Page 1

X-Rite® MA48

Multi-Angle Spectrophotometer

Operator’s Manual

Page 2

Page 3

Equipment Information

FCC

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

NOTE: Shielded interface cables must be used in order to maintain compliance

with the desired FCC and European emission requirements.

Canada

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations of

the Canadian Department of Communications.

Le présent appareil numérique n'émet pas de bruits radioélectriques dépassent

les limites applicables aux appareils numériques de la class A prescrites dans le

Règlement sur le brouillage radioélectrique édicte par le ministère des

Communications du Canada.

AVERTISSEMENT : Des câbles d'interface blindés doivent être utilisés afin de

se conformer aux règlements européens et FCC (USA)sur l'émission.

CE Declaration

Manufacturer's Name: X-Rite, Incorporated

Manufacturer's Address: 4300 44

Grand Rapids, Michigan 49512

U.S.A.

Model Name: Multi-Angle Spectrophotometer

Model No.: MA48

Directive(s) Conformance: EMC 89/336/EEC LVD 73/23/EEC

Warning:

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

WEEE

As of August 13, 2005, X-Rite products meet the European Union –

Waste Electrical and Electronic Equipment (WEEE) directive.

Please refer to www.xrite.com

compliance with the WEEE directive.

th

Street, S.E.

for more information on X-Rite’s

i

Page 4

Environmental Specifications

Operating Temp: 10° - 40°C

Relative Humidity: 0 - 85% non condensing

Usage: Indoor Only

Altitude: 2000m

Pollution Degree: 2

Overvoltage: Category II

WARNING: This instrument is not for use in explosive environment.

Input Power Requirements

12/15Vdc, 700/560mA

Use Only: X-Rite No. SE30-81 (North America)

X-Rite No. SE30-77 (International)

ii

Page 5

Table of Contents

Proprietary Notice........................................................................................................................... iv

Limited Warranty............................................................................................................................ iv

1. Setup and Overview...................................................................................................... 1-1

Unpacking and Inspection............................................................................................................. 1-1

Packaging Content................................................................................................................. 1-1

Instrument Description.................................................................................................................. 1-1

Docking Station Description.........................................................................................................1-2

Setting Up the System...................................................................................................................1-2

Main Screen Description............................................................................................................... 1-4

Button Operation........................................................................................................................... 1-4

Adjusting Display Contrast...........................................................................................................1-5

Optional Barcode Reader (BCR) .................................................................................................. 1-5

Using the Barcode Reader ..................................................................................................... 1-5

Measurement Techniques..............................................................................................................1-6

Measurement Averaging...............................................................................................................1-6

Measurement Sequence..........................................................................................................1-6

2. Instrument Calibration.................................................................................................. 2-1

General Information......................................................................................................................2-1

White Calibration Reference.........................................................................................................2-1

Zero Reflectance........................................................................................................................... 2-2

Calibration Procedure ................................................................................................................... 2-3

3. Setting Instrument Configuration................................................................................ 3-1

Display Options.............................................................................................................................3-1

Measure Options........................................................................................................................... 3-2

Set Clock.......................................................................................................................................3-3

Communications ...........................................................................................................................3-4

Languages ..................................................................................................................................... 3-5

Battery Refresh Operation.............................................................................................................3-5

4. Instrument Operation....................................................................................................4-1

Reference Mode............................................................................................................................ 4-1

Selecting a Reference Number and Measuring......................................................................4-1

Selecting the Tolerance Type and Editing Values................................................................. 4-2

Store Mode....................................................................................................................................4-3

Selecting a Group/Reference and Measurement....................................................................4-4

Changing Color Space and Illuminant/Observer ................................................................... 4-4

Switching Between Pass/Fail Indication and Difference Data...............................................4-5

Edit Menu (Print, View and Delete) ......................................................................................4-5

Tagging Samples (using the optional BCR)...........................................................................4-7

Normal Mode................................................................................................................................4-8

5. Service and General Maintenance............................................................................... 5-1

Repair Information........................................................................................................................5-1

Cleaning the Instrument and Docking Station ..............................................................................5-1

Cleaning the Optics.......................................................................................................................5-1

Battery Replacement Information.................................................................................................5-2

Cleaning the Calibration Reference ..............................................................................................5-2

Cleaning the Zero Reflectance Trap..............................................................................................5-2

Troubleshooting Tips....................................................................................................................5-3

Error Messages.............................................................................................................................. 5-4

Reading Error Messages........................................................................................................ 5-4

Calibration Error Messages....................................................................................................5-4

Miscellaneous Error Messages...............................................................................................5-4

Specifications................................................................................................................................5-5

iii

Page 6

Proprietary Notice

The information contained in this manual is derived from patent and proprietary data of

X-Rite, Incorporated. This manual has been prepared solely for the purpose of assisting

in the use and general maintenance of this instrument.

The contents of this manual are the property of X-Rite, Incorporated and are copyrighted.

Any reproduction in whole or part is strictly prohibited. Publication of this information

does not imply any rights to reproduce or use this manual for any purpose other than

installing, operating, or maintaining this instrument. No part of this manual may be

reproduced, transcribed, transmitted, stored in a retrieval system, or translated into any

language or computer language, in any form or by any means, electronic, magnetic,

mechanical, optical, manual, or otherwise, without the prior written permission of an

officer of X-Rite, Incorporated.

This instrument may be covered by one or more patents. Refer to the instrument for

actual patent numbers.

Copyright © 2007 by X-Rite Incorporated

“ALL RIGHTS RESERVED”

Limited Warranty

X-Rite, Incorporated (“X-Rite”) warrants each instrument manufactured to be free of

defects in material and workmanship (excluding battery pack) for a period of 12 months.

This warranty shall be fulfilled by the repair or replacement, at the option of X-Rite, of

any part or parts, free of charge including labor, F.O.B. its factory or authorized service

center.

This warranty shall be voided by any repair, alteration, or modification, by persons other

than employees of X-Rite, or those expressly authorized by X-Rite to perform repairs,

and by any abuse, misuse, or neglect of the product, or by use not in accordance with XRite’s published instructions.

X-Rite reserves the right to make changes in design and /or improvements to its products

without any obligation to include these changes in any products previously

manufactured. Correction of defects by repair or replacement shall constitute fulfillment

of all warranty obligations on the part of X-Rite.

THIS WARRANTY IS EXPLICITLY IN LIEU OF ANY OTHER EXPRESSED OR

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. THIS

WARRANTY OBLIGATION IS LIMITED TO REPAIR OR REPLACEMENT OF

THE UNIT RETURNED TO X-RITE OR AN AUTHORIZED SERVICE CENTER

FOR THAT PURPOSE.

This agreement shall be interpreted in accordance with the laws of the State of Michigan

and jurisdiction and venue shall lie with the courts of Michigan as selected by X-Rite,

Incorporated.

iv

X-Rite® is a registered trademark of X-Rite, Incorporated

All other logos, product names, and trademarks mentioned are the property of their respective holders.

Page 7

1. Setup and Overview

Unpacking and Inspection

After removing the instrument from the shipping carton, inspect for possible damage. If

any damage occurred during shipping, immediately contact the transportation company.

Do not proceed with installation until the carrier’s agent has inspected the damage.

Your instrument was packaged in a specially designed carton to assure against damage. If

reshipment is necessary, the instrument should be packaged in the original carton. If the

original carton is not available, contact X-Rite (1-888-826-3042 or 1-616have a replacement shipped to you.

Packaging Content

Your packaging should contain the all the items listed below. If any of these items are

missing, contact X-Rite or an Authorized Representative.

• MA48 Instrument

• Docking Station

• Interface Cable

• AC Adapter

• White Calibration Reference

• Documentation and Registration Material

803-2100) to

Instrument Description

The MA48 multi-angle spectrophotometer is designed for measuring color on metallic

and pearlescent paint finishes. The instrument incorporates a single light source and five

fixed—aspecular—viewing angles (15°, 25°, 45°, 75°, and 110°).

To ensure measurement accuracy, the MA48 also includes a two read-switch triggering

mechanism. This allows a measurement to be taken only after the spectrophotometer has

been properly positioned.

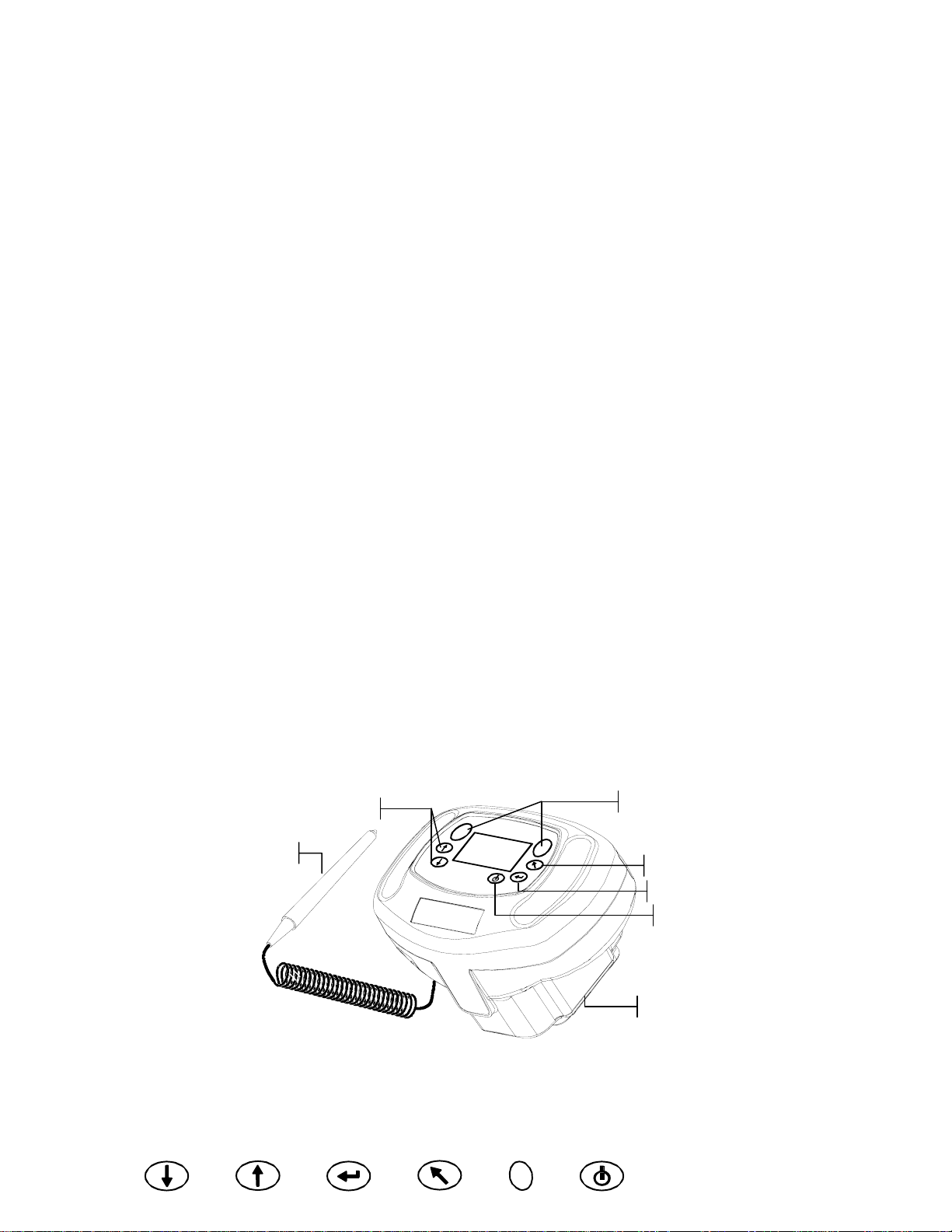

Tab Buttons

Barcode Reader

Read Buttons

Back Button

Enter Button

On/Off Button

Sensor Nose

Tab Down Tab Up Enter Back Read On/Off

1-1

Page 8

SECTION ONE

Docking Station Description

The docking station provides several important functions:

White Reflectance Standard

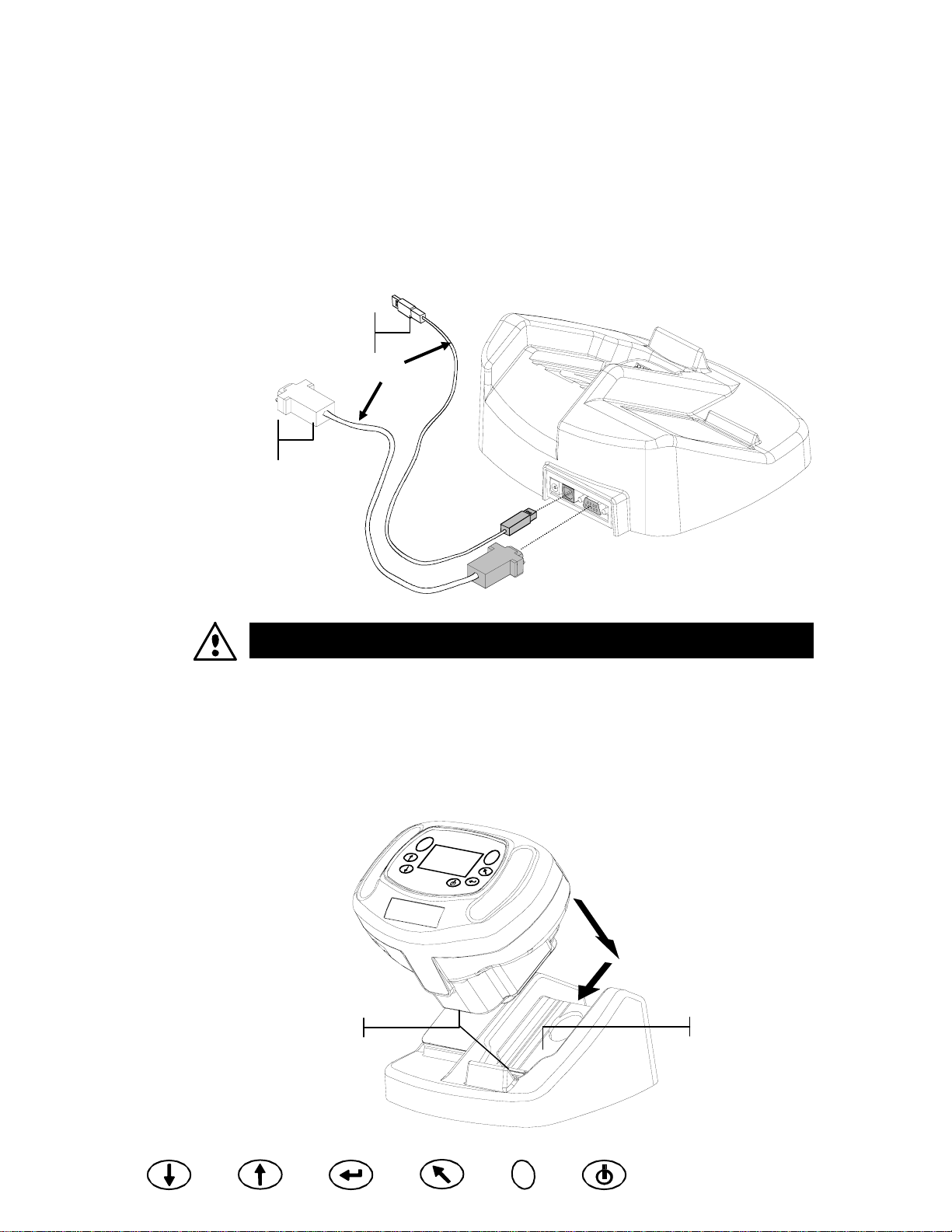

Setting Up the System

• storage of the instrument for nonuse times

• data transfer to the local computer (RS-232 or USB interface connection)

• charging of the instrument’s internal battery (refer to section 3: Battery Refresh

Operation)

• an open port for zero reflectance readings and storage for the white cal reference

Zero Reflectance Port

Computer and Charger

Connections

Use only X-Rite power supply P/N SE30-81 (manufacturer’s P/N J06ADT-53)

or P/N SE30-77 (manufacturer’s P/N PSA30U-120).

1. Locate the docking station next to the computer.

2. Plug the small connector end of the power supply into the back of the docking station.

3. Domestic Power Supply - Plug the adapter into an AC wall receptacle.

Export Power Supply - Plug the detachable line cord into the power supply and then

plug the line cord into an AC wall receptacle.

OR

Power Supply

(export)

Detachable Line Cord

Power Supply

(domestic)

1-2

4. DB9 Serial Interface (Standard)

Connect the DB9 plug onto the 9-pin I/O port on the back of the instrument. Connect

the other end into an available computer COM port.

Tab Down Tab Up Enter Back Read On/Off

Page 9

DB9 Serial Cable

(standard)

SETUP AND OVERVIEW

USB Cable Interface (optional)

Plug the square end of the USB cable into the back of the docking station. Connect

the other end of the USB cable to an available USB port on back of the computer.

After connecting the USB cable to your computer, a “Found New Hardware”

message appears on the screen. You must install the USB driver for the instrument to

communicate with your computer. Insert the Manuals and Utilities CD that came

with your instrument into the CD drive and follow the instructions on the screen.

The USB driver is located in the “Driver” folder on the CD.

USB Cable

(optional)

OR

The instrument automatically goes into “charge mode” when it is placed on the

docking station.

5. Place the instrument onto the powered docking station by positioning the sensor nose

in the recessed area and sliding downward. Make sure the connector on the

instrument is properly seated to the connector on the docking station. A “two-beep”

conformation signal is heard and a “lighting bolt” icon appears in the lower right

portion of the main screen when properly seated. The instrument must initially remain

on the docking station for a minimum of four hours to allow the internal batteries to

fully charge.

Connectors

Recessed Area

Tab Down Tab Up Enter Back Read On/Off

1-3

Page 10

SECTION ONE

A

Main Screen Description

When the instrument is powered-up, the main (top level) screen appears. The main menu

consists of two areas, Operating Modes and Instrument Data. The left side of the screen

lists all available modes. The right side of the screen lists the instrument name, firmware

version and serial number.

Instrument Name

Firmware Version and

Serial Number

“lighting bolt” icon indicates the

instrument is docked and charging

Operating Modes

–MAIN MENU–

Store

Normal

References

Calibrate

Config.

MA48

——————

XXXX

******

Button Operation

Perform reading and menu/option navigation with the six buttons arranged around the

display screen. Each button has a unique symbol for performing a specific operation.

On/Off

Controls the instrument’s power status when it is not in the docking station. As an added

feature to conserve battery life, the instrument automatically powers down after five

minutes of nonuse. The On/Off button must be used to turn on the instrument after an

auto power down.

Tab Down

Advances the highlighted bar (reverse image) to the next available “tab stop.” A tab stop

indicates an item that can be acted on further, such as a measurement or an edit option.

Tab stops generally follow a left-to-right or top-to-bottom sequence. When the last tab

stop is reached, the next button press returns to the first tab stop in that menu's list. The

button is also used to increment numeric values in the Reference mode.

1-4

Tab Up

Performs the same function as the Tab Down button except in reverse order. Tab stops

follow a right-to-left or bottom-to-top sequence.

Enter

Used to activate/select the control chosen (highlighted) with the tab buttons. If the

control can be set on or off, pressing the button toggles the option between on and off.

Back

Backs up the instrument screen one menu level. For example, if an option or value is

being modified at the time the button is pressed, the edits are aborted and the previous

screen or menu appears. The only exception to this is when the Enter button is used to

toggle an option. In this case, the Back button exits the menu without aborting the

setting.

Read

Initiates a reading when either Read button is pressed and both read switches are

activated.

Tab Down Tab Up Enter Back Read On/Off

Page 11

SETUP AND OVERVIEW

Adjusting Display Contrast

The contrast of the display can be adjusted for optimal viewing. Make sure the

instrument screen is at the main menu before changing.

To adjust, hold down Back and press Tab Up to increase contrast or Tab Down to

decrease contrast.

Increase Contrast

Decrease Contrast

–MAIN MENU–

Store

Normal

References

Calibrate

Config.

MA48

——————

XXXX

******

Optional Barcode Reader (BCR)

The barcode reader should only be used for its intended application (barcodes).

Never look directly into the beam of light or direct the beam of light luminating at

the tip of the reader in the direction of someone’s eyes.

The instrument utilizes a barcode reader as a means of attaching tags to samples. Sample

data that is uploaded from the instrument to the computer will include scanned tags.

Refer to the end of Section Four for information on scanning tags in Store Mode.

Using the Barcode Reader

The barcode reader is stored in a recessed area on the front edge of the instrument when

not in use. Simply press it into the holder area to secure.

Recessed Area

Hold Down

Follow these guidelines for successful bar code scanning.

1. Hold the BCR in your hand as you would a pencil. The BCR work s

best when slightly tilted.

2. Place the tip of the BCR on the white space to the left or right of

the barcode. Drag the BCR smoothly and lightly across the bar

code. Do not lift the tip of the BCR from the surface of the bar

code.

3. If the scan was successful, an audible beep is heard and

the instrument displays the title of the barcode. If an

audible beep is not heard, try scanning the

barcode again.

Tab Down Tab Up Enter Back Read On/Off

1-5

Page 12

SECTION ONE

Measurement Techniques

In order to obtain accurate and repeatable measurements, the bottom of the sensor nose

must be flat with the surface to be measured. Any movement of the sensor nose can cause

the measurement angles to vary, greatly affecting measurements on metallic paint finishes.

Measurements performed on a surface with a curve can cause the instrument to display a

“Light Leakage” error. This is caused by stray light entering the measurement aperture.

A measurement takes place when both switches are activated on the bottom of the sensor

nose. It may also be necessary to press one of the Read buttons to complete the

measurement if the option is set in the Configuration mode. To achieve the b est

measurement repeatability, apply even pressure to both sides of the instrument during a

measurement. The beginning and end of the measurement is signaled by audible beeps.

Hold the instrument firmly until “MEASUREMENT COMPLETE” message is

displayed.

Measurement Averaging

Measurement averaging is used to obtain an average value from various locations across

a sample. The averaging option is activated in the Configuration mode and can be set

from one to 99 measurements. All modes with the exception of Calibration use averaging

when activated.

Measurement Sequence

1. Select mode of operation (Store, Normal or Reference).

2. Position instrument on first area of sample and take the measurement. The current

measurement out of remaining measurements is displayed (e.g., 1 of 3).

NOTE: Averaging can be aborted at any time by pressing the Back button.

3. Position the instrument on the next area on the sample and take the measurement.

4. Continue with all required measurements.

5. After the last average measurement is taken, Averaging Complete appears on the

screen and then the averaged data.

1-6

Tab Down Tab Up Enter Back Read On/Off

Page 13

2. Instrument Calibration

General Information

Regular calibration of the instrument is important in maintaining accurate measurements.

The instrument should be calibrated to the white standard and docking station (zero

reference port) the first thing each day, and every twelve hours of operation

thereafter. A Cal Required message appears in the display when the calibration

procedure has not been performed for 12 hours.

Whenever this message appears in the display, the calibration procedure must be

performed. No measurements can be taken until calibration is completed.

Calibration Notes

• Dirt or dust in the optics area will cause an inaccurate calibration reading. Refer

to Section Four for optics cleaning procedure.

• The white calibration reference is dramatically affected by smudge marks, dust,

and fingerprints. Refer to Section Five for white calibration cleaning procedure.

• Do not move instrument while taking calibration measurements. If motion is

detected, an error message displays and the calibration is aborted.

White Calibration Reference

The white calibration reference is stored on the left side of the docking station and is

designed to keep the reflection tile free of dust and debr is.

White Calibration Reference

Tab Down Tab Up Enter Back Read On/Off

2-1

Page 14

SECTION TWO

The white calibration reference tile is concealed in a case that has a hinged cover.

Position the sensor nose of the instrument in the case and take the measurements. Make

sure the calibration tile is positioned directly under the measurement aperture.

Hinged Cover

Calibration Tile

Zero Reflectance

The docking station is used to perform the zero reflectance measurement portion of the

calibration procedure. Place the instrument in its normal position on the station and the

take the measurements over the cutout beneath the sensor nose.

2-2

Zero Reflectance Port

Tab Down Tab Up Enter Back Read On/Off

Page 15

INSTRUMENT CALIBRATION

Calibration Procedure

The calibration procedure consists of two white reference measurements followed by

four zero reflectance measurements.

1. Use Tab Down or Tab Up to highlight Calibrate. Press Enter to access the calibration

function.

–MAIN MENU–

Store

Normal

Reference

Calibrate

Config.

The instrument displays the calibration status and reference serial number. The serial

number displayed must match the number listed on the calibration reference. If the

calibration status is OK, no calibration is required at this time. If Cal Required is the

current status, you must perform the calibration procedure before continuing with any

additional measurements.

Calibration

Measure White Ref

Press Firmly

Status: Cal Required

S/N: XXXXX

MA48

——————

XXXX

******

2. Remove the white calibration reference from the docking station and position the

instrument on the reference as previously discussed. Hold the instrument down and

momentarily press one of the Read buttons. Hold steady until the instrument indicates

that both the white calibration readings are complete.

3. After successful white calibration readings, position the instrument in its normal position

on the docking station. The display indicates that the Black Ref measurements are now

required. Hold the instrument steady against the docking station and momentarily press

one of the Read buttons to take the measurements. You must keep the instrument steady

through all four measurements.

After the measurements are completed, the display automatically returns back to the main

menu.

Tab Down Tab Up Enter Back Read On/Off

2-3

Page 16

SECTION TWO

2-4

Tab Down Tab Up Enter Back Read On/Off

Page 17

3. Setting Instrument Configuration

The Configuration mode consists of a several settings that can be edited to customize

your instrument for your particular application.

1. Use Tab Down or Tab Up to highlight Config.

–MAIN MENU–

Store

Normal

References

Calibrate

Config.

2. Press Enter to access the Configuration mode.

CONFIGURATION

Display Options

Measure Options

Set Clock

Communications

Language

Display Options

MA48

——————

XXXX

******

The Display Options allows you to configure the following settings:

Active ∆E – Allows you to choose the Delta E method that is available in Store and

Normal modes. Available settings are: ∆E

*a*b*

, ∆Ecmc, ∆Ec6175, ∆Ep6175 and ∆Ee6175.

Active Illum/Obs – Allows you to select the illuminant/observer combinations available

in Store and Normal mode. An arrow (>) indicates the illum/obs combination is active.

Active Angles – Allows you to select which three angles are displayed on the screen in

Store mode and Reference mode. Available setting are: “15°/45°/75°”, “25°/45°/75°”,

“25°/45°/110°”, and “15°/45°/110°.”*

15°/45°/110° viewing geometry by license from E.I. DuPont de Nemours and Co., Inc. U.S. Patent No. 4,479,718.

Editing Display Options

1. Press Tab Up or Tab Down to move the highlight to Display Options.

CONFIGURATION

Display Options

Measure Options

Set Clock

Communications

Language

2. Press Enter to access the Display Options menu.

Display Options

Active ∆E

Active Illum/Obs

Active Angles

Active ∆E

1. Press Tab Up or Tab Down to move the highlight to Active ∆E and press Enter to

open the Active ∆E editor.

2. Press Tab Up or Tab Down to move the highlight to desired ∆E and press Enter to

select setting and exit editor.

Tab Down Tab Up Enter Back Read On/Off

3-1

Page 18

SECTION THREE

Active Illuminate/Observer

1. Press Tab Up or Tab Down to move the highlight to Active Illum/Obs and press

Enter to open the Active Illum/Obs editor.

2. Press Tab Up or Tab Down to move the highlight to the desired 10° combination and

press Enter to toggle the combination active or inactive. The arrow (>) indicates

active.

3. To edit 2° combinations, highlight To 2° using Tab Up or Tab Down and press Enter.

4. Press Tab Up or Tab Down to move the highlight to the desired 2° combination and

press Enter to toggle the combination active or inactive. The arrow (>) indicates

active.

5. After edits are complete, press Back to save and exit the illum/obs editor.

Active Angles

1. Press Tab Up or Tab Down to move the highlight to Active Angles and press Enter

to open the Active Angles editor.

2. Press Tab Up or Tab Down to move the highlight to Angle #1 and press Enter to

toggle between 15° and 25°.

3. Press Tab Up or Tab Down to move the highlight to Angle #3 and press Enter to

toggle between 75° and 110°.

4. After edits are complete, press Back to save and exit the editor.

Measure Options

The Measure option allows you to configure the following settings:

Auto Ref – Sets the automatic reference option. When Auto Reference is enabled (on),

the stored reference that most closely matches the measured sample is automatically

selected during a Store or Normal measurement. When Auto Reference is disabled (off),

you must manually select a reference before taking a measurement.

Averaging –Sets the number of readings (0-99) required to obtain an averaged

measurement.

Read Action – Allows you to have the measurement activated by bottom switches (Foot

Switches only), Read button (Read Key only), or in combination of the Read button and

bottom switches (Switch & Key req.).

Editing Measure Options

1. Press Tab Up or Tab Down to move the highlight to Measure Options.

CONFIGURATION

Display Options

Measure Options

Set Clock

Communications

Language

2. Press Enter to access the Measure Options editor.

Measure Options

Auto Ref: On

Averaging : 1

Read Action

3-2

Tab Down Tab Up Enter Back Read On/Off

Page 19

SETTING INSTRUMENT CONFIGURATION

Auto Reference

• Press Tab Up or Tab Down to move the highlight to Auto Ref and press Enter to

toggle between Off and On.

Averaging

1. Press Tab Up or Tab Down to move the highlight to Averaging and press Enter to

active the averaging # editor (up/down arrows appear to the left).

2. Press Tab Down to page backward through the averaging numbers, or press Tab Up

to page forward through the numbers.

3. Press Enter to select the displayed averaging number.

NOTE: Use the Back button to revert back to the original setting.

Read Switches

1. Press Tab Up or Tab Down to move the highlight to Read Action and press Enter

to open the read action editor.

2. Press Tab Up or Tab Down to move the highlight to Foot switches only, Read Key

only, or Switch & Key req. and press Enter to save selection and exit.

Exiting Measure Option

• After you have completed all the measure option editing, press Back to return to the

Configuration menu.

Set Clock

The Set Clock configuration is used to adjust the internal clock of the instrument.

1. Press Tab Up or Tab Down to move the highlight to Set Clock.

CONFIGURATION

Display Options

Measure Options

Set Clock

Communications

Language

2. Press Enter to access the Set Clock editor.

Day : 09

Month : 01

Year : 03

Hour : 10

Minute : 25

3. Press Tab Up or Tab Down to move the highlight to Day, Month, Year, Hour or Minute

and press Enter to activate the editor (up/down arrows appear to the left).

4. Press Tab Down to page backward through the digits, or press Tab Up to page forward

through the digits.

5. Press Enter to select the displayed digit.

NOTE: Use the Back button to revert back to the original setting.

6. Continue with additional date/time edits as required.

Set Clock

Exiting Clock Set Option

• After you have completed all the clock editing, press Back to return to the Configuration

menu.

Tab Down Tab Up Enter Back Read On/Off

3-3

Page 20

SECTION THREE

Communications

The Communication option allows you to configure the following settings:

Baud Rate – Determines the data input/output rate of the instrument. The rate can be set

at 9600 or 19200.

Automatic LF – Varies the delimiter at the end of each line of data. When set to LF On,

a line feed is sent at the end of a line of data. When set to LF Off, no line feed is sent at

the end of the line of data.

Data – Determines the type of data output from the instrument. When set to Color, color

space data (L*a*b*, etc.) is output. When set to Spectral, spectral data in 10nm

increments is output.

Header – Determines if the header information (L*a*b*, etc.) is output with

measurement data. If set to Off, no header information is output. If set to On, header

information is output.

Ref. Printout – Determines if the reference data is output with measurement data. If set

to Off, no reference data is output. If set to On, reference data is output.

Editing Communications Options

1. Press Tab Up or Tab Down to move the highlight to Communications.

CONFIGURATION

Display Options

Measure Options

Set Clock

Communications

Language

2. Press Enter to access the Communications editor.

Communication

Baud Rate : 9600

Automatic LF: On

Data: Color

Header: Off

Ref. Printout: Off

Baud Rate

• Press Tab Up or Tab Down to move the highlight to Baud Rate and press Enter to

toggle between 9600 and 19200.

Auto Line Feed

• Press Tab Up or Tab Down to move the highlight to Automatic LF and press Enter

to toggle between Off and On.

Data

• Press Tab Up or Tab Down to move the highlight to Data and press Enter to toggle

between Color and Spectral.

Header

• Press Tab Up or Tab Down to move the highlight to Header and press Enter to

toggle between Off and On.

Ref. Printout

• Press Tab Up or Tab Down to move the highlight to Ref. Printout and press Enter

to toggle between Off and On.

3-4

Tab Down Tab Up Enter Back Read On/Off

Page 21

SETTING INSTRUMENT CONFIGURATION

Exiting Communication Option

• After you have completed all the communications editing, press Back to return to

the Configuration menu.

Languages

The Language configuration allows you to select the language you want to display on

your instrument.

1. Press Tab Up or Tab Down to move the highlight to Language.

CONFIGURATION

Display Options

Measure Options

Set Clock

Communications

Language

2. Press Enter to access the Language editor.

Language

English Chinese Simp

Deutsch Japanese

Français

Espanol

Italiano

Portugues

3. Press Tab Up or Tab Down to move the highlight to the desired language.

4. Press Enter to save the selected language. The instrument returns to the Configuration

menu with the selected language active.

Battery Refresh Operation

Your instrument is powered by a Ni-metal hydride battery pack. Because the battery will

start to charge every time the instrument is docked in the station, this can, overtime reduce

the capacity of the battery. Refreshing is the process of allowing your instrument’s battery

to drain completely and then charging all cells in the battery to 100%. Refreshing the

battery from time-to-time helps extend the duration of use and life of the battery.

The process for refreshing the battery takes approximately eight hours and should be

performed once a month. As the instrument cannot be used during this operation and

must remain in the docking station the entire time, it is suggested that this procedure be

performed at the end of a workday to minimize disruption.

1. Place the instrument in the docking station.

2. Press Tab Up or Tab Down to move the highlight to the Battery icon and then press Enter.

CONFIGURATION

Display Options

Measure Options

Set Clock

Communications

Language

3. You are asked if you are sure you would like to begin the refresh operation. Press Tab

Up or Tab Down to move the highlight to Yes and press Enter.

The instrument displays “Please Wait, battery maintenance in progress” during the

discharge phase of the operation. This screen automatically disappears when the charging

portion of the operation begins.

NOTE: To abort the refresh operation at anytime, simply power down the

instrument and then power it back up.

Tab Down Tab Up Enter Back Read On/Off

3-5

Page 22

SECTION THREE

3-6

Tab Down Tab Up Enter Back Read On/Off

Page 23

A

A

4. Instrument Operation

Reference Mode

The instrument can store a maximum of 100 references with tolerances which are

accessible in the Store and Normal modes. The reference mode is used to measure

references and edit their tolerances. References can also be downloaded from an X-Rite

software application, such as X-RiteColor Master. If a reference is downloaded, it can be

viewed but not edited.

1. Use Tab Up or Tab Down to highlight References.

–MAIN MENU–

Store

Normal

References

Calibrate

Config.

2. Press Enter to access the reference mode.

MA48

——————

XXXX

******

Current reference number

Reference: 1

Tolerance: ∆L

Edit Tolerances

31.43 24.57 262.34

30.50 24.45 262.14

32.41 26.03 262.19

*a*b*

Tolerance type for selected reference

ccesses tolerance editing menu

ngle data for current reference

Selecting a Reference Number and Measuring

The reference mode has a special control that is used to select a reference number. The

list can be paged through either forward or backward to reduce time.

Reference number will be replaced with the reference name when downloaded from

X-RiteColor Master software.

1. Use Tab Up or Tab Down to highlight Reference: ##.

2. Press Enter to activate the editor. Up/down arrows appear at the left.

Reference: 1

Indicates the editor

control is active

Tolerance: ∆L

Edit Tolerances

31.43 24.57 262.34

30.50 24.45 262.14

32.41 26.03 262.19

3. Press Tab Down to page backward through the reference numbers, or press Tab Up to

page forward through the list. To quickly page through the references, hold down one of

the Tab keys.

4. Press Enter to select the displayed reference number.

NOTE: Use Back to revert back to the original reference.

*a*b*

5. Refer to section 1: Measurement Techniques for information on proper positioning.

Position the instrument over the reference and take the measurement. The selected angles

appear momentarily during the measurement.

NOTE: If the averaging option is activated in the Configuration mode, you must

make additional measurements on the reference. Refer to section 1:

Measurement Averaging for additional information.

Tab Down Tab Up Enter Back Read On/Off

4-1

Page 24

SECTION FOUR

Selecting the Tolerance Type and Editing Values

After selecting a reference number and measuring a reference, you can select a tolerance

type and edit tolerance values. If a tolerance is not going to be used, select the NONE

option. The tolerance type and values cannot be changed if the reference number is

empty or if the reference was downloaded.

The attributes that are available for adjustment depend on the tolerance type selected.

• ∆E*a*b*, ∆Ec6175, ∆Ep6175 and ∆Ee6175 tolerance types allows tolerance

adjustment for each angle.

• ∆FI tolerance type allows high/low tolerance adjustment for the flop index.

• ∆L*a*b* and ∆L*C*h tolerance types allows high/low tolerance adjustment for each

angle.

• ∆Ecmc tolerance type allows a global adjustment for “l” (lightness factor) and “c”

(chromaticity factor). The “cf” (commercial factor) can be adjusted for each angle).

1. Use the Tab Up or Tab Down to highlight Tolerance:.

2. Press Enter to page through the tolerance types: None, ∆L*a*b*, ∆L*C*H*, ∆FI,

∆E*a*b*, ∆Ecmc, ∆Ec6175, ∆Ep6175 and ∆Ee6175.

Reference: 1

Tolerance: ∆L

Edit Tolerances

31.43 24.57 262.34

30.50 24.45 262.14

32.41 26.03 262.19

3. After selecting the tolerance type, use Tab Down to highlight Edit Tolerances.

Reference: 1

Tolerance: ∆L

Edit Tolerances

31.43 24.57 262.34

30.50 24.45 262.14

32.41 26.03 262.19

*a*b*

*a*b*

4. Press Enter to access the tolerance editing screen.

Reference: 1

Tolerance: ∆L

Set 15° High

∆L* ∆a* ∆b

+1.00 +2.00 +1.00

<< >>

*a*b*

*

Selecting an Angle and High/Low Tolerance for Editing

The angles and high/low tolerances available for editing depends on the tolerance type

selected. All angles and high/low tolerances for each tolerance type are selected using the

same method.

1. Press Tab Up or Tab Down to move the highlight to the left double arrow (<<) or

the right double arrow (>>).

2. Press Enter to page through the available angle and/or high/low tolerance screens.

Reference: 1

Tolerance: ∆L

Set 15° High

∆L* ∆a* ∆b

+1.00 +2.00 +1.00

<< >>

Pages forward

through the angles

*a*b*

*

Reference: 1

Tolerance: ∆L*a*b*

Set 15° Low

∆L* ∆a* ∆b

-1.00 -2.00 -1.00

<< >>

Pages backward

through the angles

*

3. After selecting an angle tolerance, advance to Editing an Attribute Value.

4-2

Tab Down Tab Up Enter Back Read On/Off

Page 25

Editing an Attribute Value

The attributes available for editing depend on the tolerance type selected. Values for all

types are edited in the same manner.

1. Press Tab Up or Tab Down to move the highlight to a tolerance attribute.

2. Press Enter to activate the editor. Up/down arrows appear at the left.

Indicates the editor

control is active

3. Press Tab Down to decrease the value, or press Tab Up to increase the value.

NOTE: While the editor is activated (arrow control displayed), you can use Back

to revert back to the original value.

4. Press Enter to select the displayed value and close the editor control.

5. Press Back to exit the tolerance editing screen.

Store Mode

Reference: 1

Tolerance: ∆L

Set 15° High

∆L* ∆a* ∆b

+1.00 +2.00 +1.00

<< >>

*a*b*

*

INSTRUMENT OPERATION

Tolerance Attribute

The store mode is used to store sample measurements in selectable group numbers.

Measured samples are compared to stored references with or without tolerance values

applied. If tolerance values are applied to the reference, pass/fail indication and

difference data appears on the instrument for the three predefined angles. The instrument

is capable of storing 800 samples across 20 groups.

Store mode is also used to view and delete stored sample data, as well as output stored

data to a printer or to a software application, such as X-RiteColor Master.

1. Use Tab Up or Tab Down to highlight Store.

–MAIN MENU–

Store

Normal

References

Calibrate

Config.

MA48

——————

XXXX

******

2. Press Enter to access the store mode.

The information displayed depends upon whether tolerancing is used and if the color

space selected is displayed as absolute or difference.

Current group number (1 – 20)

Group: 1

Stored: 5

Reference: 1

*a*b*

∆L

+.10 –.04 +.04

+.13 –.02 –.07

+.29 –.06 –.08

Without Tolerancing Applied

Group: 1

Stored: 5

Reference: 1

*a*b*

∆L

PASS

PASS

FAIL

With Tolerancing Applied

D65/10

T D65/10

Number of samples stored in the group

Current selected reference (1 – 100)

15° or 25° sample difference data

45° sample difference data

75° or 110° sample difference data

Indicates difference data is available to view

for the measurement

Selectable color space and illuminant/observer

Pass/fail indication when tolerance are applied

Tab Down Tab Up Enter Back Read On/Off

4-3

Page 26

SECTION FOUR

Selecting a Group/Reference and Measurement

Groups and references are selected in the same manner. If Auto Reference is activated in

configuration, there is no need to select a reference before taking a measurement. The

instrument automatically selects the closest match to the measured sample.

NOTE: A reference cannot be edited from within the Store mode. You must

access the reference from the main menu screen.

1. Use Tab Up or Tab Down to highlight Group: ##.

2. Press Enter to activate the editor. Up/down arrows appear at the left.

Indicates the editor

control is active

3. Press Tab Down to page forward through the group numbers, or press Tab Up to page

backward through the list. Twenty groups are available.

4. Press Enter to select the displayed group number.

NOTE: Use Back to revert back to the original group.

• If Auto Reference is not activated in Configuration, select the reference in the same

manner as the group number.

• If tags are to be stored with the sample, you can scan them in at this point using the optional

BCR. Refer to Tagging Samples at the end of this section for information on tag options.

5. Position the instrument over the sample and take the measurement. You may have to

press Read to complete the measurement if the instrument is configured to do so. The

selected angles appear momentarily during the measurement and the stored sample

number increments by one.

Measurement data is displayed as absolute or difference, or pass/fail indication if

tolerancing is utilized. The instrument measures and stores five angles but only displays

the three angles in Store mode. All five angles are output when data is transmitted.

NOTE: If the averaging option is activated in the Configuration mode, you must

make additional measurements on the sample. Refer to section 1: Measurement

Averaging for additional information.

Group: 1

Stored: 5

Reference: 1

*a*b*

∆L

+.10 –.04 +.04

+.13 –.02 –.07

+.29 –.06 –.08

D65/10

Selected reference

4-4

Changing Color Space and Illuminant/Observer

Measurement angle data can be viewed under different color space and

illuminant/observer conditions.

1. Use Tab Up or Tab Down to highlight Color Space (e.g. ∆L*a*b* or Illum/Obs (e.g.

D65/10).

2. Press Enter to page through the available color space or illuminate/observer options.

Data is automatically updated to the selected option.

Group: 1

Stored: 5

Color space

selection

Reference: 1

*a*b*

∆L

+.10 –.04 +.04

+.13 –.02 –.07

+.29 –.06 –.08

NOTE: Certain illuminant/observer combinations may not appear as you page

through the list. Certain combinations may be deactivated in the configuration

options. D6510, A10 and F210 are the factory default combinations.

Tab Down Tab Up Enter Back Read On/Off

D65/10

Illuminant/Observer

selection

Page 27

INSTRUMENT OPERATION

Switching Between Pass/Fail Indication and Difference Data

Difference data can be viewed for a pass/fail measurement. A down arrow icon (T)

appears between the selected color space and illuminate observer when tolerancing is set

with a reference. A solid down arrow (T ) appears for pass/fail indication, and an open

down arrow (V ) appears for difference data displayed. Pass/Fail indication always

appears first after a measurement.

1. After a measurement, use Tab Up or Tab Down to highlight down arrow (T).

2. Press Enter to toggle between pass/fail indication (solid down arrow T) and difference

data (open down arrow V ).

Group: 1

Stored: 5

Reference: 1

*a*b*

∆L

+.10 –.04 +.04

+.13 –.02 –.07

+.29 –.06 –.08

V D65/10

Used to toggle between

pass/fail and difference data

Edit Menu (Print, View and Delete)

Stored measurement data is accessible for outputting, viewing and deleting.

1. From within Store mode, use Tab Up or Tab Down to highlight Stored: ##.

Group: 1

Stored: 5

Reference: 1

*a*b*

∆L

+.10 –.04 +.04

+.13 –.02 –.07

+.29 –.06 –.08

2. Press Enter to activate the Edit popup window.

Print

View

Delete

D65/10

Edit

3. Use Tab Up or Tab Down to highlight the Print, View or Delete option. An explanation

of each option follows.

Print (output)

The print option allows you to output the last stored sample in a group or all samples in a

group. All samples can also be output from all groups. Data that is transmitted is based

on the Communication options set in the configuration menu.

Print

Group: 1

Stored: 5

Last

Group

All

Last Sample or Group Output

1. Press Enter with Group: # highlighted. This activates the editor.

2. Use Tab Up or Tab Down to select the desired group and then press Enter.

3. Use Tab Up or Tab Down to highlight Last or Group in the lower portion of the

screen and press Enter.

4. You are asked if you are sure you want to print the last sample. Press Tab Up or

Tab Down to move the highlight to Yes and press Enter.

Tab Down Tab Up Enter Back Read On/Off

4-5

Page 28

SECTION FOUR

All Output

1. Use Tab Up or Tab Down to highlight All in the lower portion of the screen and

press Enter.

2. You are asked if you are sure you want to print all the samples. Press Tab Up or

Tab Down to move the highlight to Yes and press Enter.

View

The view option allows you to retrieve and view a stored sample from a selected group.

The selected sample can also be deleted from this screen. Absolute data is displayed in

the View menu with the current color space and illum/obs selections applied.

Group: 1

Sample: 5 of 5

Delete

30.99 -3.26 -24.41

30.13 -3.18 -24.19

31.99 -2.87 -24.63

View Sample Data

1. Press Enter with Group: # highlighted. This activates the editor.

2. Use Tab Up or Tab Down to select the desired group and then press Enter.

3. Use Tab Up or Tab Down to select Sample: # of # and press Enter. This activates

the editor.

4. Use Tab Up or Tab Down to select the sample and then press Enter. The selected

sample data is now displayed.

View

Deleting Selected Sample

1. Use Tab Up or Tab Down to highlight Delete and then press Enter.

2. You are asked if you are sure you want to delete the displayed sample. Press Tab Up

or Tab Down to move the highlight to Yes and press Enter.

Delete

The Delete option works identical to the Print option. The last stored sample in a group

or a specific group’s samples can be deleted. All stored samples can also be selected for

deletion.

Delete

Group: 1

Stored: 5

Last

Group

All

Last Sample or Group Delete

1. Press Enter with Group: # highlighted. This activates the editor.

2. Use Tab Up or Tab Down to select the desired group and then press Enter.

3. Use Tab Up or Tab Down to highlight Last or Group in the lower portion of the

screen and press Enter.

4. You are asked if you are sure you want to delete the last sample. Press Tab Up or

Tab Down to move the highlight to Yes and press Enter.

All Delete

4-6

1. Use Tab Up or Tab Down to highlight All in the lower portion of the screen and

press Enter.

Tab Down Tab Up Enter Back Read On/Off

Page 29

INSTRUMENT OPERATION

2. You are asked if you are sure you want to delete all the stored samples. Press Tab

Up or Tab Down to move the highlight to Yes and press Enter.

Tagging Samples (using the optional BCR)

Barcodes are scanned as “tags” and stored with sample measurements. Sample data that

is output includes the attached tags (up to six tags per sample). There are three tagging

options that become available once a barcode is scanned.

• Next Sample Tag option stores the scanned tag with the next sample measured.

• Current Group Tag option stores the scanned tag with every measurement saved to

a selected group. The first tag scanned in a group is also used as the group name.

• All Tag option stores the scanned tag with all measurements taken in Store mode.

1. Make sure the instrument is in Store mode and select the Group number as

previously explained.

2. Using the instrument’s optional BCR, scan the tag barcode. Refer to Section One for

additional information on use of the optional barcode reader.

The name of the barcode appears on the second line of the display. If the name does

not appear on the instrument display, refer to Troubleshooting Tips in Section Five.

Barcode Read

Sample #1234

To be stored as

an All Tag

SAVE

3. With Tag Option highlighted, press Enter to page though a current Group Tag,

the Next Sample Tag and an All Tag.

NOTE: The “All Tag” option will not appear if any samples are stored in the

instrument, and “Group Tag” option will not appear if any measurements are

stored in the selected group.

4. Use Tab Up or Tab Down to select SAVE and then press Enter.

5. If additional tags (up to six) are required for the following sample(s), scan in with

the BCR and repeat step 3 and 4.

6. After tagging, position the instrument over the sample and take the measurement.

You may have to press Read to complete the measurement if the instrument is

configured to do so.

Tab Down Tab Up Enter Back Read On/Off

4-7

Page 30

SECTION FOUR

Normal Mode

The Normal mode provides the same measurement and viewing options as Store mode

without storing any data. Measured samples can be compared to stored references with or

without tolerance values applied. If tolerance values are applied to the reference, pass/fail

indication appears on the instrument. Sample data can also be viewed under various color

space and illuminant/observer combination. Normal mode displays absolute/difference

data and pass/fail indication for all five angles.

1. Use Tab Up or Tab Down to highlight Normal.

Store

Normal

References

Calibrate

Config.

2. Press Enter to access the Normal mode.

The information displayed depends upon whether tolerancing is used and which color

space (absolute or difference) is selected.

Reference: 1

L*a*b* D65/10

29.67 -3.92 -23.67

29.72 -3.66 -23.99

30.08 -3.68 -24.69

32.94 -3.24 -25.59

29.67 -3.92 -23.67

Without Tolerancing Applied

–MAIN MENU–

MA48

——————

XXXX

******

Current reference selected

15° sample data

25° sample data

45° sample data

75° sample data

110° sample data

Reference: 1

L*a*b* T D65/10

PASS

PASS

FAIL

PASS

PASS

With Tolerancing Applied

Indicates difference data is available to view

for the measurement (see Store Mode)

Selectable color space and illuminant/observer

Pass/fail indication when tolerance are applied

3. If you want to compare stored reference data to measured samples, and Auto Reference

is not activated in the Configuration, you must manually select a reference.

Press Enter to activate the editor. Up/down arrows appear at the left.

Press Tab Down to page forward through the reference numbers, or press Tab Up to

page backward through the list.

Press Enter to select the displayed reference number.

4. Position the instrument over the sample and take the measurement. You may have to press

Read to complete the measurement if the instrument is configured to do so.

5. Use Tab Up or Tab Down to highlight color space (e.g. ∆L*a*b*) or illum/obs

(e.g. D65/10).

6. Press Enter to page through the available color space or illuminate/observer options.

Data is automatically updated to the selected option.

4-8

Tab Down Tab Up Enter Back Read On/Off

Page 31

5. Service and General Maintenance

Repair Information

The instrument is covered by a one-year limited warranty—excluding battery pack and

barcode reader—and should be referred to factory or authorized service center for repairs

within the warranty period. Attempts to make repairs within this time frame may void the

warranty.

®

X-Rite

of the circuitry, all repairs should be referred to the factory or an authorized service

center (call 1-888-826-3042 or 1-616-

X-Rite will repair any instrument past warranty. Shipping cost to the factory or

authorized service center shall be paid by the customer, and the instrument shall be

submitted in the original carton, as a complete unaltered unit.

Cleaning the Instrument and Docking Station

Whenever required, the exterior of the instrument and docking station may be wiped

clean with a cloth dampened in water or a mild cleaner.

provides a factory repair service to their customers. Because of the complexity

803-2100).

DO NOT use any solvents to clean the instrument or docking station; this

will cause damage to the covers.

Cleaning the Optics

The optics should be cleaned once a week in normal environments, and more often in

dirty or dusty environments.

Carefully lift the instrument and blow shorts bursts of clean, dry air in to the measurement

aperture. This should remove any accumulated dust in the optics area.

AIR CAN

5-1

Page 32

SECTION FIVE

Battery Replacement Information

If battery replacement is ever needed, a qualified repair technician or an authorized

service center should perform the replacement. A battery replacement kit can be obtained

by contacting an authorized service center.

Cleaning the Calibration Reference

The ceramic standard should be cleaned using a mild soap and warm water solution,

thoroughly rinsed with warm water, and wiped dry with a clean, lint-free cloth. You must

let the standard dry completely before taking a calibration reading.

Cleaning the Zero Reflectance Trap

The zero reflectance trap should be cleaned from time to time to remove any dust or

contamination.

1. Unplug the interface cable and AC adapter from the docking station.

2. Remove the instrument from the docking station and turn the docking station over.

3. Remove the four screws that hold the clean-out plate in place and then remove the

clean-out plate.

4. Blow shorts bursts of clean, dry air into the zero reflectance trap. This should remove any

accumulated dust or contamination.

5. Reinstall the clean-out plate with four screws and connect the interface cable and AC

adapter.

AIR CAN

Screws (4)

Clean-out Plate

Docking Station

5-2

Page 33

SERVICE AND GENERAL MAINTENANCE

Troubleshooting Tips

Problem Cause Solution

The instrument display is

hard to read.

The instrument’s battery

pack will not charge.

Measurements not uploading

to computer when the

instrument is seating in the

docking station.

Instrument will not calibrate

correctly.

The instrument screen does

not display anything.

The optional barcode reader

does not work.

Screen contrast set

incorrectly.

AC adapter is not

attached.

Internal battery pack is

bad.

Instrument is not properly

seated in the docking

station.

The interface cable is not

attached.

Contaminated connectors. Disconnect docking station

Calibration reference is

dirty.

Optics is dirty. Clean the optics as specified in

Instrument is in power

down mode.

Screen contrast is set too

low.

Internal batteries require

charging.

Instrument is seating in

the docking station.

Adjust the contrast as explained

in Section One.

Check the connection on the

back of the docking station and

at the AC adapter.

Contact an authorized service

center.

Make sure instrument is

properly seated over the

contacts.

Check the connection on the

back of the docking station and

at the computer.

from computer and wall outlet.

Clean connectors on the

instrument and the docking

station with a cotton swab

dampened with Isopropyl

alcohol. Cotton swab should

not be saturated.

Clean the calibration reference

as specified in section 5.

section 5.

Press the Power button to

active the instrument.

Adjust the contrast as explained

in Section One.

Place instrument on docking

station and charge battery pack

for a minimum of 4 hours

before use.

Remove the instrument from

the docking station. Barcode

reader is disabled in the

docking station.

5-3

Page 34

SECTION FIVE

Error Messages

Below is a list of typical error messages that could appear on your instrument display. If

an error message should appear, make a note of it and take the appropriate steps to try to

correct it. If an error message is consistently displayed, contact an authorized service

center.

Reading Error Messages

Read Error – Batteries are weak. Please charge them. Indicates batteries are too

low to operate the unit. Place the instrument in the docking station and allow the batteries

to charge before attempting to take measurements.

Read Error – Light leakage has occurred. Stray light is getting into measurement

aperture. Make sure measurement surface is flat.

Read Error – Max reflectance has exceeded. Surface measured is greater than the

maximum range of the instrument.

Read Error – The motor has missed sync. - Instrument could not establish motor

position. Measure again.

Read Error – Reset during read. Please check batteries. This message may

appear if the instrument is stored for an extended period of time. Recharge the batteries

for 4 hours.

Read Error – Read switch was released too soon. Both read switches were not

closed during entire reading. Try taking the reading again.

Read Error – Lamp failure! Lamp must be replaced. The lamp intensity is too

weak for accurate measurements. The lamp should only be replaced by an authorized

service center.

Calibration Error Messages

Cal Failed = #### Calibration requires that the instrument remain motionless during

the white calibration reading. If the error persists and is not due to movement, the

number that is displayed should be reported to X-Rite or an authorized service center.

Cal Failed – Max zero reflectance has been exceeded. Zero reflectance

measurement was taken on something other than the zero reflectance port (docking

station); or optics and/or zero reflectance trap require cleaning.

Cal Required – Due to user abort. The user aborted the calibration procedure

during measurement sequence.

Cal Required – Due to bad zero cal. Zero reflectance calibration measurement was

not properly updated.

Cal Required – Due to temperature. A 10°C change in temperature occurred since

the last calibration.

Miscellaneous Error Messages

Warning – Batteries are weak. Please charge them. Indicates that the batteries

are getting low and must be charged soon. The message will be displayed only while the

measurement is in progress. The instrument will still take accurate measurements.

Warning – Lamp is getting weak. Replace soon. The lamp is marginal and

should be replaced as soon as is conveniently possible.

5-4

Page 35

Specifications

Measuring Geometrics

• 45° illumination

• 15°, 25°, 45°, 75°, 110° aspecular viewing

• Angular accuracy ±0.15°

• Fiber optic pick-up, coupled with DRS technology

Measuring Area

• 0.5 in. diameter (12mm)

Light Source

• Gas-filled tungsten lamp, color corrected to approx. 4000°K

Illuminant Types

• C, D65, D50, A, F2, F7, F11 & F12

Standard Observers

• 2° and 10°

Receivers

• Blue-enhanced silicon photodiodes

SERVICE AND GENERAL MAINTENANCE

Spectral Range

• 400nm – 700nm

Spectral Interval

28 band spectral measurement:

• 10nm interval from 400nm – 640nm

• 20nm interval from 640nm – 700nm

• 15nm bandwidths

Spectral Data Output

• Spectral reflectance values are available for output from the RS-232 or USB port

via the docking station for 5 angles at 10nm intervals from 400nm – 700nm

Measurement Range

• 0 to 400% reflectance

Measurement Time

• Approx. 2.0 seconds

Inter-Instrument Agreement

• 0.20 ∆E* avg. on reference BCRA tile set

• 0.40 ∆E* max. on any chromatic tile

• 0.15 ∆E* max. on any grey tile

Short-Term Repeatability

• 0.10 ∆E*ab on white ceramic

Lamp Life

• Approx. 500,000 measurements

Power Supply

• Built-in, rechargeable Ni-metal hydride battery pack; 7.2 VDC rated @ 1400 mAh

5-5

Page 36

SECTION FIVE

AC Adapter Requirements

Charge Time

Measurements Per Charge

Data Storage (Five Angles)

Data Interface

Display

Operating Temperature Range

• MA48: 90-130VAC, 50-60Hz, 15W max

• MA48X: 90-240VAC, 50-60Hz, 30W max

• In Instrument – 4 hrs

• 1,000 5-angle measurements (continuous measurements @ 10 sec. intervals)

• 200 Standards

• 850 Samples

• Patented bi-directional RS-232 and USB, 9,600-19,200 baud

• 128 x 256 pixel graphical LCD

• 50° to 104°F (10° to 40°C)

• 85% Relative humidity max (non-condensing)

Storage Temperature Range

• -4° to 122°F (-20° to 50°C)

Weight

• 2 lbs. 7 oz. (1.1 kg)

Dimensions

• 5.27” H (13.4cm) x 5.40” W (13.7cm) x 8.05” L (20.4cm)

Accessories Provided

• Calibration standards, docking station, AC Adapter, operators manual, and wrist

strap

X-Rite standards are traceable to NIST (National Institute of Standards and Technology, USA)

Calibration report (MCSL-18).

Product design and specifications subject to change without notice.

5-6

Page 37

Page 38

Corporate Headquarters - USA

4300 44th Street SE

Grand Rapids, Michigan 49512

Phone 1 800 248 9748 or 1 616 803 2100

Fax 1 800 292 4437 or 1 616 803 2705

Corporate Headquarters - Europe

Althardstrasse 70

8105 Regensdorf

Switzerland

Phone (+41) 44 842 24 00

Fax (+41) 44 842 22 22

Corporate Headquarters - Asia

Room 808-810

Kornhill Metro Tower, 1 Kornhill Road

Quarry Bay, Hong Kong

Phone (+852) 2 568 6283

Fax (+852) 2 885 8610

Please visit www.xrite.com

for a local office near you.

P/N MA48-500 Rev. C

Loading...

Loading...