby screen.

This is “Standby State” of this Equipment.

Indicate read temperature in Chamber on Top Screen and

indicate target temperature on Bottom Screen.

The fan motor will start.

The fan motor operates when the door is open and it stops

when you open the door.

2

Display year/month/date and time

on each Screen by MENU key.

① Press key.

②

Press key few times until [

FUNC]

is indicated on

Bottom Screen and then press key.

③ Press key to display year on Top Screen and

month/date/time on Bottom Screen, When Bottom

Screen show [BUZZ].

The key can be used to reverse the process.

4. Operating procedure

Date & Time setting

10

Page 14

3

Set up year and month/date.

Set up year/month/date and clock time.

①

Flash CLOCK lamp. Year and month/date are displayed

on Top and Bottom Screen respectively.

②

Press key.

③

Set calendar year with keys and then press

key.

④

Set month/date with keys and then press

key.

※

Press key to shift setting position.

4

Set up clock time (described

according to 24-hour time).

①

Press key.

②

Press key, set clock time with keys, and

then press key.

Enter clock time in accordance with 24-hour time.

※Press key to shift setting position.

③

Press key twice to get back to initial screen after

completion of those settings.

1

Select buzzer function.

①

Press key and key to display [bUZZ] on

Bottom Screen with same process of clock time setting

described in [2], and then press key.

②

Select one from three types of buzzer function with

keys and then press key.

ON

: Activate clicking sound for all keys and beeping

sound for alarm. (Set “on” initially at Factory

shipment)

: Activate only clicking sound for "Controller

POWER key and ENTER key", and beeping sound

for alarm.

OFF

: Deactivate clicking sound for all keys.

※ The buzzer will sound when an error occurs even if

you set “bUZZ” to a setting other than ON.

③

Press key twice to get back to initial screen after

completion of those settings.

4. Operating procedure

Date & Time setting

Buzzer function selection

11

Page 15

FIX TEMP

FIX TEMP

FIX TEMP

PROGRAM

PROGRAM

AUTO START

AUTO START

AUTO STOP

Earth Leakage

Breaker

(ELB)

Press and hold

Setting target temp

Waiting time to start [TIME]

Starting time [CLOCK]

Running time [TIME] *

End time [CLOCK]

Selecting program

Waiting time to start [TIME]

Starting time [CLOCK]

CLOCK

Setting clock time

TIME

CLOCK

Setting time

Selecting PROGRAM

Setting target temp.

Setting clock time

Setting time

To stop

To cancel

To check setting time (clock

time) during operation

To check program content

during operation

Timer starts time counting once

the read temperature reached to

the target temperature.

[PRoG]

flashing.

Inputting program

patarn.

Setting target temp.

Setting time

Programming

method

Setting repeat function

Setting repeat count

Setting wait function

Setting END

Setting END: for OFF

Setting END: for ON

Press and hold

[PRoG] END.

Variable wind speed input

TIME

4. Operating procedure

Operating procedure

*

12

Page 16

FIXED TEMP(Fixed Temperature) mode is to keep running at target temperature. It will keep

running until operation stops.

SV: Set Value (Target Temperature), t:Time

Set Fixed Temperature mode.

1

Turn on the controller.

Turn on Earth Leakage Breaker(ELB) on(|) the left

side wall of this Equipment. (Idle State)

Press and hold key to turn on the controller power.

(Standby State)

Indicate read temperature in Chamber on Top Screen

and indicate target temperature on Bottom Screen.

The fan motor will start.

The fan motor operates when the door is closed and

stops while the door is open.

2

Select Fixed Temperature

Operation.

Press key to turn FIXED TEMP (Fixed

Temperature mode) lamp on.

※ Fixed Temperature mode would be selected at first

time operation. After that, most latest operated mode

is selected.

3

Set target temperature.

①

Press key. Then flash changeable digits on

Bottom Screen.

②

Shift to flashing digit with key and then

change to desired digit with keys.

Operating Temperature Range

:0~210℃(

DF832/1032)

0~310℃

(

DH832/1032)

③

Press key when target temperature setting

has completed.

Press key once or twice to cancel its setting.

▲

Start operation (manually)

SV

t

▲

Stop operation (manually)

4. Operating procedure

Fixed temperature operation

13

Page 17

4

Starting operation

Use the key to start operation.

The OPERATE (operating) lamp and the HEATER

(heater) lamp will come on and temperature control

starts.

※ Bottom screen during heating

※ Bottom screen while temperature is stable

※ Bottom screen while temperature is decreasing

5

Stopping operation

Use the key to manually stop operation.

The screen will return to the one before starting

operation when you stop operation.

※

The fan motor keeps operating even operation is

stopped. Press the key longer to turn the

controller power off to stop the fan motor.

4. Operating procedure

Fixed temperature operation

14

Page 18

6

Stop running Fixed Temperature

Opeation with timer setting.

(Quick Automatic Stop Function)

Quick Automatic Stop Function is to stop

automatically running Fixed Temperature

Operation.

①

Press key at running Fixed Temperature

operation.

②

Show [

QSTOP]

on Bottom Screen and start [TIME]

lamp flashing on the left top of Bottom Screen.

③

Select the method to stop from TIME/CLOCK with

key and then press key.

④

Set TIME(capable setting range: 0~99hr

:

59min)or CLOCK (according to 24-hour time) on

Top Screen and then press key.

Example 1. Setting time to stop:

Operation is stopped automatically in 35 hours and 30

minutes once temperature reached to target

temperature.

Example 2. Setting clock time to stop:

Operation is stopped automatically at 15:00.

⑤

The AUTO STOP (Auto Stop) lamp comes on and

the Auto Stop function starts.

※ You can use the key to check the remaining

operation time/stop time information on the Bottom

screen.

※ Screen to check the remaining operation time

※ Screen to check the operation stop time

Press the key again or wait for about 10

seconds to return to the original status.

4. Operating procedure

Fixed temperature operation

15

Page 19

⑥ When the set time duration elapses or the time

comes, the Bottom screen will indicate [END] and

operation will stop.

⑦ Use the key to eliminate the [END]

indication.

※ When you stop operation, the screen will return to

the one before starting operation.

※ The fan motor keeps operating after operation has

been stopped. Press the key longer to turn

the controller power off to stop the fan motor.

4. Operating procedure

Fixed temperature operation

16

Page 20

This operation mode is used to automatically stop operation by setting the timer.

The operation mode where operation is automatically stopped by setting an operation duration.(when

you set an operation duration)

※ When you set a time, the

wait function will be activated,

the mode will remain “waiting”

without counting down the time

until temperature indication will

be within the wait deviation

range between -3℃ and +6℃

to the set temperature.

Counting down starts when the

temperature in the chamber

reaches the temperature -3℃

(indication) to the set

temperature.

Even if the temperature in the

chamber (indication) the mode

will be “waiting” if the lower limit

of the wait width deviation is

exceeded and time counting

down will not occur until the

temperature in the chamber

(indication) returns.

Operation mode where operation stops automatically at the set time (when an operation time is set)

※ The wait function will not

work if you select a time

setting. Operation will stop

when the set time comes. The

time you can set is up to 24

hours from the present time.

When a power failure occurred

before the set time and

continued after that and then

the unit recovered

automatically, operation will

continue to the next set time so

remember to stop operation

manually.

Set Automatic Stop mode

1

Turn on the controller

Turn on(|) Earth Leakage Breaker (ELB) on the upper

right side wall of this Equipment. (Idle State)

Press and hold key to turn on the controller power.

Indicate circulating liquid temperature in Chamber on

Top Screen and indicate target temperature on Bottom

Screen.

The fan motor will start.

The fan motor operates when the door is closed and

stops while the door is open.

Temperature

Set

temperature

Lower limit of the wait

width deviation

Door open

Timer start①

Timer start②

Wait①

Wait②

Actual elapsed time=set time (timer start ①+②)+(Wait①+②)

Operation start (manual)

Operation stop (automatic)

Time

Temperature

Set

temperature

Door open

Operation start (manual)

Operation stop (automatic)

Time

Set time

4. Operating procedure

Auto stop operation

17

Page 21

2

Selecting Automatic stop Operation

Press key to turn FIXED TEMP (Fixed

Temperature mode) and AUTO STOP (Automatic Stop

mode) lamp on.

※

Fixed Temperature mode would be selected at first

time operation. After that, the latest operated mode

is selected.

3

Set target temperature and operation

running time / clock time to stop.

①

Press key.

Select stop method from TIME/CLOCK with

keys and then press key.

②

Set TIME(capable setting range: 0~99hr:59min

)

or CLOCK (according to 24-hour time) on Top

Screen and then press key.

③

Set target temperature on Bottom Screen and then

press key.

Example 1. Setting running time:

Operation is stopped automatically in 35 hours and 30

minutes once temperature reached to 250 ℃ of target

temperature.

Example 2. Setting clock time to stop:

Start operation and reach to 250℃ in Chamber of

target temperature, and operation is stopped

automatically at 15:00.

4. Operating procedure

Auto stop operation

18

Page 22

4

Starting operation

①

Use the key to start operation.

The OPERATE (operating) lamp and the HEATER

(heater) lamp will come on and temperature control

starts.

※

You can use the key to check the remaining

operation time/stop time information on the Bottom

screen.

※ Screen to check the remaining operation time

※ Screen to check the operation stop time

Press the

key again or wait for about 10

seconds to return to the original status.

5

Cancelling operation

① When the set time duration elapses or the time

comes, the Bottom screen will indicate [END] and

operation will stop.

②

Press the key to eliminate the [

END

]

indication.

※ When you stop operation, the screen will return to

the one before starting operation.

※

The fan motor keeps operating after operation has

been stopped. Press the key longer to turn

the controller power off to stop the fan motor.

4. Operating procedure

Auto stop operation

19

Page 23

AUTO START (Automatic Start) mode is to start operation automatically with timer. This operation

does not stop automatically once its start. Stop manually, if required.

Timer activate Operation start (automatically)

SV;Target temperature t;Auto start setting time (time)

Set Automatic Start mode

1

Turn on the controller.

Turn on(|) Earth Leakage Breaker(ELB) on the right

side wall of this Equipment. (Idle State)

Press and hold key to turn on the controller power.

(Standby State)

Indicate circulating liquid temperature in Chamber on Top

Screen and indicate target temperature on Bottom

Screen.

The fan motor will start.

The fan motor operates when the door is closed and

stops while the door is open.

2

Select Automatic Start mode

Press key to turn FIXED TEMP (Fixed

Temperature mode) and AUTO START (Automatic Start

mode) lamp on.

※

Fixed Temperature mode would be selected at first

time operation. After that, the latest operated mode is

selected.

3

Set target temperature and

operation wait time / clock time to

start。

①

Press key.

Select start method from TIME/CLOCK with

keys and then press key.

②

Set TIME(capable setting range: 0~99hr:59min

)

or CLOCK (according to 24-hour time) on Top

Screen and then press key.

③

Set target temperature on Bottom Screen and then

press key.

t

SV

4. Operating procedure

Auto start operation

20

Page 24

Example 1.

Setting wait time to start:

Press key to count timer for 35 hours and 30

minutes, and then start automatically operation to reach

to 250℃ of target temperature in

Example 2.

Setting clock time to start:

Press key to start automatically operation to reach

to 250℃ of target at temperature at 15:00.

4

Starting operation

① Press key to be standby mode for starting

operation.

② Press key to be standby mode for starting

operation.

※ The Top screen shows the present temperature in

the chamber while the Bottom screens shows the

operation wait duration and the operation start time.

When you have selected a wait time, counting down

of the set time starts.

※

You can check the set temperature on the Bottom

screen using the

key.

Pressing the key again will make the Bottom

screen show the operation wait duration and the

operation start time.

4. Operating procedure

Auto start operation

21

Page 25

③ When the set time duration elapses or the time

comes, the OPERATE (Operating) lamp will change

its status from flashing to staying on as well as the

HEATER (Heater) lamp comes on and temperature

control will start.

※ You cannot use the Quick auto stop function for the

Auto start operation.

5

Stopping operation

Use the key to manually stop operation.

The screen will return to the one before starting

operation when you stop operation.

※

The fan motor keeps operating even operation is

stopped. Press the key longer to turn the

controller power off to stop the fan motor.

4. Operating procedure

Auto start operation

22

Page 26

The variable wind speed function allows you to set the fan motor speed in 10 stages and is

useful for operation while changing the ventilation amount or the wind speed in the bath.

The fan motor speed is the same for the frequency of between the setting 1 (aprox.600rpm). It

is different only for the setting 10: (approx. 1350rpm).

The wind speed for the settings 1~9 may not meet the temperature performance specifications.

We recommend that the user confirm the operation on the specific conditions.

Setting a variable wind speed

1

Turn controller power on

Turn the ELB on the right side of the main unit to

“ON(|)”. You can turn power on by keeping the

key pressed longer.

The top screen shows the temperature in the bath and

the bottom screen shows the temperature setting.

The fan motor will start.

The fan motor operates while the door is closed and

stops when it is opened.

2

Use the MENU key to display the

variable wind speed screen

Press the key several times to flash the

variable wind speed screen [FAN] in the bottom

screen.

※ You can set a variable wind speed during operation

as well.

3

Setting a wind speed in the standby

Press the key to flash [S] of the wind speed screen

in the standby [FAN:S].

Press the key, enter a numeric value ”1~10” for

the setting for the main screen with the keys

and determine with the key.

4. Operating procedures

Using and setting of the variable wind speed function

23

Page 27

4

Setting a wind speed during

operation

Press the key to flash [R] of the wind speed

during operation screen [FAN:R].

Press the key, enter a numeric value ”1~10” for

the setting for the main screen with the keys

and determine with the key.

5

Setting a wind speed at the end of

operation

Press the key to flash [F] of the operation end

[END] wind speed screen [FAN:F].

Press the key, enter a numeric value ”1~10” for

the setting for the main screen with the keys

and determine with the key.

Press the key twice to return to the standby or to

the operation screen.

6

Setting a wind speed for the

programmed operation

Variable wind speed for the programmed operation can

be differently for each of the steps.

4. Operating procedures

Using and setting of the variable wind speed function

24

Page 28

PROGRAM mode is to run programmed cycle such as figure below.

Setting the program operation

1

Turning on the controller

Turn the ELB on the left side of the main unit[ON(|)].

Pressing the key longer will turn the controller

power on.

The Top screen shows the temperature in the chamber

while the Bottom screen shows the set temperature.

The fan motor will start.

The fan motor operates when the door is open and stops

when the door is opened.

*Register target program prior to start running cycle at first.

For how to register a program, see “P.29 Programming method”.

Create as many as steps up to 99 at maximum and save programmed pattern data up to 99 in total.

(For example:11 program patterns will be stored at maximum, if each pattern is programmed 9 steps.

The number of steps in the repeat intereval will be the number of the steps set in the registration

part irrespective of the number of repetitions. )

2

Select program mode

Press key to turn PROGRAM Lamp on.

The bottom screen shows [

PGM:01]

([

01]

indicates a

program you used in the last session.)

※

Fixed Temperature mode would be selected at first

time operation. After that, the latest operated mode

is selected.

Target temp.

Setting time

Start programmed cycle

End programmed

cycle

Repeat

Repeat

4. Operating procedure

Program operation

25

Page 29

3

Select program patter number

Press key. 01, a part of [

PGM:01]

, is flashing on

Bottom Screen. Select particular number of desired

program pattern with keys and then press

key.

4

Start program mode

Press key to start programmed cycle operation.

※ Never run its cycle if [END] is not set at the end step

in the program. Check again that program setting, if

cycle do not start.

※ You cannot start operation by pressing the

key for pattern numbers for which any programs are

not registered.

※ You can check the program pattern number, the

step number or the remaining operation time being

executed on the Bottom screen with the key

during operation.

※ Screen to check the number of a program pattern

being executed.

※ Screen to check the number of a program step

being executed.

※ Screen to check the remaining time of a step being

executed.

4. Operating procedure

Program operation

26

Page 30

5

Cancelling program operation

① When the set program ends, the Bottom screen

shows[END] and operation will stop.

② You can eliminate the [END] indication using the

key.

※ The screen will return to the one before starting

operation when you stop operation.

※ The fan motor keeps operating after operation is

stopped. Press the key longer to turn the

controller power off to stop the fan motor.

4. Operating procedure

Program operation

27

Page 31

Sample program setting In this example, 8 steps are registered in the program pattern 2, steps

from 4 to 7 will be repeated 5 times and the whole session will end at the

step 8.

Note: Steps 4 to 7 will be repeated 6 times.

Pattern No

Step

Set temp.

Set time

Repeat

dstn.

Repeat No.

Wait

Variable

wind speed

End

P**:01

P02:**

TEMP

TIME

REP(STEP)

REP(COUNT)

WAIT

FAN

ENDST

02

01

100

00:00 0 0

ON

10

OFF

02

100

01:15 0 0

OFF

10

OFF

03

150

00:00 0 0

ON

10

OFF

04

150

02:00 0 0

OFF

10

OFF

05

200

01:00 0 0

ON

10

OFF

06

200

01:30 0 0

OFF

10

OFF

07

150

00:00 4 5

ON

10

OFF

08

150

00:30 0 0

OFF 3 ON

※ When set time for heating or cooling steps beyond the heating or the cooling capacity (0 minute in

the example) of the unit, it will operate at the full power for a short time at wait [ON]. At wait [OFF],

the step will proceed to the next one irrespective of whether the set temperature is attained or not

and you need to take care for setting a wait for heating or cooling for a short period.

※ When set time for heating or cooling steps beyond the heating or the cooling capacity of the unit, it

will heat or cool at a fixed rate irrespective of the wait setting of [ON] or [OFF], and the operation

will proceed to the next step once the set temperature is reached within the set time.

※ When a fixed temperature step is set and wait is [ON], the wait mode will continue from the time

when the temperature in the chamber drops below the lower limit of the wait width deviation

temperature due to, for example, opening of the door until the temperature in the chamber will

recover above that lower limit. At [OFF] the process will proceed to the next step after the set time

irrespective of changes of the temperature in the chamber.

※ When you use the repeat function, program the operation so that the set temperature before shifting

to the repeat mode will be the same as the set temperature of the destination of repetition.

※ Checking the heating capacity and the cooling capacity before setting is encouraged since these

will differ depending on the environmental temperature and the operating conditions.

0 min.

0 min.

1 h. 15 min.

2 h.

1 h.

1 h. 15 min.

30 min.

0 min.

Setting heating/cooling in minimum time

Setting heating in a fixed rate heating time

Repeat five times

Temperature

Time

4. Operating procedure

Programming Method

28

Page 32

NO

Indication

Operating procedure

Ⅰ

Ⅱ

[PROG] flashes.

Ⅲ

○ The PROGRAM lamps flashes.

[

USED

] means that the program has already

been registered.

[1] of

P01:0

1

flashes.

Makes [1] of

P01:01 flash.

Input as [P02:01

].

1-1

Inputting [P02:**] of program pattern

02

[2] of P02:01 flashes and the Top screen shows [-

---] which means any programs are not registered.

4. Operating procedure

Programming Method

29

Page 33

1-2

Input pattern 02, STEP 01.

TEMP flashes.

1-3

Input 100℃.

[000] flashes

1-4

00 hour 00 minute

TIME flashes

1-5

Repeat:0(No repeat destination)

REP flashes.

1-6

Number of repetition:0(No repetitions)

REP flashes.

1-7

Wait function ON setting

( Set time counts down when the indicated

temperature is-3 ℃ to the set temperature and

within +6℃.)

WAT flashes.

1-8

Variable wind speed:10 (max wind speed)

FAN flashes

4. Operating procedure

Programming Method

30

Page 34

1-9

END setting OFF (To input the next step, set this

to OFF; to input the final step, set this to ON)

All program setting items flash.

1-10

If a setup of STEP1 is completed

Press the key longer.

2-1

Input pattern 02, STEP 02

STEP02

STEP03

STEP04

STEP05

STEP06

Input parameters from STEP #2 to #6 in

accordance with setting conditions with

same process of inputting parameters

on STEP #1.

※

Press key while registering program.

Show [

REST.P

] on Bottom Screen. And show

the rest of available steps on Top Screen.

7-1

Input pattern 02, STEP 07

TEMP flashes.

7-2

Input 150℃.

7-3

Input 00 hour 00 minute.

TIME flashes

~ ~

~

~

4. Operating procedure

Programming Method

31

Page 35

7-4

Input repeat destination (Repeat dstn:4)

REP flashes

7-5

Input the number of repetitions(Number of

repetitions:5)

※ Number of repetitions may be set between 1 and

99 or [INF], limitless.

REP flashes

7-6

Set the wait function to ON.

( Set time counts down when the indicated

temperature is-3℃ to the set temperature and within

+6℃.)

WET flashes

7-7

Variable wind speed:10 (max wind speed)

FAN flashes

7-8

END setting OFF(To input the next step, set this to

OFF; to input the final step, set this to ON)

All of the program setting items flash

8-1

Input pattern 02. STEP 08

Press the key longer.

TEMP flashes.

4. Operating procedure

Programming Method

32

Page 36

8-2

Input 150℃.

8-3

Input 00 hour 30 minutes.

※ Inputting [INF] for the final step makes its time

limitless.

TIME flashes

8-4

Input repeat [0] (No repeat dstn)

REP flashes

8-5

Input a repeat number of [0] (No repetitions)

REP flashes

8-6

Set the wait function to OFF.

WET flashes

8-7

Variable wind speed: 3 (low wind speed)

FAN flashes

4. Operating procedure

Programming Method

33

Page 37

8-8

↓

Set END to [ON].

All of the program setting items flash

※ Be sure to set the END step ON for the final

step of a program pattern. Any operation

programs without an END step ON will not be

recognized as a complete program.

4. Operating procedure

※ Duplicate and use the programming sheet at the end of this book.

Programming Method

34

Page 38

1-1

※ Copying a program

Use the key to flash [

COPYP

] on the Bottom

screen and press the key.

1-2

When [01] of

PGM

:01

flashes, input the patter

number to copy from with the keys

and then determine using the key.

1-3

[

DEST

] flashes on the Top screen shows while

pattern numbers not used and [

**

] of

PGM

:

**

flash on the Bottom screen and input a pattern

number [

**

] of the copy destination with the

keys and determine using the

key.

1-4

↓

The Top screen shows [ ] and the Bottom screen

shows the pattern number of the copy source- copy

destination number [01-02] then the screen will

move to the program copy screen.

4. Operating procedure

How to copy or delete programs

35

Page 39

2-1

※ Deleting a program

You cannot delete a program during operation.

Carry out deletion while the stand-by screen is

displayed.

Use the key to flash [DELP] on the Bottom

screen and then press the key.

2-2

When

[01] of

PGM

:01

flashes, select a pattern

number to delete with the keys or

select [AL](all delete) with the key and then

press the key longer.

2-3

When [

DEL

] flashes, determine using the

key.

2-4

↓

The Top screen shows [ ] and the Bottom

screen shows the pattern number of the copy

source- copy destination number [PGM:02] then

the screen will move to the program delete screen.

4. Operating procedure

How to copy or delete programs

36

Page 40

When the wait function is set to [ON], the mode will remain “waiting” without counting down the time until

temperature in the chamber (indication) will be within the wait deviation range between -3℃ and +6℃

to the set temperature. When you set the set time to 0 minute, the unit will operate from the “Start

temperature” to the “Set temperature” at full power.

When you have set time longer than the specified performance, the unit will control heating and cooling

so that the set temperature will be attained (within the wait width deviation range) at the set time.

Even when the indicated temperature drops while temperature is stable due to opening of the door, the

mode will remain “waiting” without counting down the time if the wait width upper or lower limit is

exceeded.

When you set the wait function to [OFF], the unit will proceed to the next step at the set time irrespective

whether the temperature is within the wait width deviation between the set temperature and the

indicated temperature.

When the set time is set to a short time exceeding the heating and cooling capacity, the unit will proceed

to the next step before the set temperature is attained and you need to make sure that the wait function

is set at [ON] when you are going to operate at the full power.

※ Example of estimated heating/cooling at indicated setting of wait [All ON] and [ALL OFF] in

the program in the table below.

Step

1 2 3 4 5 6 7 8 9

10

Set temp(℃)

100

100

50

50

100

100

50

50

75

75

Set time

0 min

30 ,on

0 min

30 min

0 min

5 min

0min

5 min

2 hr

30 min

Heating and cooling time of steps (1), (3), (5) and (7) are at the full power setting.

Heating time of the step (9) has been set longer than the specification.

【Example of estimated process at “Full ON” setting for the wait function】

【Example of estimated process at “Full OFF” setting for the wait function】

Temperature (℃)

Wait width deviation

lower limit

Wait width deviation

upper limit

Time

Step

Temperature (℃)

Time

Step

4. Operating procedure

About the wait function

37

Page 41

※ Set a type of key lock.

1

Turn the controller power off

Turn the ELB on the left side of the main unit [ON(|)].

The Bottom screen will show the current time.

While the unit is being operated, press the key

longer to turn the controller power off.

2

Enter password

↓

①

Press and hold key.

Show [

UPASS

] on Bottom Screen and [00] flashing

on Top Screen.

②

Press and keys to enter password

“11” on Top Screen and press key (The

password is fixed to “11”.).

3

Set key lock

① The Bottom screen shows [KLOCK] while the Top

screen sows [OFF]. [OFF] is the factory setting.

②

Use the keys to select a type

of key lock and then determine using the key.

OFF:Key lock function disabled (Factory setting)

ON

:

Any keys other than the and the keys

are disabled.

FLOC

:

Only the key is disabled.

mLOC

:

Only the key is disabled.

③

Pressing the key longer will return to the time

display screen.

4. Operating procedure

Setting key lock mode

38

Page 42

Calibration Offset Function offset the difference between read temperature by this Controller and

actual measured temperature of Chamber. This Function enable parallel compensation in minus

or plus direction over the whole Controller Temperature Setting Range of this Equipment.

Example

When the measured Chamber temperature is lower than read temperature by 2℃:

The read temperature can be calibrated by inputting “Calibration Offset value -2.0” for 2 ℃

compensation against actual Chamber temperature.

If read temperature is 200℃ for example, its temperature will shift to 198℃ after offset calibration.

※ This -2℃ compensation is applied over the whole controller Temperature Setting Range

(DF832/1032:0~200℃、DH8332/1032:0~300℃). Note that offset value might be changed

depending on sample setting arrangement and/or Target Temperature.

。

1

Turning the controller power off

Turn the ELB on the right side of the main unit [ON(|)].

The Bottom screen will show the current time.

While the unit is being operated, press the key

longer to turn the controller power off.

2

Enter password.

↓

①

Press and hold key.

Show [

UPASS

] on Bottom Screen and [00] flashing

on Top Screen.

②

Press and keys to enter password

“11” on Top Screen and press key (The

password is fixed to “11”.).

3

Set Calibration Offset value.

↓

① Press key to display [CAL:OS] on Bottom

Screen then press key.

② Input offset value by and keys and

then press key. You can enter an offset

amount up to ±15.0℃

Example

Read temperature:200℃ and actual measured

temperature:198℃

⇒

Offset input value: -2.0℃

※ Although you can input values up to the first decimal

place, the temperature indications and measured

temperatures will be rounded before indication.

③

Pressing the key longer will return to the time

display screen.

4. Operating procedure

Calibration offset

39

Page 43

※ Describe the recovering operation at power failure.

1

Turning the controller power off

Turn the ELB on the right side of the main unit [ON(|)].

The Bottom screen will show the current time.

While the unit is being operated, press the key

longer to turn the controller power off.

2

Enter password.

↓

③

Press and hold key.

Show [

UPASS

] on Bottom Screen and [00] flashing

on Top Screen.

④

Press and keys to enter password

“11” on Top Screen and press key (The

password is fixed to “11”.).

3

Setting recovery from a power

outage

①

Press key to display [

RECOV

] on Bottom

Screen and then press key.

②

Press key to select recovery type at power

failure and press key.

CNT:The operation will resume right at power failure

after power recovery. (set at factory)

STOP:The operation will terminate as Idle State after

power recovery.

③

Pressing the key longer will return to the time

display screen.

4. Operating procedure

Setting the recovery mode

40

Page 44

※ Explaine how to set conversion factor for CO2 emission and how to reset the integrated

CO2 volume on Top Screen.

1

Turning the controller power off

Turn the ELB on the left side of the main unit [ON(|)].

The Bottom screen will show the current time.

While the unit is being operated, press the key

longer to turn the controller power off.

2

Enter password.

↓

①

Press and hold key.

Show [

UPASS

] on Bottom Screen and [00] flashing

on Top Screen.

②

Press and keys to enter password

“11” on Top Screen and press key (The

password is fixed to “11”.).

3

Reset monitor display.

①

Pressing the key will make the monitor

function indication

ENERGY

and [

ENERG

] flash on the

Bottom screen.

②

Pressing the key will show items to reset

integrated [

POWRT

] power consumption.

③ Press key to select monitoring item on Bottom

Screen and then press key.

POWRT:Integrated power consumption

Pressing the key will result in:

OFF(lit)→RUN(flash)

Press key to reset Integrated Power

Consumption.

Press key to return to [PoW:Rt].

4. Operating procedure

Resetting integrated CO2 volume and CO2 emission factor

41

Page 45

3

KG.K:(CO2) discharge coefficient

Quoted from the substitutive values, factory setting of

550 ( 0.000550t-CO2/kWh ) , the Environmental

Ministry Press Release on 6 November 20013.

Confirm the discharge coefficient of different utility

companies with each company.

Pressing the key will result in:

550(lit)→0550(flash)

Press the keys to change a discharge

coefficient.

key is used to determine

key is used to return

CO2:RT:Integrated CO2 Emission

Press key, and then change from

OFF

(illuminate) to →

RUN

(flash) on Top Screen.

key is used to reset Integrated CO2 Emission.

key is used to return

④ Pressing the key longer will return to the time

display screen.

4. Operating procedure

Resetting integrated CO2 volume and CO2 emission factor

42

Page 46

※ Back up, read out and reset controller for various setting information.

1

Turning the controller power off

Turn the ELB on the left side of the main unit [ON(|)].

The Bottom screen will show the current time.

While the unit is being operated, press the key

longer to turn the controller power off.

2

Enter password.

↓

③

Press and hold key.

Show [

UPASS

] on Bottom Screen and [00] flashing

on Top Screen.

④

Press and keys to enter password

“11” on Top Screen and press key (The

password is fixed to “11”.).

3

Save and read out and/or reset

setting information.

①

Press key few times and show following

items on Bottom Screen, respectively:

U BKS:Back various setting information up.

key

「

RUN

」

(flash)→ key

「

OFF

」

(illuminate)

U BKR:Read backup setting information out.

key

「

RUN

」

(flash)→ key

「

OFF

」

(illuminate)

INI.U:Initialize various setting information.

key

「

RUN

」

(flash)→ key

「

OFF

」

(illuminate)

※ Various setting information will be included

registered programs, temperature offset value and

other data such as key lock mode, calibration

offset, recovery mode and so forth.

②

Pressing the key longer will return to the time

display screen.

4. Operating procedure

Backup data saving / reading out / resetting

43

Page 47

※Check Integrated Power Consumption, integrated Operating hours and so forth by this “Monitor

Item Display” function of this Equipment.

Can not modify any setting information shown on Top Screen.

1

View integrated value on Top

Screen

※Monitor Items can be checked at Controller POWER

key ON or during operation state.

Press and Hold key.

Monitor Items display screen activate and current Power

Consumption appear on Top Screen.

Use the key shows the integrated power

consumption (MW) (kW), CO2 discharge amount (t) (kg)

heater operation amount (%), integrated live time (Unit:

10000 hours) (Unit: 1000 hours), integrated operation

time (Unit: 10000 hours) (Unit: 1000 hours).

Monitor Items display screen is ended, and Idle Screen

or Standby Screen is displayed finally.

KW Current Power Consumption is calculated from

instantaneous power to power at one hour.

Power consumption may be indicated as [0.0]

and [3.6] alternately while temperature is

stable. Power consumption is indicated as [0.0]

during standby.

TOT:MW Integrated power consumption (MWh). This is

indicated in a three-digit integer number.

TOT:KW Integrated power consumption (kWh). This is

indicated in a three-digit integer number.

【 Sample indication 】 Integrated power

consumption:123,456kWh

CO2:_T CO2 discharge amount (t). This is indicated in

a three-digit integer number.

CO2 discharge amount is calculated by multiplying the

power consumption by a discharge coefficient.

Confirm the discharge coefficient of different utility

companies with each company.

The initial value input is quoted from the substitutive

values, factory setting of 0.550(k-CO2/kWh), the

Environmental Ministry Press Release on 6

November 20013. For updates of the coefficients, see

the section, Setting and resetting the monitor

indication, item [3].

CO2:KG CO2 discharge amount (kg). This is indicated

in a three-digit integer number.

【Sample indication】CO2 discharge amount:456,789kg

4. Operating procedure

Monitoring data

44

Page 48

PID:MV Heater Operation Output

Heater Operation Output is the parameter to

control output power ratio in percent of heater

rated capacity. Heater output will be controlled

by PID operation value between100 to 0% till

reaching to Target Temperature.

【Sample indication】Present heater operation amount:

45.6%

POW:TM Integrated live time (hours). Only the ten

thousand digit will be indicated.

Integrated live time shall be the accumulated

time elapsed from turning the ELB ON(|) to

OFF OFF(○).

POW:TM Integrated live time (hours). Up to the

thousand place is displayed.

【Sample indication】 Integrated Power ON Hours ;

50,067 hours

Adding capability will up to 65,535 hours.

PUN:TM Integrated operation time (hours). Only

the ten thousand digit will be indicated.

Integrated Operation Run Hours mean to add

operation hours from start to end.

PUN:TM Integrated operation time (hours). Up to the

thousand place is displayed.

【Sample indication】Integrated live time:10,023 hours

Up to 65535 hours can be cumulated.

Use the key to the standby/operating screen.

Operating procedure

Monitoring data

45

Page 49

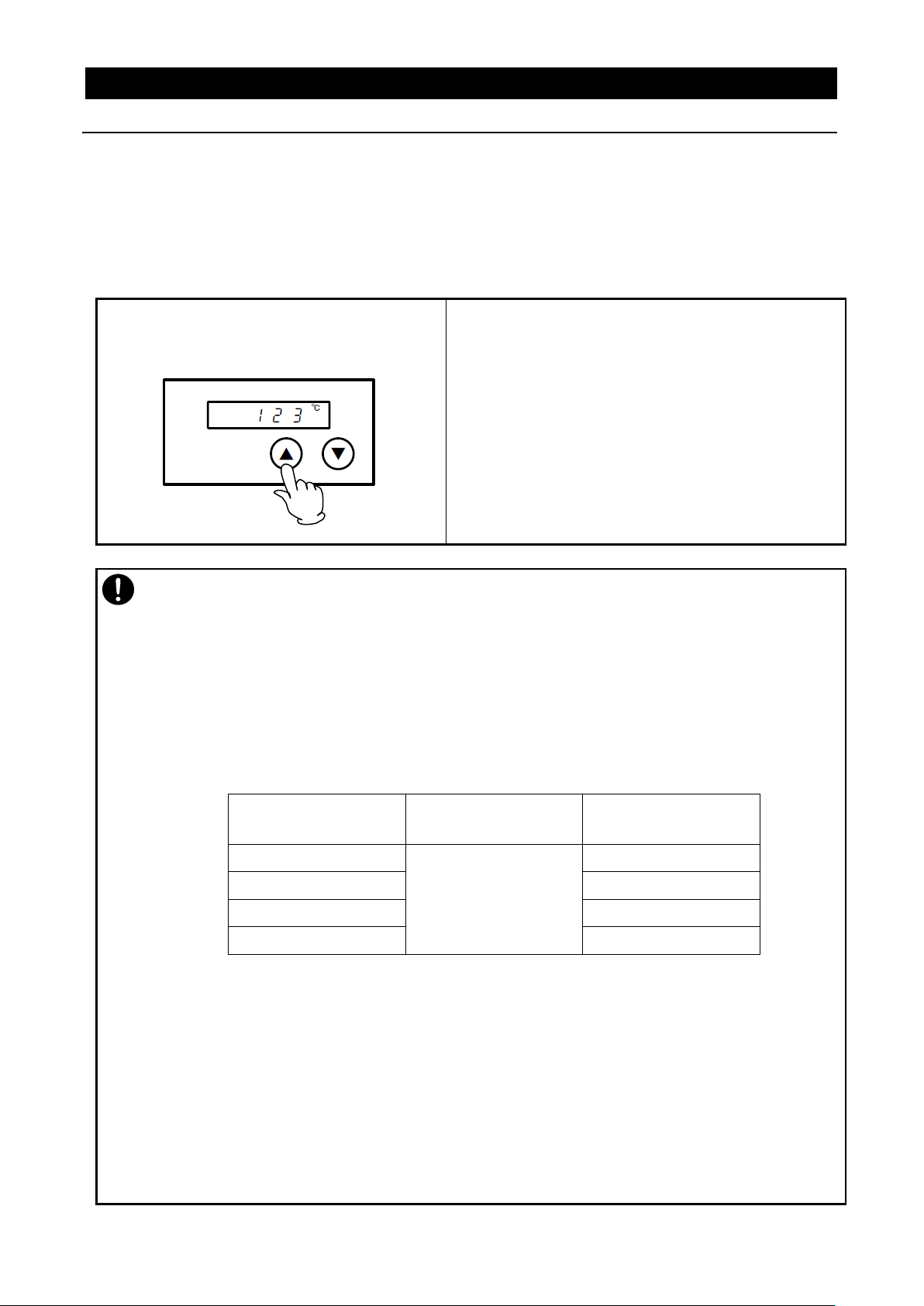

Set temperature on Independent

Overheat Prevention Device(IOPD)

※Set temperature with ▼▲ keys on its panel.

May stop its operation by activating Independent Overheat Prevention Device(IOPD) when the

difference between set temperature on IOPD and Target Temperature will be too close each other.

Must set IOPD temperature at least 20℃ higher than Target Temperature.

Note that the objective of this IOPD will not protect for samples but from overheating this

Equipment.

Factory settings and setting temperature ranges are as shown below:

Model

Set temperature at

shipment

Setting temperature

range

DF832

400℃

0℃~300℃

DF1032

0℃~300℃

DH832

0℃~400℃

DH1032

0℃~400℃

Control Chamber stable at required temperature first, and let IOPD setting temperature down

by 1℃ and then find out IOPD activating temperature, if IOPD will get to be activated at

required temperature.

Must wait for 5(five) seconds for the next 1℃ down of IOPD setting temperature, because its

function will be operated to need some times.

Display ER07 on Top Screen on Control Panel, if this IOPD is activated.

When you have set an operation temperature you want for IOPD , recording of the set

temperature takes several seconds and you need to wait for about five seconds before turning

the ELB off.

4. Operating procedure

Independent Overheat Prevention Device

This Equipment have redundant safety devices-1) Automatic Overheat Prevention (automatic reset)

function on the Controller, and -2) Independent Overheat Prevention Device(IOPD) with independent

power, circuit and sensor away from the Controller.

Main Relay of this Controller will be shut heater output power off when one of safety devices is

activated at Chamber internal temperature beyond its setting temperature.

Those functions will avail at Earth Leakage Breaker(ELB) ON(|).

46

Page 50

Never process any explosive, flammable samples and also samples contained with those

substances. It will cause fire/explosion. (See Chapter 13. List of dangerous materials on page

64.)

Be sure to check the withstand temperature before using a resin container. Using such a

container under a temperature beyond its withstand temperature will melt resin and a fire or an

explosion may result.

Turn immediately off Earth Leakage Breaker (ELB) of this Equipment and disconnect Power

Cord/Power Cable from receptacle or switch board of facilities, if smoke or strange smell is

generated from it by any chance.

Contact with local dealer or Yamato sales office and/or Yamato Customer service Center and

ask them to inspect it. If nothing is done to it, fire or electrical shock may result.

Never repair it by customer themselves to avoid any dangers.

Never insert any metal or easily flammable objects into the openings in the

chamber (radiation port, cable port, etc.). A fire, an electric shock or burning may

result.

If a foreign object has entered inside, immediately turn the ELB off and ask your

dealer, one of our sales offices or the customer service center for inspection.

Leaving as it is will cause a fire or an electric shock.

Take care not to touch samples when taking them in or out since inside the

chamber, internal wall of the door or samples are still hot for some time after

operation at a higher temperature. Be sure to put on heat-resistance gloves and

take extreme care for burning when handling samples.

When you attempt to open the door during operation at a higher temperature, never touch the

door since the internal chamber or the inside of the door are hot.

When the door is opened, the heater and the fan motor will stop for safety but note that the fan

motor will keep rotating from inertial and hot air will be blown out.

Note that if a fire alarm is installed around the unit, it may go off erroneously.

Never touch the door, the cable port or around the exhaust port during or immediately after

operation. They are hot and may cause burning.

5. Handling precautions

1. Never use any explosive or flammable substances.

2. Take extreme care when using a resin container.

3. Turn the ELB off when an abnormality occurs.

Warning

4. Do not put any foreign objects in the unit.

5. Take extreme care for handling of samples after operation at a higher temperature.

6. Take extreme care when opening the door during operation at a higher temperature.

7. Never attempt to touch hot surfaces.

47

Page 51

Do not climb on this Equipment. May cause personal injury and/or its failure by tipping it over

and being damaged.

Do not place any stuff on this Equipment. May cause personal injury falling it off.

Do not close up any flammable materials such as paper around it.

Turn immediately off the Breaker of the controller, when thundering and lightning start. If do not

so, it may cause fire or electric shock by the thunderbolt.

Do not keep Door open to cool the sample down quickly, etc. right after operation. May deform

Control Panel and cause failure of this Controller by heat wave from Chamber.

Do not process any samples containing corrosive chemicals even though Chamber is made of

stainless steel which this steel may be corroded by strong chemical acid, etc.

Operating temperature range will be room temperature+15℃~200℃(DF832/1032) and +15℃

~300℃(DH832/1032).

Never operate this Equipment at temperature out of its range. Operating the unit outside the

operating temperature range may cause a malfunction of the unit or an accident.

Do not set samples heavier than 30kg. Weight capacity of one shelf will be about 30kg

Spread samples evenly throughout on each shelf as many as possible.

Do not set excessive amount of samples on shelves. Chamber temperature may not be

controlled correctly. Must keep following procedure to control Chamber temperature correctly;

1) install the supplied shelves, 2) keep space between samples as wide as possible. 3) require

space opening more than 30% at each shelf.

Require space opening more than 30% at each shelf.

棚板

試料

30kg

Sample

Shelf

5. Handling precautions

1. Do not climb on the Equipment.

2. Do not place any stuff on the Equipment

3. Turn immediately off the Breaker of the Equipment at thundering.

4. Do not keep Door open after operation.

Caution

5. Do not process any corrosive samples.

6. Operate at the proper temperature.

7. Take extreme care when placing samples.

48

Page 52

Never set samples on bottom of Chamber. If samples will be processed at setting on bottom of

it, this Equipment may be not given as its full performance and become high temperature unlikely

and also cause failure.

Set samples on attached shelves properly installed on their brackets.

Do not allow samples to contact directly to side walls of Chamber.

Do not process humid specimens.

Water condensed inside the unit may cause an electric shock, a malfunction of the unit or

deterioration of HEPA filter.

Do not attempt to process wet samples.

The unit employs blowing to improve temperature distribution inside the chamber. When

processing powder or small samples, make sure that the sample will not scatter. A fire or an

electric shock may result if a flammable or a metal object enters the heater.

When processing smaller specimens, you can minimize circulating wind amount in the bath by

setting the variable wind speed to low, in which case the temperature performance will be out of

the warranty and the user needs to confirm the temperature characteristics.

Heating may take some time when the amount of samples is large or when processing samples

with a larger heat burden. Check the appropriate amount as necessary and set the sample. Also

note that the temperature indication may be unstable when processing heat-generating samples

(note that sample itself must be free of fear of explosion, inflammation or ignition).

Be aware of temperature sensor which it is installed on Chamber inside right portion and control

Chamber temperature. Therefore, if the amount of specimen is large or the equipment is in the

middle of heating, sensor detected temperature may not agree with temperature of the samples.

In particular, actual Chamber temperature will differ greatly from Read Temperature displayed on

Controller, right after opening or closing of this Equipment Door.

When a gap occurs between the temperature in the bath and the measured temperature requiring

adjustment, compensate temperature by referring to “P.39 Setting a calibration offset”.

When operation stopped from a power failure and then power recovers, the unit will automatically

resume operation.

See “P.40 Setting the recovery mode” for details.

Must be set temperature of Independent Overheat Prevention Device (IOPD).

Note that temperature of this IOPD must be set to temperature over 20℃ higher than Target

Temperature.

Refer to Chapter 4. Operating Procedure –“Independent Overheat Prevention Device” for how to

set and other cautions on page 46.

5. Handling precautions

8.Never set samples on bottom of Chamber.

9. Do not process humid or wet specimens.

10. Take care for processing of powder and small samples.

Caution

11. Note that the sample temperature and the measured temperature are not always

the same.

12. Check the following in terms of the recovery mode.

13. Be sure to set a temperature of the Independent Overheat Prevention Device.

49

Page 53

Be aware of Gasket on Chamber that is made from silicon rubber and may vaporize benzoic

acid, oil, etc. from volatile components of rubber used at their production during operation.

Ask specific Gasket made from fluoro-rubber for samples that are not compatible with those