Page 1

PEDAL TIMPANI

TIMBALE À PÉDALE

TIMBAL DE PEDAL

踏板定音鼓

TP-6220 /23 /26 /29 /32

TP-4223 /26 /29 /32

TP-5020(G/H) /23 (G/H) /26 (G/H) /29 (G/H) /32 (G/H)

TP-7020(H) /23(H) /26(H) /29(H) /32(H)

TP-7220 / 23 / 26 / 29 / 32

Owner’s Manual

Mode d’emploi

Manual de Instrucciones

用户手册

English

Français

Español

中国语

Page 2

Thank you for selecting a Yamaha musical instrument.

We are confident that the instrument will bring you years of musical

enjoyment and satisfaction. Please read through this booklet carefully. It contains important information about your instrument's care.

Your new Yamaha instrument, like all Yamaha musical instruments,

is the result of careful planning, testing and assembly using select

materials. Proper care will ensure that your Yamaha instrument will

deliver its full and rich sound for years to come.

When using the pedal timpani for the first time after unpacking, make

sure to set it up according to the instructions of section “Before Using

The Pedal Timpani” on pages 4 and 5.

PRECAUTIONS

• Fully depress the heel of the tuning pedal after use.

• Protect the head from heat, moisture, oil, and dust. Use a soft cloth to remove

dust and other foreign matter from the head surface, and cover the head with

the head protector when not in use.

• When using plastic heads such as the one initially supplied, loosening of the

head after use is not required.

• The kettle is very sensitive to shock and must not be bumped against another

object. Also, do not forget to remove dirt using a polishing cloth from time to

time.

2

Page 3

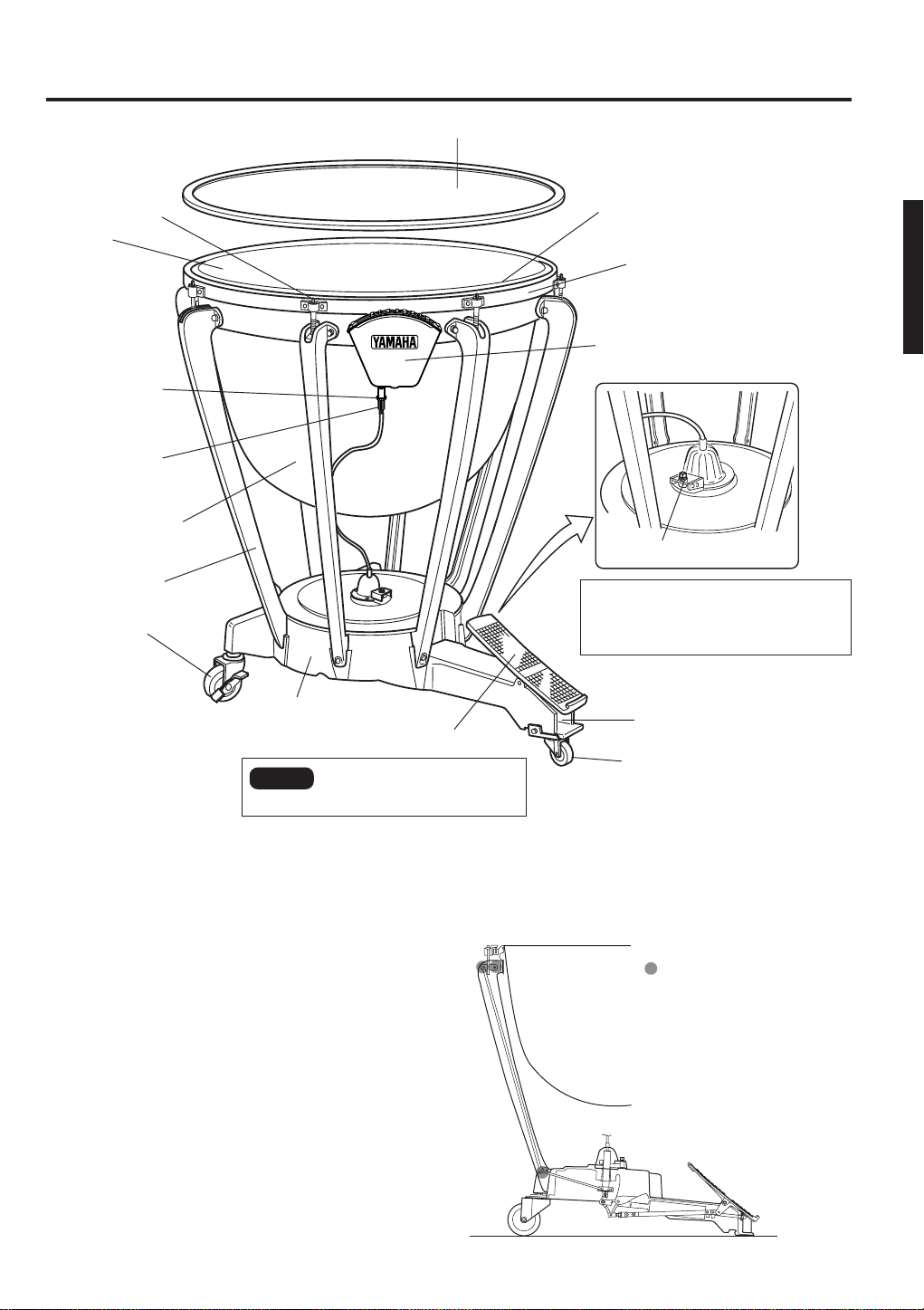

Nomenclature & Lubrication

Head Protector

Tuning Bolt

Head

Pointer Lock Nut

Pointer

Adjustment Knob

Kettle

Strut

Caster

Base

Caution

Tuning Pedal

Never put your hands etc.

under the pedal.

Kettle Edge

Hoop

(Counter Hoop)

Tuning Indicator (Tuning Gauge)

PAC Adjustment Bolt

The TP-50xx (H/G) / TP-70xx (H)

series use a wing bolt on the

PAC adjustment system.

Spring Tension

Adjustment Bolt

Third Wheel

(removable)

● Lubrication

Lubricate the moving parts of the tuning mechanism

as shown in the diagram.

This should be done at least once a year, or as

needed.

* The illustrations on this page show a pedal timpani of the

TP-6200 series.

Points of lubrication

3

Page 4

Before Using The Pedal Timpani

Your Yamaha pedal timpani is equipped with a plastic head carefully mounted and tuned

(adjusted to a note) at the factory, and thus can be used after setup immediately. However,

new heads will tend to stretch gradually during shipping and storage, resulting in a tuning

deviation when you receive the instrument. Therefore, please perform the steps below to

restore the tuning to the factory setting prior to shipment:

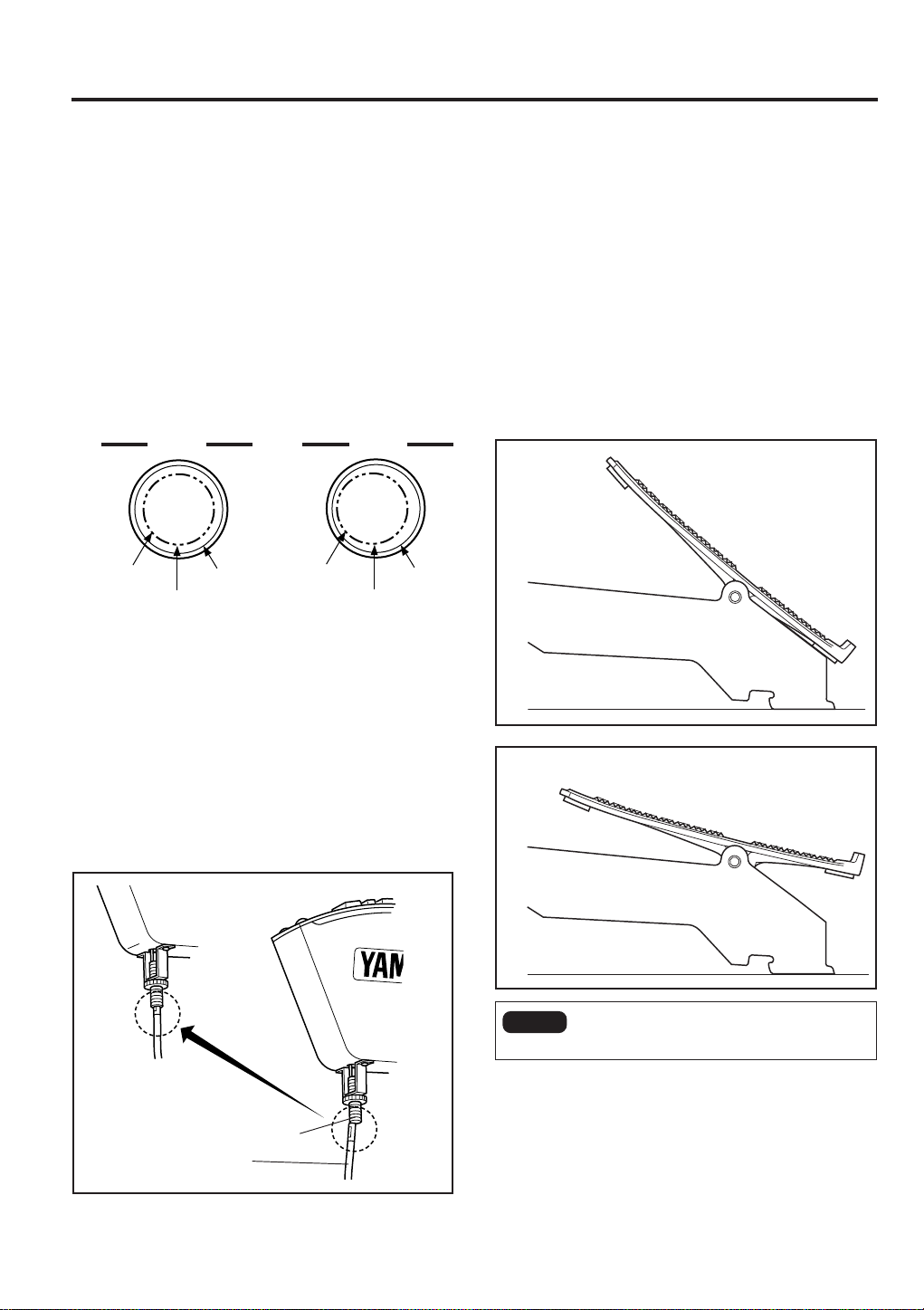

1 The area between the kettle edge and the inner

circle of the counter hoop is called the collar.

Please make sure that the width of this collar is

uniform, as shown in the illustration titled “Correct”.

Kettle

edge

Wrong

Counter

hoop

Correct

Kettle

edge

If the collar is not uniform (illustration titled

“Wrong”), keep the heel of the pedal fully depressed as shown in Fig. C, and align head and

hoop as shown in the illustration titled “Correct”.

Counter

hoop

Collar Collar

2 Make sure that the end of the wire tube is not

disengaged from the adjuster of the tuning indicator as shown in Fig. A. If it is disengaged,

insert it into the adjuster as shown in Fig. B.

3 If the heel of the pedal is fully lowered as in Fig.

C, proceed with step 5.

If the pedal position is as shown in Fig. D or the

toe of the pedal is fully lowered, perform step

first.

Fig. C

Fig. D

4

4

Fig. B

Wire tube

Adjuster

Fig. A

Caution

Never put your hands etc. under the

pedal.

4 Fully depress the heel of the pedal as shown in

Fig. C. Hold the pedal in this position, as it will

return otherwise.

Page 5

Before Using The Pedal Timpani

5 Using the supplied timpani key, tighten the tun-

ing bolts by 1/4 of a turn (90°) in the order

shown below. It is very important to always

turn all tuning bolts by the same amount.

Timpani key

26”, 29”, 32” 20”, 23”

6 Take your foot off the pedal.

● Heel still moves up

→ Repeat steps

● Heel stays down

→ Go to step

4 through 6.

7.

9 Tighten each tuning bolt by 1/8 of a turn (45°) in

the order shown in step

5.

10 ● Toe and heel feel equal

→ Go to step

● Heel still feels heavier than toe

→ Repeat steps

● Heel feels lighter than toe

→ Head is tightened too much. Loosen the

head as described in step

11

8 through 10

7.

11 Move the pedal into an intermediate position, as

shown in Fig. D, and remove your foot from the

pedal. Confirm that the pedal stays in this position and does not move.

If the pedal stops in this position, adjustment is complete. Return the pedal to the

position shown in Fig. C.

● If the toe of the pedal moves downward

→ Repeat steps

● If the heel of the pedal moves downward

→ Head is tightened too much. Loosen the

head as described in step

8 through 10.

7.

7 Put your foot on the pedal and fully depress it in

either direction (toe and heel).

● Heel feels heavier than toe

→ Go to step 8.

● Toe and heel feel equal

→ Go to step

● Heel feels lighter than toe

→ Head is tightened too much. Loosen the

head. Keeping the heel of the pedal depressed, loosen the first tuning bolt by 1/

2 turn and then retighten it by 1/4 of a

turn. Perform this operation for all other

tuning bolts in the order shown in step

If necessary, repeat this procedure, until

proper tension is obtained.

11.

8 Fully depress the heel of the pedal as shown in

Fig. C.

As the head will stretch over time, readjustment should be performed periodi-

Note

cally (starting with step

7 )

12 Strike the head lightly with the supplied mallet

etc. The standard striking point is shown below.

The standard striking

point lies at distance

B from the kettle

edge, which

Striking point

Pedal

5.

For note comparison a piano is most suitable.

When the toe of the pedal is depressed, a higher

pitch is obtained.

For details on precise tuning refer to “Adjusting

The Sound Of Your Timpani” on the following

page.

corresponds to 1/4 to

1/3 of distance A

(distance between

kettle edge and

center of head).

5

Page 6

Adjusting The Sound Of Your Timpani

When using the pedal timpani for the first time after unpacking, make sure to set it up according

to the instructions of section “Before Using The Pedal Timpani” on pages 4 and 5.

z Head Tuning* (* Adjusting the head tension to a specific note)

1 Tuning is performed for the lowest sound (note)

of the timpani.

For this reason, the heel of the pedal must stay

fully lowered during the tuning procedure.

The proper lowest note (and tonal range) depends on the size of your timpani. For example,

as shown in the figure below, the lowest sound

of a 26” timpani should be tuned to A. When

tuned properly, your Yamaha timpani will give

you its full tonal range without being

overtensioned.

■ Standard Tonal Ranges for Yamaha Timpani

32" (81cm) 29" (74cm) 26" (66cm) 23" (58cm) 20" (51cm)

Keep the heel of the pedal fully lowered during

the tuning procedure (steps

not specified otherwise.

2 through 7 below) if

When loosening the tuning bolts, always

loosen them by double the desired amount,

and then return (retighten) them by half.

When the sound lies within 1 halftone

below the desired pitch after loosening

the tuning bolts (repeatedly, if necessary),

proceed with step

3.

3 Lightly strike the head with the mallet about 2

inch (5 cm) from the kettle edge at each tuning

bolt. Check at which tuning bolt the sound is

highest.

● Pitch of highest sound higher than tuning

note

→ Loosen the corresponding tuning bolt by

about 1/16 to 1/8 of a turn. First loosen

the bolt by double the desired amount,

and then return (retighten) it by half. After

loosening the tuning bolt, repeat from the

beginning of step

● Pitch of highest sound lower than tuning

note

→ Go to step

3.

4.

2 Strike the head and check the sound. The stan-

dard striking point is shown below.

The standard striking

point lies at distance

B from the kettle

Striking point

Pedal

● Sound lower than tuning note

→ Go to step

● Sound higher than tuning note

→ Loosen tuning bolts by an equal amount

in the order shown in the figure of step

on page 5.

3.

6

edge, which corresponds to 1/4 to 1/3 of

distance A (distance

between kettle edge

and center of head).

4 Tighten the other bolts little by little (by about 1/

16 to 1/8 of a turn) until the sounds at the corresponding striking points match the pitch of the

highest sound. Please note that tightening of

one bolt will also raise the pitch at the neighboring and opposite tuning bolts. Thus, after tightening the tuning bolt with the lowest sound, first

reconfirm the sound at the other tuning bolts

before tightening the tuning bolt with the next

lower sound. While alternately tightening the other

bolts, do not touch the tuning bolt with the highest sound (reference pitch).

5 Loosen all overtightened bolts according to the

procedure described in step

5

approximately the same at each bolt, repeatedly

depress the toe and heel of the pedal several

times.

3. When the pitch is

Page 7

Adjusting The Sound Of Your Timpani

x Pedal Adjustment

6 Repeat steps 3 through 5 until the pitch at each

bolt is exactly the same.

7 Check the sound by striking the head as de-

scribed in step

● Sound lower than tuning note

→ Tune the instrument by tightening all tun-

ing bolts by an equal amount (max. 1/16

of a turn).

● Sound higher than tuning note

→ Tune the instrument by loosening all tun-

ing bolts by an equal amount (max. 1/16

of a turn) according to the procedure described in step

2.

3.

8 Operate the pedal as described in step 5. If the

pitch does not change, the instrument is tuned

properly.

(If the pitch changes, repeat from step

The instrument is now tuned to the lowest sound

(note) of its tonal range. Depress the toe of the

pedal to change to a higher pitch (note).

7.)

After depressing the toe and heel of the pedal, turn

the spring tension adjustment bolt as described below.

● Heel moves up when releasing the foot from

the pedal after depressing the heel, or heel

feels heavier than toe

→ Turn the spring tension adjustment bolt to

the left (counterclockwise)

● Toe moves up when releasing the foot from

the pedal after depressing the toe, or toe feels

heavier than heel

→ Turn the spring tension adjustment bolt to

the right (clockwise)

Turning the spring tension adjustment bolt is performed using the timpani key. Do not turn by too

many full rotations at once, but re-check the adjustment state every 2 turns by depressing the toe and

heel of the pedal.

Do not loosen the spring tension ad-

Note

justment bolt by more 3 rotations at a

time, as the toe of the pedal tends to

drop abruptly after a specific point.

9 After tuning, perform x Pedal Adjustment and

then c Tuning Indicator Adjustment.

Caution

Never put your hands etc. under the

pedal.

Spring tension

adjustment bolt

Spring

Timpani key

● Pedal balance spring mechanism

Your Yamaha pedal timpani is equipped with a unique

pedal balance spring mechanism (a coil spring counteracting the tension of the head) which allows you to

freely change the pitch (note) of the instrument at an

instant. When the pedals are moved, the pitch of the

head will change, and the balance spring ensures that

the pedal angle (pitch) will not change when you remove your foot from the pedal.

7

Page 8

Adjusting The Sound Of Your Timpani

c Tuning Indicator Adjustment

The tuning indicator shows to which note the pedal is

set. After tuning the instrument, you must set each

note of the indicator to its proper position.

1 After you have tuned your timpani to the lowest

note of its tonal range, make sure that the pointer

is located within 10 mm from the pedal-side end

of the indicator rail.

* If not, adjust referring to “Adjusting the Pointer

Position”.

2 Slide the lowest note of the indicator (“A” in case

of a 26” timpani — see “Standard Tonal Ranges

for Yamaha Timpani” on page 6) to the position

where its center line coincides with the pointer.

3 Tune the instrument to the next higher pitch

(note) by moving the pedal, and then slide the

corresponding note on the rail to the respective

pointer position. Repeat for each note.

* The tuning indicator can be set to a desired angle

by loosening the indicator mounting screw using a

Phillips screwdriver.

● Adjusting the Pointer Position

First loosen the pointer lock nut and then turn the

adjuster as follows:

● Pointer is located beyond the lower rail end

when heel of pedal is lowered fully (lowest

note)

→ Turn the adjuster to the left (counterclock-

wise) until the pointer is aligned with the

lowest note of the indicator.

● Pointer moves beyond the upper rail end

before toe of pedal reaches end of stroke,

or

Pointer does not reach lower rail end when

heel of pedal is lowered fully (lowest sound)

→ Turn the adjuster to the right (clockwise) to

correct the pointer position as required.

After adjustment, securely tighten the pointer lock

nut.

Indicator rail

8

Note

Pointer

Indicator rail

Adjuster

Note

Pointer

Adjustment nut

Page 9

Other Features

■ Pedal Adjustment Clutch

Using the PAC, you can adjust the rotational torque

of the pedal to a comfortable pedal force without

degrading the smooth pedal action. In addition, the

PAC is useful in preventing undesirable happenings

such as slight movement of the pedal when the head

is struck strongly causing a small change in pitch.

PAC adjustment bolt

The PAC (Pedal Adjustment Clutch) is an original

Yamaha mechanism that enables you to adjust the

pedal’s rotational torque (the force required to move

the pedal) by altering the amount of friction within the

pedal balance spring mechanism.

● PAC Adjustment

Use the timpani key to turn the PAC adjustment bolt

as follows:

Turn the PAC adjustment bolt to the right (clockwise)

to tighten the pedal movement.

To return the tightened pedal movement to the initial

rotational torque setting, turn the PAC adjustment

bolt to the left (counterclockwise).

* Be sure to turn the timpani key using one hand

only.

* Do not use both hands or an additional tool.

The TP-50xx (H/G) / TP-70xx (H) series use a

wing bolt on the PAC adjustment system.

Note on PAC Usage

• The pedal cannot be locked with the PAC,

even at its tightest position.

(Do not try to use the PAC for locking the

pedal, for example to prevent the toe of the

pedal from jumping up when the head is removed.)

• The PAC adjustment bolt has limit positions in

both turning directions. If the bolt is hard to

turn, do not force to overtighten it because this

may cause damage to the mechanism.

9

Page 10

Moving And Setup Your Timpani

The timpani can easily be moved when the third

wheel is attached to the pedal section as shown on

the right. Attaching and removing the third wheel can

be performed easily.

To move the timpani on a flat surface, make sure to

hold it by the frame section on the pedal side and

push it in the direction opposite the pedal (see

illustration below).

Never hold the instrument by the counter hoop, as

this may result in a deformation of the head or the

counter hoop.

On gravel and stairways the instrument should not

pushed on its casters. Instead, to prevent damage, it

should be lifted by its frame and carried by at least

two persons.

Hold the instrument by

its frame and push in

the direction opposite

the pedal.

● Attaching and Removing the Third Wheel

Pedal

Base

Locking shaft

1) Hook the mounting plate of the wheel onto

the base end, and, while pushing both ends

of the locking shaft in the direction of the

timpani, push the wheel up in the direction of

the arrow, engaging the locking shaft into

the groove of the base.

2) To remove, disengage the locking shaft by

fully pushing both ends in the direction of the

timpani, and pull the wheel down.

Mounting plate

* The illustration shows a pedal timpani of the TP-62xx

series.

After setting up the timpani, lock the other two

casters to stabilize the instrument during performance. Also, the pedal wheel should be removed

for performance. If it is left attached, it may be

the cause of noise and will also result in different

head angles when several timpani of different

size are used.

10

To stabilize the timpani, push down the “ON”

side of the caster lock.

Using the Third Wheel (TP-70xx Series)

The third wheel can be easily moved in or out of

position with a single motion. To use the third

wheel, lean the tympani slightly forward to lift

the pedal off the ground then use your foot to

manipulate the wheel into the desired position.

Page 11

Replacing The Head

1 To prevent the pedal from being pulled down by

the spring force, the heel of the pedal must be

kept down (this can easily be accomplished by

placing a piece of wood or a softball between

the base and the pedal) while the tuning bolts

are loosened alternately in the proper sequence.

Softball etc.

Caution

Never put your hands etc. under the

pedal.

2 After removing all tuning bolts, mark the pedal

side of the hoop with cellophane tape etc. and

then remove the head together with the hoop. At

this time, be careful not to lose any of the tuning

bolts and prevent dust from adhering.

Also, avoid touching the tuning bolt threads, as

they are greased.

Hoop

Cellophane tape

Pedal

* Be careful not to make any scratches in the tape

attached to the kettle edge. If the tape is peeling or

badly damaged, it must be replaced with timpani

edge tape (Teflon™ tape).

3 Place the new head with the hoop on the kettle.

When using a Yamaha timpani head, its YAMAHA

logo must be on the side opposite the pedal.

The hoop must be re-mounted in the same position as marked with cellophane tape in step

Tighten the tuning bolts alternately by hand until

the head is tensioned slightly. At this time, make

sure that head and hoop are centered on the

kettle.

Tighten each tuning bolt an additional 1/4 of a

turn using the timpani key. Repeat at least 4

times.

2.

4 Adjust the timpani as described on pages 4 and

5, “Before Using The Pedal Timpani”, starting

with step

“Adjusting The Sound Of Your Timpani” on

page 6.

● Interval For Head Replacement

The maximum head life normally is approximately 2 years and depends on the frequency

and duration of use. However, the head should

always be replaced before the sound quality

deteriorates dramatically. If a head is left on

and used more than two years, the following

problems may occur:

When the head is slightly tensioned and its

surface looks wavy or shows dents, it is time to

replace the head with a new one.

5. For precise tuning, refer to the section

• It may become impossible to tune the

head to the proper pitch range.

• It may become impossible to balance

the pedal.

• The main unit mechanisms themselves

may become damaged.

11

Loading...

Loading...