Page 1

No. CP-UM-1703E

DIGITRONIK

Digital Indicating

Controller

SDC10

User’s Manual

Index

Chapter 1 NAMES & FUNCTIONS OF PARTS ..... 1

Chapter 2 STRUCTURE ........................................2

Chapter 3 MOUNTING...........................................3

Chapter 4 WIRING ................................................. 6

Chapter 5 INITIAL SETTINGS ............................... 9

5-1 Overall Operation Flow ............................... 10

5-2 Setup Items ................................................ 11

5-3 Parameter Settings ..................................... 18

5-4 Event Settings ............................................ 21

5-5 SP Setting .................................................. 21

Chapter 6 TUNING............................................... 24

6-1 Selecting the Control Method ..................... 24

6-2 Self-tuning .................................................. 24

6-3 Cautions During Self-tuning ........................ 25

6-4 Auto-tuning ................................................ 26

6-5 Control Troubleshooting ............................. 27

Chapter 7 SPECIFICATIONS .............................. 28

Chapter 8 ALARM CODES ..................................30

Chapter 9 MAINTENANCE ..................................31

SDC10 Setup Worksheet ......................................... 32

Thank you for purchasing the DIGITRONIK Digital Indicating Controller SDC10.

This manual contains information for ensuring correct use of the DIGITRONIK

Digital Indicating Controller SDC10. It also provides necessary information

for installation, maintenance and troubleshooting. This manual should be read

by those who design and maintain devices and operator control panels that

use the DIGITRONIK Digital Indicating Controller SDC10. Be sure to keep

this manual nearby for handy reference.

Page 2

Note that incorrect wiring of the SDC10 can damage the SDC10 and lead

to other hazards. Check that the SDC10 has been correctly wired before

turning the power ON.

Before wiring, or removing/mounting the SDC10, be sure to turn the power

OFF. Failure to do so might cause electric shock.

Do not touch electrically charged parts such as the power terminals. Doing

so might cause electric shock.

Do not disassemble the SDC10. Doing so might cause electric shock or

faulty operation.

This product has been designed, developed and manufactured for general-purpose

application in machinery and equipment.

Accordingly, when used in applications outlined below, special care should be taken to

implement a fail-safe and/or redundant design concept as well as a periodic maintenance

program.

•Safety devices for plant worker protection

•Start/stop control devices for transportation and material handling machines

•Aeronautical/aerospace machines

•Control devices for nuclear reactors

Never use this product in applications where human safety may be put at risk.

This manual uses the following symbols to ensure safe operation of this controller:

i

RESTRICTIONS ON USE

REQUEST

Ensure that this User's Manual is handed over to the user before the

product is used.

Copying or duplicating this User's Manual in part or in whole is forbidden. The information and specifications in this User's Manual are subject to change without notice.

Considerable effort has been made to ensure that this User's Manual is

free from inaccuracies and omissions.

If you should find any inaccuracies or omissions, please contact

Yamatake Corporation.

In no event is Yamatake Corporation liable to anyone for any indirect,

special or consequential damages as a result of using this product.

©1995 Yamatake Corporation ALL RIGHTS RESERVED

WARNING

CAUTION

Warnings are indicated when mishandling the SDC10

might result in death or serious injury to the user.

Cautions are indicated when mishandling the SDC10 might

result in minor injury to the user, or only physical damage

to the SDC10.

WARNING

Page 3

ii

CAUTION

Do not operate the keys with a propelling pencil or sharp-tipped object.

Doing so might cause faulty operation.

In addition to the standard ON/OFF and PID controls, the SDC10 is also

equipped with self-tuning control which does not require setting control constants. Self-tuning control ensures stable control even during changes in

SP values or during disturbances. This is achieved by monitoring and learning the characteristics of the control target to automatically output control

constants.

This function should be used according to the instructions given in the

manual.

Use the SDC10 within the operating ranges recommended in the specifications (temperature, humidity, voltage, vibration, shock, mounting direction,

atmosphere, etc.). Failure to do so might cause fire or faulty operation.

Do not block ventilation holes. Doing so might cause fire or faulty operation.

Wire the SDC10 properly according to predetermined standards. Also wire

the SDC10 using specified power leads according to recognized installation methods.

Failure to do so might cause electric shock, fire or faulty operation.

Do not allow lead clippings, chips or water to enter the controller case.

Doing so might cause fire or faulty operation.

Firmly tighten the terminal screws at the torque listed in the specifications.

Insufficient tightening of terminal screws might cause electric shock or fire.

Do not use unused terminals on the SDC10 as relay terminals.

Doing so might cause electric shock, fire or faulty operation.

We recommend attaching the terminal cover (sold separately) after wiring

the SDC10.

Failure to do so might cause electric shock, fire or faulty operation.

Use the relays on the SDC10 within the service life listed in the specifica-

tions.

Continued use of the relays after the recommended service life has expired

might cause fire or faulty operation.

Use Yamatake Corporation's SurgeNon if there is the risk of power surges

caused by lightning.

Failure to do so might cause fire or faulty operation.

Page 4

iii

SAFETY REQUIREMENTS

To reduce risk of electrical shock which could cause personal injury, follow all safety notices

in this document.

This symbol warns the user of a potential shock hazard where hazardous live voltages may be

accessible.

* If the controller is used in a manner not specified by Yamatake Corporation, the protection provided

by the controller must be impaired.

* Do not replace any component (or part) not explicitly specified as replaceable by your supplier.

* All wiring must be in accordance with local norms and carried out by authorized and experienced

personnel.

* A switch in the main power supply is required near the equipment.

* Provide delayed type (T) fuses having a rated power supply of 200mA and voltage of 250V for the

mains power supply wiring of this AC power supply controller. (IEC 127)

EQUIPMENT RATINGS

Supply voltage 100 to 240Vac (operating power voltage 85 to 264Vac)

Frequency 50/60Hz

Power consumption 7VA max.

EQUIPMENT CONDITIONS

Do not operate the instrument in the presence of flammable liquids or vapors. Operation of any electrical

instrument in such an environment constitutes a safety hazard.

Temperature: 0 to 50°C

Humidity: 10 to 90%RH (condensation not allowed)

Vibration: 2m/s2 (10 to 60Hz)

Over-voltage category: Category II (IEC60364-4-443, IEC60664-1)

Pollution degree: 2

EQUIPMENT INSTALLATION

The controller must be mounted into a panel to limit operator access to the rear terminals.

Make sure that the I/O common voltage and the grounding voltage excluding the power voltage are

33Vrms max., 46.7V (peak) max. and 70Vdc max.

APPLICABLE STANDARDS

EN61010-1, EN50081-2, EN50082-2, EN61326

The CE supported model is the C10T type (panel type) only.

H

Page 5

1

Hold this key down for at least 1

second to enable either of the

following operations.

•

•

•

•

Factory setting is key lock state.

Run (RUN)/ (READY)

Cancelation of event latch state

Auto-tuning start/stop

SP No. switching

key

EV1:

EV2:

OT:

SP1:

RDY:

Lights when event 1 is ON.

Lights when event 2 is ON.

Lights when the control output is ON.

Lights (or, blinks) when No.1 to No.3

SP is switched.

Lights when READY (control stop)

Mode LEDs

Displays PV values (current

temperature, etc.) or setup items

This LED blinks in the self-tuning mode.

Displays SP values (set

temperature, etc.) and other

parameter values.

This LED blinks in the auto-tuning mode.

Upper display

Lower display

keys:

Switches the display. Hold

down for at least 3 seconds

to switch modes.

key

PARA

RDY

Used for incrementing numeric

values and performing arithmetic

shift operations.

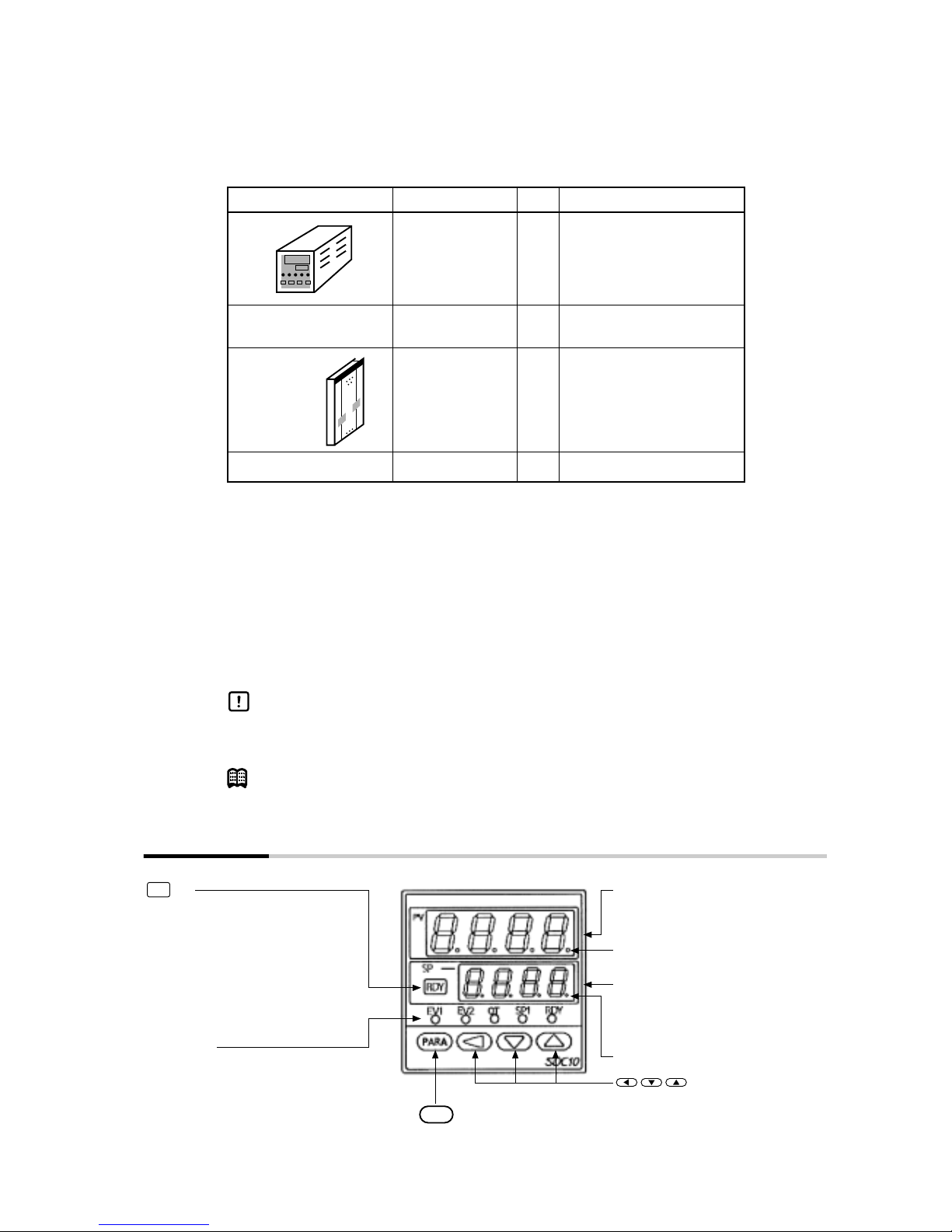

Unpacking

When unpacking the product, check that you have received all the items that you ordered.

The C10S type socket is optional.

After unpacking, handle the SDC10 and its accessories taking care to prevent damage or loss of parts.

Those using the communications function, should read the DIGITRONIK digital indicating controller

User's Manual SDC10 “Communications Function Manual”.

If an inconsistency is found or the package contents are not in order, immediately contact your dealer.

Conventions Used in This Manual

The following conventions are used in this manual.

Handling Precautions

: Handling Precautions indicate items that the user should pay attention to when

handling the SDC10.

Note : Notes indicate useful information that the user might benefit by knowing.

Name Catalog No. Q’ty Remarks

Body 1

Installation tool 81446403-001 1

(C10T type only)

User’s Manual CP-UM-1703E 1

Engineering Unit seal 1

See ■ Model Selection

Guide on page 2.

This manual

Chapter 1 NAMES & FUNCTIONS OF PARTS

Page 6

2

C10

T

(Note 1) S

0D

6D

T

R

L

A

D

00

01

(Note 2) 02

(Note 2) 03

(Note 2) 05

00

D0

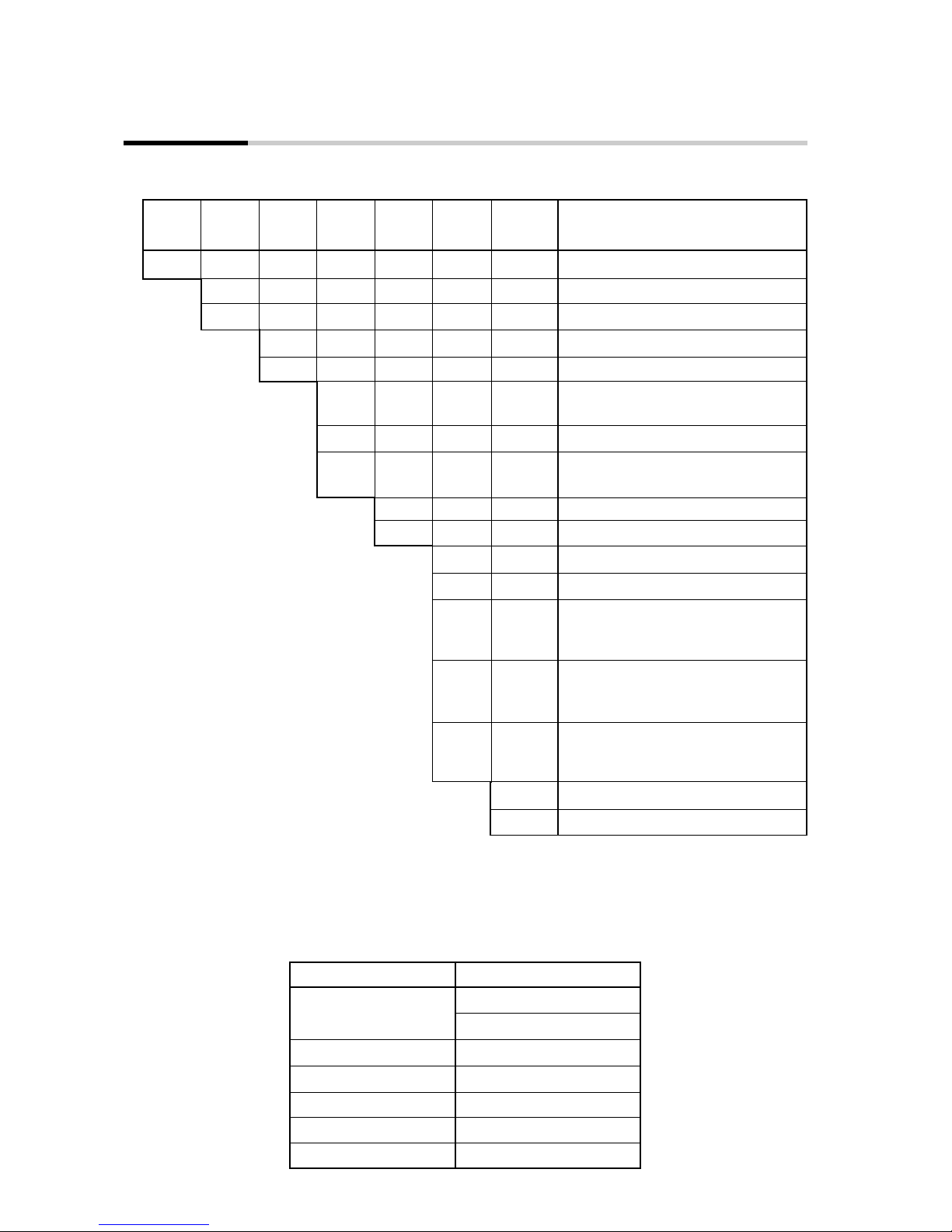

Chapter 2 STRUCTURE

■ Model Selection Guide

●

Options

Basic

Model

No.

Mounting

Control

Output

Power

Voltage

Option

Additional

Process-

ing

PV

Input

Specifications

Panel mounting

Socket mounting

Relay output

Voltage pulse output (for SSR drive)

Thermocouple input (K, J, E, T, R, DIN

U, DIN L)

RTD (Pt100/JPt100)

DC voltage input

(0 to 1Vdc, 0 to 5Vdc, 1 to 5Vdc)

100 to 240Vac, 50/60Hz

24Vdc (no polarity)

None

2 event outputs

2 event outputs

2 non-insulated external switch inputs

1 current transformer input

2 event outputs

2 insulated external switch inputs

1 current transformer input

2 event outputs

RS-485 communications (CPL)

1 current transformer input

No additional processing

Provision of Inspection Sheet

(Note 1) A socket mounted model cannot be combined with 02, 03, 05 (option). The

socket is sold as an option.

CE is not covered on socket mounted models.

(Note 2) The current transformer is sold as an option.

Name Model No.

Current transformer QN206A (5.8mm hole dia.)

QN212A (12mm hole dia.)

Socket (C10S) 81446391-001

Mounting bracket 81446403-001

Hard cover 81446442-001

Soft cover 81446443-001

Terminal cover 81446464-001

Page 7

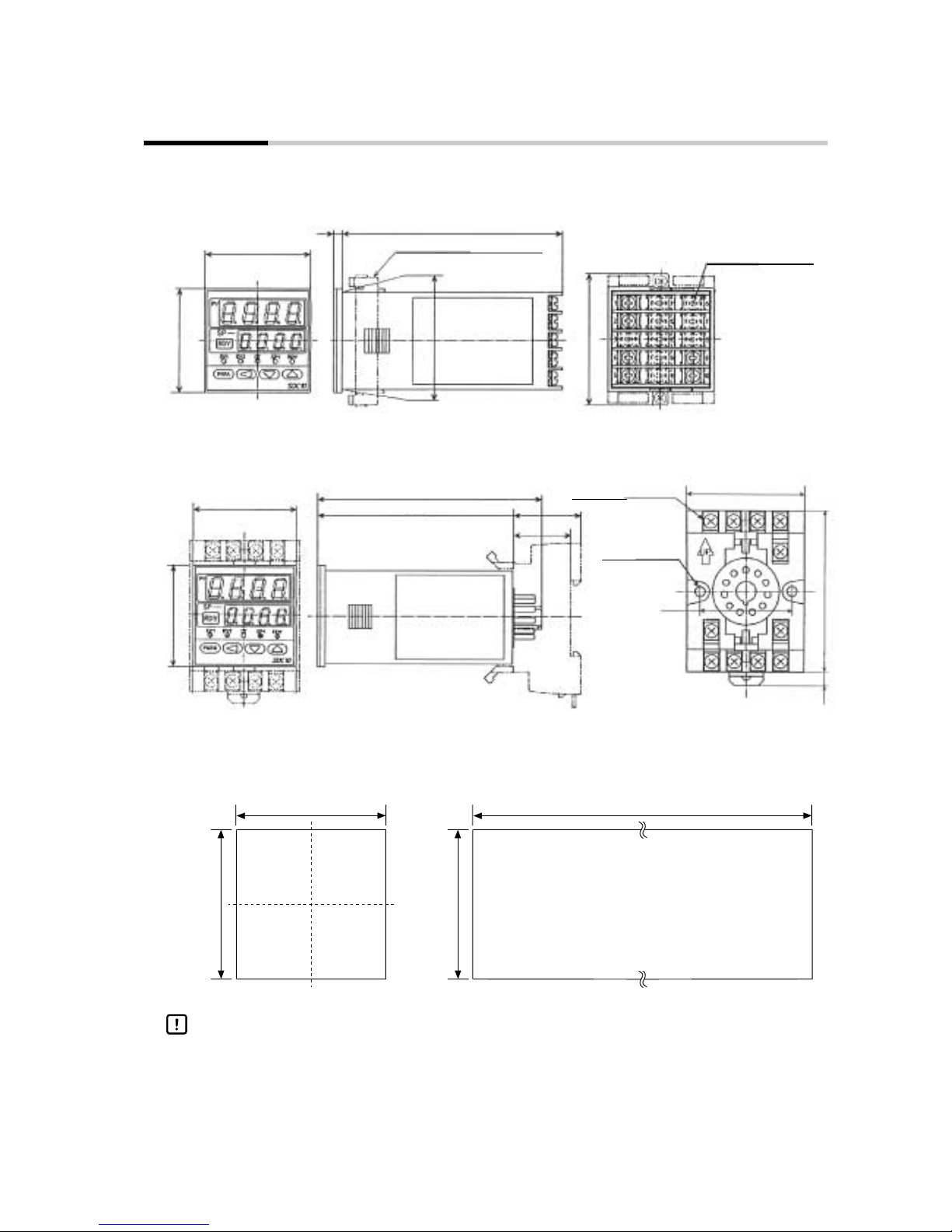

3

Chapter 3 MOUNTING

■ External Dimensions

●

C10T (panel mounted)

Mounting bracket (included)

M3.5 terminal screw

Unit: mm

48

48

1014

□45

61

●

C10S (with socket)

48

48

104

90.5 31

26.5

51

87 65

4

3

21

11

10

9

40

716.5

M3.5 terminal screw

Mounting hole

for 2-M4 screw

Socket (sold separately)

Model No.: 81446391-001

■ Panel Cut-out Dimensions

45

-0

+0.6

45

-0

+0.6

(Nx48-2.5)

-0

+1

45

-0

+0.6

N is the number of mounted units

Handling Precautions

When three or more units are gang-mounted horizontally, the maximum allowable ambient temperature is 45°C.

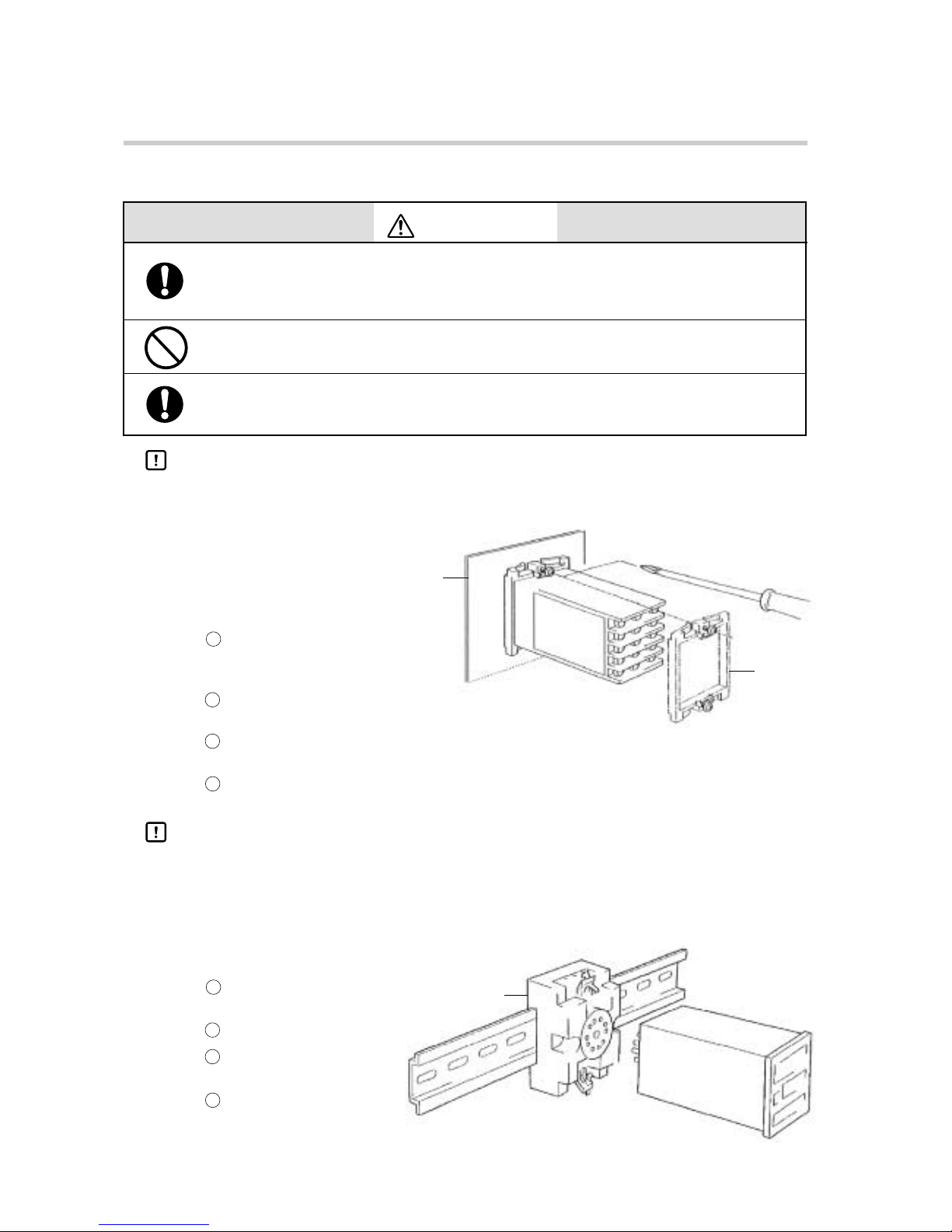

Page 8

4

CAUTION

Press the controller against the mounting bracket to make sure that the bracket claws enter the

grooves of the controller.

Tighten the top and bottom screws. (When the screws touch the panel, turn the screws another half

turn.)

● C10T

●

Required tools

Phillips screwdriver

Insert the controller into the

opening on the front side of the

panel.

Attach the mounting bracket at

the rear side of the panel.

■ Mounting Procedure

Use the SDC10 within the operating ranges recommended in the specifications (temperature, humidity, voltage, shock, mounting direction, atmosphere, etc.). Failure to do so might cause fire or faulty operation.

Do not block ventilation holes. Doing so might cause fire or faulty operation.

Be sure to attach the terminal cover (sold separately) after wiring the SDC10.

Failure to do so might cause electric shock, fire or faulty operation.

Handling Precautions

When three or more units are gang-mounted horizontally, the maximum allowable ambient

temperature is 45°C.

Panel

Mounting

Bracket

Socket

Handling Precautions

●

Do not operate the keys with a propelling pencil or sharp tipped object. Be sure to mount this

controller on a panel. Cover terminals to prevent electric shock.

An optional terminal cover is provided. (model No.: 81446464-001)

●

Do not overtighten the screws to prevent deformation of the front panel.

● C10S

Mount the socket in the panel

using a DIN rail or screws.

Wire the socket.

Insert the body of the control-

ler into the socket.

Insert the clasps at the top and

bottom of the socket into the

holes of the controller body to

firmly secure it to the socket.

Chapter 3 MOUNTING

1

2

3

4

1

2

3

4

Page 9

5

■ Location

Do not install the controller in locations where it is:

• subject to extreme temperature and humidity

• subject to sulfuric or corrosive gases

• subject to dust or oil smoke

• subject to direct sunlight, or splashing by rain or water

• subject to mechanical vibrations and shock

• subject to high-voltage lines, welding machines and sources of electric noise

• less than 15 m from high-voltage ignition devices

• subject to electromagnetic fields

• subject to flammable liquids or vapor

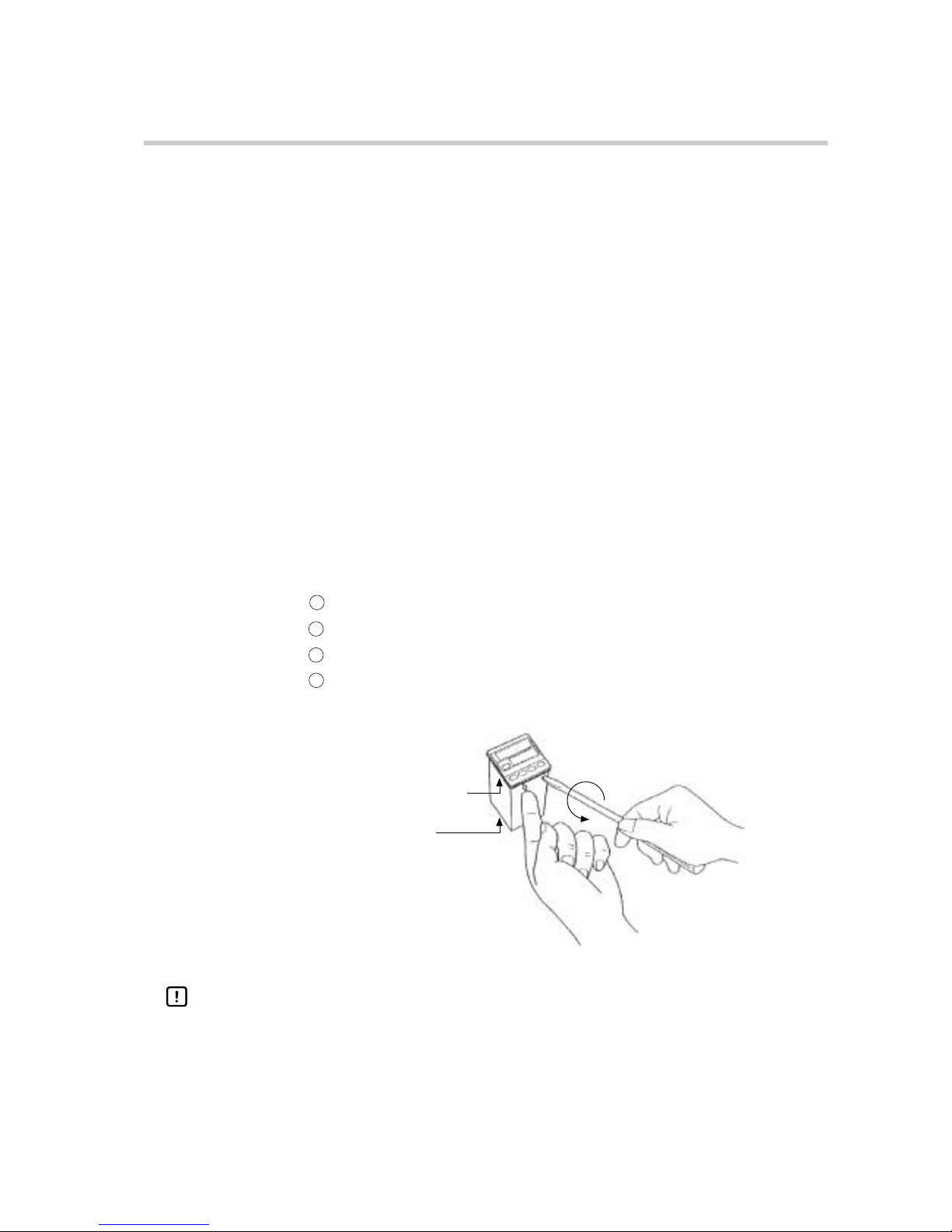

■ Removing the SDC10T Case

The following instructions show how to remove the SDC10T body from the case. This

has to be carried out only when the controller is to be replaced:

●

Required tools

Small standard screwdriver

Press the claw on the lower left side of the mask bezel with your finger.

Insert the screwdriver into the groove between the mask bezel and the controller body.

Press the claw while turning the screwdriver.

Take hold of the front end of the body as it is forced out of the case and pull it out.

Mask bezel

Case

Handling Precautions

●

Turn the power OFF before carrying out the above procedure.

●

In the case of the socket model (C10S), internal components cannot be drawn

out.

Chapter 3 MOUNTING

1

2

3

4

Page 10

6

CAUTION

Wire the SDC10 properly according to predetermined standards. Also wire

the SDC10 using specified power leads according to recognized installation methods. Failure to do so might cause electric shock, fire or faulty

operation.

Do not allow lead clippings, chips or water to enter the controller case.

Doing so might cause fire or faulty operation.

Firmly tighten the terminal screws at the torque listed in the specifications.

Insufficient tightening of terminal screws might cause electric shock or fire.

Do not use unused terminals on the SDC10 as relay terminals.

Doing so might cause electric shock, fire or faulty operation.

We recommend attaching the terminal cover (sold separately) after wiring

the SDC10. Failure to do so might cause electric shock, fire or faulty operation.

Use the relays on the SDC10 within the service life listed in the specifications.

Continued use of the relays after the recommended service life might cause

fire or faulty operation.

Use Yamatake Corporation’s SurgeNon if there is the risk of power surges

caused by lightning.

Failure to do might cause fire or faulty operation.

Make sure all wiring is correct. Incorrect wiring may damage connected

equipment.

The controller does not operate until six seconds after the power has been

turned ON. Special arrangements must be made when the relay output

from the controller is to be used as an interlock signal.

When a ground type thermocouple must be used and an external switch

input is required, PV readout error caused by sneak path current may occur. Select the insulated external switch input model (option code 03).

Chapter 4 WIRING

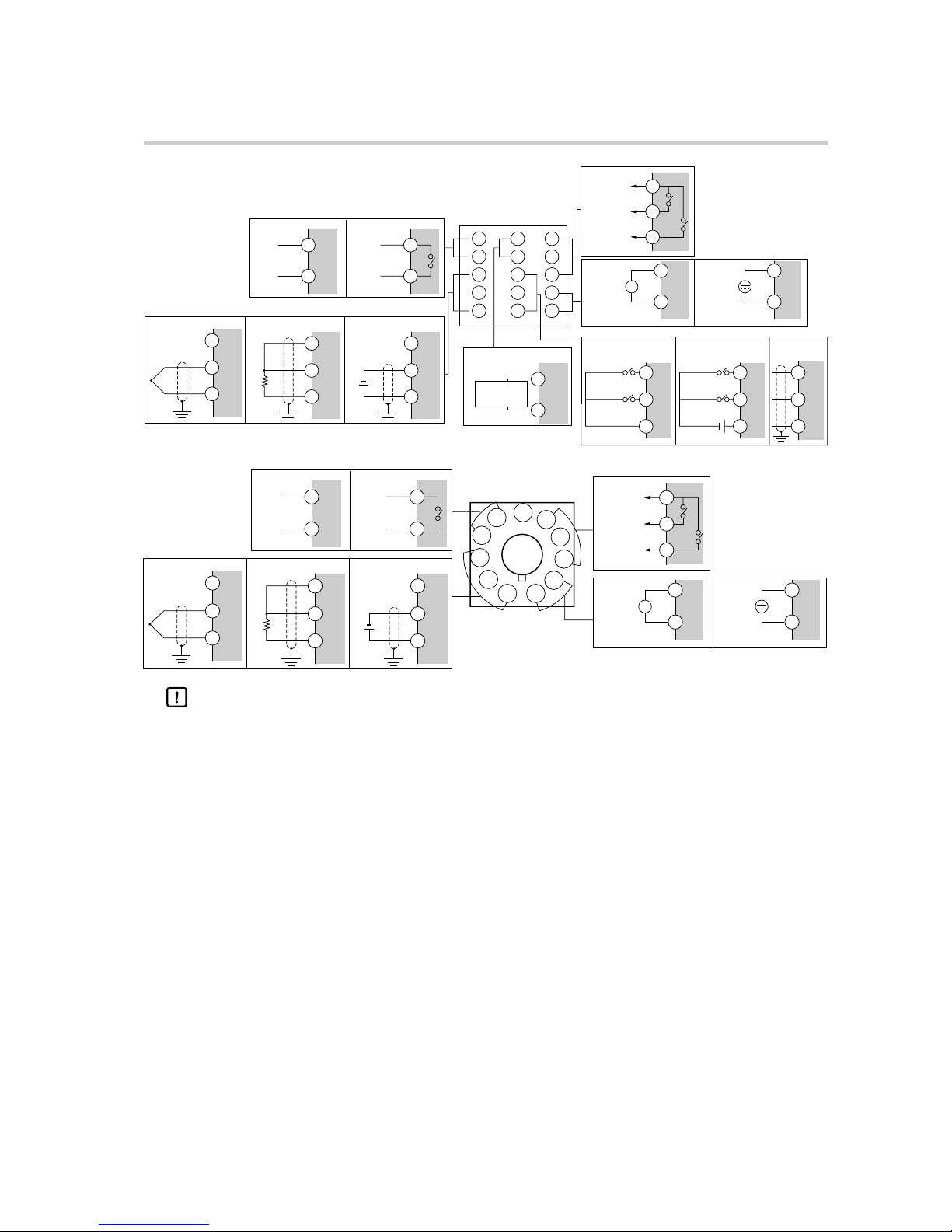

■ Terminal Array and Wiring

Before wiring, or removing/mounting the SDC10, be sure to turn the power

OFF. Failure to do so might cause electric shock.

Do not touch electrically charged parts such as the power terminals. Doing

so might cause electric shock.

WARNING

Page 11

7

● C10T

● C10S

Chapter 4 WIRING

1

2

1

2

6

7

8

4

3

5

4

3

5

C

B

A

4

3

5

1

2

3

4

5

11

12

13

14

15

6

7

8

9

10

11

12

9

10

~

13

15

14

9

10

13

15

14

13

15

14

SG

Voltage output Relay output

+

—

Thermocouple RTD DC voltage input

Current transformer

input

Current

transformer

+

—

+

—

Event output

AC power supply

Non-insulated

external switch input

RSW2

RSW1

Insulated

external switch input

RSW2

RSW1

12/24Vdc

100 to 240Vac

50/60Hz

DC power supply

24Vdc

No polarity

Event 1

Event 2

CPL communications

+

—

Voltage output

Relay output

RTDThermocouple DC voltage input

5

+

4

—

5

4

7

8

9

2

3

1

2

3

1

C

B

A

2

3

1

10

11

~

10

11

1 11

2

3

4

5

6

7

8

9

10

+

—

+

—

Event output

AC power supply

100 to 240Vac

50/60Hz

DC power supply

24Vdc

No polarity

Event 1

Event 2

Handling Precautions

●

Check the model number of the controller and terminal numbers on the label on the side of the

controller to prevent any wiring errors.

●

Use crimped solderless wire connectors for M3.5 screws.

●

I/O signal lines should be routed at least 50cm away from power lines. Also, do not route I/O

leads through the same distribution box or ducts.

●

Crimped solderless wire connectors must not contact other connectors.

●

Do not use unused terminals as relay terminals.

●

Two or more SDC10 series controllers can be connected in parallel by external switch input.

●

The controller can be connected with the Yamatake Corporation SDC20/30/40 series in parallel by non-insulated external switch inputs.

●

Before connecting in parallel to other equipment, first check the conditions of the other equipment.

●

Non-insulated external switch inputs are non-voltage contact inputs. So, use external switch for

small current.

●

Pass a lead wire for carrying the heater current through a current transformer.

Use the controller with the heater current within the specification range (allowable current).

Otherwise, the controller may be damaged.

●

The controller is designed not to function for six seconds after it is turned ON. This is to allow it

to stabilize. The controller then enters the operation mode. However, warm up the controller to

satisfy standard accuracy requirements. Warming up takes about 30 minutes.

Page 12

8

●

Current transformer input cannot be used for 3-phase motors and phase control.

●

Devices and systems to be connected to this unit must have the basic insulation sufficient to

withstand the maximum operating voltage levels of the power supply and input/output parts.

●

Use power supply with reinforced insulation for DC model.

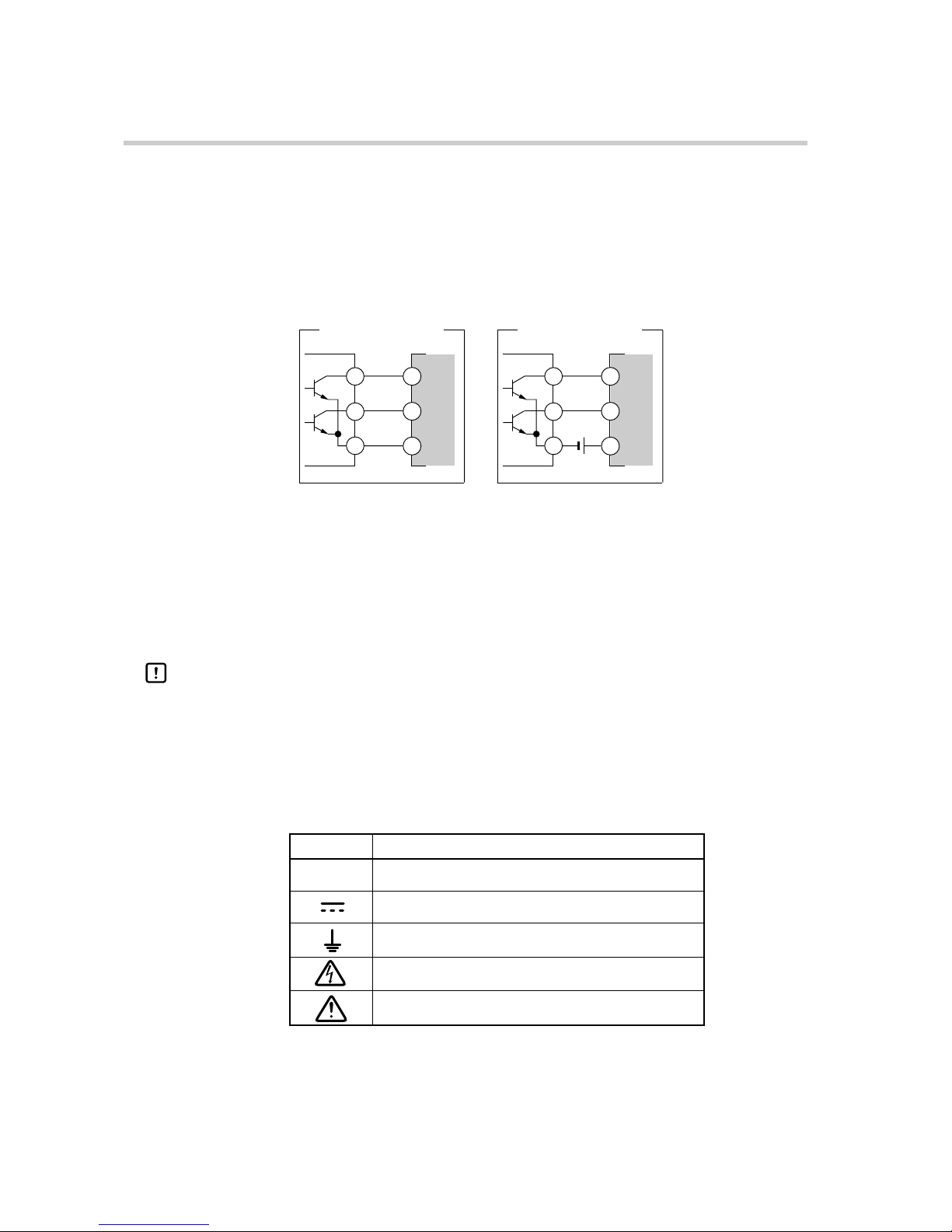

■ How to connect open collector output to external switch inputs

Chapter 4 WIRING

Symbol Description

~

Alternating current

Direct current

Earth (ground) terminal

CAUTION, risk of electric shock

CAUTION

■ Noise Countermeasures

●

Use power from a single-phase control power supply to reduce noise.

●

Install an insulating transformer when power line noise is excessive and use a line

filter.

(model number of Yamatake Corporation line filter: 81446364-001)

●

Use a CR filter to counteract fast-rising noise.

(model number of Yamatake Corporation filter: 81446365-001)

Handling Precautions

●

When noise countermeasures have been taken, do not bundle primary and

secondary cables together or route them through the same distribution box or

ducts.

■ Meanings of Symbols in the Terminal Wiring Label

The following table shows the meanings of symbols in the terminal wiring label on the

instrument top.

15

In the case of a non-insulated type

external switch input

SDC10

14

13

15

In the case of an insulated type

external switch input

SDC10

12/24Vdc

14

13

Page 13

9

RDY

PV

SP

PARA

C

0

3

0

RDY

PV

SP

C

0

3

RDY

PV

SP

C

0

3

1

Procedure

1

How to Set up Data

Numeric values blink for about

2 seconds. During blinking,

the key cannot be

used.

Blinking stops to indicate that

the data has been set.

Enter numeric values with

the keys.

PARA

1

2

3

(Note)

“L O c” is displayed in the lower

display for about 2 seconds to indicate that an incorrect key or data

entry was made. Such entries are ignored.

Chapter 5 INITIAL SETTINGS

Set up the SDC10 according to the following procedure:

See Page

10

11

18

21

21

Step

1

Step

2

Step

3

Step

4

Step

5

Enter the customer settings in the Setup Worksheet

referring to the setup items and the parameter items list.

Set up item settings (in setup mode)

Parameter settings (in parameter mode)

Event value settings (in operation mode)

SP values and start operation (in operation mode)

Carry out initial setup for basic controller operations.

Carry out control constant setup.

Set up SP values and start operation.

RDY

PV

SP

C

0

4

L O c

Page 14

10

Setup Mode Settings and Display Order

• C 0 1 : Key lock

• C 0 2 : Temperature unit

• C 0 3 : Direct/reverse operation

• C 0 4 : Input range

• C 0 5 : Decimal point position

• C 0 6 : PV range lower limit

• C 0 7 : PV range upper limit

• C 0 9 : Lower SP limit

• C 1 0 : Upper SP limit

• C 1 1 : Preset output value

• C 1 2 : Operation mode display

• C 1 3 : Number of SPs used

• C 1 4 : Event 1 type

• C 1 5 : Event 2 type

• C 1 6 : Event operation when

READY

• C 1 7 : External switch input 1

type

• C 1 8 : External switch input 2

type

• C 2 1 : READY key settings

• C 2 2 : Communications address

• C 2 3 : Communications condi-

tions

• C 2 4 : Cold junction compensa-

tion

• C 2 5 : Selection of time-propor-

tional control operation

Parameter Mode Settings and Display Order

• C T R L : Control method

• A T : Auto-tuning

• S P 0 : No. 0 SP value

• S P 1 : No. 1 SP value

• S P 2 : No. 2 SP value

• S P 3 : No. 3 SP value

• P : Proportional band

• I : Reset time

• D : Rate time

• O L : Output limit low

• O H : Output limit high

• R E : Manual reset value

• S B : Self-tuning startup width

• D I F F : Differential gap

• C Y C L : Time-proportional cycle

• P B I A : PV bias value

• H Y S I : Event 1 hysteresis

• D L Y I : Event 1 ON delay time

• H Y S 2 : Event 2 hysteresis

• D L Y 2 : Event 2 ON delay time

• F I L T : PV filter

Operation Mode Display Order

•:Basic display state

• S P

-

0 : No. 0 SP value

• S P

-

1 : No. 1 SP value

• S P

-

2 : No. 2 SP value

• S P

-

3 : No. 3 SP value

• O v T : Manipulated variable

• C T : Current value (CT)

• T 1 : Remaining timer 1 time

• T 2 : Remaining timer 2 time

• e 1 L O : Event 1

(E 1) Lower limit

• E 1 H I : Event 1

Upper limit

• E 2 L O : Event 2

(E 2) Lower limit

• E 2 H I : Event 2

Upper limit

5-1 Overall Operation Flow

The controller enters the Operation mode when power is

turned ON.

Hold down the

PARA

key for three seconds to change modes,

and use this key to move setup items between modes.

Items that are shaded are not displayed depending on the setup or installed options.

Chapter 5 INITIAL SETTINGS

RDY

PV

SP

2 0

0

0

RDY

PV

SP

e

1 l

O

0

e 2 h 1

RDY

PV

SP

PARA

PARA

PARA

RDY

PV

SP

C T R L

RDY

PV

SP

1 0

S d C

C Y C L

d

L Y

1

S

P

1

0

5

RDY

PV

SP

0

RDY

PV

SP

PARA

PARA

PARA

RDY

PV

SP

0

PARA

0

RDY

PV

SP

0

RDY

PV

SP

PARA

PARA

PARA

RDY

PV

SP

0

C 0 1

C

0 2

C

2 1

Power ON

This value is displayed

for 6 seconds.

No key operation for

1 minute or more.

No key operation for

1 minute or more.

PARA

Hold down the

key for

3 seconds.

PARA

Hold down the

key for

3 seconds.

PARA

Hold down the

key for

1 second.

Operation mode Setup modeParameter mode

PV/SP value normal display mode

key

key

key

key

key

key

key

key

key

key

Page 15

11

5-2 Setup Items

This section describes how to set the controller to the Operation mode after it is first

mounted in instruments. Before this controller is first used, the input range, event operation type and other operating conditions matched to the desired instrument application

must be set. This is referred to as “setup.”

If this controller is already mounted in instruments and the setup is already completed,

proceed to the next chapter.

The following shows the initial settings in basic controller operation:

Handling Precautions

The alarm code and blinking to indicate self-tuning or auto-tuning in progress are

not displayed while moving to the setup mode.

C

0

1

RDY

PV

SP

1 0

S d

C

RDY

PV

SP

S d

C

RDY

PV

SP

1 0

2

0

RDY

PV

SP

1 0

2

0

RDY

PV

SP

0

C t

R L

RDY

PV

SP

0

C

0

4

C

0

4

RDY

PV

SP

3

RDY

PV

SP

5

Entering the setup mode

Procedure

Operation mode

Parameter mode

Setup mode

Operation mode

Power ON

The initial screen is displayed

for about 6 seconds.

The operation mode is

displayed.

Hold down the key for

3 seconds to advance to the

parameter mode.

The setup mode is displayed.

PARA

PARA

Hold down the key for

3 seconds to advance to the

setup mode.

PARA

Press the key to scroll

the selection.

PARA

Hold down the key for

3 seconds or wait 1 minute.

Press the , and

keys to set the numeric value.

To return to the operation mode

Example:

Current PV value

Current SP value

C 0 4

(input range)

Current PV value

(in the operation mode)

Change the input range from

"K 0 to 400°C" to "J 0 to 800°C".

Item setting value

(default

3

: K 0 to 400°C)

Change to

5

. The value blinks for

2 seconds before it is fixed.

(

5

: J 0 to 800°C)

Current SP value

1

2

3

4

5

6

7

Chapter 5 INITIAL SETTINGS

Page 16

12

Function

Prompt

C 0 1 Key lock

C 0 2 Temperature

unit

C 0 3 Control output

direction

C 0 4 Input type and

range

C 0 5 Decimal point

position

C 0 6 PV range

lower limit

C 0 7 PV range

upper limit

C 0 9

SP lower limit

C 1 0

SP upper limit

C 1 1

Manipulated

variable when

READY mode

or Alarm occur

0: Key lock not engaged

1: Key lock engaged for items other than SP

value, SP set selection, event value,

RDY

key

and AT

2: Key lock engaged for items other than SP

value, SP set selection and

RDY

key

3: Key lock engaged for all items

0: °C

1: °F

0: Reverse operation (heat control)

1: Direct operation (cooling control)

Thermocouple input range

1: K 0 to 1200°C 0 to 2200°F

2: K 0 to 600°C 0 to 1100°F

3: K 0 to 400°C 0 to 700°F

4: K -200 to +400°C -300 to +700°F

5: J 0 to 800°C 0 to 1500°F

6: J -200 to +400°C -300 to +700°F

7: E 0 to 600°C 0 to 1100°F

8: T -200 to +400°C -300 to +700°F

9: DIN U -200 to +400°C -300 to +700°F

10: DIN L 0 to 800°C 0 to 1500°F

11: R 0 to 1600 °C 0 to 3000°F

12: S 0 to 1600°C 0 to 3000°F

RTD input range

21: Pt100 -200 to +500°C -300 to +700°F

22: Pt100 0 to 200°C 0 to 300°F

23: Pt100 0.0 to 200.0°C 0.0 to 300.0°F

24:JPt100 -200 to +500°C -300 to +700°F

25:JPt100 0 to 200°C 0 to 300°F

26:JPt100 0.0 to 200.0°C 0.0 to 300.0 °F

27: Pt100 -50 to +100°C -50 to +150°F

28: Pt100 -50.0 to+100.0°C -50.0 to+150.0°F

29:JPt100 -50 to +100 °C -50 to +150°F

30:JPt100 -50.0 to+100.0°C -50.0 to+150.0°F

DC voltage input range

42: 1 to 5Vdc

43: 0 to 5Vdc

44: 0 to 1Vdc

0: Decimal point not displayed (XXXX)

1: Decimal point No.1 display (XXX.X)

2: Decimal point No.2 display (XX.XX)

3: Decimal point No.3 display (X.XXX)

-1999 to +9999

-1999 to +9999

Setting range : PV range lower limit to SP upper

limit

Setting range : SP lower limit to PV range upper

limit

Setting range : 0 to 100% (no decimal point)

0

0

0

3

22

43

0

0

1000

Range

Min.

Range

Max.

0

Key lock can be

canceled anytime

Factory

Setting

Function Selections and Setting Range

Remarks

Displayed on DC voltage

input models only

Displayed on DC voltage

input models only

Displayed on DC voltage

input models only

(Applied alarm code

A L 0 1, 0 2 , 0 3 , 7 0,

9 8)

Chapter 5 INITIAL SETTINGS

● List of setup items

Page 17

13

C 1 2 Operation

mode

C 1 3

Number of SPs

used and

display

method

C 1 4 Event 1

operation type

C 1 5 Event 2

operation type

C 1 6 Event opera-

tion in READY

mode

C 1 7 External switch

input 1 operation type

C 1 8 External switch

input 2 operation type

C 2 1

RDY

key

setting

Displayed on event

output model

Displayed on event

output model

Displayed on event

output model

Displayed on external

switch input model.

All operation types are

alternated.

Do not set the same

operation type No. to

external inputs 1 and 2.

(excluding 1: SP

switching)

When “1” (SP switching) is set for both C17

and C18, the four SP

values can be

switched.

RDY

key cannot be

operated when same

functions as external

switch input have been

set.

Function

Prompt

Function

Remarks

Factory

Setting

Selections and Setting Range

1st digit 0: Displays both SP and PV values

1: Displays SP value only

2: Displays PV value only

2nd digit 0: Does not display manipulated variable

1: Displays manipulated variable

3rd digit 0: Displays event settings or heater current value

1: Does not display event settings or heater current value

2: Does not display heater current only

4th digit 0: Displays time remaining of event timers/ Displays heater current and

event setting with a resolution of 1A

1: Does not display time remaining of event timers/ Displays heater current

and event setting with a resolution of 1A

2: Displays time remaining of event timers/ Displays heater current and

event setting with a resolution of 0.1A

3: Does not display time remaining of event timers/ Displays heater current

and event setting with a resolution of 0.1A

See page 14.

See page 15.

See page 15.

0: Operation continued in READY mode

1: Event output OFF in READY mode

0000

0000

0

0

0

0

Chapter 5 INITIAL SETTINGS

0000

0: Disabled

1: Switches between RUN and READY

2: Event latch canceled

3: Auto-tuning start/stop

4: SP value switching (two to four SP values)

Valid when the 1st digit of the number of SP

sets C13 is “1” or more.

Description

0:No operation

1:Switches between

No.0 SP and No.1

SP

2:Switches between

RUN and READY

3:Event 1 timer

operation

4:Event 2 timer

operation

5:Event 1 latch

canceled

6:Event 2 latch

canceled

7:Auto-tuning starts/

stops

Operation

when ON

No.1 SP

READY

Timer

activated

Timer

activated

Latch

canceled

Latch

canceled

Started

Operation

when OFF

No.0 SP

RUN

Timer reset

Timer reset

Latch

enabled

Latch

enabled

Stopped

C12

0000

1st digit

2nd digit

3rd digit

4th digit

Page 18

14

Function

Prompt

C 2 2 Communica-

tions address

C 2 3 Communica-

tions conditions

C 2 4 Cold junction

compensation

C 2 5 Selection of

time-proportional control

operation

0 to 127

0: 9600bps, 8bits, even parity, 1 stop bit

1: 9600bps, 8bits, no parity, 2 stop bit

2: 4800bps, 8bits, even parity, 1 stop bits

3: 4800bps, 8bits, no parity, 2 stop bits

0: Yes

1: No

0: Priority given to controllability

1: Priority given to life of control target (only

1 ON/OFF operation within the timeproportional cycle)

0

0

0

0

Displayed on communications

model only

Communications disabled

when set to “0”

Displayed on communications

model only

Thermocouple input model

only

If a large fluctuation of the

manipulated variable occurs

during the time-proportional

cycle when this item is set to

“0”, control follows this

fluctuation. For this reason,

control may be turned ON and

OFF several times within the

cycle.

Factory

Setting

Function Selections and Setting Range

Remarks

Display of Front Panel LED (SP1)

*See SP1 Lighting Pattern Table.

SP No. Display in

Operation Mode

Change of SP Value during

Selection (in Operation mode)

Chapter 5 INITIAL SETTINGS

C13 (number of SPs used and display method) Setting

1st digit: Number of SPs used

This digit sets the number of SP values that are used.

Setting Number of SPs Used

01

12

23

34

2nd digit: Display/change method

Setting

0 OFF Disabled Pattern 1

1 ON Disabled Pattern 1

2 OFF Enabled Pattern 1

3 ON Enabled Pattern 1

4 OFF Disabled Pattern 2

5 ON Disabled Pattern 2

6 OFF Enabled Pattern 2

7 ON Enabled Pattern 2

• SP No. display in Operation mode

This setting selects whether or not to display the SP No. (SP0 to SP3) in the Operation mode.

• Change of SP value during selection

This setting selects whether or not to enable changing of the currently selected VP value.

• Display of front panel LED (SP1)

This setting is for distinguishing which SP value is currently selected by the lit/blinking state of

the front panel LED (SP1).

C13

0000

1st digit

2nd digit

3rd digit

4th digit

Page 19

15

ON

delay

—

x

Event Settings

Enable/Disable

Related Settings

Hyster-

esis

—

x

E1 or E1 Low

(E2) (E2 High)

E1 High

(E2 High)

C14 and C15 Settings

4th digit 3rd digit 2nd digit 1st digit

—

—

—

E1 Low to 9999

(E2 Low)

—

—

0 to 9999

E1 Low to 9999 (A)

(E2 Low)

—

—

—

-1999 to +9999

-1999 to +9999

-1999 to +9999

(E2 High)

-1999 to +9999

-1999 to +9999

0 to 9999

-1999 to E1 High (A)

(E2 High)

-1999 to +9999 (A)

1 to 9999 (s.)

0:No

1:PV upper limit

alarm

2:PV lower limit

alarm

3:PV upper and

lower limit alarms

4:Deviation upper

limit alarm

5:Deviation lower

limit alarm

6:Deviation upper

and lower limit

alarms

7:Heater line break/

overcurrent alarm

8:Control device

short-circuit alarm

9:Timer

0:No

1:Standby

2:Latch

3:Standby

and latch

4:Non

5:Standby

at chang-

ing SP

0:Direct

1:Reverse

Controller

alarm

0:No

1:Yes

(See note)

Chapter 5 INITIAL SETTINGS

Front Panel LED (SP1) Lighting Pattern

Pattern 1 Pattern 2

No.0 SP Selected Out Out

No.1 SP Selected Lit Lit

No.2 SP Selected Blinks twice Lit

No.3 SP Selected Blinks 3 times Lit

C14 and C15 settings

Digit settings: Enable/Disable

(Note) • When the event operation type is set to timer, set digits 2, 3 and 4 to “0”.

• When the controller fault alarm (4th digit) is set, the controller fault alarm

operates directly at all times.

Page 20

16

2nd Digit 1st Digit Event Description Remarks

00No

0 1 PV upper limit

alarm

0 2 PV lower limit

alarm

0 3 PV upper and

lower limit alarms

0 4 Deviation upper

limit alarm

0 5 Deviation lower

limit alarm

0 6 Deviation upper

and lower limit

alarms

0 7 Heater line break/

overcurrent alarm

0 8 Control device

short-circuit alarm

0 9 Timer

See

note 1

See

note 2

See

note 2

HyS

E1

PV

ON

OFF

HyS

E1Hl

PV

HyS

E1Lo

ON

OFF

PV

HyS

SP+E1

ON

OFF

HyS

SP+E1

PV

ON

OFF

Note 1 Set a negative value as the lower deviation limit (E1). If a positive value is set, a temperature

higher than the SP value will be used as the operating point.

Example: Enter “-10” to set an operating point of SP-10°C

Note 2 Heater line break/overcurrent and control device short-circuit alarm.

Models with a current transformer input detect heater line breaks, overcurrent conditions

and control device short-circuit alarms by input from the current transformer.

• Heater line break/overcurrent alarm (operation type: 7)

Heater line break: This alarm is activated when the current at control output ON is

lower than the event setting (Ex Low). Set Ex High to “9999” to

disable the overcurrent alarm.

Overcurrent: This alarm is activated when the current is higher than the event

setting (Ex High) when the control output is ON. Set Ex Low to

“1999” to disable the heater line break alarm.

• Control device short-circuit alarm (operation type: 8)

This alarm is activated when the current is higher than the event setting (Ex) when control

output is OFF.

Note ● The current display ( C t ) in the operation mode indicates the current value when the

control output is ON. This displayed current value is not updated when control output

is OFF and for 300ms after control output changes to ON.

Detection of the current value is not updated for 300ms after the current output state

changes.

1

Event operation type setting, direct/reverse operation

Chapter 5 INITIAL SETTINGS

HyS

E1

PV

ON

OFF

PV

HyS

E1Hl

HyS

E1Lo

ON SP

OFF

HyS

E1Hl

Current

HyS

E1Lo

ON

OFF

HyS

E1

Current

ON

OFF

RSW

Time

Time

ON

External contact input

OFF

ON

Event operation

OFF

E1

Page 21

17

● The following shows an example of how to set the event setting during detection of a

line break.

Calculate the event setting using the heater current value at control output ON (monitor the displayed CT value) and heater current value at control output OFF (cannot be

measured on the product) according to the following equation:

Event setting = {(heater current value at control output ON) + (heater current value at

control output OFF)}/2

2

Direct/reverse setting (C14 and C15 2nd digit setting)

The direct/reverse setting is used to reverse (invert an ON/OFF relationship) the operation of the event set

on the 1st digit. (0: Direct, 1: Reverse)

Handling Precautions

● Direct operation of the PV upper limit alarm and deviation upper limit alarm is the

same as the reverse limit of PV lower limit alarm and deviation lower limit alarm operation.

Example: Event operation type setting (1st digit): 3 (PV upper and lower limits)

Direct/reverse operation setting (2nd digit): 1 (reverse)

● When using the heater line break/overcurrent and control short-circuit alarm, set

the area to 3A or more.

3

Additional function settings (C14 and C15 3rd digit setting)

Standby and latch operations can be added as additional functions to an event operation type set on the 1st

digit.

Settings 0: No

1: Standby

2: Latch

3: Standby and Latch

4: Non

5: Standby at changing SP

Note ● Standby

The standby function prevents an event from turning ON, even when the ON condition of that event is satisfied at controller power ON or when the READY mode changes

to the RUN mode.

Event output is activated when an ON condition is satisfied after an OFF condition

has been satisfied. The standby state occurs at power ON when the PV value is the

shaded area.

● Latch

Once event output is ON, the latch function holds an event in the ON state even when

an OFF condition is satisfied. Follow the procedure below to reset the latch state.

Chapter 5 INITIAL SETTINGS

● When using the PV, deviation upper/lower limit and heater line break/overcurrent and

control device short-circuit alarm, set HYS so that the OFF point is not lost.

ExLo

ExHI

PV

ON

OFF

HyS

HyS

(bad example) (correct setting)

HyS HyS

ExLo ExHI

PV

ON

OFF

ExHI

HySHyS

ExLo

ON

OFF

PV

Page 22

18

RDY

PV

SP

1 0

S d

C

RDY

PV

SP

S d

C

RDY

PV

SP

1 0

2

0

RDY

PV

SP

0

C t

R L

RDY

PV

SP

1 0

2

0

RDY

PV

SP

1

C t

R L

Operation mode

Operation mode

Parameter mode

PARA

PARA

PARA

Procedure

Power ON

This initial screen is displayed

for about 6 seconds.

The operation mode is

displayed.

Hold down the key for

3 seconds to advance to the

parameter mode.

The parameter mode is

displayed.

Use the , and

keys to enter numeric values.

To set other items, press the

key to display the item

and enter numeric values as

described in Step 4 above.

Hold down the key for 3

seconds twice or wait 1 minute.

Example:

Change the control method

from "ON/OFF control" to "selftuning".

Current PV value

Current SP value

C T R L

is displayed

0

is displayed

(default: ON/OFF operation)

Change to

1

( 1: self-tuning)

The digit that is changed blinks for

about 2 seconds. Blinking stops

when the value is fixed.

Current PV value

(in the operation mode)

Current SP value

1

2

3

4

5

6

Chapter 5 INITIAL SETTINGS

1.Set “Latch Cancel” to the external switch input to turn the external switch ON.

2.Reset the additional event setting function (by setting the 3rd digit on C14 and C15 to “0”).

3.Turn the power OFF and back ON again.

4.Set “Latch Cancel” to the

RDY

key, and hold down the

RDY

key for at least one second.

Handling Precautions

Latch Cancel by the

RDY

key is enabled for both events 1 and 2. External switch input is

valid individually for events 1 and 2.

4

Controller alarm setting (C14 and C15 4th digit setting)

This function turns ON an event when a controller alarm code (AL01, AL02, AL03, AL70, AL97 and

AL98) is generated regardless of the direct/reverse setting of the operation mode. OR logic can be set on

the 1st digit of the event operation type.

Setting: 0: Disable

1: Enable

5-3 Parameter Settings

Control parameter settings are shown below.

Page 23

19

C T R L Control method

A T Auto-tuning

S P 0 No.0 SP value

S P 1 No.1 SP value

S P 2 No.2 SP value

S P 3 No.3 SP value

P Proportional band

I Reset time

D Rate time

O L Output limit low

O H Output limit high

R E Manual reset value

S B Self-tuning startup

width/correction

width setting

D I F F Differential gap

C Y C L Time-proportional

cycle

P B I A PV bias value

H Y S 1 Event 1 hysteresis

D L Y 1 Event 1 ON delay

time

H Y S 2 Event 2 hysteresis

D L Y 2 Event 2 ON delay

time

F I L T PV filter

0

0

0 (0.0)

0 (0.0)

0 (0.0)

0 (0.0)

5.0

120

30

0

100

50

2

(or 2.0)

°C/°F

0.5%

(%F.S.)

5 (0.5)

10

0 (0.0)

5

(0.5)

0

5

(0.5)

0

0.0

Function

Prompt

0: ON/OFF control

1: Self-tuning

2: Control by PID fixed values

0: Stop

1: Start

Same as normal SP value or SP limit value

range

0.1 to 999.9%

0 to 3600 s

0 to 1200 s

0% to Output limit high

Output limit low to 100%

0 to 100%

Thermocouple/RTD input:

0 to 5 (or 0.0 to 5.0) °C/°F

DC voltage input

0.0 to 3.0% (%F.S.)

1 to 250 ( or 0.1 to 25.0)

5 to 120 s (relay output)

1 to 120 s (voltage output)

-1999 to +9999 (or -199.9 to +999.9)

0 to 9999 (or 0.0 to 999.9)

0 to 9999 s

0 to 9999 (or 0.0 to 999.9)

0 to 9999 s

0.0 to 20.0 s

Function

Remarks

Factory

Setting

Selections and Setting Range

Displayed when

C T R L

(control method) is set

to

1 or 2 .

Normally, setting is not

required when C T R L

(control method) is set

to

1 (self-tuning).

Displayed when 1st digit

of

C 1 3 is "1" to "3"

Displayed when 1st digit

of

C 1 3 is "2" or "3"

Displayed when 1st

digit of

C 1 3 is "3"

Displayed when

C T R L

= 1 or 2

C T R L = 0

Displayed when

C T R L

= 1 or 2

Displayed on event

output model and when

value of 1st digit of event

type setting (

C 1 4 or

C 1 5) is 1 to 8

Chapter 5 INITIAL SETTINGS

● List of parameters

Page 24

20

Chapter 5 INITIAL SETTINGS

PV

PV

Time

ON

OFF

ON delay time

Event setting

Event output

● Self-tuning Startup Width Setting

Any deviation width (S b) for startup can be set as a startup condition of self-tuning.

Startup width (S b) is set in the parameter settings. Setting the startup width to “0” disables (self-tuning is started only when the SP value changes) self-tuning by deviation.

The startup width (S b) is set to “0” in the following applications:

- In the case of interference control targets (e.g. instruments that are easily influenced by

changes in the temperature of adjacent (up, down, left, right) zones

- In the case of control targets where disturbance is generated intermittently (e.g. packaging equipment)

SP value

PV value

Startup width (sb)

Self-tuning startup

Note Event ON delay

An event operation whose condition (exceeding an upper temperature limit, for

example) has been satisfied is not activated until a set time has elapsed.

Page 25

21

Example:

Set

E 1

in operation mode.

RDY

PV

SP

1 0

RDY

PV

SP

S d

C

RDY

PV

SP

1 0

5

0

2

0

RDY

PV

SP

0

E

1

RDY

PV

SP

5 0

RDY

PV

SP

1 0

2

0

RDY

PV

SP

RDY

PV

SP

E

1

Operation mode

PARA

PARA

Procedure

Power ON

The initial screen is displayed

for about 6 seconds.

The operation mode is

displayed.

Press the key several

times to scroll the selection.

Use the , and

keys to enter numeric values.

Hold down the key

until the PV and SP values are

displayed.

Current PV value

Current SP value

E 1

(event 1 setting) is displayed.

The digits that are changed blink

for about 2 seconds. Blinking stops

when the value is stored.

Current PV value

Current SP value

Set event 2 by the same procedure.

1

2

3

4

5

RDY

PV

SP

1 0

RDY

PV

SP

S d C

2 0

RDY

PV

SP

1 0

2

0

0

2 0

RDY

PV

SP

2 0 0

2 0

RDY

PV

SP

Operation mode

Example:

Change the SP value in the

basic display state in the

operation mode.

PARA

Procedure

Power ON

The operation mode is

displayed.

Use the , and

keys to enter numeric values.

Hold down the key

until the PV and SP values are

displayed.

Current PV value

Current SP value

Change the SP value.

The digits that are changed blink

for about 2 seconds. Blinking

stops when the value is stored.

Current PV value

Current SP value

1

2

3

4

The initial screen is displayed

for about 6 seconds.

Chapter 5 INITIAL SETTINGS

5-4 Event Settings (only with option installed)

5-5 SP Setting

The following shows how to set an SP value.

Page 26

22

Upper

display:

PV

Lower

display:

SP

S P - 0

S P - 1

S P - 2

S P - 3

O V T

C T

T 1

T 2

E 1

(E 1 L O)

E 1 H I

E 2

(E 2 L O)

E 2 H I

Normal display

mode

SP No. and SP

value displayed

Manipulated variable

displayed

Current (Ct) displayed

Timer event 1

remaining time

displayed

Timer event 2

remaining time

displayed

Event 1 (lower limit)

setting

Event 1 (upper limit)

setting

Event 2 (lower limit)

setting

Event 2 (upper limit)

setting

Function

Prompt

SP: upper and lower SP limit

Settings can be made in the

C 0 9 to C 1 0 range

Not settable

Not settable

Not settable

Not settable

Depends on event 1 operation

type

See pages 10 to 12 for details

Depends on event 2 operation

type

See pages 10 to 12 for details

Function

Remarks

Selections and Setting Range

0 Upper display (PV):

Displays

C 1 2 = XXX0, XXX2

Lower display (SP):

Displays

C 1 2 = XXX0 , XXX 1

SP No. switched by

keys.

(See note 1)

— Displays

C 1 2 = XX 1X

ON/OFF control:

“0.0” is displayed at OFF

“100.0” is displayed at ON

PID control:

Values in 0.0 to 100.0 (%)

range displayed

—

C 1 2 = X0XX is displayed on CT

model

Measurement range: 0 to 55 A

Event operable range: 3 to 50 A

Lights when control output is

300ms or more (See note 2).

— Displays

C 1 2 = 0XXX

(See note 3)

— Displays C 1 2 = 0XXX

(See note 3)

0 Displays

C 1 2 = X0XX

Displays settings

C 1 2 = 1 to 9

0 E 1 : Sets either upper or lower

limit. Displayed at event

0

E 1 L O, E 1 H I:

Displayed at events requiring upper/lower limit setting

Factory

Setting

0

Chapter 5 INITIAL SETTINGS

■ List of Operation modes

(Note 1) This value cannot be changed when SP switching by external switch input is

selected.

(Note 2) This value blinks when control output is OFF or ON at 300ms or less. During

blinking, the displayed CT value cannot be changed.

(Note 3) This value is displayed by timer events set in the event and by the operation

type of the external switch input set to the timer start setting. As long as timer

operation continues, the time elapsed after the occurrence of the event is

displayed within the range 0 to -1999 seconds.

Page 27

23

● How to Switch the SP Value

Up to four SP values can be switched by the following three methods:

1

By SP No.

2

By the

RDY

key

3

By external switch input

1

By SP No.

If the value of the 2nd digit of setup item C 1 3 is set to an odd-number (1, 3, 5, 7),

pressing the

PARA

key in the operation mode displays the SP Nos. “S P - 0” through

to “S P - 3” on the upper display.

Pressing the , keys in this state changes the SP No. in the upper display, and

switches the SP value.

The SP No. is not displayed if the value of the 2nd digit of setup item C 1 3 is set to an

even-number (0, 2, 4, 6).

2

By the

RDY

key

If the value of setup item C 2 1 is set to “4”, the SP value can be switched by the

RDY

key. Holding down the

RDY

key for at least two seconds switches the SP No.

S P 0 → S P 1 → S P 2 → S P 3 → S P 0 and so forth.

3

By external switch input (optional function)

If the values of both setup items C 1 7 and C 1 8 are set to “1” (SP switching), the four

SP values can be switched according to the ON/OFF states of the two external switch

inputs.

External External Selected SP

Switch Input 1 Switch Input 2

Set 1 OFF OFF → No.0 SP

Set 2 ON OFF → No.1 SP

Set 3 OFF ON → No.2 SP

Set 4 ON ON → No.3 SP

Chapter 5 INITIAL SETTINGS

Upper display: SP No.

Lower display: SP value

RDY

PV

SP

1 0 0

S p

_

1

RDY

PV

SP

Page 28

24

Chapter 6 TUNING

6-1 Selecting the Control Method

The SDC10 is provided with three types of control method. Select the desired method

according to the C t R l (control method) setup in parameter items.

0. ON/OFF control

1. Self-tuning : This control method automatically changes control constants when SP is changed, or disturbance

occurs.

2. Control by PID fixed values : Control follows fixed PID values set by auto-tuning or manual operation.

6-2 Self-tuning

The controller can be self-tuned by setting the control method to self-tuning ( C t R l =

1).

Tuning is automatically started and control constants are changed by the following op-

eration or when a change in state occurs in this state.

1

Start by SP change

Start conditions:

• Initial start (*1) SP change of ±10%FS (*2) or more

• 2nd start onwards SP change of ±5%FS or more

*1 “Initial start” refers to initial tuning after the C t R l setting is set to 1.

*2 “FS (full-scale)” refers to the width between the upper and lower temperatures set

by range code (setup item C04).

Example: ±10%FS when the range is -200 to +400°C becomes:

600 (°C) x 10 (%) = 60 (°C)

2

Start by generation of deviation

Startup conditions:

• When the difference between SP and PV is sb or more

* sb: Self-tuning startup width. This is set in the parameter items.

3

Start by power ON or mode change from READY to RUN

Start conditions:

• When the power is turned ON with the difference between SP and PV at ±sb or

more, or the mode is changed from READY to RUN

Self-tuning display

The lower right LED after the 1st digit in the upper display blinks when the self-tuning

function is ON. The LED goes out when learning ends and control constants are stored.

2 5 0

1 2

0

RDY

PV

SP

LED

Page 29

25

● Startup method

● Stop method

Change C t R l from 1 to 2. This fixes the PID values. PID values can also be changed

by key entry.

6-3 Cautions During Self-tuning

Observe the following when using the self-tuning function:

• Turn heaters or other control devices ON before turning the controller ON.

• To turn a control device OFF, set the controller to the READY mode. When turning a

control device back ON again, set the controller to the RUN mode.

• When the power is turned OFF during self-tuning while the LED blinks, the control

constants used during tuning are not stored in controller memory.

If any of the above mistakes have been made, unsuitable control constants are stored to

memory, which may result in unexpected control. If this happens, follow the procedure

below to reset the controller.

RDY

PV

SP

0

C t

R L

RDY

PV

SP

0

2

0

RDY

PV

SP

2 0 0

5

0

RDY

PV

SP

1

C t

R L

Parameter mode

Operation mode

PARA

PARA

Check that the control device

(heater, etc.) is ON and in an

operating state.

Hold down the key for

3 seconds to advance to the

parameter mode.

The parameter mode is

displayed.

Use the , and

keys to enter numeric values.

Hold down the key for

3 seconds twice to advance to

the operation mode.

Use the , and

key to set the SP value to the

desired temperature.

Self-tuning is automatically started for PV value

disturbances and SP changes whenever necessary.

Procedure

C T R L

is displayed.

0

is displayed.

(default: ON/OFF operation)

The

C T R L

value changes from

0

to 1.

Self-tuning starts (LED starts

blinking) simultaneously with SP

value input.

When SP reaches the PV value,

tuning stops and the LED goes out

to indicate that self-tuning has

stopped.

1

2

3

4

5

6

Chapter 6 TUNING

Page 30

26

Chapter 6 TUNING

• Use auto-tuning.

For details on how to use auto-tuning, see “6-4 Auto-tuning.”

• Reset the PID values, and resume self-tuning.

Set parameter item C t R l (control method) to “2”.

Reset the PID values to the factory settings (P = 5.0, I = 120, d = 30).

Set C t R l to “1”, and resume self-tuning.

Handling Precautions

● In the Case of Interference Control Targets

Control targets may be located to the left or right (above or below), and response may slow down as a result of mutual tuning being adversely affected by

respective changes in temperature.

If this happens, either use control by fixed PID values (C t R l = 2), or set

parameter item (S b) to “0”.

● In the Case of Control Targets Where Disturbance Is Generated Intermittently

Tuning results are sometimes adversely influenced when tuning control targets

where intermittent temperature drops occur (e.g. during sealing on packaging

machines).

If this happens, either use control by fixed PID values (C t R l = 2), or set

parameter item (S b) to “0”.

6-4 Auto-tuning

Use the auto-tuning function in the following instances:

• To automatically calculate PID constants by control by fixed PID value (C t R l = 2)

• When startup is slow in self-tuning control

• When response startup is slow in self-tuning control

The auto-tuning function can be used in either of self-tuning control (C t R l = 1) or

control by fixed PID values (C t R l = 2).

● Procedure

Hold the

PARA

key down for at least 3 seconds in the RUN mode and with the SP

value set to enter the parameter setup mode.

Press the

PARA

key with C t R l set to “1” or “2”.

A t (auto-tuning) is displayed. Set “1”.

If “1” is already set, set to “0” then back to “1”.

Auto-tuning can also be stopped by using the external switch input function. To forcibly

cancel auto-tuning midway, either set A t to “0”, or set the controller to the READY

mode.

Auto-tuning indication

The lower right LED after the 1st digit in the lower

display blinks when the auto-tuning function is ON.

The LED goes out when tuning ends.

2 5 0

1 2 0

RDY

PV

SP

LED

1

2

3

1

2

3

Page 31

27

Phenomenon Remedy

Slow startup time

Slow response

PV value fluctuates

Tuning does not end. PV value

fluctuates with a 2°C or more

error between SP and PV value.

Tuning does not end. PV value is

stable but PV does not end.

Large overshoot

Control signals repeatedly turn

ON and OFF more than necessary.

Handling Precautions

● Auto-tuning does not function normally unless the control target is connected.

● The auto-tuning time from start to finish varies according to the control target.

● When auto-tuning is executed, control is suspended, and 0 to 100% output is

repeated several times. If this hinders operation, manually set the PID values.

● Sometimes suitable PID values cannot be obtained according to the control

target. If this happens, manually set the PID values.

The following describes auto-tuning operation:

Operation when the difference between SP and PV values is 10% FS or more and

SP>PV

At startup, operation stabilizes at a temperature of about (SP - PV)/2

↓

The temperature rises again and reaches SP.

↓

Auto-tuning ends when stability is achieved.

Operation when the difference between SP and PV values is 10% FS or less and

SP<PV

Cycling is repeated around the SP value.

↓

Auto-tuning ends when stability is achieved.

Chapter 6 TUNING

TimeSP

Temperature

Execute auto-tuning.

Set

C T R L to “2”, reset PID

values to factory settings,

and set

C T R L to “1” to

execute self-tuning.

Reduce the value of time-

proportional cycle (

C y C L ).

Set the value of PV filter (parameter item) to “1.0” to “2.0”.

Operation ends though it takes

a long time. The slower the

response of the control target,

the longer tuning takes.

Temperature

Time

SP

2

SP-PV

6-5 Control Troubleshooting

1

2

1

2

5

1

2

1

2

3 4

1

2

4

3 4

1

2

3

4

1

2

5

Page 32

28

Input type

Sampling cycle

PV bias

Set points

Setting indication range

Indication accuracy

Temperature unit switching

Model number

Output

Control action

Output rating

Differential gap

Output direct/reverse switching

Chapter 7 SPECIFICATIONS

Category Item Specifications

PV Inputs

Indicators

and Settings

Control

Outputs

Additional

Functions

Thermocouple: K, J, E, T, R, DIN U, DIN L

RTD: Pt100, JPt100

DC voltage: 1 to 5 V, 0 to 5 V, 0 to 1 V

500ms

-1999 to +9999 or -199.9 to +999.9

1 or 2 to 4

Input range display: See page 12 for details

±0.5%FS ±1 digit

Negative thermocouple area: ±1%FS ±1 digit

°C/°F switchable

0D

Relay contacts

ON/OFF, time-proportional

Contact type: SPST

Contact rating: 250Vac, 3A,

30Vdc, 3A

Life: Min. 100,000 operations

(resistive load)

Min. switching specification:

5V, 100mA

6D

Voltage pulse (for SSR drive)

ON/OFF, time-proportional

Voltage (open):

22.5Vdc ±15%

Internal resistance:

1100Ω ±5%

Leakage current (OFF):

100µA max.

1 to 9999 or 0.1 to 999.9

Switchable

2 , SPST contacts, common shared

Contact rating: 250Vac 1A, 30Vdc 1A (resistive load)

PV upper limit alarm, PV lower limit alarm, PV upper/lower limit alarms,

deviation upper limit alarm, deviation lower limit alarm, deviation upper/

lower limit alarms, heater line break/overcurrent, control device shortcircuit, timer

Standby, latch, ON delay, controller alarm

0 to 9999 or 0.0 to 999.9

Min. 100,000 operations (resistive load)

5V, 10mA

1

AC 0 to 55A

AC 3 to 50A

±3A

2

SP switching, RUN/READY switching, event latch state cancel, timer

event start/stop, auto-tuning start/stop

Dry contact or open-collector

• Allowable ON contact resistance: Max. 250Ω

• Allowable OFF contact resistance: Min. 100kΩ

• Allowable ON residual voltage: Max. 1.0V

• Terminal current voltage (open): 5Vdc

• Terminal current (ON): Approx. 4mA

Event

Current

transformer

input

External

switch

input

No. of points

Type

Additional functions

Differential gap

Life

Min. switching

specifications

No. of points

Display range

Guaranteed

operating range

Accuracy

Recommended

operating conditions

No. of points

Function

Non-insulated type

No. Current

Thru Lines

Measuring

Current

CT Value

Display (ave.)

Allowable Input

Current

AC 3 to 15A 3 9 to 45A Max. AC 33A

AC 5 to 23A 2 10 to 46A Max. AC 50A

AC 9 to 50A 1 9 to 50A Max. AC 100A

Page 33

29

Wet contact or open-collector

• Input voltage range: 10 to 26.4Vdc

• Allowable ON voltage: 10V min.

• Allowable OFF voltage: 3.0V max.

• Input impedance: Approx. 2200Ω

• Terminal current (ON): Approx. 5mA (when 12Vdc is applied)

Approx. 10mA (when 24Vdc is applied)

Non-volatile semiconductor memory

AC model: 100 to 240Vac, 50/60Hz

DC model: 24Vdc (no polarity)

AC model: 7VA Max. (under operating conditions)

DC model: 7W Max. (under operating conditions)

Across power terminal and secondary terminals:

500Vdc, 20MΩ or more

AC model: Across power terminal and case: 1500Vac for 1 minute

(See note)

DC model: Across power terminal and case: 500Vac for 1 minute

AC model: Max. 30A

DC model: Max. 20A

ABS plastic/dark gray (equivalent to Munsell 5Y3.5/1)

PC plastic/light gray (equivalent to Munsell 2.5Y7.5/1)

Ambient temperature: 23 ±2°C

Ambient humidity: 60±5%RH

Power voltage: AC model: 105Vac±1%, 50/60Hz±1Hz

DC model: 24Vdc±5%

Vibration resistance: 0m/s

2

Shock resistance: 0m/s

2

Mounting angle: Reference plane ±3°

Ambient temperature: 0 to 50 °C (0 to 45 °C when 3 or more units are

gang-mounted horizontally)

Ambient humidity: 10 to 90%RH (no condensation allowed)

Power voltage: AC model: 85 to 264Vac, 50/60Hz±2Hz

DC model: 21.6 to 26.4Vdc

Vibration resistance: 0 to 2m/s2 (10 to 60Hz, 2 hours in each X, Y,

Z direction)

Shock resistance: 0 to 10m/s

2

Mounting angle: Reference plane ±10°

Altitude: Max. 2000 mm

Ambient temperature: -20 to +70°C

Ambient humidity: 10 to 95%RH (no condensation allowed)

200g max. (including installation bracket on panel mounted type)

300g max. (including socket on socket type)

0.78 to 0.98N•m

External

switch

input

Insulated type

Category Item Specifications

Additional

Functions

General

Specifications

Memory backup

Rated power supply voltage

Power consumption

Insulation resistance

Dielectric strength

Rush current (power ON)

Mask material/color

Case material/color

Standard conditions

Operating conditions

Shipping and storage

conditions

Mass

Terminal screw tightening

torque

Chapter 7 SPECIFICATIONS

(Note) The primary side and secondary side capacities are joined inside the controller. For

this reason, when performing the withstand voltage test for the panel and controller’s

power supply, disconnect the wiring of grounded secondary side terminals and PV

input terminals from those terminals. In some cases, the grounding / non-grounding

type thermocouples and resistance bulb sensors are not guaranteed for the withstand

voltage between the protecting tube and the inner sensor. Because of this, there will

be a possible cause of failure if such a withstand voltage test is performed as it is.

● I/O isolation The following table shows mutual isolation between I/O items. Items surrounded by

solid lines are insulated from other signals. Items in dashed lines are not insulated:

Power supply Digital circuit

PV input

External switch input 1

External switch input 2 *1

Current transformer input

Control output

Event output 1

Event output 2

*1 Insulated external switch inputs (option code 3) are insulated from other signals.

Page 34

30

Chapter 8 ALARM CODES

When an error occurs, the following alarm codes are displayed in the upper display:

Alarm code Error Cause Countermeasure

A L 0 1

A L 0 2

A L 0 3

A L 7 0

A L 9 7

A L 9 8

Sensor line break, incorrect wiring,

incorrect range code setting

Sensor line break, incorrect wiring,

incorrect range code setting

Terminal temperature compensation

unit failure (thermocouple)

Sensor line break, incorrect wiring

(RTD)

Defective A/D converter

• Power turned OFF during fixing of

data

• Data corrupted due to noise

Data corrupted due to noise

Check wiring or reset range

code.

Check wiring or reset range

code.

Replace unit.

Check wiring.

Replace unit.

Reset data.

Replace unit.

Abnormal PV input

(see Note)

Abnormal PV input

(see Note)

CJ failure

Abnormal PV input

(see Note)

Abnormal A/D

conversion

Abnormal parameter

Abnormal adjustment

data

An alarm code other than A L 9 7 causes the manipulated variable (control output value)

to be set to 0% (OFF). Instrument operations other than manipulated variable are unaffected.

The A L 9 7 alarm code does not affect instrument operation.

(Note) • Display and operation when thermocouple input line break occurs

Abnormal State Indication Alarm Code

Sensor line break Upscaled

A L 0 1

• Display and operation when break occurs in resistance temperature detector input

Abnormal State Indication Alarm Code

Resistor line break

Upscaled or downscaled

A L 0 1

Break in line A or A L 0 2, A L 0 3

Break in line B Downscaled A L 0 2, A L 0 3

Break in line C

Upscaled or downscaled

A L 0 1, A L 0 3

Break in 2 lines or more or A L 0 2, A L 0 3

B short-circuited Downscaled A L 0 2

C short-circuited Downscaled A L 0 2

• Display and operation when break occurs in DC voltage input

Abnormal State Indication Alarm Code

Line break Upscaled A L 0 1

Page 35

31

Chapter 9 MAINTENANCE

● Cleaning

Wipe off dirt on the controller using a soft, dry cloth.

● Parts Replacement

Only authorized personnel are allowed to replace parts.

● Fuse Replacement (AC model only)

Use only specified standard fuses when replacing fuses on the AC power supply wiring.

Standard IEC127