Page 1

4WD SHAFT-DRIVE

INSTRUCTION MANUAL

1/18 MICRO CAR1/18 MICRO CAR1/18 MICRO CAR

IT'S FUN, IT'S MICRO, IT'SI T ' S F U N , I T ' S M I C R O , I T ' SIT'S FUN, IT'S MICRO, IT'S

Page 2

1

The XRAY M18 Micro is a unique 1/18th micro-sized model racing car

that is the epitome of high-performance and fine distinctive design.

Your M18 offers highest performance, responsive handling, and

traditionally exceptional XRAY quality, engineering, and design.

The XRAY M18 enters a new frontier in micro-car design by offering

fully-adjustable suspension, responsive shaft-drive drivetrain, and

ultra-smooth gear differentials. The superb craftsmanship and

attention to detail are clearly evident everywhere on the XRAY M18.

The XRAY M18 was created by blending highest-quality materials and

excellent design. The result? A very affordable, durable, high-

performance micro race car that is extremely easy to assemble, drive,

and race. On high-speed asphalt tracks or short twisty indoor tracks,

whether driving for fun or racing to win, the M18 delivers outstanding

performance, speed, and precision handling. M18 can be used for

competition micro racing, but is also well suited for novice drivers who

choose the XRAY M18 as their entrance into the R/C hobby.

We have made every effort to make these instructions as easy to

understand as possible. However, if you have any difficulties, problems,

or questions, please do not hesitate to contact the XRAY support team

at support@teamxray.com. Also, please visit our web site at

www.teamxray.com to find the latest updates, setup information,

option parts, and many other goodies. We pride ourselves on taking

excellent care of our customers.

CONGRATULATIONS

R/C TIPS

QUALITY CERTIFICATE

• Read and fully understand the instruction manual before building.

• Always keep this instruction manual ready at hand for quick

reference, even after completing the assembly.

• Make sure all screws are tight. Check them periodically.

Make sure that the chassis screws do not protrude from the chassis.

• For the best performance, it is very important that great

care is taken to ensure the free movement of all parts.

• Clean all ball-bearings so they move very easily and freely.

• Tap or pre-thread the plastic parts when threading screws.

• Self-tapping screws cut threads into the parts when being tightened.

• Do not use excessive force when tightening the self-tapping screws,

or you may strip out the thread in the plastic. We recommended you

stop tightening a screw when you feel some resistance.

• Ask your local hobby shop for any advice.

• Please support your local hobby shop. We at XRAY Model Racing

Cars support all local hobby dealers. Therefore we ask you, if at all

possible, to purchase XRAY products at your hobby dealer and give

them your support like we do. If you have difficulty finding XRAY

products, please check out www.teamxray.com to get advice, or

contact us via email at support@teamxray.com, or contact the XRAY

distributor in your country.

XRAY MODEL RACING CARS uses only the highest quality materials,

the best compounds for molded parts and the most sophisticated

manufacturing processes. We guarantee that all parts of a newlypurchased kit are manufactured with the highest regard to quality.

However, due to the many factors inherent in model racecar competition,

we cannot guarantee any parts once you start racing the car.

We wish you enjoyment of this high-quality and high-performance

micro car and wish you best success on the track!

In line with our policy of continuous product development, the exact specifications of the kit may vary. In the unlikely event of any problems

with your new kit, you should contact the model shop were you purchased it, quoting the part number.

We do reserve all rights to change any specification without prior notice. All rights reserved.

Page 3

2

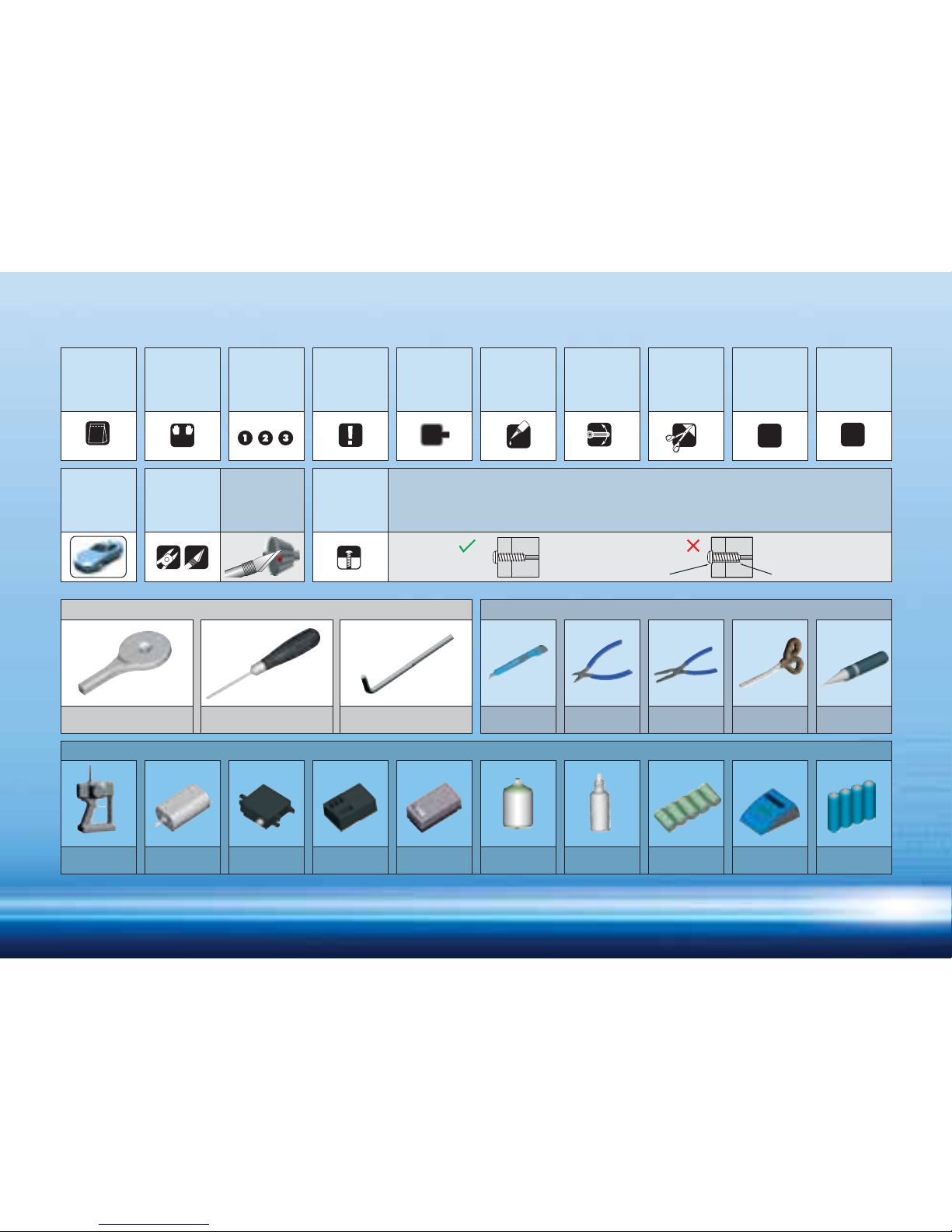

SYMBOLS USED

TOOLS REQUIRED

TOOLS INCLUDED

EQUIPMENT REQUIRED

Hobby Knife Side Cutters Needlenose Pliers Curved Scissors Hole Reamer

1:1

L=R

1

CA

2x

C

Self-tapping screws cut threads into the parts when being tightened. Excessive force may permanently damage

parts when tightening screws. It is recommended to stop tightening when the part is attached or when some

resistance is felt after the threaded portion enters the plastic.

Overtightened

CORRECT WRONG

The threads are stripped.

Micro Servo

Receiver

Transmitter Micro Motor

5-Cell Micro

Battery Pack

Battery Charger Transmitter

Batteries

Micro Speed

Controller

CA GlueLexan Paint

(Typically AA type)(Ni-MH recommended)

Differential Assembly Tool Phillips Screwdriver 1.5mm Allen Wrench

Assemble as

many times

as specified

(here twice)

Cut off

remaining

material

Cut off

remaining

material from all

plastic parts.

Cut off

shadded

portion

Ensure smooth

non-binding

movement

Apply instant

glue

Pivot ball

type used

Pay attention

here

Assemble in

the specified

order

Assemble left

and right

sides the

same way

Part bags

used

True-to-scale

diagram

Car

orientation

Tighten screw

gently

Page 4

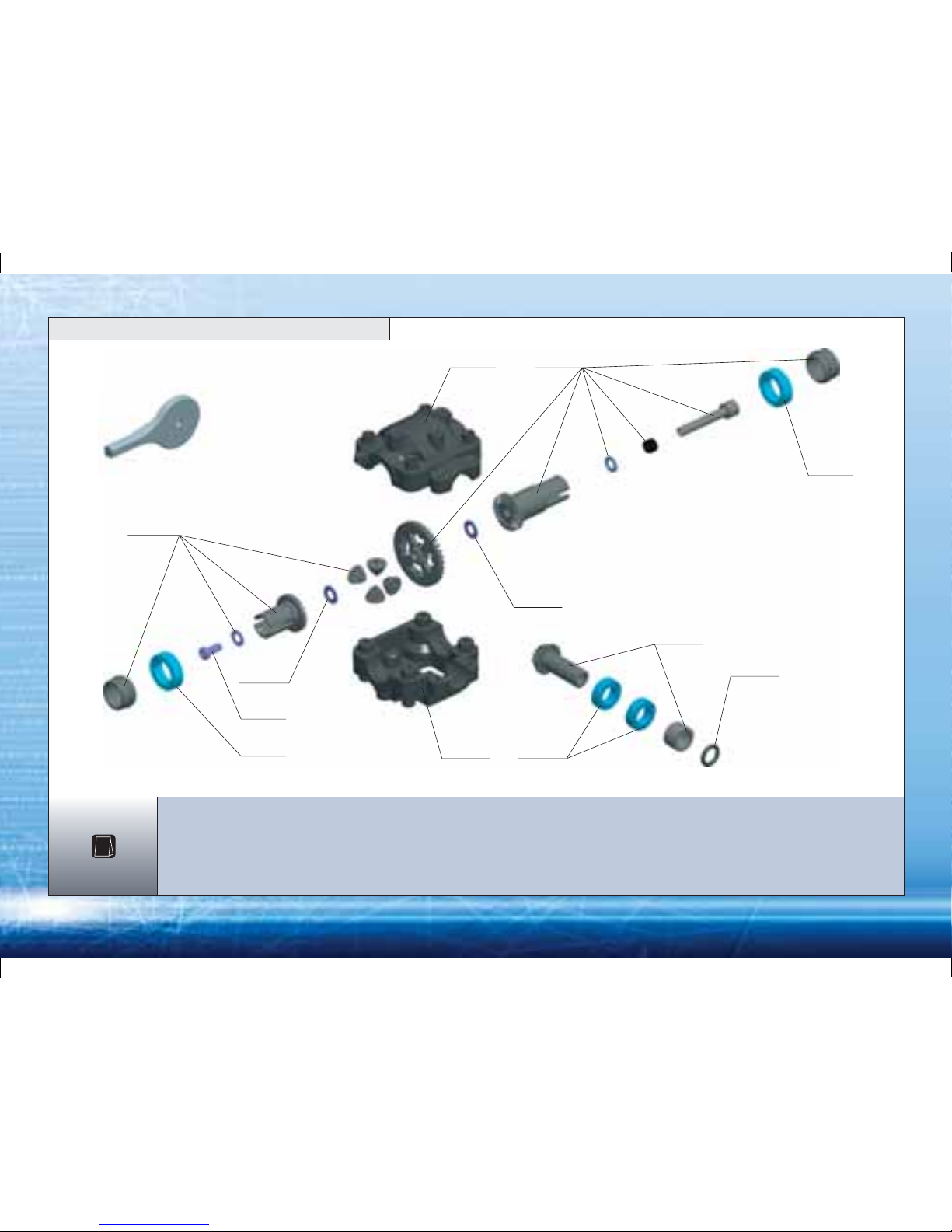

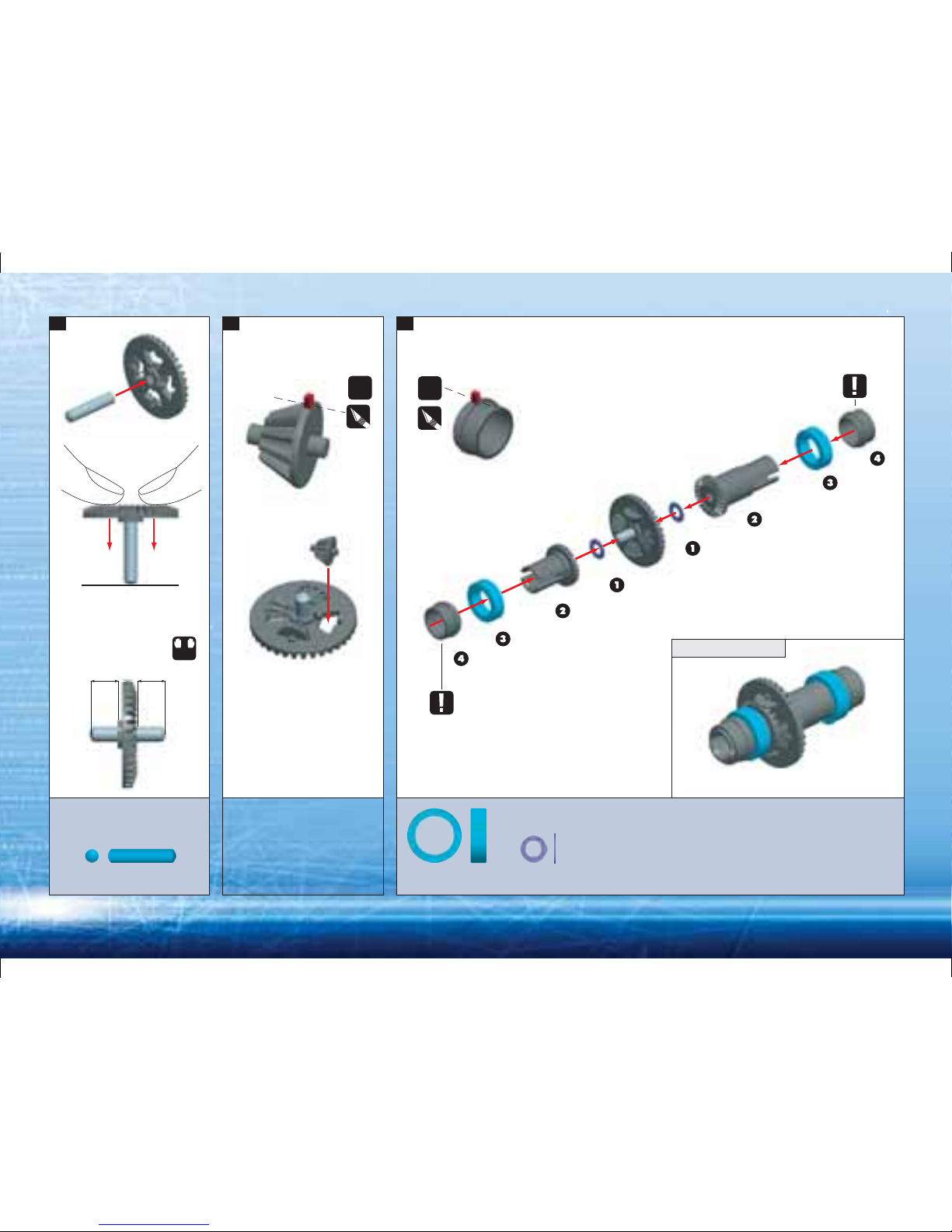

3

389343

309080

309080

389373

389373

385060

309040

385005

385060

385005

385005

DIFF ASSEMBLY TOOL

385550

309040 BALL-BEARING MR106ZZ 6x10x3 (2)

309080 BALL-BEARING MR128ZZ 8x12x3.5 (2)

385005 COMPOSITE FRONT GEAR DIFF. + DRIVESHAFT PINION GEAR

385060 GEARBOX CASE

385550 O-RING 4x1 (10)

389343 SCREW PHILLIPS 2.2 x 6 (10)

389373 WASHER S 3x6x0.3 (10)

1. FRONT DIFFERENTIAL

BAG

1

Page 5

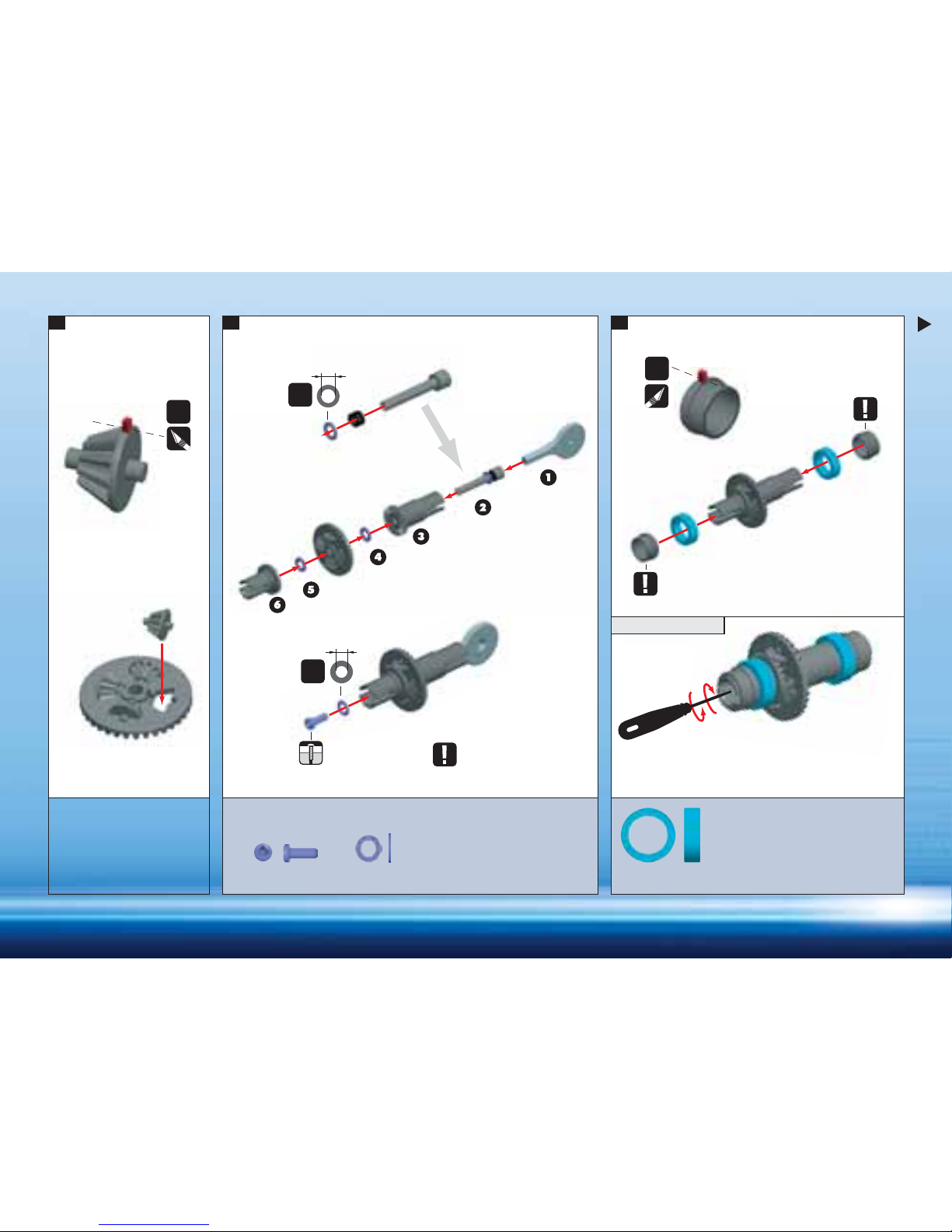

4

NOTE

ORIENTATION

TIGHTEN DIFF SCREW (CW) = TIGHTENS DIFF

LOOSEN DIFF SCREW (CCW) = LOOSENS DIFF

SET DIFF MEDIUM TIGHT SO IT ROTATES

SMOOTHLY WITHOUT BINDING

ADJUST THE DIFF SO

IT SPINS SMOOTHLY

TIGHTEN

GENTLY

NOTE

ORIENTATION

CUT OFF

CUT OFF

LARGER HOLE

SMALLER HOLE

1. 2. 3.

CCW.

CW.

ASSEMBLED VIEW

1:1

1:1

3.1mm

2.6mm

BLACK

SHIM

BLACK

SHIM

309080

BB 8x12x3.5

389373

SHIM 3x6x0.3

389343

2.2x6

4x

2x

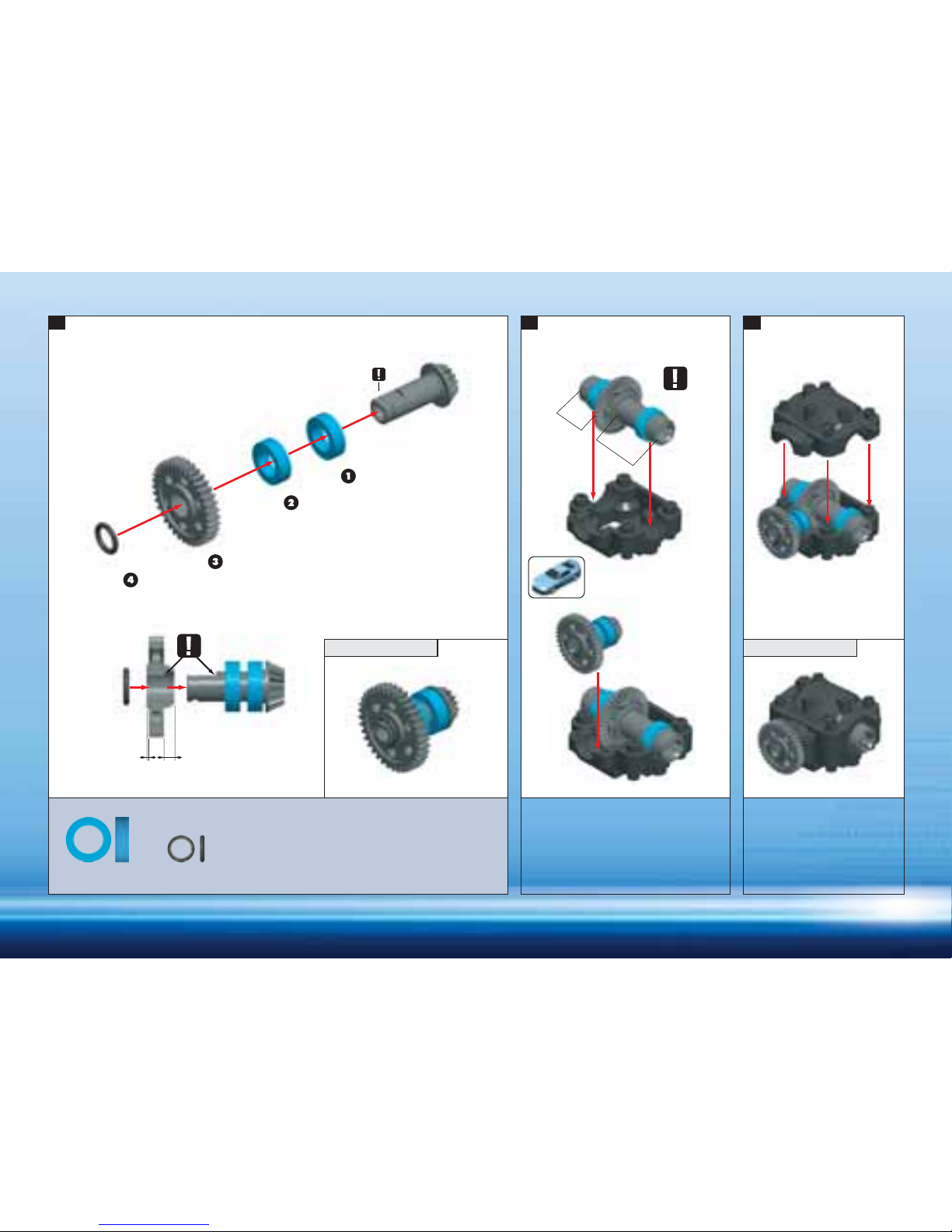

Page 6

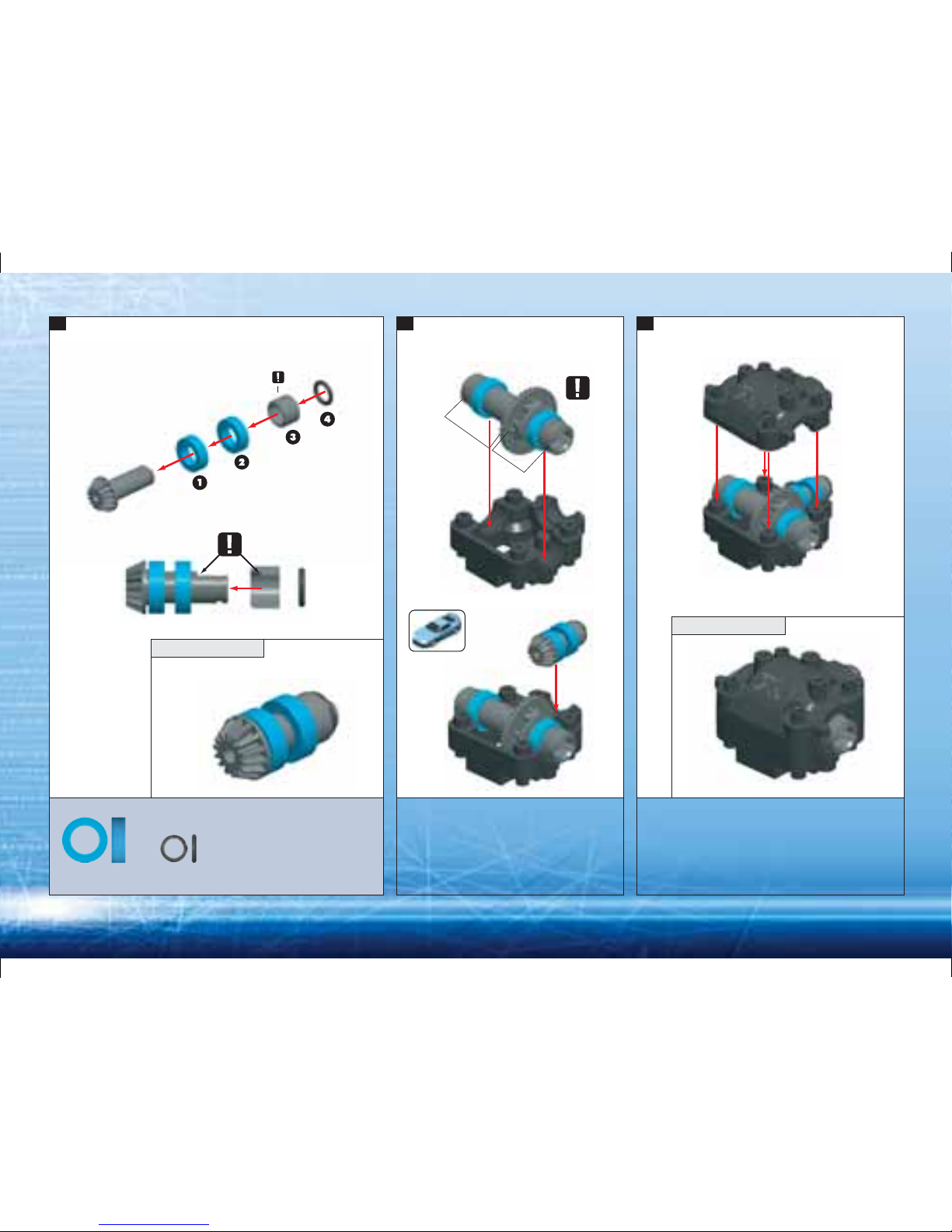

5

4. 5. 6.

ASSEMBLED VIEW

ASSEMBLED VIEW

L

O

N

G

SH

O

RT

309040

BB 6x10x3

385550

O 4x1

NOTE

ORIENTATION

ORIENTATION

NOTE

ORIENTATION

Page 7

6

309080

309460

389373

385000

309080

389373

385000

385060

385060

385000

309040

385736

385550

309040 BALL-BEARING MR106ZZ 6x10x3 (2)

309080 BALL-BEARING MR128ZZ 8x12x3.5 (2)

309460 PIN 3x16 (10)

385000 COMPOSITE REAR GEAR DIFF. + DRIVESHAFT PINION GEAR

385060 GEARBOX CASE

385550 O-RING 4x1 (10)

385736 SPUR GEAR 36T/48

389373 WASHER S 3x6x0.3 (10)

2. REAR DIFFERENTIAL

BAG

2

Page 8

7

1. 2. 3.

ASSEMBLED VIEW

NOTE

ORIENTATION

NOTE

ORIENTATION

SAME

LENGTH

LR

L=R

4x

CUT OFF CUT OFF

309080

BB 8x12x3.5

2x

389373

SHIM 3x6x0.3

309460

P 3x16

Page 9

8

L

O

N

G

SH

O

RT

NOTE

ORIENTATION

NOTE

ORIENTATION

385550

O 4x1

4. 5. 6.

ASSEMBLED VIEW ASSEMBLED VIEW

309040

BB 6x10x3

SHORTER LONGER

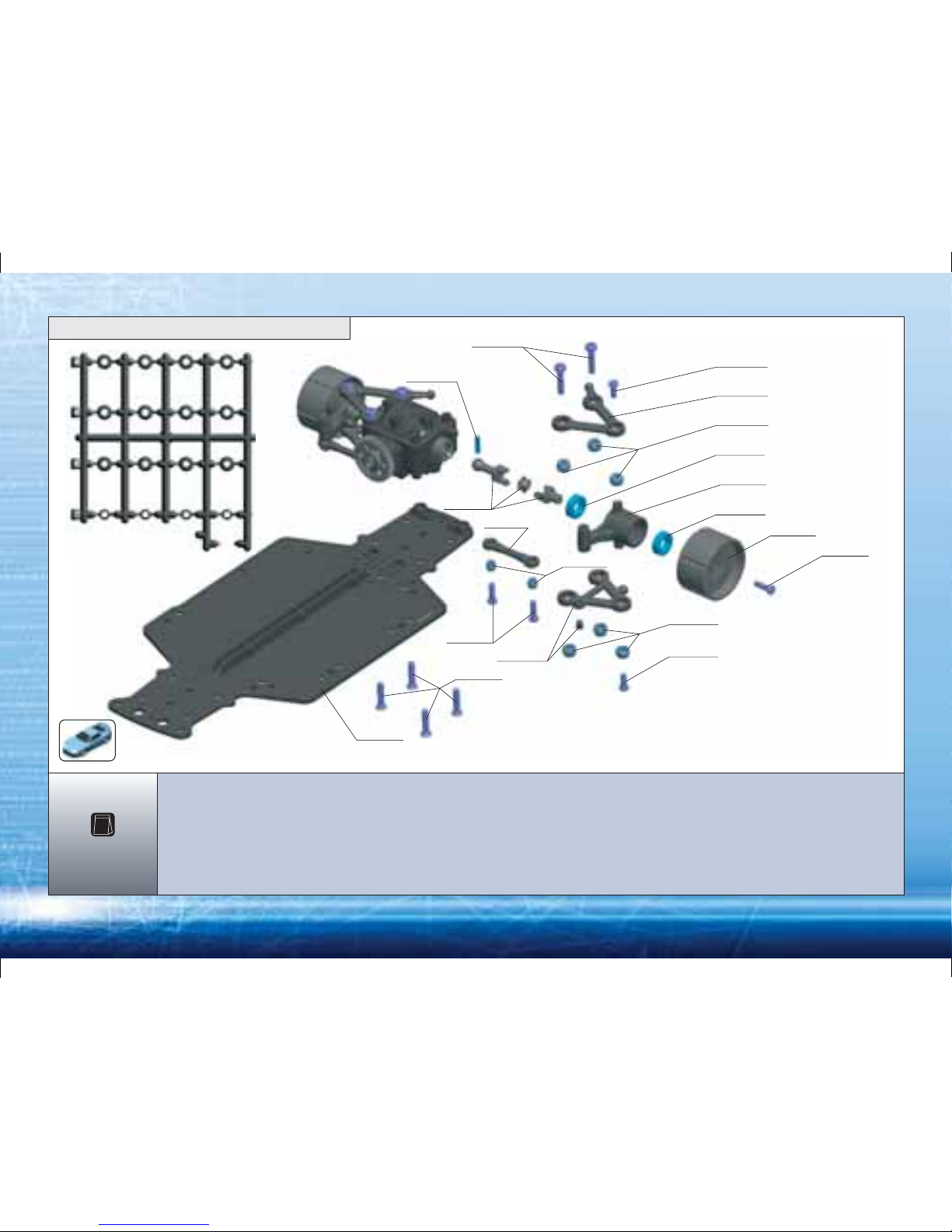

Page 10

9

389336

387400

382100

381100

387400

387400

389344

389343

387400

382100

389343

389356

383200

389343

389995

309040

382200

309040

385200

309450

309040 BALL-BEARING MR106ZZ 6x10x3 (2)

309450 PIN 2x8 (10)

381100 COMPOSITE MICRO CHASSIS

382100 SET OF SUSPENSION ARMS, LOWER + UPPER (2+1+1)

382200 COMPOSITE SUSPENSION BLOCK, L+R (2)

383200 SET OF LINKAGES + BALL JOINTS

385200 COMPOSITE DRIVE SHAFT - SET (2)

387400 SET OF COMPOSITE PIVOT BALLS

389336 SCREW PHILLIPS FH 2.5x12 (10)

389343 SCREW PHILLIPS 2.2x6 (10)

389344 SCREW PHILLIPS 2.2x8 (10)

389356 SCREW PHILLIPS 2.5x12 (10)

389995 INNER WHEEL ADAPTORS, F+R

3. REAR SUSPENSION

BAG

3

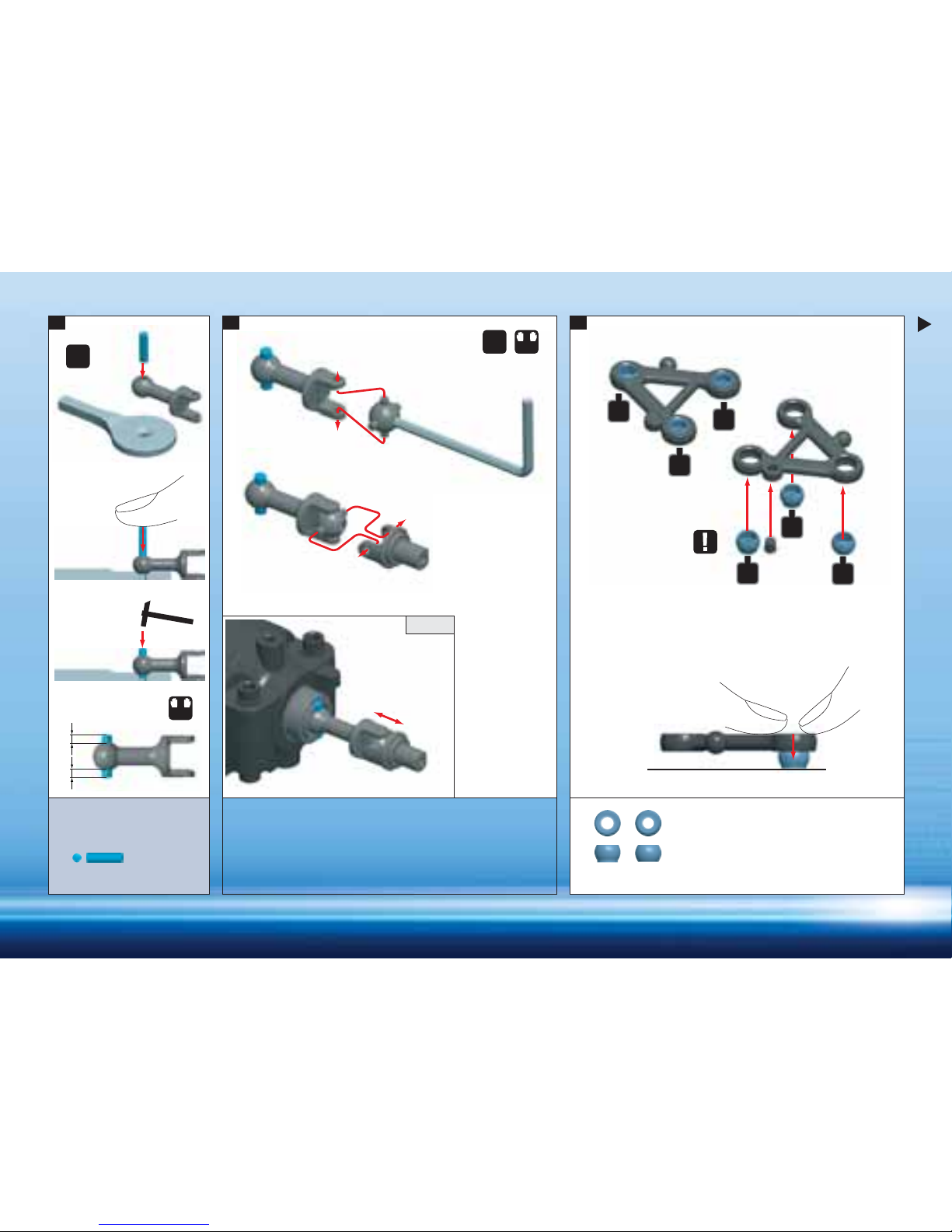

Page 11

10

NOTE ORIENTATION

OF ALL PIVOT BALLS

309450

P 2x8

1. 2. 3.

SAME

LENGTH

LEFT LOWER ARM

RIGHT LOWER ARM

L

L=R

L=R

R

2x

2x

CHECK

A

A

A

A

B

B

AB

Page 12

11

L=R

A

A

A

A

NOTE ORIENTATION

OF ALL PIVOT BALLS

DOWNSTOP SCREWS

ARE IN LAST BAG

LR

B

B

TECH TIP

ADJUSTABLE DOWNSTOPS

4. 5.

REMOVE DOWNSTOP PIN

THREAD SET SCREW

RIGHT LEFT

RIGHT LEFT

309351

SB M3x4

AB

Page 13

12

ALIGN TAB AND SLOT

BEFORE TIGHTENING SCREW

TIGHTEN SCREW,

THEN LOOSEN A LITTLE BIT

CUTAWAY ASSEMBLED VIEW

L=R

2x

ORIENTATION

6. 7. 8.

389343

2.2x6

309040

BB 6x10x3

389343

2.2x6

TIGHTEN

GENTLY

Page 14

13

2x

C

C

L=R

389356

2.5x12

389356

2.5x12

389344

2.2x8

389344

2.2x8

9. 10. 11.

ASSEMBLED VIEW

C

TIGHTEN

GENTLY

MAKE SURE ARMS

MOVE FREELY

Page 15

14

389336

2.5x12

12.

ASSEMBLED VIEW

Page 16

15

387400

389345

387400

383200

383200

387400

389344

385512

382610

389356

389343

387400

382100

389343

389995

309040 382200

309040

385200

309450

382100

387400

389336

389343

309040 BALL-BEARING MR106ZZ 6x10x3 (2)

309450 PIN 2x8 (10)

382100 SET OF SUSPENSION ARMS, LOWER + UPPER (2+1+1)

382200 COMPOSITE SUSPENSION BLOCK, L+R (2)

382610 ADJ. TURNBUCKLE 34MM

383200 SET OF LINKAGES + BALL JOINTS

385200 COMPOSITE DRIVE SHAFT - SET (2)

385512 ALU MAIN DRIVESHAFT- SILVER

387400 SET OF COMPOSITE PIVOT BALLS

389336 SCREW PHILLIPS FH 2.5x12 (10)

389343 SCREW PHILLIPS 2.2x6 (10)

389344 SCREW PHILLIPS 2.2x8 (10)

389345 SCREW PHILLIPS 2.2x10 (10)

389356 SCREW PHILLIPS 2.5x12 (10)

389995 INNER WHEEL ADAPTORS, F+R

BAG

4

4. FRONT SUSPENSION

Page 17

16

1. 2. 3.1.

309450

P 2x8

AB

SAME

LENGTH

L

L=R

L=R

R

2x

2x

CHECK

NOTE ORIENTATION

OF ALL PIVOT BALLS

DO NOT USE DOWNSTOP

PIN ON LOWER ARMS

LEFT LOWER ARM

RIGHT LOWER ARM

A

A

B

A

A

B

Page 18

17

TECH TIP4. 5.

LR

L=R

A

A

A

B

B

A

ADJUSTABLE DOWNSTOPS

RIGHT LEFT

RIGHT LEFT

REMOVE DOWNSTOP PIN

THREAD SET

SCREW

DOWNSTOP SCREWS

ARE IN LAST BAG

309351

SB M3x4

ORIENTATION

NOTE ORIENTATION

OF ALL PIVOT BALLS

AB

Page 19

18

6. 7. 8.

389343

2.2x6

309040

BB 6x10x3

389343

2.2x6

L=R

2x

CUTAWAY ASSEMBLED VIEW

ALIGN TAB AND SLOT

BEFORE TIGHTENING SCREW

TIGHTEN

GENTLY

TIGHTEN SCREW,

THEN LOOSEN A LITTLE BIT

ORIENTATION

Page 20

19

10. 11.9.

ASSEMBLED VIEW

C

C

C

C

389356

2.5x12

389356

2.5x12

389344

2.2x8

389344

2.2x8

CC

56mm

ORIENTATION

4x

TIGHTEN

GENTLY

Page 21

20

14.13. 15.

ASSEMBLED VIEW

PLASTIC SHIM

389336

2.5x12

MAKE SURE ARMS

MOVE FREELY

ORIENTATION

Page 22

21

389334

389334

381225

381200

388000

389400

381340

381300

389400

389333

381300

388000

381200 LOWER FRONT BUMPER

381225 FOAM BUMPER - BLACK

381300 COMPOSITE BODY POSTS (4) + BODY CLIPS

381340 COMPOSITE REAR BODY POST HOLDER

388000 COMPOSITE SHOCK BODY SET (4)

389333 SCREW PHILLIPS FH 2.5 x 6 (10)

389334 SCREW PHILLIPS FH 2.5 x 8 (10)

389400 MICRO BODY CLIP

BAG

5

5. FRONT AND REAR FINAL ASSEMBLY

Page 23

22

389333

2.5x6

L=R

1. 2. 3.

ORIENTATION

ORIENTATION

Page 24

23

389334

2.5x8

PLASTIC SHIM

4. 5.

ASSEMBLED VIEW

1

1

2

2

1122

SHOCK POSITION

SHOCK POSITION

ORIENTATIONORIENTATION

Page 25

24

6. 7.

ASSEMBLED VIEW

ORIENTATION

Page 26

25

389344

389334

389334

389990

382000

389400

386310

386110

386200

382580

386200

389354

389640

385700

309350

389344

383200

387400

389312

386110

309350 HEX SCREW SB M3x3 (10)

382000 COMPOSITE MOTOR PLATE - SET

382580 COMPOSITE SERVO ARMS - SET

383200 SET OF LINKAGES + BALL JOINTS

385700 COMPOSITE PINION SET

386110 COMPOSITE BATTERY HOLDER SET FOR 5 BAT.

386200 COMPOSITE SERVO MOUNT+ ANTENNA HOLDER - SET

386310 ANTENNA

387400 SET OF COMPOSITE PIVOT BALLS

389312 SCREW PHILLIPS 2.0 x 4 (10)

389334 SCREW PHILLIPS FH 2.5 x 8 (10)

389344 SCREW PHILLIPS 2.2 x 8 (10)

389354 SCREW PHILLIPS 2.5 x 8 (10)

389400 MICRO BODY CLIP

389640 RUBBER TIRES + INSERTS F+R, 40 DEG

389990 XRAY MICRO WHEEL, F+R

BAG

6

6. FINAL ASSEMBLY

Page 27

26

1:1

1. 2. 3.

ASSEMBLED VIEW

389354

2.5x8

389334

2.5x8

USE A MICRO SERVO THAT IS SIMILAR TO

OR SMALLER THAN THE SERVO SHOWN

SCREW FROM SERVO

USE HORN FOR

YOUR SERVO

USE THE MICRO SERVO INCLUDED IN

XRAY M18 POWER PACK #389100

TIP

90°

Page 28

27

4. 5. 6.

ASSEMBLED VIEW ASSEMBLED VIEW

309350

SB M3x3

389312

2x4

USE XRAY MICRO STOCK

MOTOR INCLUDED

IN XRAY M18 POWER

PACK #389100

TIGHTEN

GENTLY

PRE-THREAD THE PINION

USE MICRO STOCK OR MODIFIED MICRO MOTOR

TIP

389344

2.2x8

1mm

ORIENTATION

Page 29

28

SPUR

GEAR

PINION

GEAR

FINAL

RATIO

ACCELERATION

SPEED

14

15

16

17

18

16

17

18

19

21

23

42

36

o

o

o

x

o

o

x

o

x

x

x

x - INCLUDED WITH KIT

o - AVAILABLE OPTION

7.50

7.00

6.56

6.18

5.83

5.62

5.29

5.00

4.74

4.29

3.91

INTERNAL RATIO 1:2.5

AVAILABLE

OPTION

INCLUDED

WITH KIT

7. TECH TIP

389334

2.5x8

PINION GEAR

SPUR GEAR

THE MOTOR STAND IS ADJUSTABLE:

1. RELEASE SCREWS FROM THE BOTTOM OF CHASSIS

2. MOVE THE MOTOR STAND AS NEEDED

3. TIGHTEN THE SCREWS

ADJUST MOTOR STAND SO GEARS MESH SMOOTHLY

ORIENTATION

Page 30

29

389334

2.5x8

ORIENTATIONORIENTATION

8. 9. 10.

USE MICRO BATTERY PACK

INCLUDED IN XRAY M18

POWER PACK #389100

USE 4 OR 5 CELL PACK OF 2/3A BATTERIES

INSTALL RECEIVER

(NOT INCLUDED)

DOUBLE-SIDED

TAPE

TIP

USE MICRO SPEED CONTROL XMC180

INCLUDED IN XRAY M18 POWER PACK

#398100

SCREWS INCLUDED WITH

XRAY XMC 180

SPEED CONTROL

INSTALL MICRO SPEED CONTROL

TIP

Page 31

30

11.

FRONT

REAR

12. 13.

NO SPACE

LARGER

SMALLER

NO SPACE

NOTE

ORIENTATION

NOTE

ORIENTATION

DO NOT USE

TOO MUCH GLUE

2x

2x

2x

2x

CA

2x

CA

2x

7

BAG

Page 32

31

C

L=R

FRONT 98mm 101mm

REAR 104mm 107mm

A B

B

15.14.

PLACE BRAKE DISKS

DECAL ON INNER WHEELS

PUSH WHEEL TABS ALL

THE WAY INTO THE SLOTS

ON THE INNER WHEEL

389344

2.2x8

A

A

A

B

A TRACKWIDTH (NARROW)

B TRACKWIDTH (WIDE)

Page 33

32

ELECTRONICS ASSEMBLY

BATTERY PACK

STEERING SERVO

ANTENNA WIRE

RECEIVER

SPEED CONTROL

M18 POWER PACK ASSEMBLY SHOWN

USE XRAY M18 POWER PACK #389100 THAT INCLUDES ALL

ELECTRONICS REQUIRED FOR OPERATION. (RECEIVER & TRANSMITTER ARE NOT INCLUDED)

INSTALL ELECTRONICS ACCORDING

TO MANUFACTURER'S INSTRUCTIONS

MOTOR

TIP

1CH

2CH

Page 34

33

4x

HOLE FOR

BODY POSTS

Cut out body and wing along trim lines

Apply window masks inside body

Mask and paint body using polycarbonate paint

Apply stickers

4x

HOLE FOR

WING

WING ASSEMBLY

3mm

3mm

4.5mm

1x

HOLE FOR

ANTENNA

4.5mm

4.5mm

4.5mm

4.5mm

BODY MOUNTING

Page 35

• This product is not suitable for children except under

the direct supervision of an adult.

• Carefully read all manufacturers warnings and cautions

for any parts used in the construction and use of your model.

• Assemble this kit only in places away from the reach

of very small children.

• First-time builders should seek advice from people who have building

experience in order to assemble the model correctly and to allow the

model to reach its performance potential.

• Insulate any exposed electrical wiring (using heat shrink tubing

or electrical tape) to prevent dangerous short circuits.

• Exercise care when using tools and sharp instruments.

• Take care when building; some parts may have sharp edges.

• Keep small parts out of reach of small children.

• Do not put fingers or any objects inside or near rotating or moving

parts.

• Immediately after using your model, do NOT touch equipment

or electronic components on the model because they may

generate high temperatures.

• Follow the operating instructions for the radio equipment at all times.

• Be sure that your operating frequency is clear before turning

on or running your model, and never share the same frequency with

somebody else at the same time. Ensure that others are aware

of the operating frequency you are using and when you are using it.

• Always turn on your transmitter before you turn on the receiver/speed

controller or connect the battery pack. Always turn off the

receiver/speed controller or disconnect the battery pack

before turning your transmitter off.

• Keep the wheels of the model off the ground when checking

the operation of the radio equipment.

• Disconnect the battery pack before storing your model.

• When learning to operate your model, go to an area that has no

obstacles that can damage your model if your model suffers a

collision.

• Remove any sand, mud, dirt, grass or water before putting

your model away.

• Use a recommended charger for the batteries and follow the

instructions correctly. Over-charging, incorrect charging, or using

inferior chargers can cause the batteries to become dangerously hot.

• Regularly check the charger for potential hazards such as damage

to the cable, plug, casing or other defects. Ensure that any damage

is rectified before using the charger again.

• Do not allow the transmitter batteries to become low on charge,

otherwise you risk losing control of the model.

• Do not allow any metal part to short circuit the batteries, speed

control, or other electrical/electronic device on the model.

• If the model behaves strangely, immediately stop the model,

check and clear the problem.

• Do not stall the motor. The speed control will fail within seconds if

power is applied to the motor when the car cannot move.

DO NOT USE YOUR MODEL:

• Near real cars, animals, or people that are unaware

that an R/C car is being driven.

• In places where children and people gather

• In residential districts and parks

• In limited indoor spaces

• In wet conditions

• In the street

IMPORTANT NOTES

Take adequate safety precautions prior to operating this model. You are responsible for this model’s assembly and safe operation.

Disregard of the any of the above cautions may lead to accidents, personal injury, or property damage.

XRAY MODEL RACING CARS assumes no responsibility for any injury, damage, or misuse of this product during assembly or operation, nor any

addictions that may arise from the use of this product.

Page 36

XRAY MODEL RACING CARS, P.O.BOX 103, 911 50 TRENČÍN, SLOVAKIA, EUROPE

XRAY is a member of myTSN.com

Loading...

Loading...