Yamaha 2016 Grizzly yfm700gphg, 2016 Grizzly yfm700gplg, 2016 Grizzly yfm700fwad, 2016 Grizzly yf700gplg, 2016 Grizzly yf700gpsg Service Manual

...

2016

SERVICE MANUAL

YF70GG

YF70GPG

YF70GPSG

YF70GPLG

YFM70GDXG

YFM70GDHG

YFM70GPXG

YFM70GPHG

YFM70GPSG

YFM70GPLG

YFM700FWAD

2UD-F8197-E0

EBS20002

YF70GG/YF70GPG/YF70GPSG/

YF70GPLG/YFM70GDXG/

YFM70GDHG/YFM70GPXG/

YFM70GPHG/YFM70GPSG/

YFM70GPLG/YFM700FWAD

SERVICE MANUAL

©2015 by Yamaha Motor Co., Ltd.

First edition, July 2015

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

EBS20003

TIP

WARNING

NOTICE

TIP

IMPORTANT

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha vehicles

should have a basic understanding of mechanics and the techniques to repair these types of vehicles.

Repair and maintenance work attempted by anyone without this knowledge is likely to render the vehicle unsafe and unfit for use.

This model has been designed and manufactured to perform within certain specifications in regard to

performance and emissions. Proper service with the correct tools is necessary to ensure that the vehicle will operate as designed. If there is any question about a service procedure, it is imperative that you

contact a Yamaha dealer for any service information changes that apply to this model. This policy is

intended to provide the customer with the most satisfaction from his vehicle and to conform to federal

environmental quality objectives.

Yamaha Motor Company, Ltd. is continually striving to improve all of its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and

will appear in future editions of this manual where applicable.

Designs and specifications are subject to change without notice.

EBS30001

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following notations.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

A WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

A NOTICE indicates special precautions that must be taken to avoid damage to the vehicle or other property.

A TIP provides key information to make procedures easier or clearer.

EBS20004

1

7

3

5

4

6

2

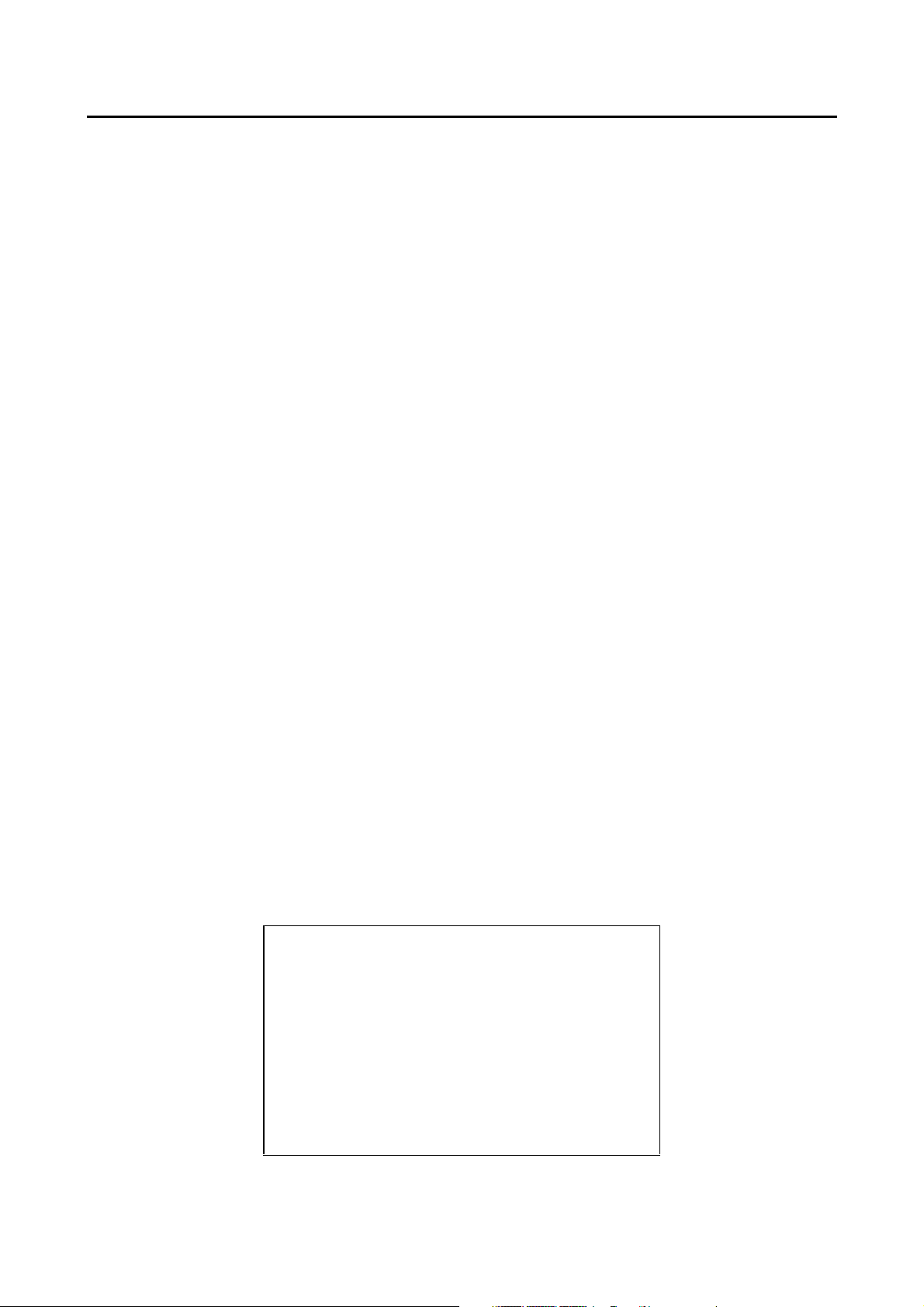

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid

out with the individual steps in sequential order.

• The manual is divided into chapters and each chapter is divided into sections. The current section title

“1” is shown at the top of each page.

• Sub-section titles “2” appear in smaller print than the section title.

• To help identify parts and clarify procedure steps, there are exploded diagrams “3” at the start of each

removal and disassembly section.

• Numbers “4” are given in the order of the jobs in the exploded diagram. A number indicates a disassembly step.

• Symbols “5” indicate parts to be lubricated or replaced.

Refer to “SYMBOLS”.

• A job instruction chart “6” accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc. This step explains removal and disassembly procedure only. For installation

and assembly procedure, reverse the steps.

• Jobs “7” requiring more information (such as special tools and technical data) are described sequentially.

EBS20005

TIP

G

M

BF

B

T

R

.

.

LS

M

S

LT

E

New

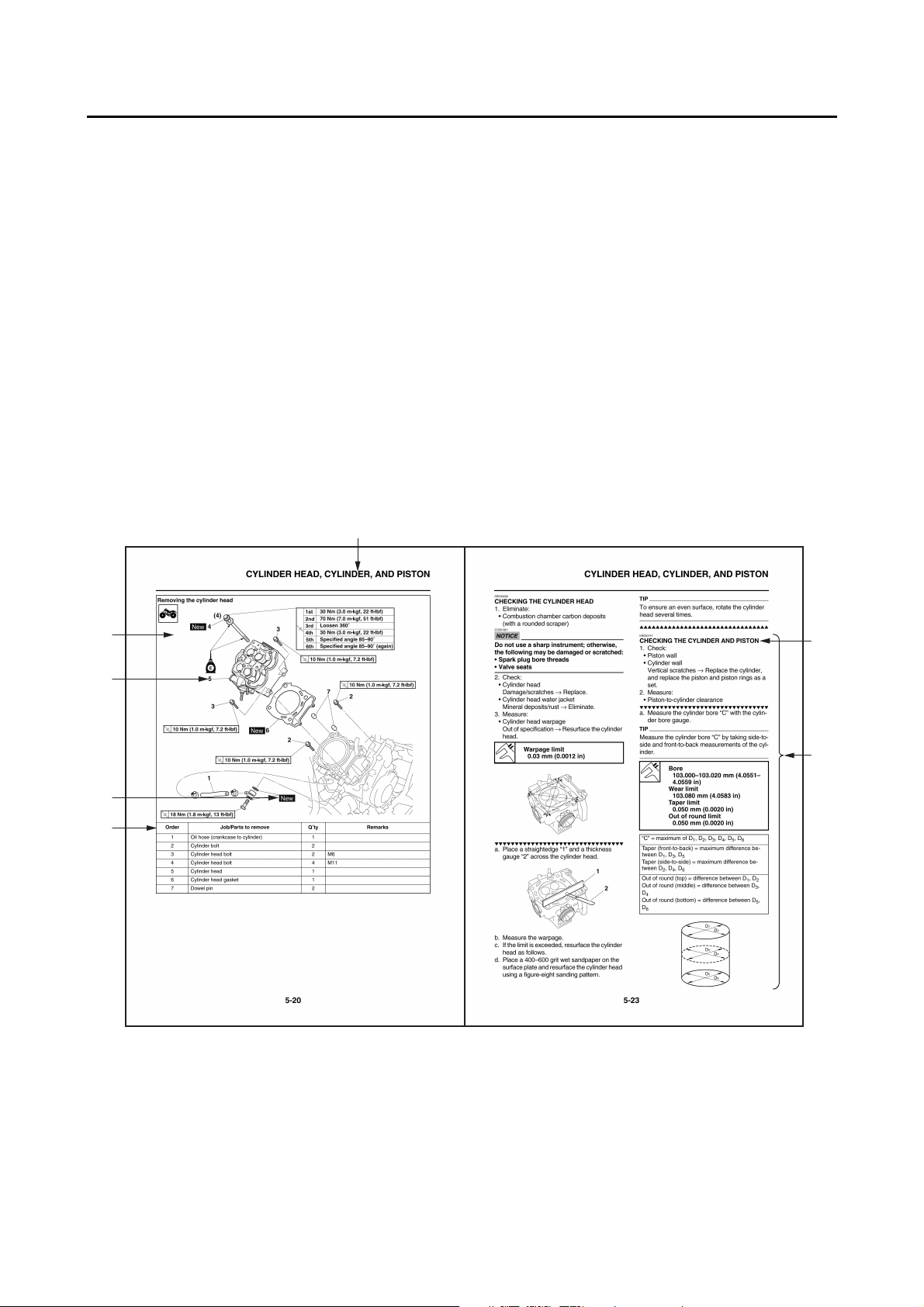

SYMBOLS

The following symbols are used in this manual for easier understanding.

The following symbols are not relevant to every vehicle.

SYMBOL DEFINITION SYMBOL DEFINITION

Serviceable with engine mounted Gear oil

Filling fluid Molybdenum disulfide oil

Lubricant Brake fluid

Special tool Wheel bearing grease

Tightening torque Lithium-soap-based grease

Wear limit, clearance Molybdenum disulfide grease

Engine speed Silicone grease

Electrical data Apply locking agent (LOCTITE®).

Engine oil Replace the part with a new one.

EBS10003

TABLE OF CONTENTS

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC CHECKS AND

ADJUSTMENTS

CHASSIS

ENGINE

1

2

3

4

5

COOLING SYSTEM

FUEL SYSTEM

DRIVE TRAIN

ELECTRICAL SYSTEM

TROUBLESHOOTING

6

7

8

9

10

GENERAL INFORMATION

IDENTIFICATION ............................................................................................1-1

VEHICLE IDENTIFICATION NUMBER .....................................................1-1

MODEL LABEL..........................................................................................1-1

FEATURES......................................................................................................1-3

OUTLINE OF THE EPS (ELECTRIC POWER STEERING) SYSTEM

(for EPS models) ......................................................................................1-3

INSTRUMENT FUNCTIONS .....................................................................1-5

IMPORTANT INFORMATION .........................................................................1-7

PREPARATION FOR REMOVAL AND DISASSEMBLY........................... 1-7

REPLACEMENT PARTS...........................................................................1-7

GASKETS, OIL SEALS AND O-RINGS .................................................... 1-7

LOCK WASHERS/PLATES AND COTTER PINS .....................................1-7

BEARINGS AND OIL SEALS ....................................................................1-8

CIRCLIPS ..................................................................................................1-8

RUBBER PARTS.......................................................................................1-8

1

BASIC SERVICE INFORMATION...................................................................1-9

QUICK FASTENERS.................................................................................1-9

ELECTRICAL SYSTEM........................................................................... 1-10

SPECIAL TOOLS ..........................................................................................1-14

EBS20009

1

IDENTIFICATION

EBS30003

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number “1” is stamped

into the frame.

EBS30004

MODEL LABEL

The model label “1” is affixed at the location in

the illustration. This information will be needed to

order spare parts.

IDENTIFICATION

1-1

IDENTIFICATION

1-2

FEATURES

4

5

7

6

1

2

3

d

ce

a

b

f

EBS20010

FEATURES

EBS30007

OUTLINE OF THE EPS (ELECTRIC POWER STEERING) SYSTEM (for EPS models)

1-3

FEATURES

NOTICE

1. Speed information from speed sensor

2. Engine RPM information from ECU

3. Battery

4. EPS control unit

5. EPS motor

6. Torque sensor

7. EPS unit

a. Operates steering

ECB01790

b. Twists torsion bar

c. Sends the torque sensor signal

d. EPS control unit calculates assist power

e. Electricity output switched by EPS control unit

f. Activates EPS motor

To prevent accidental damage to the EPS unit, it must not be disassembled.

1-4

FEATURES

TIP

TIP

4 5

7

6

1

2

3

1

2

3

EBS30008

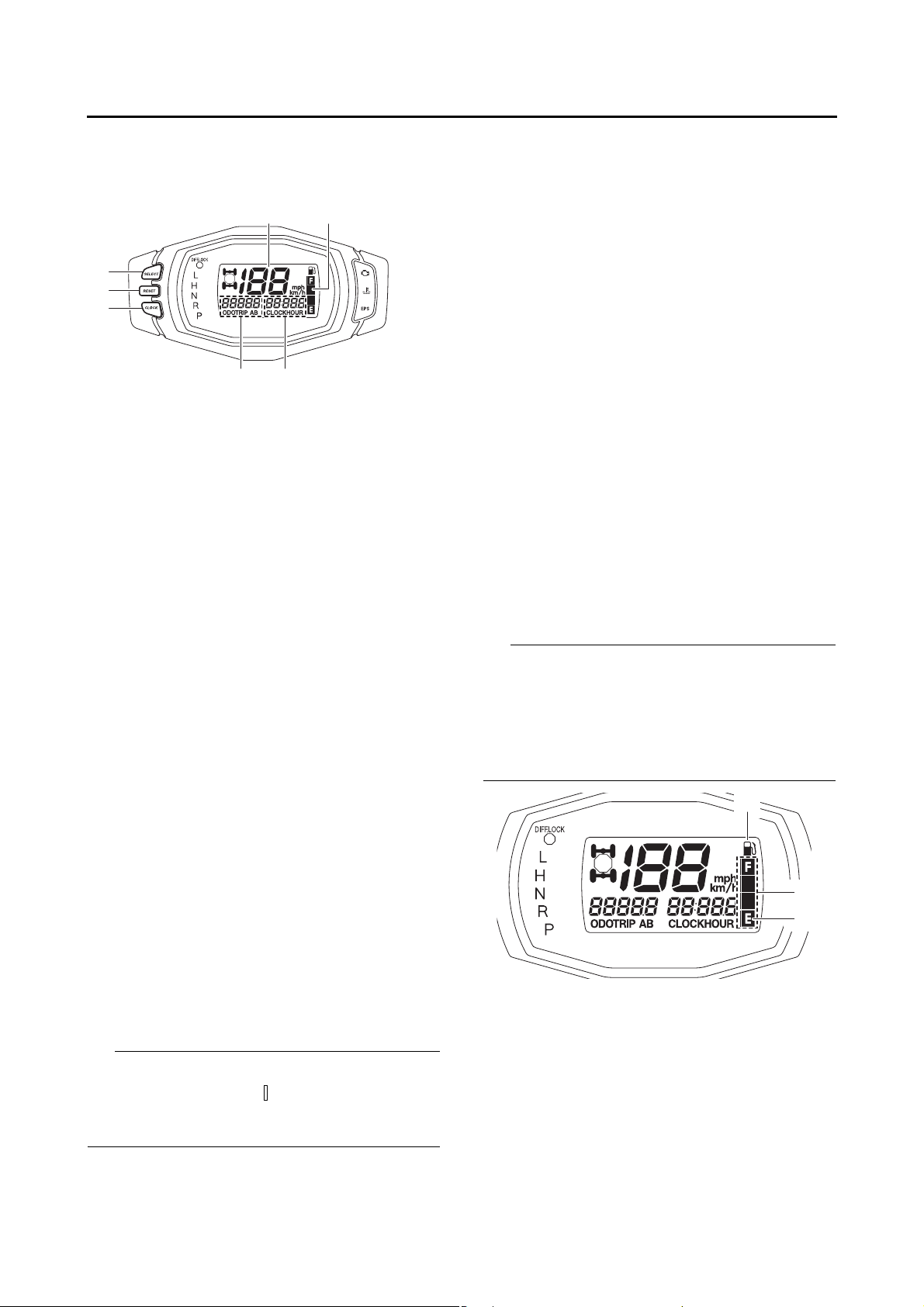

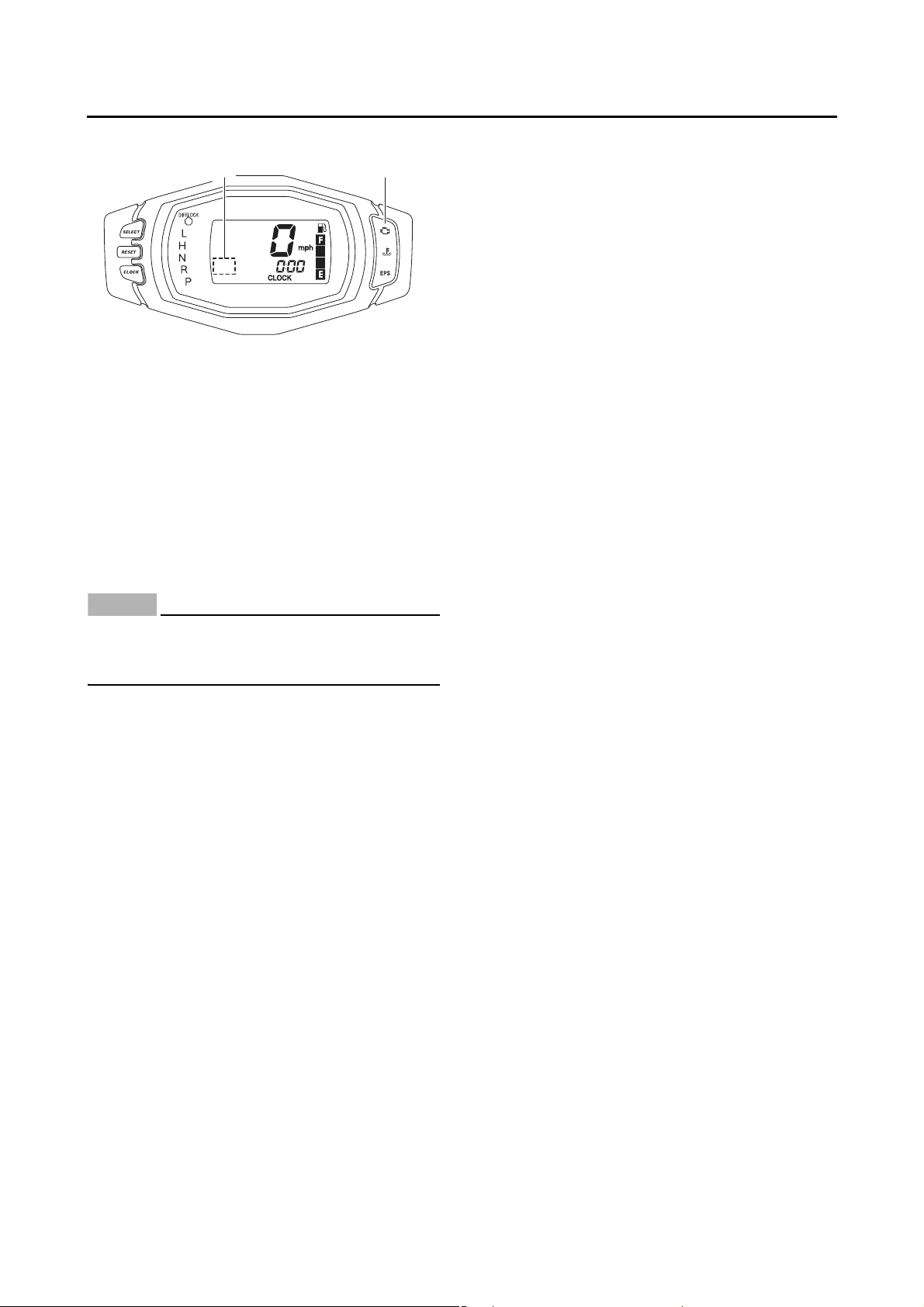

INSTRUMENT FUNCTIONS

Multi-function display

1. “SELECT” button

2. “RESET” button

3. “CLOCK” button

4. Speedometer

5. Fuel meter

6. Clock/Hour meter

7. Odometer/Tripmeter A/Tripmeter B

The multi-function display is equipped with the

following:

• a speedometer

• an odometer

• two tripmeters (which show the distance traveled since they were last set to zero)

•a clock

• an hour meter (which shows the total time the

engine has been running)

• a fuel meter

• a self-diagnosis device

Clock mode

Pushing the “CLOCK” button switches the display between the clock mode “CLOCK” and the

hour meter mode “HOUR” in the following order:

CLOCK → HOUR → CLOCK

To set the clock

1. Set the display to the clock mode.

2. Push the “SELECT” button and “RESET” button together for at least three seconds.

3. When the hour digits start flashing, push the

“RESET” button to set the hours.

4. Push the “SELECT” button, and the minute

digits will start flashing.

5. Push the “RESET” button to set the minutes.

6. Push the “SELECT” button and then release

it to start the clock.

Fuel meter

The fuel meter indicates the amount of fuel in the

fuel tank. The display segments of the fuel meter

disappear from “F” (full) towards “E” (empty) as

the fuel level decreases. When the “E” segment

disappears and the fuel level warning indicator

flashes, refuel as soon as possible.

This fuel meter is equipped with a self-diagnosis

system. If the electrical circuit is not working correctly, all the display segments and fuel level

warning indicator will start flashing. If this occurs,

check the electrical circuit.

Refer to “SIGNALING SYSTEM” on page 9-19.

Odometer and tripmeter modes

Pushing the “SELECT” button switches the display between the odometer mode “ODO” and

the tripmeter modes “TRIP A” and “TRIP B” in

the following order:

ODO → TRIP A → TRIP B → ODO

To reset a tripmeter, select it by pushing the “SELECT” button, and then push the “RESET” button for at least three seconds. The tripmeters

can be used to estimate the distance that can be

traveled with a full tank of fuel. This information

will enable you to plan future fuel stops.

1. Fuel level warning indicator

2. Fuel meter

3. “E” segment

Pushing and holding in the “SELECT” button,

and turning the key to “ ” (on) while the button

is pushed, switches the display between “mph”

and “km/h”.

1-5

Self-diagnosis device

NOTICE

1 2

1. Fault code display

2. Engine trouble warning light

This model is equipped with a self-diagnosis device for various electrical circuits.

If a problem is detected in any of those circuits,

the engine trouble warning light will come on or

flash and the multi-function display will indicate

an fault code.

If the multi-function display indicates an fault

code, note the code number, and check the vehicle.

ECB02030

FEATURES

If the display indicates a fault code, the vehicle should be checked as soon as possible

in order to avoid engine damage.

1-6

EBS20011

IMPORTANT INFORMATION

EBS30009

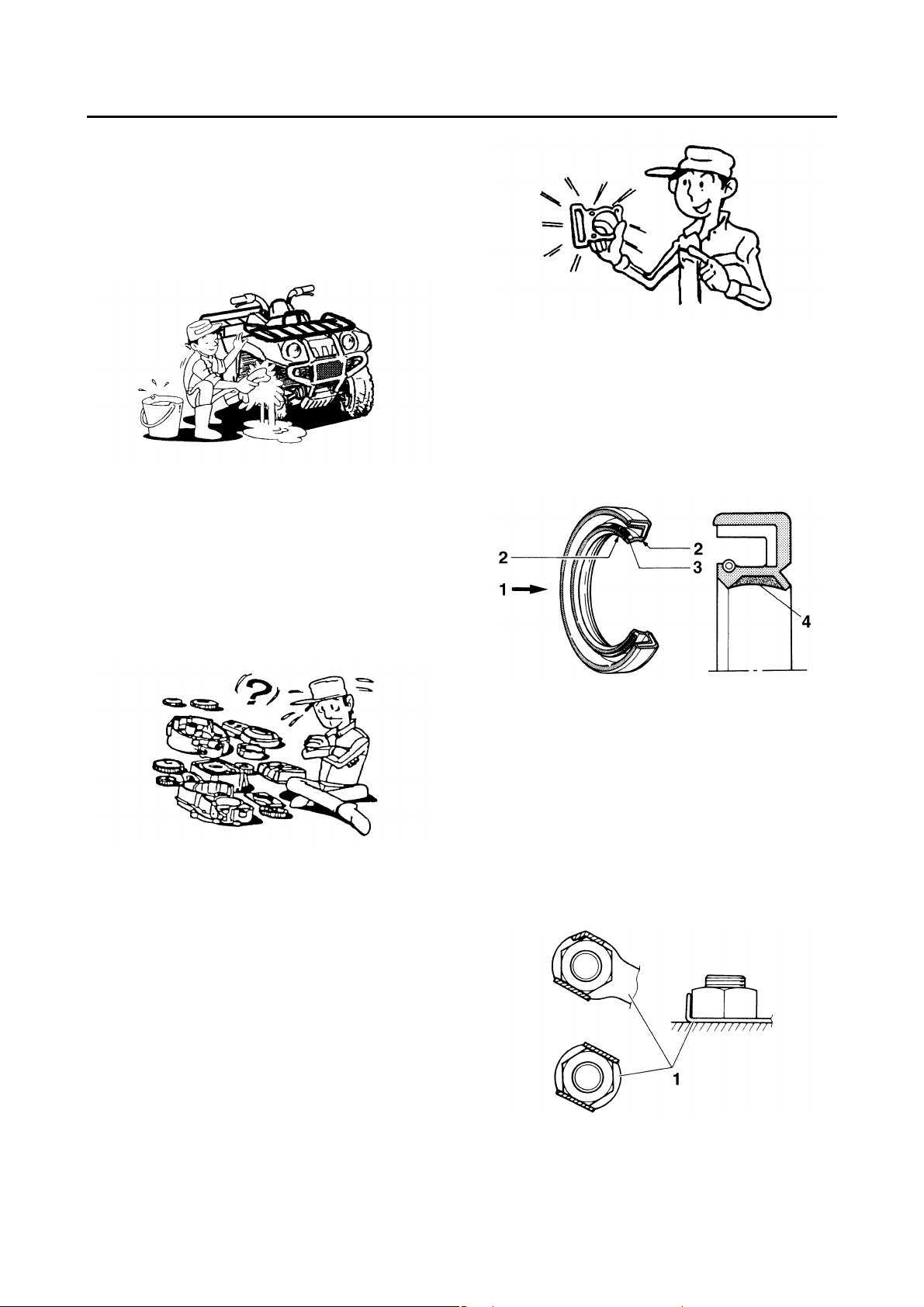

PREPARATION FOR REMOVAL AND

DISASSEMBLY

1. Before removal and disassembly, remove all

dirt, mud, dust and foreign material.

2. Use only the proper tools and cleaning equipment.

Refer to “SPECIAL TOOLS” on page 1-14.

3. When disassembling, always keep mated

parts together. This includes gears, cylinders,

pistons and other parts that have been “mated” through normal wear. Mated parts must

always be reused or replaced as an assembly.

IMPORTANT INFORMATION

EBS30011

GASKETS, OIL SEALS AND O-RINGS

1. When overhauling the engine, replace all

gaskets, seals and O-rings. All gasket surfaces, oil seal lips and O-rings must be cleaned.

2. During reassembly, properly oil all mating

parts and bearings and lubricate the oil seal

lips with grease.

4. During disassembly, clean all of the parts and

place them in trays in the order of disassembly. This will speed up assembly and allow for

the correct installation of all parts.

5. Keep all parts away from any source of fire.

EBS30010

REPLACEMENT PARTS

Use only genuine Yamaha parts for all replacements. Use oil and grease recommended by

Yamaha for all lubrication jobs. Other brands

may be similar in function and appearance, but

inferior in quality.

1. Oil

2. Lip

3. Spring

4. Grease

EBS30012

LOCK WASHERS/PLATES AND COTTER

PINS

After removal, replace all lock washers/plates

“1” and cotter pins. After the bolt or nut has been

tightened to specification, bend the lock tabs

along a flat of the bolt or nut.

1-7

IMPORTANT INFORMATION

NOTICE

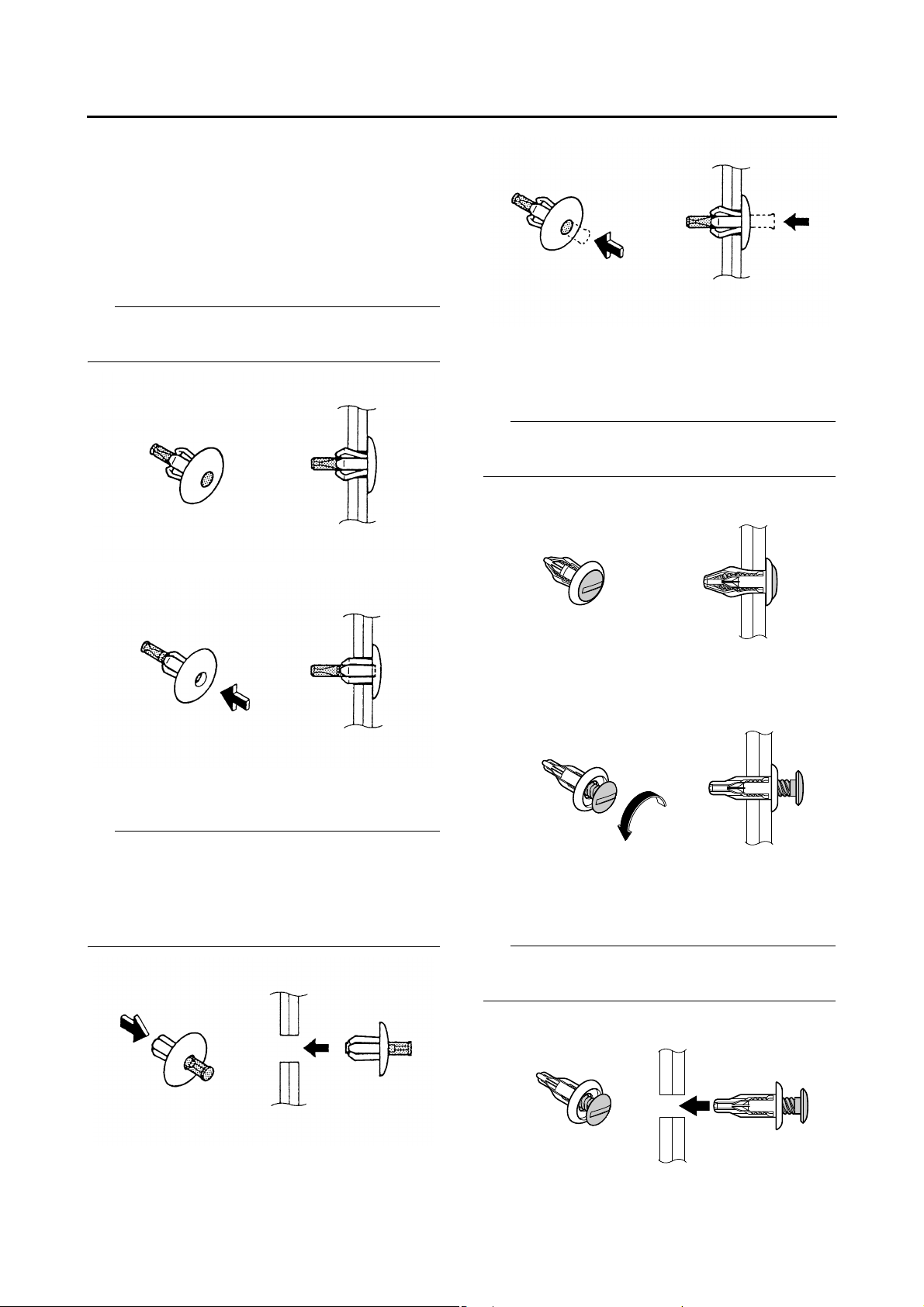

EBS30013

BEARINGS AND OIL SEALS

Install bearings “1” and oil seals “2” so that the

manufacturer’s marks or numbers are visible.

When installing oil seals, lubricate the oil seal

lips with a light coat of lithium-soap-based

grease. Oil bearings liberally when installing, if

appropriate.

ECB01260

Do not spin the bearing with compressed air

because this will damage the bearing surfaces.

EBS30015

RUBBER PARTS

Check rubber parts for deterioration during inspection. Some of the rubber parts are sensitive

to gasoline, flammable oil, grease, etc. Do not allow any items other than the specified one to

contact the parts.

EBS30014

CIRCLIPS

Before reassembly, check all circlips carefully

and replace damaged or distorted circlips. Always replace piston pin clips after one use.

When installing a circlip “1”, make sure the

sharp-edged corner “2” is positioned opposite

the thrust “3” that the circlip receives.

1-8

EBS20012

TIP

TIP

TIP

TIP

BASIC SERVICE INFORMATION

EBS30016

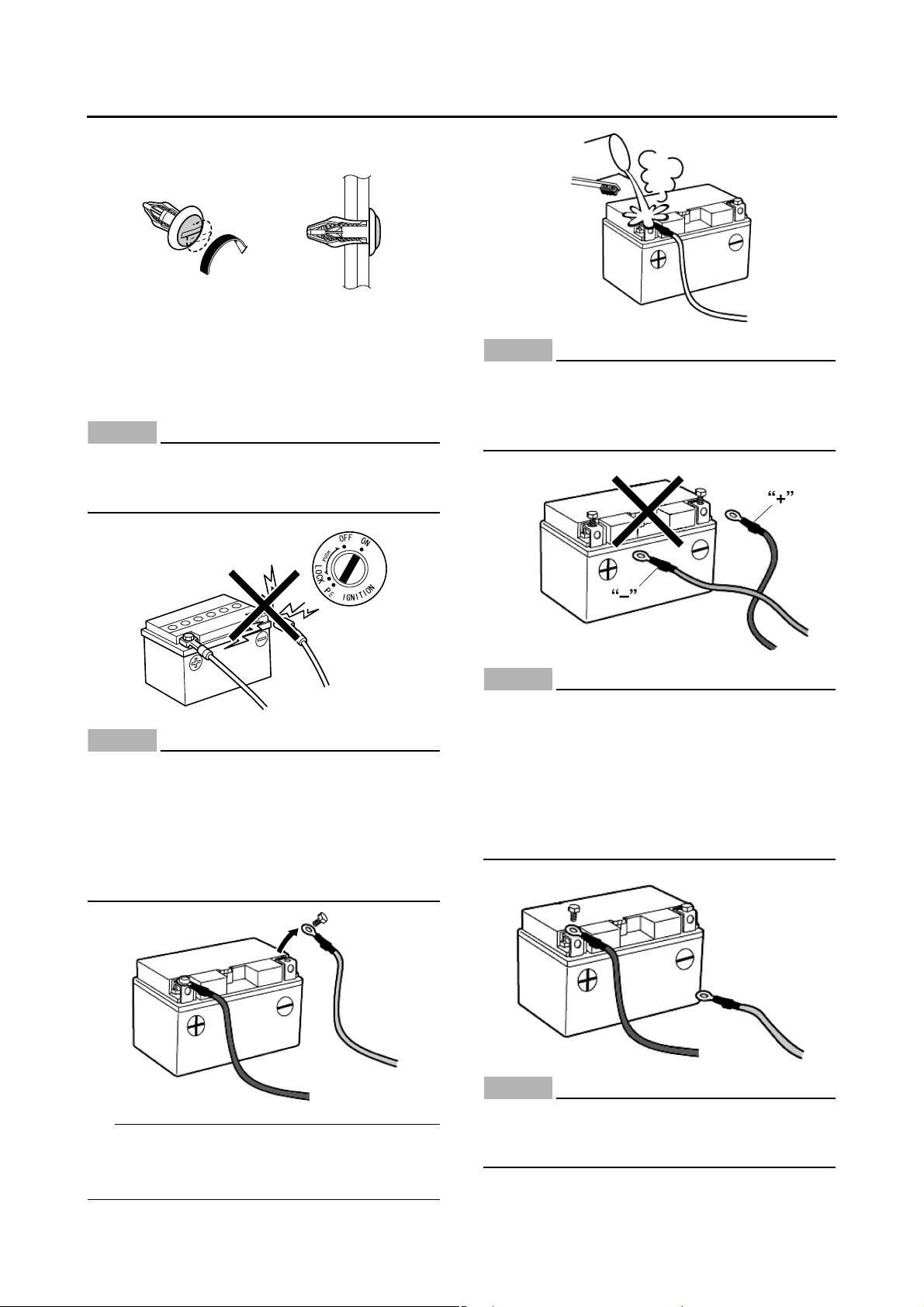

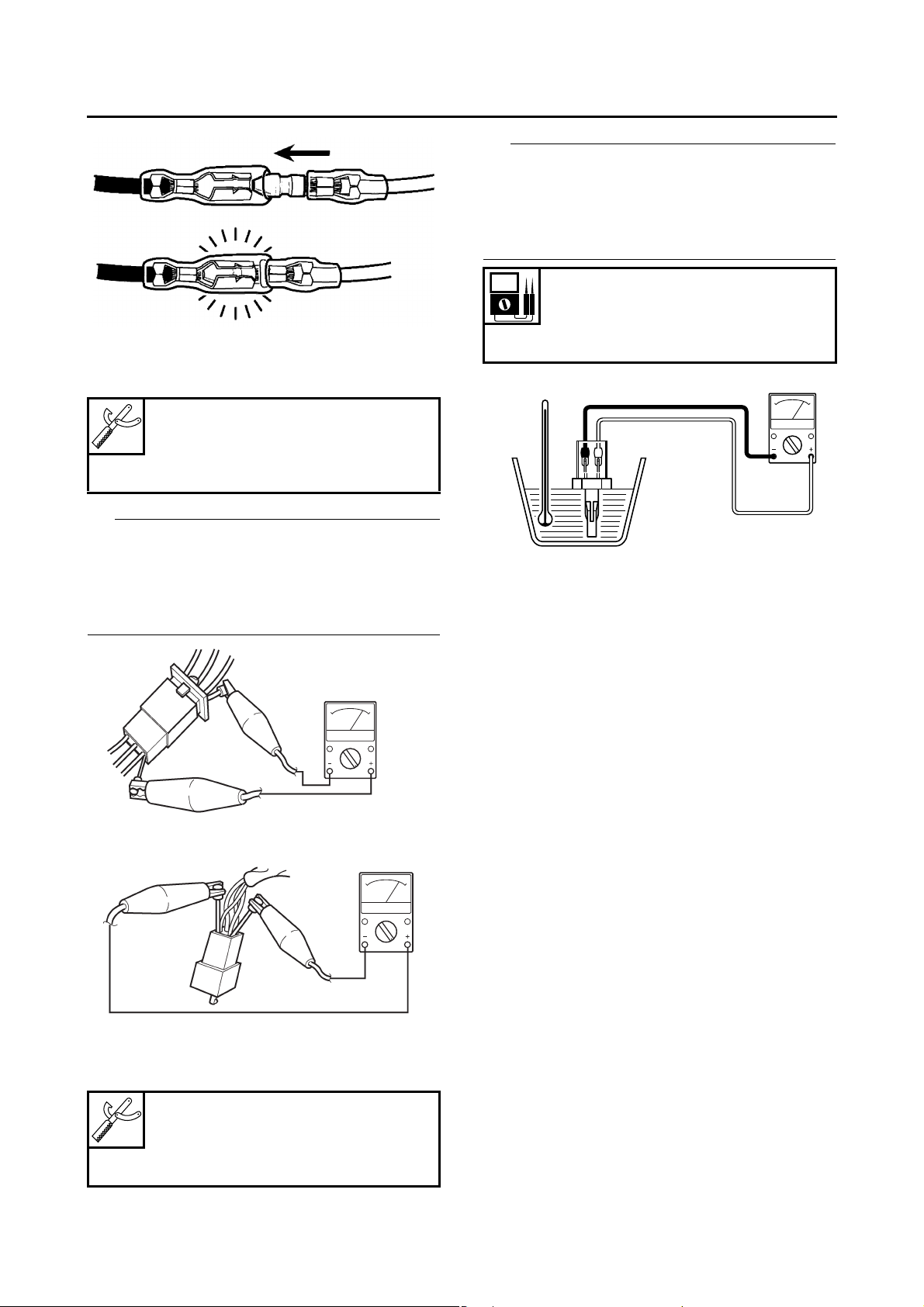

QUICK FASTENERS

Rivet type

1. Remove:

• Quick fastener

To remove the quick fastener, push its pin with a

screwdriver, then pull the fastener out.

BASIC SERVICE INFORMATION

Screw type

1. Remove:

• Quick fastener

To remove the quick fastener, loosen the screw

with a screwdriver, then pull the fastener out.

2. Install:

• Quick fastener

To install the quick fastener, push its pin so that

it protrudes from the fastener head, then insert

the fastener into the part to be secured and push

the pin in with a screwdriver. Make sure that the

pin is flush with the fastener’s head.

2. Install:

• Quick fastener

To install the quick fastener, insert the fastener

into the part to be secured and tighten the screw.

1-9

BASIC SERVICE INFORMATION

NOTICE

NOTICE

TIP

NOTICE

NOTICE

NOTICE

EBS30017

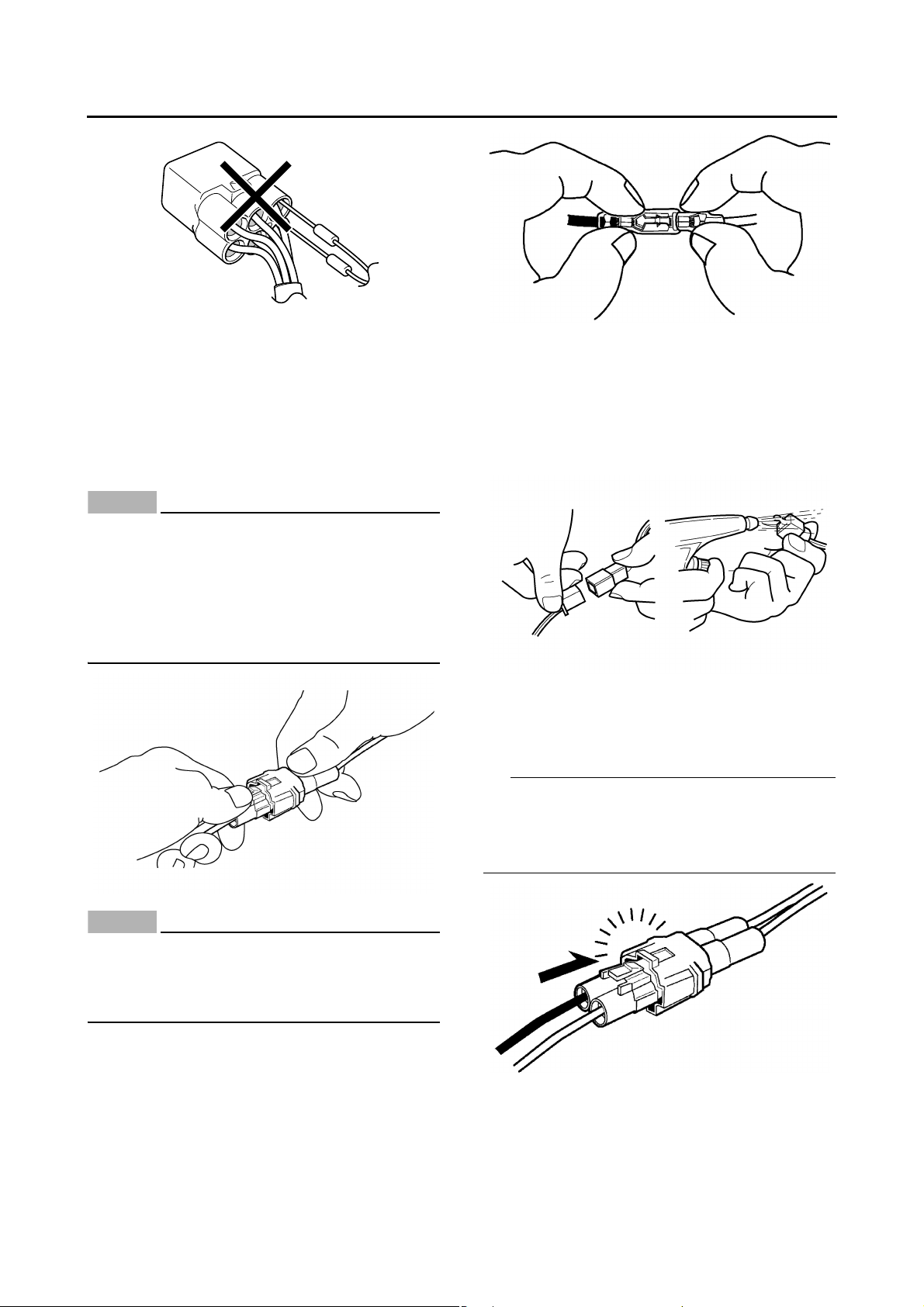

ELECTRICAL SYSTEM

Electrical parts handling

ECB01460

Never disconnect a battery lead while the engine is running; otherwise, the electrical

components could be damaged.

ECB01510

When disconnecting the battery leads from

the battery, be sure to disconnect the negative battery lead first, then the positive battery lead. If the positive battery lead is

disconnected first and a tool or similar item

contacts the vehicle, a spark could be generated, which is extremely dangerous.

ECB01520

Be sure to connect the battery leads to the

correct battery terminals. Reversing the battery lead connections could damage the

electrical components.

ECB01530

When connecting the battery leads to the

battery, be sure to connect the positive battery lead first, then the negative battery lead.

If the negative battery lead is connected first

and a tool or similar item contacts the vehicle while the positive battery lead is being

connected, a spark could be generated,

which is extremely dangerous.

If a battery lead is difficult to disconnect due to

rust on the battery terminal, remove the rust using hot water.

ECB01470

Turn the main switch to “OFF” before disconnecting or connecting an electrical component.

1-10

NOTICE

ECB01480

NOTICE

TIP

TIP

NOTICE

NOTICE

a

Handle electrical components with special

care, and do not subject them to strong

shocks.

BASIC SERVICE INFORMATION

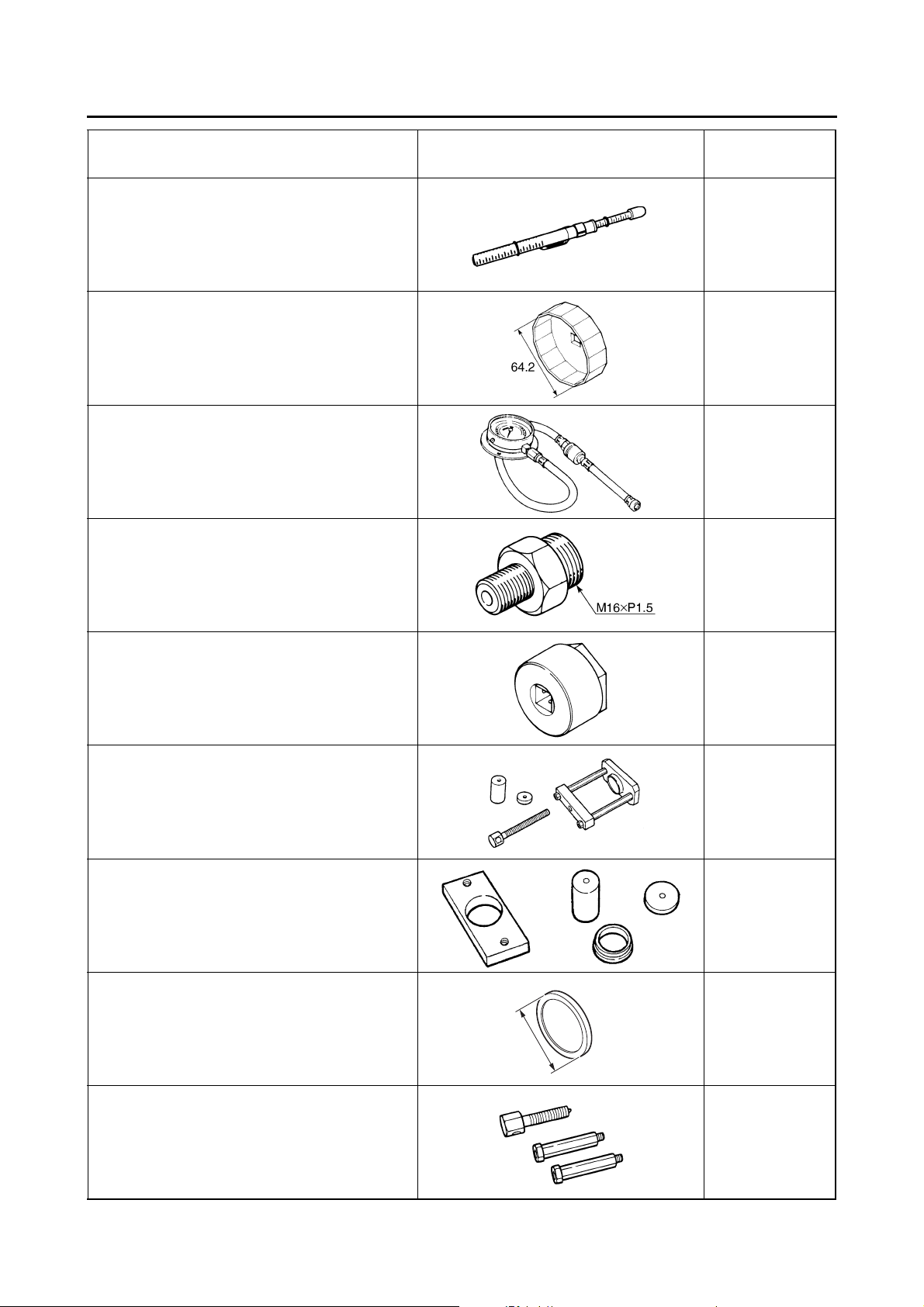

Checking the electrical system

Before checking the electrical system, make

sure that the battery voltage is at least 12 V.

ECB01490

Electrical components are very sensitive to

and can be damaged by static electricity.

Therefore, never touch the terminals and be

sure to keep the contacts clean.

When resetting the ECU by turning the main

switch to “OFF”, be sure to wait approximately 5

seconds before turning the main switch back to

“ON”.

ECB01440

Never insert the tester probes into the coupler terminal slots. Always insert the probes

from the opposite end “a” of the coupler, taking care not to loosen or damage the leads.

ECB01500

For waterproof couplers, never insert the

tester probes directly into the coupler. When

performing any checks using a waterproof

coupler, use the specified test harness or a

suitable commercially available test harness.

1-11

BASIC SERVICE INFORMATION

NOTICE

NOTICE

TIP

Checking the connections

Check the leads, couplers, and connectors for

stains, rust, moisture, etc.

1. Disconnect:

• Lead

• Coupler

• Connector

ECB01540

• When disconnecting a coupler, release the

coupler lock, hold both sections of the coupler securely, and then disconnect the coupler.

• There are many types of coupler locks;

therefore, be sure to check the type of coupler lock before disconnecting the coupler.

2. Check:

• Lead

• Coupler

• Connector

Moisture → Dry with an air blower.

Rust/stains → Connect and disconnect several times.

3. Connect:

• Lead

• Coupler

• Connector

ECB01550

When disconnecting a connector, do not pull

the leads. Hold both sections of the connector securely, and then disconnect the connector.

• When connecting a coupler or connector, push

both sections of the coupler or connector together until they are connected securely.

• Make sure all connections are tight.

1-12

4. Check:

TIP

TIP

• Continuity

(with the pocket tester)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

BASIC SERVICE INFORMATION

The resistance values shown were obtained at

the standard measuring temperature of 20 °C

(68 °F). If the measuring temperature is not 20

°C (68 °F), the specified measuring conditions

will be shown.

Intake air temperature sensor resistance

5.40–6.60 kΩ at 0 °C (32 °F)

290–390 Ω at 80 °C (176 °F)

• If there is no continuity, clean the terminals.

• When checking the wire harness, perform

steps (1) to (3).

• As a quick remedy, use a contact revitalizer

available at most part stores.

5. Check:

• Resistance

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

1-13

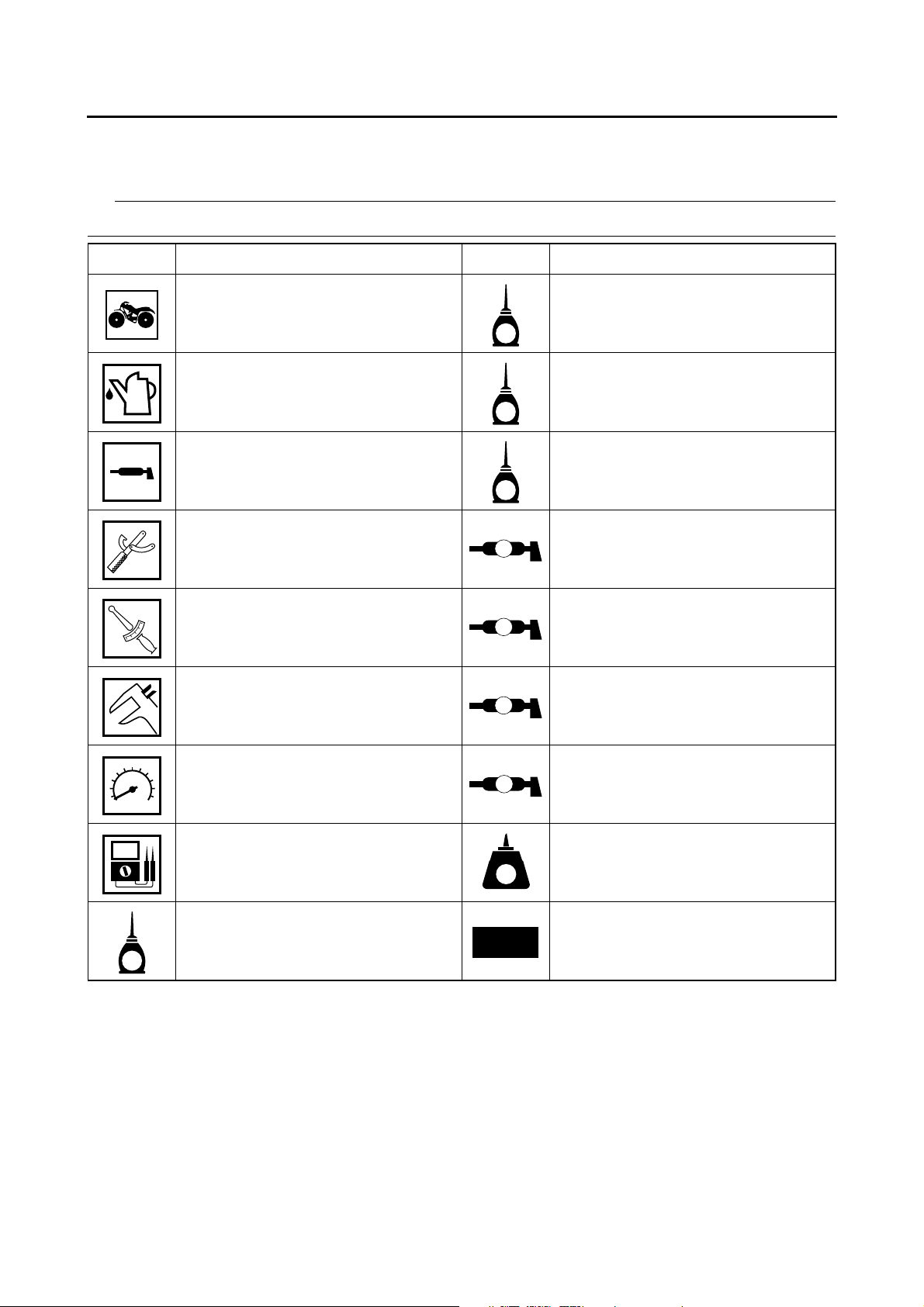

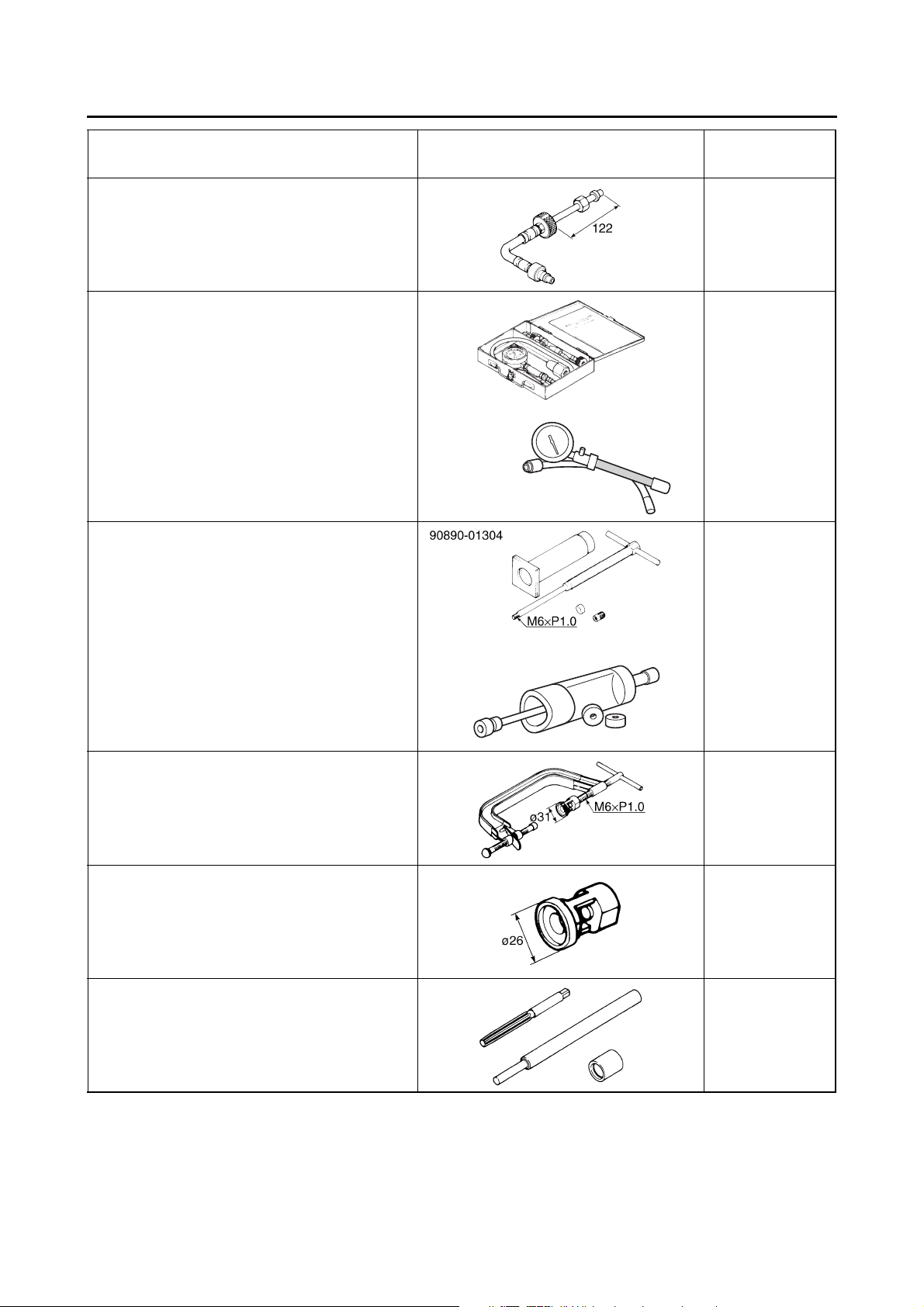

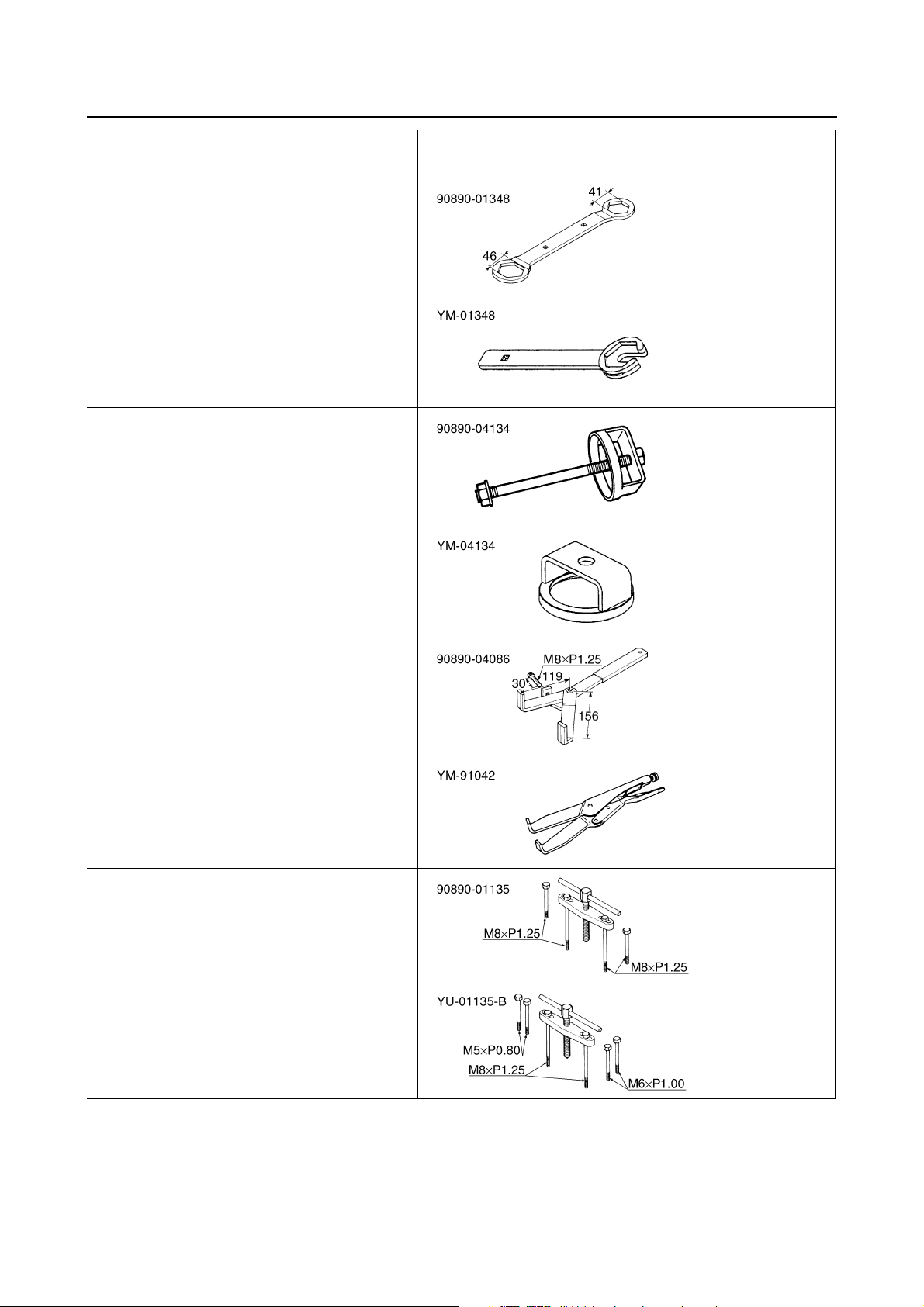

SPECIAL TOOLS

TIP

90890-04101

YM-A8998

EBS20013

SPECIAL TOOLS

The following special tools are necessary for complete and accurate tune-up and assembly. Use only

the appropriate special tools as this will help prevent damage caused by the use of inappropriate tools

or improvised techniques. Special tools, part numbers or both may differ depending on the country.

When placing an order, refer to the list provided below to avoid any mistakes.

• For U.S.A. and Canada, use part number starting with “YM-”, “YU-”, “YS-”, “YK-”, or “ACC-”.

• For others, use part number starting with “90890-”.

Tool name/Tool No. Illustration

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Thickness gauge

90890-03180

Feeler gauge set

YU-26900-9

Valve lapper

90890-04101

Valve lapping tool

YM-A8998

Reference

pages

1-13, 1-13, 9-82,

9-83, 9-84, 9-84,

9-88, 9-90, 9-91,

9-91, 9-91, 9-92,

9-92, 9-93, 9-93,

9-94, 9-94, 9-95,

9-95, 9-96, 9-96,

9-96, 9-97, 9-97,

9-98, 9-98

3-5

3-6

Yamaha diagnostic tool

90890-03231

Ring nut wrench

90890-01268

Spanner wrench

YU-01268

3-9, 9-33

3-18, 3-19

1-14

SPECIAL TOOLS

ø38

Tool name/Tool No. Illustration

Belt tension gauge

90890-03170

Rear drive belt tension gauge

YM-03170

Oil filter wrench

90890-01426

Oil filter wrench

YU-38411

Pressure gauge

90890-03153

Pressure gauge

YU-03153

Oil pressure adapter H

90890-03139

Reference

pages

3-21

3-24

3-25, 7-7

3-25

Damper rod holder (30 mm)

90890-01327

Damper rod holder (30 mm)

YM-01327

Ball joint remover

90890-01474

Ball joint remover

YM-01474

Ball joint remover attachment set

90890-01480

Ball joint adapter set

YM-01480

Ball joint installer attachment 38mm

90890-01583

Ball joint installer attachment 38mm

YM-01583

4-57, 4-57

4-63, 4-68

4-63, 4-68

4-63

Ball joint remover short shaft set

90890-01514

Ball joint remover short shaft set

YM-01514

4-63

1-15

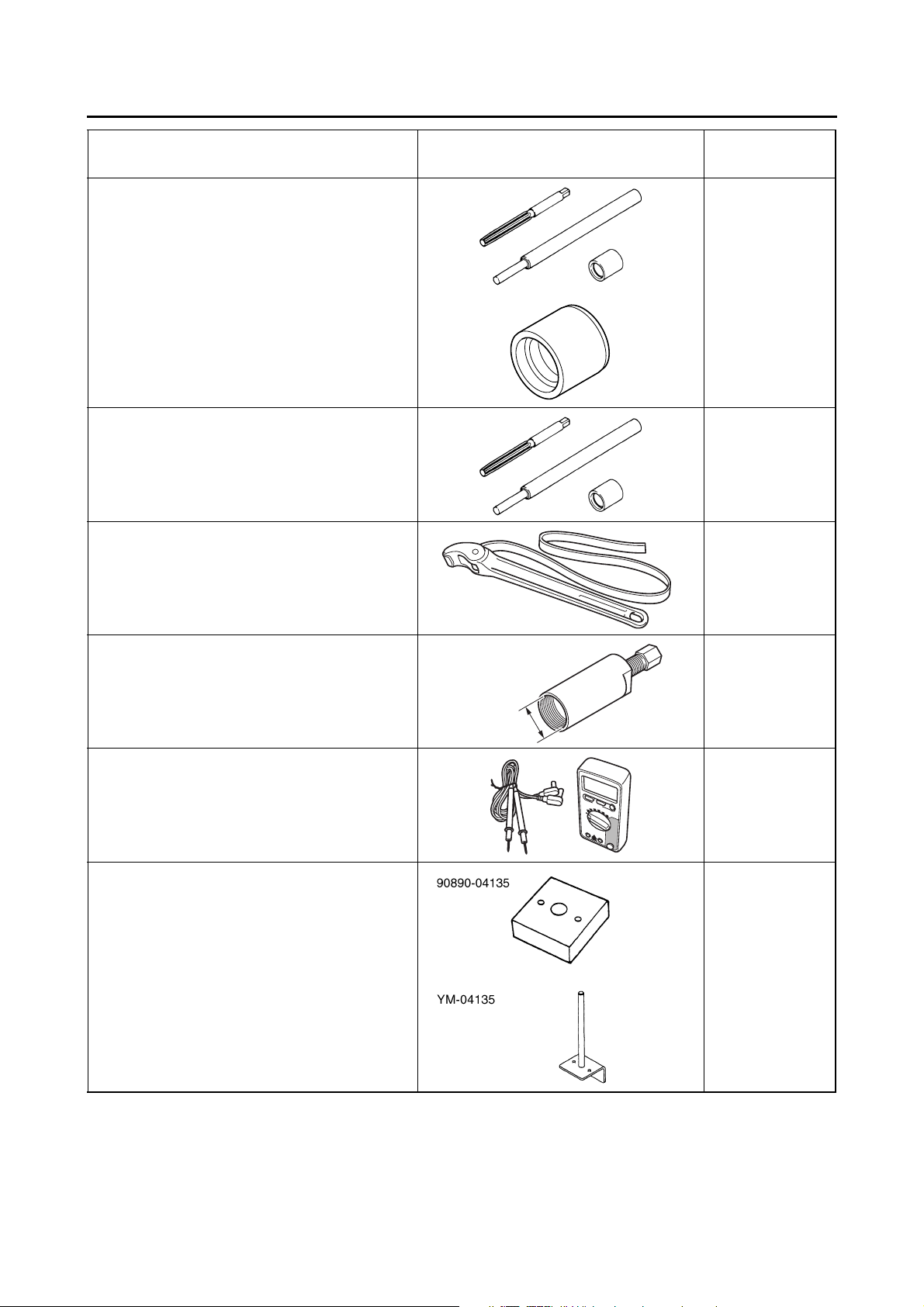

SPECIAL TOOLS

90890-03081

YU-33223

YU-01304

Tool name/Tool No. Illustration

Extension

90890-04136

Compression gauge

90890-03081

Engine compression tester

YU-33223

Piston pin puller set

90890-01304

Piston pin puller

YU-01304

Reference

pages

5-1

5-1

5-22

Valve spring compressor

90890-04019

Valve spring compressor

YM-04019

Valve spring compressor attachment

90890-01243

Valve spring compressor adapter (26 mm)

YM-01253-1

Valve guide remover & installer set (ø5.5)

90890-04016

Valve guide remover (5.5 mm)

YM-01122

5-29, 5-33

5-29, 5-33

5-31

1-16

SPECIAL TOOLS

M38×P1.5

Tool name/Tool No. Illustration

Valve guide remover & installer set (ø5.5)

90890-04016

Valve guide installer (5.5 mm)

YM-04015

Valve guide remover & installer set (ø5.5)

90890-04016

Valve guide reamer (5.5 mm)

YM-01196

Rotor holding tool

90890-04166

YM-04166

Reference

pages

5-31

5-31

5-37, 5-37, 5-38,

5-39, 5-45, 5-46,

5-52, 5-57

Flywheel puller (M38 X P1.5)

90890-04178

Flywheel puller (M38 X P1.5)

YM-04178

Digital circuit tester

90890-03174

Model 88 Multimeter with tachometer

YU-A1927

Sheave fixed block

90890-04135

Sheave fixed bracket

YM-04135

5-37

5-42, 7-8

5-52, 5-56

1-17

SPECIAL TOOLS

Tool name/Tool No. Illustration

Locknut wrench

90890-01348

Locknut wrench

YM-01348

Sheave spring compressor

90890-04134

Sheave spring compressor

YM-04134

Reference

pages

5-52, 5-56

5-52, 5-56

Universal clutch holder

90890-04086

Universal clutch holder

YM-91042

Crankcase separating tool

90890-01135

Crankcase separator

YU-01135-B

5-61, 5-62

5-67, 5-72

1-18

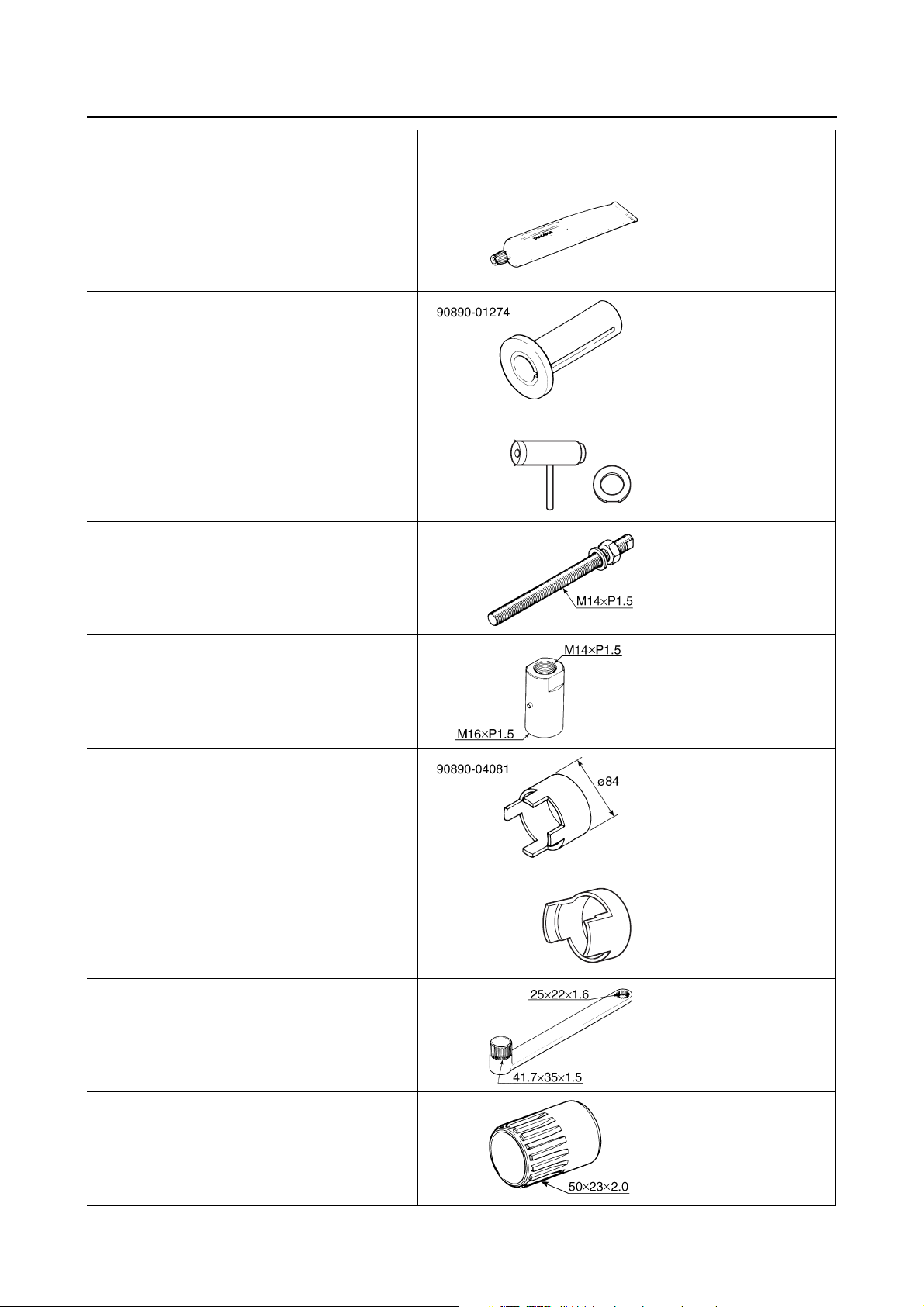

SPECIAL TOOLS

YU-90058/YU-90059

YM-91044

Tool name/Tool No. Illustration

Yamaha bond No. 1215

90890-85505

(Three bond No.1215®)

Crankshaft installer pot

90890-01274

Installing pot

YU-90058

Crankshaft installer bolt

90890-01275

Bolt

YU-90060

Reference

pages

5-68

5-74

5-74

Adapter (M16)

90890-04130

Adapter #13

YM-04059

Spacer (crankshaft installer)

90890-04081

Pot spacer

YM-91044

Coupling gear/middle shaft tool

90890-01229

Gear holder

YM-01229

5-74

5-74

5-84, 5-84, 5-87,

5-87

Bearing retainer wrench

90890-04128

Middle gear bearing retainer

YM-04128

5-85, 5-86

1-19

SPECIAL TOOLS

YU-24460-A

YU-33984

ø33.8

ø26

ø12.5

Tool name/Tool No. Illustration

Ring nut wrench

90890-01430

Ring nut wrench

YM-38404

Final gear backlash band

90890-01511

Middle drive gear lash tool

YM-01230

Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Reference

pages

5-85, 5-86

5-88, 8-29

6-6

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Mechanical seal installer

90890-01581

Mechanical seal installer

YM-01581

Middle driven shaft bearing driver

90890-04058

Middle drive bearing installer 40 & 50 mm

YM-04058

6-6

6-12

6-12

Fuel pressure adapter

90890-03176

Fuel pressure adapter

YM-03176

7-7

1-20

SPECIAL TOOLS

M10×P1.25

M14×P1.5

Tool name/Tool No. Illustration

Test harness– TPS (3P)

90890-03204

Test harness– TPS (3P)

YU-03204

Boots band installation tool

90890-01526

Boots band installation tool

YM-01526

Ring gear fix bolt (M10)

90890-01527

Ring gear fix bolt (M10)

YM-01527

Gear lash measurement tool

90890-01475

Middle drive gear lash tool

YM-01475

Reference

pages

7-8

8-9, 8-11, 8-21,

8-21, 8-23

8-13

8-13

Ring gear fix bolt (M14)

90890-01524

Ring gear fix bolt (M14)

YM-01524

8-29

1-21

Loading...

Loading...