Page 1

Immersion Cooler

NeoCool Dip

Model BE201/201F/301

Instruction Manual

First Edition

● Thank you for choosing BE series immersion Neo

Cool Dip coolers from Yamato Scientific Co., Ltd.

● For proper equipment operation, please read this

instruction manual thoroughly before use. Always

keep equipment documentation safe and close at

hand for convenient future reference.

Warning: Read instruction manual warnings and

cautions carefully and completely before

proceeding.

Yamato Scientific America Inc.

Santa Clara,CA

Printed on recycled paper

Page 2

Page 3

Table of contents

1. SAFETY PRECAUTIONS ................................................................................................................. 1

Explanation of Safety Symbols .......................................................................................................... 1

Symbol Glossary ................................................................................................................................ 2

Warnings & Cautions.......................................................................................................................... 3

2. PRE-OPERATION PROCEDURES .................................................................................................. 4

Placement Precautions & Procedures ............................................................................................... 4

3. COMPONENT NAMES & FUNCTIONS .......................................................................................... 10

Main Unit Overview .......................................................................................................................... 10

4. OPERATION PROCEDURE ............................................................................................................ 12

Main Operation ................................................................................................................................. 12

Cooling Capacity Curves (Reference Data) ..................................................................................... 13

Choosing Coolant for Low-Temp Applications (Reference Data) ............................................................ 15

5. HANDLING PRECAUTIONS .......................................................................................................... 16

6. INSPECTION & MAINTENANCE ................................................................................................... 17

7. STORAGE & DISPOSAL ................................................................................................................ 18

Extended Storage / Unit Disposal .......................................................................................................... 18

Disposal Considerations .................................................................................................................. 18

8. TROUBLESHOOTING .................................................................................................................... 19

Troubleshooting Guide ..................................................................................................................... 19

9. SERVICE & REPAIR ....................................................................................................................... 20

10. SPECIFICATIONS ......................................................................................................................... 21

11. WIRING DIAGRAM ....................................................................................................................... 22

12. LIST OF HAZARDOUS SUBSTANCES ....................................................................................... 23

Page 4

1

1. SAFETY PRECAUTIONS

Explanation of Safety Symbols

A Word Regarding Symbols

Various symbols are provided throughout this text and on equipment to

ensure safe operation. Failure to comprehend the operational hazards and

risks associated with these symbols may lead to adverse results as explained

below. Become thoroughly familiar with all symbols and their meanings by

carefully reading the following text regarding symbols before proceeding.

Warning

Caution

Signifies a situation which may result in minor injury (Note 2)

and/or property damage (Note 3)

(Note 1) Serious injury is defined as bodily wounds, electrocution, bone

breaks/fractures or poisoning, which may cause debilitation requiring

extended hospitalization and/or outpatient treatment.

(Note 2) Minor injury is defined as bodily wounds or electrocution, which will not

require extended hospitalization or outpatient treatment.

(Note 3) Property damage is defined as damage to facilities, equipment, buildings or

other property. ( Note 1 ) Serious injury is defined as bodily wounds,

Symbol Meanings

Signifies warning or caution.

Specific explanation will follow symbol.

Signifies restriction.

Specific restrictions will follow symbol.

Signifies an action or actions which operator must undertake.

Specific instructions will follow symbol.

Signifies a situation which may result in serious

injury or death (Note 1)

Page 5

2

1. SAFETY PRECAUTIONS

Symbol Glossary

Warning

General Warning

Danger!: High

Voltage

Danger!:

Extremely Hot

Danger!: Moving

Parts

Danger!: Blast

Hazard

Caution

General Caution

Caution:

Shock Hazard!

Caution: Burn

Hazard!

Caution: Do Not

Heat Without

Water!

Caution: May

Leak Water!

Caution: Water

Only

Caution: Toxic

Chemicals

Restriction

General

Restriction

No Open Flame

Do Not

Disassemble

Do Not Touch

Action

General Action

Required

Connect Ground

Wire

Level Installation

Required

Disconnect Power

Inspect

Regularly

Page 6

3

1. SAFETY PRECAUTIONS

Warnings & Cautions

Warning

Never operate equipment near combustible gases/fumes.

Do not install or operate CF301 unit near flammable or explosive gases/fumes. Unit is NOT fire

or blast resistant. Negligent use could cause a fire/explosion. See “List of Hazardous

Substances” (P.24).

Always ground equipment.

Always ground this unit properly to avoid electric shock.

DO NOT operate equipment when abnormalities are detected.

If smoke or unusual odors begin emitting from unit, or if any other abnormalities are detected,

terminate operation immediately, turn off main power switch (Earth Leakage Breaker - “ELB”) and

disconnect power cable. Continued operation under such conditions may result in fire or electric

shock.

DO NOT operate with bundled or tangled power cable.

Operating unit with the power cable bundled or otherwise tangled, may cause power cable to

overheat and/or catch fire.

DO NOT damage power cable.

Damaging the power cable by forcibly bending, pulling or twisting may cause fire or electric

shock to the operator.

DO NOT process hazardous substances.

Never process explosive or flammable items. Fire or explosion may result. See “List of

Hazardous Substances” (P.24) for more information on these items.

DO NOT handle flammable substances without proper ventilation.

Be sure there is adequate ventilation when working with certain flammable substances (such as

ethanol, etc.), which evaporate quickly at or below room temperature, and emit flammable fumes.

Insufficient ventilation may cause a fire or explosion. See “List of Hazardous Substances” (P.24).

NEVER disassemble or modify equipment.

Attempting to dismantle or modify unit in any way, may cause malfunction, fire or electric shock.

Caution

DO NOT operate equipment during thunderstorms.

In the event of a thunderstorm, terminate operation and turn off main power switch (ELB)

immediately. A direct lightning strike may cause damage to equipment, or result in fire or electric

shock.

Page 7

4

2. PRE-OPERATION PROCEDURES

Placement Precautions & Procedures

Warning

1. Ground wire MUST be connected properly.

・ Ground wire must be connected to a proper grounding line or terminal in order to

prevent electric shock.

・ Never connect ground wire to gas lines or water pipes.

・ Never connect ground wire to telephone grounding lines or to lightning conductor rods.

Doing so may result in fire or electrical shock.

・ Never insert multiple plugs into a single outlet. Doing so may result in power cable

overheating, fire or drop in voltage.

Connect to grounded outlet

Outlet with ground receptacle

When no ground terminal is found:

●Grounding to Electrical Equipment Technical

Standards, Section 19, class D (Grounding

Resistance Max. 100Ω) is required in Japan.

Contact a local dealer, electrician, or Yamato

Sales office for location-specific electrical

requirements.

Use ground adapter for ungrounded outlets

Ground adapter

Outlet with no ground receptacle

Ground adapter

●Insert grounded plug into ground adapter.

Connect grounding wire (green) from ground

adapter to a ground terminal.

2. Place in suitable locations.

Do not place BE series unit:

・ where flammable or corrosive gases/fumes are generated.

・ where external temperature will exceed 35ºC, will fall below 5ºC or will fluctuate.

・ in excessively humid or dusty locations.

・ where there is constant vibration.

・ where power supply is erratic.

・ in direct sunlight or outdoors

Place unit in locations with sufficient space, and venilation as specified as below.

20 ㎝ or more

BE

Unit

20 ㎝ or more

Ground wire

W

3-pronged plug with

ground

w

G

3-pronged plug with

ground

20 ㎝ or more

Ungrounded outlet

115V AC only

20cm or more (rear)

Page 8

5

2. PRE-OPERATION PROCEDURES

Placement Precautions & Procedures

Warning

3. Place in locations free of flammables and explosives.

・ Never place or operate unit near flammables or explosives. BE unit is NOT fire or blast

resistant. Simply switching the main power switch (ELB) “ON” or “OFF” can produce a

spark, which could relay during operation, causing a fire or explosion when near

flammable or explosive fluids, chemicals or gases/fumes.

See “List of Hazardous Substances” (P.24).

4. DO NOT disassemble or modify.

Attempting to disassemble or modifiy this unit in any way may result in malfunction, fire or

electric shock.

Page 9

6

2. PRE-OPERATION PROCEDURES

Placement Precautions & Procedures

Warning

5. Place in dry locations.

Place unit where it will be free from liquid spray and other moisture. Failure to do so may

result in control mechanisms or internal components becoming wet, causing malfunction,

electrical shock and/or fire.

Caution

6. Place on level surfaces.

Place unit on a level and even surface. Failure to do so may result in abnormal vibrations or

noise and damage to the refrigeration system.

Page 10

7

2. PRE-OPERATION PROCEDURES

Placement Precautions & Procedures

Caution

7. DO NOT forcfully pull or excessively bend cooling coil hose.

Handle cooling coil hose with care. Pulling on or bending hose to a radius of more than

50mm may break cooling line and result in malfunction or other equipment damage.

8. Connect to a properly rated power supply.

Connect power cable to a suitable facility outlet or terminal, according to the following

electrical requirements.

Power

requirements:

BE201 (50/60Hz) Single phase 115V 2.6A/2.0A Max.3.0A

BE201F (50/60Hz) Single phase 115V 3.6A/2.0A Max.3.0A

BE301 (50/60Hz) Single phase 115V 4.7A/4.3A Max.5.5A

1. Check the line voltage on outlet or terminal to be used and properly evaluate whether to

utilize a line being shared by other equipment. If the unit is not activated by turning on the

main power switch (ELB), take an appropriate course of action, such as connecting unit to

a dedicated power source.

2. If multiple power cables are connected to a single outlet, input voltage to unit may drop,

causing degraded cooling and temperature control performance.

Never connect ground wire to gas lines, water lines or telephone grounding lines. Fire or

electric shock may result.

9 Handle power cable with care.

Never operate unit with power cable bundled or tangled; and do not modifiy, bend, forcibly

twist or pull on power cable. Doing so may cause fire and/or electrical shock.

Do not risk damage to power cable by positioning it under desks or chairs, or having it

pinched between objects. Doing so may cause fire and/or electrical shock.

Do not place power cable near kerosene/electric heaters or other heat-generating devices.

Doing so may cause power cable insulation to overheat, melt and/or catch fire, which may

Turn off main power switch (ELB) immediately and disconnect from facility terminal or outlet, if

power cable becomes partially severed or damaged in any way. Failure to do so may result in

fire or electric shock. Contact a local dealer or Yamato sales office for information about

replacing power cable if it is damaged.

Always connect power cable to appropriate facility outlet or terminal.

Page 11

8

2. PRE-OPERATION PROCEDURES

Placement Precautions & Procedures

Caution

10. Place in a safe, well-ventilated area.

In the event of an earthquake or other unforeseen incident, equipment may

unexpectedly shift or fall, causing injury. Taking preventative steps to install unit in a

safe location, away from room access doors and out of harm’s way is strongly

recommended.

Place unit so that intake and heat vents (see “Main Unit Overview” on P.11 & 12 for

location) are unobstructed and allowed to adequately draw in air and diffuse heat.

Failure to do so may cause excessive internal heat, resulting in degraded performance,

malfunction or fire. See placement guide on P.5 above.

Page 12

9

2. PRE-OPERATION PROCEDURES

Placement Precautions & Procedures

11. Select anti-freeze for container based on operating temperature.

・Choose an applicable fluid for cooling relative to objective temperature.

If objective temperature is more than 10°C, use tap water or softened tap water

If objective temperature is less than 10°C, use an antifreeze solution, such as Naiburain.

⌘ DO NOT use purified and/or deionized water as coolant.

The ready-to-use Raku-raku line of Naiburain solutions from Yamato Scientific is

recommended.

Contact a local dealer or Yamato sales office to purchase Raku-raku Naiburain solutions.

Observe the following in order to prevent malfunction and personal injury:

・ Antifreeze concentration may become decreased after extended use.

Check concentration or change entirely on a regular basis.

・ If only tap water is used, change more frequently.

・ Do not use well water, purified water or deionized water.

・ Degraded unit performance may be caused by using heavy or viscous antifreeze fluids,

such as Fluorinert (by 3M), GALDEN (by Daitoku Tech), etc.

・ Never use the following substances in BE units.

1) Corrosive chemicals

2) Solutions which become corrosive when heated, such as Fluorinert (by 3M), etc.

3) Solutions which emit harmful fumes, such as methanol

If an antiseptic agent is to be used, confirm material constitution of components with

which fluid will be in contact and whether fluid will harm these components, before

selecting.

・ Assure sufficient ventilation when ethanol or other highly flammable fluids are used as

antifreeze. Never operate unit near open flame or other ignition sources (static

electricity, etc.).

Name

Product

Code

Concentratio

n

(Wt%)

Min. STD

Temperatur

e

Container

Size

( in liters)

Raku-raku

Solution: Z16005

756071

60%

-20℃

5L

Raku-raku

Solution: Z16010

756072

10L

Raku-raku

Solution: Z10005

756073

100%

-30℃

5L

Raku-raku

Solution: Z10010

756074

10L

Raku-raku

Solution:

NFP6005

756075

60%

-10℃

5L

Raku-raku

Solution:

NFP6010

756076

10L

Page 13

10

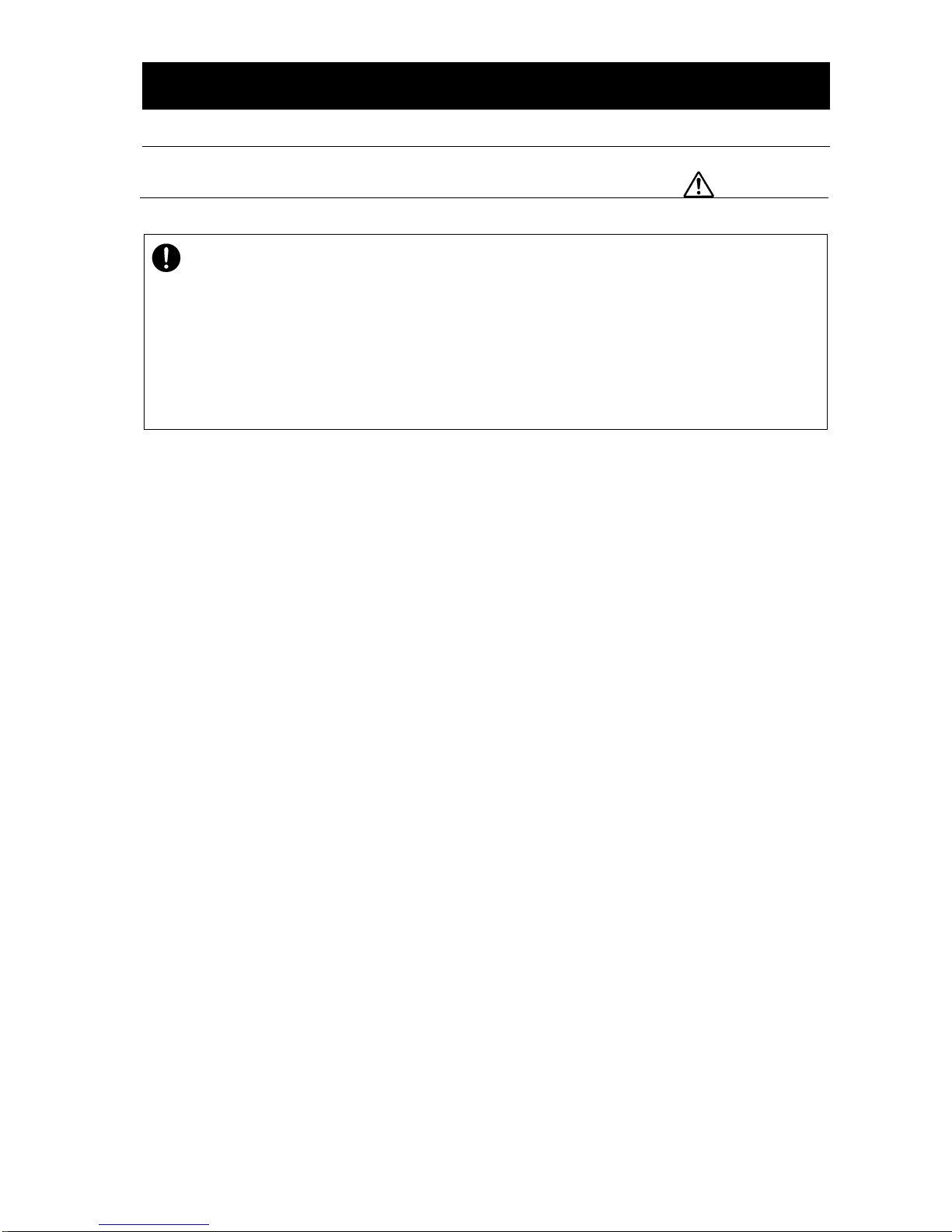

3. COMPONENT NAMES & FUNCTIONS

Main Unit Overview

BE201 front view

BE201 rear view

Power Switch (10A)

Operation

Lamp

Cooling Coil

Serial No. & Rating

Labels

Power Cable

(with plug)

Cooling Coil Sheath

Handle

Heat Vent

Side Heat Vent

Intake Grill

Page 14

11

3. COMPONENT NAMES & FUNCTIONS

Main Unit Overview

BE201F/301 front view

BE201F/301 rear view

Power Switch (10A)

Operation Lamp

Serial No. & Rating Labels

Power Cable

(with plug)

Handle

Flexible Cooling Tube

BE201F:500mm

BE301 :1000mm

Page 15

12

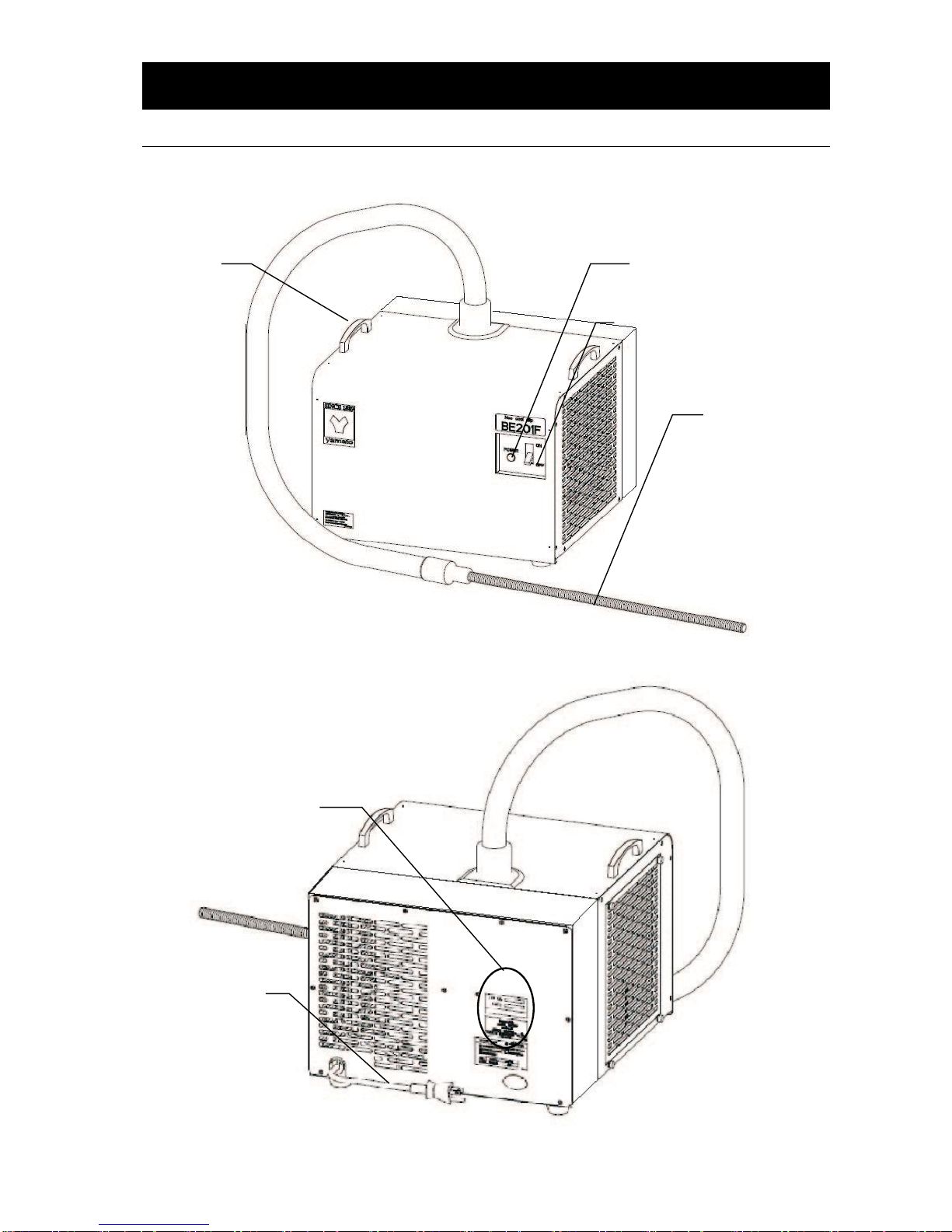

4. OPERATION PROCEDURE

Main Operation

Immerse cooling coil in fluid as shown in diagram below. Turn power switch (ELB) “ON” to start

operation.

1. Immerse cooling coil.

2. Turn power “ON”.

・ Wait at least five minutes to resume after halting an operation (e.g. turning power off). DO

NOT turn power switch “ON” and “OFF” repeatedly within a short timeframe. Damage to

the refrigeration system may result.

・ Avoid operating unit continuously at fluid temperatures abive 35°C.

Page 16

13

4. OPERATION PROCEDURE

Cooling Capacity Curves (Reference Data)

The following graphs show cooling capacities and characteristics of each BE unit by

model. Findings may vary with external temperature, fluid volume, etc. Use graph

values as reference only.

Analysis provisions

・External temperature:23°C

・Power:115V AC

・CPM:50Hz

・Antifreeze fluid: 60% Naiburain solution (covered, stirred and heat insulated)

・Fluid quantity:BE201/201F: 5 ℓ BE301: 5 ℓ /10ℓ

・Temp sensor placement:container center

BE201(5L)

BE301(10L)

BE201F(5L)

BE301(5L)

Page 17

14

4. OPERATION PROCEDURE

Cooling Capacity Curves (Reference Data)

Analysis provisions

・ Room temperature:20°C

・ Power supply: 115V AC

・ CPM:50Hz

・ Antifreeze fluid:60% Naiburain solution (covered, stirred and heat insulated)

・ Fluid quantity:BE201/201F: 5 ℓ BE301: 10ℓ

・ Temp sensor placement:container center

0

100

200

300

400

500

600

700

800

-20 -15 -10 -5 0 5 10 15 20 25 30 35 40

液温(℃)

冷凍能力

(W)

Ext. temp 20°C

BE301

BE201

BE201F

Cooling

Capacity

(W)

Fluid Temp (°C)

Page 18

15

4. OPERATION PROCEDURE

Choosing Coolant for Low-Temp Applications (Reference Data)

An anti-freeze coolant solution is required for applications below 10°C. Select a Naiburain® product

with freezing point of 10°C or more below objective temperature.

See “select coolant based on operating temperature” on P.10.

Naiburain product by type

Product Name

Characteristic

Z1、Z1-K

RH

NFP

50Wt%

100 Wt%

50Wt%

100 Wt%

50Wt%

100 Wt%

Boiling Point (in °C)

104

117

105

118

102

107

Specific Resistance

(in Ω・cm at 25°C)

625

1250

270

440

530

970

Conductivity (in S ・ m

-1

at

25°C)

0.160

0.080

0.370

0.227

0.189

0.103

Steam Pressure (KPa at

20°C)

1.7

0.5

1.7

0.5

2.3

1.3

Freezing Point (°C)

-21

Below -50

-21

Below -50

-13.5

Below -50

Specific Gravity (at 20°C)

1.05

1.10

1.07

1.134

1.026

1.048

Viscosity (mPa・s at 20°C)

2.5

9.5

2.5

9.5

2.6

9.4

Specific Heat (cal/g at 20°C)

0.850

0.670

0.850

0.670

0.773

0.642

0

-10

-20

-30

-40

-50

0

10

20

30

40

50

60

70

80

90

100

0

-10

-20

-30

-40

-50

Concentration (wt%)

Naiburain NFP

Naiburain Z, Z1-K

Naiburain® Freezing Points

(°C)

Page 19

16

5. HANDLING PRECAUTIONS

Warning

1. DO NOT process hazardous substances.

Never process explosive substances, flammable substances or substances that contain

explosives or flammables with BE units. See “List of Hazardous Substances” on P.24.

2. DO NOT operate equipment when abnormalities are detected.

If unit begins emitting smoke or abnormal odors for reasons unknown, turn off main power

(ELB) immediately, disconnect power cable from power supply, and contact a local dealer or

Yamato sales office for assistance. Continued use without addressing abnormalities may

cause fire or electric shock, resulting in serious injury or death. Never attempt to disassemble

or repair unit. Repairs should always be performed by a certified technician.

Caution

1. DO NOT climb on equipment.

Do not attempt to climb onto unit or substitute it for a proper step ladder. Units are not

designed to support bodily weight and damage may result. In addition, unit may become

unstable and tip over or fall resulting in equipment damage, serious injury or death.

2. DO NOT place objects on equipment.

Do not place any objects on unit. Doing so may cause unit to become unstable and tip over,

resulting in possible equipment damage, injury or death.

3. DO NOT operate equipment during thunderstorms.

In the event of a thunderstorm, turn off main power switch (ELB), and disconnect power cable

immediately. A direct lightning strike may cause equipment damage fire or electric shock,

resulting in serious injury or death.

4. DO NOT operate dry.

Do not operate without cooling coil immersed in fluid. Malfunction or equipment damage may

result.

5. Operate equipment as directed.

Operate BE series units only as directed in this text. Utilizing equipment for anything other

than that which it is intended may cause malfunction, damage, serious personal injury or

death. Read instruction manual thoroughly before use. Likewise, using non-Yamato

components to modify, customize or to otherwise attempt to improve unit design is not

recommended and may void warranty.

6. Keep upright.

Never tilt or place unit on its side while moving or transporting. Damage to refrigeration

system may result. If briefly tilting unit to one side or the other is unavoidable during

transport, refrain from turning power on for at least 24 hours after positioning unit upright.

Page 20

17

6. INSPECTION & MAINTENANCE

Daily general maintenance and inspection is recommended to ensure optimal performance.

Warning

● Turn off power and disconnect power cable before conducting inspection and maintenance,

unless otherwise necessary.

● Inspect and perform maintenance on unit when coolant is at room temperature.

● Do not attempt to disassemble unit.

Caution

Clean unit using a soft, damp cloth.

Never use benzene, paint thinner, scouring powder, scrubbing brush or other abrasives and

solvents to clean unit. Superficial damage and/or discoloration, as well as deformity to some

components may result.

Monthly maintenance.

Test main power switch (ELB) function.

1. Connect power cable.

2. Turn power switch ON.

3. Depress the red test switch with a fine-point object,

suchas a ballpoint pen, etc.

4. If power switch turns OFF without delay, it is

functioning normally.

Condenser fin maintenance.

・ Clogged condenser fins will degrade cooling

performance and may result in refrigeration

system malfunction. Cleaning intervals will

vary depending on usage frequency and

operating environment. Be sure to clean

condenser fins periodically.

・ Remove intake grill on left side of unit (4

screws) and clean dust from condenser fins

using a vacuum cleaner or other

suction-type cleaning device. Do not touch

fins with bare hands or fingers. Laceration

injuries may result. Do not bend or crush

fins with cleaning device.

◆ Contact local dealer or Yamato sales office for further assistance.

Test button

Page 21

18

7. STORAGE & DISPOSAL

Extended Storage / Unit Disposal

Caution

Warning

To store or to place unit out of service:

● Turn power OFF and disconnect power cable.

Disposal:

● CF301 units use a Freon alternative

refrigerant. Observe the Freon Collection Act

and request the assistance of a professional.

● Place out of reach of children.

● Dispose of as bulky or industrial waste.

Disposal Considerations

Dispose of or recycle this unit in a responsible and environmentally friendly manner.

Yamato Scientific Co., Ltd. strongly recommends disassembling unit, as far as is possible, in order to

separate parts and recycle them in contribution to preserving the global environment.

Major components and materials, comprising BE series units are listed in the table below:

Item

Composition

Main

External casing

Electrogalvanized carbon steel paneling (SFCC), baked-on

chemical-proof coating

Cooling coil

SUS304 Stainless steel

Labels

Polyethylene (PET) resin film

Caps

Synthesized rubber

Electrical

Switches and relays

Composite of resin, copper and other materials

Circuit boards

Composite of fiber glass and other materials

Power cable

Composite of synthesized rubber coating, copper, nickel and other

compounds

Refrigeration unit

Alloy of iron, copper, etc.

Internal plumbing

Hose insulation

EPM

Plumbing lines

Copper

Condenser

Iron, copper, aluminum

Cooling medium

Refrigerant

R134a(BE201/201F) R404A(BE301)

(Consult specialist for handling refrigerant.)

Page 22

19

8. TROUBLESHOOTING

Troubleshooting Guide

Troubles

Symptom

Possible Cause

Unit does not activate when

power is turned ON.

●Power cable not connected securely

●Power failure in progress

Temperature does not

decrease.

●Temperature of fluid in basin is too high or refrigeration system is

overloaded

●Cooling coil has frozen

●Condenser fins are clogged with dust

●External temperature is excessively high

●Intake vent is obstructed

●Antifreeze fluid concentration is too low

Refrigeration system does

not start.

●Refrigeration system is in overload. Turn off power switch

immediately, see possible causes for “temperature does not

decrease”, above, and turn on refrigeration system again after several

minutes.

Power failures.

In the event of a power failure, unit automatically returns to point of operation where power loss

occured and continues operating from that point when power is restored. If automatic restore

feature is not desired after power is restored, turn main power switch OFF.

◆ If problem persists, turn off power immediately, disconnect power cable and call for service.

Page 23

20

9. SERVICE & REPAIR

Requests for Repair

When a problem occurs, terminate operation immediately, turn off main power switch (ELB) and

disconnect power cable.

Contact a local dealer or Yamato sales office for assistance.

The following information is required for all repairs.

● Model name

● Serial Number

● Date (year/month/day) of purchase

● Description of problem in as much detail as possible

Guaranteed Supply Period for Repair Parts

Guaranteed maximum supply period for repair parts is 7 (seven) years from date of discontinuation for

BE series NeoCool Dip immersion coolers. “Repair parts” is defined as components which, when

installed, allow for continued unit operation.

See production/rating label on

unit. Refer to P.11 & 12 for

location.

Page 24

21

10. SPECIFICATIONS

Device

Neo Cool Dip

Model

BE201

BE201F

BE301

Operational external

temperature range

5°C~35°C

Performance

⌘ 1

Effective operating

temp.

-20°C~35°C

Cooling capacity

Approx.190W

at 0°C

Approx.190W

at 0°C

Approx.350W

at 0°C

60% Naiburain to water solution: 5L @20°C

60% Naiburain to

water solution: 10L

@20°C

Configuration

Refrigeration

system

Hitachi 160W reciprocating system

Hitachi 400W

reciprocating system

Cooling coil

Coiled tube

Flex tube

Flex tube

Φ35×170mm

SUS304

Φ15×500mm

SUS304

Φ15×1000mm

SUS304

Refrigerant,

refrigerant amount

R134a 130g

R134a 130g

R404A 170g

Safety functions

Overcurrent ELB

Standard

meausements

External

dimensions ⌘ 2

(W×D×H ㎜)

W410×D410×H303

(Excluding flex tube, cooling coil and attachment clamps.)

Power supply

(50/60Hz)

Single phase

115V 2.6A/2.0A

Max.3.0A

10A/plug included

Single phase

115V 2.6A/2.0A

Max.3.0A

10A/plug included

Single phase

115V 4.7A/4.3A

Max.5.5A

10A/plug included

Weight

Approx.26 kg

Approx.26 kg

Approx.28 kg

Included items

1 instruction manual

⌘ 1 Performance based on AC115V power supply; 20°C±5°C external temperature; 65%RH±20%

humidity; no load. Performance will vary depending on operation conditions..

⌘ 2 Protrusions excluded.

Page 25

22

11. WIRING DIAGRAM

BE201/201F/301

Symbol

Part name

Symbol

Part name

ELB1

Electric Leakage Breaker

OLR1

Over load relay

T1

Terminal block

C1

Operation capacitor

FM1

Fan motor

C2

Start capacitor

RF1

Capacitor

PTC1

PTC starting device

L1

Lamp

TF

Transformer

Page 26

23

12. LIST OF HAZARDOUS SUBSTANCES

Never process explosive substances, flammable substances or substances that contain

explosives or flammables.

Explosive

Substance

s

①Nitroglycol, Glycerine trinitrate, Cellulose Nitrate and other explosive nitrate esters

②Trinitrobenzen, Trinitrotoluene, Picric Acid and other explosive nitro compounds

③Acetyl Hydroperoxide, Methyl Ethyl Ketone Peroxide, Benzoyl Peroxide and other organic

peroxides

④Metallic Azide, including Sodium Azide, etc.

Explosive

Ssubstances

①Metal “Lithium” ②Metal “Potassium” ③Metal “Natrium” ④Yellow Phosphorus

⑤Phosphorus Sulfide ⑥Red Phosphorus⑦Phosphorus Sulfide

⑧Celluloids, Calcium Carbide (a.k.a, Carbide)⑨Lime Phosphide⑩Magnesium Powder

⑪Aluminum Powder ⑫Metal Powder other than Magnesium and Aluminum Powder

⑬Sodium Dithionous Acid (a.k.a., Hydrosulphite)

Oxidizing Substances

①Potassium Chlorate, Sodium Chlorate, Ammonium Chlorate, and other chlorates

②Potassium Perchlorate, Sodium Perchlorate, Ammonium Perchlorate, and other perchlorates

③Potassium Peroxide, Sodium Peroxide, Barium Peroxide, and other inorganic peroxides

④Potassium Nitrate, Sodium Nitrate, Ammonium Nitrate, and other nitrates

⑤Sodium Chlorite and other chlorites

⑥Calcium Hypochlorite and other hypochlorites

Flammable Substances

①Ethyl Ether, Gasoline, Acetaldehyde, Propylene Chloride, Carbon Disulfide, and other

substances with ignition point at 30 or more degrees below zero.

②n-hexane, Ethylene Oxide, Acetone, Benzene, Methyl Ethyl Ketone and other substances

with ignition point between 30 degrees below zero and less than zero.

③Methanol, Ethanol, Xylene, Pentyl n-acetate, (a.k.a.amyl n-acetate) and other substances

with ignition point between zero and less than 30 degrees.

④Kerosene, Light Oil, Terebinth Oil, Isopenthyl Alcohol(a.k.a. Isoamyl Alcohol), Acetic Acid

and other substances with ignition point between 30 degrees and less than 65 degrees.

Combustible

Gas

Hydrogen, Acetylene, Ethylene, Methane, Ethane, Propane, Butane and other gases

combustible at 15°C at one air pressure.

Excerpt from Table 1, Hazardous Substances, of Cabinet Order of the Occupational Safety and

Health Law (substances related to Articles 1, 6, and 9)

Page 27

Limited liability

Always operate equipment in strict compliance to the handling and operation procedures

set forth by this instruction manual.

Yamato Scientific Co., Ltd. assumes no responsibility for malfunction, damage, injury or

death resulting from negligent equipment use.

Never attempt to disassemble, repair or perform any procedure on BE series unit which is

not expressly mandated by this manual. Doing so may result in equipment malfunction,

serious personal injury or death.

Notice

● Instruction manual descriptions and specifications are subject to change without

notice.

● Yamato Scientific Co., Ltd. will replace flawed instruction manuals (pages missing,

pages out of order, etc.) upon request.

Instruction Manual

Immersion Cooler NeoCool Dip

BE201/201F/301

First Edition: June 6, 2017

Yamato Scientific America Inc.

925 Walsh Avenue, Santa Clara, CA 95050

Phone: 800.292.6286 / 408.235.7725

http://www.yamato-usa.com

Loading...

Loading...