FLAT PANEL INDUSTRIA

XT1502

FLAT PANEL INDUSTRIAL MONITOR

Hardware Guide

1 142027(G)

Revision

A

B

C

D

E

F

Description

Manual released

Manual updated

Manual updated

Manual updated

TIR Caution and driver installation instructions added

Corrected product dimensions

Date

07/01

06/02

07/04

05/05

G Name change, correct where applicable with document 04/07

Pro-face/Xycom Part Number 142027(G)

Trademark Information

Xycom and Xycom Automation are trademarks of Xycom Automation, L.L.C.

Xycom Automation, L.L.C. now is referred to as Pro-face through a D.B.A.

The Pro-face name and logo will replace the Xycom name and logo on all documents where possible.

Pro-face is a trademark of Digital Electronics Corporation.

Brand or product names may be registered trademarks of their respective owners.

Windows is a registered trademark of Microsoft Co the United States and other countries.

Copyright Information

This document is copyrighted by Xycom Automation, L.L.C. (Xycom) and shall not be reproduced

or copied without expressed written authorization from Xycom Automation, L.L.C.

The information contained within this document is subject to change without notice.

Pro-face does not guarantee the accuracy of the information.

United States FCC Part 15, Subpart B, Class A EMI Compliance Statement:

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference

at his own expense.

For European Users: WARNING

This is a Class A product. In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

INSTALLATION: Electromagnetic Compatibility WARNING

The connection of non-shielded equipment interface cables to this equipment will invalidate

FCC EMI and European Union EMC compliance and may result in electromagnetic interference

and/or susceptibility levels which are in violation of regulations which apply to the legal

operation of this device. It is the responsibility of the system integrator and/or user to apply the

following directions which relate to installation and configuration:

All interface cables must include shielded cables. Braid/foil type shields are recommended.

Communication cable connectors must be metal, ideally zinc die-cast backshell types, and

provide 360 degree protection about the interface wires. The cable shield braid must be

terminated directly to the metal connector shell, ground drain wires alone are not adequate.

Protective measures for power and interface cables as described within this manual must be

applied. Do not leave cables connected to unused interfaces or disconnected at one end.

Changes or modifications to this device not expressly approved by the manufacturer could void

2 142027(G)

the user's authority to operate the equipment.

Table of Contents

1. Product Overview.........….......................................................................................... 1

Product Features…………………………………………….……………………………………1

Standard XT1502 Features…………………………………………………………………….1

Parts List…………………………………………………….……………………………………1

Standard XT1502 Parts List…………………………………………………………………...1

Manual Overview…………………………………………….…………………………………..2

Text Conventions Used in this Manual …………………….……………………………………2

Product Dimensions ……………………………………….…………………………………….3

Front Panel Controls …………………………………………….……………………………3

Product Specifications and Ratings……..………………….……………………………………4

Environmental……...…….……………………………………………………………………4

Electrical ……………………………………………………………………………………...4

Front Panel/Enclosure .......…….…………………………….…………………………………..4

Regulatory Compliance ...………………………………...…………………………………..4

Safety Agency Approvals ………………….…………………………………………………4

2. Installation ..........................................…................................................................... 5

Environmental Considerations …….……….……………………………………………………5

System Power …………...……………………………………………………………………5

Excessive Heat …………..….…………..……………………………………………………5

Electrical Noise ...…………...…………..……………………………………………………6

Line Voltage Variation …...……………..……………………………………………………6

Location and Enclosure …………...…….……………………………………………………7

Panel Installation …………………….……..……………………………………………………7

Panel Mounting Dimensions ...…………..……………………………………………………7

3. Monitor Settings ..............................................….......................................................8

Mode and Image Adjustment ……………....……………………………………………………8

Video Modes Supported ………………………………………………………………………8

Onscreen Display (OSD) Functions …………..…………………………………………………9

Front Panel Controls ……….…………………………………………………………………9

Main OSD menu …………...…………………………………………………………………9

Image Submenu ………...….…………………………………………………………………9

OSD Submenu ………..………………………………………………………………………10

System Info Submenu ….….…………………………………………………………………10

Extended Submenu ...…………………………………………………………………………10

Direct Access 1 & 2 ...……...………………………………………………………………10

Language………… ...……...………………………………………………………………10

Installing the Touch Screen Driver……………………………………………………………11

4. Hardware ..............................................…...............................................…………....13

VGA Input Connector Pin Out …………………...…………………………………………….13

Back Light Replacement Procedure ……………...…………………………………………….13

Appendix A: Reaching Technical Support…...………...…...……...…………………………...15

Appendix B: Dimensions and Weight…..…...…………...…...………………………………...15

i 142027(G)

1. Product Overview

Pro-face/Xycom industrial monitors meet the rigorous requirements of the plant floor

with high-resolution flat panel displays in a rugged housing with an optional resistive

membrane touchscreen. The XT1502 flat panel monitor delivers crisp, bright text and

graphics with a low current draw, and it fits into panels that CRTs cannot.

The XT1502 is self-contained, requiring only to be panel mounted in an appropriate

enclosure and connected to 120/240 VAC and VGA source.

Product Features

Parts List

Standard XT1502 Parts List

Standard XT1502 Features

• 15.0" bright (200 Nit), easy-to-read, high contrast (150:1), color (6 bit/262,144

colors) TFT flat panel display with SVGA (1024x768) resolution

• Large viewing area and viewing angles (120° horizontal, 100° vertical)

• Operator input through an optional integrated high-performance (35 million touch)

touchscreen

• Front panel controls with onscreen menus (lock switch on rear of units)

• Long-lasting (50,000 hour) backlight

• Hinged design for easy backlight field replacement

• Simple mounting

• Shallow mounting depth

• Up to 50 foot cables

• Optional 19" EIA rackmount adapter plate

• NEMA 4/12 front panel, when properly mounted

• UL and cUL recognized, CE marked

• Units ship with all necessary cables and software

When you remove the XT1502 from its shipping carton, verify that you have the parts

listed below. Save the box and inner wrapping in case you need to reship the unit.

• XT1502 unit.

• Ten-foot VGA cable.

• Ten-foot serial cable (touchscreen units only).

• Documentation and Support Library CD-ROM. In addition to containing this manual,

this CD contains all drivers required by this unit (touchscreen drivers in the case of

XT1502T units).

1 142027(G)

Manual Overview

The manual is divided in the following chapters:

• Chapter 1 – Product Overview

• Chapter 2 – Installation

• Chapter 3 – Monitor Settings

• Chapter 4 – Hardware

Text Conventions Used in this Manual

Throughout this manual, certain terms are formatted in ways that indicate what type of

object is being described. Some information is also segregated to draw attention quickly.

Titles, labels, and messages are indicated by italic text. Computer filenames and text to

be entered by the user will appear in a monospace font. Operator interfaces (such as the

Start menu button) and keyboard keys (such as Enter) appear in a narrow bold typeface.

Other text (such as the word Note) is bold to emphasize it and draw your attention to it.

Some text is segregated into Note, Caution, or Warning boxes. Notes contain extra

information that may make the nearby text, especially the text just before the note, more

understandable. Cautions contain information necessary to prevent damage to the

hardware. Warnings contain information necessary to safeguard the operator.

2 142027(G)

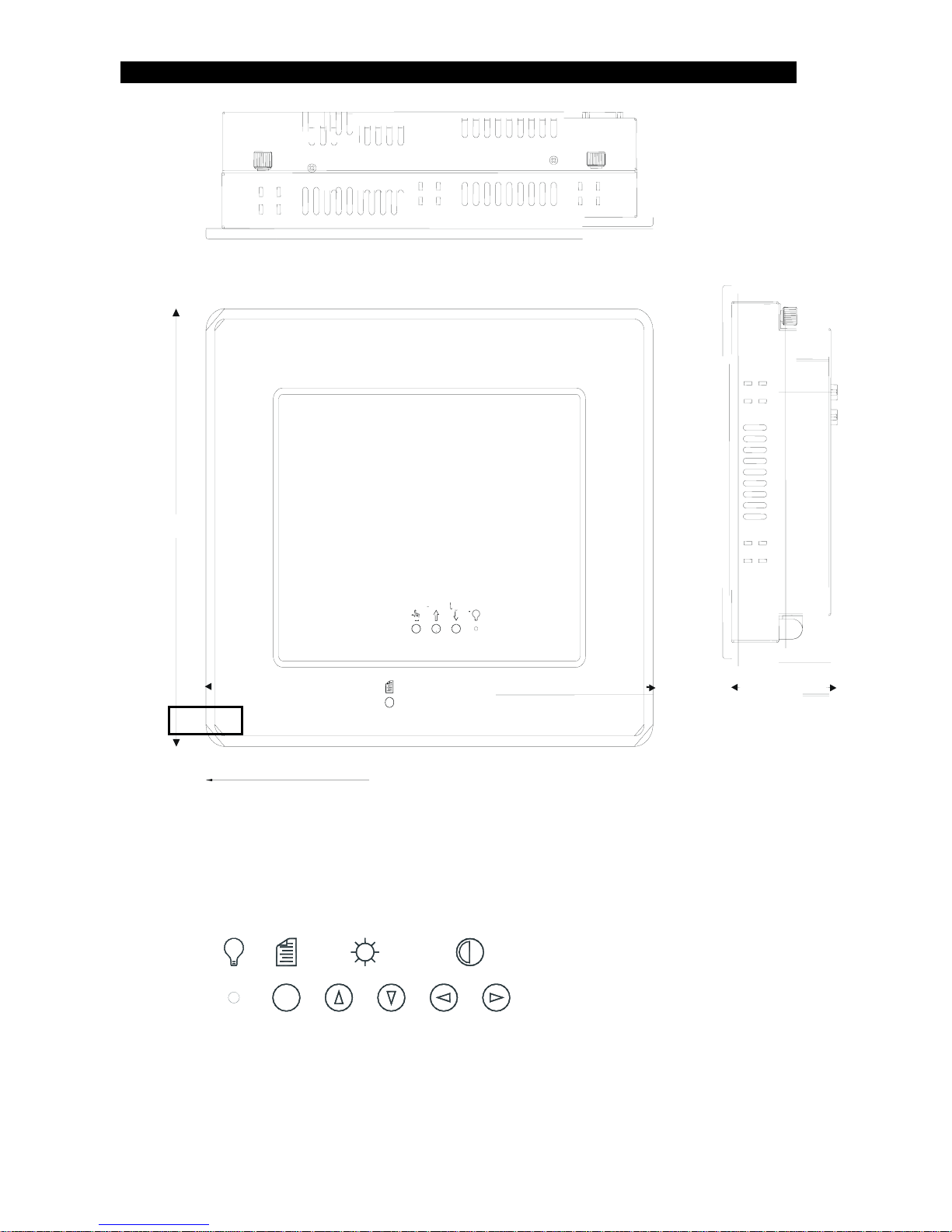

Product Dimensions

13.48[342.4]

in.[mm]

Front Panel Controls

The front panel controls, from left to right are Menu, Select, Increment, Decrement.

Their use is detailed in Chapter 3— Monitor Settings.

16.48[418.6]

3.25[82.60]

3 142027(G)

Product Specifications and Ratings

Environmental

Operating Nonoperating

Thermal

Humidity

Shock

Vibration,

5-2000 Hz

Altitude

0°C to 50°C (32°F to 122°F) -20°C to 60°C (32°F to 122°F)

20% to 80% RH, noncondensing 20% to 80% RH, noncondensing

15 g peak acceleration,

11 msec duration

0.006" peak-to-peak displacement

1.0 g maximum acceleration

Sea level to 10,000 ft. (3,000 m) Sea level to 40,000 ft. (12,000 m)

Electrical

AC power: 90-264 VAC, 1.0 A, 47-440 Hz

DC power: 24 VDC, 1 A

Front Panel/Enclosure

NEMA 4/12

Regulatory Compliance

CE

30 g peak acceleration,

11 msec duration

0.015" peak-to-peak displacement

2.5 g maximum acceleration

• EN 55022: Class A

• EN 50082-2

• EN 60950

FCC

• 47 CFR, Part 15, Class A

Safety Agency Approvals

UL

• UL 60950

CUL

• CSA-C22.2, #950

4 142027(G)

2. Installation

Environmental Considerations

The rugged design of the XT1502 allows it to be installed in most industrial

environments. Refer to the electrical and environmental specifications and tolerances

(pg. 4) for more detailed information.

System Power

It is a good practice to use isolation transformers on the incoming AC power line to the

system. An isolation transformer is especially desirable in cases in which heavy

equipment is likely to introduce noise onto the AC line. The isolation transformer can

also serve as a step-down transformer to reduce the incoming line voltage to a desired

level. The transformer should have a sufficient power rating (units of volt-amperes) to

supply the load adequately.

Proper grounding is essential to all safe electrical installations. Refer to the relevant

federal, state/provincial, and local electric codes, which provide data such as the size and

types of conductors, color codes and connections necessary for safe grounding of

electrical components. The code specifies that a grounding path must be permanent (no

solder), continuous, and able to safely conduct the ground-fault current in the system with

minimal impedance (minimum wire required is 18 AWG, 1 mm).

Observe the following practices:

• Separate the power and ground (P. E., or Protective Earth) cable from signal cables at

the point of entry to the enclosure. To minimize the ground wire length within the

enclosure, locate the ground reference point near the point of entry for the plant

power supply.

• All electrical racks or chassis and machine elements should be Earth Grounded in

installations where high levels of electrical noise can be expected. The rack/chassis

should be grounded with a ground rod or attached to a nearby Earth structure such as

a steel support beam. Connect each different apparatus to a single Earth Ground point

in a "star" configuration with low impedance cable. Scrape away paint and other

nonconductive material from the area where a chassis makes contact with the

enclosure. In addition to the ground connection made through the mounting bolt or

stud, use a one-inch metal braid or size #8 AWG wire to connect between each

chassis and the enclosure at the mounting bolt or stud.

Excessive Heat

To keep the temperature in range, the cooling air at the base of the system must not

exceed the maximum temperature specification (see pg. 4). Allocate proper spacing

between internal components installed in the enclosure.

When the air temperature is higher than the specified maximum in the enclosure (see

pg. 4), use a fan or air conditioner to lower the temperature.

5 142027(G)

Electrical Noise

Electrical noise is seldom responsible for damaging components, unless extremely high

energy or high voltage levels are present. However, noise can cause temporary

malfunctions that can result in hazardous machine operation in certain applications. Noise

may be present only at certain times, may appear at widely spread intervals, or in some

cases may exist continuously.

Noise commonly enters through input, output, and power supply lines and may also be

coupled through the capacitance between these lines and the noise signal carrier lines.

This usually results from the presence of high voltage or long, close-spaced conductors.

When control lines are closely spaced with lines carrying large currents, the coupling of

magnetic fields can also occur. Use shielded cables to help minimize noise. Potential

noise generators include switching components, relays, solenoids, motors, and motor

starters.

Refer to the relevant Federal, State/Provincial, and local electric codes, which provide

data such as the size and types of conductors, color codes and connections necessary for

safe grounding of electrical components. It is recommended that high- and low-voltage

cabling be separated and dressed apart. In particular, AC cables and switch wiring should

not be in the same conduit with all communication cables.

Line Voltage Variation

The power supply section of the unit is built to sustain the specified line fluctuations and

still allow the system to function in its operating margin. As long as the incoming voltage

is adequate, the power supply provides all the logic voltages necessary to support the

monitor unit.

Unusual AC line variations may cause undesirable system shutdowns. As a first step to

reduce line variations, correct any possible feed problems in the distribution system. If

this correction does not solve the problem, use a constant voltage transformer. The

constant voltage transformer stabilizes the input voltage to the systems by compensating

for voltage changes at the primary in order to maintain a steady voltage at the secondary.

When using a constant voltage transformer, check that the power rating is sufficient to

supply the unit.

Location and Enclosure

• Place the unit to allow easy access to the system ports.

• Account for the unit dimensions when selecting an installation location or enclosure (see pg. 3).

• You can maintain the NEMA 4 seal by mounting the unit in an approved enclosure

that has a 14 gauge (0.075"/1.9 mm thick) steel or (0.125"/3.2 mm thick) aluminum

front face.

• Place the unit at a comfortable working level.

• Mount the unit in an upright position, if possible.

• Consider locations of accessories such as AC power outlets and lighting (interior

lighting and windows) for installation and maintenance convenience.

• Prevent condensation by installing a thermostat-controlled heater or air conditioner.

• Avoid obstructing the airflow to allow for maximum cooling.

• Place any fans or blowers close to the heat-generating devices. If using a fan, make

sure that outside air is not brought inside the enclosure unless a fabric or other

reliable filter is used. This filtration prevents conductive particles or other harmful

6 142027(G)

contaminants from entering the enclosure.

• Do not select a location near equipment that generates excessive electromagnetic

interference (EMI) or radio frequency interface (RFI) (equipment such as high-power

welding machines, induction heating equipment, and large motor starters).

• Do not place incoming power line devices (such as isolation or constant voltage

transformers, local power disconnects, and surge suppressers) near the system. The

proper location of incoming line devices keeps power wire runs as short as possible

and minimizes electrical noise transmitted to the unit.

• Make sure the location does not exceed the unit's shock, vibration, and temperature

specifications (see pg. 4 for specifications).

• Install the unit so it does not cause a hazard from uneven mechanical loading.

• Incorporate a readily accessible disconnect device in the fixed wiring on permanently

connected equipment.

• Avoid overloading the supply circuit.

Panel Installation

This monitor should be mounted in and used where NEMA 4 and NEMA 12 type

enclosures are employed. When mounted properly, the monitor meets or exceeds the

sealing requirements set forth in the NEMA 4 and NEMA 12 specifications. The monitor

uses "U"-shaped clips and a special gasket to achieve the proper seal.

To install the monitor, make a cutout per the diagram below in one of the walls of your

NEMA enclosure. Enclosures made of heavier gauge metal work better in that they won't

deform or bend as easily when the monitor's sealing gasket is compressed. Next hold the

monitor in place while you install the mounting clips. Tighten the clips in a cross pattern.

This will help to develop an even pressure on the sealing gasket. Tighten the clips to the

point were the back of the monitor's front bezel just begins to contact the front of the

NEMA enclosure.

Caution: Do not over tighten, because overtightening can cause damage to the monitor

which can result in loss of seal integrity.

Panel Mounting Dimensions

12.70 +/- .02[322.58 +/- 0.51]

in.[mm]

7 142027(G)

3. Monitor Settings

Caution

Leaving your TFT LCD display on constantly can result in temporary image

retention (TIR). TIR can be avoided by using a screen saver, enabling the

idle/doze timeout feature, or by turning off the display when it is not in use.

Mode and Image Adjustment

Not all video controllers produce exactly the same video output levels or the same timing.

The XT1502 uses onscreen programming to make setup and adjustment easy. The menus

are selected and the menu items are adjusted using the buttons located on the monitor

front panel. These buttons are enabled or disabled by a rocker switch labeled SET UP

located on the side of the monitor. This feature is provided to inhibit tampering once the

monitor is in actual use. Turn the SET UP switch to the On position to enable set up and

adjustment. Prior to adjusting your monitor you should initialize the display settings in

the Windows control panel to the following choices:

Colors: 256

Vertical Refresh: 60 Hz

Resolution: 1024 x 768

Monitor Type: “Viewsonic 15”

Note: The monitor type option is not available in Windows NT.

Once the monitor is powered up, you can access the onscreen display (OSD) functions by

pressing the menu button. After the menu appears, select the Auto Setup function

following the directions given below. The monitor will automatically adjust to the

incoming video signal. Then select the Image | Auto phase function or manually fine-tune the

image. Finally, set the brightness and contrast settings to your individual preference.

Video Modes Supported

Mode Horizontal Sync

Rate (KHz)

VESA VGA

(640x480)

INDUSTRY

TEXT (720x400)

VESA SVGA

(800x600)

VESA XGA

(1024x768)

MAC (640x480)

MAC (832x624)

MAC (1024x768)

31.5

37.9

37.5

31.5

35.1

37.9

48.1

46.9

48.4

56.5

60.0

35.0

49.7

60.2

Vertical Sync

Rate (KHz)

60

72

75

70

56

60

72

75

60

70

75

67

74.6

75

Dot Freq.

(MHz)

25.175

31.5

31.5

28.3

36.0

40.0

50.0

49.5

65.0

75.0

78.75

30.5

57.3

80.0

Expansion

Factor

1.6

1.6

1.6

1.4

1.25

1.25

1.25

1.25

1.0

1.0

1.0

1.5

1.0

1.0

8 142027(G)

Onscreen Display (OSD) Functions

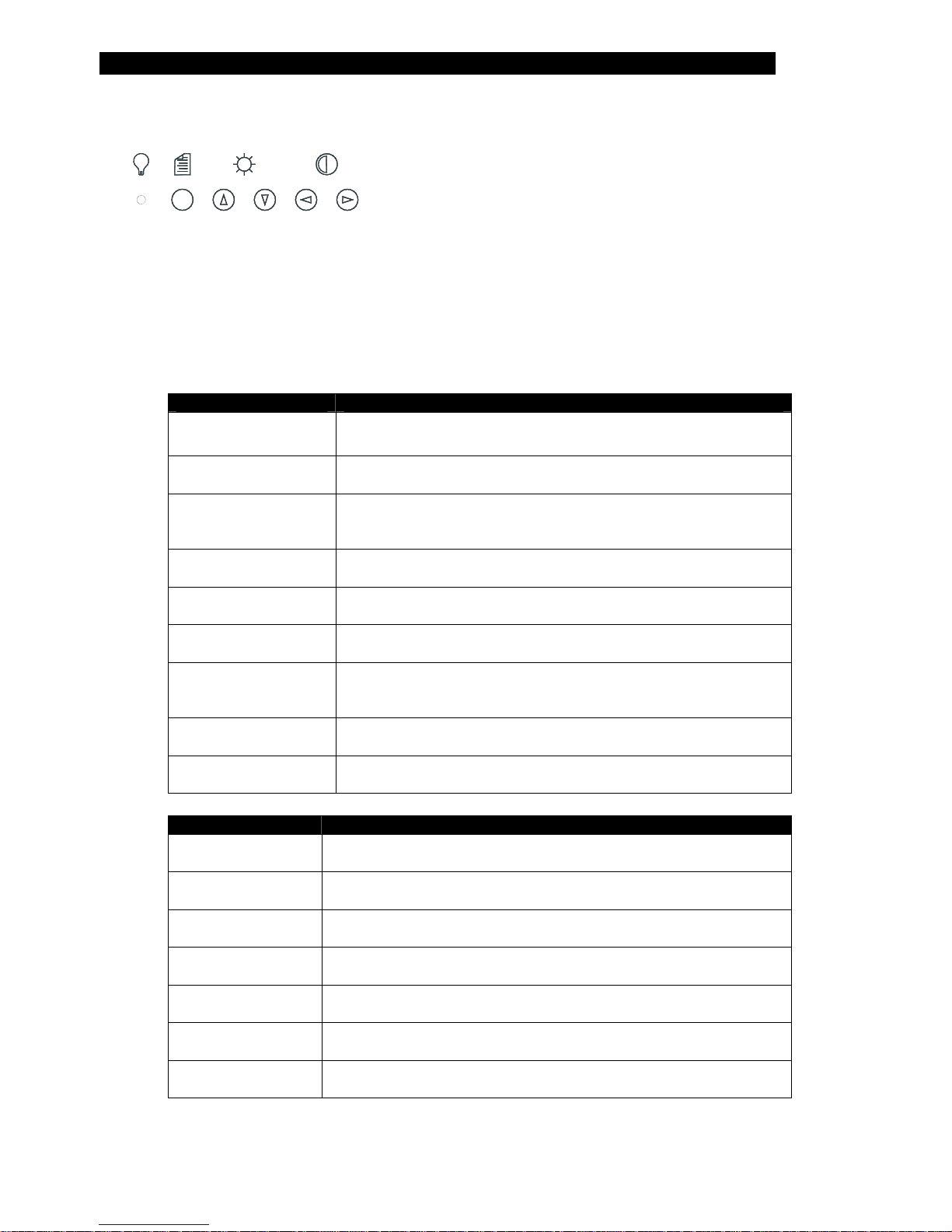

Front Panel Controls

The front panel controls, from left to right are Power, Menu, Select, Increment/Decrement.

Power: Power on LED.

Menu: Turns on the onscreen menu. Also steps to the next menu group.

Select: These buttons highlight and select menu items. They also increase or decrease

brightness.

Increment and Decrement: These buttons are used to scroll through menu items or to adjust

settings. They also increase or decrease contrast.

Main OSD menu

This menu is opened with the Menu button.

Menu Item Description

Brightness

Contrast Increase/decrease panel contrast level

Tuning Fine-tune the data sampling position (phase).

Auto Set Up Automatically adjust monitor (e.g. positions, size, tuning etc.)

Image Adjust Turns on the Image Adjust submenu

OSD Menu Turns on the OSD submenu

System Info Turns on the System Information submenu

Extended Turns on the Extended Menu

Exit Turn off the OSD menu

Image Submenu

Menu Option Description

Image Horizontal

Position

Image Vertical

Position

Image Horizontal

Size

Sharpness Adjust sharpness level

Red Adjust red color level

Green Adjust green color level

Blue Adjust blue color level

Increase/decrease panel brightness level

Press ←or → (- >>>>>>>>>>>>>>> + nnn), range: 0 to 256

Press ←or → (- >>>>>>>>>>>>>>> + nnn), range: 0 to 210

(Adjust display quality)

Press ←or → (- >>>>>>>>>>>>>>> + nn), range: 0 to 11

Press → to activate auto setup

Pressing → turns on the Image Adjust menu

Pressing → turns on the OSD menu

(Shows board information)

Pressing → turns on the System Information menu

Pressing → turns off the OSD menu

Pressing → turns off the OS D menu

Move the image position horizontally

Press ←or → (- >>>>>>>>>>>>>>> + nn), range: 0 to 58

Move the image position vertically

Press ←or → (- >>>>>>>>>>>>>>> + nn), range: 0 to 56

Change the image width horizontally

Press ←or → (- >>>>>>>>>>>>>>> + nnnn), range: 1318 to 1358

Press ←or → (- >>>>>>>>>>>>>>> + n), range: 0 to 3

Press ←or → (- >>>>>>>>>>>>>>> + nn), range: 0 to 27

Press ←or → (- >>>>>>>>>>>>>>> + nn), range: 0 to 27

Press ←or → (- >>>>>>>>>>>>>>> + nn), range: 0 to 27

9 142027(G)

OSD Submenu

Menu Option Description

Menu Horizontal Position Move the OSD horizontally

Menu Vertical Position Move the OSD vertically

Menu Transparency Adjust the transparent level of the OSD menu

Menu Timeout Set menu time-out period

Menu Auto Save

System Info Submenu

Menu Option Description

Display Type Shows display type; e.g. TFT LCD 1024 x 768.

Model Shows the model number of the board; e.g. ACL-1024

BIOS Version Shows BIOS version, e.g. V0.40 ss.ss-hh.hh

Run Time Shows the accumul ated running time of the backlight since last

Extended Submenu

Menu Option Description

DOS Test or Graphics

Direct Access 1 Turn on direct access table 1.

Direct Access 2 Turn on direct access table 2.

Language Select OSD language

Direct Access 1 & 2 Submenu

Menu Option Description

Brightness Define hot keys as brightness level increase/decrease (default):

Contrast Define hot keys as contrast level increase/decrease (default):

The direct access table 1 and 2 allow the user to define the function of the two sets of adjustment

buttons on the front of the monitor when the OSD is not in use. These sets of buttons (⇑, ⇓ and

⇐, ⇒) are “hot keys” that allow immediate adjustment without needing to access the OSD. Table

1 assigns functions for the ⇑ and ⇓ buttons and table 2 assigns functions to the ⇐ and ⇒ buttons.

Language Submenu

Menu Option Description

English Select English display.

Italiano Select Italian display.

Francais Select French display.

Espanol Select Spanish display.

Svenska Select Swedish display.

Nederland Select Dutch display.

Deutsche Select German display.

Press ←or → (- >>>>>>>>>>>>>>> + nn), range: 0 to 62

Press ←or → (- >>>>>>>>>>>>>>> + nn), range: 0 to 60

Press ←or → (- >>>>>>>>>>>>>>> + nn), range: 0 to 3

Press ←or → (10/20/30/45/60 / c ont ) sec

Set menu auto save: Off / On

reset (nn Hrs nn Min):

Press → for 5 seconds to reset counter.

Press ←or → (Text/Graphics)

Pressing → turns on table 1.

Pressing → turns on table 2.

Pressing → turns on the submenu in English

Pressing ⇒ assigns this function to the hot key set.

Pressing ⇒ assigns this function to the hot key set.

10 142027(G)

Installing the Touch Screen Driver

If your

Pro-face/Xycom flat panel monitor has the touch screen option, you will have to load the correct

touch screen driver on the computer to which you will be connecting the monitor. The following

steps should be performed on that computer.

Note: The following instructions assume that a web browser is installed on

1. Insert the Pro-face Documentation and Support Library CD into the CD-ROM

drive.

2. If the Doc CD autostarts, proceed to the next step. If the Doc CD does not autostart, open the

CD in Windows Explorer and double click on the file “index.html.”

3. Choose “Flat Panel Monitors” from the links at the top of the home page and then choose the

appropriate monitor model on the next page. From the resulting page, you can download the

User Manual and/or the touch screen driver.

4. Click on the link to “elo.zip” (the drivers for all of the operating systems are in this file).

Type a destination folder to save the file in and press the “Save” button. The download will

be very short.

5. Using Windows Explorer, go to the downloaded file and extract the compressed files into a

folder of your choosing.

6. Go to the folder “Elo\Serial Controller” and then to the folder for your operating system.

• If you are installing the DOS driver, click on “install.exe” and follow the

instructions.

• If you are installing one of the Windows drivers, click on “setup.exe” and

follow the instructions.

If your computer doesn’t have a web browser, open the CD in Windows Explorer and choose the

“ELO.zip” file from the folder:

DRIVERS/Touchscreen

Copy it to a folder on your computer and follow steps 5 & 6 above.

the computer.

11 142027(G)

4. Hardware

VGA Input Connector Pin Out

Signal Name 15-pin D-Shell (Female)

Red 1

Green 2

Blue 3

GND-Digital 5

GND-Red return 6

GND-Green return 7

GND-Blue return 8

GND-Digital 10

11

12

Hsync 13

Vsync 14

15

Back Light Replacement Procedure

After 50,000 hours of use, the two lamps used for LCD back lighting may become dim or

burn out. You may return the monitor to

new lamps and follow the procedure below to install them. You can perform the lamp

replacement procedure without removing the monitor from the NEMA enclosure where it

is mounted, but you should do this only in a clean environment. Otherwise, the procedure

is better performed at a service bench.

1. TURN THE MONITOR POWER OFF AND DISCONNECT THE LINE CORD

4

9

Pro-face for lamp replacement or you can order

2. Loosen the four thumbscrews that hold the back of the monitor on.

3. Separate the two halves of the monitor. If the unit is equipped with a touchscreen,

you will have to disconnect its cable.

4. The lamps are mounted in small plastic carriers that slide in the right side of the LCD

display at the top and bottom edges.

5. Note their orientation and then unplug the two sets of lamp wires (3" pink and white

silicone wires) from the nearby inverter.

6. Look in the hole where the lamp is presently installed and note the small black

locking tab on the front side of each hole. With a small slotted screwdriver, depress

the tab while carefully pulling on the wires and slide the lamps outward. Discard the

old lamps.

7. Carefully slide the new lamps fully into place noting the top lamp has a small triangle

molded in the end where the wires protrude. Similar triangles a stamped in the LCD

sheet metal near the top hole.

12 142027(G)

8. Reconnect the lamp wires to the inverter. These are keyed connectors permitting

insertion in only one orientation.

You may now want to clean the LCD and the inside of the monitor window or

9.

touchscreen with a slightly damp soft cloth.

Carefully reunite the two monitor halves remembering to reconnect the touchscreen

10.

cable if the unit is so equipped.

The lamp replacement procedure is now complete.

11.

13 142027(G)

Appendix A – Technical Support

Reaching Technical Support

Pro-face Technical Support offers a variety of support options to answer any

questions on

Refer to the relevant chapter(s) in your documentation for a possible solution to any

problem you may have with your system. If you find it necessary to contact Technical

Support for assistance, please have the following information at your fingertips:

1. Serial number and model number.

2. The operating system type and version (i.e., Microsoft Windows NT version 4.0).

3. Exact wording of system error messages encountered.

4. Any relevant output listing from the Microsoft Diagnostic utility (MSD) or other

diagnostic applications.

5. Details of attempts made to rectify the problem(s) and results.

6. The log number assigned from

ongoing problem.

7. The name of the Technical Support Engineer with whom you last spoke, if known.

Internet Access

Pro-face provides both World Wide Web and e-mail access via the Internet.

To access the

contains the newest product datasheets, references by industrial sector, and application

notes.

Email

Pro-face products and their implementation.

Pro-face Technical Support if this is an

Pro-face Home Page, use http://www.profaceamerica.com. This page

To reach

Phone

You can reach

Fax

You can fax your questions to

Pro-face Technical Support via email: support@profaceamerica.com

Pro-face Technical Support via phone: 734/429-4971

Pro-face Technical Support at: 734/429-1010

14 142027(G)

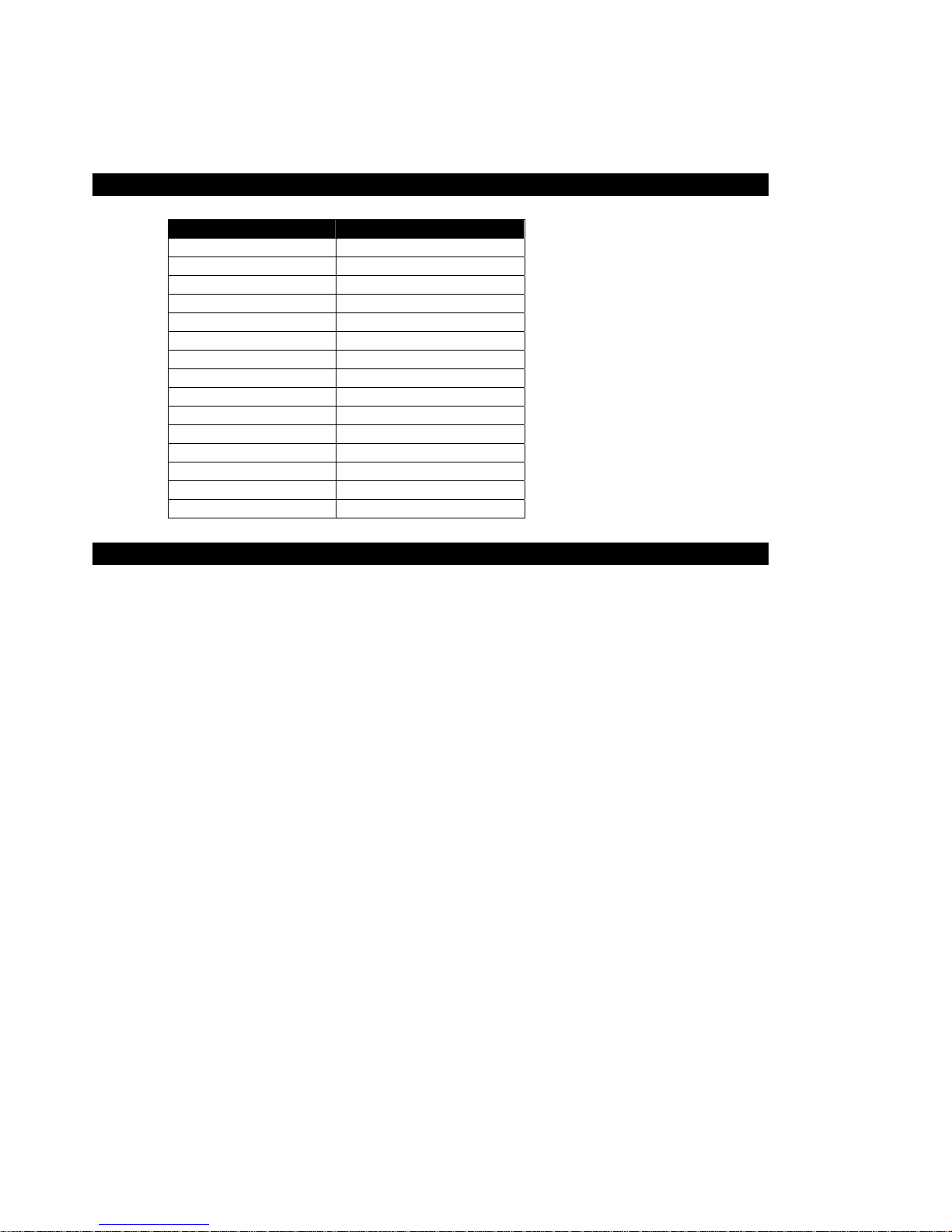

Appendix B – Dimensions/Weight

XT1500-ENC

FRONT AND BOTTOM VIEW

FRONT PANEL

CONTROLS DISABLE

13.50"[342.90 ]

mm

SECTION

A-A

REAR AND SIDE VIEW

9.72

6.77

SECTION

B-B

10-32

6 PLACES

I

11.17

8.22

5.26

O

3.15

POWER

ENTRY

1.39

2.93

A

A

4.84

11.64

WEIGHT: 19 lbs.

15 142027(G)

B

VGA

TOUCH

B

Xycom Automation, LLC. 734-429-4971 • Fax: 734-429-1010

142027(G)

750 North Maple Drive

http://www.profaceamerica.com

Saline, MI 48176

Loading...

Loading...