Page 1

Fiber Optical Multiplexer

8x E1, 1x Fast Ethernet, Hotline, 1x Fiber optic

XL-FMUX8E1F

User’s Manual

Page 2

Thank you for using XtendLan’s product. This manual provides most of the information; please do read up the

technical setup and safe keep the manual for future usage.

1 Product Description

1.1 Function Description

XTENDLAN Fiber Optical Multiplexer product family provides ideal solutions for building fiber base E1

or T1 networks.

FMUX8E1F is a staff of Fiber Optical Multiplexers, this model it can multiplex to 8 E1 signals for

transmission over an optical fiber, resulting in reaching a longer distance without a repeaters and superior

performance compared to copper media.

FMUX8E1F is the 8E1 point-to-point optical transport equipment that uses the FPGA chips and it is easy

to upgrade. It is single board structure and the largest transmission capacity is 8E1. The outer design use

the standard 19 inches rack, so the volume is little, weight is light and operation is convenient and credit.

8E1 fiber Optical Mulitplexer uses the PDH fiber transmission technologies. The 2M (E1) interfaces can

connect with the exchanger, light loop device and multi-diplexer directly to form the micro, midi or the

special network. Complete alarm function for FMUX8E1F, it is stable and easy to maintenance, install and

small in size. It has one digital service telephone.

Page 3

1.2 Features

Below lists the features for FMUX8E1F:

Offer 8 X 2Mb/s digital interfaces

Up to 8 E1 links on one fiber

Management through Console port

The supervisory control interface implements centralized monitoring and export the monitor and

control information of this port and opposite port.

One link to service telephone for duty contract

90-260VAC & -48VDC power options and the positive and negative of DC-48V can be optional

because there is the self-test circuit for the polarity inside th1e device

Standard 19 inches rack, little volume, light weight, steady capacity and convenient setup

Digital clock recovery circuit and digital smooth DPLL adopted for 2.048Mb/s port

LED indicators

1.3 Application

XtendLan FMUX8E1F can be used a high-speed baseband modem for point to point that connects two DTE

over a lease Line. From Router Æ CSU/DSU Æ FMUX8E1F Æ Fiber opticalÆ FMUX8E1FÆ

CSU/DSUÆ DTE as illustrated in the Following Diagram.

Diagram 1.1

Page 4

1.4 Specification

E1 line Interface

Number of E1 8 E1’s Interface Standard ITU-T G.703

Line Rate 2.048Mbps±50ppm E1 Impedance 120 ohm (balanced)

Line Code HDB3 HDB3 Connector Type RJ-45

Jitter tolerance

Optical Fiber Interface

Wavelength

Light Source MLM Laser Detector PIN Photodiode

System Gain 26 dB (Min.) Input Sensitivity -38dBm (Ber<10e-10)

Line Code Scrambled NRZ Output power -6 dBm

Physical/Electrical

Dimension

Mounting

Power Source 100 – 240 VAC ( 50H/60Hz)

Power consumption

Temperature Range

Relative Humidity

Management

RS485, with the two-string cable, one computer can supervise the 256pair fiber modem. It can be

Better than G.742,G.823

1310nm

Height 44 mm / 1.7 in (1U), Width 485 mm /19

In Depth 160 mm / 6.3 in

Stand-alone,19” inch rack mount, wall mount also available

0°C - 50°C (32° to 122°F)

0% - 90%, non-condensing

Connector Type SC

< 5 W

manage by our SNMP NMS device, which has a RS485 interface.

Timing

Timing derived from incoming E1

Diagnostics Test

Loop-back testing for 8 x E1 (Local and remote)

Loop-back testing for fiber optical (Local and Remote)

Indicators

Local optical signal indications for all E1s.

Remote optical signal receive indication, working and loss.

Loop-back indication.

Alarm indication, on or off.

Power on indication.

Page 5

Front panel

From left to right – 1x NMS RS-485 port, LED indicators, diagnostics and phone push buttons, phone line port

RJ-11

Rear panel

From left to right – power switch, power supply port, LAN port RJ-45 10/100Base-TX, fiber optics port SC

duplex connector, 8x RJ-45 balanced E1 port.

Page 6

2 INSTALLATION

2.1 Site Selection

This is a guideline for FMUX8E1F installation. The following list indicates a site selection guideline. User

needs to follow this guideline for the select a proper installation site.

For the FMUX8E1F unit, the location should be part of the Central Office (CO) equipment layout

design. The entrance cable routing should be consider.

The installation should provide a proper room for the adequate ventilation and cable routing at site. At

least 0.5 m should be reserve at the rear of the unit for the human access, cable, and airflow.

The site should provide a stable environment. The Ops Area (Operating Area) should be free from

extremes temperature, humidity, shock and vibration.

Do not expose the unit under the rain because FMUX8E1F is not a waterproof unit.

Relative humidity should stay between 0 and 95%.

Survey the site (power supply) before install the unit.

Page 7

2.2 Mechanical Installation

FMUX8E1F is a desktop and 19” rack mount unit. Unit supports AC power supply.

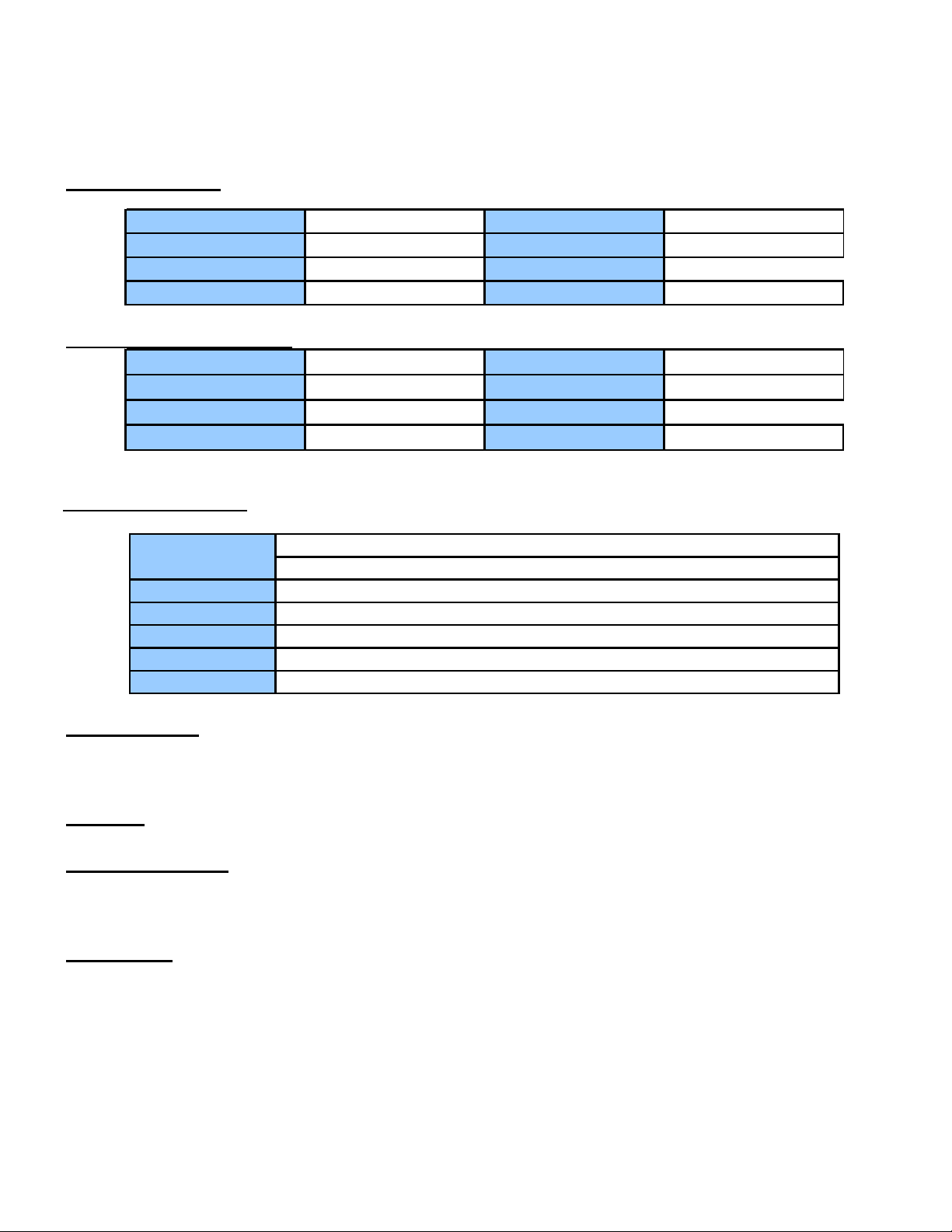

2.2.1 Light indicators

Name Color Status Describe

1 LOS1 Red Active E1 port 1 loss

2 LOS2 Red Active E1 port 2 loss

3 LOS3 Red Active E1 port 3 loss

4 LOS4 Red Active E1 port 4 loss

5 LOS5 Red Active E1 port 5 loss

6 LOS6 Red Active E1 port 6 loss

7 LOS7 Red Active E1 port 7 loss

8 LOS8 Red Active E1 port 8 loss

9E6RedActive

10 E3 Red Active

11 OPLOS Red Active Optical signal Lost

12 OPLOF Red Active Optical SYNC loss

13 LE Red Active Local device have any error(E1 and Opt)

14 RE Red Active Remote device have any error(E1 and Opt)

15 PWR Green Active Power on

Remark:Equipment Can Monitor the remote device

LRS

16 LNK/ACT

17 FDX

18 SPD

UP

DOWN

If the Device Have Lan Interface

Green Active

Green Active

Green Active

The led indicate local device status

The Led indicate remote device status

ON :full duplex,OFF:half duplex

Optical BER≥10-6

Optical BER≥10-3

LAN Link and Active

ON :100M,OFF:10M

Page 8

2.2.2 Front panel DIP definition:

Bit 1-4 ( RLOOP1-4 ): 1-8E1 remote loop.

RLOOP1-4 as 1 to 8 port’s E1 it is to indicate loop back.

If the RLOOP1 is ON, this means that at the far end the is doing a E1 loop-back

In the following table 0 means ON,1 means OFF

The Remote NO x E1 Loop Bit1 Bit2 Bit3 Bit4

1000

2001

3001

4010

5010

6011

7011

8100

ALL 8E1 Loop

Remark: Bit 5-8: Reserved

000 0

2.2.3 Front panel PUSH button definition:

In the front panel are four push buttons. It is MSK, SMSK, LRS, PH

The function described following table

1

0

1

0

1

0

1

0

Page 9

PUSH OFF (button up) ON (button down)

MAK Normal LED Display LED Alarm OFF

SMSK Sound Alarm Sound Alarm ShutDown

LRS LED Means Local LED means Remote

PH Hot line phone not used use Hot line phone

2.2.4 Hot line phone

Hot line phone, not occupy 2Mbps channel transmission.

On the front panel there is a “PH” button, press on the “PH” button on the remote site it will sound. To answer

it the remote site just need to press the “PH” button on the remote unit, the alarm will cut off and just plug in

the phone both side able to do the communication.

Setting of the manage phone.

It does not occupy the 2M circuits!

2.2.5 Ethernet

FMUX8E1F can offer a channel for 10/100M, full/duplex auto-negotiation LAN interface, support VLAN

protocol, this interface can continuous learn MAC addresses in the LAN that connected with it, and send the

address as frame in another LAN. Transparence to TCP/IP protocol, offers security connection between

different equipments in the network, used widely in network connection and monitor between WAN and

LAN.

10/100 Base-T Ethernet port parameter

Rate: 10M or 100M, full/semi duplex auto-negotiation

Ethernet rate in optical line: 2.048 Kbps

.

Page 10

Protocol: support IEEE 802.3, IEEE 802.1Q(VLAN)

MAC address table: can learn 4096 MAC address

Ethernet buffer memory: 64 Mbits SDRAM

Physical interface: RJ45 slot, support AUTO-MDIX

Ethernet operating diagram:

2.2.7 Power supply

FMUX8E1F Fiber Optical Multiplexer supports 3 type powers: AC220V, -48V and +24V. If the power of

DC-48V is used, the positive and negative terminal can be optional because there is the self-test circuit for the

polarity inside the Fiber Optical Multiplexer.

3 Operation

3.1 Equipment installation

After unpacking and before installation, make sure checking the following:

Make sure the package is well. If the package is damaged, contact service office of XTENDLAN

quickly for solution.

Check the package according to the product list, if find equipment severe damaged or lack of some

components, please contact installation worker or service office of XTENDLAN.

Check whether the equipment type is meet with the type you ordered.

Check whether the component is integrity.

Check the power supply type.

3.1.2 Quick installation

Fasten the Equipment in 19 inch. rack with the screws in the equipment package.

Use reliable ground connection at GND point of the equipment

Page 11

Use power tab to connect power according to the manual, don’t exchange the polarities.

Create user equipment connecting wire according to your demand (2M, V.35 and 10 Base-T), then

connected, don’t exchange receive and transfer wires.

Connect receive and transfer optical with optical receive and transfer port of the equipment. Don’t

exchange receive and transfer wire, make sure the optical fiber head is clean, insert optical jumper,

make sure connection well. (fiber bending radius≥50 mm)

Use multimeter to test power polarity and voltage, make sure it match with equipment requirement.

After complete installation and make sure it’s ok, power on the switch. Check indicator light meet

with practice situation (see related part of manual).

A clean, steady environment and firm installation should provided for independent or wall hanging

equipment.

3.1.3 Cautions about installation

Avoid severe libration and mechanical damage during the process of transfer and installation.

Arrange fiber appropriately, fiber bending radius≥50 mm.

Check voltage and polarity meet with back panel, or it will cause permanent damage to the

equipment.

Fiber connector can’t contaminate, wipe optical fiber head slightly using alcohol, or it will affect

transmission. If the fiber connector not butt joint well, it may be cause power decline, adjust fiber

connector according to practical situation.

The installation position should convenience for personal pass and equipment movement.

The environment should dry, clean and ventilation well.

Essential static-protective is needed during the installation and maintenance, ground the chassis to

increase anti-interference capability and prevent lightning strike. Before use the equipment,

independence work ground and protect ground should provided, make sure it ground well.

3.2 Power on the equipment

Check indicators and alarms according to manual after power on.

If both local and remote work well, fiber interface connect ok, the alarm light OPLOS and OPLOF

off, POWER indicator light is green.

Light LOSX (X=1-8) is red and voice alarm is on because of not connecting E1 signal. After

connect E1 signal, light LOSX (X=1-8) will off, voice alarm will off until all light LOSX is off.

Page 12

Branch shield: shield no using branch alarm, no red light is on when all alarm is off.

Hot line phone: after Fiber Optical Multiplexer works normally, insert microphone to hot line phone

port, press button PHONE to call remote user, then can communication after the remote user press

button PHONE and hold up the microphone. Buzzer rings when remote terminal call local terminal,

press button PHONE and hold up microphone, then communicate with remote terminal. Back the

button PHONE to norm after communication is completed.

Branch loop: when system work normally and no branch alarm happen, loop test is available with

SW. Put the SW switch to ON in local terminal, can control remote corresponding 2 Mb/s branch to

loop, then can test corresponding output signal at local 2 Mb/s output port. Use this function you

can realize loop of all the branches, and it’s easy for detect.

Use bit error instrument to analyzing performance of 2M branch, and record it.

Close voice alarm: voice alarm on when following situation happened:

A. Optical disconnected cause OPLOS alarm.

B. Signal not steady cause OPLOF alarm.

C. Some branches not use and not shielded.

Push down SW5 at local terminal, can control closing voice alarm.

Note: After failure is removed, set the button to norm, validate the alarm function

3.3 Troubleshooting

Best status is configured to this equipment before out of factory, all the functional interfaces are at the front and

back panel, don’t open the chassis yourself. If have failure, you can determine the range of failure using single

loop, and contact our corporation.

The following table list common failure and alarm, the reason may cause these alarm and solution to this alarm

for you to reference.

Equipment alarm and corresponding solution

Page 13

Alarm Possible reason Solution

1 POWER off not power on

2OPLOS on

3OPLOF on

4 E1 alarm Not receive 2M signal Check wire; receive and transfer are exchanged

5 Voice alarm Local alarm happened Shield when process failure

Not receive optical

signal

Not receive normal

frame signal

Receive signal not steady,check fiber line

Power connect not well, polarity

exchanged

Optical disconnected; remote having no

optical output

and equipment

Loading...

Loading...