Page 1

Page 2

Page 3

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and data for the

XVS650A 2004. For complete service information procedures it is necessary to use this Supplementary Service Manual together with the following manual.

XVS650 ’97 SERVICE MANUAL: 4VR-AE1

XVS650A ’98 SUPPLEMENTARY SERVICE MANUAL: 5BN4-AE1

XVS650A 2001 SUPPLEMENTARY SERVICE MANUAL: 5BN4-AE2

XVS650A 2004

SUPPLEMENTARY

SERVICE MANUAL

E2003 by Yamaha Motor Co., Ltd.

First Edition, October 2003

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Page 4

EAS00002

NOTICE

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha vehicles

should have a basic understanding of mechanics and the techniques to repair these types of vehicles.

Repair and maintenance work attempted by anyone without this knowledge is likely to render the vehicle unsafe and unfit for use.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and

will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

EAS00004

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

WARNING

CAUTION:

NOTE: A NOTE provides key information to make procedures easier or clearer.

Failure to follow WARNING instructions could result in severe injury or death

the motorcycle operator, a bystander or a person checking or repairing the motorcycle.

A CAUTION indicates special precautions that must be taken to avoid damage

to the motorcycle.

to

Page 5

EB002000

HOW TO USE THIS MANUAL

MANUAL ORGANIZATION

This manual consists of chapters for the main categories of subjects. (See “Illustrated symbols”)

1st title

2nd title

3rd title

EXPLODED DIAGRAMS

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal and disassembly section.

1. An easy-to-see exploded diagram

2. Numbers

3. An explanation of jobs and notes is presented in an easy-to-read way by the use of symbol marks

4. A job instruction chart

5. For jobs requiring more information, the step-by-step format supplements

1

: This is the title of the chapter with its symbol in the upper right comer of each page.

2

: This title indicates the section of the chapter and only appears on the first page of each

section. It is located in the upper left comer of the page.

3

: This title indicates a sub-section that is followed by step-by-step procedures accompa-

nied by corresponding illustrations.

4

is provided for removal and disassembly jobs.

5

are given in the order of the jobs in the exploded diagram. A number that is enclosed by

a circle indicates a disassembly step.

6

. The meanings of the symbol marks are given on the next page.

7

accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc.

the exploded diagram and the job instruction chart.

8

are given in addition to

1

2

5

4

7

6

3

8

Page 6

EAS0009

1

2

SYMBOLS

The following symbols are not relevant to every

vehicle.

Symbols

3

5

7

4

6

chapter.

General information

1

Specifications

2

Periodic inspections and adjustments

3

Engine

4

Carburation

5

Chassis

6

Electrical

7

Troubleshooting

8

8

1

to 8 indicate the subject of each

11

13

15

17

9

18 19

10

12

14

16

Symbols 9 to 16 indicate the following.

Serviceable with engine mounted

9

10

Filling fluid

11

Lubricant

12

Special tool

13

Tightening torque

14

Wear limit, clearance

15

Engine speed

16

Electrical data

Symbols 17 to 22 in the exploded diagrams indicate the types of lubricants and lubrication

points.

20

23 24

21 22

17

Engine oil

18

Gear oil

19

Molybdenum disulfide oil

20

Wheel bearing grease

21

Lithium soap base grease

22

Molybdenum disulfide grease

Symbols 23 to 24 in the exploded diagrams indicate the following:

23

Apply locking agent (LOCTITE)

24

Replace the part

Page 7

CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE SPECIFICATIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHASSIS SPECIFICATIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL SPECIFICATIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CABLE ROUTING 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC MAINTENANCE / LUBRICATION INTERVALS 18. . . . . . . . . .

ENGINE

ENGINE REMOVAL 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIDESTAND AND CRANKCASE COVER (LEFT) 20. . . . . . . . . . . . . .

CARBURETION

CARBURETOR 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL

SWITCH INSPECTION 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWITCH CONTINUITY INSPECTION 24. . . . . . . . . . . . . . . . . . . . . . . .

CHECKING THE LED 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMMOBILIZER SYSTEM 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM DIAGRAM 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CIRCUIT DIAGRAM 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KEY ID REGISTRATION METHOD 30. . . . . . . . . . . . . . . . . . . . . . . . . . .

SELF-DIAGNOSIS ERROR CODE INDICATION 32. . . . . . . . . . . . . . .

TROUBLESHOOTING 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING THE IMMOBILIZER SYSTEM 34. . . . . . . . . . . . . . . . . . . .

REPLACEMENT PARTS ON TROUBLES 36. . . . . . . . . . . . . . . . . . . . .

XVS650A 2004 WIRING DIAGRAM

Page 8

Page 9

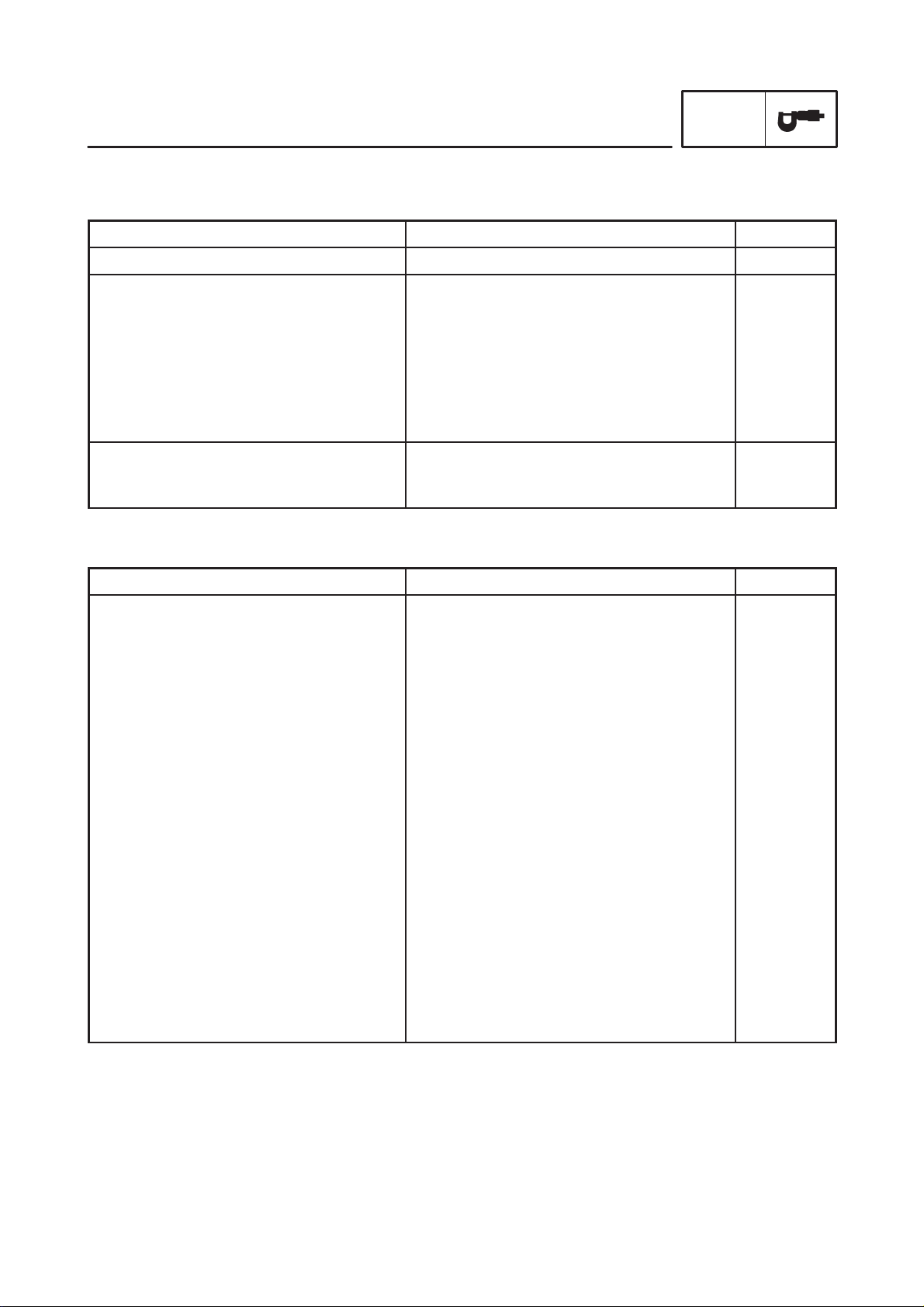

GENERAL SPECIFICATIONS/ENGINE SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Item Standard Limit

SPEC

Model code 5SCE/5SCK

Dimensions

Overall length

Overall width

Overall height

Seat height

Wheelbase

Minimum ground clearance

Minimum turning radius

Weight

Wet (with oil and a full fuel tank)

Maximum load (except motorcycle)

2,450 mm (96.5 in)

930 mm (36.6 in)

1,105 mm (43.5 in)

710 mm (28.0 in)

1,625 mm (64.0 in)

140 mm (5.5 in)

3,500 mm (137.8 in)

249 kg (549 lb)

198 kg (437 lb)

ENGINE SPECIFICATIONS

Item Standard Limit

Carburetor

I.D. mark

Main jet (M.J)

Main air jet (M.A.J)

Jet needle (J.N)

Needle jet (N.J)

Pilot air jet (P.A.J.1)

Pilot outlet (P.O)

Pilot jet (P.J)

Bypass 1 (B.P.1)

Bypass 2 (B.P.2)

Bypass 3 (B.P.3)

Pilot screw (P.S)

Valve seat size (V.S)

Starter jet (G.S.1)

Strater jet (G.S.2)

Throttle valve size (Th. V)

Fuel level (F.L)

Engine idle speed

Intake vacuum

Engine oil temperature

5SCE 00 (5SCE)

5SCK 10 (5SCK)

#91.3

#50

4CT5-2

O-4M

#100

0.85

#20

0.8

0.8

0.8

2-1/ 2

1.0

#17.5

0.9

#140

7.5 X 8.5 mm (0.30 X 0.33 in)

1,150 X 1,250 r/ min

29.3 kPa (0.30 kg/ cm

80 X 90 _C (176 X 194 _F)

2

, 220 mmHg)

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

–1–

Page 10

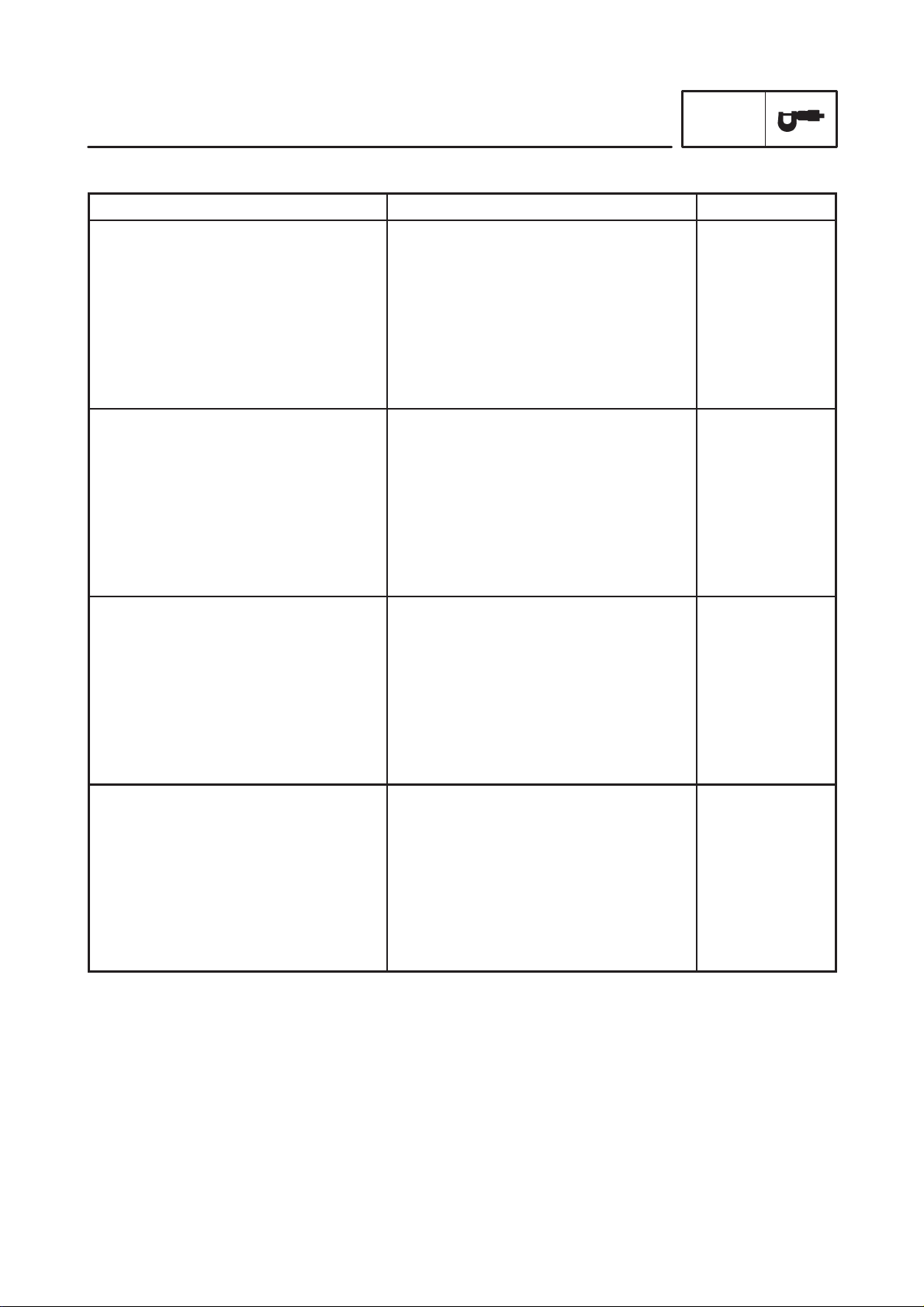

CHASSIS SPECIFICATIONS

Item Standard Limit

Front wheel

Wheel type

Rim

Size

Material

Wheel travel

Wheel runout

Max. radial wheel runout

Max. lateral wheel runout

Rear wheel

Wheel type

Rim

Size

Material

Wheel travel

Wheel runout

Max. radial wheel runout

Max. lateral wheel runout

CHASSIS SPECIFICATIONS

Spoke wheel

16 M/ C MT3.00

Steel

140 mm (5.51 in)

SSS

SSS

Spoke wheel

15 M/ C MT3.50

Steel

98 mm (3.86 in)

SSS

SSS

SPEC

SSS

SSS

SSS

SSS

1 mm (0.04 in)

0.5 mm (0.02 in)

SSS

SSS

SSS

SSS

1mm (0.04 in)

0.5 mm (0.02 in)

Front tire

Tire type

Size

Model (manufacturer)

Tire pressure (cold)

0 X 90 kg (0 X 198 lb)

90 X 198 kg (198 X 437 lb)

Min. tire tread depth

Rear tire

Tire type

Size

Model (manufacturer)

Tire pressure (cold)

0 X 90 kg (0 X 198 lb)

90 X 198 kg (198 X 437 lb)

Min. tire tread depth

With tube

130/ 90-16M/C 67S

G703 (BRIDGESTONE)

D404F (DUNLOP)

225 kPa (2.25 kgf/cm

225 kPa (2.25 kgf/cm

SSS

With tube

170/ 180-15M/C 77S

G702 (BRIDGESTONE)

D404G (DUNLOP)

225 kPa (2.25 kgf/cm

250 kPa (2.5 kgf/ cm

SSS

2

, 2.25 bar, 33 psi)

2

, 2.25 bar, 33 psi)

2

, 2.25 bar, 33 psi)

2

, 2.5 bar, 36 psi)

SSS

SSS

SSS

SSS

SSS

SSS

1.6 mm (0.06 in)

SSS

SSS

SSS

SSS

SSS

SSS

1.6 mm (0.06 in)

–2–

Page 11

CHASSIS SPECIFICATIONS/

ELECTRICAL SPECIFICATIONS

Item Standard Limit

Brake lever & brake pedal:

Brake lever free play (at pivot)

Brake lever free play (at lever end)

Brake pedal position

Brake pedal free play

Clutch lever free play (at pivot)

Clutch lever free play (at lever end)

1 X 2 mm (0.04 X 0.08 in)

10 X 15 mm (0.39 X 0.59 in)

108 mm (4.25 in)

20 X 30 mm (0.79 X 1.18 in)

2 X 3 mm (0.08 X 0.12 in)

5 X 10 mm (0.20 X 0.39 in)

ELECTRICAL SPECIFICATIONS

Item Standard Limit

T.C.I.

Pickup coil resistance/ color

T.C.I. unit model/ manufacturer

Headlight relay

Model (manufacture)

Coil resistance

189 X 231 Ω at 20_C (68_F)/ GrayBlack

J4T150/ MITSUBISHI (5SCE)

J4T151/ MITSUBISHI (5SCK)

ACA12115-1 (MATSUSHITA)

72 X 88 Ω at 20_C (68_F)

SPEC

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

Thermo switch

Model (manufacture)

Fuel pump relay

Model/ manufacturer

Circuit breaker

Type

Amperage for individual circuit

MAIN

HEADLIGHT

SIGNALS

IGNITION

PARKING LIGHT

CARBURETOR HEATER

Reserve

Reserve

Reserve

Reserve

Indicatior light

Immobilizer system indicator light

5FU (NIPPON THERMOSTAT)

UC-Z61B/ MITSUBISHI

Fuse

30 A 1

15 A 1

10 A 1

10 A 1

10 A 1

15 A 1

30 A 1

15 A 1

10 A 1

5 A 1

LED 1

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

SSS

–3–

Page 12

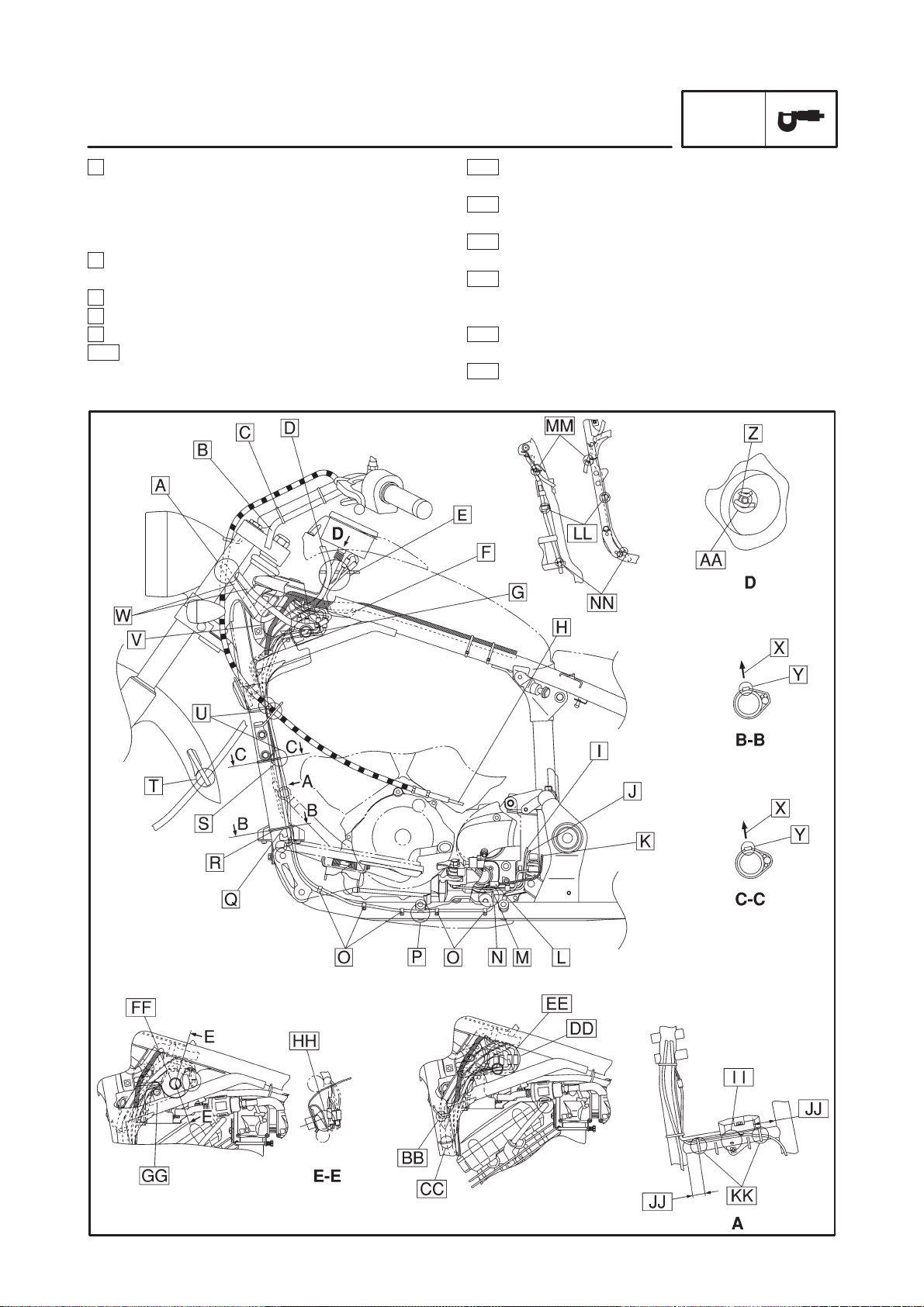

CABLE ROUTING

CABLE ROUTING

SPEC

1 Clutch cable

2 Fuel tank breather hose

3 Left handlebar switch lead

4 Speedometer

5 Speedometer lead

6 Speed sensor

7 Rectifier/ regulator

8 Rear brake light switch lead

9 Speedometer cable

10 Sidestand switch lead

11 Horn

12 Head pipe cover

13 Headlight lead

14 Right handlebar switch lead

15 Vacuum chamber air vent hose

16 Frame

17 Immobilizer

18 Main switch lead

19 Immobilizer lead

20 Fuel pump and ignition coil

bracket

21 Spark plug lead

22 Fuel hose

23 Fuel pump lead

24 Rectifier/ regulator lead

25 Sheet 1

26 Flap

–4–

Page 13

CABLE ROUTING

SPEC

A Pass the front turn signal light leads (left and right)

through the hole of headlight cover from rear side.

B Pass the left handle bar switch lead through behind

the handle ber upper bracket so that there is no

slack.

C Fasten the left handlebar switch lead to the handle-

bar with a band.

D To install the fuel tank, make sure to install the fuel

tank breather hose so that it is not bent too much.

E Pass the harness and fuel breather hose to be con-

nected to the speedometer cable and speedometer

lead through the hole of fuel tank.

F Pass the harness to be connected to the speedom-

eter lead through under the wire harness.

G Rectifier / regulator lead should not be positioned

higher than the bracket.

H To the engine

I A.C. magneto lead (from the engine)

J Pickup coil lead (from the engine)

K Harness to be connected to the speed sensor (to

the wire harness)

L Push in the coupler inside of the engine lead and

crank case after the coupler is connected so that it

does not come out.

–5–

Page 14

CABLE ROUTING

SPEC

M Pass the speed sensor lead through inside of the

engine lead.

N Pass the side stand switch lead through inside of

the side stand bracket and install so that there is no

adverse slack.

O Hold the side stand switch lead with a plastic clamp.

Any direction of the plastic clamp opening can be

accepted.

P Pass the sidestand switch lead through under the

frame boss.

Q Fasten the rear brake light switch lead, sidestand

switch lead and rectifier/ regulator lead to the frame

with a band.

R Position the band immediately under the T stud.

S Position the band immediately under the frame

boss.

T Pass the speedometer cable through the holder on

the front fender.

U Fasten the rear brake light switch lead, side stand

switch lead and rectifier/ regulator lead to the frame

with a band. They should not contact with the cylinder head cover during routing.

–6–

Page 15

CABLE ROUTING

SPEC

V Position the right handle bar switch lead and head

light switch lead at the outer position of all

harnesses and leads behind the frame head pipe.

Particularly, the right handle bar switch lead should

be positioned at the outermost section.

W Do not cross the handle bar switch lead and head

light lead at the out side of the head pipe cover.

X Inside the frame

Y Position of cutting section

Z Harness to be connected to the speedometer lead

AA Pass the harness and fuel breather hose to be

connected to the speedometer cable and

speedometer lead through the hole of fuel tank.

BB Pass the speedometer cable through the holder

of the frame.

CC Pass the fuel tank beather hose and carburetor

air vent hose through the holder of the frame.

DD Allocate the couplers for all leads behind the

frame head pipe at the rear section.

EE Allocate the coupler to be connected to the rectifi-

er/ regulator lead inside of the vehicle body and

make it not to come out.

FF Pass the flap through the hole of fuel tank stay

and install. (for both right and left sides)

GG Install the sheet 1 so that the lower edge is hidden

by the frame.

–7–

Page 16

CABLE ROUTING

SPEC

HH Position the sheet 1 so that the edge of frame

does not protrude.

II Pass the rear brake light switch lead between the

frame bracket and the rectifier/ regulator.

There should be no catching and slack between

the rectifier/ regulator attaching bracket and the

rear brake light switch lead.

JJ About 30 mm (1.18 in)

KK Fasten the rear brake light switch to the frame

with a band.

LL Clamp the fuel tank breather hose to the frame

with a holder.

MM Pass the speedometer cable through the front

guide.

NN Pass the fuel tank breather hose through the

holder of the frame.

–8–

Page 17

CABLE ROUTING

SPEC

1 Fuse box

2 Battery positive lead

3 Spark plug lead

4 Vacuum chamber air vent hose

5 Starter cable

6 Right handlebar switch lead

7 Throttle cables

8 Brake hose

9 Thermo switch

10 Thermo switch lead

11 Battery cover

12 Battery

13 Turn signal relay

14 Starter relay

15 Carburetor heater

16 Headlight relay

17 Frame bracket

18 Starting circuit cut-off relay

19 Ignitor unit

20 Starter motor positive lead

21 Battery negative lead

22 Wire harness

23 Anti-theft alarm lead

24 Rear shock absorber

–9–

Page 18

CABLE ROUTING

SPEC

A Hold the battery negative lead and tail /brake light

lead with a plastic clamp on the battery cover.

B Hold the battery negative lead coupler and

tail/ brake light coupler with a plastic clamp on the

battery cover.

C Pass the harness to be connected to the tail/ brake

light lead and battery negative lead through under

the battery positive lead.

D Clamp the harness to be connected to the starter

relay and the harness to be connected to the fuse

box with a plastic clamp. Any direction of the clamp

can be accepted.

E About 30 mm (1.18 in)

F This lead is connected to the ignition coil.

G Cut section of the band should be positioned under

the handle bar so that there is no contact with the

brake hose.

H Fasten the right handlebar switch lead to the han-

dlebar with a band.

I Route the right handle bar switch lead so that there

is no slack behind the handle bar upper bracket.

J Cross the throttle cables ahead of the wire guide.

K Clamp the grommet of the brake hose at the holder.

L Pass the left handlebar switch lead through over the

main switch.

M Position the left handle bar switch lead coupler

above the immobilizer unit.

–10–

Page 19

CABLE ROUTING

SPEC

N Hold the spark plug lead to the clamp at the end of

the front side protector.

O Pass the harness to be connected to the ignition coil

through inside of the vehicle body and connect it to

the ignition coil.

P Position of cut section

Q Neutral switch lead (from the engine)

R Pickup coil lead (from the engine)

S A.C. magneto lead (from the engine)

T This lead is connected to the speed sensor.

U Battery negative lead (from the engine)

V Starter motor positive lead (from the engine)

W Pass the starter motor positive lead through outside

of the battery negative lead.

X Fasten the pick up coil lead, A.C. magneto lead,

neutral switch lead and starter motor lead to the inside of the frame side bracket with a band.

There should be no contact with the end face of the

side cover 4.

Y Fasten the battery negative lead, starter motor posi-

tive lead, headlight relay lead and starting circuit

cut-off relay lead to the frame bracket with a band.

Z Hold the harness to be connected to the starting cir-

cuit cut-off relay with the clamp on the battery cover.

AA Pass it between the frame and the battery box.

There should be no twisting and prying with the

head light relay and starting circuit cut-off relay

during routing the leads.

–11–

Page 20

CABLE ROUTING

SPEC

BB Hold the headlight relay lead with a plastic clamp.

CC Check that the starting circuit cut-off relay is se-

curely fastened to the battery box after wiring to

the wire harness.

DD Pass it between the frame side bracket and the

battery box. Mud guard should be positioned between the frame side bracket’s end face and the

lead.

EE Hold the harness to be connected to the fuse box

with the clamp on the battery box.

FF Hold the battery positive lead with the battery box

clamp above the starter relay.

GG There should be no contact between the carbure-

tor heater relay and the wire harness.

HH Fasten the headlight relay lead and starting cir-

cuit cut-off relay lead to the frame with a band.

II Fasten the wire harness and engine lead.

JJ There should be no contact between the wire har-

ness and engine lead and the rear shock absorber.

KK To the starter relay

LL To the turn signal relay

MM To the rear fender

NN To the battery negative lead

OO Pass the harness to be connected to the igniter

unit through the hole of battery box.

PP To the carburetor heater relay

–12–

Page 21

CABLE ROUTING

SPEC

QQ Hold the wire harness and engine lead with a

plastic clamp.

RR Within 10 mm (0.39 in)

SS Fasten the wire harness and engine lead to the

frame under the wire harness junction with a

band.

TT Clamp the wire harness. Make sure to insert the

clamp to the hole of frame. Securely tighten up

the clamp at the marked point of the wire harness.

UU Fasten the starter cable to the frame tank rail with

a band.

VV Inner side of the frame in the horizontal direction

of the vehicle body

WW Fasten the anti-theft alarm harness and battery

positive lead with the battery band.

XX Push in the anti-theft alarm couplers in one

bundle to the battery box. Route the wire harness

and couplers so that they are not caught by the

end face of the side cover.

YY Clamp the brake hose at the holder.

–13–

Page 22

1 Throttle cables

2 Brake hose

3 Right handlebar switch lead

4 Clutch cable

5 Left handlebar switch lead

6 Front turn signal light (left)

7 Front turn signal light (right)

8 Rectifier/ regulator lead coupler

9 Spark plug lead

10 Ignition coil

11 Silencer

12 Wire harness

13 Frame

14 Air filer case

CABLE ROUTING

SPEC

–14–

Page 23

CABLE ROUTING

SPEC

A Cross the left handlebar switch lead and right han-

dlebar switch lead ahead of the head pipe.

Pass the left handlebar switch lead through outside

of the right handlebar switch lead during routing.

B Hold the handlebar switch leads (right and left) with

a plastic clamp. Make sure to fit the clamp pawl for 4

notches.

C Pass the throttle cable from the top side of the hold-

er located under the handlebar upper bracket.

D Fuel breather hose (to the fuel tank)

E Starter cable (to the carburetor)

F Harness to be connected to the throttle position

sensor

G Pass the starter cable between the ignition coil and

the spark plug lead and route it along the concave

on the cylinder head cover.

H Solenoid valve lead (from the carburetor)

I Position the solenoid valve lead between the igni-

tion coil and the heat resistant sheet pasted on the

cylinder head cover.

J There should be nothing located under the wire har-

ness such as a coupler (of the fuel sender lead).

–15–

Page 24

CABLE ROUTING

SPEC

K Pass the neutral switch lead, pick up coil lead, A.C.

magneto lead and fuel sender lead through under

the harness to be connected to the ignition coil and

position it above the heat resistant sheet pasted on

the cylinder head cover (Position the couplers so

that they do not contact with the rear side edge section behind the ignition coil.).

L Harness to be connected to the fuel sender lead (to

the fuel tank)

M Neutral switch lead (from the engine)

N Pick up coil lead (from the engine)

O A.C. magneto lead (from the engine)

P 40 to 50 mm (1.57 to 1.97 in)

Q About 20 mm (0.79 in) from the bottom of frame’s R

R Pass the thermo switch lead through inside of the si-

lencer breather pipe and connect it to the wire harness.

S There should be no slack with the wire harness.

T Harness to be connected to the speedometer lead

U Pass a band through the gusset hole and clamp the

wire harness. Position the fastened section of the

band on the gusset. (Cut off the excessive part.)

V Frame side in the horizontal direction of the vehicle

body

W Fasten the wire harness to the tank rail wire a band.

X Position of cut section

Y Position it lower than the frame top face.

Z Set in the wire harness between the concave of the

air filter case and the frame.

–16–

Page 25

AA Harness to be connected to the speedometer

lead

BB Speedometer cable (to the fuel tank)

CC Fuel tank breather hose (to the fuel tank)

CABLE ROUTING

SPEC

–17–

Page 26

INTRODUCTION/PERIODIC MAINTENANCE/

No.ITEM

CHECKS OR MAINTENANCE JOB

g

5

Air filter element

7*Front brake

8*Rear brake

9*Brake hose

13*Swingarm

14*Steering bearings

LUBRIATION INTERVALS

EB300000

INSP

ADJ

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and longer service life. The need for costly overhaul work will be greatly reduced. This information

applies to vehicles already in service as well as to new vehicles that are being prepared for sale. All

service technicians should be familiar with this entire chapter.

NOTE:

D The annual checks must be performed every year, except if a kilometer-based maintenance

is performed instead.

D From 50,000 km, repeat the maintenance intervals starting from 10,000 km.

D Items marked with an asterisk should be performed by a Yamaha dealer as they require special

tools, data and technical skills.

EB301000

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

ODOMETER READING ( 1,000 km)

1 10 20 30 40

1 * Fuel line D Check fuel hoses for cracks or damage. √ √ √ √ √

2 * Fuel filter D Check condition. √ √

D Check condition.

3 Spark plugs

4 * Valves

6 Clutch

*

*

*

10 * Wheels

11 * Tires

12 * Wheel bearings D Check bearing for looseness or damage. √ √ √ √

*

*

15 * Chassis fasteners D Make sure that all nuts, bolts and screws are properly tightened. √ √ √ √ √

16 Sidestand

17 * Sidestand switch D Check operation. √ √ √ √ √ √

18 * Front fork D Check operation and for oil leakage. √ √ √ √

Shock absorber

19 *

assembly

20 * Carburetors

21 Engine oil

D Clean and regap.

D Replace. √ √

D Check valve clearance.

D Adjust.

D Clean. √ √

D Replace. √ √

D Check operation.

D Adjust.

D Check operation, fluid level and vehicle for fluid leakage. √ √ √ √ √ √

D Replace brake pads. Whenever worn to the limit

D Check operation and adjust brake pedal freeplay. √ √ √ √ √ √

D Replace brake shoes. Whenever worn to the limit

D Check for cracks or damage. √ √ √ √ √

D Replace. Every 4 years

D Check runout, spoke tightness and for damage.

D Tighten spokes if necessary.

D Check tread depth and for damage.

D Replace if necessary.

D Check air pressure.

D Correct if necessary.

D Check operation and for excessive play. √ √ √ √

D Lubricate with lithium-soap-based grease. Every 50,000 km

D Check bearing play and steering for roughness. √ √ √ √ √

D Lubricate with lithium-soap-based grease. Every 20,000 km

D Check operation.

D Lubricate.

D Check operation and shock absorber for oil leakage. √ √ √ √

D Check starter (choke) operation.

D Adjust engine idling speed and synchronization.

D Change.

D Check oil level and vehicle for oil leakage.

√ √

√ √ √ √

√ √ √ √ √

√ √ √ √

√ √ √ √

√ √ √ √ √

√ √ √ √ √ √

√ √ √ √ √ √

ANNUAL

CHECK

–18–

Page 27

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

NO.ITEM

CHECKS OR MAINTENANCE JOB

23

Final gear oil

INSP

ADJ

Engine oil filter

22

element

Front and rear brake

24 *

switches

Moving parts and

25

cables

Throttle grip housing

26 *

and cable

Muffler and exhaust

27 *

pipe

Lights, signals and

28 *

switches

ODOMETER READING (x 1,000 km)

1 10 20 30 40

D Replace. √ √ √

D Check oil level and vehicle for oil leakage. √ √ √

D Change. √ √ √

D Check operation. √ √ √ √ √ √

D Lubricate. √ √ √ √ √

D Check operation and free play.

D Adjust the throttle cable free play if necessary.

D Lubricate the throttle grip housing and cable.

D Check the screw clamp for looseness. √ √ √ √ √

D Check operation.

D Adjust headlight beam.

√ √ √ √ √

√ √ √ √ √ √

ANNUAL

CHECK

NOTE:

D The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

D Hydraulic brake service

S Regularly check and, if necessary, correct the brake fluid level.

S Every two years replace the internal components of the brake master cylinder and caliper, and

change the brake fluid.

S Replace the brake hoses every four years and if cracked or damaged.

–19–

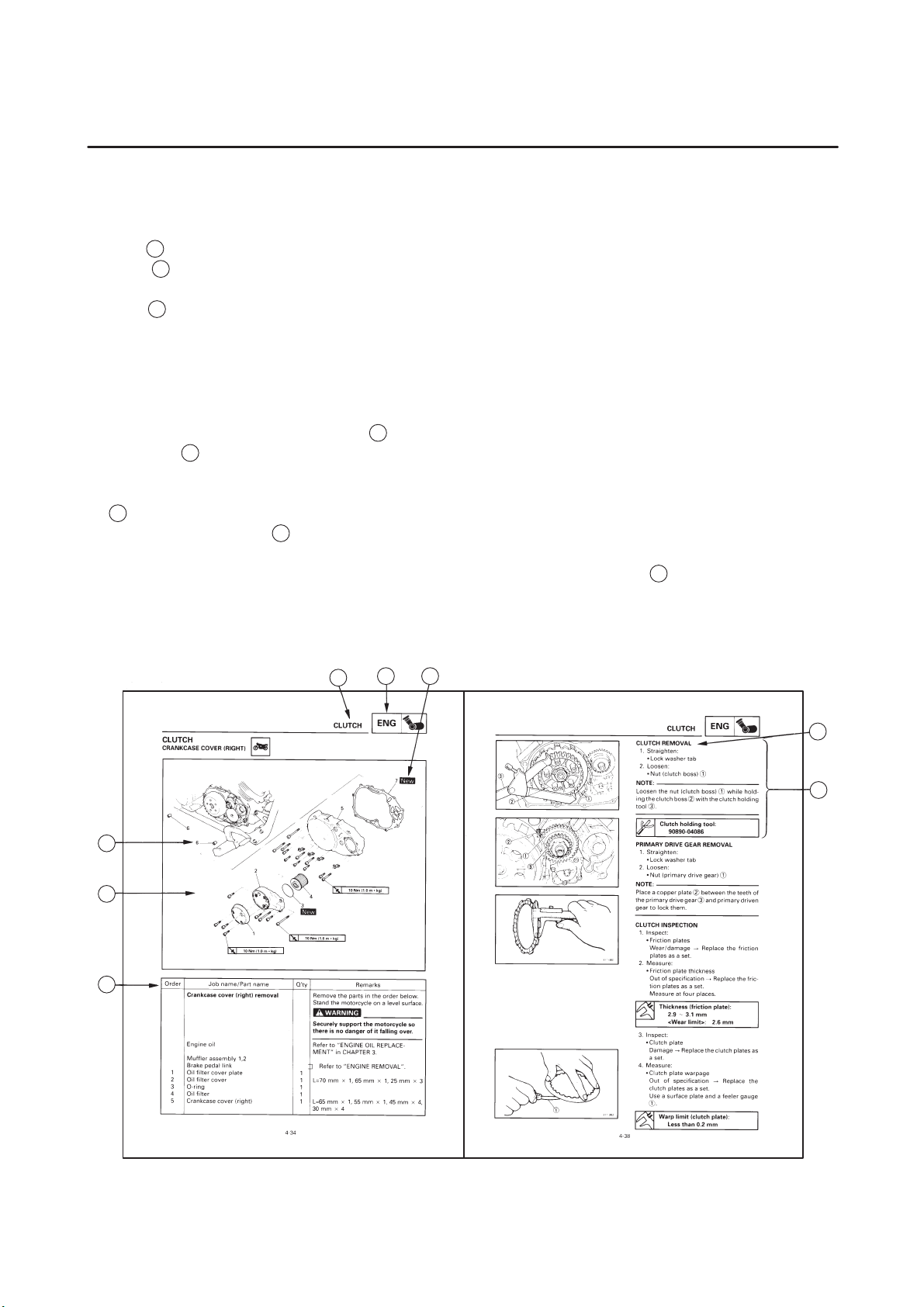

Page 28

ENGINE

ENGINE REMOVAL

SIDESTAND AND CRANKCASE COVER (LEFT)

ENGINE REMOVAL

ENG

64 Nm (6.4 mSkg, 46 ftSlb)

30 Nm (3.0 mSkg, 22 ftSlb)

13 Nm (1.3 mSkg, 9.4 ftSlb)

Order Job name/ Part name Q’ty Remarks

Side stand and crankcase cover

(left) removal

Engine oil

Side cover (left)

1

Middle gear case cover

2

Middle gear case cover stay

3

Sidestand assembly

4

Shift pedal/ footrest (left)

5

Clutch cable

6

Neutral switch lead

7

Crankcase cover (left)/ gasket

8

Dowel pins

9

10

Rectifier/ regulator

10 Nm (1.0 mSkg, 7.2 ftSlb)

Remove the parts in the order below.

Drain

Refer to “ENGINE OIL REPLACEMENT”

in CHAPTER 3. (Manual No.: 4VR-AE1)

Do not remove the “:” bolts.

1

1

1

1

Refer to “SHIFT PEDAL INSTALLATION”.

1/1

(Manual No.: 4VR-AE1)

1

1

1/1

2

1

For installation, reverse the removal

procedure.

10 Nm (1.0 mSkg, 7.2 ftSlb)

–20–

Page 29

CARBURETOR

CARBURETOR

CARBURETION

CARB

Order Job name/ Part name Q’ty Remarks

1

2

3

4

5

6

7

8

9

10

11

Carburetor removal

Fuel tank

Air filter case assembly

Air duct

Cylinder head breather hose

Throttle position sensor lead coupler

Thermo switch lead coupler

Fuel cut solenoid valve lead coupler

Fuel hose

Carburetor assembly

Starter cable

Throttle cables

Cover

Remove the parts in the order below.

Refer to “FUEL TANK AND SEATS” in

CHAPTER 3. (Manual No.: 4VR-AE1)

1

1

1

Disconnect

1

1

2

1

1

NOTE:

1

2

After removing the carburetor

assembly, remove the starter cable

and throttle cables.

1

For installation, reverse the removal

procedure.

–21–

Page 30

CARBURETOR

CARB

Order Job name/ Part name Q’ty Remarks

Carburetor disassembly

Disassemble the parts in the order

below.

Carburetor heater lead

10

11

12

1

2

Carburetor heaters 1

3

Carburetor heaters 2

4

Float chamber

5

Float

6

Needle valve set

7

Main jet

8

Jet holder

9

Pilot jet

Jet needle set

Needle jet

Starter plunger set

1

2

2

1

1

1

1

1

1

1

1

1

12V 15W

12V 30W

Refer to “CARBURETOR ASSEMBLY”

in chapter 5. (Manual No.: 4VR-AE1)

–22–

Page 31

CARBURETOR

CARB

Order Job name/ Part name Q’ty Remarks

13

Diaphragm set

1

Refer to “CARBURETOR ASSEMBLY” in

chapter 5. (Manual No.: 4VR-AE1)

14

Throttle position sensor

1

Refer to “THROTTLE POSITION

SENSOR (TPS) INSPECTION AND

ADJUSTMENT” in chapter 5. (Manual

No.: 4VR-AE1)

15

Pilot screw

1

Refer to “CARBURETOR ASSEMBLY” in

chapter 5. (Manual No.: 4VR-AE1)

16

17

18

Main air jet

Washer

Fuel out solenoid

1

2

2

For assembly, reverse the disassembly

procedure.

–23–

Page 32

SWITCH INSPECTION

ELEC

ELECTRICAL

SWITCH INSPECTION

SWITCH CONTINUITY INSPECTION

Refer to “SWITCH INSPECTION” and check for continuity between lead terminals. (Manual No.: 4VR-AE1)

Poor connection, no continuity ! Correct or replace.

: The coupler locations are circled.

–24–

Page 33

SWITCH INSPECTION

ELEC

1 Pass switch

2 Dimmer switch

3 Horn switch

4 Clutch switch

5 Turn signal switch

6 Main switch

7 Front brake switch

8 Engine stop switch

9 Start switch

10 Hazard switch

11 Fuse

12 Rear brake switch

13 Sidestand switch

14 Neutral switch

–25–

Page 34

SWITCH INSPECTION

CHECKING THE LED

The following procedures applies to the LED.

1. Check:

S LED (for proper operation)

Improper operation ! Replace.

a. Disconnect the meter assembly coupler (me-

ter assembly side).

b. Connect two jumper leads

tery terminals to the coupler terminal as

shown.

Battery positive lead ! green/ blue terminal

Battery negative lead ! black terminal

ELEC

1

from the bat-

WARNING

S A wire that is used as a jumper lead must

have at least the same capacity of the battery lead, otherwise the jumper lead may

burn.

S This check is likely to produce sparks,

therefore, make sure no flammable gas or

fluid is in the vicinity.

c. When the jumper leads are connected to the

terminals the respective LED should illuminate.

Does not light ! Replace the meter assembly.

–26–

Page 35

IMMOBILIZER SYSTEM

SYSTEM DIAGRAM

IMMOBILIZER SYSTEM

ELEC

1 MAIN SWITCH AND IMMOBILIZER UNIT

2 IMMOBILIZER SYSTEM INDICATOR LIGHT

3 IGNITOR UNIT

G/L Green/Blue. . . .

Br/ L Brown/ Blue. . .

R Red. . . . . .

R/ G Red /Green. . .

R/ W Red/ White. . .

Y/ L Yellow /Blue. . . .

–27–

Page 36

CIRCUIT DIAGRAM

IMMOBILIZER SYSTEM

ELEC

–28–

3 Immobilizer unit

4 Main switch

5 Fuse (ignition)

6 Fuse (main)

9 Battery

14 Ignitor unit

24 Immobilizer system indicator light

30 Fuse (backup)

Page 37

IMMOBILIZER SYSTEM

GENERAL INFORMATION

S When the main switch is turned “ON” with the registered key, the immobilizer system indicator light

comes on for about 0.5 second and then goes off.

S To check the immobilizer system, follow the steps in the troubleshooting chart.

S To use the immobilizer key, keep it away from other keys. Otherwise, the key code signal may not work

or the correct action may be disturbed.

S The key contains the electronic component (transponder). Do not drop or hit it with a solid metal. Do

not leave it on the dashboard of vehicle where the temperature may rise.

S Do not put it in the water. (when washing clothes for example)

S Do not place it near a magnet or a loud speaker.

S If all keys are missing, the engine control unit (ignitor unit) is required to replace together with the keys

and the immobilizer unit.

S Immobilizer unit cannot be operated with the copy key until the transponder code of the code re-regis-

tering key is registered to the immobilizer unit.

S Total three key codes are registered to the immobilizer unit, which are one code re-registering key

code and two standard key codes.

S Among them, two of standard key codes can be registered to prepare for the case when the key is lost.

To register, the code re-registering key is needed.

ELEC

1. Code re-registering key (red bow)

2. Standard key (black bow)

–29–

Page 38

IMMOBILIZER SYSTEM

KEY ID REGISTRATION METHOD

Initially one code re-registering key and two standard keys have been registered with the immobilizer

system.

In the course of use, you may encounter the following case where re-registration of code re-registering/ standard key is required.

Code re-registering key registration:

When the immobilizer unit or ignitor unit, failed and the unit was replaced, the unit cannot be used until

the key ID is registered because it is not registered to the unit.

a. As usual steps, when the main switch is turned “ON”, the immobilizer system indicator light goes on

for about one second.

b. If the immobilizer system indicator light goes off, it shows that the code re-registering key registra-

tion is finished.

c. Check that the engine can be started.

d. Consequently, carry out the standard key registration, according the section below.

Standard key registration:

ELEC

When you lost a standard key and need a new one. Or when the code re-registering key is re-registered

after the immobilizer unit or the ignitor unit, are replaced.

a. Check that the immobilizer system indicator light shows the standby mode.

To initiate the standby mode, turn “OFF” the main switch and then it will be the standby mode when it

passes 30 seconds. When 24 hours passed, the standby mode ends and the immobilizer system

indicator light stops flashing.

b. After the main switch is turned “ON” with the code re-registering key, within 5 seconds, turn “OFF”

the main switch and then turn “ON” the main switch with the standard key (the first new key) that you

want to register.

c. It becomes the key registration mode and two standard key IDs that have been stored in the memory

are erased and the first new standard key ID will be registered. At this time, the indicator light quickly

blinks (“OFF” for 0.5 sec. and “ON” for 0.5 sec.).

d. In the condition as mentioned above (while the immobilizer system indicator light continues quick

flashing), after the main switch is turned “ON” with the first new standard key, turn “OFF” the main

switch within 5 seconds, and then turn “ON” the main switch with the standard key that you want to

register (which is the second new key or the standard key remained in hand).

NOTE:

Fast flashing goes off when it elapses 5 seconds and the registration mode is finished. In this case, the

second standard key cannot be registered and only the first standard key is registered.

–30–

Page 39

IMMOBILIZER SYSTEM

ELEC

e. When the registration is finished, the immobilizer system indicator light goes off.

f. Check that the engine can be started with the registered two standard keys.

When one

Code re-registering

key

First unregistered

standard key

standard key

is registered.

Flashing ends when it elapses 5 seconds and the

registration for the seconds standard key is impossible.

When two

standard keys

Code re-registering

key

First unregistered

standard key

Second unregistered

standard key.

are registered.

Flashing ends when the registration of the seconds

unregistered standard key is complete.

Important note:

If you lost a standard key, immediately re-register your code re-registering key and the remaining standard key (if any). This will delete the stored registration data, protecting the motorcycle against being

started with the lost key.

–31–

Page 40

IMMOBILIZER SYSTEM

ELEC

SELF-DIAGNOSIS ERROR CODE INDICATION

When the system failure occurred, the error code number is flashed at the immobilizer system indicator

light. The pattern of flashing also shows the error code.

Error code Detection Symptoms Trouble Measures

51 Immobilizer

unit

52 Immobilizer

unit

53 Immobilizer

unit

54 Immobilizer

unit

55 Immobilizer

unit

56 Ignitor unit Undefinition code is re-

Cannot transmit code between the key and immobilizer unit.

Codes do not match between

the key and immobilizer unit.

Cannot transmit code between the ignitor unit and immobilizer unit.

Codes do not match between

ignitor unit and immobilizer

unit.

Key code registration error. Same standard key was attempted

ceived.

1) Objects that may keep off radio

waves exist around the keys and

antennas.

2) Immobilizer unit failure.

3) Key failure.

1) Disturbed by other transponder.

Failed to verify continually for ten

times.

2) Unregistered standard key was

used.

Noise interference or disconnected

lead/ cable.

1) Obstruction due to radio wave

noise.

2) Error by disconnection of the

communication harness.

3) Immobilizer unit failure.

4) Ignitor unit failure.

Noise interference or disconnected

lead/ cable.

1) Obstruction due to radio wave

noise.

2) Error by disconnection of the

communication harness.

3) Immobilizer unit failure.

4) Ignitor unit failure.

(When the used parts from other

vehicles are used, the code reregistering key ID is not registered to the ignitor unit.)

to continuously two times register.

Noise interference or disconnected

lead/ cable.

1) Obstruction due to radio wave

noise.

2) Error by disconnection of the

communication harness.

3) Immobilizer unit failure.

4) Ignitor unit failure.

1) Keep clear of magnets, metals

and other keys from the surroundings of keys and antennas.

2) Replace the immobilizer unit.

3) Replace the key.

1) Place the immobilizer unit away

more than 50 mm from the transponder of other vehicle.

2) Register the standard key.

1) Check the wire harness and connector.

2) Replace the immobilizer unit.

3) Replace the ignitor unit.

1) Register the code re-registering

key ID.

2) Check the wire harness and connector.

3) Replace the immobilizer unit.

4) Replace the ignitor unit.

Prepare the new standard key and

register it.

1) Check the wire harness and connector.

2) Replace the immobilizer unit.

3) Replace the ignitor unit.

Immobilizer system indicator light code indication

Digit of 10 : Cycles of 1 sec. “ON” and 1.5 sec. “OFF”.

Digit of 1 : Cycles of 0.5 sec. “ON” and 0.5 sec. “OFF”.

<Example> 52

Light ON

Light OFF

–32–

Page 41

IMMOBILIZER SYSTEM

ELEC

EAS00794

TROUBLESHOOTING

S When the main switch is turn “ON”, the

immobilizer system indicator light does

not come on or flashing.

Check:

1. main, ignition, and backup fuses

2. battery

3. main switch

4. wiring connections

(of the entire immobilizer system)

NOTE:

S Before troubleshooting, remove the following

part(s):

1. seat

2. fuel tank

3. side cowlings

S Troubleshoot with the following special tool(s).

Pocket tester

90890-03112, YU-3112

EAS00738

1. Main, ignition and backup fuses

S Check the main, ignition and backup fuses

for continuity.

Refer to “FUSE INSPECTION” in chapter 3.

(Manula No.: 4VR-AE1)

S Are the main, ignition and backup fuses OK?

EAS00739

2. Battery

S Check the condition of the battery.

Refer to “BATTERY INSPECTION” in chapter 3. (Manual No.: 4VR-AE1)

Minimum open-circuit voltage

12.8 V or more at 20_C (68_F)

S Is the battery OK?

YES NO

S Clean the battery

terminals.

S Recharge or re-

place the battery.

EAS00749

3. Main switch

S Check the main switch for continuity.

Refer to “SWITCH CONTINUITY INSPECTION”.

S Is the main switch OK?

YES NO

Replace the main

switch.

YES

NO

Replace the fuse(s).

–33–

EAS00787

4. Wiring

S Check the entire immobilizer system’s wir-

ing.

Refer to “CIRCUIT DIAGRAM”.

S Is the immobilizer system’s wiring properly

connected and without defects?

YES NO

Check the condition

of each of the immobilizer system’s cir-

Properly connect or

repair the immobiliz-

er system’s wiring.

cuits.

Refer to “CHECKING

THE IMMOBILIZER

SYSTEM”.

Page 42

IMMOBILIZER SYSTEM

ELEC

EAS00788

CHECKING THE IMMOBILIZER SYSTEM

1. The immobilizer system indicator light

does not come on.

1. Immobilizer system indicator light (LED)

S Check the immobilizer system indicator light

continuity.

Refer to “CHECKING THE LED”.

S Are the immobilizer system indicator light

(LED) OK?

YES NO

Replace the meter

assembly.

2. Voltage

3. Wiring

S Disconnect the meter coupler and immobi-

lizer unit coupler.

S Check the immobilizer system indicator light

lead (green/ blue) continuity.

(meter coupler – immobilizer unit coupler).

S Is the immobilizer system indicator light lead

OK?

YES NO

Replace the immobilizer unit.

The wiring circuit

from the meter to immobilizer unit is

faulty and must be

repaired.

S Connect the pocket tester (DC 20 V) to the

immobilizer unit coupler as shown.

Positive tester probe !

red/ white or red /green

Negative tester probe ! black

S Turn the main switch to “ON”.

S Measure the voltage (DC 12 V) on the immo-

bilizer unit coupler (wire harness side).

S Is the voltage within specification?

YES NO

1

3

2

The wiring circuit

from the main switch

to the immobilizer

unit coupler is faulty

and must be repaired.

–34–

Page 43

IMMOBILIZER SYSTEM

ELEC

2. When the main switch is turned “ON”, the immobilizer system indicator light is flashing.

S Check if the metallic obstacle or the transponder of other vehicle exists near the immobilizer unit. If

it exists, eliminate it and recheck the condition.

Turn “ON” the main switch with another

standard key and check the immobilizer system indicator light. The immobilizer system indicator light goes on for

about one second and then goes off.

Failure

Correct

First standard key (Transponder) defective

Turn “ON” the main switch with code

re-registering key and check the immobilizer system indicator light.

Failure

Check the self-diagnosis code indication.

No indication

Immobilizer Unit failure or ignitor unit

failure

Correct

Indicated

Two standard

keys (Transponder) defective

Read the error code and inspect the

corresponding part.

Refer to “SELF-DIAGNOSIS ERROR

CODE INDICATION”.

Resister

again

Failure

Replace

the key

Check the signal lead (yellow/ blue)

between the immobilizer unit and ignitor unit connector.

Correct

Replace the immobilizer unit.

Failure

Yellow/blue lead is disconnected or

short-circuited. Repair or replace the

circuit.

–35–

Page 44

IMMOBILIZER SYSTEM

ELEC

REPLACEMENT PARTS ON TROUBLES

Replacement parts

Transponder Key

When standard key is missing

and the replace standard key

is required

All keys have been lost (including code re-registering key)

Ignitor unit is defective f

When the immobilizer

unit is defective

When the main switch is

defective

When the accessory lock is

defective

*1There is no parts setting as a single unit. It will be the replacement in a set with the IMMOBILIZER UNIT.

f

f f f f f

f f f f f

Immobilizer

Unit

f

Ignitor

unit

*1Main

Switch

*2Accessory

Lock And Key

f

*2Accessory lock means the seat lock, fuel filler cap or the helmet holder.

NOTE:

S To replace the single unit of ignitor unit, first turn “ON” the main switch with the code re-registering key.

This operation allows the code re-registering key ID to be registered to the new ignitor unit. Register

the standard key subsequently.

S To replace the single unit of immobilizer unit, first turn “ON” the main switch with the code re-register-

ing key. This operation allows the code re-registering key ID to be registered to the new immobilizer

unit. Register the standard key subsequently.

–36–

Page 45

Page 46

Page 47

XVS650A 2004 WIRING DIAGRAM

1 A.C. magneto

2 Rectifier/ regulator

3 Immobilizer unit

4 Main switch

5 Fuse (ignition)

6 Fuse (main)

7 Starter relay

8 Starter motor

9 Battery

10 Starting circuit cut-off relay

11 Fuel pump

12 Sidestand switch

13 Throttle position sensor

14 Ignitor unit

15 Ignition coil #1

16 Ignition coil #2

17 Spark plug

18 Fuel cut solenoid 1

19 Fuel cut solenoid 2

20 Pickup coil

21 Meter assembly

22 Engine trouble warning light

23 Neutral indicator light

24 Immobilizer system indicator

light

25 Turn signal indicator light

26 High beam indicator light

27 Meter light

28 Neutral switch

29 Anti- theft alarm (option)

30 Fuse (backup)

31 Fuse (headlight)

32 Fuse (signal)

33 Fuse (ignitor)

34 Fuse (park)

35 Fuse (carburetor heater)

36 Right handlebar switch

37 Front brake light switch

38 Hazard switch

39 Engine stop switch

40 Start switch

41 Rear brake light switch

42 Headlight relay

43 Horn

44 Turn signal relay

45 Left handlebar switch

46 Pass switch

47 Dimmer switch

48 Horn switch

49 Clutch switch

50 Turn signal switch

51 Rear turn signal light (right)

52 Rear turn signal light (left)

53 Front turn signal light (right)

54 Front turn signal light (left)

55 Headlight

56 Auxiliary light

57 Tail/brake light

58 Thermo switch

59 Carburetor heater relay

(option)

60 Carburetor heater (option)

61 Carburetor heater

62 Carburetor heater ground

B Black. . . . .

Br Brown. . . .

Ch Chocolate. . .

Dg Dark green. . .

G Green. . . .

Gy Gray. . .

L Blue. . . . .

Lg Light green. . . .

O Orange. . . .

P Pink. . . . .

R Red. . . . .

Sb Sky blue. . . .

W White. . . .

Y Yellow. . . . .

B/ L Black / Blue. . .

B/ W Black /White. .

B/ Y Black/ Yellow. .

Br/ B Brown/ Black. .

Br/ L Brown/ Blue. .

Br/ W Brown /White.

Br/ Y Brown/ Yellow. .

G/ Y Green/ Yellow. .

L/ B Blue / Black. . .

L/ R Blue /Red. .

L/ W Blue /White. .

L/ Y Blue / Yellow. . .

R/ B Red/ Black. .

R/ W Red/ White. .

R/ Y Red/ Yellow. .

Loading...

Loading...