Page 1

Instruction Manual

SUPPER HIGH SPEED OVERLOCK MACHINE

SUPPER HIGH SPEED SA FE T Y S TIT CH MA CHINE

AZ7000SDR-8

AZ7000SDR-8,AZ7003SDR-8,AZ7016SDR-8

AZ7020SDR-8,AZ7025SDR-8,AZ7120SDR-8,AZ7125SDR-8

AZ7500SDR-8

AZ7500SDR-8,AZ7520SDR-8,AZ7525SDR-8

AZ7500SDR-31,AZ7520SDR-31,AZR7525SDR-31

class

class

Thank you for purchasing the AZ70 0 0SDR- 8 and AZ7500SDR- 8 class. Before using your

AZ70 0 0SDR-8 and A Z7500SD R- 8 class, please read the instr uction manual and understa nd

the c o ntents well.

Af ter reading the instr uctio n manual, please keep it in a loc atio n where it is easily accessible

to the operator.

Page 2

CONTENTS

SAFETY INSTRUCTIONS ⅰ-ⅵ

1. Name of each part 1

2. Installation 2

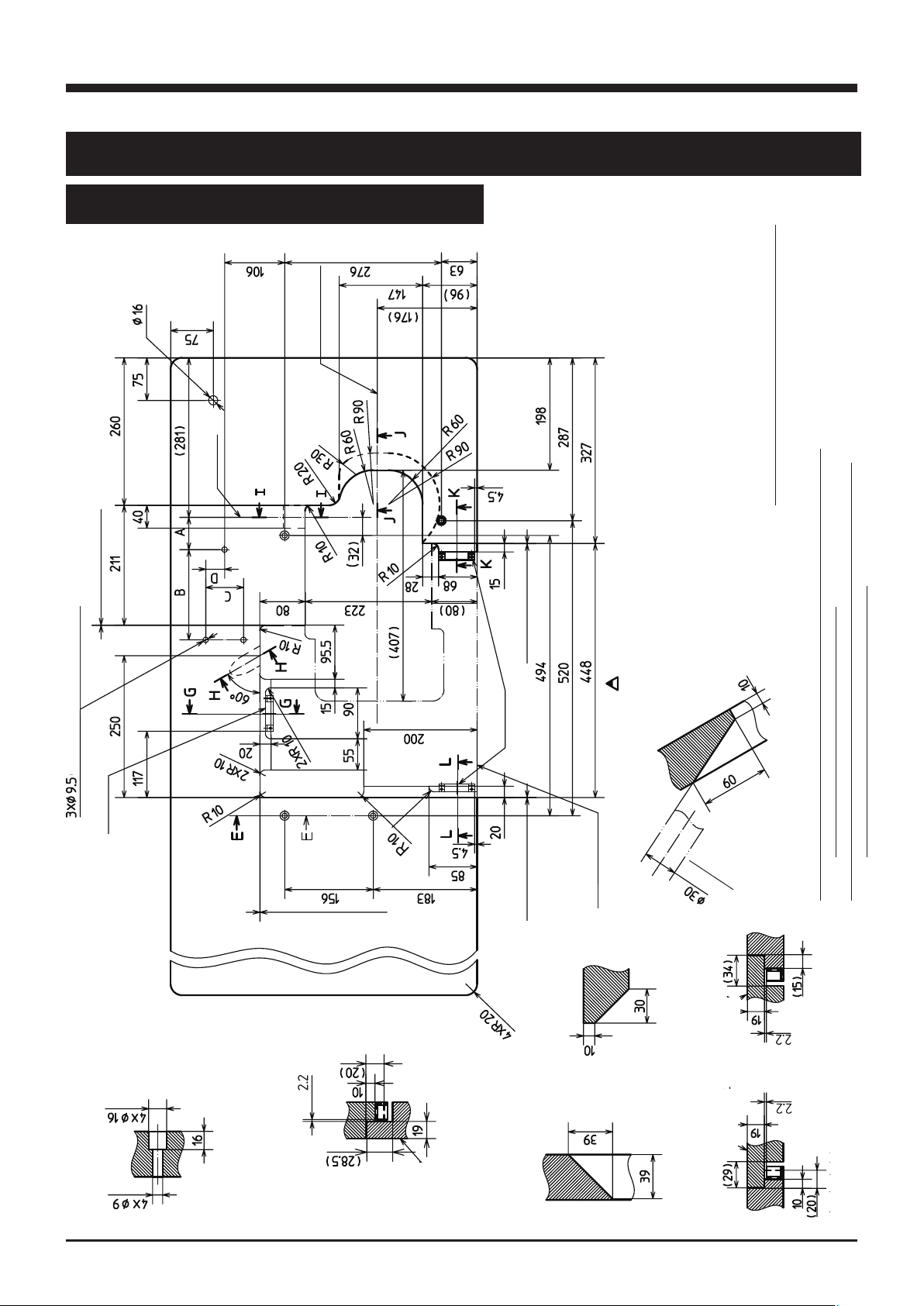

2.1 Semi-submerged type 2

2.1.1 Table cutting diagram 2

2.1.2 Installation 3

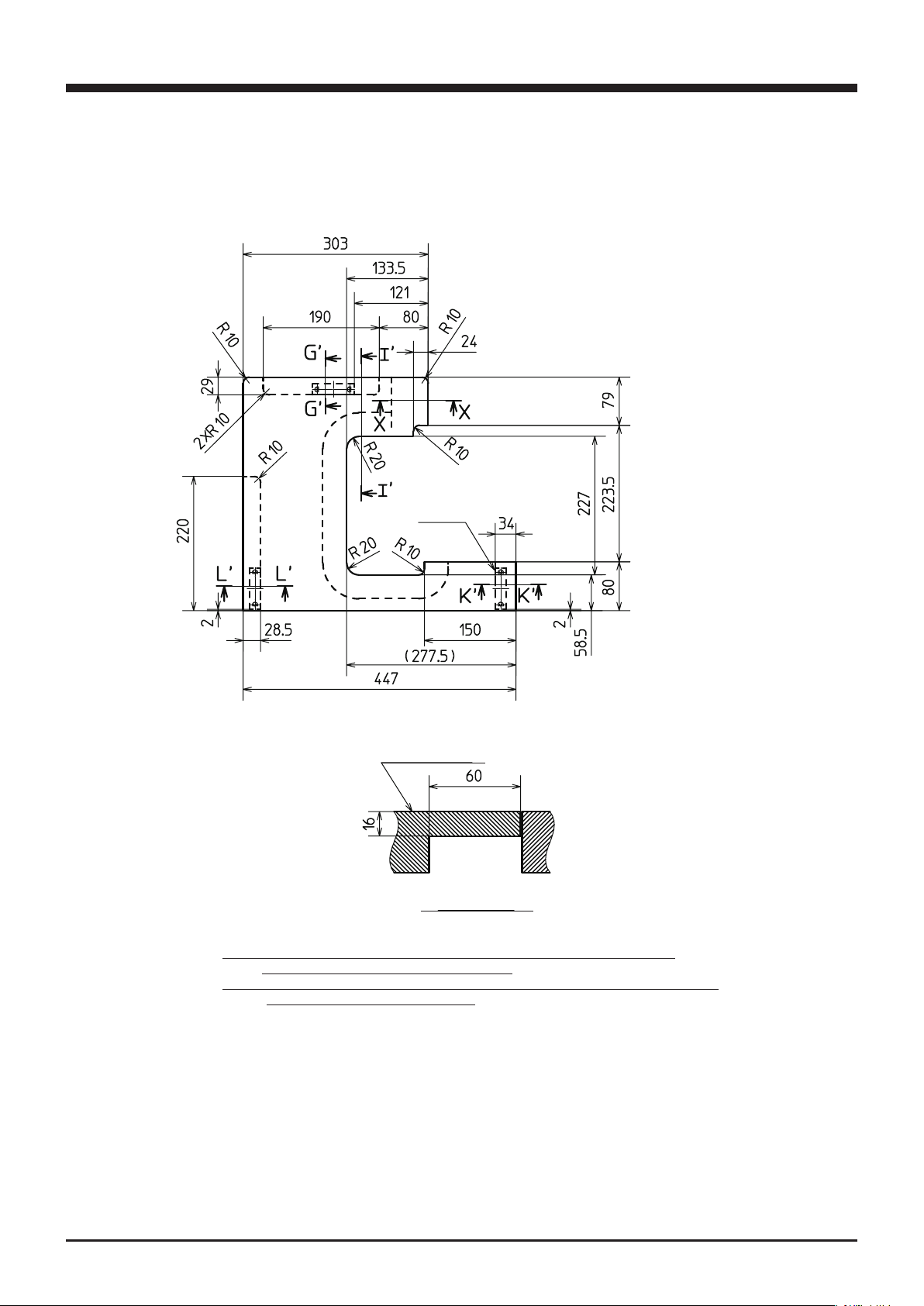

2.2 Fully-submerged type 4

2.2.1 Table cutting diagram 4

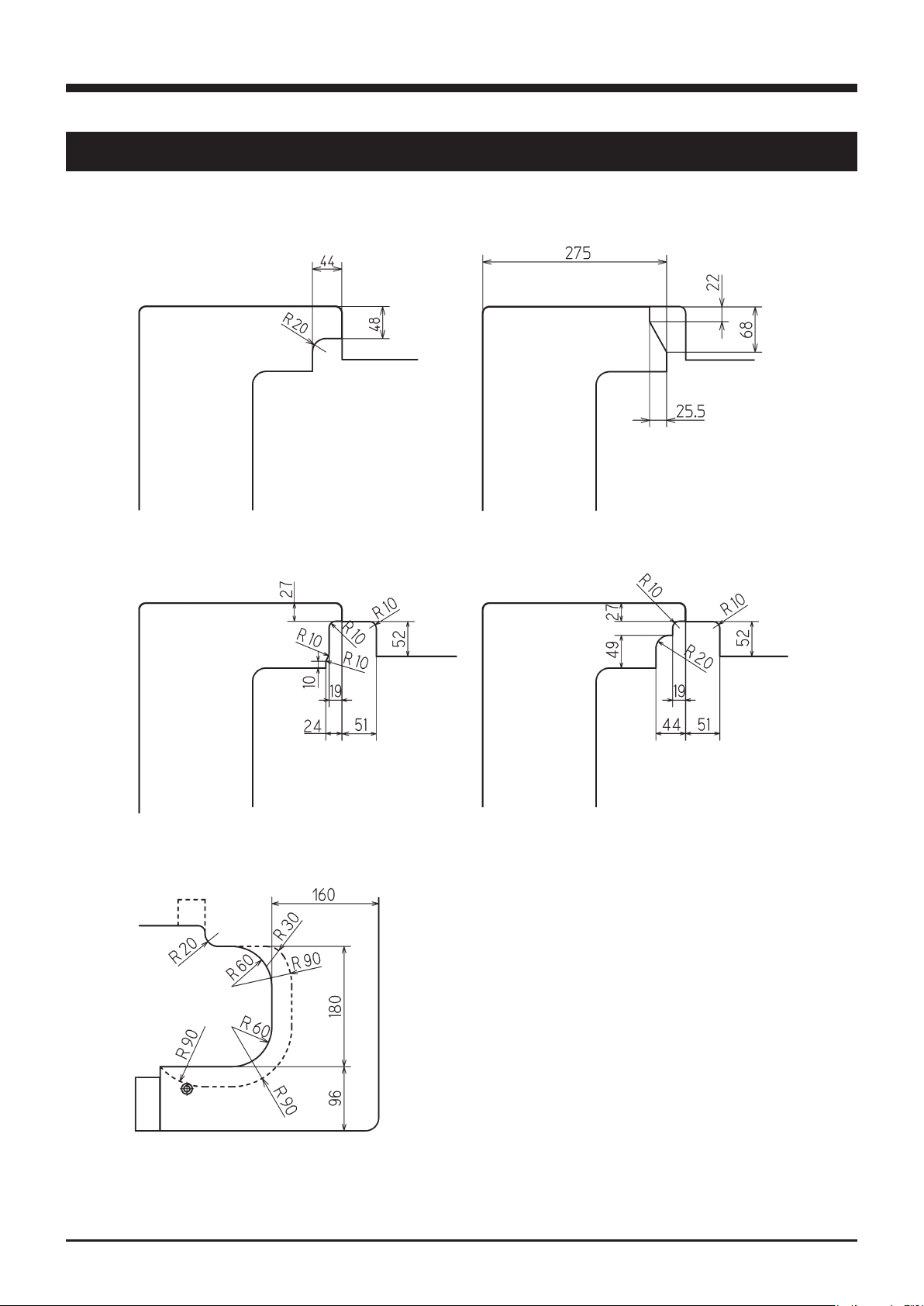

2.2.2 Table cutting diagram for fully-submerged type with device 6

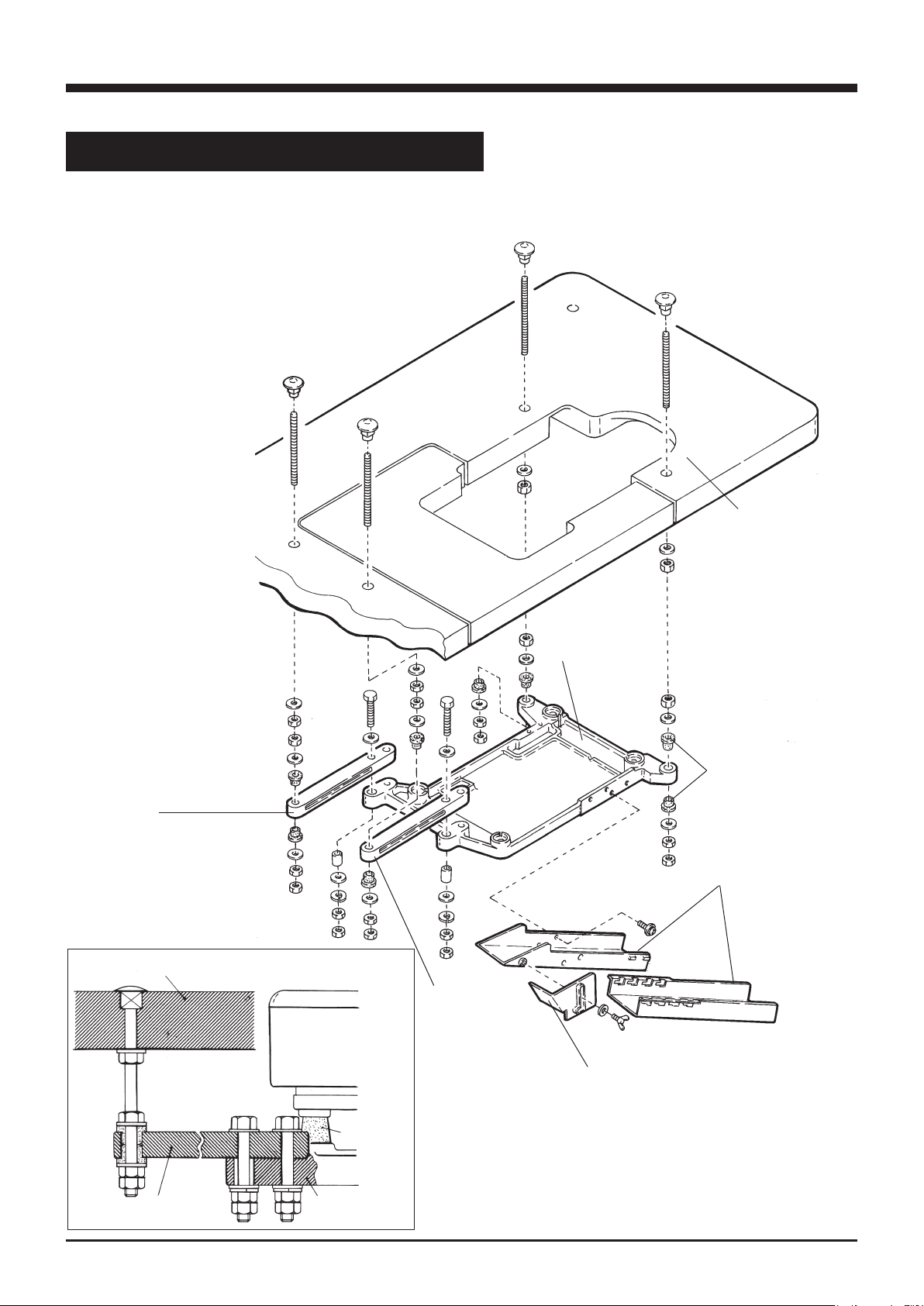

2.2.3 Installation 7

2.3 Motor, pulley and belt 8

2.4 Hanging belt 9

2.5 Belt cover 9

2.6 Eye guard and nger guard 9

3. Sewing speed and rotating direction of pulley

4. Lubrication

4.1 Lubricating oil 11

4.2 Lubricating 11

4.3 Changing oil 12

4.4 Checking and replacing oil lter 12

5. Proper operation

5.1 Needle system 13

5.2 Installing needles 13

5.3 Adjusting thread tension 14

5.4 Pressure of presser foot 15

5.5 Releasing presser foot 15

5.6 Opening cover 16

5.7 Adjusting differential feed dog 16

5.8 Adjusting stitch length 17

10

11

13

5.9 Passing tape 18

5.10 SP device and HR device 18

5.11 Cleaning the machine 19

6. Adjustment of sewing machine 20

6.1 Needle thread tension for overlock stitch 20

6.2 Looper thread tension for overlock stitch 21

6.3 Needle thread tension for double chainstitch 22

6.4 Looper thread tension for double chainstitch 23

Page 3

CONTENTS

6.5 Width of overedge seam 24

6.6 Upper and lower knives 25

6.7 Height of feed dogs 27

6.8 Tilt of feed dog 28

6.9 Needles and loopers 29

6.9.1 Height of needle 29

6.9.2 Installing angle of lower looper 30

6.9.3 Distance between needle and lower looper 30

6.9.4 Parallel of needles 31

6.9.5 Back and forth position of lower looper 32

6.9.6 Distance between needle and upper looper 33

6.9.7 Back and forth position of upper looper 34

6.9.8 Timing relation between lower looper and upper looper 34

6.10 Needle and double chaining looper 34

6.11 Needle and needle guards for AZ7000SDR-8 35

6.11.1 Needle and needle guard(rear) 35

6.11.2 Needle and needle guard(front) 35

6.12 Needle and needle guards for AZ7500SDR-8 36

6.12.1 Needle and needle guard(rear) 36

6.12.2 Needle and needle guard(front) 36

6.12.3 Needle and needle guard for double chain stitch 37

6.13 Position of presser foot 37

7. SC10 device 38

7.1 Outline 38

7.2 Adjusting ventilating amount 38

7.3 Installation 39

8. K2 device 41

8.1

8.2 Oiling 41

Adjustment for engagement between upper trimming knife and lower trimming knife

41

9. Specifications 42

9.1 AZ7000SDR-8 class 42

9.2 AZ7500SDR-8 class 43

Attention

◇ This instruction manual is designed mainly for technicians, but it is advisable that also operators read

the instructions with mark to use the machine properly.

◇ The numbers in lower left corners of figures are figure numbers. We use them in texts as needed for

your reference.

Attention

The parts used for this product are subject to change without notice. If such a change is made, any part

of the contents and illustrations of this instruction manual may not conform to this product.

In preparing the instruction manual, we have made our best efforts for making it free of any error or

omission. If any error or omission should yet be found, it might not be rectified immediately.

Page 4

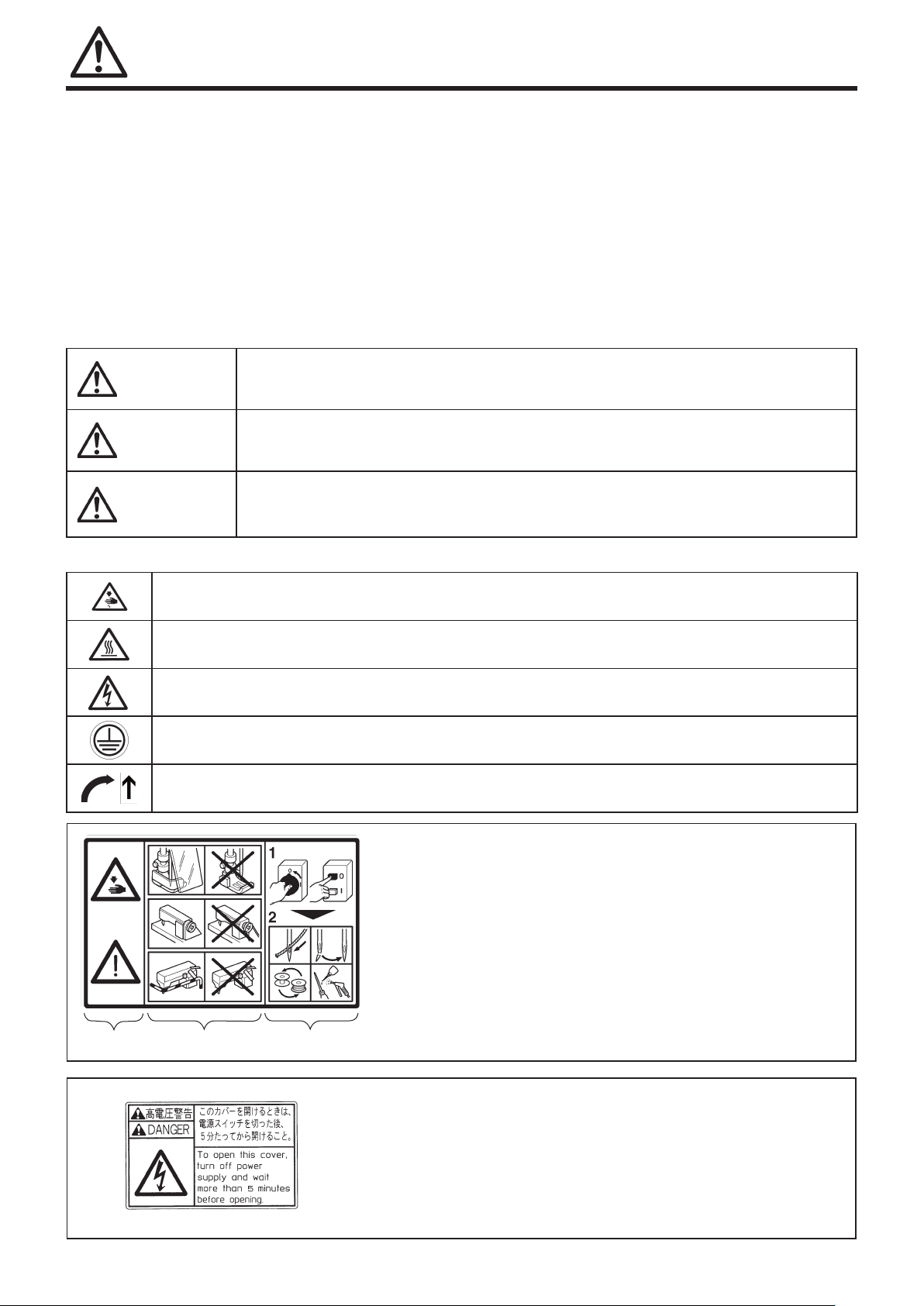

SAFETY INSTRUCTIONS

1. Safety Instruction

The sewing machine, automatic machine, and attachments (collectively called “the machine” below) involve

sewing operations that require the operator to be near moving parts of the machine. Because of this,

there is always a potential danger of unintentional contact with the moving parts. For this reason, the

operators who actually use the machine and the maintenance staff who perform maintenance and repair must

carefully read “2. Basic precautions” and “3. Precautions to be taken in various operating stage” below

and fully understand this information before operating or maintaining the machine.

The information contained in the “Safety Instruction” of this manual also includes items not found in

the product specications.

To assist in better understanding this manual and the product warning labels, warning indicators are

categorized as shown below. Be sure that you fully understand the contents and carefully follow the

instructions.

1.1 Explanation of risk levels

This indication is given when there is a danger of death or serious injury if

DANGER

WARNING

CAUTION

the person in charge or any third party mishandles the machine or does not

avoid the dangerous situation when operating or maintaining the machine.

This indication is given when there is a potential for death or serious injury

if the person in charge or any third party mishandles the machine or does not

avoid the dangerous situation when operating or maintaining the machine.

This indication is given when there is a potential danger of medium to minor

injury or damage of the sewing machine if the person in charge or any third

party mishandles the machine or does not avoid the dangerous situation when

operating or maintaining the machine.

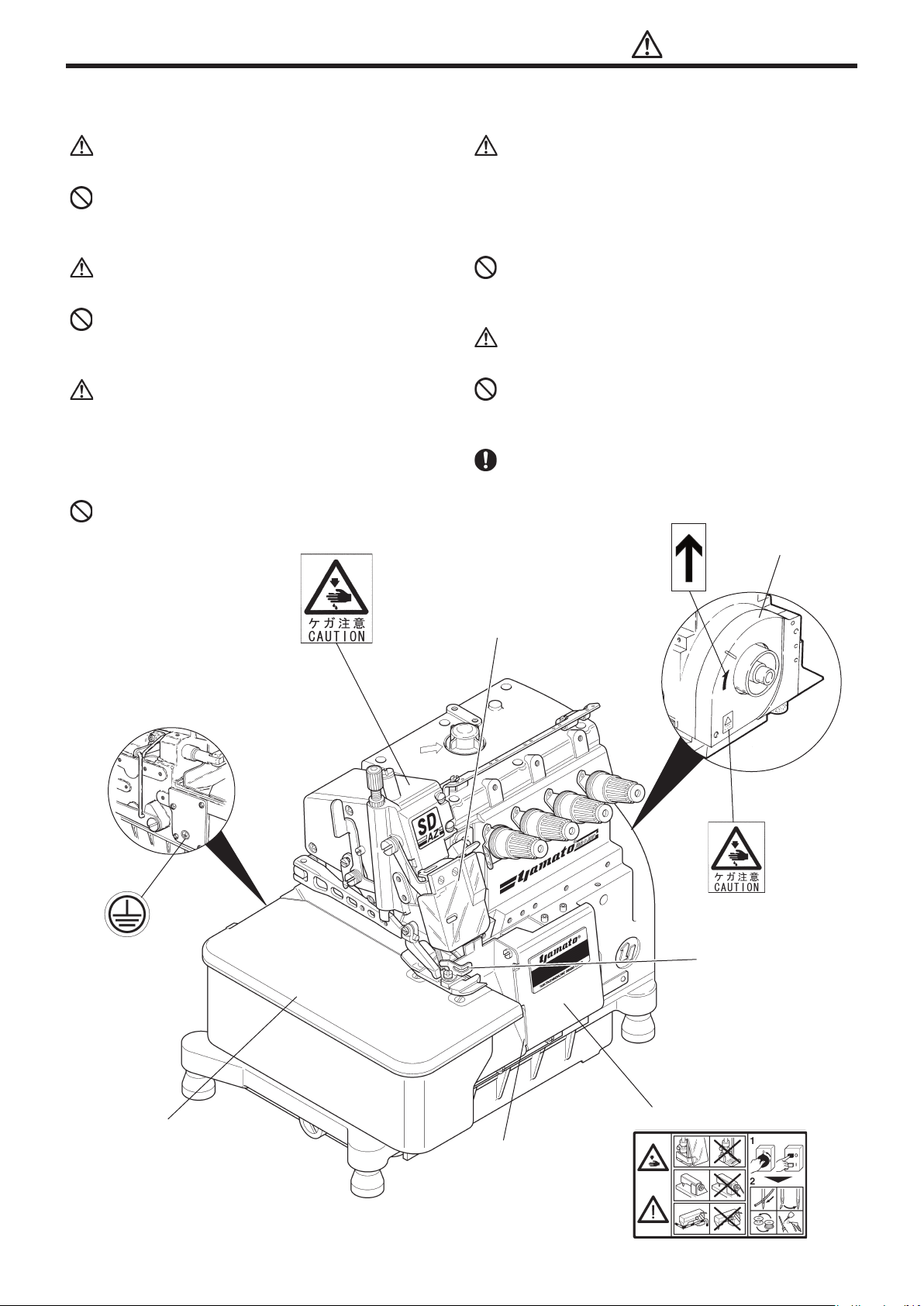

1.2 Explanation of pictorial warning indications and warning labels

There is a risk of injury if contacting a moving section.

There is a risk of a burn if contacting a high-temperature section.

There is a risk of electrical shock if contacting a high-voltage section.

Connection of an earth cable is indicated.

The correct direction is indicated.

Explanation of safety label

① There is the possibility that slight to serious injury or

death may be caused.

There is the possibility that injury may be caused by

touching the moving part.

② Perform sewing work with safety cover.

Perform sewing work with safety protection device.

③ Be sure to turn the power OFF before carrying out

“threading,” “needle changing,” “bobbin changing” or

①

②

③

“oiling and cleaning.”

i

Explanation of high-voltage warning label

High voltages are owing inside the power supply of the control

box. This indicates that there is a risk of electrical shock.

When it is necessary to open the control box containing

electrical parts, be sure to turn the power off, remove the power

plug and wait for at least ve minutes before opening the cover

in order to prevent an accident resulting in electrical shock.

Page 5

1.3 Explanation of symbols

Explains the symbols used in the instruction manual.

Failure to follow the instructions can result in an injury or damage to the machine.

Be sure to follow the instructions when you operate, check, adjust or repair the machine.

Never do this.

Be sure to remove the power plug from the source of the power supply, when checking, adjusting

and/or repairing the machine or when there is the possibility that lightning may strike.

Additional explanations and notes, etc., for operation or adjustment

2. Basic precautions

SAFETY INSTRUCTINONS

1. Be sure to read this instruction manual and

all the other explanatory documents supplied

with accessories of the machine before using

the machine. Always keep the instruction manual

where it is easily accessible for the operator

and maintenance staff.

2.

The content of this section includes items which are

not contained in the specications of your product.

3. Be sure to wear safety goggles to protect

against accidents caused by needle breakage.

2.1 Applications, purpose

Our industrial sewing machines have been

developed in order to increase quality and/or

productivity in the sewing industry.

Accordingly, never use our products for other

than the intended use as described above.

2.2 Working environment

The environment in which our industrial sewing

machines are used may seriously affect their

durability, functions, performance and/or safety.

Do not use the machine in the circumstances below.

Places of high ambient temperature and/or

humidity that seriously affects sewing machines.

Outdoors, places of high temperature or in

direct sunlight.

Environments containing dust, corrosive or

ammable gases, or in contact with chemicals.

Where the voltage uctuation range is more

than ± 10% of the rated voltage.

Location where sufcient power is not available

for the power supply capacity of the controllers

and motors that is used.

Near objects where strong electric or magnetic

elds, such as high frequency welding

machines which make noise, are generated.

As dew condensation may occur when suddenly

bringing the machine from a cold environment

to a warm place, in order to prevent accidents

caused by breakage or malfunction of the

electrical components, be sure to turn the power

on after waiting for a sufcient period of time

until there is no sign of water droplets.

When lightning occurs, be sure to stop operation

and remove the power plug in order to prevent

accidents caused by breakage or malfunction of

the electrical components.

2.3 Safety devices and warning labels

Be sure to operate the machine after verifying

that safety device(s) are correctly installed

in order to prevent accidents caused by lack

of the device(s).

With regard to safety device(s), please refer

to page vi.

If any of the safety devices is removed, be

sure to replace it and verify that it works

normally in order to prevent accidents.

Be sure to keep the safety label and/

or warning lables attached to the machine

clearly visible in order to prevent

accidents. If any of the labels has become

stained or come unstuck, be sure to replace

it with a new one.

2.4 Instruction and training

○ Operators and workers, who supervise, repair or

maintain the machine head and/or machine unit,

are required to have the adequate knowledge and

operation skills to do the job safely.

○ The manager should plan and enforce the safety

education and training of those operators and

workers beforehand.

2.5 Modication

Never modify and/or alter the machine in

order to prevent accident that can result in

personal injury or death. Yamato assumes no

responsibility for damages or personal injury

or death resulting from a machine which has

been modied or altered.

ii

Page 6

iii

SAFETY INSTRUCTINONS

WARNING

2.6 Items for which the power to the machine

has to be turned off

Be sure to immediately turn the power off if

any abnormality or failure is found or in the

case of power failure in order to protect

against accidents that can result in personal

injury or death.

To protect against accidents resulting from

abrupt starting of the machine, be sure to

carry out the following operations after

turning the power off.

● When threading to the parts such as the

needle, looper, spreader, etc., or when

changing the bobbin.

● When changing or adjusting all component

parts of the machine.

● Adjusting the stitch length

● Adjusting the differential feed ratio

● When inspecting, repairing or cleaning the

machine or leaving the machine.

○ Be sure to remove the power plug by holding

the plug section instead of the cord section

in order to prevent electrical shock, earth-

leakage or re accidents.

○ If the machine is using a clutch motor, to

protect against accidents resulting from abrupt

starting of the machine, be sure to carry out

the above operations after verifying that the

machine has stopped completely, since the

motor continues turning for a while even after

turning off the power supply switch.

3 PRECAUTIONS TO BE TAKEN IN VARIOUS

OPERATING STAGES

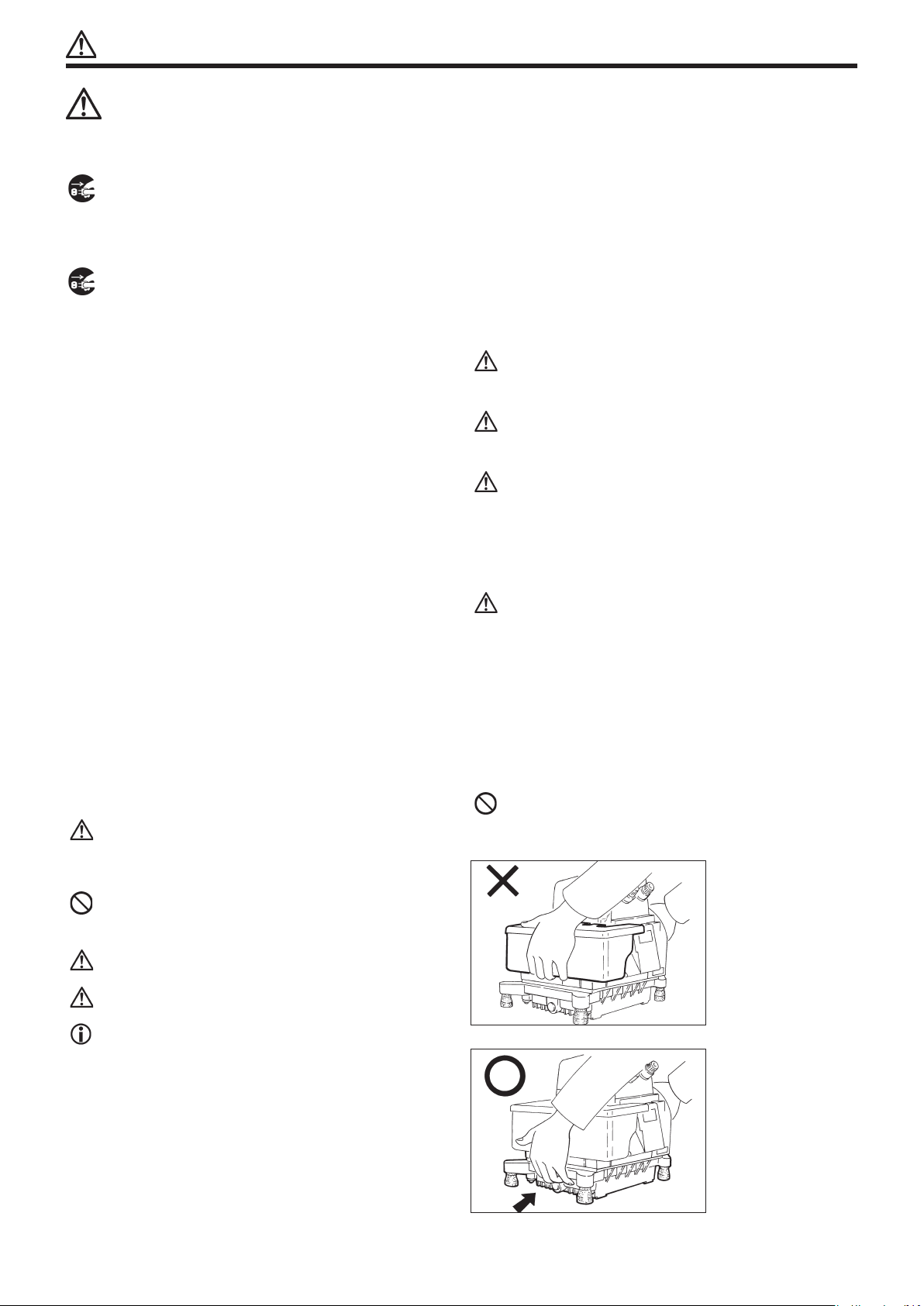

3.1 Unpacking

Be sure to unpack the machine from the top.

If the machine is packed in a wooden crate, be

careful of the nails. Remove the nails from

the board.

Never hold the parts near the needle or

threading parts when removing the sewing

machine head from the buffer of the box.

Removing and carrying the sewing machine head

should always be carried out by two or more people.

Take out the machine very carefully while

checking the position of the center of gravity.

Preserve the cardboard box and packing material

carefully in case secondary transport is

needed in the future.

Disposal of the machine waste

The proper disposal of the machine waste is the

responsibility of the customer, and must be

disposed of in accordance with the locally valid

environmental protection regulations.

The materials used in the machines are steel,

aluminum, brass and various plastics.

A specialist should be commissioned if necessary.

3.2 Transportation

Be sure to take sufcient safety measures to

prevent falling or dropping when lifting or

moving the machine.

If the machine and/or your hands are stained

with oil, the machine may easily fall to the

oor. Therefore, wipe off the oil carefully.

To prevent accidents during transportation,

repackage in the same state as the original

delivery packaging.

Be particularly sure to fully wipe off

any oil adhering to the machine before

repackaging.

The machine head should be carried by two or

more people.

The machine should be carried by people

only when moving to the table or transfer

hand truck, and all other transportation

operations should use a hand truck. When

moving to the table or hand truck, be

careful that the machine is not subjected to

excessive impact or vibrations. Otherwise the

sewing head could fall over.

When handling the machine, do not carry the

bottom part of the cloth plate cover.

Disposal of the packaging

The packaging material of the machine consists

of wood, paper, cardboard and polystyrene foam.

The proper disposal of the packaging is the

responsibility of the customer, and must be

properly disposed of in accordance with the locally

valid environmental protection regulations.

Page 7

iv

SAFETY INSTRUCTINONS

3.3 Installation, preparation

3.3.1 Machine table

Prepare a machine table (table board and legs)

that has sufcient strength to withstand the

weight of the sewing head and any reaction

while operating.

Securely join the table and legs to ensure

sufcient strength to withstand the weight

of the sewing head and any reaction while

operating.

○ Maintain a comfortable working environment

with consideration of the lighting and the

arrangement of sewing machine to enable the

operators to work smoothly.

○ Adjust the height of the table according to

the posture of the worker.

Also, when installing the control box and the

related parts on the sewing machine, make

sure not to affect the posture of the worker.

If casters are tted to the table stand, be

sure to use high-strength casters with a

locking mechanism.

Lock the casters except when moving the machine.

3.3.3 Handling machine oil

Keep machine oil out of the reach of children.

Be sure to ll or add lubrication oil to

sewing machines before operating them.

Use “Yamato SF oil 28” as specied.

If machine oil gets in your eyes, it may

cause eye inammation. Always wear protective

glasses to prevent the oil from getting in

your eyes.

*Should machine oil get in your eyes, wash

them with fresh water for 15 minutes and

then consult a medical doctor.

If oil adheres to your eyes or body, be sure

to immediately wash it off in order to prevent

inammation or irritation.

If oil is swallowed unintentionally, be sure to

consult a medical doctor in order to prevent

diarrhea or vomiting.

Methods of disposing of waste oil and/or

containers are specied by law. Dispose of

it properly as required by law. If you have

further questions on its disposal, consult

the place of purchase.

3.3.2 Wiring and grounding

Never connect the plug for power supply until

assembly is nished.

Also, be sure to avoid the usage of multipleoutlet extension cords in order to prevent

electrical shock, earth-leakage or re

accident.

Fix the connectors securely to the sewing

machine head, motor, and electric apparatus.

Also, when unplugging the connectors, hold

the connector part.

When wiring the connection cords, please take

care of the following.

○ Connect the cords away from the driving

parts.

○ Do not apply excessive force to the

connection cords.

○ Do not bend the cords excessively.

Never use staples to fasten the cables. Otherwise

it may cause a short circuit and/or re.

Arrange the ground wire securely to the designated

position on the machine head.

Also, wire separately from the grounding for

other equipment.

After opening the oil container, be sure

to seal it to prevent dust and water from

getting into the oil and keep it in the dark

to avoid direct sunlight.

Do not store in high-temperature areas or

areas exposed to an open ame.

WARNING

3.4 Before operation

○ Never put your hand under the needle or near

the moving parts of the machine when turning

on the power supply switch.

○ When operating a new sewing machine, make

sure the rotating direction of the pulley

agrees with the rotating-direction mark.

○ Before turning the power on, visually check

the cables and connectors for conditions such

as damage, disconnection and/or loosening.

○ If a table stand with casters is used, be

sure to secure the table stand by locking the

casters or securing the legs with adjusters,

if provided, in order to prevent accidents

caused by abrupt moving of the machine.

Page 8

v

SAFETY INSTRUCTINONS

WARNING

3.5 During operation

○ Be sure to operate the sewing machine using

the safeguards such as belt cover, nger

guard, and eye guard.

○ Never place your nger, hair or objects under

the needle or close to the moving parts while

operating the sewing machine.

○ Be sure to turn off the power supply switch

when threading or replacing the needles.

○ Never place your hands close to the knives

(upper and lower knives) when operating the

sewing machine with the trimming devices.

○ Be sure to turn off the power supply switch

when terminating the sewing work or leaving

the sewing machine.

○ In the event of the power failure, be sure to

turn off the power.

Also, if the sewing machine malfunctions,

makes abnormal sound or emits unusual odors

while operating, be sure to turn off the

power supply switch.

○ While operating the machine, wear clothing

that cannot be caught in the machine.

○ Do not put any tools or other unnecessary

objects on the machine table while running

the machine.

○ If a clutch motor type is used, it will

continue running for a while even after the

power is turned off. Therefore, be careful

because the machine could start running by

pressing the machine pedal.

○ If a servomotor is used, the motor does not

produce noise while the machine is at rest.

Be sure not to forget to turn the power off

in order to prevent accidents caused by

abrupt starting of the machine or motor.

○ To prevent entanglement accidents in machines

with a puller mechanism, keep your hands,

hair, and clothing away from the machine.

WARNING

3.6 Maintenance, inspection and repair

○ Maintenance, inspection, and repair must be

performed by staff that have received special

training and fully understand and follow the

information in the instruction manual.

○ Be sure to turn off the power supply switch

and make sure the sewing machine and motor

completely stop before the maintenance,

inspection, and repair. (If the machine is

using a clutch motor, take care that the

motor keeps turning for a while even after

turning off the power supply switch.)

○ Do not attempt to modify the machine at your

own discretion. We are not responsible for

accidents caused by such modication.

○ Use genuine Yamato parts when repairing the

machine and/or replacing the parts. We are

not responsible for accidents caused by any

improper repair/adjustment and substituting

other parts for those manufactured by Yamato.

○ Turn off the power supply switch if removing

or replacing any parts or during adjustment

of the sewing machine.

○ Be sure to also remove the gasket if the

cover is removed for maintenance, inspection,

and repair. If the gasket is not removed, the

edge of gasket may cause injury.

○ Do not pull the cord when removing the plug.

Be sure to hold the plug itself.

○ A high voltage is applied inside the control

box. Turn off the power supply switch and

wait for at least ve minutes before opening

the cover.

○ Be sure to replace the safety devices and/

or safety covers if removed for maintenance,

inspection and repair.

○ After performing maintenance, inspection and

repair, make sure that turning on the power

does not pose any danger to you.

When operating the machine for the rst time

after work is performed, run at low speed to

check for abnormal sounds or other problems

before performing high-speed operation.

4. Recommended check points for maintaining

machine performance

(1) Perform regular cleaning of the machine parts

by following the instruction manual.

(2) Perform regular inspection of the lubrication

oil by following the instruction manual, and

rell or replace the oil as required.

(3) Because the oil-proof parts use rubber, their

oil-proof performance is reduced over time.

○ If the seals or other stationary parts

fall off or begin to lose their sealing

performance, replace them with new parts.

○ The replacement period for parts used in

the movable sections varies depending

on the machine operating conditions,

environment, maintenance, and oil used,

but replacement every several years is

recommended.

(4) For details about the replacement procedure,

please contact your local dealer or Yamato.

Page 9

vi

SAFETY INSTRUCTINONS

5. Safety devices and warning label affixing locations

Belt cover

The belt cover prevents entanglement with the

belt.

Do not operate with the cover removed.

Front cover

The front cover prevents contact with the

moving parts inside the cover.

Do not operate with the cover opened.

Eye guard

The eye guard prevents injury to the operator’

s eyes due to breaking of needles during the

sewing operation. This section also houses

the needle thread take-up, upper knife, and

other moving parts.

Do not operate with the eye guard opened.

Finger guard

The nger guard prevents the operator’s ngers

from going under the needle. However, there

is some space at the top of the nger guard

and other sections, and so there is a risk of

nger insertion.

Do not operate when the nger guard is removed.

Cloth plate

The cloth plate prevents contact with the

moving parts inside the cloth plate.

Do not operate when the cloth plate is opened.

Safety label, warning label

Reafx the labels if they start peeling off or

become dirty and illegible.

Belt cover

Eye guard

Finger guard

Cloth plate

Safety label

Front cover

Page 10

DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY

We hereby declare that the sewing machine(sewing head) described below;

1. Must not be put into service until the machinery to which it is incorporated has been

declared inconformity with the provisions of the Directive 2006/42/EC, and

2. Conforms to essential requirements of the Directive 2006/42/EC, described in the

technical documentation, and

3. To be prepared with the above technical documentation compiled in accordance with part

B of Annex VII, and

4. Relevant information on wish should be transmitted in response to a reasoned request by

the national authorities by the electronic method or other according to the request.

Model : AZ7000SDR-8 and AZ7500SDR-8 class

Serial No. :

Description : Industrial sewing machine

Function : Make stitches and sew

Applied harmonized standards in particular :

EN ISO12100-1, EN ISO 12100-2, EN ISO10821, EN 60204-31

Manufacturer :

YAMATO SEWING MACHINE MFG. CO., LTD.

2-10-3 Hotarugaike Minami-machi Toyonaka

Osaka Japan

Page 11

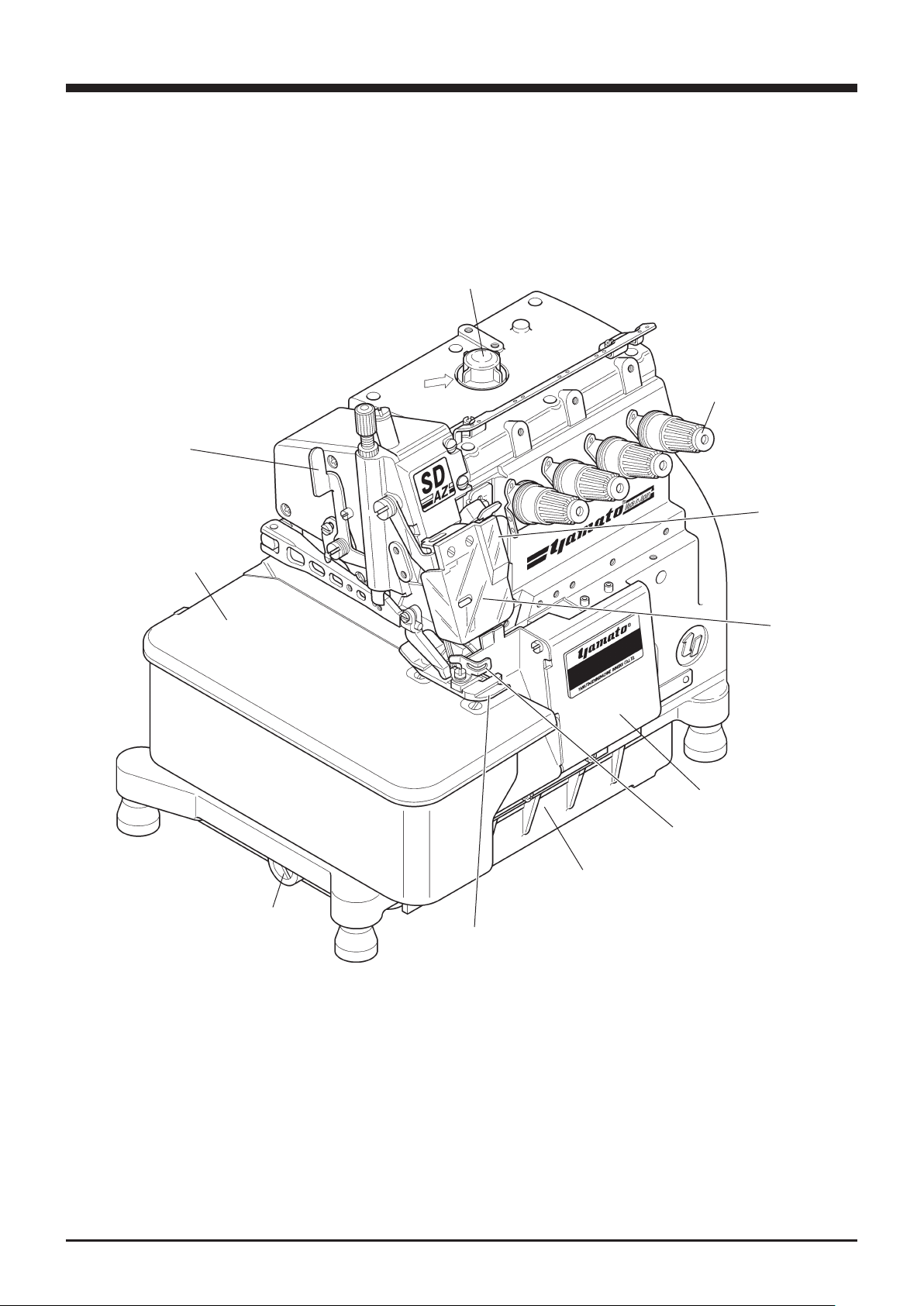

1. Name of each part

Presser foot

release lever

Oil cap

Thread tension

spring cap

SP device

(behind Eyeguard)

Fig. 1-1

Cloth plate

Eye guard

Front cover

Finger guard

Oil reservoir

Drain hole screw

Presser foot

AZ7000SDR -8, 75 00 SDR- 8

1

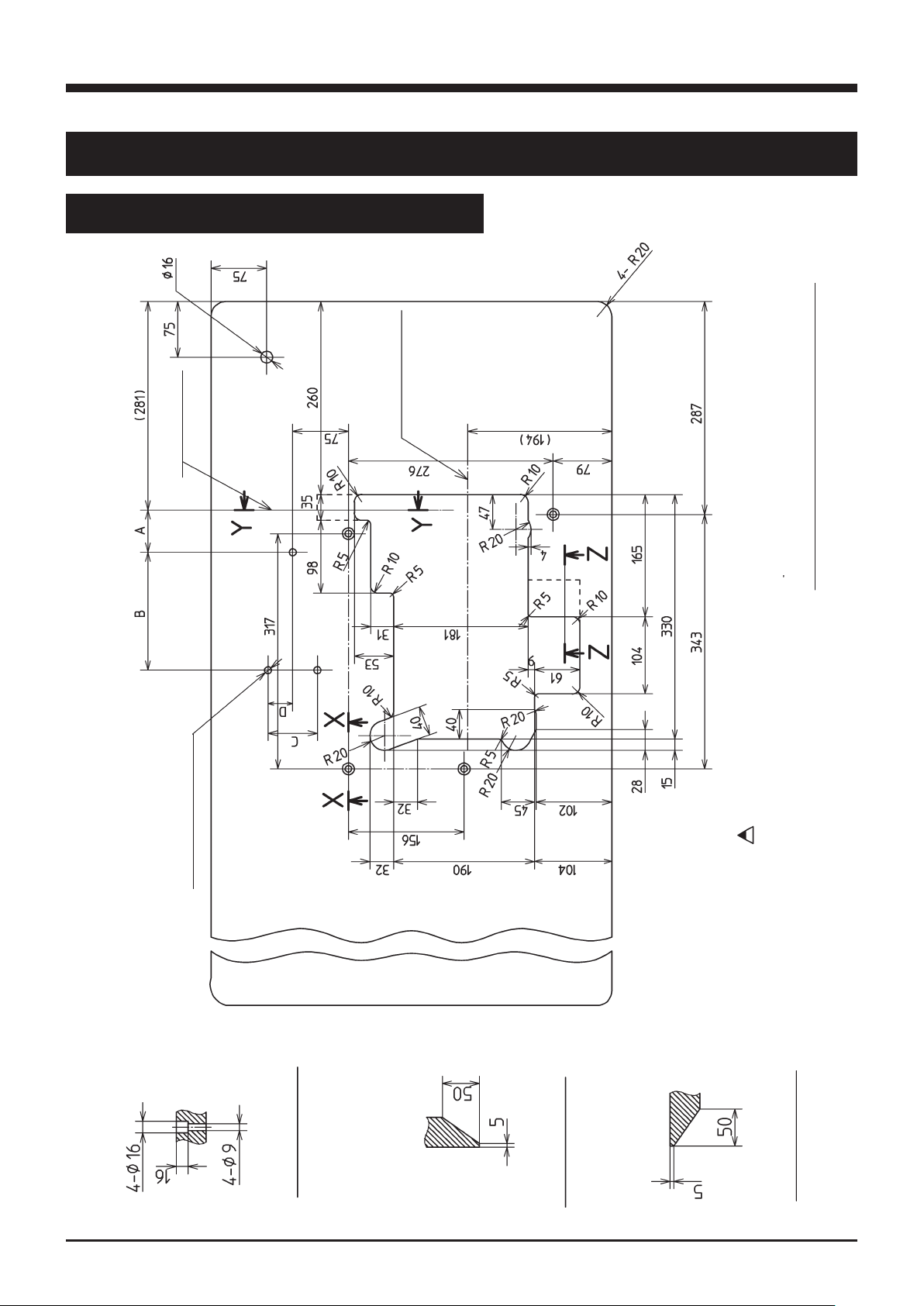

Page 12

2

AZ7000SDR -8, 75 00 SDR- 8

2. Installation

2.1 Semi-submerged type

2.1.1 Table cutting diagram

Center of

machine pulley

Center of

crank shaft

Table dimensions 1200×540×40 mm

operator

3-Φ9.5

installing hole for motor

Fig. 2-1

Section X - X

Refer to the instruction man-

ual of the motor for dimen-

sions A, B, C, and D.

Section Y - Y

Section Z - Z

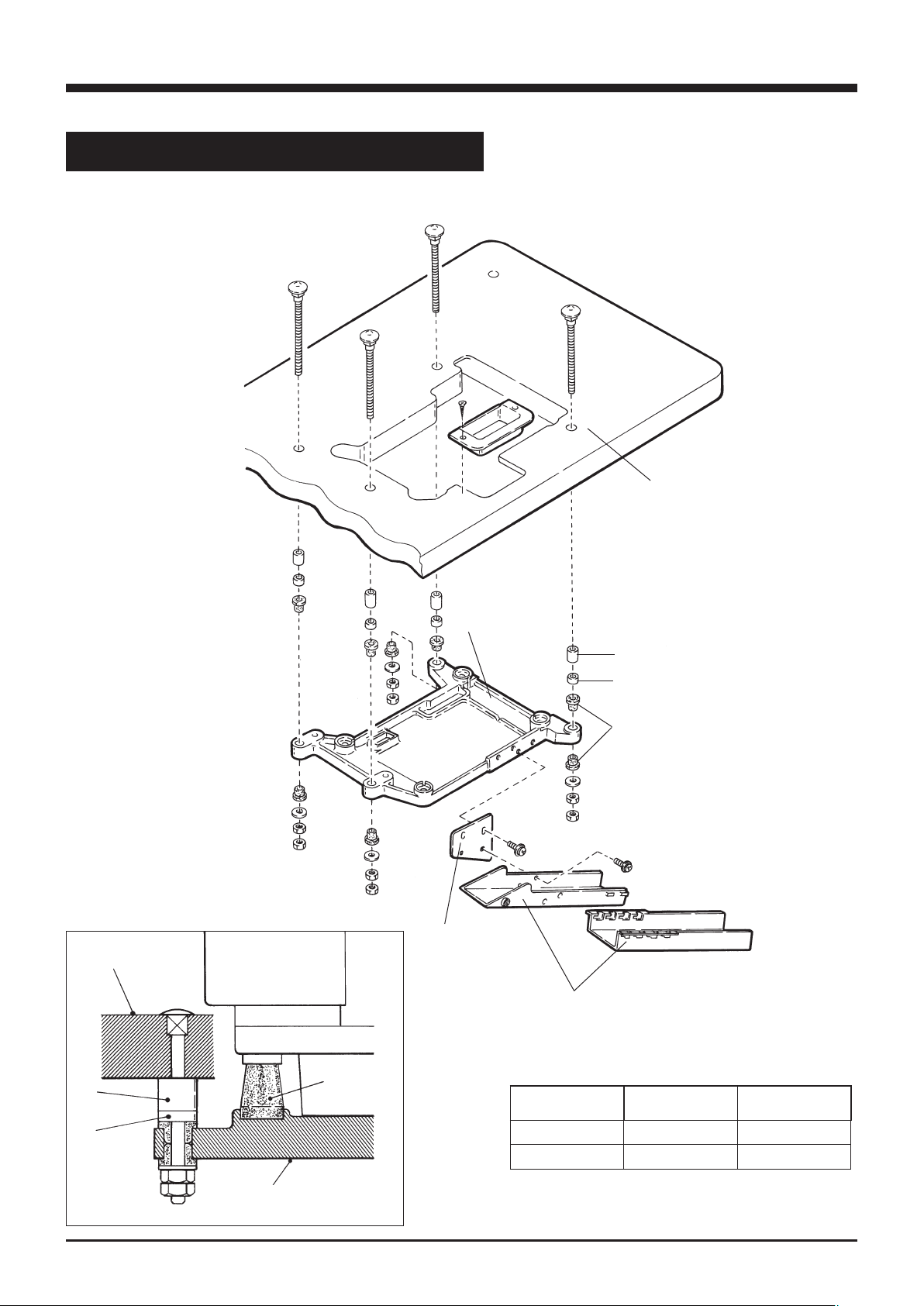

Page 13

3

AZ7000SDR -8, 75 00 SDR- 8

2.1.2 Installation

Install the machine correctly referring to Fig. 2-2 and 2-3.

machine table

③

2. Installation

①

②

③

Fig. 2-2

rubber

cushion

supporting

④

board

⑥

chute (upper)

support

①

②

supporting board

⑤

rubber cushion

chute

⑦

Table 1 The number of spacers ① and ②

thickness of

table

40㎜ 4 4

45㎜ 4 not necessary

pcs. of ① pcs. of ②

④

Size of spacers : ①=15㎜ ②=5㎜

Fig. 2-3

Page 14

2. Installation

4

AZ7000SDR-8, 7500SDR-8

2.2 Fully-submerged type

2.2.1 Table cutting diagram

center of

main shaft

center of

machine pulley

Table dimensions 1200×540×40 mm

0.5(clea rance)

Refer to the instruction man-

ual of the motor for dimen-

0.5(clearance)

sions A, B, C, and D.

operator

magnet

(installing hole for motor)

Section H-H

magnet

installation position of magnetic catch.

made by SUGATSUNE KOGYO Co. Ltd.

Section J - J

drilling

table

auxiliary

0.5 (clearance)

0.5(clea rance)

auxiliary table

Note) Indication of magnet and magnet catch plate can be referred to

K - K

Ref.) Magnetic catch JM-63G-15 and magnetic catch plate AS-68

K’- K’

Section

Fig. 2-4

Section E - E

G - G

G’- G’

table

auxiliary

I - I

Section

table

auxiliary

I’- I’

Section

L - L

L’- L’

Section

Page 15

2. Installation

5

AZ7000SDR-8, 7500SDR-8

注)マグネット、受座の表示は、マグネットキャッチを組付ける参考位置である。

参考)マグネットキャッチスガツネ工業(株)製 JM-63G-15 及び受座AS-68等

Cutting diagram of auxiliary table

3×magnet

catch

Fig. 2-5

auxiliary table

Section X - X

Note) Indication of magnet and magnet catch plate can be referred to

installation position of magnetic catch.

Ref. ) Magnetic catch JM-63G-15 and magnetic catch plate AS-68 made by

SUGATSUNE KOGYO Co. Ltd.

Page 16

2. Installation

6

AZ7000SDR-8, 7500SDR-8

2.2.2 Table cutting diagram for fully-submerged type with device

To set up a machine with device, install the device with below dimensions and refer to “2.2.1 Table cutting

diagram” (Fig. 2-4, 2-5).

AZ7000SDR-8, AZ7500SDR-8 classes

with MT22 device

AZ7000SDR-8 class with K2 deviceAZ7500SDR-8 class with K1 device

AZ7000SDR-8, AZ7500SDR-8 classes

with MU44, 45 device

Using servomotor

Fig. 2-6

Page 17

2. Installation

7

AZ7000SDR-8, 7500SDR-8

2.2.3 Installation

Install the machine correctly by referring to Fig. 2-7 and

2-8.

Adjust the position of supporting board so that the machine can be set horizontally and the cloth plate can be

set on the same height or a little higher than the machine

table.

machine table

①

③

supporting

board connector

Fig. 2-7

①

rubber

cushion

③

supporting

board connector

supporting

②

board

⑤

supplementary

chute cover

supporting board

④

rubber cushion

chute

⑥

③

②

Fig. 2-8

Page 18

2. Installation

8

AZ7000SDR-8, 7500SDR-8

ГБХФЙПО

2.3 Motor, pulley and belt

See the instruction manual for the motor to use and install

the motor properly.

To install the clutch motor, align the center of the machine

pulley with that of the motor pulley when the motor pulley

shifts to the left by toeing down the pedal.

V-belt of M-type

Fig. 2-9

NOTE: Table 2 shows the outside diameter of the motor

pulley, sewing speed of the machine, and size of

the belt when using the clutch motor of 3-phase,

2-pole, 400W(1/2HP).

The outside diameter on the table shows the

nearest size to the calculated values based on the

commercial pulleys at intervals of 5 mm.

Use only those motor pulleys applicable to the machine.

If not, the sewing speed will be over maximum and it can

cause the machine to damage.

Servomotor:

Calculate the outside diameter of a motor pulley from the

formula as below.

Or see Table 3 to select a proper motor pulley diameter.

outside

diametor

of pulley

(㎜)

90 6000 M34 M29

95 6400 M34 M30

100 6700 M35 M30

105 5900 7000 M35 M30

110 6200 7200 M35 M31

115 6500 7500 M36 M31

120 6700 M36 M32

125 6850 M37 M32

130 7000 M37 M32

135 7300 M37 M33

140 7500 M38 M33

sewing speed

of machine

(sti/min)

50 Hz 60 Hz

size of belt

semi-

submerged

Table 2

outside diameter of motor pulley

sewing speed

of machine

(sti/min)

speed of servomotor

3000 rpm 3600 rpm

(㎜)

full-

submerged

Outside diameter Usual sewing speed

of motor pulley Servomotor speed

= ×48.5 + 5 mm

Belt

Use a V-belt of M type.

For belt size, refer to Table 2.

6000 102 86

6200 105 89

6500 110 99

6700 113 95

7000 118 99

7200 121 102

7500 126 106

Table 3

Page 19

2. Installation

9

AZ7000SDR-8, 7500SDR-8

2.4 Hanging belt

ГБХФЙПО

ГБХФЙПО

②

Be sure to install belt cover to prevent you from injuring

and a material from being caught by the belt.

Use the V-belt of M-type.

(1) Hang the belt ① on the machine pulley ②, and then

on the motor pulley ③ while rotating the machine pul-

ley.

(2) Adjust the belt tension so that the belt has 10 to 20

mm slack when its center is pressed with 10 N .

(3) Lock the motor with the adjusting bar ④.

2.5 Belt cover

To prevent you from getting injured and a material from

being caught by the belt, be sure to install the belt cover.

①

10 - 20㎜

③

④

Fig. 2-10

⑤

(1) Install the auxiliary belt cover ⑤ as shown in the g-

ure.

(2) Install the belt cover ⑥ as shown in the gure.

Fig. 2-11

⑥

2.6 Eye guard and finger guard

To ensure safe use, ALWAYS install the eye guard ⑦ and the nger guard ⑧ on the prescribed position during operation.

⑧

⑦

Fig. 2-12 Fig. 2-13

Page 20

10

AZ7000SDR -8, 75 00 SDR- 8

3.

ГБХФЙПО

Table 4 shows the maximum sewing speed of each model.

Run a new machine at 15 to 20% lower sewing speed of

its maximum sewing speed during the rst 200 hours (for

about one month) so that the machine can offer a long

service life in good condition.

The rotating direction of the motor pulley ① and the machine pulley ② is clockwise as shown in the gure.

Sewing speed and rotating direction of pulley

②

①

If rotating in reverse direction, oil can not be supplied

properly. It can cause the machine to damage.

Fig. 3-1

m o d e l

AZ7000SDR-8 class

AZ7120SDR-8 class

AZ7500SDR-8 class

AZ7500SDR-31,AZ7520SDR-31 class

Table 4

max sewing

speed(sti/m in)

7500

7000

7500

7000

Page 21

11

AZ7000SDR -8, 75 00 SDR- 8

4. Lubrication

ГБХФЙПО

ГБХФЙПО

4.1 Lubricating oil

Use YAMATO SF OIL No. 28.

NEVER add additives to the oil.

If added, it can cause the deterioration of the oil and the

damage to the machine.

4.2 Lubricating

When using a new machine or a machine which has not

been run for a while, supply few drops of oil to the needle

bar ① and the looper bar ②.

①

Remove the oil cap ③ indicated “OIL-IN” and supply oil

to the upper line of the oil sight gauge ④.

Make sure that the oil splashes from the nozzle inside the

oil cap ③ when running the machine.

If oil does not splash from the nozzle, see “4.4 Checking

and replacing oil lter” on page 12.

Too much oil or insufficient oil can cause oil leakage and

machine trouble. Be sure to keep the oil level between

the lines. Also too much lubrication can cause the oil to

scatter and material to be stained.

④

Fig. 4-1

②

Fig. 4-2

③

Fig. 4-3

Fig. 4-4

Page 22

12

AZ7000SDR -8, 75 00 SDR- 8

4. Lubrication

БФФЕОФЙПО

�

ОПФЙГЕ

4.3 Changing oil

Period :

When using a new machine, change the lubricating oil after running the machine for 200 hours (about one month).

After that, change the oil once or twice a year.

Procedure :

(1) Remove the belt cover. (See page 9)

(2) Remove V-belt from the motor pulley. (See page 9)

(3) Remove the machine from the machine table.

(4) Set a container under the screw ① to receive the oil.

(5) After removing screw ①, the oil will drain out.

Be careful not to soil the V-belt and the machine pulley

with the oil.

(6) Reset the screw ①.

(7) Change the oil. (See “4.2 Lubricating” on page 11)

(8) Reinstall the machine on the machine table.

(9) Hang the V-belt on the motor pulley and reinstall the

belt cover. (See page 9)

①

Fig. 4-5

◆ If the oil lter ② is clogged with dust, lubrication can-

not be done properly.

◆ Remove the oil lter cap ③ and the oil lter ② to

check them every six months. If clogged or cracked,

clean or replace the oil lter.

◆ If the oil splashes from the nozzle insufciently or includes many bubbles even though oil is sufciently

kept, check or replace the oil lter.

Be careful the oil may spill out from the oil filter ②,

when loosening the screw ④.

4.4

Checking and replacing oil filter

②

③

④

Fig. 4-6

Page 23

13

AZ7000SDR -8, 75 00 SDR- 8

5. Proper operation

БФФЕОФЙПО

ГБХФЙПО

5.1 Needle system

AZ7000SDR-8 : DC×1 ( or 81×1 )

AZ7003SDR-8,AZ7020SDR-8,

AZ7120SDR-8 class : DC×27 ( or B27, 1886 )

AZ7500SDR-8 class : DC×27 ( or B27, 1886 )

Select proper needles in size according to the thickness

and the type of the material.

5.2 Installing needles

Before installing the needles, ALWAYS turn the motor switch OFF and check that the motor has already

stopped.

(1) Loosen the screw ① with a minus screw driver.

(Fig. 5-1)

(2) Remove the old needle with a pair of tweezers.

(3) Insert a new needle into the needle clamp ② as far as

it goes with facing its scarf to the right back.

(Fig. 5-2 and 5-3)

(4) Tighten the screw ① with the minus screw driver.

● Accessories include the minus screw driver.

japanese

standard

metric

standard

Table 5

8 9 10 11 12 13 14

60 65 70 75 80 85 90

②

①

①

front

The tightening torque of the screw ① is 0.6 N・m.

NO OK! NO

Fig. 5-2

AZ7500SDR-8AZ7020SDR-8

Fig. 5-1

OK! NO

Fig. 5-3

Page 24

5. Proper operation

14

AZ7000SDR -8, 75 00 SDR- 8

БФФЕОФЙПО

ГБХФЙПО

5.3 Adjusting thread tension

Adjust the thread tension with the thread tension spring

caps ① to ⑥ according to the type of fabric, the type of

thread, seam width, stitch length, and other sewing conditions.

④

tighten

● To tighten the thread tension, turn caps clockwise.

● To loosen the thread tension, turn caps counterclock-

wise.

model

thread

left needle

thread

right needle

thread

double chain

needle thread

upper looper

thread

lower looper

thread

double chain

looper thread

AZ7000SDR-8

single needle

overlo c k

AZ7020SDR-8

2-needle

overlo c k

AZ75 0 0SDR- 8/-31

2-needle

safety stitch

① ① ① ①

② ②

② ③

③ ③ ③ ④

④ ④ ④ ⑤

⑥ ⑥

AZ75 20SDR-8/-31

3-needle

safety stitch

Table 6

loosen

③

②

①

Fig. 5-4 AZ7020SDR-8, AZ7500SDR-8/-31

⑤

tighten

loosen

④

③

②

①

Threading

Before threading, ALWAYS turn the motor switch OFF

and check that the motor has already stopped.

Threading correctly by referring to the threading gure

which is attached on the back of the front cover.

Improper threading can cause thread breakage, skip

stitch, and uneven stitch.

Fig. 5-5 AZ7520SDR-8/-31

loosen

⑥

open the cloth plate

Fig. 5-6

AZ7500SDR-8/-31,AZ7520SDR-8/-31

tighten

Page 25

5. Proper operation

15

AZ7000SDR -8, 75 00 SDR- 8

5.4 Pressure of presser foot

ГБХФЙПО

ГБХФЙПО

Loosen the lock nut ① and adjust the pressure of the

presser foot by turning the adjusting screw ②.

● To increase the pressure, turn the adjusting screw

clockwise.

● To decrease the pressure, turn the adjusting screw

counterclockwise.

Keep the pressure as low as possible for stable stitch.

5.5 Releasing presser foot

decrease

increase

②

①

Fig. 5-7

Before adjusting, ALWAYS turn the motor switch OFF

and check that the motor has already stopped.

Rotate the machine pulley and position the needle at the

highest point. Release the presser foot to the left while

pressing the presser foot release lever ③.

To set the presser foot, slide and press the presser foot to

the right while pressing the presser foot release lever ③.

Then, release the lever.

Make sure that the presser arm ④ gets into the groove

of the presser bar ⑤.

If not, it can cause breakage to parts and injuries.

③

④

⑤

Fig. 5-8

Page 26

5. Proper operation

16

AZ7000SDR -8, 75 00 SDR- 8

5.6 Opening cover

Front cover ①

To open the front cover ①, slide it to the right and tilt

toward you.

For closing, stand the cover. The spring tension makes it

slide to the left.

Cloth plate ②

To open the cloth plate ②, shift it to the left while pressing the lever ③.

For closing, shift it to the right. Make sure that it has

been locked securely.

②

Fig. 5-9

③

①

5.7 Adjusting differential feed dog

Loosen the lock nut ④ and adjust the differential feed lever ⑤.

Moving up will make stretching and moving down will

make gathering.

Adjust differential feed lever ⑤ securely with turning the

screw ⑥.

● To lower the lever, turn the screw clockwise.

● To raise the lever, turn the screw counterclockwise.

Differential ratio up to 1:0.6 to 1:2 or 1:1 to 1:3 is available by internal adjusting mechanism respectively.

Adjust the graduation, differential ratio, and max. stitch

length according to Table 7.

④

Fig. 5-10

graduation

differential

ratio

⑥

⑤

max. stitch

length ( ㎜ )

S 1:0.7 5

1 1:1 5

2 1:1.6 4

3 1:2.3 3

Table 7

Page 27

5. Proper operation

17

AZ7000SDR -8, 75 00 SDR- 8

5.8 Adjusting stitch length

ГБХФЙПО

ГБХФЙПО

Before adjusting, ALWAYS turn the motor switch OFF

and check that the motor has already stopped.

Each graduation on the machine pulley indicates the

length (㎜) for one stitch.

Actual stitch length may different from the length on

graduations. It may changes depending on the application,

type, weight of material or the differential ratio.

(1) Rotate the pulley while pressing the push button ①. At

the point that the push button can go in, press it again

strongly.

(2) Then align the desired graduation of the pulley with

the mark ② on the belt cover.

(3) Release the push button ①.

①

Fig. 5-11

● To make stitch length smaller, turn the pulley in the

direction “S”.

● To make stitch length greater, turn it in the direction “L”.

Check that push button is released completely and the

pulley rotates smoothly.

The adjustable range of the stitch length is shown in Table

8.

Table 9 shows the number of stitches per inch (25.4 mm)

and 30 mm.

②

Fig. 5-12

model stitch length (㎜)

AZ7000SDR-8 class

AZ7500SDR-8 class

( except for below)

AZ7016SDR-8 0.6~2

Table 8

stitch length

(㎜)

1 25 30

number of stitch

(per 1 inch)

(25.4㎜)

1~4

number of stitch

(per 30㎜)

2 12 15

3 8 10

4 6 7.5

Table 9

Page 28

5. Proper operation

18

AZ7000SDR -8, 75 00 SDR- 8

ГБХФЙПО

5.9 Passing tape

Pass a tape ① by referring to Fig. 5-13 for the models of

the tape attaching.

5.10 SP device and HR device

The SP device (needle thread oiling) and HR device (

needle point cooling) are equipped as standard (excluding

some models) to prevent thread breakage and skip stitch

when running the machine at high speed or using synthetic thread and/or synthetic fabric.

①

tape guide

eye guard

tape guide

Fig. 5-13

④

③

1. When not using SP device and HR device, remove felts

③ and ⑤. It may occur irregular condition during

sewing.

2. If the silicone oil is stuck to the parts other than SP

and HR devices, it can cause the machine trouble. Be

sure to wipe it away.

Use dimethyl silicone oil.

Check the oil amount in SP tank ②. If not enough, supply

the oil into the hole ③.

Open the oil container plug ⑤ of HR device and check

the oil amount. If not enough, supply the oil.

②

Fig. 5-14 SP device

⑥

⑤

Fig. 5-15 HR device

Page 29

5. Proper operation

19

AZ7000SDR -8, 75 00 SDR- 8

5.11 Cleaning the machine

ГБХФЙПО

ГБХФЙПО

Before cleaning, ALWAYS turn the motor switch OFF and

check that the motor has already stopped.

The sewing machine should be cleaned at the end of every

working day.

Grooves of stitch plate and the area around feed dogs

should be cleaned once a week.

Clogged dust can cause breakage to parts and oil leakage.

Fig. 5-16

Checking at sewing factory

(maintenance by technician)

Daily maintenance:

(1) Before operation, remove the machine cover and re-

thread correctly. Make sure there is no slack. Check

that the thread hanger is right above the spool seat

discs of the thread stands (the thread stands should be

xed securely).

(2) Check the lubricating and silicone oil amount. Supply

them if necessary.

(3) Check the order of threads.

(4) Check bend of needles, damage to tips, and the setting

positions respectively.

(5) Check the sharpness of knives.

(6) Check the stitches by sewing a test fabric.

◆ stitch length, differential feeding

◆ adjusting knives and thread tension

Weekly maintenance:

(1) On weekends, clean the machine carefully after remov-

ing the presser foot and the stitch plate.

(2) Check the tension of V-belt.

(3) Check and supply the lubricating oil.

Page 30

20

AZ7000SDR -8, 75 00 SDR- 8

6. Adjustment of sewing machine

ГБХФЙПО

Before adjusting, ALWAYS turn the motor switch OFF and check that the motor has stopped.

6.1 Needle thread tension for overlock stitch

To set the standard position of needle thread eyelet ①,

position the center of the screw ② with the marks ③.

To set the standard position of the needle thread pull-

off ④, align the portion ⑤ with the eye ⑥ of the needle

thread eyelet (right) when the needle thread pull-off ④

comes to the extreme front.

Loosen the screw ⑦ to adjust it.

● To loosen the needle thread tension, move the nee-

dle thread eyelet and the needle thread pull-off in

the direction “L”.

● To tighten the needle thread tension, move them in

the direction “T”.

③

L

T

②

①

Fig. 6-1

L

T

⑤

④

⑥

⑦

④

Fig. 6-2

Page 31

21

AZ7000SDR -8, 75 00 SDR- 8

6.2 Looper thread tension for overlock stitch

①

6.Adjustment of sewing machine

T

L

L

⑦

T

A

L

T

Fig. 6-3

⑩⑧

⑪

The standard position of each looper thread eyelet:

Upper looper supplementary thread eyelet ①

Move it to the extreme left.

②

L

L

④

T

T

L

T

③

⑨

L

B

⑥

⑤

T

Looper thread eyelet (left) ②

Position the part A horizontally.

Upper looper thread eyelet ③

Move its left end to mark ④.

Lower looper thread eyelet ⑤

Position the center of the width B with mark ⑥.

Looper thread pull-off ⑦

Move its right end to mark ⑧.

Upper looper thread pull-off ⑨

Align the eye of the thread pull-off with the mark ⑩ when the lower looper moves to the extreme right.

Lower looper thread pull-off ⑪

Tighten it with the screw at the center of the slot.

● To tighten the thread tension, move each thread eyelet or thread pull-off in the direction “T”.

● To loosen the thread tension, move them in the direction “L”.

Page 32

22

AZ7000SDR -8, 75 00 SDR- 8

6.Adjustment of sewing machine

6.3 Needle thread tension for double chainstitch

◆ To set the standard position of the needle thread eyelet (left) (double chain) ③, adjust the needle thread of

double chain on a level with the eyelet (left) ③ when

the needle bar is at the highest point.

Loosen the screws ④ to adjust it.

◆ To set the standard position of the needle thread eyelet

holder (double chain ) ①, position the center of the

slot in the center of the screw ②.

◆ To set the standard position of the needle thread eyelet (right) (double chain) ⑦, align the portion ⑥ with

the eye ⑧ at the most front position of the needle

thread pull-off ⑤ when the needle thread eyelet holder

(double chain) and the needle thread pull-off are at the

standard position.

Loosen the screw ⑨ to make adjustment.

● To loosen the needle thread tension, move the nee-

dle thread eyelet and the needle thread pull-off in

the direction “L”.

● To tighten the needle thread tension, move them in

the direction “T”.

Fig. 6-4

④

③

⑦

②

①

⑨

⑤

⑥

⑧

⑤

Fig. 6-5

⑦

Page 33

23

AZ7000SDR -8, 75 00 SDR- 8

6.4 Looper thread tension for double chainstitch

БФФЕОФЙПО

◆ Align the eye of the double chain looper thread eyelet ③ with the surface ② of the double chain looper

thread take-up ① when being a level with the straight

line A.

Position the thread retaining nger ④ 1 mm above the

eye of the looper thread eyelet ③.

6.Adjustment of sewing machine

T

⑤

L

③

②

④

◆ To set the standard position of the double chain looper

thread eyelet ③, position the center of the slot in the

center of the screw ⑤.

● To loosen looper the thread tension, move the looper thread eyelet in the direction “L”.

● To tighten the looper thread tension, move it in the

direction “T”.

◆ At the standard timing of the looper thread take-up,

the looper thread take-up starts taking up the looper

thread when the needle starts lowering from the highest point.

Set the thread retaining finger in the center of double

looper thread take-ups when tightening the screw of it.

Fig. 6-6

A

1 ㎜

①

Page 34

24

AZ7000SDR -8, 75 00 SDR- 8

6.Adjustment of sewing machine

БФФЕОФЙПО

6.5 Width of overedge seam

Before adjustment, set the edge of the upper knife ① 0 to

0.5 mm above the lower knife ②.

To make wide overedge seam:

(1) Loosen the screw ③ on the upper knife holder ⑤.

(2) Tighten the screw ③ securely after moving the holder

⑤ as desired in the direction “W”.

(3) Loosen the screw ④ on the lower knife holder ⑥.

(4) The lower knife ② touches the upper knife ① closely

with ts spring.

(5) Tighten the screw ④ securely.

①

0 - 0.5 ㎜

②

stitch plate

To make narrow overedge seam:

(1) Loosen the screw ④.

(2) Tighten the screw ④ slightly after moving the holder

⑥ as desired in the direction “N”.

(3) Loosen the screw ③.

(4) Tighten the screw ③ with applying the upper knife ①

to the lower knife ②.

(5) Loosen the screw ④.

(6) The lower knife ② touches the upper knife ① closely

with its spring.

(7) Tighten the screw ④ securely.

1. After changing the width of overedge seam, check

the sharpness of the blades. (See“6.6.4 Sharpness of

k n i v e s ”)

2. Use a stitch plate applicable to the width of overedge

seam.

Adjustable range of overedge seam is within ±0.5 mm

based on the value indicated the gauge respectively.

However, adjustable range of stitch plate of AZ7120SDR-Y5-8 is 5 to 5.5mm.

3. Dust clogged at the connecting part of the upper knife

holder changes the installing angle of the knives. It

will make them cut badly. Be sure to clean the parts

by loosening the screw ③.

Fig. 6-7

N

Fig. 6-8

⑤

③

W

①

②

⑥

④

Page 35

25

AZ7000SDR -8, 75 00 SDR- 8

6.6

Upper and lower knives

6.6.1 Height of lower knife

Loosen the screw ② to install the edge of the lower knife

① on a level with the top surface of the stitch plate or 0

to 0.3 mm lower than it.

6.Adjustment of sewing machine

0 - 0.3 ㎜

①

②

Fig. 6-9

6.6.2 Height of upper knife (flat type)

Loosen the screw ④ to make the engagement between the

upper knife ③ and the lower knife ① to 0.5 to 1.0 mm

when the upper knife is at the lowest point.

6.6.3 Height of upper knife (angled type)

Loosen the screw ⑦ and apply the upper knife ⑤ to the

stopper ⑥ fully. It makes the height automatically.

Then tighten the screw ⑦ securely.

④

Fig. 6-10

0.5 - 1.0 ㎜

③

①

⑥

⑦

⑤

Fig. 6-11

Page 36

26

AZ7000SDR -8, 75 00 SDR- 8

6.Adjustment of sewing machine

6.6.4 Sharpness of knives

After adjusting the knives and the width of overedge seam,

check the sharpness of the blades by setting a thread between the upper and the lower knives while rotating the

machine pulley by hand.

thread

Fig. 6-12

6.6.5 Sharpening knives

If the lower knife cuts badly, re-sharpen it.

(Fig. 6-13)

The upper knife made of super hard alloy is unnecessary

to re-sharpen for about one year and normal grinder is

not useful for re-sharpening it.

Keep another upper knife for spare.

If needed, contact us directly or a dealer for re-sharpening.

10°

55°

Fig. 6-13

Page 37

27

AZ7000SDR -8, 75 00 SDR- 8

6.7 Height of feed dogs

�

БДЦЙГЕ

To set the standard position, set the tops of the main ①

and differential feed dogs ③ parallel to that of the stitch

plate when the tops of the feed dogs are raised and even

with that of the stitch plate.

6.Adjustment of sewing machine

Make the height between the top of the stitch plate and

the rear side of the main feed dog ③ to 0.8 mm when the

feed dog is at the highest point.

Install the auxiliary feed dog ⑤ depending on the machine

class as below.

AZ7000SDR-8 class

AZ7020SDR-8 class (Refer to Table 10)

Install the auxiliary feed dog ⑤ 0.5 mm lower than the

main feed dog ③ as standard.

AZ7500SDR-8 class (Refer to Table 10)

Install the auxiliary feed dog ⑤ even with the main feed

dog ③.

Loosen the screws ②④⑥ to adjust the differential feed

dog ①, the main feed dog ③, and the auxiliary feed do ⑤

respectively.

0.8 ㎜

Fig. 6-14

③

②

③

④

⑥

⑤

①

stitch

plate

①

1. Be sure to make no difference of installing height between the main feed dog ③ and the differential feed

dog ①. If different, it can cause the unstable feeding

and feed scratch mark.

2. For sewing heavy weight knitted fabric or the material having uneven thickness parts, adjust differential

feed dog ① and main feed dog ③ 1.0 mm higher than

standard position respectively.

Difference between main feed dog and auxiliary feed dog

model difference (mm)

AZ7000SDR-8 class

( exclude below )

AZ7016SDR-8 0

AZ7500SDR-8/-31 class 0

Table 10

( lower than main feed dog )

0.5

Fig. 6-15 AZ7000SDR-8 class

⑤

③

⑥

②

Fig. 6-16 AZ7500SDR-8/-31 class

④

①

Page 38

28

AZ7000SDR -8, 75 00 SDR- 8

6.Adjustment of sewing machine

6.8 Tilt of feed dog

Remove the tail cover ① to loosen the screw ②.

Move the feed bar block (rear) lid ③ to make adjustment.

● To tilt the feed dog forward down , move it up.

● To tilt the feed dog forward up, move it down.

①

Fig. 6-17

②

forward down

Fig. 6-18

③

forward up

Page 39

29

AZ7000SDR -8, 75 00 SDR- 8

6.Adjustment of sewing machine

6.9 Needles and loopers

Make adjustment by following the steps below:

In case of 2-needle overlock machines and 3-needle safety stitch machines

(1) Height of needle

(2) Installation angle of lower looper

(3) Fix the distance between needle and lower looper, the back and forth position of lower looper temporarily

(4) Parallel of needles

(5) Back and forth position of upper looper

(6) Distance between needle and upper looper

(7) Back and forth position of lower looper

(8) Distance between needle and lower looper

(9) Timing relation between lower looper and upper looper

In case of 1-needle overlock machines and 2-needle safety stitch machines

(1) Height of needle

(2) Back and forth position of upper looper

(3) Distance between needle and upper looper

(4) Installation angle of lower looper

(5) Back and forth position of lower looper

(6) Distance between needle and lower looper

(7) Timing relation between upper looper and lower looper

6.9.1 Height of needle

(1) Loosen the screws ① to remove the logo plate ②.

(Fig. 6-19)

(2) Remove the screw ③.

(3) Rotate the machine pulley to raise the needle bar to

the highest point.

(4) Loosen the screw ④ and adjust the needle bar while

moving it up and down.

②

①

When the needle bar is at the highest point, make the

height “N” from the top of the stitch plate to the needle

tip in Table 11.

③

④

Fig. 6-19

Page 40

30

AZ7000SDR -8, 75 00 SDR- 8

6.Adjustment of sewing machine

БФФЕОФЙПО

model

AZ7000SDR-8 class 1-needle 10.0 - 10.3 6-20 -1

AZ7020SDR-8 class 2-needle 10.0 - 10.3

AZ7120SDR-8 class 10.7 - 11.0

AZ7500SDR-8 class 10.0 - 10.3 6-20-3

AZ7520SDR-8 class 10.0 - 10.3 6-20-4

AZ7500SDR-31 10.7 - 11.0 6-20-3

AZ7520SDR-31 10.7 - 11.0 6-20-4

Table 11

1. Tighten the screw ④ with a tightening torque of 1.5

N・m.

2. Check the parallel setting of the needles for 3-needle

machine (See“6.9.4 Parallel of needles”).

3. Apply the liquid packing to the thread of the screw ③

when tightening it.

height of needle

“N” (mm)

Fig. No.

6-20-2

Fig. 6-20-1

Fig. 6-20-2

AZ7000SDR-8 class

single needle

N

AZ7020SDR-8 class

AZ7120SDR-8 class

2-needle

N

AZ7500SDR-8/-31 class

N

6.9.2 Installing angle of lower looper

The standard installation angle of lower looper ① is value

A in Table 12 .

Make adjustment by loosening the screw ② to make the

height difference between the rear and the tip of the lower

looper to value B in Table 12. (Fig. 6-21)

model

2-needle overlock machine

( AZ7020SDR-8 class,

AZ7120SDR-8 class )

3-needle safety stitch machine

( AZ7520SDR-8/-31 class)

1-needle overlock machine

( AZ7000SDR-8 class )

2-needle safety stitch machine

( AZ7500SDR-8/-31 class )

Table 12

A B

2~4°

2~3°

0.5 -

1.5 mm

0.5 -

1.0 mm

Fig. 6-20-3

Fig. 6-20-4

A

Fig. 6-21

①

AZ7520SDR-8/-31 class

N

①

B

6.9.3

Distance between needle and lower looper

Rotate the machine pulley clockwise and move the lower

looper ① to the extreme left. Make the distance between

the lower looper tip and the center of the needle to 3.3 to

3.8 mm.

Loosen the screw ③ on the lower looper holder to adjust

it.

3.3-3.8㎜

②

3.3-3.8㎜

③

Fig. 6-22

Page 41

31

AZ7000SDR -8, 75 00 SDR- 8

6.9.4 Parallel of needles

БФФЕОФЙПО

In the case of 2-needle machines, loosen the screw ④ of

the lower looper holder arm and turn the adjusting screw

⑤ clockwise or counterclockwise to adjust the back and

forth position of the lower looper so that the clearance

between the left needle and lower looper is set to between

0 to 0.05 mm when the lower looper has arrived at the

center of the left needle. Then, tighten screw ④ slightly.

Loosen screw ①, turn the needle clamp slightly, and ad-

just it so that the clearances between the right and the

needle on the left are the same. As with the left needle,

adjust the clearance to between 0 to 0.05 mm when the

right needle and lower looper meet.

6.Adjustment of sewing machine

0 -

0.05 ㎜

needles

Fig. 6-23

1. After checking the needle heights, tighten screw ①

of the needle bar bracket. Refer to“6.9.1 Height of

needle” on page 29.

2. Once the parallelism adjustment has been conducted

for the needles, be sure to adjust the back and forth

position of the looper.

3. Once the back and forth position of the lower looper

has been adjusted, check the distance between the

needle and the lower looper, then tighten screw ④ in

Fig. 6-25.

4. Apply the liquid packing to the thread of the screw ②

when tightening it.

②

①

Fig. 6-24

0 - 0.05 ㎜

③

⑤

④

Fig. 6-25

Page 42

32

AZ7000SDR -8, 75 00 SDR- 8

6.Adjustment of sewing machine

6.9.5 Back and forth position of lower looper

1-needle overlock stitch on AZ7000SDR-8 and

AZ7500SDR-8 classes:

Adjust so that the lower looper ① tip touches the needle

and bends it by no more than 0.03 mm when the lower

looper ① meet the center of the needle.

2-needle overlock stitch on AZ7020SDR-8 and

AZ7520SDR-8 classes:

(1) Adjust so that the lower looper ① tip touches the

needle and bends it by no more than 0.03 mm, using

the left needle as a reference, when the lower looper ①

meet the center of the left needle.

(2) Make sure that the lower looper ③ tip touches the

right needle and bends it by no more than 0.03 mm as

with the left needle when the lower looper ③ reaches

the right needle.

Procedure

Loosen the screw ② of lower looper holder arm, and turn

the adjusting screw ③ to adjust the position of the lower

looper.

● When turn it to the right, the lower looper comes to

the front.

● When turn it to the left, the lower looper goes to

the rear.

①

Fig. 6-26

①

Fig. 6-27

0 - 0.03 ㎜

③

②

0 -

0.03 ㎜

needles

Be sure to tighten the screw ② after adjustment.

Page 43

33

AZ7000SDR -8, 75 00 SDR- 8

6.9.6 Distance between needle and upper looper

БФФЕОФЙПО

6.Adjustment of sewing machine

Rotate the machine pulley clockwise and move the upper

looper to the extreme left. Make the distance between the

upper looper tip and the center of the needle to 5.0 to 5.5

mm.

(1) Loosen the screw ②. (Fig. 6-28)

(2) Make the looper thread eyelet ③ away from auxiliary

looper holder cover ④. (Fig. 6-29)

(3) Remove the screw ⑤.

(4) Remove the cover ④.

(5) Loosen the screw ⑥ to make adjustment. (Fig. 6-30)

Tighten the screw ⑥ while pressing it against to the machine, after adjustment.

③

5.0 - 5.5 mm

①

Fig. 6-28

②

④

⑤

⑤

Fig. 6-29

6.9.7 Back and forth position of upper looper

The thick portion (around the needle eye) of the upper

looper will be very close to the needle when the upper

looper moves from the extreme left to the right while rotating the machine pulley clockwise. (In case of 2-needle

machine, it will be close to the right needle.)

Loosen the screw ⑦ to make the clearance between the

back side of the upper looper ① and the needle to 0.05 to

0.1 mm.

⑥

Fig. 6-30

0.05 -

0.1 ㎜

⑦

①

①

Fig. 6-31

Page 44

34

AZ7000SDR -8, 75 00 SDR- 8

6.Adjustment of sewing machine

6.9.8 Timing relation between lower looper and upper looper

Make sure that the clearance between the back and forth

is 0.05 to 0.1 mm and between the right and left is 0.05

to 0.3 mm when the lower looper ① meets the upper looper ② while rotating the machine pulley clockwise.

Be sure to let clearances in the above mentioned ranges.

6.10 Needle and double chain looper

Timing relation:

To set the height, insert the double chain looper ③

into the looper holder until it touches the bottom of the

holder.

0.05 - 0.1 ㎜

②

0.05 - 0.3 ㎜

①

Fig. 6-32

④

③

Make the distance between the center of the double

chain needle ④ and the double chain looper tip to 2.0

to 2.2 mm when the double chain looper ③ is at the extreme left. Loosen the screw ⑤ to make adjustment.

Tighten the screw ⑥ temporarily, and make it have an

approximately 6°angle to the looper. Adjust the distance so that the looper tip can touch the double chain

needle ④ slightly.

Back and forth position:

Make the looper ③ tip pass the back of the needle and

keep them as close as possible without touching each

ot her.

Make the needle pass the back of the curved portion of

the looper and let them touch each other slightly when

the looper moves from the right to the left (the needle

goes down at the back of looper).

Fig. 6-33

Fig. 6-34

⑥

2.0 - 2.2 ㎜

⑤

③

about

6°

1.6 - 1.8 ㎜

Fig. 6-35

Page 45

35

AZ7000SDR -8, 75 00 SDR- 8

6.Adjustment of sewing machine

6.11 Needle and needle guards for AZ7000SDR-8 class

6.11.1 Needle and needle guard (rear)

This machine is equipped with a movable needle guard

(rear) ① that is interlocked with the lower looper.

The needle guard (rear) ① holds the needle from the rear

to protect the lower looper tip when the needle meets the

lower looper tip during the upward movement process from

the lowest point.

(1) Move the lower looper from the left to the right, and

align the needle with ridge line “a” of the needle guard

(rear).

(2) Loosen screw ②, and adjust so that the clearance be-

tween the needle and needle guard (rear) ① is reduced

to zero.

(3) In the case of the 2-needle machine, use the left nee-

dle as a reference and perform the same adjustment as

with the 1-needle machine.

Check that the clearance between the lower looper tip and

needle is 0 to 0.03 mm when the lower looper tip has meet

the respective centers of the left and right needles.

Fig. 6-36

a

①

0

①

needles

0 - 0.03 ㎜

6.11.2 Needle and needle guard (front)

Loosen screw ④, and adjust so that the clearance between

the needle and needle guard (front) ③ is reduced to zero

when the needle it at its lowest point.

In the case of a 2-needle machine, the clearance between

the right needle and needle guard (front) ③ is 0.05 to 0.1

mm.

Fig. 6-37

③

1-Needle

2-Needle

(left needle)

0 ㎜

Fig. 6-38

②

2-Needle

(right needle)

④

0.05 -

0.1 ㎜

Page 46

36

AZ7000SDR -8, 75 00 SDR- 8

6.Adjustment of sewing machine

6.12 Needle and needle guards for AZ7500SDR-8 class

6.12.1 Needle and needle guard (rear)

This machine is equipped with a movable needle guard

(rear) ① that is interlocked with the lower looper.

The needle guard (rear) ① holds the needle from the rear

to protect the lower looper tip when the needle meets the

lower looper tip during the upward movement process from

the lowest point.

(1) Move the lower looper from the left to the right, and

align the needle with ridge line “a” of the needle guard

(rear).

(2) Loosen screw ②, and adjust so that the clearance be-

tween the needle and needle guard (rear) ① is reduced

to zero.

(3) In the case of the 2-needle machine, use the left

needle as a reference and perform the same adjustment

as with the 1-needle machine.

Check that the clearance between the lower looper tip and

needle is 0 to 0.03 mm when the lower looper tip has meet

the respective centers of the left and right needles.

Fig. 6-39

a

①

0

needles

0 - 0.03 ㎜

①

6.12.2 Needle and needle guard (front)

Loosen screw ④, and adjust so that the clearance between

the needle and needle guard (front) ③ is reduced to zero

when the needle it at its lowest point.

In the case of a 2-needle machine, the clearance between

the right needle and needle guard (front) ③ is 0.05 to 0.1

mm.

Fig. 6-40

AZ7500SDR-8

AZ7520SDR-8

AZ7525SDR-8

0 ㎜

left needle

}

②

AZ7520SDR-8

AZ7525SDR-8

③

④

right needle

}

0.05 -

0.1 ㎜

Fig. 6-41

Page 47

37

AZ7000SDR -8, 75 00 SDR- 8

6.12.3 Needle and needle guards for double chain stitch

6.Adjustment of sewing machine

Needle guard (rear) (double chain stitch):

Loosen the screw ② to make the clearance between the

needle and the needle guard (rear) ① to 0 to 0.05 mm at

the lowest point of the needle.

Needle guard (front) (double chain stitch):

Loosen the screw ④ to make the clearance between the

needle and the needle guard (front) ③ to 0.1 to 0.2 mm.

6.13 Position of presser foot

Install the bottom surface of the presser foot parallel to

the stitch plate when looking from the front.

Slanted presser foot can cause feed scratch mark.

0 - 0.05 ㎜

0.1 - 0.2 ㎜

Fig. 6-42

①

③

④

②

To set back and forth position, adjust the clearance between needle drop of the presser foot and that of the

stitch plate to 0.2 to 0.3 mm as shown in Fig. 6-43.

Loosen the screw ⑤ to make adjustment.

⑤

Fig. 6-43

0.2 - 0.3 ㎜

Page 48

38

AZ7000SDR -8, 75 00 SDR- 8

7. SC10 device

7.1 Outline

SC10 is a self-cleaning system that can keep a clean and

comfortable environment for operators.

It eliminates clogged dust around the lower knife holder

and under the stitch plate by cutting material during the

sewing. And also makes maintenance easily and prevents

troubles caused by the lint.

7.2 Adjusting ventilating amount

Select the setting type by changing the position of the air

deector ① according to the sewing speed and sewing

condition.

To set the standard position, insert the air deector ①

into the guides ②③. (See Fig. 7-2)

For high speed and less dust during sewing, insert the air

deector ① into the guides ②④. (See Fig. 7-3)

to lint

collecting device

air ow

Fig. 7-1

①

②

③

When not using SC10 device, remove the air deector ①.

standard setting

Fig. 7-2

①

②

④

Fig. 7-3

Page 49

39

AZ7000SDR -8, 75 00 SDR- 8

7.3 Installation

7.3.1 Installing air deflector

7.SC10 device

(1) Drain the oil from the machine.

(2) Tilt the machine backward.

(3) Loosen two screws ④ and remove the wind guide plate

②.

(4) Install the air deector ③ into the guides ⑤ of the oil

reservoir ① securely.

(5) Reinstall the wind guide plate ②.

(6) Raise the machine upright and supply the oil.

②

①

Fig. 7-4

⑤

④

③

7.3.2 Installing blowing hole screen

(1) Install the blowing hole screen ⑥ on the oil reservoir

①.

(2) Install the wind guide plate (front) ⑦ on the oil reser-

voir ① while pressing the blowing hole screen ⑥ with

two screws ⑧.

⑤

⑤

Fig. 7-5

⑥

①

⑦

⑧

Fig. 7-6

Page 50

40

AZ7000SDR -8, 75 00 SDR- 8

7.SC10 device

�

БДЦЙГЕ

7.3.3 Installing lint removal pipe

(1) Put two pipe clamps ② to the lint removal pipe ①.

(2) Install the lint removal pipe ① and the pipe clamps ②

on the machine frame with two screws ③.

(3) Connect the lint removal pipe ① to the pipe from the

lint collecting device.

Suction is not enough when connecting another device to

one lint collecting device for SC10.

When using ventilation, air pressure should be 0.2 MPa

or more.

①

②

③

Fig. 7-7

Page 51

41

AZ7000SDR -8, 75 00 SDR- 8

8. K2 device

ГБХФЙПО

ГБХФЙПО

8.1 Adjustment for engagement between upper trimming knife and

lower trimming knife

Before operating, ALWAYS turn the power switch OFF

and check that the motor has already stopped.

①

(1) Remove the cloth plate spacer ①.

(2) Remove the Suction pipe cover ②.

(3) Loosen the screw ③.

(4) Make the distance between the upper trimming knife

⑤ and the front end point of lower trimming knife ⑥

to 0 to 0.5 mm when the upper knife ④ is at the lowest

point.

(5) Tighten the screw ③ securely.

Fig. 8-1

②

⑦

③

④

Fig. 8-2 Fig. 8-3

8.2 Oiling

Supply with few drops of oil into the oil supply pipe ⑧ by

hand once two weeks.

⑤

0 - 0.5 ㎜

⑥

⑧

Too much oil can cause oil stain. If insufficient, it can

cause unsharpness of the blades of the knives.

Fig. 8-4

Page 52

42

AZ7000SDR -8, 75 00 SDR- 8

9. Specifications

9.1 AZ7000SDR-8 class

Model

AZ7000SDR-8 AZ7003SDR-8 AZ7016SDR-8

Dimensions 380 (L) × 245 (W) × 310 (H) mm

Weight

26.5 kg

Construction Dust-proof, Oil-tight and completely sealed

Stitch Type

( ISO standard )

Application

Sewing Speed

Stitch Length

505 504 504 504、 514

hemming

for knitted

1.0 - 4.0 mm

overlock stitch for

knitted or woven

fabric

7500 sti/min up to 7000 sti/min

up to

Number of stitches

per inch(25.4 mm)

per 30 mm

6.5 - 25 stitches

7.5 - 30 stitches

DC×1 DC×27

Needle System

size #8 -#14(60 - 90)

Needle Stroke

23.7 mm 24.7 mm

rolled seam for

light materal

0.6 - 2.0 mm

12 - 42 stitches

15 - 50 stitches

AZ7020SDR-8

AZ7025SDR-8

overlock stitch for knitted or woven

1.0 - 4.0 mm

6.5 - 25 stitches

7.5 - 30 stitches

AZ7120SDR-8

AZ7125SDR-8

fabric

Presser Foot Lift up to 6

mm

up to 5

Feed Regulation Push button System

1 : 2.3

Differential Ratio

Max. normal differential (Gathering)

Max. reverse differential (Stretching) 1 : 0.7

(Max. reverse differential ratio is available up to 1 : 0.6 by adjusting the position of the lever pin. )

Differential Feed

Regulation

Knives for Fabric

Cutting

Adjustable by moving external lever even during operation

Adjustable by Micro adjuster

Lower Knife : Flat type, made of special steel

Upper Knife : Flat type or Angled type, made of super hard alloy

Lubrication Oil YAMATO SF OIL No.28

Capacity of

Oil Reservoir

900 ml

Lubrication Oil is fed forcedly by trochoid pump

Compliance With

Regulation

Machinery directive, RoHS directive

installation Fully-submerged type and Semi-submerged type

Lp

85db 以下 (7500 sti/min)

≦

A

Noise Declaration