Page 1

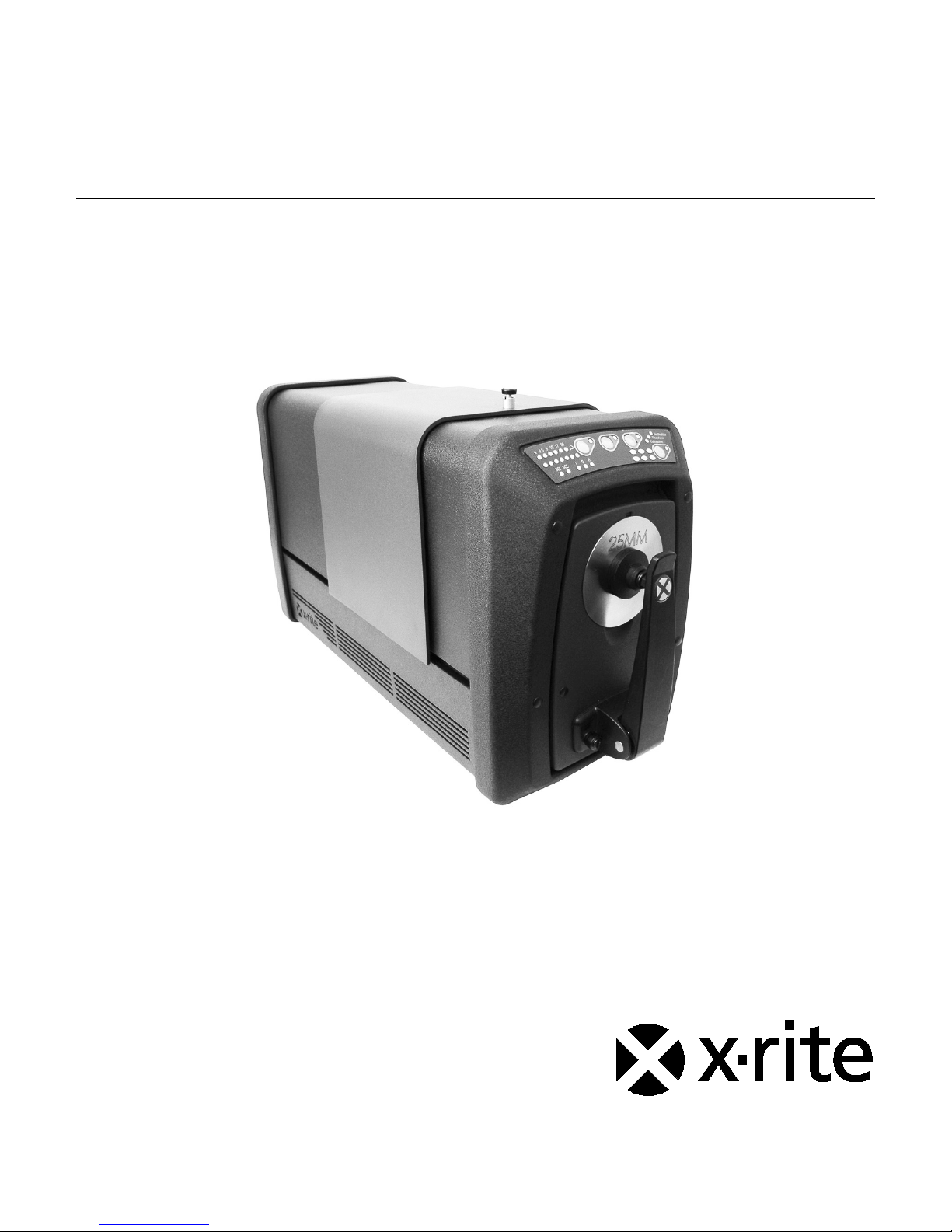

Ci7XX0

Benchtop Spectrophotometer

User Guide

Page 2

Page 3

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Consult this documentation in all cases where the Attention symbol appears.

This symbol is used to inform you of any potential HAZARD or actions that may require

your attention.

CE Declaration

Hereby, X-Rite, Incorporated, declares that this Ci7XX0 series is in compliance with the essential

requirements and other relevant provisions of Directive(s) 2014/35/EU (LVD), 2014/30/EU (EMC),

and RoHS 2011/65/EU.

US & Canadian Approvals

This product conforms to ANSI/UL 61010-1:2012 and is listed by Intertek; Control No. 3050828

This product is certified to CAN/CSA C22.2 No. 1010.1

Federal Communications Commission Notice

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

Industry Canada Compliance Statement

CAN ICES-3 (A) / NMB-3 (A)

Equipment Information

Use of this equipment in a manner other than that specified by X-Rite, Incorporated may

compromise design integrity and become unsafe.

WARNING: This instrument is not for use in explosive environments.

Do not look directly into the measurement optics when the instrument is on.

For indoor use only.

CLASS 1 LASER PRODUCT

IEC 60825-1:2007

Notice: This device emits class 1 laser radiation. Class 1 laser products are classified to be safe

during normal operation.

Laser emission specifications: continuous wave 532 nm, ≤ 0.39 mw

No user serviceable parts in this product. All warranty and non warranty repairs should

be referred to an authorized X-Rite service center.

CAUTION– Class 3B Laser Radiation from internal laser module is present when

instrument cover is removed. Avoid exposure to the beam.

Instructions for disposal: Please dispose of Waste Electrical and Electronic Equipment (WEEE) at

designated collection points for the recycling of such equipment.

1

Page 4

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Proprietary Notice

The information contained in this manual is copyrighted information proprietary to X-Rite,

Incorporated.

Publication of this information does not imply any rights to reproduce or use it for purposes other

than installing, operating, or maintaining this instrument described herein. No part of this manual

may be reproduced, transcribed or translated into any language or computer language in any

form or by any means: electronic, magnetic, mechanical, optical, manual, or otherwise; without

the prior written permission of an authorized officer of X-Rite, Incorporated.

Patents: www.xrite.com/ip

“© 2018, X-Rite, Incorporated. All rights reserved”

X-Rite® is a registered trademark of X-Rite, Incorporated. All other logos, brand names, and product names mentioned are the properties

of their respective holders.

Warranty Information

X-Rite warrants this Product against defects in material and workmanship for a period of twelve

(12) months from the date of shipment from X-Rite’s facility, unless mandatory law provides for

longer periods. During such time, X-Rite will either replace or repair at its discretion defective

parts free of charge.

X-Rite’s warranties herein do not cover failure of warranted goods resulting from: (i) damage

after shipment, accident, abuse, misuse, neglect, alteration or any other use not in accordance

with X-Rite’s recommendations, accompanying documentation, published specifications, and

standard industry practice; (ii) using the device in an operating environment outside the

recommended specifications or failure to follow the maintenance procedures in X-Rite’s

accompanying documentation or published specifications; (iii) repair or service by anyone other

than X-Rite or its authorized representatives; (iv) the failure of the warranted goods caused by

use of any parts or consumables not manufactured, distributed, or approved by X-Rite; (v) any

attachments or modifications to the warranted goods that are not manufactured, distributed or

approved by X-Rite. Consumable parts and Product cleaning are also not covered by the

warranty.

X-Rite’s sole and exclusive obligation for breach of the above warranties shall be the repair or

replacement of any part, without charge, which within the warranty period is proven to X-Rite’s

reasonable satisfaction to have been defective. Repairs or replacement by X-Rite shall not revive

an otherwise expired warranty, nor shall the same extend the duration of a warranty.

Customer shall be responsible for packaging and shipping the defective product to the service

center designated by X-Rite. X-Rite shall pay for the return of the product to Customer if the

shipment is to a location within the region in which the X-Rite service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations. Proof of purchase in the form of a bill of sale or

receipted invoice which is evidence that the unit is within the Warranty period must be presented

to obtain warranty service. Do not try to dismantle the Product. Unauthorized dismantling of the

equipment will void all warranty claims. Contact the X-Rite Support or the nearest X-Rite Service

Center, if you believe that the unit does not work anymore or does not work correctly.

THESE WARRANTIES ARE GIVEN SOLELY TO BUYER AND ARE IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

2

Page 5

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION,

AND NON-INFRINGEMENT. NO EMPLOYEE OR AGENT OF X-RITE, OTHER THAN AN OFFICER OF XRITE, IS AUTHORIZED TO MAKE ANY WARRANTY IN ADDITION TO THE FOREGOING.

IN NO EVENT WILL X-RITE BE LIABLE FOR ANY OF BUYER’S MANUFACTURING COSTS,

OVERHEAD, LOST PROFITS, GOODWILL, OTHER EXPENSES OR ANY INDIRECT, SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES BASED UPON BREACH OF ANY WARRANTY, BREACH

OF CONTRACT, NEGLIGENCE, STRICT TORT, OR ANY OTHER LEGAL THEORY. IN ANY EVENT OF

LIABILITY, X-RITE’S MAXIMUM LIABILITY HEREUNDER WILL NOT EXCEED THE PRICE OF THE

GOODS OR SERVICES FURNISHED BY X-RITE GIVING RISE TO THE CLAIM.

3

Page 6

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

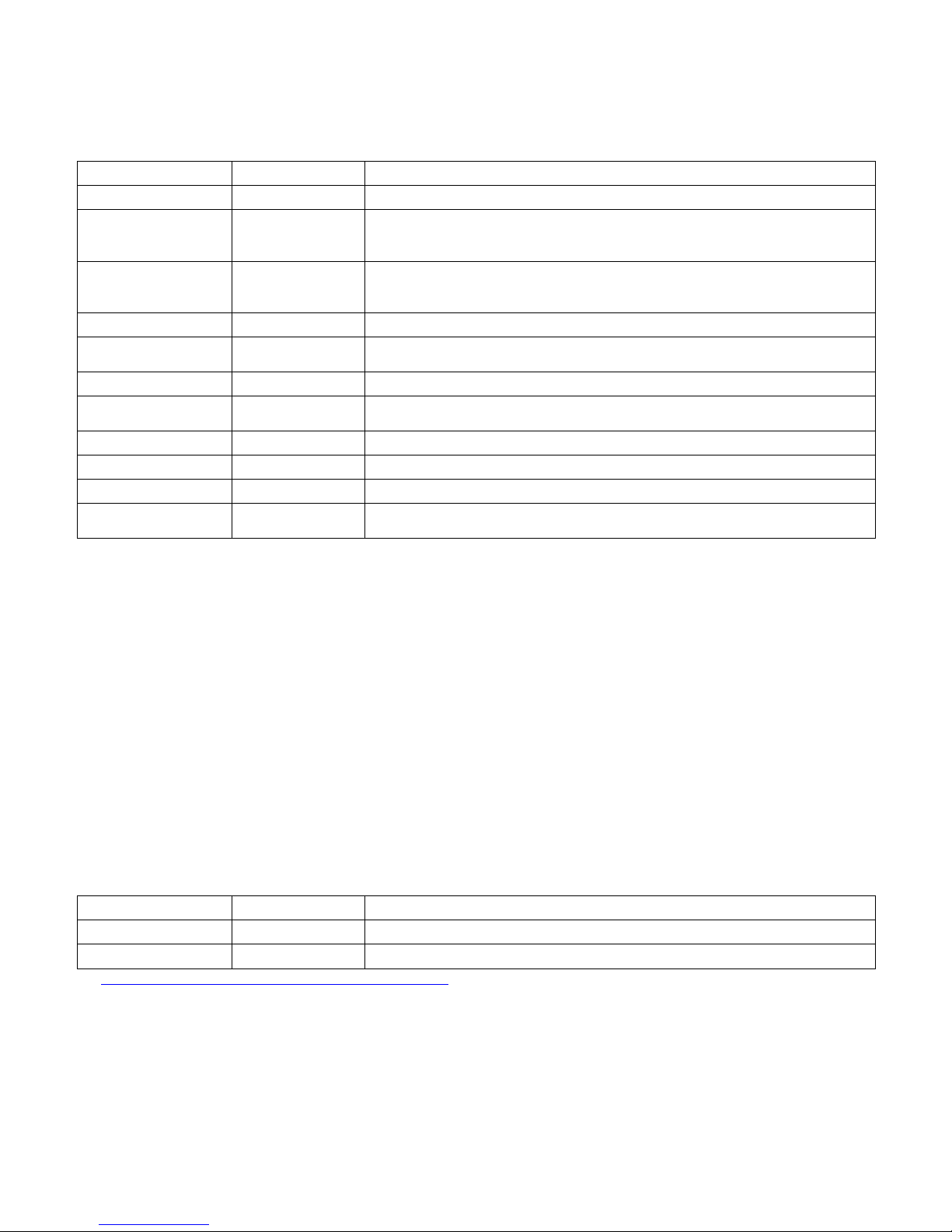

Package

libxml2

2.7.7

Copyright (C) 1998-2003 Daniel Veillard

ncurses

fontconfig

2.8.0

Copyright © 2001,2003 Keith Packard

giflib

pixman

0.20.2

Copyright 1987, 1988, 1989, 1998 The Open Group

Software Code

This X-Rite product includes software code developed by third parties. As applicable, the terms of

the code and information on obtaining access to the code used in this product, are available to

you at: www.xrite.com/opensourcelicensing

Where such specific license terms entitle you to the source code of such software, X-Rite will

provide upon written request via email and/or paper mail the applicable source code files for a

nominal cost to cover shipping and media charges (order part number CIA-700-DVD). The source

code is available from X-Rite for a period of three years after the last shipment of this product.

Please direct all inquiries for source code to the following:

Email:

opensourcelicensing@xrite.com

Mail:

Attn: Order Entry

X-Rite, Incorporated

4300 44

th

Street SE

Grand Rapids, Michigan 49512

Phone:

888-826-3059, option 1

GPL and LGPL

The GPL code and LGPL code used in this product are distributed WITHOUT ANY WARRANTY and

is subject to the copyrights of one or more authors. For details, see the GPL code and the LGPL

code for this product and the terms of the GPL and LGPL.

http://www.gnu.org/copyleft/gpl.html

http://www.gnu.org/licenses/lgpl.html

MIT

This product uses software under the MIT license:

Version

5.9 Copyright (c) 1998-2010,2011 Free Software Foundation, Inc.

4.1.6 Copyright (c) 1997 Eric S. Raymond

Owner

Copyright 1987, 1988, 1989 Digital Equipment Corporation

Copyright 1999, 2004, 2008 Keith Packard

Copyright 2000 SuSE, Inc.

Copyright 2000 Keith Packard, member of The XFree86 Project,

Inc.

Copyright 2004, 2005, 2007, 2008 Red Hat, Inc.

Copyright 2004 Nicholas Miell

Copyright 2005 Lars Knoll & Zack Rusin, Trolltech

4

Page 7

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Copyright 2005 Trolltech AS

Mesa

7.10.3

Copyright (C) 1999-2005 Brian Paul

libICE

1.0.7

Copyright 1993, 1998 The Open Group

libpciaccess

0.12.1

Copyright IBM Corporation 2006, 2007

libSM

1.2.0

Copyright 2002 Sun Microsystems, Inc.

libX11

1.4.4

Copyright (C) 2003-2006,2008 Jamey Sharp, Josh Triplett

libXau

1.0.6

Copyright 1988, 1993, 1994, 1998 The Open Group

libxcb

1.7

Copyright (C) 2001-2006 Bart Massey, Jamey Sharp, and Josh

libXcomposite

0.4.3

Copyright © 2001,2003 Keith Packard

libXdamage

1.1.3

Copyright © 2001,2003 Keith Packard

libXdmcp

libXext

1.2.0

Copyright 1986, 1987, 1988, 1989, 1994, 1998 The Open Group

Copyright 1991,1993 by Digital Equipment Corporation, Maynard,

Copyright 2007 Luca Barbato

Copyright 2008 Aaron Plattner, NVIDIA Corporation

Copyright 2008 Rodrigo Kumpera

Copyright 2008 André Tupinambá

Copyright 2008 Mozilla Corporation

Copyright 2008 Frederic Plourde

Copyright 2009 Sun Microsystems, Inc.

Copyright Eric Anholt 2006

Copyright (c) 2007, 2008, 2009, Oracle and/or its affiliates.

Copyright 2009 Red Hat, Inc.

Copyright 1993, 1998 The Open Group

Copyright © 2009 Red Hat, Inc.

Copyright 1990-1992,1999,2000,2004,2009,2010 Oracle and/or

its affiliates

Triplett.

Copyright (c) 2006, 2007, Oracle and/or its affiliates. All rights

reserved.

Copyright © 2007 Eric Anholt

1.1.0 Copyright 1989, 1998 The Open Group

Copyright (c) 1996 Digital Equipment Corporation, Maynard,

Massachusetts.

Copyright (c) 1997 by Silicon Graphics Computer Systems, Inc.

Copyright 1992 Network Computing Devices

Massachusetts,

and Olivetti Research Limited, Cambridge, England

Copyright 1986, 1987, 1988 by Hewlett-Packard Corporation

Copyright (c) 1994, 1995 Hewlett-Packard Company

Copyright Digital Equipment Corporation, 1996

Copyright 1999, 2005, 2006 Sun Microsystems, Inc. All rights

reserved.

Copyright (c) 1989 X Consortium, Inc. and Digital Equipment

Corporation.

Copyright (c) 1992 X Consortium, Inc. and Intergraph

Corporation.

Copyright (c) 1993 X Consortium, Inc. and Silicon Graphics, Inc.

5

Page 8

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Copyright (c) 1994, 1995 X Consortium, Inc. and HewlettlibXft

2.2.0

Copyright © 2001,2003 Keith Packard

libXpm

3.5.9

Copyright (C) 1989-95 GROUPE BULL

libXrandr

1.3.2

Copyright © 2000, Compaq Computer Corporation,

libXrender

0.9.6

Copyright © 2001,2003 Keith Packard

libXt

1.1.1

Copyright © 2001,2003 Keith Packard

libXxf86vm

1.1.1

Copyright (c) 1995 Kaleb S. KEITHLEY

libdrm

2.4.26

Copyright 1999 Precision Insight, Inc., Cedar Park, Texas.

xtrans

1.2.6

Copyright 1993, 1994, 1998, 2002 The Open Group

libpthread-stubs

0.3

Copyright (C) 2006 Diego Pettenò

qextserialport

1.2

Copyright (c) 2000-2003 Wayne Roth

Packard Company.

libXfixes

4.0.5 Copyright © 2001,2003 Keith Packard

Copyright (c) 2006, Oracle and/or its affiliates. All rights

reserved.

Copyright (C) 1998 Arnaud LE HORS

Copyright (C) 19896 Lorens Younes

Copyright © 2002, Hewlett Packard, Inc.

Copyright © 2000 Compaq Computer Corporation, Inc.

Copyright © 2002 Hewlett-Packard Company, Inc.

Copyright © 2006 Intel Corporation

Copyright © 2008 Red Hat, Inc.

Copyright © 2000 Compaq Computer Corporation, Inc.

Copyright © 2002 Hewlett Packard Company, Inc.

Copyright © 2006 Keith Packard

http://opensource.org/licenses/MIT

Copyright © 2000 SuSE, Inc.

Copyright (c) 1993, 2011, Oracle and/or its affiliates. All rights

reserved.

Copyright 1987, 1988 by Digital Equipment Corporation

Copyright 1987, 1988, 1998 The Open Group

Copyright 2000 VA Linux Systems, Inc., Sunnyvale, California

Copyright 1993, 1994 NCR Corporation - Dayton, Ohio, USA

Copyright (c) 2002, 2005, Oracle and/or its affiliates. All rights

reserved.

Copyright 1996 by Sebastien Marineau and Holger Veit

Copyright © 2003 Keith Packard, Noah Levitt

Copyright (c) 2004-2007 Stefan Sander

Copyright (c) 2007 Michal Policht

Copyright (c) 2008 Brandon Fosdick

Copyright (c) 2009-2010 Liam Staskawicz

Copyright (c) 2011 Debao Zhang

6

Page 9

BSD

Package

Owner

zlib

1.2.5

Copyright (C) 1995-2010 Jean-loup Gailly and Mark Adler

expat

2.0.1

Copyright (c) 1998, 1999, 2000 Thai Open Source Software Center

2005, 2006 Expat maintainers.

pcre

8.2

Copyright (c) 1997-2011 University of Cambridge

Copyright(c) 2010-2011 Zoltan Herczeg

orc

0.4.14

Copyright 2002 - 2009 David A. Schleef

freetype

2.4.7

Copyright 2001, 2002 by David Turner, Robert Wilhelm, and

Werner Lemberg

libjpeg

8c

Copyright (C) 1994-2010, Thomas G. Lane, Guido Vollbeding

libtiff

Silicon Graphics, Inc.

libogg

1.2.2

Copyright (c) 2002, Xiph.org Foundation

libvorbis

libtheora

1.1.1

Copyright (C) 2002-2009 Xiph.org Foundation

OpenCV

2.3.1

Copyright (C) 2000-2008, Intel Corporation, all rights reserved.

Copyright (C) 2009, Willow Garage Inc., all rights reserved.

Package

Owner

Copyright 2007 - 2009 Martin Heinrich

Copyright: 2012 Nikolaos Ftylitakis

This product uses software under the BSD license:

Version

Ltd and Clark Cooper Copyright (c) 2001, 2002, 2003, 2004,

Copyright (c) 2007-2011, Google Inc.

3.9.5 Copyright (c) 1988-1997 Sam Leffler Copyright (c) 1991-1997

1.3.2 Copyright (c) 2002-2008 Xiph.org Foundation

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Redistribution and use in source and binary forms, with or without modification, are permitted provided that

the following conditions are met:

1. Redistributions of source code must retain the above copyright notice, this list of conditions and the

following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the

following disclaimer in the documentation and/or other materials provided with the distribution.

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS "AS IS" AND ANY

EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE

COPYRIGHT HOLDER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL,

EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF

SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION)

HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR

TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS

SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Apache

This product contains Apache licensed software.

Version

Log4qt 0.3

QZXing 1.2

http://www.apache.org/licenses/LICENSE-2.0.txt

7

Page 10

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Table of Contents

Overview 9

Packaging Information 10

Instrument Setup 10

Powering the Instrument 10

Sample Preview Method 11

Front Panel 11

Sample Shelf 14

Sample Holder 14

Sample Door 15

Specular Control 15

UV Control 16

Aperture Control 16

Calibrating 18

Calibration Notes 18

Reflectance Calibration Procedure 18

Green Tile Color Check (optional) 19

Transmission Calibration Procedure (excludes Ci7500 series) 20

Transmission Calibration Setup 20

Total Calibration 21

Direct Calibration 22

R/T Calibration 23

UV Calibration Procedure 24

Measuring 25

Reflectance Measurements 25

Transmission Measurements (excludes Ci7500 series) 26

Total Transmission Measurement 26

Direct Transmission Measurement 28

R/T (Reflection/Total Transmission) Measurement 30

Liquid Measurements 32

Haze Measurements 33

Appendices 34

Service Information 34

Cleaning the Instrument 35

Cleaning Quick Reference Table 35

General Exterior Cleaning 36

Cleaning the Transmission Compartment 36

Cleaning the Calibration Tiles 36

Cleaning the Black Plastic Blocking Panel 36

Cleaning the Sphere 36

Cleaning the Aperture Plates 37

Cleaning the Transmission White Plaque 37

Cleaning the Black Trap 37

Cleaning the UV Calibration Plaque 38

Replacing the Fuse 39

Adjusting the Sample Holder Dampening 39

Troubleshooting 40

Specifications 41

Spare Parts and Accessories 43

System Repacking Instructions 44

8

Page 11

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Sample holder

Button and indicator

membrane label (refer to

for a

Transmission

Accessory drawer (white tile,

green tile, black trap, aperture

plates, UV cal plaque)

Ci7XX0 instrument can

Communication,

Front lifting grip

Rear lifting grip

Locking pin

Sample door

OVERVIEW

The Ci7XX0 is a reflectance / transmittance sphere benchtop spectrophotometer offering

agreement with these X-Rite/GretagMacbeth instruments: 7000A, Color i7, and Color i5. The

Ci7XX0 Spectrophotometer includes these features:

• Multiple areas of sample view in both reflectance and transmittance.

• Self-adjusting, dual zoom lens to manage the measurement area and eliminate

configuration errors between aperture plates and lens position.

• External video monitor viewing, preview video in the software application, and hinged

sample door preview for measurement accuracy and targeting purposes.

• Haze measurement mode (excludes Ci7500 series).

• Automated ultra violet (UV) adjustment for measuring fluorescent or optically brightened

samples.

• USB interface to PC and software applications.

• Indicator panel display with dual buttons for standard and sample measurements, and

warning indicators for calibration interval.

• Dampened sample arm holder that prevents sample damage.

• Embedded white sample holder ceramic. Ideal for reflectance measurements that require a

white backing, such as textiles, plastics or other less than opaque samples (Standard on

Ci7800/Ci7860 instrument and optional on the other models).

• Supports embedded NetProfiler.

access cover

Front Panel

description)

line cord and

power switch

also operate in the upright

position with optional kit.

9

Page 12

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Packaging Information

If you are reading this documentation, you have already followed the instructions detailed in the

Ci7XX0 installation sheet that was included in the shipping carton. Please keep the installation

sheet for reference. Keep your shipping carton in case you need to return your instrument to the

factory for service.

Your instrument packaging should contain all the items listed below. If any of these items are

missing or damaged, contact X-Rite or your Authorized Representative.

• Software box containing the Ci7XX0 Driver and Documentation CD along with any other

optional software you may have ordered such as Color iControl and NetProfiler.

• Ci7500 Series, Ci7600 Series, or Ci7800 Series Spectrophotometer

• Certificate of performance

• Installation instructions sheet

• USB cable

• AC power cord

• Sample shelf with thumb screws

• Transmission kit (optional on Ci7800 Series & Ci7600 Series)

The following accessories are stored in the instrument accessory drawer.

• Round white calibration tile

• Round green performance tile

• Black trap for calibration

• Ci7800 Series aperture plates: 25 mm, 17 mm, 10 mm, 6 mm, (3.5 mm optional)

Ci7600 Series aperture plates: 25 mm, 10 mm, 6 mm, (3.5 mm optional), (17 mm

optional)

Ci7500 Series aperture plates: 25 mm, 10 mm

• White UV plaque

Instrument Setup

Please follow the instructions detailed in the Ci7XX0 Installation Instructions sheet found as the

first item in your shipping box when you opened it. A PDF file of the Installation Instructions also

can be found on the Ci7XX0 Driver and Documentation CD.

Powering the Instrument

The power on-off AC switch is located on the back of the instrument. Press the top of the rocker

switch to turn on the instrument and wait 50 seconds for the instrument to boot up. If the

instrument does not power up after approximately 50 seconds, check the power connections to

the unit and main power availability (breakers, fuses). If these connections are fine, check the

instrument’s fuse. Refer to “Fuse Replacement” in the Appendix.

A power “standby” button is located on the front panel of the instrument. This button is used to

power down the instrument into a low power state, or wake the instrument after it goes into a

power down state. A power on condition is designated by a solid green light indicator. Simply

press the power “standby” button to wake or power down the instrument into “standby” mode.

Discontinue use if AC cord is damaged.

Ensure AC cord ratings meet or exceed the instrument ratings (see Specifications section in

the Appendices).

10

Page 13

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Specular Included

Specular Excluded

Lens

Standard button and indicator

Preview button and indicator

Trial button and indicator

Calibration

Transform

NetProfiler

Total Transmission

Direct Transmission

Haze

D65 Illuminate

UV Excluded

400, 420, 460 nm

cut filters

Custom UV (user defined)

Power “standby” button and indicator

Aperture plate

Sample Preview Method

The instrument has three sample preview methods:

Sample Door

This method enables you to open the sample door and look at the sample position in the viewport.

You can make manual adjustments if necessary to obtain optimum sample alignment. Refer to the

instructions on using the Sample Door Preview Method.

External Video Monitor Feature

This method requires an external preview video monitor. The monitor is plugged into the video

connector located on the back of the instrument. After the monitor is connected, the Preview

button on the spectrophotometer can be pushed to turn live preview video on and off. Video

on/off is the default functionality of the Preview button when using a reflectance measurement

mode. However, your software application may assign a different behavior to the button for

various reasons.

Live Preview Video in PC Software Application

This method requires a software application, such as Color iQC to provide a means to view video

within the application. Follow the instructions in your application to preview video for sample

alignment.

Note: DO NOT power down the instrument into “Standby” mode when preview video is actively

streaming in the application. Doing so may result in an unstable operation condition.

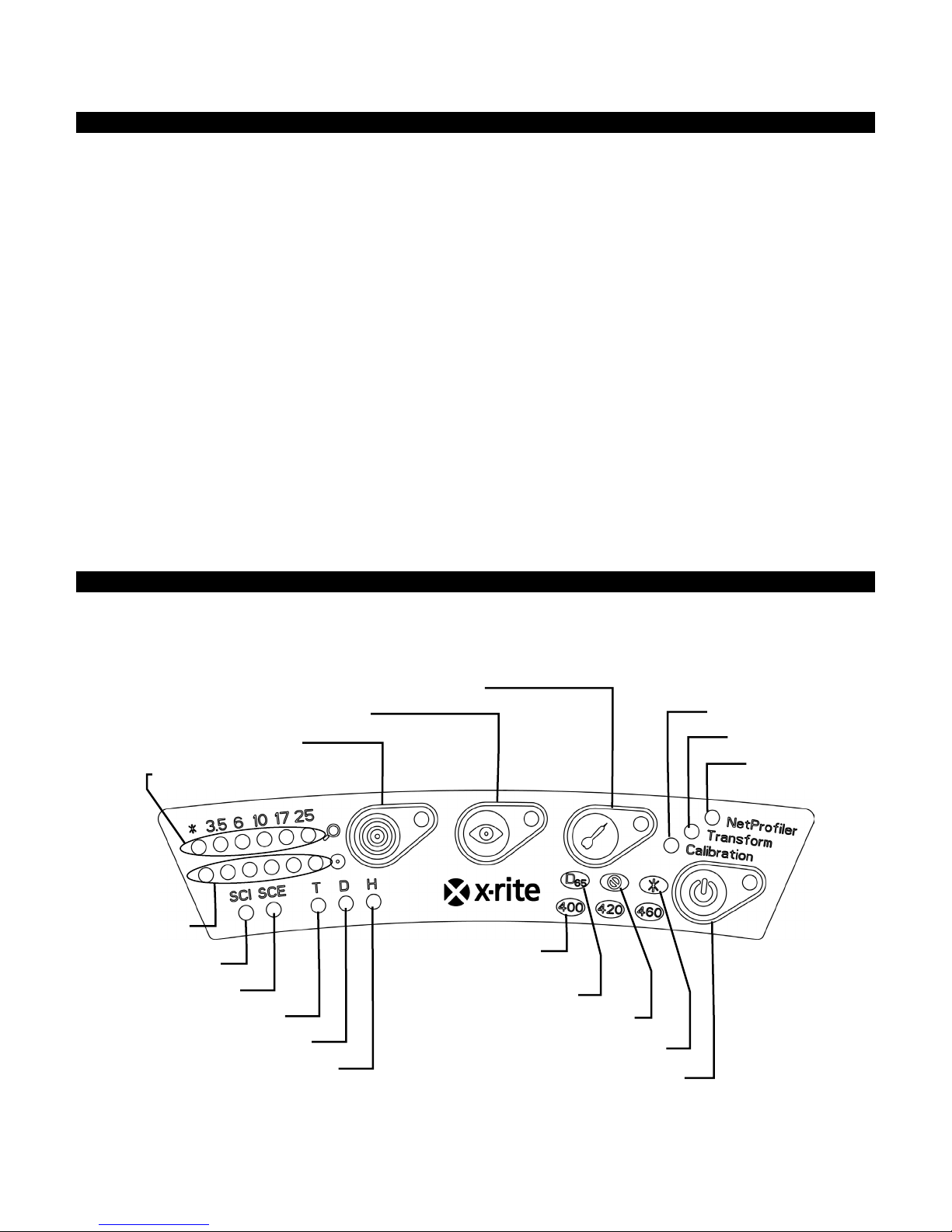

Front Panel

The front panel is used to initiate measurements and also indicate a variety of instrument

conditions, such as calibration status, measurement status, etc. Below is description for each

indicator and button.

11

Page 14

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Lens and Aperture Plate Indicators (*, 3.5, 6, 10, 17, 25)

• The top row of LEDs illuminates to indicate the current lens position. The “*” illuminates

when the lens is in a custom position. The LED will light red if the unit is configured with a

lens position larger than the installed aperture plate size.

• The bottom row of LEDs illuminates to indicate the currently installed aperture plate. The

“*” illuminates for custom plates and transmission aperture plates (with white reflective

ring), and blinks if the instrument could not detect the installed plate. If auto is enabled

for the lens, then the installation of an aperture plate automatically sets the lens to match

the aperture plate.

Standard Button and Indicator

• The standard button is used to initiate a standard measurement. Note: The button must

be supported by your application software and function as programmed.

• The indicator illuminates green when programmed to perform a measurement. It may

also be programmed to flash green to support features in your application.

Preview Button and Indicator

• The preview button is used in conjunction with the external video monitor preview

feature.

• The indicator illuminates green when it is activated.

• The video preview is toggled when a reflectance measurement mode is selected. When a

transmission measurement mode is selected, the button will toggle the green

transmission targeting laser on and off.

• The behavior of the button may also be programmed in your software application.

Trial Button and Indicator

• The trial button is used to initiate a trial measurement. Note: The button must be

supported by your software application and function as programmed.

• The indicator illuminates green when programmed to perform a measurement. It may

also be programmed to flash green to support features in your application.

NetProfiler

• Indicator Off: NetProfiler feature is not enabled.

• Solid Green: NetProfiler subscription is currently activated.

• Solid Amber: The profile has expired and updating is recommended.

Calibration

• Solid Red: Calibration is required

• Solid Green: White, black, and UV calibration are not required at this time

• Solid Amber: White and black calibration are not needed, but UV calibration has expired.

Measurements can still be taken in this condition. It is up to the user to decide if the UV

calibration should be updated at this time.

Transform

• Indicator Off: Transform feature in not enabled

• Solid Green: Transform feature is activated

Specular Included (SCI)

• Illuminates when a specular included measurement is selected.

12

Page 15

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Specular Excluded (SCE)

• Illuminates when a specular excluded measurement is selected.

Total (T) – excludes Ci7500 series

• Illuminates when a total transmission measurement is selected.

Direct (D) - excludes Ci7500 series

• Illuminates when a direct transmission measurement is selected.

Haze (H) - excludes Ci7500 series

• Illuminates when a haze measurement is selected.

D65 Illuminate

• Illuminates when it is UV calibrated to a D65 UV illumination condition.

UV Excluded (

• Illuminated when one of the UV filters fully blocks the UV component in the lamp to fully

exclude UV illumination.

Custom (

• Illuminated when a user-defined D65 or other UV condition is selected.

400

• The 400 nm UV cutoff filter is in use. This filter is adjustable and can be used to calibrate

420 - excludes Ci7500 series

• The 420 nm UV cutoff filter is in use. This optional filter is adjustable and can be used to

460 - excludes Ci7500 series

• The 460 nm UV cutoff filter is in use. This optional filter is not adjustable and can only be

Power “standby” button and indicator

• Refer to Powering the Instrument earlier in this section.

*

UV conditions.

calibrate UV conditions.

set to fully exclude UV illumination.

)

)

13

Page 16

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Screw holes

Thumbscrew

Sample shelf

Thumbscrew

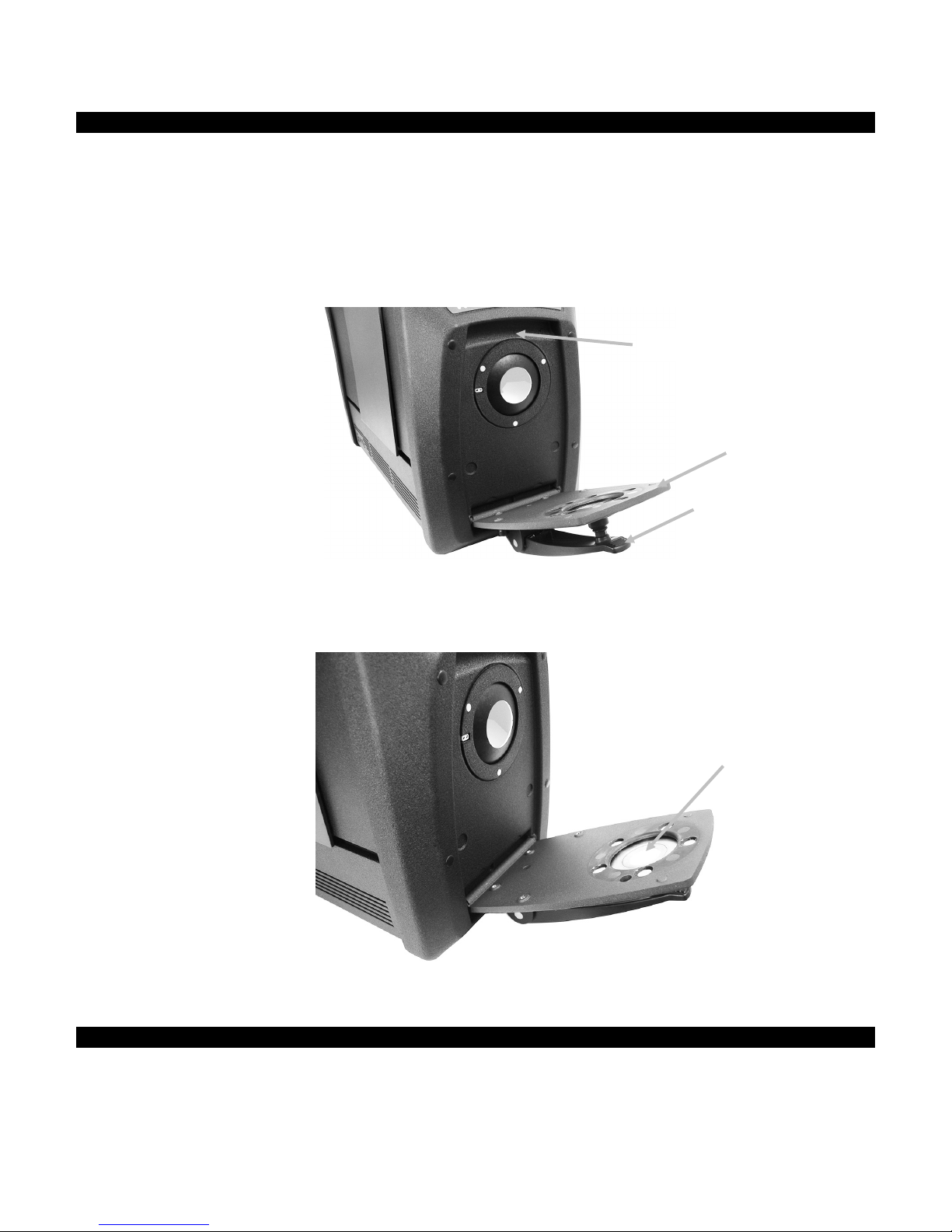

Sample Shelf

A sample shelf is provided to help align a sample with the measurement port. It is also useful for

providing consistent sample placement when multiple samples require a measurement at the

same location.

To install the sample shelf, position the shelf’s elongated slots over the two holes in the sample

door and attach it with the thumb screws provided.

Adjust the shelf by loosening the thumbscrews and sliding the shelf up or down.

Sample Holder

The sample holder can be locked in a down position. This is convenient when large samples are

measured, or when the aperture plate is changed or the sample holder is removed.

Simply open the sample holder to its maximum position to lock into position.

14

Page 17

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Pull from top

Sample door

Observe sample

here through

viewport opening

Sample holder

Sample Door

The sample door can be opened for a completely unobstructed view of the sample presented at

the view port. When completely open, the sample door allows you to adjust the sample at the

view port for optimal placement.

To use the sample door:

1. Open the sample holder by pulling it towards you. Place your sample at the view port and

close the sample holder.

2. Open the door from the top by using your fingers, and gently lower the door to the complete

open position. See the figure below.

3. With the sample door completely open, view the sample at the view port and make sure the

sample is in an optimal position for measuring.

4. Close the sample door and prepare for the measurement.

Specular Control

You can change the specular component setting on the spectrophotometer for reflectance

measurements using your software application. Select the desired specular component

measurement mode; Included (SCI), Excluded (SCE), or Dual Mode (SCE/SCI). The indicator for

15

Page 18

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Aperture plate

Notch below plate

either setting (or both if you have dual mode) on the front panel becomes illuminated based on

your selection. The instrument simultaneously measures specular included and specular excluded

for all reflectance measurements. Your software application should decide which measurement

data to request from the spectrophotometer according to the user requirements.

UV Control

Your spectrophotometer is equipped with an automated 400nm UV filter. This can be set to fully

exclude the UV portion of the light source in the spectrophotometer or can be used to calibrate and

adjust the UV level, for instance to match the UV component of D65 daylight. The instrument

supports built-in UV calibration positions for UV included, UV excluded, and D65. The instrument

also supports an unlimited number of user-defined UV positions which are set up, calibrated, and

managed using the PC software application. A UV calibration plaque is provided in the accessory

drawer that has been calibrated in the factory with a CIE whiteness value for true D65. Your system

includes a 400 nm UV filter, and may optionally include a 420 and/or 460 nm UV filter as well.

Aperture Control

By default, the spectrophotometer is configured to auto-recognize an aperture plate when

installed at the measurement port, and to auto-drive the lens to the matching size. The lens

position is also dependant on the measurement mode. If for example the instrument is configured

with the 10 mm aperture plate in a reflectance measurement mode and the user switches to a

transmission measurement mode, the instrument auto-drives the lens to create the measurement

size at the transmission measurement location.

Note: The automatic lens behavior can be overridden by the user in software if desired. If you prefer to

not have matching aperture and lens settings (to have an over illumination setup), you can use your

software application to configure the instrument. Keep in mind that a valid measurement size is less than

or equal to the aperture plate size. If the lens position and the installed aperture plate do not match, the

lens LED will illuminate red to indicate this discrepancy. Auto recognition is applicable to Reflectance

mode only.

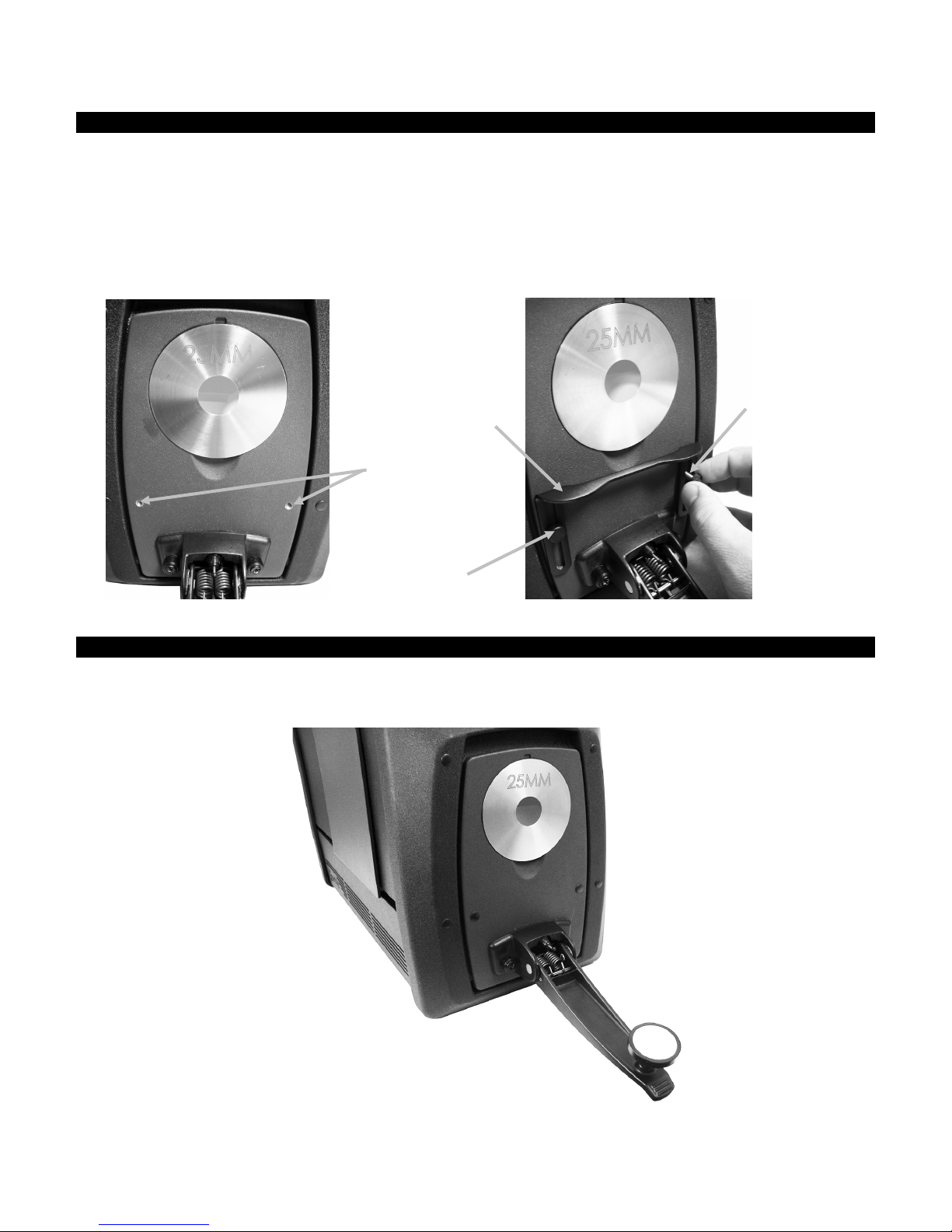

To install an aperture plate on the instrument:

1. Open the sample holder to the fully open position.

2. Using your fingers, remove the aperture by lifting outward from the notch below the existing

aperture plate.

16

Page 19

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

3. Locate the plate to be installed in the accessory drawer and fit the aperture over the rim on

the sample door. The plate is held in place by magnets.

4. Gently close the sample holder.

5. The aperture plate will be automatically recognized when the door is closed, and activate the

auto-zoom lens if set to the auto mode. Auto recognition is only valid for Reflectance mode

aperture plates. For transmission aperture plates, the asterisk LED lights up green.

17

Page 20

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

White

tile

CALIBRATING

The spectrophotometer should be calibrated every eight hours of operation.

Each spectrophotometer configuration that is used should be calibrated. A configuration consists

of the following components:

• Measurement mode: Transmission, Reflectance, R/T, or Haze

• Aperture size (3.5 mm, 6 mm, 10 mm, 17 mm, or 25 mm)

• Lens position

• Specular included or excluded condition (SCI or SCE)

• UV included, D65 calibration or excluded condition

Calibration Notes

• Dirt or dust in the optics area will cause an inaccurate calibration reading. Refer to

the Appendices for optics cleaning procedure.

• The white calibration tile is dramatically affected by smudge marks, dust, and

finger prints. Refer to Appendices for calibration tile cleaning procedures.

• The black trap should be cleaned periodically to remove any dust or

contamination. Refer to Appendices for black trap cleaning procedures.

Reflectance Calibration Procedure

To calibrate your spectrophotometer in reflectance measurement mode you need to use your

software application. Follow these steps:

1. Verify the 25 mm aperture plate is installed.

2. Launch the calibration procedure from the software application.

3. Remove the white calibration tile from the accessory drawer. Pull down on the sample holder

and position the tile on the sample holder clamp. Make sure the white ceramic side is facing

the aperture plate.

4. While holding the tile in place, close the sample holder to the aperture plate.

calibration

5. Initiate the calibration tile measurement from the software. After the measurement, remove

the calibration tile and return it to the accessory drawer.

18

Page 21

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Align

Green

6. Remove the black trap from the accessory drawer and position it on the aperture plate. Make

sure to align the tab at the top edge of the trap with the notch at the top of the aperture

plate.

7. Initiate the black trap measurement from the software.

8. Remove the black trap and return it to the accessory drawer.

9. Once the calibration process is complete, the calibration indicator becomes lit. Any change to

the spectrophotometer configuration may result in the calibration indicator changing from

green (calibrated) to red (not calibrated).

10. Continue with additional configuration calibrations as required.

Green Tile Color Check (optional)

1. Perform a calibration procedure if you have not already done so. Refer to the Calibrating section.

2. Remove the green tile from the accessory drawer. Pull down on the sample holder and

position the tile on the sample holder clamp. Make sure the green ceramic side is facing the

aperture plate.

3. While holding the tile in place, close the sample holder to the aperture plate.

calibration tile

4. Initiate the green tile check procedure from the software application. After the measurement,

remove the green tile and return it to the accessory drawer.

Note: Tile values are generated at a temperature of 22°C. Refer to the software application for

additional information.

19

Page 22

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Aperture plate

Transmission

Transmission Calibration Procedure (excludes Ci7500 series)

To calibrate your spectrophotometer in transmission measurement mode, you need to first locate

the following items in your optional transmission kit:

Aperture plates 6 mm, 10 mm, 17

mm, or 25 mm (with white

reflective ring). The plate can be

used for both transmission and

reflection measurements in the R/T

and haze modes.

Transmission sample holder

Transmission white plaque

Black plastic blocking panel

Note: NEVER use the black trap for black calibration when performing Transmission calibration.

Transmission Calibration Setup

Note: For R/T (Reflection/ Total Transmission), perform a Reflectance Calibration before

continuing.

1. Using your software application, launch the calibration process from the software interface.

2. Mount the 25 mm aperture plate (with white reflective ring) to the measurement port at the

front of the instrument.

3. Position the transmission white plaque on the sample holder.

plaque

4. Follow any prompts from the software regarding the white calibration.

5. Open the transmission cover by lifting up on the locking pin while sliding the cover to the back.

20

Page 23

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Black plastic

Carriage base

Total transmission

6. Refer to the remaining Total, Direct, or R/T Calibration procedures that follow.

Total Calibration

1. Place the sample transmission holder base inside the transmission compartment.

calibration shown

2. Attach the appropriate clamp and stop to the base with the thumb screws.

3. Center the black plastic blocking panel in the transmission sample holder and place between

the stop and clamp toward the sphere.

blocking panel

4. Close the cover and continue with calibration.

21

Page 24

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Black plastic

Carriage base

Direct transmission

5. Once the calibration process is complete, the calibration LED becomes lit. Any change to the

spectrophotometer configuration may result in the calibration LED turning from green

(calibrated) to red (not calibrated). Remember that each configuration needs to be calibrated.

Direct Calibration

1. Place the sample transmission holder base inside the transmission compartment.

calibration shown

2. Attach the appropriate clamp and stop to the carriage base with the thumb screws.

3. Center the black plastic blocking panel in the transmission sample holder and position toward

the lens side.

blocking panel

4. Close the cover and continue with calibration.

22

Page 25

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Black plastic

Carriage base

R/T calibration shown

5. Once the calibration process is complete, the calibration LED becomes lit. Any change to the

spectrophotometer configuration may result in the calibration LED turning from green

(calibrated) to red (not calibrated). Remember that each configuration needs to be calibrated.

R/T Calibration

1. Place the sample transmission holder base inside the transmission compartment.

2. Attach the appropriate clamp and stop to the carriage base with the thumb screws.

3. Center the black plastic blocking panel in the transmission sample holder and position toward

the sphere.

blocking panel

4. Close the cover and continue with calibration.

5. Once the calibration process is complete, the calibration LED becomes lit. Any change to the

spectrophotometer configuration may result in the calibration LED turning from green

(calibrated) to red (not calibrated). Remember that each configuration needs to be calibrated.

Note: The green LED will never appear for any Calibration Mode configured to include a UV Cal

option. UV cannot be calibrated in this mode.

23

Page 26

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

UV calibration

plaque

UV Calibration Procedure

Note: UV Calibration requires the configured reflectance aperture plate to be installed.

1. Perform a white and black calibration as previously explained.

2. Initiate the UV calibration procedure from the software application.

3. Enter the calibration whiteness value in the appropriate field.

4. Remove the UV calibration plaque from the protective bag in the accessory drawer.

5. Pull down on the sample holder and position the UV calibration plaque against the 25 mm

aperture plate. Make sure the white surface is facing the aperture plate.

6. Close the sample holder clamp to the UV calibration plaque.

7. Initiate the UV calibration measurement from the software.

8. Follow the procedure in the application.

9. Remove the UV calibration plaque, place in protective bag and return it to the accessory

drawer.

10. If required, repeat the normal white and black calibration procedure as before.

24

Page 27

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Sample

Hole plug

Hole plug

Hole plug

Hole plug

MEASURING

You should refer to the documentation or online help for the software application that you are

using with your instrument. All applications that use the instrument must be running during

measurements.

Reflectance Measurements

To take a measurement using your spectrophotometer, follow these steps to ensure an accurate

reading.

1. Ensure the desired aperture plate is installed.

2. Edit the current configuration or load appropriate configuration from the application.

3. Calibrate for the current configuration if needed.

4. Prepare your sample for measurement.

5. Open the sample holder on the spectrophotometer to the fully open position. Position the

sample at the view port and slowly close the sample holder. The sample holder is dampened

to prevent the holder from closing with too much force and possibly damaging the sample.

6. Use the computer screen or the drop down door to view the sample and adjust the sample

measurement targeting area.

Caution: Do not look directly into the measurement optics when the instrument is on.

7. Trigger the measurement using one of the following methods:

a. Select "Measure Standard" or "Measure Trial" from your software. Follow the software

instructions for loading the sample at the view port.

OR

b. Press the Standard or Trial button on the instrument front panel.

8. The measurement is taken. The data is displayed in your application. Follow the instructions

for saving the data in the software.

Note:

When measuring large or oddly-shaped samples you can open the sample holder completely or

remove the sample holder if necessary. The sample is then held securely against the view port.

It is also recommended that you remove the four outer hole plugs from the front of the

instrument to ensure that large samples remain flat during measurements.

When holding a sample for measurement yourself, remember to keep the sample perfectly

still. Also, the sample surface should be able to rest completely flat against the aperture plate,

preventing any light from entering the view port.

25

Page 28

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Sample stop for 6 mm, 10

.

Sample clamp

Carriage base

Clamp thumb screws (2)

Stop thumb screw (2)

Carriage base thumb screw

Base plate

Transmission Measurements (excludes Ci7500 series)

A transmission indicator illuminates on the front panel based on your selection in the software.

The transmission sample holder is designed to mount inside the transmission compartment. It is

used to measure thin films at both the sphere (total transmission) and at the lens (direct

transmission). Direct transmission is 25 mm measurements only. Each transmission kit contains:

four sample stops and clamps, four aperture plates with white reflective ring, one transmission

white plaque, one black plastic blocking panel, and one cuvette sample holder. Choose the sample

stop and clamp appropriate for your application.

Before taking a transmission measurement, make sure the instrument is calibrated for the

measurement mode and set the instrument to transmission mode using your application.

Measurement Notes:

• Liquids are measured using the cuvette sample holder

• Always make certain that the sample is flush and parallel to the opening in the sphere or

the lens

• If transmission white plaque gets soiled, it must be replaced

• Close the cover when measuring

• Use aperture plates with white reflective ring

• Use the transmission white plaque, not smooth glossy calibration tile

Transmission Sample Holder Description

mm, 17 mm and 25 mm

Total Transmission Measurement

Total measurements are taken with the sample positioned between the stop and clamp toward the

sphere. Total Transmission is appropriate for measuring translucent samples which exhibit some

scattering of the light. A total transmission measurement will make certain that all transmitted

light is measured for an accurate reading.

1. Mount the appropriate aperture plate (with white reflective ring) to the measurement port at

the front of the instrument.

2. Position the transmission white plaque on the sample holder as previously explained in the

calibration section.

26

Page 29

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Lens Side

Sphere Side

Clamp mounting holes

Base plate in total

position

3. Open the transmission cover by lifting up on the locking pin while sliding the cover to the

back.

4. Align the sample holder base plate pins to the base plate mounting channel holes inside the

transmission area.

Position the base plate with the clamp mounting holes on the sphere side. Be careful to get

the angle correct. Care should be taken to properly align the base plate so that the sample is

positioned between the stop and clamp toward the sphere.

transmission

5. Attach the appropriate sample stop to the base plate and clamp to the carriage base with the

thumb screws. We recommend using a stop plate with all sizes including 25 mm.

The sample is held in position using a sample stop on the sphere side of the sample, and a

spring loaded clamp on the side of the sample away from the sphere.

Care should be taken to properly align this holder so that the stop plate is positioned flush

and tight against the opening in the sphere. Do not tighten the thumb screws until the

sample has been positioned tight against this opening.

27

Page 30

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Transmission holder with sample at the sphere (total measurement) for 25

6. Pull the clamp back and position the sample between the clamp and stop. You may want to

temporarily tighten the carriage base thumb screw to hold the clamp in place while

positioning the sample. Slowly release the sample clamp/carriage base to secure the sample.

mm, 17 mm, 10 mm, and 6 mm, measurements

7. Once properly position, tighten the thumb screws and close the transmission cover.

8. Initiate the measurement by selecting “Measure Standard" or "Measure Trial" from your

software application, or press the Standard or Trial button on the front panel.

9. The measurement is taken. The data is displayed in your application.

10. Follow the instructions for saving the data in the application.

Direct Transmission Measurement

Direct measurements are taken with the sample positioned towards the lens in the back of the

instrument. Direct Transmission is appropriate for measuring transparent samples which exhibit

no scattering of the light. This would generally be samples colored with dyes rather than

pigments. When measuring with this method the diffuse light is collimated, this means that the

light rays are travelling in a parallel fashion as they pass through the sample.

Note: When performing Direct Transmission measurements, only the 25mm clamp, stop, and

aperture plate (with white reflective ring) should be used.

1. Mount the 25 mm aperture plate (with white reflective ring) to the measurement port at the

front of the instrument.

2. Position the transmission white plaque on the sample holder as previously explained in the

calibration section.

3. Open the transmission cover by lifting up on the locking pin while sliding the cover to the

back.

28

Page 31

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Lens Side

Sphere Side

Clamp mounting holes

Base plate in direct

4. Align the sample holder base plate pins to the base plate mounting channel holes inside the

transmission area.

Position the base plate with the clamp mounting holes on the lens side. Be careful to get the

angle correct. Care should be taken to properly align this base plate so that the sample is

positioned towards the lens. It does not sit flush against the lens. Verify the angle is correct

by looking through the front aperture plate.

5. Attach the 25 mm sample stop to the base plate and 25 mm clamp to the carriage base with

the thumb screws.

The sample is held in position using a sample stop on the lens side of the sample, and a

spring loaded clamp on the side of the sample away from the lens.

Do not tighten the thumb screws until the sample has been positioned tight against this

opening.

6. Pull the clamp back and position the sample between the clamp and stop. You may want to

temporarily tighten the carriage base thumb screw to hold the clamp in place while

positioning the sample. Slowly release the sample clamp/carriage base to secure the sample.

transmission position

29

Page 32

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Transmission holder

with sample at the lens

(direct measurement)

for 25 mm

measurements

7. Once properly position, tighten the thumb screws and close the transmission cover.

8. Initiate the measurement by selecting “Measure Standard" or "Measure Trial" from your

software application, or press the Standard or Trial button on the front panel.

9. The measurement is taken. The data is displayed in your application.

10. Follow the instructions for saving the data in the application.

R/T (Reflection/Total Transmission) Measurement

R/T measurements provide the ability to compensate for light lost through the sample (as opposed

to light absorbed). When using R/T mode for plastic formulation the formulation software will

attempt to match opacity of the standard as well as color.

Two measurements are taken to create this value. One measurement is taken with the sample

positioned at the reflection port (reflection measurement). The second measurement is taken with

the sample positioned flush against the stop at the back of the sphere (total transmission

measurement). When measuring with this method the diffuse light travels through the object from

all angles. Again the sample is illuminated from all possible angles with a diffuse light source.

1. Mount the aperture plate (with white reflective ring) to the measurement port at the front of

the instrument.

2. Position the transmission white plaque on the sample holder as previously explained in the

calibration section.

3. Position the sample at the reflection port as previously explained in the Reflectance

Measurement section.

4. Initiate the measurement by selecting “Measure Standard" or "Measure Trial" from your

software application, or press the Standard or Trial button on the front panel. The

measurement is taken.

5. Open the transmission cover by lifting up on the locking pin while sliding the cover to the back.

30

Page 33

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

6. When taking the transmission measurement the sample is held in position using the

transmission holder with a stop plate on the sphere side of the sample, and a spring loaded

clamping plate on the side of the sample away from the sphere.

7. Attach the appropriate sample stop to the base plate and clamp to the carriage base with the

thumb screws. We recommend using a stop plate with all sizes including 25 mm.

8. Remove the sample from the sample holder. Care should be taken to properly align the base

plate so that the sample is positioned between the stop and clamp toward the sphere. When

setting up for measurements, do not tighten the thumb screws until the sample has been

positioned properly.

9. Once properly position, tighten the thumb screws and close the transmission cover.

10. Initiate the measurement by selecting “Measure Standard" or "Measure Trial" from your

software application, or press the Standard or Trial button on the front panel. The

measurement is taken.

11. Follow the instructions for saving the data in the application.

31

Page 34

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

R/T correlation - Ci7XX0 to Ci7000A

Testing has shown that to achieve the best correlation between a Ci7XX0 to a Ci7000A the

following combinations of transmission port, stops, and aperture plates should be used:

• 25mm transmission port, with 25 mm stop and 25 mm aperture plate with white reflective

ring

or

• 17mm transmission port, with 17 mm stop and 17 mm aperture plate with white reflective

ring

Liquid Measurements

Measurement and Calibration Notes

• Liquids should be measured using the total transmission technique, never use direct

transmission for liquids

• Be very careful with placement of the cuvette, make certain it is positioned square and

flush to the sphere opening

• Make sure the cuvette’s position is centered over the opening in the sphere

• Perform white calibration with cuvette and clear liquid in the sample holder

• The clear liquid should be the base of whatever material you are working with

• When performing black calibration the blocker should be positioned between the cuvette

and the opening in the sphere

Cuvette Cleaning and Handling

• Care should be taken to ensure the cuvette and holder is kept clean. Carefully wash the

holder and cuvette in warm, soapy water and rinse thoroughly.

• Never touch the cuvette windows with your fingers as the oils in your skin will etch the

windows. Handle the cuvette by the edges.

• Always leave an air gap between the bottom of the lid and the top of the liquid sample.

The force of pressing the lid against the liquid sample can cause the windows to be

weakened and crack.

• Extreme care should be taken to prevent the sample liquid from being spilled into the

transmittance chamber. NEVER FILL THE CELL WHILE IT IS IN THE TRANSMISSION

COMPARTMENT.

Procedure:

1. Loosely attached the cell stand assembly to the carriage base with two thumb screws. A

clamp is not required for this measurement.

2. Slide the cell stand forward and tighten the thumb screws.

3. Make sure the cuvette is clean (see Cleaning and Handling). Carefully fill the cuvette with

the sample liquid until the liquid is approximately 8 mm from the top. If any liquid spills

on the sides of the cuvette, wipe it off with a clean cloth.

4. Insert the cuvette into the cell stand.

32

Page 35

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Cuvette in the cell stand (total

measurement)

5. Initiate the measurement by selecting “Measure Standard" or "Measure Trial" from your

software application, or press the Standard or Trial button on the front panel.

6. The measurement is taken. The data is displayed in your software application.

7. Follow the instructions for saving the data in the software.

Haze Measurements

Measurement and Calibration Notes

• To obtain a true haze measurement requires a haze meter (ASTM D1003). It is possible,

however, to use a sphere geometry spectrophotometer capable of transmission

measurements to obtain an index, known as correlated haze, with good correlation to a

haze meter.

• The sample to be measured is placed against the sphere.

• To calibrate use the 25 mm aperture plate (with white reflective ring), transmission white

plaque and black trap positioned at the reflectance port.

• Before you can take a Haze measurement you need to calibrate for the haze

measurement first, unless you are already in Haze Measurement mode using a current

haze calibration.

Procedure:

1. Mount the 25 mm aperture plate with the white ring at the measurement port as previously

explained.

2. Select “Haze” as the measurement type within your software.

3. A haze calibration is automatically launched. Follow the prompts from the software regarding

calibration.

4. Once the haze calibration is complete you can begin to take haze measurements.

5. Load your sample in the transmission sample holder at the sphere within the transmission

compartment.

6. Select “Measure Standard”, “Measure Trial”, or press the appropriate measure button on the

instrument.

7. If you later change the measurement mode to another measurement type than Haze you

may be prompted to calibrate the instrument.

33

Page 36

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

APPENDICES

Service Information

X-Rite provides repair service to their customers. Because of the complexity of the circuitry, all

warranty and non warranty repairs should be referred to an authorized service center. For non

warranty repairs, the customer shall pay shipping and repair cost to the authorized service

center, and the instrument shall be submitted in the original carton, as a complete unaltered unit,

along with all the supplied accessories.

X-Rite, Incorporated has offices around the world. You can contact us using one of the following

methods:

• To identify the X-Rite service center nearest you, please visit our web site at:

www.xrite.com and click the Contact Us link.

• For online help, visit our web site (www.xrite.com) and click the Support link. Here you

can search for software or firmware updates, white papers, or frequently asked questions

which can quickly resolve many common user problems.

• Send an e-mail to Technical Support detailing your problem and listing your contact

information. For the Americas email CASupport@xrite.com, for Europe email

EMEAtechsupport@xrite.com, for Asia email TechSupportAsiaDist@xrite.com.

• For sales questions or to order cables and accessories, visit our web site (www.xrite.com)

or contact your nearest X-Rite dealer or service center.

• Problems and questions can also be faxed or emailed to your local X-Rite office listed on

our website.

34

Page 37

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Cleaning Requirement

Clean,

Mild

Lint-

Personal

Exterior

Transmission

Black Plastic

Sphere

Aperture

Transmission

Black Trap

UV Calibration

Cleaning the Instrument

Your instrument requires very little maintenance to achieve years of reliable operation. However,

to protect your investment and maintain reading accuracy, a few simple-cleaning procedures

should be performed from time to time.

IMPORTANT:

Remove AC power from the instrument before performing any of these

cleaning procedures.

CAUTION: DO NOT use any solvents to the clean the instrument.

CAUTION: Use proper personal protective equipment (e.g., safety glasses)

when using compressed air.

If can air is used for any of the cleaning procedures that recommend air, do not

invert or tilt the can during use. This could cause damage.

CAUTION: When using chemicals, always follow the manufacturer’s personal

protection equipment recommendations in the chemical SDS.

Cleaning Quick Reference Table

Below is a quick reference to help you determine the proper cleaning methods. Refer to the

following pages for a more detailed description of the individual cleaning procedures.

Compartment

Blocking

Panel

Plates

White Plaque

Plaque

Compressed

Air

Cleaner

with Water

free

Cloth

Protection

Equipment

(per SDS)

35

Page 38

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

General Exterior Cleaning

The case, front panel, sample holder and surface of your instrument should be kept clean and

free of dust. This can be accomplished by dusting these components with a lint-free cloth.

General cleaning should be performed on a weekly basis or more often if the unit is used in a

dusty operating environment.

Cleaning the Transmission Compartment

Use clean, dry compressed air to blow any dust, dirt or other contamination out of the

transmission compartment.

Cleaning the Calibration Tiles

Ceramic standards (calibration tiles) are widely used in color science as standards of reflectance

factor. Their principal virtue is the stability of their reflection properties. If they are to serve their

intended purpose, it is necessary that the surfaces of these tiles be maintained in a stable

condition. The cleaning of any precision optic risks degrading the surface. Therefore, the need for

cleaning should be minimized by returning the tile to its storage case or covering it with a

protective bag when it is not in use. If cleaning is required, the following procedure is

recommended.

Materials Required

• Isopropyl alcohol, Glass cleaner, Lint-free wipes, and Distilled water

To remove dust, lint, and invisible particles, proceed as follows:

1. Place the tile on a stable surface and hold the tile by its edges.

2. Spray a small amount of Isopropyl Alcohol onto a portion of a lint free wipe, then wipe with a

circular motion making sure to clean the entire surface. Use a dry portion of the wipe to wipe

the surface of the tile until dry. Discard the wipe.

3. Spray a liberal amount of glass cleaner onto the surface of the tile. Using a clean lint-free

wipe, allow the wipe to become saturated with the glass cleaner on the tile, then wipe the tile

in a circular motion, making sure to clean the entire surface of the tile. Discard the wipe.

Excess glass cleaner will remain on the tile. Quickly move to the next step before it dries.

4. Hold tile vertically and spray a liberal amount of distilled water onto surface of tile allowing to

run off, rinsing off the remaining glass cleaner. Dry the surface using a lint-free wipe in a

circular motion. Discard the wipe.

Cleaning the Black Plastic Blocking Panel

Dust on the black plastic blocking panel can be very tightly bound by static electricity. To remove

the dust, blow canned air across the surface.

Cleaning the Sphere

NOTE: Do not touch the inside surface of the sphere or stick anything into the sphere.

The sphere should be inspected for any debris that may be present. Follow the procedure to clean

the sphere.

1. Open the sample door to the fully open position.

2. Use clean, dry compressed air and blow short bursts into the sphere. This should remove any

dust, dirt or other contamination off the inside surface of the sphere.

36

Page 39

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

(1)

(2)

3. Close the sample door.

Cleaning the Aperture Plates

The surface of the aperture plate may be wiped clean with a cloth dampened in water or a mild

cleaner.

Cleaning the Transmission White Plaque

Care should be taken not to touch the front surface when handling the plaque.

Blow short burst of clean, dry air, across the surface to remove any dust or contamination.

Cleaning the Black Trap

The black trap should be cleaned from time to time to remove and dust or contamination that

may collect inside.

1. Remove the base (1) from the trap (2) by turning to the left and lifting upwards.

2. Look inside of the black trap to reference how the trap glass is positioned. This is important

to remember when it comes time to reinstall it after cleaning.

3. Using your fingers, carefully remove the trap glass from the trap by the edges. Avoid

touching the surface of the glass with your fingers.

37

Page 40

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

(3)

(4)

(4)

(5)

4. Blow short bursts of clean, dry air (4) across the both surface of the trap glass and inside of

the trap.

5. Reinstall the black glass in the trap. The bottom edge of the black glass should be resting

against the felt pad (5) in the bottom of the trap when positioned properly.

6. Align the base notches over the tabs in the trap and turn to the right until it snaps into

position. NOTE: The base tabs are keyed to only allow installation in one position. Make sure

you do not force it on the trap.

Cleaning the UV Calibration Plaque

Do not use solvents or cleaners of any kind.

Blow short burst of clean, dry air onto the UV calibration plaque.

38

Page 41

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

Flat-blade

Carrier clip

Fuse

Dampening

Dampening pin locking

nut location

Replacing the Fuse

In the event the instrument does not turn ON when power is applied, make certain that power is

available at the plug. If power is available, replace the instrument fuse as follows.

Replacement fuse (5mm x 20mm 2.5A, 250V time-delay fuse type).

1. Turn the power off and unplug the detachable line cord.

2. Insert a flat-blade screwdriver into the right edge of the fuse carrier and pry out.

3. Remove the blown fuse from the carrier clip and discard.

screwdriver

4. Place the new fuse in the clip and reinsert fuse carrier into the fuse cavity. Make sure the

carrier is firmly seated.

5. Reinstall the detachable line cord.

Adjusting the Sample Holder Dampening

If required, the sample holder dampening effect can be changed when closing the sample holder.

Simply adjust the pin in the sample holder to increase or decrease dampening.

1. Remove the sample holder from the front of the instrument by loosening the two screws.

Refer to the Ci7XX0 Installation Instructions for details.

2. Loosen the locking nut on the front side of the dampening pin.

3. Adjust the dampening pin located on the back of the holder using a flat-blade screwdriver to

change the dampening effect.

4. Tighten the dampening pin locking nut after the adjustment is completed and reinstall the

sample holder.

adjustment pin

39

Page 42

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

Problem

Cause/Solution

Instrument not

AC not connected.

Calibration procedure

Calibration tile is dirty or damaged.

Instrument and

Interface cable not connected.

Repeated sample

Ensure that the sample is being measured in accordance with your

Troubleshooting

Prior to contacting the support department for instrument problems, try the applicable solution(s)

described below. If the condition persists, contact us using one of the methods listed in the Service

Information section.

responding (no

indicator lights).

fails.

software not

communicating.

measurement

failures.

Plug in AC adapter.

Fuse is blown.

Replace fuse (see Replacing the Fuse).

Clean the white tile per procedure in Appendix, or replace if damaged. If

damaged, arrange for replacement by contacting X-Rite Support.

Connect the interface cable between the computer and the instrument.

Close and restart the software application. If this does not work, reboot

the computer.

Turn the instrument off, wait 30 seconds, then turn the instrument on and

see if the condition is corrected.

Check for proper configuration setting from the software provider.

software’s documentation.

Close and restart the software application.

Perform a calibration on the instrument (see Calibration section).

Clean instrument sphere (see Cleaning).

40

Page 43

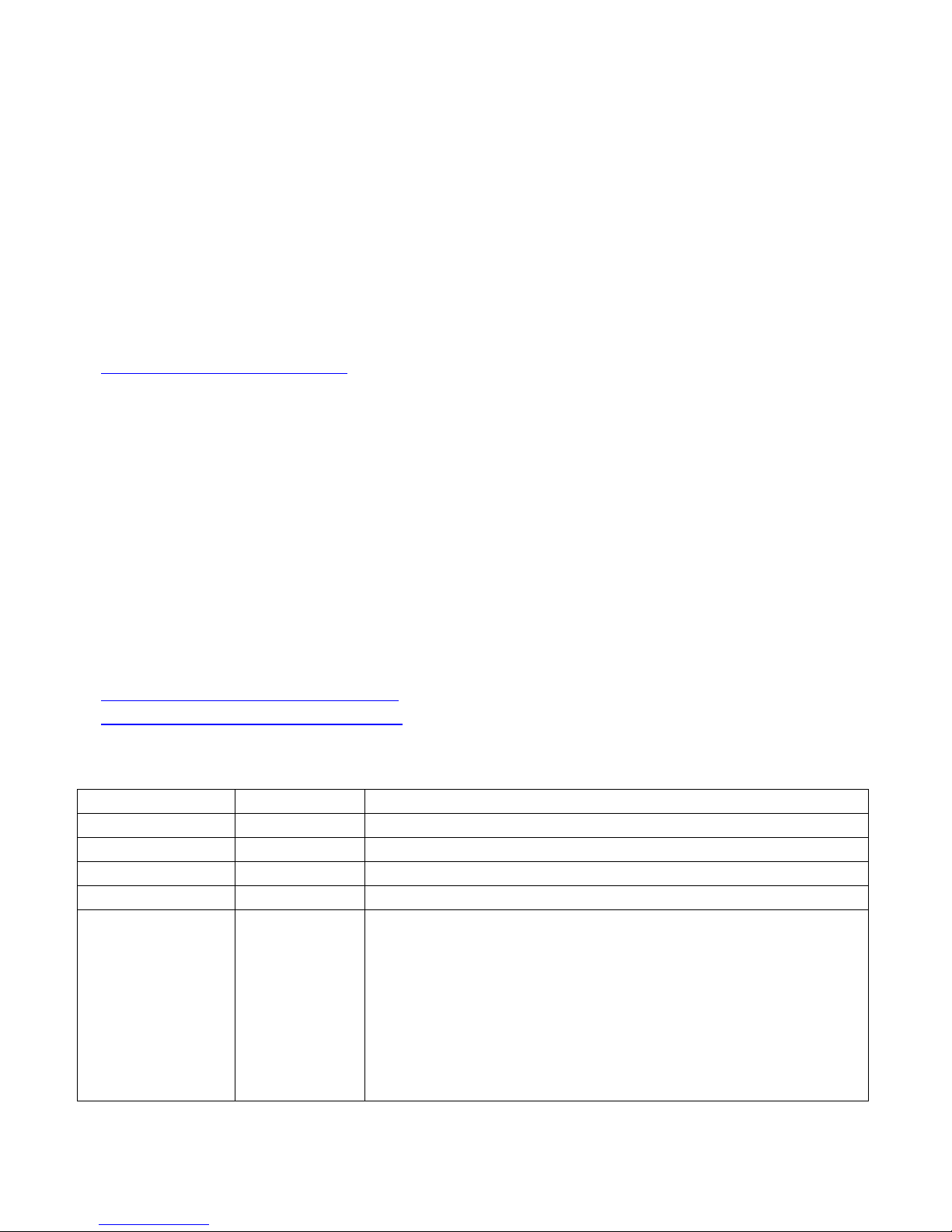

Specifications

Repeatability

Inter

Instrument

Agreement

Geometry

Illumination

Measurement

time

Duty cycle

Spectral

Range

Wavelength

Interval

Photometric

range

Photometric

resolution

Performance Specifications

Ci7860 Series Ci7800 Series Ci7600 Series Ci7500 Series

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

0.01 RMS ∆E CIELAB

Spectralon Tile

-

0.06 Avg. 13 BCRA

Series II tiles SCI

(25 mm only)

D\8 Tri-beam

simultaneous

SCE\SCI

Pulsed Xenon, D65

Calibrated

2.7 – 4.0 seconds

(flash & data

acquisition)

480 measurements

per hour max

360 to 750 nm

standard reporting

with 360 to 780 nm

extended range

0.01 RMS ∆E CIELAB

Spectralon Tile

0.08 Avg. 13 BCRA

Series II tiles SCI

(25 mm only)

D\8 Tri-beam

simultaneous

SCE\SCI

Pulsed Xenon, D65

Calibrated

2.7 – 4.0 seconds

(flash & data

acquisition)

480 measurements

per hour max

360 to 750 nm

standard reporting

with 360 to 780 nm

extended range

0.03 RMS ∆E

CIELAB Spectralon

Tile

0.15 Avg. 13 BCRA

Series II tiles SCI

(25 mm only)

D\8 Tri-beam

simultaneous

SCE\SCI

Pulsed Xenon, D65

Calibrated

2.7 – 4.0 seconds

(flash & data

acquisition)

480 measurements

per hour max

360 to 750 nm

standard reporting

0.03 RMS ∆E

CIELAB Spectralon

Tile

0.15 Avg. 13 BCRA

Series II tiles SCI

(25 mm only)

D\8 Tri-beam

simultaneous

SCE\SCI

Pulsed Xenon, D65

Calibrated

2.7 – 4.0 seconds

(flash & data

acquisition)

480 measurements

per hour max

360 to 750 nm

standard reporting

5 nm, 10 nm, and

20 nm

0.0% to 200% 0.0% to 200% 0.0% to 200% 0.0% to 200%

0.001% reflectance 0.001% reflectance 0.01% reflectance 0.01% reflectance

5 nm, 10 nm, and

20 nm

10 nm and 20 nm 10 nm and 20 nm

41

Page 44

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

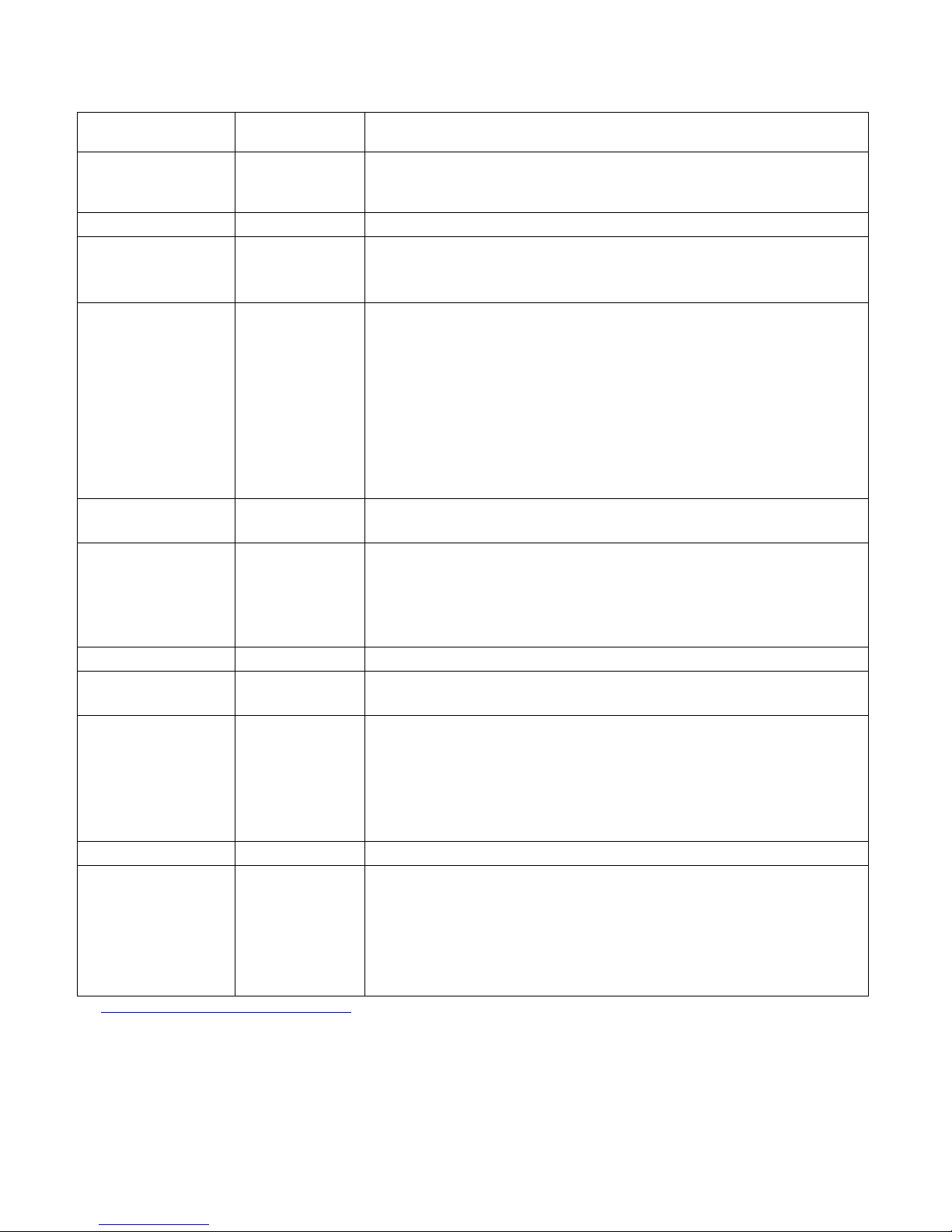

Environmental Specifications

Electrical Requirements

100-240 VAC/50-60 Hz

AC line input is 1.1 Amps max

Class 1, protective earth

Overvoltage Category Category II

EMC Compliance IEC (EN) 61326-1

Operating Temperature

Storage Temperature

5º C to 40º C

-40º C to 70º C

Altitude, operating 2000 m

Pollution Degree 2

Operating Humidity

Storage Humidity

5% to 85% relative, non-condensing

5% to 85% relative, non-condensing

Dimensions 23 cm W x 25 cm H x 47 cm D

Weight 20.5 kg

Interface USB

Design and specifications subject to change without notice.

42

Page 45

Ci7 XX0 BENCHTOP S P ECTROPHOTOMETER

NetProfiler 3 Industrial Benchtops – 1 Year License

NP3/IB1

NetProfiler 3 Industrial Benchtops – 1 Year License

NP3/IB1NT

NetProfiler 3 Industrial Benchtop Calibration Tiles

NP3/IBT

Flow Through Cell Holder kit

Ci7-801

Transmission Preform Holder kit

Ci7-802

Reflectance Cuvette Holder kit

CIA-803

Reflectance Preform Holder kit

CIA-802

Spare Parts and Accessories

The Ci7XX0 Spectrophotometer has optional accessories that you may order by calling the

Customer Service Department in the US at 1-800-248-9748. The following accessories are

available:

Ci7600

CIA-800-02

Transmission kit: this kit includes a calibration

standard, a transmission cuvette with holder, a

transmission sample holder, and a storage case.

Ci7800/Ci7860

CIA-800-01

Transmission kit: this kit includes a calibration

standard, a transmission cuvette with holder, a

transmission sample holder, and a storage case.

25 mm Glass Aperture A-AP/GLAV57

without Tile Set

43

Page 46

Ci7XX0 BENCHTOP SPECTROPHOTOMETER

System Repacking Instructions

Refer to the following instructions to repack your system in the event shipment is required. If the

original carton and packing materials are not available, contact X-Rite to have a replacement

shipped to your location.

Items to repackage with original shipped instrument:

• Original box and foam packaging (including large instrument bag)

• Aperture plates

• Black trap

• Sample holder

• Sample shelf (w/ thumb screws)

• Power line cord

• USB cable

• White calibration standard

• Green calibration standard

• UV calibration standard

• Black rubber shim

Repackaging Instructions:

1. Repackage contents of Transmission Kit (if installed)

a. Remove any transmission components from the inside of the instrument.

b. Place all transmission kit components into the original transmission case.

2. Prepare instrument for repackaging

a. Lock instrument optics for shipment.

i. Power on your instrument and connect to PC via USB.

ii. Insert the “Ci7XX0 Benchtop Spectrophotometer” CD into your optical drive. If

the main startup menu does not automatically launch, run the “start.exe”

program from the Setup Tool folder of the CD.

iii. Select “Setup Tool” from under the “Utilities” section of the software CD main

menu. Run the Setup program.

iv. Select “Lock Optics” from the main menu of the Setup program. (You can hear

the instrument position the optics into the safe transport position.)

v. Close the Setup program after the instrument optics has completed movement

into a position that is safe for transport.

vi. Power off the instrument using the rear power switch.

vii. Remove the CD from the optical drive and place into the envelope.

b. Disconnect and package the power line cord and USB cable.

i. Fold the power cord and place into the bubble bag (if available from original

packaging).

ii. Fold the USB cable and place into the plastic bag (if available from original

packaging).

c. Package the instrument sample holder arm.