Page 1

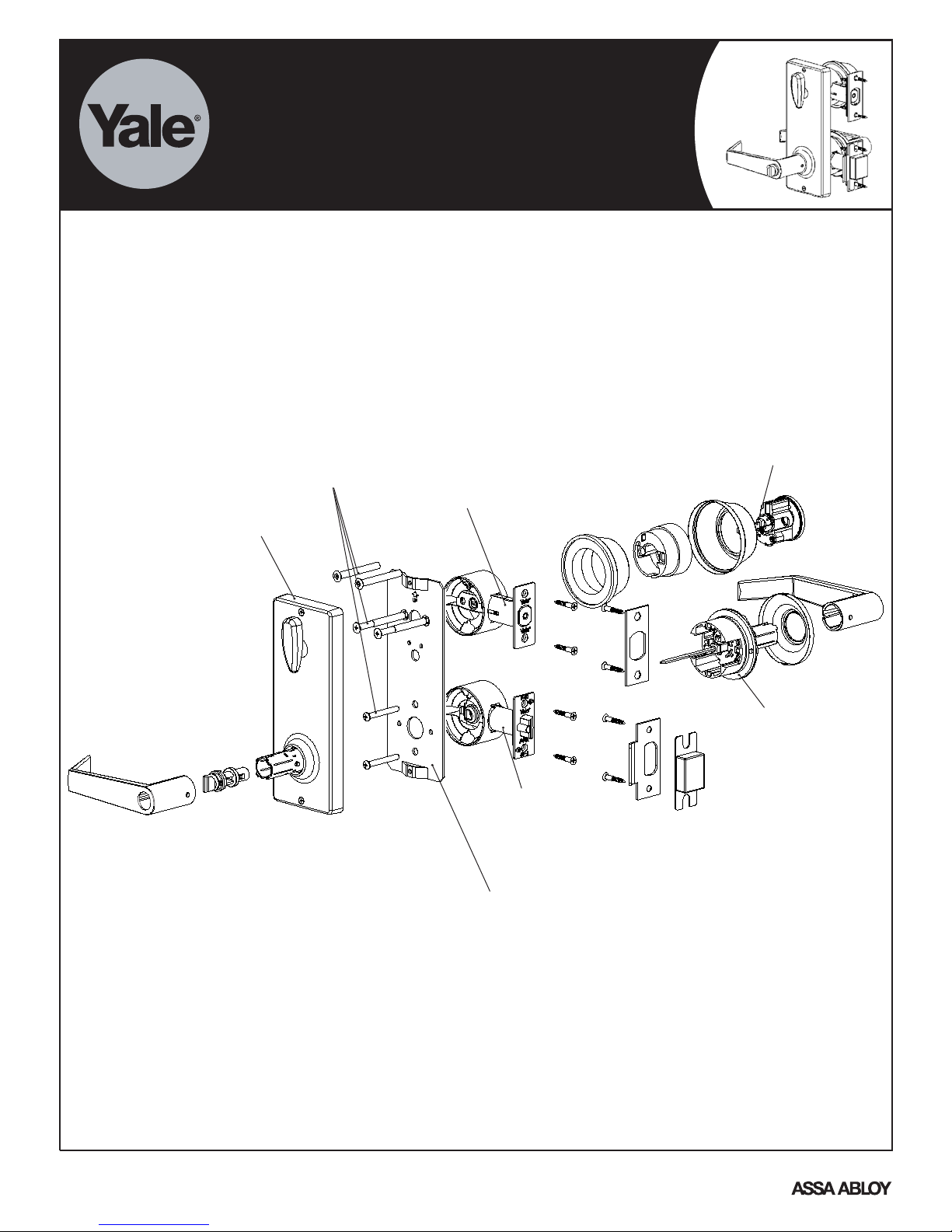

4800LN GRADE 2 INTERCONNECTED LOCKSET

INSTALLATION INSTRUCTIONS

Installation of this product requires that two 2 1/8" holes are spaced 4" apart center to center. See the hole template

sheet for accurate holelocations.

Connecting Screws

Interior Mechanism Housing

Deadbolt Latch

Installation Plate

Latch

Deadbolt

Tailpiece

Hub with Square Spindle

An ASSA ABLOY Group brand

P/N 80-9510-0056-010 Rev B

Page 2

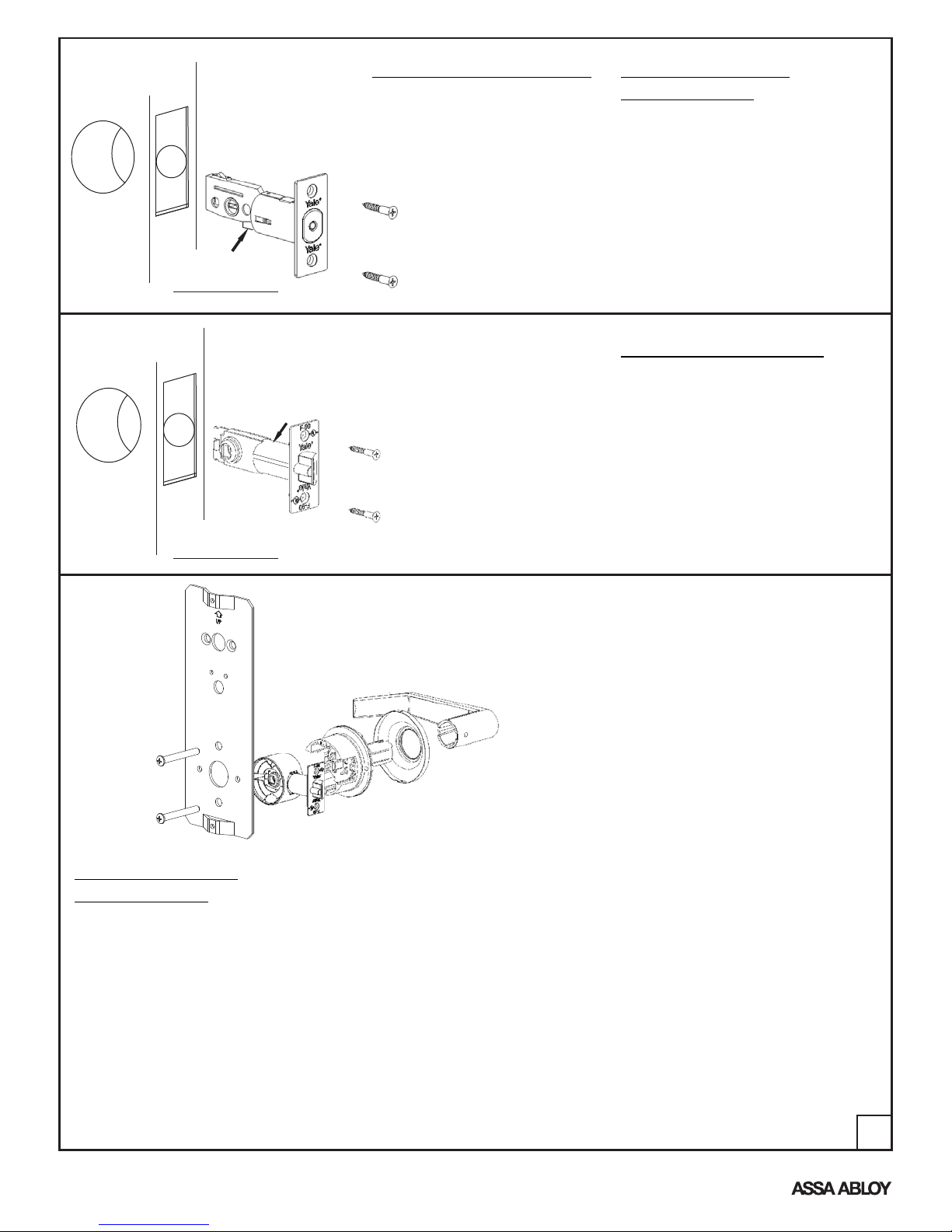

Tab

Deadbolt Fig. 1

Plastic Sleeve

BACKSET ADJUSTMENT

Firmly push and hold tab. Pull

deadbolt apart for 2-3/4"

backset and push together for

2-3/8" backset. Make sure tab

is held in through motion.

DEADBOLT LATCH

INSTALLATION

Insert latch through the hole in the

door edge and screw in place using

two 3/4" Phillips head screws. There

is a rectangular slide cam on the

back side part of the latch This is the

top of the latch. It should be up. DO

NOT INSTALL WITH THIS

POINTING DOWN.

LATCH INSTALLATION

Insert latch with plastic sleeve

through the hole in door edge and

screw in place using two 3/4" Phillips

head screws. Curved edge of latch

bolt should face in direction that door

closes.

Latchbolt Fig. 2

EXTERIOR LEVER

INSTALLATION

Exterior Assembly

There is a spring button on the tube

of the assembly. It should point

away from the door edge toward

the hinge side of the door. For

keyed entry levers, the release

button should point towards the

door’s edge. Insert the square

spindle of the exterior assembly

through the cam of the lower latch

and insert the connecting screws

loosely. Tighten these two screws.

Lever Assembly

Line up the hole in the neck of the

lever with the release button, then

slide the lever until the button

aligns with the hole. Using a key,

nail, or other pointed tool, depress

the button and push the lever onto

the tube until the button snaps into

the hole in the neck of the lever.

Assembly/Verification

Using a key from the exterior,

operate the deadbolt latch to insure

correct alignment. Operate the

exterior lever insuring smooth

operation. If the deadbolt or the

exterior lever does not operate

smoothly, adjust the installation

plate up and down or side to side to

find the correct position then

tighten all four connecting screws.

Interior Mechanism Housing

Reinstall the interior mechanism

housing on the installation plate

with the two self-thread screws

saved before. Once this operation

is done, the square

make sure

spindle for the interior mechanism

housing is inside the hub of the

lower latch and operates the latch.

Note that the thumbturn must be in

the vertical position, then slide the

lever over the bottom tube and

proceed same as with the exterior

assembly.

2

An ASSA ABLOY Group brand

P/N 80-9510-0056-010 Rev B

Page 3

DEADBOLT INSTALLATION

Unscrew the top and bottom screws from the

interior mechanism housing and remove the

installation plate. Save these screws to reinstall

housing on the installation plate.

The exterior deadbolt assembly has a blade

(tailpiece) attached to the rear of the cylinder.

This tailpiece passes through the latch and

engages the interior assembly. Insert the key in

the cylinder so that the flat edge of the key is

down and slide the tailpiece through the

horizontal slot in the latch. Insert the deadbolt

connecting screws through the installation plate

and connect the plate with the exterior deadbolt

housing. Slightly tighten these two screws.

Deadbolt screws are 1/4" x 2-1/2" for 2" to 1-1/2"

thickness doors. Use 1/4" x 2-1/16" screws also

included for 1-3/8" thickness doors. DO NOT

INSTALL WITH THE DEADBOLT EXTENDED.

INTERIOR MECHANISM HOUSING

Reinstall the interior mechanism housing on the

installation plate with the two self-thread screws

saved before. Once this operation is done,

the square spindle for the interior

sure

mechanism housing is inside the hub of the

lower latch and operates the latch. Note that the

thumbturn must be in the vertical position then

slide the lever over the bottom tube and proceed

same as with the exterior assembly.

make

NEW DOOR PREPARATION

1. Fold template as marked and place on door. If

corner of door is beveled, place template on

widest side of door.

2. Mark centers for all holes. Drill 1/8" (3mm) pilot

holes at centers. Drill completely through door

thickness.

3. Bore 2-1/8" (54mm) hole halfway through door.

Finish bore from other side to prevent

splintering.

4. To mark strike location, close the door and push

locator pin through both guide holes marking

the strike plates center position.

5. Bore 2 holes 1" (25mm) through the door edge.

6. For handleset installation only: Bore 5/16" hole

to receive bottom portion of handleset.

7. Insert the latch and then trace outlines of

latchplates. Carefully chisel away outlined areas

until plates fit flush. Drill pilot holes for

latchplates mounting screws.

An ASSA ABLOY Group brand

STRIKE PLATE INSTALLATION

1. To prepare door frame for strike

plates, locate the strike plates'

center position. Marked on the

stage 4 for “new door preparation”.

2. Trace outlines of strike plates.

Carefully chisel away outlined

areas until plates fit flush.

3. With a 1" (25mm) drill bit, drill a 1"

(25mm) deep hole at the upper

strike plate to accept the bolt.

4. With a 1"(25mm) drill bit, drill a

1/2"(13mm) deep hole at the lower

strike plate to accept the latch bolt.

5. Drill pilot holes for the plate

mounting screws.

6. Secure the strike plates with (2)

3/4" screws.

3

P/N 80-9510-0056-010 Rev B

Page 4

REMOVAL OF CYLINDER

When not installed on door

Remove the loose plate from the

back of the cylinder. Two screws

hold a metal strap in place. Under

the “C” cutout in this strap is a

semicircular indention in a spring

loaded tab. Using the cylinder

removing tool (wire with loop) or a

screwdriver, place the tip of the tool

against the tab in the indention and

push toward the center and then

clockwise. The purpose is to move

Dummy Trim

See Interior Mechanism Housing Installation

Page 3 For Installation Instructions

the cylinder and strap to the left.

When all the way left, push the

cylinder out of the housing.

Note: it may be necessary to put

the tool in between the gap created

on the right and force the cylinder

to the left. Remove the plug

assembly from the cylinder housing

for re-keying.

REMOVAL OF CYLINDER

When installed on door

Insert the key into the plug. Press

the

cylinder removing tool into the hole

positioned at 5 o’clock and turn the

key counterclockwise. This will

cause the face of the cylinder to

rotate to the left slightly. Once

turned off center, pull on the key to

remove the cylinder. Remove the

plug assembly from the cylinder

housing for re-keying.

100 Yale Avenue, Lenoir City, TN 37771 • Product Support Tel 800.438.1951 • Fax 800.338.0965 • www.yalecommercial.com

Yale® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company. Other products' brand names may be trademarks or registered trademarks of their respective

owners and are mentioned for reference purposes only. These materials are protected under U.S. copyright laws. All contents current at time of publication. Yale Security Inc., an ASSA ABLOY Group

company reserves the right to change availability of any item in this catalog, its design, construction, and/or its materials. Copyright © 2006, 2008, Yale Security Inc., an ASSA ABLOY Group company.

An ASSA ABLOY Group brand

All rights reserved. Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

4

P/N 80-9510-0056-010 Rev B

Loading...

Loading...