3500 3-Slot Manual

3510T/3510KP(T), 3512T/3512KP(T), 3535T/3535KPM(T) Flat-Panel Industrial PCs

2002 XYCOM AUTOMATION, INC. Printed in the United States of America

Revision Record

Revision Description Date

A Manual Released 5/99

B Updated Specifications 7/99

C Updated Bulb Replacement/CD-ROM Floppy addition 5/01

D Addition of 3535 Flat Panel Monitor PC 3/02

E Touchscreen Updates 7/02

Part Number 350003(E)

Trademark Information

Brand or product names are registered trademarks of their respective owners.

Windows is a registered trademark of Microsoft Corp. in the United States and other countries.

Copyright Information

This document is copyrighted by Xycom Automation Incorporated (Xycom Automation) and shall not be reproduced

or copied without expressed written authorization from Xycom Automation.

The information contained within this document is subject to change without notice. Xycom Automation does not

guarantee the accuracy of the information.

United States FCC Part 15, Subpart B, Class A EMI Compliance Statement:

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

For European Users - WARNING:

This is a Class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

INSTALLATION: Electromagnetic Compatibility WARNING:

The connection of non-shielded equipment interface cables to this equipment will invalidate FCC EMI and European

Union EMC compliance and may result in electromagnetic interference and/or susceptibility levels which are in

violation of regulations applying to the legal operation of this device. It is the responsibility of the system integrator

and/or user to apply the following directions relating to installation and configuration:

All interface cables must include shielded cables. Braid/foil type shields are recommended. Communication cable

connectors must be metal, ideally zinc die-cast backshell types, and provide 360 degree protection about the

interface wires. The cable shield braid must be terminated directly to the metal connector shell, ground drain wires

alone are not adequate.

Protective measures for power and interface cables as described within this manual must be applied. Do not leave

cables connected to unused interfaces or disconnected at one end. Changes or modifications to this device not

expressly approved by the manufacturer could void the user’s authority to operate the equipment.

EMC compliance is, in part, a function of PCB design. Third party add-on AT/XT peripheral PCB assemblies installed

within this apparatus may void EMC compliance. FCC/CE compliant PCB assemblies should always be used where

possible. XYCOM AUTOMATION can accept no responsibility for the EMC performance of this apparatus after

system integrator/user installation of PCB assemblies not manufactured and/or expressly tested and approved for

compliance by XYCOM AUTOMATION. It is the responsibility of the system integrator/user to ensure that installation

and operation of such devices does not void EMC compliance.

3

Table of Contents

CHAPTER 1 - INTRODUCTION..............................................................................................................................9

P

RODUCT OVERVIEW..................................................................................................................................................9

Standard Features.................................................................................................................................................9

Optional Features (All Units)..............................................................................................................................11

U

NPACKING THE SYSTEM .........................................................................................................................................11

Q

UICK START-UP......................................................................................................................................................12

CHAPTER 2 - TESTING..........................................................................................................................................13

P

REPARING FOR THE TESTS ......................................................................................................................................13

R

UNNING THE TESTS ................................................................................................................................................15

CHAPTER 3 – INSTALLATION............................................................................................................................17

F

RONT PANEL...........................................................................................................................................................17

3510T/12T Front Panel.......................................................................................................................................17

3510KP/3512KP and 3510KPT/3512KPT Front Panel......................................................................................19

3535T Front Panel ..............................................................................................................................................21

3535KPM(T) Front Panel....................................................................................................................................22

I/O Panel 3510/1512 ...........................................................................................................................................23

I/O Panel 3535 ....................................................................................................................................................23

Back Panel...........................................................................................................................................................25

Power Panel ........................................................................................................................................................27

Preparing the System...........................................................................................................................................27

I

NSTALLING INTERNAL HARDWARE OPTIONS ...........................................................................................................28

DRAM and Additional DRAM Single In-line Memory Modules (SIMMs)...........................................................28

PC/AT and PCI Boards.......................................................................................................................................28

I

NSTALLING EXTERNAL HARDWARE OPTIONS ..........................................................................................................29

9000-EXF External Floppy Drive .......................................................................................................................29

9000-FFK External Front Floppy and Keyboard Access Kit..............................................................................29

9000-CDK External Front Access CD-ROM and Keyboard Kit.........................................................................31

C

USTOM LOGO .........................................................................................................................................................34

C

REATING CUSTOM KEYPAD INSERTS (FOR 3510/3512KP UNITS)...........................................................................35

R

EINSTALLING OPERATING SYSTEMS .......................................................................................................................39

MS-DOS

Windows

Windows

Windows NT

Windows

I

NSTALLING DRIVERS ...............................................................................................................................................41

reinstallation.....................................................................................................................................39

95 reinstallation................................................................................................................................40

98 reinstallation................................................................................................................................40

reinstallation...............................................................................................................................40

2000 reinstallation............................................................................................................................41

Ethernet Drivers..................................................................................................................................................41

Video Expansion..................................................................................................................................................42

Touchscreen Drivers............................................................................................................................................44

Miscellaneous Drivers.........................................................................................................................................44

U

SING A TOUCHSCREEN ........................................................................................................................................... 45

Calibrating the Touchscreen ...............................................................................................................................47

I

NSTALLING THE SYSTEM INTO A PANEL ...................................................................................................................48

Mounting Considerations....................................................................................................................................48

S

YSTEM POWER........................................................................................................................................................49

E

XCESSIVE HEAT......................................................................................................................................................49

E

LECTRICAL NOISE...................................................................................................................................................49

L

INE VOLTAGE VARIATION.......................................................................................................................................51

C

REATING A POWER CABLE......................................................................................................................................51

AC Power Cable..................................................................................................................................................51

DC Power Cable..................................................................................................................................................52

5

3500 Flat Panel Industrial PCs

OUNTING THE UNIT ...............................................................................................................................................53

M

System Cutout Dimensions .................................................................................................................................. 54

P

OWER SUPPLY ............................................................................................................................... .........................56

H

AZARDOUS LOCATIONS INSTALLATIONS ................................................................................................................ 57

S

AFETY AGENCY APPROVAL ....................................................................................................................................57

Definitions ...........................................................................................................................................................59

Class I Locations.................................................................................................................................................59

Class II Locations................................................................................................................................................59

Division 1 Locations............................................................................................................................................59

Division 2 Locations............................................................................................................................................60

Hazardous Locations Group Ratings..................................................................................................................60

E

NCLOSURES ............................................................................................................................................................60

P

OWER SWITCH ........................................................................................................................................................61

C

ABLE CONNECTIONS...............................................................................................................................................61

Communication Cable Interface..........................................................................................................................61

O

PERATION AND MAINTENANCE ..............................................................................................................................62

CHAPTER 4 - KEYPAD UTILITY FOR 3510KP/3512KPM...............................................................................63

L

OADING THE KEYPAD UTILITY................................................................................................................................63

U

SING THE KEYPAD UTILITY....................................................................................................................................63

CHAPTER 5 - KEYPAD UTILITY FOR THE 3535 KPM...................................................................................7 3

CHAPTER 6 - MAINTENANCE.............................................................................................................................81

P

REVENTIVE MAINTENANCE ....................................................................................................................................81

M

AINTENANCE .........................................................................................................................................................82

Fuse Replacement................................................................................................................................................82

Fan Filter Replacement.......................................................................................................................................82

C

HEMICAL COMPATIBILITY.......................................................................................................................................83

Compatible Lubricants........................................................................................................................................84

Compatible Cleaning Agents...............................................................................................................................85

Non-compatible Cleaning Agents........................................................................................................................86

3510/3512/3510KP/3512KP/3535KPM/3535T S

P

RODUCT REPAIR PROGRAM/RETURNING A UNIT TO XYCOM AUTOMATION............................................................87

PARE PARTS LIST ........................................................................86

APPENDIX A – TECHNICAL SPECIFICATIONS..............................................................................................89

H

ARDWARE SPECIFICATIONS ....................................................................................................................................89

APPENDIX B - BLOCK DIAGRAM .....................................................................................................................91

APPENDIX C - PINOUTS.......................................................................................................................................93

KEYBOARD PORT CONNECTORS...............................................................................................................................93

A

UX PORT CONNECTOR............................................................................................................................................93

D

UAL USB CONNECTOR (USB1).............................................................................................................................94

P

ARALLEL PORT CONNECTOR (LPT1)......................................................................................................................94

S

ERIAL PORT CONNECTORS......................................................................................................................................94

COM1......................................................................................................................................................................95

COM2......................................................................................................................................................................95

VGA C

E

ONNECTOR....................................................................................................................................................96

XTERNAL FLOPPY CONNECTOR ..............................................................................................................................96

APPENDIX D – REPLACING FLAT PANEL DISPLAY BULBS.......................................................................97

3510 U

NITS ..............................................................................................................................................................97

Mitsubishi TFT Flat panel Display (model #AA104VB02)..................................................................................97

3512

AND 3512 KP UNITS........................................................................................................................................99

6

Table of Contents

Mitsubishi TFT Flat panel Display (Model #AA121SK12) .................................................................................99

I

NDEX.....................................................................................................................................................................103

7

Chapter 1 - Introduction

Product Overview

The 3500 series Flat-Panel Industrial Computers combine an Intel Celeron or

Pentium III processor with a flat-panel display to offer a powerful, compact

package for the factory floor and other harsh environments. The PC features an open

architecture to meet a wide variety of applications that require both a powerful PC

and a durable industrial enclosure.

The 3500 systems include:

• A three-slot ISA/PCI backplane which accommodates ¾ length expansion cards

• Flat panel displays

• 3510 – 10.4” – 640x480 VGA (TFT)

• 3512 – 12.1” – 800x600 SVGA (TFT)

Chapter One - Introduction

• 3535 – 15” – 1024x768 XGA (TFT)

• Touchscreen versions 3510T/3512T/3535T

• Keypad version (3510KP/3512KP/3535KPM)

• Keypad and touchscreen units (3510KPT/3512KPT/3535KPMT)

• Hard disk drive facilities

The front panel of the unit is sealed to NEMA 4/4X/12 and IP65 standards, and is

protected by an impact-resistant shield.

The system’s modular design allows easy access to expansion boards, switches,

power supply, flat-panel display, and disk drives.

Standard Features

The 3500 3-slot series ships standard with the following:

• Intel Celeron or Pentium III processor

• Up to 512 MB DRAM

• 10 GB hard drive

• 2 Serial ports

• 1 RS-232 or RS-485 port

• 1 Dedicated RS-232

• Reprogrammable keypad or analog resistive touchscreen, or both for operator input

• Two USB ports

9

3500 Flat Panel Industrial PCs

• IP65 standard

• UL listed for hazardous locations: Class I, Division 2

• Power supply

• MS-DOS operating system

• Flash BIOS

• 5.75” mounting depth (6.5” with external floppy option, 7.16” with external CD-

ROM/floppy drive option)

• External floppy connector

• Flat-panel display

• 10.4” TFT (640x480) (3510)

• 12.1” TFT (800x600) (3512)

• Three AT bus ¾ length expansion slots

• One ISA slots

• One PCI slot

• One ISA/PCI slot

• IR Port (IrDA, HPSIR, AND ASKIR compatible)

• Rear PS/2 keyboard port and mouse port (also front PS/2 keyboard port on 3510KP

and 3512KP)

• Keypads (3510KP/3512KP)

• 32 relegendable function keys (64 with the F/A function)

• Keypad (3535KPM)

• 74-position keypad and industrial mouse (touchscreen option)

• 40 relegendable keys (80 with F/A key)

• Status LEDs

• Power

• Disk

• Com

• Input

• External floppy and CD-ROM option, side access

• MS-DOS

Windows 95, Windows 98, Windows NT or Windows 2000

• Front panel sealed to meet NEMA 4/4X/12 and IP65 specifications when panel

mounted

• Status LEDs

10

• Power

• Disk

• Com

• Input

Optional Features (All Units)

Following are optional available features:

• Faster processor speeds

• Touchscreen-resistive technology with less than 1.5% linearity error

• Preinstalled Windows 95, Windows 98, Windows 2000 or Windows NT

• 9000-EXF, hot installable external floppy drive

• 9000-RF1 19-inch Rack Mount Adapter Plate (3510, 3512)

• 9000-FFK, NEMA 4 Front Floppy Kit

Chapter One - Introduction

• 9000-RFC 19-inch Floppy Door Plate

• 2005-RMA 19 inch Rack Mount Adapter Plate (3510KP, 3512KP)

• 9000-CDK, NEMA 4 front Access CD-ROM and keyboard kit

Unpacking the System

When you remove the system from its box, verify that you have the parts listed

below. Save the box and inner wrapping in the event you need to reship the unit.

• 3510T/3512T/3535T or Keypad version

• Documentation kit, which includes:

• Power connector

• Diagnostic software diskette

• 14 10-32 hex nuts (2 spares)

• Clip-on Ferrite for mouse cables

• Cable clamp and screw (for strain relief of power cord)

• 3510/3512/3535 manual

• CPU manual (CD-ROM)

• Utility diskettes

If you ordered the system with a touchscreen installed, you will also receive a

touchscreen driver diskette and a documentation CD that includes the manual.

11

3500 Flat Panel Industrial PCs

Quick Start-up

This section gives you the steps to get the system up and running without explaining

the capabilities and options.

Turn off power to the unit and disconnect the power cord before making any

adjustments to the inside or outside of the computer.

To prepare the system for use, perform the following steps.

1. Attach optional keyboard to the keyboard port.

2. Attach other optional equipment following the instructions in Chapter 3.

3. Attach the power cord from the power receptacle to a properly grounded 115/230

VAC, 50-60 Hz outlet, or 24 VDC outlet, whichever applies. (See Chapter 3,

Creating a Power Cable.)

4. Turn on the power to the unit. The system will boot up into the operating system.

Warning

5. Install application software via the external floppy, the network, or the IR port.

12

Chapter 2 - Testing

On units with MS-DOS, Xycom Automation provides diagnostic tests to verify the

operation of the system hardware functions. If any of these tests fail, either you do

not have the correct default setting or there is a failure. Check the default settings

and run the tests again. If another failure occurs, contact Xycom Automation’s

Product Repair & Customization Department (see Chapter 5).

Remove device drivers and memory resident programs (TSRs) that are installed on the

system before running Xycom diagnostics. If this step is not completed unexpected

failures may occur.

Make sure the BIOS setup menus are configured properly (factory-set configuration).

To enter the BIOS setup menus:

• Press

• Make the necessary changes by following directions on the screen.

• Press ESC

• Press ENTER twice to save the settings and exit.

Refer to the CPU manual for more information on the Setup Menu.

F2 after the POST RAM test has completed.

.

Chapter Two - Testing

Note

Preparing for the Tests

To test your system, you need the following equipment:

• Floppy disk drive

• IBM PC/AT or PS/2-compatible

• Xycom System Test Disk 3.5 inch, DS/DD disk (bootable), Xycom part number

99290-001

• Centronics-compatible printer cable

• Parallel printer (Centronics-style interface)

• Two serial loopback test connectors (refer to Figure 2- 1 for pinouts)

• Formatted 3.5-inch, DS/HD (1.44 Mbyte) disk

13

3500 Flat Panel Industrial PCs

Perform the following steps before starting the system tests:

1. Place the CPU board jumpers and switches to the factory set positions. Refer to

the CPU manual for these settings.

2. Plug the female end of the AC power cable into the side of the unit and the male

end into a properly grounded outlet.

3. Connect the serial loopback connector(s) and the printer cable to the appropriate

connectors, and connect a PC/AT or PS/2 keyboard. Figure 2-1, Serial Loopback

Connections, illustrates the wiring necessary for the loopback connection.

4. Default the CMOS setup to the factory settings.

14

Figure 2- 1. Serial Loopback Connections

Running the Tests

To run the test, insert the diagnostics disk into drive A. Turn on the computer (the

diagnostics program will boot-up). Figure 2- 2 shows the Main Menu.

Chapter Two - Testing

Copyright 1990-1998, Xycom, Inc. All rights reserved.

Diagnostic Tests Sequence/Selection Menu (Rel. xx)

1. WILL pause on error

2. SINGLE PASS test mode

3. Save setup to file

4. Extract setup from a file

A) RAM Test

B) Video RAM Test

C) Extended RAM Test

D) Real Time Clock Test

E) COM1 Serial Port Test

F) COM2 Serial Port Test

G) COM3 Serial Port Test

H) COM4 Serial Port Test

I) Math Coprocessor Test

J) Video Adjustments Test

[ENTER]=START TESTING

Use the letters to move the cursor and select/deselect, or use the arrow keys to move,

then use the [SPACE] key to select/deselect a test or function.

Figure 2- 2. Main Menu

5. Auto-select tests

6. Deselect all tests

7. Quit and exit to DOS

8. Return to previous screen

K) Video Interface Test

L) Speaker Port Test

M) LPT1: Printer Port Test

N) LPT2: Printer Port Test

O) C: Hard Drive Interface Test

P) D: Hard Drive Interface Test

Q) A: Floppy Drive Interface Test

R) B: Floppy Drive Interface Test

S) Keyboard, Keypad Tests

≡ = Test Selected

Note

Please read the DIAG.TXT file on the diagnostics disk for detailed information about

the tests.

Note

Avoid repeated running of any hard disk diagnostic utility if you use the Solid State

(Flash) drive option. The Flash drive has a limited number of writes to each logical

sector. Repeated writes from a diagnostic utility will prematurely shorten the life of the

drive.

15

Chapter 3 – Installation

This chapter illustrates the installation of, and the options for, the 3500. The figures

on the next several pages show the internal and external components on the front and

back panels of the unit to help you locate features relevant to installation.

Front Panel

The 3500 series has a NEMA 4/4X/12 and IP65 sealed front panel. The panel

protects the system’s interior when the system is properly panel mounted.

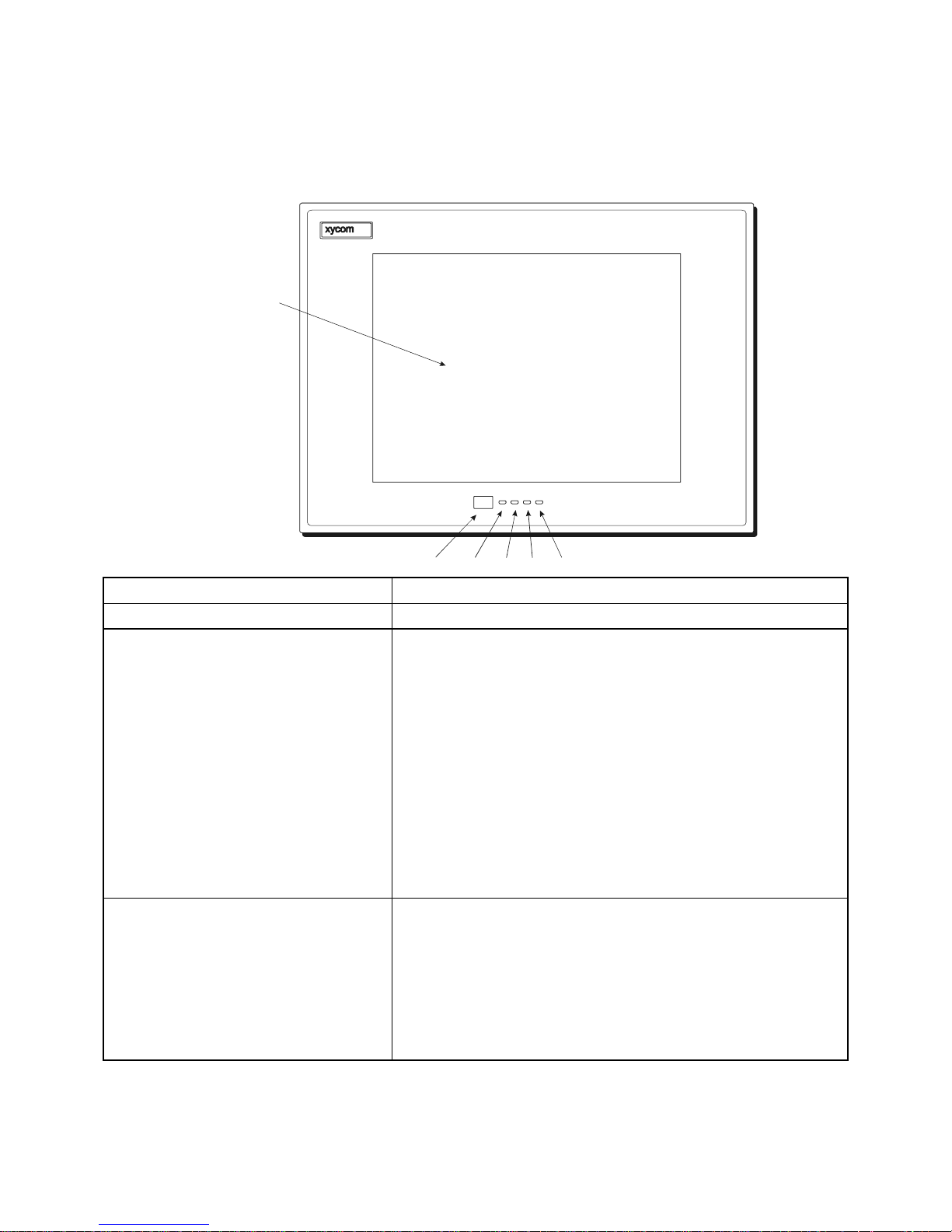

3510T/12T Front Panel

Chapter Three - Installation

Figure 3-1. 3510T/3512T Front Panel

17

3500 Flat Panel Industrial PCs

Feature Description

Display The 3510 has a 10.4-inch TFT Active Matrix Color LCD flat panel. Impact-

resistant shield protects the display from breakage. The 3512 has a 12.1”

TFT Active Matrix Color LCD flat panel. An impact-resistant shield

protects the display from breakage. If a touchscreen is factory installed, it

is backed by heat-annealed safety glass replacing the impact-resistant

shield.

Diagnostic LEDs Following is a description of the LEDs and what it means when they're lit:

Power Lit when the system has power

Disk Lit when the computer is accessing the disk drive

COM Lit when there is communication activity on one of the serial

ports, including communication between the computer module

and the touchscreen (if on COM2) or a serial mouse.

Input Lit when the unit has a touchscreen (LED gets brighter when a

touch input is detected) or a key is pressed

During power-up, firmware on the processor board checks the hardware

configuration against the configuration stored in the CMOS memory.

IR (Infrared) The IR port transceiver is located behind this window. The IR port is IrDA

and ASKIR compliant. Connect the unit to any IrDA compatible device.

Load special software (not included) to use this feature. The infrared (IR)

link is designed to operate at a distance of 0 to 1 meter. Enable the

interface through the BIOS setup menu. Note: When the IR port is

chosen in the system BIOS, COM2 is not available.

Keyboard Port Access

(Optional front access)

The 3510/3512 supports one PS/2 keyboard. Front access options are

available with the use of the 9000-FKA Front floppy/keyboard access kit

(not shown). The access is a PS/2 stacked mini-din located on the side of

the unit. Warning: To maintain safe conditions, do not use an external

keyboard and/or mouse port when the unit is operating in a hazardous

environment.

Floppy Disk Drive (Optional) The 3510/3512 has front access options available. (Refer to the External

Floppy Option section within this chapter.)

18

Chapter Three - Installation

3510KP/3512KP and 3510KPT/3512KPT Front Panel

The 3510KP and 3512KP have NEMA/4/4X/12 sealed front panels. The panel

protects the system’s interior when the system is properly panel mounted. Figure 3-2

illustrates the front panel with keypad.

Figure 3-2. 3510KP/12KP Front Panel

Feature Description

Display The 3510KP/3512KP has a 10.4-inch (640 x 420) TFT flat panel

display or a 12.1-inch SVGA (800 x 600) TFT flat panel display.

Diagnostic LEDs The 3510KP/3512KP features status LEDs on the front panel,

which allows monitoring of the system operation. Following is a

description of the LEDs and what it means when they're lit:

Power Lit when the system has power

Disk Lit when the computer is accessing the disk drive

COM Lit when there is communication activity on one of

the serial ports, including communication between

the computer module and the touchscreen (if on

COM2) or a serial mouse.

Input Lit when the unit has a touchscreen; the LED gets

brighter when a touch input is detected or a key is

pressed.

F/A key Indicates the keypads are in alpha mode

Function and User-Defined Keys These 32 relegendable function keys (64 using the F/A keys)

provide easy access to familiar routines. (F/A keys can be used

for alpha and symbol entry). See the Customizing Keypad

Inserts section in this chapter for details on customizing your

keypad inserts.

Numeric/Cursor Control Keypad Use the data entry keypad to enter data and move the cursor.

19

3500 Flat Panel Industrial PCs

Feature Description

PF10 Key (Keypad Configuration Key) This key reconfigures your keypad.

Keyboard Port (3510KP/3512KP)

(front access)

The 3510KP/3512KP provides both front and rear accessible

PS/2 keyboard connectors. The front accessible connector is

located on the lower right side of the front panel. The rear

accessible connector is located on the side of the unit.

Note: Only one keyboard port on the 3510/3512KP can be used

at a time.

Note: The installation of the touchscreen driver determines

whether a second pointing device will function correctly. If using

a mouse with a touchscreen, please review the Touchscreen

Driver Installation instructions.

20

3535T Front Panel

TOUCH

SCREEN

(OPT IONAL )

IR PORT

Chapter Three - Installation

POWER DISK COM INPUT

IR PORT POWER DISK

COM

INPUT

Feature Description

Display The 3535T has a 15-inch (1024 x 768) XGA flat panel display.

Diagnostics LED The 3535T features four status LEDs on the front panel, which

you can use to monitor system operation.

Power There is power to the 3535.

Disk The computer module is accessing the disk drive.

COM There is communication activity on one of the

computer module’s serial ports, including

communication between the computer module and the

touchscreen (if on COM2) or a serial device.

Input The unit has a touchscreen and the LED gets brighter

when touch input is detected.

During power-up, firmware on the processor board checks the

hardware configuration against the configuration stored in the

CMOS memory.

IR (Infrared) The IR port transceiver is loc ated behind this window. The

3535 IR port is IrDA, and ASK-IR compliant. You can connec t

the 3535 to any IrDA compatible device, if you load special

software (not included). The infr ar ed (IR) link oper ates at a

distance of 0 to 1 meter and is capable of 115 Kbaud transfer

rates. Enable the interface through the BIOS setup menus.

Note: When the IR port is chosen, COM2 is not available.

Correspondingly, if COM2 is in use by the touchscreen the IR is not

operational.

21

3500 Flat Panel Industrial PCs

3535KPM(T) Front Panel

Flat Panel Display

Programmable

Fun cti on K eys

Configuration

Key

Keyboar d Input

Funct ion Keys

IR DA PORT

Industrial Mouse

Programmable

Funct i on Keys

F/A Key

Windows Keys

Numeric Keypad

Cursor Control

System

Status LED

(Power)

System

Statu s LE D

(Input)

COM

DISK

Feature Description

Display The 3535KPM(T) TFT flat panel impact-resistant shield protects the display from

breakage. If a touchscreen is factory installed, the touchscreen is backed by heatannealed safety glass replacing the impact-resistant shield.

System Status LEDs The 3535 features four status LEDs on the front panel, which you can use to

monitor system operation.

Power There is power to the 3535.

Disk The computer module is accessing the disk drive.

COM There is communication activity on one of the computer module’s serial

ports, including communication between the computer module and the

touchscreen (if on COM2) or a serial device.

Input The unit has a touchscreen and the LED gets brighter when touch input

is detected.

During power-up, firmware on the processor board checks the hardware

configuration against the configuration stored in the CMOS memory.

IR (Infrared) The IR port transceiver is loc ated behind this window. The 3535 IR por t is Ir DA,

and ASK-IR compliant. You can connect the 3515 to any IrDA compatible

device, if you load special software (not included). T he inf r ared ( IR) link

operates at a distance of 0 to 1 m eter and is c apable of 115 Kbaud trans f er

rates. Enable the interface through the BIOS setup menus.

port is chosen, COM2 is not available. Correspondingly, if COM2 is in use by the

touchscreen the IR is not operational.

Note: When the IR

22

I/O Panel 3510/1512

(3)

)

EXPANSION SLOTS (3)

LID

ETHERNET

PORT

LID

REMOVAL

SCREW (2)

MOUNTING

STUD (12)

COM 2

RS-232

COM 1

RS-485

Chapter Three - Installation

MOUSE

VIDEO

FRONT PANEL

I/O Panel 3535

EXPANSION SLOTS

LID

ETHERNET

PORT

LID

REMOVAL

SCREW (2)

MOUNTING

STUD (12)

PARALLEL RS-232

KEYBD

Figure 3-3. System I/O 3510/1512Panel

COM 2

RS-232

COM 1

RS-485

MOUSE

USB PORT (2 )

VIDEO

FRONT PANEL

PARALLEL

RS-232

KEYBD

Figure 3-4 System 3535 I/O Panel

USB PORT (2

23

3500 Flat Panel Industrial PCs

Feature Description

Parallel Port The parallel printer port (LPT1) is a DB-25 pin female connector. This port provides a

standard PC compatible printer interface. An external push-button reset option is

available. Consult the CPU board manual for the jumper that controls this option.

COM Ports COM1 is RS-232/485 compatible. RS/232 is connected to the lower nine-pin stacked

DB connector. The top part of this stack is the RS/485 version of the same port. Since

these connectors are attached to the same port, only one can be used at a time. COM2

is the male 25-pin DB connector. COM2 is dedicated to the IR port, the touchscreen

controller, or the 25-pin connector. Only one option can be used at a time.

Note: If you ordered Windows NT

, the driver is on disk and a copy of the driver file is

on the hard drive. This operating system only supports COM2. Therefore, the

touchscreen will be on COM2, and COM2 will not be available for other use.

Keyboard Port The keyboard port is a PS/2 stacked mini-din so a PC/AT keyboard can be attached at

either the front or side of the unit. The keyboard port on the side of the unit is the lower

connector. Do not use when in the presence of a hazardous environment. Note: You

cannot use both keyboard ports on the 3535 at the same time.

Mouse Port The mouse port is a PS/2 stacked mini-din that allows you to attach a mouse at the

side of the unit. If you receive a unit with a touchscreen, this port may be covered with

a label stating that the port is not functional as shipped. This is dependent upon the

operating system installed.

Note: If the unit has a touchscreen and MS-DOS, Windows

3.x or Windows 95, the

touchscreen is configured for the mouse port, making the mouse port unavailable.

Reconfigure the touchscreen for use on COM2 to make mouse port functional.

Warning: To maintain a safe condition, do not use an external keyboard and/or

mouse port when the unit is operating in a hazardous environment.

Video Port The video port is a 15-pin D-sub VGA connector at the side of the unit. This connector

supports any standard VGA connection. The video port is shipped disabled. This port is

active if an LCD flat panel is not connected. A jumper can be used to switch between

the VGA port and the LCD flat panel. To use both a video display on the video port and

the flat panel display, you must enable “Simultaneous Video” on the Advanced Menu in

the BIOS setup. Refer to the CPU manual for details.

USB Universal Serial Bus (not available with AHIP4+ CPU)

Ethernet Port

This port provides a 10BASE-T/100BASE-TX autosensing Ethernet connection.

(optional)

24

Back Panel

A

Chapter Three - Installation

Figure 3-4. System Back Panel with Optional Removable Floppy Drive

OPTIONAL

FLOPPY

DRIVE

MOUNTING

STUD (12)

FRONT PANEL

BACK PANEL

SCREWS

SCREWS

FRONT PANEL

TTAC HMENT SCREWS

LID SCREWS

LID

FAN

FILTER

BACK PANEL

LID REMOVAL

Figure 3-5. System Back Panel with Optional Pre-installed Non-removable Floppy Drive

25

3500 Flat Panel Industrial PCs

CD-ROM/Floppy Drive Covers

Mounting Screw

Figure 3-6. System Back Panel with Optional Pre-installed Non-removable CD-ROM/Floppy Drive

CD-ROM/Floppy Drive

Mounting Screws ( 4)

Back Panel

Feature Description

Fasteners There are two protruding screws (lid removal screws) along the

top of the back panel. Loosen these screws to remove the lid.

There are four screws located across the top and bottom of the

back panel. Loosen these screws (using a Phillip-head

screwdriver) to remove the front panel.

Note: If your system has a touchscreen, disconnect the

touchscreen cable from the CPU board before removing the back

of the system from the front bezel.

Optional External Removable Floppy

Disk Drive

Optional Non-removable Floppy Disk

Drive

Optional Non-removable CDROM/Floppy Drive

You can install the optional 9000-EXF external floppy disk drive

to the back of the 3500.

You can order the 3500 with an optional non-removable floppy

disk drive on the back of the 3500.

You can order the 3500 with an optional CD-ROM/Floppy disk

drive mounted on the rear of the system.

26

Chapter Three - Installation

Power Panel

Figure 3-7. Bottom Panel with Power Connector and External Floppy Connector

Feature Description

Power Connector This is a three-pin connector. Refer to the special hazardous

location installation instructions later in this chapter.

External Floppy Drive Connector This is a 26-pin connector.

Product ID Label The product ID label is located on the bottom panel

Fan and Filter The filter can be replaced or removed for cleaning. See Chapter 5

for details on the fan filter assembly.

Preparing the System

Read this chapter first, comply with all the safety requirements, and then mount the

unit according to the following instructions.

1. Locate a position that meets the required specifications.

2. Create a panel cutout. The dimensions are given in this chapter.

3. Install optional equipment following the instructions in Installing Internal

Hardware Options and Installing External Hardware Options in this chapter.

4. Create a power cable. Refer to the Creating a Power Cable section in this

chapter.

5. Mount the system and properly secure the unit into the panel. See Installing the

System section in this chapter.

6. Attach one end of the power cord to the power receptacle and the other end to a

properly grounded 115/230 VAC, 50-60 Hz outlet or a 24 VDC outlet,

whichever applies (refer to the Hazardous Location Installations section later in

this chapter).

7. Turn on power to the system. The system will boot up to the operating system

installed.

8. Install the application software via a floppy drive.

27

3500 Flat Panel Industrial PCs

If a touchscreen is factory installed, along with MS-DOS, the mouse port is

unavailable. The unit will arrive with a sticker placed over the port. If you would like

to reconfigure the touchscreen to use the COM2 port, follow the instructions in the

Using a Touchscreen section in this chapter.

Installing Internal Hardware Options

Caution

Turn off the unit before installing internal hardware.

Warning

Installation of expansion boards may void safety and/or EMC compliance.

Remove the lid to install internal hardware options.

DRAM and Additional DRAM Single In-line Memory Modules

(SIMMs)

You can order the 3500 system CPU factory-configured for many configurations of

DRAM. You can reconfigure the DRAM capacity by changing the DRAM SIMMs

on your board. For more information refer to the CPU manual.

PC/AT and PCI Boards

1. Check that the memory and I/O configuration of the board you want to install

does not conflict with the CPU and I/O memory maps in your CPU board

manual.

2. Remove the lid.

3. Remove the ORB screw in the desired track.

4. Slide the PC/AT expansion board into a corresponding rail.

5. Push the board into the backplane connectors.

Do not force the boards or apply uneven pressure.

6. Secure the board by installing the screw through the hole in the board’s metal

ORB and into the top of the track.

Note

7. Replace the lid.

28

Installing External Hardware Options

This section explains how to install the external hardware options available with the

system.

Note

When using the external floppy drive, do NOT attach the drive with a diskette installed.

You may corrupt the disk.

9000-EXF External Floppy Drive

The external floppy (9000-EXF) can be mounted on the back of the unit. There are

four screw holes on the back of the unit for the floppy mounting. A fifth screw hole

is on the back for the cable clamp screw. See the Figures 3.4 and 3.7 of the back

panel and the bottom panel.

Front mounting options are also available.

Chapter Three - Installation

Note

Make sure the floppy drive cable will reach the external floppy connector on the system

before making the cutout.

9000-FFK External Front Floppy and Keyboard Access Kit

If you want to relocate the floppy drive to the front of the computer module, you

must install the 9000-FFK (Front Floppy Keyboard Access Kit), which includes a

front access keyboard port. The floppy drive access door is provided for installations

using the 9000-RFC Rack Filler Plate with Cutout, or panel mount installations that

provide a cutout for the front mounted floppy drive.

29

3500 Flat Panel Industrial PCs

Mount the floppy drive access door to the rack filler plate or the panel, using the four

mounting nuts, as shown in Figure 3.9. Torque the nuts to 35 in/lb. (3.95 NM).

Figure 3-8. Front Mounted Floppy Cutout Dimensions

The following figure shows an overhead view of the Front Floppy Kit (9000FFK)

with the floppy drive mounted.

30

Figure 3-9. 9000FFK - Front Mounting Option

Chapter Three - Installation

Figure 3-10. Floppy Drive - Front Mounting Option (top view)

9000-CDK External Front Access CD-ROM and Keyboard Kit

The 9000-CDK is a front access CD-ROM. This option (purchased separately)

connects to the parallel and keyboard ports on the 3500. The 9000-CDK assembly

functions as a parallel port CD-ROM while providing an additional parallel port for

printer use. The 9000-CDK includes a separate power supply that must be connected

for the CD-ROM to work. The supplied driver also needs to be installed on the 3500

unit for the CD-ROM to function. The 9000-EXF can be mounted in the 9000-CDK

(purchased separately) if front access floppy is desired. Refer to Figure 3-13 for

cutout dimensions.

31

3500 Flat Panel Industrial PCs

.26 (6.604)

4.20 (106.68)

DOOR KNOB

6.83 (173.482)

.180 DIA - .000 THRU

(6 PLACES)

CUTOUT

3.675 (93.345)

(2 PLACES)

7.350 (186.69)

(2 PLACES)

Figure 3-13. 9000-CDK - Cutout

4.800 (121.92)

(3 PLACES)

INCHES (mm)

9000-EXF

5.6 (142.24)

CD-ROM DRIVE

FRONT PANEL

Figure 3-14. 9000-CDK – Front Mounting Option (side view)

INCHES (mm)

32

3 (76.2)

2 (50.8)

9000-EXF

FLOPPY DRIVE MOUNT

10.2 (259.08)

FLOPPY DRIVE

MOUNTING SCREWS (4)

PANEL

MOUNTING STUD (6)

Chapter Three - Installation

DOOR KNOB

8.15 (207.01)

CD-ROM FRONT PANEL

INCHES (mm)

Figure 3-15. 9000-CDK Front Mounting Option – Top View

33

3500 Flat Panel Industrial PCs

e

Custom Logo

You have the option to place a custom label on the unit. Refer to Figure 3-13 for the

dimensions and recommended requirements for a customized label. Once a

customized label is procured, place the new label over the “Xycom Automation”

label (inside the recessed area).

0.55 (13.97)

0.06 (1.52)

(4 Places)

Your Logo On

Entire Surfac

2.05 (52.07)

NOTE: All dimensions are in inches (mm)

RECOMMENDED MATERIA L : 0.007 (0.176) thick

polyester with 3M #468 adhesive on far side

Figure 3-16. Logo Label Dimensions

34

Chapter Three - Installation

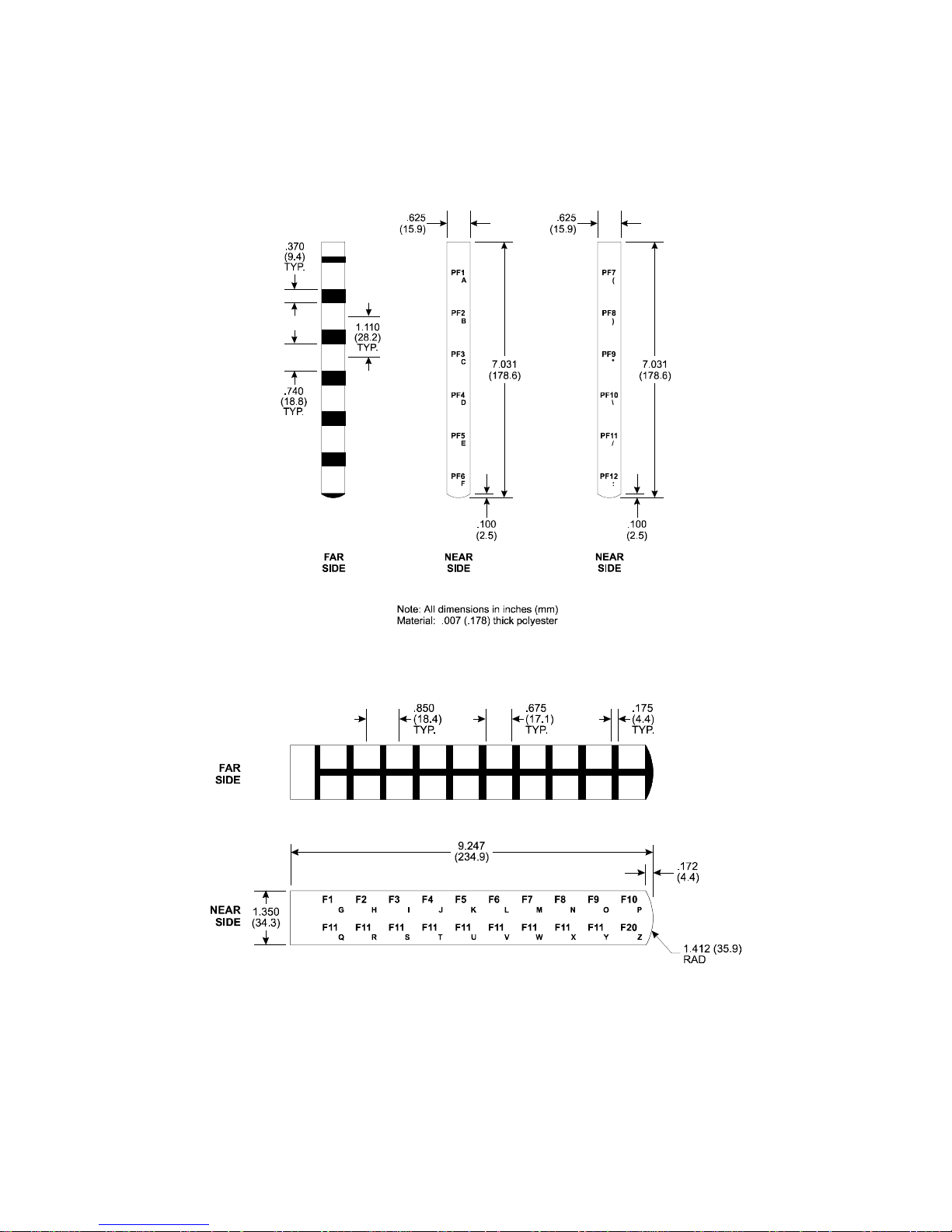

Creating Custom Keypad Inserts (for 3510/3512KP Units)

You can customize your keypad with keypad inserts. Refer to Figures 3-14, 3-15, and

3-16 for insert dimensions and installation.

Figure 3-17. 3510KP/3512KP Keypad Inserts with Dimensions (PF1 – PF12)

Figure 3-18. 3510KP/3512KP Insert with Dimensions (F1 - F20)

35

3500 Flat Panel Industrial PCs

Figure 3-19. 3510KP/3512KP Keypad Insert Position

Creating Custom Keypad Inserts (3535)

You can customize your keypad with keypad inserts. Refer to Figure 3-15 and Figure

3-16 for insert dimensions and installation.

36

Chapter Three - Installation

Figure 3-15. Keypad Inserts with Dimensions (PF1 - PF20)

37

3500 Flat Panel Industrial PCs

Figure 3-16. Keypad Insert with Dimensions (F1 - F20)

Figure 3-15 provides information on positioning keypad inserts.

38

Chapter Three - Installation

Figure 3-17. Keypad Insert Position

Reinstalling Operating Systems

The 3500 CPU ships with MS-DOS pre-installed. Optionally available, are

Microsoft Windows 95, Windows 98, Windows NT, and Windows 2000

operating systems. If you want to install a different operating system, refer to that

operating system’s manual for directions.

MS-DOS reinstallation

If you need to reinstall MS-DOS, refer to the Xycom Automation Workstation

Recovery Media Software Installation Instructions for Microsoft

(shipped with systems pre-installed with MS-DOS). This document is devoted to the

reinstallation of your MS-DOS operating system and drivers utilizing the Recovery

Media provided with your Xycom Automation industrial computer.

NOTE: This procedure assumes that the computer hard disk drive has been completely

corrupted or replaced.

WARNING: This procedure will destroy data that may exist on the hard disk drive.

DOS 6.22

39

3500 Flat Panel Industrial PCs

Windows 95 reinstallation

If you need to reinstall the Windows 95 operating system, refer to the Xycom

Automation Workstation Recovery Media Software Installation Instructions for

Microsoft

This document is devoted to the reinstallation of your Microsoft Windows 95

operating system and drivers utilizing the Recovery Media provided with your

Xycom Automation industrial computer.

NOTE: This procedure assumes that the computer hard disk drive has been completely

corrupted or replaced.

WARNING: This procedure will destroy data that may exist on the hard disk drive.

Windows 95 (shipped with systems preinstalled with Windows 95).

Windows 98 reinstallation

If you need to reinstall Windows 98 refer to the Xycom Automation Workstaion

Recovery Media Software Installation Instructions for Microsoft

(shipped with systems preinstalled with Windows 98). This document is devoted to

the reinstallation of your Windows Workstation operating system and drivers

utilizing the Recovery Media provided with your Xycom Automation industrial

computer.

Windows 98

NOTE: This procedure assumes that the computer hard disk drive has been completely

corrupted or replaced.

WARNING: This procedure will destroy data that may exist on the hard disk drive.

Windows NT reinstallation

If you need to reinstall Windows NT refer to the Recovery for Xycom Automation

Windows NT

This document is devoted to the reinstallation of your Windows NT Workstation

4.0 operating system and drivers utilizing the Recovery Media provided with your

Xycom Automation industrial computer.

NOTE: This procedure assumes that the computer hard disk drive has been completely

corrupted or replaced.

WARNING: This procedure will destroy data that may exist on the hard disk drive.

Note: If you need to reinstall the Windows NT or Windows 95 operating system, you

must have an internal CD-ROM drive or an external parallel port CD-ROM drive.

Windows NT ships only on a CD-ROM disk.

Workstation (shipped with systems preinstalled with Windows NT).

If you want to install a new operating system or re-install a current operating system,

refer to the operating system’s manual for directions.

40

Windows 2000 reinstallation

If you need to reinstall Windows 2000 refer to the Xycom Automation Workstation

Recovery Media Software Installation Instructions for Microsoft

(shipped with systems preinstalled with Windows2000). This document is devoted

to the reinstallation of your Windows2000 Workstation operating system and

drivers utilizing the Recovery Media provided with your Xycom Automation

industrial computer.

NOTE: This procedure assumes that the computer hard disk drive has been completely

corrupted or replaced.

WARNING: This procedure will destroy data that may exist on the hard disk drive.

Installing Drivers

This section describes how to install the drivers associated with the system.

Chapter Three - Installation

Windows 2000

Ethernet Drivers

If Windows 95 or Windows NT 4.0 is pre-installed on your system and you

ordered the Ethernet card option, Ethernet drivers are installed on your hard drive in

the C:\netdrv directory.

If you want to use Ethernet capabilities with Windows 95, your system must have

BIOS revision level 1.1 or higher. If the AHIP4+ board is installed, your system must

have BIOS revision level 1.7 or higher.

If MS-DOS is installed on your system, the Ethernet drivers are supplied on your

hard drive in the C:\netdrv directory, but they are not installed.

To install the MS-DOS Ethernet drivers,

1. At the C: prompt, type “cd netdrv”.

2. Once the C:\netdrv path is specified, type “install”.

3. Follow the on-screen instructions to complete installation.

Note

Note

If you install Windows NT 4.0 or Windows 95 on your system, the Ethernet drivers

that are provided do not work with the Ethernet controller installed. You must use the

drivers provided by Xycom Automation. These drivers can be found on the Ethernet

Drivers disk that ships with your system.

Consult the Info directory on the drivers disk for additional installation information.

41

3500 Flat Panel Industrial PCs

Video Drivers

Video drivers and the expansion utilities are on the diskette included with the

documentation kit as well as on the hard drive.

For the AHIP6+ system, the video drivers are in the following directories:

C:\VGA\C&T554\WIN95

C:\VGA\C&T554\WINNT

C:\VGA\C&T\DOS\UTILITIES

For the AHIP4+ system, the video drivers are in the following directories:

C:\VGA\C&T550\WIN95

C:\VGA\C&T550\WINNT

C:\VGA\C&T\DOS\UTILITIES

Video Expansion

This section deals with the hardware expansion capability of the video controller

chip in DOS applications.

Note

It is not necessary to read this section if you are a Windows or OS/2 user and do not

plan to run DOS applications, and have not modified the default expansion mode in

the BIOS setup,

Unlike a CRT, a flat panel display has a fixed horizontal and vertical resolution.

There are many DOS video modes whose resolution is less than that of a flat panel

display. In order to more efficiently make use of the flat panel display’s active area,

it is necessary to employ an expansion technique which stretches the lower

resolution information to fill the higher resolution of the display. For example, DOS

defaults to VGA video mode 3+. This is an 80 column, 25-row text only screen

whose effective resolution is 640 dots x 400 scan lines. Because of this, the 800 x

600 display of the system will be partially filled by the 640 x 400 resolution of this

particular mode. By enabling the expansion function, these lower resolutions will

better utilize the display by stretching the information in an attempt to fill the

display. Operating systems such as Microsoft Windows 95, and Windows NT use

display drivers to handle the different flat panel displays. Here expansion is not

necessary since there is a specific driver for each resolution display.

Expansion does not add any resolution to the existing information; it simply stretches

the information to better fit the display. Text and graphic screens can look somewhat

grainy from the process of expansion. If the effect of expansion is undesirable, it can

be turned off either in the BIOS setup, or by executing an included utility program.

See the table below for the three utility programs included to allow expansion to be

turned on, turned off, and set back to the BIOS default state and what effect they

have on the display.

42

Video Expansion Options

Chapter Three - Installation

Utility Mode Panel Type/Size

12.1” TFT

EXP_ON.EXE Text Vert/Hor

Expansion On Graphics Vert/Hor

EXP_DEF.EXE Text Vert/Hor

Expansion Default Graphics Off

EXP_OFF.EXE Text Vert/Hor*

Expansion Off Graphics Off

Definitions:

Vert - Vertical only expansion is invoked

Vert/Hor - Vertical and Horizont al expansion is invoked

Expansion Default - The video BIOS default on power up

* Text expansion cannot be turned off

With an 800 x 600 display, the stretching algorithm does not completely fill the

display horizontally or vertically. A greater vertical text expansion can be achieved

by changing to VGA mode 3* (see Note below). This is also an 80 column, 25 row

text mode but with an effective resolution of 640 x 350. The 350 lines stretch better

to fill the 768-line display than does the default DOS mode 3+.

Note

The utility diskette includes a program titled MOD3_350.EXE, to allow switching to

the VGA mode 3*. Another utility program, MOD3_400.EXE, is provided to put the

mode back to the DOS default of 3+.

Windows may come up with a blank screen when using Windows 3.X with

expansion turned on either through the BIOS setup or the EXP_ON.EXE utility. The

two options (second option being the best) for this situation are listed below:

• Option 1 – Pressing the

display, letting you know that pressing

CTRL-ALT-DEL keys simultaneously. A blue screen will

CTRL-ALT-DEL again will reboot the

system or pressing any key will return you to Windows. At this point, press any

key and the normal Windows screen should appear.

• Option 2 – Turn off the expansion, set the BIOS default in the BIOS setup menus

using the appropriate utility as shown in the Video Expansion Options table.

Note

For further assistance, call Xycom Automation technical support at 1-800-289-9266.

43

3500 Flat Panel Industrial PCs

Touchscreen Drivers

If you have a touchscreen factory installed, you will also receive at no charge: MSDOS, and Windows 95 touchscreen drivers on diskette. Touchscreen drivers for

Windows NT (9460-DRVNT) and OS/2 (9460-DRVOS/2) must be purchased

separately.

The Windows 95 touchscreen driver is available in a COM2 and a mouse port

version. Windows NT touchscreen driver is only available in a version for COM2

If you order Windows NT pre-loaded on a system, the Windows NT touchscreen

drivers are provided.

You must install the corresponding touchscreen driver software if you change the

operating system. Refer to the touchscreen manual for instructions.

Note

If you ordered Windows 95 and a touchscreen on your system, the touchscreen driver

has been installed. If you ordered Windows NT, the driver is on diskette and a copy

of the driver file is on the hard drive. Windows NT only supports COM2. Therefore,

the touchscreen will be on the COM2 port and COM2 will not be available for other

use.

Miscellaneous Drivers

Refer to your operating system and peripheral manuals for information on installing

drivers related to these items.

If you had Windows NT preloaded on your system, you may have to purchase and

install an external parallel port CD-ROM drive, or order your system with CD-ROM

drive to install Windows NT drivers. The Windows NT operating system only ships

on CD-ROM.

Note

Note

44

Using a Touchscreen

Xycom Automation’s touchscreen complies with environmental specifications and

maintains a NEMA 4 seal when panel mounted. It remains operational even after 30

million touches. The touchscreen Monitor Mouse driver emulates a Microsoft

mouse.

Depending upon the date of purchase, the Xycom Automation unit will have one of

two possible touchscreen controllers:

• The Microtouch Controller P/N 114084

• The Xycom Controller P/N 140554

These controllers function similarly. However, the following sections require

attention to the type of controller installed.

Microtouch Controller

If MS-DOS, or Windows 95 is installed on your

system, the touchscreen is configured for the mouse port

and the mouse port is unavailable.

Chapter Three - Installation

Note

If Windows NT is installed on your system, the

touchscreen is set up on COM2 and the COM2 port is

unavailable for other use.

To reconfigure the touchscreen to use the COM2 port, perform the

following steps:

1. Disconnect the power.

2. Remove the lid.

Figure 3-17A. Touchscreen Controller Card

3. Remove the touchscreen controller card (Figure 3-

45

3500 Flat Panel Industrial PCs

A

B

CO

Xycom Controller

To reconfigure the touchscreen to use the COM2 port, perform the

following steps:

17A).

4. Reconfigure Jumpers J1-J5. Position A = COM2.

Position B = PS/2 mouse.

5. Reinstall the touchscreen controller card.

6. Reboot the computer.

7. Using the touchscreen manual do the following:

• Load the touchscreen drivers.

• Reconfigure the touchscreen driver for COM2.

• Recalibrate the touchscreen.

8. Replace the lid.

1. Disconnect the power.

2. Remove the lid.

J1

J2

J3

J4

JUMPERS

J5

J7

J8

J9

2

1

TOUCH SCREEN

NTROL CONN.

Figure 3-17B. Touchscreen Controller Card

3. Remove the touchscreen controller card (Figure 3-

17B).

4. Reconfigure Jumpers J1-J9. Position A = COM2.

Position B = PS/2 mouse.

40

39

46

5. Reinstall the touchscreen controller card.

6. Reboot the computer.

7. Using the touchscreen manual, do the following:

• Uninstall the UPDD touch driver.

• Locate the Touch-Base Serial Mode driver on

the Xycom Documentation CD

• Follow the instructions in the readme.txt file for

the installation of the UPDD driver in serial

mode.

8. Replace the lid.

Calibrating the Touchscreen

Depending upon the date of purchase, the Xycom Automation unit will have one of

two possible touchscreen controllers:

• The Microtouch Controller P/N 114084

• The Xycom Controller P/N 140554

Chapter Three - Installation

These controllers function similarly. However, the following sections require

attention to the type of controller installed.

Microtouch Controller

If you need to recalibrate the touchscreen, refer to the

sections in the touchscreen manual that explain

calibrating the touchscreen and using the diagnostic

utility.

Note

The touchscreen and controller are a matched pair

calibrated at the factory.

Xycom Controller

If you need to recalibrate the touchscreen, run the

Pointer Devices Control Panel applet. Select Help for

details about calibrating. For best results, use the 25

point calibration setting with Start In At set to 0.

You need to calibrate the touchscreen if

• The cursor does not follow the movement of your finger or pen

• You adjust the size of the video image or change the video mode

47

3500 Flat Panel Industrial PCs

Installing the System into a Panel

The system’s rugged design allows it to be installed in most industrial environments.

The system is generally placed in a NEMA 4/4X/12 enclosure to protect against

contaminants such as dust, moisture, etc. Metal enclosures also help minimize the

effects of electromagnetic radiation that nearby equipment can generate.

Mounting Considerations

Once you have established a location for the 3500, install it in the enclosure

according to the instructions that follow:

• Select a NEMA rated enclosure and place the unit to allow easy access to the system

ports.

• Account for the unit’s depth when choosing the depth of the enclosure.

• Provide a NEMA 4 seal by mounting the unit in an approved enclosure that has a 14

gauge (0.075"/1.9mm thick) steel or (0.125"/3.2mm thick) aluminum front face.

• Mount the unit in an upright position.

• Place the unit at a comfortable working level.

• Consider locations of accessories such as AC power outlets and lighting (interior

lighting and windows) for installation and maintenance convenience.

• Prevent condensation by installing a thermostat-controlled heater or air conditioner.

• To allow for maximum cooling, avoid obstructing the airflow.

• Place any fans or blowers close to the heat generating devices. If using a fan, make

sure that outside air is not brought inside the enclosure unless a fabric or other

reliable filter is used. This filtration prevents conductive particles or other harmful

contaminants from entering the enclosure.

• Do not select a location near equipment that generates excessive electromagnetic

interference (EMI) or radio frequency interface (RFI) (equipment such as high power

welding machines, induction heating equipment and large motor starters).

• Place incoming power line devices (such as isolation or constant voltage

transformers, local power disconnects, and surge suppressers) away from the system.

The proper location of incoming line devices keep power wire runs as short as

possible and minimizes electrical noise transmitted to the unit.

• Make sure the location does not exceed the unit’s shock, vibration, and temperature

specifications.

• Install in the rack or panel in such a way as to ensure that it does not cause a hazard

from uneven mechanical loading.

• Incorporate a readily accessible disconnect device in the fixed wiring on permanently

connected equipment.

• Avoid circuit overloading of the supply circuit.

48

System Power

Using isolation transformers on the incoming AC power line to the system is always

a good practice. An isolation transformer is especially desirable in cases in which

heavy equipment is likely to introduce noise onto the AC line. The isolation

transformer can also serve as a step-down transformer to reduce the incoming line

voltage to a desired level. The transformer should have a sufficient power rating

(units of volt-amperes) to supply the load adequately.

Proper grounding is essential to all safe electrical installations. Refer to the relevant

Federal, State/Provincial, and local electric codes which provides data such as the

size and types of conductors, color codes and connections necessary for safe

grounding of electrical components. The code specifies that a grounding path must

be permanent (no solder), continuous, and able to safely conduct the ground-fault

current in the system with minimal impedance (minimum wire required is 18 Awg, 1

mm).

Observe the following practices:

• Separate ground wires (P.E. or Protective Earth) from power wires at the point of

entry to the enclosure. To minimize the ground wire length within the enclosure,

locate the ground reference point near the point of entry for the plant power supply.

Chapter Three - Installation

• All electrical racks or chassis and machine elements should be Earth Grounded in

installations where high levels of electrical noise can be expected. The rack/chassis

should be grounded with a ground rod or attached to nearby Earth structure such as a

steel support beam. Each different apparatus should be connected to a single Earth

Ground point in a “star” configuration with low impedance cable. Scrape away paint

and other nonconductive material from the area where a chassis makes contact with

the enclosure. In addition to the ground connection made through the mounting bolt

or stud, use a one-inch metal braid or size #8 AWG wire to connect between each

chassis and the enclosure at the mounting bolt or stud.

Excessive Heat

The units withstand temperatures from 0º to 50ºC. The systems are cooled by

convection, in which a vertical column of air is drawn in an upward direction over

the surface of its components. To keep the temperature in range, the cooling air at

the base of the system must not exceed 50°C. Allocate proper spacing between

internal components installed in the enclosure.

When the air temperature is higher than the specified maximum in the enclosure, use

a fan or air conditioner to lower the temperature.

Electrical Noise

Electrical noise is seldom responsible for damaging components, unless extremely

high energy or high voltage levels are present. However, noise can cause temporary

malfunctions that can result in hazardous machine operation in certain applications.

Noise may be present only at certain times, may appear as widely spread intervals, or

in some cases may exist continuously.

Noise commonly enters through input, output, and power supply lines and may also

be coupled through the capacitance between these lines and noise signal carrier lines.

49

3500 Flat Panel Industrial PCs

This usually results from the presence of high voltage or long, close-spaced

conductors. When control lines are closely spaced with lines carrying large currents,

the coupling of magnetic fields can also occur. Use shielded cables to help minimize

noise. Potential noise generators include switching components relays, solenoids,

motors, and motor starters.

Refer to the relevant Federal, State/Provincial, and local electric codes which

provides data such as the size and types of conductors, color codes and connections

necessary for safe grounding of electrical components. It is recommended that the

high voltage and low voltage cabling be separated and dressed apart. In particular,

the AC cables and switch wiring should not be in the same conduit with all

communication cables.

50

Line Voltage Variation

The unit’s power supply is built to operate with output voltage ranges of 90-132

VAC and 180-264 VAC or 20-36 VDC, whichever applies, and still allow the system

to function within its operating margin. As long as the incoming voltage is adequate,

the power supply provides all the logic voltages necessary to support the processor,

memory, and I/O.

In cases in which the installation is subject to unusual AC line variations, use a

constant voltage transformer to prevent the system from shutting down too often.

However, a first step toward the solution of the line variations is to correct any

possible feed problem in the distribution system. If this correction does not solve the

problem, use a constant voltage transformer.

The constant voltage transformer stabilizes the input voltage to the 3510/3512 by

compensating for voltage changes at the primary in order to maintain a steady

voltage at the secondary. When using a constant voltage transformer, check that the

power rating is sufficient to supply the unit.

Creating a Power Cable

Chapter Three - Installation

This section describes how to create both an AC and DC power cable.

AC Power Cable

You must create an AC power cable to supply power to units with AC power

supplies. You will need the following materials:

• A three-position power connector (supplied).

• A braid/foil shielded power cable, terminated at power source end, with three 18 (1.0

mm), 16 (1.3 mm), or 14 (1.6 mm) AWG solid or stranded copper wire, rated 80º C

or better.

Perform the following steps to create the cable:

1. Cut the wire cable to the desired length.

2. Strip 0.25-inch (6 mm) of insulation from the end of the conductor wire. No bare

wire should be exposed when the cable is connected to the workstation.

3. Tin the wire ends with solder if using stranded wire. This will keep the wire

from fraying.

Warning

When inserting the wire ends of the power cable into the block plug, be sure there is no

exposed wire. Trim the wire ends of the cable or cut a new cable if necessary.

4. Insert the three wire ends of the power cable into the three holes of the block

plug. Insert the Protective Earth GND ground, L1, and L2/N wires into the

corresponding holes, as shown in Figure 3-8. Be sure that no bare wires are

exposed.

51

3500 Flat Panel Industrial PCs

5. Tighten the three screws above the wires to hold them firmly in place.

Never tighten the three screws of the block plug when the cable is connected to a power

source. The screws are conductive and have full contact with the cable wire.

6. Use a cable clamp and #6-32 screw (provided) to secure and provide strain relief

to the power cable. When installing the power cable to the unit, use the securing

screws on each side of the plug. This strain relief is mandatory for hazardous

locations compliance.

Figure 3-21. AC Power Connector

Warning

Warning

Completely loosen the two securing screws on the plug when disconnecting the power

cord from the unit.

DC Power Cable

You must create a DC power cable to supply power to units with DC power supplies.

You will need the following materials:

• A three-position power connector (supplied)

• A braid/foil shielded power cable with three 18 (1.0 mm), 16 (1.3 mm), or 14 (1.6

mm) AWG solid or stranded copper wire, rated 80º C or better.

Perform the following steps to create the DC power cable:

1. Cut the wire cable to the desired length.

2. Strip 0.25-inch (6 mm) of insulation from the end of the conductor wire. No bare

wire should be exposed when the cable is connected to the workstation.

3. Tin the wire ends with solder if using stranded wire. This will stop fraying.

Warning

When inserting the wire ends of the power cable into the block plug, be sure there is no

exposed wire. Trim the wire ends of the cable or cut a new cable if necessary.