Page 1

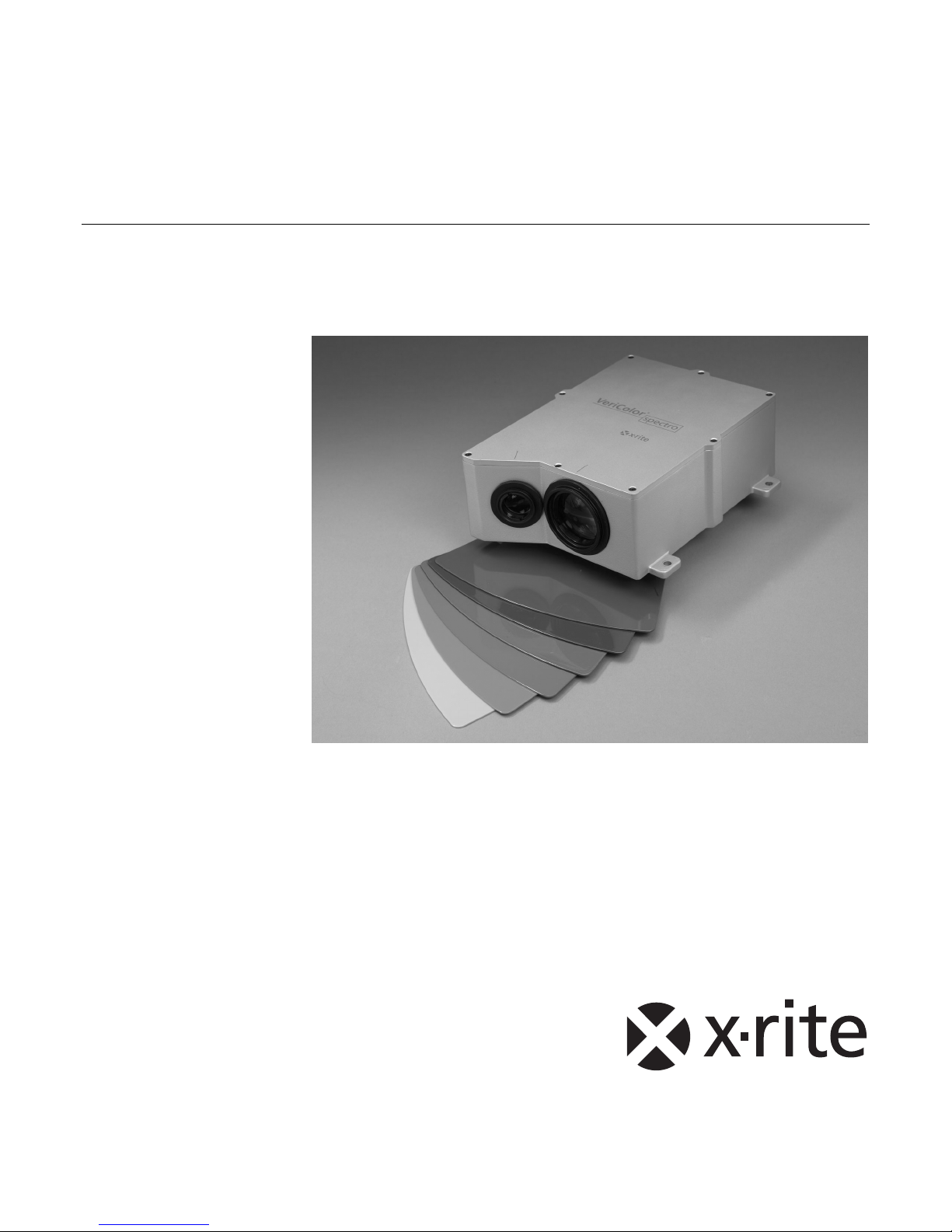

®

VeriColor

Spectro

Non-Contact Spectrophotometer

Setup and Operator Manual

Page 2

Page 3

CE Declaration

Manufacturer's Name: X-Rite, Incorporated

Authorized Representative: X-Rite, Incorporated

Siemensstraße 12b

Phone:+49 (0) 61 02-79 57-0

Model Name: VeriColor Spectro

Model No.: VS410

Directive(s) Conformance: EMC 89/336/EEC LVD 73/23/EEC

Note:

This is a class A product. In a domestic environment this product may cause interference in which case

the user may be required to take adequate measures.

Federal Communications Commission Notice

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

VERICOLOR® SPECTRO

• 63263 Neu-Isenburg • Germany

• Fax: +49 (0) 61 02 -79 57-57

Industry Canada Compliance Statement

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Equipment Information

Use of this equipment in a manner other than that specified by X-Rite, Incorporated may compromise

design integrity and become unsafe.

WARNING: This instrument is not for use in explosive environments.

ADVERTENCIA - NO use este aparato en los ambientes explosivos.

AVVERTIMENTO - NON usare questo apparecchio in ambienti esplosivi.

WARNUNG: Das Gerät darf in einer explosiven Umgebung NICHT verwendet werden.

AVERTISSEMENT: Cet instrument ne doit pas être utilisé dans un environnement explosif.

RoHS/WEEE

X-Rite products meet the Restriction of Hazardous Substances (RoHS) Directive 2002/95/EC and

European Union – Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC. Please

refer to www.xrite.com

for more information on X-Rite's compliance with the RoHS/WEEE directives.

3

Page 4

VERICOLOR® SPECTRO

Proprietary Notice

The information contained in this manual is derived from patent and proprietary data of

X-Rite, Incorporated. The contents of this manual are the property of X-Rite, Incorporated

and are copyrighted. Any reproduction in whole or part is strictly prohibited. Publication of

this information does not imply any rights to reproduce or use this manual for any purpose

other than installing, operating, or maintaining this instrument. No part of this manual may

be reproduced, transcribed, transmitted, stored in a retrieval system, or translated into any

language or computer language, in any form or by any means, electronic, magnetic,

mechanical, optical, manual, or otherwise, without the prior written permission of an officer

of X-Rite, Incorporated.

This product may be cover ed by one or more patents. Refer to the instrument for actual

patent numbers.

Copyright © 2007 by X-Rite, Incorporated “ALL RIGHTS RESERVED”

X-Rite and VeriColor are registered trademarks of X-Rite, Incorporated. All other logos, brand names, and product names mentioned

are the properties of their respective holders.

Warranty Information

X-Rite, Incorporated (“X-Rite”) warrants each instrument manufactured to be free of defects

in material and workmanship for a period of 12 months. This warranty shall be fulfilled by

the repair or replacement, at the option of X-Rite, of any part or parts, free of charge

including labor, F.O.B. its factory or authorized service center.

This warranty shall be voided by any repair, alteration, or modification, by persons other

than employees of X-Rite, or those expressly authorized by X-Rite to perform repairs, and by

any abuse, misuse, or neglect of the product, or by use not in accordance with X-Rite's

published instructions.

X-Rite reserves the right to make changes in design and /or improvements to its products

without any obligation to include these changes in any products previously manufactured.

Correction of defects by repair or replacement shall constitute fulfillment of all warranty

obligations on the part of X-Rite.

THIS WARRANTY IS EXPLICITLY IN LIEU OF ANY OTHER EXPRESSED OR IMPLIED

WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR PURPOSE. THIS WARRANTY OBLIGATION IS LIMITED TO REPAIR OR

REPLACEMENT OF THE UNIT RETURNED TO X-RITE OR AN AUTHORIZED SERVICE CENTER

FOR THAT PURPOSE.

This agreement shall be interpreted in accordance with the laws of the State of Michigan and

jurisdiction and venue shall lie with the courts of Michigan as selected by X-Rite,

Incorporated.

4

Page 5

Table of Contents

VERICOLOR® SPECTRO

Overview 7

VeriColor Spectro Description 7

Unpacking and Inspection 7

VeriColor Spectro Installation 8

Measurement Distance 8

Height Insensitivity 9

Measurement Angle 9

VeriColor Spectro Dimension Drawing 10

Cable Connection and Wiring 11

Hardware Interface Description 13

Discrete Input Lines 13

Power/Comm/Control Cable (p/n: VCS50-EUR8-DB5) 13

Discrete Output Lines 14

Discrete Interface Cable (p/n: SE108-EUR8-5M) 16

Computer Interface 16

Status LED Indicator 17

Software Installation and Overview 18

Basic System Requirements 18

Installing the Software 18

Starting the Application 18

Application Overview 19

VeriColor Spectro System Operation 20

Configuring the Software Options 20

Administrative (Admin) Setup 20

Language Tool 26

Targeting a Part 27

Calibration/Verification of the VeriColor Spectro 28

Attaching the Calibration Tool 28

Performing Calibration (first time, out of box) 29

Performing Verification 30

Performing Calibration (after verification failure) 31

Calibration Configuration 32

Color Standards and Projects 34

Creating Palettes and Color Standards 34

Verify Mode 39

Project Mode 40

Configuration PLC Values 42

Monitor Mode 44

Selecting a Single Standard (no auto target) 44

Selecting a Project for Auto Targeting 45

Measuring a Standard 45

Setting Tolerances 46

Creating a Standard from a Series of Measurements 47

Manual Sample Measurement 47

Interval Sample Measurements 48

Viewing Sample Data 49

Lookup Mode 52

Compare Mode 54

Selecting a Standard from File 54

Measuring a Standard 55

Setting Tolerances 55

Selecting a Trial from file 56

Measuring a Trial 56

Deleting Trials 56

5

Page 6

VERICOLOR® SPECTRO

General Maintenance 58

Repair Information 58

Cleaning the Spectro Instrument Lenses 58

Cleaning the Calibration Tool 58

Hardware Troubleshooting 59

Appendices 61

Specifications 61

Accessories 62

Electrical Interface Details 63

6

Page 7

Overview

VeriColor Spectro Description

The VeriColor® Spectro is used to evaluate and identify colors in industrial applications. The

VeriColor Spectro is a spectrophotometer that delivers 100% in-line, non-contact, absolute

(L*a*b*) color measurement and identification.

Like other color sensors, the VeriColor Spectro allows you to “learn” (measure) standard

colors and measure samples for comparison. The system uses these comparisons to

determine the closest standard or pass/fail a sample based on a tolerance.

The system is composed of two main components: the VeriColor Spectro which stores

standard colors and captures sample color, and the software application.

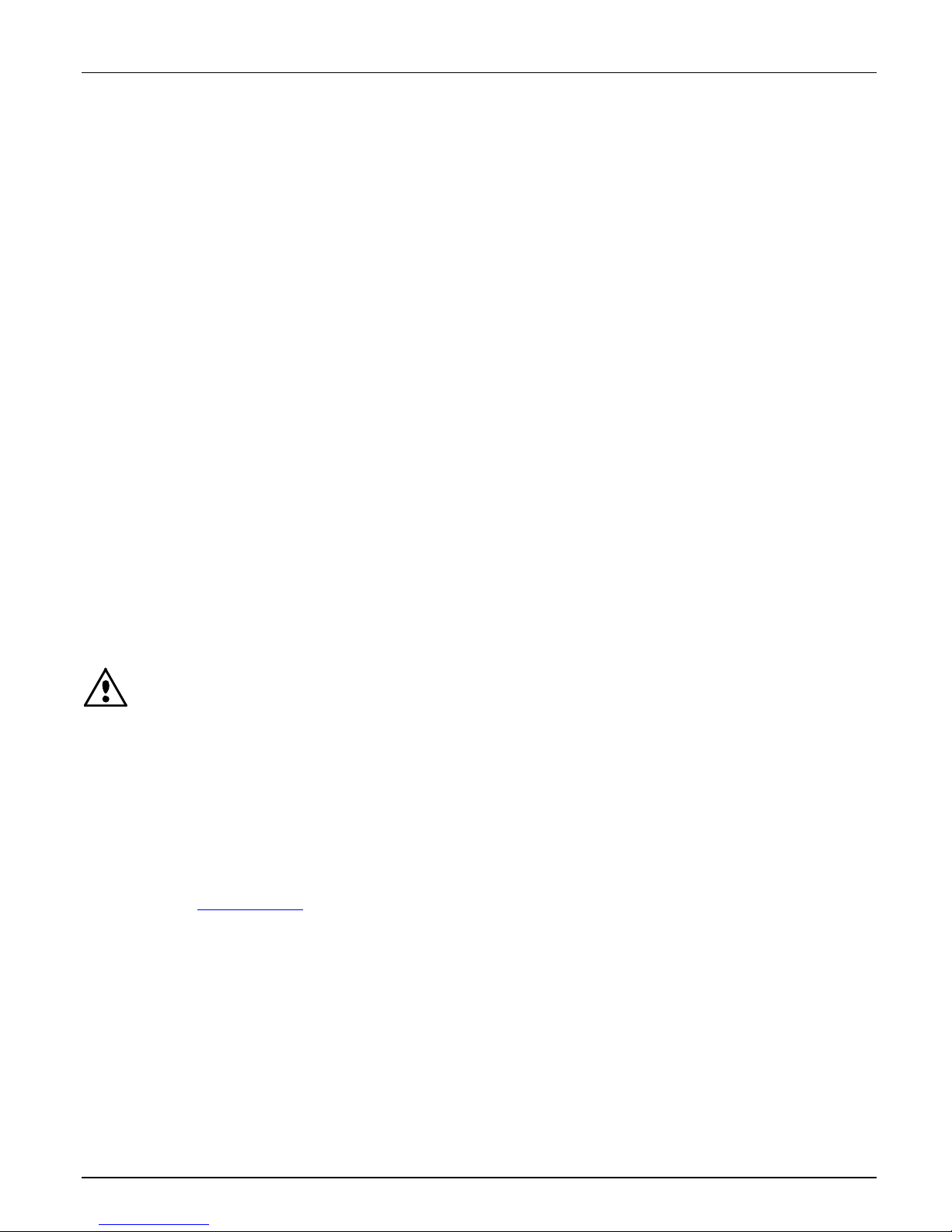

Sensor Lens

Illumination Lens

VERICOLOR® SPECTRO

Mounting Flange (4)

Unpacking and Inspection

After removing the VeriColor Spectro from the shipping carton, inspect it for damage. If any

damage has occurred during shipping, immediately contact the transportation company. Do

not proceed with installation until the carrier's agent has inspected the damage.

Your VeriColor Spectro was packaged in a specially designed carton to assure against

damage. If shipment is necessary, the VeriColor Spectro should be packaged in the original

carton along with all the accessories. If the original carton is not available, contact X-Rite to

have a replacement shipped to you.

Packaging Contents:

• VeriColor Spectro P/N VS410-00-01

• 5 Meter Male 8-Circuit Open Ended Cable P/N SE108-EUR8-5M

• 5 Meter Female 8-Circuit Open Ended P/N VCS50-EUR8-5DB

• Calibration Tool P/N VS410-63

• VeriColor Spectro Application Software CD P/N VS410-500-CD

• Setup and Operation Manual P/N VS410-500

• Registration Form (multi-language) P/N SD01-99

RS-232 Connector

RS-485 / PLC Connector

Status LED Indicator

7

Page 8

VERICOLOR® SPECTRO

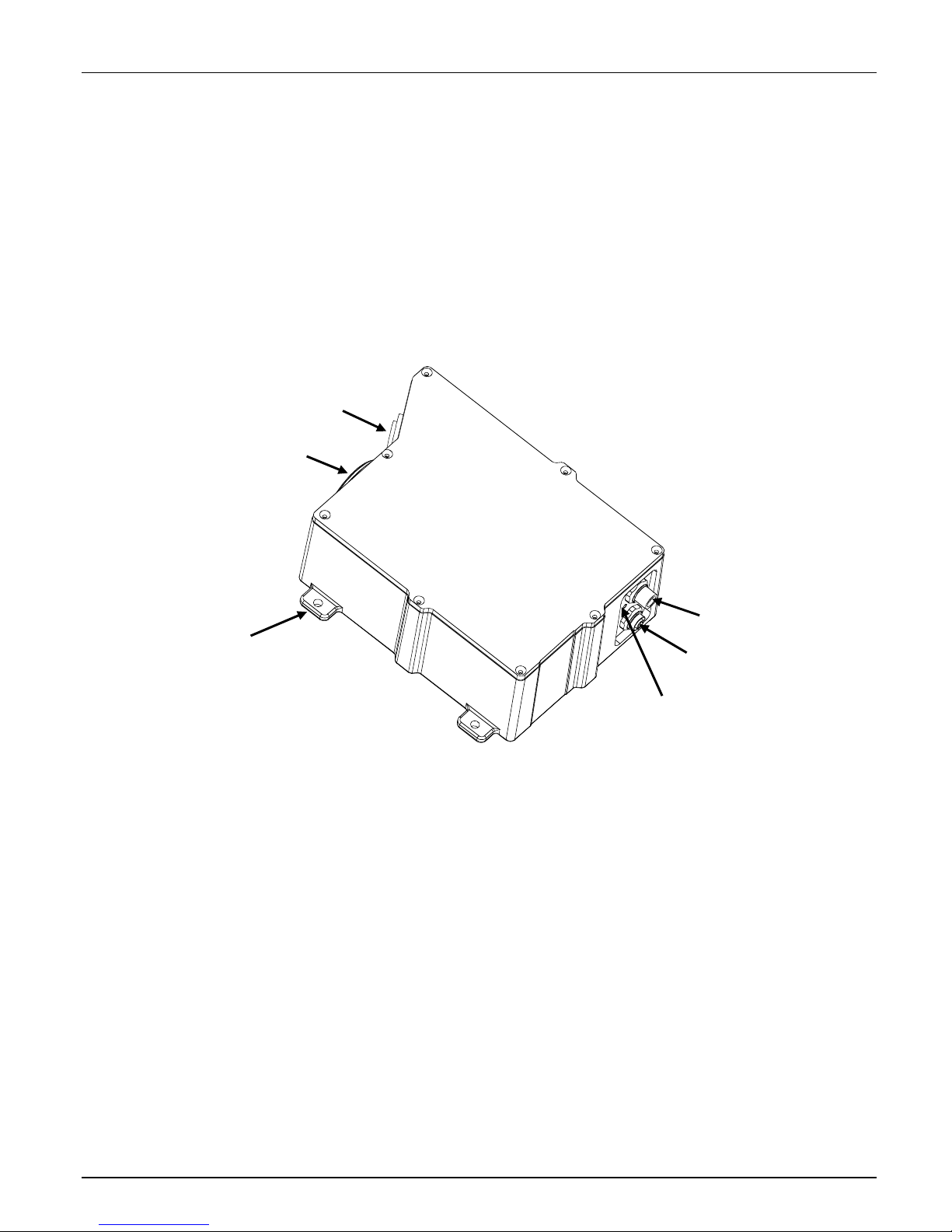

VeriColor Spectro Installation

Measurement Distance

Mount the VeriColor Spectro to the fixture using the holes provided at each flange.

VeriColor Spectro must be set to measure at a distance of 4” nominal to the measurement

surface. If the instrument is mounted in a 0°/30° geometry (preferred), the distance is that

from the center of the illumination lens to the sample. If the instrument is mounted in a

30°/0° geometry (alternate), the distance is measured from the center of the sensor lens to

the measurement surface.

CAUTION: Keep the sensor lens and illumination lens free from dust, smudge

marks, and finger prints.

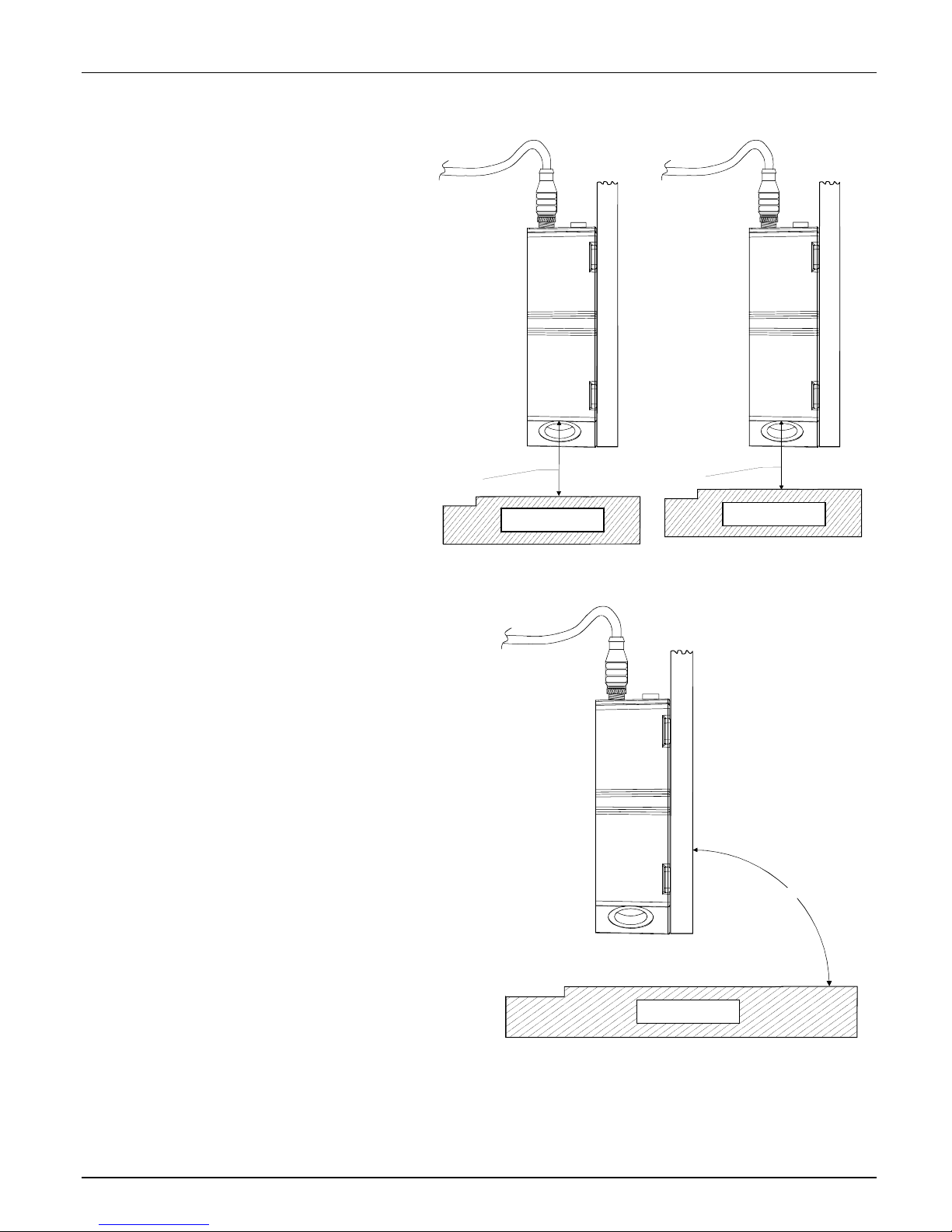

0°/30° Mounting - Preferred 30°/0° Mounting - Alternate

Mounting

Flange (4)

Sensor Lens

Sample Part

Mounting

Flange (4)

Illumination Lens

4.0"

Sensor Lens

4.0"

Illumination Lens

Sample Part

IMPORTANT: The Geometry setting in the

software will require editing from the default

setting of “0°/30°” if the alternate 30°/0° mounting

method is used. Refer to the Calibration

Configuration section later in this manual for the

procedure.

8

Page 9

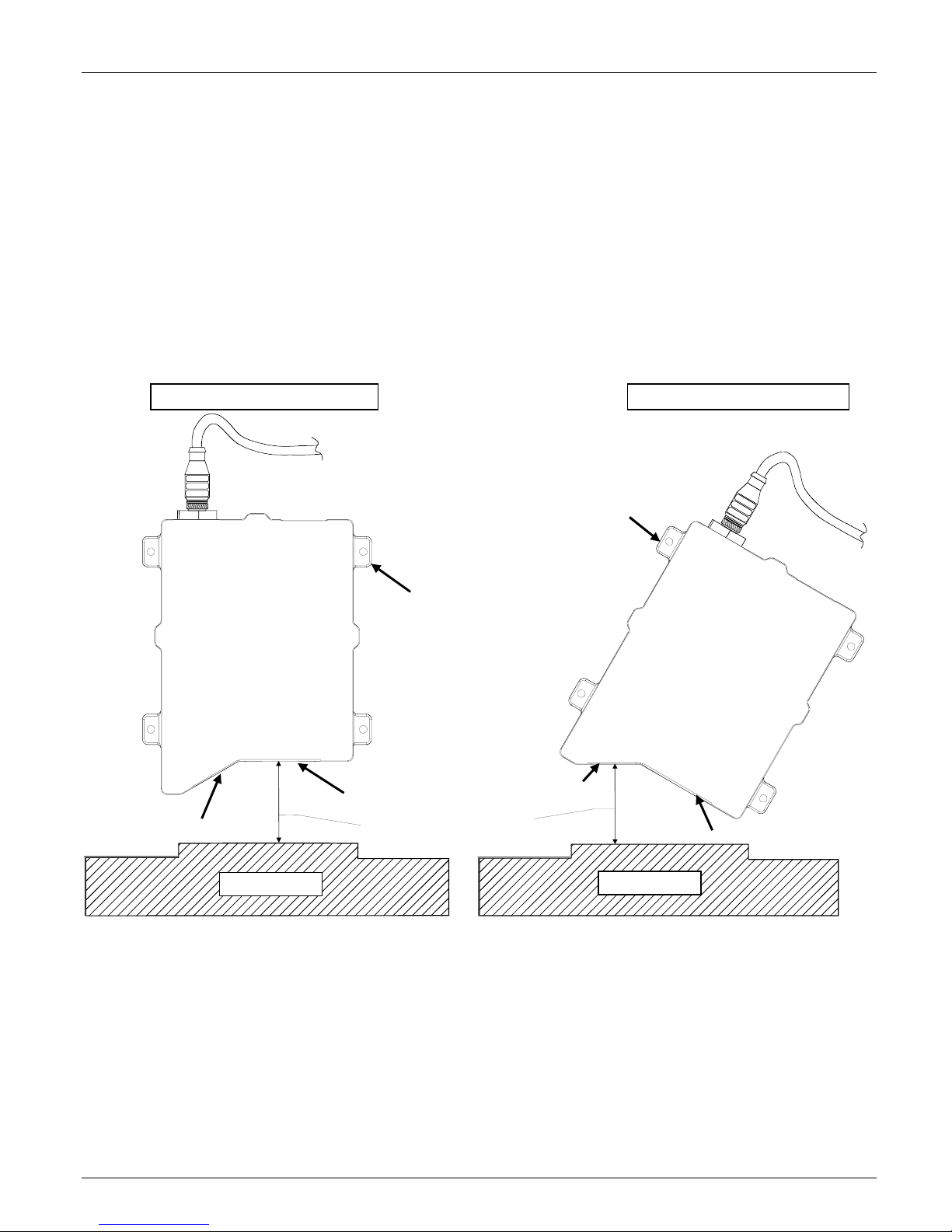

Height Insensitivity

Vericolor Spectro can tolerate

variation in depth of the

measurement distance of +/- 0.25”.

This means that if the sample being

measured fluctuates up and down

by no more than +/-0.25”, the

measurement will not be affected

beyond specified tolerances (refer

to the Specifications in the

Appendix). Any more than +/- 0.25”

it is suggested that the sample

being measured be stabilized to

prevent the variation in the

measurement distance.

VERICOLOR® SPECTRO

4.25"

Sample Part

3.75"

Sample Part

Measurement Angle

It is important when installing the

instrument in-line that the geometry and

axis angle be set appropriately. The

instrument can be set at a 0°/30°

illumination or 30°/0° illumination (see

illustrations on previous page). The 0°/30°

position is preferred for best repeatability

and correlation to an X-Rite 964 or similar

hand held spectrophotometer. Other angles

may be used (example 7.5/37.5) but care

must be taken to avoid sensing specular

reflections from the illuminator. Once the

instrument has been trained on a sample in

the preferred position, it is critical that

future samples be measured for comparison

against the standard at the same

measurement angle. Any deviation in the

measurement angle (called off axis

measurement) will affect the color reading

and indicate a fail condition, when in fact

the sample might be completely within the

specified tolerance range.

It is preferred that the instruments

mounting plane be as close to 90° to

sample plane as possible.

It is recommended that once the mounting angle of measurement is determined, the

instrument fixed position should be marked or documented. This will allow you to more easily

reposition the instrument to the original and correct position when measuring that sample

profile and color.

90°

Sample Part

9

Page 10

VERICOLOR® SPECTRO

(

)

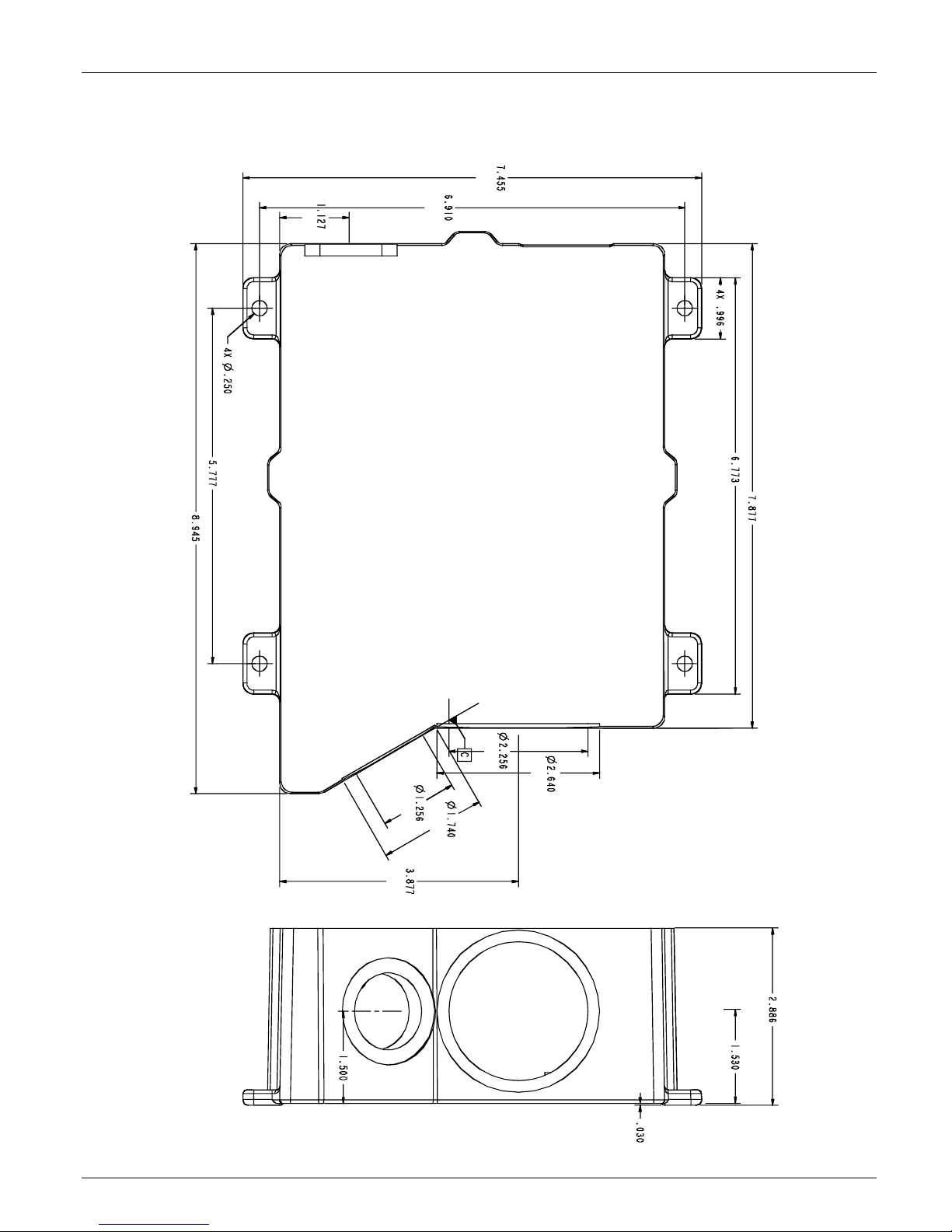

VeriColor Spectro Dimension Drawing

(189.35 mm)

227.20 mm

(28.62 mm)

(6.35 mm)

(146.73 m m )

(175.51 mm)

(25.29 mm)

(172.03 mm)

(200.07 mm)

(57.30 mm)

(67.05 mm)

(31.90 mm)

(44.19 mm)

(98.47 mm)

(73.30 mm)

(38.10 mm)

(0.76 mm)

(38.86 mm)

10

Page 11

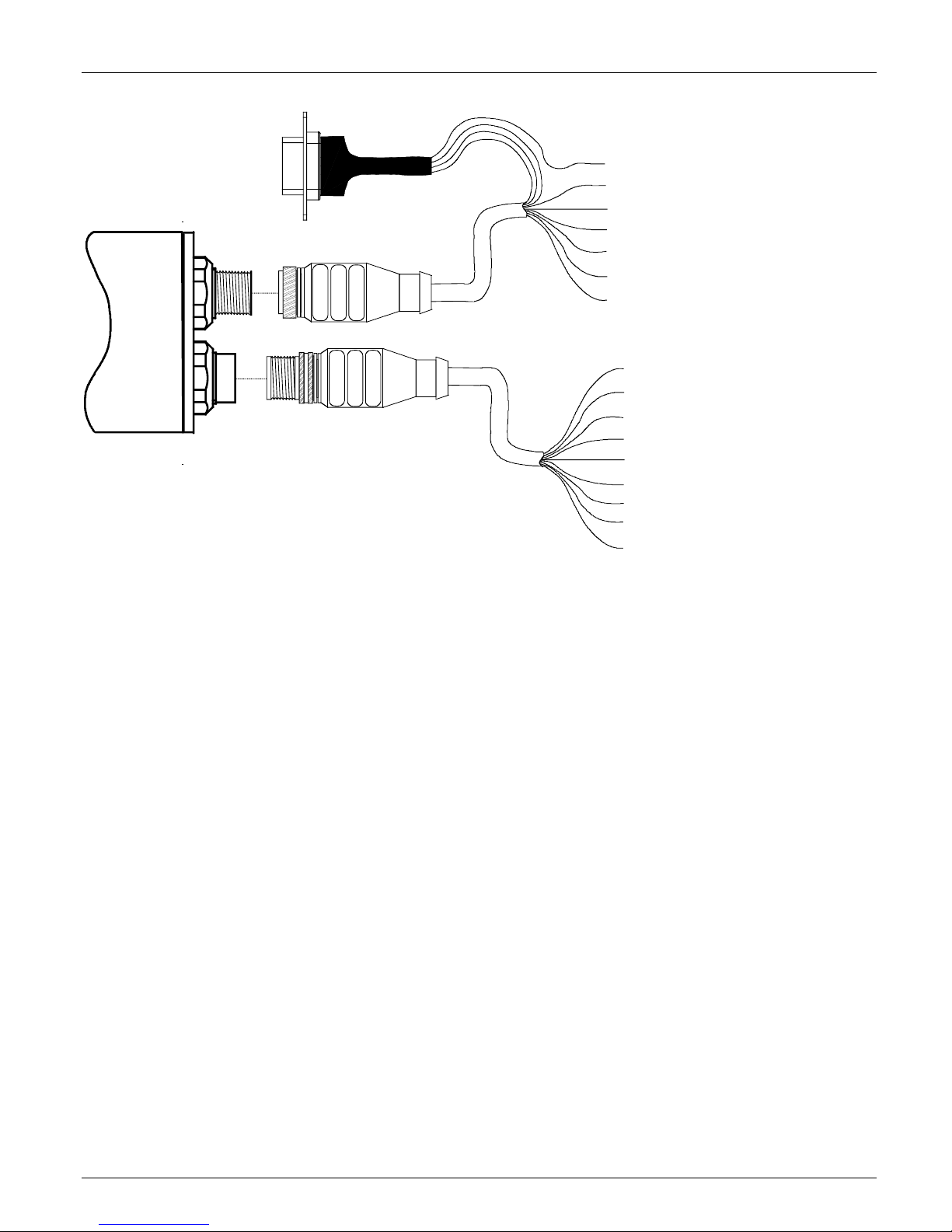

Cable Connection and Wiring

The VeriColor Spectro is designed to utilize the same cable configuration as the VeriColor

Solo; however, due to the increased power requirements of the VeriColor Spectro, RS232

communication should be limited to cable lengths of less than 15 meters. For cable distances

longer than 15 meters it is recommended that the RS485 communication scheme be utilized.

The VeriColor Spectro RS485 communications wiring may be configured as either half or full

duplex on a single drop RS485 line. Usage of the RS485 communication requires proper

ground termination for both the power supply cable and the RS485 cable; any notable

differences in potential between the cable grounds may result in intermittent communication,

communication failure and possible damage to the instrument.

1. After the instrument has been mounted, attach the female connector of the

'Power/Comm/Control' cable (p/n: VCS50-EUR8-5DB) to the male connector (longer,

threaded), located on the back end of the VeriColor Spectro, and tighten.

2. The other end of this cable has a DB9 connector and several stripped and tined wires.

This end interface to power, computer and discrete devices.

a. Instrument power is applied via the white (+) and brown (-) wires (+24 Vdc ±2 Vdc)

IMPORTANT: A limited current source must be used. The applied operational power

shall be a filtered +24 Vdc, ±2 Vdc tolerance, having a 3-Amp capacity.

b. RS232 communications is obtained via the pre-wired DB9 connector.

c. If manual or discrete operation is needed, attach the appropriate wires to controlling

device (relay, PLC terminal, etc.). These lines are the READ, 10's, 1's, and DSR inputs

and are low-power, active high inputs. Refer to next section for details.

3. If discrete output, PLC feedback or RS485 interfacing is needed, attach and tighten the

male connector of the 'Discrete Interface' cable (p/n: SE108-EUR8-5M) to the female

connector (short, non-threaded). The connector is located on the back of the VeriColor

Spectro instrument.

4. The other end of this cable has several stripped and tined wires allowing low power

interface to discrete devices and/or attachment to an RS485 port (4-wire).

a. 'Pass', 'Fail', 'Action' and 4 discrete channels are the default output signal set-up.

b. Optional RS485 control (communications) is set-up by changing the 4 discrete

channels.

c. Attach the appropriate wires to the controlling device (relay, PLC terminal, etc.).

These outputs all use a common feed or return line. Refer to next section for details.

5. See the diagrams on the next several pages and appendices for electrical interface details

plus examples.

VERICOLOR® SPECTRO

11

Page 12

VERICOLOR® SPECTRO

DB9 Connector

Pin 5 – #2 Ground (brown)

Pin 2 – #3 Txout (green)

Pin 3 – #4 Rvin (yellow)

Power/Comm/Control Cable

(VCS50-EUR8-5DB)

#2 – Negative (brown)

#1 - +24 Vdc (white)

#5 – DSR (gray)

#6 – 10's (pink)

#7 – 1's (blue)

#8 – READ (red)

Cable Shield (Panel or fixture ground)

Discrete Interface Cable

(SE108-EUR8-5M)

#1 – PASS (white)

#2 – FAIL (brown)

#3 – Output Comm (green)

#4 – CH-E 16 / 'ACTION' (yellow)

#5 – CH-D 8 / RS485-TX-A (gray)*

#6 – CH-C 4 / RS485-RX-A (pink)*

#7 – CH-B 2 / RS485-RX-B (blue)*

#8 – CH-A 1 / RS485-TX-B (red)*

Cable Shield**

*Connect the “#5 – CH-D 8 / RS485-TX-A (gray)” and “#6 – CH-C 4 / RS485-RX-A (pink)” wires together for

Half Duplex. Also, connect the “#7 - CH-B 2 / RS485-RX-B (blue)” and “#8 – CH-A 1 / RS485-TX-B (red)”

wires together for Half Duplex.

**Use as common return to controller ground (insert a 10Ω resistor if voltage potential between the controller

and VeriColor Spectro is significant).

12

Page 13

Hardware Interface Description

The VeriColor Spectro interconnects externally using serial communications and/or discrete

signals to a computer or programmable device; detailed as follows. Additionally, there is a

visual indicator which provides system status during set-up or local maintenance monitoring.

Refer to the appendices for electrical interface details and examples.

Discrete Input Lines

These control lines are part of the 'Power/Comm/Control' cable and are low power, active

high inputs, as referenced to the ground return power supply input. Each input has an on/off

timing cycle which creates the signal that the VeriColor Spectro recognizes and then takes a

responsive action.

The active high condition means to initiate an action utilizing a positive voltage signal (+9Vdc

to +24Vdc) for a specific time period. The time period is typically 65 milli-seconds, ±15 milliseconds in duration. The 'Discrete Select Request' (DSR) has longer special conditions that

are explained later.

Power/Comm/Control Cable (p/n: VCS50-EUR8-DB5)

Discrete Select Request (DSR) – gray wire

This input is used to prompt the selection of a different color standard before the next

measurement is taken. It is the control input (request) that allows the toggling of the 1's and

10's input, so it must be activated first.

VERICOLOR® SPECTRO

During the activation of DSR, new measurement triggers are locked out (ignored) until DSR

is completed. Each time DSR is enabled, the color number selection starts at 0 (zero) and

increments according to the 1's and 10's toggling. After the new color number has been

selected, when DSR is completed, the new color number is stored. If the DSR input is

released without changing the color number (toggling the 1's or 10's), the color number

remains at the previous stored value.

There is a maximum of 250 colors that can be stored and therefore selected.

Due to the requirement that this input remain on (active) while the 1's and 10's are toggled,

the time duration or period is dependent on the number of those 1 and 10 activations

combined.

1's Select – blue wire

This input can only be used while DSR is active.

Each time this input is toggled the color number will increment by 1.

This input can be used at the same time as the 10's input, so it should only toggle a

maximum of 9 times to prevent selection errors.

10's Select – pink wire

This input can only be used while DSR is active.

Each time this input is toggled the color number will increment by 10.

This input can be used at the same time as the 1's input, so it should only toggle a maximum

of 24 times to prevent selection errors (i.e. 24 toggles times 10 is 240 and added with 9

ones is 249).

13

Page 14

VERICOLOR® SPECTRO

Discrete Output Lines

These individual signal lines are part of the 'Discrete Interface' cable and all are low power

outputs which use a common control line referenced (“ComO”; the green wire). This common

line is either a supply or ground return connection for these outputs.

a. Low power means these outputs are intended for +9Vdc min to +24Vdc max @ 120 mA.

Refer to Electrical Interface Details in the Appendix for additional information.

b. All outputs default as normally open contacts, but can be configured as to normally

closed contacts. Note they still all use a common control line.

c. If the common control line is connected to ground, then all outputs are in low-side or

return path configuration. This means when VeriColor Spectro activates the 'pass' output,

it is providing a ground return for an external light or relay coil to turn on. See Figure 1.

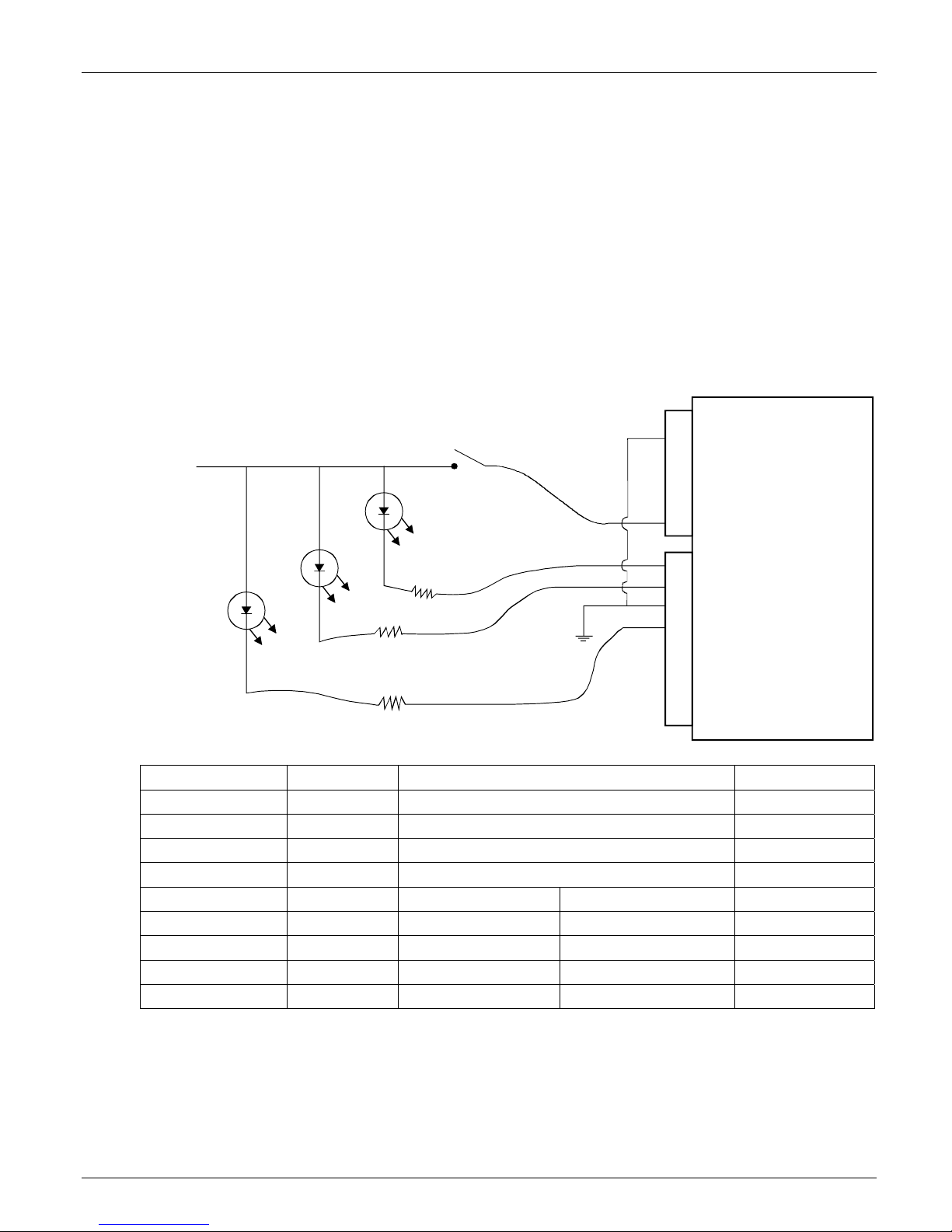

Discrete I/O Connections (Example: Low-side output enable)

+24 Vdc

read

brn

2

Pwr & RS232

J1

male 8-pin

red

8

Pass

Rx

Fail

Action

Rx = current limiting resisto r as nee ded

Rx

Rx

Connector J2 Color Description

Pin 1 White PASS = pass result Output

Pin 2 Brown FAIL = fail result Output

Pin 3 Green ComO = common discrete outputs Output

Pin 4 Yellow CH-E = 'ACTION' result Output

Instrument Outside Control

Pin 5 Gray TXD A RXD A Output

Pin 6 Pink RXD A TXD A Output

Pin 7 Blue RXD B TXD B Output

Pin 8 Red TXD B RXD B Output

A (-) B (+)

wht

brn

grn

yel

nu

nu

nu

nu

1

2

3

4

5

6

7

8

VC Spectro

nu = not used

J2

Discrete I/O

female 8-pin

d. If the common is connected to power (voltage ranging from +9Vdc to +24Vdc), then all

outputs are in high-side or supply path configuration. This means when VeriColor Spectro

activates the 'pass' output it is providing a positive voltage signal for an external light or

relay coil to turn on. See figure 2 on the next page.

14

Figure 1

Page 15

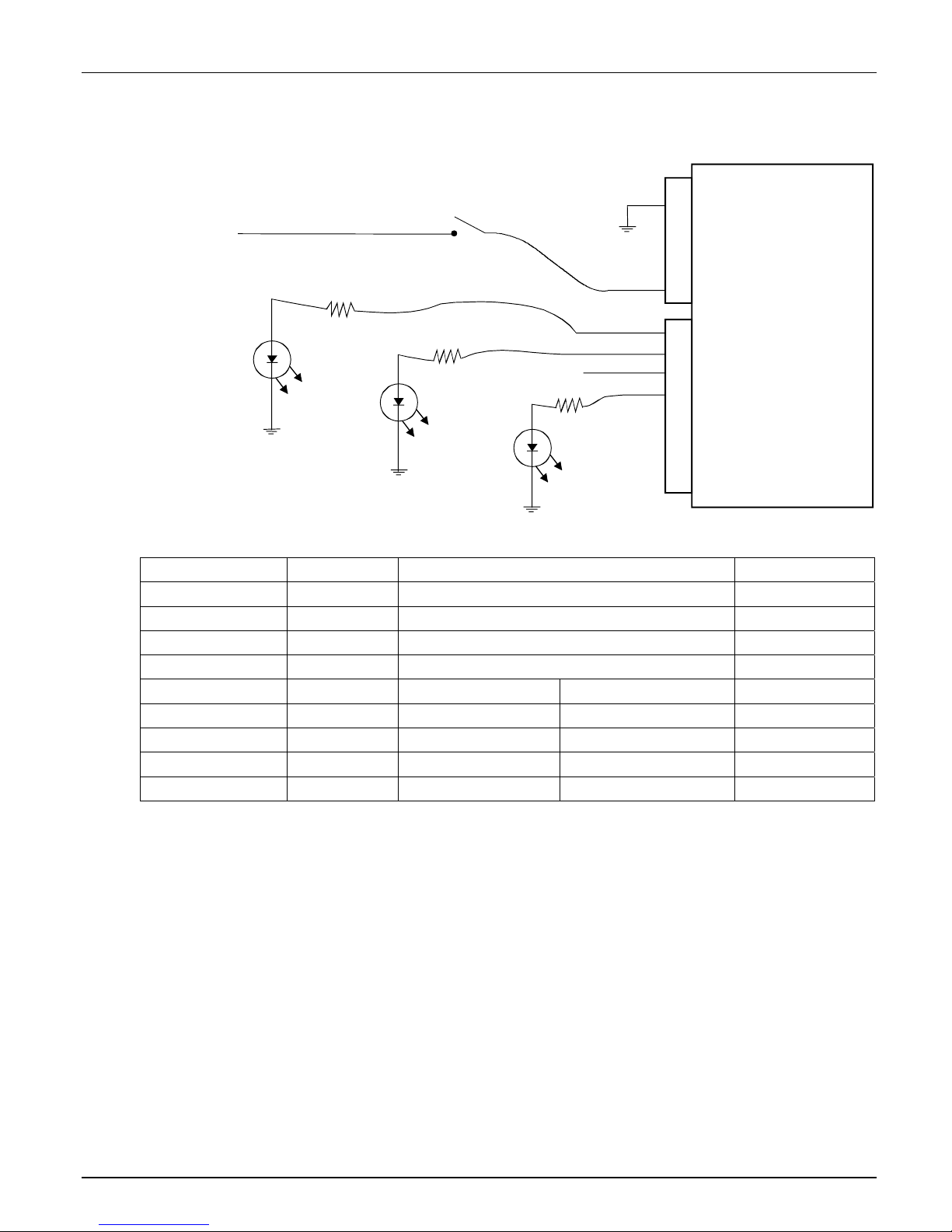

Discrete I/O Connections (Example: High-side output enable)

VERICOLOR® SPECTRO

+24 Vdc

read

brn

2

J1

Pwr & RS232

male 8-pin

red

8

Rx

Rx

Pass

Fail

Rx = current limiting resisto r as nee ded

+24 Vdc

Rx

Action

Connector J2 Color Description

Pin 1 White PASS = pass result Output

Pin 2 Brown FAIL = fail result Output

Pin 3 Green ComO = common discrete outputs Output

Pin 4 Yellow CH-E = 'ACTION' result Output

Instrument Outside Control

Pin 5 Gray TXD A RXD A Output

Pin 6 Pink RXD A TXD A Output

Pin 7 Blue RXD B TXD B Output

Pin 8 Red TXD B RXD B Output

A (-) B (+)

wht

brn

grn

yel

nu

nu

nu

nu

1

2

3

4

5

6

7

8

VC Spectro

nu = not used

J2

Discrete I/O

female 8-pin

In the default project set-up these wires are all discrete lines. Pass, Fail and ComO are

always the same, while CH-A through CH-D and Action can have an alternate configuration.

a. Action is the default but can be configured as CH-E (channel-E).

b. CH-A through CH-D are the defaults but can be configured into a 4-wire RS485 port.

Once these lines are set as RS485, they cannot also be used as discrete outputs.

Figure 2

15

Page 16

VERICOLOR® SPECTRO

Discrete Interface Cable (p/n: SE108-EUR8-5M)

Pass – white wire

This output is a VeriColor Spectro measurement response. It is activated when the last

sample was determined to be within the set tolerance for the selected color.

Fail – brown wire

This output is a VeriColor Spectro measurement response. It is activated when the last

sample was determined to NOT be within the set tolerance for the selected color, or had a

greater difference than allowed for the selected color.

Action – yellow wire

In the default set-up state 'Action', this output activates to a VeriColor Spectro measurement

response. It is activated when the last sample was determined to be within the set tolerance

for the selected color, but is either very close to being out of tolerance or is statistically

trending toward the limits.

However, if configured as a discrete channel output 'CH-E', then its activation will depend on

how the user has determined what this output is used as (project set-up conditions).

CH-A through CH-D / RS485

In the default set-up state 'CH-A through CH-D', these outputs activate to a VeriColor

Spectro measurement response. Their activation will depend on how the user has

determined what this output is used as (project set-up). They can be individual control lines

or a group output (binary/HEX).

However, if configured as an RS485, 4-wire port, then only RS485 operation is allowed.

• CH-A / RS-485-Tx-A - red wire

• CH-B / RS-485-Rv-A - blue wire

• CH-C / RS-485-Rv-B - pink wire

• CH-D / RS-485-Tx-B - gray wire

NOTE: Connect the “CH-A / RS-485-Tx-A - red wire” and “CH-B / RS-485-Rv-A - blue wire”

together for Half Duplex. Also, connect the “CH-C / RS-485-Rv-B - pink wire” and “CH-D /

RS-485-Tx-B - gray wire” together for Half Duplex.

Computer Interface

Normal computer communications between the user and the VeriColor Spectro is by the

serial RS232 interface. This interface is part of the 'Power/Comm/Control' cable, which has a

DB9 connector pre-wired for this feature. The VeriColor Spectro can also be configured to

communicate using RS485, if the appropriate discrete outputs are project set-up to operate

in this mode. Other communication schemes can be utilized if an external adapter is attached

(see note on RS232 to RS485 Adaptors below).

Note: On the Use of RS232 to RS485 Adaptors

While RS232 to RS485 adaptors are common and relatively inexpensive, the use of such

adaptors can be problematic in half duplex operation. For example, many such adaptors do

not have adequate power resources to generate currents for the longer periods of time

necessary when operating at low baud rates into terminated lines. Furthermore, until

recently, adaptors did not have the intelligence to know when to hold or release the transmit

condition. Often, a delay was inserted to hold the transmit condition until it was thought that

no more characters were coming through the RS232 interface. This delay was accomplished

with a simple timer that required the user to change a resistor in the adaptor to select the

right delay for the right baud rate. This meant that any requirements that differed from the

adaptor's default state would require the operator to “tweak” hardware or configuration

jumpers until things began to work properly.

16

Page 17

VERICOLOR® SPECTRO

X-Rite recommends the use of PCI to RS485 adaptors for installations where a PC is the

controlling device. These adaptors are usually free from the limitations previously mentioned,

may provide features that simply are not available in other adaptor designs, and are cost

effective. Ethernet to RS485 and USB to RS485 adaptors are also available, and while these

types may be ideal for a given installation, they usually have fewer configuration options.

Important: The VeriColorSpectro does NOT support simultaneous communication over

RS232 and RS485. Response should be finished before attempting to use the other port.

RS232 Interface

The default computer communications is by way of the serial RS232 interface which is part of

the 'Power/Comm/Control' cable, via a DB9 connector.

The communications protocol is serial using X-Rite's RCI command set. See appropriate

documentation for this command set.

Status LED Indicator

On the back plate of the VeriColor Spectro, located between the 2 rear mounted connectors,

is a LED indicator which visually provides system status. This LED indicator is capable of

displaying three colors: green, amber and red. A description of each color status is listed

below.

Off (no color) – This generally indicates the VeriColor Spectro has no power.

Solid Green – indicates the VeriColor Spectro is ready and waiting for further input (discrete

input or serial port).

Solid Amber – indicates the VeriColor Spectro is busy and performing a requested task.

Whenever a PLC input or serial command is being processed, the status light should remain

amber until it is ready for the next request.

Solid Red – indicates system error/failure. If this occurs then the VeriColor Spectro is not

functioning and cannot be used until the problem is resolved.

Flashing Amber – When the VeriColor Spectro is first powered up, it will slowly flash while

undergoing system test, and waiting for the illumination LED pack to warm up to

temperature.

Flashing Red – Indicates that the VeriColor Spectro is above operating temperature and will

shut down shortly.

Flashing Green – Indicates that the red LED has burned out and the yellow light is non

operable.

17

Page 18

VERICOLOR® SPECTRO

Software Installation and Overview

The VeriColor Spectro system includes a software application that provides an interface for

the VeriColor Spectro. The application is used to configure the VeriColor Spectro, store

projects which consist of color standards, and provide visual feedback of sample

measurements.

Before installing the software, make sure the VeriColor Spectro is set up as explained earlier

and the cable is connected to appropriate communication port.

Basic System Requirements

• Windows 2000 or XP Pro

• Minimum Screen resolution (1024 x 768)

Installing the Software

The software uses a standard Windows installation procedure.

1. Insert the software CD into your computer's CD-ROM drive. Browse to the Application

folder and double-click the setup.exe file on the CD.

2. The setup program guides you through the rest of the installation process. Follow the

instructions on each setup screen to complete the installation.

Starting the Application

The software application can be launched using the “VeriColor Spectro” short-cut on the

desktop or from within the Programs> VeriColor Spectro application group.

NOTE: If the VeriColor Spectro is not connected to COM 1, you will need to select the correct

communications port after launching the application for the first time. Click Admin and

select the General page to set correct COM port. Refer to Configuring the Software Options

later in this section for additional information. After the correct port is selected, you will need

to perform a calibration. Please refer to the Calibration procedure in the System Operation

section for additional information.

18

Page 19

VERICOLOR® SPECTRO

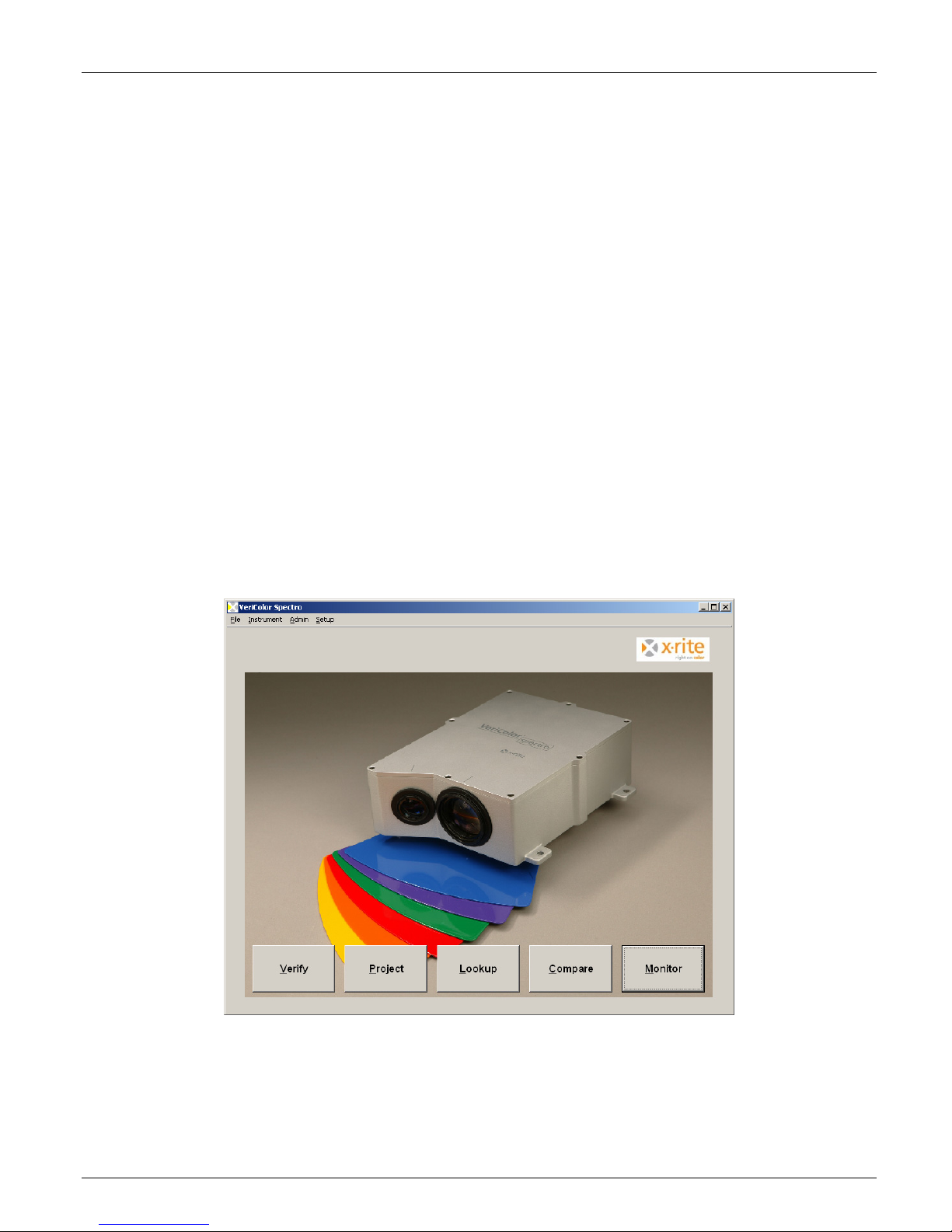

Application Overview

The VeriColor Spectro application consists of four menus and five application modes. The

menus are located at the top and the mode bottoms are at the bottom of the application.

Menus

• File – used to exit the application and launch a language translation tool (if activated

in Admin)

• Instrument – used for testing, calibrating and targeting of the VeriColor Spectro

• Admin – used to configure the default settings for the application

• Setup - used to create palettes and standards

Application Modes

• Verify – used to find the closest stored standard to a measured sample

• Project – used to create projects

• Lookup – used to auto select a standard from a palette

• Compare – used to compare stored or measured trial and standard data

• Monitor - used to monitor sample measurements after the system is set up

Refer to the VeriColor System Operation section that follows for detailed information on

setting up the software and using the VeriColor Spectro with the software application.

19

Page 20

VERICOLOR® SPECTRO

VeriColor Spectro System Operation

Configuring the Software Options

The software should be configured before proceeding with the color standards setup and

sample measurements.

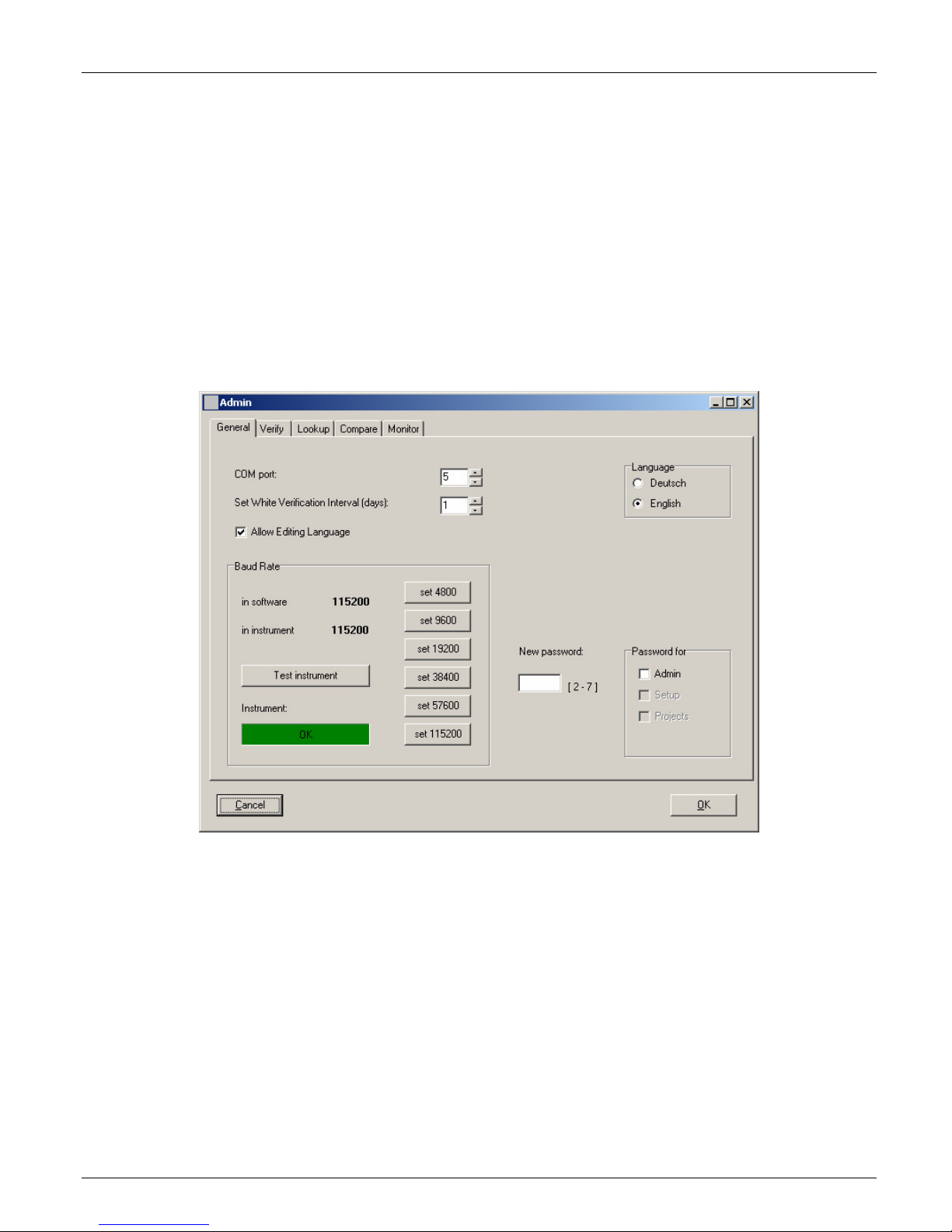

Administrative (Admin) Setup

Administrative setup is used to configure the General, Verify, Lookup, Compare, and Monitor

options. The Admin dialog is accessed by clicking Admin menu at the top of the application.

General Screen Page

The general screen is used to establish serial communications, select the language the

application will run in, and setup password protection.

1. Click in the COM port field and enter an appropriate port number, or use the up/down

arrows to select the connection port. The default port is one.

2. Click in the Set White Verification … field and select the number of days that pass

before you would like to be reminded to perform a verification. Use the up/down arrows

to select the number of days, ranging from 1 to 30. The default number is 1.

3. Click one of the Baud Rate buttons to select the desired baud rate. Once selected, the

instrument and software will both be configured. The default baud rate is 115200. You

can click the Test instrument button to check the baud rate selected. If the connection

is fine, OK should appear in a green box below the instrument field.

4. Select the Language that you would like that application to run in by clicking the

appropriate option. The default language is set to English. If the desired language is not

available, you can use the Language Tool option located in the File menu to localize the

application to a different language. Refer to the Language Tool later in this section.

NOTE: The Allow Editing Language option must be checked before the Language Tool

item appears in the File menu. The default is un-checked.

20

Page 21

VERICOLOR® SPECTRO

5. You can password protect the Admin menu, Setup menu, and Project mode from

unauthorized access by checking the desired Password for option and entering a

password in the New password field. The password must be between 2 and 7 characters

to be acceptable. You will then be asked to enter this password before you can access the

mode selected.

6. Click the OK button to save your setting and exit Admin; or select the Verify, Lookup,

Compare, or Monitor page to continue with option settings.

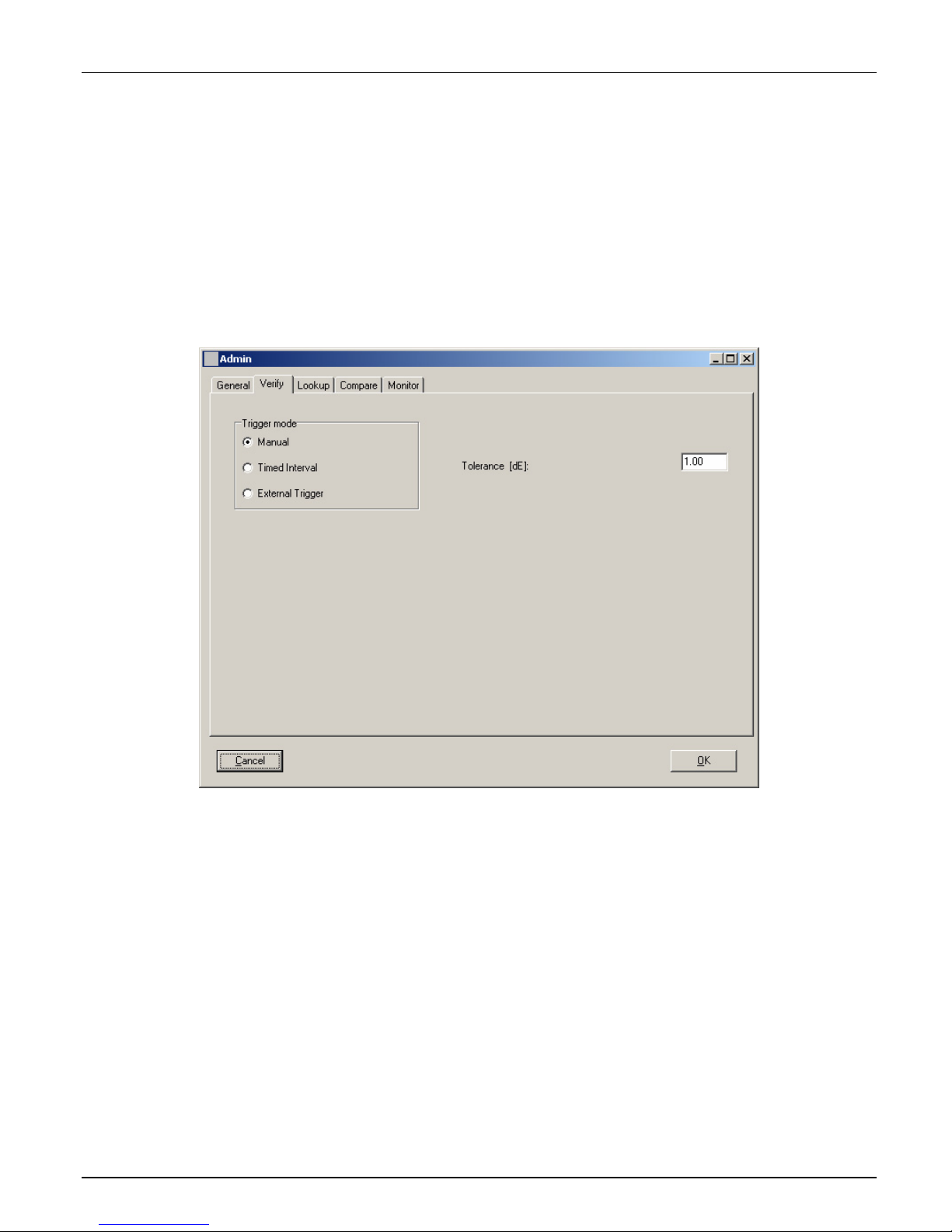

Verify Screen Page

The verify screen is used to choose how the measurement will be triggered, measurement

interval time (for timed interval), and the Tolerance dE value used for Verify mode.

1. Select Manual, Timed interval, or External Trigger as the trigger mode. This

determines the measurement method that is used in Verify mode. The default mode is

Timed interval. Manual selection requires a Measure button click for each measurement.

Timed interval allows automatic interval measurements to take place. External trigging

requires an external device (PLC) to activate a measurement.

2. Click in the Tolerance dE field and enter desired tolerance value. This determines the dE

value used in the Verify mode.

3. Click the OK button to save your setting and exit Admin; or select the General, Lookup,

Compare, or Monitor page to continue with option settings.

21

Page 22

VERICOLOR® SPECTRO

Lookup Screen Page

The lookup screen is used to enter the Tolerance dE cmc value and averaging number used

for Lookup mode.

1. Click in the Tolerance dE cmc field and enter desired tolerance value. This determines

the dE cmc value used in the Lookup mode.

2. Click the OK button to save your setting and exit Admin; or select the General, Verify,

Compare, or Monitor page to continue with option settings.

22

Page 23

VERICOLOR® SPECTRO

Compare Screen Page

The compare screen is used to enter sample/operator information for the Compare mode

screen and print outs.

1. Click in the Term 1 and/or Term 2 fields and enter desired text. This determines the

default attributes that appear in the Compare mode.

2. Click in the Operator field(s) and enter the desired name(s). This establishes a list of

operators that can be selected from in the Compare mode.

3. Click in the Title, Company, Street and Town fields and enter appropriate information.

This determines the information that will be printed in a Compare report. Checking with

mean value causes the average values to also print on the report.

4. Click the OK button to save your setting and exit Admin, or select the General, Verify,

Lookup, or Monitor page to continue with option settings.

23

Page 24

VERICOLOR® SPECTRO

Monitor Screen Page

The monitor screen is used to set the triggered mode, auto target options, and storing

options.

1. Select Manual, Timed interval, or External Trigger as the trigger mode. This

determines the measurement method that is used in Monitor mode. The default mode is

Timed interval. Manual selection requires a Measure button click for each measurement.

Timed interval allows automatic interval measurements to take place. The interval

amount is set in the Monitor mode. External trigging requires an external device (PLC) to

activate a measurement.

2. Check Only last record for PASS/FAIL to display only the last failed (red), warning

(yellow), or pass (green) measurement status in the traffic light after a measurement.

When the option is unchecked (default setting), the traffic light will continue to display a

failed or warning status until the single measurement or measurement average that

caused the condition scrolls from the screen in the trend graph. Note: When unchecked,

the alert level will also increase if applicable (warning to fail). Refer to Viewing Sample

Data in the Monitor Mode section for additional information.

3. Check Auto Target from Project to automatically search the database for a standard

that more closely matches the sample measurement. Search criteria is set by entering

the delta E value in the Limit for holding field. Limit for holding value causes VeriColor

Spectro to compare the sample against the selected standard until the set dE value is

exceeded. Once exceeded, VeriColor Spectro searches the database for a closer standard

match.

4. Check the Log data option to automatically save measurement data in the Monitor mode

to a .txt file. The default setting is not checked. Refer to the next page to view a sample

log data report. Check Unlimited number of records if you do not

want to save the

trend data to a file. The default setting is not checked.

5. Click the OK button to save your setting and exit Admin, or select the General, Verify,

Lookup, or Compare pages to continue with option settings.

24

Page 25

SAMPLE LOG REPORT

VERICOLOR® SPECTRO

25

Page 26

VERICOLOR® SPECTRO

Language Tool

The language tool is used to localize or update the application string text to a language of

choice if the desired language in not available in the Admin dialog. The Language Tool dialog

is accessed by selecting the File menu and then Language Tool.

NOTE: The Language Tool option will not appear if it is not activated in the Admin/General

page.

1. Select a form to translate from the Choose Form dropdown list. The list contains all the

forms (screens) present in the application. When you select a form, the text for that form

appears in the columns below. The column on the left is the reference column and cannot

be edited. The column on the right is the column that is used to localize the text strings.

2. Translate the text in the column on the right and then select another form.

3. Click the Test in Form button to view the translation made to the application without

saving them.

4. Click the Save to file button to save the localized text strings to the application. You will

need to restart the application for the changes to take affect.

Copy Single Language

The Copy Single Language option is used to copy a translated language file (.lgu) to the

VeriColor Spectro application.

1. Click the Copy Single Language button.

2. Click the Source button and browse to the translated file location.

3. Click the Destination button and choose the location to copy the translated file (.lgu).

26

Page 27

Targeting a Part

Because the VeriColor Spectro instrument over illuminates, it is sometime difficult to tell

exactly where the instrument is viewing to determine color. This is particular true for small

part measurements.

Targeting a part is the method of adjusting the VeriColor Spectro to the required position for

part measurements. Performing the targeting procedure is only needed if the location of the

part to be measured is critical. For example, the measurement area is small or very close to

the spot size of the VeriColor Spectro.

1. Targeting is started by selecting Target Light from the Instrument menu, Setup menu,

Verify mode, Compare mode, or Monitor mode.

2. Target Light dialog and a red ring (elliptical at 0°/30° and circle at 30°/0°) approximately

1.00” in diameter begins flashing. This is the VeriColor Spectro's measurement viewing area.

You can turn the targeting light off or on by clicking the appropriate button.

VERICOLOR® SPECTRO

3. Without disturbing the pre-aligned height and position of the VeriColor Spectro, carefully

adjust the VeriColor Spectro (x and y coordinates) so the red circle is centered on the

area of the part you wish to measure.

NOTE: The illumination area is an

approximation and is intended to help you

visually locate your sample. When the

instrument is mounted at 0°/30°, the

illumination will be more of an elliptical shape,

and you should make your 1.00” reference

0°/30° Mounting

starting from the outside edge of the

illuminating circle.

Approximate

Illumination

area

Outside edge

Area of part

Red alignment spot

to measure

1” diameter

4. After the desired positioning is achieved, secure the VeriColor Spectro.

5. Click the Close button to turn off the light and close the Target Light dialog.

27

Page 28

VERICOLOR® SPECTRO

Calibration/Verification of the VeriColor Spectro

The VeriColor Spectro comes with a calibration tool that is used to verify measurement

performance and for calibrating the instrument.

Calibration should be performed the very first time you turn on the system, and anytime

thereafter that the user defined white verification tolerance is exceeded.

Verification is performed whenever a verification is requested by the software (user definable

from 1 to 30 days), or anytime that measurement performance is in question. Poor

measurement performance can be caused by dust or dirt on the sensor lens and illumination

lens. Refer to the Cleaning section later in this document for procedure on cleaning the

VeriColor Spectro instrument.

NOTE: The calibration tool supplied with your VeriColor Spectro is configured for that specific

instrument. If a replacement calibration tool is used, you will need to reconfigure the

instrument for that replacement tool. Refer to Calibration Configuration later in this section

for details on reconfiguring for a new calibration tool.

Attaching the Calibration Tool

IMPORTANT: Do not touch the white reference in the bottom of the calibration tool. It must

be kept clean to ensure accurate measurements. Always store the calibration tool in its bag

when not in use. If the calbration tool requires cleaning, refer to the General Maintenance

section later in this manual.

1. Locate the calibration tool that is shipped with your VeriColor Spectro instrument.

2. Make sure the cutout side of the calibration tool is facing the sensor lens side. Snap the

tool onto the illumination lens of the VeriColor Spectro instrument.

NOTICE: Caution should be

used not to touch the white

reference in the bottom of

the calibration tool.

Sensor lens

28

Cutout

Page 29

VERICOLOR® SPECTRO

Performing Calibration (first time, out of box)

1. Make sure the VeriColor Spectro is connected and setup according to procedures shown

in the Installation section and then launch the application. A “Need white calibration”

screen appears. Click the OK button.

2. The Calibration dialog appears. Click the White Calibration button.

3. Make sure that the lenses on the VeriColor Spectro are clean (refer to the Cleaning

section later in this document) and then click OK on the “Insure lenses are …” screen.

4. Attach the calibration tool as requested. Refer to Attaching the Calibration Tool as

previously explained. When tool is properly attached, click the OK button on the “attach

calibration tube” screen.

The instrument takes five calibration measurements.

5. Click Exit on the Calibration dialog.

6. Remove the calibration tool and place in its storage bag.

NOTE: If an error message appears after calibration, make sure the calibration tool is

located correctly over the illumination lens and is clean. You may also want to clean the

illumination lens and sensor lens on the VeriColor Spectro. Refer to the General Maintenance

section for cleaning procedures. After checking the calibration tool and cleaning the

instrument, click the White Calibration button again and repeat the procedure.

If an error still appears after calibration, contact X-Rite Customer Support at the number

listed on the back cover of this manual.

29

Page 30

VERICOLOR® SPECTRO

Performing Verification

1. Start the application; if verification is not automatically required, select the Instrument

menu and then the Calibrate item to display the Calibration dialog. The screen lists

information on when the last verification and calibration were performed on the VeriColor

Spectro instrument.

2. You should perform a white verification if time has expired since your last defined

verification time period. (The white verification time interval is set in the

Admin/General page.) Click White Verification.

3. Make sure that the lenses on the VeriColor Spectro are clean (refer to the Cleaning

section later in this document) and then click OK on the “Insure lenses are …” screen.

4. Attach the calibration tool as requested. Refer to Attaching the Calibration Tool as

previously explained. When the tool is properly attached, click the OK button on the

“attach calibration tube” screen.

The instrument takes one measurement, updates the White Verification Difference

value and the Last Verification Time stamp date. The value listed is the White

Verification Dif field is the difference between the cal values stored in the instrument

and the measured values.

5. Click OK on the Verification Ok screen.

6. Click the Exit button and remove the calibration tool and place in its storage bag.

NOTE: If an “Out of white verification tolerance” appears, you will need to perform a

calibration procedure. Refer to the next page.

30

Page 31

VERICOLOR® SPECTRO

Performing Calibration (after verification failure)

Instrument calibration is required when the white verification measurement fails. The

verification measurement fails when the user defined white verification tolerance value is

exceeded. This tolerance is set on the Configuration Calibration dialog.

1. Click OK on the “Out of White Verification Tolerance screen”.

2. Make sure that the lenses on the VeriColor Spectro are clean (refer to the Cleaning

section later in this document) and then click OK on the “Insure lenses are …” screen.

3. Attach the calibration tool as requested. Refer to Attaching the Calibration Tool as

previously explained. When the tool is properly attached, click the OK button on the

“attach calibration tube” screen.

4. The instrument takes five calibration measurements and updates the Last Calibration

Time stamp.

5. Click OK on the “Calibration Ok” screen.

6. Remove the calibration tool and place in its storage bag.

NOTE: If an error message appears after calibration, make sure the calibration tool is

located correctly over the illumination lens and is clean. You may also want to clean the

illumination lens and sensor lens on the VeriColor Spectro. Refer to the General Maintenance

section for cleaning procedures. After checking the calibration tool and cleaning the

instrument, click the White Calibration button again and repeat the procedure.

If a failure still occurs, contact X-Rite Customer Support at the number listed on the back

cover of this manual.

31

Page 32

VERICOLOR® SPECTRO

Calibration Configuration

The configuration dialog is used to enter the white verification tolerance value and select the

mounting geometry. The other options are only edited if a replacement cal tube or reference

is used.

To access the Configuration dialog, click the Configuration button on the Calibration dialog.

Entering a White Verification Tolerance

The tolerance value entered is used to determine the verification difference tolerance. The

default value is set to 1.00.

1. Click in the White Verification Tol field and edit the value.

2. Click the Load New Values button to download to the instrument.

3. Click the Close button to close the Configuration Calibration Values dialog.

Selecting the Mounting Geometry

This option is used to select the mounting geometry of the VeriColor Spectro.

1. Select 0°/30° or 30°/0° option.

2. Click the Close button to close the Configuration Calibration Values dialog.

32

Page 33

VERICOLOR® SPECTRO

Editing the Calibration Tool Plaque Value (for X-Rite calibration tool replacement)

Each calibration tool has a unique number assigned to it that is specific to the instrument

that it is used with. If the calibration tool is replaced with another, the serial number and

calibration plaque value listed on the replacement tool must be entered and then downloaded

to the instrument. Refer below for the procedure.

1. Locate the serial number and calibration plaque value that is assigned to the calibration

tool you are using. The serial number and calibration plaque value are located on the end

cap of the tool. The calibration plaque value ranges from 0 to 199.

2. Click in the Calibration Plaque SN field and enter the serial number.

3. Click in the Calibration Plaque Value field and enter the assigned number (0 to 199).

4. Click the Load New Values button to download to the instrument.

5. Click the Close button to close the Configuration Calibration Values dialog.

6. Perform a calibration procedure with the replacement calibration tool.

Editing the White Calibration Plaque Values (for non X-Rite calibration reference)

If desired, you can use a non X-Rite calibration reference with the VeriColor Spectro. Values

assigned to the reference must be entered into VeriColor Spectro via the software

application. The calibration plaque values list all wavelength values for the current (old)

plaque. The “old” values are also mirrored in the new column until edited. Refer below for

the procedure.

NOTE: Please write down and retain the current factory wavelength values listed in the “old”

column before making any changes. Also record the current Calibration Plaque Value. These

factory values will need to be reentered if the X-Rite calibration tool is ever used.

1. Click in the Calibration Plaque Value field and enter the value 100.

2. Click in the 390 wavelength field in the New column and edit the value to match the

value of your white reference.

3. Continue until all wavelength values match the values listed on the calibration reference

you are using.

4. Click the Load New Values button to download to the instrument.

5. Click the Close button to close the Configuration Calibration Values dialog.

6. Perform a calibration procedure with your calibration reference.

33

Page 34

VERICOLOR® SPECTRO

Color Standards and Projects

Color Standards and Projects are created using the Setup menu and Project mode functions.

Up to 250 color standards can be created and saved in a project for transferring to the

VeriColor Spectro instrument.

When creating a standard in Setup Mode, it is best to create the standard in the way in which

the instrument will be reading the sample for comparison. If the instrument is mounted inline and the sample will be moving, it is best to create the standard in this dynamic

environment. It is recommended that the standard be created based on the average of a

series of multiple measurements (5 – 10).

Creating Palettes and Color Standards

The Setup mode is used to create and edit standards and palettes. A palette is used for

grouping color standards.

The Setup dialog is accessed by clicking the Setup menu item at the top of the application.

1. Click the New Palette button, enter a palette name and click OK. Color standards are

grouped in palettes.

2. If desired, set the Averaging from 1 (no average) to a maximum of 20, using the

up/down arrows. The average number must be selected before a standard name is

entered.

34

Page 35

VERICOLOR® SPECTRO

3. Click the Add Standard button. The Choose Standard field changes to Name of new

standard. Enter a standard name in the field and click Enter or press the Enter key on

the keyboard.

4. Position the color standard under the VeriColor Spectro as specified earlier, or click

Import CSV to import the standard data. Refer to Importing a CSV File later in this

section for more detailed information on using this feature.

5. Perform targeting if required (refer to Targeting a Part earlier in this section) and then

click the Measure button on the Setup dialog to take the measurement.

6. Take additional measurement if averaging is used for the color standard.

7. Click the Save button to save the standard to the database and return to the main Setup

dialog. The color standard number, measurement time stamp, simulated color, and data

values are displayed below the name.

8. If required, enter specific tolerance values other than the default values for the standard.

Refer to the next page for information on adjusting tolerances.

9. Continue with additional color standards by clicking the Add Standard button.

10. When you have finished creating color standards, click the Close button to return to the

main application screen. Continue on to the Creating Project section.

11. Refer to the following pages for information on additional Setup dialog controls.

35

Page 36

VERICOLOR® SPECTRO

Tolerancing

Whenever a new standard is created and saved, it is stored with the default tolerances. If you

need to use specific tolerances for individual standards, you would use the tolerancing option.

1. Click the Tolerance button on the Setup dialog to open the Tolerances dialog. Within the

Tolerance dialog, you have the ability to enter individual tolerances and an action limit.

2. Select Type of Tolerance dropdown list select the tolerance type. Available types are:

dLab+-, DLCH+-, dEcmc,and dEab, or None at all.

3. Click in the Tolerance fields and edit the default tolerance limits for the selected

standard.

4. Click in the Action limit [%] and edit the percentage value. This option is used to

establish the percentage amount required to trigger a yellow “warning” display in the

traffic light. This signifies that a sample is trending toward a fail condition, but still is

within the defined tolerance. You can select between 25 and 99 as a action limit

percentage. This percentage is applied to the upper and lower user defined tolerances in

L* a* b*, L* c* h, * dEcmc, and DE*.

EXAMPLE: If the tolerance for a standard is 1.00 dE on L*, a* and b*, setting the action

limit to 75% will activate the yellow warning light if the standard drifts to or above 0.75

DE on one or more of the L*a*b* values. The same is true for L*c*h* and DE* if these

tolerancing modes are selected.

The default setting is no value entered.

5. If you want only the current standard to use the edited tolerances, click the OK button to

save the tolerances and exit the dialog. If you want all of the new standards stored to

use these tolerances, click the save as default button. You will be asked to confirm that

you want to overwrite the default tolerances. Click OK to continue and then click OK

again to exit the Tolerance dialog.

Clicking the Use Default button will set the tolerance type and limits to the current

system default settings.

36

Page 37

Additional Setup Dialog Controls

VERICOLOR® SPECTRO

(1) Choose Palette list displays the current palette (if available) selected. The same

control can be used to select a different palette if more than one exists.

(2) Rename Palette button is used to rename the selected palette.

(3) Delete Palette button is used to delete the selected palette. All associated color

standards will also be deleted.

(4) Choose Standard list displays the current standard in the field. The same control can

be used to select a different standard if more than one exists.

(5) Standards field lists the number of standards that exist in the selected palette.

(6) Edit Standard button is used to edit the name or measured data of a standard. You

would first select the standard from the Choose Standards list to edit and then click the

Edit Standards button.

(7) Delete Standard button is used to access the Delete Standards dialog where

standards are deleted.

(8) Import CSV button is used to import reflectance data for use as a new standard or

existing standard. Refer to the next page for details.

37

Page 38

VERICOLOR® SPECTRO

Importing a CSV File

The CSV import function allows you to create a new standard or edit a previously created

standard in Setup. This is accomplished by measuring a sample in monitor mode and then

saving the data using the process below to import as a new standard.

NOTE: When importing .csv data using Import CSV, the data is not added to the existing

standard when editing. The existing standard data is replaced with the new data.

Creating a .csv file for a standard

1. Take a series of measurements in monitor mode and save the data to an Excel

“master” .csv file. Any new measurements that you want to add to the master file

should be saved in a new file. The data is then selected from the new file and then

copied into the master .csv.

2. Delete any data not needed in the “master file” and then average the R values.

3. Once averaged, copy the reflectance values into fields “B1” through “AF1” of the

NewImport.csv file located on the VeriColor Spectro CD. Field “A1” is reserved for

import code VS31RV required by the software.

4. Save the NewImport.csv file to a location on your computer where it can be

accessed for importing.

5. Use the Import CSV function in Standard Setup to import the newly created

NewImport.csv file from the stored location on your computer.

Example .csv file

38

Page 39

Verify Mode

The Verify mode is used to locate a standard color that closely matches a measured sample.

The standard found is based on the project selected and the tolerance dE entered in the

Admin/Verify page.

The Verify dialog is accessed by clicking the Verify button at the bottom of the application.

VERICOLOR® SPECTRO

1. Select the project where your color standards are stored from the Project drop down list.

Color standards from the selected project appear in the numbered list on the right side of

the screen.

2. If desired, set the Averaging from 1 (no average) to a maximum of 20, using the

up/down arrows.

3. Determines the amount of time that needs to elapse between timed interval sample

measurements. Set the amount of time in the Interval fields using up/down arrows.

Time intervals can range from 2 second up to 60 minutes.

4. Position the color standard under the VeriColor Spectro as specified earlier.

5. Perform targeting if required (refer to Targeting a Part earlier in this section) and then

click the Measure button on the Verify dialog to take the measurement.

The closest color standard name and simulated color appears in the first rectangle, with

the color name highlighted in the list. The simulated measured color appears in the

second rectangle. If the standard found is within the specified tolerance, PASS appears

next to the measured color rectangle. If the standard found is not within the specified

tolerance, FAIL appears next to the measured color rectangle.

6. When you have finished with the Verify mode, click the Close button to return to the

main application screen.

39

Page 40

VERICOLOR® SPECTRO

Project Mode

The Project mode is used project maintanence (create, delete and edit), perform

uploads/downloads to the instrument, and setup PLC configurations. A single project can

consist of up to 250 color standards and configuration settings. After creating a project, it

would be downloaded and stored in the VeriColor Spectro instrument. Once the VeriColor

Spectro instrument is programmed with a project, it can execute independent of the software

application.

The Project dialog is accessed by clicking the Project button at the bottom of the

application.

1. Select the palette where your color standards are stored from the Palette pull down list.

Color standards from the selected palette appear in the Standards numbered list on the left

side of the screen.

2. Click the New project button, enter a project name and click OK. The new name will

appears in the Project list.

The Projects list is used to select the project from the database that you would like to

download to the instrument. The selected project shows all associated standards in the

Standards number list on the left.

40

Page 41

VERICOLOR® SPECTRO

3. Using your mouse, drag and drop the color standards from the left Standards list to the

right Standards list. This will save the color standards under the newly created project.

Color standards that are moved to the right column will be “grayed out” in the left column.

4. Click the Save Project button to save the project to the database.

5. To download the Project to the VeriColor Spectro, click the Download project to

instrument button. You will be prompted that the existing project in the instrument will be

deleted. Click Yes to continue.

6. When you have finished creating project, click the Close button to return to the main

application screen.

Additional Project Dialog Controls

Drag outside

of list to delete

(1) Upload project from instrument button is used to retrieve the project currently

stored in VeriColor Spectro. The retrieved project name and standards will appear in the

list on the right side of the screen.

(2) Delete color standards from project list is performed by clicking on the standard in

right side list and dragging it outside of the list.

(3) Standards field lists the number of standards that exist in the selected project.

(4) Delete Project button is used to delete the selected project.

41

Page 42

VERICOLOR® SPECTRO

(5) Rename Project button is used to rename the selected project.

(6) Configuration button is used to access the Configuration PLC Values dialog. Refer

below for detailed information.

(7) Clear project from instrument button is used to clear the current project stored in

the instrument.

Configuration PLC Values

The Configuration PLC Values dialog is used to configure the instrument for use with external

PLC control.

The Configuration PLC Values dialog is accessed by clicking the Configuration button at the

bottom of the Project dialog.

Auto Transmit – Determines if measurement data is automatically transmitted after a

measurement. When set to OFF (default setting), no data is automatically transmitted

after a measurement. When set to ON, you would choose what data is transmitted.

Select Status only, LabCh (Smp), LabCh (Std, Dif), Refl (Smp), or Refl (Smp, Std)

option for the type of data to transmit.

Output – Allows you to select an instrument configuration that dedicates the outputs of

channels A-E to support your setup requirements.

Discrete Outputs

(max. 15) of the closest matching standard within the downloaded project.

RS485 Port

– Channels A-D are used to support communications for an RS485

connection.

Action Indicator

indicator in correlation to the assigned action limit applied to the active standard.

42

– Channels A-D provide Binary outputs indicating the number

– Configures the output of channel E to function as a Warn

Page 43

VERICOLOR® SPECTRO

Bit 5 of Binary Output - Configures the output of channel E to function as Bit 5 in

the Binary output configuration indicating the number (max. 31) of the closest

matching standard within the downloaded project.

Searching – Determines the standard search method. When set to Searching disabled

(default setting), no standard search is used. The active standard is used for sample

comparison. When set to Searching enabled, the instrument is searched for the closest

standard match to the measured sample.

Averaging - Determines the method used to derive an average, along with the number of

measurement taken to obtain a normal or weighted value digitally filtered average, and

how much time elapses between measurements. The Digital Filtering option is an

alternative to simply averaging a set of readings. This method applies a weighting factor

across multiple readings selected. The averaging control can be turned off by setting it to

(0) zero (default setting), or adjusted from 2 to 10 measurements to average. Time

delayed between measurements can be set from 0 to 10 seconds. When the control is set

to 0, the Measure button must be clicked to take the measurement. When set to a time

increment (10 = 1 sec, 20 = 2 sec., etc.), the instrument will pause the defined amount

between measurements.

PLC - Determines the amount of time the instrument will “pause” after seeing the Read

input go activate (discrete input only), and how long the instrument holds its outputs

active after a measurement occurs. The Time between external trigger and reading

control occurs before an actual measurement is taken and can be adjusted from 0 to 10

seconds, in tenths of a second increments (11 = 1.1 sec, 22 = 2.2 sec., etc.). The Time

output control remains active control can be set from 0 to 100 seconds, in tenths of a

second increments (11 = 1.1 sec, 22 = 2.2 sec., etc.).

Use Defaults button

Clicking the Use Defaults button will set all options in the Configuration PLC dialog to

the factory default settings.

Load Settings button

Clicking the Load Setting button will download the current settings in the Configuration

PLC dialog to the Vericolor Spectro instrument.

43

Page 44

VERICOLOR® SPECTRO

Monitor Mode

The Monitor mode is the “main” mode of the application. The Monitor mode is used to view

sample measurement performance once the color standards are set up.

The Monitor dialog is accessed by clicking the Monitor button at the bottom of the

application.

The first step is to select a target (standard) or measure a target (standard). If Auto Target

was setup in the Admin/Monitor page, you would select the project where the standards are

located. If auto targeting is not used, you would select a specific target.

Selecting a Single Standard (no auto target)

1. Click the Target from file button to open a dialog where a stored standard is selected as

the target color.

2. Click the left arrow button (<) located between the Palette and Project lists to active the

Palette list.

44

Page 45

VERICOLOR® SPECTRO

3. Select the palette from the Palette list where the standard is stored.

4. Click the right arrow button (>) located between the Palette and Project lists to active

the Project list.

5. Select the project from the Project list that the standard is associated with.

6. Select the standard from the as standard list.

7. Click Choose to select the standard and close the Standard from file dialog. The standard

name appears in the Target field, and the data values and tolerances appear below that.

Selecting a Project for Auto Targeting

NOTE: Auto targeting is setup in the Admin/Monitor page and cannot be selected in the

Monitor mode. You can select a specific standard here; however the standard may change to

a closer standard based on the sample measurement taken.

1. Click the Target from file button to open the Standard from file dialog.

2. Note that the Palette list and Project list are disabled on this dialog.

Select the standard from the as standard list.

3. Click Choose to select the standard and close the Standard from file dialog. The standard

name appears in the Target field, and the data values and tolerances appear below that.

Auto Target appears to the left of the Target from file button to let you know auto

targeting is activated.

Measuring a Standard

NOTE: Auto targeting must be disabled (unchecked) in the Admin/Monitor page to allow a

target measurement.

1. Prepare the sample for measurement.

2. Perform targeting if required (refer to Targeting a Part earlier in this section) and then

click the Measure target button. If a previous target exists, you will be asked if you

want to overwrite the current standard. Click Yes to continue. The sample is measured

and the data, default tolerances, and simulated color appear in the target area.

45

Page 46

VERICOLOR® SPECTRO

3. If you would like to name the target, click in the Target field and enter a name.

Setting Tolerances

The Tolerance button is used to open the Tolerance dialog. Here the tolerance type,

tolerance limits, and action limit for the standard used in Monitor mode are set or adjusted.

Tolerances that were created for a standard opened from the file will be carried over. You

can edit these tolerances without overwriting the stored tolerance values.

1. Click in the Tolerance button to open the dialog where the tolerances are edited.

2. Select the desired tolerance from the Type of Tolerance list.

3. Enter tolerance values in the available fields and adjust the Action limit if required.

4. Click OK when finished. Adjusted values or new values now appear in the tolerance fields

below the standard data.

46

Page 47

VERICOLOR® SPECTRO

Creating a Standard from a Series of Measurements

NOTE: Auto targeting must be disabled (unchecked) in the Admin/Monitor page to create a

standard from a series of measurements.

1. Prepare the sample(s) for measurement that will be used for that standard.

2. Click the Measure target button to obtain the first standard measurement.

3. Set the amount of time that elapses between measurements in the Interval fields using

up/down arrows. Time intervals can range from 2 second up to 60 minutes.

4. Click the Start new series button at the bottom of the Monitor dialog to start the

measurement sequence.

5. After the required amount of samples are measured for the average, click the Pause

button.

6. Click the Mean as Target button that appears at the top of the dialog after the Pause

button was clicked. You will be asked to confirm that you want to overwrite the existing

standard. Click Yes to continue.

Clicking the Mean as Target button will change the standard to the mean average of the

series of measurements taken. The target name changes to “Mean” and indicates the

number of samples measured to obtain an average.

IMPORTANT

If you choose your standard from file, and then change the standard to the mean average of

the series of measurements, the tolerances that carried over from the standard from file will

no longer apply. You will need to manually adjust the tolerance to compensate for the

difference in the current mean average vs. the standard from file.

Example: My tolerance is 1.0 DE on L*, a*, and b*. My sample has been running at 0.50 DE

to the standard. I choose to change the standard to the mean average of this series. My new

standard is now 0.5 DE beyond the original standard tolerance. A tolerance of 1.0 means

that I can be running at a DE of 1.5 to the original standard and the instrument will give a

pass indication.

In order to avoid this, the tolerance for the new Standard should be adjusted from 1.0 DE to

0.5 DE.

Also, the new standard created from the mean average cannot be saved or replace the

current standard in file.

Manual Sample Measurement

Manual measurement mode is used to take single sample measurements. Manual should

appear as the trigger method. If not, the option will need to be set as the trigger mode in the

Monitor options page of the Admin dialog.

47

Page 48

VERICOLOR® SPECTRO

1. Select the standard as previously explained and prepare a sample for measurement.

2. If desired, set the Averaging Samples from 1 (no average) to a maximum of 20, using

the up/down arrows.

3. Click the Start new series button at the bottom of the Monitor dialog.

4. Click the Measure button at the bottom of the Monitor dialog. A single measurement is

taken and results displayed on the screen.

5. Each time the button is clicked, a measurement is taken and results displayed.

6. Click End of Series button at the bottom of the Monitor dialog to end the manual

measurement mode.

7. Click the Store button (if activated) to save the measurement data as a .txt, .csv, or .mif

file.

Interval Sample Measurements

Interval measurement mode causes the VeriColor Spectro to take continuous measurements

at specified intervals. Timed interval should appear as the trigger method and an interval

time amount should be set. If not, the option will need to be set as the trigger mode in the

Monitor options page of the Admin dialog.

1. Select the standard as previously explained and prepare the samples for measurement.

2. Determines the amount of time that needs to elapse between timed interval sample

measurements. Set the amount of time in the Interval fields using up/down arrows.

Time intervals can range from 2 second up to 60 minutes.

3. If desired, set the Averaging Samples or Sliding Averaging from 1 (no averaging) to

a maximum of 20, using the up/down arrows. Sliding average reports the average across

the number of measurements defined as they are measured. For example, if 5 is selected

as the sliding average, then the last 5 measurements taken are continually averaged.

NOTE: It is possible for the traffic light to display as red (failed) even if the last sample

measured in the sliding average group were in tolerance. Refer to the Traffic Light

explanation later in this section for additional details.

4. Perform targeting if required (refer to Targeting a Part earlier in this section), and then

click the Start new series button at the bottom of the Monitor dialog to start the

measurement sequence.

NOTE: You can click the Pause button at the bottom of the dialog to temporarily stop a

measurement sequence. Once a measurement sequence is paused, the button's name

changes to Run, allowing you to restart the measurement sequence.

48

Page 49