Page 1

DigitroniK

Digital Program Controller

DCP32

User’s Manual

No. CP-SP-1042E

Thank you for purchasing the DigitroniK

Digital Program Controller DCP32.

This manual contains information for

ensuring correct use of the DCP32. It

also provides necessary information for

installation, maintenance, and

troubleshooting.

This manual should be read by those

who design and maintain devices that

use the DCP32.

Be sure to keep this manual nearby for

handy reference.

Page 2

When using this product in applications that require particular safety or when using this

product in important facilities, pay attention to the safety of the overall system and

equipment. For example, install fail-safe mechanisms, carry out redundancy checks

and periodic inspections, and adopt other appropriate safety measures as required.

RESTRICTIONS ON USE

DigitroniK®is a registered trademark of Yamatake Corporation.

DCP31, DCP32, SDC20, SDC21, SDC30, SDC31, SDC40, MA500 and MX200

are registered trademarks of Yamatake Corporation.

© 1998 Yamatake Corporation ALL RIGHTS RESERVED

Make sure that this Instruction Manual is handed over to the user before

the product is used.

Copying or duplicating this Instruction Manual in part or in whole is forbidden. The information and specifications in this Instruction Manual are

subject to change without notice.

Considerable effort has been made to ensure that this Instruction

Manual is free from inaccuracies and omissions.

If you should find any inaccuracies or omissions, please contact

Yamatake Corporation.

In no event is Yamatake Corporation liable to anyone for any indirect,

special or consequential damages as a result of using this product.

REQUEST

Page 3

■ About Icons

Safety precautions are for ensuring safe and correct use of this product, and for

preventing injury to the operator and other people or damage to property. You must

observe these safety precautions. The safety precautions described in this manual

are indicated by various icons.

The following describes the icons and their meanings. Be sure to read and

understand the following descriptions before reading this manual.

■ Examples

i

Triangles warn the user of a possible danger that may be caused by

wrongful operation or misuse of this product.

These icons graphically represent the actual danger. (The example on

the left warns the user of the danger of electrical shock.)

White circles with a diagonal bar notify the user that specific actions are

prohibited to prevent possible danger.

These icons graphically represent the actual prohibited action. (The

example on the left notifies the user that disassembly is prohibited.)

Black filled-in circles instruct the user to carry out a specific obligatory

action to prevent possible danger.

These icons graphically represent the actual action to be carried out.

(The example on the left instructs the user to remove the plug from the

outlet.)

SAFETY PRECAUTIONS

WARNING

Warnings are indicated when mishandling this product might

result in death or serious injury to the user.

CAUTION

Cautions are indicated when mishandling this product might

result in minor injury to the user, or only physical damage to

this product.

Page 4

ii

WARNING

CAUTION

Use the DCP32 within the operating ranges recommended in the specifications (temperature, humidity, voltage, vibration, shock, mounting direction,

atmosphere, etc.).

Failure to do so might cause fire or faulty operation.

Do not block ventilation holes.

Doing so might cause fire or faulty operation.

Do not allow lead clippings, chips or water to enter the DCP32 case.

Doing so might cause fire or faulty operation.

Wire the DCP32 properly according to predetermined standards.

Also wire the DCP32 using designed power leads according to recognized

installation methods.

Failure to do so might cause electric shock, fire or faulty operation.

Inputs to the current input terminals and on the DCP32 should be

within the current and voltage ranges listed in the specifications.

Failure to do so might cause fire or faulty operation.

Firmly tighten the terminal screws at the torque listed in the specifications.

Insufficient tightening of terminal screws might cause electric shock or fire.

Do not use unused terminals on the DCP32 as relay terminals.

Doing so might cause electric shock, fire or faulty operation.

We recommend attaching the terminal cover (sold separately) after wiring

the DCP32.

Failure to do so might cause electric shock.

33

31

Before removing or mounting the DCP32, be sure to turn the power OFF.

Failure to do so might cause electric shock.

Do not disassemble the DCP32.

Doing so might cause electric shock or faulty operation.

Before connecting the DCP32 to the measurement target or external control

circuits, make sure that the FG terminal is properly grounded (100

Ω max.).

Failure to do so might cause electric shock or fire.

Turn the DCP32 OFF before starting wiring.

Failure to do so might cause electric shock.

Do not touch electrically charged parts such as the power terminals.

Doing so might cause electric shock.

Page 5

iii

CAUTION

Use Yamatake Corporation's SurgeNon if there is the risk of power surges

caused by lightning.

Failure to do might cause fire or faulty operation.

Before replacing the battery, be sure to turn the power OFF.

Failure to do so might cause electric shock.

Do not touch internal components immediately after turning the power OFF

to replace the battery.

Doing so might cause burns.

・Do not insert the battery with the polarities (+, -) reversed.

・Do not use damaged (broken battery skin, leaking battery fluid) batteries.

・Do not throw batteries into fires, or charge, short-circuit, disassemble or

heat batteries.

・Store batteries in low-temperature, dry locations.

Failure to observe the above cautions may cause batteries to emit heat or

split, or battery fluid to leak.

Store batteries out of the reach of small children.

Batteries are small and are easy to swallow. If a child swallows a battery,

consult a physician immediately.

Do not throw used batteries into fires or dispose at the user site.

Return used batteries to Yamatake Corporation or your dealer.

If you touch components inside the DCP32, touch a grounded metal object

to discharge any static electricity from your body.

Otherwise, static electricity might damage the components.

Handling Precautions

After turning the power ON, do not operate the DCP32 for at least 15

seconds to allow the DCP32 to stabilize.

Page 6

iv

To reduce of electrical shock which could cause personal injury, all safety notices in

this documentation.

This symbol warns the user of a potential shock hazardous live voltages may be

accessible.

・ If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment must be impaired.

・ Do not replace any component (or part) not explicity specified as replaceable by your

supplier.

・ All wiring must be in accordance with local norms and carried out by authorized

experienced personnel.

・ The ground terminal must be connected before any other wiring (and disconnected last).

・ A switch in the main supply is required near the equipment.

・ In the case of AC power supply models, the main power supply wiring requires a (T) 1.0 A,

250 V fuse(s).(IEC127)

EQUIPMENT RATINGS

Supply voltages 100 to 240 Vac (operation power voltages 90 to 264 Vac)

Frequency 50/60 Hz

Power or current ratings 30 VA maximum

EQUIPMENT CONDITIONS

Do not operate the instrument in the presence of flammable liquids or vapors. Operation of any

electrical instrument in such an environment constitutes a safety hazard.

Temperature 0 to 50

℃

Humidity 10 to 90%RH

Vibration Frequency 10 to 60 Hz

Acceleration 1.96 m/s

2

maximum

Installation category Category II (IEC664-1, EN61010-1)

Pollution degree 2

EQUIPMENT INSTALLATION

The controller must be mounted into a panel to limit operator access to the rear terminal.

Specification of common mode voltage; The common mode voltages of all I/O except for main

supply and relay outputs are less than 30 Vrms, 42.4 V peak and 60 Vdc .

APPLICABLE STANDARDS

EN61010-1, EN50081-2, EN50082-2

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batterries according to the manufacturer’s instructions.

SAFETY REQUIREMENTS

Page 7

Request

v

The Role of This Manual

The filter on the front of the DCP32 is covered with a protective film to protect the surface of the DCP32.

When you have finished mounting and wiring the DCP32, fix cellophane adhesive tape on the corners of the filter,

and pull in the direction of the arrow to peel off the protective film.

Pull towards you.

Handling Precautions

Peeling off the protective film with your fingernail might scratch the surface

of the DCP32.

DigitroniK CPL Communications DCP31/32 Version

Manual No. CP-UM-1760E

This manual is required reading for those using the CPL communications

functions of the DCP32.

This manual describes an outline of CPL communications, wiring,

communications procedures and DCP communications data, how to

remedy trouble, and communications specifications.

XXXXX

XXXXXX

ser's anua

XXXXX

No.CP-UM-XXXXE

XXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

Product Manual Manual No. CP-SP1042E

This manual

This manual is provided with the DCP32 (single-loop model).

It is required reading for those in charge of designing, producing and

maintaining control systems incorporating the DCP32, and for those using

the DCP32 in other applications.

It describes mounting onto control panels, wiring, parameter setup,

program setup, operation methods, maintenance and inspection,

troubleshooting and specifications.

XXXXX

XXXXXX

ser's anua

XXXXX

No.CP-UM-XXXXE

XXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

The following two manuals have been prepared for the DCP32. The following gives a brief outline of the manual.

If you do not have the required manual, contact Yamatake Corporation or your dealer.

Page 8

Organization of This User’s Manual

vi

This user's manual comprises the following ten chapters.

Chapter 1. GENERAL

This chapter describes DCP32 applications, features and basic function blocks.

It also gives a list of model numbers.

Chapter 2. NAMES & FUNCTIONS OF PARTS

This chapter describes the names and functions of DCP32 parts, input types and

range Nos.

Chapter 3. INSTALLATION & MOUNTING

This chapter describes how to mount the DCP32 on control panels. This chapter is

required reading for designers of control systems using the DCP32.

Chapter 4. WIRING

This chapter describes the precautions when wiring the DCP32 to a control system

and how to wire the DCP32. This chapter is required reading for designers of

control systems and supervisors of wiring work.

Chapter 5. FUNCTIONS

This chapter describes the functions of the DCP32. This chapter is required

reading for designers of control systems using the DCP32.

Chapter 6. OPERATION

This chapter describes how to switch the basic display states of the DCP32, and

select and run programs. This chapter is required reading for designers of control

systems using the DCP32 and users of control systems.

Chapter 7. PARAMETER SETUP

This chapter describes how to set up parameters on the DCP32 and the meaning of

settings.

Chapter 8. PROGRAM SETUP

This chapter describes how to set up programs on the DCP32 and the meanings of

settings.

Chapter 9. MAINTENANCE & TROUBLESHOOTING

This chapter describes points to check when the DCP32 is not working properly or

how to remedy trouble that might occur.

Chapter 10. SPECIFICATIONS

This chapter describes the general specifications, performance specifications and

external dimensions of the DCP32.

Page 9

Contents

vii

SAFETY PRECAUTIONS

SAFETY REQUIREMENT

Request

The Role of This Manual

Organization Used in This Manual

Contents

Conventions Used inThis Manual

Chapter 1. GENERAL

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Basic Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-3 Data Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-4 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

■ System configuration by CPL communications . . . . . . . . . . . . . . . . . . . 1-4

1-5 Model Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2. NAMES & FUNCTIONS OF PARTS

2-1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

■ Basic display state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

■ Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

■ Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

■ Combined key operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

■ Loader jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-3 Input Type and Range No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

■ Inputs 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

■ Inputs 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Chapter 3. INSTALLATION & MOUNTING

3-1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

■ Mounting locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

■ Noise generating sources and countermeasures . . . . . . . . . . . . . . . . . . 3-2

■ Dust-proof cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

■ Panel cutout dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

■ Mounting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Chapter 4. WIRING

4-1 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Compensating Lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-3 Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-4 Layout of Terminals and Recommended Lead Draw-out Direction. . . . . . . 4-5

4-5 Connecting the Ground and Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

■ Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

■ Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-6 Wiring of Standard and Add-on Terminal Base . . . . . . . . . . . . . . . . . . . . . . . 4-7

■ Standard terminal layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

■ Add-on terminal layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Page 10

4-7 Connecting Inputs (analog inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

■ Connecting input 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

■ Connecting input 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-8 Connecting Control Outputs (outputs 1, 2, 3) . . . . . . . . . . . . . . . . . . . . . . . 4-10

■ Relay output (0D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

■ Current output (5G) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

■ Position-proportional output (2G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

■ Heat/cool output (3D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

■ Heat/cool output (5K) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4-9 Connecting Auxiliary Outputs (output 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

■ 0D, 5G auxiliary outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4-10 Connecting Event Output (relay output). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-11 Connecting Time Event Output (open-collector). . . . . . . . . . . . . . . . . . . . . 4-16

4-12 Connecting External Switch (RSW) Input. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4-13 Connecting for Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

■ RS-485 interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4-14 Isolating Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

■ Control outputs 0D, 5G, 3D, 5K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

■ Control output 2G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Chapter 5. FUNCTIONS

5-1 Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

■ Data types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 Program Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

■ Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

■ Events 1 to 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

■ Time events 1 to 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

■ PID set selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

■ G.Soak (guarantee soak) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

■ PV start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

■ Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

■ Pattern link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

■ Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5-3 Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

■ Mode type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

■ Mode transition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

■ Mode transition operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

■ Mode transition limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5-4 Controller and Programmer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5-5 Input Processing Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5-6 Output Processing Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

■ Exchanging MV1/MV2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

■ Control output CH1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

■ SP output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

■ Auxiliary output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

viii

Page 11

ix

Chapter 6. OPERATION

6-1 Turning the Power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 Switching the Basic Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

■ Display in program operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

■ Display in constant-value operation mode . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-3 Program Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

■ How to select the program No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6-4 External Switch (RSW) Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

■ External switch (RSW) input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

■ Program selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

■ Read timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-5 Manual Operation and Auto-tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

■ Manual operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

■ Auto-tuning (AT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Chapter 7. PARAMETER SETUP

7-1 Parameter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

■ Selecting the setting group in the parameter setup . . . . . . . . . . . . . . . . 7-1

■ Moving individual items in the parameter setup . . . . . . . . . . . . . . . . . . 7-2

■ Changing individual items and how to return from the setup state . . . 7-2

7-2 How to Use PARA Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

■ How to register functions to PARA keys . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7-3 Parameter Setup List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

■ Variable parameter settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

■ Description of variable parameter settings . . . . . . . . . . . . . . . . . . . . . . . 7-9

■ Variable parameter 2 settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

■ Description of variable parameter 2 settings. . . . . . . . . . . . . . . . . . . . . 7-17

■ Event configuration data settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

■ Description of event configuration data. . . . . . . . . . . . . . . . . . . . . . . . . 7-24

■ PID parameter 1 settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

■ PID parameter 2 settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

■ Setup data settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

■ Description of setup data settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

■ Table data settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

■ Description of table data settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-47

■ Constant-value operation data settings . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Chapter 8. PROGRAM SETUP

8-1 Program Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

■ How to enter program setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

■ Selecting the program No. to set up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

■ Mode transition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

■ Programming map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

■ Display details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

■ Setting up pattern items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

■ Setting up SP 2 items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

■ Setting up events 1 to 3 items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

■ Setting up time events 1 to 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Page 12

x

■ Setting up PID set No. items (CH1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

■ Setting up PID set No. items (CH2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

■ Setting up G.Soak (guarantee soak) items (CH1) . . . . . . . . . . . . . . . . . 8-11

■ Setting up G.Soak (guarantee soak) items (CH2) . . . . . . . . . . . . . . . . . 8-12

■ Setting up PV start items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

■ Setting up cycle items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

■ Setting up pattern link items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

■ Deleting programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

■ Inserting and deleting segments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8-2 Copying Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

■ Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

8-3 General Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

■ Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Chapter 9. MAINTENANCE & TROUBLESHOOTING

9-1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9-2 Self-diagnostics and Alarm Code Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

■ Self-diagnostics at power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

■ Self-diagnostics at each sampling cycle . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

■ Intermittent self-diagnostics during operation . . . . . . . . . . . . . . . . . . . . 9-3

■ Self-diagnostics only when certain functions are operating . . . . . . . . . 9-3

■ Alarm code display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

■ Alarm categories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9-3 Trouble during Key Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

■ Trouble in the basic display state. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

■ Trouble in the parameter setup state . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

■ Trouble in the program setup state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9-4 Motor Adjustment is Impossible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

■ Normal wiring for direct motor rotation . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

■ Normal wiring for reverse motor rotation. . . . . . . . . . . . . . . . . . . . . . . . 9-12

■ Alarm display caused by wrong wiring and causes . . . . . . . . . . . . . . . 9-12

9-5 When BAT LED Blinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

■ BAT LED blinking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

■ Replacing the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Chapter 10.

SPECIFICATIONS

10-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

■ Accessories/option list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10-2

External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

■ DCP32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

■ Soft dust-proof cover (sold separately) . . . . . . . . . . . . . . . . . . . . . . . . 10-10

■ Hard dust-proof cover (sold separately) . . . . . . . . . . . . . . . . . . . . . . . 10-10

■ Terminal cover set (sold separately) . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Index

Page 13

Conventions Used in This Manual

xi

The following conventions are used in this manual.

Handling Precautions

: Handling Precautions indicate items that the user should pay attention

to when handling the DCP32.

Note : Notes indicate useful information that the user might benefit by

knowing.

: Circled numbers indicate steps in a sequence or indicate corresponding

parts in an explanation.

» : Indicates the DCP32 state after an operation.

DISP + ↑ keys : These icons represent keys on the DCP32's console.

FUNC + PROG keys : Key combinations like these indicate keys that must be pressed while

being held down together.

PA01, C21

: These represent indications on the upper and lower 7-segment

displays.

Page 14

1-1

Chapter 1. GENERAL

1 - 1 Features

The DCP32 is:

• a general-purpose double-loop program controller for controlling temperature, pressure, flow rate and other

inputs

• a 2-loop program controller for controlling temperature and relative humidity.

On the DCP32, you can set up to 19 program patterns, and set up to 30 segments to each program pattern.

● High accuracy achieved by multi-range input

Multi-range input allows you to choose between the following input types:

thermocouple, resistance temperature detector (RTD), DC voltage and DC current.

Accuracy of ±0.1%FS±1 digit (±0.2%FS±1 digit for Input 2 only) and a sampling

cycle of 0.1 seconds ensures consistently high-precision control.

● Wide range of control output types

A wide range of models supporting various control output types are available:

relay time-proportional output, position-proportional output, current output,

voltage time-proportional output, and heat/cool output.

On models other than heat-cool control output, you can also choose neural netbased auto-tuning and smart-tuning for inhibiting overshoot, in addition to 2

degrees of freedom PID.

● Enhanced compatibility with PLCs

12 external switch inputs (eight optional), three event outputs and five time event

outputs (optional) ensure compatibility with automating systems designed around

a PLC core.

● Easy operation

Up to eight frequently changed parameter setups can be registered to the PARA

key, facilitating recall of item setups.

Page 15

1-2

Chapter 1. GENERAL

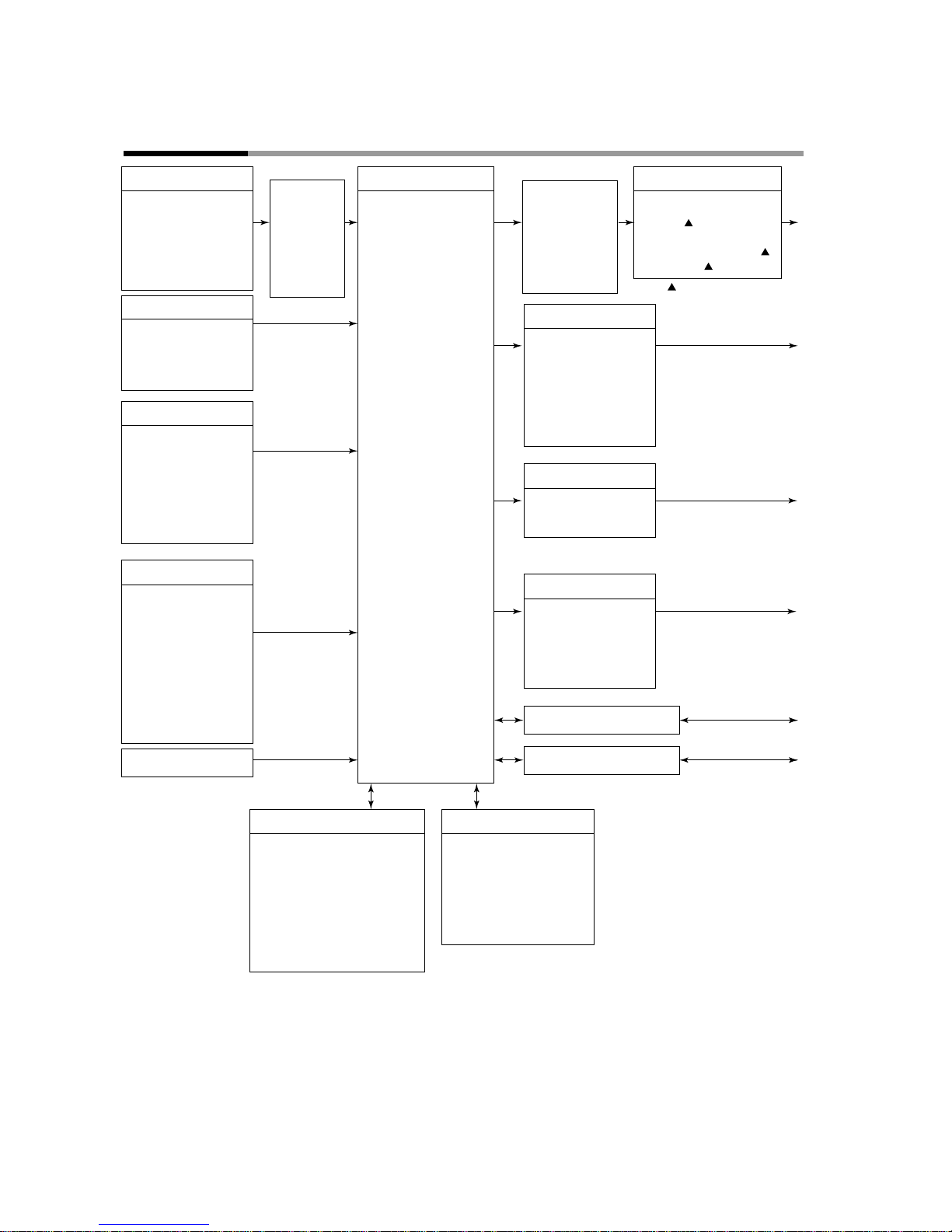

1 - 2 Basic Function Blocks

4 External Switch Inputs

• RUN

• HOLD

• RESET

• ADV

* indicates options.

Inputs 1/2

• Thermocouple

• Resistance

• DC current

• DC voltage

8 External Switch Inputs

• Program No.

• FAST

• PV start

• AUTO/MANUAL

• AT start/stop

• G.Soak cancel

• Direct/reverse action

Key Operation

• Display selection

• Program No.

• RUN/HOLD

• RESET

• ADV

• FAST

• AUTO/MANUAL

• AT start/stop

• Program setup

• Parameter setup

MFB input

• Square root

extraction

•

• Bias

• Filter

Control Operation Block

• Mode transition

• PID control

• Auto-tuning

• Neuro & Fuzzy

• Forward/reverse action

• ON-OFF control

• SP limit

• SP bias

• Output change

limitter

• Upper/lower

limitter

• SP output

• Exchanging

MV1/MV2

Outputs 1/ 2/ 3

• Current

• Relay ( )

• Voltage

• Position-proportional ( )

• Heat-cool ( )

Event Outputs

• PV

• SP

• Deviation

• MV

• MFB

• Modes

• Alarm

Time Event Outputs

• Time event

• Segment code

Auxiliary Outputs

• PV

• SP

• Deviation

• MV

• MFB

CPL communications I/O

Loader communications I/O

*

*

*

Program

• 19 patterns x 30 segments

• Events

• Time events

• PID sets

• G.Soak

• PV start

• Cycle

• Pattern link

Parameters

• Variable parameters

• Event configuration

• PID parameters (8 sets)

• Setup

• Tables

• Constant-value operation

*

temperature detector

(input 1 only)

Linearization table

approximation

( ) indicates output for

one loop only.

Page 16

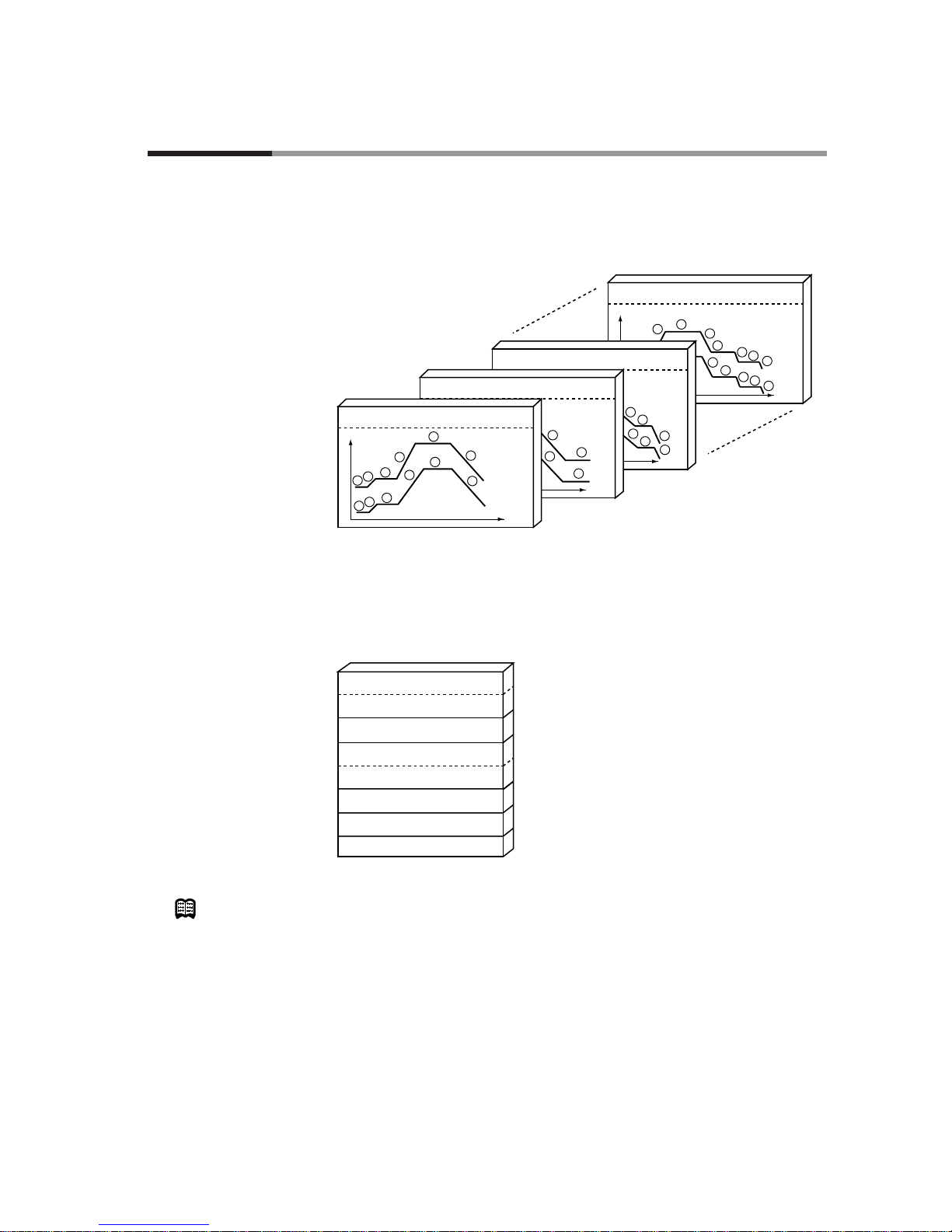

Data is made up of “parameters” that are used mainly for setting controller functions and “programs” that are used

for setting operation during program operation of the DCP32.

● Total of 19 program patterns

Up to 19 program patterns can be set.

1-3

Chapter 1. GENERAL

● Parameters

Parameters are provided for six types of data: variable parameters, event

configuration data, PID parameters, setup data, table data and constant-value

operation data.

Note

Variable parameters contain common parameters regardless of channels CH1 and

CH2.

Program No. = 19 Number of segments = 8

SP

Time

4

5

6

7

8

Program No. = 3 Number of segments = 15

SP

Time

13

15

14

Program No. = 2 Number of segments = 19

SP

Time

18

19

Program No. = 1 Number of segments = 6

SP

Time

1

2

3

4

5

6

4

5

6

7

8

13

15

14

18

19

1

2

3

4

5

6

SP1

SP2

2

3

Variable parameters

Variable parameters 2

Event configuration data

PID parameter 1

PID parameter 2

Setup data

Table data

Constant-value operation data

1 - 3 Data Structure

Page 17

1-4

Chapter 1. GENERAL

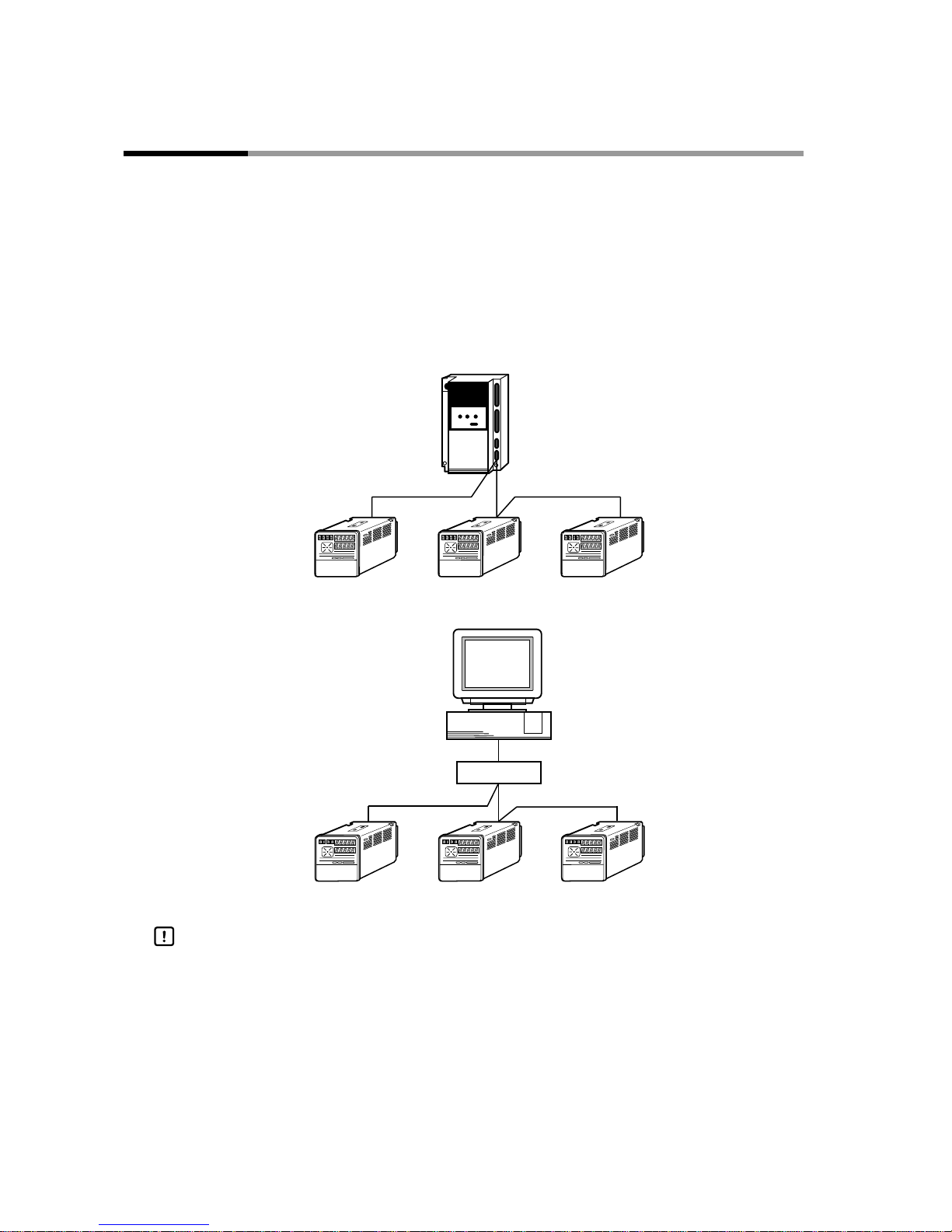

■ System configuration by CPL communications

On DCP32 models supporting RS-485 communications (optional), DigitroniK

series controllers can be connected as slave stations on the CPL communications*

network.

Yamatake Corporation’s MA500 FA controller or MX200 machine controller can

be used as the host station in this case.

* “CPL communications” refers to standard host communications defined in

Yamatake CPD.

Handling Precautions

On a 3-lead wire RS-485 configuration, the Yamatake CMA50A105 cannot

be used as the converter for the master or slave station.

MA500 or MX200

RS-485

DCP32 (slave station)

Personal computer

DCP32 (slave station)

RS-232C

CMA50A105 or CMC410A102 (master station)

RS-485

1 - 4 System Configuration

Page 18

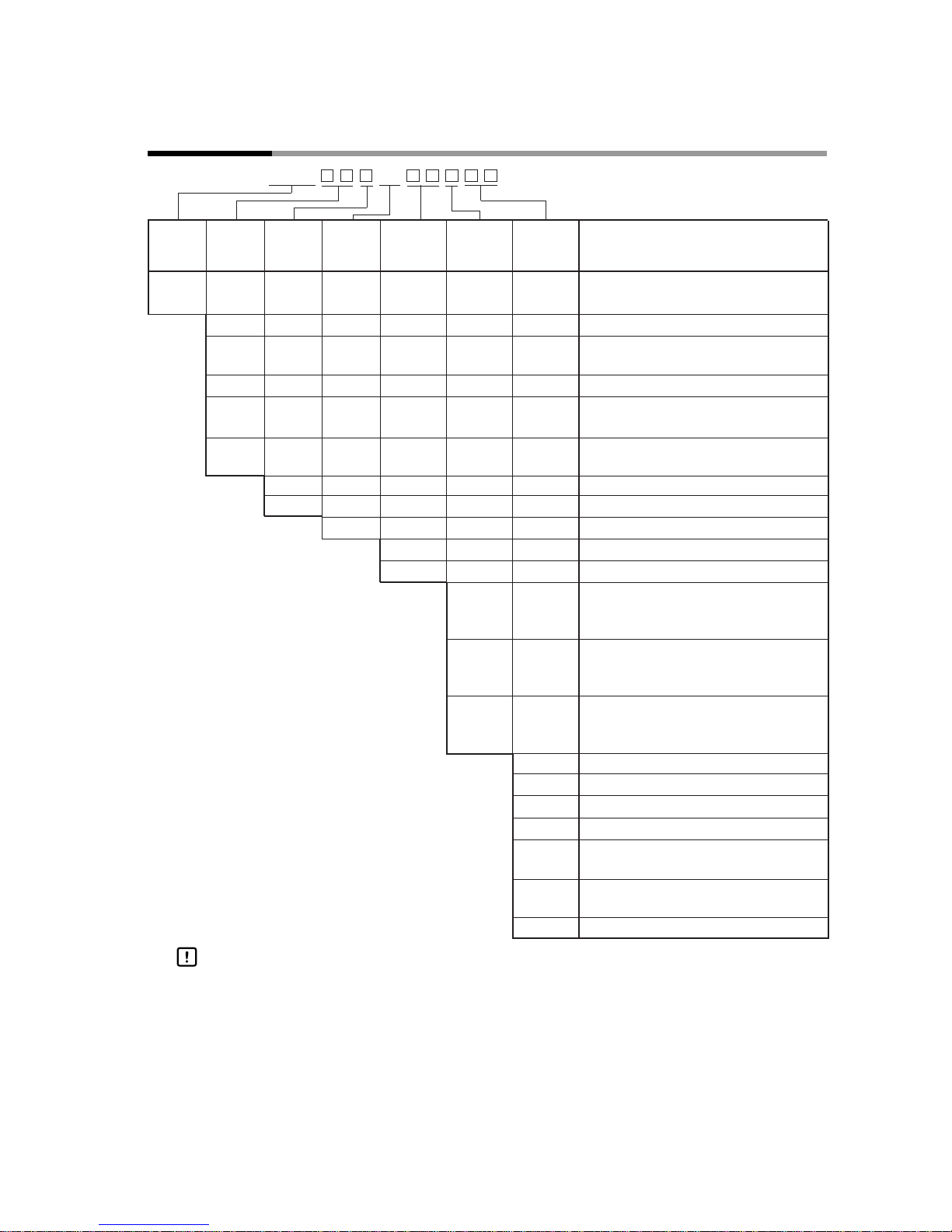

1-5

Chapter 1. GENERAL

Basic

Model Output Function Power Option 1 Option 2 Additions Description

No.

P32A Digital Program Controller (2-loop

model)

0D Relay outputs + current output

2G Position-proportional output + current

output

5G Current output + current output

3D Heat-cool output (relay output + relay

output) + current output

5K Heat-cool output (current output +

current output) + current output

1 Input 2 channel

2 Temperature/humidity calculation

AS Free power supply (90 to 264 Vac)

00 No auxiliary output

01 1 auxiliary output

0 External switch inputs (4), time events

not supported, communications not

supported

1 External switch inputs (12), 5 time

events supported, communications not

supported

2 External switch inputs (12), 5 time

events supported, RS-485

communications supported

00 Additional treatment not supported

T0 Tropical treatment

K0 Antisulfide treatment

D0 Inspection Certificate provided

B0 Tropical treatment + Inspection

Certificate provided

L0 Antisulfide treatment + Inspection

Certificate provided

Y0 Traceability Certificate

Basic Model No. : P32A AS

Handling Precautions

• On 2G, 3D and 5K output models, only 00 (auxiliary output OFF) can be

designated for option 1.

• On current output models other than heat/cool output, you can choose

between use of the DCP32 as a controller or a programmer.

• Current output can be changed to voltage output (with current value

adjustment function).

• Relay output on 0D output models is time-proportional output.

• Relay output on 3D output models is either time-proportional output or

3-position control output.

• Voltage output is time-proportional output.

1 - 5 Model Numbers

Page 19

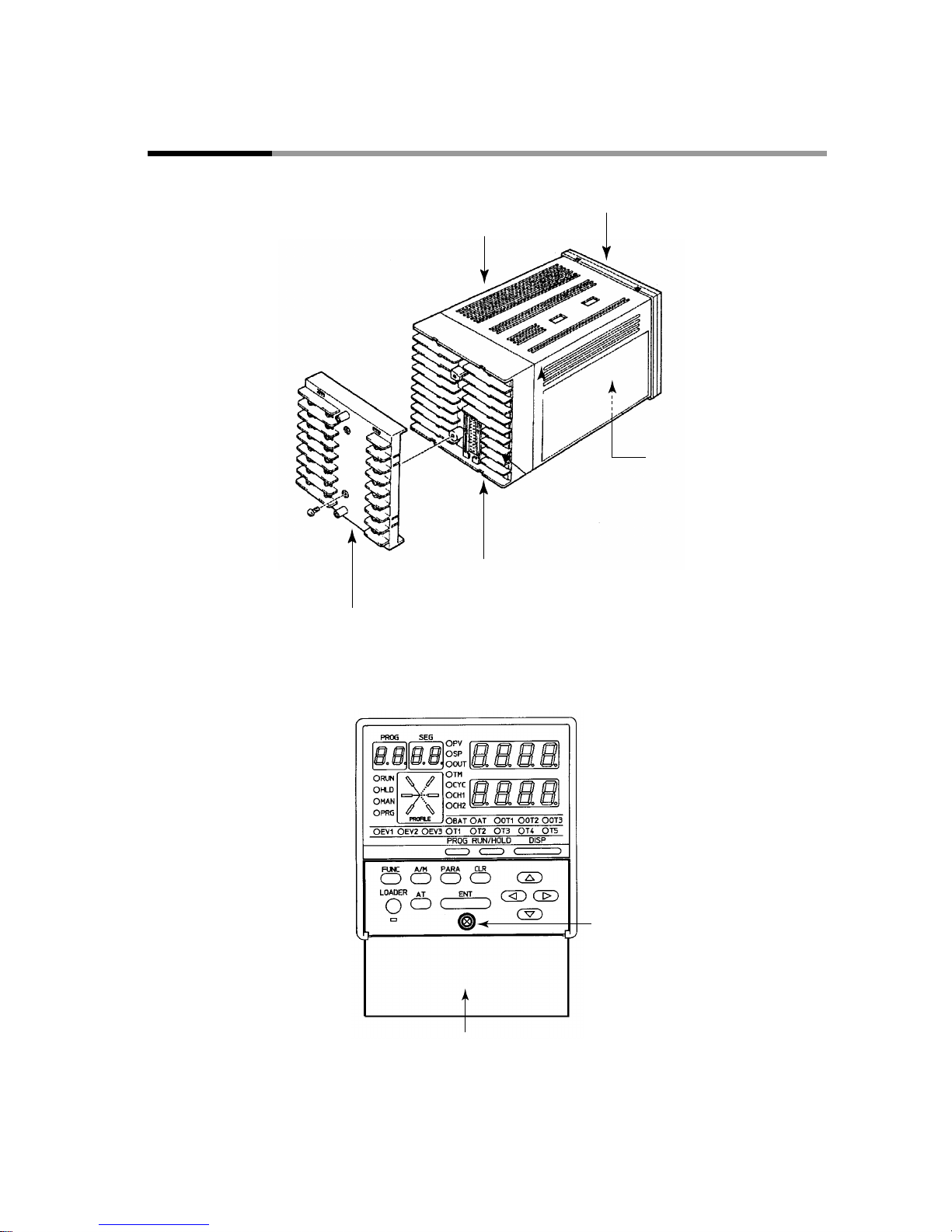

2-1

Chapter 2. NAMES & FUNCTIONS OF PARTS

2 - 1 Structure

The DCP32 comprises a body, console, case, standard terminal base and add-on terminal base.

Case

Console

Body

Standard terminal base

Contains 7-segment display, LEDs,

operation keys and loader

connector.

Contains console and electrical

circuits.

Connectors for connecting power, input, output, event outputs, external

switch inputs (4) and auxiliary outputs (options).

Add-on terminal base

Terminal for connecting external switch inputs (8 options), time event outputs (options) and

CPL communications (options).

This base is not provided on models not supporting external switch inputs (8) and time event

outputs.

Key lock screw

Fixes the case to the body.

Key cover

Cover for preventing erroneous operation.

Page 20

2-2

Chapter 2. NAMES & FUNCTIONS OF PARTS

2 - 2 Console

The console comprises keys for operating the DCP32, and displays and LEDs.

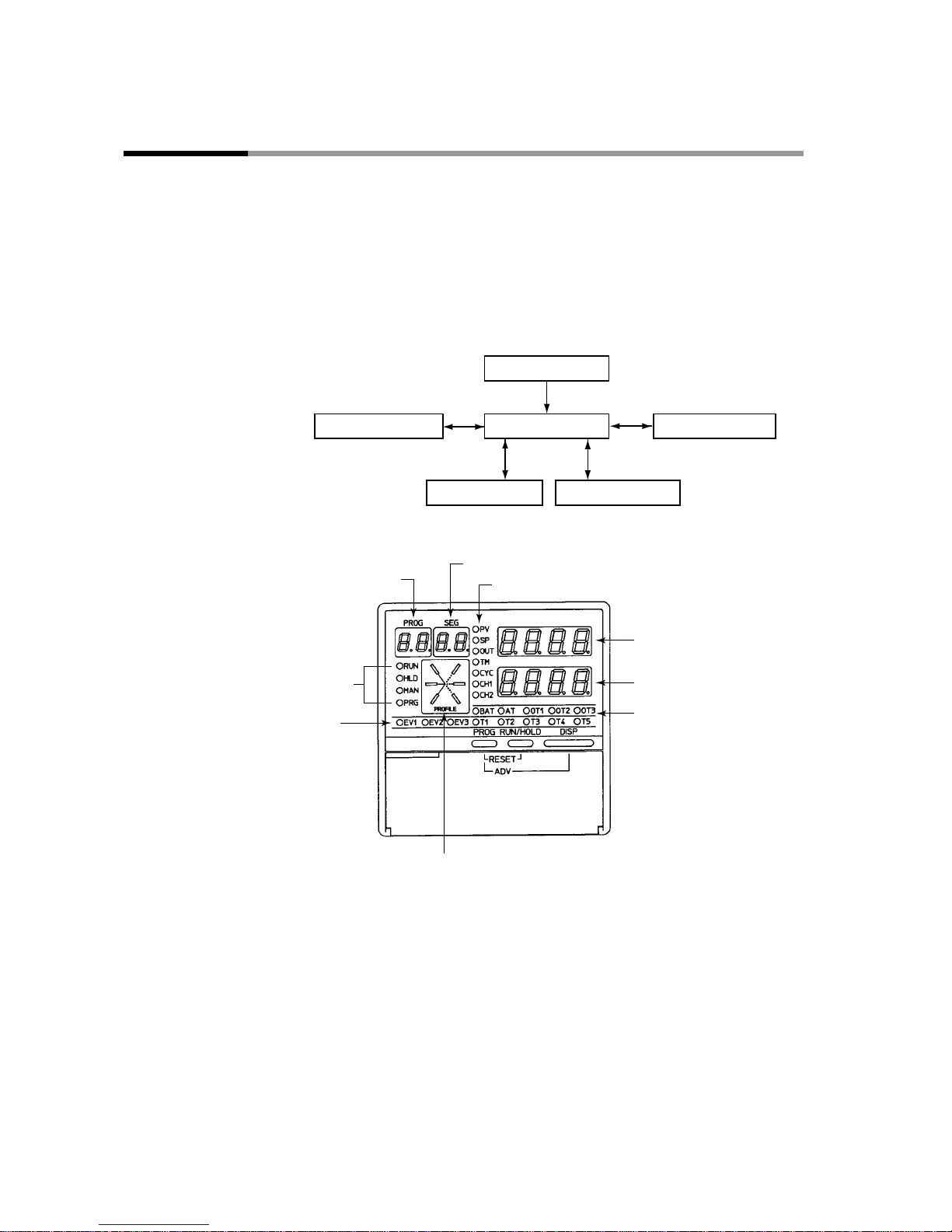

■ Basic display state

The “basic display state” is the state in which the DCP32 operating state is

displayed on the console.

When the power is turned ON, the DCP32 is in this state.

Key operation changes the DCP32 from the basic display state to one of the

parameter setup, program setup, program copy or general reset states. Key

operation also returns the DCP32 to the basic display state.

■ Display

● Program No. display

In the basic display state, this display indicates the currently selected program No.

In the program setup state, this display indicates the program No. currently being

set up.

During constant-value operation, this display goes out in the basic display state.

When an alarm occurs in the basic display state, alarm code “AL” is displayed.

● Segment No. display

In the basic display state, this display indicates the currently selected segment No.

In the program setup state, this display indicates the segment No. currently being

set up.

During constant-value operation, this display goes out in the basic display state.

In the parameter setup state, this display indicates the item No.

When an alarm occurs in the basic display state, the alarm code No. is displayed.

Power ON

Parameter setup state

Program setup state Program copy state

General reset state

Basic display state

Program No. display

Mode indicator

LED lamps

Event LEDs

Segment No. display

Basic indicator LED lamps

Upper display

Lower display

Low battery voltage LED (BAT)

Control/output state LED

Profile display

Page 21

Chapter 2. NAMES & FUNCTIONS OF PARTS

● Mode indicator LEDs

RUN, HLD : Display the READY, RUN, HOLD, FAST and END modes. (See

following table.)

MAN : Lights when the displayed channel (CH1 or CH2 whose LED is lit)

is in the MANUAL mode, blinks when the displayed channel is in

the AUTO mode or the undisplayed channel is in the MANUAL

mode, and goes out when both channels are in the AUTO mode.

PRG : Lights in the program setup state. Otherwise, this LED is out.

● Upper display

In the basic display state, displays PV and other values.

In the parameter setup state, displays the item code.

● Lower display

In the basic display state, displays SP, time, output and other values.

In the parameter setup state, displays the item setting value.

● Low battery voltage LED

BAT : Blinks when the battery voltage is low. Otherwise, this LED is out.

● Control/output state LED

AT : The channel currently displayed in the upper or lower displays

(

CH1 or CH2 whose LED is lit) blinks during auto-tuning, and

lights during smart-tuning. Otherwise, this LED is out.

OT1 : When relay or voltage are assigned to output 1, lights when output

is ON and goes out when output is OFF. In the case of 2G output

models, lights when the open-side relay is ON and goes out when

the relay is OFF.

Lights when current output is assigned to output 1.

OT2 : When relay or voltage are assigned to output 2, lights when output

is ON and goes out when output is OFF. In the case of 2G output

models, lights when the closed-side relay is ON and goes out when

the relay is OFF. Lights when current output is assigned to output 2.

OT3 : Lights when voltage output assigned to output 3 is ON, and goes

out when voltage output is OFF. Lights when current output is

assigned to output 3, and goes out when output 3 is auxiliary output.

● Basic indicator LEDs

PV : Lights during PV display. Otherwise, this LED is out.

SP : Lights during SP display. Otherwise, this LED is out.

OUT : Lights during output display. Otherwise, this LED is out.

TM : Lights during time display. Otherwise, this LED is out.

CYC : Lights during cycle display. Otherwise, this LED is out.

CH1 : Lights when CH1 data is displayed, blinks when CH1 data is

displayed with

CH2 data. Otherwise, this LED is out.

CH2 : Lights when CH2 data is displayed, blinks when CH2 data is

displayed with

CH1 data. Otherwise, this LED is out.

Mode

LED

READY RUN HOLD FAST END

RUN Out Lit Out Blinking Out

HLD Out Out Lit Out Blinking

2-3

Page 22

2-4

Chapter 2. NAMES & FUNCTIONS OF PARTS

● Event LEDs

EV1, EV2, : ・ In the basic display state or parameter setup state, these LEDs

EV3 light when each of EV3 events 1 to 3 are ON, and go out when

OFF.

・ In the program setup (programming) state, these LEDs light

when each of the items for events 1 to 3 are displayed.

Otherwise, these LEDs are out.

T1, T2, T3, : ・ These LEDs light when each of time events 1 to 5 are ON, and

T4, T5 go out when OFF.

・ In the program setup (programming) state, these LEDs light

when each of the items for time events 1 to 5 are displayed.

Otherwise, these LEDs are out.

● Profile display

Displays the tendencies (rise, soak, fall) of the program pattern of the displayed

channel (CH1 or CH2 whose LED is lit) in the upper/lower display. Blinks during

G.Soak standby, and light successively after the power is turned ON.

Page 23

2-5

Chapter 2. NAMES & FUNCTIONS OF PARTS

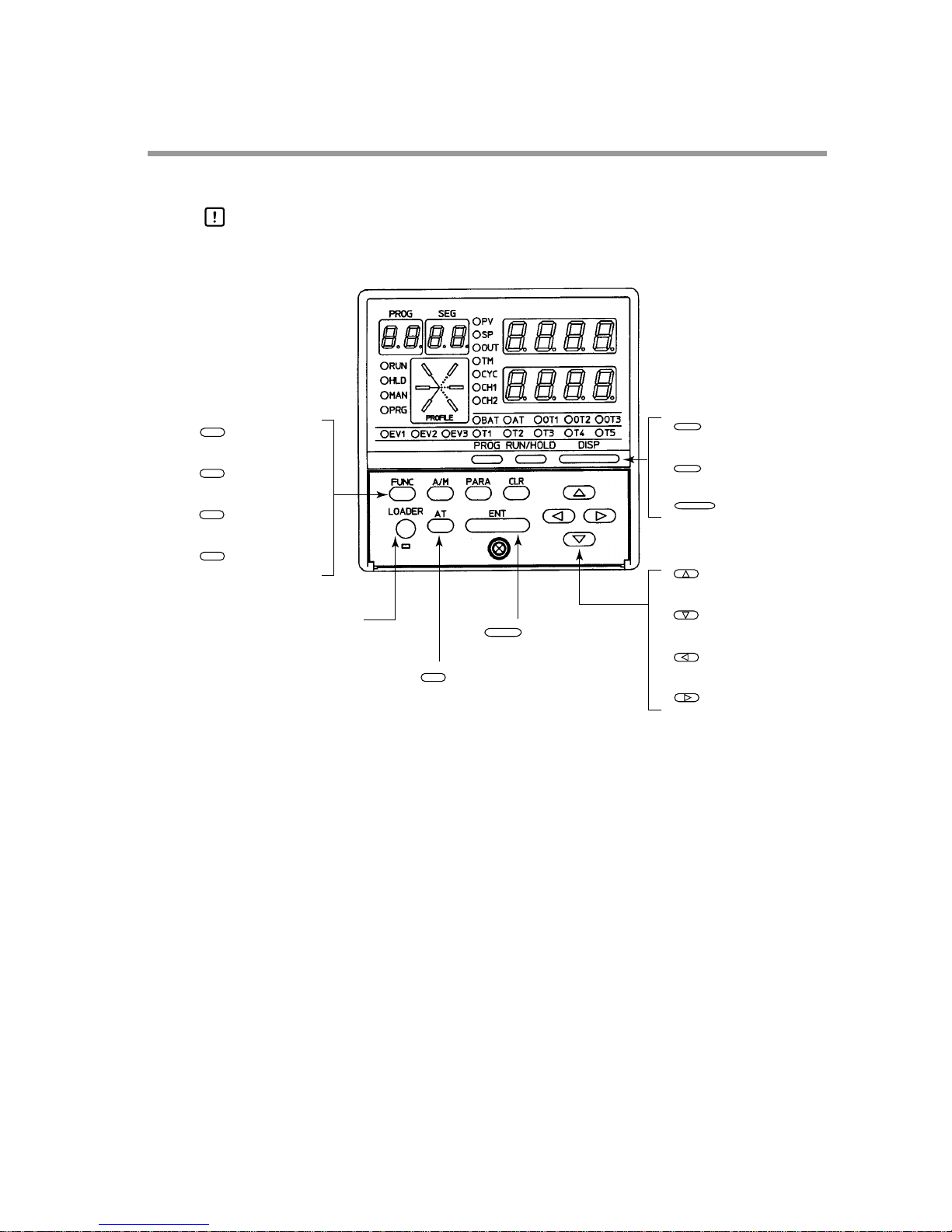

■ Keys

Handling Precautions

Do not operate the console keys using a sharp-pointed object such as a

propelling pencil or needle. Doing so might damage the console.

Function key

(FUNC key)

:

:

:

:

Auto/Manual key

(A/M key)

Parameter key

(PARA key)

Program key

(PROG key)

:

:

:

Run/Hold key

(RUN/HOLD key)

Display key

(DISP key)

Clear key

(CLR key)

Up arrow key

(↑ key)

:

Enter key

(ENT key)

:

Auto-tuning key

(AT key)

:

:

:

:

Down arrow key

(↓ key)

Left arrow key

(← key)

Right arrow key

(→ key)

Loader jack

RUN/HOLD

PROG

PARA

FUNC

ENT

DISP

CLR

AT

A/M

Page 24

2-6

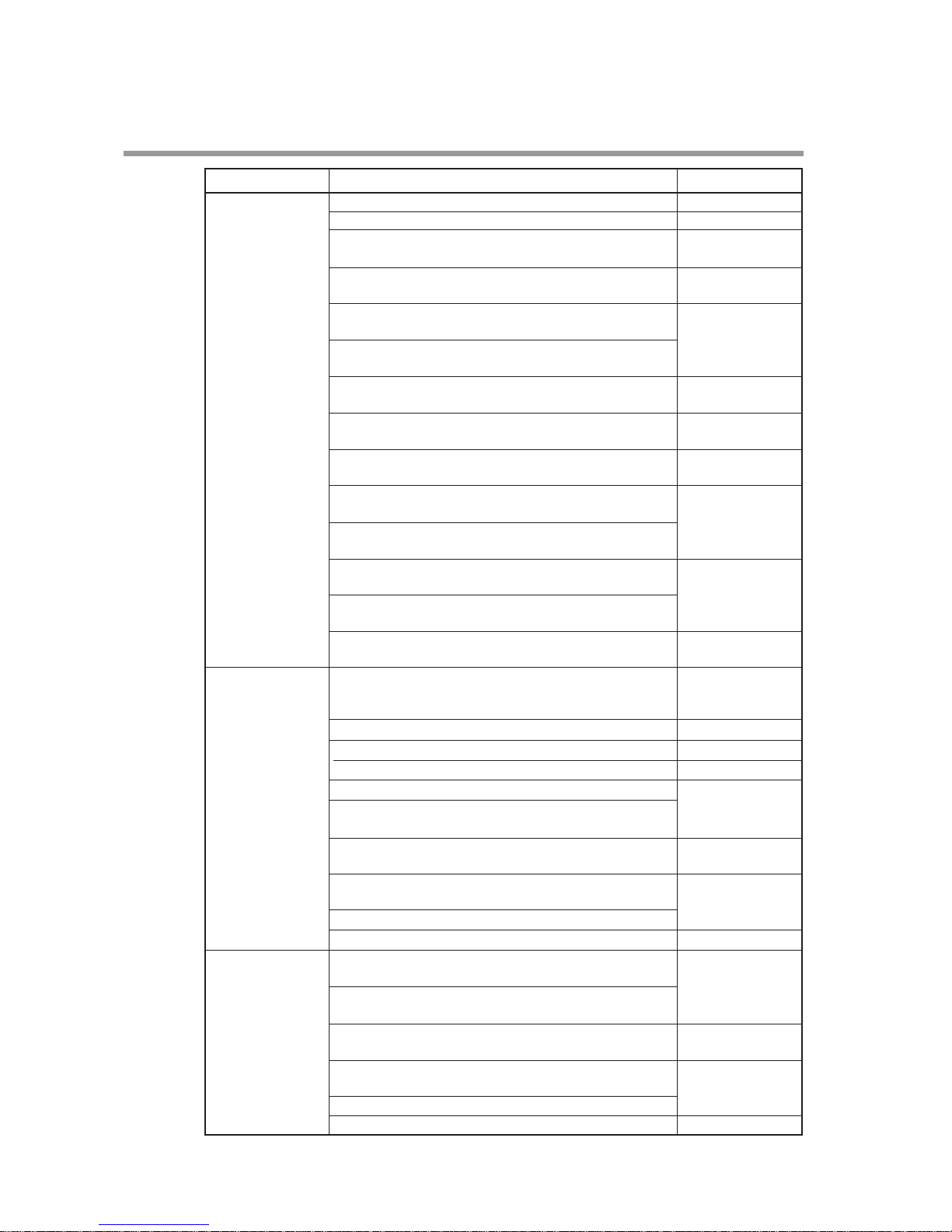

Chapter 2. NAMES & FUNCTIONS OF PARTS

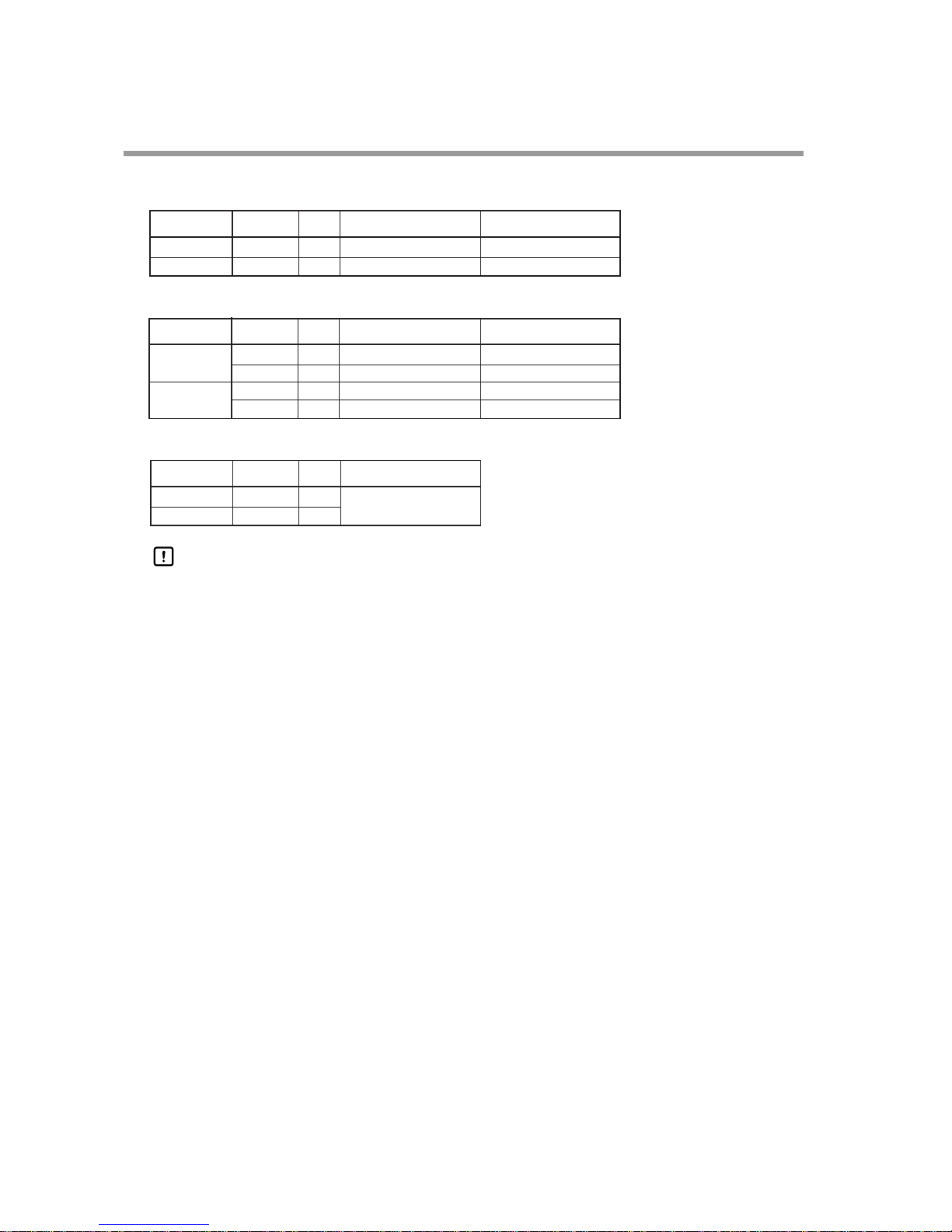

Category

Basic display state

Parameter setup

PARA key

Assignment item

setup

Function

To change the display

To switch the display channel

To change the program No. in ascending order

(in READY mode)

To change the program No. in descending order

(in READY mode)

To run the program

(in READY, HOLD, FAST modes)

To hold the program

(in RUN mode)

To reset the program

(in READY, HOLD, FAST, END modes)

To advance the program

(in RUN, HOLD, FAST modes)

To run the program fast

(in RUN, HOLD modes)

To execute manual operation

(in AUTO mode)

To execute automatic operation

(in MANUAL mode)

To start auto-tuning

(when not executing auto-tuning)

To cancel auto-tuning

(when executing auto-tuning)

To change values during manual operation

(when MV or SP is blinking)

Starts parameter setup. So, the controller enters

selection of setup group (major item).

(in basic display state)

To change the setup group (major item)

To fix the setup group (major item)

To move between individual items (minor items)

To start changing of individual item setting values

To end changing of individual item setting values

(while setting value is blinking)

To change individual item setting values

(while setting value is blinking)

To cancel changing of individual item setting values

(in basic display state)

To select setup group

To end parameter setup

To start changing assignment item setting values

(in basic display state)

To move to next item by assignment item, and start

changing setting values

To change assignment item setting values

(while setting value is blinking)

To end changing of assignment item setting values

(while setting value is blinking)

To start changing assignment item setting values

To end assignment item setup

Key operation

DISP

FUNC + DISP

PROG

↓

RUN/HOLD

PROG +

RUN/HOLD

PROG + DISP

FUNC +

→

A/M

AT

↑ ↓ ← →

FUNC + PARA

PARA ↑ ↓

ENT

↑ ↓ ← →

ENT

↑ ↓ ← →

PARA

DISP

PARA

↑ ↓ ← →

ENT

DISP

Page 25

2-7

Chapter 2. NAMES & FUNCTIONS OF PARTS

Category

Program setup

Program copy

General reset

Function

To start program setup (programming)

(in basic display state)

To move between program items and segment Nos.

To start changing of item setting values

(while setting value is blinking)

To end changing of item setting values

(while setting value is blinking)

To change item setting values

(while setting value is blinking)

To clear item setting

(while setting value is blinking)

To cancel changing item setting values

(while setting value is blinking)

To insert/delete segments

To change the program No. in ascending order

To change the program No. in descending order

To end program setup (programming)

To start program copy

(in basic display state)

To change the copy destination program No.

To execute program copy

(while setting value is blinking)

To end program copy

To check general reset

(in basic display state)

To execute general reset

To cancel general reset

Key operation

FUNC + PROG

↑ ↓ ← →

ENT

↑ ↓ ← →

FUNC + CLR

DISP

FUNC + ENT

FUNC + PROG

FUNC +

↓

DISP

↑ + PROG

↑ ↓

ENT

DISP

FUNC + CLR +

DISP

ENT

DISP

■ Combined key operations

FUNC + DISP : Displayed channel switching keys

Press the DISP

key with the FUNC key held down in the basic

display state to switch the displayed channel.

PROG + RUN/HOLD

: Reset keys

Press the

RUN/HOLD key with the PROG key held down in the

basic display state to reset the DCP32.

The DCP32 enters the READY mode from the RUN, HOLD,

FAST or END modes.

The DCP32 cannot be reset in the READY mode by key operation.

PROG + DISP : Advance keys

Press the DISP key with the PROG key held down in the program

operation mode in the basic display state to advance the program.

In the RUN, HOLD or FAST modes, the program advances to the

next segment.

The DCP32 cannot advance in the READY mode by key operation.

FUNC + → : Fast keys

Press → with the FUNC key held down in the program operation

mode in the basic display state to fast-operate the program.

The DCP32 enters the FAST mode from the RUN or HOLD

modes.

Page 26

2-8

Chapter 2. NAMES & FUNCTIONS OF PARTS

FUNC + PARA : Parameter setup keys

Press the PARA key with the FUNC key held down in

the basic display state to move to selection of the setting

group (major items) in the parameter setup state.

FUNC + PROG : Program setup (programming) keys

Press the PROG key with the FUNC key held down in

the program operation mode in the basic display state to

move to the program setup (programming) state.

Press the PROG key with the FUNC key held down in

the program setup state to change the No. of the

program to be set up in ascending order.

FUNC + ↓ : Program No. change keys

Press ↓ with the FUNC key held down in the program

setup state to change the No. of the program to be set up

in descending order.

FUNC + CLR : Program item delete keys

Press the CLR key with the FUNC key held down

during entry of settings in the program setup state to

clear the setting.

FUNC + ENT : Segment insert/delete keys

Press the ENT key with the FUNC key held down at the

SP or time items in the program setup state to move to

the segment insert/delete screen.

↑ + PROG : Program copy keys

Press the PROG key with ↑ held down in the program

operation READY mode in the basic display state to

move to the program copy screen.

FUNC + CLR + DISP : General reset keys

Press the CLR key and the DISP key with the FUNC

key held down in the READY AUTO mode in the basic

display state to move to the general reset confirmation

screen.

■ Loader jack

This jack is for connecting the loader.

Objects other than the loader plug should not be inserted into this jack.

The loader jack is not isolated from internal digital circuits. Be sure to cap the

loader jack when it is not in use.

Page 27

2-9

Chapter 2 NAMES & FUNCTIONS OF PARTS

2 - 3 Input Type and Range No.

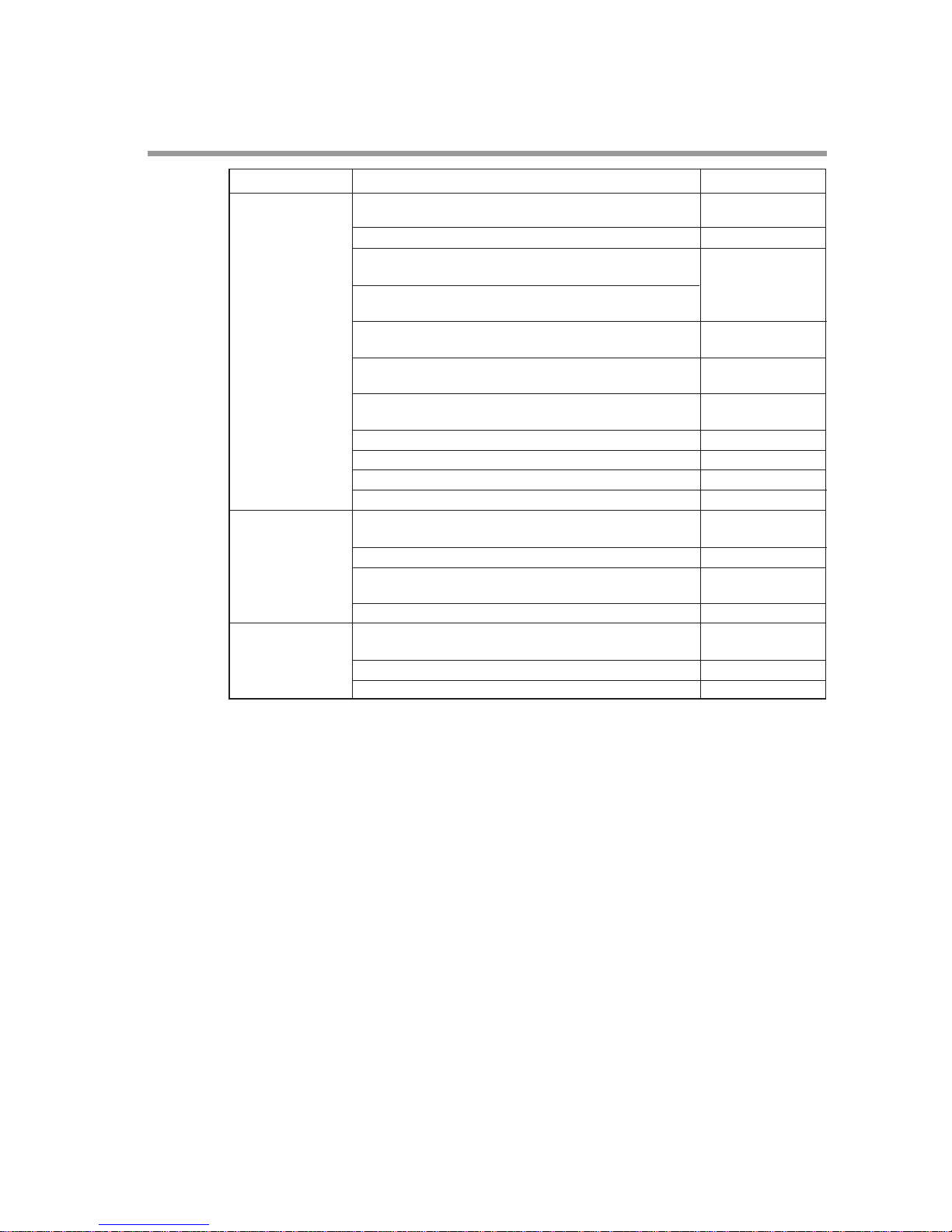

■ Input 1

● Thermocouple

● Resistance temperature detector (RTD)

Input Type Range No. Code Temp. Range (°C) Temp. Range (°F)

K (CA) 0 K09 0 to 1200 0 to 2400

K (CA) 1 K08 0.0 to 800.0 0 to 1600

K (CA) 2 K04 0.0 to 400.0 0 to 750

K (CA) 3 K29 -200 to +1200 -300 to +2400

K (CA) 4 K44 -200.0 to +300.0 -300 to +700

K (CA) 5 K46 -200.0 to +200.0 -300 to +400

E (CRC) 6 E08 0.0 to 800.0 0 to 1800

J (IC) 7 J08 0.0 to 800.0 0 to 1600

T (CC) 8 T44 -200.0 to +300.0 -300 to +700

B (PR30-6) 9 B18 0 to 1800 0 to 3300

R (PR13) 10 R16 0 to 1600 0 to 3100

S (PR10) 11 S16 0 to 1600 0 to 3100

W (WRe5-26) 12 W23 0 to 2300 0 to 4200

W (WRe5-26) 13 W14 0 to 1400 0 to 2552

PR40-20 14 D19 0 to 1900 0 to 3400

Ni-Ni•Mo 15 Z13 0 to 1300 32 to 2372

N 16 U13 0 to 1300 32 to 2372

PL II 17 Y13 0 to 1300 32 to 2372

DIN U 18 Z08 -200.0 to +400.0 -300 to +750

DIN L 19 Z07 -200.0 to +800.0 -300 to +1600

Golden iron 20 Z06 0.0 to +300.0 K —

chromel

Input Type Range No. Code Temp. Range (°C) Temp. Range (°F)

JIS’89 Pt100 32 F50 -200.0 to +500.0 -300 to +900

(IEC Pt100 Ω) 33 F46 -200.0 to +200.0 -300 to +400

34 F32 -100.0 to +150.0 -150.0 to +300.0

35 F36 -50.0 to +200.0 -50.0 to +400.0

36 F38 -60.0 to +40.0 -76.0 to +104.0

37 F33 -40.0 to +60.0 -40.0 to +140.0

38 F05 0.0 to 500.0 0.0 to 900.0

39 F03 0.0 to 300.0 0.0 to 500.0

40 F01 0.00 to 100.00 0.0 to 200.0

JIS’89 JPt100 48 P50 -200.0 to +500.0 -300 to +900

49 P46 -200.0 to +200.0 -300 to +400

50 P32 -100.0 to +150.0 -150.0 to +300.0

51 P36 -50.0 to +200.0 -50.0 to +400.0

52 P38 -60.0 to +40.0 -76.0 to +104.0

53 P33 -40.0 to +60.0 -40.0 to +140.0

54 P05 0.0 to 500.0 0.0 to 900.0

55 P03 0.0 to 300.0 0.0 to 500.0

56 P01 0.00 to 100.00 0.0 to 200.0

Input Type Range No. Code

Range

(programmable)

4 to 20 mA 64 C01

0 to 20 mA 65 C08

0 to 10 mA 66 M01

-10 to+10 mV 67 L02 -1999

0 to 100 mV 68 L01 to

0 to 1 V 69 L04 +9999

-1 to +1 V 70 L08

1 to 5 V 71 V01

0 to 5 V 72 L05

0 to 10 V 73 L07

● DC current, DC voltage

Page 28

2-10

Chapter 2. NAMES & FUNCTIONS OF PARTS

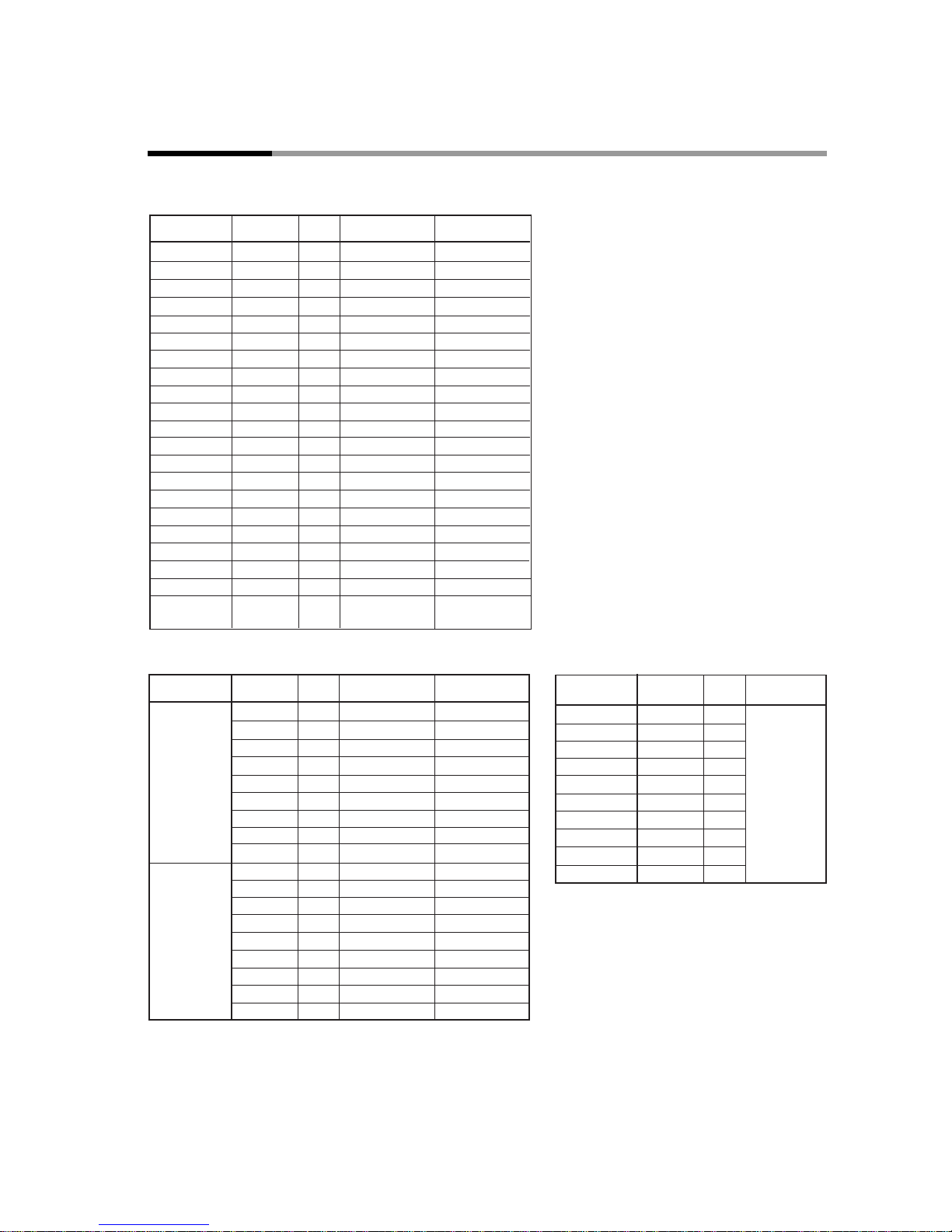

■ Input 2

● Thermocouple

● Resistance temperature detector (RTD)

● DC current, DC voltage

Handling Precautions

• The unit of code Z06 is Kelvin (K)

• The lower limit readout of code B18 is 20°C.

The lower limit readout of codes K44, K46, T44, Z08 and Z07 is

-199.9°C.

• The lower limit readout of codes F50, F46, P50 and P46 is -199.9°C.

• The upper limit readout of codes F01 and P01 is 99.99°C.

• The PV lower limit alarm does not occur with code F50.

However, note that the PV lower limit alarm occurs at a line

disconnection if input has been downscaled when input is disconnected

during setup.

• The number of digits past the decimal point for DC current and DC

voltage is programmable within the range 0 to 3.

Input Type Range No. Code Temp. Range (°C) Temp. Range (°F)

K (CA) 128 K44 -200.0 to +300.0 -300 to +700

K (CA) 129 K29 -200 to +1200 -300 to +2400

Input Type Range No. Code Temp. Range (°C) Temp. Range (°F)

JIS’89Pt100 160 F36 -50.0 to +200.0 -50.0 to +400.0

(IEC Pt100 Ω) 161 F01 0.00 to 100.00 0.0 to 200.0

JIS’89 JPt100 176 P36 -50.0 to +200.0 -50.0 to +400.0

177 P01 0.00 to 100.00 0.0 to 200.0

Input Type Range No. Code Range (programmable)

0 to 10 V 192 L07

-1999 to +9999

1 to 5 V 193 V01

Page 29

3-1

Chapter 3. INSTALLATION & MOUNTING

3 - 1 Installation

■ Mounting locations

Avoid installing the DCP32 in the following locations:

• Locations subject to low and high temperature and humidity

• Locations subject to direct sunlight, wind or rain

• Locations subject to splashing by liquids (e.g. water, oil or chemicals).

• Locations subject to corrosive gases or flammable gases

• Locations subject to dust or oil smoke

• Locations subject to vibration or shock

• Locations where magnetic fields are generated

• Locations near sources of electrical noise (such as high-voltage ignition

equipment, welders)

• Locations near flammable liquid or steam

WARNING

Before removing or mounting the DCP32, be sure to turn the power OFF.

Failure to do so might cause electric shock.

Do not disassemble the DCP32.

Doing so might cause electric shock.

CAUTION

Use the DCP32 within the operating ranges recommended in the

specifications (temperature, humidity, voltage, vibration, shock, mounting

direction, atmosphere, etc.).

Failure to do so might cause fire or faulty operation.

Do not block ventilation holes.

Doing so might cause fire or faulty operation.

Do not allow lead clippings, chips or water to enter the DCP32 case.

Doing so might cause fire or faulty operation.

Page 30

3-2

Chapter 3. INSTALLATION & MOUNTING

■ Noise generating sources and countermeasures

• Generally, the following generate electrical noise:

①Relays and contacts

②Solenoid coils, solenoid valves

③Power lines (in particular, 90 Vac min.)

④Induction loads

⑤Inverters

⑥Motor commutators

⑦Phase angle control SCR

⑧Radio communications equipment

⑨Welding equipment

⑩High-voltage ignition equipment

• If the influence of electrical noise cannot be eliminated, we recommend taking

the following countermeasures:

• Provision of a CR filter for fast-rising noise

Recommended CR filter: Yamatake Model No. 81446365-001

• Provision of a varistor for high wave height noise.

Recommended varistor: Yamatake Model No. 81446366-001 (100 V)

81446367-001 (200 V)

Handling Precautions

The varistor may become short-circuited when trouble occurs. Pay

attention to this when providing a varistor on the DCP32.

■ Dust-proof cover

Use the dust-proof cover when using the DCP32 in a dusty or dirty location, and

to prevent inadvertent operation.

Two dust proof-covers are provided, hard or soft, each with the following

differing functions.

Type Confirmation on Display Operation

Hard

« X

Soft ««

« indicates that a function can be used.

Page 31

3-3

Chapter 3. INSTALLATION & MOUNTING

3 - 2 Mounting

The following describes how to mount the DCP32.

■ Panel Cutout Dimensions

Use a steel panel at least 2 mm thick for mounting the DCP32.

Handling Precautions

When mounting the DCP32, take care to prevent the temperature at the

lower surface of the DCP32’s case from exceeding the operating

temperature range (0 to 50°C), particularly when mounting vertically or

during multiple mounting.

92

+0.8

0

92

+0.8

0

150 min.

(when vertically

installed)

99 min.

(when horizontally installed)

Unit: mm

Page 32

3-4

Chapter 3. INSTALLATION & MOUNTING

• Firmly secure the top and bottom of the DCP32 by the mounting brackets.

• When mounting the DCP32, secure by lower mounting bracket 1 first.

Panel

Mounting bracket 81405411-001

Mounting bracket

①

➁

Panel

Mounting bracket

Panel

■ Mounting method

Handling Precautions

To secure the DCP32, tighten the screw on the mounting bracket

(supplied) until there is no more play and then tighten a further full turn.

Take care not to overtighten the screw. Doing so might deform or

damage the case.

• Keep the mounting angle to within 10° from the horizontal at both the DCP32

rear top and bottom.

Lift up from rear by

10° max.

Pull down from rear by

10° max.

Page 33

4-1

Chapter 4. WIRING

4 - 1 Wiring Precautions

WARNING

Before connecting the DCP32 to the measurement target or external control

circuits, make sure that the FG terminal is properly grounded (100

Ω max.).

Failure to do so might cause electric shock or fire.

Before wiring, be sure to turn the power OFF.

Failure to do so might cause electric shock.

Do not touch electrically charged parts such as the power terminals.

Doing so might cause electric shock.

CAUTION

Wire the DCP32 properly according to predetermined standards. Also wire

the DCP32 using designed power leads according to recognized installation

methods.

Failure to do so might cause electric shock, fire or faulty operation.

Do not allow lead clippings, chips or water to enter the DCP32 case.

Doing so might cause fire or faulty operation.

Inputs to the current input terminals and on the DCP32 should be

within the current and voltage ranges listed in the specifications.

Failure to do so might cause fire or faulty operation.

Firmly tighten the terminal screws at the torque listed in the specifications.

Insufficient tightening of terminal screws might cause electric shock or fire.

Do not use unused terminals on the DCP32 as relay terminals.

Doing so might cause electric shock, fire or faulty operation.

We recommend attaching the terminal cover (sold separately) after wiring the

DCP32.

Failure to do so might cause electric shock.

Use the relays on the DCP32 within the service life listed in the specifications.

Continued use of the relays after the recommended service life might cause

fire or faulty operation.

Use Yamatake Corporation's SurgeNon if there is the risk of power surges

caused by lightning.

Failure to do might cause fire or faulty operation.

33

31

Page 34

4-2

Chapter 4. WIRING

Handling Precautions

• Before wiring the DCP32, check the DCP32 model No. and terminal Nos.

on the label on the rear of the body.

After wiring the DCP32, be sure to check the wiring for any mistakes

before turning the power ON.

• Maintain a distance of at least 50 cm between I/O signal leads or

communications leads and the power lead. Also, do not pass these leads

through the same piping or wiring duct.

• When wiring with crimped terminals, take care to prevent contact with

adjacent terminals.

• When connecting the DCP32's thermocouples in parallel to other

controllers, make sure that the total input impedance of the other

controllers is at least 1 MΩ.

If the input impedance is less than 1 MΩ, the DCP32 may not be able to

detect sensor disconnection.

• Precautions when combining the DCP32 with other data input device

When inputting the DCP32’s I/O (parallel connection in case of input) to

an A/D converter or analog scanner, read data may fluctuate.

To prevent this, adopt one of the following measures.

①Use a low-speed, integrating type A/D converter.

②Insert an isolator without a switching power supply between the

DCP32 and A/D converter.

③Average the data on a personal computer when reading data.

④If possible, set a filter for the input.

• Provide a switch within the operator's reach on the instrumentation

power supply wiring for turning the mains power OFF.

• Provide a delay-type (T) rated current 1A and rated voltage 250 V fuse

on the instrumentation power supply wiring. (IEC 127)

Page 35

4-3

Chapter 4. WIRING

4 - 2 Compensating Lead

When a thermocouple input is input to the DCP32, connect the bare thermocouple lead to the terminal. If the

thermocouple is located a long way from the DCP32 or the thermocouple is connected to a terminal, extend the

connection using a compensating lead and then connect to the terminal. Use shielded compensating leads only.

Note

• For I/O other than thermocouples, use JCS-364 shielded instrument

polyethylene insulated vinyl sheath cable or equivalent product. (This is

generally referred to “shielded twisted cable for instruments.”) The following

cables are recommended.

• Shielded, multi-core microphone cord (MVVS) can be used if there is little

electromagnetic induction.

Fujikura Cable Co. 2-core IPEV-S-0.9 mm2x 1P

3-core ITEV-S-0.9 mm

2

x 1T

Hitachi Cable Co. 2-core KPEV-S-0.9 mm2x 1P

3-core KTEV-S-0.9 mm

2

x 1T

Page 36

4-4

Chapter 4. WIRING

4 - 3 Terminal Connections

Use crimped terminals that fit onto M3.5 screws.

Handling Precautions

• When installing the DCP32 in locations subject to vibration or impact, be

sure to use round crimped terminals to prevent the lead from coming

loose from the terminal.

• When wiring with crimped terminals, take care to prevent contact with

adjacent terminals.

• The recommended tightening torque for the terminal screws is 0.78 to

0.98 N•m.

7.4

ø3.7

Unit: mm

7.3 max.6.6 max.

Page 37

4-5

Chapter 4. WIRING

4 - 4

Layout of Terminals and Recommended Lead Draw-out Direction

Wiring is carried out on the standard terminal base or add-on terminal base. The following diagram shows the

recommended draw-out directions for the leads on the standard terminal base.

The lead draw-out directions are the same when using the add-on terminal base.

Lead draw-out direction Lead draw-out direction

Standard terminal base

Page 38

4-6

Chapter 4. WIRING

4 - 5 Connecting the Ground and Power Supply

■ Power supply

Connect the DCP32 to a single-phase power supply for instrumentation, and take

measures to prevent the influence of electrical noise.

Handling Precautions

・ If the power supply generates a lot of electrical noise, we recommend

inserting an insulating transformer in the power circuit and using a line

filter.

Recommended line filter:

Yamatake Corporation, model No. 81446364-001

・ After providing anti-noise measures, do not bundle primary and

secondary power leads together, or pass them through the same piping

or wiring duct.

■ Ground

When it is difficult to ground shielded cable, prepare a separate ground terminal

(earth bar).

Ground type: 100 Ω max.

Ground cable: 2 mm sq. min. annealed copper wire (AWG14)

Cable length: Max. 20 m

1

3

2

1

2

E

3

4

GND

Instrument

power supply

90 to 264 Vac

50/60 Hz

Other circuits

GND GND

Recommended

line filter

81446364-001

DCP32

200/200 V

100/100 V

Insulated transformer

3

FG

terminal

DCP32

GND terminal plate

GND (100 Ω min.)

Shielded cable

Handling Precautions

Use only the FG terminal 3 on the DCP32 for grounding. Do not ground

across other terminals.

Page 39

4-7

Chapter 4. WIRING

4 - 6

Wiring of Standard and Add-on Terminal Base

■ Standard terminal layout

2G, 3D or 5K models do not support auxiliary output.

On 0D or 5G models, terminal Nos. 'and ( are the auxiliary outputs.

Relay

Relay

Relay

2

3

1

Y

T

G

1

2

3

4

5

6

7

8

9

10

Instrument

power supply

90 to 264 Vac

50/60 Hz

FG (Frame GND)

EV1

EV2

EV3

Event

outputs

11

12

13

14

15

16

17

18

19

20

4 to 20 mA

voltage

4 to 20 mA

4 to 20 mA

voltage

5G output

5K output

Auxiliary output

0D output

3D output

2G output

Output 1

Output 2

Output 3

(Auxiliary output)

26

27

28

29

30

31

32

33

34

21

22

23

24

25

RSW1

RSW2

RSW3

RSW4

COM

V

Thermocouple

input

Resistance

temperature

detector

Resistance

temperature

detector

DC mA

V, mV

Voltage input

Thermocouple input

Input 2

Input 1

✽

Auxiliary output

4 to 20 mA

Recorder, etc.

44

45

46

47

48

43

41

42

55

56

53

54

51

52

49

50

63

64

62

59

60

57

58

61

RSW5

T1

T2

T3

T4

T5

SDA

SDB

RDA

RDB

SG

RSW6

RSW7

RSW8

RSW9

RSW10

RSW11

RSW12

External switch

inputs

To terminals

Time event outputs

Load

Load

Load

Load

Load

External

10 to 29 Vdc power supply

Bias circuit

RS-485

communications

25

Page 40

4-8

Chapter 4. WIRING

4 - 7 Connecting Inputs (analog inputs)

CAUTION

Inputs to the current input terminals and on the DCP32 should be

within the current and voltage ranges listed in the specifications.

Failure to do so might cause fire or faulty operation.

33

31

34

A

B

C

33

32

31

34

33

32

31

34

33

32

31

34

33

32

31

mV • V

mA

■ Connecting input 1

Multiple input 1 supports various sensor inputs. Connect as follows according to

the sensor being used:

• Thermocouple input • RTD input

• DC voltage input • DC current input

30

A

B

C

29

28

31

30

29

28

31

26

27

26

27

■ Connecting input 2

Multiple input 2 supports various sensor inputs. Connect as follows according to

the sensor being used:

• Thermocouple input • RTD input

Page 41

4-9

Chapter 4. WIRING

30

29

28

31

26

27

V

• DC voltage input

Handling Precautions

• Applying voltage across DC current input terminals and may

cause faulty operation.

• Pay attention to polarities (+, -) when wiring inputs.

• Use only shielded cable for wiring inputs.

• When a thermocouple is used as the input, prevent wind from blowing

against the terminals. This may cause an error in readings.

33

31

Page 42

4-10

Chapter 4. WIRING

4 - 8

Connecting Control Outputs (outputs 1, 2, 3)

WARNING

Before wiring, or removing/mounting the DCP32, be sure to turn the power

OFF.

Failure to do so might cause electric shock.

15

14

13

31

11

12

16

Load

Power supply

Load

(SSR)

Output 1 (MV1 or MV2)

Contact rating, resistive load

5 A (30 Vdc/120 Vac)

4 A (240 Vac)

Minimum switching current: 100 mA

Output 2 (MV2 or MV1)

• Current output

4 to 20 mA dc/0 to 20 mA

Resistive load 600 Ω max.

• Voltage output

2 to 22 mA dc

With current adjustment function

(setup data

C79

)

■ Relay output (0D)

Connect as follows:

15

14

13

31

11

12

16

Load

Load

(SSR)

(SSR)

Output 1 (MV1 or MV2)

• Current output

4 to 20 mA dc/0 to 20 mA dc

Resistive load 600 Ω max.

• Voltage output

2 to 22 mA dc

With current adjustment function

(setup data

C78

)

Output 2 (MV2 or MV1)

• Current output

4 to 20 mA dc/0 to 20 mA dc

Resistive load 600 Ω max.

• Voltage output

2 to 22 mA dc

With current adjustment function

(setup data

C79

)

Handling Precautions

• When switching small currents, connect a bleeder resistor to allow

current flow of the minimum relay switching input (100 mA min.).

• Current output and voltage output can be selected by setup data

C 76

.

Voltage output is reliant on an internal fixed-current circuit.

Set the current value in the setup data so that the optimum voltage is

obtained matched to the conditions of the SSR in use and the load.

Factory setting: general-purpose SSR voltage value.

• Internal connection of MV1 (CH1 MV) and MV2 (CH2 MV), and output 1

and output 2 can be selected in setup data

C44

.

• 4 to 20 mA dc and 0 to 20 mA dc can be selected in setup data

C90

.

■ Current output (5G)

Connect as follows.

Page 43

Chapter 4. WIRING

15

14

13

31

11

12

16

Load

Power

supply

Output 1 (MV1 or MV2)

Contact rating, resistive load

4 A (120 Vac cosø = 0.4)

2 A (240 Vac cosø = 0.4)

Feedback resistance

100 to 2500 Ω

18

17

19

Load

(SSR)

Load

2

3

1

Open

side

Closed

side

Closed side

Open side

Output 3 (MV2 or MV 1)

• Current output

4 to 20 mA dc/0 to 20 mA dc

Resistive load 600 Ω max.

• Voltage output

2 to 22 mA dc

With current adjustment function

(setup data

C80

)

Y

T

G

Handling Precautions

• Current output and voltage output can be selected by setup data

C 75

and

C 76

.

Voltage output is reliant on an internal fixed-current circuit.

Set the current value in the setup data so that the optimum voltage is

obtained matched to the conditions of the SSR in use and the load.

Factory setting: general-purpose SSR voltage value.

• Internal connection of MV1 (CH1 MV) and MV2 (CH2 MV), and output 1

and output 2 can be selected in setup data

C44

.

• 4 to 20 mA dc and 0 to 20 mA dc can be selected in setup data

C90

.

■ Position-proportional output (2G)

Connect as follows paying attention to the switching direction:

Handling Precautions

• The life of internal relays is limited.

Avoid setting the PID constant in such a way that results in excessive

repeated ON/OFF switching.

• When using a 100/200 Vac motor, pay attention to rush current and the

contact rating. If necessary, provide an external auxiliary relay.

• Maintain a distance of at least 30 cm between the wiring for motor

terminals !" # and feedback resistor terminals $% &.

(Do not wire the leads in the same duct or use 6-core cable. Doing so

might result in faulty controller operation caused by electrical noise when

the motor is started up.)

• When controlling without motor feedback with variable parameter

m-C

set to “2”, terminals $% &need not be connected.

• Current output and voltage output can be selected by setup data

C77