Page 1

Page 2

2

BEFORE YOU START

The XB8E is a high-competition, high-quality, 1/8 electric buggy intended for

persons aged 16 years and older with previous experience building and operating

RC model racing cars. This is not a toy; it is a precision racing model. This model

racing car is not intended for use by beginners, inexperienced customers, or

by children without direct supervision of a responsible, knowledgeable adult.

If you do not fulfill these requirements, please return the kit in unused and

unassembled form back to the shop where you have purchased it.

Before building and operating your XB8E, YOU MUST read through all of the

operating instructions and instruction manual and fully understand them to get

the maximum enjoyment and prevent unnecessary damage. Read carefully and

fully understand the instructions before beginning assembly.

Make sure you review this entire manual, download and use set-up book from the

web, and examine all details carefully. If for some reason you decide the XB8E is

not what you wanted or expected, do not continue any further. Your hobby dealer

cannot accept your XB8E kit for return or exchange after it has been partially or

fully assembled.

Contents of the box may differ from pictures. In line with our policy of continuous

product development, the exact specifications of the kit may vary without prior

notice.

SAFETY PRECAUTIONS

Contains:

LEAD (CAS 7439-92-1) ANTIMONY (CAS 7440-36-0)

WARNING: This product contains a chemical known to the state of California to

cause cancer and birth defects or other reproductive harm.

CAUTION: CANCER HAZARD

Contains lead, a listed carcinogen. Lead is harmful if ingested. Wash thoroughly

after using. DO NOT use product while eating, drinking or using tobacco

products. May cause chronic effects to gastrointestinal tract, CNS, kidneys, and

blood. MAY CAUSE BIRTH DEFECTS.

When building, using and/or operating this model always wear protective

glasses and gloves.

Take appropriate safety precautions prior to operating this model. You are

responsible for this model‘s assembly and safe operation! Please read the

instruction manual before building and operating this model and follow

all safety precautions. Always keep the instruction manual at hand for quick

reference, even after completing the assembly. Use only genuine and original

authentic XRAY parts for maximum performance. Using any third party parts on

this model will void guaranty immediately.

Improper operation may cause personal and/or property damage. XRAY and

its distributors have no control over damage resulting from shipping, improper

construction, or improper usage. XRAY assumes and accepts no responsibility for

personal and/or property damages resulting from the use of improper building

materials, equipment and operations. By purchasing any item produced by XRAY,

the buyer expressly warrants that he/she is in compliance with all applicable

federal, state and local laws and regulation regarding the purchase, ownership

and use of the item. The buyer expressly agrees to indemnify and hold harmless

XRAY for all claims resulting directly or indirectly from the purchase, ownership

or use of the product. By the act of assembling or operating this product, the

user accepts all resulting liability. If the buyer is not prepared to accept this

liability, then he/she should return this kit in new, unassembled, and unused

condition to the place of purchase.

IMPORTANT NOTES – GENERAL

• This product is not suitable for children under 16 years of age without the

direct supervision of a responsible and knowledgeable adult.

• Carefully read all manufacturers warnings and cautions for any parts used in

the construction and use of your model.

• Assemble this kit only in places away from the reach of very small children.

• First-time builders and users should seek advice from people who have

building experience in order to assemble the model correctly and to allow the

model to reach its performance potential.

• Exercise care when using tools and sharp instruments.

• Take care when building, as some parts may have sharp edges.

• Keep small parts out of reach of small children. Children must not be allowed

to put any parts in their mouth, or pull vinyl bag over their head.

• Read and follow instructions supplied with paints and/or cement, if used (not

included in kit).

• Immediately after using your model, do NOT touch equipment on the

model such as the motor and speed controller, because they generate high

temperatures. You may seriously burn yourself seriously touching them.

• Follow the operating instructions for the radio equipment at all times.

• Do not put fingers or any objects inside rotating and moving parts, as this

may cause damage or serious injury as your finger, hair, clothes, etc. may get

caught.

• Be sure that your operating frequency is clear before turning on or running

your model, and never share the same frequency with somebody else at the

same time. Ensure that others are aware of the operating frequency you are

using and when you are using it.

• Use a transmitter designed for ground use with RC cars. Make sure that no

one else is using the same frequency as yours in your operating area. Using

the same frequency at the same time, whether it is driving, flying or sailing,

can cause loss of control of the RC model, resulting in a serious accident.

• Always turn on your transmitter before you turn on the receiver in the car.

Always turn off the receiver before turning your transmitter off.

• Keep the wheels of the model off the ground when checking the operation of

the radio equipment.

• Disconnect the battery pack before storing your model.

• When learning to operate your model, go to an area that has no obstacles

that can damage your model if your model suffers a collision.

• Remove any sand, mud, dirt, grass or water before putting your model away.

• If the model behaves strangely, immediately stop the model, check and clear

the problem.

• To prevent any serious personal injury and/or damage to property, be

responsible when operating all remote controlled models.

• The model car is not intended for use on public places and roads or areas where

its operation can conflict with or disrupt pedestrian or vehicular traffic.

• Because the model car is controlled by radio, it is subject to radio interference

from many sources that are beyond your control. Since radio interference can

cause momentary loss of control, always allow a safety margin in all directions

around the model in order to prevent collisions.

• Do not use your model:

- Near real cars, animals, or people that are unaware that an RC car is being

driven.

- In places where children and people gather

- In residential districts and parks

- In limited indoor spaces

- In wet conditions

- In the street

- In areas where loud noises can disturb others, such as hospitals and

residential areas.

- At night or anytime your line of sight to the model may be obstructed or

impaired in any way.

To prevent any serious personal injury and/or damage to property, please be

responsible when operating all remote controlled models.

Failure to follow these instructions will be considered as abuse and/or neglect.

CUSTOMER SUPPORT

XRAY Europe

K Vystavisku 6992

91101 Trenčín

Slovakia, EUROPE

Phone: 421-32-7401100

Fax: 421-32-7401109

E-mail: info@teamxray.com

We have made every effort to make these instructions as easy to understand as possible.

However, if you have any difficulties, problems, or questions, please do not hesitate to

contact the XRAY support team at info@teamxray.com. Also, please visit our Web site

at www.teamxray.com to find the latest updates, set-up information, option parts, and

many other goodies. We pride ourselves on taking excellent care of our customers.

You can join thousands of XRAY fans and enthusiasts in our online community at:

www.teamxray.com

XRAY USA

RC America, 2030 Century Center Blvd #15

Irving, TX 75062

USA

Phone: (800) 519-7221 * (214) 744-2400

Fax: (214) 744-2401

E-mail: xray@rcamerica.com

Page 3

3

IMPORTANT NOTES – ELECTRICAL

• Insulate any exposed electrical wiring (using heat shrink tubing or electrical

tape) to prevent dangerous short circuits. Take maximum care in wiring,

connecting and insulating cables. Make sure cables are always connected

securely. Check connectors for if they become loose. And if so, reconnect

them securely. Never use R/C models with damaged wires. A damaged wire

is extremely dangerous, and can cause short-circuits resulting in fire. Please

have wires repaired at your local hobby shop.

• Low battery power will result in loss of control. Loss of control can occur due to

a weak battery in either the transmitter or the receiver. Weak running battery

may also result in an out of control car if your car‘s receiver power is supplied

by the running battery. Stop operation immediately if the car starts to slow

down.

• When not using RC model, always disconnect and remove battery.

• Do not disassemble battery or cut battery cables. If the running battery shortcircuits, approximately 300W of electricity can be discharged, leading to fire

or burns. Never disassemble battery or cut battery cables.

• Use a recommended charger for the receiver and transmitter batteries

and follow the instructions correctly. Over-charging, incorrect charging, or

using inferior chargers can cause the batteries to become dangerously hot.

Recharge battery when necessary. Continual recharging may damage battery

and, in the worst case, could build up heat leading to fire. If battery becomes

extremely hot during recharging, please ask your local hobby shop for check

and/or repair and/or replacement.

• Regularly check the charger for potential hazards such as damage to the

cable, plug, casing or other defects. Ensure that any damage is rectified

before using the charger again. Modifying the charger may cause short-circuit

or overcharging leading to a serious accident. Therefore do not modify the

charger.

• Always unplug charger when recharging is finished.

• Do not recharge battery while battery is still warm. After use, battery retains

heat. Wait until it cools down before charging.

• Do not allow any metal part to short circuit the receiver batteries or other

electrical/electronic device on the model.

• Immediately stop running if your RC model gets wet as may cause short circuit.

• Please dispose of batteries responsibly. Never put batteries into fire.

WARRANTY

XRAY guarantees this model kit to be free from defects in both material and

workmanship within 30 days of purchase. The total monetary value under

warranty will in no case exceed the cost of the original kit purchased. This

warranty does not cover any components damaged by use or modification or

as a result of wear. Part or parts missing from this kit must be reported within

30 days of purchase. No part or parts will be sent under warranty without proof

of purchase. Should you find a defective or missing part, contact the local

distributor. Service and customer support will be provided through local hobby

store where you have purchased the kit, therefore make sure to purchase any

XRAY products at your local hobby store. This model racing car is considered

to be a high-performance racing vehicle. As such this vehicle will be used in

an extreme range of conditions and situations, all which may cause premature

wear or failure of any component. XRAY has no control over usage of vehicles

once they leave the dealer, therefore XRAY can only offer warranty against all

manufacturer‘s defects in materials, workmanship, and assembly at point of

sale and before use. No warranties are expressed or implied that cover damage

caused by what is considered normal use, or cover or imply how long any

model cars‘ components or electronic components will last before requiring

replacement.

Due to the high performance level of this model car you will need to periodically

maintain and replace consumable components. Any and all warranty coverage

will not cover replacement of any part or component damaged by neglect,

abuse, or improper or unreasonable use. This includes but is not limited to

damage from crashing, chemical and/or water damage, excessive moisture,

improper or no maintenance, or user modifications which compromise the

integrity of components. Warranty will not cover components that are considered

consumable on RC vehicles. XRAY does not pay nor refund shipping on any

component sent to XRAY or its distributors for warranty. XRAY reserves the right

to make the final determination of the warranty status of any component or part.

Limitations of Liability

XRAY makes no other warranties expressed or implied. XRAY shall not be liable

for any loss, injury or damages, whether direct, indirect, special, incidental, or

consequential, arising from the use, misuse, or abuse of this product and/or any

product or accessory required to operate this product. In no case shall XRAY‘s

liability excess the monetary value of this product.

Take adequate safety precautions prior to operating this model. You

are responsible for this model’s assembly and safe operation.

Disregard of the any of the above cautions may lead to accidents,

personal injury, or property damage. XRAY MODEL RACING CARS

assumes no responsibility for any injury, damage, or misuse of this

product during assembly or operation, nor any addictions that may

arise from the use of this product.

All rights reserved.

QUALITY CERTIFICATE

XRAY MODEL RACING CARS uses only the highest quality materials, the best

compounds for molded parts and the most sophisticated manufacturing processes

of TQM (Total Quality Management). We guarantee that all parts of a newlypurchased kit are manufactured with the highest regard to quality. However, due

to the many factors inherent in model racecar competition, we cannot guarantee

any parts once you start racing the car. Products which have been worn out,

abused, neglected or improperly operated will not be covered under warranty.

We wish you enjoyment of this high-quality and high-performance RC car and

wish you best success on the track!

In line with our policy of continuous product development, the exact specifications of the kit may

vary. In the unlikely event of any problems with your new kit, you should contact the model shop

where you purchased it, quoting the part number.

We do reserve all rights to change any specification without prior notice. All rights reserved.

R/C & BUILDING TIPS

• Make sure all fasteners are properly tightened. Check them periodically.

• Make sure that chassis screws do not protrude from the chassis.

• For the best performance, it is very important that great care is taken to ensure

the free movement of all parts.

• Clean all ball-bearings so they move very easily and freely.

• Tap or pre-thread the plastic parts when threading screws.

• Self-tapping screws cut threads into the parts when being tightened. Do not use

excessive force when tightening the self-tapping screws because you may strip

out the thread in the plastic. We recommended you stop tightening a screw

when you feel some resistance.

• Ask your local hobby shop for any advice.

Please support your local hobby shop. We at XRAY Model Racing Cars support

all local hobby dealers. Therefore we ask you, if at all possible, to purchase

XRAY products at your hobby dealer and give them your support like we do. If

you have difficulty finding XRAY products, please check out www.teamxray.com

to get advice, or contact us via email at info@teamxray.com, or contact the XRAY

distributor in your country.

Page 4

4

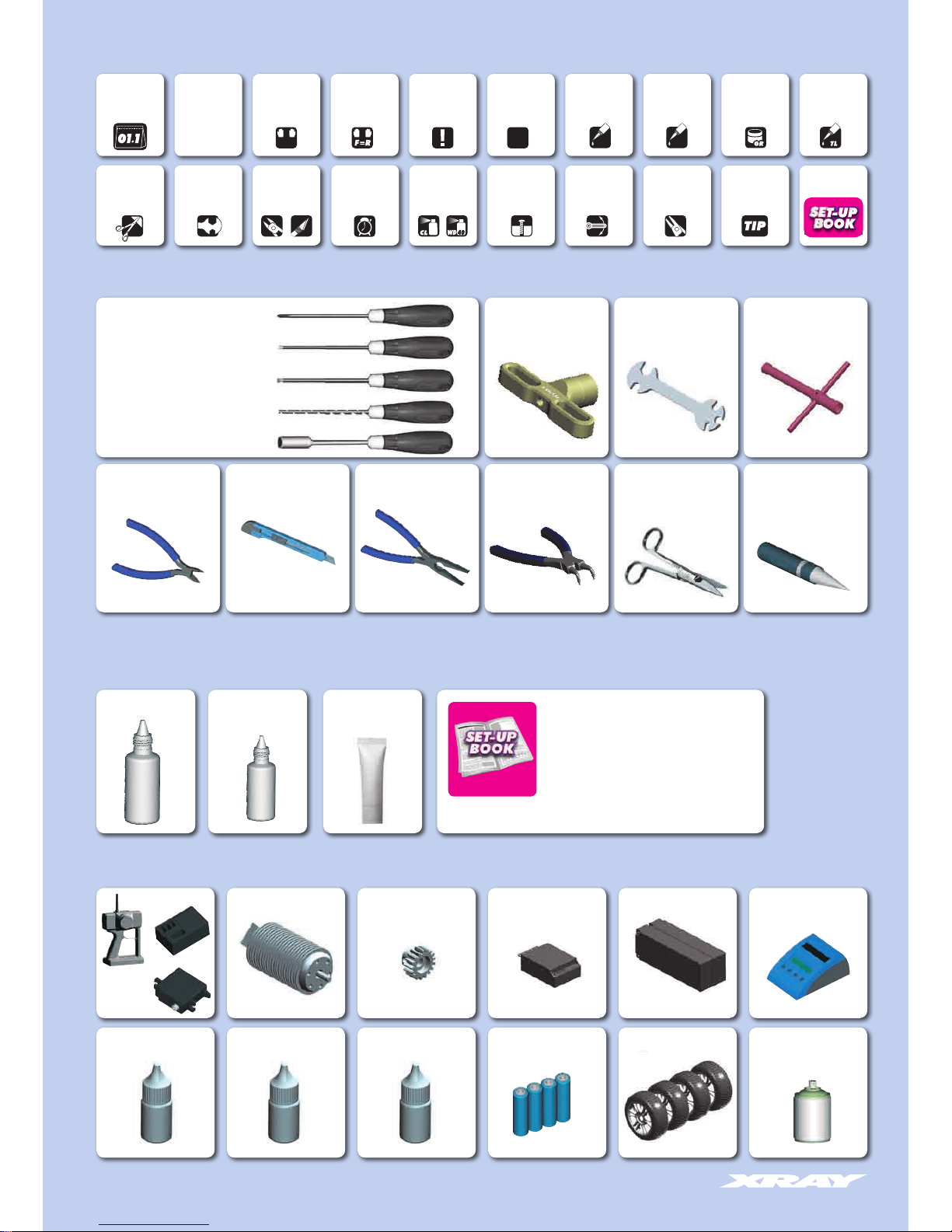

SYMBOLS USED

L=R

2x

CA

OIL

Part bags used Assemble left and

right sides the

same way

Assemble in the

specified order

Pay attention

here

Assemble as

many times

as specified

(here twice)

Apply instant

glue

Cut off shaded

portion

Cut off

remaining

material

Tighten screw

gently

TOOLS REQUIRED

EQUIPMENT REQUIRED

TOOLS & EQUIPMENT INCLUDED

Assemble front

and rear the same

way

Apply oil

Use special

tool

Silicone Shock Oil Silicone Diff Oil

Transmitter

Steering

Servo

Battery ChargerElectric Motor Speed Controller LiPo Battery

Tires & Wheels

Receiver

Lexan™ Paint

Special Tool for all turnbuckles,

nuts (HUDY #108090)

CA Glue

Phillips 5.0mm (HUDY TOOLS)

Socket 5.0 / 5.5mm (HUDY TOOLS)

Allen 1.5 / 2.0 / 2.5 / 3.0mm (HUDY TOOLS)

17mm Wheel Nut Tool

(HUDY #107570)

Side Cutters

(HUDY #189010)

Hobby Knife Body Reamer

(HUDY #107600)

or

(HUDY #107601)

Cross Wrench

(HUDY #107581)

Scissors

(HUDY #188990)

Needle Nose Pliers

(HUDY #189020)

Snap Ring Pliers

(HUDY #189040)

➊ ➋ ➌

Apply grease Apply

threadlock

Ensure smooth

non-binding

movement

Use pliers Follow tip here

Arm Reamer 3mm/4mm (HUDY TOOLS)

Graphite Grease

(HUDY #106210)

Transmitter Batteries

Pinion Gear

ThreadlockBearing Oil

Follow Set-Up

Book

Use cleaner

or WD-40

Time

Ball Allen 2.5mm (HUDY TOOLS)

To ensure that you always have access to the most

up-to-date version of the XRAY Set-up Book, XRAY

will now be offering only the digital online version

at our Web site at www.teamxray.com. By offering

this online version instead of including a hardcopy

printed version in kits, you will always be assured

of having the most current updated version.

Page 5

5

XB8E TECH TIPS

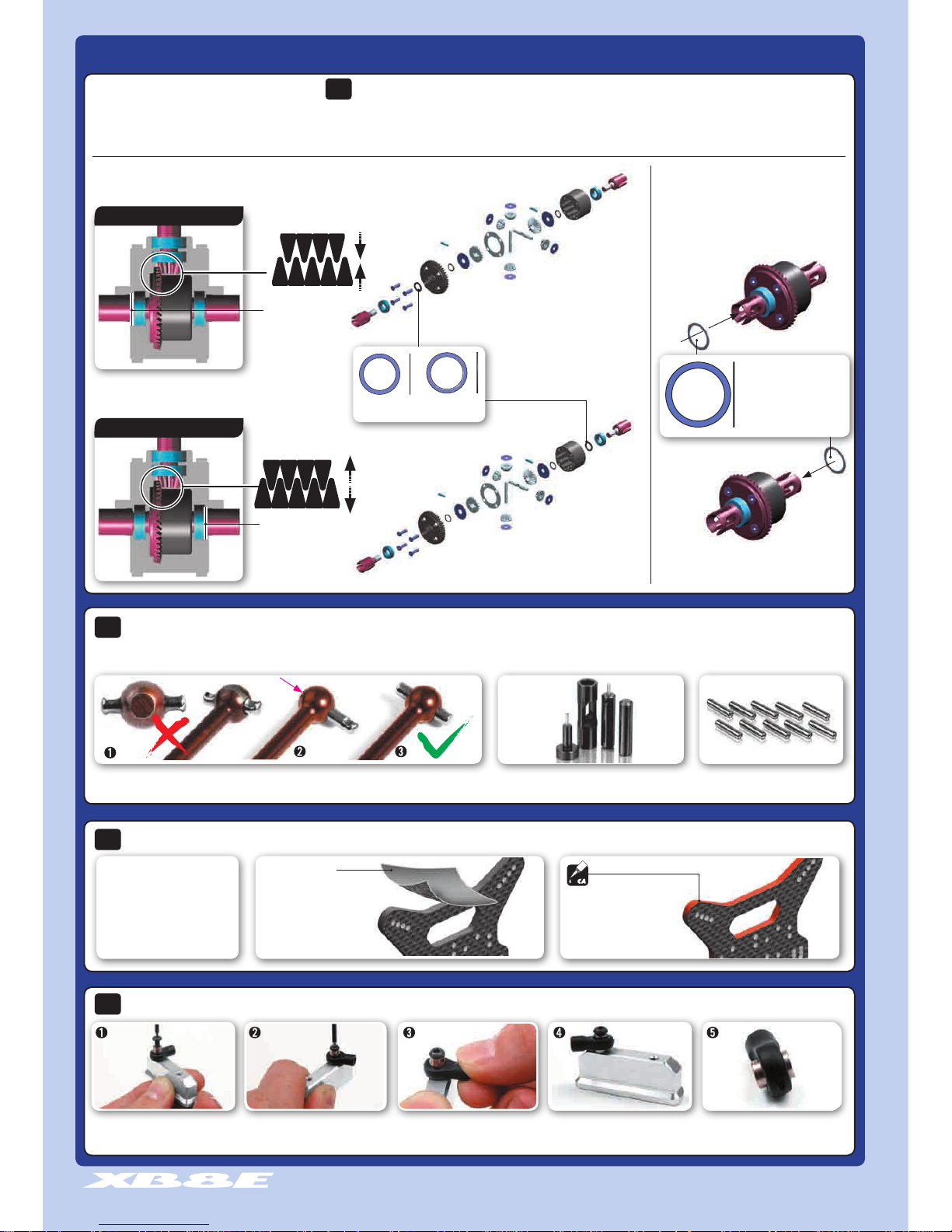

Before filling in the differentials with oil we suggest that you first check gear mesh as below. If there is too much or too little diff side play, this may create non-optimal gear mesh between the diff gear and the pinion

drive gear. This is easily resolved by inserting 1 or 2 of the included thin shims behind a diff outdrive ball-bearing, depending on how much play there is.

For easier gear mesh adjustments, OPTION S13 x 0.2

shims are used. These shims can be placed behind the

bearing which is quicker.

FRONT & REAR DIFF GEAR MESH ADJUSTMENT

THE LOCATION OF THE SHIM(S) DEPENDS ON WHETHER YOU ARE TRYING TO CLOSE OR OPEN THE GAP:

INCLUDED SHIM

OPTION SHIM

TO CLOSE A WIDE GAP

TO OPEN A NARROW GAP

TIP

insert shim(s) here

insert shim(s) here

TIP

Tighten screw until pivot ball is tight

against block.

Lift ball joint until it snaps into place

over pivot ball. Ball joint should move

freely.

The finished joint. Loosen and remove screw.

INSTALLING PIVOT BALLS INTO COMPOSITE BALL JOINTS

Place the pivot ball on the ball joint

and use a screw to tighten it to an

engine mount or some other part.

DRIVE SHAFT PINS SERVICING

TIP

To enjoy the longest possible lifespan of the drive shafts and diff outdrives, it is extremely important to properly service the drive shaft pins.

Inspect the pins after every 3 hours of run time. If the pins show any wear, replace them with new pins.

For easy drive pin replacement use #106000

HUDY Drive Pin Replacement Tool.

To replace the worn pins use only

premium HUDY drive pins #106050.

GRAPHITE PARTS PROTECTION

TIP

Follow this tech tip to protect the graphite parts.

Fine sandpaper

Use fine sandpaper to sand

smooth the edges of all

graphite parts.

Apply CA glue to all edges of

the graphite parts.

Protect all XB8

Graphite Parts:

• Front shock tower

• Rear shock tower

Do not use drive shafts

when the pins are worn.

Press out the worn pins.

Press in new pins and

regularly inspect for wear.

962080

S 8x0.1

962081

S 8x0.2

To close a wide gap:

add 1 or 2 shims against diff

spur gear

To open a narrow gap:

add 1 or 2 shims on the other side

of the diff, away from spur gear

#962080 WASHER S 8 x 0.1 mm (10)

#962081 WASHER S 8 x 0.2 mm (10)

#962130 WASHER

S 13 x 16 x 0.2 mm (10)

#962131 WASHER

S 13x16x0.1 mm (10)

To close a wide gap:

add 1 or 2 shims against diff spur gear

To open a narrow gap:

add 1 or 2 shims on the other side of the diff, away

from spur gear

OPEN A NARROW GAP

CLOSE A WIDE GAP

Page 6

6

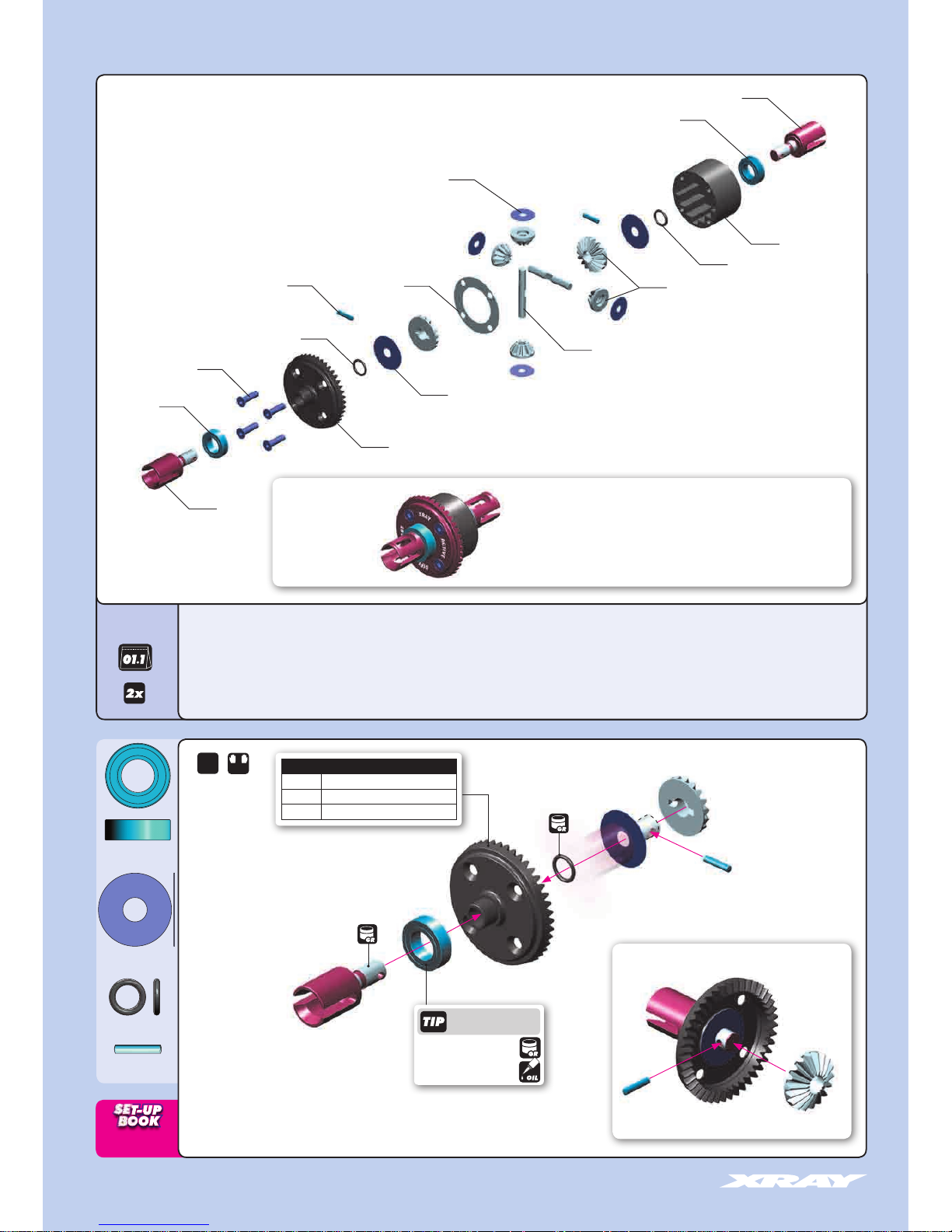

DIFFERENTIAL GEARS

1. FRONT & REAR DIFFERENTIALS

2x

F=R

STEP DETAIL

➊

➋

➌

➍

➎

➎

➎➏

➏

35 5003 XB8 FRONT/REAR DIFFERENTIAL 46T - SET

35 5020 DIFFERENTIAL CASE

35 5030 STEEL DIFF BEVEL & SATELLITE GEARS (2+4)

35 5046 FRONT/REAR DIFF LARGE BEVEL GEAR 46T - HUDY STEEL

35 5063 F/R DIFF OUTDRIVE ADAPTER - LIGHTW. - HUDY SPRING STEEL™ (2)

35 5080 DIFF PIN (2)

35 5090 DIFF GASKET (4)

90 3312 HEX SCREW SFH M3x12 (10)

94 0816 HIGH-SPEED BALL-BEARING 8x16x5 BLUE COVERED (2)

96 4030 WASHER S 3.5x12x0.2 (10)

96 4060 WASHER S 6x18x0.2 (10)

97 1060 SILICONE O-RING 6x1.5 (10)

98 0212 PIN 2x11.6 (10)

BAGS

940816

903312

355046

964060

355030

971060

355020

940816

355090

964030

980212

971060

355080

355063

355063

940816

BB 8x16x5

964060

S 6x18x0.2

971060

O 6x1.5

980212

P 2x11.6

Graphite Grease

(HUDY #106210)

Graphite Grease

(HUDY #106210)

* These OPTIONAL bevel gears must be used

with OPTIONAL #355110 bevel gear 12T

FRONT/REAR DIFF LARGE BEVEL GEAR

#355038

DIFF LARGE BEVEL GEAR 38T (OPTION) *

#355040

DIFF LARGE BEVEL GEAR 40T (OPTION) *

#355046

DIFF LARGE BEVEL GEAR 46T (STANDARD)

➏

• High-performance adjustable front Active Differential for improved speed & handling

• Fully adjustable on- and off-power performance using different internal segments and gears

• Improves diff action and increases traction

• Easy and consistent steering

OPTION

#355105 ACTIVE FRONT DIFF

Use HUDY Ball-Bearing

Grease or Oil for servicing:

#106220 - Standard

#106221 - Extra

#106222 - Premium

#106230 - Bearing Oil

Page 7

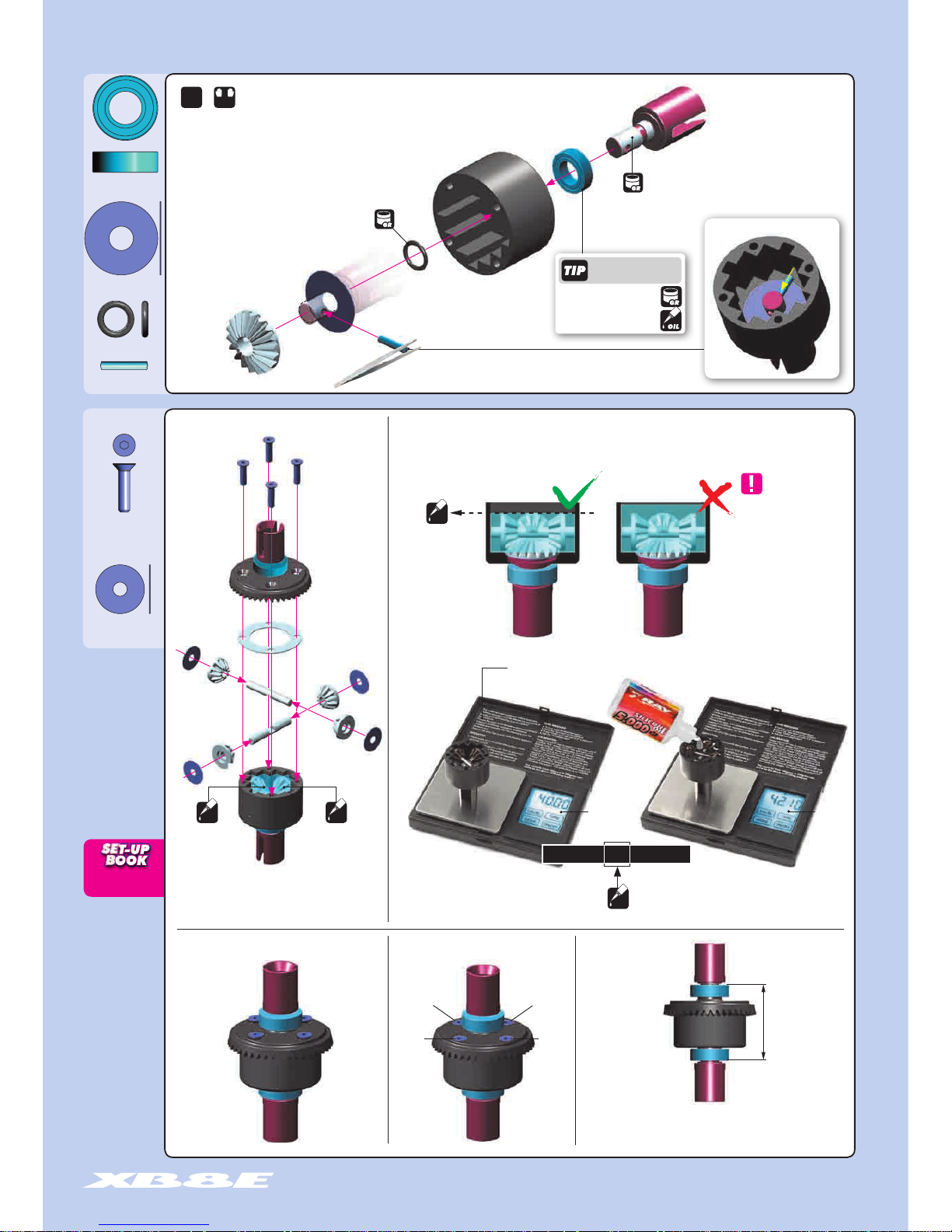

7

DIFFERENTIAL OIL

Fill the differentials

with oil just above the

satellite gears.

IMPORTANT!

After assembly the differentials should have a length of 32.3~32.5 mm

measured from the ends of the installed ball-bearings. If differentials are

longer, retighten the 4 screws holding the crown gears.

32.3~32.5 mm

VERY IMPORTANT!

OIL

INCORRECT

CORRECT

OIL OIL

#107865 HUDY Ultimate Digital Pocket Scale 300g±0.01g

40g

42.1g

1. Put the diff (without oil) on the scale and

check the weight (approximately 40g).

40g + 2.1g = 42.1g

2. Slowly pour oil into the diff and watch

the weight. Add 2.1g of oil into the diff. The

approximate weight of the diff+oil is 42.1g.

Do not overfill the differential.

If there is too much oil in the

differential, it may leak after

it cools down after use.

To enure you have the same amount of oil from rebuild to rebuild, do the following:

OIL

FRONT & REAR DIFFERENTIALS

964030

S 3.5x12x0.2

903312

SFH M3x12

2x

F=R

➊

➋

➌

➍

➎

➎

➏

➊

➋

➌

➍

940816

BB 8x16x5

964060

S 6x18x0.2

971060

O 6x1.5

980212

P 2x11.6

STEP DETAIL

Use these silicone oils included in the kit for initial settings:

Front diff: 5000cSt / Rear diff: 2000cSt

Rear diff:

Silicone oil 2 000cSt

Fill just above the

satellite gears.

Front diff:

Silicone oil 5000cSt

Fill just above the

satellite gears.

Graphite Grease

(HUDY #106210)

Graphite Grease

(HUDY #106210)

Tighten the screws equally Finish tightening in this order

Use HUDY Ball-Bearing

Grease or Oil for servicing:

#106220 - Standard

#106221 - Extra

#106222 - Premium

#106230 - Bearing Oil

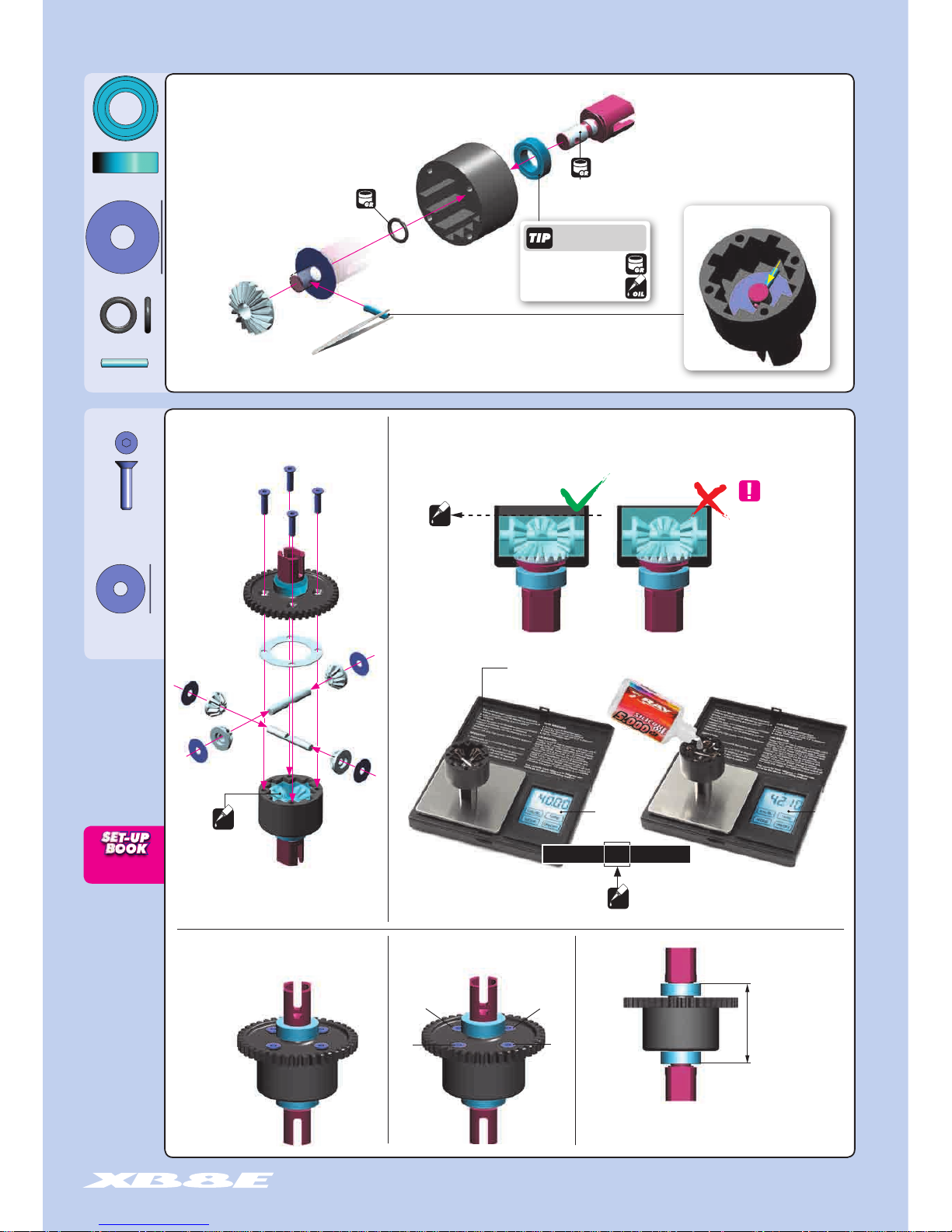

Page 8

8

DIFFERENTIAL GEARS

STEP DETAIL

CENTER DIFFERENTIAL

BAG

➊

➋

➌

➍

➎

➎

➏

➏➎

355071

940816

903312

355050

971060

355030

971060

355020

940816

355090

964060

964030

980212

355080

355071

35 5012 CENTRAL DIFFERENTIAL - SET

35 5020 DIFFERENTIAL CASE

35 5030 STEEL DIFF BEVEL & SATELLITE GEARS (2+4)

35 5050 CENTER DIFF SPUR GEAR 46T

35 5071 CENTER DIFF OUTDRIVE ADAPTER - LIGHTWEIGHT - HUDY STEEL (2)

35 5080 DIFF PIN (2)

35 5090 DIFF GASKET (4)

90 3312 HEX SCREW SFH M3x12 (10)

94 0816 HIGH-SPEED BALL-BEARING 8x16x5 BLUE COVERED (2)

96 4030 WASHER S 3.5x12x0.2 (10)

96 4060 WASHER S 6x18x0.2 (10)

97 1060 SILICONE O-RING 6x1.5 (10)

98 0212 PIN 2x11.6 (10)

940816

BB 8x16x5

971060

O 6x1.5

964060

S 6x18x0.2

980212

P 2x11.6

Graphite Grease

(HUDY #106210)

Graphite Grease

(HUDY #106210)

CENTER DIFF SPUR GEAR

#355048 48T

(

OPTION

)

#355049 47T (

OPTION

)

#355050 46T

(

STANDARD

)

#355051 45T (OPTION)

#355052 44T

(OPTION)

➏

Use HUDY Ball-Bearing

Grease or Oil for servicing:

#106220 - Standard

#106221 - Extra

#106222 - Premium

#106230 - Bearing Oil

Page 9

9

DIFFERENTIAL OIL

After assembly the differential should have a length of 32.3~32.5 mm

measured from the ends of the installed ball-bearings. If differential is

longer, retighten the 4 screws holding the spur gear.

➊

➋

➍

➎

➎

➏

➌

971060

O 6x1.5

964060

S 6x18x0.2

980212

P 2x11.6

VERY IMPORTANT!

Fill the differentials

with oil just above

the satellite gears.

OIL

INCORRECT

CORRECT

Center diff:

Silicone oil 5000cSt

Fill to just above the satellite gears.

OIL

#107865 HUDY Ultimate Digital Pocket Scale 300g±0.01g

40g

42.1g

1. Put the diff (without oil) on the scale and

check the weight (approximately 40g).

40g + 2.1g = 42.1g

2. Slowly pour oil into the diff and watch

the weight. Add 2.1g of oil into the diff. The

approximate weight of the diff+oil is 42.1g.

To enure you have the same amount of oil from rebuild to rebuild, do the following:

OIL

940816

BB 8x16x5

IMPORTANT!

Do not overfill the differential.

If there is too much oil in the

differential, it may leak after

it cools down after use.

32.3~32.5 mm

CENTER DIFFERENTIAL

964030

S 3.5x12x0.2

903312

SFH M3x12

Tighten the screws equally Finish tightening in this order

➊

➋

➌

➍

STEP DETAIL

Use the following silicone oil included in the kit for initial setting:

Center diff: 5000cSt

Graphite Grease

(HUDY #106210)

Graphite Grease

(HUDY #106210)

Use HUDY Ball-Bearing

Grease or Oil for servicing:

#106220 - Standard

#106221 - Extra

#106222 - Premium

#106230 - Bearing Oil

Page 10

10

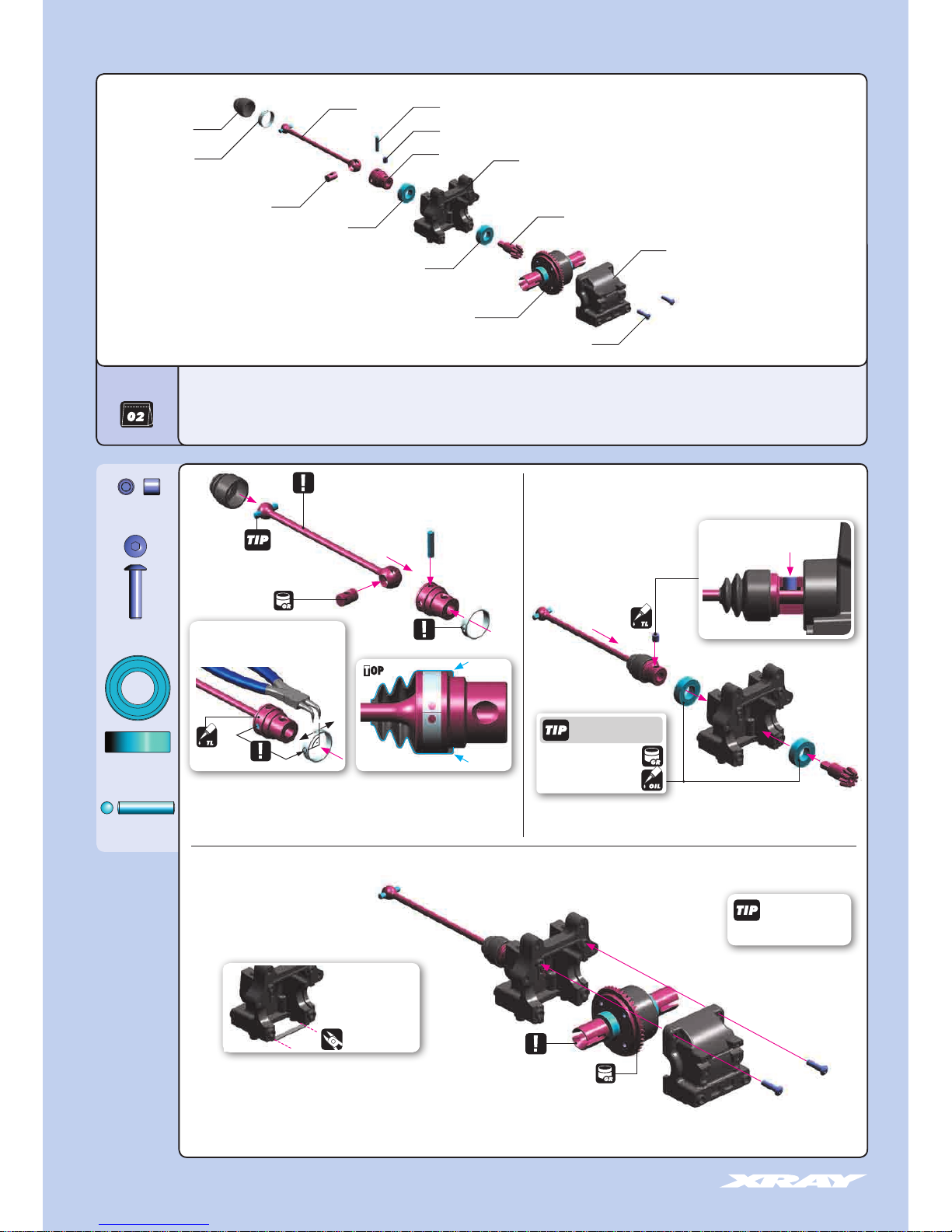

2. FRONT TRANSMISSION

940816

BB 8x16x5

902312

SH 3x12

980314

P 3x14

901404

SB 4x4

Graphite Grease

(HUDY #106210)

Follow the TECH TIP on page 5

for drive shaft pin servicing

NOTE

ORIENTATION

SHORT CVD DRIVE SHAFT

ASSEMBLED VIEW

Cut on both front

and rear bulkhead blocks

Follow the TECH TIP

on page 5 to properly

adjust the gear mesh.

BEFORE inserting the clip on the central CVD shaft joint, apply a small amount of

threadlock on the area where the clip goes.

AFTER inserting the clip on the central CVD shaft joint, turn the clip so that the slot is

90°from the pin. This will prevent the pin from opening the clip.

PIN

➊

➊

➋

➋

➌

➌

➍

➍

STEP DETAIL

➍

STEP DETAIL

➎

355003

FRONT DIFF

902312

35 2005 XB8 DIFF BULKHEAD BLOCK SET FRONT/REAR

35 5003 XB8 FRONT/REAR DIFFERENTIAL 46T - SET

35 5114 BEVEL DRIVE GEAR 14T

35 5236 CVD DRIVE SHAFT COUPLING - HUDY SPRING STEEL™

35 5416 CENTRAL CVD SHAFT UNIVERSAL JOINT - HUDY SPRING STEEL™

35 5425 FRONT CENTRAL CVD DRIVE SHAFT - HUDY SPRING STEEL™

35 5471 DRIVE SHAFT LOCKING RING (2)

35 5472 DRIVE SHAFT BOOT (2)

90 1404 HEX SCREW SB M4x4 (10)

90 2312 HEX SCREW SH M3x12 (10)

94 0816 HIGH-SPEED BALL-BEARING 8x16x5 RUBBER SEALED (2)

98 0314 PIN 3x14 (10)

BAG

➎

➎

➎

SHORT

DETAIL

FRONT DIFF 5000 cSt

Graphite Grease

(HUDY #106210)

Push joint against gear to remove gap.

Tighten set screw onto gear flat spot.

The ring can be assembled by hand but

for easy disassembling, we recommend

using snap ring pliers (HUDY #189040)

355472

355471

355425

355236

355416

352005

355114

352005

980314

901404

940816

940816

step 1 step 2

step 3

Use HUDY Ball-Bearing

Grease or Oil for servicing:

#106220 - Standard

#106221 - Extra

#106222 - Premium

#106230 - Bearing Oil

Page 11

11

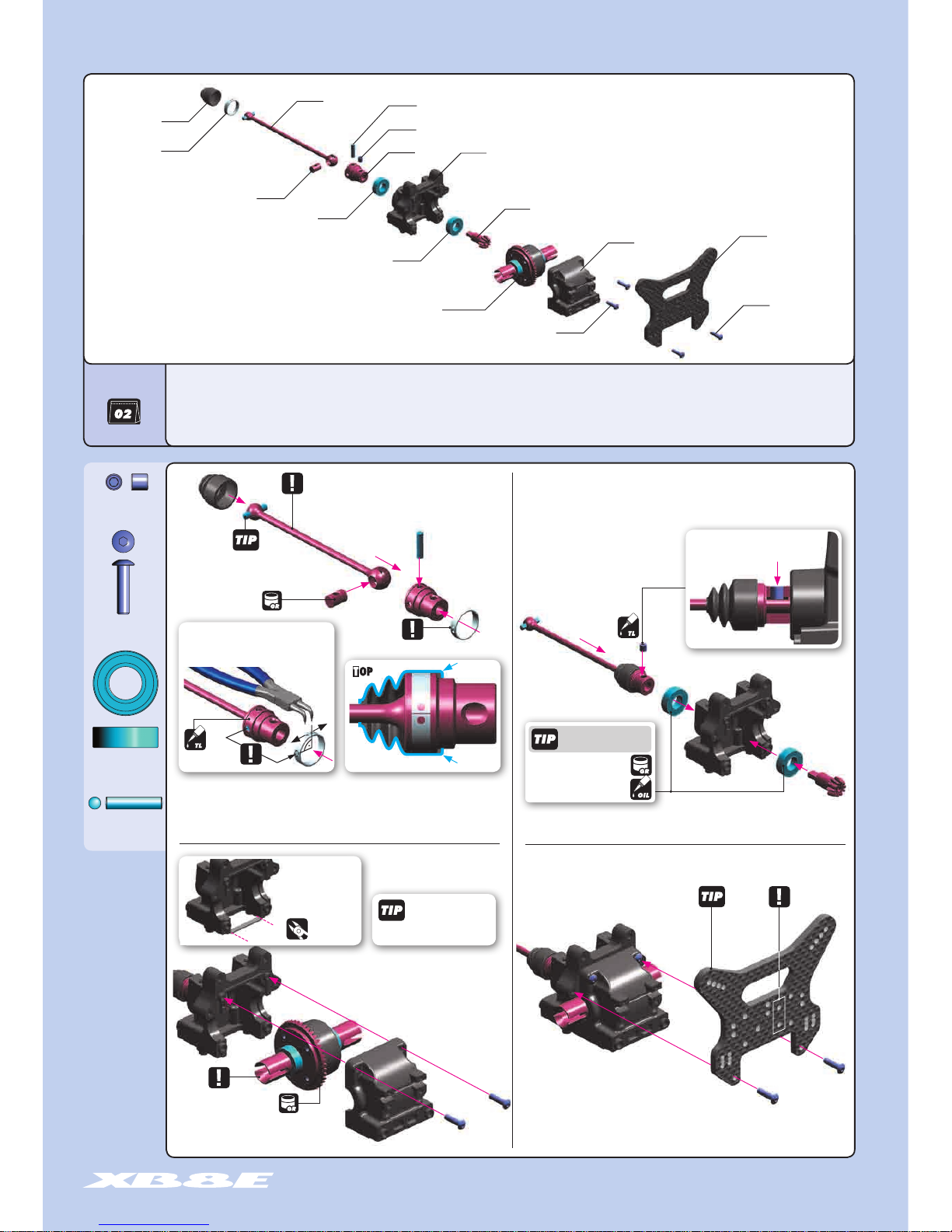

REAR TRANSMISSION

940816

BB 8x16x5

902312

SH 3x12

980314

P 3x14

901404

SB 4x4

Graphite Grease

(HUDY #106210)

Follow the TECH TIP on page 5

for drive shaft pin servicing

NOTE

ORIENTATION

LONG CVD DRIVE SHAFT

ASSEMBLED VIEW

Follow the TECH TIP

on page 5 to properly

adjust the gear mesh.

Cut on both front

and rear

bulkhead blocks

BEFORE inserting the clip on the central CVD shaft joint, apply a small amount of

threadlock on the area where the clip goes.

AFTER inserting the clip on the central CVD shaft joint, turn the clip so that the slot is

90°from the pin. This will prevent the pin from opening the clip.

BAG

➊

➊

➋

➋

➌

➌

➍

➍

STEP DETAIL

➎

355003

REAR DIFF

902312

35 2005 XB8 DIFF BULKHEAD BLOCK SET FRONT/REAR

35 5003 XB8 FRONT/REAR DIFFERENTIAL 46T - SET

35 3096 XB8 GRAPHITE REAR SHOCK TOWER - CNC MACHINED 3.5MM

35 5114 BEVEL DRIVE GEAR 14T

35 5236 CVD DRIVE SHAFT COUPLING - HUDY SPRING STEEL™

35 5416 CENTRAL CVD SHAFT UNIVERSAL JOINT - HUDY SPRING STEEL™

35 5625 REAR CENTRAL CVD DRIVE SHAFT - HUDY SPRING STEEL™

35 5471 DRIVE SHAFT LOCKING RING (2)

35 5472 DRIVE SHAFT BOOT (2)

90 1404 HEX SCREW SB M4x4 (10)

90 2312 HEX SCREW SH M3x12 (10)

94 0816 HIGH-SPEED BALL-BEARING 8x16x5 RUBBER SEALED (2)

98 0314 PIN 3x14 (10)

➎

➎

➎

LONG

DETAIL

Graphite Grease

(HUDY #106210)

Follow the TECH TIP on page 5

to protect graphite parts

NOTE

ORIENTATION

REAR DIFF 2000 cSt

The ring can be assembled by hand but

for easy disassembling, we recommend

using snap ring pliers (HUDY #189040)

Push joint against gear to remove gap.

Tighten set screw onto gear flat spot.

902312

355472

355471

355625

355236

355416

352005

355114

352005

353096

980314

901404

940816

940816

PIN

STEP DETAIL

➍

step 1 step 2

step 3 step 4

Use HUDY Ball-Bearing

Grease or Oil for servicing:

#106220 - Standard

#106221 - Extra

#106222 - Premium

#106230 - Bearing Oil

Page 12

12

BAG

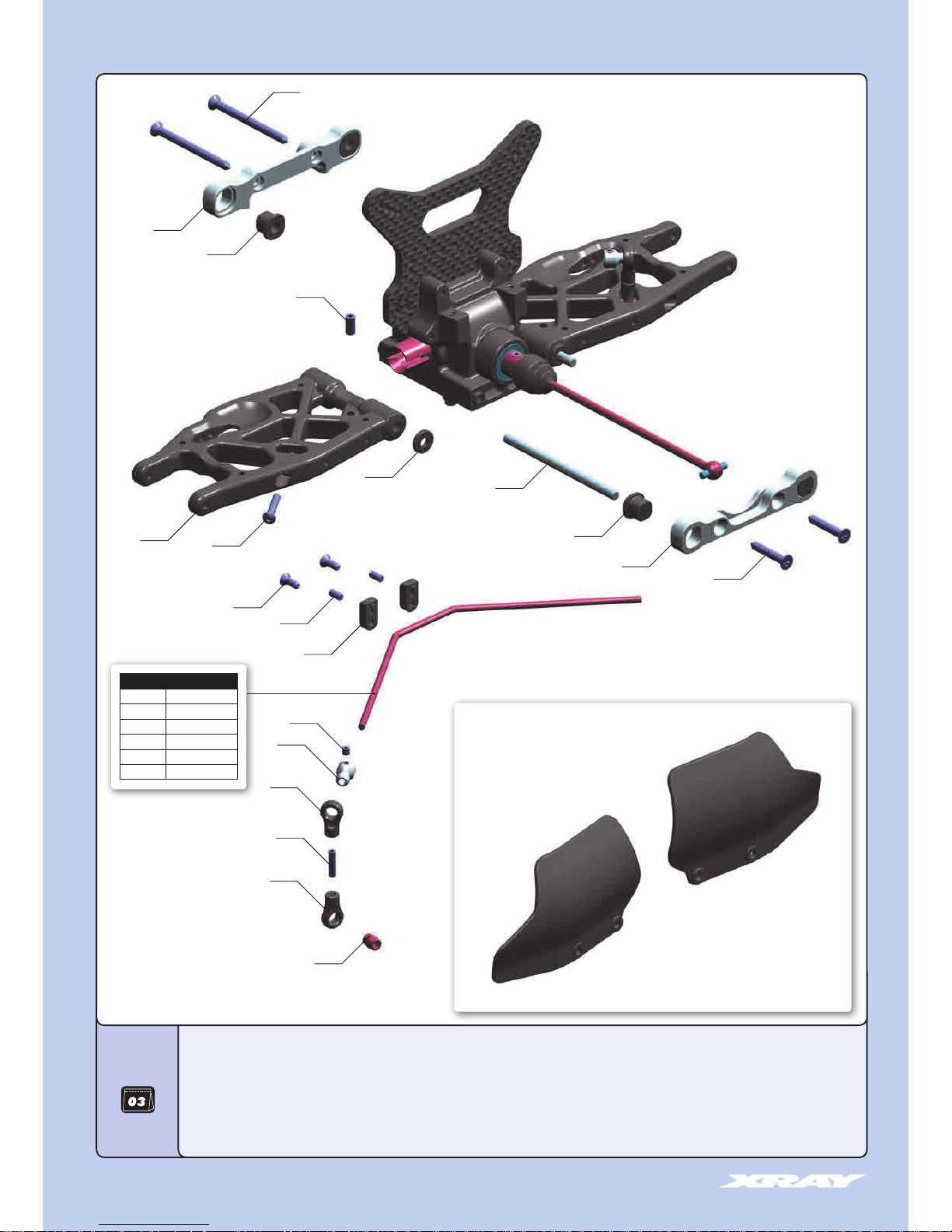

3. REAR SUSPENSION

REAR ANTI-ROLL BARS

#353422 2.2mm

(OPTION)

#353424 2.4mm

(OPTION)

#353426 2.6mm (STANDARD

)

#353428 2.8mm (

OPTION

)

#353430 3.0mm

(OPTION)

#353432 3.2mm

(OPTION)

909395

901408

353325

352314

353371

352005

909372

353317

352314

357212

OPTION

# 353192 Composite Rear Mud Protector (L+R)

902318

353117

903308

901305

901303

333450

352470

901312

352470

352460

33 3450 ANTI-ROLL BAR BALL JOINT 5.8 MM (2)

35 2005 XB8 DIFF BULKHEAD BLOCK SET FRONT/REAR

35 2314 COMPOSITE ECCENTRIC BUSHINGS - V2 (2)

35 2460 PIVOT BALL 5.8 (10)

35 2470 BALL JOINT 5.8 (8)

35 3117 XB8 COMPOSITE REAR LOWER SUSPENSION ARM

35 3192 XB8 COMPOSITE REAR MUD PROTECTOR (L+R)

35 3317 XB8 ALU REAR LOWER SUSP. HOLDER - FRONT - SQUARE ADJ. ROLL-CENTER

35 3325 XB8 ALU REAR LOWER SUSP. HOLDER - REAR - SQUARE ADJ. ROLL-CENTER

35 3371 SET OF COMPOSITE LOWER ARM SHIMS

35 3426 REAR ANTI-ROLL BAR 2.6MM

35 7212 LOWER INNER PIVOT PIN F+R (2)

90 1303 HEX SCREW SB M3x3 (10)

90 1305 HEX SCREW SB M3x5 (10)

90 1312 HEX SCREW SB M3x12 (10)

90 1408 HEX SCREW SB M4x8 (10)

90 2318 HEX SCREW SH M3x18 (10)

90 3308 HEX SCREW SFH M3x8 (10))

90 9372 SCREW PHILLIPS SS 3.5x22 (10)

90 9395 SCREW PHILLIPS SS 3.5x45 (10)

Page 13

13

TOE-IN

ANTI-SQUAT

ROLL CENTER

DOWNSTOP

TRACK-WIDTH

REAR SUSPENSION

909395

SS 3.5x45

909372

SS 3.5x22

901408

SB M4x8

353371

SHIM 4x10x2

ECCENTRIC BUSHINGS HAVE TWO DIFFERENT OFFSETS FROM THE CENTER.

Middle position = 0.5 mm or 0.5° from center

Outer position = 1mm or 1° from center

The new XRAY rear alu lower suspension holders provide even greater range of adjustment for the rear suspension. Using different combinations of eccentric bushings, fine adjustment of rear anti-squat, rear

toe-in, rear roll center, and rear track-width can be obtained. For more information about the influence of rear anti-squat, rear toe-in, rear roll center and rear track width on car handling, please refer to HUDY

Off-Road Set-up Book (#209099).

The tables describe the amounts of rear anti-squat, rear toe-in, rear track-width change depending

on the combinations of eccentric bushings used with 0 and 1mm, 1° off set. The 0.5mm, 0.5° represent

the half change.

Example:

0(RR) - 0 (RF) = 3°

0(RR) - 0.5 (RF) = 3.5°

0(RR) - 1 (RF) = 4°

ANTI-SQUAT ROLL CENTER TRACK-WIDTH TOE-IN

RR RR RR RRRF RF RF RF(°) (mm) (mm) (°)

=3°

=4°

=2°

=4°

=3°

=5°

=2°

=3°

=1°

= 3°

= 3.5°

= 4°

=0

mm

=1mm

=-1mm

=308

=306

=310

=3°

=4°

=2°

=2°

=3°

=1°

=4°

=5°

=3°

L=R

3.3mm

DOWNSTOP SETTING

Check for free movement

REAR ARM

(HUDY #107634)

ARM REAMER

If the suspension arm does not move freely use a

HUDY Arm Reamer to resize the holes of the arms.

➊

➊

➋

➌

➌

➍

➍

➎

2mm

4x8

RR

RF

Composite eccentric bushings

INITIAL SETTING

1 10.5 0.50

All possible mounting

alternatives of eccentric bushings

Composite eccentric bushings

INITIAL SETTING

1 10.5 0.50

L=R

Push the arm from both sides to create play

Page 14

14

REAR SUSPENSION

ANTI-ROLL BAR

➋

901303

SB M3x3

901305

SB M3x5

901312

SB M3x12

902318

SH M3x18

➊

➋

➌

➍

3x5

3x8

903308

SFH M3x8

-2~0mm

L=R

STEP DETAIL

➍

L=R

2x

1.5mm

6mm

Follow the TECH TIP on page 5 to

install the pivot balls

3x3

Step check for free movement

➊

3x18

DETAIL

DETAIL

Loosen the 3x5 setscrew if

the anti-roll bar does not

turn freely

Step

➊

Page 15

15

980317

P 3x17

941319

BB 13x19x4

901504

SB M5x4

903416

SFH M4x16

980263

P 2.5x13

➊

➋

L=R

➌

➍

➑

➐

➒

➏

➍

➎

ASSEMBLED VIEW

353370

SHIM 3x9x2

960030

N M3

940814

BB 8x14x4

4. REAR SUSPENSION

35 1330 COMPOSITE REAR BODY POST - LONG

35 2234 XB8 ALU REAR HUB MOUNTING PLATE - SWISS 7075 T6

35 2633 ADJ. TURNBUCKLE M5 L/R 72 MM - HUDY SPRING STEEL™ (2)

35 2657 BALL STUD 6.8MM WITH BACKSTOP L=8MM - M4x6 (2)

35 3131 REAR UPPER INNER CAMBER LINK BALL JOINT - V3 (2)

35 3160 MOUNTING BALL 6.8 (4)

35 3352 XB8 COMPOSITE REAR UPRIGHT

35 3370 SET OF COMPOSITE REAR HUB CARRIER SHIMS

35 3521 REAR WING POSTS

35 3559 COMPOSITE REAR WING MOUNT BRACE (2)

35 5211 CVD DRIVE AXLE - HUDY SPRING STEEL™

35 5221 CVD UNIVERSAL DRIVE SHAFT - HUDY SPRING STEEL™

BAG

2x

L=R

Ensure that the rear upright moves freely.

If it does not move freely, use sandpaper

to thin both wheelbase adjustment shims.

Shims for

wheelbase

adjustment

L=R

L=R

Graphite Grease

(HUDY #106210)

INITIAL SETTING

2mm

Check for free

movement

To tighten the setscrew you can

also use the HUDY 17mm Wheel

Nut Tool #107570

3x17

2.5x13

8x14x4

13x19x4

Follow the TECH TIP on page

5 for drive shaft pin servicing

Do not overtighten the self-locking nut.

Overtightening may result in suspension binding.

If the rear upright does not move freely, use a HUDY Arm Reamer to resize the hole.

ARM REAMER

2mm

OFFSET WHEEL AXLES

#355250 0mm (STANDARD)

#355251 +1mm

(OPTION)

#355252 +2mm

(OPTION)

2.5mm

INITIAL SETTING

35 5237 CVD DRIVE SHAFT COUPLING - HUDY SPRING STEEL™

35 5250 ALU WHEEL AXLE - BLACK COATED (2)

35 7331 XB808 REAR LOWER OUTER PIVOT PIN SCREW 3MM (2)

90 1504 HEX SCREW SB M5x4 (10)

90 2310 HEX SCREW SH M3x10 (10)

90 2314 HEX SCREW SH M3x14 (10)

90 2318 HEX SCREW SH M3x18 (10)

90 2320 HEX SCREW SH M3x20 (10)

90 3416 HEX SCREW SFH M4x16 (10)

94 0814 HIGH-SPEED BALL-BEARING 8x14x4 BLUE COVERED (2)

94 1319 HIGH-SPEED BALL-BEARING 13x19x4 BLUE COVERED (2)

96 0030 NUT M3 (10)

98 0263 PIN 2.5x13 (10)

98 0317 PIN 3x17 (10)

(HUDY #107633)

902314

902320

903416

352234

980317

901504

940814

941319

357331

902310

980263

960030

902318

960030

902318

960030

353521

353559

353521

353352

355250

353370

355211

355237

355221

352657

353131

352633

353160

353131

351330

Use HUDY Ball-Bearing

Grease or Oil for servicing:

#106220 - Standard

#106221 - Extra

#106222 - Premium

#106230 - Bearing Oil

Page 16

16

CAMBER

REAR SUSPENSION

REAR WING

902318

SH M3x18

960030

N M3

902314

SH M3x14

960030

N M3

902318

SH M3x18

902320

SH M3x20

902310

SH M3x10

353380

SHIM 4x7.5x1

353381

SHIM 4x7.5x2

ROLL CENTER

Follow the TECH TIP on page 5

to install the pivot balls

DETAIL

Use tools

to tighten as shown

Special Tool for all turnbuckles & nuts (HUDY #108090)

NOTE ORIENTATION

NOTE ORIENTATION

NOTE ORIENTATION

NOTE

ORIENTATION

Right threadLeft thread Right thread Left thread

47.3 mm

INITIAL POSITIONS

3x18

3x18

3x10

3x20

3x14

3x14

47.3 mm

RIGHT

THREAD

RIGHT THREAD

LEFT

THREAD

LEFT THREAD

F1

F3

F2

F4

R1R3R2

R4

Follow the TECH TIP on page 5

to install the pivot balls

For stiffer wing mounting use OPTIONAL

alu wing mount brace #353550.

INITIAL POSITIONS

Single Body Post

INITIAL SETTING

INITIAL POSITIONS

OPTION shims from the Last Aid Bag can be

used for roll center adjustment.

#353380 - Alu shim 4x7.5x1mm

#353381 - Alu shim 4x7.5x2mm

OIL

OIL

OIL

OIL

Double Body Posts

OPTION SETTING

Page 17

17

5. FRONT SUSPENSION

33 3450 ANTI-ROLL BAR BALL JOINT 5.8 MM (2)

35 2005 DIFF BULKHEAD BLOCK SET FRONT/REAR

35 2117 XB8 COMPOSITE FRONT LOWER SUSPENSION ARM

35 2323 ALU FRONT LOWER SUSP. HOLDER - FRONT - SQUARE ADJ. ROLL-CENTER - V2

35 2324 ALU FRONT LOWER SUSP. HOLDER - REAR - SQUARE ADJ. ROLL-CENTER - V2

35 2314 COMPOSITE SQUARE ADJ. ROLL-CENTER BUSHINGS - V2 (2)

35 2460 PIVOT BALL 5.8 (10)

35 2470 BALL JOINT 5.8 (8)

35 2494 FRONT ANTI-ROLL BAR 2.4MM

35 3371 SET OF COMPOSITE LOWER ARM SHIMS

35 7212 LOWER INNER PIVOT PIN F+R (2)

90 1303 HEX SCREW SB M3x3 (10)

90 1305 HEX SCREW SB M3x5 (10)

90 1312 HEX SCREW SB M3x12 (10)

90 1408 HEX SCREW SB M4x8 (10)

90 2318 HEX SCREW SH M3x18 (10)

90 3308 HEX SCREW SFH M3x8 (10))

90 9372 SCREW PHILLIPS SS 3.5x22 (10)

90 9395 SCREW PHILLIPS SS 3.5x45 (10)

BAG

FRONT ANTI-ROLL BARS

#352492 2.2mm

(OPTION)

#352494 2.4mm (STANDARD

)

#352496 2.6mm

(OPTION)

909372

901408

902318

352117

909395

901303

901312

901305

903308

352324

352314

357212

352314

353371

333450

352470

352470

352460

352005

352323

Page 18

18

FRONT SUSPENSION

KICK UP

ROLL CENTER

DOWNSTOP

WHEELBASE

TRACK WIDTH

901408

SB M4x8

909395

SS 3.5x45

909372

SS 3.5x22

All possible mounting alternatives

of eccentric bushings

Composite eccentric bushings

INITIAL SETTING

1 10.5 0.50

Composite eccentric bushings

INITIAL POSITION

1 10.5 0.50

353371

SHIM 4x10x2

(HUDY #107634)

ARM REAMER

If the suspension arms do not move freely, use

a HUDY Arm Reamer resize the holes.

L=R

1.7mm

DOWNSTOP SETTING

The tables below describe the amounts of kick-up, front track-width change depending on the combinations of

eccentric bushings used with 0 and 1mm, 1° off set. The 0.5mm, 0.5° represent the half change.

TRACK-WIDTH ROLL CENTER

FF FFFR FR(mm) (mm)

=308

=306

=310

=1

=0

=-1

The new XRAY alu front lower suspension holders provide even greater range of adjustment for the front

suspension. Using different combinations of eccentric bushings, fine adjustment of front kick-up, roll center, and

front track-width can be obtained. For more information about the influence of kick-up, front track-width, and

roll centers on car handling, please refer to HUDY Off-Road Set-up Book (#209099).

Eccentric bushings have two different offsets from the center.

Middle position = 0.5 mm or 0.5° from center

Outer position = 1mm or 1° from center

➊

➊

➋

➌

➌

➍

➍

➎

4x8

FR

FF

2mm

FRONT ARM

L=R

Check for free movement

DETAILDETAIL

Use the shim from Bag 03

Push the arm from both sides to create play

Page 19

19

FRONT SUSPENSION

ANTI-ROLL BAR

901303

SB M3x3

901305

SB M3x5

901312

SB M3x12

902318

SH M3x18

903308

SFH M3x8

3x3

3x5

3x8

-2~0mm

3x18

L=R

2x

Step check for free movement

➊

DETAIL

DETAIL

Loosen the 3x5 setscrew if

the anti-roll bar does not

turn freely

Step

➊

➊

➋

➌

➍

L=R

STEP DETAIL

➍

1.5mm

6mm

Follow the TECH TIP on page 5 to

install the pivot balls

Page 20

20

941319

BB 13x19x4

901504

SB M5x4

940814

BB 8x14x4

➊

➋

L=R

980317

P 3x17

980263

P 2.5x13

903416

SFH M4x16

Use HUDY Ball-Bearing

Grease or Oil for servicing:

#106220 - Standard

#106221 - Extra

#106222 - Premium

#106230 - Bearing Oil

6. FRONT SUSPENSION

35 2132 XB8 FRONT UPPER ARM RIGHT

35 2142 XB8 FRONT UPPER ARM LEFT

35 2153 XB8 FRONT UPPER ARM BALL JOINT (L+R)

35 2231 XB8 ALU STEERING KING PIN PLATE - SWISS 7075 T6 - L+R 14°

35 2240 XB8 STEERING BLOCK

35 2623 ADJ. TURNBUCKLE M5 L/R 28 MM - HUDY SPRING STEEL™ (2)

35 3172 PIVOT BALL 11.0 (2)

35 5211 CVD DRIVE AXLE - HUDY SPRING STEEL™

35 5221 CVD UNIVERSAL DRIVE SHAFT - HUDY SPRING STEEL™

35 5237 CVD DRIVE SHAFT COUPLING - HUDY SPRING STEEL™

35 5250 ALU WHEEL AXLE - BLACK COATED (2)

35 7250 STEEL PIVOT BALL 13.9 MM (2)

35 7252 ALU ADJUSTING NUT M15x1 (2)

35 7253 BRASS ADJUSTING NUT M15x1 (2) (OPTION)

35 7254 COMPOSITE BALL CUP 13.9 MM (2)

35 7256 ALU SHIM 6x13x1 (2)

90 1504 HEX SCREW SB M5x4 (10)

90 3416 HEX SCREW SFH M4x16 (10)

94 0814 HIGH-SPEED BALL-BEARING 8x14x4 BLUE COVERED (2)

94 1319 HIGH-SPEED BALL-BEARING 13x19x4 BLUE COVERED (2)

98 0263 PIN 2.5x13 (10)

98 0317 PIN 3x17 (10)

BAG

2x

Graphite Grease

(HUDY #106210)

352231

357256

357250

352240

941319

355211

355221

352142

352153

352231

352153

352623

352132

980317

355250

901504

357254

357252

940814

355237

980263

353172

903416

To tighten the setscrew you can also use the

HUDY 17mm Wheel Nut Tool #107570

Follow the TECH TIP on page 5

for drive shaft pin servicing

OFFSET WHEEL AXLES

#355250 0mm (STANDARD)

#355251 +1mm

(OPTION)

#355252 +2mm

(OPTION)

OFFSET WHEEL AXLES

#355250 0mm (STANDARD)

#355251 +1mm

(OPTION)

#355252 +2mm

(OPTION)

ASSEMBLED VIEW

2.5mm

➎

➍

➍

➏

➐

➑

➌

3x17

2.5x13

8x14x4

13x19x4

4x16

OPTION

#357253 Brass

Adjusting Nut M15x1

KING PIN PLATES

#352231 L+R 14° (STANDARD)

#352235 L+R 10°

(OPTION)

#352237 L+R 6°

(OPTION)

KING PIN PLATES

#352231 L+R 14° (STANDARD)

#352235 L+R 10°

(OPTION)

#352237 L+R 6°

(OPTION)

Page 21

21

CAMBER

ROLL CENTER

L=R

PIVOT BALLS MUST MOVE FREELY

During initial assembly, tighten each composite hex nut until the pivot ball starts to

bind, then loosen slightly. Verify that the pivot balls move freely.

IMPORTANT

Check that the pivot balls move freely after every run especially in dusty conditions.

Tighten composite hex nuts using

HUDY tool #107581

2.5mm

2.5mm

2.5mm

357256

SHIM 6x13x1

353380

SHIM 4x7.5x1

353381

SHIM 4x7.5x2

(HUDY #107634)

ARM REAMER

If the front upper arm does not move freely use a

HUDY Arm Reamer to resize the holes of the arms.

FRONT SUSPENSION

DETAIL

OPTION shims from the Last Aid Bag can be used for

Roll Center adjustment.

#353380 - Alu shim 4x7.5x1mm

#353381 - Alu shim 4x7.5x2mm

Apply WD-40 to protect against rust

CUTAWAY VIEW

HUDY Tool Allen 2.5mm

HUDY Tool Allen 2.5mm

SHORT LONG

HUDY Tool Allen Ball 2.5mm

Marked (L) = Marked (L) Marked (R) = Marked (R)

22mm

102.3mm 102.3mm

2x

1mm

L=R

L=R

L=R

2x

2x

2x

OPTION

#357253 Brass Adjusting Nut M15x1

Page 22

22

903412

SFH M4x12

FRONT & REAR ASSEMBLY

35 1109 XB8E ALU CHASSIS - SWISS 7075 T6 (3MM) - HARD COATED

35 1200 FRONT & REAR BUMPER - V2

35 3088 COMPOSITE REAR BRACE - V2 (OPTION)

35 3089 COMPOSITE REAR BRACE - LONG

90 2316 HEX SCREW SH M3x16 (10)

90 3312 HEX SCREW SFH M3x12 (10)

90 3412 HEX SCREW SFH M4x12 (10)

96 0030 NUT M3 (10)

BAG

902316

960030

960030

903412

903312

903412

351200

351109

353089

351200

OPTION

#353088 Short Rear Brace

Page 23

23

903312

SFH M3x12

902316

SH M3x16

903412

SFH M4x12

960030

N M3

FRONT & REAR ASSEMBLY

3x16

INITIAL SETTING

Add for extra stiffness

(use from Last Aid Bag)

3x12

DETAIL

Screw from the Last Aid Bag can be

used for extra stiffeness adjustment

OPTION

#358088 Short Rear Brace

REAR BRACES

TRACK TYPE

FLAT MEDIUM JUMPS LARGE JUMPS

Long Brace

Short Brace

Page 24

24

7. STEERING

30 3122 ALU SHIM 3x6x1.0MM (10)

30 3123 ALU SHIM 3x6x2.0MM (10)

35 1301 BODY POSTS

35 1347 XB8 GRAPHITE UPPER PLATE

35 2088 COMPOSITE FRONT BRACE

35 2096 XB8 GRAPHITE FRONT SHOCK TOWER - CNC MACHINED 4 MM

35 2314 COMPOSITE SQUARE ADJ. ROLL-CENTER BUSHINGS - V2 (2)

35 2333 XB8 ALU FRONT UPPER ARM HOLDER - SWISS 7075 T6 (6MM)

35 2381 XB8 CASTER CLIPS (2)

35 2503 XB8 SERVO SAVER COMPLETE SET

35 2513 XB8 COMPOSITE SERVO SAVER

35 2576 STEERING PLATE BUSHING (2)

35 2578 XB8 ALU STEERING PLATE - SWISS 7075 T6

35 2611 ADJ. TURNBUCKLE M4 L/R 52.5 MM - HUDY SPRING STEEL (2)

35 2652 BALL STUD 6.8MM (4)

35 2664 COMPOSITE STEERING BALL JOINT 6.8MM - V3 (2)

35 2666 COMPOSITE RELIEF STEERING BALL JOINT 6.8MM (2)

35 7220 FRONT UPPER PIVOT PIN (2)

90 2308 HEX SCREW SH M3x8 (10)

90 2310 HEX SCREW SH M3x10 (10)

90 2312 HEX SCREW SH M3x12 (10)

90 2314 HEX SCREW SH M3x14 (10)

90 3306 HEX SCREW SFH M3x6 (10)

90 3310 HEX SCREW SFH M3x10 (10)

90 3312 HEX SCREW SFH M3x12 (10)

90 3320 HEX SCREW SFH M3x20 (10)

90 3410 HEX SCREW SFH M4x10 (10)

94 0610 HIGH-SPEED BALL-BEARING 6x10x3 BLUE COVERED (2)

96 0030 NUT M3 (10)

97 0121 O-RING 12.1 x 1.6 (10)

BAG

352576

352513

902308

960030

303123

352333

357220

352381

352652

352666

903320

960030

902310

903310

960030

352611

351301

903310

903306

940610

352503

352513

960030

352578

303122

352652

352664

903320

352513

352503

352503

970121

940610

352503

903410

902314

351347

352088

352381

352314

902312

352096

903312

Page 25

25

ROLL CENTER

SERVO SAVER

902308

SH M3x8

940610

BB 6x10x3

902314

SH M3x14

903312

SFH M3x12

903410

SFH M4x10

902310

SH M3x10

903310

SFH M3x10

960030

N M3

903306

SFH M3x6

970121

O 12.1x1.6

3x10

3.0mm

HUDY Tool Allen 3.0mm

For servicing use

Bearing Oil (HUDY #106230)

NOTE ORIENTATION

step 1 step 2 step 3

STEERING

4x10

3x8

3x8

3x12

3x14

3x10

3x10

3x10

3x6

3x6

NOTE

ORIENTATION

NOTE

ORIENTATION

All possible mounting

alternatives of eccentric bushings

INITIAL SETTINGS

1 10.5 0.50

ASSEMBLED

VIEW

Composite eccentric bushings

INITIAL POSITION

4~5mm

INITIAL PRELOAD SETTING

Follow the TECH TIP on page 5

to install the pivot balls

RIGHT THREAD

LEFT THREAD

32.2 mm

32.2 mm

Left thread

Right thread

Left thread Right thread

Follow the TECH TIP on page 5

to install the pivot balls

RIGHT THREAD

LEFT THREAD

NOTE

ORIENTATION

NOTE

ORIENTATION

Page 26

26

ROLL CENTER

CASTER

ACKERMANN

BUMP STEER

TOE-IN

960030

N M3

903320

SFH M3x20

303122

SHIM 3x6x1

303123

SHIM 3x6x2

902312

SH M3x12

CASTER

UPPER CLIP

(Behind arm)

LOWER SHIM (Behind arm)

2mm 0

4mm 24º 21º

3mm 25.5º 22.5º

2mm 27º 24º

1mm 28.5º 25.5º

0 30º 27º

STEERING

L=R

2x

INITIAL POSITION

NOTE ORIENTATION

Adjustment block towards outside

NOTE ORIENTATION

Adjustment block towards outside

2.0mm

1.0mm

Check for free

movement

Check for free

movement

All possible mounting

alternatives of eccentric bushings

IMPORTANT

Check free movement of the front upper arm after every run especially

in dusty conditions. In case of binding resize the front upper arm and/or

clean the eccentric bushings.

Cutaway view

Shock Tower

Composite eccentric bushings

INITIAL SETTINGS

1 10.5 0.50

1.0mm

1.0mm

2.0mm

NOTE

ORIENTATION

DETAIL

NOTE

ORIENTATION

INITIAL POSITION

UPPER CLIP

LOWER SHIM

Behind arm

Behind arm

CASTER

Page 27

27

908312

SCH M3x12

8. CENTER DIFF & MOTOR

BAG

35 1158 XB8 CHASSIS SIDE GUARDS L+R W/OUT RIB

35 2290 COMPOSITE BUSHING FOR ALU STEERING BLOCK (4)

35 4011 CENTER DIFF MOUNTING PLATE SET - HIGHER

35 4053 XB9E GRAPHITE CENTER DIFF MOUNTING PLATE

35 5712~17 XB808E 12~17T PINION GEAR (OPTION)

35 8783 XB9E ALU MOTOR MOUNT PLATE

35 8784 XB8E ALU MOTOR MOUNT

90 2330 HEX SCREW SH M3x30 (10)

90 3308 HEX SCREW SFH M3x8 (10)

90 3310 HEX SCREW SFH M3x10 (10)

90 3314 HEX SCREW SFH M3x14 (10)

90 3412 HEX SCREW SFH M4x12 (10)

90 8312 HEX SCREW SOCKET HEAD CAP M3x12 (10)

90 8314 HEX SCREW SOCKET HEAD CAP M3x14 (10)

96 0030 NUT M3 (10)

96 1032 WASHER S 3.2 (10)

The motor mount is designed for 3mm

motor screws. In case your motor

requires larger diameter screws please

drill the holes in the motor mount

accordingly.

351158

902330

352290

903308

354053

960030

903314

354011

354011

903412

960030

908314

961032

Motor

(not included)

358783

903310

903314

903412

351158

903310

355012

(Center Diff)

358784

355712-17

(not included)

908312

PINION

355712-17

(not included)

Page 28

28

902330

SH M3x30

903308

SFH M3x8

903412

SFH M4x12

CENTER DIFF & MOTOR

NOTE ORIENTATION

NOTE ORIENTATION

NOTE ORIENTATION

Page 29

29

903310

SFH M3x10

903310

SFH M3x10

903314

SFH M3x14

903314

SFH M3x14

960030

N M3

960030

N M3

908314

SCH M3x14

961032

S 3.2

CENTER DIFF & MOTOR

Gear mesh adjustment

Adjust gear mesh so there is minimal play between the gears.

Too tight gear mesh will put excessive strain on all parts and damage the parts.

Too loose gear mesh may result in stripped gears.

3x10 3x10 3x10

3x14

3x14

3x10 3x10

Page 30

30

902312

SH M3x12

10. RADIO CASE

BAG

30 2610 ADJ. TURNBUCKLE L/R 40 MM - HUDY SPRING STEEL (2)

30 6310 ANTENNA TUBE (2)

33 6000 COMPOSITE RECEIVER CASE - V2

33 6060 RECEIVER SWITCH - SET (OPTION)

35 2460 PIVOT BALL 5.8 (10)

35 2670 SERVO BALL JOINT 5.8MM (4)

35 6118 XB9E GRAPHITE RECEIVER CASE TOP PLATE

35 6120 STEERING SERVO MOUNT - SET

35 6151 XB9E COMPOSITE BATTERY PLATE

35 6160 VELCRO BATTERY STRAP 20x300MM (2)

35 6194 XB9E ALU MOUNT FOR RECEIVER BOX

35 6200 BRAKE/THROTTLE ARMS & STEERING SERVO ARMS - SET

38 9135 CONNECTING CABLE RECEIVER/BATT. PACK (OPTION)

90 2308 HEX SCREW SH M3x8 (10)

90 2312 HEX SCREW SH M3x12 (10)

90 2314 HEX SCREW SH M3x14 (10)

90 3410 HEX SCREW SFH M4x10 (10)

90 3412 HEX SCREW SFH M4x12 (10)

90 3416 HEX SCREW SFH M4x16 (10)

90 7206 SCREW PHILLIPS 2x6 (10)

96 0030 NUT M3 (10)

96 0040 NUT M4 (10)

NOTE

ORIENTATION

LEFT THREADRIGHT THREAD

HUDY ALU SERVO HORNS

#293501 23T KO Propo, Airtronics, JR, Sanwa (OPTION)

#293502 24T Hitec (OPTION)

#293503 25T Futaba (OPTION)

Use appropriate servo arm:

K - (23T) H - (24T) F - (25T)

356200

356120

356194

903412

Receiver

(not included)

336000

336000

902308

306310

Speed Controller

(not included)

Servo Screw

(not included)

LiPo Battery Pack

(not included)

356151

960040

907206

356151

356160

903416

903410

902312

Servo Grommet

(not included)

Steering Servo

(not included)

902308

356118

352460

352670

902312

302610

352670

960030

902314

10

The length of the linkages varies according to the type of servo.

21 mm

LEFT

THREAD

RIGHT

THREAD

Follow the TECH TIP on page

5 to install the pivot balls

Page 31

31

902312

SH M3x12

902308

SH M3x8

902308

SH M3x8

907206

2x6

RADIO CASE

If the receiver box has 2 different-size openings

for cable entry (narrow and wider), cut away

the tab for the appropriate opening to allow the

cables to fit properly.

Receiver

(not included)

Antenna

Servo Screw

(not included)

Page 32

32

902314

SH M3x14

903410

SFH M4x10

903410

SFH M4x10

903416

SFH M4x16

960030

N M3

960040

N M4

Cut the foam as needed to fill in space between

the batteries and holder.

DOUBLE-SIDED TAPE

(not included)

BATTERY

(not included)

TIE STRAP

(not included)

SPEED CONTROLLER

(not included)

VELCRO BATTERY STRAP

RADIO CASE

4x16

4x10

Page 33

33

SHOCK DAMPING

SHOCK PISTONS

971034

O 3.4x2

960026

N M2.5

358040

S 2.5x6x0.5

970100

O 10x1.5

INCORRECT INCORRECT

CORRECT

CUTAWAY VIEW

BAGS

11.1

35 2460 PIVOT BALL 5.8 - V3 (10)

35 8019 COMPOSITE SET OF SHIMS FOR SHOCKS - V2 (2)

35 8020 COMPOSITE SHOCK PARTS

35 8032 SHOCK PISTON SET 8-HOLE (1.2; 1.3) 10-H. (1.1MM) - DELRIN - V2

35 8033 COMPOSITE SHOCK 6-HOLE PISTON SET (1.2; 1.3; 1.4MM) - DELRIN - V2

35 8040 HARDENED SHOCK SHIMS (4)

35 8041 STEEL SHOCK BUSHING (2)

35 8042 COMPOSITE SHOCK BUSHING & SHIM - V2 (2+2)

35 8053 XB8 ALU SHOCK CAP NUT - BLACK COATED (2)

35 8054 XB8 ALU SHOCK CAP NUT WITH VENT HOLE - BLACK COATED (2) (OPTION)

35 8074 FOLDING SHOCK BOOT (4)

35 8084 SHOCK RUBBER MEMBRANE BOTTOM RIBBED (4)

35 8124 XB8 ALU FRONT SHOCK BODY - HARD COATED (2)

35 8142 ALU SHOCK BODY NUT FOR SHOCK BOOT (2)

35 8150 ALU SHOCK BODY ADJ. NUT (2)

35 8162 FRONT SHOCK SHAFT (2)

35 8224 XB8 ALU REAR SHOCK BODY - HARD COATED (2)

35 8263 XB8 REAR SHOCK SHAFT (2)

35 8277 XRAY PROGRESSIVE SPRINGS - MEDIUM - 3 STRIPES - V2 (2)

35 8279 XRAY LONG PROGRESSIVE SPRINGS - SOFT-MEDIUM - 2 STRIPES - V2 (2)

96 0026 NUT M2.5 - SHORT (10)

97 0100 O-RING 10 x 1.5 (10)

97 0180 O-RING 18 x 1.8 (10)

97 1034 SILICONE O-RING 3.5x2 (10)

11. SHOCK ABSORBERS

FRONT SHOCKS (SHORT)

2x

FRONT

SHOCK

11.1

BAG BAG

REAR

SHOCK

CORRECT

INCORRECT

There are two different thickness shims, use them as

shown. Use the same procedure when building both front

and rear shocks.

REAR SHOCKS (LONG)

2x

358041

358263

352460

358162

358042

358042

358084

960026

358040

358224

358124

970100

971034

970180

358074

358019

358142

358150

358279

358277

358053

358032

358033

358020

FRONT LINEAR SPRINGS

#358182 C=0.65 White

SHORT

(OPTION)

#358183 C=0.70 Grey

SHORT

(OPTION)

#358184 C=0.75 Silver

SHORT

(OPTION)

#358185 C=0.80 Grey-Blue

SHORT

(OPTION)

#358186 C=0.86 Blue

SHORT

(OPTION)

#358187 C=0.92 Violet

SHORT

(OPTION)

#358188 C=0.98 Purple

SHORT

(OPTION)

REAR LINEAR SPRINGS

#358282 C=0.47

White

LONG

(OPTION)

#358283 C=0.50

Grey

LONG

(OPTION)

#358284 C=0.53

Silver

LONG

(OPTION)

#358285 C=0.57

Grey-Blue

LONG

(OPTION)

#358286 C=0.61

Blue

LONG

(OPTION)

#358287 C=0.65

Violet

LONG

(OPTION)

#358288 C=0.70

Purple

LONG

(OPTION)

FRONT & REAR PROGRESSIVE SPRINGS

#358174 C=0.7-0.8

Grey

SHORT

(OPTION)

#358274 C=0.5-0.6

Grey

MEDIUM

(OPTION)

#358275 C=0.65-0.7

1 STRIPE

MEDIUM

(OPTION)

#358276 C=0.7-0.75

2 STRIPES

MEDIUM

(OPTION)

#358277 C=0.72-0.8

3 STRIPES

MEDIUM

(STANDARD)

#358278 C=0.75-0.83

4 STRIPES

MEDIUM

(OPTION)

REAR PROGRESSIVE SPRINGS

#358279 C=0.55-0.63

2 STRIPES

LONG

(STANDARD)

#358280 C=0.6-0.68

3 STRIPES

LONG

(OPTION)

#358281 C=0.65-0.7

4 STRIPES

LONG

(OPTION)

8 holes

ø1.2mm

pistons

8 holes

ø1.2mm

pistons

DETAIL

DO NOT OVERTIGHTENTIGHTEN GENTLY

NOTE

ORIENTATION

The self-locking nut is

gently tightened. The piston

remains undistorted and

fits inside the shock body

perfectly, ensuring smooth

movement of the piston.

The self-locking nut is

overtightened, causing

distortion of the piston. This

will negatively affect the free

movement of the piston in the

shock body.

(LONG)(SHORT)

O-ring

Thin Shim

O-ring

Thick Shim

PISTONS DETAIL

10 holes/ø1.1mm

6 holes/ø1.2mm

8 holes/ø1.2mm

6 holes/ø1.4mm

OPTION

#358054 XB8 Alu Shock Cap Nut With

Vent Hole - Black Coated (2)

8 holes/ø1.3mm

6 holes/ø1.3mm

.......................................................

Grip the shock rod at top of

exposed threads with side

cutting pliers. Be careful not

to damage the shock rod.

Page 34

34

SHOCK OIL

970180

O 18x1.8

INCORRECT

INCORRECT

CORRECT

INCORRECT

CORRECT

FRONT SHOCKS

REAR SHOCKS

1 mm

Gently push the shock shaft

completely into the shock

body. Excess oil will flow

through the hole in the

shock cap.

Keep the shock shaft

pushed in the shock body

and tighten the shock cap

completely.

The rebound will be at

approximately 0%.

➐

HALF TIGHTEN TIGHTEN FULLY

100%

Follow the steps below to set the shock rebound to the default setting of 0%.

CUTAWAY VIEW

Grip the shock rod at top of exposed

threads with side cutting pliers. Be

careful not to damage the shock rod.

SHOCK ABSORBERS

DETAIL

Follow the TECH TIP on page

5 to install the pivot balls

FRONT SHOCKS

2x

REAR SHOCKS

2x

FRONT (SHORT)

Oil 550cSt

2x

REAR (LONG)

Oil 400cSt

2x

2x

SHORT SHOCK BODY

SHORT SHOCK ROD

2x

LONG SHOCK BODY

LONG SHOCK ROD

EXTREMELY IMPORTANT

Do not push the shock rod straight

through the lower shock body

assembly; O-ring damage may result.

Twist the shock rod through the

lower shock body assembly.

Extend the shock shaft

completely. Fill the shock

body with the shock oil. For

the FRONT shocks (short)

use 550cSt oil. For the

REAR shocks (long) use

400cSt oil.

Move the shock shaft up and

down a few times to release

the air bubbles trapped

beneath the piston.

Orient the filled shock

vertically for several

minutes with the shock

shaft fully extended. The

remaining air bubbles will

release.

Install the shock membrane

into the groove in the

upper shock cap.

Gently place the shock cap

assembly onto the filled

shock body. Excess oil will

spill from the shock. Screw

the shock cap onto the

body by only a few turns.

➊ ➋ ➌ ➍ ➎ ➏

DETAIL

3~5x

UP & DOWN

50%

DEFAULT SHOCK REBOUND SETTING 0% (LOW REBOUND)

Page 35

35

SPRING RATE

SHOCK PRELOAD

RIDE HEIGHT

Fill the shock body with shock

oil up to the top. Make sure to

use same viscosity shock oil as

is in the shock.

➋

Orient the filled shock

vertically for several minutes

with the shock shaft fully

extended. The remaining air

bubbles will release.

Gently place the shock cap

assembly onto the filled shock

body. Excess oil will spill from

the shock.

➌

➍

50%

HALF TIGHTEN

Push the shock shaft 50% into

the shock body. Excess oil will

bleed thgrough the hole in the

shock cap.

Keep the shock shaft pushed

50% into the shock body

and tighten the shock cap

completely.

The rebound will be at

approximately 50%.

➍

Gently place the shock cap assembly onto the filled

shock body. Keep the shock shaft extended 100% from

the shock body and tighten the shock cap completely.

The rebound will be at approximately 100%.

➎ ➏

TIGHTEN FULLY

100%

50%

The default shock rebound setting is 0% (as described on page 35).

Alternatively, you may set the shock rebound setting to 50% or 100% as described below. Remove the shock springs before performing shock rebound adjustment.

Fill the shock body with shock oil up to the top.

Make sure to use same viscosity shock oil as is

in the shock.

➋

Orient the filled shock vertically for several

minutes with the shock shaft fully extended.

The remaining air bubbles will release.

➌

TIGHTEN FULLY

100%

50%

100%

SHORT FRONT SHOCKS

LONG REAR SHOCKS

IMPORTANT!

Both front shocks

must be the same

overall length.

IMPORTANT!

IMPORTANT!

Both rear shocks

must be the same

overall length.

FRONT SHOCKS

2x

REAR SHOCKS

FRONT & REAR SHOCKS

2x

SHORT SPRING

LONG SPRING

SETTING THE SHOCK REBOUND TO 50% (MEDIUM REBOUND)

SHOCK ABSORBERS

➊

Extend the shock shaft completely

and remove the shock cap.

REMOVE SHOCK CAP

SETTING THE SHOCK REBOUND TO 100% (HIGH REBOUND)

ALTERNATE SHOCK REBOUND SETTING (50% AND 100%)

➊

Extend the shock shaft completely and remove

the shock cap.

REMOVE SHOCK CAP

REAR SHOCK

PRELOAD

FRONT SHOCK PRELOAD

approx. 2mm

approx. 2mm

Page 36

36

SHOCK ABSORBERS

902319

SH M3x18

LEFT thread

960030

N M3

902318

SH M3x18

12. FINAL ASSEMBLY

12

BAG

35 2030 XB8 FRONT SHOCK TOWER PROTECTOR

35 3511-K XB8 REAR WING - BLACK

35 3511 XB8 REAR WING - WHITE (OPTION)

35 3511-Y XB8 REAR WING - YELLOW (OPTION)

35 3565 COMPOSITE REAR WING SHIM - BLACK (2)

35 5261 WHEEL NUT - RIBBED - HARD COATED (2)

35 5265 WHEEL NUT WITH COVER - HARD COATED (2) (OPTION)

35 8047 STEEL SCREW SHOCK PIVOT BALL WITH HEX (2)

35 8105 XB8 FRONT SHOCK ABSORBERS + BOOTS COMPLETE SET (2)

35 8205 XB8 REAR SHOCK ABSORBERS + BOOTS COMPLETE SET (2)

35 9400 BODY CLIP (10)

35 9709 XRAY XB8E BODY FOR 1/8 ELECTRIC BUGGY - LOW DOWNFORCE

35 9809 WHEELS STARBURST - YELLOW (4) (OPTION)

90 2318 HEX SCREW SH M3x18 (10)

90 2319 HEX SCREW SH M3x18 - LEFT THREAD (10)

90 3312 HEX SCREW SFH M3x12 (10)

96 0030 NUT M3 (10)

353511-K

353565

902318

902319

358047

Tires

(not included)

358205

358047

355261

960030

960030

960030

358105

960030

960030

903312

359400

FRONT SHOCKS (SHORT)

NOTE ORIENTATION

(SHORTER) (LONGER)

INITIAL SETTING

355261

Inserts

(not included)

359809

(not included)

On the front right arm use the SILVER M3x18

screw - this screw has LEFT THREAD

Use STANDARD

M3x18 screw

3x18

1

2

3

4

3

4

2

1

L=R

L=R

INITIAL SETTING

1

2

2x

352030

Page 37

37

SHOCK ABSORBERS

960030

N M3

902319

SH M3x18

LEFT thread

902318

M3x18

903312

SFH M3x12

960030

N M3

Body Reamer (HUDY #107600)

DETAIL

FINAL ASSEMBLY

REAR SHOCKS (LONG)

L=R

INITIAL SETTING

INITIAL SETTING

On the rear left arm use the SILVER M3x18

screw - this screw has LEFT THREAD

Use STANDARD

M3x18 screw

M3x18

1

2

1

1

2

2

3

3

4

4

NOTE

ORIENTATION

(SHORTER) (LONGER)

L=R

2x

CA

XRAY STARBURST WHEELS

#359808 Pink

(OPTION)

#359809 Yellow

(OPTION)

To tighten the setscrew you can also use the

HUDY 17mm Wheel Nut Tool #107570

NOTE

ORIENTATION

DETAIL

➍

Before cutting and making holes on the body, put the unpainted body on the chassis to confirm the

mounting position and location for holes and cutouts.

Before painting, wash the inside of the body with mild detergent, and then rinse and dry thoroughly.

Mask all windows.

Apply paint masks as appropriate.

Paint the body using paints formulated for polycarbonate bodies.

When the paint is dry, remove the masking.

Carefully cut out the body using appropriate scissors or cutting tools.

When you have finished cutting, peel off the external protective films.

➊

➋

➌

➎

➏

➐

➑

Ensure to make this rear body

mount hole oval so in the case of

chassis flex after a big jump the

body mount will not tear up the

hole.

Page 38

38

PROBLEM CAUSE SOLUTION

CAR IS HARD TO

CONTROL

• Weak transmitter and/or receiver batteries

• Low reception from radio antennas

• Servo linkages not adjusted properly

• Recharge or replace batteries

• Fully extend transmitter and receiver antennas

• Move servo to neutral then re-adjust linkage(s)

STEERING DOES NOT

WORK PROPERLY

• Weak transmitter and/or receiver batteries

• Bent linkages or driveshafts

• Loose steering components

• Drivetrain damage

• Recharge or replace batteries

• Check tightness of steering components and tighten if necessary

• Replace damaged parts

HANDLING PROBLEMS

• Shocks are not working properly

• Suspension is binding

• Improper tires

• Rebuild the shocks and replace worn or broken parts

• Make sure suspension moves freely. Replace worn or broken parts

• Use different tires

STEERING FEELS

SLUGGISH OR VAGUE

• Suspension is binding

• Damaged steering servo

• Make sure suspension moves freely, and replace worn or broken parts

• Check the steering servo for damage and wear, and replace/repair if necessary

THE CAR DOES NOT

DRIVE STRAIGHT

• Suspension is binding

• Steering trim is off-center

• Wheels are loose

• Damaged steering servo

• Make sure suspension moves freely, and replace worn or broken parts

• Adjust steering trim until car drives straight

• Check the make sure the wheel nuts are properly tightened

• Check the steering servo for damage and wear, and replace/repair if necessary

TROUBLESHOOTING GUIDE

Page 39

39

• For club racing, it is recommended to check the shocks for air inside before each race

and only re-fill and bleed them if necessary. Before each race day, make sure you take

the spring off of each shock, hold it up to your ear, and quickly compress the shock rod

fully into the body while listening for any air making a “whistling” or “squishy” sound as

it passes through the piston holes. If you hear any air, refill and bleed your shocks. For

high-competition racing, it is recommended that the shocks be re-filled and bled before a

large event.

• If building or pairing new shocks, always make sure they are the same length using a

shock length measuring tool and adjust the lower ball joints as needed.

• If installing new rubber bladders, carefully trim the thin excess rubber from the edges of

their lips. Curved body scissors work the best.

• Regularly inspect the amount of dirt on the felt protector in the shocks (if present) and

regularly replace with a new one.

• During regular shock operation, oil naturally gets on the shock shaft and drop-by-drop

slightly gets out of the shock body. Shocks should be inspected regularly after each race,

and oil replaced as required.

1. Remove the seals on both sides of the bearing (if present). If the seals bend a little and

you can see a kink, carefully flatten the kink out by hand.

2. Spray the seals with motor cleaner and blow dry with compressed air.

3. Spray the bearing on both sides with motor cleaner.

4. Spin the bearing while it is still wet to dislodge any particles with the cleaner.

5. Spray the bearing on both sides again.

6. Blow both sides of the bearing dry with compressed air to make sure particles come out.