Page 1

ATD

AUTO-TRACKING DENSITOMETER

Scanning Instrument Manual

(covers ATD Sheet and ATD News Systems)

Page 2

Page 3

I N T R O D U C T I O N

User Information

FCC

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

NOTE: Shielded interface cables must be used in order to maintain compliance with

the desired FCC and European emission requirements.

Canada

This Class A digital apparatus meets all requirements of the Canadian InterferenceCausing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement

sur le matériel brouilleur du Canada.

AVERTISSEMENT : Des câbles d'interface blindés doivent être utilisés afin de se

conformer aux règlements européens et FCC (USA)sur l'émission

Keep Cal Plaques Clean At All Times.

Kalibrierstandard stets sauber halten!

Siempre mantenga la placa de calibración limpia.

Tenir le plaque de calibration propre tout le temps.

Sempre mantenga la placca della calibrazione pulita.

Do Not Oil Moving Parts.

Bewegliche Teile nicht ölen!

No lubrifique las peizas en movimiento

Ne pas lubrifier les pièces en mouvement

Non lubrificare le parti mobili.

i

Page 4

CAUTION: Use only the 24v Adapter (P/N ATS40-109) to supply power to the

Docking Station.

VORSICHT: Benutzen Sie nur den X-Rite- 24V-AC-Adapter (P/N SE30-75) als

Stromanschluß zur Kopplerstation.

ADVERTENCIA: Use solamente el Adaptador de 24v (pieza Nº ATS40-109) para

suministrar la energía al mecanismo de conexión.

AVERTISSEMENT: Utiliser seulement l’adaptateur de 24v (P/N ATS40-109) pour

fournir l’alimentation au mécanisme de connexion.

AVVERTIMENTO: Usare solamente l’adattatore di 24v (parte n. ATS40-109) per

fornire l’alimentazione al meccanismo del collegamento.

The Manufacturer: X-Rite, Incorporated

Der Hersteller: 4300 44th Street, S.E.

El fabricante: Grand Rapids, Michigan 49512

Le fabricant:

Il fabbricante:

Declares that: Auto Tracking Densitometer

gibt bekannt: ATD

advierte que:

avertit que:

avverte che:

is not intended to be connected to a public telecommunications network.

an ein öffentliches Telekommunikations-Netzwerk nicht angeschlossen werden soll.

no debe ser conectado a redes de telecomunicaciones públicas.

ne doit pas être relié à un réseau de télécommunication publique.

non deve essere connettuto a reti di telecomunicazioni pubblici.

ii

CE DECLARATION

Manufacturer's Name: X-Rite, Incorporated

Manufacturer's Address: 4300 44

Grand Rapids, Michigan 49512 U.S.A.

Model Name: Auto Tracking Densitometer

Model No.: ATD

Directive(s) Conformance: EMC 89/336/EEC LVD 73/23/EEC

WEEE

As of August 13, 2005, X-Rite products meet the European Union – Waste

Electrical and Electronic Equipment (WEEE) directive. Please refer to

www.xrite.com

WEEE directive.

for more information on X-Rite’s compliance with the

th

Street, S.E.

Page 5

PROPRIETARY NOTICE

The information contained in this manual is derived from patent and

proprietary data of X-Rite, Incorporated. This manual has been prepared

solely for the purpose of assisting in the use and general maintenance of

this instrument.

Any reproduction in whole or part is strictly prohibited. Publication of this

information does not imply any rights to reproduce or use this manual for

purposes other than installing, operating, or maintaining this instrument. No

part of this manual may be reproduced, transcribed, transmitted, stored in a

retrieval system, or translated into any language or computer language, in

any form or by any means, electronic, magnetic, mechanical, optical,

manual, or otherwise, without the prior written permission of an officer of

X-Rite, Incorporated.

This instrument may be covered by one or more patents. Refer to the

instrument for actual patent numbers.

Copyright © 2007 by X-Rite, Incorporated

“ALL RIGHTS RESERVED”

I N T R O D U C T I O N

X-Rite® is a registered trademark of X-Rite, Incorporated

All other logos, product names, and trademarks mentioned are the property of their respective holders.

iii

Page 6

LIMITED WARRANTY

X-Rite, Incorporated (“X-Rite”) warrants each instrument manufactured to

be free of defects in material and workmanship (excluding battery pack) for

a period of 36 months. This warranty shall be fulfilled by the repair or

replacement, at the option of X-Rite, of any part or parts, free of charge

including labor, F.O.B. its factory or authorized service center.

This warranty shall be voided by any repair, alteration, or modification, by

persons other than employees of X-Rite, or those expressly authorized by

X-Rite to perform repairs, and by any abuse, misuse, or neglect of the

product, or by use not in accordance with X-Rite’s published instructions.

X-Rite reserves the right to make changes in design and /or improvements

to its products without any obligation to include these changes in any

products previously manufactured. Correction of defects by repair or

replacement shall constitute fulfillment of all warranty obligations on the

part of X-Rite.

THIS WARRANTY IS EXPLICITLY IN LIEU OF ANY OTHER

EXPRESSED OR IMPLIED WARRANTIES, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR PURPOSE. THIS WARRANTY OBLIGATION IS

LIMITED TO REPAIR OR REPLACEMENT OF THE UNIT

RETURNED TO X-RITE OR AN AUTHORIZED SERVICE CENTER

FOR THAT PURPOSE.

This agreement shall be interpreted in accordance with the laws of the State

of Michigan and jurisdiction and venue shall lie with the courts of

Michigan as selected by X-Rite, Incorporated.

iv

Always include serial number in any correspondence concerning the unit.

Serial numbers are located on the bottom of the scanning head and right end

plate of the track.

Page 7

INSTRUMENT TRACEABILITY

The spectral reflectance values for the supplied white reference are

traceable to the National Institute of Standards and Technology through the

RIT Munsell Color Laboratory. The RIT Laboratory maintains standards to

which NIST assigned values. These standards were used in assigning values

to X-Rite’s two primary standard white porcelain on steel plaques.

A calibration report (MCSL-18) issued by Munsell Color Science

Laboratory contains measurement methods, measurement values, and

verifies the ceramic plaques’ NIST traceability path. These two plaques are

used to generate the supplied white reference.

ABOUT THIS MANUAL

This document covers the installation, operation, calibration and general

maintenance of your instrument. Refer to your software documentation and

on-line help for complete software installation and operation instructio ns.

This manual is organized into four sections and two appendices. In order to

make the best use of your system, it is recommended that you read all

sections and appendices.

I N T R O D U C T I O N

v

Page 8

I N T R O D U C T I O N

Table of Contents

SECTION ONE—Installing the System

Unpacking and Inspection..........................................................1-1

Packaging Drawing and Parts List.......................................1-1

System Description..................................................................... 1-2

Track and Docking Station................................................... 1-3

Scanning Head .................................................................... 1-4

Vacuum Pump......................................................................1-4

Reattaching the Scanning Head................................................. 1-5

System Connections...................................................................1-6

Vacuum Pump Connections ................................................1-6

RS-232 Interface Connection .............................................. 1-8

Connecting Power................................................................ 1-9

SECTION TWO—Operating the System

Calibrating the Scanning Instrument.......................................... 2-2

Sheet Loading and Alignment.................................................... 2-3

Standard Track Positioning.................................................. 2-3

Feed-Through Track Positioning ......................................... 2-4

Taking a Measurement with the ATD Sheet Instrument ............2-5

Taking a Measurement with the ATD News Instrument............. 2-6

vi

SECTION THREE—General Maintenance

Repair Information...................................................................... 3-1

Overview..................................................................................... 3-1

Scanning Head........................................................................... 3-1

Cleaning............................................................................... 3-2

Maintenance......................................................................... 3-3

Scanning Track........................................................................... 3-3

Cleaning............................................................................... 3-3

Maintenance......................................................................... 3-3

Cleaning the Scanning Instrument Calibration Disks................. 3-4

SECTION FOUR—Troubleshooting Tips .................4-1

APPENDIX A—Technical Specifications................A-1

APPENDIX B—Parts List and

Packaging Drawing

.........................................................B-1

Page 9

S E C T I O N O N E

Installing the System

This section covers unpacking, inspection, and installation of your system.

System description and vocabulary illustrations are also included. You

should read through this entire section to familiarize yourself with your

instrument.

Section Contents

• Unpacking and Inspection................ 1-1

• System Description.......................... 1-2

• Reattaching the Scanning Head...... 1-5

• System Connections........................ 1-6

UNPACKING AND INSPECTION

The main system components are packaged separately:

• Track/Docking Station, Scanning Head, Cabling, Software,

Documentation, and Accessories

• Vacuum Pump

After removing the components from each shipping carton, inspect them for

damage. If any damage has occurred during shipping, immediately contact

the transportation company that shipped them. Do not proceed with

installation until the carrier’s agent has inspected the damage.

Your components were packaged in specially-designed cartons to help

prevent damage. If reshipment is necessary, the components should be

packaged in the original carton. If the original carton is not available,

contact X-Rite to have replacements shipped to you.

Packaging Drawings and Parts Lists

Check your package contents against your packing list and original order. A

detailed packaging drawing and parts list is included in this manual as

Appendix B.

1-1

Page 10

S E C T I O N O N E

SYSTEM DESCRIPTION

The ATD Sheet instrument provides density measurements while

automatically locates and center itself on a color bar that is within 38mm of

the paper’s edge.

The ATD News instrument scans news print gray balance rules or

continuous color mastheads that are manually aligned to the track LED’s.

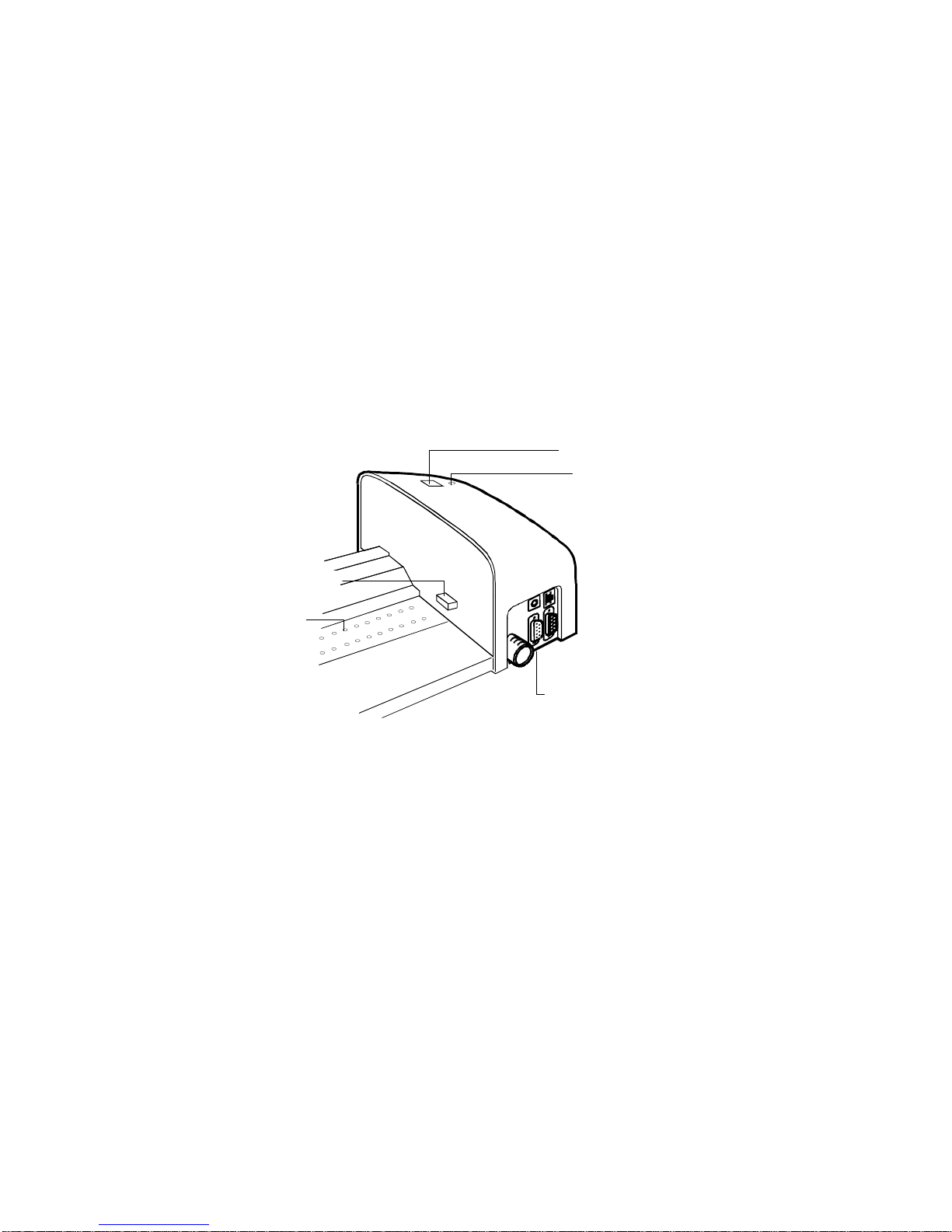

Docking Station

Indicator Lamp

Operation Button

Scanning Head

Scanning Track

1-2

Page 11

I N S T A L L I N G T H E S Y S T E M

Track and Docking Station

The press sheet or news paper is held securely to the track with a series of

vacuum holes while the Scanning Head measures. The Operation button is

used to activate a measurement sequence.

The indicator light on the Docking Station illuminates three separate colo rs

for varies mode conditions:

• Solid Green Light—indicates that the scanning head is docked and

ready for use.

• Solid Yellow Light— indicates that the scanning head is away from

the docking station.

• Solid Red Light— indicates that an error or problem exists with the

system.

• Flashing Yellow Light—indicates unit powered up to take reading.

• Flashing Red Light—indicates there is a problem and unit needs

service.

• Flashing Yellow & Green—indicates system needs to be reset.

Pressing and holding Operation button for 5-seconds performs reset.

Operation Button

Indicator Lamp

Scanning Head Contact

Vacuum Holes

System Connections

1-3

Page 12

S E C T I O N O N E

V

Scanning Head

The ATD Sheet scanning head scans a color bar at a rate of 100mm a

second using a 4.5mm color patch size.

The ATD News scanning head scans a gray balance rule or continuous

color bar at a rate of 8in./sec. The head take approximately five

measurements per inch and averages all the reading across the user-defined

zone.

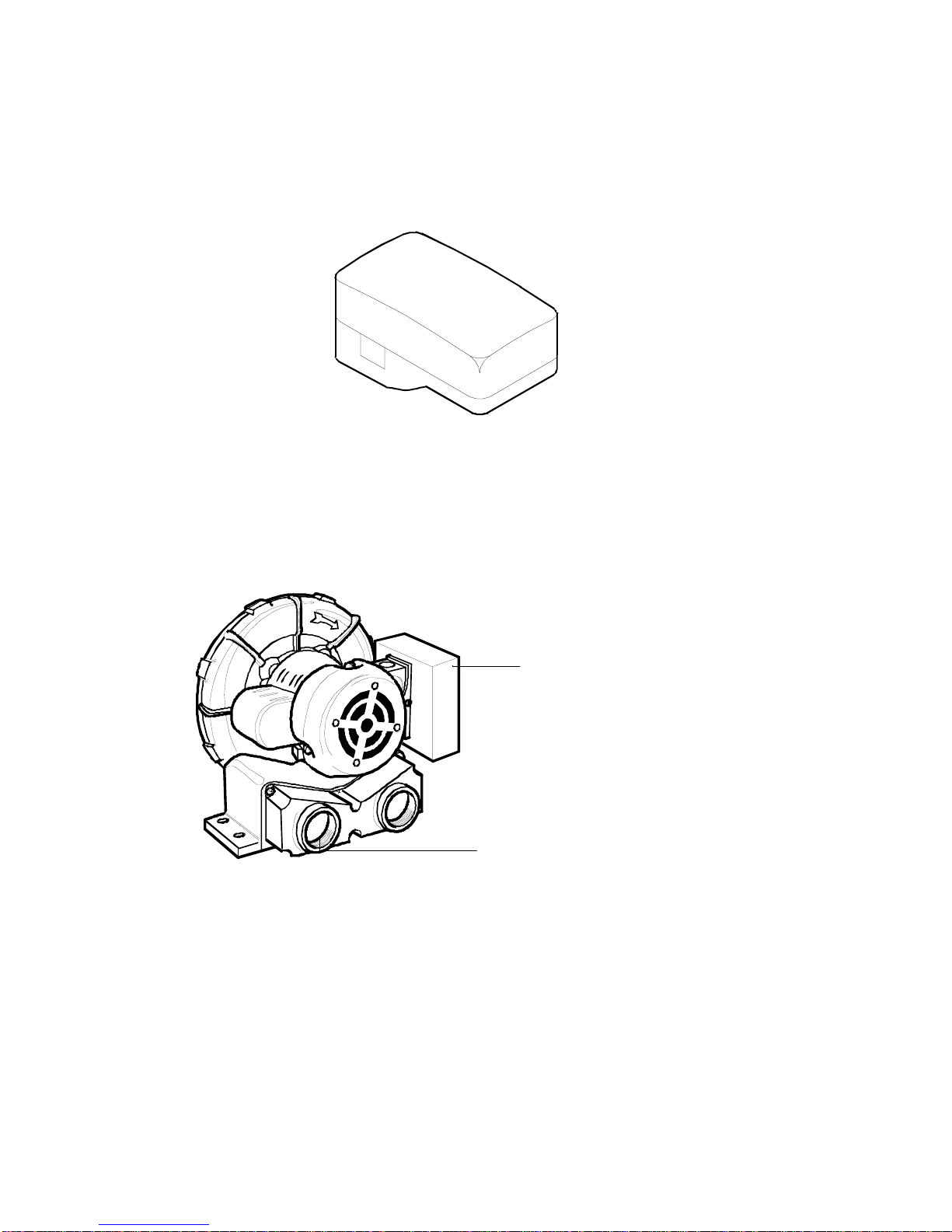

Vacuum Pump

A series of small holes located in the surface of the Track are used to hold

the press sheet in place during a measurement. This is accomplished by the

use of a Vacuum Pump. The Vacuum Pump is connected to the Docking

Station allowing automatic activation during a measurement cycle.

Interconnect Box

acuum Inlet Port

1-4

Page 13

I N S T A L L I N G T H E S Y S T E M

REATTACHING THE SCANNING HEAD

In the event that the scanning head is removed, follow the procedure below

to reattach it to the Trolley.

1. Position the Scanning Head Trolley approximately 12 inches from the

Docking Station. This is accomplished by sliding the Trolley away

from the Docking Station with your hand.

2. Position the Scanning Head over the Trolley and slide forward

allowing the Holding Disks to insert into the Scanning Head.

3. Align the Mounting Plate Thumbscrews with the Posts and Post Holes

in the Scanning Head.

4. Loosely secure the thumbscrews to the Scanning Head. Alternately

tighten until firmly seated.

NOTE: Scanning Head must be securely fastened to Trolley to allow

proper operation of instrument.

Scanning Head

Holding Disks

Head Connector

Docking Station

Thumbscrew

Posts

Post Hole

Trolley

1-5

Page 14

S E C T I O N O N E

V

SYSTEM CONNECTIONS

The System requires a few simple connections before operating. Connection

procedures for the individual components are covered on the following pages.

Back of Docking Station

Power Input

Vacuum Pump I/O Port

Computer I/O Port

Vacuum

Pump Hose

Connection

Vacuum Pump Connections

1. Push one end of Vacuum Hose onto the Barbed Adapter at back of the

Docking Station.

1-6

2. Push other end of Vacuum Hose onto the Barbed Adapter on Vacuum

Pump.

NOTE: To obtain up to 15% more vacuum from the pump, remove the

exhaust port barbed adapter.

Docking Station

N

I

acuum Hose

Exhaust Port

OUT

Page 15

I N S T A L L I N G T H E S Y S T E M

3. Make sure the Voltage Selection Switch—located below Line Cord

Receptacle—has been set to the proper line voltage for your region.

4. Connect one end of I/O Interface Cable to the Vacuum Pump I/O Port

on the Docking Station.

5. Connect other end of I/O Interface Cable to an I/O Port on the Vacuum

Pump Connect Box (either port can be used).

6. Connect the Line Cord to the Vacuum Pump AC Cord Receptacle.

7. Plug Line Cord into AC wall receptacle.

NOTE: Vacuum Pump only operates during a measurement sequence.

Vacuum Pump I/O Port

I/O Interface Cable

I/O Port

Vacuum Pump

Connect Box

To AC Wall

Receptacle

Line Cord

Voltage Selection Switch

AC Cord Receptacle

1-7

Page 16

S E C T I O N O N E

RS-232 Interface Connection

1. Connect one end of the DB-9 Interface Cable to an available Serial

Port on back of your computer. Secure with thumbscrews.

2. Connect opposite end of DB-9 Interface Cable to Serial I/O Port on

back of Docking Station. Secure with Thumbscrews.

Serial I/O Port

Computer Serial

I/O Port

Thumbscrews

DB-9 Interface

Cable

Thumbscrews

1-8

Page 17

I N S T A L L I N G T H E S Y S T E M

Connecting Power

The system must be allowed to stabilize at room temperature before

plugging the adapter into an AC wall receptacle.

CAUTION: Use only the 24v Adapter (P/N ATS40-109) to supply

power to the Docking Station.

Power is applied to the Scanning System when the 24v Adapter is plugged

into an AC wall receptacle. The System does not have an ON/OFF switch.

NOTE: Scanning Head must be attached before power is applied.

1. Insert the adapter jack of the 24v Adapter into the Power Input on back

of Docking Station.

2. Insert the Detachable Line Cord into the socket on the 24v Adapter.

3. Plug the three-prong plug from the Line Cord into an AC Wall

Receptacle.

Detachable Line Cord

Power Input

24v Adapter Jack

24v Adapter

1-9

Page 18

S E C T I O N O N E

1-10

Page 19

S E C T I O N T W O

Operating the System

Now that you have made all the necessary connections (and loaded your

software) you are ready to operate your system. The heart of the Scanning

Instrument is the compact, scanning head. The ATD Sheet head moves along

the track at approximately 150mm/sec. The ATD News head moves along

the track at approximately 8in./sec. After a measurement, the scanning head

uploads the data to the computer via RS-232 communications.

This section covers instrument calibration, sheet loading and alignment, and

measurement procedures.

Refer to your software documentation or on-line help for information

regarding software operation.

Section Contents

• Calibrating the Scanning

Instrument........................................ 2-2

• Sheet Loading and Alignment.......... 2-3

• Taking a Measurement

with the ATD Sheet Instrument........ 2-5

• Taking a Measurement

with the ATD News Instrument ........ 2-6

2-1

Page 20

S E C T I O N T W O

CALIBRATING THE SCANNING INSTRUMENT

Calibrating the Scanning Instrument is virtually automatic, there is no

calibration reference to position. The Calibration References are a

permanent part of the Track assembly—located near the Docking Station.

The references are covered by a retractable cover when the Scanning Head

is away from the Docking Station, and exposed when the scanning head is

next to the docking station.

The Scanning Head automatically calibrates to the references when required

or when you request it.

Retractable Cover

2-2

NOTE: The calibration references should be cleaned periodically to

maintain calibration accuracy. Refer to Section Three, General Cleaning for

procedure.

Page 21

O P E R A T I N G T H E S Y S T E M

V

SHEET LOADING AND ALIGNMENT

Loading a press sheet or paper onto the Scanning Instrument is fast and

easy. There are no guides or clamps to adjust. The press sheet or paper is

loaded onto the track from the back over the plate that contains the vacuum

holes and LED’s (if a feed-through track). A vacuum is created once a

measurement sequence is started, holding the press sheet or paper in place.

The sheet or paper should be placed 90mm away from the docking station

or centered on the track, and at least 60mm away from the end of the track.

Standard Track Positioning

The press sheet must be positioned against the “sheet stops” that run along

the back edge of the vacuum plate. The color bar on the sheet cannot be

over 38mm from the paper’s edge.

In the event that a color bar is not properly aligned on a press sheet (this is

recognized during a job setup), the scanning system takes corrective action

by automatically adjusting the ATD scanning head. This ensures all color

patches are measured accurately even when a color bar is slightly skewed.

Press sheet should

Sheet Stops

not be positioned

directly under the

scan head.

A sheet alignment mark is located

in the center of the track.

acuum Holes

Color bar can be

38mm maximum

from paper edge

Press Sheet

Scanning

Track

2-3

Page 22

S E C T I O N T W O

V

Feed-Through Track Positioning

The feed-though track allows measurements at any location within the

paper. This is possible because the track has a slotted opening, allowing the

paper to be slide through the track.

The gray balance bar or color masthead bar is easily position on the track

using a series of LED’s that illuminate from the track through the paper.

The LED’s are located between the vacuum holes approximately every 5

inches along the track. Open the paper and position it so the LED’s are

shining down the center of the bar. The LED’s automatically shut off once

the scanning head starts in motion.

Bar position

acuum Holes

Newspaper

LED’s illuminate

through the

newspaper

2-4

Page 23

O P E R A T I N G T H E S Y S T E M

TAKING A MEASUREMENT WITH THE ATD SHEET

INSTRUMENT

After the press sheet is properly positioned on the track, you are ready to

perform a color bar recognition/measurement. The sequence is started in

one of two ways: by selecting the recognition/measurement function from

the Software, or by pressing the Operation button located on top of the

Docking Station.

Once a scan is set in motion, the vacuum pump activates and the “green”

light on the station changes to “yellow,” indicating a scan is in progress.

The scan head travels the entire length of the track before returning to the

docking station. If additional color bars are located on the opposite edge,

you will need to change sides. The software informs you when this is

required. Refer to your software documentation for additional information.

If a problem is encountered during a measurement, the scanning head

immediately returns to the docking station. View your computer monitor to

see if an error message is displayed. If no message is displayed, try to

rescan sheet; if a problem still occurs, refer to the Troubleshooting section

in this manual.

*Operation Button Activation

* Pressing the Operation Button

once during a scan aborts the scan

procedure. *Pressing and holding

the Operation button for five

seconds resets the System.

2-5

Page 24

S E C T I O N T W O

TAKING A MEASUREMENT WITH THE ATD NEWS

INSTRUMENT

After the newspaper is properly positioned on the track, you are ready to

perform a measurement. Press the Operation button located on top of the

Docking Station once to activate the vacuum pump. Then, press the button

again to start the measurement sequence.

Once a scan is set in motion, the “green” light on the station changes to

“yellow,” indicating a scan is in progress. The scan head travels the entire

length of the paper before returning to the docking station. Refer to your

software on-line help for specific information on the software operation.

If a problem is encountered during a measurement, the scanning head

immediately returns to the docking station. View your computer monitor to

see if an error message is displayed. If no message is displayed, try to

rescan the paper; if a problem still occurs, refer to the Troubleshooting

section in this manual.

*Operation Button

2-6

Page 25

S E C T I O N T H R E E

General Maintenance

This section will cover the maintenance procedures for the system.

Section Contents

• Repair Information ........................... 3-1

• Overview .......................................... 3-1

• Scanning Head ................................ 3-1

• Scanning Track................................ 3-3

• Cleaning the Calibration Disks......... 3-4

REPAIR INFORMATION

Your ATD System is covered by a three-year limited warranty and should

be referred to the factory for repairs within the warranty period. Attempts to

make repairs within this time frame may void the warranty.

X-Rite provides a factory repair service to their customers. Because of the

complexity of the circuitry, all repairs should be referred to the factory.

X-Rite will repair any ATD System past warranty. Shipping cost to the

factory shall be paid by the customer, and the instrument shall be submitted

in the original carton as a complete, unaltered unit.

OVERVIEW

The System requires little preventative maintenance to achieve years of reliable

operation. However, to protect your investment and maintain measurement

accuracy, a few simple cleaning procedures should be performed.

SCANNING HEAD

NOTE: DO NOT use any solvents or harsh cleaners of any kind.

NOTE: DO NOT move the trolley up and down the track manually without

the scanning head attached.

In the course of normal use, spray powder, paper dust, and other airborne

contaminants will likely enter the instrument's optics. This can eventually

reduce the sensitivity of the instrument and may lead to calibration errors.

Follow the steps below to clean the optical components.

3-1

Page 26

S E C T I O N T H R E E

Cleaning (1 to 2 times a month)

1. Obtain a source of clean, dry, compressed air. This air should be of the

2. Remove the scanning head from the track. To do this:

3. Being careful to hold the compressed air source upright, blow short,

quality used to clean delicate camera lenses.

- Disconnect power from the track.

- Gently slide the head away from the docking station.

- Loosen the two thumbscrews that lock the head to its trolley.

- Gently free the head from the trolley.

gentle bursts of compressed air directly into the instrument's aperture.

Be careful to ensure the compressed air nozzle is approximately 10mm

away from the optics.

3-2

4. Re-attach the scanning head to the trolley. To do this:

- Carefully align the head back onto the trolley. Take care to ensure

that the head is properly seated on the alignment pins.

- Tighten the thumbscrews that secure the head to the trolley. Gently

wiggle the head as you tighten the screws to ensure that the head is

fully seated.

- Slowly slide the head back into the docking station.

- Re-connect the power to the track.

Page 27

G E N E R A L M A I N T E N A N C E

5. Note that the process of cleaning the optics will affect the instrument's

sensitivity as dust and powder will no longer block the optical path. It is

essential that the head be fully calibrated following the cleaning process.

6. The exterior of the scanning head and docking station can be wiped

clean with a lint-free cloth dampened in water or a mild cleaner.

Maintenance

1. Replace the five (5) Read Head Pogos if they display any signs of

wear or discoloration.

2. On newer read heads, replace the Paper Stop Push Plate if anodize is

broke or worn through.

SCANNING TRACK

NOTE: DO NOT reverse the intake/exhaust port on the vacuum to blow

out the track vacuum chamber. This will force any dust inside the track into

the read head optics.

NOTE: DO NOT use any solvents or harsh cleaners of any kind.

NOTE: DO NOT use any type of lubrication (oil) on any part of the system.

Cleaning (1 to 2 time a month)

1. The exterior of the docking station can be wiped clean with a lint-free

cloth dampened in water or a mild cleaner.

2. The track can be wiped clean with a lint-free cloth dampened in glass

cleaner. When cleaning the track, make sure to clean the entire track.

This includes the portion of the track that resides under the reading

head when it is in its docked position. You can simply slide the head

over when cleaning is required.

3. Inside of track assembly – use compressed air to remove all print dust.

Maintenance

- Replace the following items at 500,000 scans.

- Trolley bearings and wheels

- Power cable

- End plate bearings (both ends)

- Nut on drive screw

- Station home sensor pogos

Usage Approximation

Usage Scans per day Year to reach 500,000

Heavy 300 4.5

Medium 150 9.0

Light 75 13.5

3-3

Page 28

S E C T I O N T H R E E

CLEANING THE SCANNING CALIBRATION DISKS

On a daily basis you may need to clean the Calibration Disks located in the

Track. This is a relatively easy procedure requiring only a few minutes of

time.

1. Carefully slide the Scanning Head away from the Docking Station.

2. Pull Calibration Cover towards the Docking Station to expose the

3. Clean Disks with a cotton swab or lint-free cloth.

4. Blow off Disks with compressed air.

5. Blow out under the Calibration Cover with compressed air.

4. Carefully release Calibration Cover and slide Scanning Head back

Calibration Cover

Disks.

against Docking Station.

Cotton Swab

3-4

Black Cal Disk

White Cal Disk

Docking Station

Scanning Head

Page 29

S E C T I O N F O U R

Troubleshooting Tips

The Software constantly scans the system looking for any type of problems

that may arise. When a problem is discovered, the Software displays an

error message on the computer monitor, pinpointing the problem area. A list

of “hardware” related error messages are listed below.

Error Messages and Reason/Solution

Error Messages Reason/Solution

Docking Failure

Lamp Burned Out

Lamp Intensity Low

Lamp Voltage High

Lamp Voltage Low

Motor Jammed

Motor Too Fast

Scanning Head not

at Docking Station

Measurement was initiated—scanning

head returned and docked—but the data

was not transmitted from the scanning

head. Check for loose cabling.

Scanning head needs service. Contact

X-Rite, Incorporated.

Measurement was initiated but the

scanning head was not at the docking

station. Slide head against docking

station.

4-1

Page 30

S E C T I O N F O U R

Other problems that may occur and not be detected by Software are as

follows.

Problems and Reason/Solution

Problems

Reason/Solution

Scanning head will not

activate when the

Software performs a

measurement cycle.

Measurements

incorrect or not

repeatable.

Check to see if Software displayed any

error message.

Check for proper connection of interface

cables and adapters between computer

and Scanning System.

Scanning System needs calibration.

Scanning head need service. Contract

X-Rite, Incorporated.

4-2

Page 31

A P P E N D I X A

Technical Specifications

ATD SHEET INSTRUMENT

Measurement Geometry 45°/0° per ANSI PH2.17

Light Source Gas Pressure @ 2850°K

Color Response Status T or Status E

Density Range 0 - 2.5D

Repeatability on White ±0.01 Density max.

Density Reproducibility ±0.02 Density @ 1.5 Density

Calibration Automatic

Patch Width

Patch Height Large Spot - 5.0mm min.

Medium Spot - 3.2mm min.

Small Spot - 1.6mm min.

Paper Thickness 1.5mm max.

Scanning Rate 150mm/sec. (6.8 mm patch)

Color Bar Location Paper Edge to 38mm from edge.

Color Bar Alignment Automatic centering of measurement on

color bar. Paper set against stop.

Color Bar Quantity Multiple Rows

Paper Hold Down Vacuum activated with measurement

command.

Power Required Station

Specifications and design subject to change without notice.

(along scan path) 3.8mm min.

110/240 VAC, 50-60Hz, 4/2A

Pump

115/230 VAC, 50-60Hz, 4/2A

A-1

Page 32

A P P E N D I X A

ATD NEWS INSTRUMENT

Measurement Geometry 45°/0° per ANSI PH2.17

Light Source Gas Pressure @ 2850°K

Color Response Status T or Status E

Density Range 0 - 2.5D

Repeatability on White ±0.01 Density max.

Density Reproducibility ±0.02 Density @ 1.5 Density

Calibration Automatic

Scan Spot Size

(total scanned spot) 1.2mm (.0475in.) x 4.75mm (.187in.)

[5 scans averaged in a 1in. key (25.4mm)]

Paper Thickness .25mm (.01in.) max.

Scanning Rate 200mm/sec. (8in./sec.)

Gray Balance Bar Alignment Centering of gray balance bar on

integrated LED’s

Paper Hold Down Vacuum activated with measurement

command.

Power Required Station

110/240 VAC, 50-60Hz, 4/2A

Pump

115/230 VAC, 50-60Hz, 4/2A

Specifications and design subject to change without notice.

A-2

Page 33

Packaging Drawing

ATD SHEET INSTRUMENT PARTS LIST

A P P E N D I X B

Parts List and

B-1

Page 34

A P P E N D I X B

ATD SHEET PACKAGING DRAWING

B-2

Page 35

P A R T S L I S T A N D P A C K A G I N G D R A W I N G

ATD NEWS INSTRUMENT PARTS LIST

B-3

Page 36

A P P E N D I X B

ATD NEWS PACKAGING DRAWING

B-4

Page 37

Page 38

Corporate Headquarters - USA

4300 44th Street SE

Grand Rapids, Michigan 49512

Phone 1 800 248 9748 or 1 616 803 2100

Fax 1 800 292 4437 or 1 616 803 2705

Corporate Headquarters - Europe

Althardstrasse 70

8105 Regensdorf

Switzerland

Phone (+41) 44 842 24 00

Fax (+41) 44 842 22 22

Corporate Headquarters - Asia

Room 808-810

Kornhill Metro Tower, 1 Kornhill Road

Quarry Bay, Hong Kong

Phone (+852) 2 568 6283

Fax (+852) 2 885 8610

Please visit www.xrite.com

for a local office near you.

P/N ATD40-500 Rev. R

Loading...

Loading...