Page 1

8800 SERIES

GRADE

1 MORTISE LOCKSET

MORTISE

8800

PARTS & SERVICE MANUAL

PARTS

Page 2

August 2004

HOW TO ORDER PARTS

Page 2

8800 Series Parts & Service Manual

To order parts, use the appropriate part number and specify finish if necessary.

For example, to order 10 curved lip strikes for any function:

Quantity Part Number Description

10 50-8800-2023-FIN Strike, Curved Lip

To order 10 cylinder latch levers for an Entrance Function (8807):

Quantity Part Number Description

10 50-8899-0010 Cylinder Latch Lever

For further assistance, contact your authorized Yale distributor or contact Yale directly at (800) 438-1951.

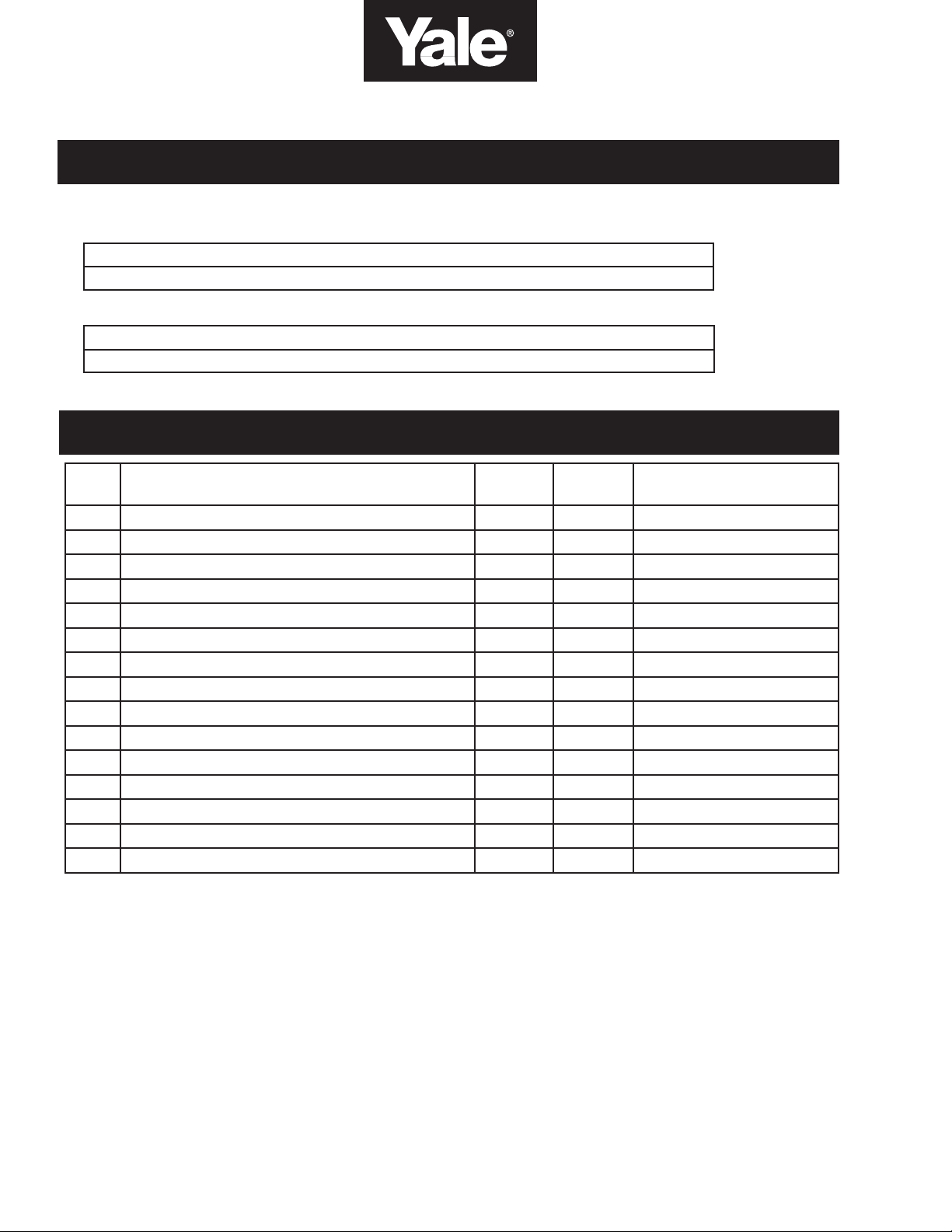

FINISH CHART

ANSI

Code

Finish Description Roses Levers Armor Fronts/Strikes

605 Bright Brass, Clear Coated 003 003 003

605e Bright Brass, PVD 003 003 003

606 Satin Brass, Clear Coated 004 004 004

606e Satin Brass, PVD 004 004 004

609 Satin Brass, Blackened, Satin Relieved, Clear Coated 609 609 009

611 Bright Bronze, Clear Coated 009 009 009

612 Satin Bronze, Clear Coated 010 010 010

613 Satin Bronze, Oxidized & Oil Rubbed 007 007 007

613e Satin Bronze, Oxidized, PVD 007 007 007

616 Satin Bronze, Blackened, Satin Relieved, Clear Coated 616 616 616

619 Satin Nickel Plated, Clear Coated 619 619 619

625 Bright Chrome Plated 026 026 032

626 Satin Chrome Plated 025 025 033

629 Bright Stainless Steel 032 032 032

630 Satin Stainless Steel 033 033 033

FINISH CARE

8800 Series Mortise Locks are designed to provide the highest standard of product quality and performance. Care should be

taken to ensure a long-lasting finish. When cleaning is required, use a soft damp cloth. Using lacquer thinners, caustic

soaps, abrasive cleaners or polishes could damage the coating and result in tarnishing.

PVD LIFETIME FINISH

Physical Vapor Deposition (PVD) is a technologically advanced finish coating that provides the ultimate surface protection against

environmental elements and everyday wear and tear. PVD matches clear coated finishes in appearance, yet surpasses them in

durability. Yale

®

warrants all its PVD finishes against corrosion, tarnish, wear, discoloring and peeling for the lifetime of the part to

which it has been applied. Ask your sales representative for specific warranty information.

MAINTENANCE

Yale

®

8800 Series Mortise Locks are manufactured to be maintenance-free under normal operating conditions and environments. Subjection to extremely heavy traffic and/or particularly dusty and dirty environmental conditions, however, may eventually cause unsatisfactory operation due to slow-moving parts or sticking cylinders. In this case, it may be necessary to clean

and

re-lubricate the lockset to maintain optimum performance. To clean the lockset mechanism, use a penetrating or solvent type

lubricant to loosen sticking components, then lubricate with lithium grease. To free sticking or jammed cylinders, lubricate with

graphite or a non-oily lubricant (such as Lock-EZE). Do not use petroleum-based lubricants in the cylinder keyway.

Page 3

August 2004

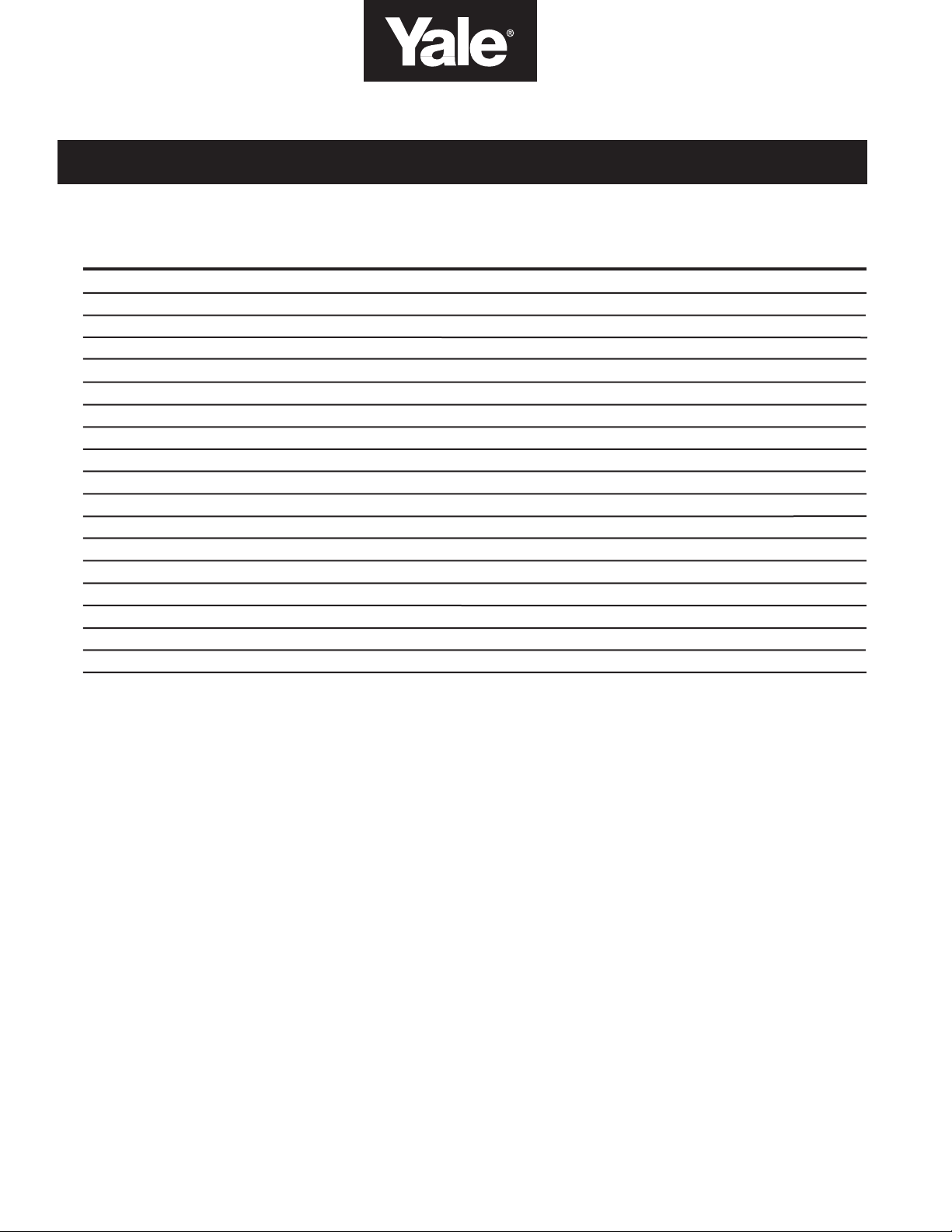

TABLE OF CONTENTS

Page 3

8800 Series Parts & Service Manual

How to Order Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Finish Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Lock Body Assemblies (by Function) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-45

Function ANSI Description

8801 F01 Passage Latch

8802 F19 Privacy Lock

8805 F07 Storeroom or Closet Lock

8807 F04 Entrance Lock

8808 F05 Classroom Lock

8808-2 -- Double Cylinder Classroom Lock

8811-2 F33 Double Cylinder Classroom Deadbolt Lock

8812-2 F34 Double Cylinder Classroom Security Lock

8813ST F29 Classroom Deadlock

8813ST-2 -- Double Cylinder Classroom Deadlock

8814 F18 Deadlock

8814-2 F16 Double Cylinder Deadlock

8815 F17 Deadlock

8817-2 F09 Apartment, Exit or Public Toilet Lock

8818-2 -- Classroom Security Intruder Lock

8820 F15 Hotel/Motel Lock

8822 F13 Dormitory Lock

8823 -- Storeroom Lock

8828 F31 Exit Latch

8829 -- Closet Lock

8830-2 F30 Asylum Lock

8832 -- Hotel/Motel Lock

8833 -- Exit Lock

8833-2 -- Double Cylinder All Purpose Lock

8847 F20 Entrance or Apartment Door Lock

8860 F21 Entrance or Storeroom Lock

8860-2 F14 Double Cylinder Entrance or Storeroom Lock

8861 -- Dormitory or Storeroom Lock

8862 F22 Bathroom Lock

8867 F12 Dormitory or Exit Lock

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

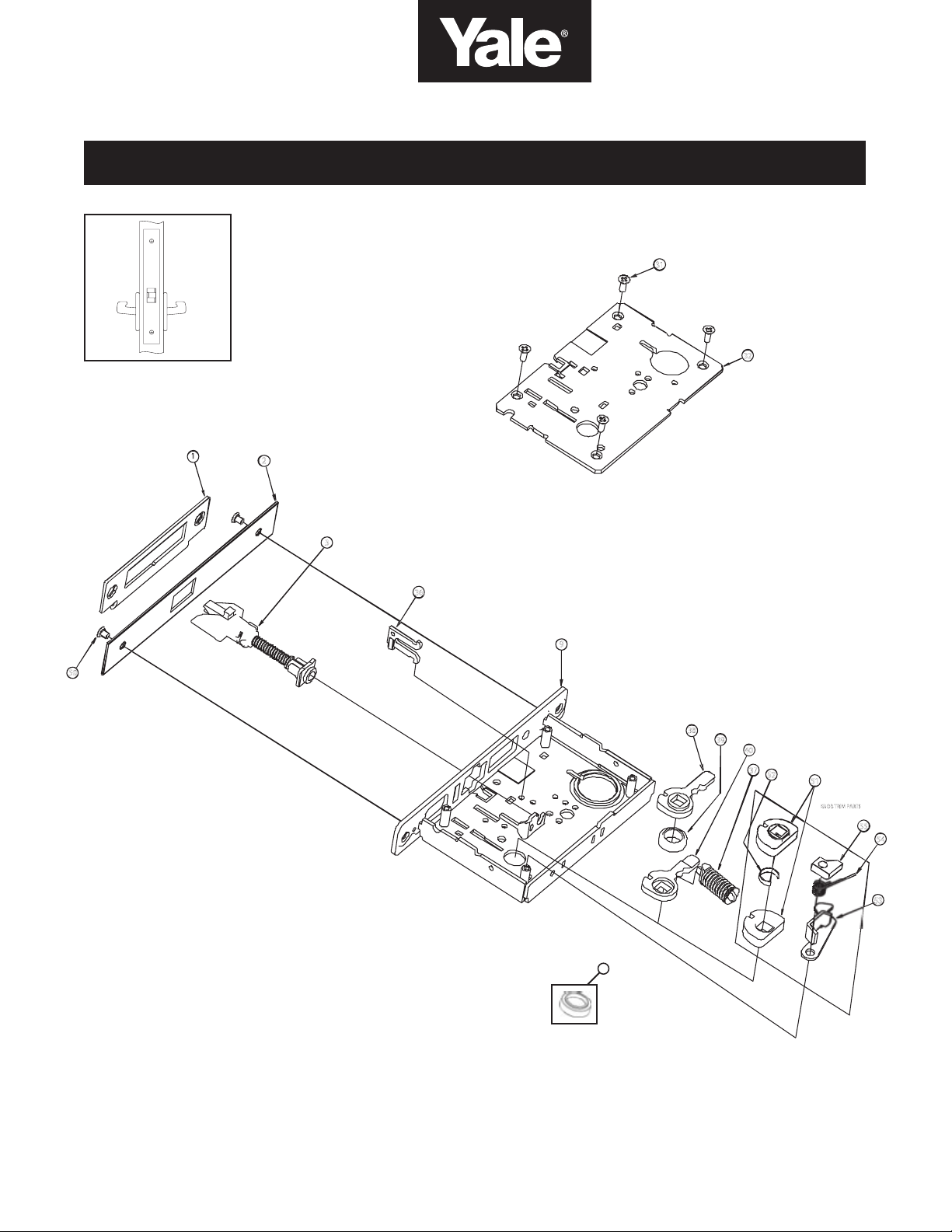

Page 4

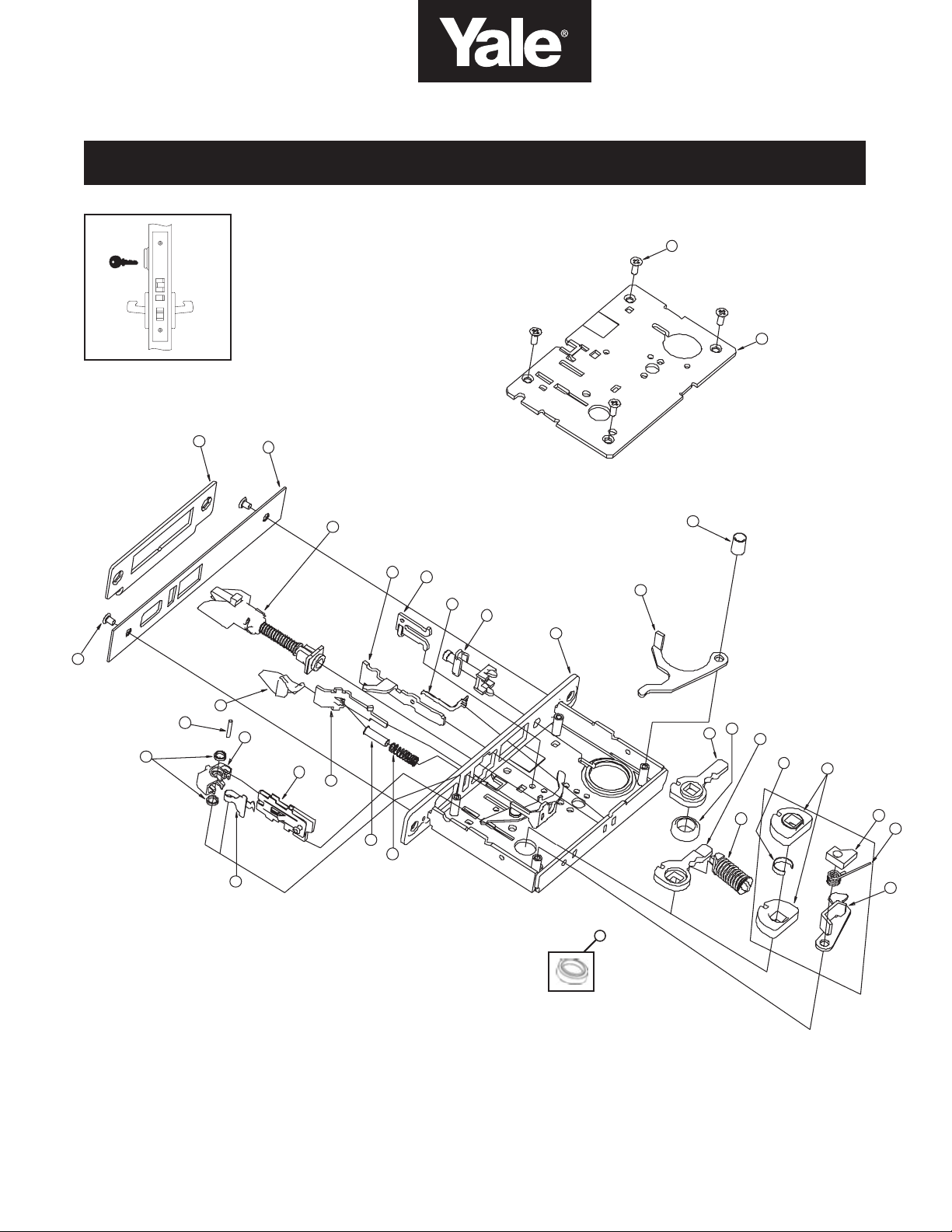

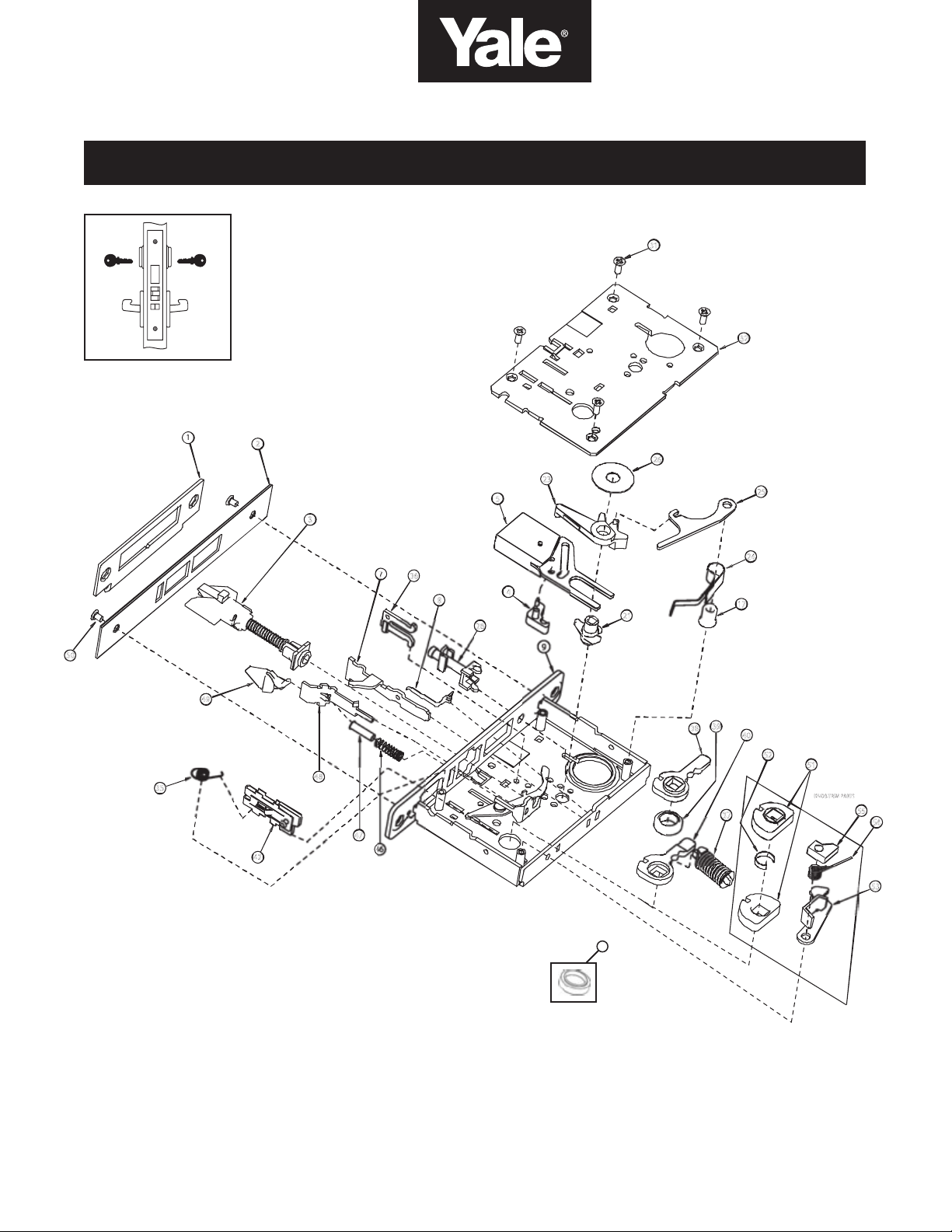

1 50-8800-X023 Strike, Curved Up 1

2 50-8801-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

9 50-8899-0001 Case Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Spacer, Hub (Knob Trim) 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

August 2004

8801

Page 4

8800 Series Parts & Service Manual

Page 5

August 2004

8801

Page 5

8800 Series Parts & Service Manual

2

50

3

36

9

55

54

53

39

40

4

37

51

31

Passage Lock (F01)

SL Trim

56

Page 6

August 2004

8802/8811-2/8822

Page 6

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8802-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

4 50-8899-0001 Auto Unlock Insert 1

5 50-8899-0002 Deadbolt Assembly 1

9 50-8800-0002 Case Assembly 1

17 50-8899-0014 Spacer (Classroom) 1

21 50-8800-1120 Deadbolt Hub 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

25 50-8899-0020 Auto Retract Lever 1

26 50-8899-0021 Deadbolt Washer 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

35 50-8899-0032 Unlock Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

42 50-8899-0036 Locking Piece Assembly 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 7

August 2004

8802/8811-2/8822

Page 7

8800 Series Parts & Service Manual

KNOB TRIM PARTS

1

50

35

285212625

17

385553

37

51

32

Privacy Lock (F19)

Dormitory Lock (F13)

Classroom Deadbolt Lock

(F33)

SL Trim

56

Page 8

August 2004

8805

Page 8

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8805-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0001 Case Assembly 1

11 50-8899-0010 Cylinder Latch Lever 1

16 50-8899-0015 Spacer (1/2 Width) 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

33 50-8899-0030 Locking Piece Jamb 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

42 50-8899-0036 Locking Piece Assembly 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 9

August 2004

8805

Page 9

8800 Series Parts & Service Manual

2

50

42

3

36

8

9

11

28

32

48

47

33

38

55

39

40

4

37

51

Storeroom or

Closet Lock (F07)

SL Trim

56

Page 10

August 2004

8807

Page 10

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8807-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0002 Case Assembly 1

11 50-8899-0010 Cylinder Latch Lever 1

16 50-8899-0015 Spacer (1/2 Width) 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

34 50-8899-0031 Toggle Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

41 50-8899-0035 Connector Pin, Toggle Button 1

42 50-8899-0036 Locking Piece Assembly 1

44 50-8899-0038 Toggle Washer 2

45 50-8800-6003 Stopworks Button 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

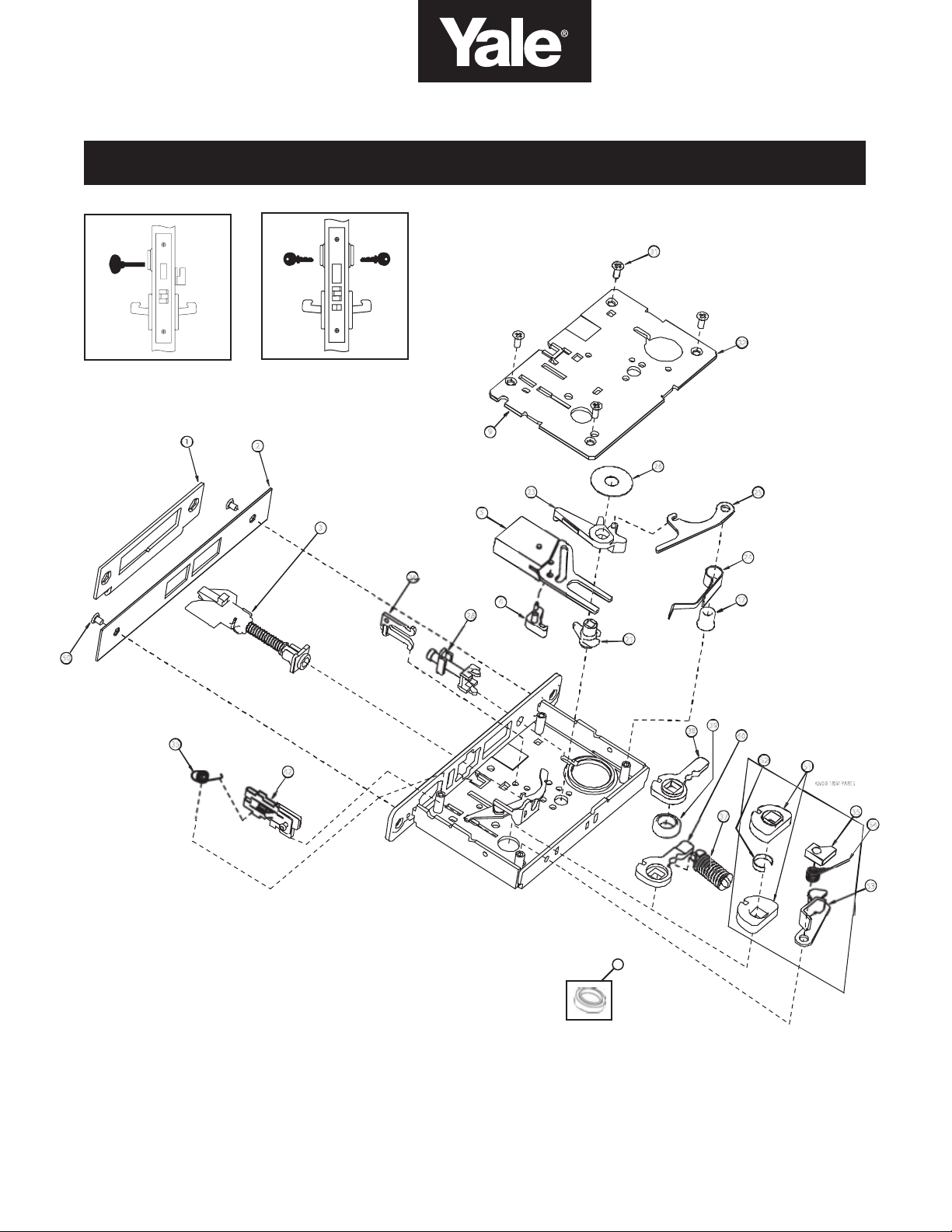

Page 11

August 2004

8807

Page 11

8800 Series Parts & Service Manual

88078807

KNOB TRIM PARTSKNOB TRIM PARTSKNOB TRIM PARTS

313131

323232

1

2

505050

414141

444444

424242

454545

3

363636

7

8

9

111111

161616

282828

484848

343434

494949

474747

464646

383838

393939

555555

545454

535353

404040

373737

515151

525252

Entrance Lock (F04)

SL Trim

56

Page 12

August 2004

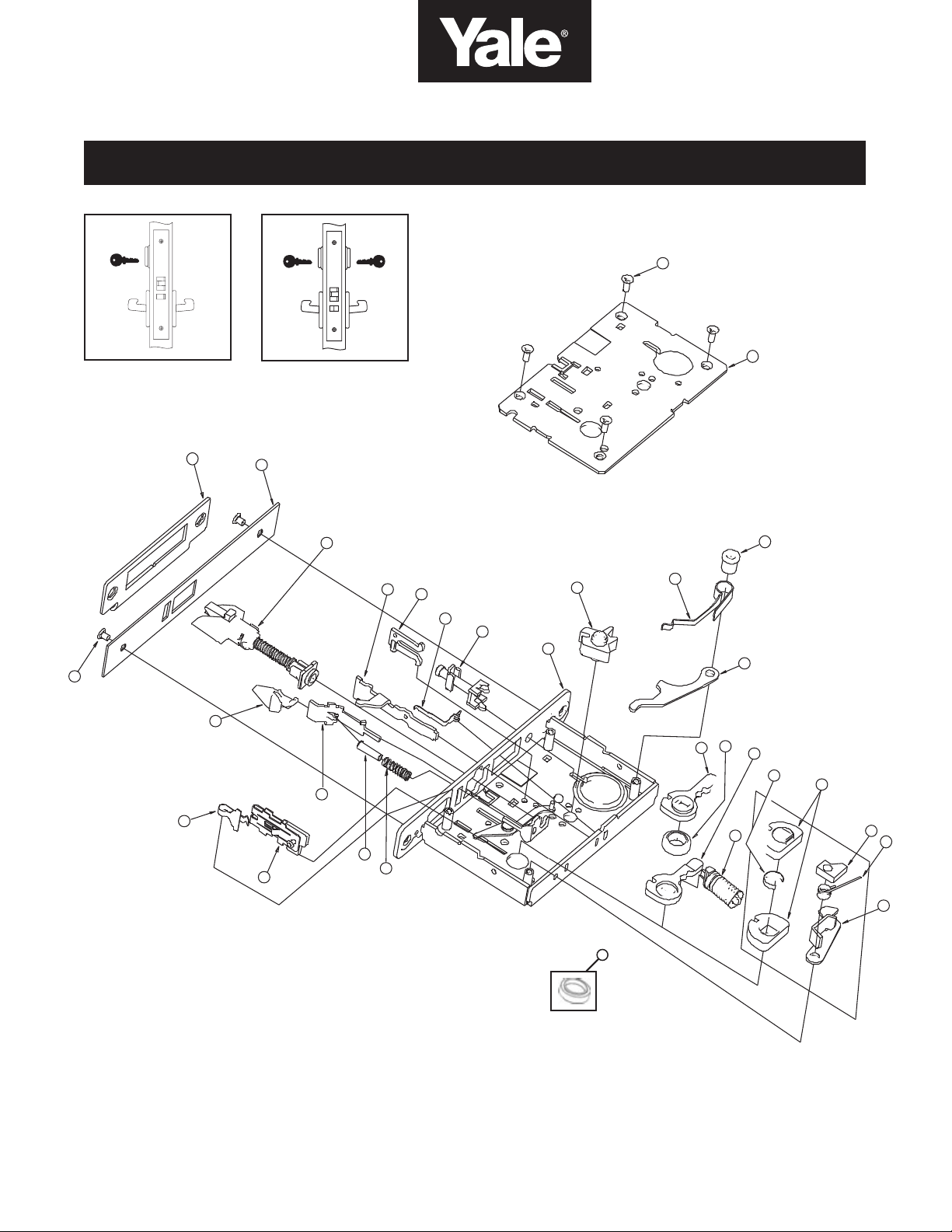

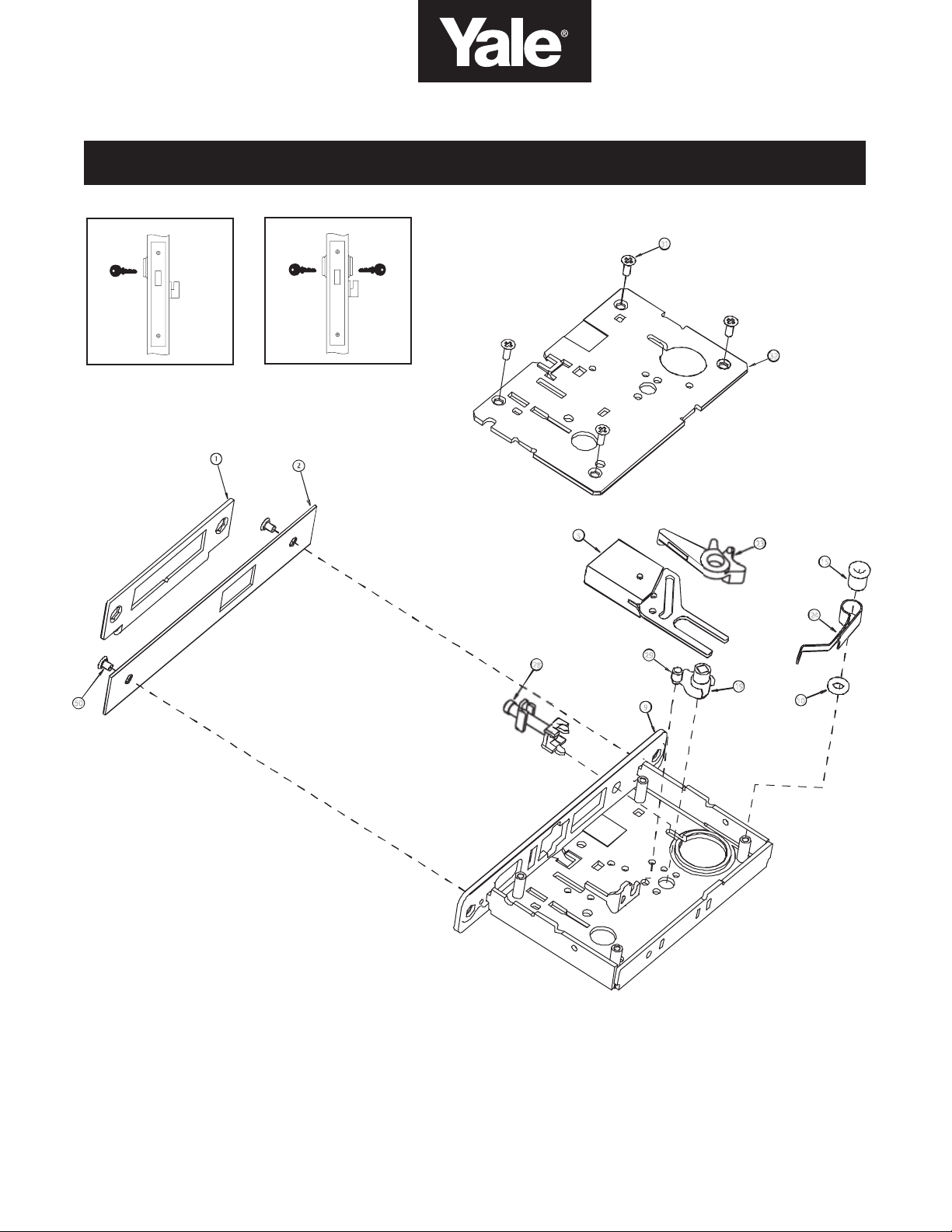

8808/8808-2

Page 12

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8805-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0003 Case Assembly 1

12 50-8899-0011 Cylinder Latch Lever 1

15 50-8899-0014 Spacer (Classroom) 1

20 50-8800-1015 Classroom Hub 1

22 50-8899-0017 Classroom Spring 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

34 50-8899-0031 Toggle Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

42 50-8899-0036 Locking Piece Assembly 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 13

August 2004

8808/8808-2

Page 13

8800 Series Parts & Service Manual

8808 / 88108808 / 8810

KNOB TRIM PARTS

KNOB TRIM PARTSKNOB TRIM PARTS

1

2

50

5050

3

36

3636

7

8

9

22

2222

20

2020

28

2828

48

4848

42

4242

49

4949

34

3434

47

4747

46

4646

38

3838

39

3939

55

5555

54

5454

53

5353

40

4040

37

3737

51

5151

52

5252

31

3131

32

3232

15

1515

12

1212

1

Classroom Lock (F05)

Classroom Lock (F32)

SL Trim

56

Page 14

August 2004

8812-2

Page 14

8800 Series Parts & Service Manual

1 50-8800-2020 Strike, Curved Lip 1

2 50-8820-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

4 50-8899-0001 Auto Lock Insert 1

5 50-8899-0002 Deadbolt Assembly 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0002 Case Assembly 1

17 50-8899-0014 Spacer (Classroom) 1

21 50-8800-1120 Deadbolt Hub 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

25 50-8899-0020 Auto Retract Lever 1

26 50-8899-0021 Deadbolt Washer 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

35 50-8899-0032 Unlock Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

42 50-8899-0036 Locking Piece Assembly 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 15

August 2004

8812-2

Page 15

8800 Series Parts & Service Manual

50

3

36

7

8

5

23

25

24

17

48

47

395453

40

4

37

52

32

Classroom Security

Lock (F34)

SL Trim

56

Page 16

August 2004

8813

Page 16

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Up 1

2 50-8813-X019 Armor Front 1

5 50-8899-0002 Deadbolt Assembly 1

9 50-8800-0001 Case Assembly 1

10 50-8899-0009 Washer 1

15 50-8899-0014 Spacer (Classroom) 1

19 50-8800-7017 Hub Core 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

28 50-8899-0023 Cylinder Retainer Assembly 1

29 50-8899-0024 Post 1

31 50-8899-0029 Machine Screw (8-32 x x5/16) 4

32 50-8800-1008 Cover 1

50 81-00X2-0404 Armor Front Screw 2

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 17

August 2004

8813

Page 17

8800 Series Parts & Service Manual

1

2

50

Classroom Deadlock

Classroom Deadlock

Page 18

August 2004

8814/8815

Page 18

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Up 1

2 50-8813-X019 Armor Front 1

5 50-8899-0002 Deadbolt Assembly 1

9 50-8800-0001 Case Assembly 1

10 50-8899-0009 Washer 1

15 50-8899-0014 Spacer (Classroom) 1

21 50-8800-1120 Deadbolt Hub 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x x5/16) 4

32 50-8800-1008 Cover 1

50 81-00X2-0404 Armor Front Screw 2

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 19

August 2004

8814/8815

Page 19

8800 Series Parts & Service Manual

24

32

Deadlock (F18)

Deadlock (F17)

Page 20

August 2004

8817-2

Page 20

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8805-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0004 Case Assembly 1

11 50-8899-0010 Cylinder Latch Lever 1

16 50-8899-0015 Spacer (1/2 Width) 1

28 50-8899-0023 Cylinder Retainer Assembly 1

30 50-8899-0025 Pivotal 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-0022 Cover Assembly 1

34 50-8899-0031 Toggle Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

42 50-8899-0036 Locking Piece Assembly 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 21

August 2004

8817-2

Page 21

8800 Series Parts & Service Manual

49

Apartment, Exit or

Public Toilet Lock

(F09)

SL Trim

56

Page 22

August 2004

8818-2

Page 22

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8820-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

6 50-8800-0021 Deadbolt with Retraction Lever 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0005 Case Assembly 1

13 50-8899-0012 Cylinder Latch Lever 1

18 50-8899-0016 Spacer (7/16 Width) 1

21 50-8800-1120 Deadbolt Hub 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

25 50-8899-0020 Auto Retract Lever 1

26 50-8899-0021 Deadbolt Washer 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

34 50-8899-0031 Toggle Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

42 50-8899-0036 Locking Piece Assembly 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 23

August 2004

8818-2

Page 23

8800 Series Parts & Service Manual

2

6

Classroom Security

Intruder Lock

SL Trim

56

Page 24

August 2004

8820/8832

Page 24

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8820-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

6 50-8800-0021 Deadbolt with Retraction Lever 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0002 Case Assembly 1

14 50-8899-0013 Cylinder Latch Lever 1

18 50-8899-0016 Spacer (7/16 Width) 1

21 50-8800-1120 Deadbolt Hub 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

25 50-8899-0020 Auto Retract Lever 1

26 50-8899-0021 Deadbolt Washer 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

33 50-8899-0030 Locking Piece Jamb 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

42 50-8899-0036 Locking Piece Assembly 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 25

August 2004

8820/8832

Page 25

8800 Series Parts & Service Manual

2

6

424926

Hotel/Motel Lock

(F15)

Hotel/Motel Lock

SL Trim

56

Page 26

August 2004

8823

Page 26

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8802-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

4 50-8899-0001 Auto Unlock Insert 1

5 50-8899-0002 Deadbolt Assembly 1

9 50-8800-0001 Case Assembly 1

10 50-8899-0009 Washer 1

15 50-8899-0014 Spacer (Classroom) 1

21 50-8800-1120 Deadbolt Hub 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

35 50-8899-0032 Unlock Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

43 50-8899-0036 Locking Piece Assembly (Solid) 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 27

August 2004

8823

Page 27

8800 Series Parts & Service Manual

KN

B TRIM PART

4

2

4

35

3

9

4

1

0

1

2

Storeroom Lock

SL Trim

56

Page 28

August 2004

8828

Page 28

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8805-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0001 Case Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 29

August 2004

8828

Page 29

8800 Series Parts & Service Manual

2949

Exit Latch (F31)

SL Trim

56

Page 30

August 2004

8829

Page 30

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8805-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0004 Case Assembly 1

28 50-8899-0023 Cylinder Retainer Assembly 1

30 50-8899-0025 Pivotal 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

34 50-8899-0031 Toggle Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

43 50-8899-0036 Locking Piece Assembly (Solid) 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 31

August 2004

8829

Page 31

8800 Series Parts & Service Manual

31

32

2

43

49

Closet Lock

SL Trim

56

Page 32

August 2004

8830-2

Page 32

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8805-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0001 Case Assembly 1

16 50-8899-0015 Spacer (1/2 Width) 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

33 50-8899-0030 Locking Piece Jamb 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

43 50-8899-0036 Locking Piece Assembly (Solid) 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 33

August 2004

8830-2

Page 33

8800 Series Parts & Service Manual

8830

9

49

Asylum Lock

SL Trim

56

Page 34

August 2004

8833/8833-2

Page 34

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8805-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0001 Case Assembly 1

16 50-8899-0015 Spacer (1/2 Width) 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 35

August 2004

8833/8833-2

Page 35

8800 Series Parts & Service Manual

2

9

49

Exit Lock

All Purpose Lock

SL Trim

56

Page 36

August 2004

8847

Page 36

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8847-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

6 50-8800-0021 Deadbolt with Retraction Lever 1

7 50-8899-0007 Guard Lever 1

8 50-8899-0008 Guard Lever Spring 1

9 50-8800-0002 Case Assembly 1

13 50-8899-0012 Cylinder Latch Lever 1

18 50-8899-0016 Spacer (7/16 Width) 1

21 50-8800-1120 Deadbolt Hub 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

25 50-8899-0020 Auto Retract Lever 1

26 50-8899-0021 Deadbolt Washer 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

34 50-8899-0031 Toggle Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

41 50-8899-0035 Connector Pin, Toggle Button 1

42 50-8899-0036 Locking Piece Assembly 1

44 50-8899-0038 Toggle Washer 1

45 50-8800-6003 Stopworks Button 1

46 50-8899-0039 Guardbolt Spring 1

47 50-8899-0040 Spring Guide 1

48 50-8800-1016 Guardbolt Guide 1

49 50-8800-7014 Guardbolt 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 37

August 2004

8847

Page 37

8800 Series Parts & Service Manual

9

42

49

44

40

4

Entrance or

Apartment Door Lock

(F20)

SL Trim

56

Page 38

August 2004

8860/8860-2

Page 38

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8820-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

5 50-8899-0002 Deadbolt Assembly 1

9 50-8800-0001 Case Assembly 1

10 50-8899-0009 Washer 1

15 50-8899-0014 Spacer (Classroom) 1

21 50-8800-1120 Deadbolt Hub 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

35 50-8899-0032 Unlock Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

42 50-8899-0036 Locking Piece Assembly 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 39

August 2004

8860/8860-2

Page 39

8800 Series Parts & Service Manual

KNOB TRIM PARTS

42

Entrance or

Storeroom Lock (F21)

Entrance or

Storeroom Lock (F14)

SL Trim

56

Page 40

August 2004

8861

Page 40

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8802-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

4 50-8899-0001 Auto Unlock Insert 1

5 50-8899-0002 Deadbolt Assembly 1

9 50-8800-0002 Case Assembly 1

10 50-8899-0009 Washer 1

15 50-8899-0014 Spacer (Classroom) 1

21 50-8800-1120 Deadbolt Hub 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

35 50-8899-0032 Unlock Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

42 50-8899-0036 Locking Piece Assembly 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 41

August 2004

8861

Page 41

8800 Series Parts & Service Manual

40

4

52

Dormitory or

Storeroom Lock

SL Trim

56

Page 42

August 2004

8862

Page 42

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8801-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

9 50-8800-0003 Case Assembly 1

10 50-8899-0009 Washer 1

15 50-8899-0014 Spacer (Classroom) 1

20 50-8800-1015 Classroom Hub 1

22 50-8899-0017 Classroom Spring 1

27 50-8899-0022 Push Lever (65 Function) 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

34 50-8899-0031 Toggle Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

42 50-8899-0036 Locking Piece Assembly 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 43

August 2004

8862

Page 43

8800 Series Parts & Service Manual

2

42

Bathroom Lock (F22)

SL Trim

56

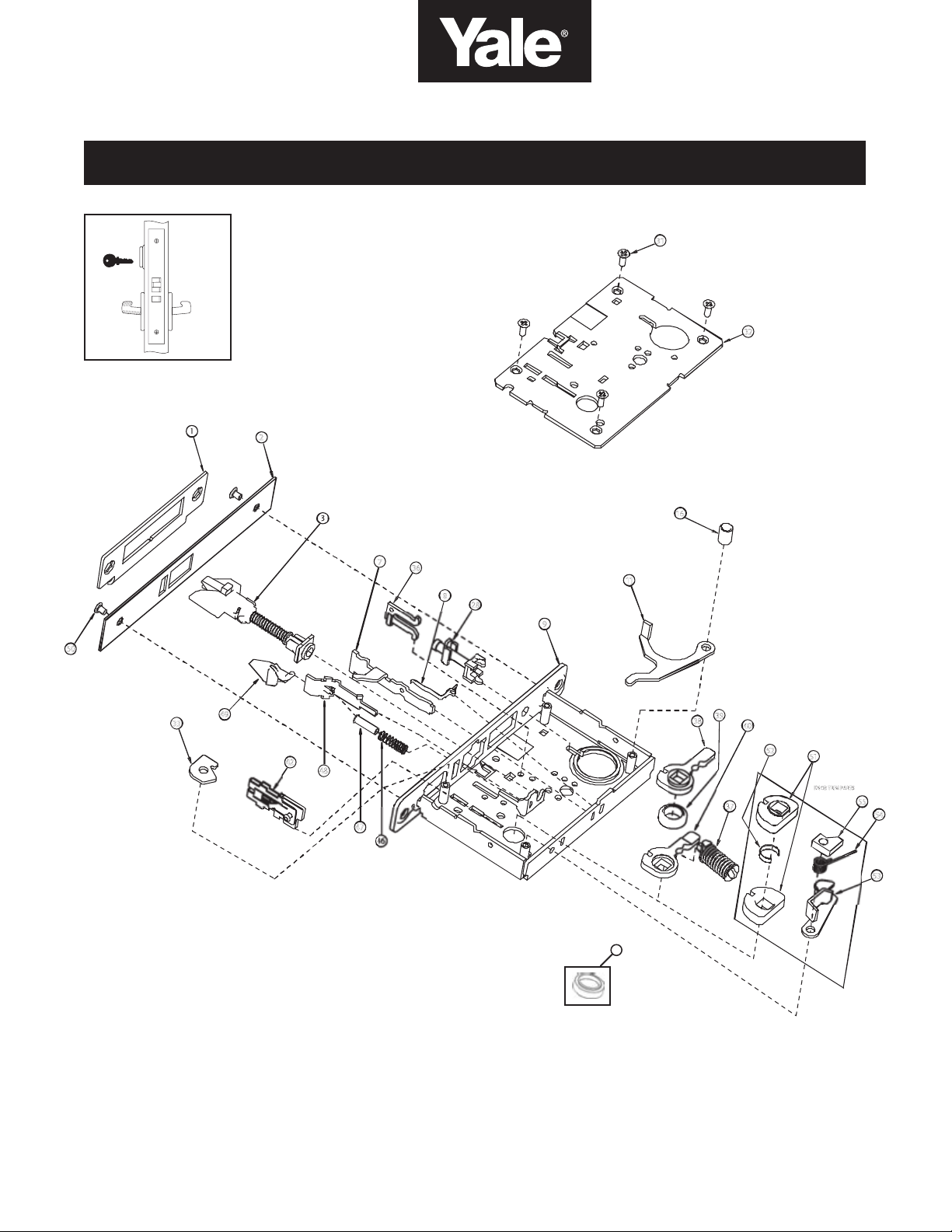

Page 44

August 2004

8867

Page 44

8800 Series Parts & Service Manual

1 50-8800-2023 Strike, Curved Lip 1

2 50-8867-X019 Armor Front 1

3 50-8800-0010 Reversible Latchbolt Assembly 1

6 50-8800-0021 Deadbolt with Retraction Lever 1

9 50-8800-0002 Case Assembly 1

13 50-8899-0012 Cylinder Latch Lever 1

18 50-8899-0016 Spacer (7/16 Width) 1

21 50-8800-1120 Deadbolt Hub 1

23 50-8899-0018 Deadbolt Arm 1

24 50-8899-0019 Deadbolt Spring 1

25 50-8899-0020 Auto Retract Lever 1

26 50-8899-0021 Deadbolt Washer 1

28 50-8899-0023 Cylinder Retainer Assembly 1

31 50-8899-0029 Machine Screw (8-32 x 5/16) 4

32 50-8800-1008 Cover 1

34 50-8899-0031 Toggle Spring 1

36 50-8899-0033 Fire Stop Assembly 1

37 50-8899-0034 Spring Cartridge Assembly 1

38 50-8800-1005 Cap Hub 1

39 50-8800-1011 Spacer, Hub 1

40 50-8800-1004 Case Hub 1

41 50-8899-0035 Connector Pin, Toggle Button 1

42 50-8899-0036 Locking Piece Assembly 1

44 50-8899-0038 Toggle Washer 1

45 50-8800-6003 Stopworks Button 1

50 81-00X2-0404 Armor Front Screw 2

51 50-8800-1034 Knob Hub 2

52 50-4601-1005 Knob Hub Spacer 1

53 50-8899-0059 Latch Lever 1

54 50-8899-0061 Latch Lever Spring 1

55 50-8899-0060 Spacer Stop 1

56 50-8800-1031 SL Hub Spacer 1

ITEM PART NUMBER DESCRIPTION QUANTITY

Page 45

August 2004

8867

Page 45

8800 Series Parts & Service Manual

KNOB TRIM PARTS

2

6

42

40

4

Dormitory or Exit Lock

(F12)

SL Trim

56

Page 46

August 2004

INSTALLATION INSTRUCTIONS

Page 46

8800 Series Parts & Service Manual

Yale®Mortise Locks

8800 Series (Knob, FL and SL Trim)

NOTES

The following is a step by step approach to installing a mortise lock and trim to both wood and steel doors.

1) Determine Hand of Door 7) Install Strike

2) Mark Position and Door Template 8) Sectional Trim

3) Drill Holes in Door 9) Escutcheon Plate Trim (Thru-bolted)

4) Mark Frame for Strike and Mortise Cavities 10) Escutcheon Plate Trim (Surface Mounted)

5) Drill Mortise Cavities in Door and Frame 11) Single Operational Trim (Sectional and Escutcheon)

6) Install Lock (Wood or H.M Door) 12) Check Operation of Lock

1) DETERMINE HAND OF DOOR

a. Face the door from the outside to determine its hand. Please note the outside is either the key side of an entrance

door or the corridor side of a room door. The outside of a single communicating door is the side opposing the hinges.

The outside of twin communicating doors is the space between the doors.

2) MARK POSITION AND DOOR TEMPLATE

a. Draw a horizontal centerline for the lock on both sides of door at desired height above finished floor line. Standard

height for horizontal centerline is 39-15/16” above finished floor.

b. Select template by comparing handing of door to Fig. 4, 5 and 6.

c. Compare the lock function number being installed with (See Fig. 3) to determine the holes to be marked.

d. Position the installation template on the door so that the horizontal centerline lines up with the horizontal line on the

door. Mark the holes to be drilled using a scribe, center punch, or nail on the inside and outside of door. To avoid

shifting of the template, it may be taped to the door during this step.

e. On the edge of the door mark the holes to be drilled for the mortise cavity and armor front attaching screw holes.

3) DRILL HOLES IN DOOR

a. Bore marked lock trim holes (steps 2d and 2e). To avoid splintering wood, bore thru holes from both sides of door. For

hole sizes refer to hole chart. Note: Hole “A” diameter is different for FL & SL Applications.

4) MARK FRAME FOR STRIKE MORTISE CAVITIES

a. Mark vertical position of strike on jamb using the reference centerline on installation template (see Fig. 4, 5 or 6).

Mark location of strike lip. (FIRST DETERMINE IF SILENCERS ARE TO BE USED) To locate horizontal centerline of

strike, take half the door thickness PLUS the thickness of silencer (if used). Use this dimension to locate the strike

centerline from the doorstop. (See Fig. 1.)

5) DRILL MORTISE CAVITIES IN DOOR AND FRAME

a. Mortise door edge for lock body. Drill pilot holes for attaching screws.

b. Slide lock body into cavity with armor front attached. Align armor front with top mark. Use lock front as template. Mark outline.

c. Mortise door edge for lock front (7/32”) deep.

d. Mortise jamb for strike (3/32” deep). Be sure to mortise 1” (25mm) deep to accommodate lock bolts or strike box

if used. (See Fig. 1)

Note: Before installing lock, prepare door trim per sections 8, 9,10 or 11.

6) INSTALL LOCK (WOOD OR H.M. DOOR)

a. Remove armor front.

b. If necessary, change handing of lock by following instructions on lock. Do this to match your door hand.

c. Insert lock body into cavity in door and secure base front with two #12 combination attaching screws. Make sure lock

is positioned in cutout properly. (See Fig. 3.) Note: Installation may require leaving #12 combination screws loose until

trim and cylinder are assembled in lock body.

Page 47

August 2004

INSTALLATION INSTRUCTIONS

Page 47

8800 Series Parts & Service Manual

7) INSTALL STRIKE

a. Attach strike to jamb using two #12 combination attaching screws. (See Fig. 1.)

(Figure 1) 8800 Series Strike Shown

(Figure 3)

(Figure 2) 8800 Series Lock Shown

Hole Chart

Size

Used for

Hole

H.M. Door

Wood Door

A

FL

1-1/8 Dia.

(29)

1-1/8 Dia.

(29)

Knobs

SL

1-7/8 Dia.

(48)

1-7/8 Dia.

(48)

B

1-1/4 Dia.

(32)

1-1/4 Dia.

(32)

Cylinder

C

3/4 Dia.

(19)

3/4 Dia.

(19)

Thumbturn or

Emergency Key

D

3/4 Dia.

(19)

3/4 Dia.

(19)

Hotel Indicator

E

5/16 Dia.

(8)

5/16 Dia.

(8)

Rose

Through-Bolts

F

.116 Dia.

(2.9)

#32 Drill

1/16 Dia.

(1.6)

Thumbturn Plate

Attaching Screws

G

1/2 Dia.

(13)

1/2 Dia.

(13)

Escutcheon Plate

Through-Bolts

H

.116 Dia.

(2.9)

#32 Drill

1/16 Dia.

(1.6)

Surface

Escutcheon Plate

Attaching

J

.152 Dia.

(3.9)

#24 Drill

11/64x1 Dp.

(4.4x25)

C’bore

1/2x1/8

Dp.

(13x3)

Surface

Escutcheon Plate

Attaching

K

106 Dia.

(2.7)

#36 Drill

Tap (#6-32

UNC)

1/16 Dia.

(1.6)

8862 Visual

Indicator

(See Step 12)

Lock Function

(Knob, FL and SL)

Holes in Door

Holes in Door

Holes in Door

Sectional Trim

Through-Bolted Esc.

Surface Esc.

Outside

Inside

Outside

Inside

Outside

Inside

8801, 8870DT, 8871DT

8872DT, 8880, 8881

8884, 8885, 836A & B

836A & B

A, E

A, E

A, G

A, G

A, H

A, E, H

8802

A, C, E, F

A, C, E, F

A, C, E, F

A, C, E, F

A, C, E, F

A, C, E, F

8805, 8807, 8808

A, B, E

A, E,

A, B, G

A, G

A, B, H

A, H

8890, 8891

A, B*, E

A, B*, E

A, B*, G

A, B*, G

A, B*, H

A, B*, H

8808-2, 8810-2, 8811-2

8812-2, 8817-2, 8818-2

8830-2, 8860-2, 8894-2

8895-2

A, B, E

A, B, E

A, B, G

A, B, G

A, B, H

A, B, H

8820, 8827

A, C, D, E

A, C, E, F

A, B, D, G

A, C, G

A, B, D, H

A, C, H

8811, 8822, 8832

8847, 8860, 8861

8867

A, B, E

A, C, E, F

A, B, G

A, C, G

A, B, H

A, B, H

8828

NONE

A, E

NONE

A, J**

NONE

A, H

8833

B ONLY

A, E

B ONLY

A, J**

B ONLY

A, H

8823, 8829

A, B, E

NONE

B ONLY

A, B, J**

B ONLY

A, B, H

8813ST-2, 8829

B ONLY

C, F, B

—

—

—

—

8814

B ONLY

NONE

—

—

—

—

8814-2, 8833-2

B ONLY

B ONLY

—

—

—

—

8862

A, D, E, K

A, C, E, F

—

—

—

—

* Lock can be mounted with cylinder outside or inside. Check for proper application.

** CO 7 WG Escutcheon plates cannot be used as half trim on H.M. Doors.

Page 48

August 2004

INSTALLATION INSTRUCTIONS

Page 48

8800 Series Parts & Service Manual

(Figure 4) RH & LHR Door ONLY

For door sizes other than

1/3/4” cut along these lines

Page 49

August 2004

INSTALLATION INSTRUCTIONS

Page 49

8800 Series Parts & Service Manual

(Figure 5) LH & RHR Door ONLY

For door sizes other than

1/3/4” cut along these lines

Page 50

August 2004

INSTALLATION INSTRUCTIONS

Page 50

8800 Series Parts & Service Manual

(Figure 6) Non-Beveled Door

For door sizes other than

1/3/4” cut along these lines

Page 51

August 2004

INSTALLATION INSTRUCTIONS

Page 51

8800 Series Parts & Service Manual

8) SECTIONAL TRIM

9) ESCUTCHEON PLATE TRIM (THROUGH-BOLTED)

Page 52

August 2004

INSTALLATION INSTRUCTIONS

Page 52

8800 Series Parts & Service Manual

11) SINGLE OPERATING TRIM (SECTIONAL & ESCUTCHEON)11) SINGLE OPERATING TRIM (SECTIONAL & ESCUTCHEON)

10) ESCUTCHEON PLATE TRIM (SURFACE-MOUNTED)

Page 53

August 2004

INSTALLATION INSTRUCTIONS

Page 53

8800 Series Parts & Service Manual

RAMPED SPINDLE ASSEMBLY

12) VISUAL OCCUPANCY INDICATOR

Installation Trouble Shooting Tips

Problem

Possible Cause

Solution

Difficult to operate lock

by lever or by key.

Loose (Trim H.M. Doors)

(Vibration caused by normal

operation of door opening and

closing can loosen attaching

screws)

Adjust and tighten - as necessary. If

screws continually loosen up, use a

screw locking compound (such as

Loctite) on all attaching screws.

Door is warped or sagging,

binding up latch bolt in strike

cutout.

Check to see where latch is hanging up

in strike. If door is sagging, tightening top

hinge screws may solve problem. Hole in

strike plate mave have to be filed to

relieve bind. Doors can warp when

weather changes:

warm inside - cold outside

cool inside - hot outside

(Exterior doors painted in a dark color are

particularly susceptible to warpage when

exposed to direct sunlight.) It may take a

few seasonal changes to work out all

binding problems.

Loose Trim (wood

doors)

Wood doors after being

installed will sometimes shrink

slightly as the building dries out.

Tighten all screws as needed

Latch bolt hangs up in

lock body

Foreign object in lock body

(metal shavings, saw dust,

wood particles, mineral ore etc.)

Remove lock from door and remove

foreign object from body. *Lubricate if

necessary.

Lock body lacks lubrication or

lubrication has gummed up

with age.

Use penetrating or solvent type lubricant

as a cleaning agent to loosen frozen or

sticking components. Lubricate with

silicon base or Lithium Grease.

Cylinder jams up

Dirt or other foreign object may

be in keyway affecting operation.

Lubricate cylinder with graphite or other

non-oily lubricant (such as Lock-EZE) Do

not use oil based lubricants in Keyway.

* Please note: Disassembling lock body will void warranty.

Page 54

For the latest information on Yale

Commercial Lock and Hardware products,

visit our website at www.yalecommercial.com.

Click on the “Literature” button to find:

■ Catalogs

■ Parts manuals

■ Templates

■ Specifications

■ Installation instructions

Yale

®

customers can click on the ebusiness

symbol on the website to register for an

ebusiness account to:

■ Check the status of orders

■ Check availability of Quick Ship items

■ Track your order and confirm delivery

■ Receive email notification of template

changes

And More...

42192-MA-12.2-08/04N

Yale Commercial Locks and Hardware

Address: 1902 Airport Road, Monroe, NC 28110 USA

Tel: 1-800-438-1951

•

Fax: 1-800-338-0965•www.yalecommercial.com

Yale-Corbin Canada Ltd.

Address: 6940 Edwards Boulevard, Mississauga, Ontario, Canada L5T 2W2

Tel: 1-800-461-3007

•

Fax: 1-800-461-8989•www.yalecorbin.on.ca

Yale®and Yale Security Inc.® are registered trademarks of Yale Security Inc. Other products brand names may be trademarks or registered trademarks of their respective

owners and are mentioned for reference purposes only. Copyright© 2004 Yale Security Inc. All rights reserved. These materials are protected under US copyright laws. All contents

current at time of publication. Yale Security Inc. reserves the right to change availability of any item in this bulletin, its design, construction, and/or its materials.

The ASSA ABLOY Group is the world’s leading manufacturer and supplier of locking solutions, dedicated to satisfying end-user needs for

security, safety and convenience.

online literature

and templates

www.yalecommercial.com

Loading...

Loading...