Page 1

FAST TAP

ASSEMBLY OPERATION MAINTAINANCE

Page 2

Page 3

Fast Tap Warranty.

The high speed Air Motor must be lubricated.

What is not covered

:

This limited warranty provided by XYZ does not cover:

1. Products which have been subject to abuse, accident, alteration modification,

tampering, negligence, misuse, faulty installation, lack of reasonable care, if

repaired or serviced by anyone other than our service facility, if affixed to any

attachment not provided with the product or if the model or serial number bas

been altered, tampered with, defaced or removed.

2. Initial installation and removal for repair

3. Operational adjustments covered in the owners manual and normal

maintenance

4. Tooling

5. Air prep system

6. Damage caused by insufficient lubrication

There are no express warranties except as listed above and any different guarantee

made by others is not authorised by us.

For customer use:

Entered below is the Model # and Serial # which is located on the label on the top

of the Balancer

Model # ……………………… Serial # ……………………… Purchase Date ………………………

Page 4

Page 5

Instructions for

FAST TAP

Reversible Air Motors

Be sure to Lubricate

All XYZ Fast Tap air tools are manufactured to extremely close tolerances.

Reasonable care and preventative maintenance will greatly prolong their service life.

This line of tools is designed for a long life of continuous duty on assembly lines, with

a minimum of service and maintenance. Rotating parts are mounted on extracapacity ball bearings, rotors and spindles are finished to extreme accuracy for

power and low air consumption, gears and pinions are oversize and correctly

hardened for quietness and long life.

Special attention has been given to ease of servicing. These tools can be

disassembled and reassembled with ease.

Before connecting the tool, blow the air line to remove water and dirt which may have

accumulated. This is especially important for a new line or when the line has not

been used for some time.

Gears

The gears are lubricated at the factory. Every 100 hours of operation add ¼oz gear

grease.

Operation

The air motor is started by depressing the operating lever or trigger. Motor speed

may be controlled by adjusting the slotted head control which is located on the tool

housing or on some models on the trigger surface.

If the tool is equipped with a reversing button, always depress the button fully to

obtain maximum power.

Air supply hose should not be less than 3/8” I.D. If extension hose is necessary, use

½” I.D. hose, with couplings not less than 3/8 I.D.

Page 6

Safety Precautions

1. Keep Work Area Clean: Cluttered areas and benches invite accidents.

2. Wear Proper Apparel: No loose clothing or jewellery to get caught in moving

parts.

3. Use Safety Glasses: Protect your eyes.

4. Secure Work: Use clamps or a vice to hold work. Its safer than using your

hand and it frees both hands to operate the equipment.

5. Don’t Overreach: Keep proper footing and balance at all times.

6. Maintain Tools With Care: Keep tools sharp and clean for best safety and

performance. Follow instructions for lubricating and changing accessories.

7. Disconnect Tools: When not in use, before servicing, when changing

accessories such as blades and bits etc.

8. Remove Adjusting Keys and Wrenches: Form a habit of checking to see

that keys and adjusting wrenches are removed from tool before use.

9. Caution: The use of an accessory with this tool not provided or

specified by XYZ Machine Tools may be hazardous, and will result of

cancellation of warranty.

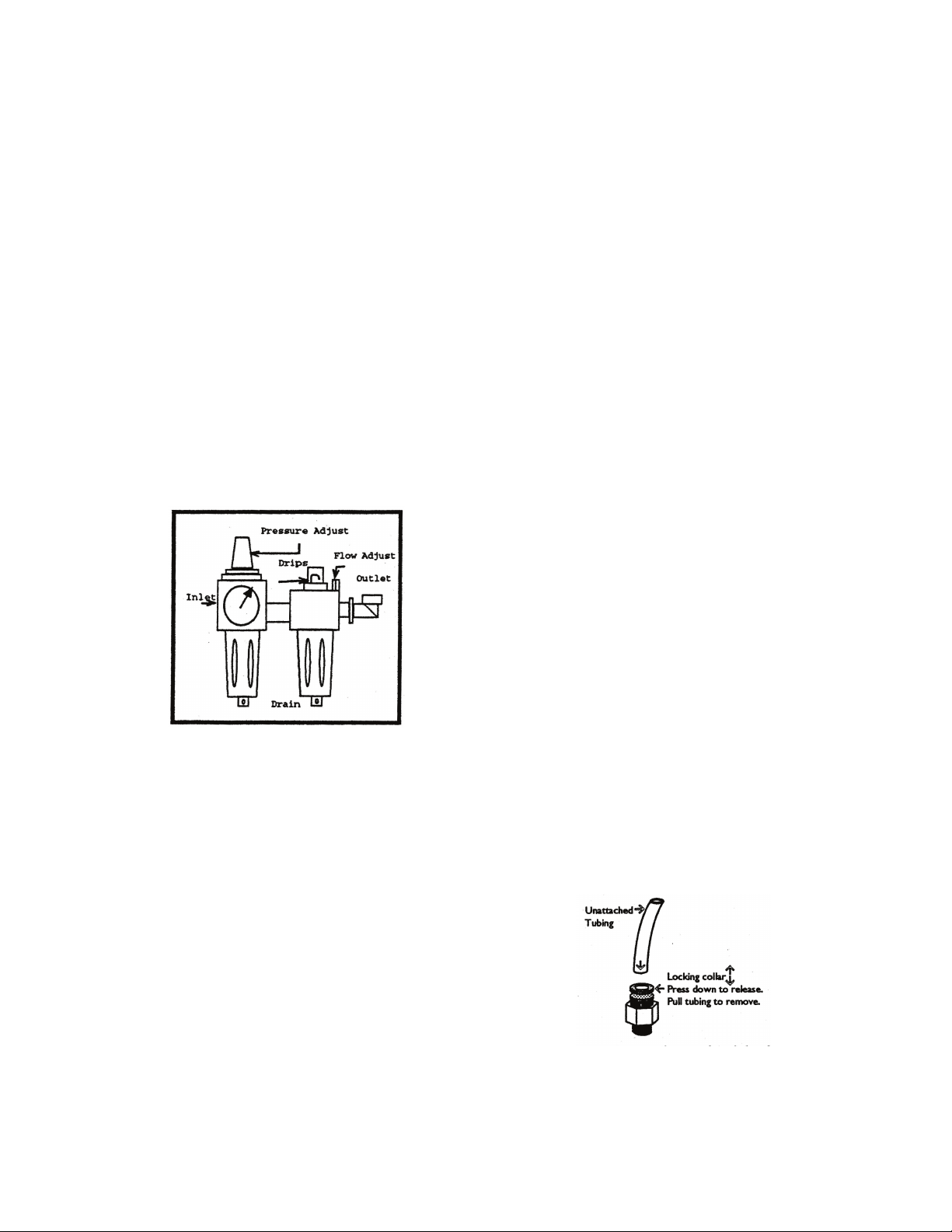

Automatic Mist Lubricator

An automatic must lubricator supplies oil to the air

motors. The oil should be checked daily and kept

topped up to the level using replacement oil

shown in the table below.

When used, adjust lubricator to deliver as follows:

Fast Tap Models 1000, 800, 400

2 to 4 drops of Pneumatic Air Tool Oil to tool per

minute.

Fast Tap Models 200, 90

60 to 76 drops of Pneumatic Air Tool Oil to tool

per minute.

Oil Specification Equivalent Equivalent Equivalent

Castrol Shell Mobil Oil BP

AWS Tellus 32 DTE24 Energol HLP 32

Air Connection

The RPM and capacity of the air motors are related to

the air pressure and to the available volume. It is

important that hoses with as large a bore as possible

are used and that the XYZ Tapping Machine is placed

near the main supply pipe. The inner diameter of the

hose connection should not be less than 3/8”.

The machine is packaged with the regulator end of the

air supply tube unattached. This is done to protect the

tube and the finish of the arms during shipping.

Completing the connection is a simple matter. Press the tube into the quick connect

coupler. Press firmly past the first step, inserting the tube 3/8 of an inch. To remove

the tube from either coupler, press down on the locking ring and withdraw the tube.

Page 7

Operation of XYZ Fast Tap Machines

Air Motors

By depressing the lever at the front of the air motor Forward Motion is started. By

keeping this lever depressed and operating the button opposite to the lever Reverse

Motion is started. If the lever is depressed and the button operated on and off, both

forward and reverse motions are available.

Speed control is possible by using both the lever and the button. This will reduce the

RPM when trying out tapping and cutting in new and difficult materials.

Parallel Arms

The Pantographic and perpendicular characteristics of the XYZ Fast Tap arms

ensure that the tap or other tools are presented at right angles to the work piece over

the working radius of the machine arms.

These arms are finely balanced and little effort is required to position or hold the arm

unit in position. The operator should not force the tap into the work piece or assist in

the withdrawal of it. The tap should be allowed to find its own entry and cut and

withdraw naturally without the assistance of the operator. The pitch of the tap

determines the feed both when going down and back up. This was the tap will selfcentre itself in the hole and produce the thread hole as intended. The operator can

operate the machine with little effort.

Positioning of the arm over the work piece is

gained by use of the corner bracket and angle

of the arm, but generally an angle of 75

degrees is the normal position at which the

arm is best balanced for maximum operator

convenience. Avoid working continuously in

positions lower than 18 inches below the table

surface.

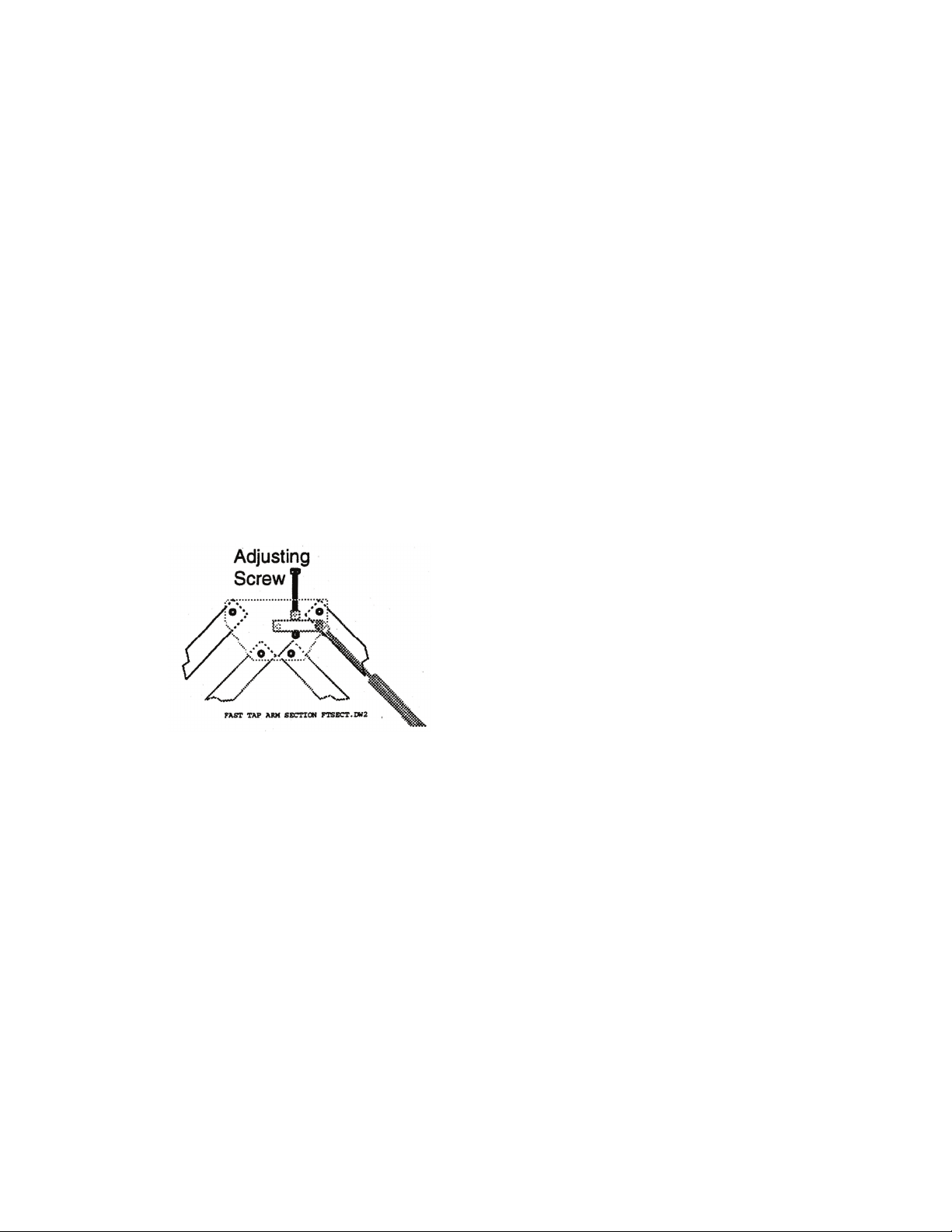

Adjusting the Balance of the Arms

The balance is controlled with 2 gas shocks with adjustable fastening. Turn the

Adjustment Screws in or out. See above diagram.

XYZ Fast Tap Applications

The XYZ Fast Tap is generally designed to produce tapped holes in a variety of

materials and locations and improving production time while reducing tap breakage

and wear etc. The XYZ Fast Tap have other applications, some of which are

described below.

Counter Sinking

The XYZ Fast Tap is excellent for this type of work. The positioning between several

holes is extremely fast and much time can be saved by taking these operations away

from conventional drilling or CNC machines.

Page 8

Reaming

Parallel or taper reamers can be used in the machine.

De-burring

Time can be saved by putting de-burring operations on the XYZ Fast Tap, especially

parts with holes to be de-burred before tapping. Some users de-burr large sheet

metal profiles on the XYZ Fast Tap.

Re-Tapping

The XYZ Fast Tap can be used to re-tap after painting or plating processes without

interfering with the thread tolerance. Similar uses in tapping missed holes are

recommended.

Die Work (Male Threads)

XYZ Fast Taps are useful for the threading or mounting of studs etc. Suitable die

holders can be offered on request.

Extension Taps and Tapping

Extension taps can be used on the XYZ Fast Tap, alternatively simple extension

pieces can be made up to utilise the standard length taps. A series of proprietary tap

holder extensions are available and will be offered on request. It is important that the

extension tap and the tap have the same diameter of shaft, allowing the XYZ Fast

Tap Torque Adaptor to work at the proper torque.

Daily and Periodic Maintenance

Very little maintenance is required to ensure the satisfactory operation of your

machine. The following instructions should however be carried out.

Air Motors

The air motors should normally not be repaired but returned to XYZ Machine Tools

for replacement. Under extreme working conditions, the motors may however need

attention periodically (entry of dirt etc). The motor should be carefully stripped down

and washed out and reassembled in clean conditions, lubricating the turbine parts etc

with the oil specified previously.

When dismounting the motor, disconnect the main air supply first and disconnect the

hose at the motor.

Parallel Arms

The bearing (iolite bushings) and pivot pins are lubricated on assembly and need

little attention. Some periodic lubrication of these points my be necessary at the

discretion of the user.

Page 9

The oil and water trap.

The oil and water trap should be checked and emptied daily or more frequently if the

air supply to the machine is not providing clean and water free air. Entry of particles

into the air motor will result in poor performance and stoppage. If the main air supply

should contain too much water to allow cleaning as described above an extra filter

should be installed on the incoming pipe to safeguard against disrupted operation of

the air motors.

Roll Tapping

Roll taps can be used quite easily, attention should be given to the instructions

regarding hole diameter etc, in the roll tap suppliers leaflet.

High Speed Thread Gauging

Where 100% inspection of threaded holes in required, a standard “no go” SPG can

be fitted to the XYZ Fast Tap to speed up this type of inspection. The torque limiter

on the XYZ Fast Tap holders will slip if the “no go” gauge will not enter the tapped

hole.

Heli-Coil Inserts

The parallel arm characteristics of the XYZ Fast Tap ensure that Heli-Coil inserts are

presented and inserted in the correct manner and show and improvement over hand

inserted methods. The Heli-Coil unit is fitted to the parallel arm using a special

fastening bracket.

Combined Drill & Tap Operations

Drill point taps are obtained from most leading tap manufacturers and can be used

on the XYZ Fast Tap, e.g. for cleaning holes.

Page 10

Quick-Change Tap Holders

Do not select adaptors beyond the capacity of tapping unit its selfAdaptor

series & tap

size range

Tap Size Order code

number

D I

5

C S

0-6 FT01 .87 .28 .77 .141

8 FT02 .87 .28 .84 .168

10 FT03 .87 .28 .84 .194

12 FT04 .87 .28 .87 .220

QCP – 0

# 0 - 14

¼ FT05 .87 .28 .87 .255

0-6 FT06 1.18 .28 .85 .141

8 FT07 1.18 .28 .92 .168

10 FT03 1.18 .28 .92 .194

12 FT09 1.18 .28 .95 .220

¼ FT10 1.18 .28 .95 .255

5/16 FT12 1.18 .28 .98 .318

3/8 FT13 1.18 .28 1.05 .381

7/16 FT14 1.18 .28 1.08 .323

½ FT15 1.18 .28 1.11 .367

9/16 FT155 1.18 .28 1.06 .429

1/8SS FT166 1.18 .28 1.05 .313

QCP – 1

# 0- 9/16

1/8”

Pipe

1/8LS FT177 1.18 .28 1.05 .438

5/16 FT18 1.89 .43 1.49 .318

3/8 FT19 1.89 .43 1.56 .381

7/16 FT20 1.89 .43 1.59 .323

½ FT21 1.89 .43 1.62 .367

9/16 FT22 1.89 .43 1.68 .429

5/8 FT23 1.89 .43 1.74 .480

11/16 FT24 1.89 .43 1.81 .542

¾ FT25 1.89 .43 1.87 .652

QCP – 2

5/16” – 7/8”

13/16 FT27 1.89 .43 1.87 .652

7/8 FT27 1.89 .43 1.93 .697

1/4P FT288 1.89 .43 1.18 .562

1/8P FT299 1.89 .43 1.24 .700

QCP – 2

¼” – ½”

Pipe 1/2P FT300 1.89 .43 1.37 .687

XYZ Offers “Blitz-style” Quick-Change Systems

Page 11

Do not select adaptors beyond the capacity of tapping unit its selfAdaptor

series &

tap size

range

Tap Size Order

code

number

D I

5

C S Permissible

torque lb/ft

0-6 FT46 .91 .83 .77 .141 1.1

8 FT47 .91 .83 .84 .168 1.7

10 FT48 .91 .83 .84 .194 2.2

12 FT49 .91 .83 .87 .220 2.5

QCP – 0

# 0 - 14

¼ FT50 .91 .83 .87 .255 4.3

0-6 FT51 1.26 .98 .85 .141 1.1

8 FT52 1.26 .98 .92 .168 1.7

10 FT53 1.26 .98 .92 .194 2.2

12 FT54 1.26 .98 .95 .220 2.5

¼ FT55 1.26 .98 .95 .255 4.3

5/16 FT56 1.26 .98 .98 .318 7.2

3/8 FT57 1.26 .98 1.05 .381 10.8

7/16 FT58 1.26 .98 1.08 .323 17.0

½ FT59 1.26 .98 1.11 .367 25.0

9/16 FT595 1.26 .98 1.06 .429 29.0

1/8SS FT600 1.26 .98 1.05 .313 7.0

QCP – 1

# 0- 9/16

1/8”

Pipe

1/8LS FT611 1.26 .98 1.05 .438 29.0

5/16 FT62 1.97 1.34 1.49 .318 7.2

3/8 FT63 1.97 1.34 1.56 .381 10.8

7/16 FT64 1.97 1.34 1.59 .323 17.0

½ FT65 1.97 1.34 1.62 .367 25.0

9/16 FT66 1.97 1.34 1.68 .429 29.0

5/8 FT67 1.97 1.34 1.74 .480 36.0

11/16 FT68 1.97 1.34 1.81 .542 40.0

¾ FT69 1.97 1.34 1.87 .652 53.0

QCP – 2

5/16” –

7/8”

13/16 FT70 1.97 1.34 1.87 .652 57.0

7/8 FT71 1.97 1.34 1.93 .697 69.0

1/4P FT22 1.97 1.34 1.18 .562 11.0

1/8p FT44 1.97 1.34 1.24 .700 14.0

QCP – 2

¼” – ½”

Pipe

1/2p FT44 1.97 1.34 1.37 .687 32.0

Top Shank Conversion Chart ISO to American Standard

NOTE: Most US manufacturers of metric taps supply them with U.S. standard shanks.

Following is a list of the more popular metric sizes and the American standard shanks used.

ISO US ISO US

M1.6, 1.8, 2, 1.2, #0 - #6 M7,7 5/16”

3, 3.5 #0 - #6 M10 3/8”

M4 #8 M12, 12.5 ½”

M4.5, 5 #10 M14 9/16”

M6, 6.3 ¼” M16 5/8”

Page 12

Tap Chuck Torque Adjustment

The XYZ Fast Tap

Torque Adaptor is

adjustable for

different materials.

The torque is

factory set for mild

steel. Practice will

enable you to

achieve the proper

torque for a

particular material

and tap

configuration. To make an adjustment, disengage the snap ring from the adjustment

slots on the Torque Adaptor. Turn the adjustment collar clock-wise for torque

increase and counter clock-wise for torque decrease.

Always reinstall the snap ring into an adjustment slot before using the XYZ Fast Tap.

Quick Change Adaptor

The XYZ Fast Tap facilitates the changing of tools with the Quick Change Adaptor.

To insert a tool lift up on the locking collar. This will snap into an indent. Insert the

Torque Adaptor or tool holder aligning the bosses and notches and press up against

the Quick Change Adaptor.

The locking collar will snap

into the locking position if

the tool holder is correctly

installed. XYZ Machine

Tools recommends careful

attention not to introduce

chips or debris into the

Quick Change Adaptor.

During installation of the

tool holder. The locking

collar will not reset unless

you press against the inner

shaft of the Quick Change

Adaptor. This is

automatically

accomplished by the tool

holder. The Quick Change

Adaptor and the Torque

Adaptor should be kept

clean and lightly oiled.

Blowing chips into the

Quick Change Adaptor

could cause jamming, and

is NOT recommended.

Page 13

General Notes on Tapping

XYZ Fast Tap is most suitable for tapping through and blind holes. The choice of tap

and speed is, of course, the choice of the user, and your current tap supplier will

advise you on the type of tap to employ on various materials.

A good tapping result also demands a suitable cutting oil.

Generally for machine tapping operations, gun nose taps are used for through holes

because, by virtue of a short gash on the chamfer portion, the swarf is directed

ahead of the tap. The flutes serve only as a channel for lubrication and these are

narrower than those of a conventional straight tap resulting in a stronger cross

section on the fluted portion. Chamfer lead is usually a second tap. Spiral fluted taps

are for tapping blind holes as the swarf is directed backout of the hole by virtue of

helix cutting (RH spiral, RH cutting, LH spiral, LH cutting). Chamfer lead is usually the

same as that for a bottoming tap.

The RPM and capacity of the air motors are related to the air pressure and to the

available volume. It is important that hoses with a large a bore as possible are used

and that the XYZ Fast Tap is placed near the main supply pipe. The inner diameter of

the hose connection should not be less than 3/8”.

When the machine is shipped the air connection tube is not attached at the regulator

/ lubricator end. To complete this connection press the tube into the quick coupling.

Press firmly, past the first resistance until 3/8” of the tubing has been inserted. To

remove the tubing from either coupling just press down on the locking ring and pull

on the tubing.

Page 14

EC MACHINERY DIRECTIVE

98/392/EEC

DECLARATION OF CONFORMITY

We hereby certify that the machinery stipulated below complies with all the relevant

provisions of the EX Machinery Directive as amended and the National Laws and

Regulations adopting this directive.

Name of Supplier. XYZ Machine Tools Ltd. Woodlands Business Park, Burlescombe,

Nr Tiverton, Devon.

Tel:- 01823 674 200 FAX: 01823 674201

Machine Description: Fast Tap

Model:

Serial Number:

Harmonized standards applied.

EX292 pt.1, EN292 pt.2.

Signed:

Date:

Name: Keith Wilson

Position: Director

Being the responsible person appointed by the supplier.

Page 15

Noise Test Report

Fast Tap Series

Introduction

This is a report of the noise measurement tests carried out on the Fast Tap Series

supplied by XYZ Machine Tools Ltd.

Test Procedures

The noise is measured at four positions around the Fast Tap at a distance of 1 metre

from the machinery and 1.6 metres above the ground where the machinery is

operated. The type of sound level meter is used is manufactured by DAWE

Instruments Model 1422C, which is a digital impulse meter. The meter was calibrated

prior to the test using a DAWE Instruments D-1411E Acoustical Calibrator.

Machinery Condition

The machine used for the test s a new machine. The metal cutting test was done dry

so the noise will be higher than if cutting wet. The machine was fitted with the noise

baffle which is supplied as standard equipment.

Cutting Conditions

The material used was EN8 (medium carbon steel) with the following chemical

composition.

C=0.421 %

Si=0.259% Mn=0.818%

P=0.011%

S=0.033%

Cr=0.039%

Ni=0.028%

The material is in normalised condition.

Tools used: - Dormer Spiral Flute/model 1000 ‘M6 Tap’/model 800 ‘M10 Tap’/model

400 M12 Tap’/model 200 ‘M16 Tap’

Page 16

Test Results

1. Background noise

The background noise was about 54 dB

2. Noise without cutting

Fast Tap 1000

Location 1 = 82.8 dB

Location 2 = 83.2 dB

Location 3 = 82.4 dB

Location 4 = 81.5 dB

Fast Tap 800

Location 1 = 83.5 dB

Location 2 = 80.1 dB

Location 3 = 78.6 dB

Location 4 = 81.5 dB

Fast Tap 400

Location 1 = 82.5 dB

Location 2 = 79.8 dB

Location 3 = 79.8 dB

Location 4 = 78.3 dB

Fast Tap 800

Location 1 = 81.8 dB

Location 2 = 79.2 dB

Location 3 = 80.2 dB

Location 4 = 77.9 dB

3. Noise with cutting

The machine was run cutting the specified material under the specified conditions.

Fast Tap 1000

Location 1 = 85.0 dB

Location 2 = 84.9 dB

Location 3 = 84.6 dB

Location 4 = 83.6 dB

Fast Tap 800

Location 1 = 85.0 dB

Location 2 = 85.1 dB

Location 3 = 85.1 dB

Location 4 = 82.5 dB

Fast Tap 400

Location 1 = 83.5 dB

Location 2 = 83.5 dB

Location 3 = 84.2 dB

Location 4 = 81.4 dB

Fast Tap 800

Location 1 = 83.0 dB

Location 2 = 82.3 dB

Location 3 = 84.1 dB

Location 4 = 79.0 dB

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Loading...

Loading...