XYZ Machine Tools ProTURN SLX 1630, ProtoTRAK SLX CNC Safety, Installation, Maintenance, Service & Parts List Manual

Page 1

Document: 25099

Version: 032813

ProTURN SLX 1630

ProtoTRAK SLX CNC

Safety, Installation, Maintenance,

Service & Parts List Manual

Southwestern Industries, Inc.

2615 Homestead Place

Rancho Dominguez, CA 90220-5610 USA

T | 310.608.4422 | F | 310. 764.2668

Service Department: 800.367.3165

e-mail: sales@southwesternindustries.com

| service@southwesternindustries.com

| web: southwesternindustries.com

Page 2

Service Department

Tel:

01823 674214

Fax:

01823 674201

Copyright © 2011, XYZ Machine Tools, Ltd. All rights are reserved. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted, in any form or by any means, mechanical,

photocopying, recording or otherwise, without the prior written permission of XYZ Machine Tools, Ltd.

While every effort has been made to include all the information required for the purposes of this guide, XYZ

Machine Tools assumes no responsibility for inaccuracies or omission and accepts no liability for damages

resulting from the use of the information contained in this guide.

All brand names and products are trademarks or registered trademarks of their respective holders.

XYZ Machine Tools

Woodlands Business Park

Burlescombe, Nr Tiverton

Devon, EX16 7LL

Page 3

i

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Table of Contents

1.0 Safety Specifications

1.1 Safety Publications 1

1.2 Safety Precautions 2

2.0 Installation

2.1 Floor Plan, Layout & Space Requirements 5

2.2 Uncrating 6

2.3 Shortages: Inventory Checklist 6

2.4 Installation, Instructions & Checklist 7

2.5 Machine Specifications 9

2.6 ProtoTRAK SLX Control Hardware 10

2.7 Lifting and/or Moving the Machine 10

2.8 Cleaning 12

2.9 Leveling 12

2.9.1 SLX 1630 13

2.10 Electrical Connection 13

2.10.1 Phase Converters 14

2.11 Mounting the Display Pendant 14

2.12 Cable Interconnections 15

2.13 Lubrication System 18

2.13.1 Headstock 18

2.13.2 Automatic Way Lubrication Pump 19

2.13.3 Lube Pump Operation 19

2.13.4 Factory Default Values 19

2.14 Cutting the Test Part 20

2.15 Measurement of the Test Part 20

3.0 Troubleshooting by Symptom

3.1 Problems relating to Machining Results 21

3.1.1 Poor Finish 21

3.1.2 Turning Diameters out of Round 22

3.1.3 Cutting Taper 22

3.1.4 Parts have Incorrect Dimensions 22

3.1.5 Threading Problems 23

3.2 Problems regarding the Motion

of the Machine 23

3.2.1 Run Away Axis 23

3.2.2 Slow Down Axis 24

3.2.3 Axis will not Jog 24

3.2.4 Axis Motor Motion is not Smooth 25

3.2.5 Vibration in Motion 25

3.2.6 Searching Axis 26

3.3 Problems Relating to the Operation Control 26

3.3.1 Display Blanks 26

3.3.2 Bad Picture on the Display 26

3.3.3 Keyboard Lockup 26

3.3.4 Fault X or Z 27

3.3.5 Problems Reading the Floppy Disk 27

3.3.6 System Will Not Turn ON 28

3.3.7 System Will Not Boot Up 28

3.3.8 System Reboots by Itself 28

3.3.9 System Shuts Off 28

3.3.10 Will Not Hold Calibration 29

3.3.11 E-Stop Error 29

3.4 Problems with the Measurements 30

3.4.1 X & Z-Axis Measurements Do Not

Repeat 30

3.4.2 X & Z-Axis Measurements are not

Accurate 31

3.4.3 The DRO is not Counting 31

3.4.4 X & Z-Axis DRO Counting in the

Wrong Direction 31

3.4.5 X & Z-Axis Electric Handwheels

Turn in Wrong Direction 32

3.5 Problems with the Machine Tool 32

3.5.1 Spindle Stalls or Turns Off During

Machining 32

3.5.2 Spindle Motor Hums or Will Not

Run 32

3.5.3 Spindle Runs Backwards 32

3.5.4 Excess Gearbox Noise 33

3.5.5 Headstock is Leaking Oil 33

3.5.6 Tailstock Barrel is Stiff 33

4.0 Diagnostics

4.1 The Machine Tool & Set Up 35

4.1.1 Leveling 35

4.1.2 A Special Word about the X Gib 35

4.1.3 Lubrication 35

4.1.4 Machining Set-Up 35

4.2 The Mechanical Drive Train (X, Z) 37

4.3 Computer/Pendant Diagnostics 38

4.4 Motor Diagnostics 39

4.4.1 Cable Connections 39

4.4.2 To Check the Motor Encoders 40

4.4.3 Encoder Counts to Pendant 40

4.4.4 Moving Problem from One Axis

to Another 40

4.5 Servo Drivers 40

4.6 Electrical 41

4.6.1 Checking A/C Voltage 41

4.6.2 Checking Fuses 41

4.6.3 Main Electrical Box 42

4.6.4 Cable Breakout Box Connections 48

4.6.5 Cable Connections 48

4.7 Door Interlock Switch 49

4.8 Service Codes 49

4.8.1 Software Codes 49

4.8.2 Machine Set-Up Codes 50

4.8.3 Diagnostic Codes 53

4.8.4 Operator Defaults/Options Codes 54

5.0 Procedures for Replacements &

Maintenance

5.1 Replacements 57

5.1.1 Motor Replacement 57

5.1.2 Servo Driver Replacement 57

Page 4

ii

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

5.1.3 Computer Module Replacement 57

5.1.4 System Flash Disk Replacement 60

5.1.5 Cable Routing on Machine 62

5.1.6 Electronic Handwheels & Jogstick 62

5.1.7 Cable Routing in Electrics Box 62

5.1.8 Spindle Drive Belt Replacement 62

5.1.9 Spindle Motor Removal 63

5.1.10 Spindle Encoder Replacement 63

5.1.11. X-Axis Ball Screw Removal 63

5.1.12 Installing Angular Contact Bearings 67

5.1.13 Z-Axis Ball Screw Removal 68

5.1.14 Align Z-Axis Ball Screw Assembly 68

5.1.15 Headstock Taper Adjustment 72

5.1.16 Spindle Bearing Preload 72

5.1.17 Aligning Tailstock to Spindle 73

5.1.18 Spindle Motor Wiring 73

5.2 Maintenance 74

5.2.1 Gib Adjustments 74

5.2.2 Calibration & Backlash Constants 76

5.2.3 Lubrication 78

6.0 Indexer Options

6.1 Dorian Indexer Option 83

6.1.1 Field Installation Instructions 83

6.1.2 Removing the Indexer from the

Lathe 83

6.1.3 Troubleshooting the Indexer 84

6.1.4 Troubleshooting from LED’s in

Black Box 84

6.1.5 Indexer Encoder Re-Alignment 85

6.1.6 Indexer Maintenance 85

6.1.7 Warranty Issues 85

6.2 4 Tool Indexer Option 88

6.2.1 Field Installation Instructions 88

6.2.2 Removing the Indexer from the

Lathe 88

6.2.3 Troubleshooting the Indexer 89

6.2.4 Troubleshooting the Cable

Breakout Box 89

7.0 Drawings & Parts Lists

Fig. 1 SLX 1630 Floor Plan, Layout & Space

Specifications 5

Fig. 2 Anchor Bolt Specifications 6

Fig. 3 Lifting SLX 1630 & 1840SX 11

Fig. 4 Leveling 13

Fig. 5 Wiring the 1630 & 1840 14

Fig. 6 Cable Connections 16

Fig. 7 Pendant Cable Connections, Left Side 17

Fig. 8 Pendant, Right Side 18

Fig. 9 Taper Test 20

Fig. 10 Electrical Box Parts 43

Fig. 11 Spindle Control Module LED’s 47

Fig. 12 Computer Module & LCD/Enclosure

Replacement 59

Fig. 13 Flash Disk Replacement 61

Fig. 14 Spindle Drive Belt/Motor Mounting 63

Fig. 15 1630 X-Axis Drive Train 64

Fig. 16 Angular Control Bearings 67

Fig. 17 1630 Z-Axis Drive Train 69

Fig. 18 Headstock Alignment 72

Fig. 19 Tailstock Alignment 73

Fig. 20 X-Axis Gib Adjustment 75

Fig. 21 Z-Axis Gib 76

Fig. 22 Calibration Set-Up 77

Fig. 23 SLX 1630 & 1840SX Lubrication 80

Fig. 24 Tailstock Oil 80

Fig. 25 Indexer Mounting 86

Fig. 26 Indexer Cable Routing 87

Fig. 27 Motor Drive Adjustment & PLC Inputs &

Outputs 92

Fig. 28 Indexer Mounting Cable Breakout Box 93

Fig. 29 4 Tool Indexer Cable Routing 94

Fig. 30 Lathe Apron Assembly 97

Fig. 31 1630 Machine Assembly 99

Fig. 32 1630 Machine Assembly 100

Fig. 33 1630 Machine Assembly 101

Fig. 34 1630 Headstock Assembly 104

Fig. 35 1630 Headstock Assembly 105

Fig. 36 1630 Tailstock Assembly 108

Fig. 37 1630 Tailstock Assembly 109

Fig. 38 1630 Tailstock Assembly 110

Page 5

1

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

1.0 Safety Specifications

The safe operation of the PROTURN SLX 1630 depends on its proper use and the precautions

taken by each operator.

Read and study the PROTURN SLX 1630 CNC Safety, Programming, Operating, and

Care Manual. Be certain that every operator understands the operation and safety

requirements of this machine

before

its use.

Read and study this PROTURN SLX 1630 Safety, Installation, Maintenance, Service &

Parts List Manual. Be certain that every operator understands the operation and

safety requirements of this machine

before

servicing.

Always wear safety glasses and safety shoes.

Always stop the spindle and check to ensure the CNC control is in the stop mode

before changing or adjusting the tool or workpiece.

Never wear gloves, rings, watches, long sleeves, neckties, jewelry, or other loose

items when operating, or around the machine.

Use adequate point of operation safeguarding. It is the responsibility of the

employer to provide and ensure point of operation safeguarding.

STATEMENT OF INTENDED USE

To be used for the turning of cold metal within the stated capacity of the lathe, axes

movement by manual use of handwheels or CNC control.

Only to be operated by trained and experienced operators.

To be used in a standard workshop environment, not suitable for potentially

explosive atmosphere.

Any other uses should first be subjected to a risk assessment by a responsible

person.

1.1 Danger, Warning, Caution, and Note Labels and

Notices As Used In This Manual

DANGER - Immediate hazards that

will

result in severe personal injury or death.

Danger labels on the machine are red in color.

WARNING - Hazards or unsafe practices that

could

result in severe personal injury

and/or damage to the equipment. Warning labels on the machine are gold in color.

CAUTION - Hazards or unsafe practices that

could

result in minor personal injury or

equipment/product damage. Caution labels on the machine are gold in color.

NOTE - Call attention to specific issues requiring special attention or understanding.

Page 6

2

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

1.2 Safety Precautions

WARNING!

Use only chucks which are rated to the maximum RPM of the lathe.

1. Do not operate this machine before the PROTURN SLX 1630 ProtoTRAK SLX CNC

Programming, Operating and Care Manual have been studied and understood.

2. Read and study this PROTURN SLX 1630 Safety, Installation, Maintenance, Service &

Parts List Manual. Be certain that every operator understands the operation and

safety requirements of this machine

before

servicing.

3. Do not run this machine without knowing the function of every control key, button,

knob, or handle. Ask your supervisor or a qualified instructor for help when needed.

4. Protect your eyes. Wear approved safety glasses (with side shields) at all times. Do

not rely on the lexan vision panels for eye protection.

5. Don't get caught in moving parts. Before operating this machine, remove all jewelry,

including watches and rings, neckties, and any loose-fitting clothing.

6. Keep your hair away from moving parts. Wear adequate safety headgear.

7. Protect your feet. Wear safety shoes with oil-resistant, anti-skid soles, and steel

toes.

8. Take off gloves before you start the machine. Gloves are easily caught in moving

parts.

9. Remove all tools (wrenches, chuck keys, etc.) from the machine before you start.

Loose items can become dangerous flying projectiles.

10. Never operate any machine tool after consuming alcoholic beverages, or taking

strong medications, or while using non-prescription drugs.

11. Protect your hands. Stop the machine spindle and ensure that the CNC control is in

the STOP mode:

Before changing tools.

Before changing parts.

Before you clear away the chips, oil or coolant. Always use a chip scraper or

brush.

Before you make an adjustment to the part, chuck, coolant nozzle or take

measurements.

Before you open safeguards (protective shields, etc.). Never reach for the

part, tool, or fixture around a safeguard.

12. Protect your eyes and the machine as well. Don't use a compressed air hose to

remove the chips or clean the machine (oil, coolant, etc.).

13. Stop and disconnect the power to the machine before you change belts, pulley, gears, etc.

14. Keep work area well lighted. Ask for additional light if needed.

15. Do not lean on the machine while it is running.

Page 7

3

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

16. Prevent slippage. Keep the work area dry and clean. Remove the chips, oil, coolant

and obstacles of any kind around the machine.

17. Avoid getting pinched in places where the spindle, carriage, cross slide or sliding door

create "pinch points" while in motion.

18. Securely clamp and properly locate the workpiece in the chuck or in the fixture. Use

proper tool holding equipment.

19. Use correct cutting parameters (speed, feed, and depth of cut) in order to prevent tool breakage.

20. Use proper cutting tools for the job.

21. Prevent damage to the workpiece or the cutting tool. Never start the machine

(including the rotation of the spindle) if the tool is in contact with the part.

22. Don't use dull or damaged cutting tools. They break easily and may become

airborne. Inspect the sharpness of the edges, and the integrity of cutting tools and

their holders.

23. Large overhangs on cutting tools when not required result in accidents and damaged parts.

24. Prevent fires. When machining certain materials (magnesium, etc.) the chips and

dust are highly flammable. Obtain special instruction from your supervisor before

machining these materials. Do a risk assessment before machining flammable

materials.

25. Prevent fires. Keep flammable materials and fluids away from the machine and hot,

flying chips.

26. Do not rotate the spindle by hand unless the Red Emergency Stop button is pressed.

Page 8

4

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

2.0 Installation

Read and understand this entire installation section before beginning the installation

procedure.

2.1 Floor Plan, Layout & Space Requirements

Figure 1 (May not represent actual machine)

SLX 1630 Floor Plan, Layout & Space Requirements

Page 9

5

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

2.2 Uncrating

Carefully remove the protective packaging, paying attention not to scratch, damage,

or mar any parts of the machine.

Remove the cardboard boxes with the PENDANT DISPLAY (handle carefully). The

leveling pads and screws for the machine can be found in the toolbox.

Loosen and remove 4 screws and nuts holding the machine to the wood pallet.

ATTENTION!

Immediately report, in writing, any damages observed at this time that can be attributed to the

transportation or improper handling/moving of the machine.

2.3 Shortages: Inventory Checklist

______Machine (check model and serial number)

______Leveling pads and screws (4 for 1630)

______Pendant Display (24000-4)

______Pendant Cable Cover (24324)

______Toolbox with various tools

______SLX 1630 Safety, Operation & Programming Manual (P/N 24494)

______SLX 1630 ProtoTRAK SLX CNC Safety, Install, Maint, Service & Parts List Manual (P/N

25099)

In case of shortages, contact the representative from whom you purchased the machine.

Page 10

6

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

2.4 Installation Instructions & Checklist

Installer: Use this checklist to assure a complete set-up of the SLX 1630. * Items

checked before leaving the factory

1.

Shut off power to the machine.

2.

Visually inspect the 415V going into the electrical panel. Visually verify the wiring is correct per

our wiring diagram. Make sure a strain relief is being used where the wiring enters the cabinet.

Have the customer repair any wiring discrepancies. Note: Machine can only be wired for 415

VAC.

3.

Clean the machine if needed and remove any remaining grease.

4.

Mount the pendant on the bracket that is attached to the chip enclosure for the 1630.

5.

Make and check all the proper electrical connections from the pendant to the electric box. Be

sure to mount the cable cover to the left side of the pendant.

6.

Slide the doors back and forth to make sure they slide smoothly. Adjust as necessary.

7.

Remove the protective plastic covers from the headstock and the windows on the sliding doors.

8.

Turn on the power to the machine and to the pendant. Make sure that the 115-volt line is

plugged into the pendant.

9.

Check to make sure the coolant pump is rotating in the correct direction.

10.

Visually inspect the oil level through the site glass which is found under the rear spindle cover

and verify that the oil level is correct in the head stock prior to turning on the machine tool. Add

oil if necessary. Make a notation on the installation summary sheet if the oil level is incorrect.

For the 1630, oil will only be visible on the headstock site glass when the spindle is running.

11.

Manually override the automatic way oiler and pump oil to lubricate all sliding surfaces. This can

be done by running service code 300 a few times.

12.

Jog the saddle and cross slide back and forth until the way surfaces are well lubricated. Oil

should be visible on all the way surfaces.

13.

Position the saddle and tailstock to the center of the bed for leveling.

14.

Check the level of the machine. The machine should be level to within 0.02 mm longitudinally

and 0.01 mm transversely. Even though it is the responsibility of the customer, make any

adjustments if necessary (see section 2.9 Leveling).

15.

Check the tailstock and the tailstock barrel locks by locking and unlocking. Run the tailstock

barrel in and out to ensure proper function.

16.

Run the spindle at 500 rpm or so for 15 to 20 minutes in order to warm the headstock. *

17.

Run the spindle through it's various speeds.

18.

Open and close the doors and verify the door switches are functional. The control should

display a message of “DOOR OPEN” in DRO mode when the doors are open and it should

disappear when the doors are closed. Open and close the chuck guard and verify a message is

present on the screen and the spindle does not run with the chuck guard open.

19.

Make sure the X and Z electronic handwheels and jogstick are functional.

20.

Check to make sure that the E-Stop button on the pendant is functioning correctly. The 1630

only has an e-stop on the pendant. Undo the e-stop ad press the screen button on the right

side of the pendant to reset.

21.

Perform Service Code 12, Feed Forward Constant.*

22.

Perform Service Code 123 to calibrate the X and Z-axis using a 150mm standard. *

23.

Perform Service Code 127 and 128 to manually calculate the backlash for the X and Z-axis.*

24.

Check for positional accuracy and repeatability on the X and Z-axis using programs X LATHE

REPEAT.PT4 and Z LATHE REPEAT.PT4 respectively. Positioning and repeatability values should

be less than or = to 0.01 mm. Programs can be found on the parts program disk that comes

with each pendant. It may also be found in the PT4 folder followed by the SWI TEST

PROGRAMS folder if the customer ordered the Network/Memory software option. Note: the

doors must be closed to run these programs.*

25.

Perform Service Code 100 in both directions for the X and Z-axis to verify that the feed rate

shown on the display is at least 4572 mm/min (180 ipm) for Z and 3048 mm/min (120 ipm) for

X.*

Page 11

7

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

26.

Use accessory key on pendant and make sure the coolant pump turns on. The accessory key

should be in the ON position in DRO to test.

27.

Wipe down the machine prior to leaving.

CAUTION!

If the PRO TURN 1630 has a chuck mounted to the spindle, make sure the cam locks are tight, and

the chuck jaws are engaged onto themselves or a piece of material before running the machine.

Check to make sure the chuck is rated for the maximum rpm’s of the machine. If it is not, do not run

the machine above the chuck’s maximum rated rpm.

Page 12

8

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

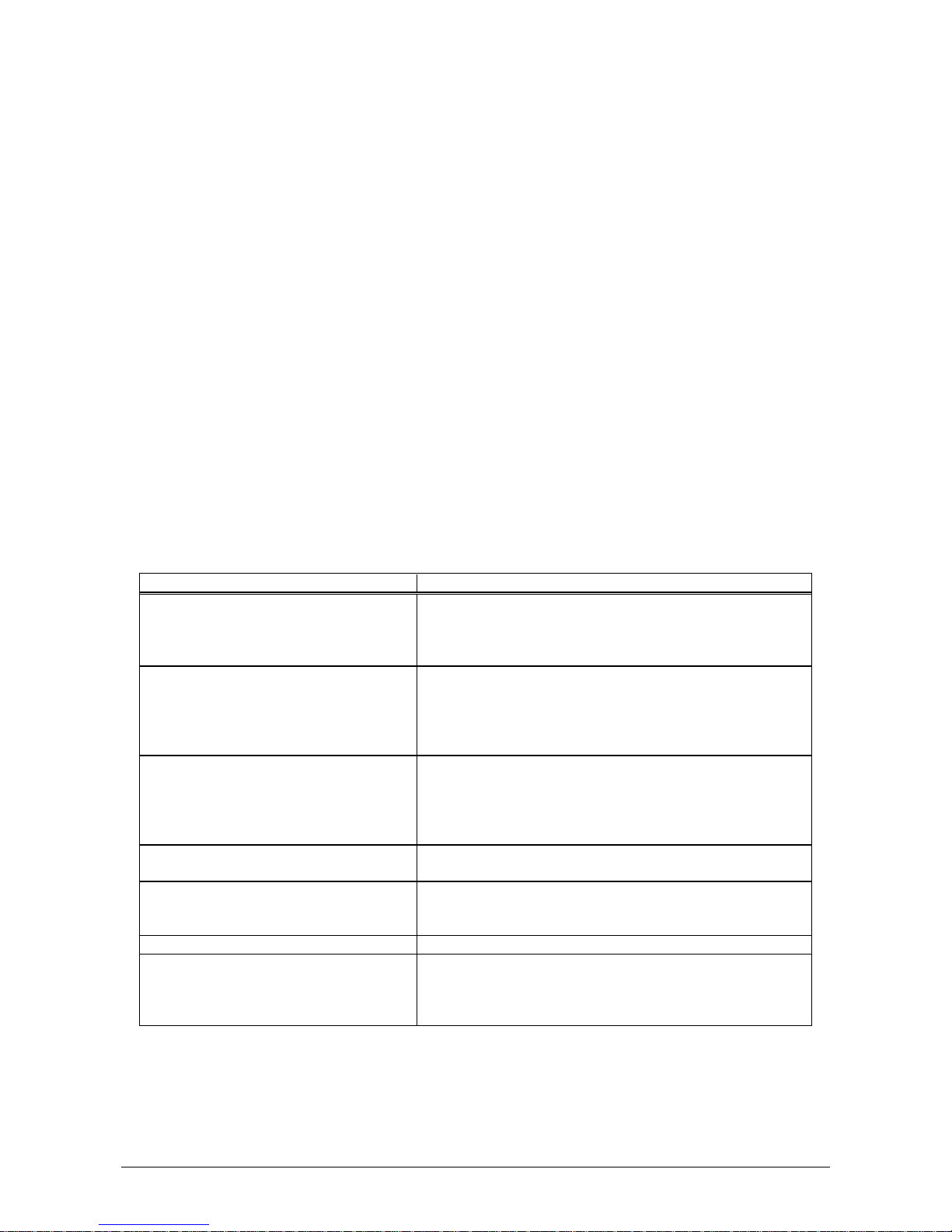

2.5 Machine Specifications

Capacity

SLX 1630

Height of Centers

203.2 mm

Distance Between Centers

762 mm

Swing Over Bed

406.4 mm

Swing Over Saddle Wings

406.4 mm

Swing Over Cross Slide

218.4 mm

Cross Slide Travel

215.9 mm

Tool Section Max.

19 mm

Coolant

41.6 liter

Oil Pump – Way Lubrication

2 liter

Oil Reservoir – Headstock

13.3 liter

Bed

Width

320 mm

Height

320 mm

Headstock

Spindle Nose

D1-6

Spindle Through Hole

53.9 mm

Spindle Taper

MT#6

Taper in Reduction Sleeve

n/a

Spindle Diameter Front Bearing

80 mm

Number of Bearings

2

Bearing Class (Radial Runout)

P5

Number of Spindle Speed Ranges

1

Spindle Speed Range (RPM)

150-2500

Tailstock

Quill Travel

127 mm

Quill Diameter

59.9 mm

Quill Taper Hole

MT#4

Spindle Motor

H.P.

7.5

Voltage

415

Amps, Full Load

13

Phase, Hz

3/50

Dimensions

Net meters L x W x H kg.

2.08 x 1.02 x 1.80m, 998

Ship meters L x W x H kg.

2.21 x 1.14 x 1.70m, 1247

Other

Coolant Pump Motor, H.P.

1/8

Spindle Motor Brake

Dynamic Braking

Way Surface Hardness

400-450 HB

Headstock Lubrication

Oil Bath

Options

Steady Rest (Type, Diameter)

Roller 12.7 – 139.7 mm

Tooling Kit

20 mm

Chuck

203 mm, D1-6

Indexer Option – 8 tool

20 mm

Indexer Option – 4 tool

20 mm

Gang Tooling

n/a

Noise Emissions (workstation) max RPM running

with no material

69dB (A)

Page 13

9

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

2.6 ProtoTRAK SLX Control Hardware

2 -axis CNC, 2-axis DRO

400 MHz PC-based processor

256 MB of RAM

D.C. Servo Motors rated at 280 in-oz continuous torque for X, and 560 in-oz for

the Z-axis.

Precision ground ballscrews in the carriage and cross-slide to ensure smooth

accurate contours without backlash

Feedrate override of programmed feedrate and rapid

Speed override of programmed RPM

Polycarbonate sealed membrane and gasket sealed control enclosure to lock out

contamination

266.7 mm color LCD for clear presentation of prompts, status information and

part graphics

Modular design simplifies service and maximizes uptime

256 MB flash drive

(2) USB Ports

Single floppy disk drive for additional part program storage

2.7 Lifting and/or Moving the Machine

CAUTION!

The 1630 machine weighs approximately 1247 kg when shipped. Proper equipment of sufficient capacity

must be used when lifting and/or moving the machine.

To lift the machine, remove the chip pan. Place the forks of the forklift at least 813

mm apart as shown in the figure 3. Be certain to lift the lathe toward the headstock.

Page 14

10

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Figure 3

Lifting SLX 1630

(May not represent

actual machine)

Do not attempt to lift this

machine with a forklift

having less than 2722 kg

capacity for the 1630. The

shipping weight of the

machines including

electronics is 1247 kg.

Place the machine in position

on top of the (4) rest pads

for the SLX 1630.

For proper operation, the

machine should be set on a

substantial floor capable of

supporting the weight safely.

For the location of the bolt

holes, size and

recommended mounting (see

Figures 1 & 2).

Page 15

11

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

2.8 Cleaning

1. Remove rust protective coating from the machine before moving any slideways

2. The coating is best removed with clean, dry rags. Do not use a cleaning solution

that may damage the rubber way scrapers, plastic parts, or paint.

WARNING!

Do not use gasoline or other flammable cleaning agents for cleaning the machine.

3. It may be necessary to move the carriage back and forward and the cross-slide left

and right.

CAUTION!

Never move any of the above parts over ways that were not previously cleaned. Serious

damage to the TURCITE surface of slideways can occur.

4. Be certain the carriage, cross slide and spindle move freely and smoothly over their

entire length.

2.9 Leveling

The precision and durability of the lathe depends on it being leveled properly. Final

inspection can be done only when the machine has been correctly leveled.

After the machine is in position on top of the 4 rest pads, it must be leveled by the

use of the leveling bolts. It is important that the lathe be level in order to produce

accurate work. It may be necessary to lag bolt the machine in order to eliminate a

small amount of twist.

NOTE: The use of a precision level having a minimum accuracy of 0.01 mm over 254 mm

will be required.

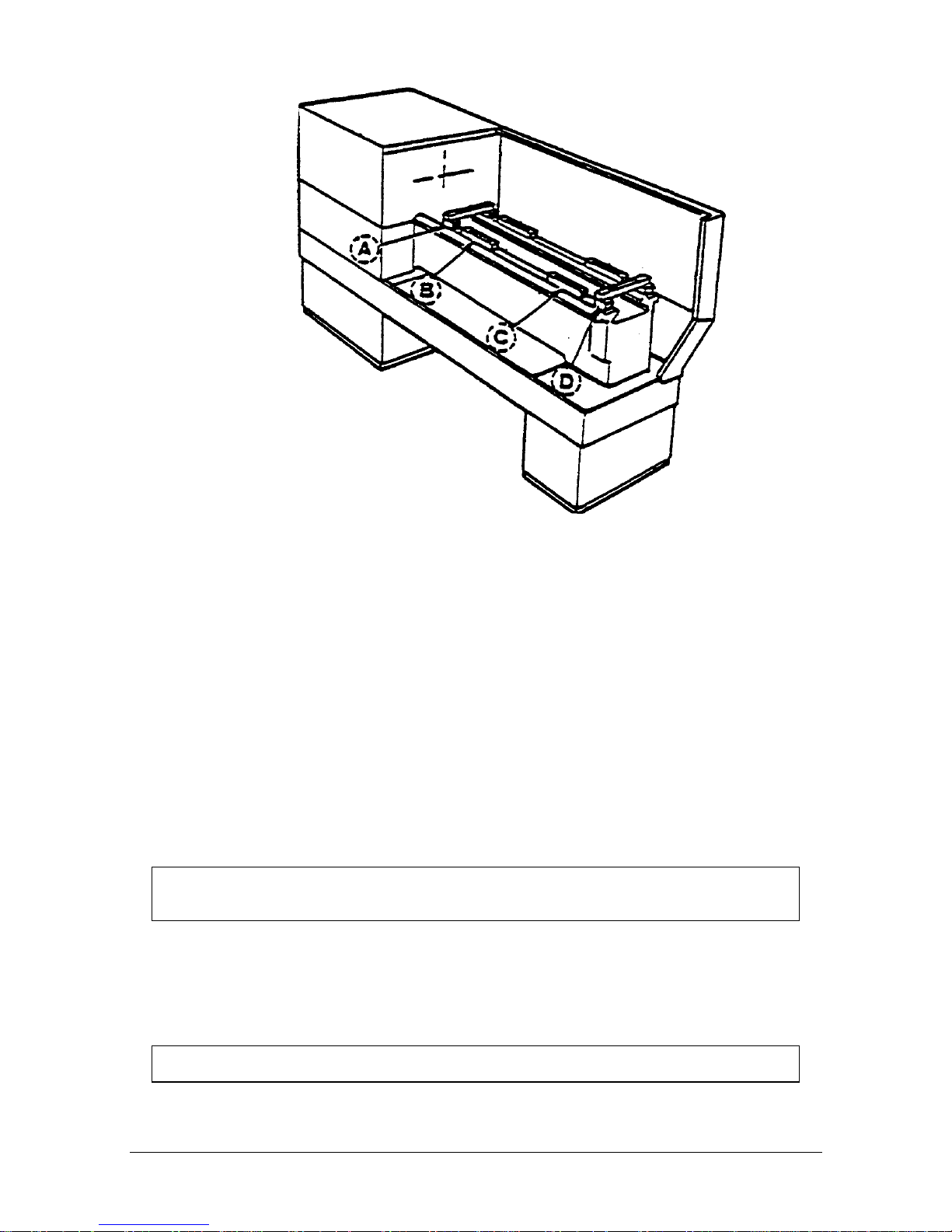

Move the saddle and tailstock to the center of the bed. To take a reading off the level

longitudinally, place the level at each of the four (4) corners of the bedways (Figure 4,

Positions B & C). To take a reading off the level transversely, place it on top of 19 mm

parallels at each end of the bedways (Figure 4, Positions A & D).

Page 16

12

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

i00193

Figure 4

Leveling

2.9.1 SLX 1630

Use the four (4) leveling screws, located at both ends of the base, to adjust the level

of the machine.

For a newly installed machine, check the level once every week. Once the

foundation is rigid enough, then check it once per month.

2.10 Electrical Connection

The SLX 1630 can only be wired for 415 volts, 3-phase electricity.

A 110-volt power source is needed for the pendant and is provided by the

transformer.

DANGER!

Be certain that 415-volt electricity is used only with a machine labeled 415 volts and at the

electric cabinet, in the back of the machine.

The incoming 415-volt power is wired to the machine through the electric cabinet

located on the back of the machine. The wire enters the cabinet through a hole,

from the top of the cabinet. The wires are to be wired into the door breaker. The

main ground wire should be fastened to the breaker mounting bracket with the screw

provided.

DANGER!

The 415 VAC, 3-phase electricity should be wired only by a qualified electrician.

Page 17

13

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Figure 5

Wiring the 1630

2.10.1 Phase Converters

For those machines that will be run with a phase converter it must be a rotary type

rather than a static phase converter. Rotary phase converters allow for varying loads

in the system. The electrical load on the machine will vary based on the type of cut

taken and the speed of the motor. Static phase converters can only be used on

machines with a non-varying load.

2.11 Mounting the Display Pendant

The 1630 pendant is fixed to a L bracket. The L bracket is attached to a 2nd bracket

that comes mounted to the top of the chip enclosure.

Make the 6 cable connections to the left side of the pendant and cover these cables

with the cable cover provided with the machine.

Page 18

14

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

2.12 Cable Interconnections

All cable interconnections are made at the factory except for those connecting to the

pendant display. There are a total of 6 cables that need to be connected to the

pendant. See Figure 6 for pendant cable connections.

With the main 415 volt power to the machine turned off plug in the connectors that

are bundled on the side of the machine. Each cable fits to only one connector on the

pendant display, on the left side of the pendant. Use the key on the pendant to

match up the connectors with the correct port. The machine ID key and option keys

should be plugged into the port labeled as such. The test port and X and Y

handwheel ports will be left empty during installation. If the customers sets this

machine up on a network, this cable will also need to be plugged in.

Make sure the machine ID key is plugged in, otherwise the machine will not run.

Also make sure there is a hardware (option) key plugged into the parallel port of the

pendant. This key activates any converters or options ordered. The key must be

programmed according to the type of machine it is on and the options ordered.

CAUTION!

Make sure the main 415-volt power switch is disconnected on the back of the electrical cabinet

before plugging in the cables.

Page 19

15

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Figure 6

Cable Connections

Page 20

16

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Figure 7

Pendant Cable Connections

Left Side

Page 21

17

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Figure 8

Pendant, Right Side

2.13 Lubrication System

2.13.1 Headstock

Before turning ON the spindle, check to make sure the headstock oil reservoir is full.

A site glass is located under the spindle cover. If low, fill the site level with Mobil

DTE 24 or equivalent oil through the plug located on the headstock cover.

For the 1630, oil will only be visible on the headstock site glass when the spindle is

running. If oil is not flowing to the site glass when the spindle is on, stop running

Page 22

18

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

the spindle immediately and call for service. Failure to do so may ruin the spindle

bearings.

2.13.2 Automatic Way Lubrication Pump

The 1630 auto lube system provides centralized automatic lubrication for the

carriage, cross slide and ballscrews. The lube pump has a 2-liter reservoir filled with

S.A.E. 30-weight oil.

CAUTION!

Oil that is too heavy and viscous such as 50W or 90W oil can clog oil line tubing. Do not mix detergent

type automotive or multi-purpose oils with the S.A.E. No. 30 lubricating oil used in this application.

The lube pump has electronic memory, which acts as an internal clock to keep track

of the running time of the axis motor. Even when the axis motors are turned off, the

lube pumps internal clock will not reset. The interval between pump cycles is based

on axis motor movement time. Also, every time the control is first turned on, the

lube pump will run for 1 lube cycle as soon as the axis motors are commanded to

run.

2.13.3 Lube Pump Operation

The pumping output can be regulated electronically to control the Interval Time

between pumping cycles, and the Discharge Time of each pumping cycle. The pump

can also be run manually through a key found under service codes. The following

describes the steps used to program the lube pumps Interval and Discharge times.

Setting Interval Time: Service Code 301

Press "Mode", "Set up", "Service Codes", "E" (Lube Pump Setup), Code 301, and

then enter the desired Interval time in minutes.

Setting Discharge Time: Service Code 302

Press "Mode", "Set up", "Service Codes", "E" (Lube Pump Setup), Code 302, and

then enter the desired Discharge time in seconds.

To Manually Pump Oil: Service Code 300

Press "Mode", "Set up", "Service Codes", press "E", and then press Code 300

(Lubrication Pump Switch). The pump will pump oil for the amount of time

programmed in Code 302. The spindle does not need to be turned on.

2.13.4 Factory Default Values

Interval Time - 20 min

Discharge Time - 15 sec

Discharge Pressure - Approximately 690 – 1034 kPa (100-150 PSI)

To adjust the amount of Discharge Pressure displayed on the lube pump gauge,

loosen the jam nut and turn the adjustment screw located on the top right side of

the lube pump while the lube pump is activated. To activate the lube pump use

Service Code 300.

CAUTION!

Failure to properly lubricate the lathe will result in the premature failure of ball screws

and sliding surfaces.

Page 23

19

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

CAUTION!

Failure to manually activate the pump at the beginning of each day, or allowing the Auto

Lube to run dry may cause severe damage to the 1630 lathe way surfaces and ballscrews.

The settings for the lube pump can be viewed by doing the following: press Service

Codes, press “A” (software), press Code 313. This screen lists the values

programmed for the cycle time and discharge time.

Page 24

20

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

3.0 Troubleshooting by Symptom

Electrical and Mechanical maintenance should only be carried out by

trained and experienced machine tool engineers who fully understand the

hazards of working with machine tools.

Use this section to begin the process of resolving a service problem. Each problem type is

described in a few words and then more fully described in an explanatory paragraph.

Following this is a chart that directs in the most logical steps.

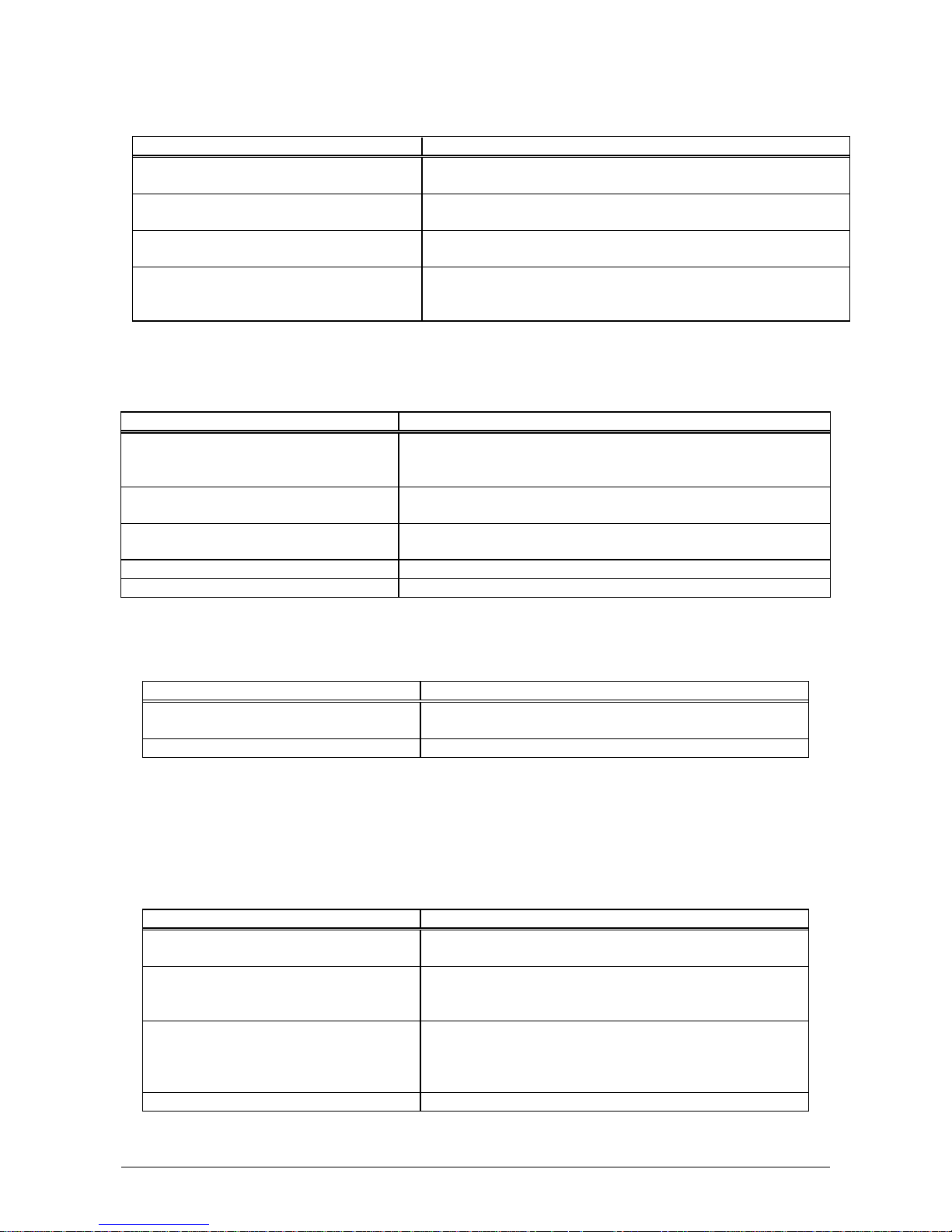

3.1 Problems Relating to Machining Results

3.1.1 Poor Finish

Poor finish can be caused by a number of variables including: speeds, feeds,

tooling, machine setup and chatter.

Do the following Service Codes:

Code 33 Software Identification. This is needed if you call Customer Service

Code 12 Feed Forward Constant

Code 127 Measures backlash in the system (not used on Dual Feedback

systems)

Code 128 Enter backlash compensation

Possible Cause

Check This

Inadequate or no Lubrication to

Ballscrews and Way surfaces

Make sure all the Way surfaces are getting proper

lubrication. If not, check to make sure that the lube pump

is functioning properly. Also check for any pinched or

blocked oil lines.

X & Z-axis Drive Trains are loose

Check Repeatability using the Repeatability and Positional

Accuracy procedure. Step by step, carefully inspect the

Drive Train for any looseness. It may be necessary to

disassemble and then reassemble the Drive Train. See

Mechanical Drive Train (X, Z) Section 4.2.

Way surfaces are pocked, scarred, or

excessively worn

Visually check the condition of all the Way surfaces. For

machines that may have excessively worn Way surfaces

you may need to adjust the Gibs in this area. This will

affect performance when using the machine outside of

this area. Check lubrication to affected areas.

Machine set-up problem

Machine’s feet are not equally supporting weight. See

Leveling, Section 2.9.

Tooling problem

Improper tooling, Work piece not properly supported

speeds too fast, Feeds too slow.

See Machine Tool & Setup, Section 4.1.

X gib too tight or loose

See Gib Adjustment, Section 5.2.1.

Loose bearing problem

Looseness in the spindle bearings. Adjust spindle preload.

Ball screw misalignment,

See Mechanical Drive Train (X,Z), Section 4.2. See Spindle

Bearing Preload, Section 5.1.16.

Page 25

21

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

3.1.2 Turning Diameters Out of Round

Parts are not round within .015 mm TIR for SLX 1630. This is best measured by

using a .002 mm dial indicator and mounting to the inside taper of the spindle.

Rotate the spindle and measure the indicator movement.

Do the following service code and procedures:

Possible Cause

Check This

Tooling problem

Improper tooling, workpiece not properly supported.

See Machine Tool & Setup, Section 4.1.

Loose bearing problem

Looseness in the spindle bearings. See Mechanical Drive Train (X, Z),

Section 4.2. Spindle bearing not preloaded correctly. Reseat bearing and

preload. See Spindle Bearing Preload, Section 5.1.16.

3.1.3 Cutting Taper

Parts are considered to be cutting on a taper if there is a difference in diameter of more than

.02 mm over 152.4 mm. This is best measured by using a .002 mm micrometer.

Do the following service code and procedures:

Code 12 Determines the feed forward constant for the axis motors.

Possible Cause

Check This

Machine set-up problem

Machine not leveled properly

See Leveling - Section 2.9.

Tooling problem

Improper tooling; Work piece not properly supported. Use steady rest or

follow rest, reduce overhang from chuck headstock or tailstock.

Looseness in the gib or

misalignment of ball screw

Gib adjustment.

See Gib Adjustment - Section 5.2.1.

See Z Ball screw Alignment - Section 5.1.14.

Loose bearing problem

Looseness in the spindle bearings.

See Mechanical Drive Train (X,Z) - 4.2.

See Spindle Bearing Preload - Section 5.1.16.

Headstock and/or tailstock

not aligned

See Adjust Headstock for Taper - Section 5.1.15.

To adjust tailstock from side to side, adjust gib screw. See Aligning

Tailstock to Spindle Section 5.1.17.

3.1.4 Parts Have Incorrect Dimensions

Parts are being machined with dimensions that are different than those programmed.

Typical accuracy expectations should be:

Parts should be round within .015 mm TIR on both the SLX 1630.

The acceptable measurement of parallelism of spindle axis to carriage movement

is .02 mm over 152.4 mm.

3.1.4.1 Every Part Has the Same Error

Possible Cause

Check This

Programming Error

Programmed dimensions not correct. Check

absolute and incremental values.

Machine & Setup Related

See Machine Tool & Setup - 4.1.

3.1.4.2 Errors are Random or Accumulate in Size over the Part Run

Possible Cause

Check This

Machining Setup

See Machine Tool & Setup - 4.1.

Looseness in the Drive Train, ball nut loose in

yoke, split nut loose, yoke loose

See Mechanical Drive Train (X,Z) - 4.2.

Page 26

22

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

3.1.5 Threading Problems

Threads can be cut with an unlimited number of pitches and up to 10 leads.

To reduce the relief area when threading up to a shoulder the spindle speed should be

reduced as much as possible. The slower the speed of the spindle, the closer the cutting

tool can come to the end of the programmed thread before it pulls out and retracts. If a

nut must be turned all the way up to a shoulder, machine a relief area behind the last

thread.

NOTE: No machine can thread up to a shoulder and instantaneously pull out.

Do the following service codes and procedures:

Code 12 Determines the feed forward constant for the axis motors

Code 133 Spindle encoder test

3.1.5.1 Cross Threading

Threaded parts are cross-threaded after completion of the threading event.

Possible Cause

Check This

Looseness in the Gib

Gib adjustment

See Gib Adjustment - Section 5.2.1.

Looseness in the drive train

The drive train Diagnostics

See Mechanical Drive Train (X,Z) - Section 4.2.

Calibration

See Section 5.2.2 Calibration.

Failure of the spindle encoder

Run service code 133 to check if the encoder

counts.

Replace spindle encoder

See Spindle Encoder replacement - Section

5.1.10.

3.1.5.2 Not Threading

The machine will not cut a thread at all.

Possible Cause

Check This

Spindle speed too fast

Slow down spindle speed.

Failure of the spindle encoder

Run service code 133 to check if the encoder

counts.

Replace spindle encoder

See Spindle Encoder replacement - Section

5.1.10.

Broken or slipping encoder coupling

Check and replace as necessary

3.2 Problems Regarding the Motion of the Machine

3.2.1 Run Away Axis

The axis makes an unwanted move at rapid speed in one direction and faults out.

This is usually caused by an encoder signal being interrupted.

Do the following Service Codes:

Code 33 Software Identification. This is needed if you call Customer Service.

Code 100 Axis open loop test. Used to check the maximum feedrate of an axis

and if the encoders are counting.

Possible Cause

Check This

The home positions or tools are not set

correctly

See the Controls Programming, Operations and Care

manual.

Bad Motor Encoder

See Motor Diagnostics Section 4.4.

Page 27

23

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

3.2.2 Slow Down Axis

The axis slows down and moves at a feedrate that is lower than rapid or than the

programmed feedrate.

Do the following Service Codes:

Code 33 Software Identification. This is needed if you call Customer Service.

Code 100 Axis open loop test. Used to check the maximum feedrate of an axis

and if the encoders are counting.

Code 129 Set's the maximum allowable arc accuracy error. This applies to arcs only.

Possible Cause

Check This

The maximum allowable Arc Accuracy is

set too low.

This value will only slow down the machine during arc moves.

The factory default is set at 0.13 mm. Perform Code 129 to

check or change this value. See Service Codes Section 4.8.

Values lower than 0.13 mm may reduce the feedrate even

more.

Incoming AC voltage is inadequate

Perform Code 100. See Service Codes Section 4.8. and

Electrical Section 4.6.

Inadequate or no Lubrication to

Ballscrews and Way surfaces

Make sure all the Way surfaces are getting proper lubrication.

If not, check to make sure that the lube pump is functioning

properly. Also check for any pinched or blocked oil lines. See

Lubrication Section 2.13.

X-axis Gib is not adjusted properly

Check the adjustment of the X-axis Gibs using the X-axis Gib

adjustment procedures. See section 5.2.1.

Binding in the Drive Train

Check Repeatability using the Repeatability and Positional

Accuracy procedure. Check the torque reading of the Drive

Train. Step by step, carefully inspect the Drive Train for any

binding. It may be necessary to disassemble and then

reassemble the Drive Train. See Mechanical Drive Train (X, Z)

Section 4.2.

Servo Drive failure

See Servo Drive Section 4.5.

Motor failure

See Motor Section 4.4.

3.2.3 Axis Will Not Jog

The system powers up but will not respond to the jog command.

Do the following Service Codes and procedures:

Code 33 Software Identification. This is needed if you call Customer Service.

Code 100 Axis open loop test. Used to check the maximum feedrate of an axis

and if the encoders are counting.

Possible Cause

Check This

Improper Boot-up

Shut down the system and wait 10 seconds before rebooting

E-Stop is pressed in

Check E-Stop. Especially if both axes will not jog

E-Stop reset button

Press the E-Stop reset button on the side of the pendant.

Servo Drive failure

Especially, if only one axis will not jog;

See Servo Driver Section 4.5.

Shorted motor

See Motor Section 4.4.

Poor cable or wiring connections

See Cable Interconnection Section 2.12.

Computer/Pendant failed

See Computer/Pendant diagnostics Section 4.3.

3.2.4 Axis Motor Motion Is Not Smooth

While under motor power, the motion is not smooth. The motion appears to be "rough" or jerky”.

Do the following Service Codes and procedures:

Page 28

24

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Code 33 Software Identification. This is needed if you call Customer Service.

Code 12 Feed Forward Constant

Code 127 Measure's the backlash in the system

Code 128 Enter backlash compensation

Code 100 Axis open loop test. Used to check the maximum feedrate of an axis

and if the encoders are counting

Possible Cause

Check This

X-axis Gib are not adjusted

properly

Check the adjustment of the X-axis Gib using the X-axis Gib

adjustment procedures, See Section 5.2.1..

Calibration or Backlash problem

Recalibrate the machine. Reset the Backlash. Check

Repeatability and Positional Accuracy. See Calibration &

Backlash Constants section 5.2.2.

Binding in the Drive Train

Check Repeatability using the Repeatability and Positional

Accuracy procedure. Check the torque reading of the Drive

Train. Step by step, carefully inspect the Drive Train for any

binding. It may be necessary to disassemble and then

reassemble the Drive Train. See Mechanical Drive Train (X, Z)

Section 4.2.

3.2.5 Vibration in Motion

While axis is moving there is vibration or noise coming from the X or Z-axis.

Do the following Service Codes and procedures:

Code 12 Feed Forward Constant

Code 127 Measure's the backlash in the system.

Code 128 Enter backlash compensation

Possible Cause

Check This

Too much backlash entered in Code 128.

Recheck the machines backlash. See Section 5.2.2.

Inadequate or no Lubrication to

Ballscrews and Way surfaces

Make sure all the Way surfaces are getting proper lubrication.

If not, check to make sure that the lube pump is functioning

properly. Also check for any pinched or blocked oil lines. See

Lubrication Section 2.13.

X Gib not making good contact.

Pull gibs out and mark with a blue die to check where the gibs

are making contact. It is recommended that the gibs

uniformly contact at least 80% of the surface. See Section

5.2.1 Crosslide gib adjustment.

Binding or looseness in the Drive Train

Check Repeatability using the Repeatability and Positional

Accuracy procedure. Check the torque reading of the Drive

Train. Step by step, carefully inspect the Drive Train for any

binding or looseness. It may be necessary to disassemble and

then reassemble the Drive Train. See Mechanical Drive Train

(X, Z) Section 4.2.

Axis Motor belt too tight.

Loosen belt.

Misalignment of ball screw

See Mechanical Drive Train (X, Z) Section 4.2.

3.2.6 Searching Axis

The ballscrews are slowly turning back and forth when the servos are engaged.

Do the following Service Code and procedures:

Code 12 Sets a feed forward power constant to drive axis motors.

Code 128 Backlash compensation on single feedback machines.

Page 29

25

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Possible Cause

Check This

Most often causes by excess backlash

compensation

Check physical backlash in system and re-enter in code 128.

Run code 11 on single feedback machines

High feed forward values

Check ball screw torque. Typical values should be between 1.1

– 1.7 N-m.

Excessive friction in the sliding ways

Lubrication, gib adjustments, gib locks.

See Machine Tool & Setup - Section 4.1.

Looseness in the drive train

The drive train of the axis that is searching, especially the

tightness of the drive assembly.

See Mechanical Drive Train (X, Y) - Section 4.2.

3.3 Problems Relating to the Operation of the Control

3.3.1 Display Blanks

The display is completely blank.

Possible Cause

Check This

Screen saver has been activated

Press any key to turn back on. All LED keys on pendant will

blink when the screen saver is on. Press any key to deactivate.

Hitting this key will not activate any feature on the control.

The system has shut down

Turn the power switch off, check the computer/

pendant fuses and cable connections. See Electrical Section 4.6.

Poor cable connection from Computer

Module to LCD (Liquid Crystal Display)

Double-check the connection from the computer module to the

LCD, see Section 5.1.3.

Fuse blown in pendant

Remove fuse and check continuity

Computer/Pendant failed

See Computer/Pendant Section 4.3.

3.3.2 Bad Picture on the Display

The display has strange characters, horizontal bars or other unfamiliar images, or the

display continually rolls.

Possible Cause

Check This

Poor cable connection from Computer

Module to LCD (Liquid Crystal Display)

Check the ribbon cable connection from the LCD screen

to the computer module . See Section 5.1.3.

Computer/Pendant failed

See Computer/Pendant Section 4.3.

3.3.3 Keyboard Lockup

The screen display is normal, but the system will not respond to key presses.

Do the following Service Codes and procedures:

Code 81 press each key on the pendant. The screen will display a keypad

that signifies if a key is working. The pendant will also beep.

Possible Cause

Check This

Voltage drop/spike has occurred

Shut down the system and wait 10 seconds to reboot the

system.

Remote Stop-Go (RSG) switch has a

short (if connected)

Remove the RSG. Turn the system off and then on again.

If the problem goes away and then re-appears when the

RSG is plugged-in, replace the RSG.

Poor cable connections from the

Computer Module to the Distribution

Board and from the Distribution Board

to the Keyboard

Re-seat cable connectors by pulling out and pushing back

in.

Computer/Pendant failed

See Computer/Pendant Section 4.3.

Page 30

26

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

3.3.4 Fault X or Z

The program run or jogging operation is interrupted with a Fault Message on the

display.

Do the following Service Codes and procedures:

Code 33 Software Identification. This is needed if you call Customer Service.

Code 12 Feed Forward Constant.

Code 100 Axis open loop test. Used to check the maximum feedrate of an axis

and if the encoders are counting.

Possible Cause

Check This

Servo cables at pendant switched around.

Make sure during an installation the X and Z servo

cables at the pendant are in the correct ports.

X-axis Gibs are adjusted extremely tight

Check the adjustment of the X-axis Gibs using the X

Gib adjustment procedures. See X-axis Gib

Adjustments Section 5.2.1.

Excessive friction in the slideways

See Machine Tool & Setup Section 4.1.

Binding or looseness in the Drive Train

See Mechanical Drive Train (X, Z) Section 4.2.

Incoming electrical power

Incoming voltage. See Electrical Section 2.10.

Servo Drive failure

See Servo Driver - Section 4.5.

Motor failure

See Motor diagnostics, Section 4.4.

Computer/Pendant failure

See Computer/Pendant diagnostics, Section 4.3.

3.3.5 Problems Reading the Floppy Disk; Programs Not Saved

Properly

The floppy drive will not read or write programs from a disk.

Possible Cause

Check This

Improper Boot-up

Shut down the system and wait 10 seconds before

rebooting.

Floppy Disk failure

The Floppy Disk may be bad. See if the Floppy Disk

can be read by a Personal Computer. Does the green

light on the floppy drive come on when you access the

disk? If so, power is getting to the floppy drive. If

not check connections of floppy drive inside the

computer module. See Computer/Pendant Section 4.3

for more information.

Floppy Disk full

Put the Floppy Disk into a Personal Computer to see

how many bytes remain.

3.3.6 System Will Not Turn On

Nothing happens when the switch is turned on.

Possible Cause

Check This

110 V line is not plugged in

Check incoming 110 V power source to electrical cabinet

Pendant On/Off switch is Off.

Check the Pendant On/Off switch

Fuse blown in pendant or electrical

cabinet

Remove fuses and check continuity.

Transformer output

Check 110 V Transformer output

Computer/Pendant has failed

See Computer/Pendant diagnostics Section 4.3.

3.3.7 System Will Not Boot-Up

The system does not boot-up when the switch is turned on.

Page 31

27

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Flash Drive failure

When the Computer Module starts the boot-up process,

look at the 8th line on the Display Screen. If the Mother

Board of the Computer Module is communicating with

the Flash Drive you will see "Detecting IDE Primary

Master…Scan Disk SDCFB-256". If the Mother Board of

the Computer Module is not communicating with the

Flash Drive you will see "Detecting IDE Primary Master …

None".

Also, check the wiring connection between the Flash

Drive and the Mother Board. See Computer/Pendant

diagnostics Section 4.3.

Computer/Pendant has failed

See Computer/Pendant diagnostics Section 4.3.

Disk in drive A

Verify that there is no disk inserted in drive A.

System Bios

Verify the system bios is set correctly.

3.3.8 System Reboots by Itself

During operation, the screen suddenly blanks and then shows that the system has

begun the boot-up sequence.

Possible Cause

Check This

Incoming 415 VAC is too high, too low

or not present

Using a Voltmeter, check the incoming 415 VAC to the machine.

See Electrical Section 4.6.

Poor wiring and cable connections

Check for any loose wiring.

Computer/Pendant failed

See Computer/Pendant diagnostics Section 4.3.

Transformer output

Check 110 V Transformer output

3.3.9 System Shuts Off

During operation, the system shuts off and will not turn back on.

Possible Cause

Check This

Fuse blown in pendant

Remove fuse and check continuity

Incoming 415 VAC is too high, too low or not

present

Using a Voltmeter, check the incoming 415 VAC to the

machine. See Electrical Section 4.6.

Poor wiring and cable connections

Check for any loose wiring.

Flash disk failure

Remove and reseat the flash disk. The flash disk is inside of

the computer module. Please see section 5.1.4.

Transformer output

Check 110 V Transformer output

Computer/Pendant has failed

See Computer/Pendant diagnostics Section 4.3.

3.3.10 Will Not Hold Calibration

The control will not hold calibration. Go to the "Configuration Values" screen and

write down the calibration values for the motor encoders (Encoder) and the position

feedback encoders (Scales). Recalibrate the system and see if the values change.

Turn the system off and on and see if the values are held.

Do the following service codes and procedures:

Code 33 Software Identification. This is needed if you call Customer Service.

Code 313 Configuration Values

Code 123 Calibration Mode

Possible Cause

Check This

Not saving Calibration values

Replace Computer/Pendant module.

See Computer/Pendant Diagnostics Section 4.3.

Page 32

28

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

If calibration factors are being saved, but the measurements are not repeating or are not

accurate:

See Measurements Are Not Repeating

See Measurements Are Not Accurate

3.3.11 E-Stop Error

The E-Stop turns the power off to the axis and spindle motors. The 1630 has an estop on the front of the pendant and a green E-stop reset button on the side of the

pendant. (See figures 6 & 8)

For the axis motors this is done by stopping 110V power from reaching

the cable breakout box through the use of a relay in the pendant. The

AC E-stop out connector on the pendant should not have 110 volts

coming out of it when the E-stop is pressed.

The AC drive power is turned off by a contact relay (K1), located on the

power module. The contact relay (K1) is turned off by the dual channel

relay (safety relay), which is controlled by the E-stop on the pendant.

The E-stop LED on the spindle control module will be on when the e-stop

is in the out position. The LED will turn off when the E-stop is depressed.

(See figure 11)

Once power reaches the cable breakout box it distributes power to the

axis motors, auxiliary functions. If power does not reach the cable

breakout box then none of these functions will work.

If the E-Stop button is depressed, and no message is displayed on the screen, then

either the E-Stop button, pendant, spindle control module, cables from pendant to

spindle control module, or cables from spindle control module to dual channel relay

(safety relay) is at fault.

Possible Cause

Check This

E-Stop reset button

Press the E-Stop reset button on the side of the

pendant.

Faulty E-Stop switch

Check the cable connections from the computer

module to the E-Stop switch. Check the E-Stop switch

for functionality.

Bad pendant

Does 110 V power come out of the cable breakout box

power cord on the pendant? If yes and the screen

has an E-stop message then replace the pendant.

Poor cable connection

Check spindle control cable connection at the pendant

and spindle control box.

E-Stop jumper

Verify the E-Stop jumper in the electrical box on the

spindle control module is correct.

3.4 Problem with the Measurements

3.4.1 X and Z-Axis Measurements Do Not Repeat

With a dial indicator mounted to the bottom of the spindle, touch off a fixed surface

either in the X or Z-axis direction and then set the DRO equal to 0. Crank away

several inches and then touch off again at the same place. If the reading has not

returned to 0 on the DRO, zero the display and repeat the procedure. If the

measurement does not repeat, you have a repeatability problem that must be

resolved.

Page 33

29

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Test for accumulative error by moving the axis a number of times to see if the error

gradually grows by a small amount. If the error abruptly changes by a large amount it may

be caused by a bad encoder.

Expected repeatability numbers should be 0.01 mm or less.

Possible Cause

Check This

Machine Tool & Setup problem

Check for any looseness in the setup. See Machine Tool

& Setup Section 4.1.

X and Z-axis Gibs are loose

Check the adjustment of the X-axis Gib using the X-axis

Gib adjustment procedures. See section 5.2.1.

X and Z-axis Drive Trains are loose

Check Repeatability using the Repeatability and Positional

Accuracy procedure. Step by step, carefully inspect the

Drive Train for any looseness. It may be necessary to

disassemble and then reassemble the Drive Train. See

Mechanical Drive Train (X, Z) Section 4.2.

Encoder Disk or Reader Head on

motor are loose

Swap the motor in question with a known good motor.

For example, swap the X-axis motor with the Z-axis

motor. If the symptom stays with the motor in question,

then replace the motor. If not, then the motor is not at

fault and something else is causing the problem.

3.4.2 X and Z-Axis Measurements Are Not Accurate

Measurements repeat, but with a dial indicator mounted to the spindle, traversing the

length of a gage block or some other measurement standard, the measurement is

not accurate.

Note: If your part has incorrect dimensions, see Parts Have Incorrect Dimensions, Section

3.1.4.

Note: First check for repeatability of the DRO: With a dial indicator touch off a fixed surface

either in the X or Z-axis direction and set the DRO equal to 0. Crank away several inches and

touch off again at the same place. If the reading has not returned to 0 on the DRO, zero the

display and repeat the procedure. If the measurement does not repeat, you have a

repeatability problem that must be resolved before the accuracy problem can be resolved. See

Measurements That Do Not Repeat, Section 3.4.1.

Possible Cause

Do This

The Calibration is incorrect

Recalibrate the machine.

See Calibration & Backlash Constants

Incorrect backlash values

If the machine does not repeat bi-directionally check the

backlash on the axis in question. See Calibration and

Backlash Constant Section 5.2.2.

3.4.3 The DRO Is Not Counting

The DRO for one axis is not counting when an axis is moved. Often times if this is

the case the axis will fault. See section on faulting.

Do the following Service Codes:

Code 33 Software Identification. This is needed if you call Customer Service.

Code 100 Axis open loop test. Used to check the maximum feedrate of an axis

and if the encoders are counting.

Code 132 Electronic handwheel test.

Code 131 Manual Encoder Test.

Page 34

30

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Possible Cause

Check This

Electronic handwheel failure

The Z handwheel should count 2.54 mm per revolution in both

directions in fine mode and 10.2 mm per revolution in course

mode. The X handwheel should count 0.51 mm per revolution in

both directions in fine mode and 2.54 mm per revolution in

course mode.

Servo driver failure

See Servo driver Section 4.5.

Motor Encoder not counting

See Motor diagnostics (not applicable with Glass Scale option)

Computer/Pendant failure

See Computer/Pendant diagnostics section 4.3.

3.4.4 X and Z-Axis DRO Counting in Wrong Direction

The DRO is counting in the wrong direction.

The positive directions for each axis are:

X-axis – cross slide moves toward the operator

Z-axis – carriage moves toward tailstock

Do the following service code and procedures:

Code 33 Software Identification. This is needed if you call Customer Service.

Code 313 Check the line that specifies the product.

If the product does not match the machine then the machine ID key will need to be replaced.

3.4.5 X and Z-Axis Electric Handwheels Turn in Wrong

Direction

The Electric Handwheels turn in the wrong direction.

The positive directions for each Electric Handwheel are:

X-axis - Electric Handwheel turns counterclockwise.

Z-axis - Electric Handwheel turns clockwise.

Do the following service code and procedures:

Code 308 Reverse X-axis Handwheel Direction.

Code 310 Reverse Z-axis Handwheel Direction.

3.5 Problems with the Machine Tool

3.5.1 Spindle Stalls or Turns-Off During Machining

During machining, the spindle turns off and loses power. First check incoming

voltage and connections.

Possible Cause

Check This

Machine Tool and Setup problem

Check the type of material being cut, type and size of cutting tool,

RPM, and Feed rate. Also check the condition of the cutter to

verify that the cutter is not dull. See Machine Tool & Setup Section

4.1.

Motor drive Belt is slipping

Check the alignment, condition, and tension of the Drive Belt.

Cut more than the machine is capable

Check speeds, feeds and depth of cut

Page 35

31

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

3.5.2 Spindle Motor Hums or Will Not Run

The spindle motor makes a constant humming noise during operation or will not turn

on.

Possible Cause

Check This

Wrong voltage

Check the 415V voltage to the machine

Poor wiring connections

Check all the wiring connections to the electric’s box.

Defective cable connections

Check all cable connections

Spindle Motor is bad

Check the resistance of the Spindle Motor windings on the Spindle

Motor between L1 & L2, L2 & L3, and L1 & L3, using an Ohmmeter.

The resistance should range from ".7 to 1.8 Ohm". If the Ohmmeter

reads "0 Ohms" or "OL", then replace Spindle Motor. Next, check the

resistance between L1 & Ground, L2 & Ground, and L3 & Ground,

using an Ohmmeter. The resistance should read "OL". If not then

replace Spindle Motor.

3.5.3 Spindle Runs Backwards

The spindle motor runs in the opposite direction.

Possible Cause

Check This

3-Phase wires backwards

Need to switch any 2 of the 3 wires either coming out of the

Spindle Drive (T1, T2, and T3) or going into the Spindle Motor (U,

V, and W). Caution: Be sure to shut off all power to the machine

before attempting to switch any wires.

3.5.4 Excess Gearbox Noise

Gearbox noise is louder than normal. Run the lathe at the gear where the noise is

most noticeable. Remove the gearbox lid and try to isolate where the noise is

coming from.

Possible Cause

Check This

Insufficient amount of oil in headstock

Check site glass to make sure oil is at sufficient level.

Spindle bearing not being lubricated

properly, worn bearing

Remove top lid and check to make sure oil is

overflowing freely to the spindle bearings.

Spindle preload loose

Tighten spindle preload on bearing. The spindle

preload should be approximately 1.1 – 1.7 N-m.

3.5.5 Headstock is Leaking Oil

A Form-A-Gasket sealant should be use to seal any leaking areas. Make sure the

sealant fills the leaking area thoroughly. Sealant must cure for 24 hours for best

results.

3.5.5.1 Leaking Oil from Rear of Gearbox

Possible Cause

Check This

Leaking from behind belt drive pulley

Replace shaft seal - o-rings or gaskets.

Oil leaking from behind the spindle

encoder.

Remove spindle encoder and pinion shaft cover.

Check the seal.

Oil leaking from the rear bearing

assembly.

Make sure the spindle shaft cover is mounted

correctly, if so remove the cover and check the o-ring.

Page 36

32

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

3.5.5.2 Leaking Oil From Front of Gearbox

Possible Cause

Check This

Oil leaking between cover and gearbox

Remove gearbox cover. Thoroughly clean cover & top

of gearbox. Replace gasket and reassemble.

3.5.6 Tailstock Barrel is Stiff

The tailstock barrel is stiff or not smooth moving through its travel. The tailstock

barrel subassembly jams inside the tailstock.

Possible Cause

Check This

Misalignment of tailstock housing

Realign bearing housing and tailstock screw. Loosen

screw support and realign.

Too much grease.

Disassemble and remove excess grease.

Vernier Dial is binding or rubbing on

screw support.

Remove dial and machine off a couple of thousandths

or shim.

Page 37

33

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

4.0 Diagnostics

Electrical and Mechanical maintenance should only be carried out by

trained and experienced machine tool engineers who fully understand the

hazards of working with machine tools.

This section explains the diagnostic procedures used to isolate service problems.

4.1 The Machine Tool & Set-Up

4.1.1 Leveling

Leveling is one of the most important aspects of setting up the machine properly.

Improper leveling can lead to a variety of machining problems.

The machine should be level to within .02 mm longitudinally and .01 mm

transversely. See Leveling Procedures, Section 2.9.

4.1.2 A Special Word About The X Gib

The X gib is vital to the performance of your lathe.

Gibs should be:

flat

free of twist

free of burrs

free of blockages in the oil passages and channels

Defective or scarred gibs must be replaced. Shimming of gibs will not yield

acceptable results.

It is good machining practice to avoid the use of shop air to clean the chips off a

machine. This risks blowing chips into the sliding way surfaces and compromising

the performance of the machine.

See Gib Adjustments, Section 5.2.1.

4.1.3 Lubrication

Lubrication is one of the single, most important maintenance issues and plays a key

role in assuring the performance and durability of the lathe. At the beginning of each

day manually supply oil to the way surfaces by doing service code 300.

Lack of lubrication can lead to a variety of problems with your machine motion due to

increased friction in the sliding ways. This increased friction may lead to part

inaccuracies and decreased life expectancies of your ballscrews and way surfaces.

Lack of lubrication in the headstock can lead to increased wear of the gear train as

well as premature wearing or failure of the spindle bearings. For the 1630, oil will be

flowing only when the spindle is on.

4.1.4 Machining Set-Up

The machining set-up itself is always something that can greatly influence the

performance of the lathe. The following are some things to keep in mind.

Page 38

34

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

Problems With

Can Contribute To:

Feed and Speeds (spindle rpm)

See below

Poor finish

Excessive speeds and feeds can break cutting tools

or wear out too fast.

Tooling

Using the wrong cutter for an application

Poor finish

Parts incorrect

Cutting too deep

Part dimensions incorrect

Driving and cutting forces cause deflections, since no

material is totally rigid

No coolant

Poor finish, decrease the life of the cutter

The following is a list of common machining problems and some possible solutions.

Problem

Check or Try This

Poor surface finish

Dull tool

Reduce feedrate

Increase spindle speed

Use a higher rake angle tool

Make sure tool is not dull or chipped

Use proper grade of cutting tool

Use coolant

Check to see if tools are on the centerline

Long workpieces out of round

Use a follow or steady rest

Excessive chatter

Tool bit improperly ground or not on center

Avoid extreme negative rake inserts

Tool overhang too great, tool deflection

Improper feeds and speeds

X gib loose. See

Gib Adjustment, Section 5.2.1

Work improperly supported

Machine tool out of level - See

Leveling Procedures,

Section 2.9.

4.1.4.1 Spindle Speeds

Spindle speeds are influenced by a number of variables:

Material

Rigidity of the Machine Setup

Coolant

Insert, geometry and material of insert

Depth of cut

4.1.4.2 Feedrates

Factors that affect feedrates:

Depth of cut

Design or type of insert

Sharpness of the insert

Workpiece material

Type of finish or accuracy required

Page 39

35

XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

4.2 The Mechanical Drive Train (X,Z)

Indications:

Troubleshooting instructions indicate that the drive train is potentially the

problem and other, more easily checked, variables have been exhausted.

Roughness, looseness, tightness or jamming movement in the carriage or cross slide.

Carriage walk-up due to Z ball screw misalignment.

1. Check for machine considerations, especially X gib adjustments and leveling. See

Gib Adjustments, Section 5.2.1.

2. Do the following special service codes:

Code 12 - this is a procedure that helps the control adjust to the friction

characteristics unique to the machine. Write down the resulting values from

the display. If your problem is control related, check to see if this procedure

has resolved the problem.

3. The torque required to manually turn the X and Z-axis ballscrews should be

between 10-15 in-lbs. These values should be consistent in both directions and

along all areas of the axis travel. Values that differ from that of above may

correspond to misaligned ball screws.

The following steps take you in a logical sequence through the assemblies. If the

step doesn’t isolate or resolve the problem, it will be necessary to disassemble

the indicated item and move to the next step.

1. Ensure that the screws that hold the bearing housing in place are not loose.

2. Ensure that the Clamp Nut is secured. The following applies to the clamp nut:

When loosening, make sure to back out the 10-32 screw from the clamp nut.

3. When tightening, snug the 10-32 screw to keep the clamp nut from spreading,

after applying the appropriate torque (50 ft lbs), tighten the 10-32 screw.

4. Take out the angular contact bearings in the X & Z-axis and inspect them. They

should roll smoothly and be lightly greased. If not, replace them. The Z-axis has

2 bearing housings. The tailstock bearing housing only contains 1 ball bearing.

NOTE: The bearing housing and spacer rings are matched sets - keep them together.

5. With the motor and drives removed, inspect the ball screw, ball nut and yoke for

the potential problems shown in the chart below.

CAUTION!