Page 1

Multi-Angle Spectrophotometer

(Covers models: MA94, MA96, and MA98)

User Guide

Page 2

Page 3

MULTI- ANGLE SPECTROPHOTOMETER

CE Declaration

Hereby, X-Rite, Incorporated, declares that this MA9X Series is in compliance with the essential

requirements and other relevant provisions of Directive(s) 2014/35/EU (LVD), 2014/30/EU

(EMC)

Bluetooth equipped devices additional comply with Directive RED 2014/53/EU.

, and RoHS 2011/65/EU.

Federal Communications Commission Notice

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Industry Canada Compliance Statement

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Equipment Information

Use of this equipment in a manner other than that specified by X-Rite, Incorporated may

compromise design integrity and become unsafe.

WARNING: This instrument is not for use in explosive environments.

Transportation: This product contains a lithium-ion battery. Should you need to ship this device,

you may wish to consult published guidance documents by one or more of these organizations for

advice on how to comply with the regulations: IATA, ICOA, IMDG & PHMSA. The battery contained

in the MA9X series device is 107g in weight, 7.4V, 2.4 Ah, and complies with the UN 38.3 tests in

effect the year it was originally shipped.

Instructions for disposal: Please dispose of Waste Electrical and Electronic Equipment (WEEE) at

designated collection points for the recycling of such equipment.

1

Page 4

MULTI- ANGLE SPECTROPHOTOMETER

If your device is equipped with a Bluetooth wireless transmitter, it contains the following

module.

Microchip RN42

Microchip Technology Inc.

2355 West Chandler Blvd.

Chandler, Arizona 85224

TEL: 480-792-7200

Module meets the following standards:

EN 300328 V1.8.1 (2012)

EN 301489-1 V1.9.2 (2011)

EN 301489-17 V2.2.1 (2012)

EN 60950-1:2006 ITE General Requirement

EN 62479 (2010)+A11:2009+A1:2010+A12:2011

FCC RF Radiation Exposure Statement:

This device complies with FCC radiation exposure limits set forth for an uncontrolled environment.

End users must follow the specific operating instructions for satisfying RF exposure compliance. This

transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

Contains Microchip RN42 module:

FCC-ID: T9JRN42

IC: T9JRN42

2

Page 5

MULTI- ANGLE SPECTROPHOTOMETER

Proprietary Notice

The information contained in this manual is copyrighted information proprietary to X-Rite,

Incorporated.

Publication of this information does not imply any rights to reproduce or use it for purposes other

than installing, operating, or maintaining this instrument described herein. No part of this manual

may be reproduced, transcribed or translated into any language or computer language in any

form or by any means: electronic, magnetic, mechanical, optical, manual, or otherwise; without

the prior written permission of an authorized officer of X-Rite, Incorporated.

Patents: www.xrite.com/ip

“© 2018, X-Rite, Incorporated. All rights reserved”

X-Rite® is a registered trademark of X-Rite, Incorporated. All other logos, brand names, and product names mentioned are the properties

of their respective holders.

Warranty Information

X-Rite warrants this Product against defects in material and workmanship for a period of twelve

(12) months from the date of shipment from X-Rite’s facility, unless mandatory law provides for

longer periods. During such time, X-Rite will either replace or repair at its discretion defective

parts free of charge.

X-Rite’s warranties herein do not cover failure of warranted goods resulting from: (i) damage

after shipment, accident, abuse, misuse, neglect, alteration or any other use not in accordance

with X-Rite’s recommendations, accompanying documentation, published specifications, and

standard industry practice; (ii) using the device in an operating environment outside the

recommended specifications or failure to follow the maintenance procedures in X-Rite’s

accompanying documentation or published specifications; (iii) repair or service by anyone other

than X-Rite or its authorized representatives; (iv) the failure of the warranted goods caused by

use of any parts or consumables not manufactured, distributed, or approved by X-Rite; (v) any

attachments or modifications to the warranted goods that are not manufactured, distributed or

approved by X-Rite. Consumable parts and Product cleaning are also not covered by the

warranty.

X-Rite‘s sole and exclusive obligation for breach of the above warranties shall be the repair or

replacement of any part, without charge, which within the warranty period is proven to X-Rite‘s

reasonable satisfaction to have been defective. Repairs or replacement by X-Rite shall not revive

an otherwise expired warranty, nor shall the same extend the duration of a warranty.

Customer shall be responsible for packaging and shipping the defective product to the service

center designated by X-Rite. X-Rite shall pay for the return of the product to Customer if the

shipment is to a location within the region in which the X-Rite service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations. Proof of purchase in the form of a bill of sale or

receipted invoice which is evidence that the unit is within the Warranty period must be presented

to obtain warranty service. Do not try to dismantle the Product. Unauthorized dismantling of the

equipment will void all warranty claims. Contact the X-Rite Support or the nearest X-Rite Service

Center, if you believe that the unit does not work anymore or does not work correctly.

THESE WARRANTIES ARE GIVEN SOLELY TO BUYER AND ARE IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

3

Page 6

MULTI- ANGLE SPECTROPHOTOMETER

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION,

AND NON-INFRINGEMENT. NO EMPLOYEE OR AGENT OF X-RITE, OTHER THAN AN OFFICER OF

X-RITE, IS AUTHORIZED TO MAKE ANY WARRANTY IN ADDITION TO THE FOREGOING.

IN NO EVENT WILL X-RITE BE LIABLE FOR ANY OF BUYER’S MANUFACTURING COSTS,

OVERHEAD, LOST PROFITS, GOODWILL, OTHER EXPENSES OR ANY INDIRECT, SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES BASED UPON BREACH OF ANY WARRANTY, BREACH

OF CONTRACT, NEGLIGENCE, STRICT TORT, OR ANY OTHER LEGAL THEORY. IN ANY EVENT OF

LIABILITY, X-RITE’S MAXIMUM LIABILITY HEREUNDER WILL NOT EXCEED THE PRICE OF THE

GOODS OR SERVICES FURNISHED BY X-RITE GIVING RISE TO THE CLAIM.

4

Page 7

MULTI- ANGLE SPECTROPHOTOMETER

Table of Contents

Introduction and Setup 7

How to Use this Manual 7

Packaging 7

Installing the Battery Pack 8

Turning the Instrument On and Off 8

Power Down Mode 9

About the Battery Pack 9

Using the Charging Station 10

Connecting the AC Adapter 11

Connecting the USB Cable 11

Attaching the Safety Strap 12

Attaching the Dust Cover 12

User Interface 13

Instrument Controls 13

Navigation Buttons (up/down and left/right) 13

Select Button 13

Measure Button 13

Pressure Sensors and Indicator LEDs 14

Instrument Positioning 15

Additional Tips 15

Main Screen Menu 16

Measure Mode 16

Job Mode 16

Calibration Mode 16

Configuration Mode 16

Wireless Mode 16

Display Screen Layout 16

Header Bar 17

Main Column 17

View Column 17

Content Area 18

Progress Column 18

Wireless Operation 18

Configuration Mode 19

Entering Configuration Mode 19

Lamp Selection (MA98 only) 20

Measurement Trigger 20

Pressure Sensor Sensitivity 20

Averaging 21

Calibration Timeout 21

Sample Storage 21

Sample Deletion 21

Sample History 21

Standard Selection Method 21

Standard Creation 22

Group Selection 22

Allowed Color Spaces 22

Allowed Illuminant/Observers 22

Language 22

Date Format 22

Beeper Volume 22

Display and Power Down Time 23

5

Page 8

MULTI- ANGLE SPECTROPHOTOMETER

Instrument Orientation 23

Clear All Samples 23

Load Defaults 23

Calibration Mode 24

Positioning the Instrument on the Black Trap 24

Positioning the Instrument on the Calibration Reference 25

Calibrating the Instrument 25

Measure Mode 27

Entering Measure Mode 27

Measure Mode Icons 27

Selecting a Group 28

Manually Selecting a Standard 29

Selecting a Color Space 30

Selecting Illuminant/Observer Combinations 31

Measuring a Sample 32

Using Measurement Averaging 33

Using Graph View 34

Viewing Stored Measurements 35

Viewing Pass/Fail Data 35

∆L*a*b* Color Space (pass/fail) 35

∆L*a*b* Color Space (pass/warning) 36

Pass/Fail Option 36

Using Quick Compare 37

Creating Standards 38

Job Mode 39

Accessing Job Mode 39

Job Mode Icons 39

Selecting and Running a Job 40

Appendices 42

Service Information 42

Cleaning the Instrument 43

General Cleaning 43

Cleaning the Optics 43

Cleaning the Calibration Reference 43

Cleaning the Black Trap 44

Replacing the Battery Pack 44

Troubleshooting 45

Screen Messages 46

Resetting the Instrument 46

Instrument Specifications 47

6

Page 9

MULTI- ANGLE SPECTROPHOTOMETER

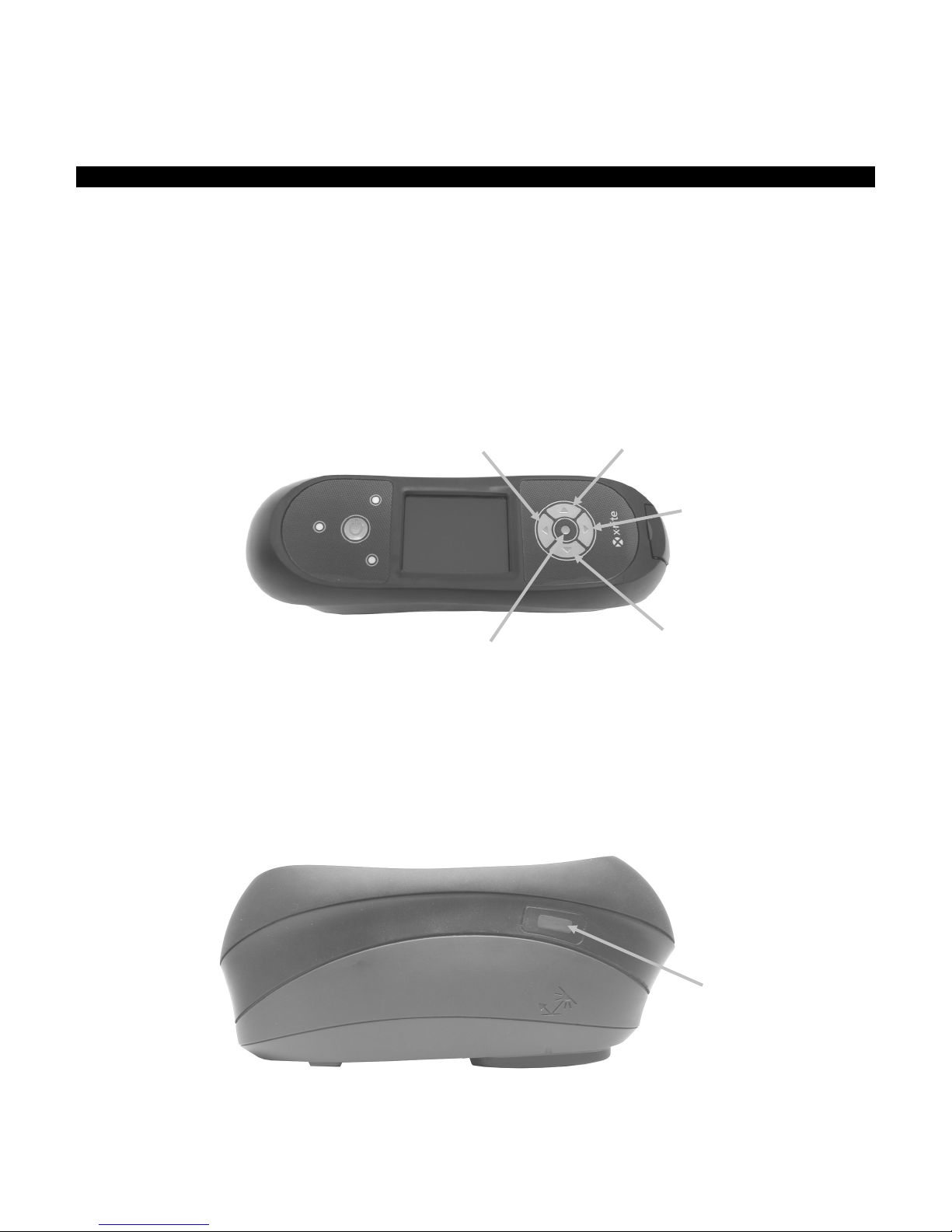

LCD color display

USB input

Measure button

AC adapter input

Dust cover

Select button and navigation buttons

On/off power button

Positioning LEDs (3)

• 2 Li-ion rechargeable battery packs

•

•

•

•

•

Safety strap connection

INTRODUCTION AND SETUP

The multi-angle spectrophotometer is designed for consistent, precise color measurement of

metallic, pearlescent, and other complex special effect finishes. The MA98 provides 10

measurement angles and 2 illumination angles to create a unique master profile of each color that

serves as a benchmark for optimizing color communication from initial design, through

formulation, processing, and quality assurance.

Key features of the instrument are:

• Hi-resolution 240 x 320, 18-bit color display

• Controls that include navigation buttons for easy screen selections, measure button, and

power on/off.

• Three pressure sensors located on the bottom of the instrument to aid in proper

positioning.

(up, down, left, and right)

How to Use this Manual

This manual is intended to provide setup, operation and general maintenance of the instrument.

Specific software application information is available in the software help system.

Packaging

Your instrument packaging should contain all the items listed below. If any of these items are

missing or damaged, contact X-Rite or your Authorized Representative.

• Multi-angle instrument

• Carrying case

• USB interface cabling

• AC adapter (X-Rite P/N SE30-277)

and line cord

• Calibration reference

• Black trap

Charging station

Safety strap

Dust cover

Manuals CD

Documentation and registration material

7

Page 10

MULTI- ANGLE SPECTROPHOTOMETER

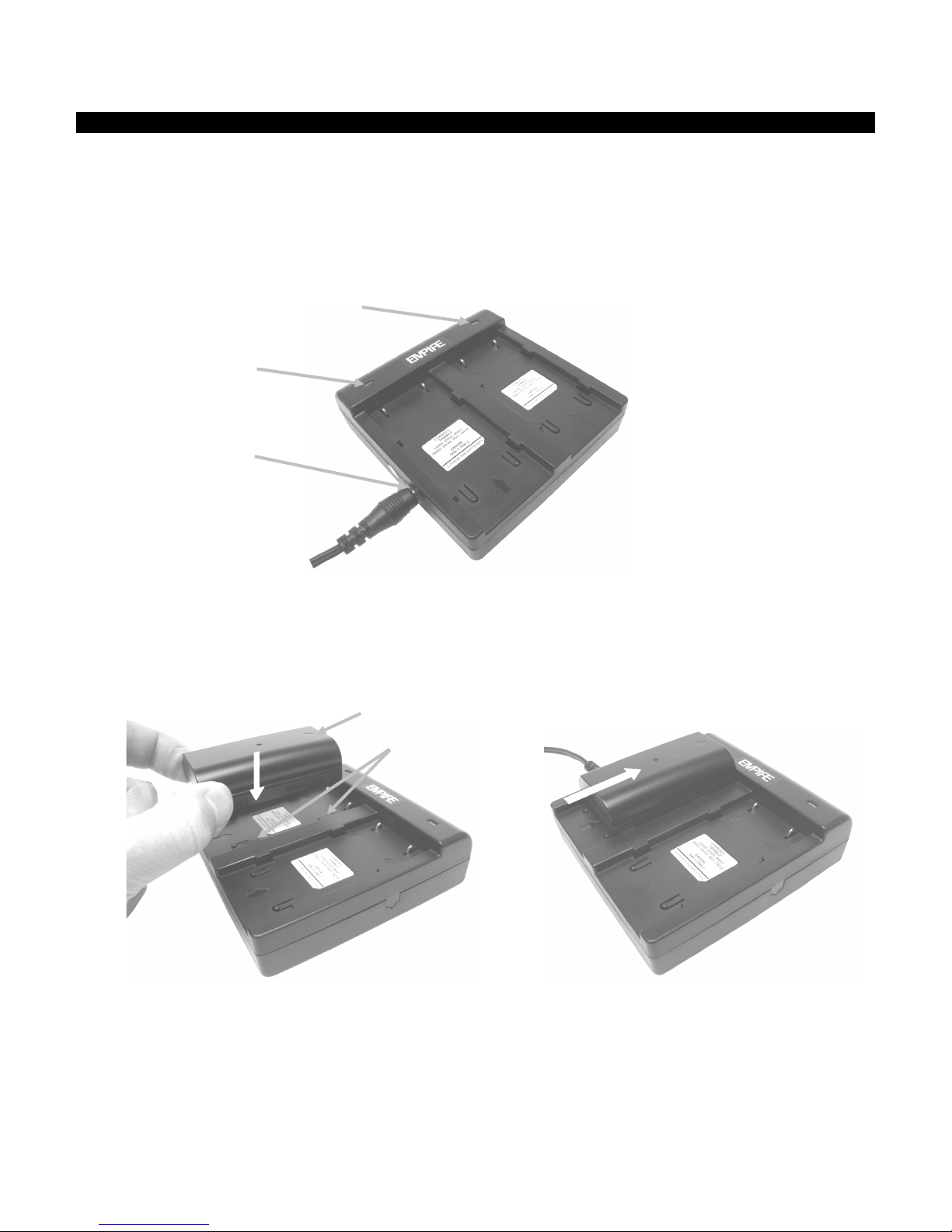

Access cover

Latch

Battery contacts

Power button

Powering Off

The instrument can be

manually powered off by

pressing and holding the

power button for five

seconds.

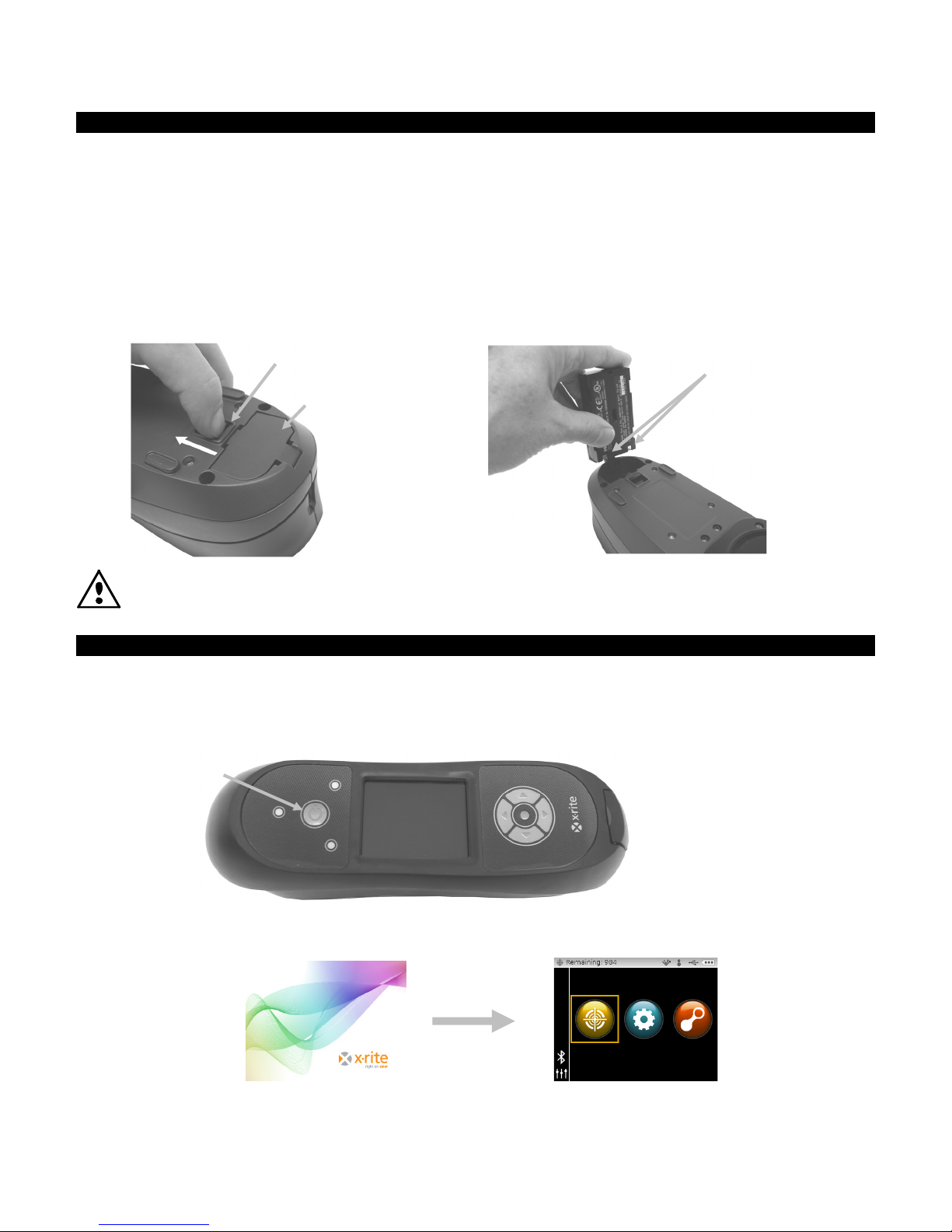

Installing the Battery Pack

Your new instrument is shipped from the factory with the battery pack removed. Two battery

packs (one is a spare) are located in the instrument case and should be charged before use. Refer

to "About the Battery Pack" later in this section for charging details. The instrument will also

operate from the AC adapter without a battery pack installed.

1. Carefully turn the instrument over and slide the latch that secures the battery pack access

cover towards the front of the instrument. Open the access cover.

2. While holding the latch open, slide the battery pack into the instrument with the battery

contacts facing down.

3. Release the latch and close the access cover by pressing downward until it locks into position.

Use the rechargeable Li-ion batteries provided or equivalent; other types may burst causing

personal injury.

Turning the Instrument On and Off

The power button is used to initiate the instrument from a power off state. Simply press and hold

the button for three seconds to turn on the instrument. If the instrument does not power up after

pressing the power button, the batteries may require charging. Refer to Charging the Battery

Pack.

When first powered up, the instrument goes through a diagnostics test and displays a splash

screen before the main menu screen appears.

Splash Screen Main Menu

8

Page 11

MULTI- ANGLE SPECTROPHOTOMETER

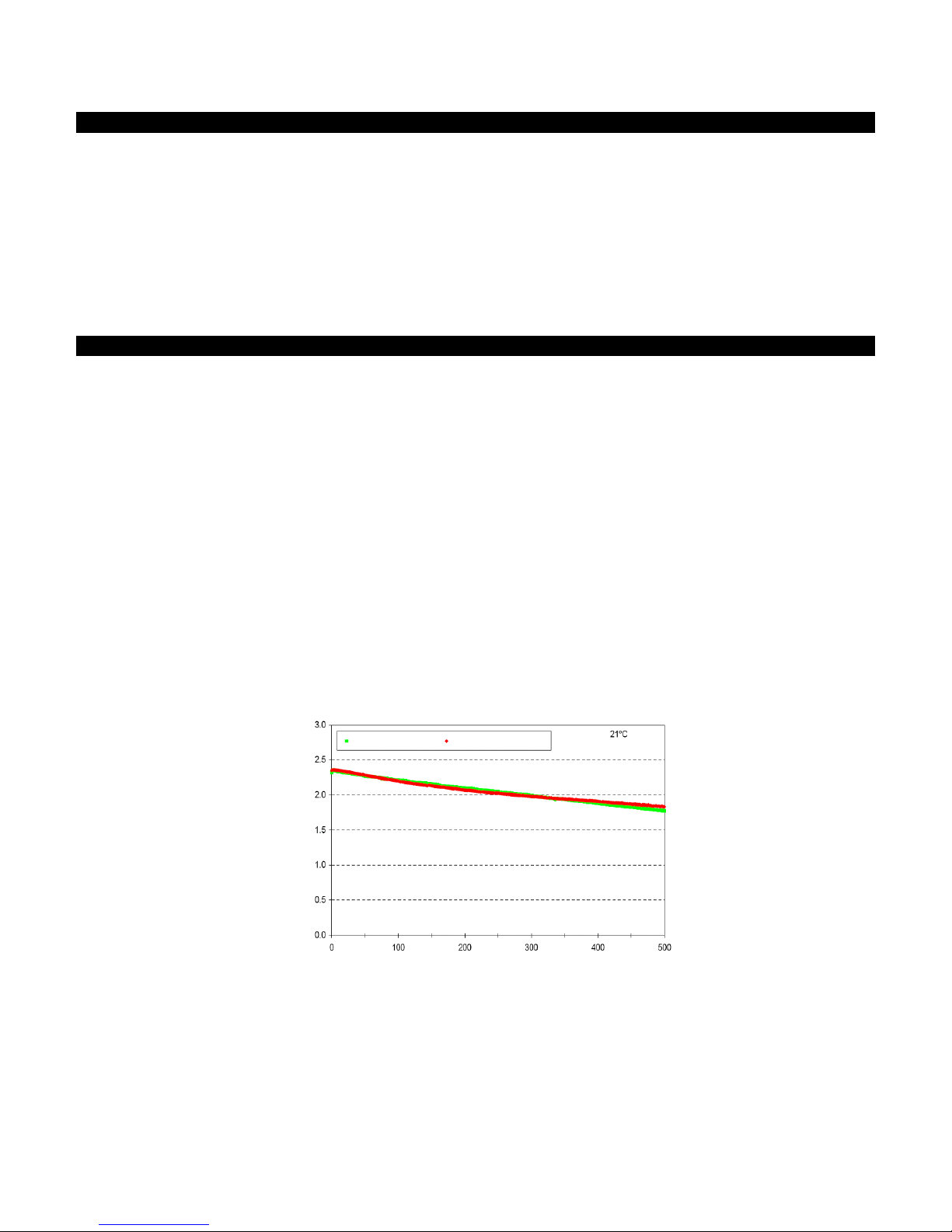

Cycle Life Characteristics

Cycles

1.0 C Discharge

C/2 Discharge

1.25 A CC/CV Charge, 4.2 V, 3 hrs.

Capacity (Ah)

Power Down Mode

The instrument utilizes two power down modes to conserve battery life during nonuse times. The

power down mode is preset in the Configuration Mode.

Standby Mode - The instrument is ready to measure, however the display is not on. A button

press, measurement, power connection (if not connected), or USB connection will wake up the

instrument. Standby mode does not occur when the AC adapter is attached to the instrument.

Off Mode - The power button must be pressed and held for three seconds to wake up the

instrument before a measurement can be taken. Plugging in the AC adapter will also wake up the

instrument from power off mode. Off mode does not occur when the AC adapter is attached to the

instrument.

About the Battery Pack

General

The battery packs for your new instrument come in a low to medium charge state and should be

charged before use (up to 4 hours for full charge).

A charged battery pack may eventually lose partial charge if not used for an extended amount of

time. You should charge the battery from time to time and store in a cool environment when not

in use to maintain battery performance.

The battery pack can be charged in the instrument (see Connecting the AC Adapter) or by use of

the charging station. The charging station is useful for charging up to two battery packs.

Lifespan Expectations

Lithium-ion batteries typically decay to 80% capacity after 400 charge cycles (see chart below). A

charge cycle can be defined as several partial charges equaling 100%. Partial charge and

discharge cycles will help maintain the life of the battery. It is best to avoid full discharge and

charge cycles. After roughly 400 charge cycles are reached, the amount of measurements you

can expect to achieve from one full charge is reduced. At this point, you may wish to replace the

battery pack.

Disposal

Dispose of the battery pack in a designated disposal location for recycling.

9

Page 12

MULTI- ANGLE SPECTROPHOTOMETER

AC adapter input

Battery arrow

LED indicator

LED indicator

Locking tabs

Note: The AC adapter

Using the Charging Station

The charging station has a separate indicator LED for each charging position. The LEDs illuminate

“red” when a battery pack is charging, amber when battery pack is close to a full charge, and

“green” when no battery is inserted or after the battery is fully charged. A battery pack takes

approx. 4 hours to reach a full charge from a completely discharged state.

1. Insert the small plug from the AC adapter into the input on the side of the charging station.

2. Plug the detachable line cord into the AC adapter and plug the line cord into the wall

receptacle.

used for the charging

station is the same

adapter that is used to

power the instrument.

3. Position a battery pack over one of the charging locations with the locking tabs in the station

directly below the slots in the battery. Make sure the arrow on the top of the battery pack is

facing the LED end of the station.

4. Lower the battery pack into position and slide it toward the LED until it stops. Depending on

the battery packs current charge state, the LED will illuminate "red", "amber", or "green"

when properly seated.

5. After charging is complete, slide the battery in the opposite direction of the LED until it stops

and lift upward to remove.

10

Page 13

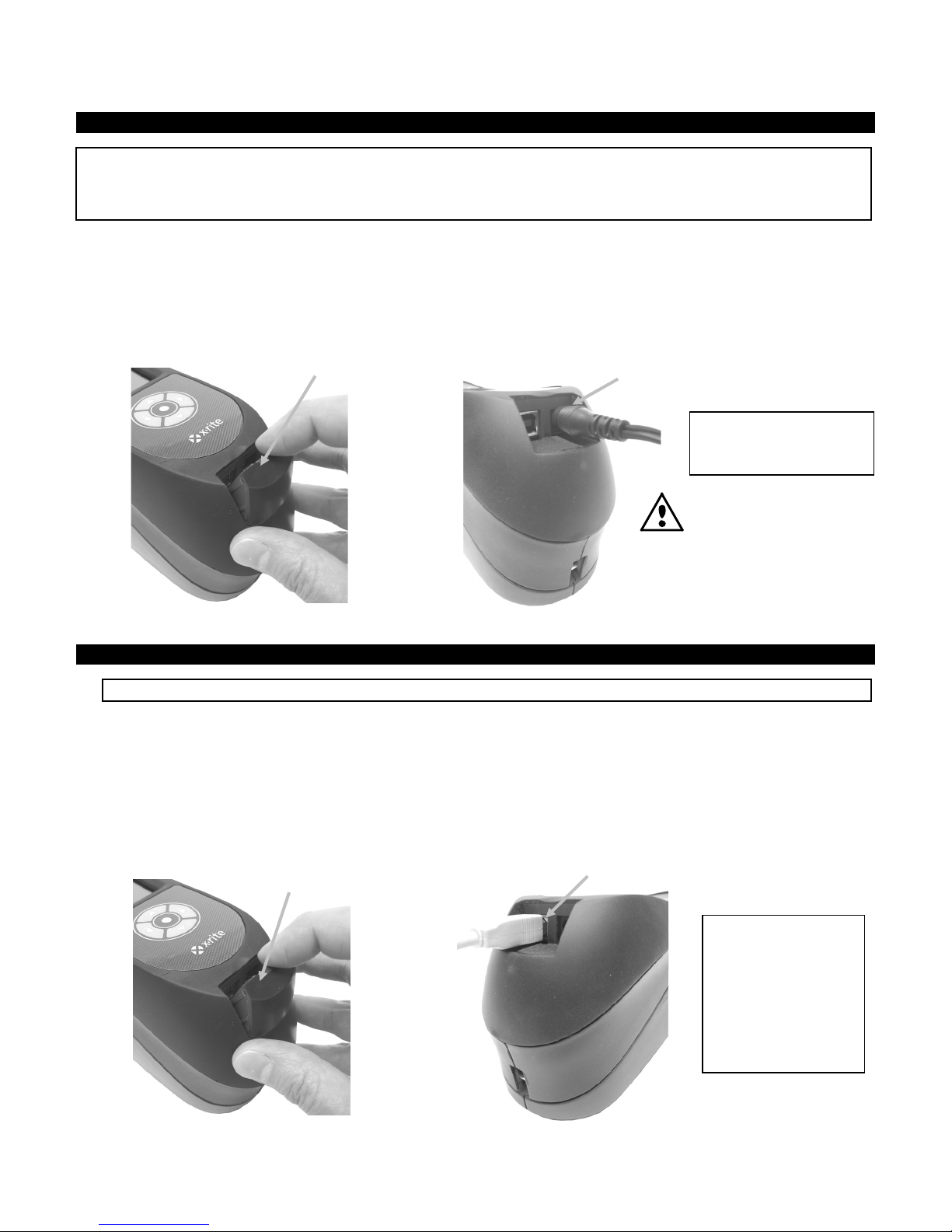

MULTI- ANGLE SPECTROPHOTOMETER

AC adapter input

AC Adapter Ratings

IMPORTANT:

Never unplug the USB

Small access cover

Operational hazard

USB input

Small access cover

Connecting the AC Adapter

NOTE: The instrument can operate from the AC adapter only. The battery pack does not need to be

installed. The AC adapter (X-Rite P/N SE30-277) overrides any charge condition of the battery pack in the

instrument. Measurements can be taken even with a very low battery condition when using the AC

adapter.

1. Verify the voltage indicated on the AC adapter complies with the AC line voltage in your area.

2. Remove the small access cover that is located above the AC adapter and USB inputs.

3. Insert the small plug from the AC adapter into the input connector on the instrument.

4. Plug the detachable line cord in the AC adapter and plug the line cord into the wall receptacle.

Input: 100-240V 50-60 Hz

Output: 12VDC @ 2.5A

exists if an AC adapter

other than X-Rite

SE30-277 is used.

Connecting the USB Cable

IMPORTANT: You must install the software before connecting the instrument to your computer.

1. Install the software application if not already installed. Refer to the software documentation

for additional information.

2. Remove the small access cover that is located above the AC adapter and USB inputs.

3. Turn the instrument on and plug the square end of the USB cable into the back of the

instrument.

4. Plug the USB cable into an available port on your computer. The instrument should

acknowledge USB presence by displaying the USB icon in the header bar of the screen.

cable when data is

being transferred.

It is recommended

that the AC adapter

be connected before

a data transfer.

11

Page 14

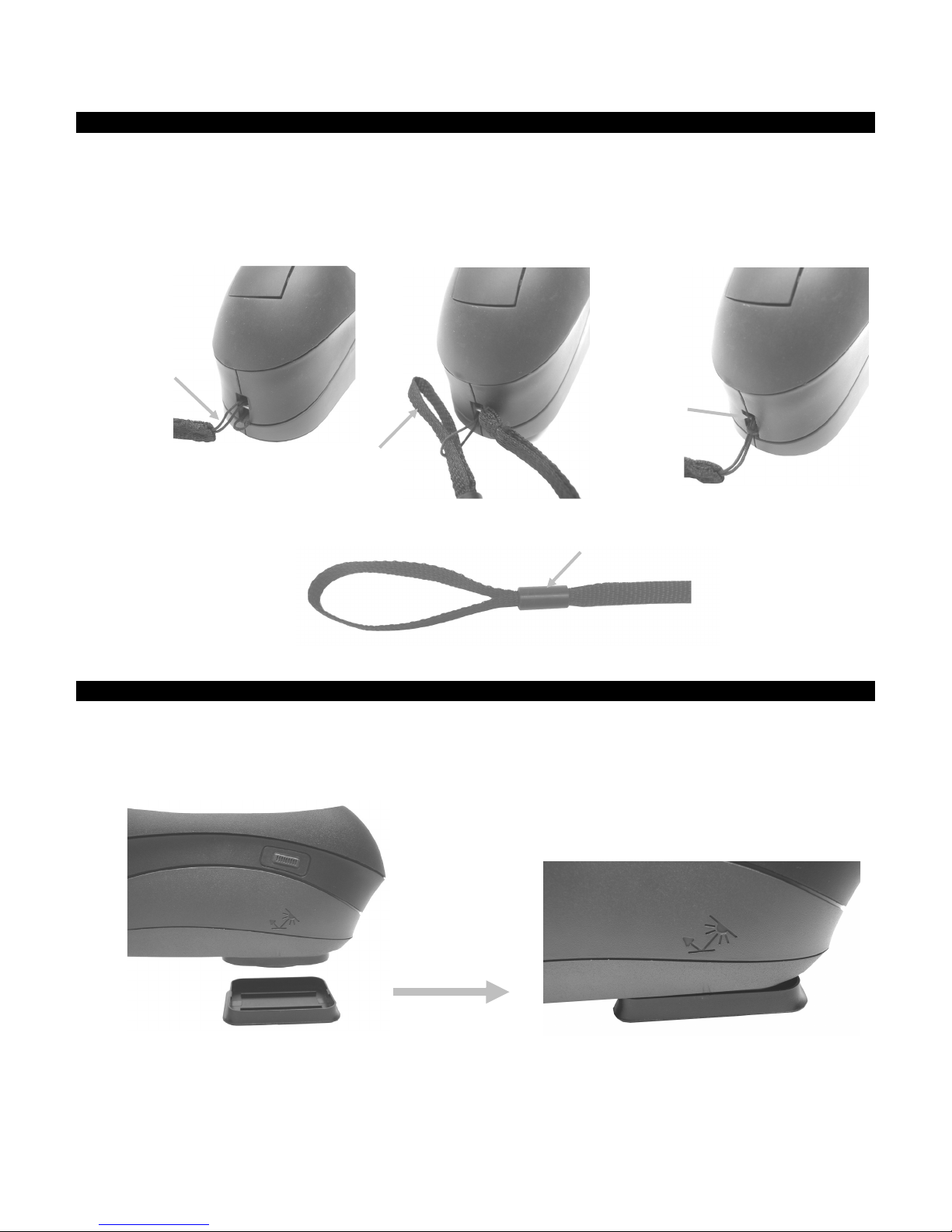

MULTI- ANGLE SPECTROPHOTOMETER

Small loop

Wrist strap

Secured to

Tightening slide

Attaching the Safety Strap

A safety strap is included with your instrument. The strap attaches to the back of the instrument

and around your wrist. The strap should not be used to carry the instrument.

1. Feed the small looped end of the strap around the strap pin at the back of the instrument.

2. Insert the wrist strap end through the small loop.

3. Pull on the wrist strap to secure to the strap pin.

strap pin

4. Use the slide to tighten the strap around your wrist.

Attaching the Dust Cover

The dust cover protects the measurement port and internal optics components. Make sure the

instrument is always stored with the cover installed.

1. Position the cover in either direction below the measurement port.

2. Snap the dust cover into place on the measurement port.

12

Page 15

MULTI- ANGLE SPECTROPHOTOMETER

Down button

Right button

Select button

Left button

Up button

Measure button

USER INTERFACE

Instrument Controls

The instrument controls are used to navigate the screen, configure options, and perform

measurements.

Navigation Buttons (up/down and left/right)

The navigation buttons are used to move the focus of the highlight around the screen. Pressing

on the left () button moves the focus to the next available control to the left. Pressing on the

right () button moves the focus to the next available control to the right. The up () and down

() buttons perform the same function, only in an up and down direction. The navigation buttons

change control direction when the instrument screen orientation is changed from right handed

operation (default) to left handed operation in the Configuration Mode.

Select Button

The Select button activates the control that has focus, such as a mode or option.

Measure Button

The Measure button is located on the side of the instrument. The button can be configured to

initiate a measurement on its own or in conjunction with the pressure sensors. Refer to

Configuration mode for additional information on the measure button configuration.

13

Page 16

MULTI- ANGLE SPECTROPHOTOMETER

Back LED

Back LED

Front LED

Pressure Sensors and Indicator LEDs

To aid in proper positioning and ensure repeatability of sample measurements, the instrument

incorporates three pressure sensors that are integrated into the measurement port. When this

option is activated in configuration, an even amount of pressure must be applied across all three

sensors before a measurement can occur. The pressure sensor option is typically used when

critical instrument positioning is required on a sample.

Positioning feedback is provided by way of three LEDs located on the top of the instrument. The

LEDs are arranged in the same pattern as the pressure sensors located in the measurement port.

Refer below for LED definitions.

NOTE: The Pressure sensor option must be enabled in Configuration mode.

• LED Off – little or no pressure is being applied to the corresponding sensor.

• LED Amber – not enough force is being applied to the corresponding sensor. You must

apply additional pressure to achieve a green LED.

• LED Green – ideal pressure is being applied to the corresponding sensor. A measurement

will be taken when all three LEDs illuminate green. If required pressure is not maintained

for the duration of the measurement (red or amber LED condition), an error message will

appear on the display and the measurement must be retaken.

• LED Red – too much pressure is being applied to the corresponding sensor. Less pressure

must be applied to achieve a green LED condition.

14

Page 17

MULTI- ANGLE SPECTROPHOTOMETER

Side alignment mark

Measurement port flat

Instrument Positioning

In order for the instrument to obtain accurate and repeatable measurements, the bottom of the

measurement port must be flat with the sample surface to be measured. Any movement of the

instrument can cause the measurement angles to vary, greatly affecting measurements on

metallic and pearlescent paint finishes.

Using the pressure sensor feature to activate measurements will ensure measurement data

integrity.

The instrument should be held with both hands during a measurement. During a measurement,

simply rock the instrument forward until the measurement port is flat on the surface. If the

pressure sensor option is activated, apply the correct amount of pressure to the measurement

port until all three indicator LEDs turn green.

on sample

Additional Tips

• Measurements performed on a surface with a curve can cause measurement errors

especially at the near specular angles (±15° and 25°). Measurements should be made on

the flattest part of a sample whenever possible. When measuring parts where a flat area is

not available, a fixture should be made to repeatedly and accurately position the sample

tangent to the measurement plain.

• Hold the instrument firmly by the front and top during a measurement.

• When measuring dark colors or non-uniform samples, several readings should be averaged

together for a single measurement. The instrument can be set to average up to five

measurements.

The alignment marks located on the left and right sides of the instrument can be used as guides

to center the measurement port over the desired sample area. These are useful when precise

positioning is required, or if the sample is somewhat small.

15

Page 18

MULTI- ANGLE SPECTROPHOTOMETER

Measure mode

Job mode

Configuration mode

Calibration mode

Header bar

Main column

View column

Content area

Progress column

Wireless operation

Main Screen Menu

When the instrument is powered-up, the main (top level) screen appears after the diagnostics

test is complete. The main screen consists of the header bar and operation modes. The operation

modes are selected by using the navigation buttons located to the side of the display screen.

(no USB connection)

Measure Mode

The measure mode is the main mode of operation. Sample measurements are taken and analyzed

in this mode. Refer to the Measurement Mode section for information.

Job Mode

The job mode is used to select and run downloaded jobs. Refer to the Job Mode section for

information.

Calibration Mode

The calibration mode is use to perform a black and white reference calibration. Refer to the

Calibration Mode section for information.

Configuration Mode

The configuration mode is used to set and edit the instruments configuration options. The

configuration options should be set before you use your instrument for the first time. Refer to the

Configuration Mode section for information.

Wireless Mode

®

If available, the instrument can communicate over a wireless Bluetooth

connection with the

X-Color QC software. Refer to the Wireless Operation section for information.

Display Screen Layout

The display screen is divided into five main areas.

16

Page 19

MULTI- ANGLE SPECTROPHOTOMETER

Indicates that the 45° lamp is currently in use.

Indicates the pressure sensors around the measurement port are active,

Indicates the measure button on the side of the instrument must be

Indicates neither the sensors nor measure button will initiate a

Indicates that both the pressure sensors and measure button are required

Indicates the battery pack has a sufficient charge for a substantial number

Indicates the battery pack is low, but measurements are still possible.

Indicates the battery pack is very low and only a few measurements

Indicates the AC adapter is plugged in and the battery pack is charging

Indicates that battery pack is removed and the instrument is operating

Header Bar

The header bar at the top displays the sample storage locations remaining, lamp configuration,

measurement trigger method, USB connection, and battery gauge.

• Storage Capacity Indication - Displays the number of remaining sample storage

locations.

• Lamp Indication (MA98 only) – Depicts the current lamp configuration. The lamp

configuration is selected in the configuration mode.

Indicates that both the 45° and 15° lamps are currently in use.

• Measurement Trigger Method - Depicts the measurement method currently selected

for the instrument.

requiring proper positioning to take a measurement.

pressed to take a measurement.

measurement. A software command is required to initiate a measurement.

to take a measurement.

• USB or Bluetooth Connection – The USB icon appears when the instrument is plugged

®

into the USB port on the computer. The Bluetooth

icon appears when searching for a

connection and when a connection is established to the X-Color QC computer.

• Battery Gauge - Depicts the current condition of the battery pack.

Indicates the battery pack is fully charged.

of measurements.

Battery pack should be charged soon.

remain. Battery pack should be charged immediately.

(battery indication segments cycle). The battery indicator will stop cycling

and display all segments when the battery pack is fully charged.

from the AC adapter only.

Main Column

The main column is used to access the main instrument screen, wireless connection, and the

configuration mode.

View Column

The view column lists any options that may be available for the selected mode. The highlighted

option is the one that is currently displaying in the content area.

17

Page 20

MULTI- ANGLE SPECTROPHOTOMETER

Bluetooth icon appears in the

Content Area

The content area displays the data, steps, and graphs for the currently selected option.

Progress Column

The progress column displays icons used to activate a step sequence, delete samples, page

through stored samples, and toggle between color space options and graph view.

Wireless Operation

If available, the instrument uses Bluetooth® technology and can communicate wirelessly with your

computer. Data from the X-Color QC application can be transmitted within a short range (<10 m)

to/from the instrument.

To utilize the Bluetooth feature in the MA9x, you must pair the instrument with the Bluetooth

adapter in your Windows computer. The pairing procedure is only required the very first time you

use the wireless feature to establish a connection. Once complete, the instrument automatically

connects to the computer when used. Please see the procedure that follows to pair your

instrument to the computer.

Pairing Procedure

1. Make sure the USB cable is not connected to the instrument.

®

2. Use the Navigation buttons to move the highlight focus to the Bluetooth

icon in

the Main column (USB must be disconnected).

3. Press the Select button to put the instrument into discoverable mode. The

instrument will stay in discoverable mode for up to 60 seconds. If a connection is not

successful after 60 seconds, the connection attempt will stop. If this occurs, you will need to

reselect the Bluetooth icon before continuing.

header bar when searching and

while connected.

4. Start the Windows procedure for pairing a Bluetooth device. For additional information on this

procedure, select Help and Support in the Windows Start menu.

5. When required, select the MA9x_... icon from the list of available devices and enter the

pairing code default (lowercase) into the available field.

6. After pairing is successful, you are now ready to use the MA9x in wireless mode.

7. Refer to the X-Color QC application for information on transferring standard and sample data.

18

Page 21

MULTI- ANGLE SPECTROPHOTOMETER

Configuration mode icon

Options column

Instrument information

Available settings

CONFIGURATION MODE

Configuration mode is used to adjust and view the instrument’s settings. You should set the

configuration options before using the instrument for the first time. However, you can go back

and change these settings at any time. Each configuration option is explained in detail on the

following pages.

Entering Configuration Mode

1. From the Main screen, use the Navigation buttons to move the highlight focus to the

Configuration icon.

2. Press the Select button to access the main configuration screen. The screen displays the

instrument information (model, serial number and firmware).

screen

3. From the Configuration screen, use the Up or Down navigation buttons to move the highlight

focus to the desired configuration icon in the Options column.

NOTE: The arrow icon ( or ) at the end of the Options column indicates that additional

options are available. Move the highlight focus to the arrow icon and press the Select button

to access the additional options.

4. Press the Right navigation button to enter the option settings area.

5. Use the Up or Down navigation buttons to move the highlight focus to the desired setting and

press the Select button to change your setting. An arrow () appears next to the selected

setting.

6. Press the Left navigation button to return to the Options column.

19

Page 22

MULTI- ANGLE SPECTROPHOTOMETER

Main screen icon

Exiting Configuration Mode

After configuring options, use the Left navigation button to move the highlight focus to the Main

screen icon in the Main column and press the Select button to exit.

Lamp Selection (MA98 only)

This option is used to select single (default) or dual lamp configuration in the instrument.

Single Lamp – Indicates the 45° lamp is only in use.

Dual Lamp - Indicates both the 45° lamp and 15° lamp are in use.

Measurement Trigger

This option is used to determine which inputs are used to trigger a measurement on the

instrument. The available settings are Pressure (default), Button, Software Only, and Pressure

and Button.

Pressure – Pressure sensors are required to take a measurement.

Button – Measure button is required to take a measurement.

Software Only – No button or pressure sensors are required to take a measurement. This

setting would be selected when software input is used to trigger a measurement.

Pressure and Button – Both the pressure sensors and measure button are required to a take a

measurement.

Pressure Sensor Sensitivity

This option works in conjunction with the pressure sensor measure option, by allowing you

to adjust the amount of pressure required before a reading would occur. The available settings

are Minimum, Light (default) and Normal.

Minimum – A minimal amount of pressure is required to trigger a measurement.

Light – Little pressure is required to trigger a measurement.

Normal – Firmer pressure is required to trigger a measurement. This option would be used when

very precise positioning is always required.

20

Page 23

MULTI- ANGLE SPECTROPHOTOMETER

Averaging

This option is used to set the number of measurements required for calculating a single

measurement. Measurements are taken at different locations on a sample to achieve average

measurement values. The available settings are No Averaging (default), Simple Average of 2, 3,

4, and 5, and SMC. SMC settings are SMC 5:12, SMC 10:12, SMC 20:20, and Custom SMC 50:5.

The first number after SMC indicates the grade limit followed by the number of measurements

allowed. Custom SMC setting is adjustable through the Configuration screen in X-Color QC.

SMC (Statistical Measurement Control) is a method of performing a statistical analysis of several

measurements to determine the quality of the measurements and/or the sample, before an

average value is calculated. A statistical analysis of the measurements' mean and standard

deviations eliminates outliers and determines the variability of the measurements. Additional

measurements may be required until a minimum of 5 outlier-free measurements are achieved, or

the sample is determined too variable.

Calibration Timeout

This option is used to set the amount of time that elapses before a calibration is required.

The available settings are: Disabled, 8 Hours, 12 Hours, 24 hours (default), 48 Hours, and 1 Week.

Sample Storage

This option is used to enable or disable (default) the storage of samples in the instrument.

Enabled – Sample storage is on.

Disabled - Sample storage is off.

Sample Deletion

This option is used to enable or disable (default) the ability to delete stored samples in the

measure mode. NOTE: The option requires sample storage to be enabled.

Enabled – Allows sample deletion.

Disabled - Disallows sample deletion.

Sample History

This option is used to enable (default) or disable the ability to view stored samples in the

measure mode. NOTE: The option requires sample storage to be enabled.

Enabled – Allows stored sample navigation.

Disabled - Disallows stored sample navigation.

Standard Selection Method

This option is used to set auto standard (default) or manual standard.

Auto Select – The instrument automatically selects a stored standard that is the closest to the

sample being measured.

Manual Select – A standard must be selected before a measurement.

21

Page 24

MULTI- ANGLE SPECTROPHOTOMETER

Standard Creation

This option is used to enable or disable (default) the ability to create standards in the

Measure mode.

Enabled – Allows standard creation.

Disabled - Disallows standard creation.

Group Selection

This option is used to enable (default) or disable the ability to select a standard group in

the measure mode. Grouped standards are downloaded into the instrument using the X-Color QC

software application.

Enabled – Group selection is allowed.

Disabled – No group selection is allowed.

Allowed Color Spaces

This option is used to select the allowed color spaces that appear in the Measure Mode. You

can select as many color spaces as desired.

An arrow () appears next to the selected color spaces.

Allowed Illuminant/Observers

This option is used to select the allowed illuminant/observer combinations that appear in

the Measure Mode. You can select as many illumination/observers as desired.

An arrow () appears next to the selected illuminant/observer combinations.

Language

This option is used to set the language that is displayed on the instrument. The available

settings are English (default), German, French, Spanish, Italian, Chinese Simplified, and

Japanese.

Date Format

This option is used to adjust the date format the instrument uses. The available settings

are: MM/DD/YYYY (default), DD/MM/YYYY, DD.MM.YYYY, YYYY/MM/DD, and YYYY-MM-DD.

NOTE: The date format automatically changes to the correct format for the selected language. If

desired, you can change the format after selecting the language.

Beeper Volume

This option is used to adjust the volume of the instrument speaker. The instrument beeps

after a measurement and calibration. The available settings are: Off (default), Low, and High.

22

Page 25

MULTI- ANGLE SPECTROPHOTOMETER

Display and Power Down Time

This option is used to set the desired display and power down time. The available settings

are Disabled, Long, Medium (default), and Short. All times are ignored when the AC adapter is

plugged into the instrument.

Disabled – The instrument goes into standby mode after 24 hours of inactivity. The instrument

never shuts completely off in this mode.

Long – The instrument goes into standby mode after 60 minutes and shuts completely off after 2

hours of inactivity.

Medium - The instrument goes into standby mode after 5 minutes and shuts completely off after

15 minutes of inactivity.

Short - The instrument goes into standby mode after 1 minute and shuts completely off after 2

minutes of inactivity.

Instrument Orientation

This option is used to change the display direction to accommodate both right and left

handed users. The available settings are Right Handed (default) and Left Handed.

Clear All Samples

This option is used to clear all samples stored in the instrument. To clear all samples, use

the Right navigation button to move highlight focus to the check mark icon in the Progress

column and press the Select button.

Load Defaults

This option is used to restore the instrument’s configuration settings back to their original

factory settings. To restore the default settings, use the Right navigation button to move

highlight focus to the check mark icon in the Progress column and press the Select button.

23

Page 26

MULTI- ANGLE SPECTROPHOTOMETER

Measurement opening

Black trap

Hole plug

CALIBRATION MODE

The instrument comes with a calibration reference and black trap. A calibration should be

performed when called for by the instrument or when desired. The calibration timeout is set in

Configuration mode.

Refer to Cleaning section in the Appendices for information on cleaning the optics area and

references.

NOTE: Make sure to use the calibration reference supplied with the instrument for calibrating.

Do not substitute this reference with a reference from another instrument. The serial number

on the reference should match the reference (plaque) serial number displayed in the main

calibration screen.

Calibration Notes

• Dirt or dust in the aperture area will cause an inaccurate calibration reading. Refer to the

Appendices for optics cleaning procedure.

• The white plaque in the calibration reference is dramatically affected by smudge

marks, dust, and finger prints. Refer to Appendices for calibration reference cleaning

procedures.

• The black trap should be cleaned periodically to remove any dust or

contamination. Refer to Appendices for black trap cleaning procedures.

• Do not move instrument while taking a calibration measurement. If motion is

detected, an error message will be displayed and calibration aborted.

Positioning the Instrument on the Black Trap

The black trap is used to perform the zero reflectance measurements. The instrument’s

measurement port is positioned over the opening. The black trap snaps onto the instruments

measurement port and can only be positioned in one direction. The black trap can be taken apart

for easy cleaning. Refer to the Appendices for procedure on cleaning the black trap.

Always store the black trap with the hole plug installed.

properly positioned

24

Page 27

MULTI- ANGLE SPECTROPHOTOMETER

Exit icon

Calibration reference

properly positioned

White plaque

Hinged cover

Calibration mode icon

Next icon

Information that appears

Positioning the Instrument on the Calibration Reference

The calibration reference is designed to keep the white plaque free of dust and debris. The white

plaque is concealed in a case that has a hinged cover. The measurement port is positioned on

the white plaque and the measurement taken. Make sure the white plaque in the calibration

reference is positioned squarely under the measurement port, with the cover open to the

Measure button side of the instrument.

Calibrating the Instrument

1. From the Main screen, use the Navigation buttons to move the highlight square to the

Calibration icon.

2. Press the Select button to access the calibration screen.

White Calibration Expired appears if calibration is needed. If calibration is not currently

needed, the time remaining before the next calibration, along with the temperature of the last

calibration and white reference (plaque) serial number will appear. To exit calibration mode

without calibrating, select the Exit icon (x) in the Progress column.

when calibration is not

currently required

25

Page 28

MULTI- ANGLE SPECTROPHOTOMETER

→

→

3. Use the Right navigation button to move the highlight focus to the Progress column. Use the

Down navigation button to highlight the Next arrow icon (

) if not highlighted and press the

Select button.

4. Remove the hole plug and snap the instrument on the black trap as previously explained.

Make sure the Next arrow icon (

) is highlighted in the Progress column and press the Select

button.

The instrument takes 4 or 8 measurements depending on the model. After the black

calibration measurements are complete, remove the instrument from the black trap, install the

hole plug, and return the black trap to its storage location.

NOTE: If an error message appears during or after black trap calibration, press the Select

button to clear the message and try measuring the black trap again. If an error still occurs,

clean the black trap as explained in the Appendices.

5. Position the instrument on the white reference as previously explained and press the Select

button. Take the measurement(s) by applying the appropriate amount of pressure to the port

to activate the pressure sensors (green indicator LEDs). Hold the instrument steady

throughout the measurement sequence.

The instrument takes 1 or 2 measurements depending on the model. After the white

calibration measurement(s) is complete, press the Select button to return the display to the

main screen.

Remove the instrument from the calibration reference and return the reference to its storage

location.

NOTE: If an error message appears during or after white calibration, Press the Select button

to clear the message and try measuring the white reference again. If an error still occurs,

clean the white calibration reference as explained in the Appendices.

26

Page 29

MULTI- ANGLE SPECTROPHOTOMETER

Icon

Description

Access color space selection screen. Arrow points to current color space selected.

Access illuminant/observer selection screen. Arrow points to current illum/obs

Access group detail and selection screen. Arrow points to current group selected.

Access standard detail, selection, and creation screen. Arrow points to current

Measure mode

45° lamp angle data

Measure option

icons

When the MA98 instrument is

MEASURE MODE

The measure mode is the main operation mode of the instrument used to analyze and collect

sample data. After taking a measurement, you can view the results for the angles under various

color spaces and illuminant/observer combinations.

NOTE: You must select a standard if auto standard is disabled before measuring.

Entering Measure Mode

1. From the Main screen, use the Navigation buttons to move the highlight square to the

Measure icon.

2. Press the Select button to access the main measure screen.

icon

configured for dual lamps, the

15° lamp angle data (-15°

and 15°) appears.

Measure Mode Icons

A description of the various icons found in the measure mode is shown below.

Access the main measurement screen.

selected.

standard selected.

Delete current measurement.

27

Page 30

MULTI- ANGLE SPECTROPHOTOMETER

Pages through the list of color spaces allowed in the Configuration mode.

Access graph view screen.

Access quick compare function.

Exits sample averaging for the current sample.

SMC only – cancels averaging and calculates an average on previous measurements.

Access previous measurement data screen when browsing stored measurements.

Access next measurement data screen when browsing stored measurements.

Indicates a passed sample measurement.

Indicates a failed sample measurement.

Group icon

Selecting a Group

The group option lists grouped standards that were created and downloaded from the X-Color QC

application. When multiple standard groups are available, you must select the desired group

before taking a measurement when using auto standard. The auto standard select function does

not recognize standards across multiple groups. The selected group is used until a different group

is chosen.

NOTE: Group selection is only available if it is activated in the configuration mode.

To select a group:

1. From the Measure screen, use the Up or Down navigation buttons to move the highlight focus

to the Group icon

.

2. Press the Right button to access the group selection area.

28

Page 31

MULTI- ANGLE SPECTROPHOTOMETER

Standard Icon

Available standards

Selecting No Stand ard

Available groups

3. Use the Up or Down navigation buttons to move the highlight focus to the desired group and

press the Select button. An arrow () appears next to the selected group.

4. Press the Left navigation button to return to the View column.

Manually Selecting a Standard

The instrument can be set to "auto select" or "manual select" a standard in the Configuration

Mode. In "auto select" mode, the instrument automatically chooses the closest standard to the

measured sample. In "manual select" mode, you must choose the standard before a

measurement. The manually selected standard is used until a different standard is chosen.

To select a standard:

1. From the Measure screen, use the Up or Down navigation buttons to move the highlight focus

to the Standard icon

.

2. Press the Right navigation button to access the standard selection area.

causes no standards to be

used during sample

measurements. The Manual

Select standard option must

be activated in Configuration

to perform this function.

29

Page 32

MULTI- ANGLE SPECTROPHOTOMETER

Color Spaces

L*a*b*

∆L*a*b*

∆E*

∆Eeff

∆E94

∆DNA10

∆F19

∆SI

L*C*h°

∆L*C*H*

∆Ecmc

∆Ec

∆F10

SI

∆G19

∆IL

Flop Index

∆Flop Index

∆Ep

∆E00

∆G

IL

∆DNA19

MA98

Available color spaces

Color space page icon

Color space icon

3. Use the Up or Down navigation buttons to move the highlight focus to the desired standard

and press the Select button. An arrow () appears next to the selected standard.

4. Press the Left navigation button to return to the View column.

Selecting a Color Space

The instrument has several colorimetric systems (absolute and difference) to choose from. Any

color space can be selected after a measurement to view the measurement results under a

different method. The color space page icon is used to quickly page through the list of allowed

color spaces without leaving the current view. Simply press the Enter key when the icon is

highlighted to change to the next allowed color space.

(default)

(default)

(default)

(default)

10

only

NOTE: Delta color spaces will not appear if no standard is selected. Certain color spaces may not

appear if they are not allowed in the Configuration mode.

To select a color space:

1. From the Measure screen, use the Up or Down navigation buttons to move the highlight focus

to the Color Space icon

.

2. Press the Right navigation button to access the color space selection area.

3. Use the Up or Down navigation buttons to move the highlight focus to the desired color space

and press the Select button. An arrow () appears next to the selected color space.

4. Press the Left navigation button to return to the View column.

30

Page 33

MULTI- ANGLE SPECTROPHOTOMETER

Illuminant/Observers

A/10

D50/10

F2/10

F11/10

C/2

D65/2

F7/2

F12/2

C/10

D65/10

F7/10

F12/10

List of allowed illuminant/observer

Illum/Obs icon

Selecting Illuminant/Observer Combinations

The instrument has several illuminant/observer combinations to choose from. Any combination

can be selected after a measurement to view the measurement results under various conditions.

A/2 D50/2 F2/2 F11/2

(default)

(default)

NOTE: Certain illuminate/observer combinations may not appear if they are not allowed in the

Configuration mode.

To select illuminant/observer combinations:

1. From the Measure screen, use the Up or Down navigation buttons to move the highlight focus

(default)

to the Illuminant/Observer icon

.

2. Press the Right navigation button to access the illuminant/observer selection area.

combinations

3. Use the Up or Down navigation buttons to move the highlight focus to the desired

illuminant/observer combination and press the Select button. An arrow () appears next to

the selected illuminant/observer.

4. Press the Left navigation button to return to the View column.

31

Page 34

MULTI- ANGLE SPECTROPHOTOMETER

Measure icon

You can delete the last stored

Indicates Auto Standard is

selected in Configuration.

Measurement number and timestamp

The check mark indicates a

Current standard selected

Measuring a Sample

Absolute or difference measurement data is displayed for all angles that can be toleranced. Data

will automatically recalculate if you select a difference color space after a measurement. If

tolerance values are included with the downloaded standard, red or green status bars appear for

each angle that includes tolerancing.

To measure a sample:

1. Select the group, standard, illum/obs, and color space as previous explained.

2. From the Measure screen, use the Up or Down navigation buttons to move the highlight focus

to the Measure icon

.

3. Position the instrument on the sample using the techniques previously explained.

4. Take a measurement via pressure sensors and/or the measure button.

5. If averaging is used, reposition the instrument on the sample and take additional

measurements. Refer to Using Measurement Averaging later in this section for information.

6. View measurement results on the display.

passed measurement.

appear for each measurement. The

Sample Storage option must be

activated in Configuration to display

when the instrument is plugged into

the measurement number.

The timestamp is automatically set

the computer

NOTE: If an error occurs during a measurement, try measuring the sample

again. If the error still occurs, refer to the Troubleshooting section in the

Appendices.

32

measurement by moving the

highlight to the trash can icon

and pressing the Select

button. The Delete Sample

option must be activated in

Configuration to perform this

function.

Page 35

MULTI- ANGLE SPECTROPHOTOMETER

If you want to exit sample

Averaged data values

Using Measurement Averaging

NOTE: Measurement Averaging must be activated in Configuration before averaging can be

performed. Refer to the Configuration Mode for procedure on setting averaging.

Measurement averaging can be set to Simple Average 1 to 5, or SMC 5:12, SMC 10:12, SMC

20:20, and Custom SMC 50:5. SMC (Statistical Measurement Control) requires a minimum of 5

measurements taken at various locations on a sample. Refer to Configuration Mode for additional

information on SMC.

The following example has a simple average setting of 2.

To measure using averaging:

1. Select the group, standard, illum/obs, and color space as previous explained.

2. From the Measure screen, use the Up or Down navigation buttons to move the highlight focus

to the View column and then to the Measure icon

.

3. Position the instrument on the first area of the sample and take a measurement. After the

measurement, the instrument displays "Averaged 1 of 2" in the screen, indicating one more

measurement is required for results.

averaging, move the highlight

and press

Note: When averaging using SMC, a cancel icon

to the exit icon

the Select button. The

display returns to the

previous measurement.

appears in the Progress column after the

third measurement. This allows you to cancel SMC and average the previous measurements for

the current sample.

4. Position the instrument on the second area of the sample and take a measurement. After the

measurement, the instrument momentarily displays "Processing Results" and then the

averaged data values.

33

Page 36

MULTI- ANGLE SPECTROPHOTOMETER

45° lamp angles

Current color space

and angle selected

45° angle view with tolerance

Graph view icon toggles

Graph view icon

15° lamp angles

Using Graph View

The graph view allows you to display L*a*b* color space coordinates and associated tolerances

for ∆L*a*b*, ∆L*C*H*, ∆E*, ∆Ecmc, ∆E, ∆Ep, ∆Eeff, ∆Ec, ∆E00, and ∆E94 measurements.

To activate the graph view:

1. From the Measure screen, use the Right navigation button to move the highlight focus to the

Progress column.

2. Use the Up or Down navigation buttons to highlight the Graph View

icon and press

Select.

Note: The Graph icon will not appear in the Progress column unless one of the delta color

spaces listed above is first selected.

3. With the Content area highlight, use the Up or Down navigation buttons to page through a

graph view for each angle.

4. To exit the graph view, highlight the Graph View

icon and press Select. The screen

returns back to the data display.

34

between graph view and

data view.

Page 37

MULTI- ANGLE SPECTROPHOTOMETER

∆

This example shows the 15°

White check mark and green

Passed Example

Next sample icon

Previous sample icon

Viewing Stored Measurements

NOTE: Sample Storage must be enabled in Configuration to view stored data. Refer to the

Configuration Mode for procedure on enabling sample storage.

Measurements stored can be retrieved on the instrument for viewing at a later time. The

measurement data will display under the last color space and illuminant/observer combination

selected.

To view stored data:

1. From the Measure screen, use the Right navigation button to move the highlight focus to the

Progress column.

2. Use the Up or Down navigation buttons to highlight the

or icon and press Select.

Each time Select is pressed, the screen displays the next or previous store measurement.

Viewing Pass/Fail Data

A red or green bar displays for any aspecular standard angle that has a tolerances set. Angles

that have no tolerance set will remain gray in color. Refer to X-Rite's X-Color QC software

application for information on setting tolerancing for standards.

L*a*b* Color Space (pass/fail)

The following two pass/fail examples are using the ∆L*a*b* color space. Tolerance limits of "0.50"

were set on DL*, Da*, and Db* for the 15° and 45° angles.

and 45° angles highlighted in

green, indicating those angles

passed.

bar indicated that all angle

tolerances passed.

35

Page 38

MULTI- ANGLE SPECTROPHOTOMETER

∆

This example shows the 15°

The "X" and red bar indicate

Failed

Passed

Failed Example

Pass/Warning

Passed with Warning

This example shows the -15°

Yellow checkmark and green

The “a* attribute exceeded

The “L* attribute exceeded

that at least one angle failed

tolerance.

angle highlighted in red and

the 45° angle highlighted in

green, indicating the 15°

angle failed.

L*a*b* Color Space (pass/warning)

the 0.50 tolerance set.

The following is a pass/warning example using ∆L*a*b* color space. Tolerance limits of "1.00"

were set to DL* Da*, and Db* for the -15°, 45°, and 110 angles. In this example, the 80%

warning limit set for the -15° tolerance has been exceeded. This is indicated by a yellow

highlighted checkmark and status bar for the angle.

Example

angle highlighted in yellow

has exceeded the warning

limit.

bar indicated at least one

angle has exceeded the

warning limit.

the 80% warning for the 1.00

tolerance set.

Pass/Fail Option

The Pass/Fail display option located in the color space group gives you a quick pass/fail view of a

sample. Select the [

/X] option to activate the pass/fail display screen.

36

Page 39

MULTI- ANGLE SPECTROPHOTOMETER

Quick Compare icon

Sample to use

for comparison

Quick Compare mode

Color space page icon

Using Quick Compare

The Quick Compare function is used for comparing measurements without storing data. You can

compare measurements to a previously stored measurement or to a new measurement.

Use the color space page icon to quickly page through a list of color spaces without leaving the

current view. Simply press the Enter key when the icon is highlighted to change to the next

allowed color space.

To compare data:

1. Select a stored sample or take new measurement to use for comparison.

2. From the Measure screen, use the Right navigation button to move the highlight focus to the

Progress column.

3. Use the Up or Down navigation buttons to highlight the Quick Compare

icon and press

Select. A small “x” appears next to the Compare icon and “Quick Compare” appears in the

header bar. The Content Area will change to the delta color space of the last selected color

space before the comparison measurement.

4. Position the instrument on the sample to compare and take the measurement.

5. View measurement result or take additional measurements.

6. To exit quick compare, highlight the Quick Compare

returns back to the normal sample measurement mode.

icon and press Select. The screen

37

Page 40

MULTI- ANGLE SPECTROPHOTOMETER

Standard Icon

The Create Standard option must

The newly created standard

Creating Standards

NOTE: The instrument must have standards loaded and Sample Storage must be enabled in

Configuration to create standards.

Standards are downloaded to the instrument from X-Rite's X-Color QC software application.

However, a standard can be created using the instrument. The new standard will duplicate an

existing sample measurement stored with a downloaded standard. Any tolerance values that exist

with that downloaded standard will get copied to the newly created standard. The instrument

automatically number increments the created standards. (For example: "0002", 0003", etc).

These automatically generated numbers cannot be changed on the instrument.

To create a standard:

1. From the Measure screen, use the Right navigation button to move the highlight focus to the

Progress column.

2. Use the Up or Down navigation buttons to highlight the

or icon and press the Select

button to find the sample you want to use as a standard.

3. After the desired sample is displayed, use the Navigation buttons to move the highlight focus

back to the View column and then to the Standard icon

.

4. Press the Right navigation button to access the standard selection area.

be activated in Configuration for it

to appear in the list.

5. Use the Up or Down navigation buttons to move the highlight focus to "Create Standard" and

press the Select button. A new custom standard appears in the list.

6. Press the Left navigation button to return to the View column.

38

can now be used for sample

comparison.

Page 41

MULTI- ANGLE SPECTROPHOTOMETER

Icon

Description

Access the main job screen.

Used to view the steps of the selected job without measuring samples.

Used to move the display to the next step in the job sequence.

Used to go back one step in the job.

Used to undo the last sample measurement.

Used to exit the selected job.

Job mode icon

Available jobs

JOB MODE

The Job mode is used to select and run a job downloaded from X-Rite’s X-Color QC software

program. A typical job would display a sequence of measurement prompts on the instrument

screen. The job mode also allows you view the job step sequence without performing actual

measurements. Refer to X-Rite X-Color QC software for specific information on downloading jobs

to the instrument, and uploading job data to the software application.

Accessing Job Mode

1. From the Main screen, use the Navigation buttons to move the highlight square to the Job

icon.

2. Press the Select button to access the main job screen.

Job Mode Icons

A description of the various icons found in the job mode is shown below.

39

Page 42

MULTI- ANGLE SPECTROPHOTOMETER

→

Available jobs

Next arrow icon

1st step instruction

2nd step measurement

Instructions screen

Measurement screen

Selecting and Running a Job

The following job example downloaded from X-Color QC consists of one instruction screen and two

measurement screens.

1. Use the Up and Down navigation buttons to move the highlight focus to the desired job and

press the Select button. An arrow () appears next to the selected job.

2. Use the Right navigation button to move the highlight focus to the Progress column. Use the

Down navigation button to highlight the Next arrow icon (

Select button to open the job. The first step in the job sequence is displayed.

) if not selected and press the

3. Make sure the Next arrow icon (→) is selected and press the Select button.

4. Position the instrument on the sample as described on the screen and take the measurement.

instruction with graphic

40

Page 43

MULTI- ANGLE SPECTROPHOTOMETER

1st measurement data

Next arrow icon

3rd step measurement

2nd measurement data

5. Data for the first measurement appears on the display. Make sure the Next arrow icon (→) is

selected and press the Select button.

6. Position the instrument on the sample as described on the screen and take the measurement.

instruction with graphic

7. Data appears on the display for the second measurement.

8. The job is now completed. Make sure the Next arrow icon (→) is selected and press the Select

button to return to the main job screen.

41

Page 44

MULTI- ANGLE SPECTROPHOTOMETER

APPENDICES

Service Information

X-Rite provides repair service to their customers. Because of the complexity of the circuitry, all

warranty and non warranty repairs should be referred to an authorized service center. For non

warranty repairs, the customer shall pay shipping and repair cost to the authorized service

center, and the instrument shall be submitted in the original carton, as a complete unaltered unit,

along with all the supplied accessories.

X-Rite, Incorporated has offices around the world. You can contact us using one of the following

methods:

• To identify the X-Rite service center nearest you, please visit our web site at

www.xrite.com and click the Contact Us link.

• For online help, visit our web site and click the Support link. Here you can search for

software or firmware updates, white papers, or frequently asked questions which can

quickly resolve many common user problems.

• Send an e-mail to Technical Support (casupport@xrite.com) detailing your problem and

listing your contact information.

• For sales questions or to order cables and accessories, visit our web site or contact your

nearest X-Rite dealer or service center.

• Problems and questions can also be faxed to your local X-Rite office listed on our web site.

42

Page 45

MULTI- ANGLE SPECTROPHOTOMETER

Cleaning the Instrument

Your instrument requires very little maintenance to achieve years of reliable operation. However,

to protect your investment and maintain reading accuracy, a few simple-cleaning procedures

should be performed from time to time.

General Cleaning

The exterior of the instrument may be wiped clean with a cloth dampened in water or mild

cleaner.

NOTE: DO NOT use any solvents to the clean the instrument, this will cause damage to the

cover.

Cleaning the Optics

The optics should be cleaned once a week in a normal environment. If the instrument is used in a

dirty or dusty environment, more frequent cleaning may be required.

Carefully lift the instrument and blow short bursts of clean, dry air into the measurement port.

This should remove any accumulated debris from the optics.

IMPORTANT: If can air is used for cleaning, do not invert or tilt the can during use. This could

cause damage to the optics.

Cleaning the Calibration Reference

The white plaque in the calibration reference should be cleaned using a mild soap and warm water

solution, thoroughly rinsed with warm water, and wiped dry with a clean, lint-free cloth. You must

let the plaque dry completely before taking a calibration measurement.

43

Page 46

MULTI- ANGLE SPECTROPHOTOMETER

Locking tab

Use clean, dry air to

Access cover

Latch

Battery contacts

Cleaning the Black Trap

The black trap should be cleaned with clean, dry air from time to time to remove any dust or

contamination.

The black trap can be taken apart for easy cleaning. Simply compress the two locking tabs on

both sides of the case with your fingers, and separating the two sections.

clean the inner

surfaces

Replacing the Battery Pack

Use the rechargeable Li-ion batteries provided or equivalent; other types may burst causing

personal injury.

1. Carefully turn the instrument over and slide the latch that secures the battery pack access

cover towards the front of the instrument. Open the access cover.

2. While holding the latch open, turn instrument over allowing old battery back to slide out.

3. Insert the new battery pack into the instrument with the battery contacts facing down.

4. Release the latch and close the access cover by pressing downward until it locks into position.

44

Page 47

MULTI- ANGLE SPECTROPHOTOMETER

Problem

Cause

Solution

Instrument not

Instrument is in power

Press and hold the Select button for 3

Battery pack is very low or

Charge the battery.

Reset the instrument. See Appendix for

No battery pack installed.

Install batteries or plug in AC adapter.

Measurement error or

Material being measured is

Obtain new material.

Instrument requires

Refer to Calibration mode for procedure.

Calibration procedure

Calibration reference is

Clean the reference per procedure in

Instrument and

Interface cable not

Connect the interface cable between the

Close and restart the software application. If

Reset the instrument. See Appendix for

Instrument and

Wireless function not

Activate Bluetooth wireless connection in the

Reset the instrument. See Appendix for

Troubleshooting

Prior to contacting X-Rite support department for instrument problems, try the applicable

solution(s) described below. If the condition persists, contact us using one of the methods listed in

the Service Information section.

responding.

results appear

inaccurate.

fails.

software not

communicating (USB

connection).

down mode.

bad.

seconds to wake up the instrument.

If battery pack is bad, replace using the

procedure in the Appendix.

procedure.

damaged (e.g. scratched)

Optics requires cleaning. Refer to Optics cleaning procedure in

Appendix for procedure.

calibration.

dirty or damaged.

connected.

Appendix, or replace if damaged.

computer and the instrument.

this does not work, reboot the computer.

procedure.

software not

activated.

communicating

(wireless connection).

Activate Bluetooth wireless connection on

Close and restart the software application. If

device. Refer to the Wireless Operation

section for information.

your computer. Refer to the manufacturer's

manual of your computer.

this does not work, reboot the computer.

procedure.

45

Page 48

MULTI- ANGLE SPECTROPHOTOMETER

Sample Error

Message

Screen Messages

Screen messages can appear on the display during error conditions or for informational purposes.

Some messages are cleared from the instrument screen by navigating to the "X" icon and

pressing the Select button.

Messages may also be accompanied by a number to indicate a specific condition. If an error

condition persists, please contact our technical support using one of the methods listed in the

Service Information section.

Resetting the Instrument

To reset the instrument:

1. Unplug the interface cable and AC adapter from the instrument if connected.

2. Open the battery access cover and remove the battery.

3. Reinstall the battery and power up the instrument.

If you are still experiencing problems after a reset, contact X-Rite support using one of the

methods listed in the Service Information section.

46

Page 49

Instrument Specifications

General

Measurement Geometries

Illumination: 45°

Aspecular Viewing: -15° (MA96, MA98), 15°, 25°, 45°, 75°, 110°

Out-of-plane (MA98): 25°az90°, 25°az-90°, 60°az125.3°, 60°az-125.3°

Secondary Illumination (MA98): 15°

Aspecular Viewing (MA98): -15°, 15°

Angular Accuracy: ±0.15° Fiber Optic pick up coupled with DRS technology

Measuring Area: Approx. 12 mm (.5")

Light Source: Gas filled tungsten lamp

Lamp Life: 750,000 measurements, typical

Spectral Range: 400nm – 700nm

Spectral Interval: 10nm (31 measured points)

Measurement Range: 0 - 400%

Colorimetric Illuminants: A, C, D50, D65, F2, F7, F11 and F12

Colorimetric Standard Observers: 2° & 10°

Colorimetric Scales: L*a*b*, L*C*h°, ∆E*, ∆E

Effect Parameters: xDNA, Flop Index

Measurement Time: Approx. 2 seconds

Reproducibility: 0.18 ΔE* avg on reference Series II BCRA tile set

(Inter-instrument agreement)

Repeatability: 0.03 ∆E* on white cal plaque (20 measurements at 5 sec

Power Supply: Rechargeable Lithium Ion battery pack 7.4vDC @

AC Adapter: Input 100-240V 50-60 Hz

Measurements per charge: Up to 750

Measurement storage: 250 Standards

Data interface: USB 2.0

Weight: 2.5 lbs (1.13 kgs)

Dimensions: 3.4 x 4.5 x 10.6 (8,7 cm x 11,4 cm x 26,9 cm)

MULTI- ANGLE SPECTROPHOTOMETER

intervals)

2400 mAh

Output 12VDC @ 2.5 A

1000 Samples

, ∆E DIN6175, ∆E

CMC

2000

47

Page 50

MULTI- ANGLE SPECTROPHOTOMETER

Environmental

Operating Temp: 50°F to 104°F (10°C to 40°C)

Humidity Max: 85% RH max (non condensing)

Storage Temp: -4°F to 122°F (-20°C to 50°C)

Usage: Indoor Only

Altitude: 2000m

Pollution Degree: 2

Transient Overvoltage: Category II

Standards

ASTM: D 2244, E 308, E 1164, E 2194, E 2539 (MA98)

DIN 5033, 6174, 6175-2

ISO 7724

SAE J1545

Design and specifications subject to change without notice.

48

Page 51

Page 52

Page 53

Corporate Headquarters

X-Rite, Incorporated

4300 44th Street SE

Grand Rapids, Michigan 49512

Phone 1 800 248 9748 or 1 616 803 2100

Fax 1 800 292 4437 or 1 616 803 2705

European Headquarters

X-Rite Europe GmbH

Althardstrasse 70

8105 Regensdorf

Switzerland

Phone (+41) 44 842 24 00

Fax (+41) 44 842 22 22

Asia Pacific Headquarters

X-Rite Asia Pacific Limited

Suite 2801, 28th Floor, AXA Tower

Landmark East, 100 How Ming Street

Kwun Tong, Kowloon, Hong Kong

Phone (852)2568-6283

Fax (852)2885 8610