Page 1

Page 2

BEFORE YOU START

The X12 is a high-quality, 1/12-pan car intended for persons aged 16 years and older with previous experience building and operating RC model racing cars. This

is not a toy; it is a precision car model. This model racing car is not intended for use by beginners, inexperienced customers, or by children without direct supervision

of a responsible, knowledgeable adult. If you do not fulfill these requirements, please return the kit in unused and unassembled form back to the shop where you

have purchased it. Before building and operating your X12, YOU MUST read through all of the operating instructions and instruction manual and fully understand

them to get the maximum enjoyment and prevent unnecessary damage. Read carefully and fully understand the instructions before beginning assembly. Make sure

you review this entire manual and examine all details carefully. If for some reason you decide the X12 is not what you wanted or expected, do not continue any

further. Your hobby dealer cannot accept your X12 kit for return or exchange after it has been partially or fully assembled.

Contents of the box may differ from pictures. In line with our policy of continuous product development, the exact specifications of the kit may vary without prior

notice.

CUSTOMER SUPPORT

We have made every effort to make these instructions as easy to understand as possible. However, if you have any difficulties, problems, or questions, please do not

hesitate to contact the XRAY support team at info@teamxray.com. Also, please visit our Web site at www.teamxray.com to find the latest updates, set-up information,

option parts, and many other goodies. We pride ourselves on taking excellent care of our customers.

You can join thousands of XRAY fans and enthusiasts in our online community at: www.teamxray.com

K Výstavisku 6992 , 91101 Trenčín

XRAY Europe

Slovakia

EUROPE

Phone: 421-32-74401100

Fax: 421-32-74401109

E-mail: info@teamxray.com

RC America, 2030 Century Center Blvd #15 Irving,

Phone: (800) 519-7221 * (214) 744-2400

E-mail: xray@rcamerica.com

XRAY USA

TX 75062

USA

Fax: (214) 744-2401

Failure to follow these instructions will be considered as abuse and/or neglect.

In line with our policy of continuous product development, the exact specifications of the kit may vary. In the unlikely event of any problems with your new kit, you

should contact the model shop where you purchased it, quoting the part number. We reserve all rights to change any specification without prior notice. All rights

reserved.

2

Page 3

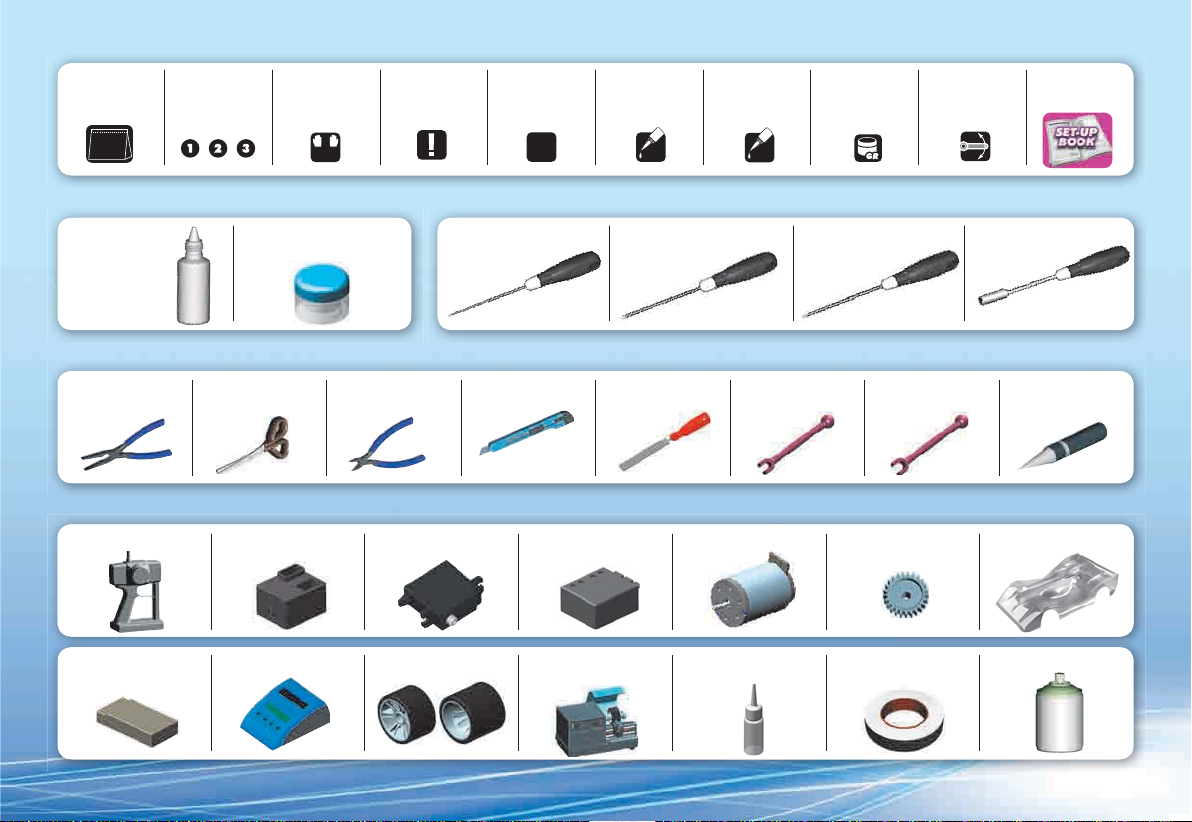

SYMBOLS USED

Part bags

used

Assemble in the

specified order

05

XRAY Premium

Silicone Oil 700cSt

(#359270) &

Silicone Oil 3000cSt

(#359303)

TOOLS REQUIRED

Pliers

(HUDY #189020)

Scissors

(HUDY #188990)

EQUIPMENT REQUIRED

Transmitter Steering ServoReceiver

Assemble left and

right sides the

same way

L=R

Diff. Grease

(HUDY #106211)

(HUDY #189010)

Pay attention

Side Cutters

here

TOOLS REQUIREDEQUIPMENT INCLUDED

Allen Wrench 1.5mm

(HUDY #111540)

Assemble as many

times as specified

(here twice)

2x

Hobby Knife File Turnbuckle 4mm

Speed Controller

Apply CA glue Apply oil

CA

Allen Wrench 2.0mm

(HUDY #112040)

1.5 mm

OIL

2.0 mm

Turnbuckle 3mm

(HUDY #181030)

Apply grease Ensure smooth

non-binding

movement

Allen Wrench 2.5mm

(HUDY #112540)

2.5 mm

(HUDY #181040)

Pinion Gear and Setscrew BodyshellElectric Motor

Follow Set-up

Book

Socket Driver 5.5mm

(HUDY #170055)

5.5 mm

Reamer

(HUDY #107600)

LiPo Battery Pack

Tire Truer

(HUDY #102003)

(HUDY #106230)

Fibre Tape

(HUDY #107870)

Lexan™ PaintBattery Charger Front & Rear Tires Bearing Oil

3

Page 4

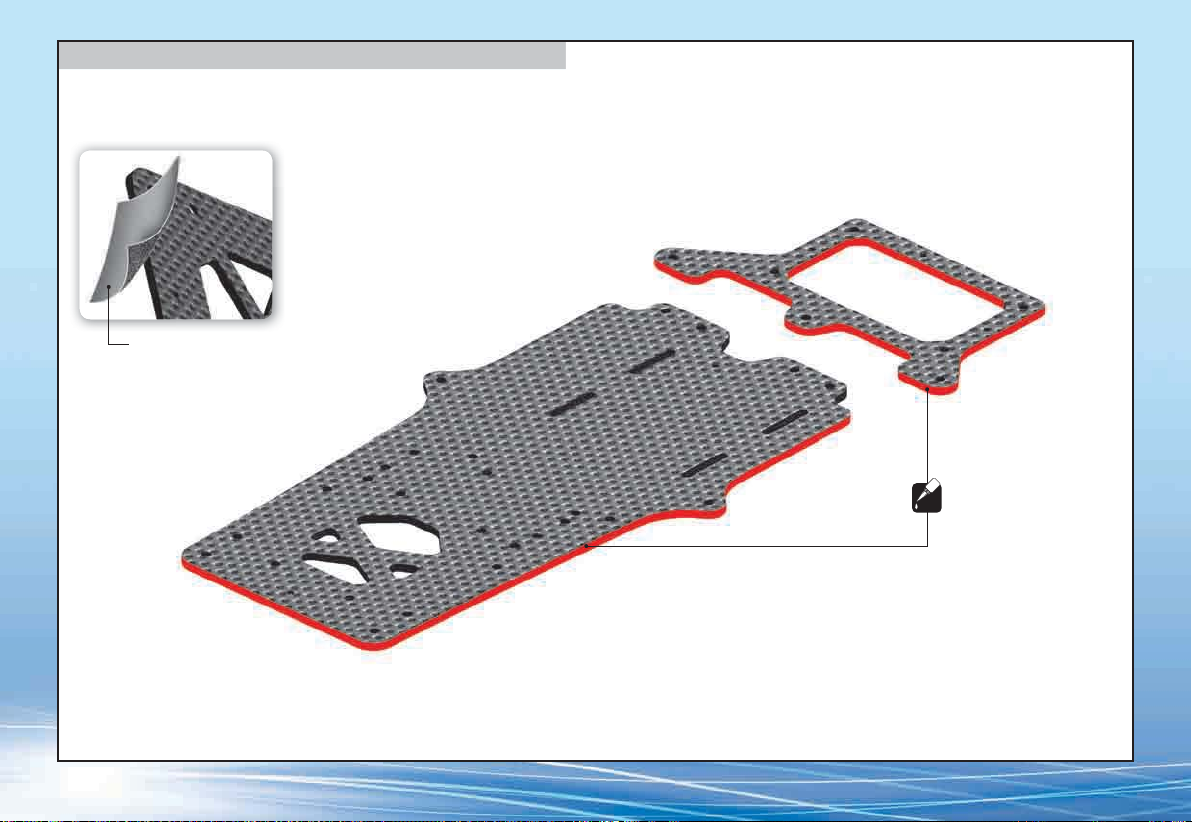

GRAPHITE PART PREPARATION

PREPARE ALL GRAPHITE PARTS

To protect and seal edges of graphite parts, sand edges smooth and then apply CA glue.

Fine sandpaper

Use fine sandpaper to sand smooth

the edges of all graphite parts.

Apply CA glue to all adges

CA

of the graphite parts.

4

Page 5

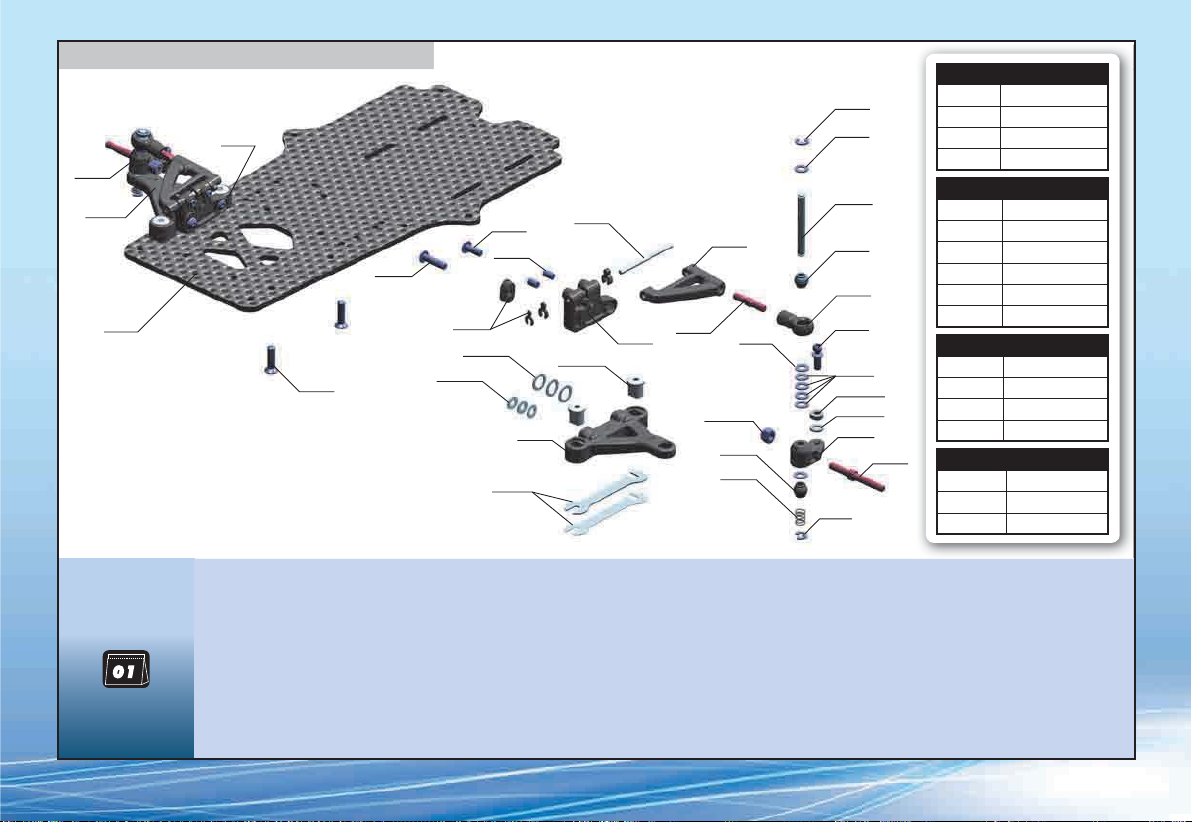

1. FRONT SUSPENSION

372011

372211

372112

371105

903312

902312

372315

373120-O

303121-O

902310

901304

372292

372293

372294

372122

377220

372316-O

372021

372620

372131

296530-O

373241

372180

372290

965019

372290

372280

373240

372130

372650

964032

303123-O

303122-O

372221

965019

375220

SUSPENSION ARMS

#372112 RIGHT - HARD

#372113 RIGHT - GRAPHITE

#372122 LEFT - HARD

#372123 LEFT - GRAPHITE

UPPER ARM MOUNTS

#372010 RIGHT - STANDARD

#372011 RIGHT - HARD

#372012 RIGHT - GRAPHITE

#372020 LEFT - STANDARD

#372021 LEFT - HARD

#372022 LEFT - GRAPHITE

FRONT COIL SPRINGS

#372180 C=3.5 - GOLD

#372181 C=4.0 - SILVER

#372182 C=5.0 - BLACK

#372183 C=6.0 - GREY

ALU ECCENTRIC BUSHINGS

#372316-O 0MM - STANDARD

#372317 0.5MM - OPTION

#372318 1.0MM - OPTION

BAG

303121-O ALU SHIM 3x6x0.5MM - ORANGE (10)

303122-O ALU SHIM 3x6x1.0MM - ORANGE (10)

303123-O ALU SHIM 3x6x2.0MM - ORANGE (10)

371105 X12‘15 CHASSIS - 2.5MM GRAPHITE

372011 COMPOSITE FRONT UPPER ARM MOUNT - RIGHT - HARD

372021 COMPOSITE FRONT UPPER ARM MOUNT - LEFT - HARD

372112 COMPOSITE SUSPENSION ARM FRONT LOWER - RIGHT - HARD

372122 COMPOSITE SUSPENSION ARM FRONT LOWER - LEFT - HARD

372130 COMPOSITE FRONT UPPER SUSPENSION ARM & BALL JOINT

372131 COMPOSITE FRONT UPPER SUSPENSION ARM - HARD

372180 FRONT COIL SPRING 3.6x6x0.5MM; C=3.5 - GOLD (2)

372211 COMPOSITE STEERING BLOCK - RIGHT - HARD - V2

372221 COMPOSITE STEERING BLOCK - LEFT - HARD - V2

372280 KING PIN (2)

372290 ALU SHIM 3.2x4.8x0.5 (4)

372292 STEEL SHIM 0.2MM - SILVER (2)

372293 STEEL SHIM 0.4MM - BLACK (2)

372294 STEEL SHIM 0.6MM - GOLD (2)

372315 COMPOSITE ECCENTRIC BUSHINGS + CASTER CLIPS (2)

372316-O ALU ECCENTRIC BUSHING 0.0MM - ORANGE (2)

372620 ADJ. TURNBUCKLE M3x17 MM - HUDY SPRING STEEL™ (2)

372650 BALL-END 4.2MM - THREADED - HUDY SPRING STEEL™ (2)

373120-O ALU SHIM 5.3x7.8x0.5MM - ORANGE (10)

373240 PIVOTBALL UNIVERSAL 6.0 MM - HUDY SPRING STEEL™(2)

373241 COMPOSITE PIVOTBALL 6.0 MM (2)

375220 FRONT WHEEL AXLE (2)

377220 FRONT UPPER PIVOT PIN 2x31MM (2)

296530-O ALU NUT M3 - ORANGE (10)

901304 HEX SCREW SB M3x4 (10)

902310 HEX SCREW SH M3x10 (10)

902312 HEX SCREW SH M3x12 (10)

903312 HEX SCREW SFH M3x12 (10)

964032 WASHER S 3.2 x 4.8 x 0.2 (10)

965019 E-CLIP 1.9 (10)

5

Page 6

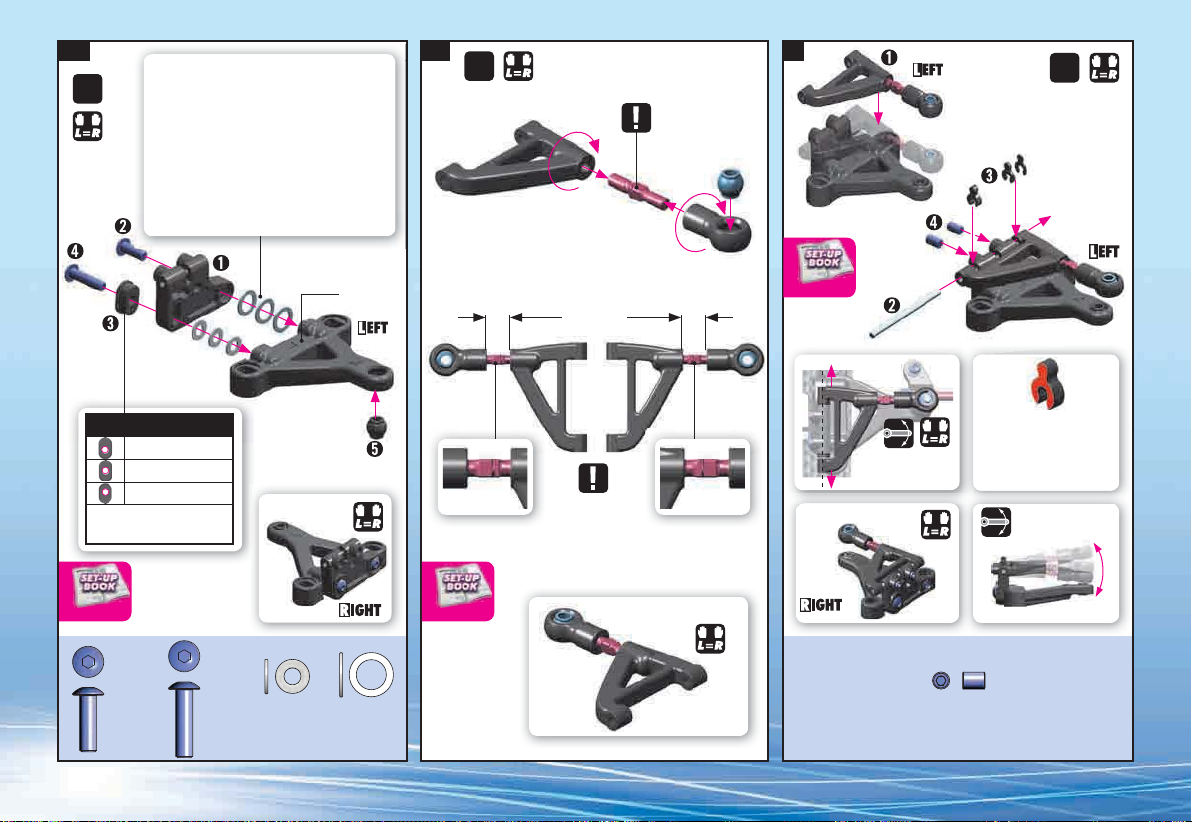

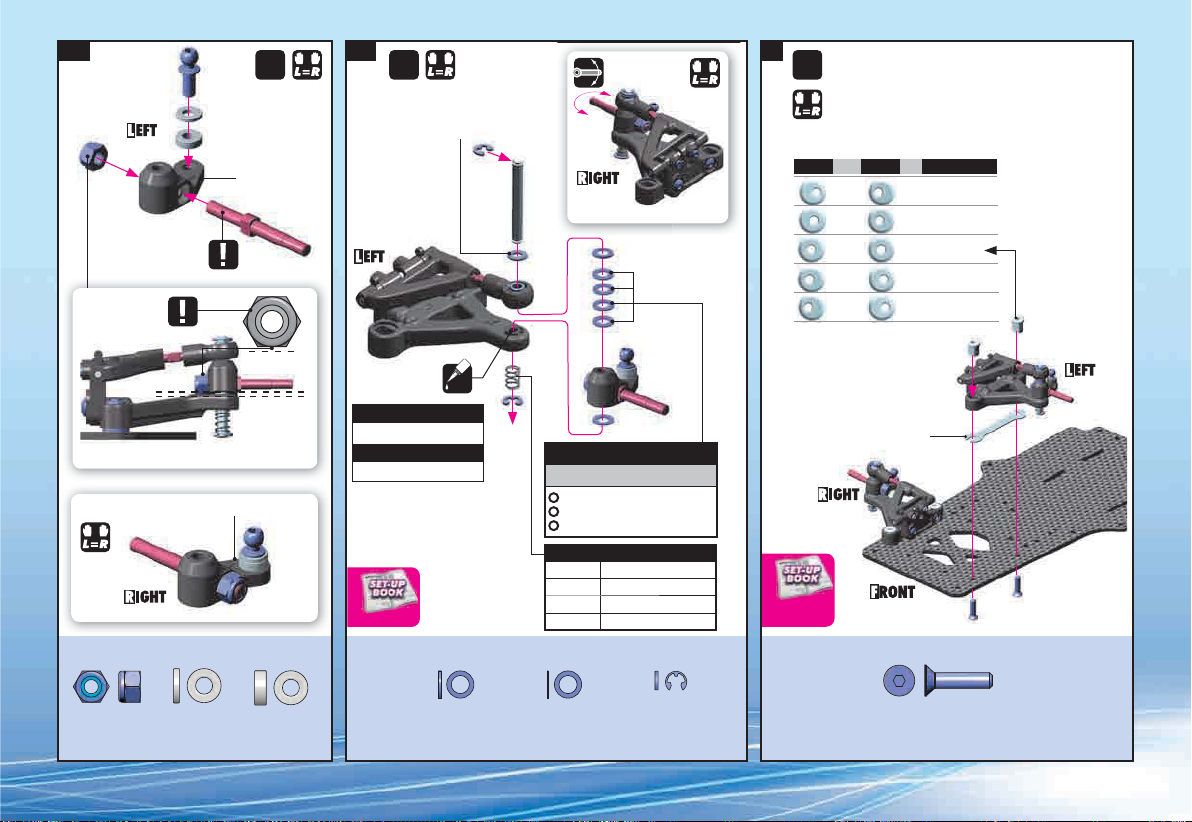

1. 2. 3.

2x

3x12

Upper Arm Position Adjustment Shims

The shims influence the camber gain change.

MORE shims = less camber gain, reduced initial

steering, reduced steering sensitivity (less twitchy).

LESS shims = more camber gain, increased initial

steering, increased steering sensitivity.

3x10

Use same shim thickness in left and right sides.

2x

NOTE

ORIENTATION

STEEL BALL

2x

1+0.5mm

2mm

5.3x7.8x0.5

3x6x0.5

REACTIVE CASTER SETTING

= 2.5°

= 5° INITIAL SETTING

= 7.5°

Use same bushings in left and

right sides.

CASTER CAMBER

902310

SH M3x10

902312

SH M3x12

ASSEMBLED VIEW

303121-O

SHIM 3x6x0.5

Marked “L“

COMPOSITE

BALL

373120-O

SHIM 5.3x7.8x0.5

6

7.2mm

NOTE ORIENTATION

7.2mm

ASSEMBLED VIEW

CASTER

ASSEMBLED VIEW

Make sure that

arm moves freely.

If the arm does not have

enough play, remove the clips

and thin the clips slightly with

sandpaper. The arms must have

free movement and not bind.

Moves freely

901304

SB M3x4

Page 7

4. 5. 6.

2x 2x 2x

Moves freely

The number of shims used affects the ride

1mm

2mm

height of the car, so determine the proper

amount of shimming based on tire diameter.

Marked “L“

ASSEMBLED VIEW

NOTE

ORIENTATION

NOTE

0.5mm

0.5mm

0.2mm (4x)

ORIENTATION

The X12 has adjustable front track-width. There are 3 different

bushings - 0mm centric (included in kit), or 0.5mm or 1.0mm

eccentric (optional). Use the same bushing in front and rear, and

also use the same orientation of the bushing on both right and left

sides.

Use the proper bushing, to achieve requested front track-width.

+=

LEFT RIGHT TRACK WIDTH

-1mm

-0.5mm

0mm

+0.5mm

+1mm

165mm

166mm

167mm

168mm

169mm

Initial setting

The flat of the nut must be PARALLEL to the lower arm.

303122-O

SHIM 3x6x1

Marked “R“

303123-O

SHIM 3x6x2

ASSEMBLED VIEW

296530-O

ALU N M3

USE XRAY

SILICONE OIL

OIL

LOW traction & bumpy track

10K cSt (#359310 XRAY)

HIGH traction & flat track

30K cSt (#359330 XRAY)

RIDE HEIGHT

372290

S 3.2x4.8x0.5

0.2mm

FRONT RIDE HEIGHT ADJUSTMENT

INITIAL SETTING

above upper arm (0.5mm)

above steering block (1.3mm)

beneath steering block (0.2mm)

FRONT COIL SPRINGS

#372180 C=3.5 - GOLD

#372181 C=4.0 - SILVER

#372182 C=5.0 - BLACK

#372183 C=6.0 - GREY

964032

S 3.2x4.8x0.2

965019

C 1.9

The number of washers used affects the

ride height of the car, so determine the

proper amount of shimming based on

tire diameter.

INITIAL SETTING = 0.6mm washer

RIDE HEIGHT

TRACK-WIDTH

903312

SFH M3x12

7

Page 8

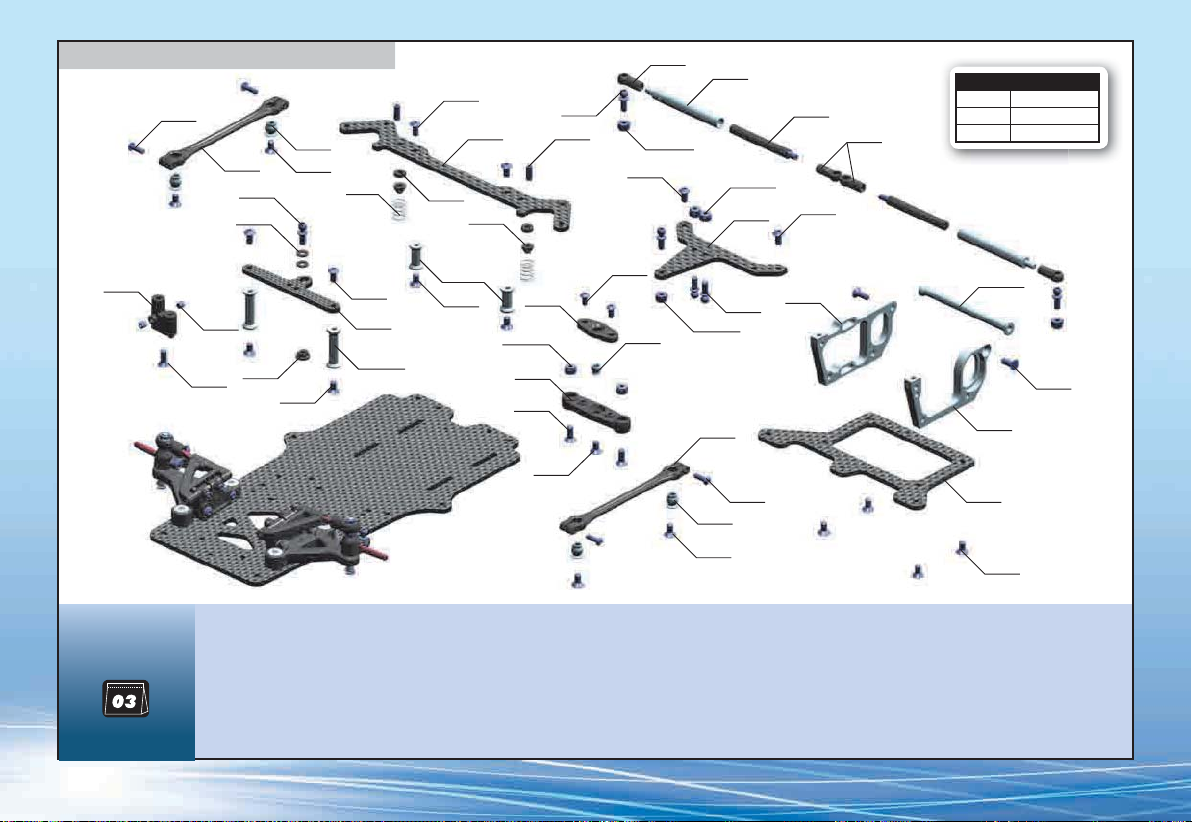

3. REAR SUSPENSION

902258

371190

372650

306219

303241

903306

373585

902306

306219

373084

373591

372650

901308

902306

372662

296530-O

378140

296530-O

373545

378150

902306

372662

SIDE SPRINGS

#373584 C=0.6 - SILVER

#373585 C=0.9 - GOLD

#373586 C=1.2 - BLACK

376300

901303

903308

373590

903306

902306

376352

376362-O

373073-O

903306

373092

296530-O

373092

903310

902306

373066

296530-O

371190

372650

373011

373030-O

903310

373021

903306

902258

371146

303241

903306

903306

BAG

303241 BALL UNIVERSAL 5.8 MM HEX (4)

306219 COMPOSITE SET OF SERVO SHIMS (4)

371146 LINK GRAPHITE 2.5MM REAR POD LOWER PLATE

371190 COMPOSITE POD LINK (2)

372650 BALL-END 4.2MM THREADED HUDY SPRING STEEL™(2)

372662 COMPOSITE BALL-JOINT 4.2 MM (4)

373011 ALU REAR BULKHEAD - MOTOR (RIGHT)

373021 ALU REAR BULKHEAD - LEFT

373030-O ALU REAR BULKHEAD BRACE - ORANGE

373066 ALU PIVOT BALL

373073-O ALU REAR BRACE MOUNT 16MM- ORANGE (2)

373084 LINK REAR BRACE - GRAPHITE 2.5MM

373092 COMPOSITE LOWER & UPPER PIVOT BRACE - LOW ROLL-CENTER

373545 X12‘15 REAR POD UPPER PLATE - GRAPHITE

373585 SIDE SPRING C=0.9 - GOLD (2)

373590 COMPOSITE SPRING HOLDER (2)

373591 COMPOSITE SIDE SPRING HOLDER (2)

376300 COMPOSITE ANTENNA MOUNT

376352 GR . PLATE FOR ANTENNA HOLDER

376362-O ALU ANTENNA HOLDER MOUNT - ORANGE (2)

378140 SIDE LINKAGE TUBE (2)

378150 SIDE SHOCK SHAFT (2)

296530-O ALU NUT M3 - ORANGE (10)

901303 HEX SCREW SB M3x3 (10)

901308 HEX SCREW SB M3x8 (10)

902258 HEX SCREW SH M2.5x8 (10)

902306 HEX SCREW SH M3x6 (10)

903306 HEX SCREW SFH M3x6 (10)

903308 HEX SCREW SFH M3x8 (10)

903310 HEX SCREW SFH M3x10 (10)

8

Page 9

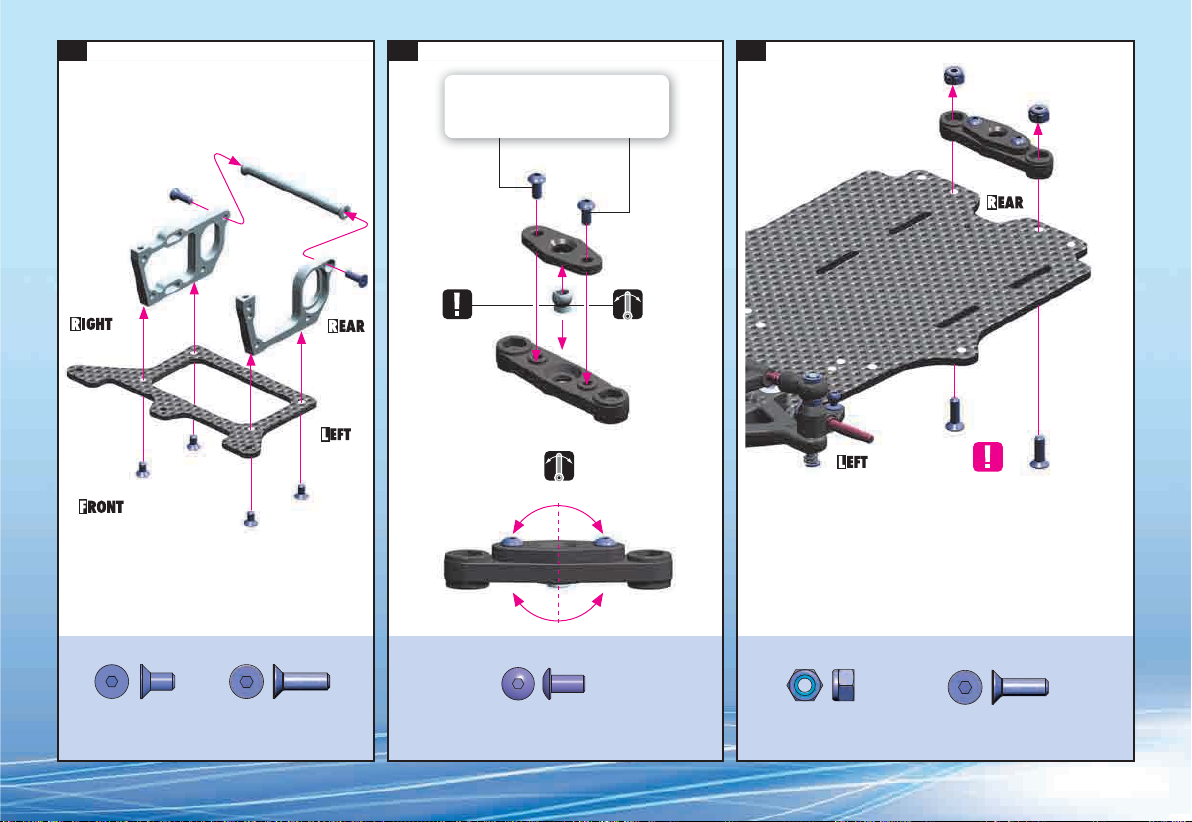

1. 2. 3.

Lightly tighten the screws so there is no free

play, but do not overtighten otherwise the

pivotball will not move freely.

3x10

3x10

NOTE

ORIENTATION

3x6

3x6

Ensure free, smooth movement without excessive freeplay.

DO NOT TIGHTEN FULLY

903306

SFH M3x6

903310

SFH M3x10

902306

SH M3x6

296530-O

ALU N M3

903310

SFH M3x10

9

Page 10

4. 5. 6.

2x 2x

DO NOT TIGHTEN FULLY,

PIVOTBALLS MUST TURN

FREELY.

ASSEMBLED VIEW

TIGHTEN

FULLY

10

903306

SFH M3x6

902258

SH M2.5x8

903306

SFH M3x6

Page 11

7. 8.

NOTE ORIENTATION

3x6x2

3x6x2

0.5mm

"CLICK"

306219

SHIM 3x6x2

901308

SB M3x8

296530-O

ALU N M3

902306

SH M3x6

903306

SFH M3x6

11

Page 12

9. 10. 11.

3x6x1

3x6x1

SHOCK MOUNTING POSITION

For alternative shock mounting

positions, see page 20.

12

902306

SH M3x6

296530-O

ALU N M3

306219

SHIM 3x6x1

901303

SB M3x3

903308

SFH M3x8

902306

SH M3x6

903306

SFH M3x6

Page 13

12. 13.

2x

OPTIONAL SIDE SHOCK

Optional side shock can be used to improve traction in

low- and medium-grip conditions.

2x

FACTORY PRE-ASSEMBLED

Add oil in each slot of the Derlin™ side shock tubes.

OIL

NOTE: Add oil only in the slots, not on the whole tube.

After assembling the side tubes, check for smooth operation.

NOTE: It is very important to re-oil the side tubes, as least once per race day.

NOTE: You may use different oil thicknesses depending on track conditions.

OILS

#359301 1000cSt

#359302 2000cSt

#359303 3000cSt

2x

For high grip: use softer oils

For low grip or asphalt: use harder oils

901310

SB M3x10

#359305 5000cSt

#359306 6000cSt

#359307 7000cSt

#359308 8000cSt

#359310 10000cSt

The angle of the side tubes has a fine effect on car

performance. The higher the angle, the stiffer it feels and

the less it rolls. The less (flatter) the angle, the softer it feels

and the more it rolls.

OPTIONAL PARTS (not included):

#378100 Side Shock Absorber Set

#302654 Ball End 4.9mm with 8mm Thread - V2 (2)

#303120 Set of Alu Shims (0.5mm, 1.5mm, 2.5mm)

#372651 Ball Universal 4.9mm - HUDY Spring Steel™ (2)

#902308 Hex Screw SH M3x8 (10)

902308

SH M3x8

3x6x2.5mm

372651

302654

3x6x2.5mm

13

Page 14

4. BALL DIFFERENTIAL

296530-O

375050-O

375030

963030

#375876 76T / 64P

#375878 78T / 64P

#375880 80T / 64P

#375896 96T / 64P

14

930138

SPUR GEARS

BAG

941438

375080

372070 COMPOSITE RIDE HEIGHT ADJUSTER SET (2)

375012 STEEL REAR AXLE SHAFT - HUDY SPRING STEEL™

375030 ALU REAR WHEEL HUB - RIGHT

375040 ALU REAR WHEEL HUB - LEFT

375050-O ALU DIFF HUB - ORANGE

375080 D-LOCK DIFF PLATE (2)

375090-O SET OF ALU SHIMS (0.5MM, 1.0MM, 2.0MM) - ORANGE

375896 COMPOSITE SPUR GEAR - 96T / 64P

375896

930130

941438

375080

296530-O ALU NUT M3 - ORANGE (10)

908258 HEX SCREW SOCKET HEAD CAP M2.5x8 (10)

930130 CARBIDE BALL 3.175MM (12)

930138 CARBIDE BALL-BEARING AXIAL F3-8 3x8x3.5

941438 HIGH-SPEED BALL-BEARING 1/4“x3/8“x1/8“ RUBBER SEALED (2)

951438 BALL-BEARING 1/4“ x 3/8“ x 1/8“ FLANGED (2)

963030 CONE WASHER ST 3x8x0.5 (10)

375012

951438

375090-O

372070

375090-O

375040

951438

908258

Page 15

1. 2.

Bearing Oil

(HUDY #106230)

OIL

Flanged

Bearing Oil

(HUDY #106230)

OIL

Flanged

Use additional shims to widen the rear

track-width. Use the same shims on

both sides. For initial assembly use

6.4x8.4x1mm shims.

Use these Ride Height

Adjusters for initial assembly.

0 2.02.5 1.5 1.0 0.5

951438

BB 1/4“x3/8“x1/8“

The axle must have a VERY small amount of side

play. If there is no side play, the axle may bind

and damage the ball-bearings.

TRACK-WIDTHRIDE HEIGHT

375090-O

6.4x8.4x1.0

908258

SCH M2.5x8

15

Page 16

3.

DIFFERENTIAL

Diff Grease

(HUDY #106211)

930130

B 3.1

NOTE

ORIENTATION

Bearing Oil

(HUDY #106230)

OIL

930138

BA 3x8

(HUDY #106211)

Diff Grease

(HUDY #106211)

Diff Grease

NOTE

ORIENTATION

(HUDY #106230)

941438

BB 1/4“x3/8“x1/8“

3.2mm

8.0mm 7.8mm

OIL

Bearing Oil

3.0mm

NOTE

ORIENTATION

Diff Grease

(HUDY #106211)

296530-O

ALU N M3

This nut affects the tightness and stiffness of the

rear differential.

Tighten the nut gently so the diff does not slip

under power, but do not overtighten or damage

to the diff balls and plates may occur.

963030

ST 3x8

16

Page 17

5. SHOCK ABSORBER

378011

SHOCK SPRINGS

#378092 C=1.5 - SILVER

#378093 C=1.8 - GOLD

#378094 C=2.1 - BLACK

378050-O

SHOCK OILS

#359210 100cSt

#359215 150cSt

#359220 200cSt

#359225 250cSt

#359230 300cSt

#359235 350cSt

#359240 400cSt

#359245 450cSt

BAG

378080

965015

378020

#359250 500cSt

#359255 550cSt

#359260 600cSt

#359270 700cSt

#359280 800cSt

#359290 900cSt

#359301 1000cSt

#359302 2000cSt

378001 SHOCK ABSORBER SET

378011 COMPOSITE SHOCK PARTS - FRAME

378020 ALU THREADED SHOCK BODY - HARDCOATED

378030-O ALU SHOCK BODY CAP - LOWER - ORANGE

378040-O ALU SHOCK ADJUSTABLE COLLAR - ORANGE

378050-O ALU SHOCK BODY CAP - UPPER - ORANGE

378011

378061

378011

378040-O

378061 SHOCK SHAFT

378070-O ALU SHOCK SPRING COLLAR - ORANGE

378071-O ALU SHOCK ADAPTER - ORANGE

378080 SHOCK RUBBER MEMBRANE (2)

378093 SHOCK SPRING - GOLD

971022

378030-O

378093

901303

378071-O

378011

378070-O

901303 HEX SCREW SB M3x3 (10)

965015 E-CLIP 1.5 (10)

971022 SILICONE O-RING 2x2 (10)

17

Page 18

1. 2. 3.

Carefully remove the shock piston from the

frame, and remove all excess plastic flash

OIL

Shock Oil

OIL

Shock Oil

ASSEMBLED VIEW

18

965015

C 1.5

971022

O 2x2

Page 19

4.

DEFAULT SHOCK SETTING FOR CENTER SHOCK ABSORBER

Follow the steps below to set the shock.

HALF TIGHTEN TIGHTEN FULLY

50%

Oil 700cSt

3~5x

UP & DOWN

➊➋➌➍➎➏

Extend the shock shaft

completely. Fill the shock

body with the shock oil.

Move the shock shaft up and

down a few times to release

the air bubbles trapped

beneath the piston.

Orient the filled shock

vertically for several

minutes with the shock

shaft fully extended. The

remaining air bubbles will

release.

Install the shock membrane

into the groove in the

upper shock cap.

Gently place the shock cap

assembly onto the filled

shock body. Excess oil will

spill from the shock. Screw

the shock cap onto the body

by only a few turns, approx.

50%. Excess oil will flow

through the hole in the

shock cap.

Gently push the shock shaft

completely into the shock

body. Excess oil will flow

through the hole in the

shock cap.

100%

➐

Keep the shock shaft

pushed in the shock body

and tighten the shock cap

completely.

Tighten the cap fully but

do not overtighten or the

rubber membrane may be

damaged. Make sure that

there is no oil leakage

after the cap is tightened.

19

Page 20

5.

ALTERNATIVE 1

SHORT SHOCK (REARWARD POSITION)

An innovative new feature is to change the center shock

front mounting position & shock length. By moving the

center shock mounts on the chassis to either the forward or

rearward position, the damping and steering characteristics

can be changed.

REARWARD shock position (SHORT shock):

Improved steering response, quicker direction changes.

FORWARD shock position (LONGER shock with adapter):

Improved driveability over bumps, improved on-power

traction.

DOWNSTOP ADJUSTMENT

The length of the shock absorber affects the amount of

rear downstop. To adjust, thread the ball-joint on or off the

bottom spring cap or adapter.

ALTERNATIVE 2 (INITIAL SETTING)

LONG SHOCK (FORWARD POSITION)

For the long shock

alternative, the shock

adaptor must be used.

20

SHORT

Press the collar FULLY onto

the end of the shock shaft and

tighten the M3x3 setscrew.

For initial setting,

thread fully.

901303

SB M3x3

LONG

5mm5mm

Press the collar FULLY onto

the end of the shock shaft and

tighten the M3x3 setscrew.

ADAPTER

For initial setting,

thread fully.

Page 21

37

6. FINAL ASSEMBLY

SPEED CONTROLLER

(not included)

STEERING SERVO

(not included)

301159-O

903310

372650

372503

FROM SERVO

372661

372503

RECEIVER

(not included)

372610-O

306219

372661

376255-O

903305

376310

376130

903305

LiPo BATTERY

(not included)

371320

309400

981210

306219

902310

TIRES

(not included)

375390

371320

309400

902308

MOTOR & PINION

(not included)

371200

903310

BAG

06

981210

301159-O ALU COUNTERSUNK SHIM - ORANGE (4)

305968~306000 PINION GEAR HARDCOATED 18~50T/64P

306219 COMPOSITE SET OF SERVO SHIMS (4)

309400 BODY CLIP FOR 5MM BODY POST (8)

371200 COMPOSITE CHASSIS PROTECTOR (2)

371320 COMPOSITE BODY POST (2)

372503 COMPOSITE SERVO SAVER - STIFF - SET

372610-O ALU ADJ. TURNBUCKLE M3x42 MM - ORANGE (2)

372650 BALL-END 4.2MM - THREADED - HUDY SPRING STEEL™ (2)

372661 COMPOSITE STEERING BALL-JOINT 4.2 MM OPEN (4)

375390 ALU HEX SCREW M3x8 FOR REAR WHEELS (6)

376130 COMPOSITE LiPo BATTERY BACKSTOP (2)

376255-O ALU SERVO MOUNT - ORANGE (2)

376310 FIBERGLASS SOLID ANTENNA ROD + CAP

951851

TIRES

(not included)

951851

296530-O

296530-O ALU NUT M3 - ORANGE (10)

902308 HEX SCREW SH M3x8 (10)

902310 HEX SCREW SH M3x10 (10)

903305 HEX SCREW SFH M3x5 (10)

903310 HEX SCREW SFH M3x10 (10)

951851 BALL-BEARING 1/8“ x 5/16“ x 9/64“ FLANGED (2)

981210 PIN 2x10 (10)

21

Page 22

1. 2. 3.

We recommend using a servo

for 1/12 pan cars.

3x6x1 for

Configuration

Left

initial setting

Configuration

Right

Servo

(not included)

ACKERMANN

2x

Servo screw

INITIAL POSITION

22

NOTE

ORIENTATION

Futaba

Hitec KO Propo

Use the adapter that

matches the steering servo.

306219

SHIM 3x6x1

Note the orientation of

servo saver when servo

is in neutral.

903310

SFH M3x10

90º

The position of the servo depends on the

weight of the electronics. If the car is

heavier on the right, use a left-side servo

position; if the car is heavier on the left,

use a right-side servo position.

903305

SFH M3x5

27.2mm

Left thread

27.2mm

Left thread

TOE

Page 23

4. 5. 6.

2x 2x 2x

NOTE

ORIENTATION

Note groove

position

NOTE

ORIENTATION

Note groove position

ACKERMANN

306219

SHIM 3x6x3

902310

SH M 3x10

981210

P 2x10

3x6x3

903310

SFH M 3x10

981210

P 2x10

23

Page 24

7. 8.

Motor

(not included)

PINION GEARS ALU HARDCOATED

#305968 18T / 64P (option)

#305969 19T / 64P (option)

#305970 20T / 64P (option)

Pinion

(not included)

#305971 21T / 64P (option)

#305972 22T / 64P (option)

#305973 23T / 64P (option)

#305974 24T / 64P (option)

#305975 25T / 64P (option)

#305976 26T / 64P (option)

#305977 27T / 64P (option)

#305978 28T / 64P (option)

#305979 29T / 64P (option)

#305980 30T / 64P (option)

#305981 31T / 64P (option)

#305982 32T / 64P (option)

Adjust the gear mesh

so there is appropriate

space between the

spur gear and pinion

teeth. There should be

a very small amount of

freeplay.

GEAR RATIO

#305983 33T / 64P (option)

#305984 34T / 64P (option)

#305985 35T / 64P (option)

#305986 36T / 64P (option)

#305987 37T / 64P (option)

#305988 38T / 64P (option)

There are two alternative battery positions,

inline and cross-chassis alignment.

Depending on the battery position, the

position of the electronics change as well.

See pages 25 and 26.

Speed controller

(not included)

➌

Double-sided tape

(not included)

Receiver wire

➊

Receiver

(not included)

➋

24

902308

SH M 3x8

901303

SB M3x3

After inserting the antenna rod, fully

tighten both setscrews. Do not overtighten

or you may strip the plastic.

Page 25

9A

LIPO BATTERY CONFIGURATION 1 Inline alignment:

INITIAL ASSEMBLY

Inline battery alignment improves cornering speed and reduces the chance that

the rear of the car will „diff out.“ Recommended for high-traction conditions.

Receiver

(not included)

Battery Pack

(not included)

Speed controller

(not included)

Battery Pack

(not included)

The battery pack has to be angled when

installing or removing it from the car.

Fibre Tape

(HUDY #107870)

(not included)

903305

SFH M3x5

25

Page 26

9B

LIPO BATTERY CONFIGURATION 2 Cross-chassis alignment:

Cross-chassis alignment provides more neutral handling, making the car less sensitive to set-up

changes and gives reduced steering responsive. Recommended for low- and medium-traction

conditions.

2x

Cut

26

Speed controller

(not included)

Battery Pack

(not included)

Receiver

(not included)

903305

SFH M3x5

Fibre Tape

(HUDY #107870)

(not included)

Page 27

10.

Front Wheels & Tires

ASSEMBLED VIEW

(not included)

375390

ALU SCH M3x8

951851

BB 1/8“x5/16“x9/64“

4x

OIL

296530-O

ALU N M3

Bearing Oil

(HUDY #106230)

Rear Wheels & Tires

(not included)

Gently tighten the wheel nuts

so the wheel turns freely, but

without excessive axial play.

NOT INCLUDED

To ensure that you always have access to the most up-to-date version of the XRAY Set-up Book, XRAY will

now be offering only the digital online version at our website at www.teamxray.com. By offering this online

version instead of including a hardcopy printed version in kits, you will always be assured of having the

most current updated version. The Set-up Book features the T-bar version of the XII, however the majority

of all set-up adjustments and theory are the same. we strongly recommend that you read and understand

the Set-up Book completely.

27

Page 28

ÊÊÊ

Ê

Ê

Ê

ÊÊÊÊÊÊÊ

Ê

,К,]КУдОдКiМХАЮКiМiАКЫ`К£x]КАЫ}]К/8КЗxдИУ

*" \ÊÓ£{Ç{{Ó{ää]Ê8\ÊÓ£{Ç{{Ó{ä£]ÊÝÀ>ÞJÀV>iÀV>°V

ЬЬЬ°v>ViL°VЙМi>ЭА>ЮКККККККККККККККЬЬЬ°МЬММiА°VЙМi>ЭА>ЮКККККККККККККÊÊÜ ÜÜ°ÞÕÌÕLi°VÉÝÀ>ÞÀ>V}

Loading...

Loading...