Page 1

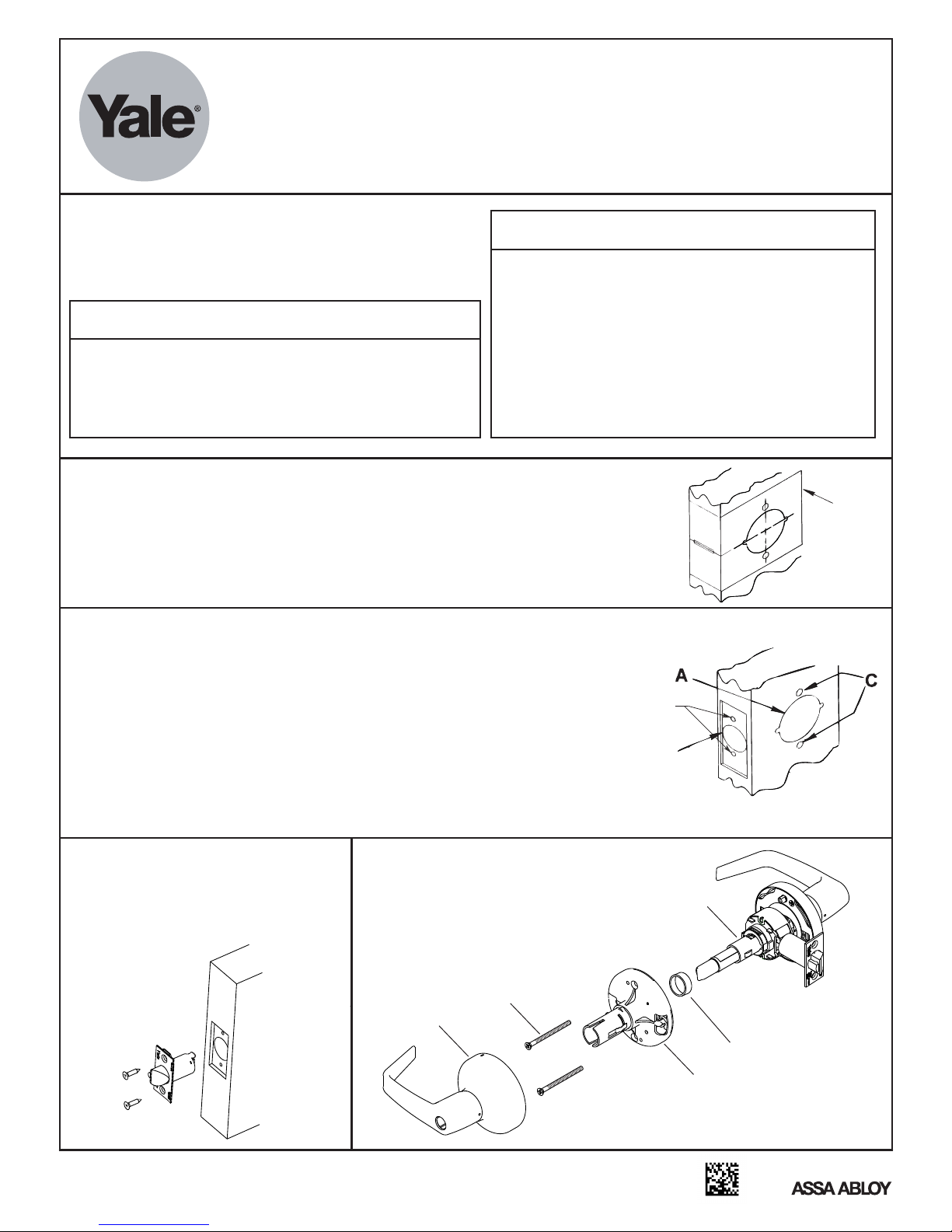

5300LN Grade 2 or 4700LN Grade 1

Cylindrical Lever Locksets

Installation Instructions

IMPORTANT: The accuracy of the door preparation is

critical for the proper functioning and security of this lever

handle lock. Misalignment can cause premature wear and

tear and a lessening of security.

Tools Required

• 2-1/8" (54mm) hole saw

• 1" (26mm) boring bit

• 5/16" (8mm) drill bit

• 7/64" (2.5mm) drill bit

1. Mark door.

Mark horizontal line across edge of

door for centerline of lock at desired

installation height. Fold template over

edge of door, centering on horizontal

line. Mark centers of holes at proper

backset.

2. Drill door.

A. Drill 2-1/8" (54mm) dia. hole thru

the door. Cut notches as shown on

template. See note. (Except

Dummy Trim)

B. Drill 1" (26mm) dia. hole in edge of

door. Mortise for latch front 1-1/8"

(29mm) wide x 2-1/4" (57mm) high

x 5/32" (4mm) deep. (Except

Dummy Trim)

• Chisel & hammer

• #2 phillips screw driver

• Handle removal tool (supplied)

• 3/8" or 1/2" drill

For beveled and square edge doors,

mark both sides of the door.

Note:

Be sure to verify backset before

marking & drilling door.

C. Drill two (2) 5/16" (8mm) dia.

holes thru door. See note.

D. Drill pilot holes for latch

screws. 7/64" (2.5mm) dia.

(Except Dummy Trim)

Note: To avoid splintering wood

doors, drill holes (A) and (C) from

both sides of the door.

Attention Installer

Installation of cylindrical locks and latches must be through

bolted in all doors. If installation instructions are not followed this

may result in damage to the lock and void the factory warranty.

Any retrofit or other field modification to a fire rated opening can

potentially impact the fire rating of the opening, and Yale Locks &

Hardware makes no representations or warranties concerning

what such impact may be in any specific situation. When

retrofitting any portion of an existing fire rated opening, or

specifying and installing a new fire-rated opening, please consult

with a code specialist or local code official (Authority Having

Jurisdiction) to ensure compliance with all applicable codes and

ratings.

D

B

Door

Marker

3. Install latch.

Insert latch in door. (Be sure bevel

edge of bolt faces strike plate.)

Attach with two screws supplied.

An ASSA ABLOY Group brand

4. Unpack lock.

Through Bolts

Inside Lever

Handle

Outside Assembly

(stays assembled)

Inside Rose

Support Assembly

Bushing

80-9150-0060-010 (11-16)

Page 2

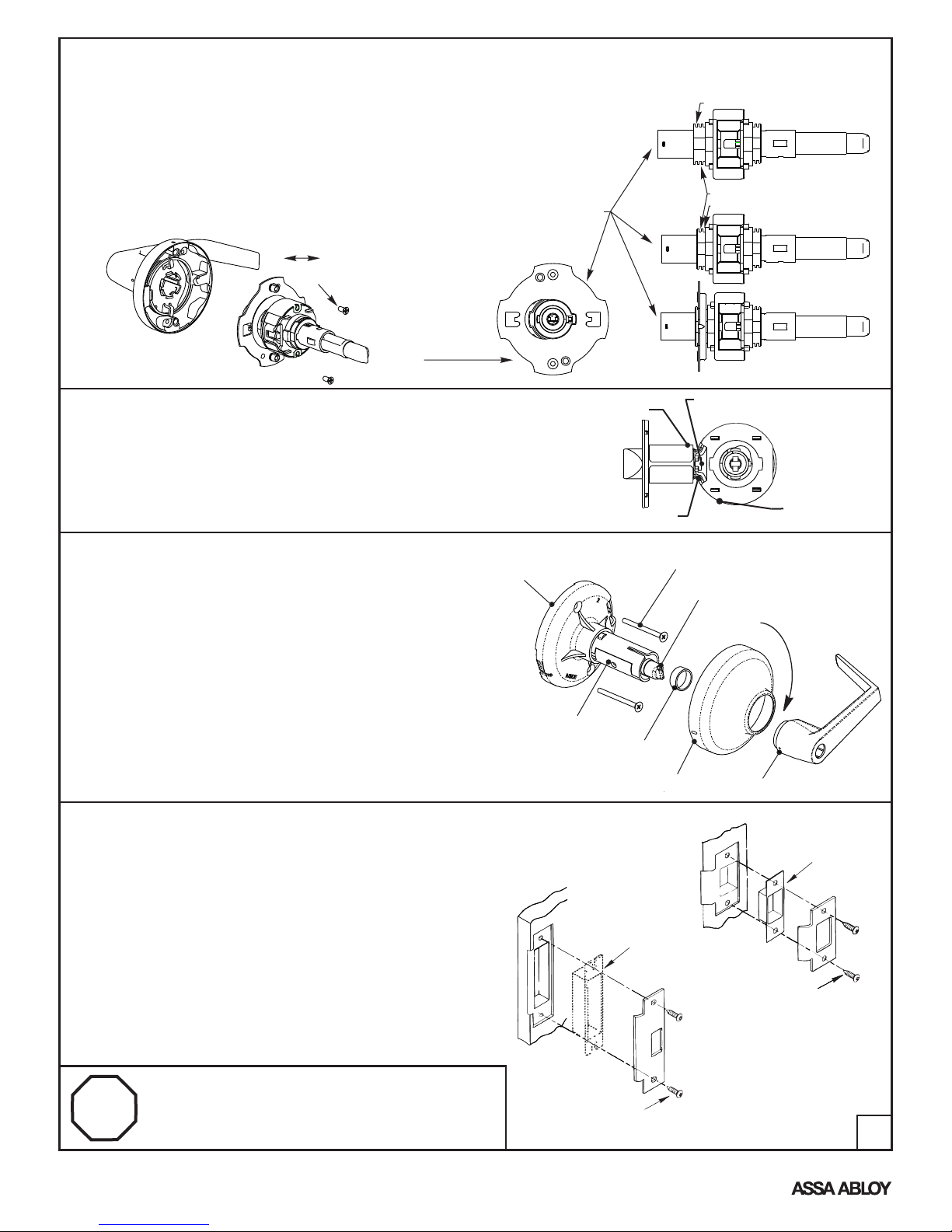

5. Adjust lock for door thickness (if necessary).

(Lock is packed preadjusted for 1-3/4" (44mm) doors. Available for 2-1/4" (57mm) doors upon request.)

2-1/4" door

To Adjust for Thicker Door

A. Remove two (2) screws from outside rose.

B. Slide outside rose away from lock body.

C. Adjust rose plate to desired door thickness per illustration at right.

D. Fasten outside rose to lock body with two (2) screws.

B

A

Slide plate

to disengage

C

2" door

1-3/4" door

6. Install lock.

Insert lockbody into door from outside making sure that

lockbody frame hooks latch case and retractor engages

bolt tail(s). DO NOT FORCE. (If lockbody does not

engage latch easily, check door preparation for errors.)

7. Install inside components.

Inside Rose

Support Assembly

A. Slide inside rose support assembly onto lockbody

and tighten through bolts.

B. Place black plastic bushing over push/turn button.

C. Place rose scalp on rose support assembly aligning the

dimple with the notch. Rotate the rose scalp clockwise

to lock. Note: Repeat on outside rose if necessary.

D. Install lever handle. For double cylinder functions,

install the inside cylinder and lever as shown on the

next page.

8. Strike installation (Wood Frames Only).

A. Close door and mark a horizontal line from the center of

the template to the frame of the door.

Latch

Frame engages latchcase

Set Screw Hole

Bushing

STRIKES

Machine Screw

Push/Turn Button

Rose Scalp

Retractor engages

bolt tail(s)

Lockbody

Inside Lever

371

Standard Strike Box

14-5301-1033

B. Measure half the thickness of the door. Mark this same

distance with a vertical line starting from the stop side of

the frame and where both lines cross. Make a 1 inch

(26mm) diameter hole and 1/2 inch (13mm) in depth.

C. Align the holes of the strike with the vertical line. Trace the

outline of the strike and mortise with 1/16 inch (1.6mm)

depth. Attach the strike with two screws (provided).

TEST THE OPERATION OF THE LOCKSET

Cycle the lock in both the locked and unlocked positions. If lock

STOP

An ASSA ABLOY Group brand

functions smoothly when door is open, but binds when closed,

check door and frame alignment. If problems are found see

Troubleshooting on page 3.

Optional Strike Box

Attaching Screws

81-2012-0620

#12-12-24x1"

497

#202

Attaching Screws

81-2012-0416

#8-8-32x3/4"

2

80-9150-0060-010 (11-16)

Page 3

Troubleshooting

1. Check door.

2. Check hinges. They should not be loose or have excessive wear on

knuckles.

3. Latchbolt will not deadlock.

Either strike is out of line or gap between door and jamb is too great.

Realign strike or shim strike out towards flat area of latchbolt.

4. Latchbolt does not retract or extend properly.

Latchbolt tail and retractor not properly positioned.

A. Remove lockset. Look through 2-1/8" hole and verify latchbolt tail

centered between top and bottom of hole.

B. Remove latchbolt and insert lockset. Look through latch hole and

verify retractor mouth centered in hole. Adjust outside rose plate if

not. (See #5 on page 2)

C. Rebore holes if necessary to line up retractor and tail.

Door Must Not Bind

Door Must Not Sag

Door Must Not Be Warped

Door Must Swing Freely

TO REMOVE CYLINDER HANDLE

A. Insert key and rotate 45° counterclockwise.

B. Depress retainer with tool provided.

C. Slide lever off lock. (Also applies to inside

lever of 5321LN or 4721LN Function).

TO REPLACE OR INSTALL CYLINDER

A. Remove the sleeve from inside the shank or

from the old cylinder.

B. Slide cylinder into sleeve.

C. Rotate key 45° counterclockwise. Depress retainer

plate, push the handle onto the shank until fully

seated. Pull on handle to ensure properly seated.

Yale Cylinder

DUMMY TRIM INSTALLATION

Secure the Rose Support assembly to the door using screws

and washers provided and install the rose scalp and inside

lever.

Machine Screws

Washers

Inside Rose

Support Assembly

Rose Scalp

Inside Lever

5328LN, 5329LN, 5339LN, 4728LN, 4729LN

or 4739LN Functions Only

Adjust for Door Thickness

Tailpiece

Cylinder Sleeve

(Note: Cylinder and Sleeve must be properly installed or

the security of the lock will be compromised.)

Finish Care

This lockset is designed to provide the highest standard of product quality and performance. Care should be

taken to insure a long-lasting finish. When cleaning is required use a soft,damp cloth. Using lacquer thinners,

caustic soaps, abrasive cleaners or polishes could damage the coating and result in tarnishing.

An ASSA ABLOY Group brand

3

80-9150-0060-010 (11-16)

Page 4

5300LN or 4700LN

Cylindrical Lever Lockset

Use this end o f T emplate

f or Square Edge Doors

2-3/4" (69.9)

Between Centers

Square Ed g e

Door On l y

5/32" x 1/8"

(4mm x 3mm)

Deep 2 place s .

Both sides of

doo r .

5/16" Dia.

(8mm)

Th r u Door

2 Holes

2-3/4"

(70)

A B

C

K

S

T E

T E

S

K

C

A B

Ma r k Center of

Door thi c kness f or

7/8" or 1" Dia . Hol e .

F old on Edge of Door

at proper Ba c kset Line

2-3/8"

(60)

B A

CKSET

T E

S

K

C

A B

2-1/8" Dia.

(54mm)

Th r u Door

5"

TO CHECK, MEASURE SCALE ACROSS.

CAUTION: IF PRINTED FROM WEBSITE, PRINT 1:1 SCALE.

4"

Use this end o

or B e v eled Edge Doors

f

f T emplate

All rights reserved. Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

(60)

2-3/8"

(70)

2-3/4"

Ma r k Center of

Door thi c kness f or

7/8" or 1" Dia . Hol e .

Product Support Tel 800.438.1951 • www.yalelocks.com

Yale Locks & Hardware is a division of Yale Security Inc., an ASSA ABLOY Group company.

Copyright © 2002, 2016, Yale Security Inc., an ASSA ABLOY Group company.

F old on Edge of Door

at proper Ba c kset Line

Place Solid F old Line

on High Edge of Door

B e veled Ed g e

Door On l y

Place Dotted F old Line

on L o w Edge of Door

3"

2"

1"

1"2"3"

4

An ASSA ABLOY Group brand

80-9150-0060-010 (11-16)

Loading...

Loading...