Page 1

OPERATING,

MAINTENANCE &

PARTS MANUAL

HAND OPERATED

CHAIN HOIST

Rated Loads:

Hand Hoists ⁄ through 10 tons.

Low Headroom Trolley Hoists fi through 6 tons.

Follow all instructions and warnings for

inspecting, maintaining and operating this

hoist.

The use of any hoist presents some risk of personal injury or property damage. That risk is

greatly increased if proper instructions and

warnings are not followed. Before using this

hoist, each operator should become thoroughly

familiar with all warnings, instructions and

recommendations in this manual. Retain this

manual for future reference and use.

Forward this manual to operator.

Failure to operate equipment as directed in

manual may cause injury.

LH2 HAND HOIST

AND LOW HEADROOM

TROLLEY HOIST

414 WEST BROADWAY AVE.

MUSKEGON, MICHIGAN 49443

Before installing hoist, fill in the information below.

Rated Load

Serial no.

Purchase date

46221

Manual No. Y646

®

YYaallee

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 2

i

YALE HOIST PARTS AND SERVICES ARE AVAILABLE IN THE UNITED STATES.

As a Yale Hoist and Trolley user, you are assured of reliable repair and parts services through a network of Authorized

Parts Depots that are strategically located in the United States. These facilities have been selected on the basis of their

demonstrated ability to handle all parts and repair requirements promptly and efficiently. To quickly obtain the name

of the Authorized Parts Depot or Repair Station located nearest you, call (866) 805-2962, Fax (800) 742-9270.

NOTES

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 3

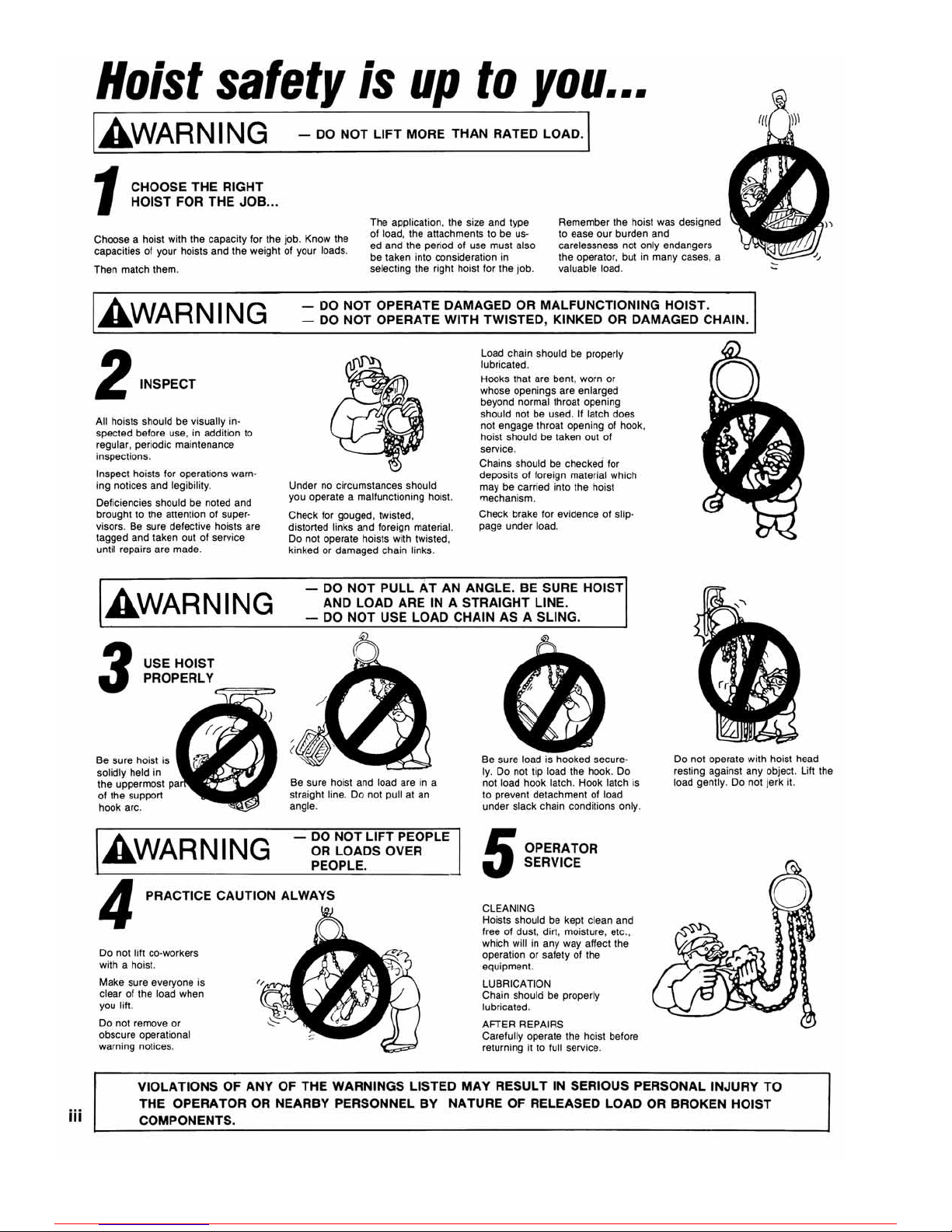

SAFETY PRECAUTIONS

Each Yale Hand Hoist and Low Headroom Trolley Hoist is built in accordance with the specifications contained herein and at

the time of manufacture complies with our interpretation of applicable sections of the American Society of Mechanical

Engineers Code B30.16 “Overhead Hoist” and the Occupational Safety and Health Act.

The safety laws for elevators and for dumbwaiters may specify construction details that are not necessarily

incorporated in Yale industrial hoist. We recommend the use of equipment that meets state and national safety codes. Yale cannot be responsible for applications other than those for which Yale equipment is recom-

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS.

READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED WITH THE

EQUIPMENT BEFORE ATTEMPTING TO OPERATE YOUR YALE HOIST.

Consult Yale for any usage of Yale Hoists that do not involve raising of the load on the lower hook, or usage of Yale Hoists in the inverted position.

Using hoists, without special precautions, in such applications may cause an accident that could result in injury and/or property damage.

Improper operation of a hoist can create a potentially

hazardous situation which, if not avoided, could result

in death

or serious injury. To avoid such a potentially

hazardous situation, the operator shall:

1.

NOT operate a malfunctioning or unusually performing

hoist.

2. NOT

operate the hoist until you have thoroughly read and

understand this manufacturer’s Operating, Maintenance and

Parts Manual.

3. NOT operate a hoist which has been modified without the

manufacturer’s approval or certification to be in conformity

with applicable OSHA regs.

4. NOT

lift or pull more than rated load for the hoist.

5. NOT use damaged hoist or hoist that is Not working properly.

6. NOT use hoist with twisted, kinked, damaged, or worn load

chain.

7. NOT use the hoist to lift, support, or transport people.

8. NOT lift loads over people and make sure all personnel remain

clear of the supported load.

9. NOT

attempt to lengthen the load chain or repair damaged load

chain.

10. Protect the hoist’s load chain from weld splatter or other damaging

contaminants.

11. NOT

use load chain as a sling or wrap load chain around load.

12. NOT

apply the load to the tip of the hook or to the hook latch.

13. NOT apply load unless load chain is properly seated in the chain

wheel(s) or sprocket(s).

14. NOT apply load if bearing prevents equal loading on all load

supporting chains.

15. NOT

operate beyond the limits of the load chain travel.

16. NOT leave load supported by the hoist unattended unless specific

precautions have been taken.

17. NOT allow the chain or hook to be used as an electrical or welding

ground.

18. NOT

allow the chain or hook to be touched by a live welding

electrode.

19. NOT remove or obscure the warnings on the hoist.

20. NOT

operate a hoist which has Not been securely attached to a

suitable support.

21. NOT operate a hoist unless load slings or other approved single

attachments are properly sized and seated in the hook saddle.

22. NOT

operate a hoist when it is restricted from forming a straight

line from hook to hook in the direction of loading.

23. NOT lift loads that are Not balanced and that the holding action is

Not secure, taking up slack carefully.

24. NOT

operate a hoist unless all persons are and remain clear of the

supported load.

25. Report malfunctions or unusual performances of a hoist, after it

has been shut down until repaired.

26. NOT

operate a hoist on which the safety placards or decals are

missing or illegible.

27. Be familiar with operating controls, procedures, and warnings.

ii

WARNING

Improper operation of a hoist can create a potentially

hazardous situation which, if not avoided, could result

in minor

or moderate injury. to avoid such a potentially

hazardous situation, the operator shall:

1. Maintain a firm footing or be otherwise secured when

operating the hoist.

2. Check brake function by tensioning the hoist prior to

each lift or pulling operation.

3. Use hook latches. Latches are to retain slings, chains, etc.

under slack conditions only.

4. Make sure the hook latches are closed and not supporting

any parts of the load.

5. Make sure the load is free to move and will clear all

obstructions.

6. Avoid swinging the load or hook.

7. Inspect the hoist regularly, replace damaged or worn

parts, and keep appropriate records of maintenance.

8. Use the hoist manufacturer’s recommended parts when

repairing the unit.

9. Lubricate load chain per hoist manufacturer’s recommendations.

10. NOT

use the hoist load limiting or warning device to

measure load.

11. NOT operate except with manual power.

12. NOT

permit more than one operator to pull on a single

hand chain at the same time. More than one operator is

likely to cause hoist overload.

13. NOT

allow your attention to be diverted from operating

the hoist.

14. NOT

allow the hoist to be subjected to sharp contact with

other hoists, structures, or objects through misuse.

15. NOT

adjust or repair the hoist unless qualified to perform

such adjustments or repairs.

CAUTION

!

!

!

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 4

iii

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 5

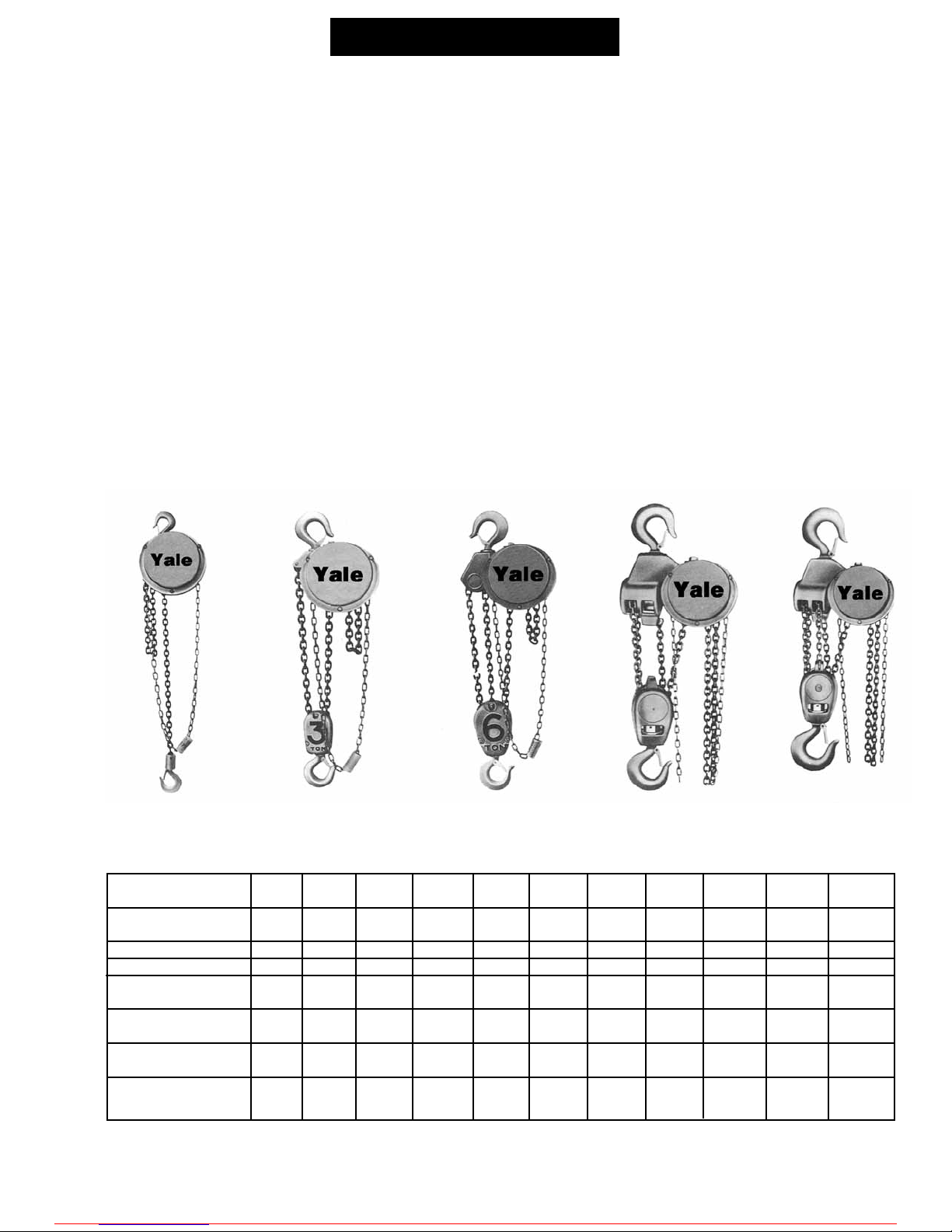

GENERAL INFORMATION

SPECIFICATIONS

Yale LH2 Hand Hoists

The Yale LH2 Hand Hoist is a highly versatile

tool that can be used to lift loads. The hoist has

aluminum frame, handwheel, handwheel cover

and gear cover to provide dependable strength

at minimum weight. The internal gears are made

of high grade, heat treated steel. Shielded ball

bearings are used at each rotating point in the

mechanism. Latch type, heat treated, forged steel

upper and lower hooks are standard. The load chain

is strong and durable Hoistaloy

®

. A pawl and ratchet,

dry-operating, Weston-type friction brake supplies

very positive load control and will suspend the load

at any point. A Load Limiter is provided on every unit.

As a result, the application of an excessive overload

disengages the driving handwheel and prevents

hoisting. Note that the Load Limiter is not intended

for use as a scaling device. Removal of the excess

load automatically restores normal hoisting action

(see Figure 1 for specifications of available models).

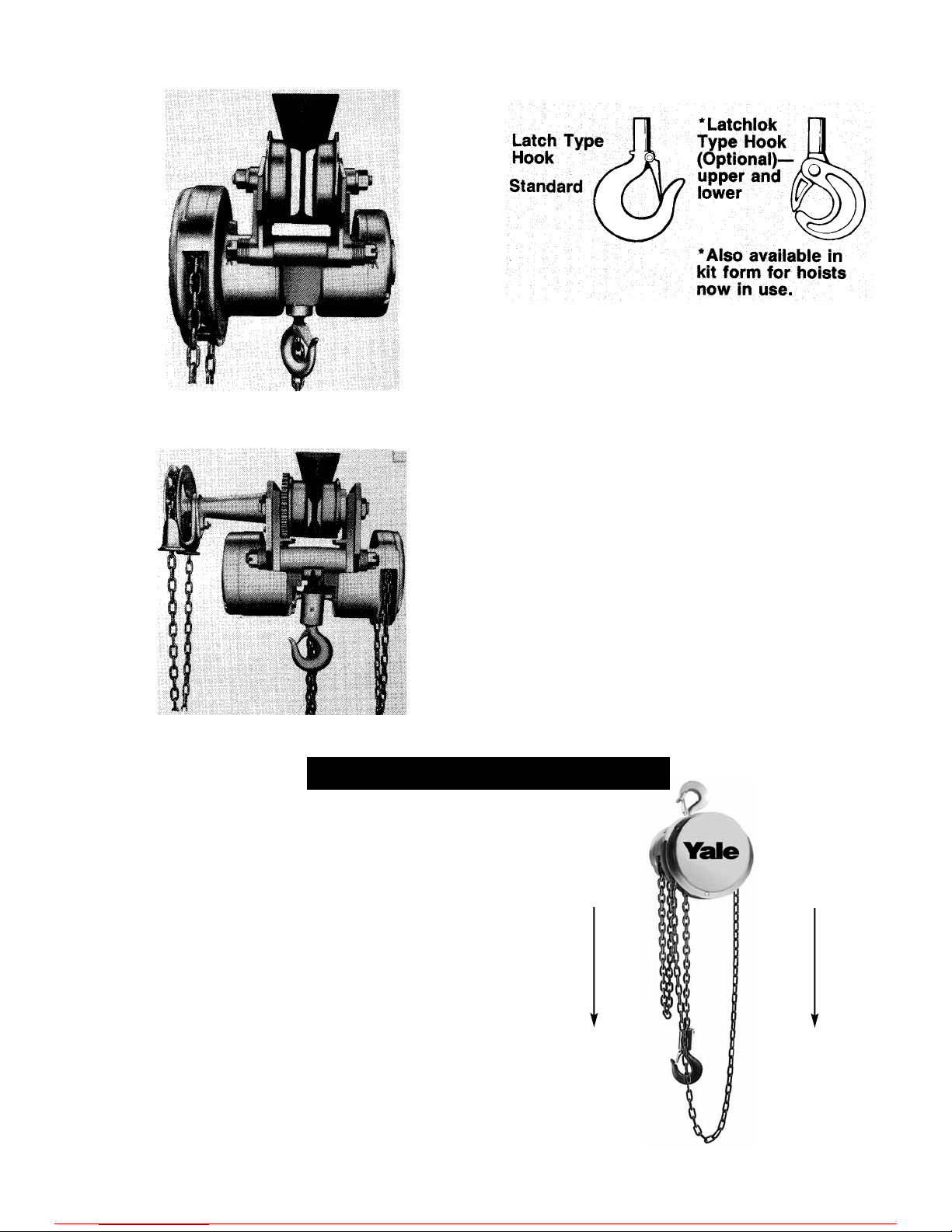

Yale Low Headroom Trolley Hoists

The Yale Low Headroom Trolley Hoists (Figure 2, page 2)

are a combination of the Yale Hand Hoist built

integral with a rugged trolley to provide better headroom than that obtained with the standard hoist and

trolley. The basic hoist is similar to the Yale LH2 Hand

Hoist except the frame, aluminum on the 1/2 through

3 ton units and cast iron on the 4 through 6 ton units,

which is designed to provide low headroom and

attachment to the trolley. The trolley has a rugged

frame, cast iron on the 1/2 through 1 ton units, and

steel plates on the 1-1/2 through 6 ton units. Crowned

tread, flanged trackwheels are provided to minimize

rolling friction. Hardened, pressed steel ball bearing

wheels are used on the 1/2 and 1 ton units. Hardened,

cast iron wheels with Timken bearings are used on the

1-1/2 through 6 ton units. Trolleys are adjustable for

operation on various American standard beams and

the 1-1/2 through 6 ton units are available in a geared

type trolley.

Figure 1. Yale Hand Hoist, Available Models

Maximum

Capacity (Tons)

Code

Standard Lift (Ft.)

Net Weight (Lbs.)

Shipping Weight

(Lbs.)

Shortest Distance

Between Hooks (In.)

Chain Overhauled to

Lift Load 1 Foot (Ft.)

Chain Pull to

Lift Full Load (Lbs.)

1/4

924-

02100

8

33

35

12-7/8

22-1/2

23

1/2

924-

03100

8

33

35

12-7/8

22-1/2

46

1-1/2

924-

06100

8

59

63

17-5/16

40-1/2

80

1

924-

05100

8

36

38

14

30

69

2

924-

07100

8

60

64

17-5/16

52

83

4

924-

11100

8

91

98

21-1/2

104

88

3

924-

09100

8

84

91

21-1/2

81

85

5

924-

13100

8

122

129

24-1/4

156

75

6

924-

14100

8

127

134

25-1/4

156

90

8

924-

16100

8

207

237

35-1/2

208

89

10

924-

17100

8

219

244

35-1/2

260

95

1

1/4 to 2 Ton

3 & 4 Ton

5 & 6 Ton

8 Ton

10 Ton

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 6

UNPACKING INFORMATION

After removing the hoist from the carton, check to

be sure there has been no damage in shipment.

Before cutting the cord ties on multiple-reeved

units, be sure that all strands of chain are straight

with no twist (due to a capsized hook block). If

length of lift is to be modified, follow disassembly

and assembly instructions for correct procedure.

OPERATING INSTRUCTIONS

After mounting and before placing in service,

check the hoist for proper operation. On multireeved units, be sure that all strands of chain are

straight with no twist (due to a capsized hook

block).

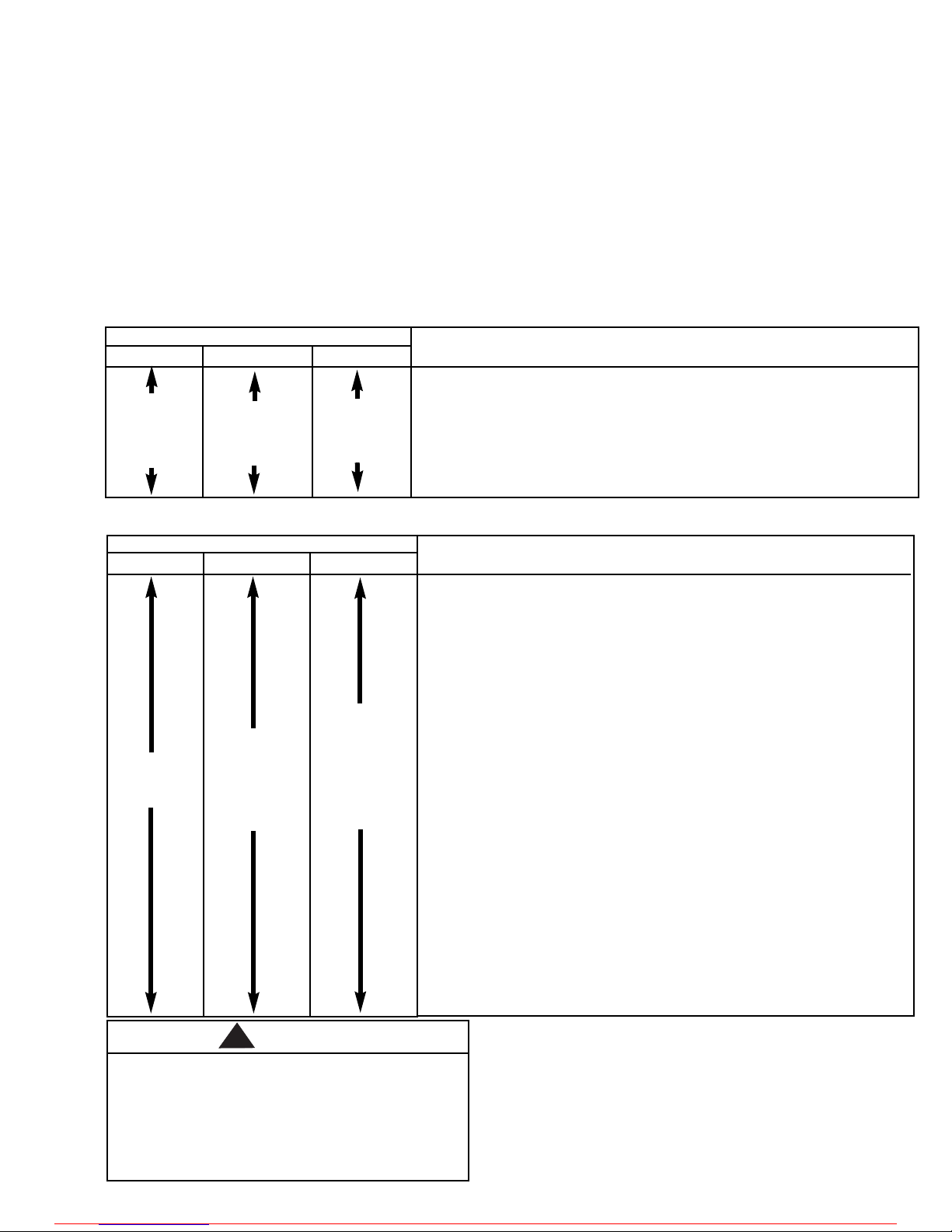

The Yale Hand Hoist must always be rigged to lift

in a straight line from hook to hook (see Figure 4).

The hoist must always be free to swivel on the

upper hook. Under no condition should the hoist

be allowed to bear on any support when in use as

this would cause bending of the hook or frame

and damage the unit.

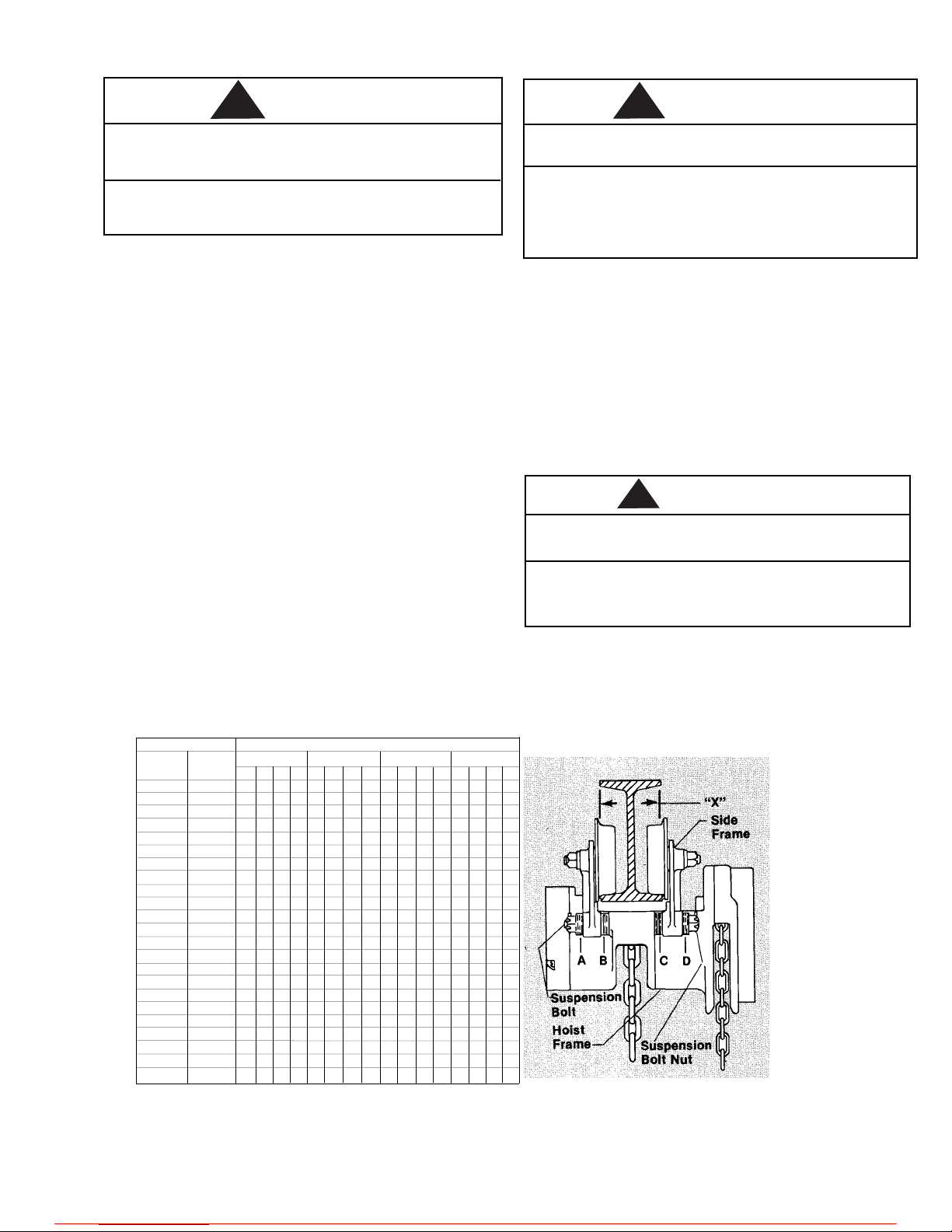

HOOKS

Type of hooks supplied on the Yale Hoists are shown

in Figure 3.

YALE REPAIR/REPLACEMENT POLICY

All Yale LH2 Hand Hoists and Low Headroom Trolley

Hoists are thoroughly inspected and performance

tested prior to shipment. If any properly maintained

Yale Hoist develops a performance problem due to a

material or workmanship defect, as verified by Yale or

an authorized service station, repair or replacement

of the unit will be made to the original purchaser

without charge. This repair/replacement policy applies

only to Yale Hoists installed, maintained and operated

as outlined in this manual, and specifically excludes

parts subject to normal wear, abuse, improper installation, improper or inadequate maintenance, hostile

environmental effects, and unauthorized repairs/

modifications.

We reserve the right to change materials or design if

in our opinion, such changes will improve our product.

Abuse, repair by an unauthorized person, or use of

non-Yale replacement parts voids the guarantee and

could lead to dangerous operation. For full Terms of

Sale, see Sales Order Acknowledgement. Also, refer to

the back cover for Limitations of Warranties, Remedies

and Damages and, Indemnification and Safe Operation.

2

To Lower Hook

Pull on This

Part of

Hand Chain

To Raise Hook

Pull on This

Part of

Hand Chain

Figure 4. Raising and Lowering Hook

Figure 2.

Yale Low Headroom Trolley Hoists

OPERATION AND INSTALLATION

With Geared Trolley

With Plain Trolley

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 7

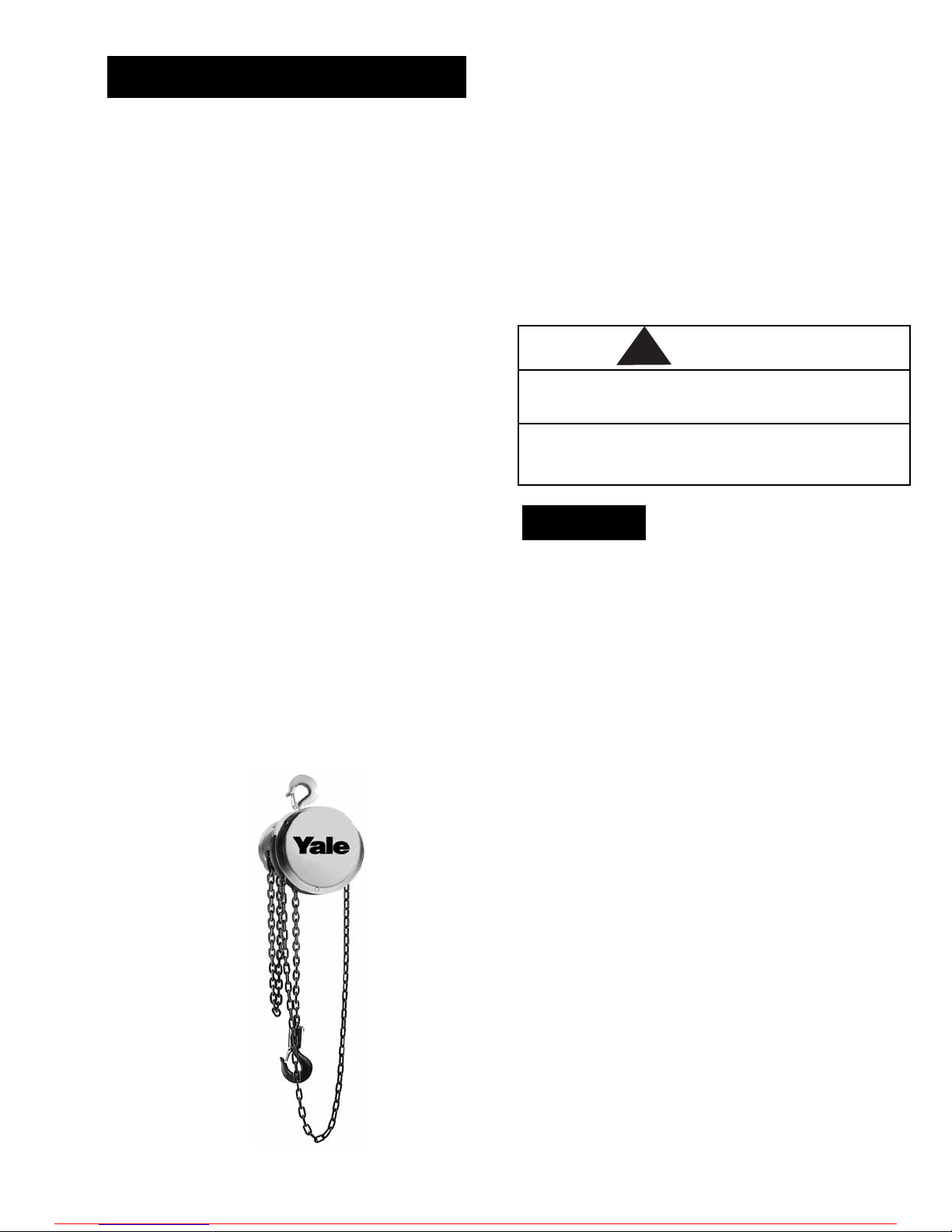

TROLLEY INSTALLATION

Operating the trolley hoist on a beam that has no rail

stops may allow the trolley hoist to fall off the end of

the beam.

To Avoid Injury:

Install rail stops at each end of the beam on which

the trolley hoist is to operate.

The railstops must be positioned so as to not exert

impact force on the hoist portion of the unit or the

trolley wheels. They must contact the ends of the

trolley side frames.

Due to the variations in beam flange widths, it is suggested that the beam flange width be measured to

determine the exact distribution of spacer washers.

The distance between trackwheel flanges (dimension

“X”) should be 1/8 to 3/16 inch greater than the

beam flange width for straight runway beams, and

3/16 to 1/4 inch greater than the beam flange width

if runway system includes sharp curves. Also, the use

of other than Yale supplied washers may result in

trackwheel to beam flange variations and thus Figure

5 will not apply.

Assemble the trolley on the beam by sliding one side

out far enough to allow the wheels to clear the

beam flange. Draw side frames together and tighten

nuts securely (do not over tighten) and then install

the cotter pins.

If washer spacing recommendations are not followed,

trolley hoist may fall from beam.

To Avoid Injury:

Measure the actual beam flange on which the trolley

hoist is to operate and use figure 5 to determine the

arrangement of the spacer washers for that flange

width.

Immediately after installation, operate trolley with a

capacity load over the entire length of runway or

monorail system to be sure that all adjustments and

operations are satisfactory.

When applying a load, it should be directly under

the trolley. Avoid off center loading of any kind.

Side loading may spread trolley side frames.

On systems with curves, the edges of the rail at the

curved sections should be lightly lubricated with

grease.

An excessively worn beam flange may fail and

allow the trolley hoist to fall from the beam.

To Avoid Injury:

Periodically inspect the beam flange for wear.

Replace beam if flange is worn.

3

WARNING

4”x 7.7

4”x 9.5

5”x 10.0

5”x 14.7

6”x 12.5

6”x 17.2

7”x 15.3

7”x 20.0

8”x 18.4

8”x 23.0

10”x 25.4

10”x 35.0

12”x 31.8

12”x 35.0

12”x 40.8

12”x 50.0

15”x 42.9

15”x 50.0

18”x 54.7

18”x 70.0

20”x 65.4

20”x 75.0

24”x 79.9

2-5/8

2-3/4

3

3-1/4

3-3/8

3-5/8

3-5/8

3-7/8

4

4-1/8

4-5/8

5

5

5-1/8

5-1/4

5-1/2

5-1/2

5-5/8

6

6-1/4

6-1/4

6-3/8

7

S-Beam

Number of Spacers

Size

Flange 1/2-1 Ton 1 1/2-2 Ton

3 Ton 4-5-6 Ton

A

4

4

2

0

10

9

8

7

6

5

2

0

0

B

0

0

2

4

0

1

2

3

4

5

8

10

10

C

0

1

2

3

0

2

2

3

4

5

8

10

10

D

4

3

2

1

10

8

8

7

6

5

2

0

0

A

13

12

11

10

9

8

5

3

3

3

2

0

0

B

0

1

0

1

2

3

6

8

8

8

9

11

11

C

0

1

0

1

2

3

6

8

8

9

10

11

11

D

13

12

11

10

9

8

5

3

3

2

1

0

0

A

11

10

9

8

5

3

3

3

2

0

0

B

0

1

2

3

6

8

8

8

9

11

11

C

0

1

2

3

6

8

8

9

10

11

11

D

11

10

9

8

5

3

3

2

1

0

0

A

18

17

14

12

12

12

11

9

9

8

6

4

4

3

0

B

0

1

4

6

6

6

7

9

9

10

12

14

14

15

18

C

0

1

4

6

6

7

8

9

9

10

12

13

13

14

18

D

18

17

14

12

12

11

10

9

9

8

6

5

5

4

0

FIGURE 5. Low Headroom Trolley Spacer Arrangement

WARNING

WARNING

!

!

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 8

OPERATING AND SAFETY PROCEDURES

For safety precautions and a list of do’s and do not’s

for safe operation of hoists, refer to page ii.

The Yale LH2 Hand Hoist (see Figure 6) must always

be rigged to lift in a straight line from hook to

hook. The hoist must always be free to swivel on

the upper hook. Under no condition should the

hoist frame or hanger be allowed to bear on any

support when in use as this would cause bending of

the hook or frame and damage the unit.

When preparing to lift or move a load, be sure that

the attachments to both hooks are firmly seated in

the saddles of the hooks. Avoid off center loading

of any kind especially loading on the point of the

hook.

When lifting, raise the load only enough to clear

the floor or support, and check to be sure brake will

hold load and that attachments to the load are

firmly seated. Continue the lift only after you are

assured the load is free of all obstructions.

Do not load beyond the rated capacity of the hoist.

Overloading can cause immediate failure of some

load carrying part or result in damage causing failure at less than rated capacity. When in doubt, use

the next larger capacity of Yale LH2 Hoist.

Do not wrap load chain around the load or bring

the load in contact with the hoist. Doing this will

result in the loss of the swivel effect of the hook

which could cause twisted chain and a jammed liftwheel. The chain could be damaged at the hook.

Rail stops must be installed for all trolleys operating

on open end beams. These stops must be positioned

to exert impact force on the trolley side frames only.

Do not use this or any other overhead materials

handling equipment for lifting persons.

Stand clear of all loads and avoid moving a load over

the heads of any people. Warn any people of your

intention to move a load in their area.

Do not leave the load suspended in the air unattended.

Do not lower the hook to a point where the chain

becomes taut between the liftwheel and loose end

screw. (See Troubleshooting, Item 5C).

The Yale LH2 Hand Hoist and Yale Low Headroom

Trolley Hoist have been designed for manual

operation only.

Power operation may result in structural damage or

premature wear that may cause a part to break and

allow the load to fall.

To Avoid Injury:

Operate Yale LH2 Hand and Trolley Hoists using

hand power only.

To maintain continuous and satisfactory operation, a

regular inspection procedure must be initiated to

replace worn or damaged parts before they become

unsafe. Inspection intervals must be determined by

the individual application and are based on the type

of service to which your hoist will be subjected and

the degree of exposure to wear, deterioration or

malfunction of the critical components.

The type of service to which the hoist is subjected

can be classified as “Normal”, “Heavy” and “Severe”.

Normal Service: involves operation with randomly

distributed loads within the rated load limit, or

uniform loads less than 65% of rated load for not

more then 25% of the time.

Heavy Service: involves operating the hoist within

rated load limit which exceeds normal service.

Severe Service: is normal or heavy service with

abnormal operating conditions.

Following are the recommended, minimum intervals

of inspection. When the unit is subjected to extra

heavy usage or dusty, gritty, moist, or other adverse

atmospheric conditions, shorter time intervals must

be assigned. During the Periodic Inspection, inspection

must be made of all parts for unusual wear, corrosion

effect or damage in addition to those specifically

mentioned.

Before working on the hoist, review the disassembly

and assembly information on pages 8 through 13.

INSPECTION

FIGURE 6. Yale LH2 Hand

4

WARNING

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 9

Minimum Inspection Schedule

Frequent Inspections: These inspections are

visual examinations by the operator or other designated personnel. Records of such inspections are

not required. The frequent inspections are to be

performed monthly for normal service, weekly to

monthly for heavy service, and daily to weekly for

severe service and they should include those items

listed in Table 1.

Periodic Inspections: These inspections are visual inspections of external conditions by an appointed person. Records of periodic inspections are to

be kept to provide the basis for continuing evaluation of the condition of the hoist.

Periodic inspections are to be performed yearly for

normal service, semi-annually for heavy service and

quarterly for severe service and they are to include

those items listed in Table 2.

Any parts that are deemed unserviceable are to be

replaced with new parts before the unit is returned

to service. It is very important that the unserviceable

parts be destroyed and properly disposed of to

prevent their possible future use as a repair item.

TYPE OF SERVICE

Normal Heavy Severe

TYPE OF SERVICE

Normal Heavy Severe

ITEM

a) Brake for evidence of slippage.

b) Hooks for damage, cracks or excessive throat opening, latch

engagement and latch operation - see page 6.

c) Inspect load chain for adequate lubrication, signs of wear,

damaged links or foreign matter - see page 6.

d) Inspect reeving of the load chain to make sure it is proper -

see page 6.

ITEM

a) Frequent inspections per Table 1.

b) External evidence of loose bolts or nuts.

c) External evidence of worn, corroded, cracked or distorted hook

blocks, suspension bolts, gears, pins, bearings, hand chain wheel,

frames, hoist hanger, load chain guide, hook block pin on 1/4

thru 2 ton units, dead end pin on 3, 4, 8 and 10 ton units, and

dead end screw on 5 and 6 ton units.

d) External evidence of damage to hooks, hook nuts or collars and

hook nut or collar pins.

e) External evidence of damage or excessive wear of the pockets of

the liftwheel, handwheel, hook block sheaves and hanger sheaves.

f) External evidence of worn, glazed or oil contaminated friction

discs, scoring of handwheel hub, ratchet, and friction hub.

g) External evidence of worn pawl and ratchet teeth; corroded,

stretched or broken pawl spring.

h) Supporting structure and trolley, if used, for continued ability to

support the imposed loads.

i) Inspect trolley wheels for external wear on the tread and flange,

and for wear on the internal bearing as evidenced by looseness

on the stud.

j) Warning label and tube for absence or illegibility.

k) Check for proper connections at dead end and loose end of load

chain.

l) Load Limiter components for corrosion.

Monthly

Weekly

to

Monthly

Daily

to Weekly

Table 1 Minimum Frequency Inspections

Table 2 Minimum Periodic Inspections

Yearly

Twice a Year

Every 3 Months

Any deficiencies are to be corrected before returning the

hoist to service. Operating a hoist with worn or damaged

parts or a malfunctioning hoist may result in serious

personal injury to the operator, nearby personnel and/or

property damage.

Also, the external conditions may show the need for disassembly to permit a more detailed inspection which, in

turn, may require the use of nondestructive type testing.

PREVENTIVE MAINTENANCE

In addition to the above inspection procedure, a preventive

maintenance program should be established to prolong

the useful life of the hoist and maintain its reliability and

continued safe use. The program should include the

periodic inspections with particular attention being paid

to the lubrication of various components using the

recommended lubricants.

5

WARNING

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 10

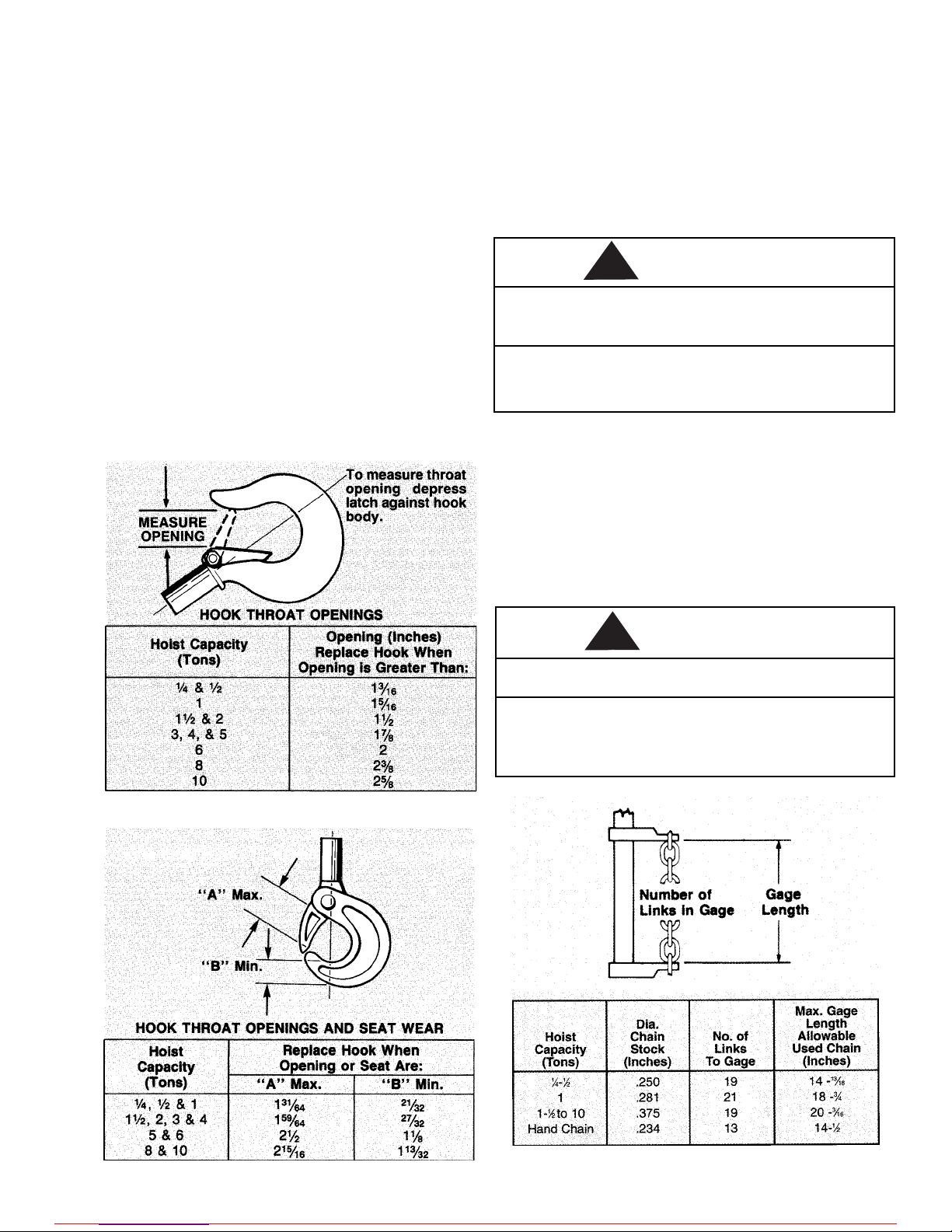

HOOK INSPECTION

Hooks damaged from chemicals, deformation or

cracks, or that have more than a 10 degree twist

from the plane of the unbent hook or excessive

opening or seat wear must be replaced.

Also, on latch type hooks, hooks that are opened

and allow the latch to disengage the tip, must be

replaced.

Any hook that is twisted or has excessive throat

opening indicates abuse or overloading of the unit.

Other load sustaining components of the hoist

should be inspected for damage.

Check to assure latch is not damaged or bent and

that it operates properly with sufficient spring

pressure to keep the latch tightly against the tip of

the hook and allow the latch to spring back to the

tip when released. If the latch does not operate

properly, it should be replaced.

The charts below (Figures 7 and 8) should be used

to determine when the hook must be replaced.

LOAD CHAIN

Cleaning and Inspection

First clean the load chain with a non-acid or non-caustic

type solvent, then slack the chain and make a link-by-link

inspection for nicks, gouges, twisted links and excessive

wear or stretching. Worn chain should be gaged throughout its entire length and replaced if beyond serviceable

limits. Also, these chains are specially heat treated and

hardened and should never be repaired.

Using other than a Yale supplied load chain may

cause the chain to jam and this, in turn may break

the chain and allow the load to drop.

To Avoid Injury:

Use only Hoistaloy®load chain in the Yale LH2 Hand

and Low Headroom Trolley Hoists.

Gaging Load Chain Wear

To determine if the load chain should be continued in

service, check gage lengths as indicated in Figure 9.

Chain worn beyond length indicated, nicked, gouged

or twisted should be replaced before returning the

hoist to service. Chain should be clean, free of twists

and pulled taut before measuring. To aid in checking

gage length, Yale can provide a chain gage. This can

be obtained by ordering chain gage part number 3191.

Worn load chain may break suddenly without visual

deformation.

To Avoid Injury:

Never use load chain for any other purposes such as

slings or tow chains. Cut worn chain into short

lengths to eliminate use after disposal.

FIGURE 7. Latch Hook Opening

FIGURE 8. Latchlok Hook Opening

FIGURE 9. Gaging Load Chain Wear

6

WARNING

WARNING

!

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 11

Note that worn chain can be an indication of

worn hoist components. For this reason, the

hoists chain guide, hook blocks and liftwheel

should be examined for wear and replaced as

necessary when replacing worn chain.

The proper installation of the load chain is

covered in the section on reeving, (see Pages

10 through 13.

HAND CHAIN

Hand chain should be cleaned, inspected and gaged in

the same manner as load chain. It is not hardened and

can be cut with a hacksaw.

The hoist hand chain contains one unwelded connecting

link. This link can be placed in a vise and twisted open

to facilitate changing chain length. Additional connecting

links can be made by cutting the weld side of a standard

link.

Care must be taken to assure that there is no twist in

the hand chain loop.

MAINTENANCE

LUBRICATION

The lubricants used in and recommended for the

Yale LH2 Hand and Trolley Hoists may contain hazardous materials that mandate specific handling and

disposal procedures.

To Avoid Contact and Contamination:

Handle and dispose of lubricants only as directed

in applicable material safety data sheets and in

accordance with applicable local, state and federal

regulations.

NOTE: To assure extra long life and top performance, be sure to lubricate the various

parts of the Yale Hoist using the lubricants

specified below. If desired, these lubricants

may be purchased from Yale. Refer to page 18

for information on ordering the lubricants.

LOAD CHAIN

Lubricate chain with a light coat of Lubriplate®, Bar

and Chain Oil (Fiske Bros. Refining Co.) or equal

lubricant. Be sure the lubricant reaches the bearing

surface between the links. Remove excess oil from

the chain.

Used motor oils contain known carcinogenic materials.

To Avoid Health Problems:

Never use used motor oils as a chain lubricant.

Only use Lubriplate

®

Bar and Chain Oil 10-R as a

lubricant for the load chain.

The hoist normally requires no additional lubrication except when a unit has been disassembled for cleaning or repairs (see page 8).

NOTE: The brake is designed to operate dry.

Do not use any grease or lubricant on the

braking surfaces. On reassembly when

lubricating parts adjacent to the brake, do

not use an excessive amount of lubricant

which could seep onto the brake surfaces.

Load Limiter. Place a small amount of stay-put lubri-

cant such as Moly-Duolube Style 69 (Hercules Packing

Co.) on load limiter handwheel threads. Do not allow

lubricant to contact brake surfaces or friction surfaces

of load limiter.

Gears. Lubricate the gears with Texaco Novatex #2 or

equal, 3 ounces for the 1/4-1 ton units and 4 ounces for

the 1-1/2-10 ton units. Spread some grease on gear

teeth, place the balance in gear housing in contact

with the gears.

Geared Trolleys. Upon installation and once a month

lubricate trackwheel gears and pinion with Texaco

Novatex #2 or an equivalent heavy cup grease or

graphite grease.

Brake. The brake parts should be thoroughly cleaned

(by wiping with a cloth - not by washing with a

solvent) and inspected for wear or scoring. The friction

surfaces of the handwheel, ratchet and friction hub

must be smooth and free from any score marks. When

friction washers are visibly worn to a thickness of 0.100

inches or less, scored excessively, or coated with foreign

matter, replace with new washers. Keep washers and

brake surfaces clean and dry.

RECOMMENDED SPARE PARTS. Refer to page 19 for

the list of recommended spare parts.

EXTERIOR FINISH

The exterior surfaces of the hoist and trolleys have a

durable, scratch resistant baked powder coating.

Normally, the exterior surfaces can be cleaned by

wiping with a cloth. However, if the finish is damaged,

compatible touch-up paint can be purchased from Yale.

Refer to page 18 for information on ordering

the paint.

7

WARNING

WARNING

!

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 12

DISASSEMBLY

Care must be exercised in disassembly of the

hoist to assure proper assembly. The following

pins have tapered splines and can only be

removed by tapping on the end opposite the

splined grooves.

Lower Hook Block, Upper Hook Collar

and Dead End Pins

When removing or installing the Lower Hook

Block Pins (646-29J or 646-129J) on the 1/4 thru

2 ton units, the Upper Collar Pins (646-1E or 646101E) on the 1/4 thru 2 ton units and the Dead

End Pins (646-259) on the 3, 4, 8 and 10 ton units,

care must be taken so as to prevent damaging

the pin and/or the part into which the pin is driven.

These pins are tapered groove pins and as a

result, they can only be removed and installed in

one direction. To remove the pin, a drift and

hammer (or slow acting press) are required. For

the lower hook block pins, a V-block will also be

necessary. The drift should be the same diameter

as the pin (5/16” diameter for the 1/4 thru 1 ton

units and 7/16” diameter for the 1-1/2, 2, 3, 4, 8

and 10 ton units) and it should be placed on the

small end of the pin. The small end of the pin is

the end opposite the end on which the 3 grooves

are visible. Place the drift on the small end of

the pin and drive the pin out using a hammer or

slow acting press. When removing the pin from

the lower hook block, the hook block should be

placed in a V-block.

To re-install the pin, the parts must be arranged

the same as they were when the pin was

removed. To do this, use the small end of the pin

as a gauge. After it is determined which end of

the hole is the largest, arrange the parts so that

the large holes are aligned and insert the small

end of the pin into the hole. Push the pin in by

hand until it stops and then use a hammer or

slow acting press to drive the pin into position

so that the end of the pin is flush with the

outside surface of the hook block body, upper

hook collar or hoist hanger.

Using other than the Yale supplied, high

strength pins may cause the pin to break and

allow the hoist and/or load to fall.

To Avoid Injury:

Use only the special high strength pin as

supplied by Yale.

ASSEMBLY

Consideration must be given to the following

when assembling the hoist:

Brake. Assemble the brake components per Figure 10.

Check the ratchet to be sure the bushing is flush with

or below the surface on both sides. When installed, the

teeth must face as shown in Figure 10 and engage the

pawl. Do not lubricate. The brake operates dry.

FIGURE 10. Brake Assembly

Load Limiter. Place a small amount of stay-put lubricant such as Moly-Duolube Style 69 (Hercules Packing

Co.) on Load Limiter handwheel threads to lubricate

the friction hub at assembly. Do not allow lubricant to

contact brake surfaces or friction surfaces of Load

Limiter.

The handwheel shaft nut and washer must tighten

against the friction hub, not the Load Limiter (see

Figure 11). the Load Limiter must be free to revolve

slightly on the friction hub. If the Load Limiter is

disassembled, it must be recalibrated before being

placed in service.

FIGURE 11. Load Limiter Assembly

8

WARNING

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 13

Components must be assembled in the order

shown with the friction washers seated on the

handwheel projections. Handwheel, spring washer, lockwasher and nut must face as shown.

Tighten the adjuster nut hand tight, then turn

clockwise one notch. A NOTCH is turning the nut

sufficient to bring a slot in the nut and a tang of

the lockwasher in line. The next notch brings a

different slot and tang in line.

Do not bend the lockwasher tang at this time.

The Load Limiter

must be calibrated

after assembly.

Calibration. Install

the Load Limiter

(see Figure 11) and

hand chain but not

the handwheel

cover. Mount the

hoist where a load

greater than that

shown in Table 3

can be applied.

Connect a straight

spring scale to the

hand chain so that

a pull can be

applied in the

hoisting direction.

FIGURE 12. Load Limiter Calibration

Table 3 Minimum Hoist Loads & Pull

Hoist

Capacity

(Tons)

1/4

1/2

1

1-1/2

2

3

4

5

6

8

10

Minimum

Load

(Pounds)

650

1,300

2,600

3,900

5,200

7,800

10,400

13,000

15,600

20,800

26,000

Average Pull

To Slip Load Limiter

(Pounds)

33

67

100

113

117

118

121

106

127

133

139

With the load chain taut, apply a steady pull to

the scale to slip the handwheel one revolution

(approx. 2 ft. of hand chain travel - see Figure

12). Record several pull values and obtain the

average. Disregard the initial “break free” pull use only values obtained after the handwheel has

started to slip. When properly adjusted, the

average pull should be as indicated in Table 3.

If the average pull is low, turn the adjuster nut

one notch clockwise and repeat the pull operation. Do this until the correct value is obtained,

then bend the lockwasher tang into the locknut

notch. Load Limiter is now ready for service.

If the handwheel does not slip or the pull is too

high, back off the adjuster nut and start over.

After the proper calibration is obtained, install

the handwheel cover.

Bearing Retainer Screws. Whenever the bearing

retainer screws have been removed and replaced,

they must be locked in place by prick punching the

head (see Figure 13). Always use new spots for locking.

FIGURE 13. Bearing Retainer Screw

Hoist Hanger. The Hoist Hanger and Hoist are not

bolted together to form a rigid unit but can move

relative to each other.

When installing a new hoist hanger screw (646-234A),

tighten the screw firmly and back off one flat (1/6

turn). Then:

3 and 4 ton hoists: Install hoist hanger set screw

(646-233B).

5 to 10 ton hoists: Using the hole in the end of the

hoist hanger as a guide, drill a 0.250 to 0.256 inch

diameter hole through the hoist hanger screw and the

other side of the hoist hanger. Complete the assembly

by driving the hoist hanger screw pin (646-234D) into

hole so that the end of the pin is flush with the end of

the hoist hanger (see Figure 14).

FIGURE 14. Hoist Hanger

9

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 14

Hooks. Both upper and lower hooks must be free

to swivel. Those that are held by nuts must be

adjusted to provide 1/32” clearance as shown in

Figure 15 before the hook nut pin is inserted.

FIGURE 15. Hook Mounting

Lower Hook Thrust Bearings. The 1/4 thru 6

ton lower hook thrust bearings are mounted with

the outer shell down (see Figure 15).

Hand Chain. Hand chain must have an odd

number of links.

Join the ends with the “hand chain connecting

link”(646-45) so that there is no twist in the

completed chain loop. The connecting link must

be completely closed so that it will seat in the

handwheel the same as the welded links.

REEVING

Improper installation (reeving) of the load

chain can result in a dropped load.

To Avoid Injury:

Reeve and attach the ends of the load in

accordance with the following instructions.

1/4-1/2-1 Ton Hoists

Attach approximately 20 inches of wire to the

loose end of the load chain. Feed the wire around

the liftwheel as shown in Figure 16 until the first

link starts over it. The first and third links must

stand on edge with the weld away from the liftwheel. After the chain has been started, pull the

hand chain or turn the handwheel in the hoisting

direction until about 2 feet of load chain has

passed over the liftwheel.

If it becomes difficult to pull the hand chain in

the hoisting direction, pull it in the lowering

direction to release the load chain. Start over. This

will prevent the load chain from being jammed

between the liftwheel and frame.

Remove the wire and attach the loose end of

chain to the hoist using the loose end screw and

washer (see Figure 16). The chain must not be

twisted between the liftwheel and loose end screw.

10

FIGURE 16. Reeving ⁄-fi-1 Ton Hoists

Mount hoist in a vertical position and check that the

lower hook is on the same side of the liftwheel as the

upper hook and in line with it.

1-1/2-2 Ton Hoists

Attach approximately 20 inches of wire to the loose

end of the load chain. Feed the wire around the liftwheel as shown in Figure 17 until the first link starts

over it. The first link must lay flat on the liftwheel.

The second link must stand on edge with the weld

away from the liftwheel. After the chain has been

started, pull the hand chain or turn the handwheel in

the hoisting direction until about 2 feet of load chain

has passed over the liftwheel.

If it become difficult to pull the hand chain in the

hoisting direction, pull it in the lowering direction to

release the load chain. Start over. This will prevent the

load chain from being jammed between the liftwheel

and frame.

Remove the wire and attach the loose end of chain to

the hoist using the loose end screw, washer and lockwasher (see Figure 17). The chain must not be twisted

between the liftwheel and loose end screw.

Mount hoist in a vertical position and check that the

lower hook is on the same side of the liftwheel as the

upper hook and in line with it.

WARNING

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 15

3-4 Ton Hoists

Load chain must have an even number of links.

Check at each stage of assembly to be sure chain

has no twist.

Attach approximately 20 inches of wire to one end

of the load chain. Feed the wire around the liftwheel as shown in Figure 17 until the first link starts

over it. The first link must lay flat on the liftwheel.

The second link must stand on edge with the weld

end away from the liftwheel. After the chain has

been started, pull the hand chain or turn the handwheel in the hoisting direction until about 2 feet of

load chain has passed over the liftwheel.

If it becomes difficult to pull the hand chain in

the hoisting direction, pull it in the lowering

direction to release the load chain. Start over.

This will prevent the load chain from being

jammed between the liftwheel and frame.

Remove the wire and attach the loose end of

chain to the hoist using the loose end screw,

washer and lockwasher (see Figure 17).

Mount hoist in a vertical position. Operate in

the hoisting direction until the remaining load

end of chain is approximately 5 feet long. Reeve

load end of chain as shown in Figure 18 in the

following sequence.

1. Down around the lower hook block sheave.

2. Up the the hoist hanger.

Secure chain end to hoist hanger with dead end

pin. The first link around the hook block sheave

must stand on edge (be upstanding).

FIGURE 17. Reeving 1fi-10 Ton Hoists

FIGURE 18. Reeving 3-4 Ton Hoists

5-6 Ton Hoists

Load chain must have an even number of links. Check

at each stage of assembly to be sure chain has no twist.

Attach approximately 20 inches of wire to one end of

the load chain. Feed the wire around the liftwheel as

shown in Figure 17 until the first link starts over it. The

first link must lay flat on the liftwheel. The second link

must stand on edge with the weld away from the liftwheel. After the chain has been started, pull the hand

chain or turn the handwheel in the hoisting direction

until about 2 feet of load chain has passed over the

liftwheel.

If it becomes difficult to pull the hand chain in the

hoisting direction, pull it in the lowering direction to

release the load chain. Start over. This will prevent the

load chain from being jammed between the liftwheel

and frame.

Remove the wire and attach the loose end of chain

to the hoist using the loose end screw, washer and

lockwasher (see Figure 17).

Mount hoist in a vertical position. Operate in the

hoisting direction until the remaining load end of chain

is approximately 10 feet long. Reeve load end of chain

as shown in Figure 19 in the following sequence.

1. Down around the lower hook block sheave.

2. Up around the hoist hanger sheave.

3. Down the lower hook block.

11

Dead End Pin

Loose End of Chain

Hand Chain omitted

for clarity

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 16

Place end of chain in slot in top of hook block

and secure in place with hook block screw, lockwasher and nut. The first link around the hook

block and hanger sheaves must stand on edge

(be upstanding).

FIGURE 19. Reeving 5-6 Ton Hoists

8 Ton Hoists

Load chain must have an even number of links.

Check at each stage of assembly to be sure chain

has no twist.

Attach approximately 20 inches of wire to one

end of the load chain. Feed the wire around the

liftwheel as shown in Figure 17 until the first link

starts over it. The first link must lay flat on the

liftwheel. The second link must stand on edge

with the weld away from the liftwheel. After the

chain has been started, pull the hand chain or

turn the handwheel in the hoisting direction

until about 2 feet of load chain has passed over

the liftwheel.

If it becomes difficult to pull the hand chain in

the hoisting direction, pull it in the lowering

direction to release the load chain. Start over.

This will prevent the load chain from being

jammed between the liftwheel and frame.

Remove the wire and attach the loose end of

chain to the hoist using the loose end screw,

washer and lockwasher (see Figure 17).

Mount hoist in a vertical position. Operate in the

hoisting direction until the remaining load end

of chain is approximately 15 feet long.

Reeve load end of chain as shown in Figure 20 in the

following sequence.

1. Down around the lower hook block sheave.

2. Up around the hoist hanger sheave.

3. Down around the second hook block sheave.

4. Up the the hoist hanger.

Secure end of chain to the chain anchor with the dead

end pin. The first link around the hook block sheaves

must stand on edge and the first link around the hoist

hanger sheave must lay flat.

Loose End of Chain

Hand Chain omitted

for clarity

FIGURE 20. Reeving 8 Ton Hoists

10 Ton Hoists

Load chain must have an odd number of links. Check at

each stage of assembly to be sure chain has no twist.

Attach approximately 20 inches of wire to one end of

the load chain. Feed the wire around the liftwheel as

shown in Figure 17 until the first link starts over it. The

first link must lay flat on the liftwheel. The second link

must stand on edge with the weld away from the liftwheel. After the chain has been started, pull the hand

chain or turn the handwheel in the hoisting direction

until about 2 feet of load chain has passed over the liftwheel.

If it becomes difficult to pull the hand chain in the hoisting direction, pull it in the lowering direction to release

the load chain. Start over. This will prevent the load

chain from being jammed between the liftwheel and

frame.

Remove the wire and attach the loose end of chain to

the hoist using the loose end screw, washer and lockwasher (see Figure 17).

12

Hand Chain omitted

for clarity

Loose End of Chain

Dead End Pin in

Chain Anchor

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 17

FIGURE 21. Reeving 10 Ton Hoists

Mount hoist in a vertical position. Operate in the

hoisting direction until the remaining load end

of chain is approximately 20 feet long. Reeve

load end of chain as shown in Figure 21 in the

following sequence.

1. Down around the lower hook block sheave.

2. Up around the hoist hanger sheave.

3. Down around the second hook block sheave.

4. Up around the second hoist hanger sheave.

5. Down to the lower hook block.

Secure end of chain to the hook block with the

dead end pin. The first link around the hook block

sheaves must lay flat and the first link around the

hoist hanger sheaves must stand on edge.

Cutting Chains

Hoistaloy®load chain is hardened for wear

resistance and is difficult to cut. However, the

following methods are recommended when

cutting a length of new chain from stock or cutting

off a length of worn chain.

FIGURE 22. Cutting Chain by Nicking

(1) Use a grinder and nick the link on both sides

(see Figure 22), then secure the link in a vise

and break off with a hammer.

(2) Use a 7 inch minimum diameter by 1/8 thick

abrasive wheel (of type recommended by wheel

supplier) that will clear adjacent links.

(3) Chain may also be cut using a bolt cutter (see

Figure 23) similar to the H.K. Porter No. 0590MTC

with special cutter jaws for cutting hardened

chain (1 inch long cutting edge).

FIGURE 23. Cutting Chain with a Bolt Cutter

Cutting chain can produce flying particle.

To Avoid Injury:

• Wear eye protection.

• Provide a shield, such as a heavy rag, over the chain

to prevent flying particles.

TESTING

Prior to initial use, all altered or repaired hoists or used

hoists that have not been operated for the previous 12

months shall be tested by the user for proper operation.

Test the unit first in the unloaded state and then with

a light load of 50 pounds times the number load supporting parts of load chain to be sure it operates properly and the brake holds the load when the hand chain

is released; then test with a load of

*

125% of rated

capacity by or under the direction of an appointed person and a written report prepared for record purposes.

After this test, the function of the Load Limiter is to be

tested (see Table 3, page 9).

*

If load limiter prevents lifting of a load of 125% of rated capacity, reduce load

to rated capacity.

NOTE: For additional information on inspection

and testing, refer to the current issue of ASME

B30.16 “Overhead Hoists” obtainable from ASME

Order Department, 22 Law Drive, Box 2300,

Fairfield, NJ 07007-2300, U.S.A.

Yale

13

WARNING

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 18

14

TROUBLESHOOTING

For disassembly and assembly follow instructions on pages 8 through 13. Always test the Yale LH2 Hoists under

load after reassembly of any parts to be sure it operates properly and holds the load when the hand chain is

released.

PROBLEM

1 Hoist is hard to

operate in either

direction.

2. Hoist is hard to

operate in the

lowering direction.

3. Hoist is hard to

operate in the hoisting

direction.

4) Hoist will not operate

in either direction.

5) Hoist will not operate in

the lowering direction.

6. Hoist will not operate

in the hoisting direction.

7. Hoist will not hold load

in suspension.

CAUSE MAY BE

A) Load chain worn long to gage, thus

binding between liftwheel and chain guide.

B) Load chain rusty, corroded or clogged up

with foreign matter such as cement or

mud.

C) Load chain damaged.

D) Liftwheel clogged with foreign matter or

worn excessively, causing binding between

the liftwheel and chain guide.

E) Hand chain worn long to gage, thus

binding between handwheel and cover.

F) Handwheel clogged with foreign mater or worn.

G) Liftwheel or gear teeth deformed.

A) Brake parts corroded or coated with

foreign matter.

B) Chain binding.

A) Chain binding.

B) Chain twisted. (3 ton capacity or larger).

C) Overload.

A) Liftwheel gear key or friction hub key

missing or sheared.

B) Gears jammed.

A) Locked brake due to a suddenly applied

load, shock load, or load removed by

means other than by operating unit in

the lowering direction.

B) Chain binding.

C) Lower hook all the way out. Load chain

fully extended.

A) Chain binding.

A) Lower hook or load side of chain on

wrong side of liftwheel.

B) Ratchet assembled in reverse.

C) Pawl not engaging with ratchet.

D) Ratchet teeth or pawl worn or broken.

E) Worn brake parts.

F) Oily, dirty or corroded brake friction surfaces.

REMEDY

A) Check gage of chain (see Page 6). Replace

if worn excessively.

B) Clean by tumble polishing or using a non-

acid or non-caustic type solvent. Lubricate

with Lubriplate

®

Bar and Chain Oil 10-R

(Fiske Bros. Refining Co.) or equal lubricant.

C) Check chain for gouges, nicks, bent or

twisted links. Replace if damaged.

D) Clean out pockets. Replace if worn

excessively.

E) Check gage of chain (see Page 6).

F) Clean out pockets. Replace if worn excessively.

G) Excessive overload has been applied.

Replace damaged parts.

A) Disassemble brake and clean thoroughly.

(By wiping with a cloth - not by washing

in a solvent). Replace washers if gummy,

visibly worn or coated with a foreign

matter. Keep washers and brake surfaces

clean and dry.

B) See Items 1A, 1B and 1C.

A) See Items 1A, 1B and 1C.

B) Rereeve chain on 3 and 4 ton unit, if both

chains are twisted, capsize hook block

through loop in chain until twists are

removed. Caution - do not operate unit in

hoisting direction with twisted chain or

serious damage will result.

C) Reduce load or use correct capacity hoist.

A) Install or replace key.

B) Inspect for foreign matter in gear teeth.

A) With hoist under load keep chain taut,

pull sharply on hand chain in the lowering

direction to loosen brake.

B) See Items 1A, 1B and 1C.

C) Chain taut between the liftwheel and loose end

screw. Operate unit in hoisting direction only.

A) See Items 1A, 1B and 1C.

A) Lower hook must be on same side of lifwheel

as upper hook.

B) Ratchet must be assembled as shown in Figure 10.

C) Pawl spring missing or broken. Pawl binding on

pawl stud. Replace spring and clean so pawl

operates freely and engages properly with

ratchet. Do not oil.

D) Replace pawl and/or ratchet.

E) Replace brake parts which are worn.

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 19

15

PARTS LIST

ORDERING INFORMATION

The following information must accompany all

correspondence or repair parts orders.

1) Hoist capacity.

2) Serial Number - this is stamped on the hoist

frames as shown below.

Using “Commercial” or other manufacturer’s parts to

repair the Yale LH2 Hand and Low Headroom Trolley

Hoists may cause load loss.

To Avoid Injury:

Order all replacement parts from Yale. Parts may

look alike but often Yale parts are made of specific

materials or processed to achieve specific properties.

For parts orders also specify:

1) Quantity desired.

2) Key number of part.

3) Part name.

4) Part number.

When ordering replacement parts, consideration

should be given to the need to replace other items:

bearings, fasteners, gaskets, etc. Items that may be

damaged or lost during disassembly or just unfit for

future use because of deterioration from age or service.

Parts should be ordered from Yale’s Authorized Parts

Depots conveniently located throughout the United

States. Refer to page i of this manual to locate the

parts depot nearest you.

WARNING

I.D. Label

646-276

I.D. Label

646-276

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 20

Key

No.

646-1

646-1A

646-1B

646-1B

646-1C

646-1D

646-1E

646-1F

646-2A

646-2B

646-2C

646-3A

646-3B

646-3C

646-4

646-4A

646-4B

646-4C

646-4D

646-5

646-5A

646-6

646-7

646-8

646-9

646-9A

646-9B

646-9CD

646-9D

646-10

646-11

646-12

646-13

646-14

646-14A

646-15

646-15A

646-16

646-16A

646-16B

646-16C

646-16D

646-17A

646-17B

646-18

646-19

646-20

646-24

646-24A

646-24B

646-24C

646-24D

646-25A

646-25B

646-29

646-29A

646-29A

646-29B

646-29D

646-29E

646-29F

646-29G

646-29H

646-29J

646-30

646-31

646-32

646-38

646-45

646-101

646-101A

No.

Req’d

1

1

1

1

2

1

1

1

1

2

2

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

2

1

1

1

1

1

2

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

Part Name

Frame with Upper Hook (includes Items 646-1A

thru 646-1F and 646-15) - Not Shown

Frame

Upper Hook (Includes Latch) - Latch Type

Upper Hook - Latchlok Type

Upper Hook Washer

Upper Hook Collar

Upper Hook Collar Pin

Upper Hook Sleeve

Load Chain Guide

Load Chain Guide Screw

Load Chain Guide Screw L.W.

Stripper

Stripper Screw

Stripper Screw L.W.

Handwheel Shaft and Pinion with Bearings (Items

646-4A thru 646-4D - Not Shown)

Handwheel Shaft and Pinion

Pinion Shaft Bearing (Handwheel End)

Pinion Shaft Bearing (Gear End)

Handwheel Shaft Snap Ring

Pawl

Pawl Bushing

Pawl Retaining Washer

Pawl Stud Snap Ring

Pawl Spring

Brake Assembly (Items 646-9A, 646-9B and 6469CD) - Not Shown

Friction Hub

Friction Washer

Ratchet with Bushing

Ratchet Bushing

Non-Load Limiter Handwheel

Handwheel Shaft Nut Washer

Handwheel Shaft Nut

Friction Hub Key

Handwheel Cover

Cover Label

Operating Instruction Label (See Page 16) - Not Shown

Handwheel Cover Screw

Liftwheel with Bearings (Items 646-16A thru 646-16D)

- Not Shown

Liftwheel

Liftwheel Bearing (Handwheel End)

Liftwheel Bearing (Gear End)

Liftwheel Snap Ring

Frame Bearing Retainer

Frame Bearing Retainer Screw

Liftwheel Gear

Liftwheel Gear Key

Liftwheel Gear Snap Ring

Gear Cover with Capacity Insert

Capacity Insert

Capacity Insert Pin

Gear Cover Screw

Gear Cover Gasket

Loose End Screw

Loose End Screw Washer

Lower Hook and Block Assembly-Latch Type Hook

Lower Hook with Latch-Latch Type Hook

Lower Hook-Latchlok Type Hook

Hook Block Body

Lower Hook Washer

Lower Hook Thrust Bearing

Lower Hook Nut

Lower Hook Nut Pin

Lower Hook Chain Block

Hook Block Pin

Load Chain (Specify Lift or Length Req’d)

Hand Chain (Specify Lift or Length Req’d)

Warning Tube

Latch Kit

Hand Chain Connecting Link

Frame with Upper Hook (Includes Items 646-101A

thru 646-101E and 646-15) - Not Shown

Frame

Capacity - Ton

1/4 & 1/2 1 1-1/2 & 2 3 & 4 5 & 6 8 & 10

Part Number

C701Y C702Y --

45612Y --

45601Y 45602Y --

1020 1022 --

45930 -41350 27359 -45940 45941 -45390 -- -45047 45048 --

945807 --

945851 --

45043 -983745 -940830 --

C703 C704 --

45353 45354 --

88437 -88444 -45873 --

45038

45735

45910

45767

45730

C705

45007

45741 For Units With Load Limiter, 45831 For Units Without Load Limiter

45614

45718

46699

45915

931717

45770

46236

46200

946900

982698

C706 C707 --

45364 45365 --

88489 -88429 -45871 -45750 --

987716 --

45061 45060 --

989101 --

68703 --

C708Y for 1/4 Ton, C721Y for 1/2 Ton and C722Y for 1 Ton

46705 (1/4 Ton) --

46706 (1/2 Ton) --

46707 (1 Ton) --

988271

987322 --

45747 -946801 -954807 --

28683 45668 --

28686 35611

1051 --

45401 -945921 --

88485 -982526

983772 --

28007 45016 --

45943 --

85839 85841 --

85808

946735

45661 45662 --

945490

-- C730Y --

-- 45613Y

16

YALE LH2 HAND HOIST PARTS LIST

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 21

Key

No.

646-101B

646-101B

646-101C

646-101D

646-101E

646-102A

646-102B

646-102C

646-103A

646-103B

646-104

646-104A

646-104B

646-104C

646-116

646-116A

646-116B

646-116C

646-116D

646-116E

646-118

646-119

646-121

646-121A

646-121B

646-121C

646-122

646-124

646-124A

646-124B

646-124C

646-124D

646-125A

646-125B

646-125C

646-129

646-129A

646-129A

646-129B

646-129E

646-129F

646-129G

646-129H

646-129J

646-130

646-131

646-132

646-133

646-134

646-135

646-136

646-137

646-138

646-139

646-144

646-201B

646-201B

646-201C

646-201E

646-201F

646-206

646-229

646-229A

646-229A

No.

Req’d

1

1

2

1

1

1

3

3

1

2

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

2

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

2

1

1

2

1

1

1

Part Name

Upper Hook (Includes Latch) Latch Type

Upper Hook-Latchlok Type

Upper Hook Washer

Upper Hook Collar

Upper Hook Collar Pin

Load Chain Guide

Load Chain Guide Screw

Load Chain Guide Screw L.W.

Stripper

Stripper Screw

Handwheel Shaft and Pinion with Bearings (Items

646-104A, 646-104B and 646-104C) - Not Shown

Handwheel Shaft and Pinion

Handwheel Shaft Bearing (Handwheel End)

Handwheel Shaft Bearing (Pinion End)

Liftwheel with Bearings (Items 646-116A thru

646-116E) - Not Shown

Liftwheel

Liftwheel Bearing (Handwheel End)

Liftwheel Bearing (Gear End)

Liftwheel Snap Ring

Liftwheel Bearing Retaining Ring (Gear End)

Liftwheel Gear

Liftwheel Dowel Pin

Intermediate Gear and Pinion with Bearings (Items

646-121A, 646-121B and 646-121C) - Not Shown

Intermediate Gear & Pinion

Intermediate Gear Bearing (Pinion End)

Intermediate Gear Bearing (Cover End)

Gear Cover Dowel

Gear Cover with Capacity Insert

Capacity Insert

Capacity Insert Pin

Gear Cover Screw

Gear Cover Gasket

Loose End Screw

Loose End Screw L.W.

Loose End Screw Washer

Lower Hook and Block Assembly-Latch Type Hook

Lower Hook with Latch-Latch Type Hook

Lower Hook-Latchlok Type Hook

Hook Block Body

Lower Hook Thrust Bearing

Lower Hook Nut

Lower Hook Nut Pin

Lower Hook Chain Block

Hook Block Pin

Load Chain (Specify Lift or Length Req’d)

Hand Chain (Specify Lift or Length Req’d)

Load Limiter Complete

Handwheel Sub-Assembly

Load Limiter Hub

Friction Washer

Steel Washer

Spring Washer

Lockwasher

Nut

Latch Kit

Upper Hook (Includes Latch)-Latch Type

Upper Hook-Latchlok Type

Upper Hook Washer

Upper Hook Nut Pin

Upper Hook Nut

Latch Kit

Lower Hook Block Assembly - Not Shown

Lower Hook (Includes Latch)-Latch Type

Lower Hook-Latchlok Type

Capacity - Ton

1/4 & 1/2 1 1-1/2 & 2 3 & 4 5 & 6 8 & 10

Part Number

-- 45604Y --

-- 1023 --

-- 45918 --

-- 35478 --

-- 45946 --

-- 45049

-- 945815

-- 45852

-- 45420

-- 982709

-- C710 For 1-1/2 & 3 Ton, C711

-- For 2, 4, 5, 6, 8 & 10 Ton

--

45355 for 1-1/2 & 3 Ton, 45356 for 2, 4 , 5, 6, 8 & 10 Ton

-- 88437

-- 83671

-C712

-- 45057

-- 88445

-- 83669

-- 45766

-- 46800

-- 45008

-- 45771

C713 for 1-1/2 & 3 Ton, C714 for 2, 4, 5, 6, 8 & 10 Ton

-- 45014 for 1-1/2 & 3 Ton (7 & 45 Teeth)

-- 45015 for 2, 4, 5, 6, 8 & 10 Ton (7 & 47 Teeth)

-- 83682

-- 88437

-- 46730

C715Y for 1-1/2 Ton, C723Y for 2 Ton, C724Y for 3 Ton, C725Y for 4 Ton,

C726Y for 5 Ton, C727Y for 6 Ton, C728Y for 8 Ton & C729Y for 10 Ton

46708 (1-1/2 Ton), 46709 (2 Ton), 46710 (3 Ton)

46711 (4 Ton), 46712 (5 Ton), 46713 (6 Ton),

46714 (8 Ton), 46715 (10 Ton)

-- 988271

-- 983732

-- 46704

-- 945815

-- 945852

-- 954806

-- 45669 --

-- 45603 --

-- 1024 --

-- 45399 --

-- 88505

-- 45382

-- 983779

-- 45017

-- 45948

85839 85864

85808

44602 for 1/4 Ton, 44601 for 1/2 Ton, 44600 for 1 thru 10 Ton

45675

45012

45886

45032

45888

45033

45737

-- 45663 --

-- 45607Y 45606Y (5T.) 45609Y

40607Y (6T.)

-- 1025 1027 1028

-- 40736 988005

-- 983787 983788

-- 940834 945836

-- 45664 45664 (5T.) 45697

45665 (6T.)

46230 for 3 Ton, 46231 for 4 Ton.

46232 for 5 Ton, 46233 for 6 Ton

46234 for 8 & 10Ton

-- 45605 45606 (5T.) 45609

40607 (6T.)

-- 1026 1027 1028

17

YALE LH2 HAND HOIST PARTS LIST

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 22

Key

No.

646-229B

646-229G

646-229K

646-229L

646-233A

646-233B

646-234A

646-234C

646-234D

646-235

646-236

646-237

646-238

646-239

646-241

646-242

646-243

646-244

646-245

646-246A

646-246B

646-247

646-248

646-249A

646-249B

646-249C

646-250

646-252

646-253

646-254

646-256A

646-256B

646-257

646-258

646-259

646-260

646-275

646-276

No.

Req’d

1

1

1

1

1

1

1

1

1

1

1

1

1

1 or 2

1 or 2

2

1

2

2

1

1

2

1

3

3

3

1 or 2

1 or 2

2

1 or 2

1

1

1

1

1

2

1

1

Part Name

Lower Hook Sleeve

Lower Hook Pin

Lower Hook Nut

Lower Hook Thrust Bearing

Hoist Hanger (Also order 646-234A and 646-234B

or 646-234D as applicable)

Hoist Hanger Set Screw

Hoist Hanger Screw (Also order 646-234B or

646-234D as applicable)

Hoist Hanger Screw Washer

Hoist Hanger Screw Pin

Hoist Hanger Screw Sleeve

Hoist Hanger Sheave Cap (Tapped)

Hoist Hanger Sheave Cap (Drilled)

Hoist Hanger Chain Anchor

Hoist Hanger Sheave

Hoist Hanger Bearing

Hoist Hanger Sheave Bearing

Hoist Hanger Snap Ring

Hoist Hanger Bearing Retainer

Hoist Hanger Sheave Shaft

Hoist Hanger Sheave Shaft Bolt

Hoist Hanger Sheave Shaft Bolt L.W.

Lower Hook Block (Also order Capacity Insert

646-275 for 5 & 6 Ton Units)

Lower Hook Block Body (Also order Capacity

Insert 646-275)

Lower Hook Block Screw

Hook Block Screw Nut

Hook Block Screw L.W.

Hook Block Sheave

Hook Block Sheave Bearing

Hook Block Sheave Bearing

Hook Block Sheave Shaft

Hook Block Sheave Shaft Bolt

Hook Block Sheave Shaft Bolt L.W.

Hook Block Sheave Cap (Tapped)

Hook Block Sheave Cap (Drilled)

Dead End Pin

Reeving Caution Plate

Capacity Insert

I.D. Label

Capacity - Ton

1/4 & 1/2 1 1-1/2 & 2 3 & 4 5 & 6 8 & 10

Part Number

-- 45394 45393 45410

-- 983787 983788

-- 940834 945836

-- 88507 88511

-- 45090Y 45091Y 45094Y

-- 986304 --

-- 987223 987179

-- 945916 --

-- 983789

-- 45391 --

-- 45123Y

-- 45124Y

-- 45134Y (8T.)

-- 45085 45106

-- 88542

-- 83670 --

-- 45765 --

-- 45151 --

-- 45425

-- 89411

-- 987919

45107Y (3T.)

-- 45096Y (4T.) 45101Y --

-- 45104Y

-- 945796 45812 --

-- 945820 945822 --

-- 945851 945853 --

-- 45086 45106

-- 88542

-- 83670 --

-- 45425

-- 89411

-- 987919

-- 45123Y

-- 45124Y

-- 45945 -- 45944

-- 45757 --

46712 for 5 Ton, 46713 for 6 Ton, 45837 for 8 Ton & 45838 for 10 Ton

46211 46210

Part Numbers for packaged lubricants used in

Yale LH2 Hand and Low Headroom Trolley Hoists

Lubricant

Usage

Gears

Handwheel

Threads

Chain

Trackwheel

Bearings

Trackwheel

Gears

Handwheel

Shaft

Type of

Lubricant

Grease

Spray

Oil

Grease

*Heavy Cup

Grease

*Light Machine

Oil

Part Numbers

and Packaged

Quantities of

Lubricants

28610 (1#can)

28632 (4#can)

46698 (16 oz.)

28608 (1 pt. can)

28619 (1 gal. can)

28610 (1#can)

28632 (4#can)

--

--

*These are not furnished by Yale in Packaged Quantities.

When ordering lubricants, specify the type of lubricant, part number and

packaged quantity required.

Touch-up Paints for Yale LH2 Hand and Low Headroom Trolley Hoists:

1. Hoist. Order *(1) case (12-12 oz. Aerosol Cans) of Yellow Touch-up paint

Part Number 40215.

2. Trolley. Order *(1) case (12-12 oz. Aerosol Cans) of Black Touch-up paint

Part Number 84189.

*Touch-up paints are only available in case quantities.

NOTE: When painting hoists or trolleys, also order warning labels,

identification labels, etc. that may be coated during painting.

18

YALE LH2 HAND HOIST PARTS LIST

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Page 23

RECOMMENDED SPARE PARTS

Key No.

646-5

646-5A

646-6

646-7

646-8

646-9B

646-24D

646-124D

648-124C

Part Name

Pawl

Pawl Bushing

Pawl Retaining Washer

Pawl Stud Snap Ring

Pawl Spring

Friction Washer

Gear Cover Gasket (1/4, 1/2 & 1 T.)

Gear Cover Gasket (1-1/2 - 10T.)

Gear Cover Gasket (Trolley Hoist)

Qty. for each Hoist in service

1

1

1

1

1

2

1

1

1

To insure continued service of the Yale LH2 Hand and Low Headroom Trolley Hoist, the following is a

list of the parts that are recommended to be kept on hand at all times to replace parts that are worn.