Page 1

Doc. No. OSA 013U-03

INSTRUCTION

OIL LUBRICATOR

SGR-55 MODEL No.880267

WARNING

Prior to operating this pump, be sure to read this operation manual for safety. After reading the manual, please

keep it at hand any time for your quick reference.

Page 2

- Preface

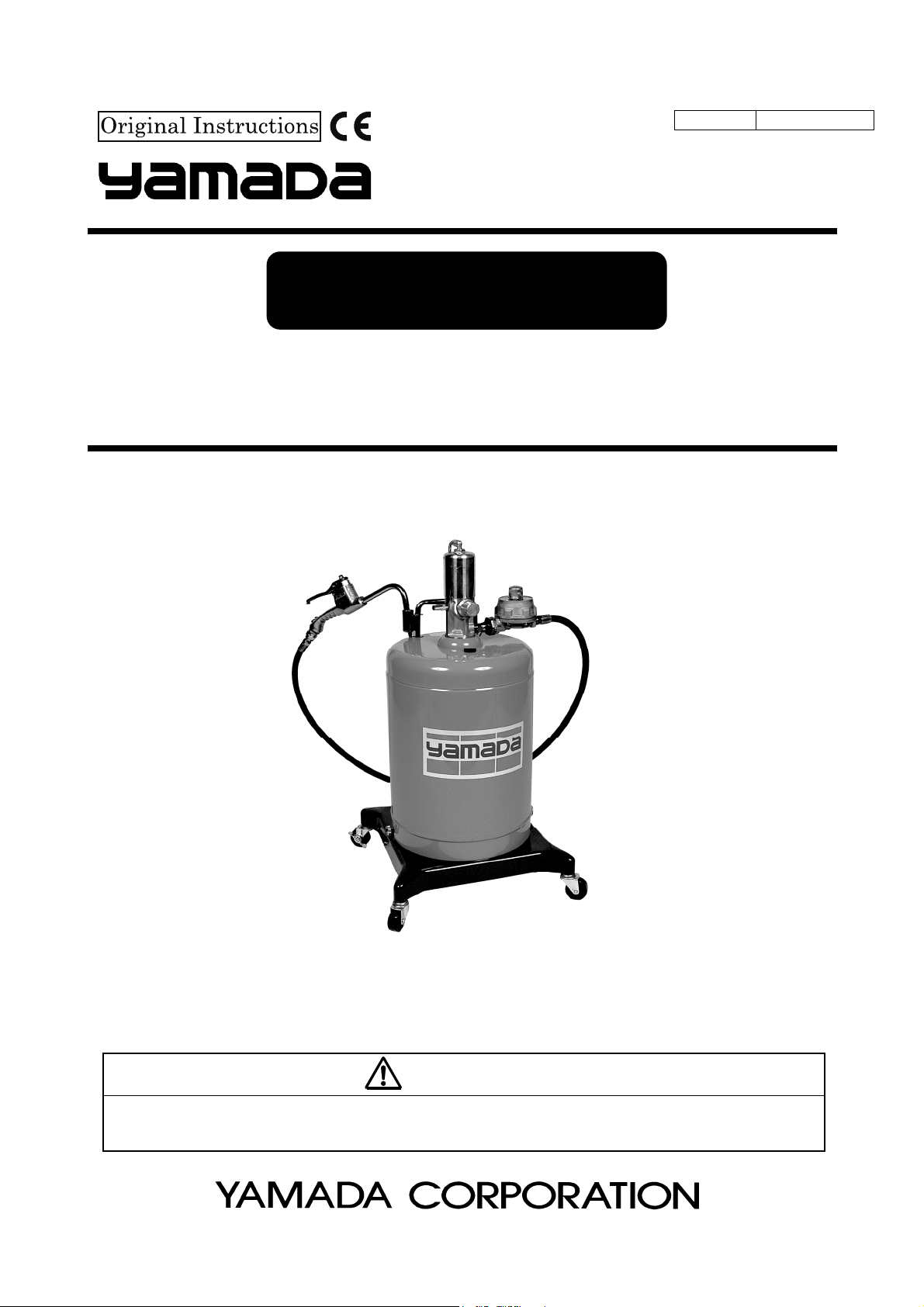

Thank you for purchasing a Yamada Pump. This machine is a portable type oil lubricator to supply lubricant to

machines and vehicles. The machine is provided with a 65 type air-powered pump on the cabinet with a capacity of

20 L, which is suitable to supply of oil.

The machine is also provided with a flow meter in the standard specification, which permits grasp the oil supply

volume accurately.

<Note>

This machine, which is designed exclusively for oil, cannot be used for any substance other than lubricant.

- For Safe Operation

This manual describes the items that are important for the user to operate this product safely, correctly, and efficiently.

Before operating this product, read this manual thoroughly, in particular, “Warnings and Cautions” at the beginning of

this manual.

- Warnings and Cautions

For safe use of this product, be sure to note the following: In this document, warnings and cautions are indicated by

symbols. These symbols are for those who will operate this product and for those who will be nearby, for safe

operation and for prevention of personal injury and property damage. The following warning and caution symbols

have the meanings described below. Be sure to remember their meanings.

WARNING :

This indicates the existence of potential hazard which, if not avoided, will

result in death or serious injury.

1/3

CAUTION :

Furthermore, to indicate the type of danger and damage, the following symbols are also used along with those

mentioned above:

This symbol indicates a DON'T, and will be accompanied by an explanation on something you must not

do.

This symbol indicates a DO, and will be accompanied by instructions on something you must do in a

certain situation.

This indicates the existence of potential hazard which, if not avoided, may

result in bodily injury or in physical damage.

Page 3

- Precautions on Use

The following warnings and cautions are very important. Be sure to observe them.

- The operator and maintenance engineer should read the operation manual thoroughly before operating

this product and performing maintenance in respect of this product.

- Always wear proper safety equipments (facemask, ear plugs, and safety shoes, etc.) when installing,

operating and disassembling this product.

- Lock caster's stopper during and after the work, so that this product should not move unexpectedly.

Also, do not use or leave this product in a slope or any unstable locations. This product moves freely

when the caster is not locked and the damage only accident and the facilities pollution, etc. might occur.

Such a secondary disaster becomes a responsibility on the user side.

- Make ground connection when working with flammable material or in explosive atmosphere. Rapid

pumping of material can result in static electrical charge.

Also, be sure to provide proper ventilation where a flammable atmosphere may exist.

- Execute the daily checkup.

- Use this product according to the product specification.

2/3

WARNING

- Attach a valve (for stop in emergency) or regulator to the air supply pipe to keep supply air pressure

under 0.7MPa.

- Be careful not to drop the cabinet when lifting it up to replace a pail. Catching a falling cabinet may

cause hand injury by its edge.

- Make sure the valve of the oil gun is closed before running the pump. Operating with the valve open

can cause a hose runaway.

- Discontinue it when you feel a hazard or abnormality during the work. And correspond according to the

troubleshooting.

- Keep your face away from the exhaust and discharge ports. Material may suddenly come out. There is

a possibility of losing eyesight if it strikes eyes.

- Stop pump operation immediately when a drum becomes empty. Running the pump dry will cause

excessive vibration, resulting in reduction of pump life and damage to other equipment.

- Be very careful not to drop the grease gun. It may become damaged, resulting in leakage and

malfunction.

- Do not aim exhalation part of this product at any person. Residual pressure may be left inside the gun

even when the pump is not in operation. There is a possibility of losing eyesight if it strikes eyes.

- Before maintenance operation, be sure to stop air from being supplied to the pump, and release the

internal pressure (both air and material) of the pump. There is danger such as spouting of the material

when the maintenance work is done with air supplied.

- Gasoline is a high volatile fuel. Do not use it to clean the pump in any case, otherwise ignition or

explosion may be caused.

- Modification of this pump may lead to death, bodily injury, or a failure. Do not modify it in any case

because it involves a risk.

- Do not discharge material directly onto the ground. Dispose of harmful materials according to the

requirements specified in MSDS or local regulations. Also, dispose of this product according to the local

regulations after removing residual material from inside this product. (Please contact industrial waste

disposal service.)

Page 4

3/3

CAUTION

- Use this product for the material suitable for the specification. Parts may be corroded and material leak

from the damaged parts can lead to environmental pollution. Also, follow handling notes (MSDS) of the

manufacturer about the handling of the material used.

- Move this product slowly and carefully. Avoid any sudden movements like sudden start, stop, and turn.

Material in this product may spill out.

- Take protective measures against rainwater and dust. It is likely to lead to the pollution of the material.

- Watch your step around this product to avoid tripping over the base and casters.

- Be careful about your hands when mounting/dismounting the cabinet or installing a pail. The edges of

the cabinet and pail may cause hand injury. Also, be careful about your posture when moving the pump

or lifting the cabinet to avoid back injury.

- Material remaining inside or on the surface of the pump may spill out by inserting or removing the pump

into/from a pail. Be very careful not to get your clothing dirty.

- Keep hands and fingers away from this product during operation to avoid injury from moving parts.

- Do not touch the surfaces of the pump and the hose when pumping high-temperature material. Risk of

burns exists.

- Be careful when handling the grease gun. Avoid finger injury from being caught between the lever and

gun. The finger might be injured.

- Stop the air supply source after the end of work when not using this pump for a long time such as

nighttimes and holidays. Also, open the valve of the exhalation port and liberate pressure in the pump

and the hose. There is a possibility of polluting facilities because of the damage of the hose and the

leakage of the valve. Such a secondary disaster becomes a responsibility on the user side.

Page 5

Table of Contents

- Preface

- For Safe Operation

- Warnings and Cautions

- Precautions on Use

1. Names and Materials of Parts

1.1 Names and Materials of Parts ............................................................................................. 1

1.2 Contents of Package ........................................................................................................... 1

2. Principle of Operation

2.1 Function of the Air Motor ..................................................................................................... 2

2.2 Function of the Lower Pump ................................................................................................ 2

3. Preparations before Operation ........................................................................................... 3

4. How to Operate the Machine

5. Maintenance and Inspection

5.1 Troubleshooting and Corrective Measures .......................................................................... 5

5.2 Maintenance and Inspection................................................................................................ 6

6. Disassembly and Assembly................................................................................................. 6

7. Parts Disassembly Drawing and Parts List

7.1 880267 SGR-55................................................................................................................... 8

7.2 850206 Oil Gun Ass’y .......................................................................................................... 8

7.3 850792 Pump Ass’y............................................................................................................. 9

8. Specification............................................................................................................................ 10

9. Limited Warranty

.................................................................................................................... 11

............................................................................................... 4

Page 6

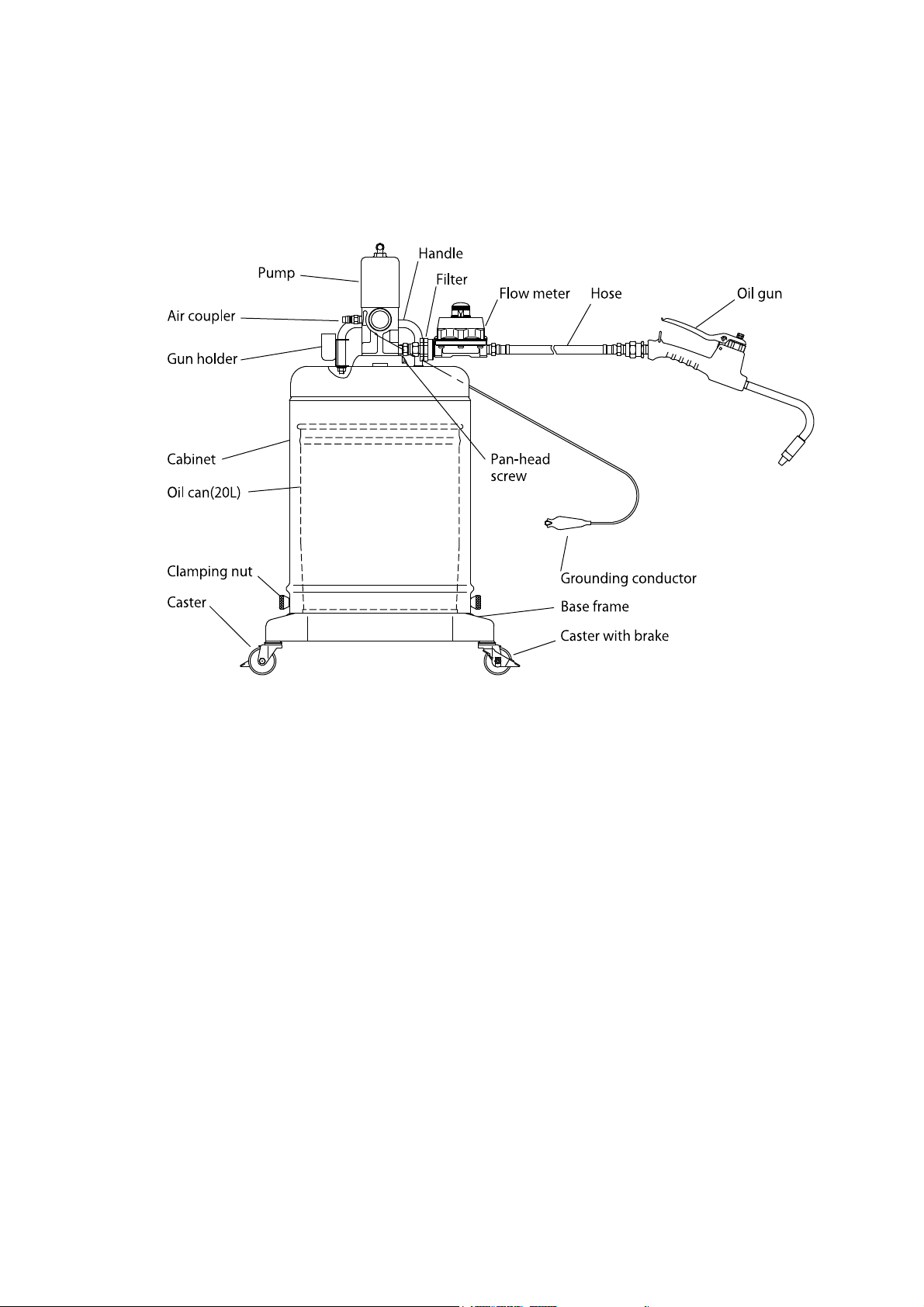

1. Names and Materials of Parts

1.1 Names and Materials of Parts

1.2 Contents of Package

The main equipment and accessories are packed in different cases. Open the top part of the corrugated fiberboard

case and check if the pump assembly and oil can are not damaged and if accessories are all contained in the

package.

1

Page 7

2. Principle of Operation

The YAMADA Air-powered Pump is a reciprocating type pump that is driven by compressed air. This pump consists

of an air motor to drive the pump and a lower pump to draw up the liquid material as shown in the figure.

2.1 Function of the Air Motor

1) In the status shown in the figure at right, the air piston reaches the

upper limit and is now about to go down.

2) The compressed air fed from the air supply port is applied to the

chamber A through the air passage tube from the path provided in

the lower part of the slide valve. The air pressure of the chamber

B is discharged out through the slide valve.

3) As a result, the air piston starts to go down.

4) When the air piston collides with the trip shoe, the slide valve is

momentarily tripped downward by the function of the trip

mechanism.

5) As a result, the air supply is conducted to the chamber B and the

chamber A is conducted to the exhaust port, so that the air piston

is changed to go up.

6) Thus, the air motor continues its reciprocating motion

automatically as long as the supply air is fed to it.

2.2 Function of the Lower Pump

1) The lower pump integrated with the air motor traces the

reciprocating motion of the air motor.

2) This reciprocating motion of the piston causes a sucking operation

and a compressive operation to the suction valve and the piston

valve of the lower pump, thereby discharging the liquid

intermittently.

3) This reciprocating motion is automatically continued until the

delivery side is closed and the liquid compressive pressure of the

lower pump is balanced with the pressure of the air motor.

2

Page 8

3. Preparations before Operation

1) First loosen the pan-head screw and take out the pump from

the cabinet.

Remove the rubber cap at the bottom of the pump Ass’y, insert

the pump into the cabinet, and fix it with a pan-head screw.

Refer to <Assembly of Equipment> indicated on the top

surface of the corrugated fiberboard case. (Fig.1)

2) Loosen the two clamping nuts at the bottom of the cabinet

(turn them counterclockwise), and remove the cabinet from the

base frame. (Fig.2)

3) Transfer the oil to the exclusive use oil can. (Fig.2)

4) Place a oil can in the middle of the base frame and install the

cabinet as it was. Tighten the clamping nut on both sides

equally. (Fig.2)

5) Install the attached hose and the gun at the oil discharge port

of the pump, and clamp the connecting portion securely.

6) Connect the attached air coupler to the air hose and fix it with

a hose band. (The air hose is separately available.) If the air

coupler to be connected to the compressor is not available,

purchase it separately.

7) When the air coupler is connected to the pump, the pump will

be operated for a while, and the pump and hose will be filled with oil.

After that, the pump operation will stop. If the gun lever is pulled in

this status, the oil lubricator can be used any time.

<Note>

- Install the air regulator (separately available) at the air supply port

of the pump. The dedicated air regulator is available as the

standard product. Please use it

- Using the air regulator permits adjusting the supply air pressure to

the pump and reducing the wasteful motion of the pump, with the

result that the operability is improved and the pump life is extended.

In the normal operating status, the pointer of the pressure gauge

should be at 0.3 to 0.5 MPa.

3

Page 9

4. How to Operate the Machine

WARNING

- When the machine is operated, electrostatic sparks may give a shock to the human body or cause

death or bodily injury due to a fire or explosion. Be sure to perform grounding securely by using a

grounding conductor according to the operating environment.

CAUTION

- The supply air pressure should be 0.7 MPa or less. If the primary pressure is more than 0.7 MPa,

install an air regulator on the air line and adjust the pressure to 0.7 MPa or less.

- After the end of daily work or when the machine is not operated for a long time, be sure to shut off the

supply air and open the discharge port valve to bleed the internal pressure of the pump and hose. Any

secondary accident such as pollution of installation, due to hose damage or leakage from the valve

without shutting off the supply air, shall be attributable to the user’s responsibility.

- During machine operation or after completion of movement, be sure to lock

the caster brake for locking. A turnover of equipment may pollute the

installation. (Fig.3)

- During oil change, take extreme care not to allow sand and dust to adhere on the suction tune of the

pump. If sand is mixed in the oil, it will give breakage to the pump and also damage to the important

machine.

<Note>

Using the air regulator permits adjusting the supply air pressure to the pump and reducing the wasteful motion of

the pump, with the result that the operability is improved and the pump life is extended. In the normal operating

status, the pointer of the pressure gauge should be at 0.3 to 0.5 MPa.

1) First loosen the pan-head screw and take out the pump from Before

starting oil supply, be sure to turn the knob of the oil meter

counterclockwise to reset to the “0” position.(Fig.4a)

2) The pump is operated by pulling the lever of the oil gun, and oil is

discharged. To continuously discharge the oil, hook the lever to the

hardware provided at the gun rear. (Fig.4b)

If the discharge oil pressure is so high as to cause splashes, adjust the

supply air pressure with the air regulator.

3) After completion of oiling work, be sure to shut off the supply air of the

pump and bleed the internal air of the hose. For bleeding the internal

pressure of the pump and hose, Insert the oil gun in the return hole of

the lid and pull the gun lever. (Fig.5)

Fig. 4b

Fig. 5

Fig. 3

Fig. 4a

4

Page 10

5. Maintenance and Inspection

5.1 Troubleshooting and Corrective Measures

If the pump operation becomes unstable or trouble is caused to its oil discharge during operation, make a check

according to the following procedure.

Symptom Cause Contents of inspection and corrective measures

The pump cannot be

operated.

The pump is

continuously

operated without

stop.

The pump operated

but the material is

not fed by pressure.

The pump can be

operated but the

discharge volume is

insufficient.

Check if the air regulator

is normally operated.

YES

Check if the valve on the

outlet on the pump side

is not closed.

NO

Remove the lower pump

and operate the air motor

independently.

Check if the material

does not leak at the

exhaust port of the air

motor.

Check if there is any

open valve on the

material output side.

NO

When the outlet side is

closed, check if any leak

does not occur on the

pipe, connecting hose or

its connecting portion.

The material vessel is

empty.

Check if the supply air

pressure is not lowered.

inoperable

check

check

operable

YES

NO

YES

YES

NO

Check if the valve in the

course of piping is not

closed.

Clogging occurs in the

connecting hose, pipe,

outlet valve, or gun.

The lower pump is faulty.

The air motor is faulty.

The packing seal of the

air motor is worn away.

The valve of the lower

pump or the packing is

worn away.

Check and re-supply, or

replace.

Increase the pressure up

to 0.7MPa by the air

regulator. At this time, the

oil volume does not reach

the specified level.

The valve seat surface of

the lower pump, the

packing is worn away or

clogging is caused by

dust or foreign

substances.

Ask for servicing the

lower pump and see

P. 7 .

Ask for servicing the

air motor

The air supply volume

to the pump is

insufficient. Replace

the air hose with a

thicker one or check

the air compressor.

5

Page 11

5.2 Maintenance and Inspection

[Oiling]

For lubrication of the pump, perform oiling once every 10 days with lubricating oil. (Fig.6)

Supply the lubricating oil as following.

1) Remove the air regulator.

2) Inject a few drops of lubricating oil (approx. 0.5 ml) into the air supply port as shown in

the figure at right.

Use turbine oil class 1 ISO (VG-32) or equivalent as the lubricating oil.

[Inspection]

1) Oil is a fluid and easily polluted. Keep it clean at all times.

2) To protect the oil meter, a filter is installed between the pump and

the oil gun. If filter clogging occurs, the oil flow is get worse. Clean

the filter sometimes. (Fig.7)

3) The oil-proof hose is a consumable product. Check it periodically.

If any blemish or leakage is found, replace the hose a little earlier.

4) The packing of the pump will be worn away. Check and replace it

at least once a year.

6. Disassembly and Assembly

Fig. 6

Fig. 7

When the pump operation becomes defective or stops, do not disassemble the pump thoughtlessly but refer to the

item on P.5 (Troubleshooting and Corrective Measures), and judge the condition carefully and disassemble only the

minimum necessary parts.

The air motor is rarely touched directly, so its failure rate is very low. The air motor does not need to be disassembled.

If disassembling is required, ask the dealer to disassemble the air motor.

WARNING

- Gasoline is a high-volatility material. Do not use gasoline to clean the pump in any case, otherwise it

may cause ignition or explosion.

CAUTION

- Before starting disassembling or inspecting the machine, be sure to shut off the supply air and open

the outlet valve to release the internal pressure of the machine.

- When washing parts, do not use such a liquid as corrodes aluminum, copper alloy, iron, etc.

6

Page 12

[Disassembling the air motor and the lower pump]

1) Shut off the air that is supplied to the pump to release the internal

pressure of the pump.

2) Disconnect the air connection hose, material hose, etc. from the pump.

3) Unscrew the pan-head screw of the body supporter that fixes the pump.

Pull out the pump upward, and the pump can be removed from the

cabinet.(Fig.8)

4) Fix the air motor body of the pump on a vise. (Fig.9)

<Note>

The air cylinder is easily damaged. Do not fix it on the vise in any case.

5) Set a pipe wrench on the knurling part of the suction tube and unscrew the

suction tube to remove the suction tube. (Fig.9)

6) Pull out the pin of the piston rod and unscrew the connecting rod to

remove it. Then, the air motor and the lower pump can be separated from

each other.

[Disassembling the lower pump]

1) Disconnecting the piston rod of the air motor from the connecting rod by

removing the pin. (Fig.10)

2) The ball, cap-packing, spring, etc. can be disassembled by unscrewing the

valve seat with the housing of the intake valve ass’y secure. Wash and

check each part. Replace the worn parts, if any. (Fig.11)

[Disassembling the air motor]

Fig. 8

Fig. 9

Fig. 10

Fig. 11

- The air motor is not easily adjusted at assembly. If an air motor

failure is found at maintenance and inspection, ask the dealer to

repair the air motor.

- For the user who intends to perform maintenance, the manual

related to the disassembly and structure of the motor is available

as a separate volume.

Ask the dealer for further information.

7

Page 13

7. Parts Disassembly Drawing and Parts List

7.1 880267 SGR-55

7.2 850206 Oil Gun Ass’y

No.1~20 : 800683 Valve body Ass’y

No.21~25 : 800680 Nozzle Ass’y

No.26~29 : 800684 Swivel joint Ass’y

No. Parts No. Descriptions Q’ty

1 850792 Pump Ass’y 1

2 680743 Air coupler (plug) 1

3 802538 Filter 1

4 802570 Oil meter 1

5 695052 Hose 1

6 850206 Oil gun 1

7 830138 Gun holder 1

8 705841 Handle 1

9 770754 Return 1

10 682276 Nut with flange 2

11 830800 Cabinet 1

12 602296 Pan-head screw 1

13 682905 Oil can 1

14 704570 Clamping nut 2

15 831098 Base frame 1

16 681767 Caster(with brake) 2

17 680136 Caster 2

18 681769 Grounding conductor 1

19 685370 Union adapter 1

No. Parts No. Descriptions Q’ty

1 627290 Nut 2

2 703095 Handle 1

3 703097 Link 1

4 703096 Pin 1

5 703098 Pin 1

6 630777 E-stop ring 4

7 703089 Packing holder 1

8 640019 O-ring 1

9 680275 Packing 1

10 703090 Washer 1

11 707378 Spring 1

12 703094 Spring holder 1

13 703093 Spring 1

14 703088 Valve stem 1

15 770319 Packing 1

16 795021 Valve 1

17 703100 Valve seat 1

18 703101 Washer 1

19 703091 Body 1

20 703099 Handle hanger 1

21 703323 Union 1

22 630316 Ball 1

23 703322 Spring 1

24 703324 Nozzle 1

25 703321 Nozzle pipe 1

26 703328 Swivel nut 1

27 703327 Swivel stud 1

28 640014 O-ring 1

29 703329 Swivel body 1

8

Page 14

7.3 850792 Pump Ass’y

<Note>

Air Motor Lower Pump

If an air motor failure is found at maintenance and inspection, ask the dealer to repair the air motor.

No. Parts No. Descriptions Q’ty No. Parts No. Descriptions Q’ty

1 701768 Elbow 2 24 701825 Spring 1

2 701765 Tube sleeve 2 25 682976 O-ring 1

3 701766 Tube gland 2 26 710672 Spring cover 1

4 708523 Air passage tube 1 27 706068 Piston rod 1

5 708311 Air cylinder bonnet 1 28 702725 Washer 1

6 701811 Cap nut 1 29 770287 Gland packing 4

7 701815 Plate 2 30 702726 Packing retainer 1

8 770180 Piston packing 1 31 702727 Spring 1

9 701810 Washer 1 32 704297 Washer 1

10 706067 Spindle bush 1 33 703010 Suction tube 1

11 640012 O-ring 1 34 706091 Union 1

12 706066 Gland housing 1 35 632039 Pin 2

13 770182 O-ring 1 36 703011 Connecting rod 1

14 706077 Air motor body 1 37 632039 Pin 1

15 770181 Valve seat gasket 1 38 702772 Valve housing 1

16 701822 Valve seat 1 39 702773 Washer 1

17 590085 Valve guide plate 1 40 770292 Cap-packing 1

18 701823 Valve slide 1 41 702774 Washer 1

19 701816 Valve supporter 1 42 702776 Spring 1

20 705659 Trip shoe 1 43 630324 Ball 1

21 681768 Screw (w/spring) 2 44 702775 Valve seat 1

22 705661 Trip shoe guide 1 45 803484 Foot valve ass’y 1

23 704893 Spring holder 1

9

Page 15

8. Specification

■Specification

TYPE

MODEL No.

PUMP RATIO (NOMINAL)

FLUID CONNECTION DISCHARGE PORT Oil gun

AIR CONNECTION SUPPLY PORT Coupler plug,PS-20PM

OPERATING AIR PRESSURE

MAXIMUM

OPERATING NOISE

AMB. TEMP. RANGE

WEIGHT

ACCESSORIES

*1 Measurement method of A-weighted sound pressure level is based on ISO 1996.

*2 Measurement method of A-weighted sound power level is based on ISO 3744.

■Performance Curve (only the pump)

<Note>

The continuous pump operation should be

avoided if the desired delivery is in the range

shaded in the figure below.

A-WEIGHTED SOUND

PRESSURE LEVEL *1

A-WEIGHTED SOUND

POWER LEVEL *2

ENV. TEMPERATURE

MATERIAL TEMP.

Hose (695052) 3/8×1.5m

Oil gun (850206)

Oil meter (802570) 3~10 L/min

Oil can (682905) 20 L

Air coupler (680743)

■Dimensions

SGR-55

880267

1.8 x 1

0.2 ~ 0.7 MPa

86 dB

96 dB

℃

0 ~ 60

℃

0 ~ 80

16.0 kg

10

Page 16

9. Limited Warranty

● If an abnormality occurs during normal operation in accordance with the operating instructions and other operating

cautions within the warranty period (12 months after date of purchase) that can be attributed to a manufacturing

defect, the defective parts of this product will be serviced or the product will be replaced free of charge. However,

this warranty will not cover compensation for incidental damage or any malfunction listed below.

1. Warranty period

This warranty will be valid for a period of 12 months after the date of purchase.

2. Warranty

If, during the warranty period, any of the material of the genuine parts of this product or the workmanship of this

product is found defective, and is so verified by our company, the servicing cost will be fully born by our company.

3. Exclusion

Even during the warranty period, this warranty does not cover the following:

1) Malfunction arising from use of parts other than manufacturer-specified genuine parts

2) Malfunction arising from misuse or operating errors, or lack of storage or maintenance care

3) Malfunction arising from use with a fluid that may cause corrosion, inflation or dissolution of the component

parts of the product

4) Irregularity arising from repair made by other than by our firm, our regional office, dealer or authorized service

personnel

5) Malfunction arising from modification of the product by other than authorized service personnel

6) Wear and tear of parts that must be regularly replaced in the course of normal operation, such as packings,

O-rings, balls, and valve seats

7) Malfunction and/or damage due to transportation, moving or droppage of the product after purchase

8) Malfunction and/or damage due to fire, earthquake, flood or other force majeure

9) Malfunction arising from use of compressed air that contains impurities or excessive moisture, or use of

gases or fluids other than the specified compressed air

10) Malfunction arising from use with a fluid that causes excessive abrasion or use of lubricating oil other than

that specified for this product

Furthermore, this warranty does not cover the rubber parts, or other parts that are subject to wear in normal

operation, used in this product and its accessories.

4. Parts

Parts for this product will be kept available for 5 years after discontinuation of production. Once 5 years have

elapsed after close of production, availability of parts for this product cannot be guaranteed.

11

Page 17

MEMO.

Page 18

Manufactured by

YAMADA

CORPORATION

INTERNATIONAL DEPARTMENT

No.1-3, 1-Chome, Mimami-Magome, Ohta-Ku, Tokyo, 143-8504, Japan

PHONE : +81-(0)3-3777-0241

FAX : +81-(0)3-3777-0584

YAMADA

Aquamarijnstraat 50, 7554 NS Hengelo (0), The Netherlands

PHONE : 31(0) 74-2422032

FAX : 31(0) 74-2421055

EUROPE

B.V.

201303 OSA013U

Loading...

Loading...