Page 1

X-Rite® 882

(An Addendum to the X-Rite 881 Operation Manual)

The X-Rite 882 was designed to meet the quality control needs of the professional

photofinisher processing E-6, as well as the other common processes.

The 882 is very much like the X-Rite 881, except that the 881 has only Status M for

transmission operation, and the 882 has Status A and M for transmission operation.

Transmission Status A is used for checking Positive transparencies (i.e., E-6 films) and

Status M for checking Negative transparencies (i.e., C41 negatives). The 881 Operation

Manual explains all of the functions and operation of the 882. However, there are a few

differences in operation and they are explained in this 882 addendum.

The 882 has the additional capability of:

•Measuring E-6 (Kodak & Fuji), Q-Lab, AP44, and P-5 film strips

•Measuring 2 different types of Internegatives

The additional film strips are selected and measured in the same manner as the other

film strips explained in the 881 Operation Manual. The procedure for selecting and

measuring internegative strips is explained in Section 1 of this addendum. Refer to

Section 2 for definition on the additional film strips and internegatives.

The following are registered trademarks: Kodak; Fuji; Agfa; Ilford

All products mentioned are trademarks of their respective companies.

P/N 882-500 Rev. F-07/16/93

Page 2

1. Measuring an Internegative

The 882 allows measurements of internegatives. It will optional compute the changes in exposure

and filter pack necessary to balance the internegative using the Density Difference method.

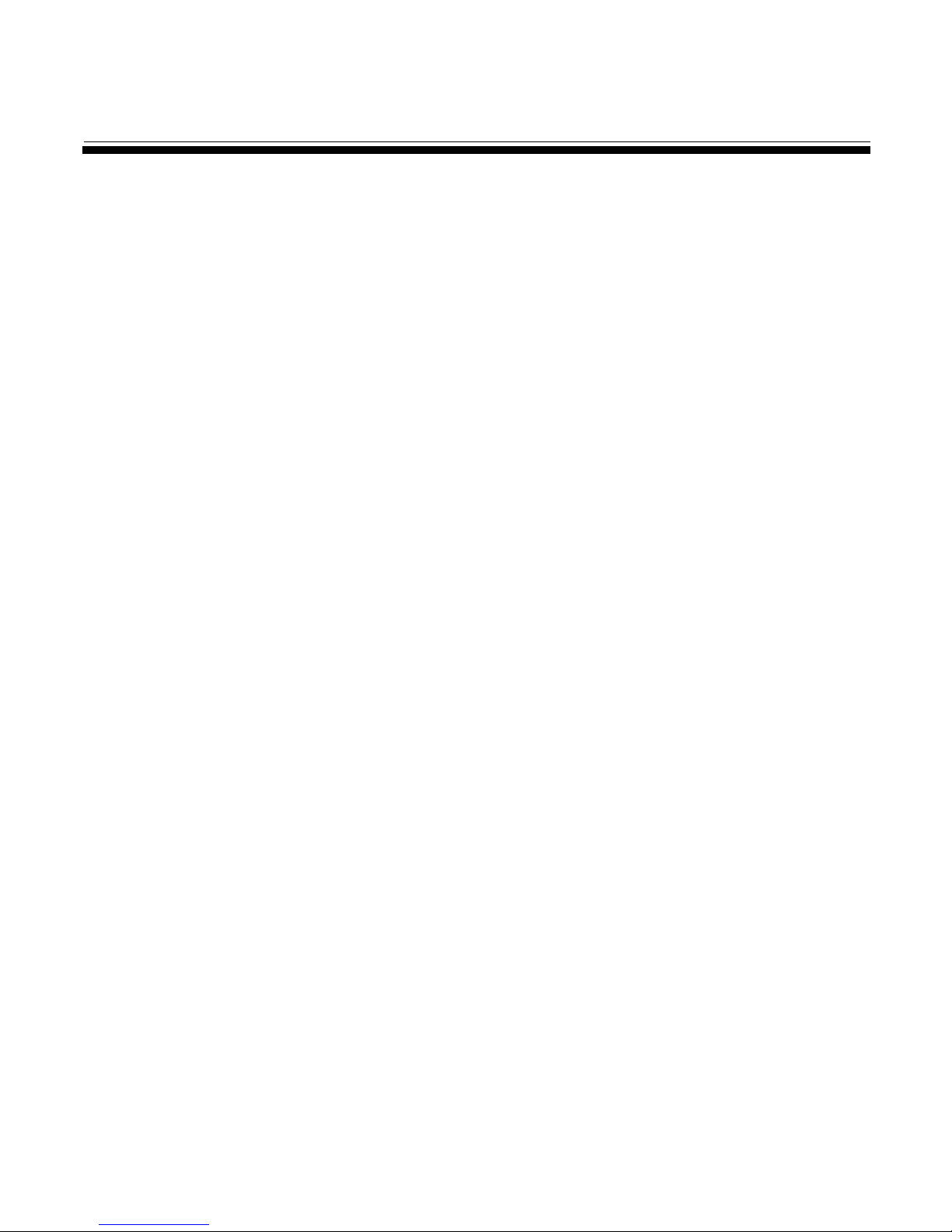

Step 1 - Press [film].

Step 2 - Press [other] until "Ineg Step 1" is

displayed.

Step 3 - Select the interneg type (see Section 2

for type definition).

Each depression of the [type] key will

alternate between "type 1" and "type 2"

(for this example "type 2" is selected).

Step 4 - Select interneg film type.

CHANNEL MENU

p1 pap film pbM

Process Type

READ

Typ 1 other

READ

Typ 2

Interneg

Selection

READ

Typ 2

Ineg Step 1

6011

Ineg Step 1

6011

Ineg Step 1

4114

other

Other

Film Strips

other

Press either center key to select the film

type. Select "6011" if you are using film

similar to Kodak 6011 or 4112 Interneg

film. Select "4114" if you are using film

similar to Kodak 4114.

Step 5 - Insert strip into the 35mm slot (step 1

inserted first) until it rests against the

drive rollers.

Film Type

Selection

35mm SLOT

30

20 3010

10

20

1

Page 3

Measuring an Internegative - continued

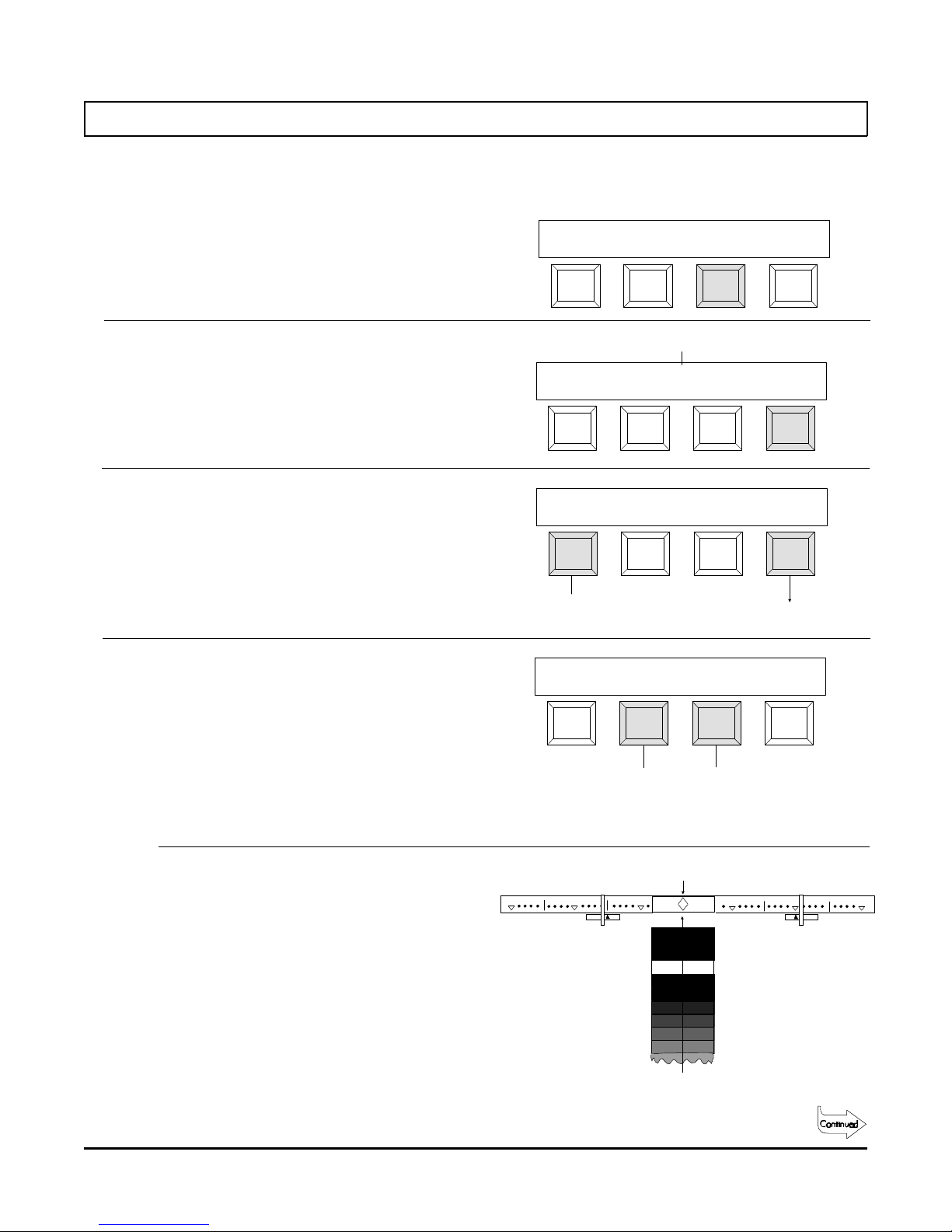

Step 6 - When the reading is completed, the

display will indicate which step pair will be

used on subsequent calculations.

•Pressing the [view] key allows viewing

of density difference numbers (refer to

Section 1.1).

•Pressing the [+Step-] key allows

viewing of the individual steps on the

strip (refer to Section 1.2)

•Pressing the [auto] key performs filter

pack and exposure calculations

automatically (refer to Section 1.3).

› If the strip is severely over exposed, the warning message

"STRIP TOO FAR OVEREXPOSED" will appear briefly. You will

then be allowed to view the individual steps using [+] or [-]

step keys, but will not be able to use the view and auto

functions. If this happens, reduce your exposure by three or

four stops and try another strip.

1.1 View (continued from Step 5 in Section 1)

STEP PAIR

view + step - auto

See Section 1.1 See Section 1.2 See Section 1.3

= 3, 13

The View function allows you to view the density difference values and recommended

filter pack changes. Density difference values are calculated by simply subtracting the

density values of the higher numbered step from the densities of the lower numbered

step. These are used to look up your filter pack changes from the table.

Step 6 - Press [∆fp] key to get the filter pack

changes from the internal table and

D = 0.62

0.75 0.80

fp exit

display them.

› These numbers are changes (indicated by the Greek letter

∆) and should be added to the filter pack which was used

for exposing this internegative.

Step 7 - Press [∆den] key to display the density

FP -03C

+05M +02Y

den exit

difference values again.

Step 8 - Press [exit] to return to the Step Pair

Menu so that further viewing or

calculations can be performed.

To Step Pair Menu

To Step Pair Menu

2

Page 4

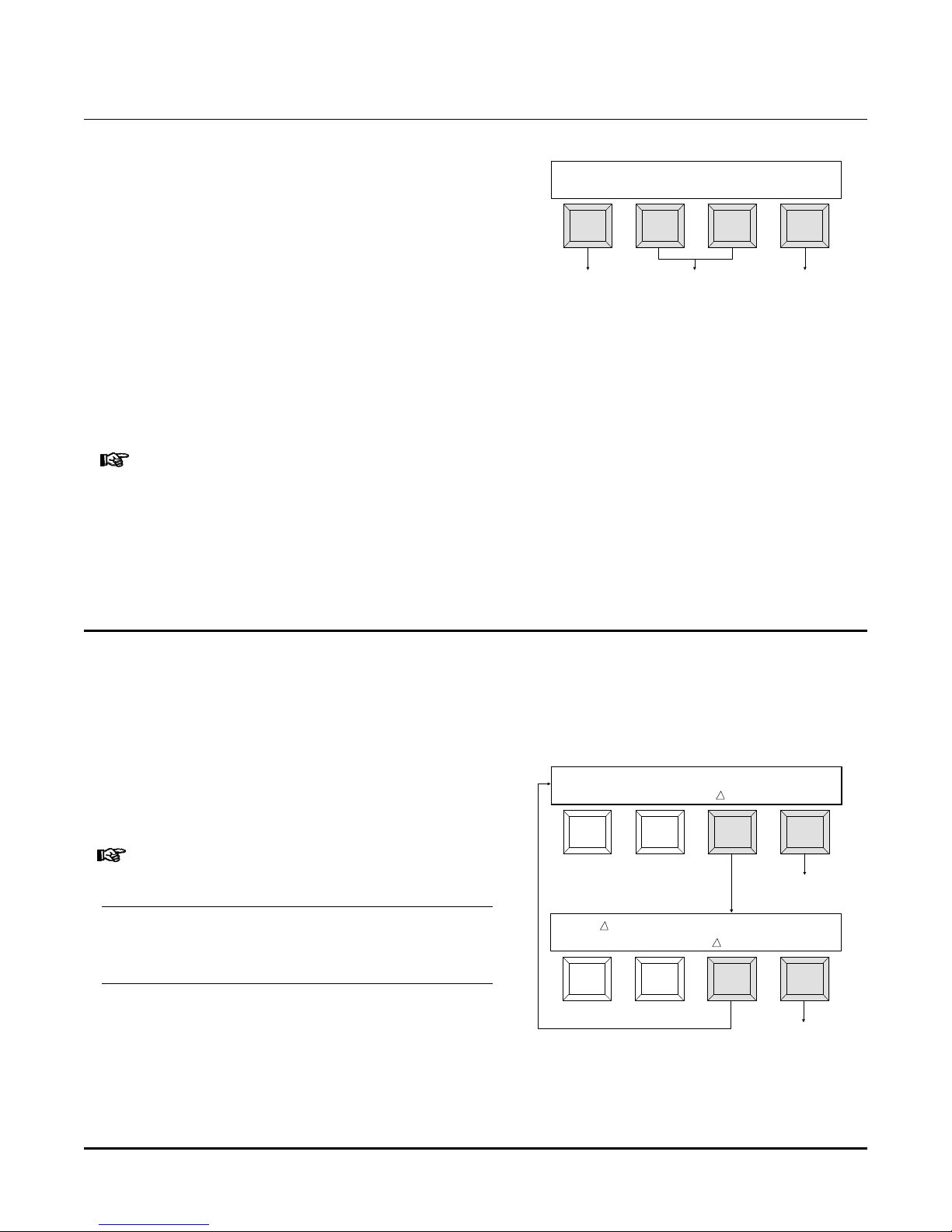

1.2 +Step- (continued from Step 5 in Section 1)

The +Step- function allows viewing of the individual steps on the strip.

Step 6 - Press either the [+] or [-] key to view

data on each step of the internegative.

•[+] increments to the next step (step 21 will

advance to step 1).

•[-] decrements to the next step (step 1 will

advance to step 21).

Step 7 - Press [exit] to return to the Step Pair

Menu so that further viewing or

calculations can be performed.

› For "Type 1" internegatives (4 x 5 format), all of the even

numbered steps are computed internally using a curve

fitting algorithm because the actual internegative contains

only the odd numbered steps.

1.3 Auto (continued from Step 5 Section 1)

0.20

0.47 0.83

+ step - exit#21

Next

Step

Previous

Step

To Step

Pair Menu

The Auto function initiates the automatic

exposure and filter pack compensation.

Step 6 - "Enter Starting Filter Pack..." is

momentarily displayed. Enter the values

of the filter pack used to make this

internegative.

•[↑] increases the value marked by cursor.

•[↓] decreases the value marked by cursor.

•[→] moves the cursor to the next position.

Press [cont] when finished.

Step 7 - "Enter Exposure" is momentarily

displayed. Enter your exposure time and

aperture.

› The "f" stop values increase or decrease in 1/6 stop steps

and values can range from f/4.0 to f/32.0.

•[↑] increases the value marked by cursor.

Moves

Cursor

Enter Starting

Filter Pack . . .

FP

EXP

00C

Enter Exposure

10 sec

30M 30Y

DecreasesIncreases

f/8.0

cont

To Next

Step

cont

•[↓] decreases the value marked by cursor.

•[→] moves the cursor to the next position.

Press [cont] when finished.

Moves

Cursor

DecreasesIncreases

To Next

Step

3

Page 5

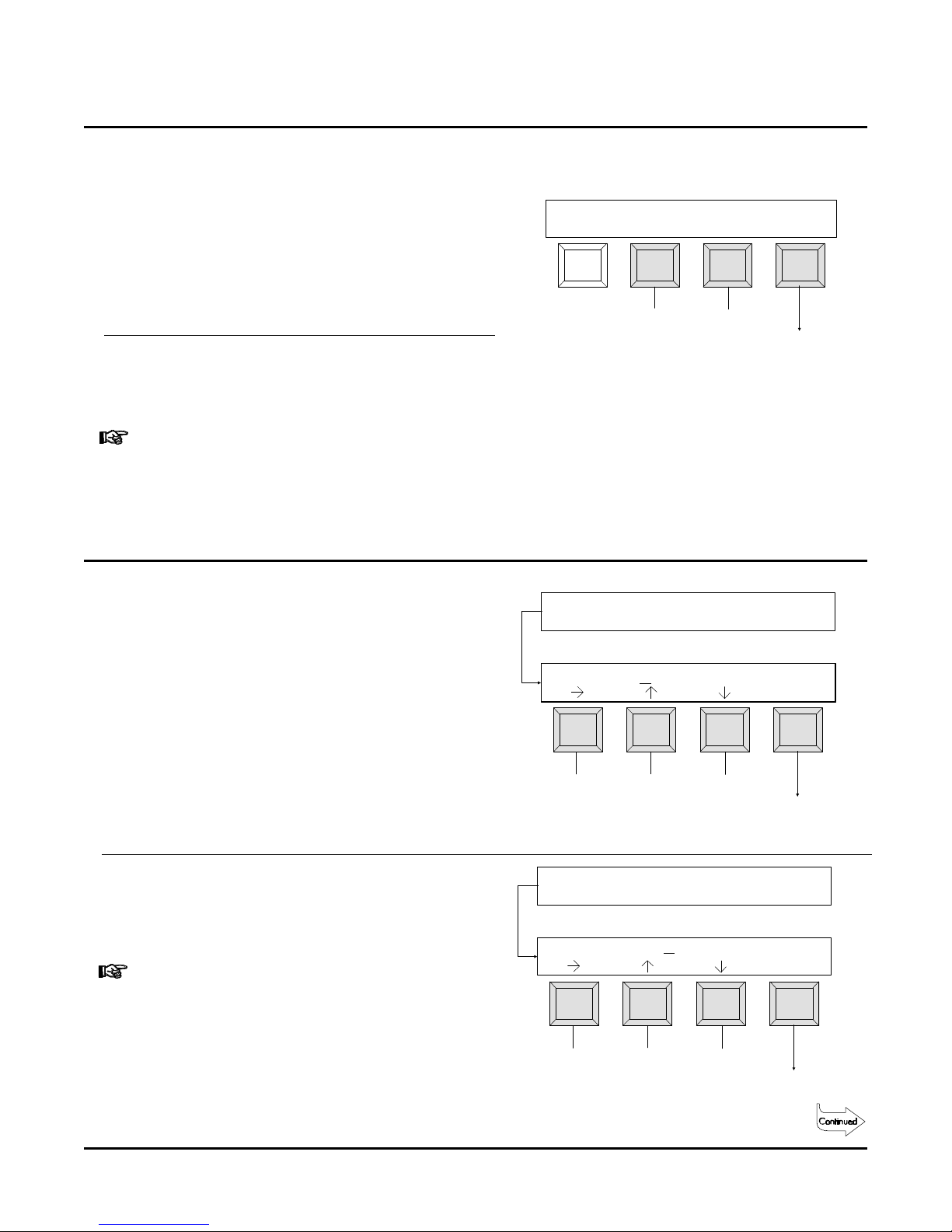

Auto - continued

Step 8 - The display now indicates suggested

changes to your filter pack.

› The numbers displayed are changes (indicated by "∆")

and should be added to the filter pack which was used to

expose this internegative.

Press [∆off] to turn the "change mode"

off and view "absolute" filter pack values.

Absolute values are the addition of your

starting filter pack (entered earlier) to

the changed values.

› These values are adjusted to remove any neutral density.

Therefore, one of these values (usually cyan) will always

be zero. These values constitute your new filter pack

which should be used for subsequent exposures.

Step 9 - Press [exp] to display the suggested

exposure.

› Any neutral density adjustments to the filter pack will

affect exposure as well. To avoid reciprocity problems,

exposure time is held within 1/2 stop of your starting

exposure time. This will sometimes cause an aperture

change if the calculated exposure time adjustment is

greater than 1/2 stop.

FP

-03C +05M +02Y

off

FP 00C 39M 36Y

on

FP 00C 39M 36Y

on

exp

read

readexp

readexp

Step 10 - Press the [read] key to measure another

internegative. The entire procedure

described is repeated except that the

exposure and filter pack values you have

just viewed will be used as the starting

values.

Step 11 - Press the two keys labeled "MENU" to

exit out of the interneg function.

› Since internegatives are a setup tool rather than a process

control tool, any internegatives read are not stored in

channel memory. Data that is currently stored in the

channel memory is not destroyed.

EXP 11 sec f/8.0

READ

Typ 2

Ineg Step 1

4114

Displays

Filter

Pack

readfp

MENU

4

Page 6

2. Film Strip Definition

2.1 Positive Film Strips

•E-6 (Kodak)

5-1/4" Strip

Format: k:E-6 Process: E-6 Densitometry: Transmission, Status A

Fields Measured Computed Values Transformation Rules Action Control Spread

Field #1 "D-min" D-min R1; G1; B1; ±.03 +.05 ---Field #2 "LoDen" SPEED R2; G2; B2; ±.08 ±.10 ---Field #3 "HiDen" COLOR R3; G3; B3; ±.12 ±.15 ---Field #4 "D-max" D-max R4; G4; B4; -- .20 -- .25 ----

NOTES:

1) Strips must have at least a 1-1/8" (28mm) leader before outside edge of first target, in order for first target to be detected (see Sec.2.1

in the Control Strip & Balance Print Format Guide).

2) -------------> Indicates strip pass direction.

3) Yel, Mag, and Cyn patches on the Kodak strip are not measured.

Limits

5

Page 7

Positive Film Strip - continued

•E-6 (Kodak) Used for Q-Lab

Format: q:E-6 Process: QLab Densitometry: Transmission, Status A

Fields Measured Computed Values Transformation Rules Action Control Spread

Field #1 "D-Min" D-Min R1; G1; B1; + .02 +.03 ---Field #2 "TD" TD R2; G2; B2; ±.03 ±.04 ---Field #3 "LD" LD R3; G3; B3; ±.04 ±.05 ---Field #4 "HD" HD R4; G4; B4; ±.06 ±.08 ---Field #5 "D-Max" D-Max R5; G5; B5; -- .10 -- .13 ---Field #6 LDSpr R3-G3; ; B3-G3; ---- ±.10 ----

NOTES:

1) Strips must have at least a 1-1/8" (28mm) leader before outside edge of first target, in order for first target to be detected (see Sec.2.1

in the Control Strip & Balance Print Format Guide).

2) -------------> Indicates strip pass direction.

Limits

•E-6 (Fuji)

Format: f:E-6 Process: E-6 Densitometry: Transmission, Status A

Fields Measured Computed Values Transformation Rules Action Control Spread

Field #1 "D-min" D-min R1; G1; B1; ±.03 +.05 ---Field #2 "LoDen" SPEED R2; G2; B2; ±.08 ±.10 ---Field #3 "HiDen" COLOR R3; G3; B3; ±.12 ±.15 ---Field #4 "D-max" D-max R4; G4; B4; -- .20 -- .25 ----

NOTES:

1) Strips must have at least a 1-1/8" (28mm) leader before outside edge of first target, in order for first target to be detected (see Sec.2.1

in the Control Strip & Balance Print Format Guide).

2) -------------> Indicates strip pass direction.

Limits

6

Page 8

Positive Film Strip - continued

•P-5 (Ilford)

Format: i:P-5 Process: P-5 Densitometry: Transmission, Status A

Fields Measured Computed Values Transformation Rules Action Control Spread

Field #1 "D-Min" D-min R1; G1; B1; ± .03 + .05 ---Field #2 "LD" LD R2; G2; B2; ± .08 ± .10 ---Field #3 "HD" HD R3; G3; B3; ± .12 ± .15 ---Field #4 "D-Max" D-max R4; G4; B4; -- .20 -- .25 ----

NOTES:

1) Strips must have at least a 1-1/8" (28mm) leader before outside edge of first target, in order for first target to be detected (see Sec.2.1

in the 881 Operation Manual).

2) -------------> Indicates strip pass direction.

3) Yel, Mag, Cyn, Red, Grn, and Blu patches are not measured.

Limits

•AP44 (Agfa)

Format: a:AP44 Process: AP44 Densitometry: Transmission, Status A

Fields Measured Computed Values Transformation Rules Action Control Spread

Field #1 "D-Min" D-Min R1; G1; B1; ---- +.05 ---Field #2 "LD" LD R2; G2; B2; ---- ±.10 .08

Field #3 "HD" HD R3; G3; B3; ---- ±.15 .13

Field #4 "D-Max" D-Max R4; G4; B4; ---- -- .20 ----

NOTES:

1) Strips must have at least a 1-1/8" (28mm) leader before outside edge of first target, in order for first target to be detected (see Sec.2.1

in the Control Strip & Balance Print ).

2) <-------------> Indicates that strip may be inserted in either direction.

3) Small color patches are not measured.

Limits

7

Page 9

Positive Film Strip - continued

•Q-Lab (Kodak)

Format: k:Q-LAB Process: QLab Densitometry: Transmission, Status A

Fields Measured Computed Values Transformation Rules Action Control Spread

Field #1 "D-Min" D-Min R1; G1; B1; +.02 +.03 ---Field #2 "TD" TD R2; G2; B2; ±.03 ±.04 ---Field #3 "LD" LD R3; G3; B3; ±.04 ±.05 ---Field #4 "HD" HD R4; G4; B4; ±.06 ±.08 ---Field #5 "D-Max" D-Max R5; G5; B5; -- .10 -- .13 ---Field #6 LDSpr R3-G3; ; B3-G3; ---- ±.10 ----

NOTES:

1) Strips must have at least a 1-1/8" (28mm) leader before outside edge of first target, in order for first target to be detected (see Sec.2.1

in the 881 Operation Manual).

2) -------------> Indicates strip pass direction.

Limits

8

Page 10

2.2 Internegative Film Strips

•Type 1 (4 x 5)

The "Type 1" interneg consists of a

Kodak Step Tablet No. 1A cut between

steps 11 and 13, with the two halves

mounted side by side in a slide frame (see

illustration). Make sure that the full

length of the steps 11 and 13 show (i.e.,

not covered by the inside edge of the slide

frame).

This slide is then projected on to a 4 x 5

interneg such that each step is 1/2" wide.

Step 11 and 13 should begin

approximately 1/4" in from the edge of the

interneg. Note: Steps 1 and 21 can go off

the other end during projection - this is

OK.

Step 13 Step 21

Some

Overlapping

Permissible

Step 11 Slide Frame

Step 1 Step 21

Step 1

1/2"

Approx. 1/4"

Resulting Interneg

9

Page 11

Type 1 (4 x 5) - continued

To Measure the Type 1 Strip:

30

20 3010

10

20

1) Center step 1 over diamond and insert

until it rests against the drive rollers.

2) Center step 21 over diamond and insert

until it rests against the drive rollers.

30

Step 1

20 3010

10

Pass 1

20

Step 21

Pass 2

10

Page 12

•Type 2 (35mm)

The Type 2 interneg consists of a Kodak

Step Tablet No. 3 contact printed onto

35mm internegative film. To enable the

resulting interneg to be recognized by the

882, a piece of opaque tape must be

placed over part of step 1 on the step

tablet as shown. The tape should be

placed such that 0.4" (approx. 3/8") of step

1 is still exposed adjacent to step 2.

To satisfy the leader requirements of the

882, a 1-1/8" leader should precede the

taped area on the resulting interneg.

Tape

0.4"

0.4"

Step 1

White

Step 2

Step 3

Step Tablet

This strip is inserted into the 35mm slot

with step 1 entering first.

35mm SLOT

20 10

Light stripe

caused by tape.

10

20

1-1/8" Leader

Step 1

Step 2

Resulting Interneg

11

Page 13

3. Densitometer Specifications

Transmission Process Control

Film Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35mm fixed slot or 1.4 - 6.0 inch adjustable

Measurement Speed . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3 inches/second

Spectral Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . Status A & M

Density Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 - 4.0D

Density Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +/- .02D (0-3.00D), +/- 1% (3.01-3.40D,

+/- 3% (3.41-4.00D)

Density Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . +/- .01D (0-3.00D), +/- .02D (3.01-3.40D),

+/- 0.04D (3.41-4.00D)

Control Strip Measurement Area . . . . . . . . . . . . . . . 0.375" (length) x 0.5" (wide) minimum

Reflection (paper) Process Control and Printer Balance

Paper Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 - 6.0 inches (adjustable slot)

Measurement Speed . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3 inches/second

Control Strip Measurement Area . . . . . . . . . . . . . . . 0.375" (length) x 0.5" (wide) minimum

Printer Balance Measuring Area . . . . . . . . . . . . . . . .0.75" diameter minimum

Spectral Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . Status A

Density Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 - 2.5D

Density Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +/- .02D

Density Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . +/- .01D

General Specifications

A.C. Adaptor (115VAC - P/N SE30-61) (230VAC - P/N SE30-62) . . . . . 12VDC @ 0.7amp

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2" x 6.0" x 2.75"

(182.8mm x 152.4mm x 69.8mm)

Specification and design subject to change without notice.

12

Loading...

Loading...