Page 1

Thank you for purchasing the CS1D.

Information regarding PM1D System Software V1.41

When using the PM1D system software V1.41, please keep in mind the following supplementary explanations.

Note regarding file compatibility

●

Files that you created using system software V1.41 cannot

be loaded into a system that is running system software

V1.3 or earlier. Data that you created using system software V1.3 or earlier can be loaded into system software

V1.41. In this case, memories related to functions that were

added in 1.41 will be the same as the factory setting.

The following issues concern timecode events,

and should be read in conjunction with page

33 of the CS1D Reference Manual (Software).

●

When registering several events close together, up to five

events can be safely registered within any three second period. If you register six or more events, the sixth and subsequent events may not be recalled properly.

●

Since it takes a few seconds to chase the time code, events

are typically executed three seconds after the time code

begins running. Therefore, you must start the time code

at least three seconds before any events that you want to

execute. Note also that scenes cannot be recalled manually during this three-second period.

●

Events in the time code event list are executed only once

during each time code pass.

●

Since time code events set to INC or DEC are executed

relative to the scene number selected when the time code

first begins running, they are not affected by scene recalls

performed by other means that occur once the time code

is up and running.

●

If a scene is recalled via the time code event list while a

scene recall by some other means is being processed, the

scene recall will be executed once the first recall operation

is complete. However, if a scene recall by some other means

occurs while a scene recall via the time code event list is

being processed, the second recall may sometimes fail.

●

Time code events can be executed on the console even

without a ENGINE connected so long as TC IN SELECT

is set to either [INT GEN] or [CONSOLE]. The FADE

TIME function, however, will not operate.

●

RECALL UNDO cannot be used to undo scenes recalled

via the time code event list.

The following issues concern Mirror mode, and

should be read in conjunction with page 10 of

the CS1D Operation Manual (Start-up).

●

Reliable operation cannot be guaranteed if Engine A and

Engine B are connected differently.

●

The C port of the AI8 analog input unit cannot be used.

●

From system software V1.3 onward, functionality was

added for automatic switching from ENGINE A to ENGINE

B in mirror mode. This will automatically switch the engine from A to B when the following problems are detected.

This function automatically switches from engine A to B

if either of the following problems are detected.

1. Failure of engine A itself

2. Failure of the CONTROL I/O cable

However in order for this function to work correctly, the

following conditions must be met.

1. Engine A and engine B must both be connected correctly and functioning

2. The DIGITAL I/O cable must be connected

3. In addition, the entire system must be installed as described in the operating manual

Please also be aware of the following cautionary notes regarding the automatic engine switching function.

1. Automatic switching from engine B to engine A will

not occur.

2. If a problem occurs in the CONTROL I/O cable, switching between engines A/B will take priority over switching between connectors 1/2.

3. If the power of engine A fails during operation, it will

take approximately one second for automatic switching to occur, engine B to be selected, and audio output

to begin.

(Sound will not be interrupted if the problem is only

in the CONTROL I/O cable.)

4. If there is a problem with connections when the console is powered-on, the automatic switching may not

occur in some cases. You will need to switch manually

as needed.

Addition explanation for PREVIEW mode

●

PREVIEW mode lets you view the scene settings that have

been stored by scene memory operations on the CS1D.

The various parameters in PREVIEW mode indicate the

current state of the signal processing.

If one unit is connected to more than one engine, and you

select PREVIEW mode for the system connected to the

engine not specified for the control port, you will not be

able to operate GAIN GANG or A/B LINK.

Regarding the software version printed in the

manuals

●

All manual references to PM1D system software “version

1.0” should be read as “version 1.41”.

●

The PC connection will be denied for reasons of safety if

the “PM1D Manager for Windows” application software

is a different version than the system version of the PM1D

itself. You must use the software from the same CD-ROM

to ensure that the versions match.

Page 2

1

Thank you for purchasing the CS1D.

Additions and changes to PM1D system software V1.25

This document explains the functionality that been added or changed in PM1D system software version 1.25.

Change in how fade-time processing of each channel is defeated

Up through PM1D system software v1.2, operating a

fader while the fade time was being executed caused

fade-time processing for that channel to be cancelled.

However since it is easy to operate a fader inadvertently,

this version of the software disables this automatic cancellation, in order to prevent accidents.

If you want to cancel fade-time processing as before,

operate the fader while holding down one of the following:

•

The [SHIFT/GRAB] switch of the data entry block

•

The [SHIFT] switch in the CHANNEL SELECT section of the SELECTED INPUT CHANNEL block

•

The [SHIFT] switch in the CHANNEL SELECT section of the SELECTED OUTPUT CHANNEL block

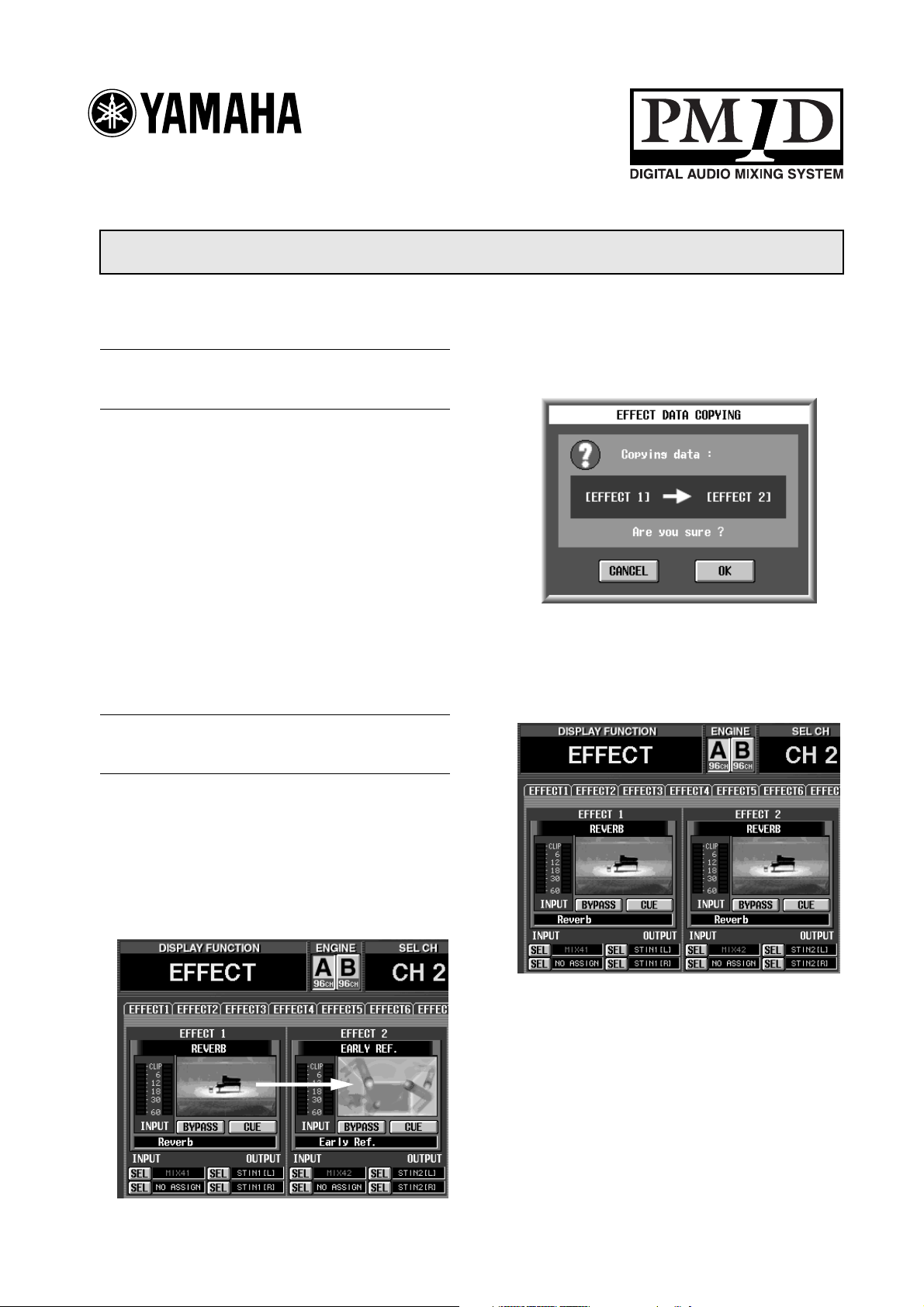

Drag & drop effect data (EFFECT ASSIGN screen)

In the EFFECT function EFFECT ASSIGN screen, you

can now use Drag & Drop to copy all settings of an

effect. Here’s how to do this.

A popup window will ask you to confirm the copy

operation.

2. To execute the copy, click the OK button. To cancel,

click the CANCEL button.

When you click the OK button, all parameters

including the effect type will be copied.

1. In the EFFECT ASSIGN screen, click the effect type

graphic for the copy source internal effect (1–8),

and drag & drop it onto the graphic for the copy

destination internal effect.

Reference pages

•

Software section, page 12

Page 3

Recalling effect parameters (EFFECT ASSIGN screen)

In the EFFECT function EFFECT ASSIGN screen, you

can now access the corresponding EFFECT 1–8 screen

by clicking the graphic that indicates the effect type. This

lets you operate effect parameters more quickly.

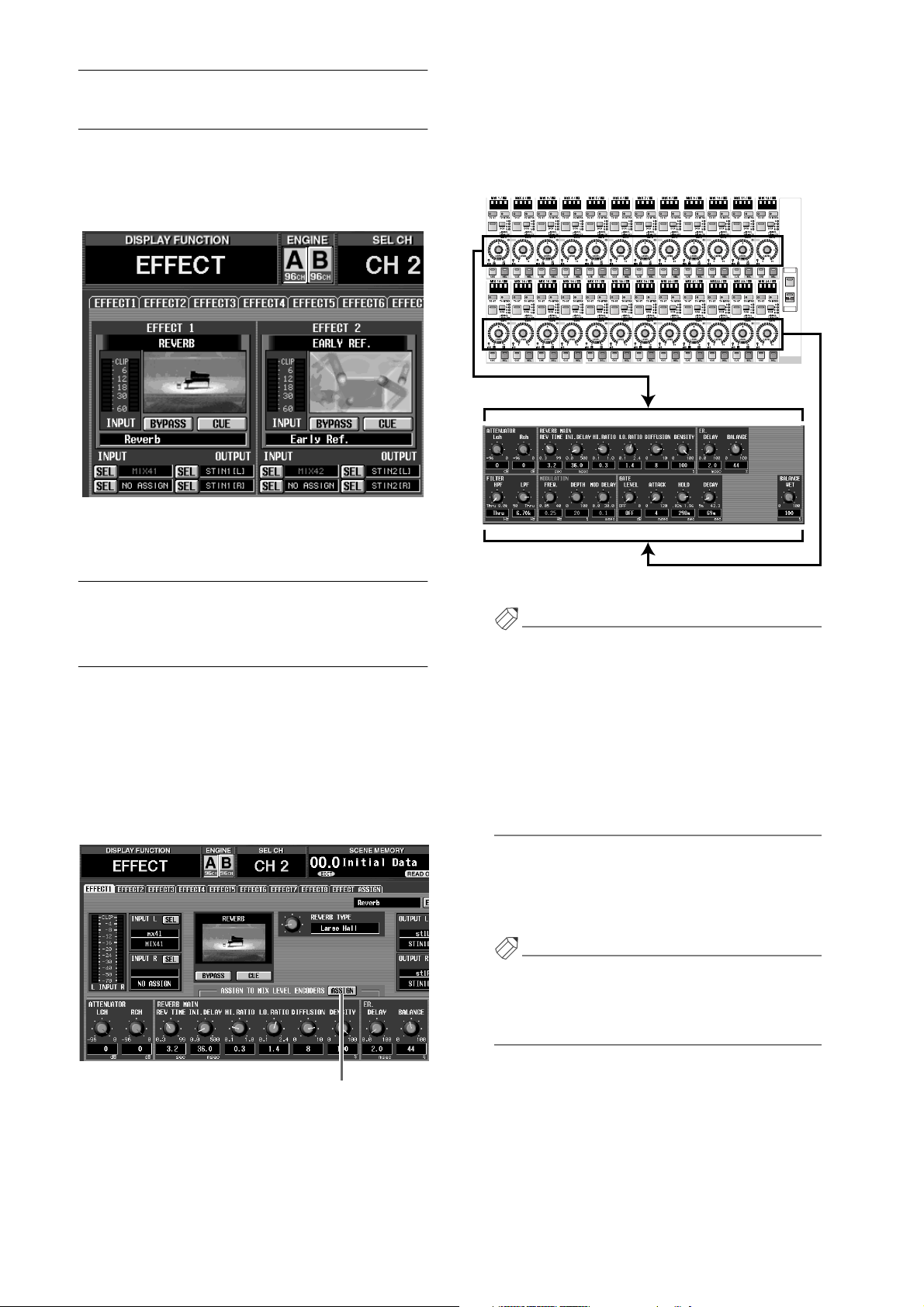

The parameters of the currently selected effect will be

assigned to the MIX [LEVEL/BAL] encoders as

shown in the following diagram. At this time, the

MIX OUTPUT block MIX [NAME] indicator will

show the parameter name (up to four characters).

CS1D MIX OUTPUT block

PAIR

ONONONONONONONONONONONONONONONONONONONONONONON

PAIR PAIR

Encoders 1–12

PAIR

PAIR

PAIR PAIR

PAIR

PAIR PAIR

PAIR

ON

1-24

PAIR

MIX

LAYER

Reference pages

•

Software section, page 12

Using the encoders to control effect parameters (EFFECT 1–EFFECT 8 screens)

When the EFFECT function EFFECT 1–8 screens are

displayed, you can now use the encoders of the MIX

OUTPUT block to control the effect parameters. To do

this, use the following procedure to.

1. Access one of the EFFECT 1–EFFECT 8 screens.

2. Click the ASSIGN button located in the center of

the screen to turn it on.

Encoders 13–24

Hint

•When an EFFECT 1–EFFECT 8 screen is displayed,

you can hold down the [SHIFT/GRAB] switch of

the data entry block and press the MIX LAYER [124] switch or the [25-48] switch to obtain the same

result.

•The ASSIGN button on/off setting is common to

all of the EFFECT 1–EFFECT 8 screens. If you

switch between EFFECT 1–EFFECT 8 screens

when the ASSIGN button is on, the parameters of

the new screen will be assigned.

3. To return to the previous state, click the ASSIGN

button to turn it off.

The encoder functions will return to their previous

state.

Hint

The encoder functions will also return to their previous state if you access a screen other than EFFECT 1–

EFFECT 8, or if you press either the MIX LAYER [124] or [25-48] switch.

ASSIGN button

2

Reference pages

•

Basic operation, page 130

•

Software section, page 11

Page 4

1

2

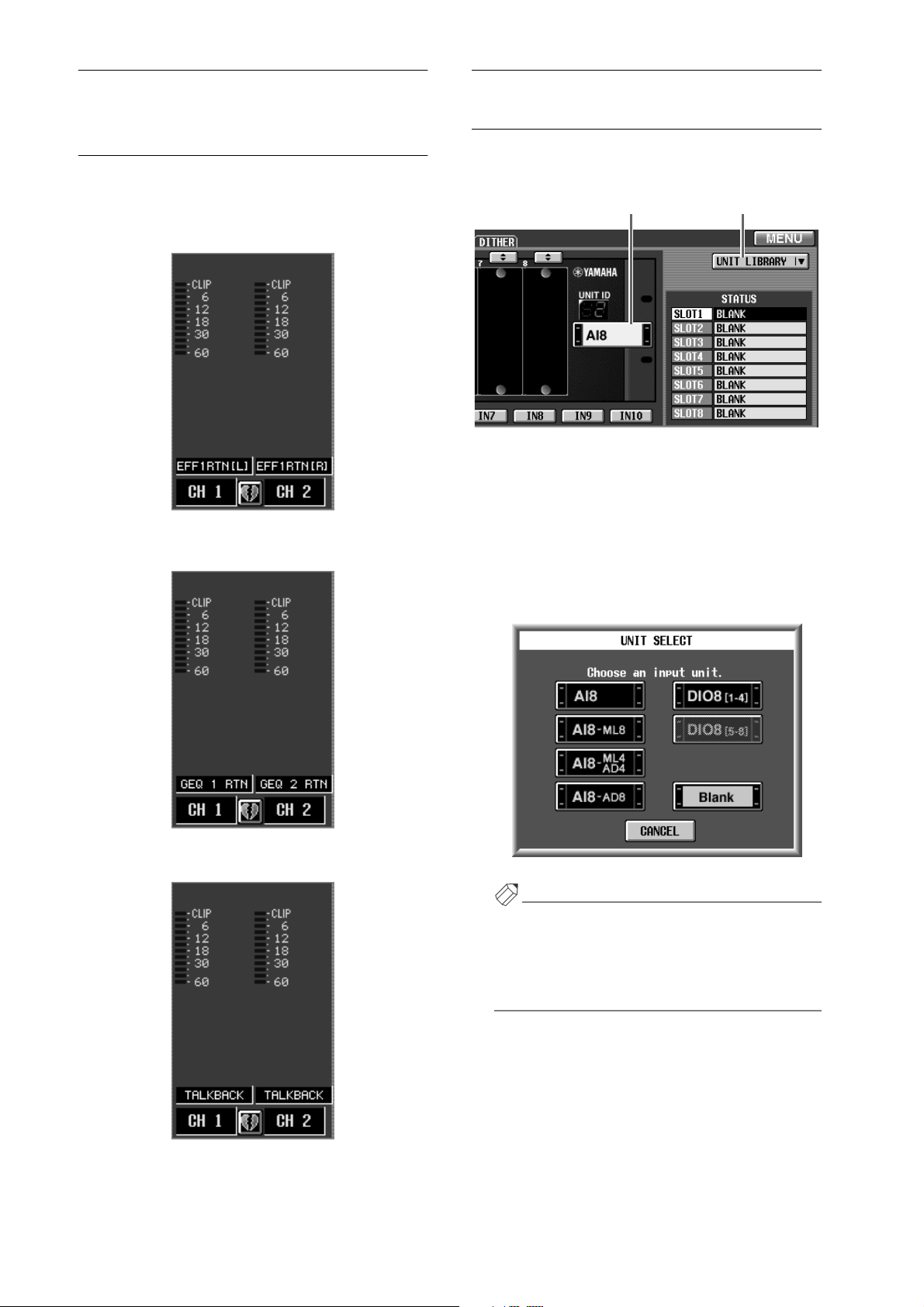

Automatic GEQ insertion (GEQ PARAMETER screen)

When you select a graphic EQ insert destination in the

GEQ function GEQ PARAMETER screen, insertion will

automatically be switched on in the corresponding

channel.

For example if you select a input channel as the GEQ

insert destination, the INS. button of the corresponding

channel will now automatically be turned on in the IN

PATCH function INSERT/DIRECT POINT screen. (It is

no longer necessary to manually turn the INS. button

on, as in earlier versions.)

“When you select an input channel as a GEQ insert

destination, ...”

Additional functions in GEQ ASSIGN 1-12 / 13-24 screens

The following buttons have been added to the GEQ

ASSIGN 1-12/13-24 screens.

2

1

GEQ ON/OFF button

This button switches each GEQ on/off.

DISPLAY ORDER REVERSE button

This button reverses the order of the GEQs in the

GEQ ASSIGN 1-12/13-24 screens. By default, the

GEQs are arranged in ascending order from bottom

to top, but will be arranged in ascending order from

top to bottom when you turn on this button.

“the INS. button of that channel will automatically be

turned on in the IN PATCH function INSERT/DIRECT

POINT screen.”

In the same way, if you select an output channel as the

insert destination, the INS. button of the corresponding

channel will automatically be turned on in the OUT

PATCH function INSERT POINT screen.

When you defeat graphic EQ insertion in the GEQ

PARAMETER screen, insert will automatically be

switched off for the corresponding channel.

Reference pages

•

Basic operation, pages 134–135

•

Software section, page 13

“Order when the DISPLAY ORDER REVERSE button is

on”

Reference pages

•

Software section, pages 16–17

3

Page 5

1

2

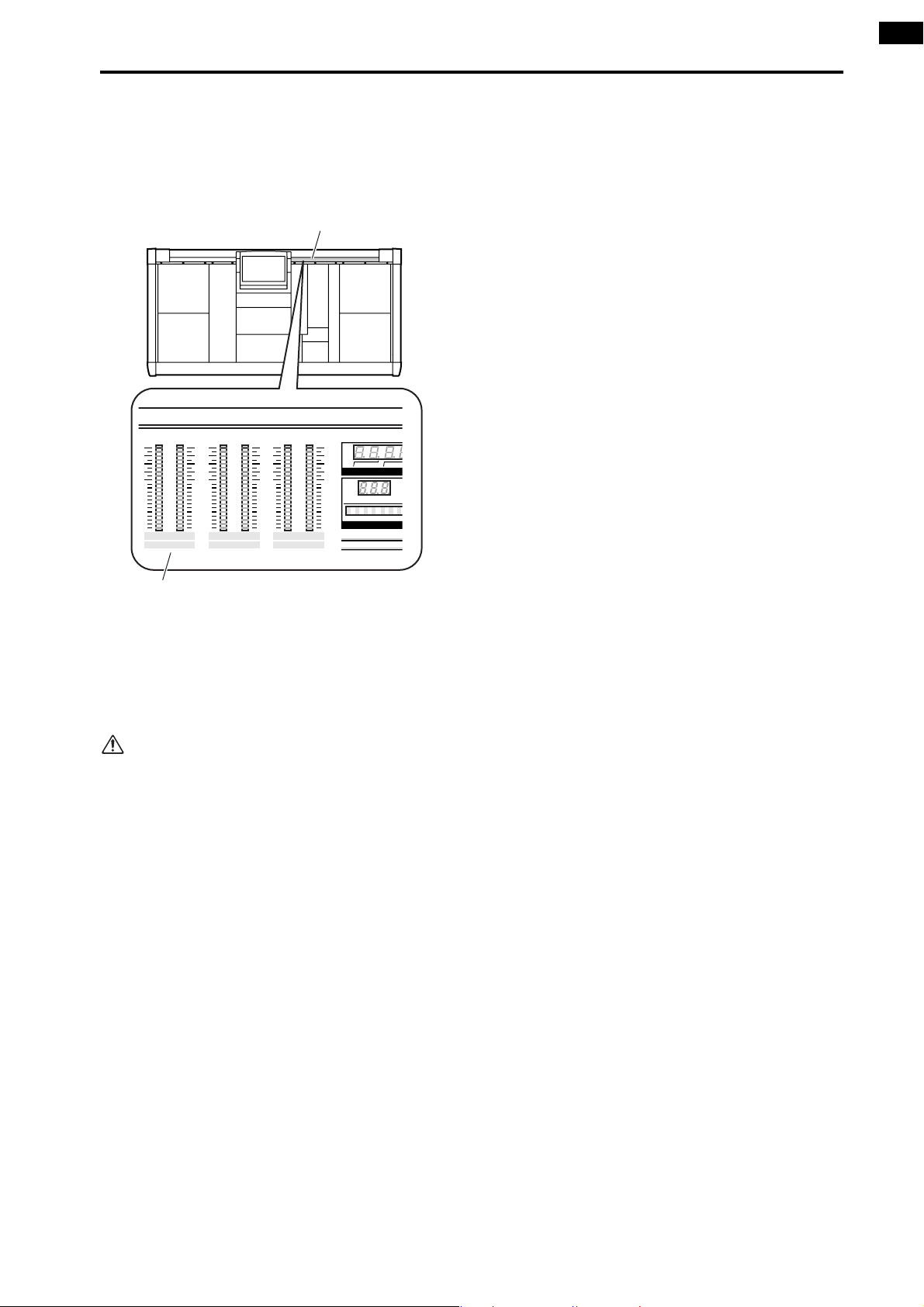

Meter display in the IN HA/ INSERT function / OUT INSERT function

In the IN HA/INSERT function and the OUT INSERT

function, meters are now displayed even for the effect

return, the graphic EQ output, and units to which the

talkback signal is assigned.

“Units to which an effect return is assigned”

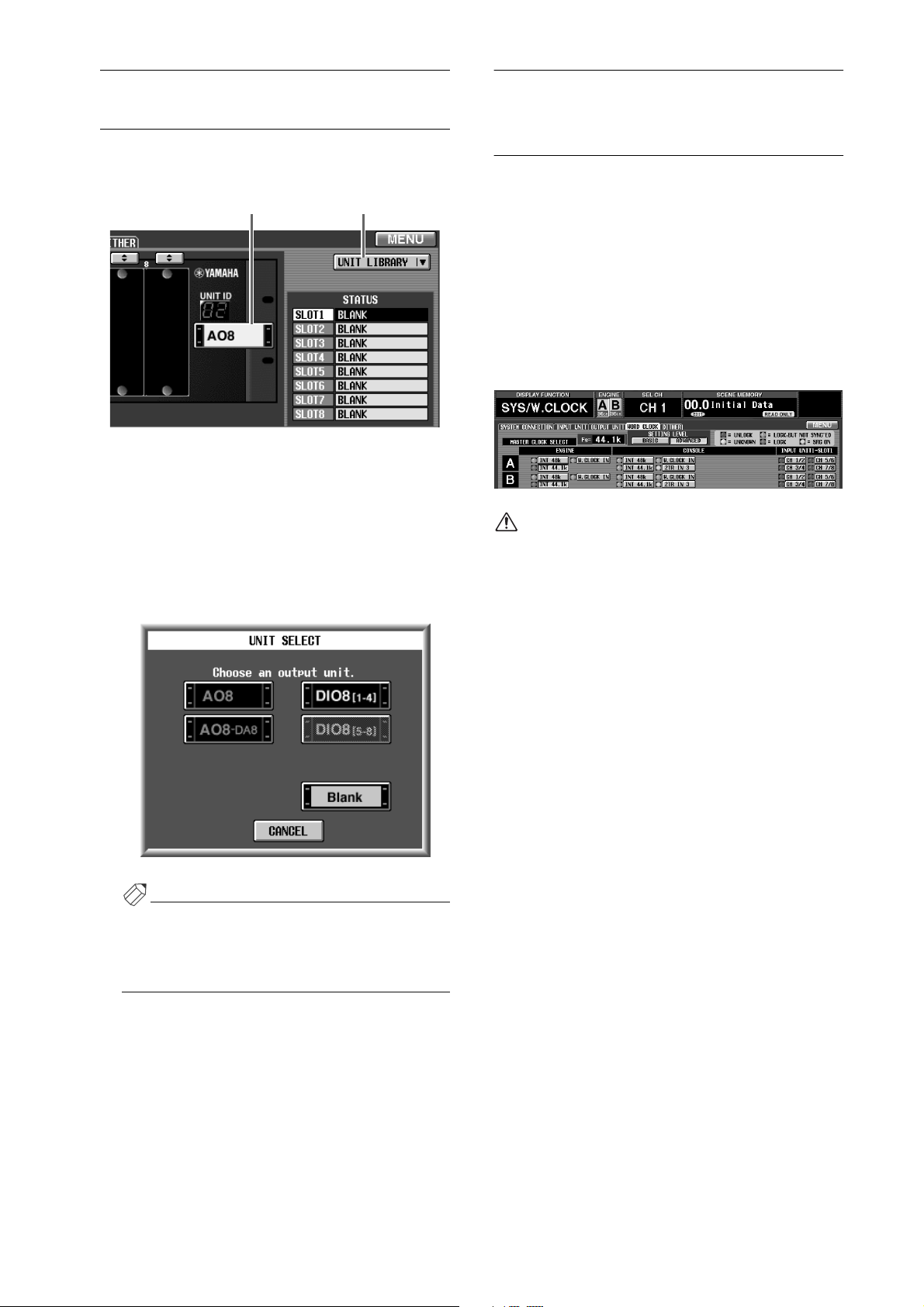

Additions and changes in the INPUT UNIT screen

The following two additions/changes have been made in

the SYS/W.CLOCK function INPUT UNIT screen.

1 2

UNIT SELECT button

This button virtually connects a unit to the jack

selected by the IN 1–IN 10 buttons. This is the same

function as the UNIT SELECT button located in the

upper right of the screen in the previous version of

the software.

When you click this button, a popup window will

appear, allowing you to select a unit.

“Units to which a graphic EQ output is assigned”

“Units to which the talkback signal is assigned”

Reference pages

•

Software section, pages 87 and 132

4

Hint

In V1.25, the above popup window lets you directly

select the model names (AI8-ML8, AI8-ML4AD4,

AI8-AD8) of currently-installed cards. If you select

one of these model names, it will not be necessary to

specify the installed card.

UNIT LIBRARY button

This button access the UNIT LIBRARY window,

where you can store/recall setting data for all units.

This button has the same function as the UNIT

LIBRARY button found in the ST IN INS/UNIT LIB

screen (IN HA/INSERT function).

Reference pages

•

Software section, pages 47–48

Page 6

1

2

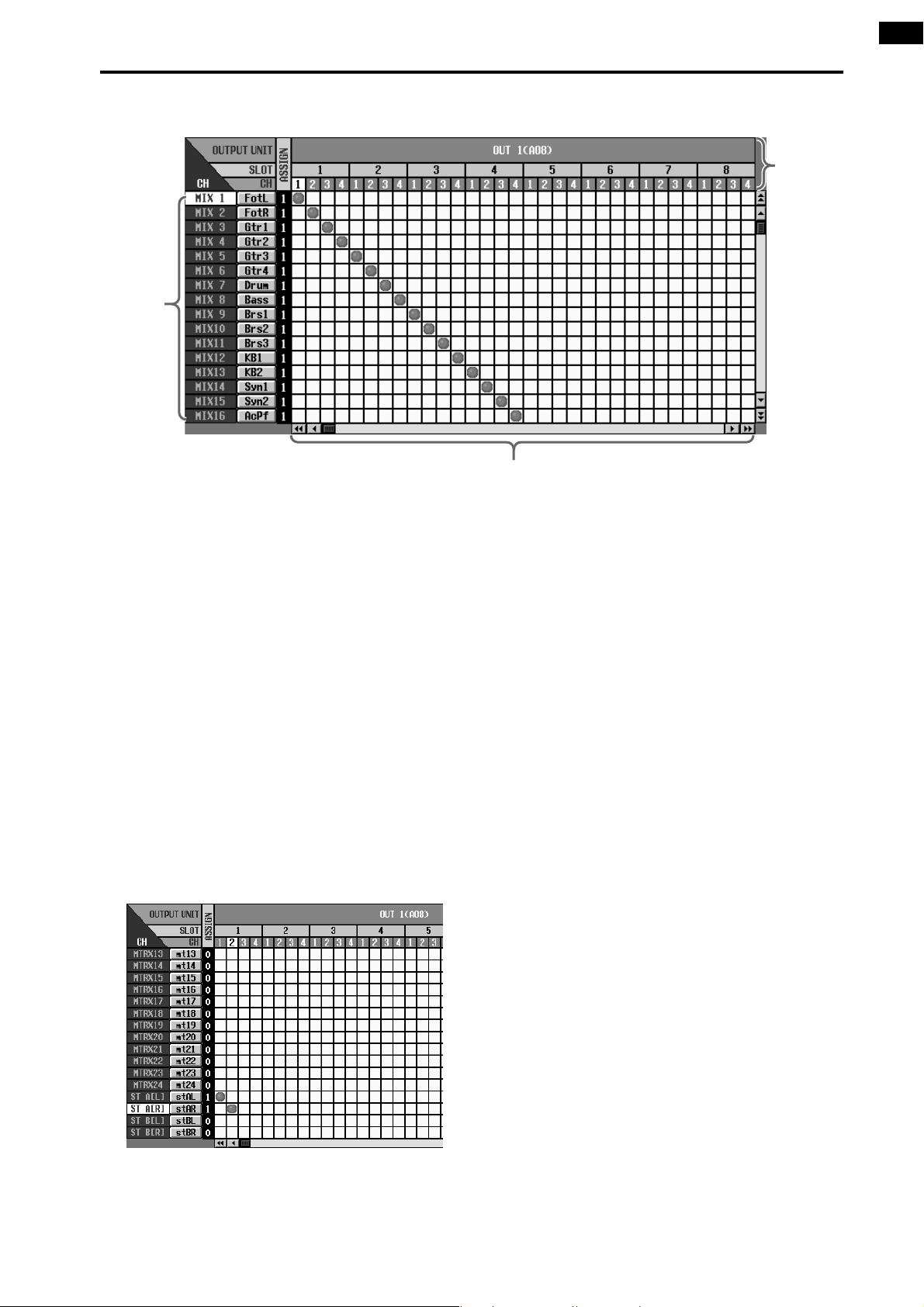

Additions and changes in the OUTPUT UNIT screen

The following two additions/changes have been made in

the SYS/W.CLOCK function OUTPUT UNIT screen.

1 2

UNIT SELECT button

This button virtually connects a unit to the jack

selected by the OUT 1–OUT 6 buttons. This is the

same function as the UNIT SELECT button located

in the upper right of the screen in the software of the

previous version.

When you click this button, a popup window will

appear, allowing you to select a unit.

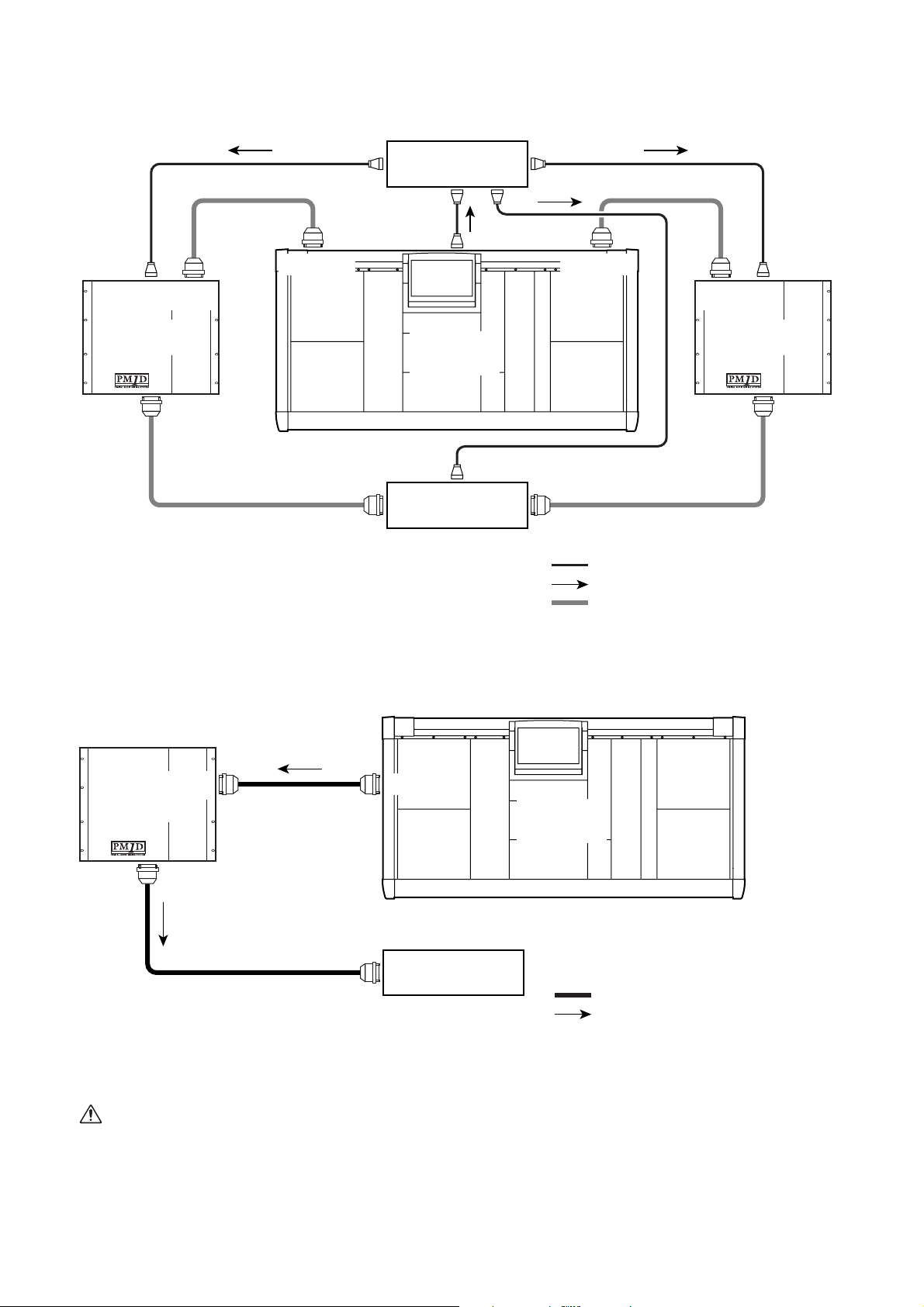

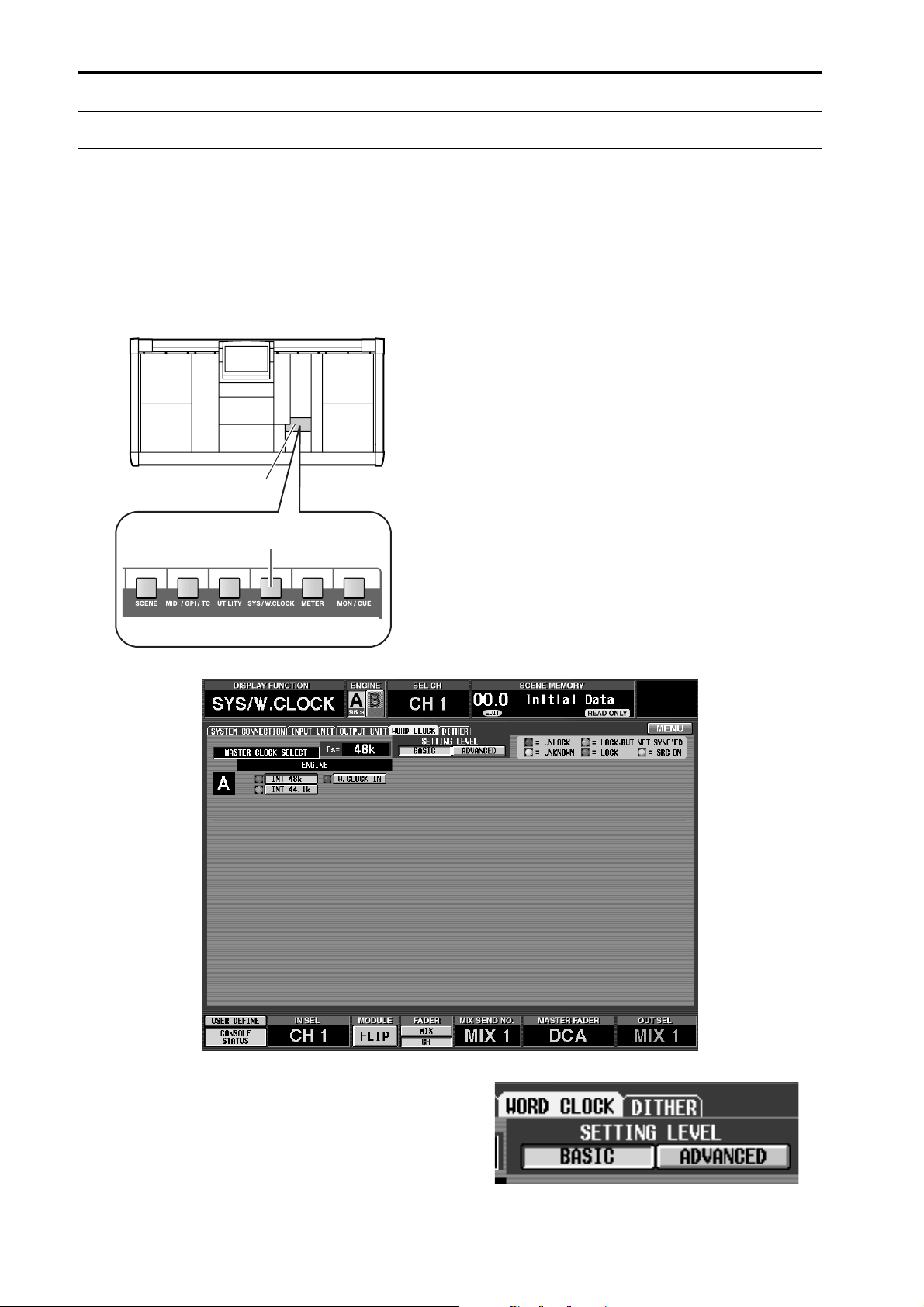

Additional master clocks available for selection (WORD CLOCK screen)

In the SYS/W.CLOCK function WORD CLOCK screen,

the following three types have been added to the master

clocks that can be selected.

•

CONSOLE INT 48k

The internal clock of the CS1D (48 kHz)

•

CONSOLE INT 44.1k

The internal clock of the CS1D (44.1 kHz)

•

W.CLOCK IN

The word clock supplied to the WORD CLOCK IN

jack of the CS1D

•The above master clocks are displayed only if the

setting level is set to “ADVANCED” in the WORD

CLOCK screen.

•Some of the buttons in the WORD CLOCK

screen are arranged differently in V1.25.

In particular when using Mirror mode, selecting the

console’s INT 48k or INT 44.1k as the master clock will

allow you to construct a system that does not use an

external clock generator.

In this case, connections and settings will be as shown

on the following page.

Hint

In V1.25, the model names (A08-DA8) of cards that

are already installed can be selected directly. If you

select a model name, it will not be necessary to specify the installed card.

UNIT LIBRARY button

A button has been added that allows you to access the

UNIT LIBRARY window, where you can store/recall

setting data for all units. This button has the same

function as the UNIT LIBRARY button located in the

OUT INSERT function ST MAS INS/UNIT LIB

screen.

Reference pages

•

Software section, pages 50–51

5

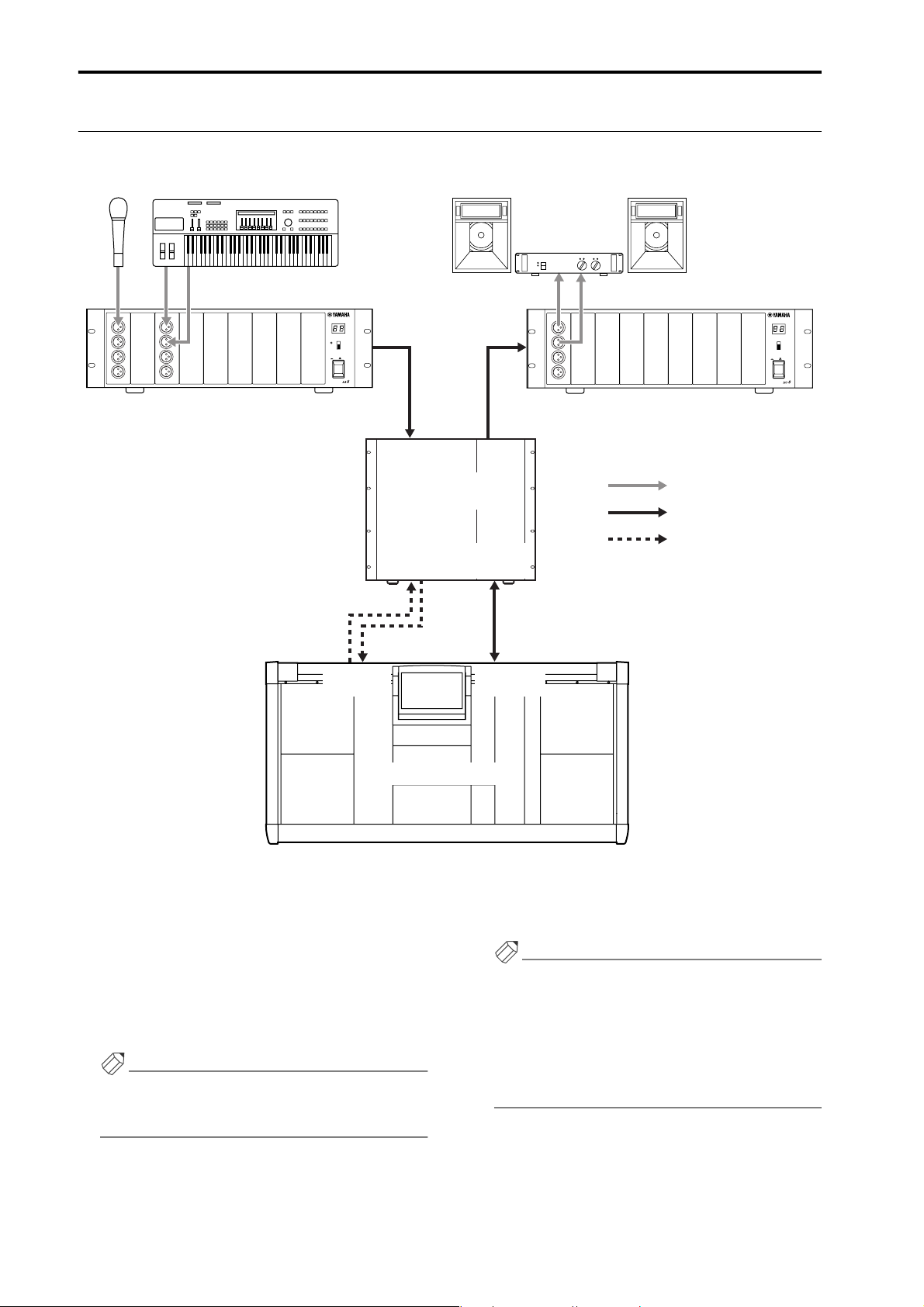

Page 7

• Example setting 1

The word clock output from the console is distributed, and supplied to the various components. In this example, the

console fills the role of the clock generator.

Clock distributor

WORD

CLOCK OUT

WORD

CLOCK IN

CONSOLE

I/O

DIGITAL I/O DIGITAL I/O

CONSOLE

I/O

DSP1D (-EX)DSP1D (-EX)

CS1D

WORD

CLOCK IN

INPUT/

OUTPUT

• Word clock settings

MASTER CLOCK SELECT

Console INT 48k or INT 44.1k

WORD CLOCK INPUT SELECT

Engine: W.CLOCK IN

Each unit: W.CLOCK IN

WORD CLOCK IN

INPUT/OUTPUT INPUT/OUTPUT

Each unit

: BNC cable connection

: Word clock signal flow

: D-sub half-pitch 68-pin cable connection

INPUT/

OUTPUT

• Example setting 2

The word clock is supplied via the digital audio signal that is output from the DIGITAL I/O jack of the console. In this case,

each component that is connected by a 68-pin D-sub cable will extract the word clock from the 68-pin D-sub connector.

CONSOLE

DSP1D (-EX)

I/O

DIGITAL I/O

CS1D

INPUT/

OUTPUT

INPUT/OUTPUT

• Word clock settings

MASTER CLOCK SELECT

Console INT 48k or INT 44.1k

WORD CLOCK INPUT SELECT

Engine: 68-pin D-sub connector (AUTO and W.CLOCK IN both turned off)

Each unit: 68-pin D-sub connector (AUTO and W.CLOCK IN both turned off)

The CONSOLE INT 48k and CONSOLE INT 44.1k

settings were added so that when Mirror mode is

used, a system can be constructed without using an

external clock generator. If this is used for other

purposes, or if you have connected a device that

requires a high-precision word clock, it may not

6

Each unit

: D-sub half-pitch 68-pin cable connection

: Word clock signal flow

operate correctly. In such cases, either use an external clock generator or select INT 48k/INT 44.1k of

the engine as the master clock.

Reference pages

•

Installation, pages 24, 28–29

•

Software section, page 54

Page 8

1

2

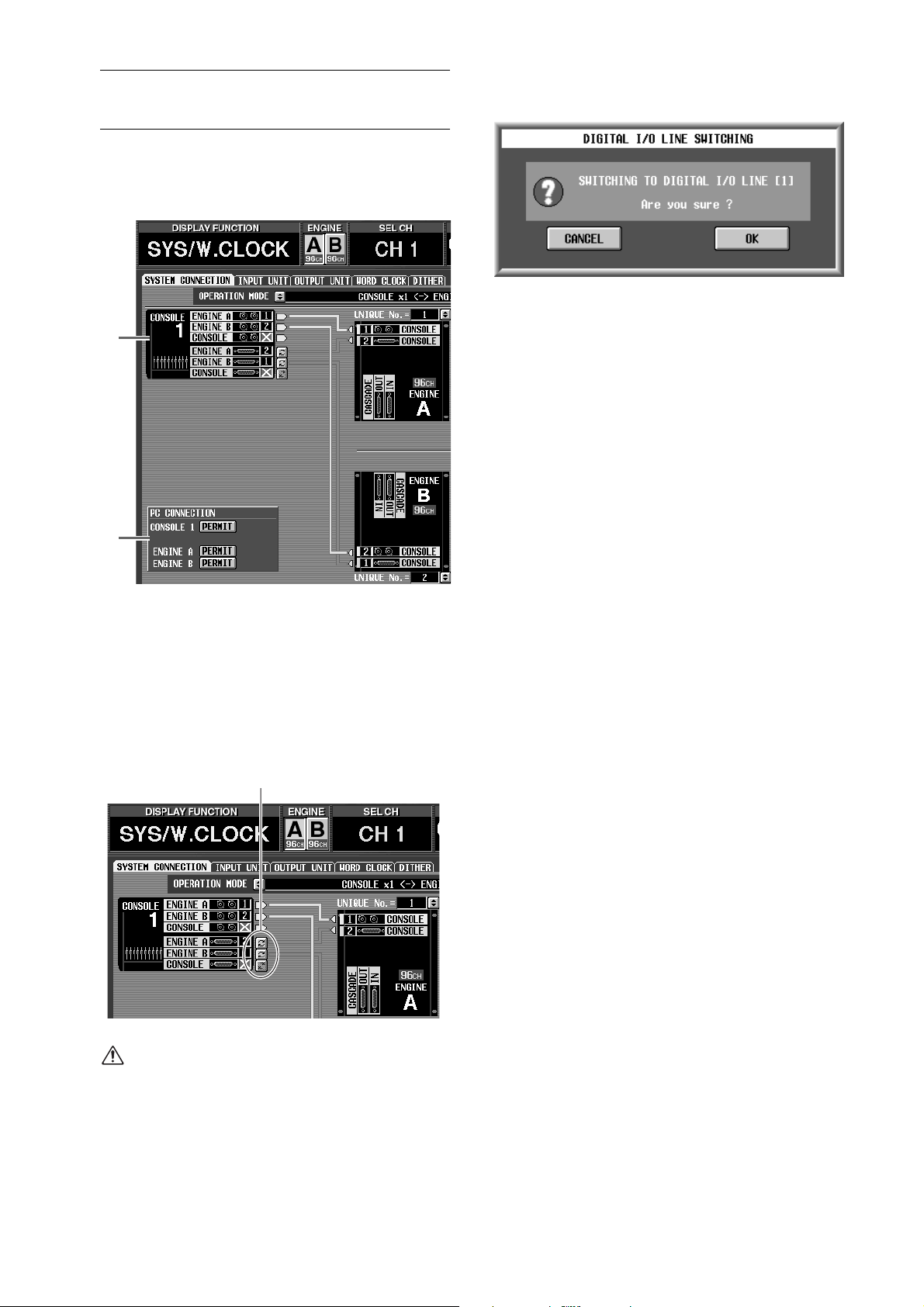

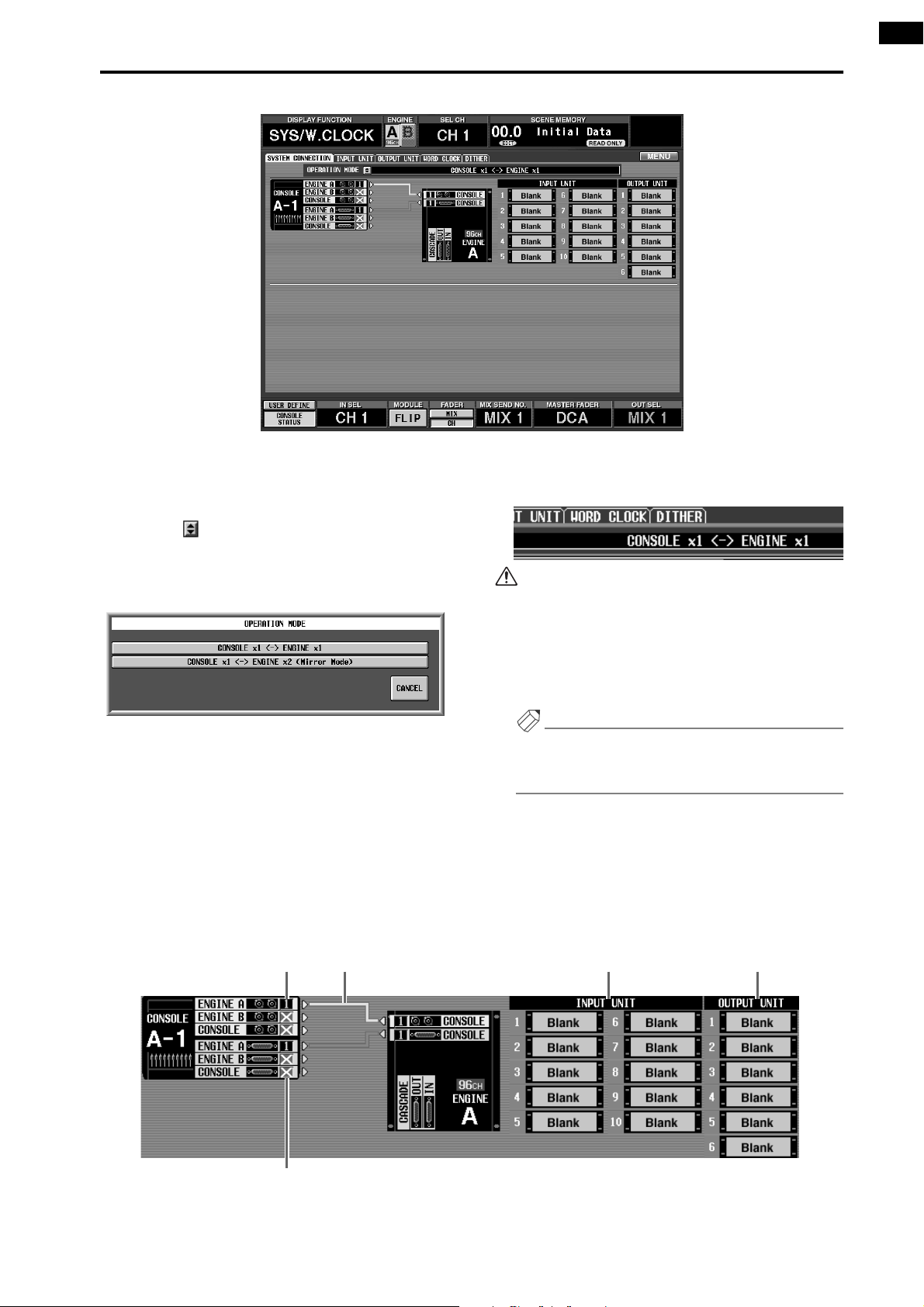

Additions and changes in the SYSTEM CONNECTION screen

The following two additions/changes have been made to

the SYS/W.CLOCK function SYSTEM CONNECTION

screen.

1

2

Manual switching of the DIGITAL I/O connectors

You can now manually switch the number (1 or 2) of

the DIGITAL I/O connector that connects the console and engine.

To do so, click the button beside the number corresponding to the DIGITAL I/O connector of the console or engine.

Click here

A switching popup window will appear, so press the

OK button to perform the switch.

Display PC connection status

The status of the connection between the console/

engine and the PC is now displayed in the PC CONNECTION section of the screen. The display has the

following significance.

•

PERMIT button

This button specifies whether to permit connection between the console/engine and the PC. When

this button is on, data transfer will be enabled

between the console/engine and PC whose serial

ports are connected to each other. For details refer

to the manual of the PC software “PM1D Manager

for Windows.”

•

OFFLINE/ONLINE

This indicates the status of connections between

the console/engine and PC. When the serial ports

are connected to each other and data can be transferred, the ONLINE symbol will be displayed. If

data cannot be transferred even though the serial

ports are connected, the OFFLINE symbol will be

displayed.

Reference pages

•

Installation, pages 23, 26, 27

•

Software section, pages 44, 45, 46

Even if you switch the number of the DIGITAL I/O

connector in the SYSTEM CONNECTION screen,

the previous connector will automatically be valid if

the appropriate signals are not being input from the

newly selected connector.

7

Page 9

1

2

1

2

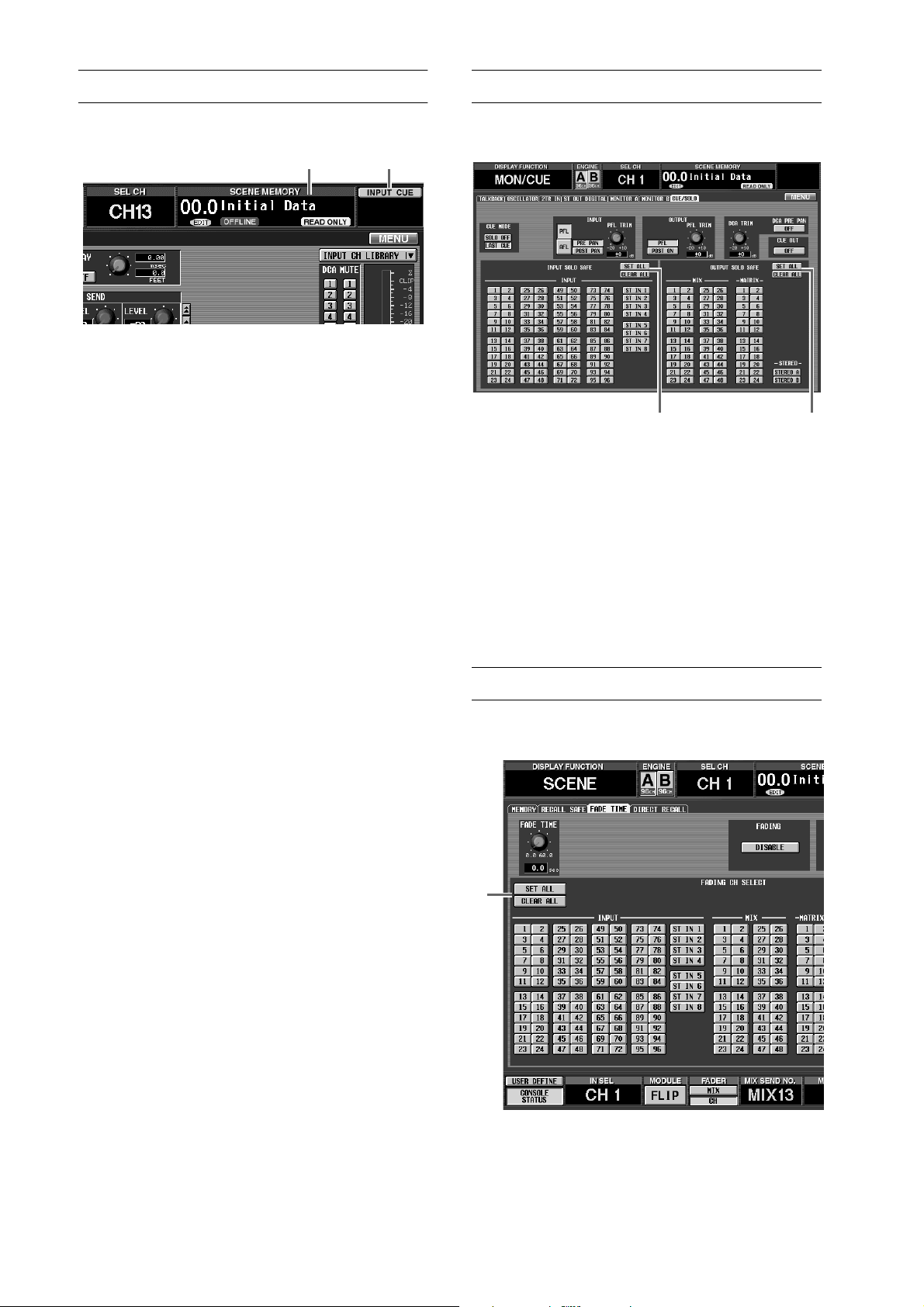

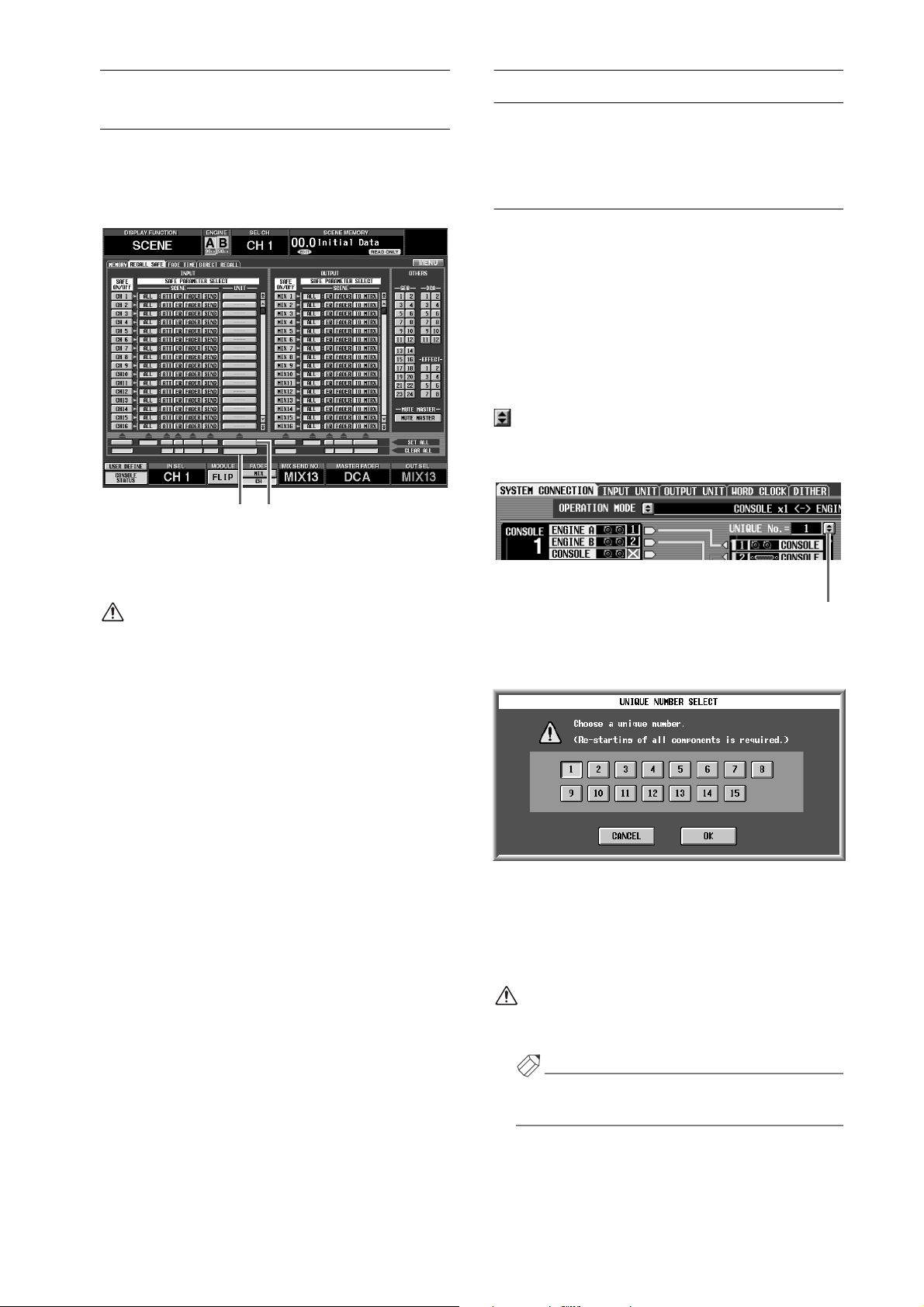

Changes in the main display

The main display has been changed as follows.

1 2

Cancel a modified scene memory number

When the scene memory title area is blinking, you

can click this area to return to the scene number that

was last stored/recalled. This is the same function as

the [CLEAR] switch of the SCENE MEMORY block.

CUE symbol

CUE symbols that indicate the section in which the

[CUE] switch is currently on have been added to the

screen. Each symbol has the following meaning.

•

INPUT CUE

This symbol will be displayed if the [CUE] switch

of an input channel is on.

•

OUTPUT CUE

This symbol will be displayed if the [CUE] switch

of an output channel is on.

•

DCA CUE

This symbol will be displayed if the [CUE] switch

of a DCA group is on.

•

SUB IN CUE

This symbol will be displayed if the SUB IN CUE

button is turned on in the MATRIX/ST function

SUB IN screen.

•

EFFECT CUE

This symbol will be displayed if the CUE button is

on in the EFFECT function EFFECT 1–EFFECT 8

screen or the EFFECT ASSIGN screen.

•

KEY IN CUE

This symbol will be displayed if the KEY IN CUE

button is on in the IN GATE/COMP function

GATE PRM screen.

Changes in the CUE/SOLO screen

The MON/CUE function CUE/SOLO screen has

changed as follows.

SET ALL/CLEAR ALL button added to INPUT

SOLO SAFE section

This button sets/clears all Solo Safe settings for the

input channels.

SET ALL/CLEAR ALL button added to OUTPUT

SOLO SAFE section

This button sets/clears all Solo Safe settings for the

output channels.

Reference pages

•

Software section, pages 74–75

Changes in the FADE TIME screen

A SET ALL button has been added to the SCENE function FADE TIME screen.

1

21

Reference pages

•

Software section, page 3

8

When you click the SET ALL button ( 1 ), the fade function will be enabled for all input channels, output channels, and DCA groups.

Reference pages

•

Software section, pages 25–26

Page 10

Changes in the RECALL SAFE screen

A SET ALL button and CLEAR ALL button have been

added to the SCENE function RECALL SAFE screen,

allowing Recall Safe to be set/cleared simultaneously for

all units.

12

Input/output unit sharing

Multiple PM1D systems can now share various types of

input/output unit (AI8, AO8, DIO8).

Specifying the Unique ID

If you want multiple PM1D systems to share an input/

output unit, you must first specify a Unique ID for each

engine. The Unique ID is an identifying number that

specifies the engine that will be the control source when

multiple engines (DSP1D-EX {DSP1D}) are connected

in parallel to an input/output unit. (When the PM1D

system is in the default state, engine A is set by default to

ID=1, and engine B to ID=2.)

If you want to change this ID, access the SYS/W.CLOCK

function SYSTEM CONNECTION screen, and click the

button located above the graphic of the engine.

(Alternatively, move the cursor to the button and press

the [ENTER] key.)

When you click the SET ALL button (1), all units will

be set to Recall Safe. When you click the CLEAR ALL

button (2), Recall Safe will be defeated for all units.

If the SET ALL button is on, all units (including

units that are not displayed in this screen) will be

set to Recall Safe. Please be aware that Recall Safe

will be applied to units that are not currently

patched, and to units that are patched to Insert.

Reference pages

• Basic operation, page 106

• Software section, pages 23, 24

UNIQUE No. button

When you click the button, a popup window will appear,

allowing you to select the Unique ID.

In this window, the button of the currently-selected ID

will be on. Select a new ID, and click the OK button.

The modified Unique ID will not take effect until you

restart the PM1D system. Turn off the power of all components, and then turn the power on again.

Make sure that the Unique ID of each engine does

not coincide. If the ID numbers coincide, the units

may malfunction.

Hint

Unique ID settings need to be made only if an input/

output unit is being shared by multiple engines.

9

Page 11

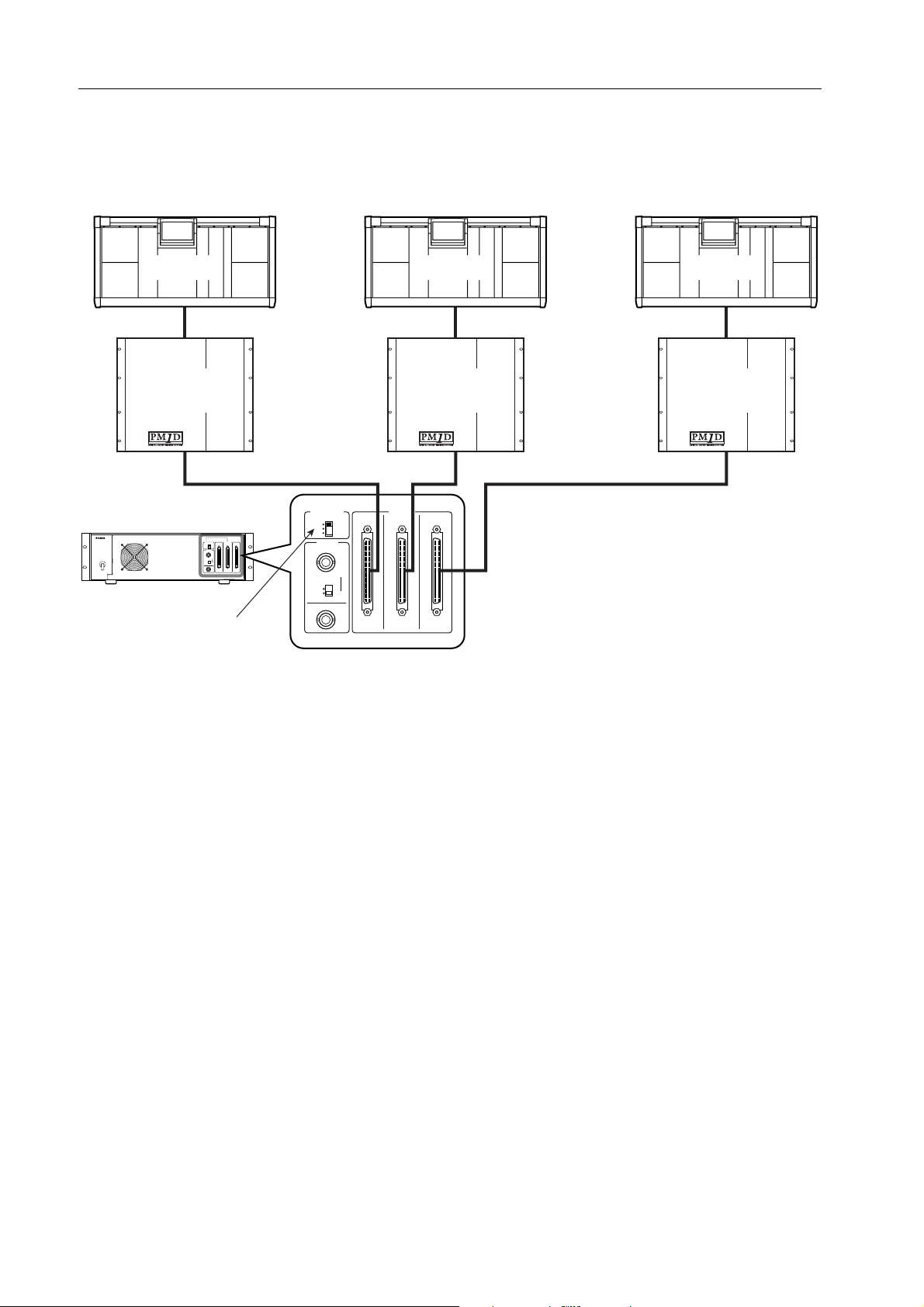

Sharing an input/output unit between multiple engines (Standard mode)

The following diagram shows example connections when sharing an AI8 input unit in Standard mode. The AI8’s OUTPUT jacks A–C are connected to engines (DSP1D) 1–3, each with a different Unique ID.

The control source engine (DSP1D) is selected by the CONTROL PORT switch of the AI8. In this diagram, the CONTROL PORT switch is set to A, so engine (DSP1D) 1 (ID=1) which is connected to the AI8’s OUTPUT jack A will be the

control source, and will adjust all parameters including gain.

CS1D-3

DSP1D-3

[UNIQUE No. : 3]

AI8 input unit

CONTROL

OUTPUT

PORT

A

CBA

B

C

WORD

CLOCK

IN

OFF

75Ω

ON

OUT

Set to A

CONTROL

PORT

A

CB A

B

C

WORD

CLOCK

IN

OFF

75Ω

ON

OUT

CBA

[UNIQUE No. : 2]

OUTPUT

Although engine (DSP1) 2 (ID=2) and engine (DSP1D)

3 (ID=3) can also recognize the AI8, they cannot adjust

its parameters. (Unit-related parameters will be shaded

in the screen.) Settings for the entire unit (such as word

clock-related settings) will also be controllable only from

engine (DSP1D) 1 (ID=1). If you want to change the

control source engine (DSP1D), change the position of

the AI8’s CONTROL PORT switch.

CS1D-2

DSP1D-2

CS1D-1

DSP1D-1

[UNIQUE No. : 1]

10

Page 12

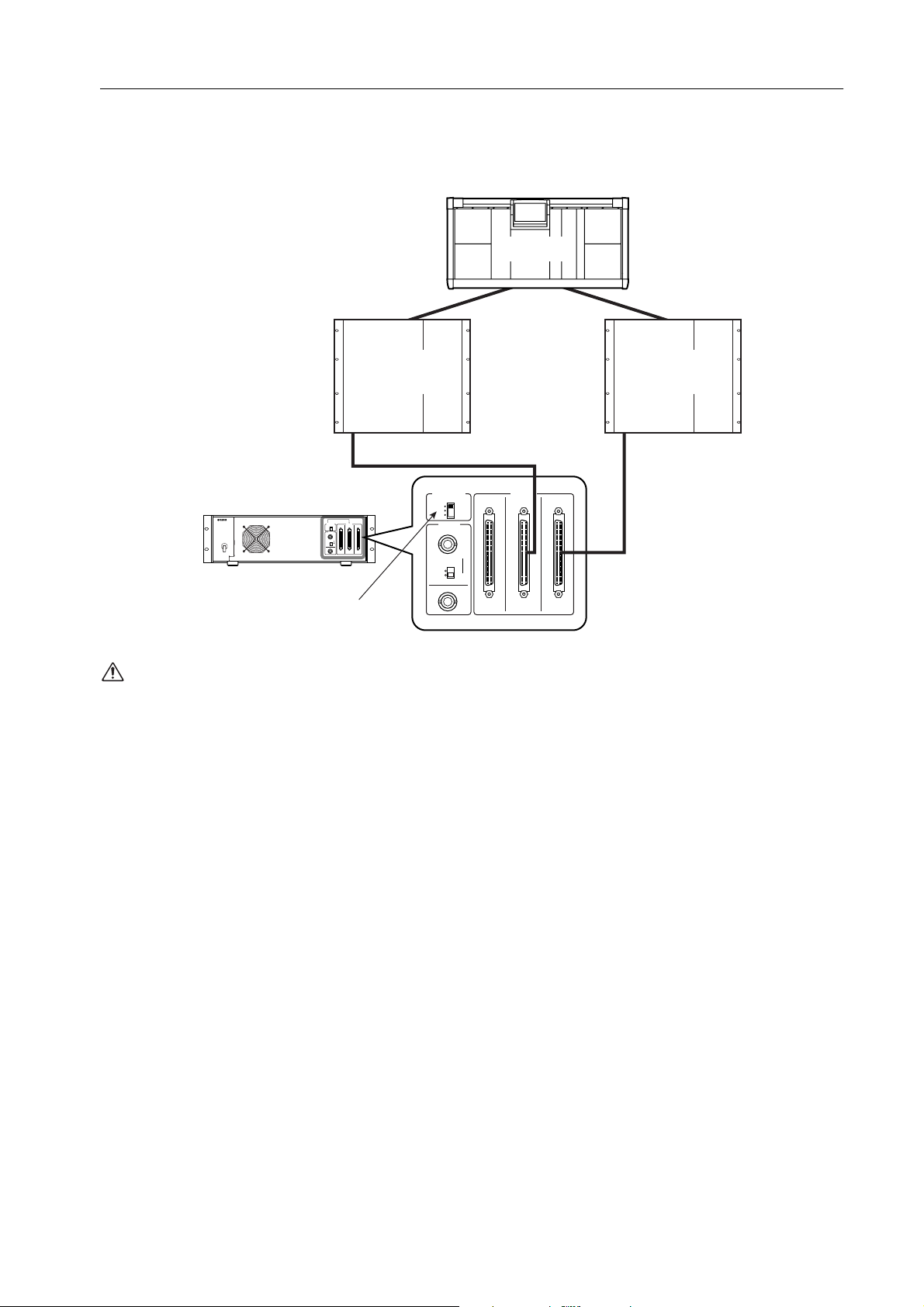

Sharing an input/output unit between multiple engines (Mirror mode)

The following diagram shows example connections when sharing an AI8 input unit in Mirror mode. The AI8’s OUTPUT

jack A is connected to engine (DSP1D-1) A, and OUTPUT jack B is connected to engine (DSP1D-2) B. In Mirror mode,

the connected jack for each unit is controlled in software. For this reason, engine A must be connected to jack A of each

unit, and engine B must be connected to jack B of each unit. (In Mirror mode, the AI8’s jack C cannot be used.)

CS1D-1

DSP1D-B

[UNIQUE No. : 2]

INPUT

1

AI8 input unit

CONTROL

OUTPUT

PORT

A

CBA

B

C

WORD

CLOCK

IN

OFF

75Ω

ON

OUT

Set to A or B

The vacant jack of a unit used in Standard mode

must not be connected to a Mirror mode system.

Doing so will cause malfunctions.

CONTROL

PORT

A

CB A

B

C

WORD

CLOCK

IN

OFF

75Ω

ON

OUT

DSP1D-A

[UNIQUE No. : 1]

INPUT

1

OUTPUT

CBA

11

Page 13

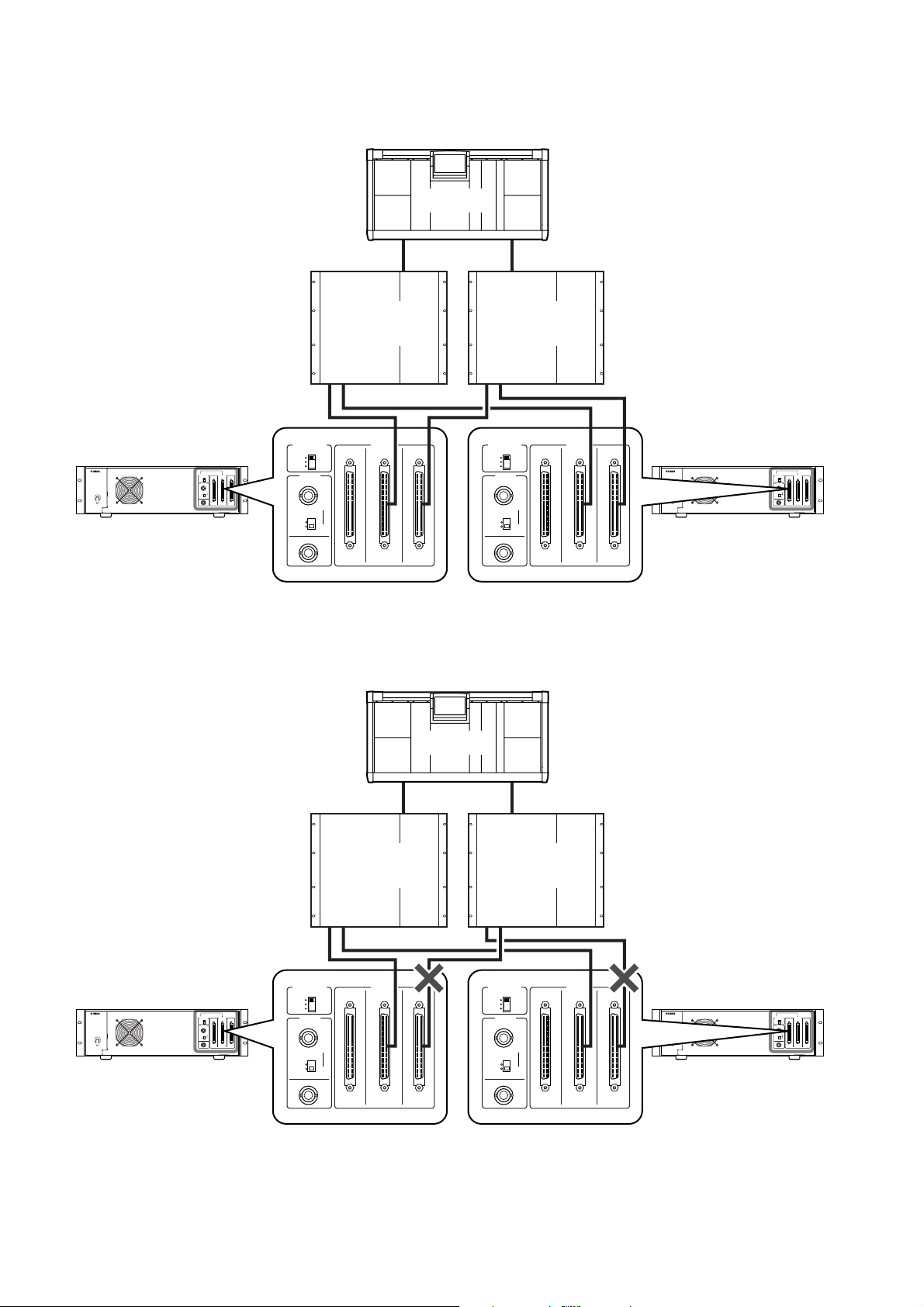

When multiple units (AI8) are shared in Mirror mode, each unit (AI8) must be connected to the identically-numbered

jack of engine (DSP1D) A/B.

Correct connections

• Mirror mode

CS1D-1

DSP1D-B

[UNIQUE No. : 2]

INPUT

1 2 3 4 5

CONTROL

PORT

OFF

A

B

C

CLOCK

ON

WORD

IN

75Ω

OUT

AI8-1 input unit AI8-2 input unit

CONTROL

OUTPUT

PORT

A

CBA

B

C

WORD

CLOCK

IN

OFF

75Ω

ON

OUT

OUTPUT

CB A

CBA

DSP1D-A

[UNIQUE No. : 1]

INPUT

1 2 3 4 5

CONTROL

PORT

A

CB A

B

C

WORD

CLOCK

CBA

IN

OFF

75Ω

ON

OUT

OUTPUT

CONTROL

PORT

A

B

C

WORD

CLOCK

OFF

ON

CBA

IN

75Ω

OUT

OUTPUT

Incorrect connections

If separate units are connected to the identically-numbered jack of engines (DSP1D) A/B as shown in the following diagram, the HA settings etc. will change when you switch between engines (DSP1D) A/B.

• Mirror mode

CS1D-1

DSP1D-B

[UNIQUE No. : 2]

INPUT

1 2 3 4 5

CONTROL

PORT

AI8-1 input unit AI8-2 input unit

CONTROL

OUTPUT

PORT

A

CBA

B

C

WORD

CLOCK

IN

OFF

75Ω

ON

OUT

A

CB A

B

C

WORD

CLOCK

IN

OFF

75Ω

ON

OUT

CBA

*1: The AI8-1’s OUTPUT jack A must be connected to the DSP1D-A’s INPUT1.

*2: The AI8-2’s OUTPUT jack A must be connected to the DSP1D-A’s INPUT2.

12

OUTPUT

DSP1D-A

[UNIQUE No. : 1]

INPUT

1 2 3 4 5

*1 *2

CONTROL

PORT

A

B

C

WORD

CLOCK

OFF

ON

IN

75Ω

OUT

OUTPUT

CB A

CBA

CONTROL

PORT

A

B

C

WORD

CLOCK

OFF

ON

CBA

IN

75Ω

OUT

OUTPUT

Page 14

Owner’s Manual

Page 15

FCC INFORMATION (U.S.A.)

1. IMPORTANT NOTICE: DO NOT MODIFY THIS UNIT! This product, when installed as indicated in the instructions contained in this manual, meets FCC

requirements. Modifications not expressly approved by Yamaha may void your authority, granted by the FCC, to use the product.

2. IMPORTANT: When connecting this product to accessories and/or another product use only high quality shielded cables. Cable/s supplied with this product MUST

be used. Follow all installation instructions. Failure to follow instructions could void your FCC authorization to use this product in the USA.

3. NOTE: This product has been tested and found to comply with the requirements listed in FCC Regulations, Part 15 for Class “B” digital devices. Compliance with

these requirements provides a reasonable level of assurance that your use of this product in a residential environment will not result in harmful interference with

other electronic devices. This equipment generates/uses radio frequencies and, if not installed and used according to the instructions found in the users manual, may

cause interference harmful to the operation of other electronic devices. Compliance with FCC regulations does not guarantee that interference will not occur in all

installations. If this product is found to be the source of interference, which can be determined by turning the unit “OFF” and “ON”, please try to eliminate the

problem by using one of the following measures: Relocate either this product or the device that is being affected by the interference. Utilize power outlets that are on

different branch (circuit breaker or fuse) circuits or install AC line filter/s. In the case of radio or TV interference, relocate/reorient the antenna. If the antenna lead-in

is 300 ohm ribbon lead, change the lead-in to coaxial type cable. If these corrective measures do not produce satisfactory results, please contact the local retailer

authorized to distribute this type of product. If you can not locate the appropriate retailer, please contact Yamaha Corporation of America, Electronic Service

Division, 6600 Orangethorpe Ave, Buena Park, CA 90620

The above statements apply ONLY to those products distributed by Yamaha Corporation of America or its subsidiaries.

ADVARSEL!

Lithiumbatteri—Eksplosionsfare ved fejlagtig

håndtering. Udskiftning må kun ske med batteri

af samme fabrikat og type. Levér det brugte

batteri tilbage til leverandoren.

VARNING

Explosionsfara vid felaktigt batteribyte. Använd

samma batterityp eller en ekvivalent typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti

asennettu. Vaihda paristo ainoastaan

laitevalmistajan suosittelemaan tyyppiin. Hävitä

käytetty paristo valmistajan ohjeiden

mukaisesti.

NEDERLAND THE NETHERLANDS

● Dit apparaat bevat een lithium batterij voor geheugen

back-up.

● Raadpleeg uw leverancier over de verwijdering van de

batterij op het moment dat u het apparaat ann het einde

van de levensduur afdankt of de volgende Yamaha Service

Afdeiing:

Yamaha Music Nederland Service Afdeiing

Kanaalweg 18-G, 3526 KL UTRECHT

Te l. 030-2828425

● This apparatus contains a lithium battery for memory

back-up.

● For the removal of the battery at the moment of the

disposal at the end of the service life please consult your

retailer or Yamaha Service Center as follows:

Yamaha Music Nederland Service Center

Address: Kanaalweg 18-G, 3526 KL

UTRECHT

Te l: 030-2828425

● Gooi de batterij niet weg, maar lever hem in als KCA.

● Do not throw away the battery. Instead, hand it in as small

chemical waste.

Page 16

Important

Read the following before operating the CS1D

•

Warnings

•

Do not allow water to enter this unit or allow the

unit to become wet. Fire or electrical shock may

result.

•

Connect this unit’s power cord only to an AC outlet

of the type stated in this Owner’s Manual or as

marked on the unit. Failure to do so is a fire and electrical shock hazard.

•

Do not place heavy objects, including this unit, on

top of the power cord. A damaged power cord is a

fire and electrical shock hazard. In particular, be

careful not to place heavy objects on a power cord

covered by a carpet.

•

Do not modify the unit. Doing so is a fire and electrical shock hazard.

•

Do not place a container with liquid or small metal

objects on top of this unit. Liquid or metal objects

inside this unit are a fire and electrical shock hazard.

Cautions

•

This unit has ventilation holes at the top and bottom

to prevent the internal temperature rising too high.

Do not block them. Blocked ventilation holes are a

fire hazard.

•

Since this device is heavy, please use an appropriate

number of people (two or more) when moving it.

•

Before moving the CS1D, you must be sure to lower

the display toward the back until it is fastened in

position.

Operating Notes

•

The digital circuits of this unit may induce a slight

noise into nearby radios and TVs. If noise occurs,

relocate the affected equipment.

Using a mobile telephone near this unit may induce

noise. If noise occurs, use the telephone away from

the unit.

•

XLR-type connectors are wired as follows: pin 1:

ground, pin 2: hot (+), and pin 3: cold (–).

•

If the message “WARNING LOW BATTERY !”

appears when you turn on this unit, contact your

dealer as soon as possible about replacing the internal data backup battery. The unit will still operate

correctly, but data other than the presets will be lost.

We recommend that you save the data on an ATAcompatible PC flash storage card before replacing the

battery.

•

The performance of components with moving contacts, such switches, rotary controls, faders, fans, and

connectors, deteriorates over time. The rate of deterioration depends on the operating environment and

is unavoidable. Consult your dealer about replacing

defective components.

•

The CS1D is cooled by fan exhaust openings located

on its rear panel. Check these regularly and use a vacuum cleaner etc. to ensure that the openings do not

become clogged with dust. Before performing this

maintenance, you must turn off the POWER switch

of the PM1D power supply unit and make sure that

the CS1D is not operating.

•

The power must be turned on/off using the POWER

switch of the PW1D power supply unit. Do not turn

the power on/off by plugging in the power cable, or

by using a power strip or circuit breaker. Doing so

may cause malfunctions.

•

Do not rapidly turn on and off the POWER switch of

the PW1D power supply unit. Doing so may cause

excessive current to damage the system. You must

allow at least five seconds to elapse between poweron and power-off.

Handling the included PM1D System Software disc

The included PM1D System Software Disc is CD-R media containing documentation and software for the PM1D.

A computer with a connected CD drive is required in order to use this documentation and software.

For details on the contents, refer to the documentation on the disc.

Please observe the following points when handling the disc.

Failure to do so may cause problems such as the recorded data being lost, the drive to malfunction, or the printed label to

become blurred.

•

Do not place the disc in locations of direct sunlight,

high temperature, or high humidity.

•

Do not touch either surface of the disc.

Hold the disc at the edges. Gently wipe dust or dirt

off of the recording surface of the disc.

ii

•

Do not wipe the disc with chemicals or detergents.

•

Do not bend or drop the disc.

•

Use an air duster or cleaner to remove dust. Vigorously rubbing the surface of the disc with a dry cloth

may scratch the disc.

Page 17

Important

•

Do not write on the disc or affix labels to it.

•

Keep water droplets or condensation off of the label

surface.

•

Yamaha Corporation makes no guarantee of a disc

that is rendered unreadable due to careless handling.

CS1D Exclusion of Certain Responsibility

Manufacturer, importer, or dealer shall not be liable for any incidental damages including personal injury or any other

damages caused by improper use or operation of the CS1D.

About the LCD display

The LCD screen built into the CS1D has the following characteristics. Please be aware that even if the following symptoms occur, this is not a malfunction or a defect.

•

Since the LCD display is manufactured with

extremely delicate technology, individual pixels may

not display correctly. (A pixel may be constantly lit or

constantly dark.)

•

The LCD screen may be affected by changes in the

ambient temperature.

•

Depending on the environment of use, you may

notice unevenness in brightness or small spots.

•

Since the LCD screen uses a cold cathode tube for a

backlight, the state of the display will gradually

change over time.

Cautions when handling the track pad

•

Place your hand and arm in a relaxed, natural position, and operate the track pad by moving your finger lightly across the surface or tapping it gently.

•

This device is designed to be operated with one finger. It will not operate in the following situations.

1) When operated by a gloved finger

2) When operated with a pen, ballpoint pen, or pencil etc.

3) When operated by two or more fingers

4) When operated with an object placed on it

•

The unit may not operate correctly if water droplets

or condensation are present on the surface, or if

operated using a soiled or sweaty finger. If condensation occurs, dry the unit thoroughly, or wipe it dry

before use.

Trademarks

ADAT MultiChannel Optical Digital Interface is a trademark and ADAT and Alesis are registered trademarks of Alesis

Corporation. Tascam Digital Interface is a trademark and Tascam and Teac are registered trademarks of Teac Corporation. Windows and Windows NT are trademarks of Microsoft Corporation. Compact Flash is a trademark of SanDisk

Corporation. Yamaha is a trademark of Yamaha Corporation. All other trademarks are the property of their respective

holders and are hereby acknowledged.

•

To avoid malfunctions, please observe the following

cautions.

1) Do not drop objects on the unit, strike it, or subject it to strong physical shock.

2) Do not spill coffee, juice, or other liquids on the

unit.

•

Do not operate the unit with a pointed metal object

such as a pen, since this will damage the unit.

•

If the surface becomes soiled, wipe it clean with a dry

cloth. If the surface is severely soiled, wipe with a

moist cloth, and dry carefully before use.

•

Do not touch the surface while the por is being

turned on.

Copyright

No part of the CS1D software or this Owner’s Manual may be reproduced or distributed in any form or by any means

without the prior written authorization of Yamaha Corporation.

© 2000 Yamaha Corporation. All rights reserved.

Yamaha website

Yamaha manual Library http://www2.yamaha.co.jp/manual/english/

http://www.yamaha.co.jp/product/proaudio/homeenglish

iii

Page 18

Operating Manual

Page 19

Operating Manual

(Start-up)

Page 20

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

About the “CS1D Operating Manual (Start-up)” . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Printing conventions in “CS1D Operating Manual (Start-up)”. . . . . . . . . . . . . . . . 1

Introducing the various components . . . . . . . . . . . . . . . . . . . . .2

Terms used in the “CS1D Operating Manual (Start-up)” . . . . . . . . . . . . . . . . . . . . 4

Connections (Standard mode). . . . . . . . . . . . . . . . . . . . . . . . . . .6

Connecting the console and engine (Standard mode) . . . . . . . . . . . . . . . . . . . . . . 6

Connecting an analog input/output unit to the engine (Standard

mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting a digital input/output unit to the engine (Standard mode) . . . . . . . . 9

Connections (Mirror mode). . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Connecting the console and engines (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . 10

Connecting an analog input/output unit to the engines (Mirror mode) . . . . . . . 12

Connecting a digital input/output unit to the engines (Mirror mode) . . . . . . . . 13

Turning on the power and verifying the connections . . . . . . .14

Turning on the power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Checking the status of each device (Standard mode). . . . . . . . . . . . . . . . . . . . . . 15

Checking the engine (Standard mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Checking the analog input unit (Standard mode) . . . . . . . . . . . . . . . . . . . . . . 16

Checking the analog output unit (Standard mode) . . . . . . . . . . . . . . . . . . . . . 17

Digital input/output unit (Standard mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Checking the status of each device (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . 18

Engines (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Checking the analog input unit (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . 19

Checking the analog output unit (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . 20

Checking the digital input/output unit (Mirror mode) . . . . . . . . . . . . . . . . . . . 21

Basic settings (Standard mode). . . . . . . . . . . . . . . . . . . . . . . . .22

Selecting the operation mode (Standard mode) . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setting the word clock (Standard mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ii

Page 21

Contents

Basic settings (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Selecting the operation mode (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting the word clock (Mirror mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Checking the operation of input units . . . . . . . . . . . . . . . . . . . 30

Preparations for checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connect the monitor system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Connect an input source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Patch the input unit to an input channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Monitor the input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Checking the operation of an output unit . . . . . . . . . . . . . . . . 38

Preparations for checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connect the monitor system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Connect an input source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Patch the input unit to an input channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Patch the STEREO A channel to an output unit . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Send the input signals of input channels 1/2 to the STEREO bus . . . . . . . . . . . . 44

Turn off the power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

iii

Page 22

Introduction

About the “CS1D Operating Manual (Start-up)”

The “CS1D Operating Manual (Start-up)” is an introductory manual that explains how to connect the various components of the PM1D system and verify that the PM1D system is operating correctly.

When starting up the PM1D system for the first time, or if you have changed the configuration of the system such as

when the PM1D system has been moved to another location and/or re-connected, we recommend that you follow the

procedure described in this manual to verify that the system is operating correctly.

•

This manual explains only the minimum operations.

For details on operating the PM1D system, please

refer to “CS1D Operating Manual (Basic operation)”

•

For details on the specifications and functionality of

the engine (DSP unit DSP1D-EX {DSP1D}) and I/O

units, please refer to the owner’s manual included

with each device.

•

For details on the function and operation of the controllers and connectors found on the top panel, rear

panel, and front panel of the console (CS1D), refer to

“CS1D Reference Manual (Hardware).”

•

For details on the software in the display screen of

the console (CS1D), refer to “CS1D Reference Manual (Software).”

Screen shots shown in this manual are taken from a

prototype. Please be aware that they may differ

slightly from the actual screens on your unit.

Printing conventions in “CS1D Operating Manual (Start-up)”

•

Differences between the 96 channel model and 48

channel model

In general, the “CS1D Operating Manual (Start-up)”

is written with the 96 channel model PM1D system

(the model with the DSP1D-EX as the engine) in

mind. Where the functionality of the 96 channel

model differs from the 48 channel model (the model

with the DSP1D as the engine), the functionality of

the 48 channel model is enclosed in curly brackets { }.

•

Standard mode and Mirror mode

The PM1D system has two operation modes (elements that determine system structure and connection method); “Standard mode” in which one

console is connected to one engine, and “Mirror”

mode in which one console is connected to two

engines of which only one is used.

Be aware that the mode used by the PM1D system

will depend not only on the number of engines, but

also on the type of connections and on the internal

settings.

Explanations that apply only to Standard mode will

be indicated by the following symbol.

DSP

x1x1

The PM1D system version 1.0 does not support any

other operation mode (i.e., other than Mirror

mode) in which two engines are used.

•

Distinguishing between the controls of the CS1D

and the on-screen knobs/buttons

Names of controls (switches, encoders, faders) on the

top panel, rear panel, and front panel of the CS1D

are enclosed in square brackets [ ] in order to distinguish them from the knobs and buttons etc. that are

displayed in the screen.

Example : Tu rn on the [TO ST] switch.

(This indicates an operation on the top panel of the

CS1D.)

Example : Click the BASIC button.

(This indicates an operation in the display screen.)

•

Va r ious icons

The following icon is used to call your attention to

various tips for operation or to reference pages.

Hint

The following icon is used to indicate particularly

important items or operations that you must be

aware of.

Explanations that apply only to

indicated by the following symbol.

DSP

x2x2

Mirror mode will be

1

Page 23

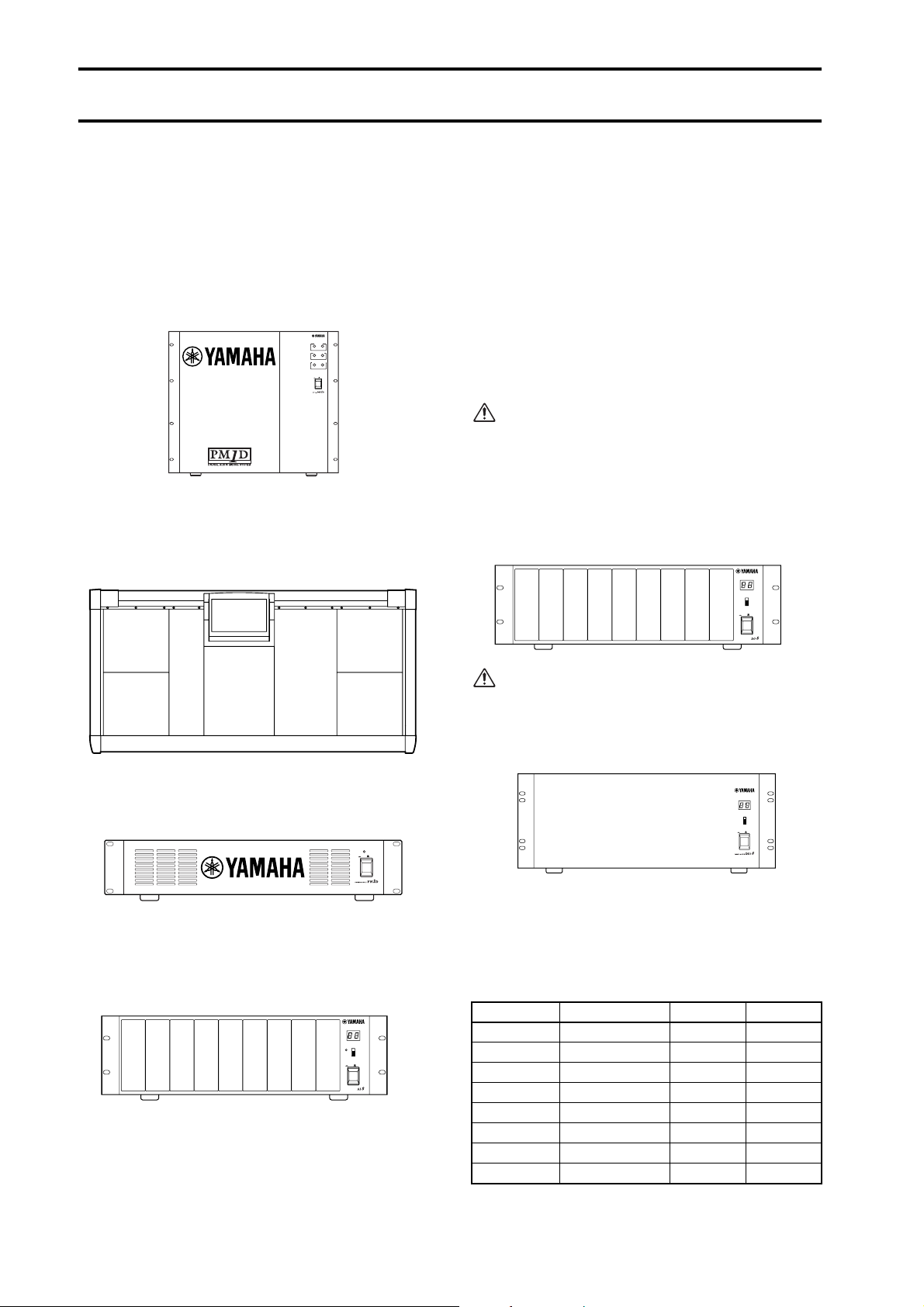

Introducing the various components

The PM1D system consists of the following types of components. (The components that are actually included will differ

depending on your system.)

Engine (DSP1D-EX {DSP1D})

This is the DSP unit that performs the majority of the

audio processing in the PM1D system, such as audio signal input/output, mixing, and effects. There are two

models of engine: the 96 channel DSP1D-EX , and the

48 channel DSP1D .

ENGINE ID

A B

CONTROL I/O

1 2

INPUT

CONFIGURATION

48CH 96CH

POWER

ON/ OFF

Console (CS1D)

The mixing operations, scene memory/library operations, and various editing operations of the PM1D system are performed from this console.

The following models of AI8 are available, depending on

the type of analog input cards that are installed.

•

AI8-ML8

A unit with eight mic/line input cards installed

•

AI8-AD8

A unit with eight AD cards installed

•

AI8-ML4AD4

A unit with four mic/line input cards + four AD

cards installed

Cards can be installed in the AI8 only by a Yamaha

service engineer. The user must never attempt to

install a card himself.

Analog output unit (AO8)

This is an output unit that outputs analog audio signals

from the engine, and can accommodate eight DA cards

(LMY4-DA).

1234567

8

OUTPUT UNIT NO.

INPUT SELECTOR

A

B

POWER

ON/ OFF

ANALOG OUTPUT BOX

Power supply (PW1D)

This power supply provides power to the console.

POWER

ON OFF

Analog input unit (AI8)

This is an input unit that inputs analog audio signals to

the engine, and can accommodate up to eight analog

input cards.

12345678

INPUT UNIT NO.

PHANTOM MASTER

ON

OFF

POWER

ON/ OFF

ANALOG INPUT BOX

+48V

The following types of cards can be installed in the AI8.

•

Mic/line input card (LMY2-ML)

•

AD card (LMY4-AD)

Cards can be installed in the AO8 only by a Yamaha

service engineer. The user must never attempt to

install a card himself.

Digital input/output unit (DIO8)

I/O UNIT ID

PORT B SELECTOR

5-8

1-4

POWER

ON/ OFF

This unit performs input/output of ADAT, Tascam, and

AES/EBU format digital audio signals and input/output

of analog audio signals to and from the engine of the

PM1D system. Each DIO8 unit can accommodate up to

eight digital I/O cards or analog I/O cards.

The following types of card can be installed.

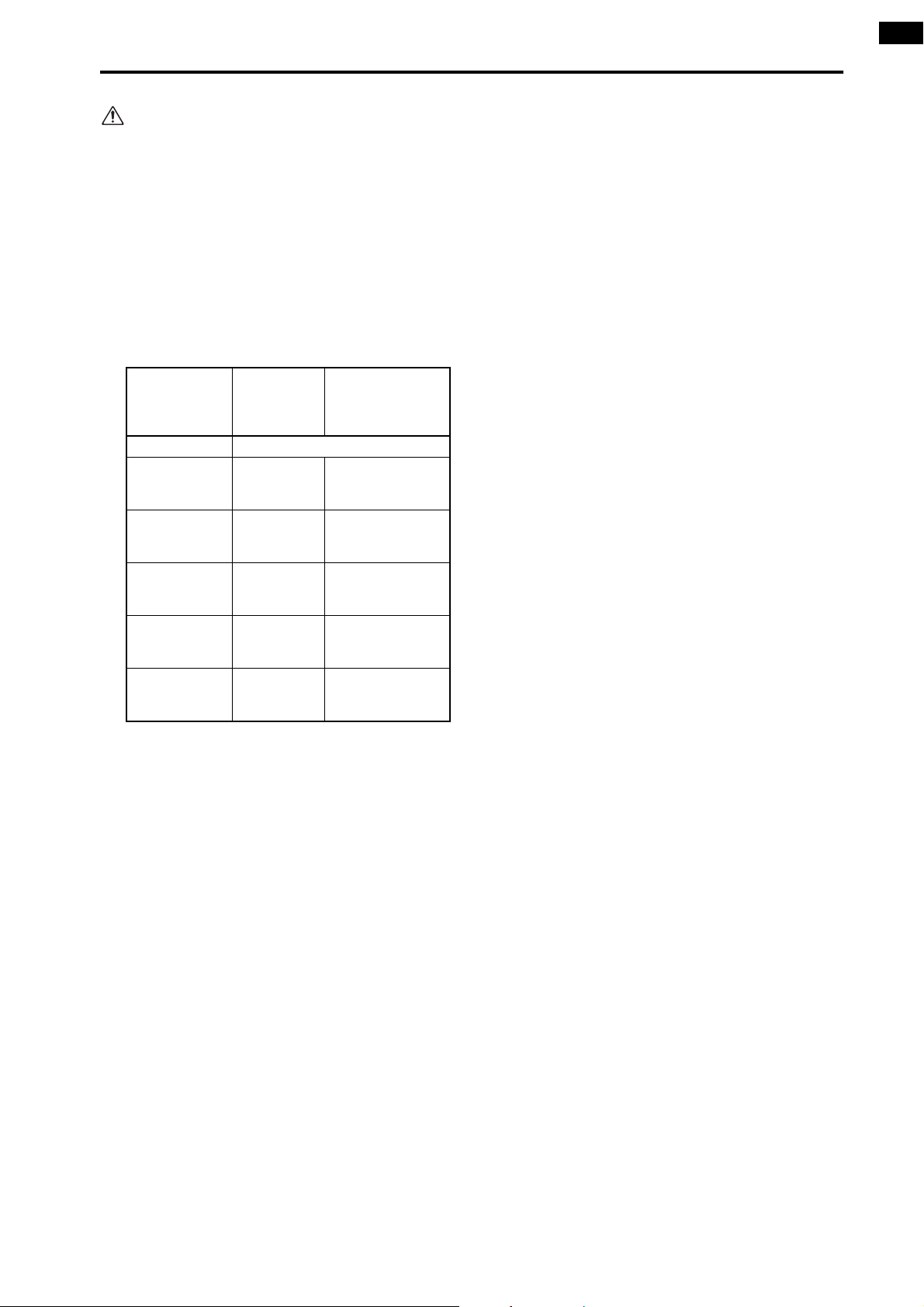

Card Format Input Output

MY8-TD TASCAM 8 IN 8 OUT

MY8-AT ADAT 8 IN 8 OUT

MY8-AE AES/EBU 8 IN 8 OUT

MY8-AD ANALOG IN 8 IN —

MY4-AD ANALOG IN 4 IN —

MY4-DA ANALOG OUT — 4 OUT

AP8AD* ANALOG IN 8 IN —

AP8DA*

*: Manufactured by Apogee Corporation

ANALOG OUT — 8 OUT

* As of September 1, 2000

2

Page 24

It is not possible to install and use a total of five or

more AP8AD/AP8DA cards. Also, if you are using

AP8AD/AP8DA cards simultaneously with MY8AD/MY4-AD/MY4-DA cards, there are restrictions

on the number of cards, as described below. Never

exceed the allowable number of cards, since

attempting to use a greater number of cards than

allowed may damage the DIO8 due to excessive

current. If you are not using AP8AD or AP8DA

cards, or if you are using AP8AD or AP8DA cards

simultaneously with an MY8-TD/MY8-AT/MY8AE card, there is no limitation on the number of

MY8-TD/MY8-AT/MY8-AE cards that can be used.

Introducing the various components

[AP8AD] +

[AP8DA] cards

used

Total 0 cards Up to a total of 8 cards

Total 1 card Up to 6 cards

Total 2 cards Up to 4 cards

Total 3 cards Up to 2 cards

Total 4 card Up to 1 card

Total 5 or more

cards cannot

be used

[MY8-AD] +

[MY4-AD] +

[MY4-DA]

cards used

——

[MY8-TD] +

[MY8-AT] +

[MY8-AE] cards

used

Up to the number

of vacant DIO8

slots

Up to the number

of vacant DIO8

slots

Up to the number

of vacant DIO8

slots

Up to the number

of vacant DIO8

slots

3

Page 25

CS1D Operating Manual (Start-up)

Terms used in the “CS1D Operating Manual (Start-up)”

Of the specialized terms used in operating the CS1D, this section will explain the terms that appear in “CS1D Operating

Manual (Start-up).” For a more detailed explanation of terms, refer to “CS1D Operating Manual (Basic Operation).”

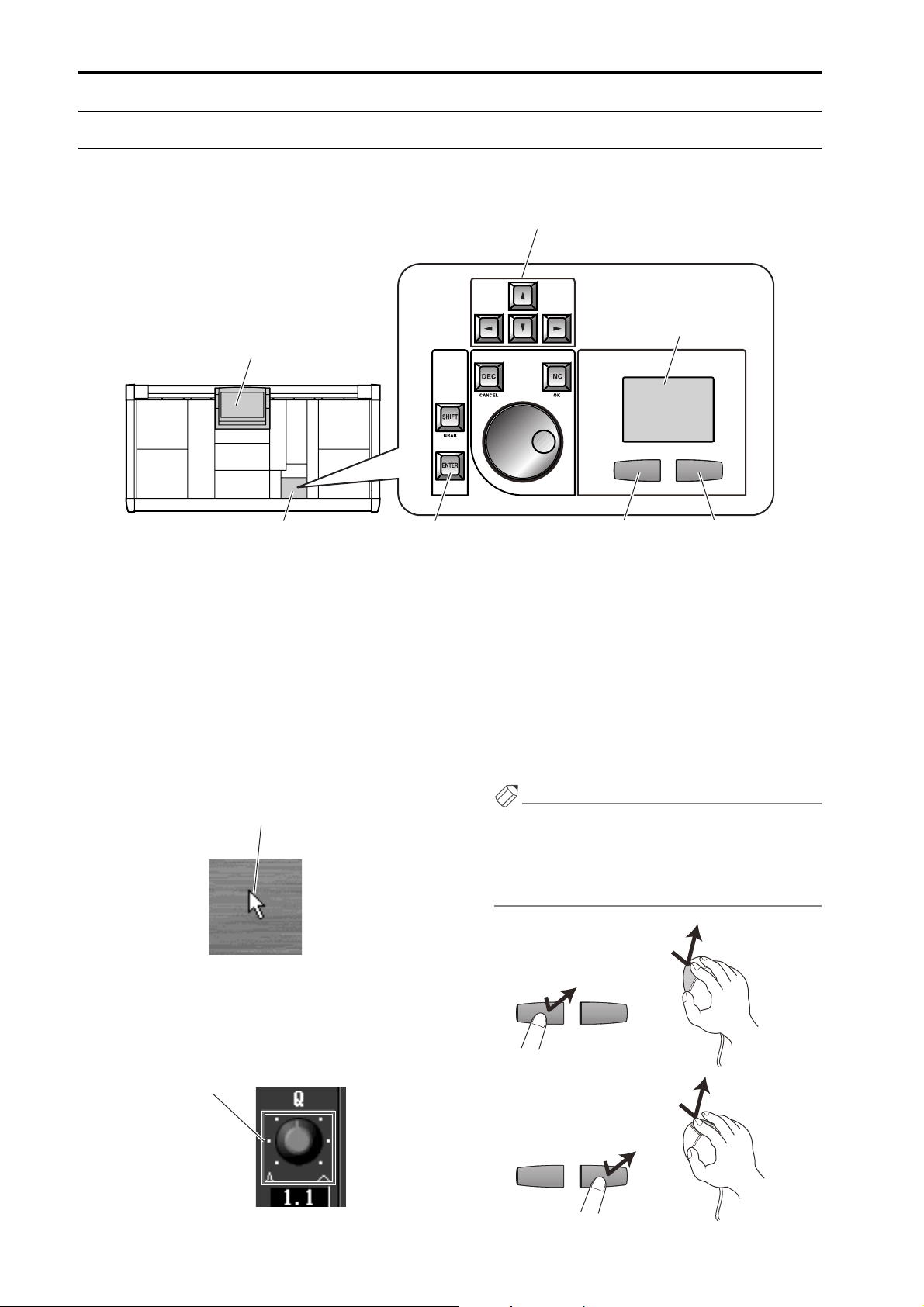

[CURSOR] switches

Track pad

Display

Data entry block

•

Display

This refers to the LCD display located in the upper

center of the CS1D console. When you wish to

change an internal setting of the CS1D, you can recall

the appropriate screen in the display, and use the

buttons or knobs in the display to edit the setting.

•

Pointer

The arrow shown in the display is called the

“pointer,” and is used to select the object that you

wish to modify. You can move the pointer by pressing

your finger on the track pad (located in the data

entry block) and dragging it up/down/left/right.

Pointer

Right switch

•

Left switch[ENTER] switches

Click

“Click” refers to the action of placing the pointer on

a specific item in the display, and pressing the left or

right switch of the track pad (located in the data

entry block). This action is used to turn an on-screen

button on/off, or to move the cursor to a specific

item.

Using the [CURSOR] switches (located in the data

entry block) to move the cursor to a specific item and

then pressing the [ENTER] switch will have the same

result as clicking on that item.

Hint

As alternative ways to perform this action, you can

use a mouse connected to the MOUSE connector of

the CS1D, or use the arrow keys and ENTER key of a

keyboard connected to the KEYBOARD connector of

the CS1D.

Mouse left click

•

Cursor

The red frame shown in the display is called the “cursor.” An on-screen item will be enclosed by the cursor to indicate that this item is selected for

modification.

Cursor

4

Left switch

Click

Mouse right click

Right switch

Click

Page 26

•

Drag

“Drag” refers to the action of placing the pointer

over a specific object on the screen, and holding

down the left or right switch while you slide your finger left/right/up/down across the track pad.

This action is used to continuously adjust a knob or

slider in the screen, or to move a specific item to

another location.

Hint

As an alternative way to perform this action, you can

use a mouse connected to the MOUSE connector of

the CS1D.

Introducing the various components

Track pad

Drag

While pressing

Drag

Mouse

5

Page 27

1

Connections (Standard mode)

DSP

x1x1

This section explains connections for Standard mode, in which one console (CS1D) is connected to one engine (DSP1DEX {DSP1D}).

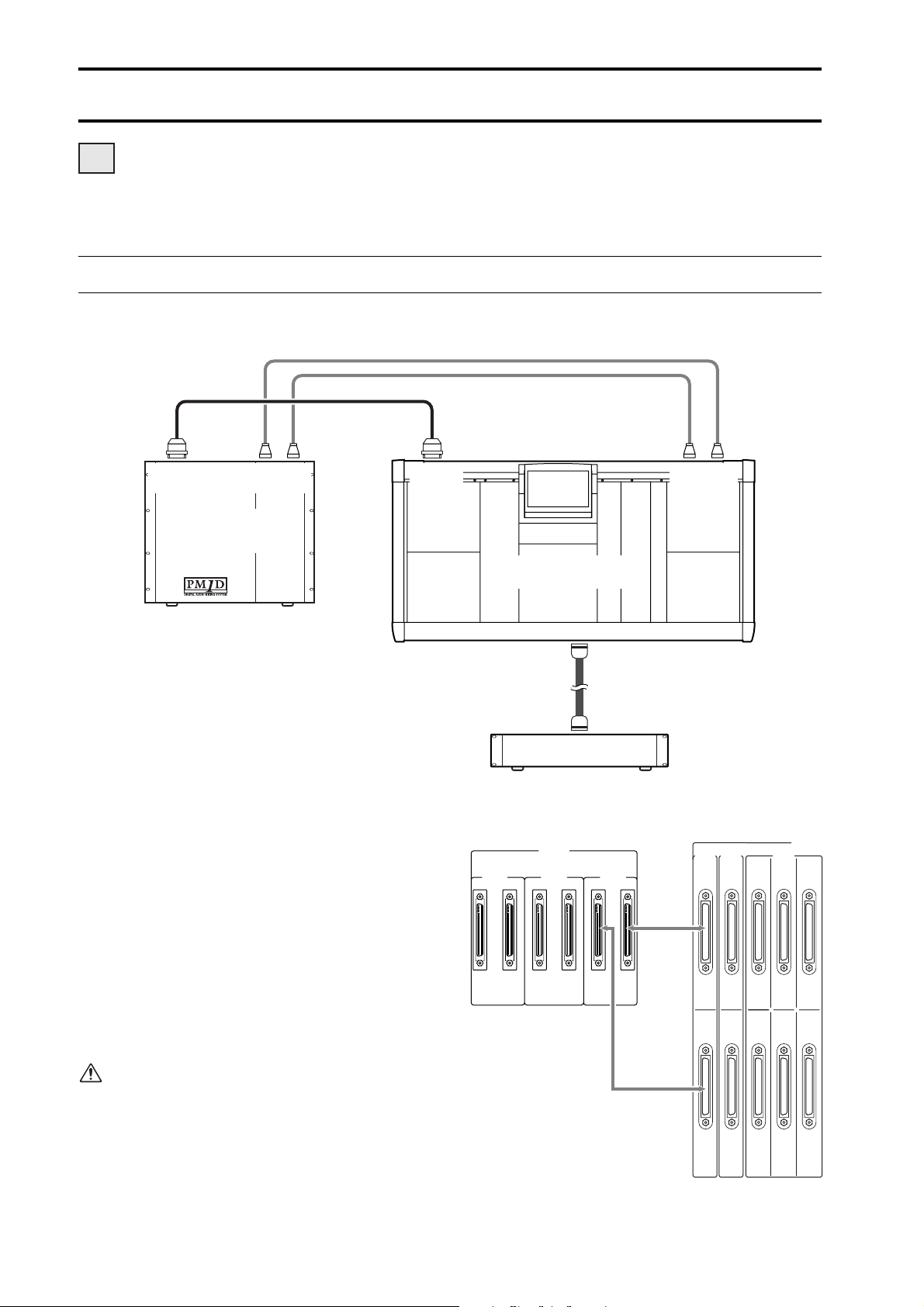

Connecting the console and engine (Standard mode)

The following diagram shows typical connections between the console and engine for Standard mode.

ENGINE A

IN OUT

CONSOLE

I/O

CONTROL

I/O

DIGITAL

ENGINE A

(DSP1D-EX{DSP1D})

Digital input/output connections

Use the included D-sub half pitch 68 pin cable to

connect the DIGITAL I/O ENGINE A connector of

the console to the CONSOLE I/O connector of the

engine.

These connectors transmit and receive multi-channel

digital audio signals.

The console and engine each have two identical digital input/output connectors, numbered 1 and 2.

These two sets of connectors are completely identical, and the system will operate normally if just one

set is connected. However, you may connect both 1

and 2 so that one of them can be used as a backup.

You must connect the identically-numbered con

nectors of the console and engine to each other. If

differently-numbered connectors are connected to

each other, the system will not function correctly.

I/O

1

ENGINE A

IN OUT

CONTROL

2

I/O

CONSOLE (CS1D)

DC POWER

INPUT A

3

POWER SUPPLY (PW1D)

This method of connection is recommended for

most cases.

DIGITAL I/O

CONSOLE

2

ENGINE B

1 2121

Console (CS1D)

ENGINE A

CONSOLE

CASCADE

I/O

1IN531

2 OUT 6 4 2

DIGITAL I/O

OUTPUT

6

Engine

(DSP1D-EX {DSP1D})

Page 28

Connections (Standard mode)

22

22

Hint

If both digital input/output connectors 1 and 2 are

connected, connector 1 will be given priority when

the power is turned on.

If the word clock stops being supplied from either

connector 1 or 2 (whichever is the currently-used

connector), the receiving device will automatically

switch to the other connector.

•

Use only Yamaha-manufactured D-sub half pitch 68

pin cables to connect the digital input/output connectors. Operation cannot be guaranteed if any other

cables are used.

•

If you need a cable of a different length than the

included D-sub half pitch 68 pin cable, please contact your dealer.

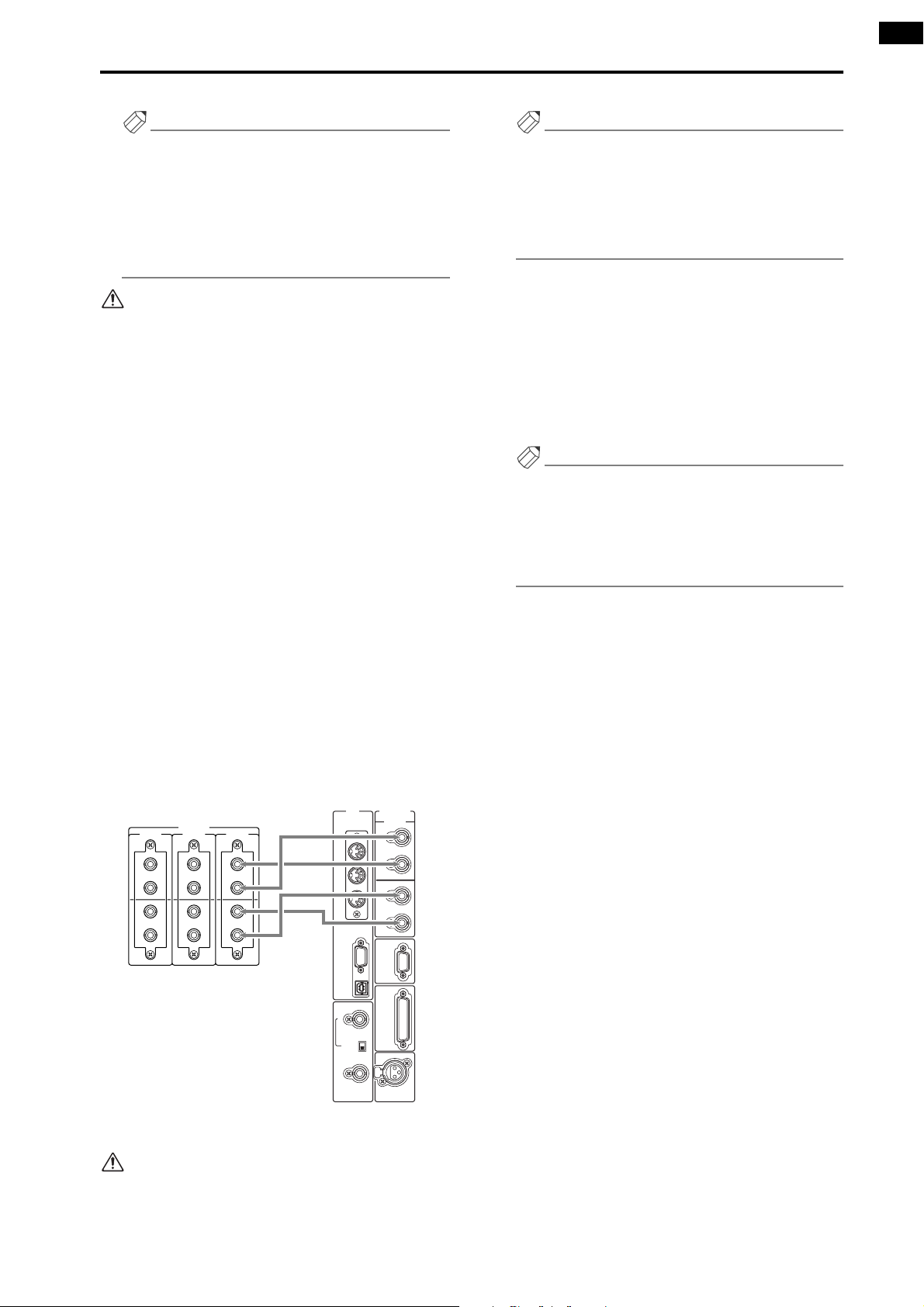

Control input/output connections

Use BNC cables (50

Ω

) to connect the CONTROL I/

O ENGINE A IN connector of the console to the

CONTROL I/O OUT connector of the engine, and

the CONTROL I/O ENGINE A OUT connector of

the console to the CONTROL I/O IN connector of

the engine.

These connectors transmit and receive control signals between the console and engine.

The console and engine each have two identical sets

of connectors, numbered 1 and 2.

These two sets of connectors are completely identical, and the system will operate normally if just one

set is connected. However, you may connect both 1

and 2 so that one of them can be used as a backup.

This method of connection is recommended for

most cases.

MIDI CONTROL I/O

IN

USB

WORD CLOCK

IN

OFF

75Ω

ON

CONSOLE

1

IN

OUT

2

IN

OUT

REMOTE

RS-422

GPI

TIME CODE IN

CONTROL I/O

CONSOLE ENGINE B ENGINE A

1

IN

OUT

IN

OUT

1

IN

OUT

2

2

IN

OUT

Console (CS1D)

1

IN

OUT

2

IN

OUT

OUT

THRU

PC

CONTROL

RS-232-C

OUT

Hint

If both control input/output connectors 1 and 2 are

connected, connector 1 will be given priority when

the power is turned on.

If the currently-used control output connector stops

functioning correctly, the receiving device will automatically switch to the other connector.

Power supply connections

Use the included special cable to connect the DC

POWER INPUT connector of the console to the DC

OUTPUT connector of the PW1D power supply.

The rear panel of the console has two DC POWER

INPUT connectors, A and B.

If you are using only one power supply, you may connect it to either DC POWER INPUT connector.

Hint

You can also connect two power supplies to the two

DC POWER INPUT connectors A and B. If this connection method is used, the PM1D system will continue to operate even if one of the power supplies

should unexpectedly fail, since the other power supply will continue to supply power to the system.

2

Engine

(DSP1D-EX {DSP1D})

You must connect the identically-numbered con

nectors of the console and engine to each other. If

differently-numbered connectors are connected to

each other, the system will not function correctly.

-

3

7

Page 29

CS1D Operating Manual (Start-up)

Connecting an analog input/output unit to the engine (Standard mode)

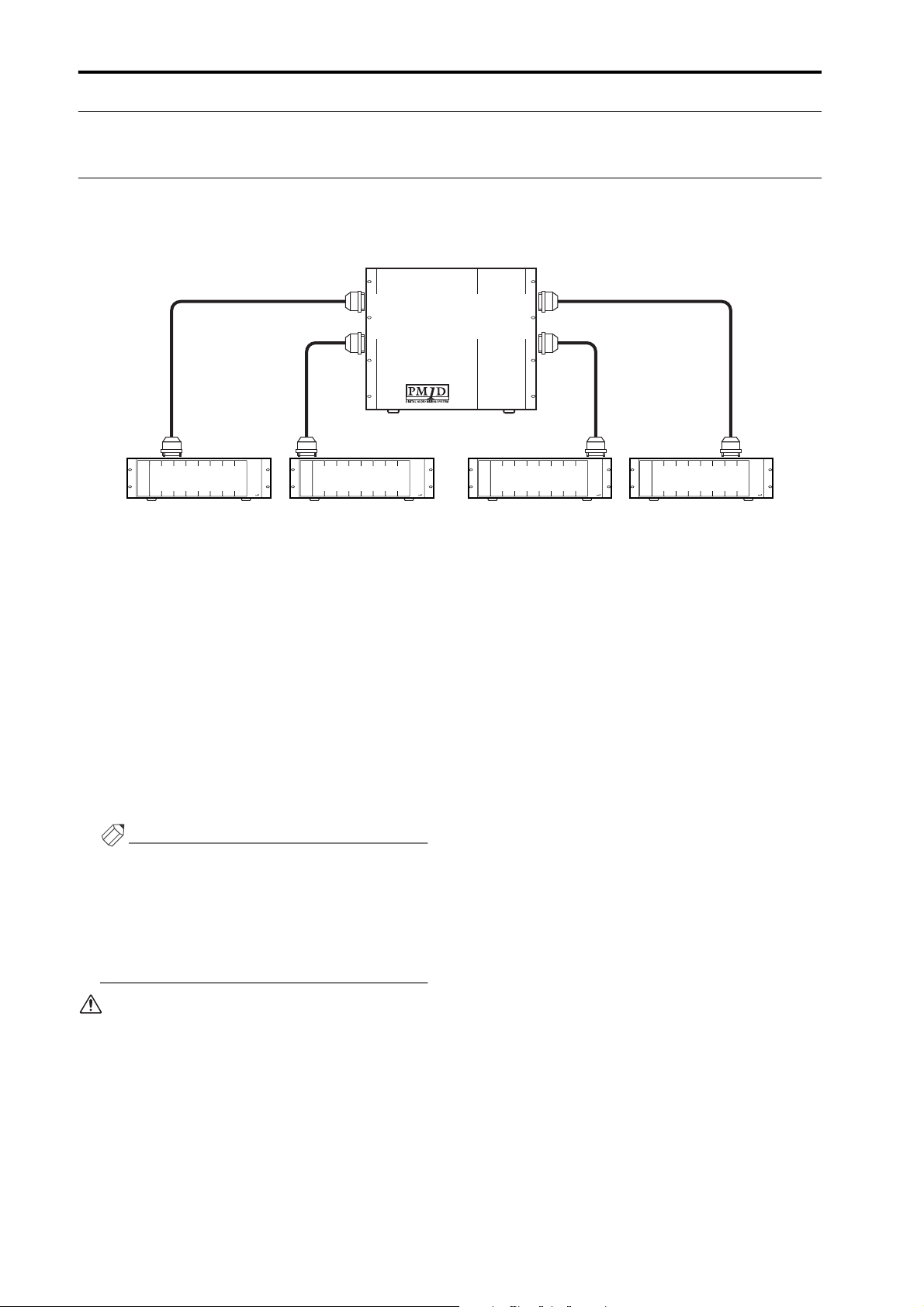

The following diagram shows a common way of making connections between the engine and analog input/output units

for Standard mode.

12

INPUT 2

INPUT 1

ENGINE A

(DSP1D-EX{DSP1D})

OUTPUT 2

OUTPUT 1

INPUT A INPUT AOUTPUT A OUTPUT A

AI8 (ID=2) AI8 (ID=1) AO8 (ID=1) AO8 (ID=2)

ANALOG INPUT BOXANALOG INPUT BOX

CONTROL PORT

Switch = A

CONTROL PORT

Switch = A

Analog input unit AI8 connection

Connect the OUTPUT A connector of the AI8 analog

input unit to one of the INPUT 1–INPUT 10 connectors of the engine. Set the CONTROL PORT

switch (located on the rear panel of the AI8) to the A

position.

Analog output unit AO8 connection

Connect the INPUT A connector of the AO8 analog

output unit to one of the OUTPUT 1–OUTPUT 6

connectors of the engine. Set the INPUT SELECTOR

switch (located on the front panel of the AO8) to the

A position.

Hint

An AI8 analog input unit can be connected to any

INPUT connector of the engine, and the number of

that INPUT connector will be the ID number of that

unit. Similarly, an AO8 analog output unit can be

connected to any OUTPUT connector of the engine,

and the number of that OUTPUT connector will be

the ID number of that unit.

INPUT SELECTOR

Switch = A

ANALOG OUTPUT BOX ANALOG OUTPUT BOX

INPUT SELECTOR

Switch = A

Be careful not to connect inputs and outputs in

reverse. If such a connection is made, the unit will

not be recognized and cannot be controlled.

8

1

2

Page 30

Connections (Standard mode)

Connecting a digital input/output unit to the engine (Standard mode)

When connecting a DIO8 digital input/output unit to the engine in Standard mode, the method will depend on whether

you use only slots 1–4 (of the DIO8’s slots 1–8) or slots 1–4 as well as slots 5–8.

If input/output cards are installed only in DIO8

slots 1–4

The following diagram shows example connections

for when input/output cards are connected only to

slots 1–4 of the DIO8.

ENGINE A

INPUT 1

Connect the OUTPUT A connector of the digital

input/output unit to one of the INPUT 1–10 connectors of the engine, and connect the INPUT A connector of the digital input/output unit to one of the

OUTPUT 1–6 connectors of the engine. In this case,

set the PORT B SELECTOR switch (located on the

front panel of the DIO8) to the 5-8 position.

(DSP1D-EX{DSP1D})

OUTPUT A INPUT A

DIO8 (ID=1)

PORT B SELECTOR=5–8

OUTPUT 1

If input/output cards are also installed in DIO8

slots 5–8

The following diagram shows example connections

for when input/output cards are installed in DIO8

slots 1–4 and also in slots 5–8.

INPUT 1

ENGINE A

INPUT 2

Connect the OUTPUT connectors A/B of the digital

input/output unit to the INPUT 1–10 connectors of

the engine, and connect the INPUT connectors A/B

of the digital input/output unit to OUTPUT 1–6

connectors of the engine. In this case, set the PORT B

SELECTOR switch (located on the front panel of the

DIO8) to the 5-8 position.

(DSP1D-EX{DSP1D})

BBAA

OUTPUT INPUT

DIO8 (ID=1)

PORT B SELECTOR=5–8

OUTPUT 2

OUTPUT 1

Hint

The DIO8 digital input/output unit can be connected to any INPUT connector/OUTPUT connector of the engine. The DIO8 will automatically select

a control connector according to the status of connections, and the connector number of the engine

connected to that connector will be displayed in the

LED display as the unit ID. In the example shown

above, the INPUT 1 connector number is the unit ID

number.

Be careful not to connect inputs and outputs in

reverse. If such a connection is made, the unit will

not be recognized and cannot be controlled.

When using an MY8-AT card to handle ADAT for

mat signals, synchronization may tend to be lost

easily, depending on the device that is connected.

1

2

For more reliable synchronization, we recommend

that the word clock for the combination of digital

audio equipment you are using be taken from other

than the ADAT format connector.

-

9

Page 31

Connections (Mirror mode)

DSP

x2x2

This section explains connections for Mirror mode, in which one console (CS1D) is connected to two engines (DSP1DEX {DSP1D}).

Connecting the console and engines (Mirror mode)

The following diagram shows typical connections between the console and engines for Mirror mode.

12

CONSOLE

I/O

ENGINE A ENGINE B

IN OUT IN OUT

CONTROL

I/O

DIGITAL

I/O

ENGINE A

(DSP1D-EX{DSP1D})

CONSOLE (CS1D)

WORD

CLOCK IN

WORD

CLOCK IN

DC POWER

INPUT A

POWER SUPPLY (PW1D)

Clock Generator

Digital input/output connections

Use the included D-sub half pitch 68 pin cables to

connect the DIGITAL I/O ENGINE A connector of

the console to the CONSOLE I/O connector of engine

A, and the DIGITAL I/O ENGINE B connector of the

console to the CONSOLE I/O connector of engine B.

These connectors transmit and receive multi-channel

digital audio signals.

ENGINE A ENGINE B

IN OUT

CONTROL

I/O

CONSOLE

I/O

IN OUT

CONTROL

ENGINE B

(DSP1D-EX{DSP1D})

WORD

CLOCK IN

3

4

set is connected. However, you may connect both 1

and 2 so that one of them can be used as a backup.

This method of connection is recommended for

most cases.

CONSOLE

CASCADE

I/O

1IN5

2

CONSOLE

DIGITAL I/O

ENGINE B

1 2121

ENGINE A

I/O

CONSOLE

CASCADE

I/O

1IN5

•

Use only Yamaha-manufactured D-sub half pitch 68

pin cables to connect the digital input/output connectors. Operation cannot be guaranteed if any other

cables are used.

•

If you need cables of a different length than the

included D-sub half pitch 68 pin cables, please contact your dealer.

•

The console and engines A/B each have two identical

sets of digital input/output connectors, numbered 1

and 2.

These two sets of connectors are completely identical, and the system will operate normally if just one

10

Console

2 OUT 6

Engine B Engine A

(CS1D)

2 OUT 6

1

Page 32

Connections (Mirror mode)

22

22

22

22

Hint

If both digital input/output connectors 1 and 2 are

connected, connector 1 will be given priority when

the power is turned on.

If the word clock stops being supplied from either

connector 1 or 2 (whichever is the currently-used

connector), the receiving device will automatically

switch to the other connector.

2 Control input/output connections

Use BNC cables (50Ω) to connect the CONTROL I/

O ENGINE A IN and OUT connectors of the console

to the CONTROL I/O OUT and IN connectors of

engine A. In the same way, connect the CONTROL I/

O ENGINE B IN and OUT connectors of the console

to the CONTROL I/O OUT and IN connectors of

engine B. These connectors transmit and receive

control signals between the console and engines A/B.

The console and engines A/B each have two identical

sets of connectors, numbered 1 and 2. These two sets

of connectors are completely identical, and the system will operate normally if just one set is connected.

However, you may connect both 1 and 2 so that one

of them can be used as a backup.

This method of connection is recommended for

most cases.

1

2

MIDI CONTROL I/O

IN

OUT

THRU

PC

CONTROL

RS-232-C

USB

WORD CLOCK

IN

OFF

75Ω

ON

OUT

MIDI CONTROL I/O

IN

OUT

THRU

PC

CONTROL

RS-232-C

USB

WORD CLOCK

IN

OFF

75Ω

ON

OUT

CONSOLE

1

IN

OUT

2

IN

OUT

REMOTE

RS-422

GPI

TIME CODE IN

CONTROL I/O

CONSOLE ENGINE B ENGINE A

1

IN

OUT

IN

OUT

1

IN

OUT

2

2

IN

OUT

Console (CS1D)

IN

OUT

IN

OUT

CONSOLE

1

IN

OUT

2

IN

OUT

REMOTE

RS-422

GPI

TIME CODE IN

Power supply connections

Use the included special cable to connect the DC

POWER INPUT connector of the console to the DC

OUTPUT connector of the PW1D power supply.

The rear panel of the console has two DC POWER

INPUT connectors, A and B. If you are using only

one power supply, you may connect it to either DC

POWER INPUT connector.

You can also connect two power supplies to the two

DC POWER INPUT connectors A and B. If this connection method is used, the PM1D system will continue to operate even if one of the power supplies

should unexpectedly fail, since the other power supply will continue to supply power to the system.

Wor d cl ock connections

Use BNC cables (75

Ω

) to connect the clock output

connector of an external clock generator to the

WORD CLOCK IN connector of the console, and to

the WORD CLOCK IN connectors of engines A/B.

Connect the word clock transmitting and receiving

devices in a one-to-one relationship, and turn on the

75

Ω

screen for the receiving device.

The word clock transmission/reception circuit is

designed with one-to-one connection in mind. For

this reason, if you connect multiple receiving

devices to a single clock transmission connector,

performance may be impaired and the system may

fail to operate correctly.

If you cannot avoid using this type of connection,

turn on the 75

devices, and turn off the 75

Ω

switch for one of the receiving

Ω

switches for all

remaining devices.

In Mirror mode, you can also switch to the other

engine manually if the currently-used engine experiences difficulties.

In order to minimize the clock switching time in

such cases, we recommend that you supply a word

clock from an external clock generator to the console and to engines A/B.

Of course, switching will occur even without this

type of supply method.

Engine B Engine A

Hint

If both control input/output connectors 1 and 2 are

connected, connector 1 will be given priority when

the power is turned on.

Control output connectors 1/2 will always output the

same signals. If the currently-used control output

connector stops functioning correctly, the receiving

device will automatically switch to the other connector.

You must connect the identically-numbered con

nectors of the console and engine to each other. If

differently-numbered connectors are connected to

each other, the system will not function correctly.

-

3

4

11

Page 33

CS1D Operating Manual (Start-up)

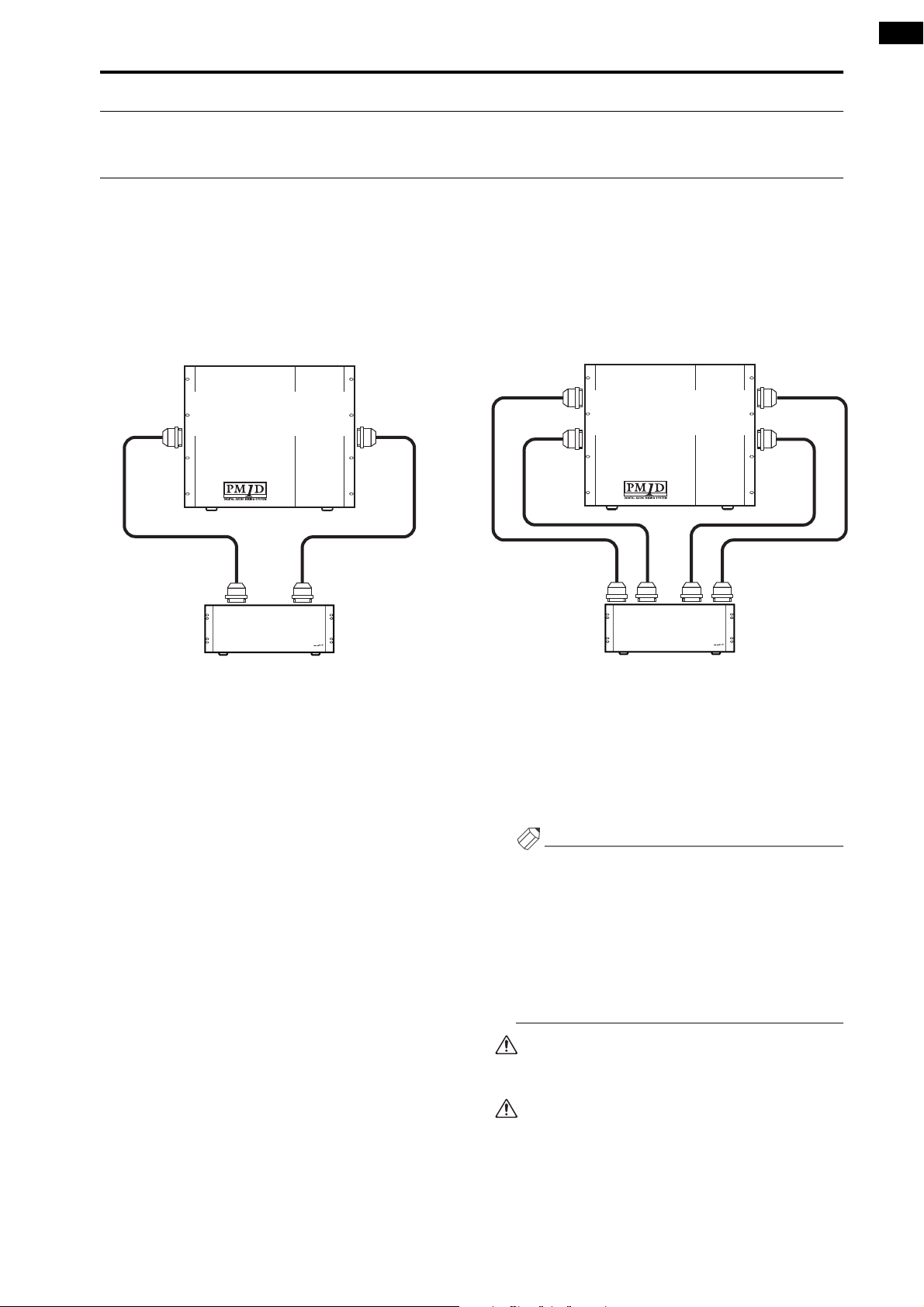

Connecting an analog input/output unit to the engines (Mirror mode)

The following diagram shows a common way of making connections between the engine and analog input/output units

for Mirror mode.

WORD

CLOCK IN

INPUT 2

ENGINE A

INPUT 1

(DSP1D-EX{DSP1D})

12

OUTPUT 2

OUTPUT 1

INPUT A INPUT AOUTPUT A OUTPUT A

AI8 (ID=2) AI8 (ID=1) AO8 (ID=1) AO8 (ID=2)

WORD

CLOCK

IN

CONTROL

PORT

Switch = A

CONTROL

PORT

Switch = A

INPUT 1

INPUT 2

WORD

CLOCK IN

(DSP1D-EX{DSP1D})

Clock Generator

Analog input unit AI8 connection

Connect the OUTPUT A connector of the AI8 analog

input unit to one of the INPUT 1–INPUT 10 connectors of engine A, and connect the OUTPUT B

connector of the AI8 to one of the INPUT 1–INPUT

10 connectors of engine B.

ANALOG INPUT BOXANALOG INPUT BOX

WORD

CLOCK IN

ENGINE B

ANALOG OUTPUT BOX ANALOG OUTPUT BOX

INPUT B INPUT BOUTPUT B OUTPUT B

INPUT

SELECTOR

Switch = A

OUTPUT 1

OUTPUT 2

INPUT

SELECTOR

Switch = A

WORD

CLOCK IN

Analog output unit AO8 connection

Connect the INPUT A connector of the AO8 analog

output unit to one of the OUTPUT 1–OUTPUT 6

connectors of engine A. Connect the INPUT B connector of the AO8 to one of the OUTPUT 1–OUTPUT 6 connectors of engine B.

•

When using Mirror mode, OUTPUT connectors A

and B of the AI8 must be connected to the identically-numbered INPUT connector of engines A and

B. Be aware that if these are connected to differentlynumbered INPUT connectors, the content of the

input signals will change when you switch between

engines A and B.

•

When using Mirror mode, leave the CONTROL

PORT switch of the AI8 in the A position as the

default setting.

12

•

When using Mirror mode, INPUT connectors A and

B of the AO8 must be connected to the identicallynumbered OUTPUT connector of engines A and B.

Be aware that if these are connected to differentlynumbered OUTPUT connectors, the content of the

output signals will change when you switch between

engines A and B.

•

When using Mirror mode, leave the INPUT SELECTOR switch of the AO8 in the A position as the

1

2

default setting.

•

Be careful not to reverse the input and output. If you

do so, the unit will not be recognized, and cannot be

controlled.

Page 34

Connections (Mirror mode)

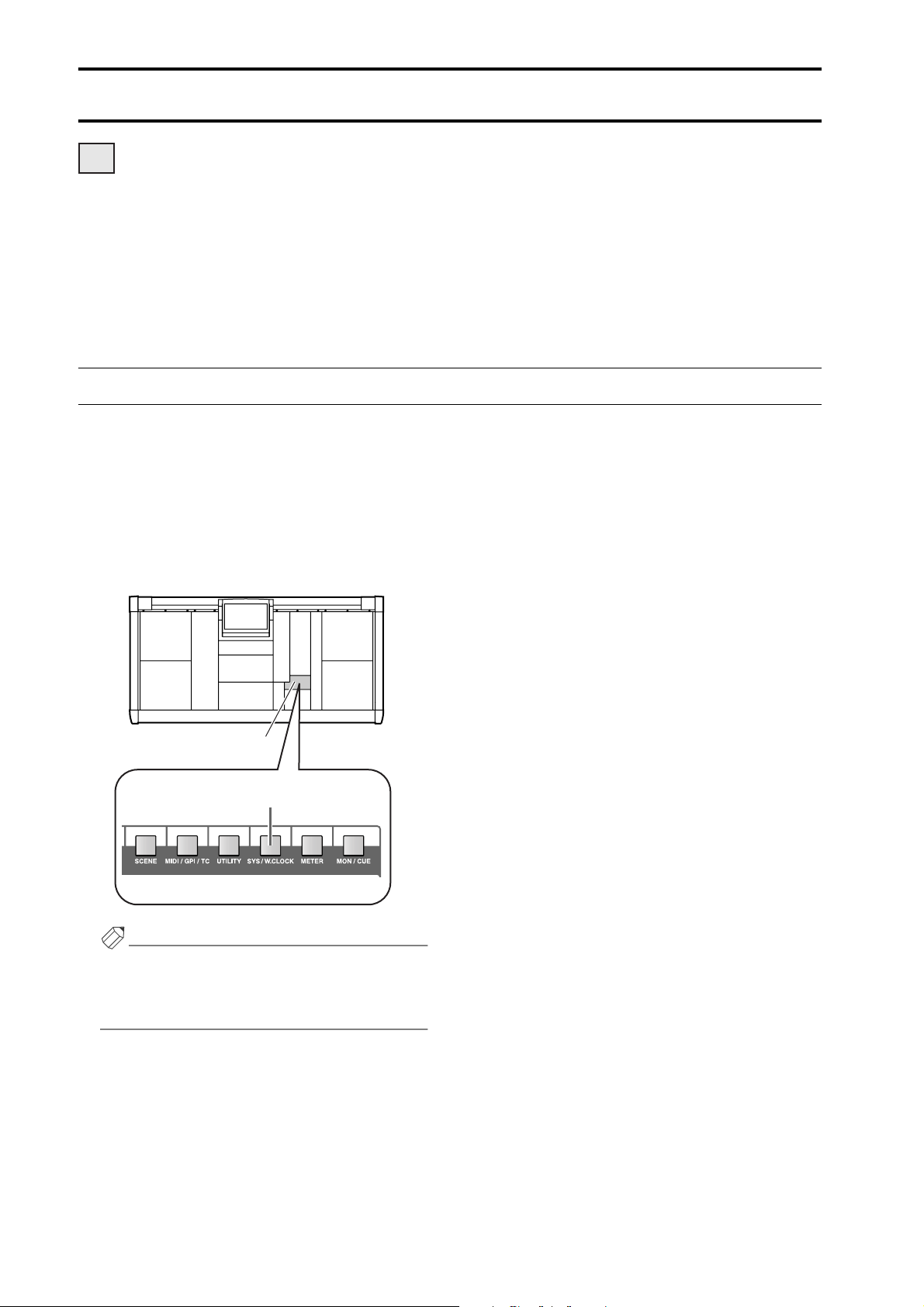

Connecting a digital input/output unit to the engines (Mirror mode)

The following diagram shows the usual method of connecting the engines to a digital input/output unit in Mirror mode.

WORD

CLOCK IN

ENGINE A

INPUT 1

(DSP1D-EX{DSP1D})

OUTPUT 1

OUTPUT A INPUT A

DIO8 (ID=1)

OUTPUT B INPUT B

ENGINE B

(DSP1D-EX{DSP1D})

INPUT 1 OUTPUT 1

When using a DIO8 digital input/output unit in Mirror

mode, only the input/output cards installed in slots 1–4

can be used.

Connect the OUTPUT A connector of the DIO8 digital

input/output unit to one of the INPUT 1–10 connectors

of engine A, and connect the OUTPUT B connector to

an INPUT 1–10 connector of engine B. In the same way,

connect the INPUT A connector of the DIO8 to one of

the OUTPUT 1–6 connectors of engine A, and connect

the INPUT B connector to an OUTPUT 1–6 connector

of engine B.

•

In Mirror mode, INPUT connectors A and B of the

DIO8 must be connected to the identically-numbered OUTPUT connector of engines A and B. Similarly, OUTPUT connectors A and B of the DIO8

must be connected to the identically-numbered

INPUT connector of engines A and B.

•

Be aware that if differently-numbered connectors are

used, the content of the input and output signals will

change when you switch between engines A and B.

WORD

CLOCK IN

WORD

CLOCK IN

•

•

Clock Generator

When using the system in mirror mode, set the

DIO8’s front panel PORT B SELECTOR switch to 5–