Page 1

Setup and Operation

Auto-Scan

Page 2

Page 3

eXact Auto- Scan System

Consult this documentation in all cases where the Attention symbol appears.

This symbol is used to inform you of any potential HAZARD or actions that may require your attention.

CE Declaration

Hereby, X-Rite, Incorporated, declares that this device is in compliance with the essential requirements

and other relevant provisions of Directives 2014/35/EU (LVD), 2014/30/EU (EMC), and RoHS

2011/65/EU.

Federal Communications Commission Notice

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Industry Canada Compliance Statement

CAN ICES-3 (A) / NMB-3 (A)

Equipment Information

Use of this equipment in a manner other than that specified by X-Rite, Incorporated may compromise

design integrity and become unsafe.

WARNING: This instrument is not for use in explosive environments.

ADVERTENCIA: NO use este aparato en los ambientes explosivos.

AVVERTIMENTO: NON usare questo apparecchio in ambienti esplosivi.

WARNUNG: Das Gerät darf in einer explosiven Umgebung NICHT verwendet werden.

AVERTISSEMENT: Cet instrument ne doit pas être utilisé dans un environnement explosif.

CAUTION: CLASS 1 LASER PRODUCT - Wavelength 637 nm

Conforms to IEC 60825-1: 2007 and 21CFR1040.10 Safety of Laser Products.

LI635-5-3(8x26)42-F1500 P/N 70107593 Picotronic GmbH

ATTENTION : PRODUIT LASER DE CLASSE 1 - Longueur d'onde de 637 nm

Conforme aux normes IEC 60825-1 : 2007 et 21CFR1040.10 relatives à la sécurité des produits laser.

Puissance de sortie max. 3 mW - géométrie à laser en ligne (source laser 3 mm max. dans la direction de

la ligne 76,8 cm x 1 cm à 1 m de distance).

Instructions for disposal: Please dispose of Waste Electrical and Electronic Equipment (WEEE) at

designated collection points for the recycling of such equipment.

1

Page 4

e X act Auto- S can Syste m

Proprietary Notice

The information contained in this manual is derived from patent and proprietary data of X-Rite,

Incorporated. The contents of this manual are the property of X-Rite, Incorporated and are copyrighted.

Any reproduction in whole or part is strictly prohibited. Publication of this information does not imply

any rights to reproduce or use this manual for any purpose other than installing, operating, or

maintaining this instrument. No part of this manual may be reproduced, transcribed, transmitted, stored

in a retrieval system, or translated into any language or computer language, in any form or by any

means, electronic, magnetic, mechanical, optical, manual, or otherwise, without the prior written

permission of an officer of X-Rite, Incorporated.

This product may be covered by one or more patents. Refer to the instrument for actual patent numbers.

Copyright © 2019 by X-Rite, Incorporated “ALL RIGHTS RESERVED”

X-Rite® is a registered trademarks of X-Rite, Incorporated. All other logos, brand names, and product names mentioned are the properties of

their respective holders.

Warranty Information

X-Rite warrants this Product against defects in material and workmanship for a period of twelve (12)

months from the date of shipment from X-Rite’s facility, unless mandatory law provides for longer

periods. During such time, X-Rite will either replace or repair at its discretion defective parts free of

charge.

X-Rite’s warranties herein do not cover failure of warranted goods resulting from: (i) damage after

shipment, accident, abuse, misuse, neglect, alteration or any other use not in accordance with X-Rite’s

recommendations, accompanying documentation, published specifications, and standard industry

practice; (ii) using the device in an operating environment outside the recommended specifications or

failure to follow the maintenance procedures in X-Rite’s accompanying documentation or published

specifications; (iii) repair or service by anyone other than X-Rite or its authorized representatives; (iv)

the failure of the warranted goods caused by use of any parts or consumables not manufactured,

distributed, or approved by X-Rite; (v) any attachments or modifications to the warranted goods that are

not manufactured, distributed or approved by X-Rite. Consumable parts and Product cleaning are also

not covered by the warranty.

X-Rite‘s sole and exclusive obligation for breach of the above warranties shall be the repair or

replacement of any part, without charge, which within the warranty period is proven to X-Rite‘s

reasonable satisfaction to have been defective. Repairs or replacement by X-Rite shall not revive an

otherwise expired warranty, nor shall the same extend the duration of a warranty.

Customer shall be responsible for packaging and shipping the defective product to the service center

designated by X-Rite. X-Rite shall pay for the return of the product to Customer if the shipment is to a

location within the region in which the X-Rite service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other

locations. Proof of purchase in the form of a bill of sale or receipted invoice which is evidence that the

unit is within the Warranty period must be presented to obtain warranty service. Do not try to

dismantle the Product. Unauthorized dismantling of the equipment will void all warranty claims.

Contact the X-Rite Support or the nearest X-Rite Service Center, if you believe that the unit does not

work anymore or does not work correctly.

THESE WARRANTIES ARE GIVEN SOLELY TO BUYER AND ARE IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION, AND NON-INFRINGEMENT.

NO EMPLOYEE OR AGENT OF X-RITE, OTHER THAN AN OFFICER OF X-RITE, IS AUTHORIZED TO MAKE ANY

WARRANTY IN ADDITION TO THE FOREGOING.

2

Page 5

IN NO EVENT WILL X-RITE BE LIABLE FOR ANY OF BUYER’S MANUFACTURING COSTS, OVERHEAD, LOST

PROFITS, GOODWILL, OTHER EXPENSES OR ANY INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES BASED UPON BREACH OF ANY WARRANTY, BREACH OF CONTRACT, NEGLIGENCE, STRICT

TORT, OR ANY OTHER LEGAL THEORY. IN ANY EVENT OF LIABILITY, X-RITE’S MAXIMUM LIABILITY

HEREUNDER WILL NOT EXCEED THE PRICE OF THE GOODS OR SERVICES FURNISHED BY X-RITE GIVING

RISE TO THE CLAIM.

Table of Contents

Overview and Setup 4

About this manual 4

Unpacking and Inspection 5

System Connections 5

Connecting the Vacuum Pump Only (optional) 6

Connecting the Foot Switch and Vacuum Pump (optional) 7

Installing the eXact InkKeyControl 2 Software (Optional) 8

System Requirements 8

Installing the Software 8

eXact Auto-Scan Indicator 8

Setting Up the eXact Instrument 9

Operating the System 12

Sheet Loading and Alignment 12

Measuring a Color Bar 13

Performing a Spot Color Measurement 14

Calibration 15

Appendices 16

Service Information 16

Troubleshooting 16

eXact Auto-Scan Reset 16

Cleaning the System 17

General eXact Auto-Scan Cleaning 17

System Contacts Cleaning 17

General eXact Cleaning 18

Cleaning the eXact Optics 18

Cleaning the eXact Calibration Plaque 18

Laser Alignment Procedure 19

eXact Auto-Scan Specifications 20

eXact Auto-Scan Vacuum/Foot Switch Interface Wiring 21

eXact Auto- Scan System

3

Page 6

e X act Auto- S can Syste m

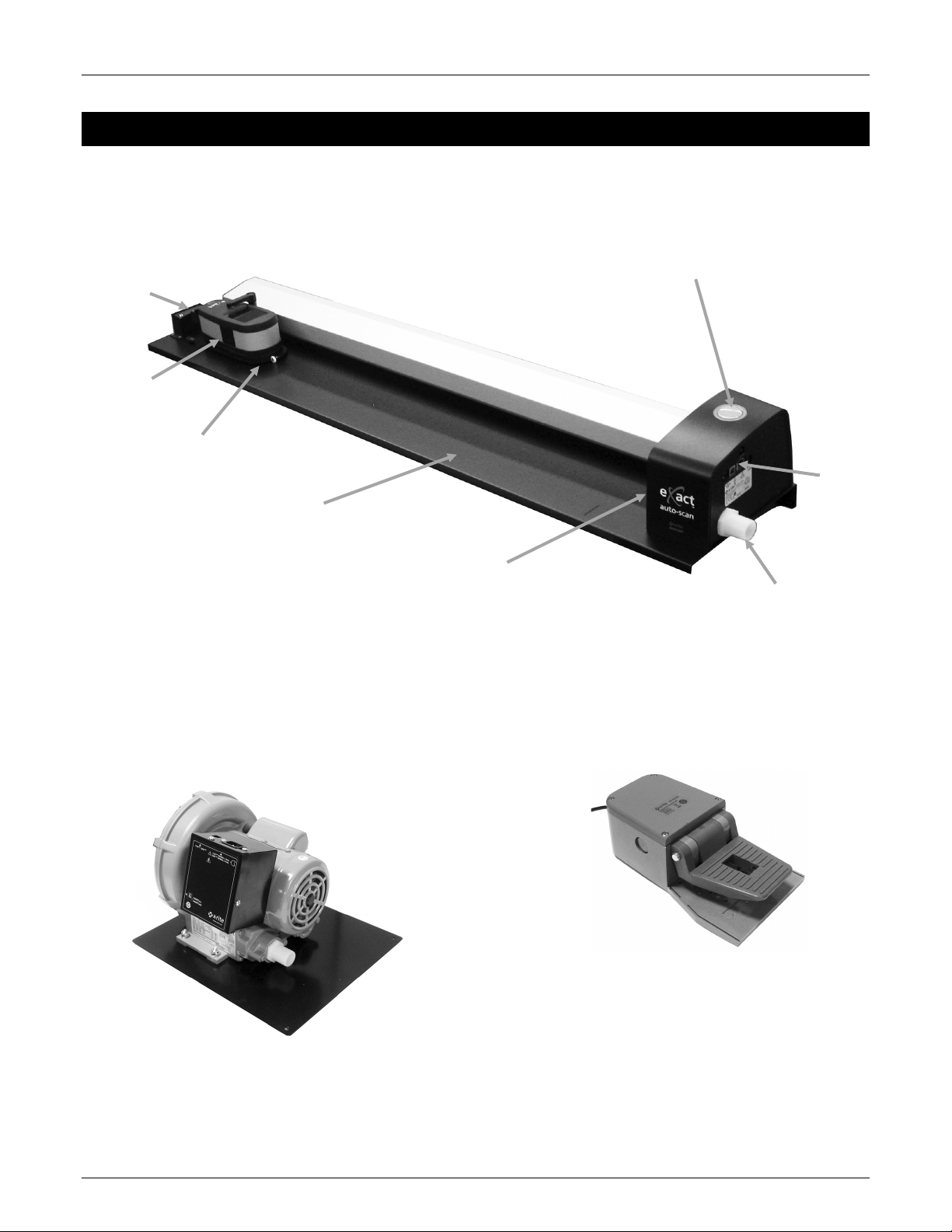

Operation button and Instrument Indicator

(surrounds operation button)

eXact instrument

not included)

USB, vacuum

pump

adapter

connection

location

Scanning track with

Vacuum connector

Laser location

eXact charging

Vacuum Pump (optional)

Scanning trolley

Foot Switch (optional)

Overview and Setup

The eXact Auto-Scan system provides fast, press-side color control. The instrument can also be detached

from the scanning trolley to allow you to take spot check measurements.

station

(

vacuum holes

and AC

s

A series of small holes located in the surface of the

track hold down the press sheet when the optional

vacuum pump is connected.

The optional foot switch provides “hands-free”

measurement activation.

About this manual

This manual covers the installation, basic operation and maintenance of the system. Specific instructions

4

for using the instrument with your software application can be found in the software online help.

Page 7

Unpacking and Inspection

• eXact Auto-Scan

• Handled paper stop (2)

• Charging Adapter

• Vacuum pump (optional)

• USB interface cable

• Foot switch (optional)

• AC adapter (X-Rite P/N SE30-277) and line cord

• eXact InkKeyControl 2 software (optional)

• Paper stop / flat hold down magnet (4)

Power supply (2)

USB port (1)

Optional vacuum pump hose connection

Optional vacuum

USB cable

Computer

Ethernet port (not used)

Laser alignment wheel (refer to the

After removing the instrument from the shipping carton, inspect it for damage. If any damage has

occurred during shipping, immediately contact the transportation company. Do not proceed with

installation until the carrier’s agent has inspected the damage.

Your instrument was packaged in a specially designed carton to assure against damage. If shipment is

necessary, the instrument should be packaged in the original carton along with all the accessories. If the

original carton is not available, contact X-Rite to have a replacement shipped to you.

Packaging Contents:

System Connections

Note: Please allow the system to stabilize at room temperature before plugging the power supply into

an AC wall receptacle.

Operational hazard exists if a power supply other than X-Rite SE30-277 is used.

1. Plug one end of the USB cable into the port on your computer.

2. Plug the other end of the cable into the USB port (1) on the right side of the system.

3. Plug the input connector from the eXact Auto-Scan power supply into the input port (2) located on

the right side of the system.

eXact Auto- Scan System

Appendix)

pump/foot switch

connection

4. Plug the detachable line cord into the power supply and then plug the line cord into the AC wall

receptacle.

5. Connect the computer power supply, monitor, keyboard and mouse (if applicable) to the computer

according to the instructions supplied with those devices.

NOTE: Refer to the following pages for information on connecting the optional vacuum pump and foot

switch if required.

5

Page 8

e X act Auto- S can Syste m

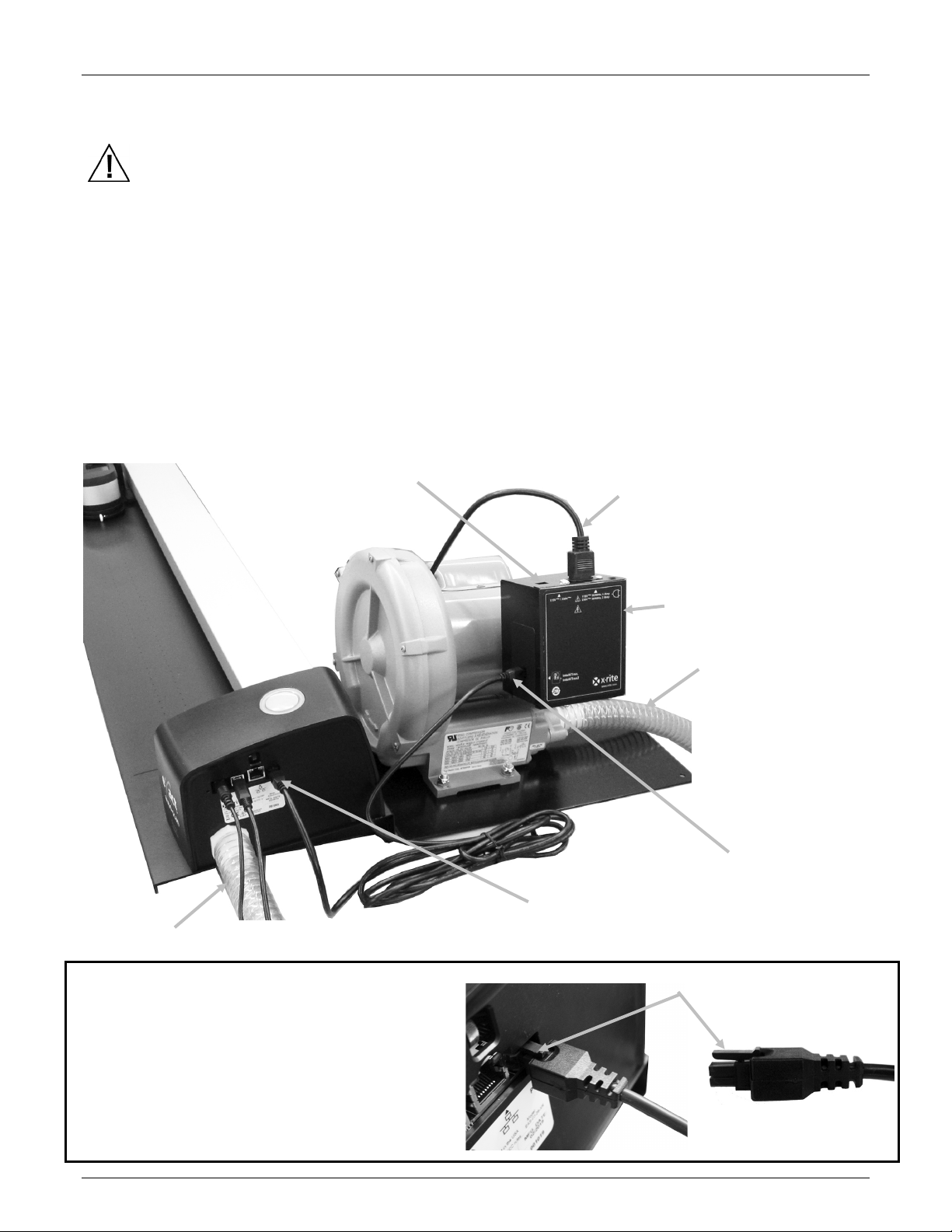

Vacuum hose (1)

Vacuum pump cable (2)

Control box (3)

Voltage selection

)

Line cord (5)

Vacuum pump cable (2)

Vacuum hose (1)

Connector clip

Connecting the Vacuum Pump Only (optional)

1. Connect one end of the vacuum hose (1) to the barbed input fitting located on the vacuum pump,

and the other end to the barbed fitting on the right side of the system.

2. Plug one end of the vacuum pump cable (2) into the connecter on the control box (3) and the other

end of the cable into the connector on the right side of the system.

IMPORTANT: Refer to the bottom of the page for the proper procedure to remove the vacuum

pump cable connectors from the eXact Auto-Scan and control box.

3. Make sure the voltage selection switch (4) on the top of the control box (3) is set to the proper line

voltage for your region.

4. Connect the detachable line cord (5) to the control box (3), and then plug the line cord into an easily

accessible, grounded AC wall receptacle. Note: Only use appropriately approved AC Line Cord that

X-Rite provides. Any other AC Line cord can compromise the integrity of regulatory agencies

approvals for this product. Please contact X-Rite for replacement of the AC Line cord suitable

maintaining this products compliance.

switch (4

Proper Vacuum Pump Cable Removal Procedure

1. Press downward on the clip at the top of the

2. Slowly pull cable connector outward.

6

cable connector.

Page 9

Connecting the Foot Switch and Vacuum Pump (optional)

Foot switch

cable

Foot switch cable (2)

Control

Voltage selection

Line cord (7)

Vacuum

(1)

Vacuum hose (1)

Foot Switch (3)

Connector clip

The foot switch option can only be used in conjunction with the optional vacuum pump.

1. Connect one end of the vacuum hose (1) to the barbed input fitting located on the vacuum pump,

and the other end to the barbed fitting on the right side of the system.

2. Plug one cable (2) from the foot switch (3) into the connector on the right side of the system.

3. Plug the other cable (4) from the foot switch (3) into the connector on the vacuum pump control

box (5).

IMPORTANT: Refer to the bottom of the page for the proper procedure to remove the foot switch

cable connectors from the eXact Auto-Scan and control box.

4. Make sure the voltage selection switch (6) on the top of the control box (4) is set to the proper line

voltage for your region.

5. Connect the detachable line cord (7) to the control box (5), and then plug the line cord into an easily

accessible, grounded AC wall receptacle. Note: Only use appropriately approved AC Line Cord that

X-Rite provides. Any other AC Line cord can compromise the integrity of regulatory agencies

approvals for this product. Please contact X-Rite for replacement of the AC Line cord suitable

maintaining this products compliance.

eXact Auto- Scan System

switch (6)

box (5)

(4)

hose

Proper Foot Switch Cable Removal Procedure

1. Press downward on the clip at the top of the

cable connector.

2. Slowly pull cable connector outward.

7

Page 10

e X act Auto- S can Syste m

Indicator light

Installing the eXact InkKeyControl 2 Software (Optional)

System Requirements

• 2 GHz computer processor, 3 GHz recommended

• 2 GB minimum, 4 GB recommended

• Windows 7, Windows 8, Windows 10

• 100 GB hard drive or higher

• 17” touch-screen monitor with 1280 x 1024 resolution minimum, 22” touch-screen monitor with

1920 x 1080 resolution recommended

Installing the Software

NOTE: Shut down the Windows firewall and any anti-virus software you may be running. If you are

reinstalling or updating the software, you must first uninstall the current version of eXact InkKeyControl

2 from your computer. This will not delete any of your stored database files. All information will be

retained.

The eXact InkKeyControl 2 software uses a standard Windows installation procedure.

1. Insert the eXact InkKeyControl 2 software flash drive into the USB port. If eXact InkKeyControl 2

setup screen does not open automatically, open Windows Explorer and browse to the USB drive

letter. Double-click the Setup.exe file.

2. The setup program guides you though the rest of the installation process. Follow the instructions on

each setup screen to complete the installation.

3. Refer to the eXact InkKeyControl 2 online help system for information on operation of the software.

NOTE: eXact InkKeyControl 2 uses a free version of SQL Server. This version is fully functional with a few

limitations. Please refer to the online help in the Database Administration Tool for more information.

eXact Auto-Scan Indicator

The indicator that surrounds the operation button illuminates system operation conditions.

Solid Green: indicates that the eXact instrument is docked at the charging station and ready for use.

Solid Orange: indicates that the instrument is taking a measurement.

8

Page 11

Setting Up the eXact Instrument

Charging

Target window (3)

Target base (2)

USB cable

1. Activate the Bluetooth function on your instrument and pair it with your computer. Refer to the

eXact User Guide for additional information.

2. Plug the charging adapter (1) into the back of the eXact instrument. The adapter is properly

attached when the tab on the bottom snaps into the security cable slot on the back.

To remove the charging adapter, push up on the locking tap and pull outward.

adapter (1)

eXact Auto- Scan System

NOTE: If the Bluetooth function is not used, route the USB for the

eXact instrument in the channel at the top of charging adapter.

This will help prevent the cable from interfering with the charging

station and track during operation. This USB cable is separate

from the eXact Auto-Scan system USB cable that was previously

installed. Plug the square end of the USB cable into the back of

the instrument. Plug the USB cable into an available port on your

computer.

3. Lock the eXact target base (2) against the instrument.

4. Flip the target window (3) back 180° on the bottom of the eXact target base.

9

Page 12

e X act Auto- S can Syste m

Scanning trolley (4)

Locking arm (6)

Charging station (5)

5. Move the scanning trolley (4) a few inches from the charging station (5).

6. Position the eXact instrument over the scanning trolley (4) and lower into place.

7. Secure the eXact to the scanning trolley by rotating the locking arm (6) counterclockwise until it

stops. This holds the instrument in place during scanning.

10

8. Slide the instrument and scanning trolley against the charging station (5).

Page 13

eXact Auto- Scan System

Charging station (5)

11

Page 14

e X act Auto- S can Syste m

White dash mark

Laser line

Operating the System

You should refer to the online help in the software application for procedures on creating and selecting

color bars. The following information is provided to familiarize you with the mechanical aspects required

when measuring.

Sheet Loading and Alignment

The press sheet can be loaded from the back and passed through the track or from the front to align the

color bar. The press sheet is held in place by the supplied magnets or series of vacuum holes if the

optional pump is used.

CAUTION: CLASS 1 LASER PRODUCT

1. If not already done, slide the instrument and scanning trolley against the charging station. This will

activate the alignment laser.

NOTE: Make sure the laser line is centered on the white dash mark at the end of the scanning trolley. If

the laser is not centered, you will need to align the laser before scanning. Refer to the Laser Alignment

Procedure in the Appendix.

12

2. Place the edge of the press sheet at the white line (1) in front of the scanning trolley.

3. Manually align the color bar so that the laser line (2) runs down the center of the color bar to be

measured.

NOTE: After 30 seconds, the laser line will turn off if a measurement is not started. To reactivate the

laser use one of the following methods:

• move the trolley away from the charging station and then return it back to the charging

station

• turn on the laser using the icon in the eXact InkKeyControl software

• press the Operation button on the eXact-Scan system

• use the optional foot switch if that is part of your configuration

4. If required, locate paper stop/flat hold down magnets (3) at the top edge of the press sheet to help

with the alignment of additional sheets. Refer to the next page for additional paper stop alignment

option.

Page 15

eXact Auto- Scan System

White line (1)

Laser line (2)

Paper stops (3)

Flat hold down

magnet (4)

Flat hold down

magnet (4)

Handled paper stop

5. For systems that do not use a vacuum pump: Position the paper stop/flat hold down magnets (4)

over the sheet along the bottom edge of the track.

Handled Paper Stop Option: You can

also position the handled paper stops

(5) along the bottom edge of the sheet

for alignment if your system is located

on a metal table/console.

magnets (5)

Measuring a Color Bar

The following instructions describe the procedures required to measure a color bar.

Caution: Moving parts – please keep hands clear when the scanning trolley is in motion.

1. Make sure the press sheet is properly aligned as previously explained.

2. Open a job from the software application.

3. Select the Measure option in the software or press the Operation button on the eXact Auto-Scan

system to start the measurement. You can also press the optional Foot switch to start a

measurement.

IMPORTANT:

The first press of the Operation button or Foot switch will turn on the laser. If the laser is already on,

the next press of the Operation button or Foot switch will start a measurement.

Once the measurement has been initiated, the laser turns off, the vacuum pump activates (if the

optional vacuum pump is used) and the “green” light on the eXact Auto-Scan system changes to

13

Page 16

e X act Auto- S can Syste m

Operation button

“solid orange”, indicating a scan is in progress. After the color bar is scanned, measurement results

are reported to the computer monitor.

You can abort a measurement by pressing the Operation button or optional Foot switch when the

instrument is scanning the color bar.

Performing a Spot Color Measurement

The instrument can be used to measure ink colors and make spot check measurements as needed. The

target base of the instrument should rest flat and steady on the sample area.

The following instructions describe the procedures required to perform a spot measurement with the

eXact instrument.

1. Remove the eXact instrument from the scanning trolley.

2. Flip the target window 180° on the bottom of the eXact target base back to the spot measurement

position.

3. Position the target window over the sample to measure. The opening should be completely filled

with the sample color.

4. Press the instrument firmly to the target base. Measuring appears in the display.

5. Hold steady until “Complete!” is displayed. Measurement results are reported to the computer

monitor.

14

6. If the instrument is moved during measurement or is not held closed for the entire measurement,

no data will display on the computer monitor. Simply take another measurement if this occurs.

Page 17

7. When finished, flip the target window back to the scan position and reattach the instrument to the

scanning trolley.

Calibration

IMPORTANT: The calibration plaque is dramatically affected by smudge marks and dust, and must be

kept clean. It is recommended that the instrument is cleaned regularly. Refer to the cleaning procedure

in the Appendix.

1. When prompted for a calibration, remove the eXact instrument from the scanning trolley if

required.

2. Open the instrument (not locked) and tap the START button on the eXact screen. The instrument

will display a countdown screen and then perform the calibration.

eXact Auto- Scan System

15

Page 18

e X act Auto- S can Syste m

Reset button location

Appendices

Service Information

The eXact Auto-Scan is covered by a one-year limited warranty and should be referred to an authorized

service center for repairs within the warranty period.

X-Rite provides repair service to their customers. Because of the complexity of the circuitry, all repairs

should be referred to an authorized service center.

X-Rite will repair any instrument past warranty. The customer shall pay shipping and repair cost to the

authorized service center. The instrument shall be submitted in the original carton, as a complete

unaltered unit along with all the supplied accessories.

Troubleshooting

Prior to contacting X-Rite’s Customer Service for instrument problems, try the applicable solution(s)

described below. If the condition persists, contact X-Rite Customer Service by phone at 1-888-826-3059;

by fax at 1-888-826-3061; or by email at gisupport@xrite.com. Additional X-Rite office numbers are

located on the back cover of this manual. You can also visit X-Rite’s Support page at www.xrite.com;

here you can find answers to common help desk questions.

Scanning instrument indicator not illuminating:

Ensure that the power supply is plugged in.

Reset the instrument (see eXact Auto-Scan Reset).

Scanning instrument and software not communicating:

Check the USB cable for proper connection.

Close the software application, cycle power on the instrument and restart the software application. If

this does not work reboot the computer.

Reset the instrument (see eXact Auto-Scan Reset).

eXact Auto-Scan Reset

16

The following procedure performs a hardware reset

on the eXact Auto-Scan system.

1. Make sure the system is powered on.

2. Using a small screwdriver or paperclip, press in

the reset button. The reset button is located in

the hole to the left of the power supply cable.

3. The indicator light will change to orange and

then back to green. Release the reset button

when indicator light is back to green.

Page 19

Cleaning the System

(1)

(2)

Your system requires very little preventative maintenance to achieve years of reliable operation.

However, to protect your investment and maintain reading accuracy, a few simple-cleaning procedures

should be performed from time to time.

ATTENTION: A properly grounded wrist strap is recommended when cleaning, removing or installing the

scanning head.

Make sure AC power is disconnected from the system before performing any instrument cleaning

procedure.

General eXact Auto-Scan Cleaning

The system covers may be wiped clean with a cloth dampened in water or mild cleaner.

DO NOT spray water or cleaning solution directly on the end covers or scanning track.

DO NOT use any solvents or harsh cleaners of any kind.

The track should be wiped clean with a lint-free cloth dampened in glass cleaner weekly or more often if

needed. When cleaning the track, make sure to clean the entire track. This includes the portion of the

track that resides under the eXact instrument trolley when it is in its docked position. You can slide it

over when cleaning is required.

eXact Auto- Scan System

System Contacts Cleaning

1. Remove the eXact instrument from the scanning trolley and power it off.

2. Turn the eXact instrument over and wipe the contacts on the charging adapter (1) weekly with a

cotton cloth dampened (not wet) in isopropyl alcohol.

3. Make sure power is disconnected from the eXact Auto-Scan system.

4. Wipe the contacts on the eXact charging station (2) weekly with a cotton cloth dampened (not wet)

in isopropyl alcohol.

17

Page 20

e X act Auto- S can Syste m

(1)

(2)

(1)

(2)

General eXact Cleaning

The exterior of the instrument and touch display should only be wiped clean with a cotton cloth

dampened (not wet) in water or isopropyl alcohol.

Cleaning the eXact Optics

The optics should be cleaned once a week in a normal environment. If the instrument is used in a dirty

or dusty environment, more frequent cleaning may be required.

1. Remove the instrument from the scanning trolley.

2. Rotate the reference holder (1) towards the back and hold.

3. Blow short bursts of clean, dry air (2) into the measurement port. This should remove any

accumulated debris from the optics.

4. Carefully return the calibration holder to its normal position.

IMPORTANT: If can air is used for cleaning, do not invert or tilt the can during use. This could cause

damage to the optics.

Cleaning the eXact Calibration Plaque

The calibration plaque should be cleaned periodically.

Do not use solvents or cleaners of any kind.

The calibration tile is embedded in the underside of the reference holder.

1. Remove the eXact instrument from the scanning trolley and open the target base.

2. Rotate the reference holder (1) towards the back and hold.

3. Blow short bursts of clean, dry air (2) onto the calibration tile. This should remove any accumulated

debris.

4. Carefully return the calibration holder to its normal position.

18

Page 21

Laser Alignment Procedure

The laser will require alignment if the laser line is not centered on the white dash mark at the end of the

scanning trolley. Follow the steps below for the proper alignment procedure.

1. Make sure the instrument and scanning trolley are pushed up against the charging station to

activate the laser line.

2. View the location of the laser line at the front of the scanning trolley.

Laser line not properly aligned

Incorrect back alignment Incorrect front alignment

eXact Auto- Scan System

3. If the laser line is to the back of the white dash mark, rotate the alignment wheel adjustment

upward to center the laser line on the white dash mark.

If the laser line is to the front of the white dash mark, rotate the alignment wheel adjustment

downward to center the laser line on the white dash mark.

Laser line adjustment wheel Laser line properly aligned

19

Page 22

e X act Auto- S can Syste m

Measurement System

Spectral Analyzer

DRS spectral engine

Spectral Range

400 nm – 700 nm with 10 nm interval

Measurement Geometry

45°/0° ring illumination optics, ISO 5-4:2009(E)

Light Source

Gas filled tungsten (illuminant type A) and UV LED

Measurement Conditions

M0, M1 (method 1 and method 2), M2, M3* (all according

*M3 option not available for Xp models

Calibration

On integrated white reference

Inter-instrument agreement

Average: 0.25 ∆E*ab, Max: 0.45 ΔE*ab (M3 0.55 ΔE*ab)

ceramic reference (D50, 2°))

Short term repeatability - White

0.05 ∆E*ab, (standard deviation) White BCRA

5 seconds)

Short term repeatability - Density

+/-0.01 D for CMYK measurements

Data Interface

Bluetooth

Scan System

Track Lengths

29”/74 cm, 40”/102 cm

Min. Patch Size (Strip Height)

3.0 mm (with 1.5 mm aperture)

4.0 mm (with 2 mm aperture)

Scan Speed

1.5 mm aperture on 4 mm patches: >= 160 mm (7”)/sec.

Data Port

USB, Ethernet

eXact InkKeyControl

Software

Colors

Up to 16 colors

Print Standard Support

G7, PSO, Japan Color ISO 12647-2

Density Functions

Density, TVI (incl. SCTV), Trapping, Contrast, Gray Balance

Colorimetric Functions

CIE L*a*b*, CIE L*C*h°

dE methods

dE*76, dE*94, dE*00

Special Functions

BestMatch

Density White Base

Absolute, Paper

Pantone Color Libraries

Included

PantoneLIVE Support

Optional

Environmental

Operating Temp:

+10° (50°F) to +35°C (95°F)

Humidity Range:

0 - 85% RH non-condensing

Storage Temp:

-20°C to +50°C

Usage:

Indoor only

Altitude:

2000m

Pollution Degree:

2 Overvoltage:

Category II

Power Supply:

X-Rite P/N SE30-277, 100-240VAC 50/60Hz, 12VDC @ 2.5A

Vacuum Pump:

X-Rite P/N: SD07-07, 115/230 VAC 60/50 HZ 3.6/1.8 AMPS

Design and specifications subject to change without notice.

eXact Auto-Scan Specifications

to ISO 13655:2009)

(Measurements using X-Rite manufacturing standards at a

temperature of 23°C +/- 1°C, 40-60% RH for all

measurement modes on 12 BCRA color tiles and a white

(Error compared to mean value of 10 measurements every

20

Page 23

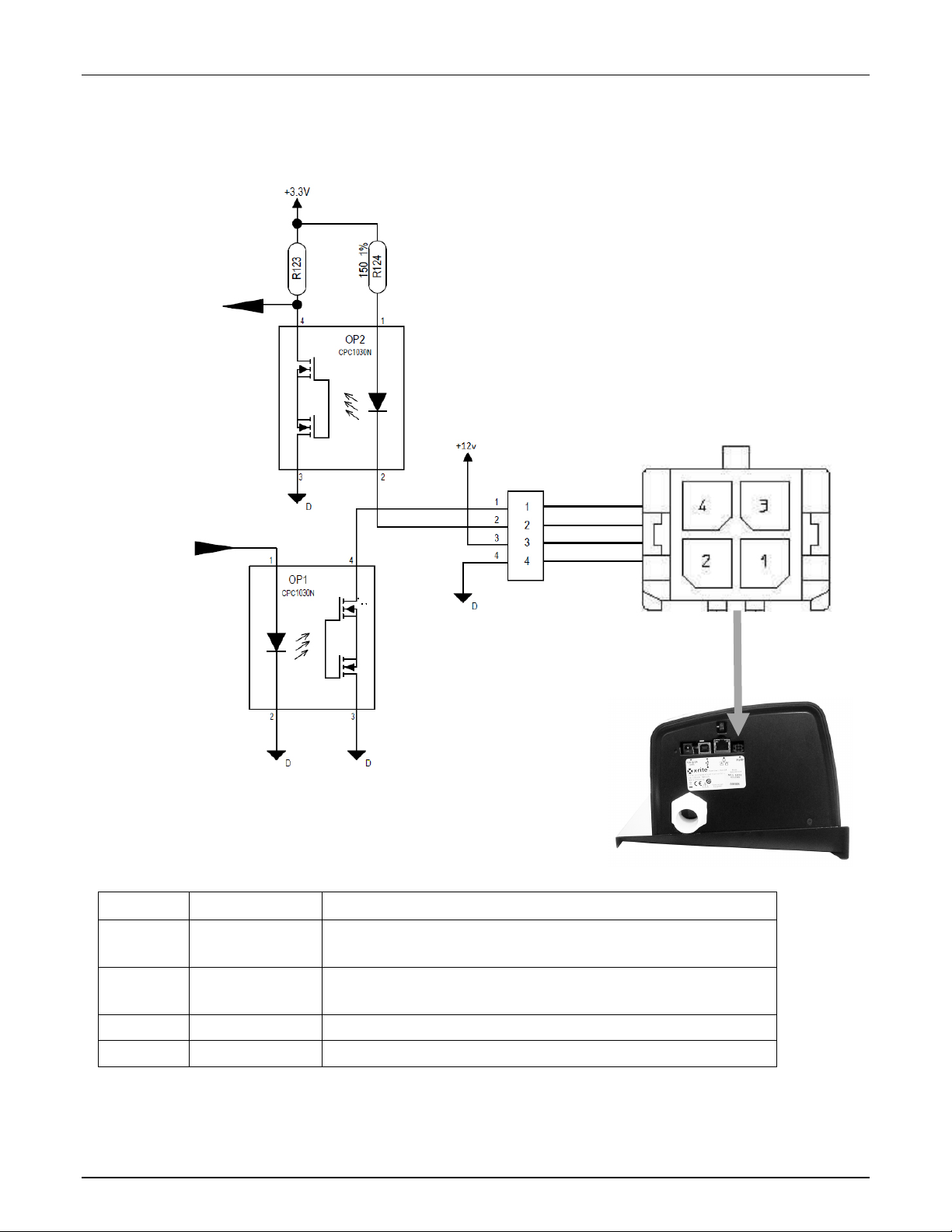

eXact Auto-Scan Vacuum/Foot Switch Interface Wiring

Pin

Name

Description

1

Output

External Control Line: provides up to 120mA current sink

2

Input

External Trigger Line: turns on laser when pulled to ground, if

3

+12v

Provides +12 VDC, up to 500mA (not fused).

4

GND

DC Ground

INPUT

OUTPUT

The CPC1030 has a maximum

eXact Auto- Scan System

current of 120mA.

during measurement sequence.

laser is already on a measurement will begin.

21

Page 24

Corporate Headquarters

X-Rite, Incorporated

4300 44th Street SE

Grand Rapids, Michigan 49512

Phone 1 800 248 9748 or 1 616 803 2100

Fax 1 800 292 4437 or 1 616 803 2705

European Headquarters

X-Rite Europe GmbH

Althardstrasse 70

8105 Regensdorf

Switzerland

Phone (+41) 44 842 24 00

Fax (+41) 44 842 22 22

Asia Pacific Headquarters

X-Rite Asia Pacific Limited

Suite 2801, 28th Floor, AXA Tower

Landmark East, 100 How Ming Street

Kwun Tong, Kowloon, Hong Kong

Phone (852) 2568 6283

Fax (852) 2885 8610

Please visit www.xrite.com

for a local office near you.

P/N EASEN-500 Rev. B

Loading...

Loading...