Page 1

1/10 LUXURY TOURING CAR1/10 LUXURY TOURING CAR

1/10 LUXURY TOURING CAR

INSTRUCTION

MANUAL

Page 2

2

BEFORE YOU START

The T2‘007 is a high-competition, high-quality, 1/10-scale touring car intended

for persons aged 16 years and older with previous experience building and

operating RC model racing cars. This is not a toy; it is a precision racing model. This

model racing car is not intended for use by beginners, inexperienced customers,

or by children without direct supervision of a responsible, knowledgeable adult.

If you do not fulfill these requirements, please return the kit in unused and

unassembled form back to the shop where you have purchased it.

Before building and operating your T2‘007, YOU MUST read through all of the

operating instructions and instruction manual and fully understand them to get

the maximum enjoyment and prevent unnecessary damage. Read carefully and

fully understand the instructions before beginning assembly.

Make sure you review this entire manual, the included set-up book, and examine

all details carefully. If for some reason you decide the T2‘007 is not what you

wanted or expected, do not continue any further. Your hobby dealer cannot

accept your T2‘007 kit for return or exchange after it has been partially or fully

assembled.

Contents of the box may differ from pictures. In line with our policy of continuous

product development, the exact specifications of the kit may vary without prior

notice.

SAFETY PRECAUTIONS

Contains:

LEAD (CAS 7439-92-1) ANTIMONY (CAS 7440-36-0)

WARNING: This product contains a chemical known to the state of California to

cause cancer and birth defects or other reproductive harm.

CAUTION: CANCER HAZARD

Contains lead, a listed carcinogen. Lead is harmful if ingested. Wash thoroughly

after using. DO NOT use product while eating, drinking or using tobacco

products. May cause chronic effects to gastrointestinal tract, CNS, kidneys, and

blood. MAY CAUSE BIRTH DEFECTS.

When building, using and/or operating this model always wear protective

glasses and gloves.

Take appropriate safety precautions prior to operating this model. You are

responsible for this model‘s assembly and safe operation! Please read the

instruction manual before building and operating this model and follow

all safety precautions. Always keep the instruction manual at hand for quick

reference, even after completing the assembly. Use only genuine and original

authentic XRAY parts for maximum performance. Using any third party parts on

this model will void guaranty immediately.

Improper operation may cause personal and/or property damage. XRAY and

its distributors have no control over damage resulting from shipping, improper

construction, or improper usage. XRAY assumes and accepts no responsibility for

personal and/or property damages resulting from the use of improper building

materials, equipment and operations. By purchasing any item produced by XRAY,

the buyer expressly warrants that he/she is in compliance with all applicable

federal, state and local laws and regulation regarding the purchase, ownership

and use of the item. The buyer expressly agrees to indemnify and hold harmless

XRAY for all claims resulting directly or indirectly from the purchase, ownership

or use of the product. By the act of assembling or operating this product, the

user accepts all resulting liability. If the buyer is not prepared to accept this

liability, then he/she should return this kit in new, unassembled, and unused

condition to the place of purchase.

IMPORTANT NOTES – GENERAL

• This product is not suitable for children under 16 years of age without the

direct supervision of a responsible and knowledgeable adult.

• Carefully read all manufacturers warnings and cautions for any parts used in

the construction and use of your model.

• Assemble this kit only in places away from the reach of very small children.

• First-time builders and users should seek advice from people who have

building experience in order to assemble the model correctly and to allow the

model to reach its performance potential.

• Exercise care when using tools and sharp instruments.

• Take care when building, as some parts may have sharp edges.

• Keep small parts out of reach of small children. Children must not be allowed

to put any parts in their mouth, or pull vinyl bag over their head.

• Read and follow instructions supplied with paints and/or cement, if used (not

included in kit).

• Immediately after using your model, do NOT touch equipment on the

model such as the motor and speed controller, because they generate high

temperatures. You may seriously burn yourself seriously touching them.

• Follow the operating instructions for the radio equipment at all times.

• Do not put fingers or any objects inside rotating and moving parts, as this

may cause damage or serious injury as your finger, hair, clothes, etc. may get

caught.

• Be sure that your operating frequency is clear before turning on or running

your model, and never share the same frequency with somebody else at the

same time. Ensure that others are aware of the operating frequency you are

using and when you are using it.

• Use a transmitter designed for ground use with RC cars. Make sure that no

one else is using the same frequency as yours in your operating area. Using

the same frequency at the same time, whether it is driving, flying or sailing,

can cause loss of control of the RC model, resulting in a serious accident.

• Always turn on your transmitter before you turn on the receiver in the car.

Always turn off the receiver before turning your transmitter off.

• Keep the wheels of the model off the ground when checking the operation of

the radio equipment.

• Disconnect the battery pack before storing your model.

• When learning to operate your model, go to an area that has no obstacles

that can damage your model if your model suffers a collision.

• Remove any sand, mud, dirt, grass or water before putting your model away.

• If the model behaves strangely, immediately stop the model, check and clear

the problem.

• To prevent any serious personal injury and/or damage to property, be

responsible when operating all remote controlled models.

• The model car is not intended for use on public places and roads or areas where

its operation can conflict with or disrupt pedestrian or vehicular traffic.

• Because the model car is controlled by radio, it is subject to radio interference

from many sources that are beyond your control. Since radio interference can

cause momentary loss of control, always allow a safety margin in all directions

around the model in order to prevent collisions.

• Do not use your model:

- Near real cars, animals, or people that are unaware that an RC car is being

driven.

- In places where children and people gather

- In residential districts and parks

- In limited indoor spaces

- In wet conditions

- In the street

- In areas where loud noises can disturb others, such as hospitals and

residential areas.

- At night or anytime your line of sight to the model may be obstructed or

impaired in any way.

To prevent any serious personal injury and/or damage to property, please be

responsible when operating all remote controlled models.

Failure to follow these instructions will be considered as abuse and/or neglect.

CUSTOMER SUPPORT

XRAY Europe

Pred Polom 762

91101 Trenčín

Slovakia, EUROPE

Phone: 421-32-7440180

Fax: 421-32-7440179

Email: info@teamxray.com

We have made every effort to make these instructions as easy to understand as possible.

However, if you have any difficulties, problems, or questions, please do not hesitate to

contact the XRAY support team at info@teamxray.com. Also, please visit our Web site

at www.teamxray.com to find the latest updates, set-up information, option parts, and

many other goodies. We pride ourselves on taking excellent care of our customers.

You can join thousands of XRAY fans and enthusiasts in our online community at:

www.teamxray.com

XRAY USA

RCAmerica, 167 Turtle Creek Boulevard Suite C

Dallas, Texas 75207

USA

Phone: (800) 519-7221 * (214) 744-2400

Fax: (214) 744-2401

Email: xray@rcamerica.com

Page 3

3

IMPORTANT NOTES – ELECTRICAL

• Insulate any exposed electrical wiring (using heat shrink tubing or electrical

tape) to prevent dangerous short circuits. Take maximum care in wiring,

connecting and insulating cables. Make sure cables are always connected

securely. Check connectors for if they become loose. And if so, reconnect

them securely. Never use R/C models with damaged wires. A damaged wire

is extremely dangerous, and can cause short-circuits resulting in fire. Please

have wires repaired at your local hobby shop.

• Low battery power will result in loss of control. Loss of control can occur due to

a weak battery in either the transmitter or the receiver. Weak running battery

may also result in an out of control car if your car‘s receiver power is supplied

by the running battery. Stop operation immediately if the car starts to slow

down.

• When not using RC model, always disconnect and remove battery.

• Do not disassemble battery or cut battery cables. If the running battery shortcircuits, approximately 300W of electricity can be discharged, leading to fire

or burns. Never disassemble battery or cut battery cables.

• Use a recommended charger for the receiver and transmitter batteries

and follow the instructions correctly. Over-charging, incorrect charging, or

using inferior chargers can cause the batteries to become dangerously hot.

Recharge battery when necessary. Continual recharging may damage battery

and, in the worst case, could build up heat leading to fire. If battery becomes

extremely hot during recharging, please ask your local hobby shop for check

and/or repair and/or replacement.

• Regularly check the charger for potential hazards such as damage to the

cable, plug, casing or other defects. Ensure that any damage is rectified

before using the charger again. Modifying the charger may cause short-circuit

or overcharging leading to a serious accident. Therefore do not modify the

charger.

• Always unplug charger when recharging is finished.

• Do not recharge battery while battery is still warm. After use, battery retains

heat. Wait until it cools down before charging.

• Do not allow any metal part to short circuit the receiver batteries or other

electrical/electronic device on the model.

• Immediately stop running if your RC model gets wet as may cause short

circuit.

• Please dispose of batteries responsibly. Never put batteries into fire.

WARRANTY

XRAY guarantees this model kit to be free from defects in both material and

workmanship within 30 days of purchase. The total monetary value under

warranty will in no case exceed the cost of the original kit purchased. This

warranty does not cover any components damaged by use or modification or

as a result of wear. Part or parts missing from this kit must be reported within

30 days of purchase. No part or parts will be sent under warranty without proof

of purchase. Should you find a defective or missing part, contact the local

distributor. Service and customer support will be provided through local hobby

store where you have purchased the kit, therefore make sure to purchase any

XRAY products at your local hobby store. This model racing car is considered

to be a high-performance racing vehicle. As such this vehicle will be used in

an extreme range of conditions and situations, all which may cause premature

wear or failure of any component. XRAY has no control over usage of vehicles

once they leave the dealer, therefore XRAY can only offer warranty against all

manufacturer‘s defects in materials, workmanship, and assembly at point of

sale and before use. No warranties are expressed or implied that cover damage

caused by what is considered normal use, or cover or imply how long any

model cars‘ components or electronic components will last before requiring

replacement.

Due to the high performance level of this model car you will need to periodically

maintain and replace consumable components. Any and all warranty coverage

will not cover replacement of any part or component damaged by neglect,

abuse, or improper or unreasonable use. This includes but is not limited to

damage from crashing, chemical and/or water damage, excessive moisture,

improper or no maintenance, or user modifications which compromise the

integrity of components. Warranty will not cover components that are considered

consumable on RC vehicles. XRAY does not pay nor refund shipping on any

component sent to XRAY or its distributors for warranty. XRAY reserves the right to

make the final determination of the warranty status of any component or part.

Limitations of Liability

XRAY makes no other warranties expressed or implied. XRAY shall not be liable

for any loss, injury or damages, whether direct, indirect, special, incidental, or

consequential, arising from the use, misuse, or abuse of this product and/or any

product or accessory required to operate this product. In no case shall XRAY‘s

liability excess the monetary value of this product.

Take adequate safety precautions prior to operating this model. You

are responsible for this model’s assembly and safe operation.

Disregard of the any of the above cautions may lead to accidents,

personal injury, or property damage. XRAY MODEL RACING CARS

assumes no responsibility for any injury, damage, or misuse of this

product during assembly or operation, nor any addictions that may

arise from the use of this product.

All rights reserved.

QUALITY CERTIFICATE

XRAY MODEL RACING CARS uses only the highest quality materials, the best

compounds for molded parts and the most sophisticated manufacturing processes

of TQM (Total Quality Management). We guarantee that all parts of a newlypurchased kit are manufactured with the highest regard to quality. However, due

to the many factors inherent in model racecar competition, we cannot guarantee

any parts once you start racing the car. Products which have been worn out,

abused, neglected or improperly operated will not be covered under warranty.

We wish you enjoyment of this high-quality and high-performance RC car and

wish you best success on the track!

In line with our policy of continuous product development, the exact specifications of the kit may

vary. In the unlikely event of any problems with your new kit, you should contact the model shop

where you purchased it, quoting the part number.

We do reserve all rights to change any specification without prior notice. All rights reserved.

R/C & BUILDING TIPS

• Make sure all fasteners are properly tightened. Check them periodically.

• Make sure that chassis screws do not protrude from the chassis.

• For the best performance, it is very important that great care is taken to ensure

the free movement of all parts.

• Clean all ball-bearings so they move very easily and freely.

• Tap or pre-thread the plastic parts when threading screws.

• Self-tapping screws cut threads into the parts when being tightened. Do not use

excessive force when tightening the self-tapping screws because you may strip

out the thread in the plastic. We recommended you stop tightening a screw

when you feel some resistance.

• Ask your local hobby shop for any advice.

Please support your local hobby shop. We at XRAY Model Racing Cars support

all local hobby dealers. Therefore we ask you, if at all possible, to purchase

XRAY products at your hobby dealer and give them your support like we do. If

you have difficulty finding XRAY products, please check out www.teamxray.com

to get advice, or contact us via email at info@teamxray.com, or contact the XRAY

distributor in your country.

Page 4

4

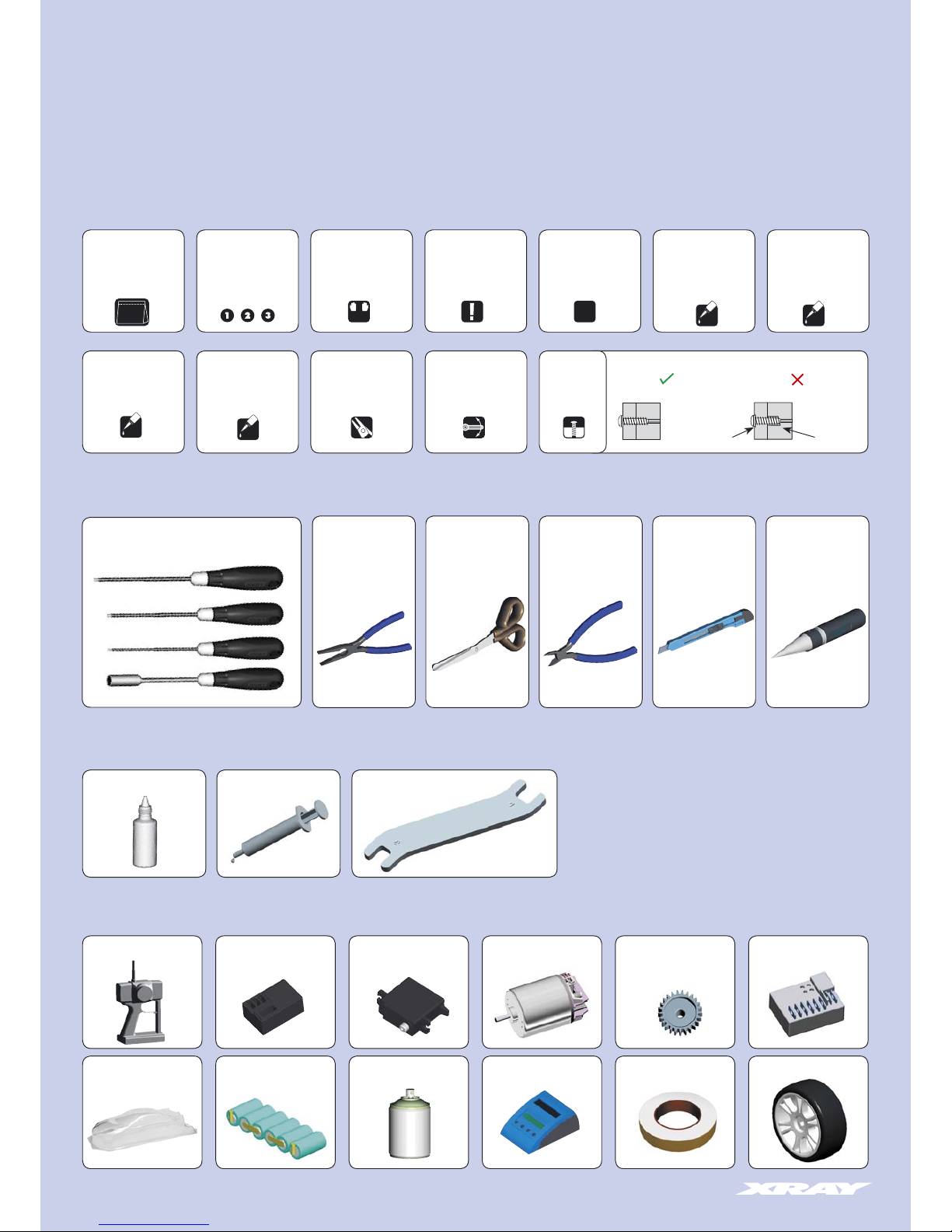

SYMBOLS USED

L=R

2x

CA

OIL

CORRECT WRONG

Overtightened

The threads

are stripped.

Part bags used Assemble left and right

sides the same way

Assemble in the specified

order

Pay attention here Assemble as many times

as specified (here twice)

Apply CA glue

TOOLS REQUIRED

EQUIPMENT REQUIRED

EQUIPMENT INCLUDED

Apply oil Use pliers

Silicone Shock Oil

Scissors Side Cutters Hobby Knife Reamer

(HUDY #107600)

Pliers

HUDY TOOLS: Allen: 1.5mm, 2.0mm, 2.5mm, 3.0mm

Socket: 7.0mm

Transmitter Steering ServoReceiver

Grease

TL

05

Tighten screw

gently

Apply thread lock

Lexan Paint Battery Charger Wheels & Tires & Inserts

Apply grease

GR

Turnbuckle Tool

Ensure smooth non-

binding movement

2.0 mm

3.0 mm

1.5 mm

7.0 mm

CONTENTS

Speed Controller

6-cell Battery Pack

(Inline)

Pinion Gear and Setscrew

190mm Bodyshell

Electric Motor

Fibre Tape

WARNINGS

2-3

TOOLS AND ACCESSORIES

4

0. KIT

5

1. BALL DIFFERENTIAL & FRONT MULTI-DIFF

6-7

2. FRONT & REAR SUSPENSION

8-10

3. CENTRAL TRANSMISSION

11-13

4. FRONT & REAR TRANSMISSION

14-17

5. STEERING

18-19

6. SHOCK ABSORBERS

20-21

7. FRONT & REAR ASSEMBLY

22-24

8. FINAL ASSEMBLY

25-27

Page 5

5

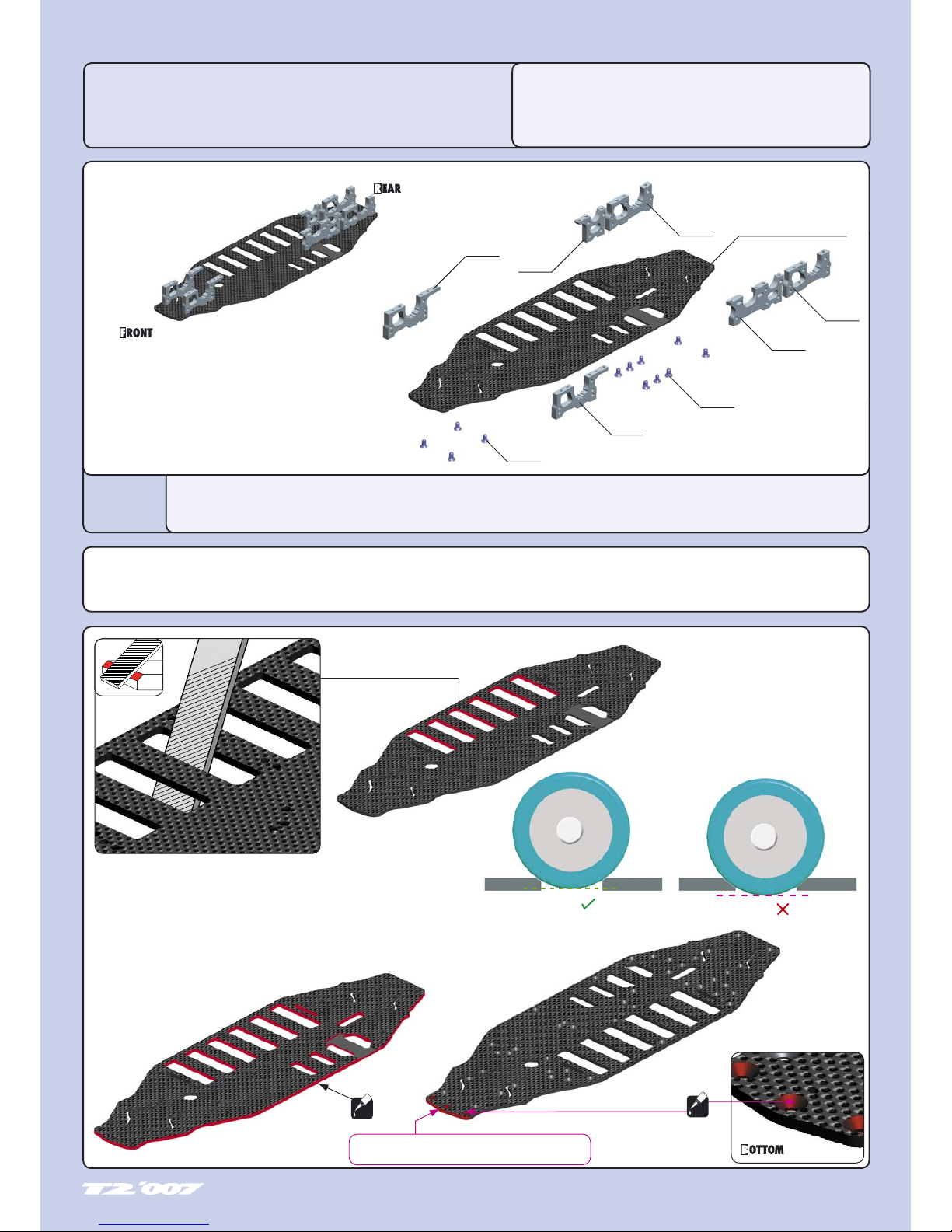

KIT

The XRAY T2’007 comes partially pre-assembled. Before starting assembly, disassemble the chassis parts, noting the position and orientation of the parts, particularly

the bulkheads. Keep the parts, including the screw hardware, close at hand. In the assembly steps that follow, each section begins with a parts list. Parts indicated

with STYLE B are from the previously disassembled chassis parts in section 0.

CA

At the beginning of each section is an exploded view of the parts to be assembled. There is also a

list of all the parts and part numbers that are related to the assembly of that section.

The part descriptions are color-coded to make it easier for you to identify the source of a part.

Here are what the different colors mean:

STYLE A - indicates parts that are included in the bag marked for the section.

STYLE B - indicates parts that were set aside in Section 0.

STYLE C - indicates parts that are already assembled from previous steps.

0. KIT

(FACTORY PRE-ASSEMBLED)

COLOR INDICATIONS

CORRECT

INCORRECT

Lightly file edges of battery slots to remove

sharp edges.

Please note that the US Foam-Spec 3.5mm

Extra-Thick Chassis requires the battery slots to

be filed more than the standard 2.5mm thick

chassis.

Do not file battery slots too much, or batteries

may protrude below the chassis bottom.

To protect and seal edges of graphite parts, sand edges smooth and then apply CA glue.

Do this for: chassis edges; filed battery slots, countersunk holes for front bumper screws.

For the US extra-thick chassis, we recommend rounding the bottom forward edge of the

chassis (using a file or sandpaper).

CA

Apply only a bit of CA glue on

the countersunk holes

903306

903306

302018

303029

303018 301122 (EU RUBBER-SPEC)

301123 (US FOAM-SPEC)

302018

303018

303019

For the US extra-thick chassis, we recommend rounding the

bottom forward edge of the chassis (using a file or sandpaper).

30 1122 T2 CHASSIS 2.5MM GRAPHITE - RUBBER-SPEC - MULTI-FLEX™

30 1123 T2 CHASSIS 3.5MM GRAPHITE - EXTRA-THICK - FOAM-SPEC

30 2018 T2‘007 ALU FRONT LOWER SUSP. ADJUST. BULKHEAD

30 3018 T2‘007 ALU REAR LOWER SUSP. ADJUST. BULKHEAD

30 3019 T2‘007 RIGHT ALU LAYSHAFT BULKHEAD

30 3029 T2‘007 MOTOR MOUNT BULKHEAD

90 3306 HEX SCREW SFH M3x6 (10)

Page 6

6

FACTO RY PREASSEMBLED

GREASE

966080

C 8

963030

ST 3x8

930138

BA 3x8

930508

BB 5x8

930120

B 2.4

FRONT MULTI-DIFF™

EU RUBBER-SPEC ONLY

30 5000 BALL DIFFERENTIAL WITH LABYRINTH DUST COVERS™ - SET - 7075 T6

30 5010 ALU DIFF LONG OUTPUT SHAFT - HARD COATED - 7075 T6

30 5020 ALU DIFF SHORT OUTPUT SHAFT - HARD COATED - 7075 T6

30 5040 SCREW FOR EXTERNAL DIFF ADJUSTMENT - HUDY SPRING STEEL

30 5050 DIFF PULLEY 34T WITH LABYRINTH DUST COVERS

30 5082 DIFF WASHER 17x23x1 (2)

30 5102 XRAY MULTI-DIFF™ T1FK'05, T2

30 5112 MULTI-DIFF MAIN AXLE T1FK‘05, T2

30 5121 MULTI-DIFF LOCKING AXLE - HUDY SPRING STEEL

30 5131 INNER DRIVESHAFT ADAPTER - HUDY SPRING STEEL (2)

30 5150 TIMING BELT PULLEY 34T

30 9319 UNIVERSAL SET OF PLASTIC SHIMS (included in Last Aid Bag)

90 2305 HEX SCREW SH M3x5 (10)

93 0120 CARBIDE BALL 2.4 MM (12)

93 0138 CARBIDE BALL-BEARING AXIAL F3-8 3x8x3.5

93 0508 BALL-BEARING MR85ZZ 5x8x2.5 (2)

96 3030 CONE WASHER ST 3x8x0.5 (10)

96 6080 CH-CLIP 8 (10)

97 0100 O-RING 10x1.5 (10)

98 1212 PIN 2x11.8 (10)

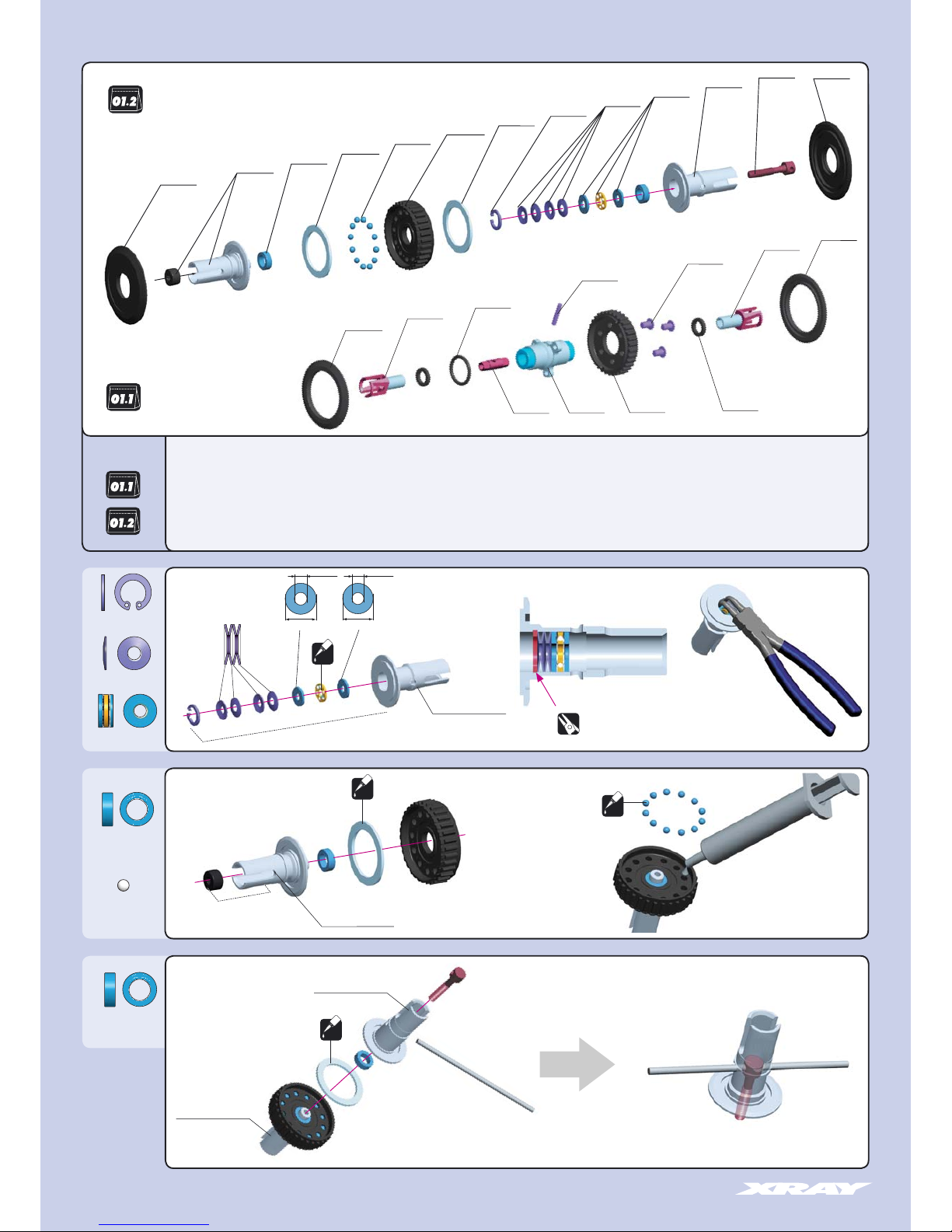

1. BALL DIFFERENTIAL & FRONT MULTI-DIFF

™

FA

CTOR

Y P

REASS

EMBLED

LONG DIFF SHAFT

SHORT DIFF SHAFT

BAG

930508

BB 5x8

SHORT DIFF SHAFT

LONG DIFF SHAFT

CUTAWAY VIEW

GR

GR

GR

305150

305150

305112

305131

970100

981212

902305

309319

(included in Last Aid Bag)

305131

305150

305121

GR

Insert CH-clip into the groove with nose pliers

CUTAWAY VIEW

BALL DIFFERENTIAL

8.0 mm

3.2 mm

7.8 mm

3.0 mm

305050

305020

930508

305082

930120

305050

305082

966080

963030

930138

305010

305040

305050

Page 7

7

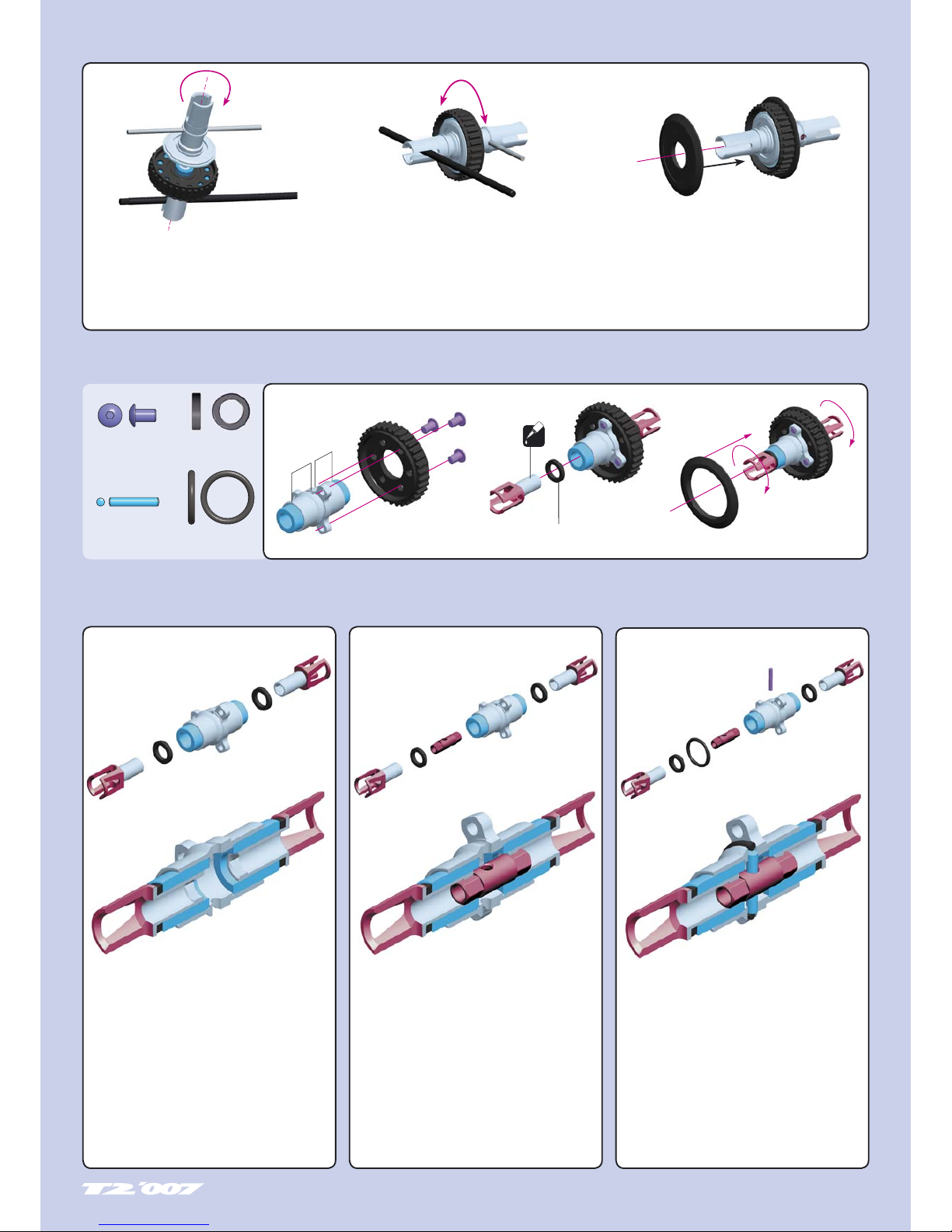

BALL DIFFERENTIAL & FRONT MULTI-DIFF

™

902305

SH M3x5

309319

SHIM 6x9x2

FRONT MULTI-DIFF

™ (EU RUBBER-SPEC ONLY)

981212

P 2x12

970100

O 10x1.5

DIRECTION OF TURN

FRONT MULTI-DIFF

™

SETTINGS

STANDARD ONE-WAY SOLID ONE-WAY FULL-TIME SOLID AXLE

Outdrive shafts (left and right) are not connected to each

other, nor to front main axle.

Off-power:

Outdrive shafts rotate forward independently of each other

and front main axle.

On-power:

Both outdrive shafts rotate with front main axle (locked in

one-way bearings)

Best used when...

traction is high, the car leans towards off-power understeer

and the track does not require braking for the corners. Will

give maximum off-power steering and increase efficiency

(more runtime). Best suited to a smooth driving style.

Both outdrive shafts (left and right) are connected

together by internal locking axle, but are not

connected to front main axle.

Off-power:

Both connected outdrive shafts rotate forward

together (but independent of front main axle).

On-power:

Both outdrive shafts rotate with front main axle

(locked in one-way bearings).

Best used when...

traction is medium to high and the track does not

require braking for the corners. Will give good offpower steering and efficiency.

Both outdrive shafts (left and right) are connected

to front main axle by internal locking axle and

locking pin.

Off-power and on-power:

Both outdrive shafts rotate with front main axle.

Best used when...

traction is low to medium, the car leans towards

off-power oversteer and/or the track requires

braking for the corners. Will give less off-power

steering and efficiency (less runtime). Best suited to

an aggressive driving style.

Cutaway view Cutaway view Cutaway view

Front main axle

Outdrive shaft

(Left)

Outdrive shaft

(Right)

Front main axle

Outdrive shaft

(Left)

Outdrive shaft

(Right)

Locking axle

Front main axle

Outdrive shaft

(Left)

Outdrive shaft

(Right)

Locking

axle

Locking

pin

O-ring

Spacer

Spacer

Spacer

Spacer

Spacer

Spacer

DO NOT TIGHTEN THE DIFF COMPLETELY

THE DIFF MUST BE BROKEN IN PROPERLY !

IMPORTANT: When you build the differential, do not tighten it fully initially; the differential needs to be broken in properly. When you build the diff tighten it very

gently. When you put the diff in the car and complete the assembly, run the car for a few minutes, tighten the diff a little bit, and then recheck the diff. Repeat this

process several times until you have the diff tightened to the point you want it. Final adjustments should ALWAYS be made with the diff in the car and on the track.

Apply one-way lube

In case of excessive play use composite shims

included in the Last Aid bag.

OIL

LO

N

G

S

H

O

RT

Page 8

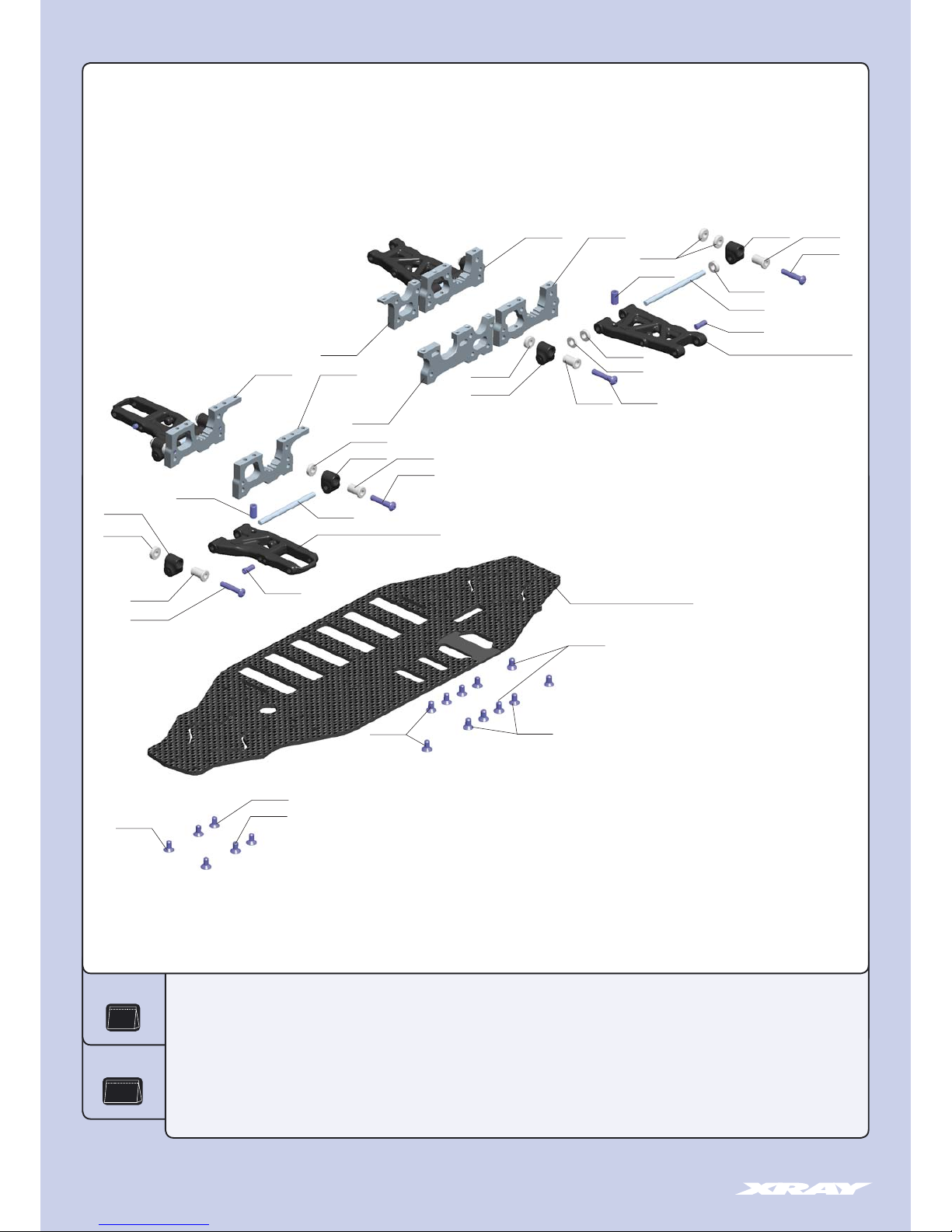

8

303134

903306

301122 (EU RUBBER-SPEC)

301123 (US FOAM-SPEC)

903306

302044

303018 303018

302033

902318

303122

303123

307313

303123

901408

303161 (EU RUBBER-SPEC)

303162 (US FOAM-SPEC)

902316

302044

302033

901308

303134

903306

903306

903306

903306

302018 302018

303134

302044

302033

902316

303134

302044

302033

902316

901308

901408

307215

302161

(EU RUBBER-SPEC)

302162 (US FOAM-SPEC)

303019

303029

2. FRONT & REAR SUSPENSION

BAG

02

30 2033 T2 ALU NUT FOR SUSPENSION HOLDER (2)

30 2044 T2 LOWER SUSPENSION HOLDERS (2+2+2)

30 2161 T2 FRONT SUSPENSION ARM - HARD - RUBBER-SPEC

30 2162 T2 FRONT SUSPENSION ARM - EXTRA-HARD - FOAM-SPEC

30 3122 ALU SHIM 3x6x1.0MM (10)

30 3123 ALU SHIM 3x6x2.0MM (10)

30 3134 ALU SHIM FOR LOWER SUSP. HOLDER 3x7.5x1.5 (10)

30 3161 T2 REAR SUSPENSION ARM - HARD - RUBBER-SPEC

30 3162 T2 REAR SUSPENSION ARM - EXTRA-HARD - FOAM-SPEC

30 7215 T2 FRONT SUSPENSION PIVOT PIN (2)

30 7313 T2 REAR SUSPENSION PIVOT PIN (2)

90 1308 HEX SCREW SB M3x8 (10)

90 1408 HEX SCREW SB M4x8 (10)

90 2316 HEX SCREW SH M3x16 (10)

90 2318 HEX SCREW SH M3x18 (10)

90 3306 HEX SCREW SFH M3x6 (10)

30 1122 T2 CHASSIS 2.5MM GRAPHITE - RUBBER-SPEC - MULTI-FLEX™

30 1123 T2 CHASSIS 3.5MM GRAPHITE - EXTRA-THICK - FOAM-SPEC

30 2018 T2‘007 ALU FRONT LOWER SUSP. ADJUST. BULKHEAD

30 3018 T2‘007 ALU REAR LOWER SUSP. ADJUST. BULKHEAD

30 3019 T2‘007 RIGHT ALU LAYSHAFT BULKHEAD

30 3029 T2‘007 MOTOR MOUNT BULKHEAD

90 3306 HEX SCREW SFH M3x6 (10)

BAG

02.1

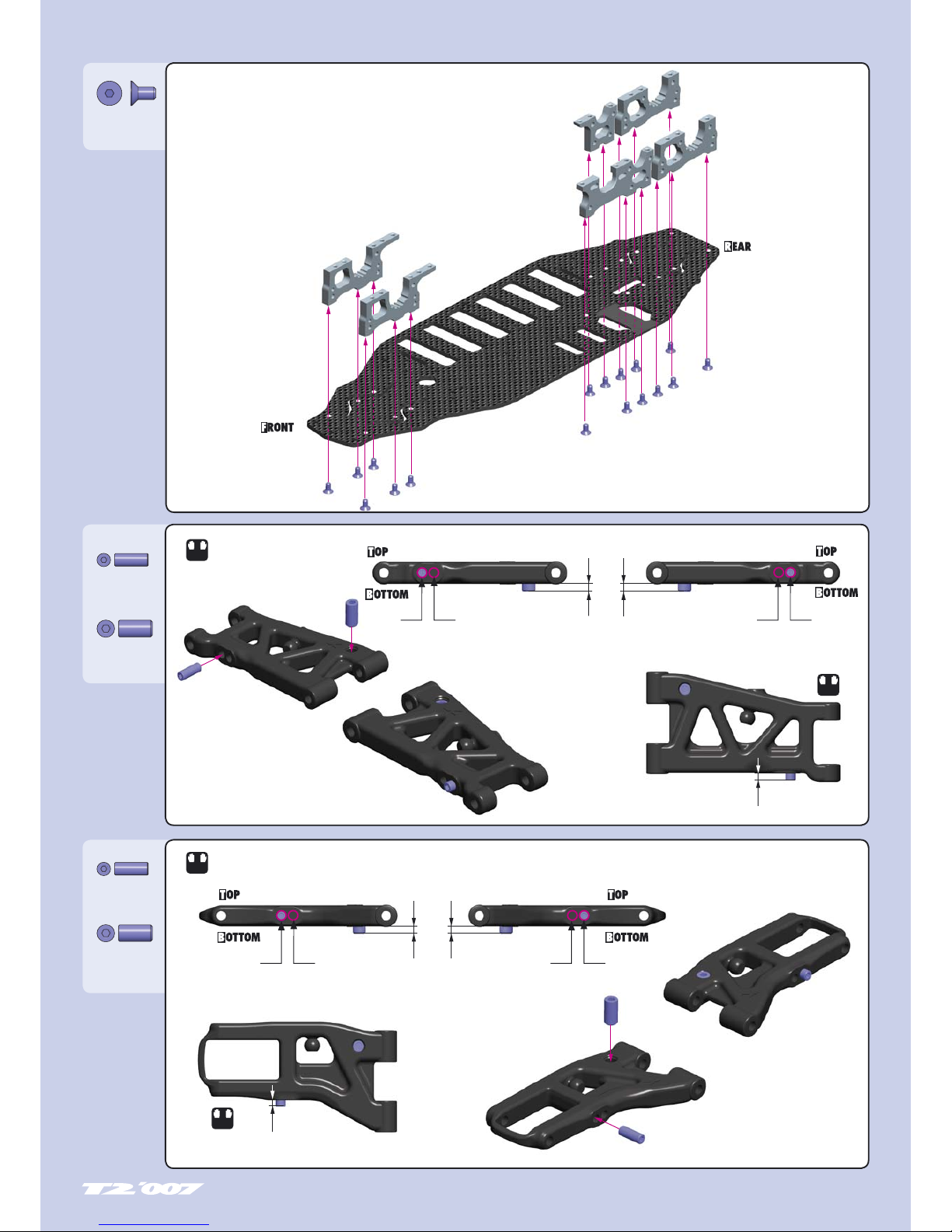

Page 9

9

903306

SFH M3x6

901308

SB M3x8

901408

SB M4x8

901308

SB M3x8

901408

SB M4x8

REAR LEFT ARM REAR RIGHT ARM

RIGHT REAR ARM

FRONT LEFT ARMFRONT RIGHT ARM

LEFT REAR ARM

REAR ARMS

2. FRONT & REAR SUSPENSION

3mm

2.0mm

3mm

4x8mm

3x8mm

L=R

FRONT LEFT ARM

FRONT RIGHT ARM

L=R

COMPLETED ASSEMBLY

3x8mm

4x8mm

COMPLETED ASSEMBLY

FRONT ARMS

L=R

EU RUBBER-SPEC

0.8mm

US FOAM-SPEC

1.7mm

EU RUBBER-SPEC

0.5mm

US FOAM-SPEC

INITIAL POSITION

US EU

INITIAL POSITION

USEU

INITIAL POSITION

US EU

INITIAL POSITION

USEU

L=R

Page 10

10

DETAIL

2. FRONT & REAR SUSPENSION

47.5 mm

3x16mm

51.5 mm

3x7.5x1.5mm

3x6x2mm

3x6x1mm

3x7.5x1.5mm

3x16mm

3x18mm

DETAIL

DETAIL

2x

1:1

L=R

L=R

2x

3x7.5x1.5mm

3x7.5x1.5mm

3x16mm

DETAIL

L=R

REAR LEFT ARM

REAR RIGHT ARM

Roll Center Position:

-0.75mm

Roll Center Position:

0mm

Standard Setting

Roll Center Position:

+0.75mm

Use these suspension holders for

initial assembly

Use these suspension holders for

initial assembly

Roll Center Position:

-0.75mm

Roll Center Position:

0mm

Standard Setting

Roll Center Position:

+0.75mm

FRONT LEFT ARM

FRONT RIGHT ARM

303122

SHIM 3x6x1

902316

SH M3x16

303123

SHIM 3x6x2

303134

SHIM 3x7.5x1.5

902318

SH M3x18

902316

SH M3x16

303134

SHIM 3x7.5x1.5

Page 11

11

305431

305784 (EU RUBBER-SPEC)

305886 (US FOAM-SPEC)

940510

902306

303044

306513

903306

902306

302022

902305

302078

941015

305000

302078

940510

965050

305575

305519

981212

302078

902306

902306

302098

902306

303094

302022

305442

941015

302078

305102 (EU RUBBER-SPEC)

305000 (US FOAM-SPEC)

3. CENTRAL TRANSMISSION

BAG

30 2022 T2 ALU UPPER CLAMP FOR BULKHEADS (2)

30 2078 T2‘007 SET OF COMPOSITE HUBS FOR BULKHEADS (4+2)

30 2098 T2 SHOCK TOWER FRONT 3.0MM GRAPHITE

30 3044 T2‘007 REAR UPPER DECK 2.5MM GRAPHITE - WIDE

30 3094 T2 SHOCK TOWER REAR 3.0MM GRAPHITE

30 5431 HIGH-PERFORMANCE KEVLAR DRIVE BELT FRONT 3 x 507 MM

30 5442 HIGH-PERFORMANCE KEVLAR DRIVE BELT REAR 3 x 180 MM

30 5519 T2 ALU SOLID LAYSHAFT

30 5575 FIXED PULLEY 20T (2)

30 5784 SPUR GEAR 84T / 48

30 5787 SPUR GEAR 87T / 48 (OPTION)

30 5790 SPUR GEAR 90T / 48 (OPTION)

30 5882 SPUR GEAR 112T / 64 (OPTION)

30 5884 SPUR GEAR 114T / 64 (OPTION)

30 5886 SPUR GEAR 116T / 64

30 5888 SPUR GEAR 118T / 64 (OPTION)

30 6513 T2‘007 ALU LOW TOP DECK MOUNT (2)

90 2305 HEX SCREW SH M3x5 (10)

90 2306 HEX SCREW SH M3x6 (10)

90 3306 HEX SCREW SFH M3x6 (10)

90 3308 HEX SCREW SFH M3x8 (10)

94 0510 HIGH-SPEED BALL-BEARING 5x10x4 RUBBER SEALED (2)

94 1015 HIGH-SPEED BALL-BEARING 10x15x4 RUBBER SEALED (2)

96 5050 E-CLIP 5 (10)

98 1212 PIN 2x12 (10)

30 5000 BALL DIFFERENTIAL WITH LABYRINTH DUST COVERS™ - SET - 7075 T6

30 5102 XRAY MULTI-DIFF T1FK’05, T2, T2R

03

BAG

03.1

Page 12

12

902305

SH M3x5

965050

C5

981212

P 2x12

940510

BB 5x10x4

941015

BB 10x15x4

NOTE ORIENTATION

XRAY Multi-Diff is not included

in US FOAM-SPEC kit. The US

FOAM-SPEC kit includes front

ball-differential.

TO LOOSEN FRONT BELT:

Rotate both front nylon hubs in arrow direction

(A)

TO TIGHTEN FRONT BELT:

Rotate both front nylon hubs in arrow direction

(B)

FRONT BELT TENSION ADJUSTMENT

A B

TO LOOSEN REAR BELT:

Rotate both front nylon hubs in arrow direction

(A)

TO TIGHTEN REAR BELT:

Rotate both front nylon hubs in arrow direction

(B)

REAR BELT TENSION ADJUSTMENT

B

A

INITIAL POSITION:

PLACE TAB IN THIS NOTCH

L=R L=R

INITIAL POSITION:

PLACE TAB IN THIS NOTCH

! IMPORTANT

Insert composite bushings perfectly straight

in bulkheads so the bearings spin freely. If the

bearings do not spin freely, reinstall the composite

bushings properly.

CUTAWAY VIEW

3. CENTRAL TRANSMISSION

Page 13

13

902306

SH M3x6

902306

SH M3x6

903306

SFH M3x6

902306

SH M3x6

L=R L=R

Position the rear top deck inside of the rear drive belt

DETAIL

! IMPORTANT

When building the EU Rubber-Spec

chassis, DO NOT use these alu stands

for initial set-up. These alu stands are

recommended for use only on the US

Foam-Spec chassis, when running foam

tires, or in very high-grip conditions.

3. CENTRAL TRANSMISSION

Page 14

14

901302

SB M3x2.5

981210

P 2x10

902312

302663

303141

303361

902205

305350

901304

940510

303210

303032

305231

901302

302664

305240

305323

305340

981210

303351

307321

902314

302663

302346

302291

902205

305350

901304

303210

303032

305240

305323

981210

307221

307455

302664

902306

901302

305231

940510

302252

305340

902310

302345

902306

307455

TIP

1.5MM ALLEN WRENCH

GR

THREAD LOCK

4x

DO NOT OVERTIGHTEN

GREASE

For easy and comfortable installation of

the plastic caps use pliers as shown.

BAG

4. FRONT & REAR TRANSMISSION

04

30 2252 T2 COMPOSITE STEERING BLOCK

30 2291 T2 STEEL STEERING BUSHING (2+2)

30 2345 T2 COMPOSITE C-HUB FRONT BLOCK, RIGHT - 4° DEG.

30 2346 T2 COMPOSITE C-HUB FRONT BLOCK, LEFT - 4° DEG.

30 2663 T2 BALL JOINT 5 MM - OPEN (8)

30 2664 T2 BALL JOINT 5 MM UNIDIRECTIONAL - OPEN (4)

30 3032 T2 ALU QUICK ROLL-CENTER HOLDER™ 4.9MM (2)

30 3141 ALU SHIM 3x5x1.0MM (10)

30 3210 REAR TURNBUCKLE L/R 25 MM - HUDY SPRING STEEL (2)

30 3351 T2 COMPOSITE UPRIGHT 1° OUTBOARD TOE-IN - RIGHT

30 3361 T2 COMPOSITE UPRIGHT 1° OUTBOARD TOE-IN - LEFT

30 5231 T2 DRIVE SHAFT COUPLING - HUDY SPRING STEEL

30 5240 DRIVE SHAFT REPLACEMENT PLASTIC CAP 3 MM (4)

30 5323 T2 DRIVE SHAFT - HUDY SPRING STEEL

30 5340 T2 DRIVE AXLE - HUDY SPRING STEEL

30 5350 T2 ALU WHEEL HUB (2)

30 7221 T2 FRONT ARM PIVOT PIN (2)

30 7321 T2 REAR ARM PIVOT PIN (2)

30 7455 T2 PIVOT BALL 5.0 MM DOUBLE BEVEL SHOULDERS (10)

90 1302 HEX SCREW SB M3x2.5 (10)

90 1304 HEX SCREW SB M3x4 (10)

90 2205 HEX SCREW SH M2x5 (10)

90 2306 HEX SCREW SH M3x6 (10)

90 2310 HEX SCREW SH M3x10 (10)

90 2312 HEX SCREW SH M3x12 (10)

90 2314 HEX SCREW SH M3x14 (10)

94 0510 HIGH-SPEED BALL-BEARING 5x10x4 RUBBER SEALED (2)

98 1210 PIN 2x10 (10)

TL

Page 15

15

902205

SH M2x5

940510

BB 5x10x4

981210

P 2x10

902205

SH M2x5

940510

BB 5x10x4

981210

P 2x10

902310

SH M3x10

53.0 mm52.5 mm

1:1

1:1

4. FRONT & REAR TRANSMISSION

1R = RIGHT SUSPENSION BLOCK 1° OUTBOARD TOE-IN

1L = LEFT SUSPENSION BLOCK 1° OUTBOARD TOE-IN

2x

COMPLETED ASSEMBLY

LEFT STEERING BLOCK = RIGHT STEERING BLOCK

2x

COMPLETED ASSEMBLY

L=R

2x

COMPLETED ASSEMBLY

MOLDED DOT

FRONT RIGHT = FRONT LEFT

REAR RIGHT = REAR LEFT

SPECIAL UNIDIRECTIONAL BALL-JOINT WITH MOLDED DOT

4x

4x

L=R

RIGHT C-HUB "4R"

LEFT C-HUB "4L"

4x

SHORT

LONG

Page 16

16

303141

SHIM 3x5x1

902306

SH M3x6

902312

SH M3x12

307455

PB 5mm

901304

SB M3x4

1:1

4. FRONT & REAR TRANSMISSION

REAR VIEW

Quick Roll CenterTM tabs in lower inner holes

25 mm

2x

3x5x1mm

L=R

TIGHTEN GENTLY

After you tighten the screw into the upright, pull

the linkage upward so the ball joint

"

snaps" onto

the pivot ball. The whole assembly should move

freely.

DETAIL STEP

"1L"

"1R"

"CLICK"

INITIAL POSITION

Page 17

17

902306

SH M3x6

902314

SH M3x14

307455

PB 5mm

901304

SB M3x4

1:1

4. FRONT & REAR TRANSMISSION

FRONT VIEW

23 mm

2x

L=R

"4L"

"4R"

DETAIL STEP

"CLICK"

TIGHTEN GENTLY

Quick Roll CenterTM tabs in lower inner holes

INITIAL POSITION

After you tighten the screw into the upright, pull

the linkage upward so the ball joint

"

snaps" onto

the pivot ball. The whole assembly should move

freely.

Page 18

18

BAG

30 1159 ALU COUNTERSUNK SHIM (4)

30 1178 T2‘007 UPPER DECK - NARROW - RUBBER-SPEC - MULTI-FLEX™

30 1179 T2‘007 UPPER DECK - WIDE - FOAM-SPEC - MULTI-FLEX™

30 2504 XRAY QUICK-SAVER™ - ADJUSTABLE SERVO SAVER SET

30 2551 SERVO SAVER PLASTIC COVER - ECCENTRIC (2)

30 2581 T2‘007 COMPOSITE SERVO HORN - KO, JR, AIRTRONICS

30 2583 T2‘007 COMPOSITE SERVO HORN - FUTABA, ROBE

30 2610 ADJ. TURNBUCKLE M3 L/R 40 MM - HUDY SPRING STEEL (2)

30 2630 ADJ. TURNBUCKLE L/R 20 MM - HUDY SPRING STEEL (2)

30 2652 T2‘007 BALL END 5 MM WITH THREAD (2)

30 2663 T2 BALL JOINT 5 MM - OPEN (8)

30 3210 REAR TURNBUCKLE L/R 25 MM - HUDY SPRING STEEL (2)

30 6513 T2‘007 ALU LOW TOP DECK MOUNT (2)

30 7455 T2 PIVOT BALL 5.0 MM DOUBLE BEVEL SHOULDERS (10)

90 2305 HEX SCREW SH M3x5 (10)

90 2306 HEX SCREW SH M3x6 (10)

90 2310 HEX SCREW SH M3x10 (10)

90 3306 HEX SCREW SFH M3x6 (10)

90 3310 HEX SCREW SFH M3x10 (10)

93 0407 BALL-BEARING MR74ZZ 4x7x2.5 (2)

302551

930407

903310

301159

306513

903306

307455

302663

307455

302610

302663

902310

302581

or 302583

302652

301178 (EU RUBBER-SPEC)

301179 (US FOAM-SPEC)

902310

302630

902305

902306

302504

302504

307455

302663

902310

302551

930407

902306

902306

902306

05

1:1

1:1

903310

SFH M3x10

302504

FACTORY ASSEMBLED

approximately 49mm

SERVO LINK

65.5mm 63.5mm

Adjust servo link to fit your servo

There are 5 different Ackermann settings possible to set with the Quick-Saver

™

5. STEERING

INITIAL POSITION

1 STEP OUT

5 STEPS OUT

5

4

3

2

1

5

4

3

2

1

Page 19

19

307455

PB 5mm

902310

SH M3x10

902305

SH M3x5

902306

SH M3x6

903306

SFH M3x6

930407

BB 4x7x2.5

307455

PB 5mm

902310

SH M3x10

RIGHT STEERING

ROD 63.5mm

LEFT STEERING

ROD 65.5mm

SERVO LINK

! IMPORTANT

The hole in top deck for the eccentric bearing holder is not

directly along the centerline of the top deck, but rather is

slightly off-center. Mount the top deck so that the off-center

hole is to the RIGHT of the centerline.

! IMPORTANT

When building the EU

Rubber-Spec chassis, DO

NOT use these alu stands

for initial set-up. These alu

stands are recommended

for use only on the US

Foam-Spec chassis, when

running foam tires, or in

very high-grip conditions.

US Foam-Spec

Top Deck

EU Rubber-Spec

Top Deck

5. STEERING

F = Futaba, Robe

K = KO, JR, Airtronics, Sanwa

Splines for servo

on this side

FREE MOVEMENT

FREE MOVEMENT

INITIAL POSITION

FRONT

TAB TO FRONT

INITIAL POSITION

TAB TO FRONT

3x5mm

Page 20

20

30 3241 BALL UNIVERSAL 5.8 MM HEX (4)

30 8035 COMPOSITE PISTONS ADJUSTABLE + NON-ADJUST. (SET 2+6)

30 8040 SHOCK ADJ. NUT ALU + O-RING (4+4)

30 8080 SHOCKABSORBER MEMBRANES (4)

30 8090 SHOCK FOAM INSERTS (4)

30 8301 T2 XRAY SHOCK ABSORBER-SET 4-STEP - SHORT (2)

30 8316 T2 SHOCK BALL JOINT - OPEN (4)

30 8330 T2 COMPOSITE FRAME SHOCK PARTS 4-STEP - SHORT

30 8351 T2 SHOCK CAP-NUT ALU (2)

30 8361 T2 HARDENED SHOCK SHAFT (2)

30 8380 ADDITIONAL XRAY ULTIMATE RACING SPRINGS (20)

30 8390 XRAY SELECTED ULTIMATE RACING SPRINGS (24)

96 1032 WASHER S 3.2 (10)

96 5019 E-CLIP 1.9 (10)

96 5023 E-CLIP 2.3 (10)

97 0050 O-RING 5x1 (10)

97 0121 O-RING 12.1x1.6 (10)

97 1031 SILICONE O-RING 3.1x1.6 (10)

Properly functioning shocks are very important to the performance of your car. This XRAY shock set contains parts to build four externally-adjustable or non-adjustable shocks.

Both adjustable and non-adjustable shocks feature XRAY's unique keying system that positively locks the pistons to the shock rods.

Carefully cut the parts from the frames, and then VERY carefully trim any excess flash with a sharp hobby knife. We recommend you use extra-fine sandpaper to gently smooth small

flashing. The side walls of the pistons must be perfectly round and smooth for proper operation.

We recommend you build all four shocks simultaneously. Ensure you have a clean work area to build the shocks.

Assemble FOUR adjustable shock rod assemblies by performing the following steps.

1. Press a #965023 (C 2.3) E-clip into the lower groove in the shock rod.

2. Place a #961032 (S 3.2) washer onto the shock rod atop the C-clip.

3. Press the piston assembly onto the shock rod, aligning flat in pistons

with flat on the shock rod.

4. Press a #965019 (C 1.9) E-clip into the upper groove in the shock rod.

5. Apply a drop or two of shock oil to the piston rod assembly,

and then insert the shock rod assembly into the shock body.

Cutaway view of

assembled adjustment collar

1. Lubricate the inner edge of a #970121 (O12.1x1.6) O-ring with

a drop or two of shock oil. Insert it into the groove of a #308040 threaded collar.

2. Carefully thread the collar onto the shock body as shown.

Be careful not to cross-thread the collar on the shock body.

965019

C 1.9

965023

C 2.3

961032

S 3.2

965019

C 1.9

965023

C 2.3

Apply a drop or two of shock oil to the piston pieces. Press upper piston (A) into lower

piston (B) as shown. The upper piston with holes (A) has a small tab that must exactly fit

into one of the notches in lower piston (B).

A

B

Assemble FOUR non-adjustable piston rod assemblies by performing the following steps.

Use the 3-hole non-adjustable pistons.

1. Press a #965023 (C 2.3) E-clip into the lower groove in the shock rod.

2. Press a 3-hole piston onto the shock rod, aligning flat in piston with flat on the shock rod.

3. Press a #965019 (C 1.9) E-clip into the upper groove of the shock rod.

4. Apply a drop or two of shock oil to the piston rod assembly, and then insert the shock rod assembly

into the shock body.

ADJUSTABLE PISTONS

NON-ADJUSTABLE PISTONS

970121

O 12.1x1.6

Cutaway view of

adjustable piston

BAG

A

B

OIL

OIL

4x

4x

4x

4x

ADJUSTABLE PISTONS

NON-ADJUSTABLE PISTONS

Large E-clip

Small E-clip

06

308330

! IMPORTANT

USE ONLY special T2 ball-joints (part #308316).

DO NOT USE ball joints on #308330 parts tree.

OIL

OIL

6. SHOCK ABSORBERS

308351

308330

308090

308080

308330

970121

308040

308382~308388

308393~308398

970050

971031

308330

308330

308316

303241

308361

965023

308035

965019

308035

2 HOLES 3 HOLES 4 HOLES 1-4 HOLES

NON ADJUSTABLE

ADJUSTABLE

961032

308035

Page 21

21

1. Insert the larger #970050 (O 5x1) O-ring onto the shock body,

until it seats around the shock body extension.

2. Lubricate the small #971031 (O 3.1x1.6) O-ring with a drop

or two of shock oil. Taking care not to rip or damage the O-ring,

slide it over the end of the shock rod.

3. Install the end-cap onto the bottom of the shock body. Lock it in

place by pressing it on, then turning it CW about 1/8 of a turn.

For easy assembly, use a #183010 HUDY Shock Assembly Tool.

Shock bleeding:

Turn the shock upside down and pull the shock rod out to full extension. Release the shock end-cap by turning it CCW and pulling it slightly

away from the shock body. Let the shock “vent” for at least 10 minutes; excess oil should seep out the end of the shock body. If the shock

rod doesn’t retract slightly into the shock body, push it in by 1~2mm. Replace the end-cap.

Check the shock for proper operation. The shock rod must move in and out freely with only “hydraulic” dampening. The shock rod should

not extend out fully (rebound) by itself when pushed in and released, nor should it be drawn into the shock body fully when extended and

released. It is normal to have anywhere from 25% to 75% of rebound. If it extends out more than 75% repeat the bleeding procedure and

let the shock sit for a few more minutes. Make sure that all four shocks have very similar natural rebound.

Shock length adjustment:

It is VERY important that all shocks are equal length.

Fully extend the shock absorber and measure the end-toend length; we recommend using digital calipers to give an

accurate measurement. If a shock absorber is shorter or longer

than others, adjust the shock length by tightening or loosening

the ball joint on the shock rod.

Damping adjustment:

If you built the adjustable shocks, fully extend the

shock rod and turn it slightly to lock the piston in the

shock body.

Turning the shock rod fully CCW aligns 4 holes in

the pistons (softest damping). Turning the shock

rod fully CW aligns 1 hole in the pistons (hardest

damping). The shocks have four settings, each of which can be

felt by a slight "click".

Set all four shocks initially to position 3 (3 holes open).

1. Fully extend the piston rod so the piston is at the bottom of the shock body.

2. Hold the shock upright and slightly overfill the shock body with shock oil.

3. Let the oil settle and allow air bubbles to rise to the top. Slowly move

thepiston up and down until no more air bubbles appear.

Add shock oil as necessary.

4. Pull the piston rod most of the way out of the shock body.

5. Place the rubber bladder on top of the shock body from a side. Some oil

should spill out.

6. Move the piston out very slightly so the bladder seals against the top of the

shock body.

HINT: Pre-thread the ball joint using an M3 screw.

WARNING! Be careful not to pre-thread too far, since the ball joint may split or the plastic threads may strip out

1mm

Cutaway view of

assembled

shock absorber

TOOL OPTIONAL

(HUDY #183010)

970050

O 5x1

971031

O 3.1x1.6

DETAIL

HARDEST

SOFTEST

FRONT

(Silver springs - EU)

(Light-Purple springs - US)

REAR

(Gold springs - EU)

(White springs - US)

OIL

4x

Grip the shock rod. Use either a shock rod

clamping tool, or grip the top of the shock

rod’s exposed thread with side-cutting pliers.

Thread the ball joint onto the shock rod until

approximately 1mm of thread is exposed.

CORRECT

INCORRECT

4x

4x

INCORRECT

4x

CORRECT

Follow the handy tip

TIP

! IMPORTANT

USE ONLY special T2 ball-joints (part #308316).

DO NOT USE ball joints on nylon parts tree.

1. Place foam insert into cavity in top mount.

2. Place top mount onto top of bladder.

3. Install and tighten alum. cap nut.

4x

1

2

3

4

6. SHOCK ABSORBERS

DETAIL

SHINY FINISH SIDE

SHINY FINISH SIDE

NOTE ORIENTATION

OF THE PIVOT BALLS

DETAIL

Page 22

22

BAG

30 1202 T2 COMPOSITE BUMPER

30 1218 T2 COMPOSITE UPPER HOLDER FOR BUMPER

30 1322 T2 FRONT BODY MOUNT SET 6MM

90 2306 HEX SCREW SH M3x6 (10)

90 3308 HEX SCREW SFH M3x8 (10)

90 3310 HEX SCREW SFH M3x10 (10)

902306

308301

301322

301218

981212

301202

301222

960030

903308

903310

903310

903308

301322

96 0030 NUT M3 (10)

98 1212 PIN 2x12 (10)

30 1222 T2 FOAM BUMPER

30 8301 T2 XRAY SHOCK ABSORBER-SET 4-STEP - SHORT (2)

07

903308

SFH M3x8

903310

SFH M3x10

960030

N M3x10

7. FRONT & REAR ASSEMBLY

3x10mm

3x10mm

3x8mm

3x10mm

Page 23

23

903308

SFH M3x8

981212

P 2x12

902306

SH M3x6

INITIAL POSITION

FRONT SHOCK

(SILVER SPRING - EU)

(LIGHT-PURPLE SPRING - US)

L=R

7. FRONT & REAR ASSEMBLY

INITIAL POSITION

L=R

Page 24

24

BAG

07

902306

SH M3x6

981212

P 2x12

902308

SH M3x8

301332

981212

902308

3

08301

902306

L=R

7. FRONT & REAR ASSEMBLY

30 1332 T2 REAR BODY MOUNT SET 6MM

90 2306 HEX SCREW SH M3x6 (10)

90 2308 HEX SCREW SH M3x8 (10)

98 1212 PIN 2x12 (10)

30 8301 T2 XRAY SHOCK ABSORBER-SET 4-STEP - SHORT (2)

INITIAL POSITION

REAR SHOCK

(GOLD SPRING - EU)

(WHITE SPRING - US)

L=R

INITIAL POSITION

Page 25

25

BAG

306200

903308

903308

NOT INCLUDED

902308

NOT INCLUDED

FROM SERVO

902306

960140

960140

306131

903306

903306

903308

306300

309402

306310

309319

NOT INCLUDED

NOT INCLUDED

08

902308

SH M3x8

903306

SFH M3x6

For improved weight balance, we

recommend using a narrow, light

servo.

8. FINAL ASSEMBLY

305716~34 PINION GEAR ALU HARD COATED - SHORT (OPTION)

30 6131 SET OF BATTERY BACKSTOPS

30 6163 T2 6-CELL GRAPHITE BATTERY STRAP (SET) - (OPTION)

30 6200 ALU SERVO MOUNT (2)

30 6300 ANTENNA MOUNT

30 6310 ANTENNA TUBE (2)

30 9319 UNIVERSAL SET OF PLASTIC SHIMS

30 9402 BODY CLIP FOR 6MM BODY POST (4)

90 2306 HEX SCREW SH M3x6 (10)

90 2308 HEX SCREW SH M3x8 (10)

90 3306 HEX SCREW SFH M3x6 (10)

90 3308 HEX SCREW SFH M3x8 (10)

96 0140 NUT M4 WITH FLANGE (10)

DETAIL

FROM SERVO

SERVO NOT INCLUDED

If the servo does not fit properly, you may have to add shims

between the servo tabs and the mounting posts. Shims are

included in the Last Aid bag.

90°

Servo arm must be perpendicular to

linkage when servo is in neutral.

Page 26

26

902306

SH M3x6

903308

SFH M3x8

903306

SFH M3x6

903308

SFH M3x8

8. FINAL ASSEMBLY

DOUBLE-SIDED TAPE

(NOT INCLUDED)

RECEIVER

(NOT INCLUDED)

SPEED CONTROLLER

(NOT INCLUDED)

Feed the receiver wire into the antenna tube

3x8mm

3x6mm

3x8mm

PINION

(NOT INCLUDED)

MOTOR

(NOT INCLUDED)

When installing the motor on the bulkhead, rotate the spur gear so the motor

screw can be installed through a hole in the spur gear. See the detail image below.

Adjust the motor so the pinion meshes with the spur gear properly. Make sure the

gear mesh is not too tight.

There should be a small amount of play between the teeth of the pinion gear and

spur gear.

DETAIL

Page 27

27

960140

N M4

DETAIL

8. FINAL ASSEMBLY

WARNING!

Follow the adhesive manufacturer's instructions for proper use and safety. Wear proper eye and hand protection.

CA

Make sure the wheel nuts are very tight, so the

wheels do not loosen during racing.

FIBRE TAPE

(NOT INCLUDED)

6-CELL INLINE BATTERY PACK

(NOT INCLUDED)

US Foam-Spec Notice:

Some foam wheels may be slightly wider and may touch the front steering blocks. To

avoid this, we recommend grinding the inside edge of the wheel, using a tire truer

and a file. Make sure that both front tires/wheels end up being the same width, and

that there are no rough edges.

WHEELS & TIRES & INSERTS

(NOT INCLUDED)

Make also sure that the front wheels and tires will not touch the steering blocks

when steering is applied. Also make sure that the wheels and tires do not touch the

shocks.

4x

Page 28

XRAY MODEL RACING CARS

P.O.Box 103,

911 50 Tre nč ín

Slovakia, Europe

Phone: +421 32 7440180

info@teamxray.com

XRAY MODEL R ACING CARS

P.O.Box 103,

911 50 Trenčín

Slovakia, Europe

Phone: +421 32 7440180

info@teamxray.com

XRAY MODEL R ACING CARS

P.O.Box 103,

911 50 Trenčín

Slovakia, Europe

Phone: +421 32 7440180

info@teamxray.com

XRAY MODEL RACING CARS

P.O.Box 103,

911 50 Tre nč ín

Slovakia, Europe

Phone: +421 32 7440180

info@teamxray.com

581703 9100918

1/10 LUXURY TOURING CAR1/10 LUXURY TOURING CAR

www.teamxray.com

Loading...

Loading...