Page 1

COLOR TELEVISION

TK2716D

(TS2716)

Page 2

CONTENTS

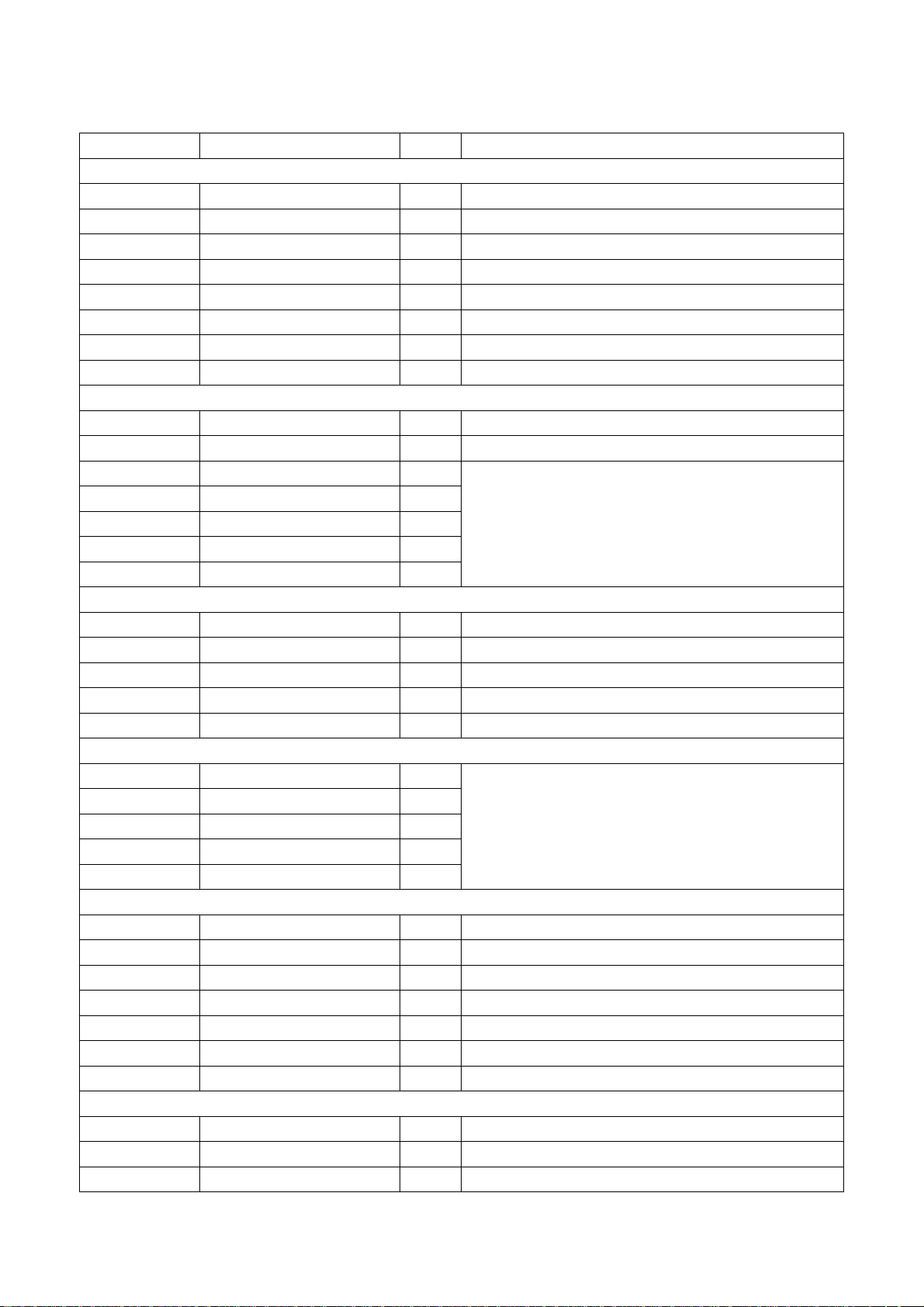

Safety Precautions………………………………………………………………………..……

Alignment instruction. ………………………………….…………………………….…….

Debugging instruction …………………………………………….………………………….

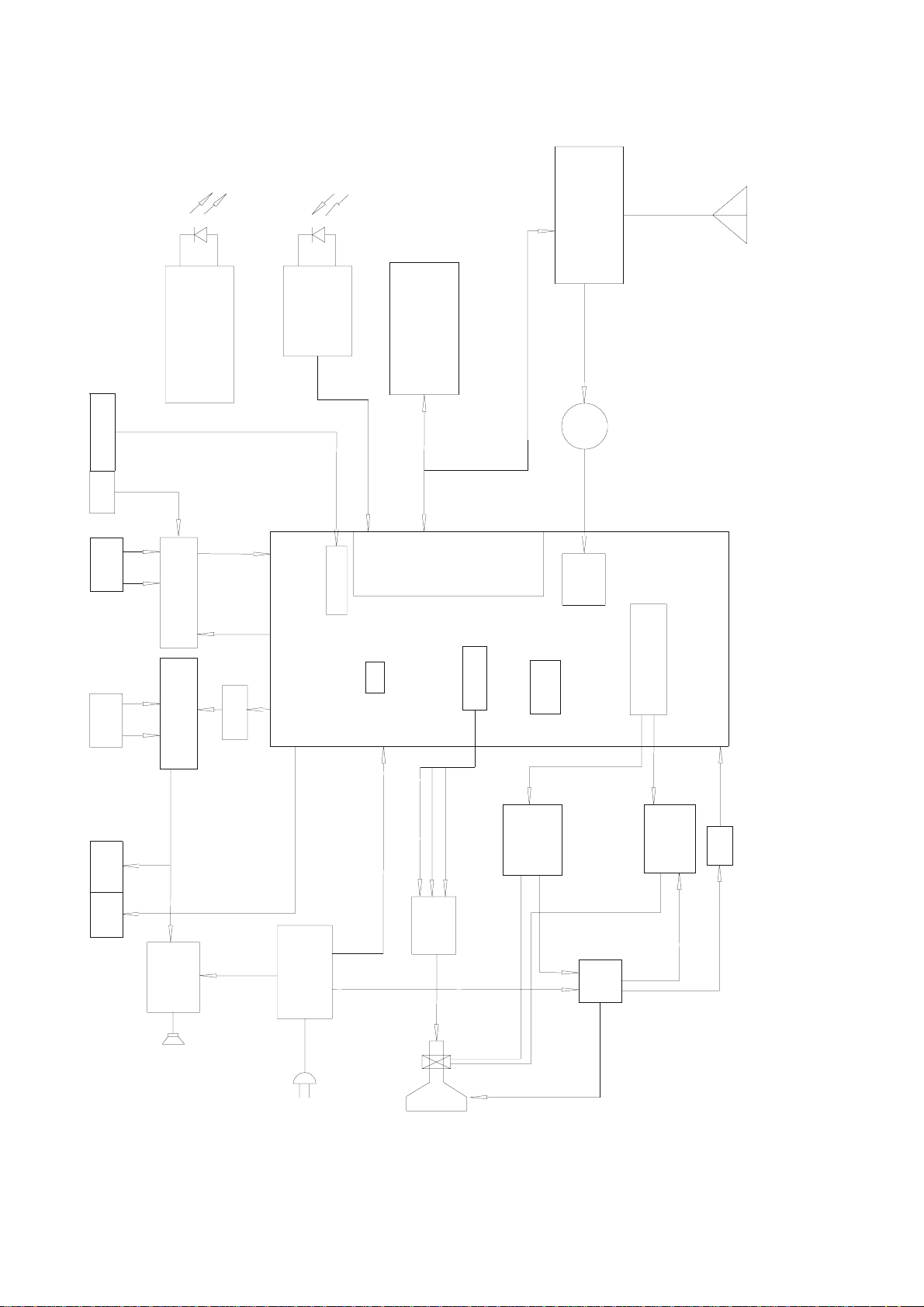

Block diagram ……………………………..…..…..…..…..…..…….………….……………

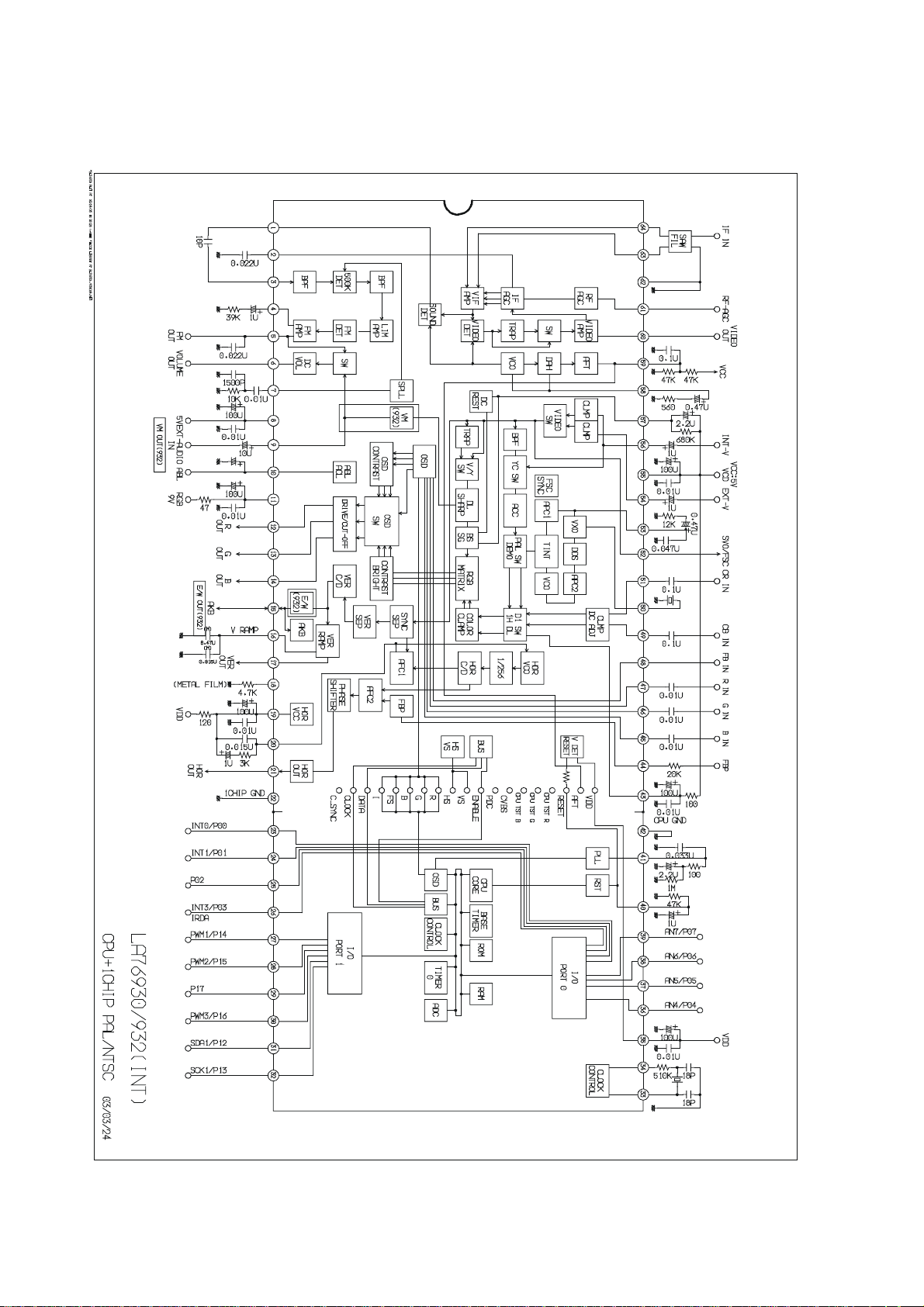

IC Block diagram……………………..……………………….………………………………

Wiring diagram……………………………………………………………………………..…

Schematic diagram …………………………………………………………………….……..

APPENDIC:Exploded view

Part list

1

2

3

9

10

14

15

Page 3

Note:This service manual is only for professional service personnel’s reference. Before

1. SAFETY INSTRUCTION AND GENERAL INSTRUCTION

1.1 X-RAY RADIATION PRECAUTION

1) Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid such

2) Each time a receiver requires servicing, the high voltage should be checked following the HIGH

3) The primary source of X-RAY RADIATION in this TV receiver is the picture tube. For continuous

servicing the unit, please read the following items carefully.

Before servicing and aligning this equipment, please read the following “X-RAY RADIATION

PRECAUTION” , “SAFETY PRECAUTION” and “PRODUCT SAFETY NOTICE”.

hazards, the high voltage must not be above the specified limit. The normal value of the high voltage

of this receiver is below 31.5kV at 1.6A beam current, the high voltage must not, under any

circumstances, exceed 33kV.

VOLTAGE CHECK procedure in this manual. It is recommended the reading of the high voltage be

recorded as a part of service record. It is important to use an accurate and reliable high voltage

meter.

X-RAY RADIATION protection, the replacement tube must be exactly the same type tube as

specified in the parts list.

4) Some parts in this receiver have special safety-related characteristics for X-RAY RADIATION

protection. For continuous safety, parts replacement should be undertaken only after referring to the

PRODUCT SAFETY NOTICE below.

1.2 SAFETY PRECAUTION WARNING:

Service should not be attempted by anyone unfamiliar with the necessary precaution on this receiver.

The following are the necessary precautions to be observed before servicing this chassis.

1) Since the power supply circuit of this receiver is directly connected to the AC power line, an isolation

transformer should be used during any dynamic service to avoid possible shock hazard.

2) Always discharge the picture tube anode to the CRT conductive coating before handling the picture

tube. The picture tube is highly evacuated and if broken, glass fragments will be violently expelled.

Use shatter proof goggles and keep picture tube away from the unprotected body while handling.

3) When replacing a chassis in the cabinet, always be certain that all the protective devices are put

back in place, such as: non-metallic control knobs, insulating covers, shields, isolation

resistor-capacitor network etc.

4) When replacing parts or circuit boards, disconnect the power cord.

5) When replacing a high wattage resistor (oxiode metal film resistor) on the circuit board, keep the

resistor 10mm (1/2in) away from circuit board.

6) Connection wires must be kept away from components with high voltage or high temperature.

7) If any fuse in this TV receiver is blown, replace it with the FUSE specified in the chassis parts list.

1.3 PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the chassis have special safety-related characteristics. These

1

Page 4

characteristics are often passed unnoticed by a visual inspection and the X-RAY RADIATION protection

afforded by them cannot necessarily be obtained by using replacement components rated for higher

wattage, etc. Replacement parts which have these special safety characteristics are identified in this

manual and its supplement electrical components having such features are shaded on the schematic

diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of

substitute replacement parts which do not have the same characteristics as specified in the parts list

may create shock, fire, X-RAY RADIATION or other hazards.

2 Alignment items and procedure

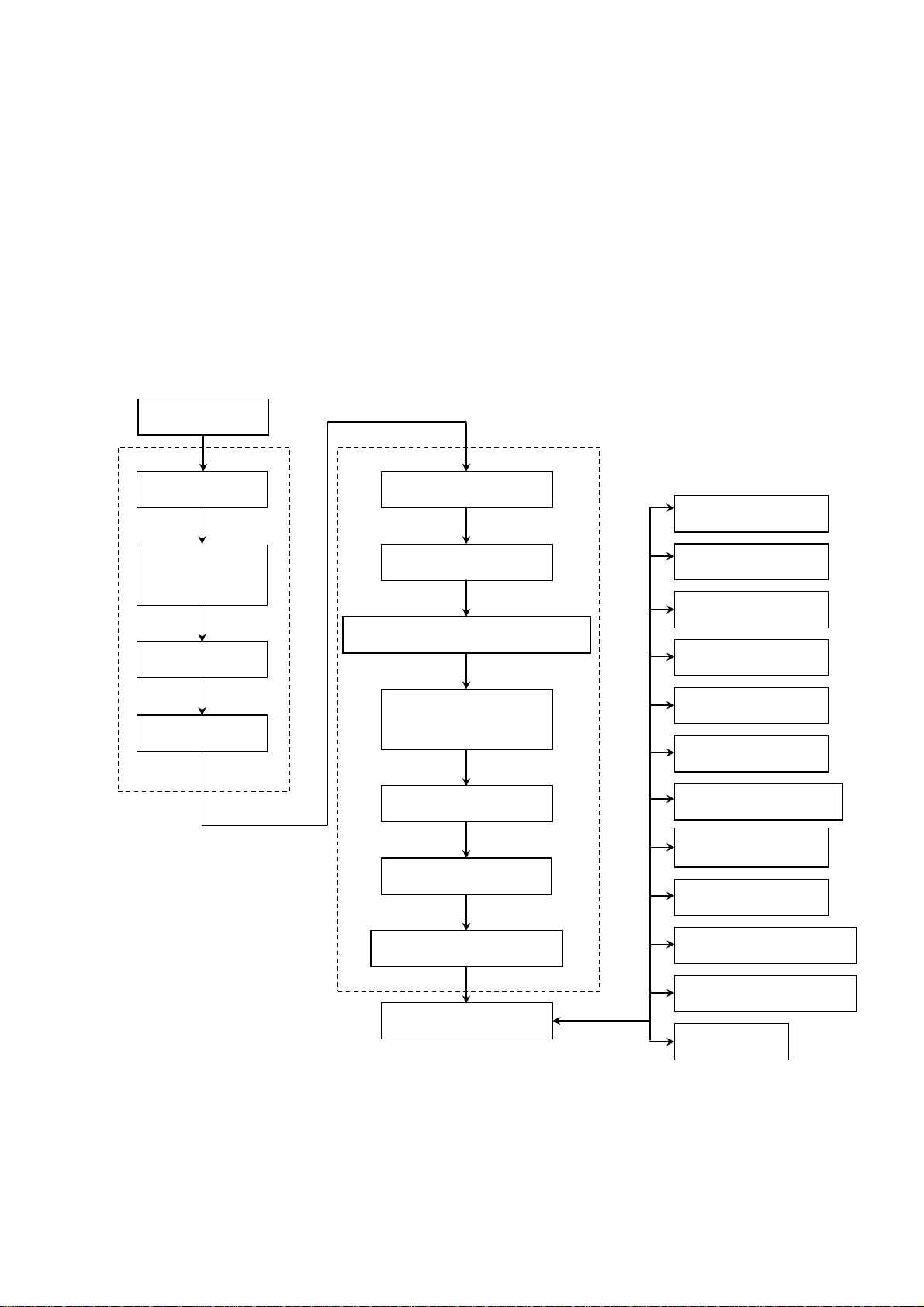

The alignment flow chart (see below figure).

EEPROM copy

B+ check

Focus adjust and aging

High-handed

Field breadth

and field line

White balance and sub-bright

RF AGC adjust

Audio check

VG2 adjust

H-field and center

field and field breadth

Filament voltage

X-ray protect

Picture and audio

Sub-brightness

White balance

OSD center position

Color pure and assemble

Foucs fine adjust

AV (S.DVD)

The button check

Leave factory state setup

Remote control check

check

Assemble check

Safety check

3 TEST EQUIPMENT

3.1 AUDIO VOLTAMETER

2

Page 5

3.2 OSCILLOGRAPH

3.3 HIGH-VOLTAMETER

3.4 DIGITAL MULTIMETER

3.5 AC ATTACK PULL TEST EQUIPMENT

3.6 SCAN frequency signal generator BT-3

4 Debugging instruction

4.1 enter into the factory debugging menu

use to the remote control(RC-A23),follow to the blow model enter into the factory:

DISPLAY → MUTE → MUTE → MUTE → enter into the factory

press “sleep” button for pages upward, press “return” button for pages downward, press “CH+/-” to

select alignment items and “VOL+/-” to adjust volume, press “MUTE” to exit.

If the remote sensor designed for alignment is unavailable, press the following buttons to enter by

using user remote sensor

4.2 B+ voltage adjustment

Check B+ voltage ( negative pole of VD509) by using DC voltmeter DC 200V of 135V±2.

4.3 AGC adjustment

Measure the voltage of RF AGC by connecting digital DC voltmeter with TP3, receive weak signal

(40dBu) and the static AGC voltage of TP1 AGC should be V1=4V±0.2V; the receive antenna signal

(60dBu), adjust the value of P6 RF. AGC of factory menu and the start-control voltage of TP1 AGC

should be V2=3.5V±0.2.if V2>3.5V, then the voltage is -1 or -2,if V2<3.5V, then the voltage is+1 or+2. the

antenna input 100dBu signal, after the picture should not be appeared no-sync , distortion and moire;

input 35-40dBu weak signal ,it should not be appeared distortion and no-sync and sound abnormity

electrophoresis of it.

4.4 White balance and screen-grid voltage adjustment

After enter P5 of factory menu, use remote sensor directly to adjust white balance by pressing the

following digital buttons:

“1”=R.BIAS(+) “2”=G.BIAS(+) “3”=B.BIAS(+)

“4”=R.BIAS(-) “5”=G.BIAS(-) “6”=B.BIAS(-)

press “p-p” button to select picture mode custom→T1→T2→bright→soft→nature→user→custom will

be display on the screen.

The T1 mode has the maximum value of brightness and contrast with all the other items minum. Value of

all the analog are minimum while in T2 mode.

Before adjustment you should set the following items: SUB-BRIGHT=50, R.B=100, G.B=100, B.B=100,

R.D=100, G.D=15, B.D=100

press “P-P” button to select T2 picture mode, press CH+/- to select LINE, press vol+ to let the field

scanning fail to oscillate, adjust the screen-grid potentiometer on FBT clockwise to let horizontal bright

line just appear on the screen; let the value of G.B unchanged, adjust R-B and B-B to let the horizontal

bright line appear white. If the green horizontal line don’t appear firstly, fine-turn the screen-grid voltage,

green and blue just appear. After adjustment press VOL- to obtain normal field scanning mode.

4.5 Receive signal (A7), enter P6 of factory menu, adjustment SUB-BRIGHT to let picture on the screen

micro-bright.

4.6 receive white balance adjustment signal

enter P5 of factory menu, press PP to select T1 picture mode, let the value of G.D unchange, adjust R.D

and B.D to let the white part of the picture appear “white”.

3

Page 6

4.7 Use white balancer to rectify the white balance under following conditions

color temperature:12000K+8MPCD x =0.270± 0.008 Y=0.283±0.008; dark space: 4.5nit, bright space:

60nit

Note:1. While the colour saturation changed from maximum to minimum, if the dark balance appears

changeable,adjust RY.TV and BY.TV (P12) to let it coincide with white balance.

2. If the dark balance appears changeable while connected with DVD, adjust BY.YUV and RY.YUV

(P12) to let it conincide with white balance.

4.8 line-filed scanning amplitude and linearity and center adjustment and raster correct adjstment.

4.9 receive signal (A28), press the PP button the picture model, set standard adjustment the P1 of

V.SIZE and V.SHIFT and H..PAHSE and V.LINE and VSC, let the P2 coincide with request.

4.10 receive signal (G43), press the PP button the picture model, set standard adjustment the P3 of

V.SIZE and V.SHIFT and H..PAHSE and V.LINE and VSC, let the P4 coincide with request.

4.11 High voltage and filament voltage check

Connect a high-voltage meter between anode cap of picture tube and the ground, measure the filament

voltage using rms voltmeter, set the picture mode to “standard”, the high-voltage: 29KV±1.5KV,filament

voltage: 6.3±0.1Vrms.

4.12 x -ray protection check

Receive local TV signal, set the picture mode to “standard”, shorten the circuit and measure the

value of TP1-TP2, restart the TV 30 seconds after turn off the power source and it should return to

normal.

4.13 AV function check

according to the owner’s manual require, connect to the AV equipment and the AV interface:

VIDEO IN: 1 Vp-p 75OHM AUDIO IN: (-8±3)dBm>47 kOHM

S interface Y IN: 1 Vp-p 75OHM C IN: 0.3 Vp-p 75OHM

DVD Y IN: 1 Vp-p 75OHM Cr IN: 0.7 Vp-p 75OHM

Cb IN: 0.7 Vp-p 75OHM

4.14 AV parts check

incept to standard the TV signal:

a) AV and crossfire and allophone and shake ;

b) The user control function ana picture model

c) The remote control function check;

d) Color pure and converge check.

4.15 leave factory state setup

Picture model (PP) STENDARD

language All the country language

Color system AUTO

C.CAPTION C1

CCD ON MUTE OFF

RECEPTION AIR

AFT ON

MTS AUTO

PASSWORD CLEAR

volume 30

4

Page 7

4.16 the factory menu adjustment model pre-set

OSD item Pre-set model

P1-60

V SIZE 60HZ field amplitude 63 4.9

V SHIFT 60HZ field center 0 4.9

H-PHASE 60HZ H-center 15 4.9

V LINE 60HZ V-line 15 4.9

V SC 60HZ field S-correct 23 4.9

V COMP field amplitude compensate 7 fixed

L.BLK Left blanking 7 fixed

R.BLK Right blanking 0 fixed

P2-EW-60

COR.SW margin correct 1 Fixed

H.SIZE.COMP High voltage compensate 7 fixed

TILT 60HZ echelon correct 44

DC 60HZ H-amplitude 32

AMP 60HZ pincushion correct 25

COR.TOP 60HZ Top margin correct 4

COR.BOT 60HZ bottom margin correct 3

V SIZE 50HZ field amplitude 75 4.10

V SHIFT 50HZ field center 0 4.10

H-PHASE 50HZ H-center 10 4.10

V LINE 50HZ V-line 16 4.10

V SC 50HZ field S-correct 20 4.10

P4 EW-50

TITL 50HZ echelon correct 49

DC 50HZ H-amplitude 35

AMP 50HZ pincushion correct 41

COR.TOP 50HZ Top margin correct 6

COR.BOT 50HZ bottom margin correct 10

LINE Level bright line 0 0=normal 1= Level bright line

RB Red cut off 100 4.4

GB Green cut off 100 4.4

BB Blue cut off 100 4.4

RD Red driver 100 4.4

GD Green driver 15 4.4

BD Blue driver 100 4.4

RF AGC RF AGC 30 4.3

SUB-BRI Sub-brightness 60 4.4

SUB-CNT Sub-contrast 31 fixed

Receive signal A12, adjust the linearity scanning and

geometric distortion and over-scanning coincide with it

P3-50

Receive signal G35, adjust the linearity scanning and

geometric distortion and over-scanning coincide with it

P5

P6

5

Page 8

SUB-COL Sub-colour 3 fixed

SUB-SHP Sub-definition 0 fixed

SUB-TINT Sub-tint 28 fixed

P7

VOL.FIL Volume control ADC filter 0 fixed

OSD.COT OSD contrast 5 fixed

OSD.HPOS OSD center 10 fixed

AFT

VIF SW IF3=45.75MHZ 3 fixed

SIF SW Sound IF0=4.5MHZ 0 fixed

VIDEO LEVEL VIDEO LEVEL 2 fixed

A2 .SW 0 fixed

GY ANGLE G-Y demodulation angle 0 fixed

V.R TM Filed scan strting time 0 fixed

R/B ANG R-Y/B-Y demodulation angle 8 Fixed

R/B BAL

C TRAP Color trap filter 6 fixed

H FREQ H-frequency 16 fixed

C.BPF TEST

P9

OVER.MOD.SW

OVER.MOD.LVL

BLK.STR

BLK.GAIN Dark level expand gain 2 Fixed,0=MIN 2=MAX

Y.APF Selection color trap filter 1 0=trap filter,1= direct pass(YcbCr&Y/C)

PRE.ADJ Pre-shoot 3 fixed, 0=narrow 3=width

OVER ADJ overshoot 3 Fixed,a 0=narrow 3=width

C.VCO.ADJ

BRT.ABL.DEF Brightness ABL 0 fixed,0=ABL ON 1=ABL OFF

MID.STP.DEF ABL start control point 0 fixed

BRT.ABL.THR ABL threshold 7 fixed

WPL.OPE White peak limit 2 fixed

V BLK.SW Field blanking switch 0 fixed ,0=nomarl;1=width model

Line AFC loop gain and sync

gate switch

R-Y/B-Ydemodulation

balance

Color band filter center

frequency

Selection over-modulation

function

Adjustment over-modulation

working point

Dark level expand starting

control point

Color VCO frequency

adjustment

0

P8

8 fixed

0 fixed

0 Fixed,0=nothing 1=have

0 fixed

2 Fixed,0=40IRE 2=60IRE 3-OFF

4 fixed,0-4-7=-120KHZ-0-90KHZ

P10

fixed

6

Page 9

FBP BLK SW Horizontal blanking switch 1 fixed,0=inside produce;1=FBP and inside logic “and”

DC REST DC recover rate 1 fixed,0=100% 1=107%

CD.MODE

CORE GAIN Noise reduction 2 fixed,0=OFF 1=MIN 3=MAX

γ.GAMA r-correct 0 fixed,0=OFF

RGB TEMP.SW

A.MONI SW Selection pin5 output 1 fixed,1=SAO

SVO OR FSC Selection pin5 output 0 fixed,0=VIDEO 1=FSC(color sub-carrier wave)

CROSS B/W Selection test signal 0 fixed,0=TV

CRAY.MODE Test signal 0 fixed,0=white(75%)1=grey(15%)

BY TV Blue chromatism DC level 8 4.4 adjustment dark white balance(TV/AV model)

RY TV Red chromatism DC level 8 4.4 adjustment dark white balance(TV/AV model)

BY YUV

RY YUV

S.TRAP.TEST Sound trap filter adjustment 6 fixed

LOW.BRI Min-brightness 28 fixed

LOW.CONT Min-contrast 30 fixed

COL.KILL Achromatic level 7 fixed,0=-30dB 3=-40dB

VCO.FREQ VCO frequency 32 fixed

VM.GAIM VM gain adjustment 0 fixed

VM.DELAY ADJ VM relay time adjustment 0 fixed

VCO TEST VCO adjustment 0 fixed

VPOS-50

VPOS-60

Y GAIN 0 fixed

Y TH 0 fixed

B OFFSET 0 fixed

B WIDTH 0 fixed

C OFFSET 0 fixed

C WIDTH 0 fixed

CAN.V CHIP V-CHIP 0/1 1=CAN.V-CHIP

Field frequency division

model

RGB DC output

temperature speciality

DVD input Blue chromatism

DC level

DVD input Red chromatism

DC level

50HZ field center voltage

adjustment

60HZ field center voltage

adjustment

0 fixed,0=auto

P11

1 fixed

P12

8 4.4 adjustment dark white balance (DVD input)

8 4.4 adjustment dark white balance(DVD input)

P13

15

15

P14

OPTION

fixed

fixed

7

Page 10

AV AV selec t i o n 3 AV input select(3=AV1/AV2/S/DVD)

MTS MTS IC selection 1/0 0=nothing,1=72700 2=AN5832

V.OFF.MOTE Turn off model 1 0=discharge,1=close

PWR.MEM Turn on model 0/2 0=standby,1=auto turn on,2=memory

1115 select LV1115 0 fixed,0=nothing;1=have

BLCK GROND

N/PN

VOL.OFFSET 0

GAIN 3

PWM LOGIC 0

AVL MODE 2

AVL DET LEVEL 0

AVL SLOPE 0

PWM.VOL Volume control of PWM set 1 fixed

1-CHIP.VOL Volume control of mono 0 fixed

VOL 1 1% volume control speciality 20 fixed

VOL 25 25%volume control speciality 60 fixed

VOL 50 50%volume control speciality 90 fixed

VOL 75 75%volume control speciality 100 fixed

ALC ALC 1 fixed ,1=ALC ON

VOL

SAP LEVEL SAP level 1 fixed

SIF.M/BB.M SIF and baseband model 0 fixed,0=SIF MODE 1=BB MODE

AGC 1 fixed

No signal background

selection

South America and North

America selection

Baseband model ,input level

adjustment

1 0=nothing 1/3=blue background;2=black background

1/0 0=south america;1=north america

1115(the unit no use)

PWM SET

72700

0 The unit no use

5832

Note:above “/” are the adjustment data for north america, below it are for south america.

8

Page 11

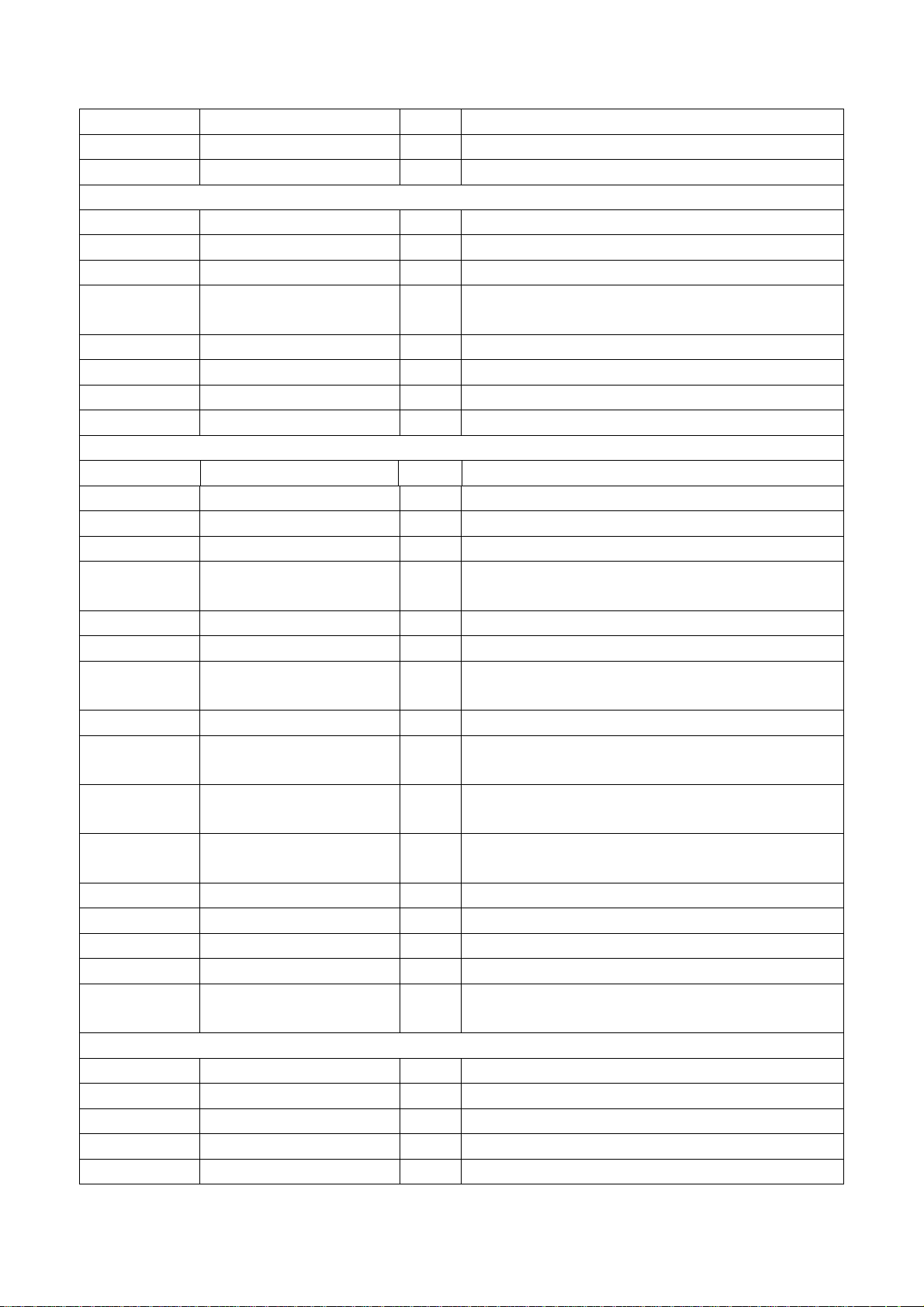

BLOCK DIAGRAM

A

A

/

A

IR TX

M3428M1-D48GP

T101

TUNER

RF

IR RX

MEMORY

N202

M24C08

IF

Y Cr C b

REM

S IN

VIDEO

IN

V SWITCH

4053

A SWI TCH

AUDIO

IN

AUDIO

OUT

4053

VIN

Y Cr Cb

TV OUT

SIF

A OU T

MTS

V OUT

I2C BUS LINE

CPU

CHROMA

H VCC

G

B

R

2SC2539

V302

SAWF

PIF

DEFLECTION

VIDEO

HOUT

L

78041

N301

LA76932

5V-1

VOUT

N503

VIDEO

OUT

POWER

N501

CQ12656RT

UDIOAMPAN7522

14V

C 120V

110 V

110V

DRIVE

CRT

CRT

T301

FBT

EHV

28V

9

Page 12

MAIN IC

LA76930 BLOCK DIAGRAM

10

Page 13

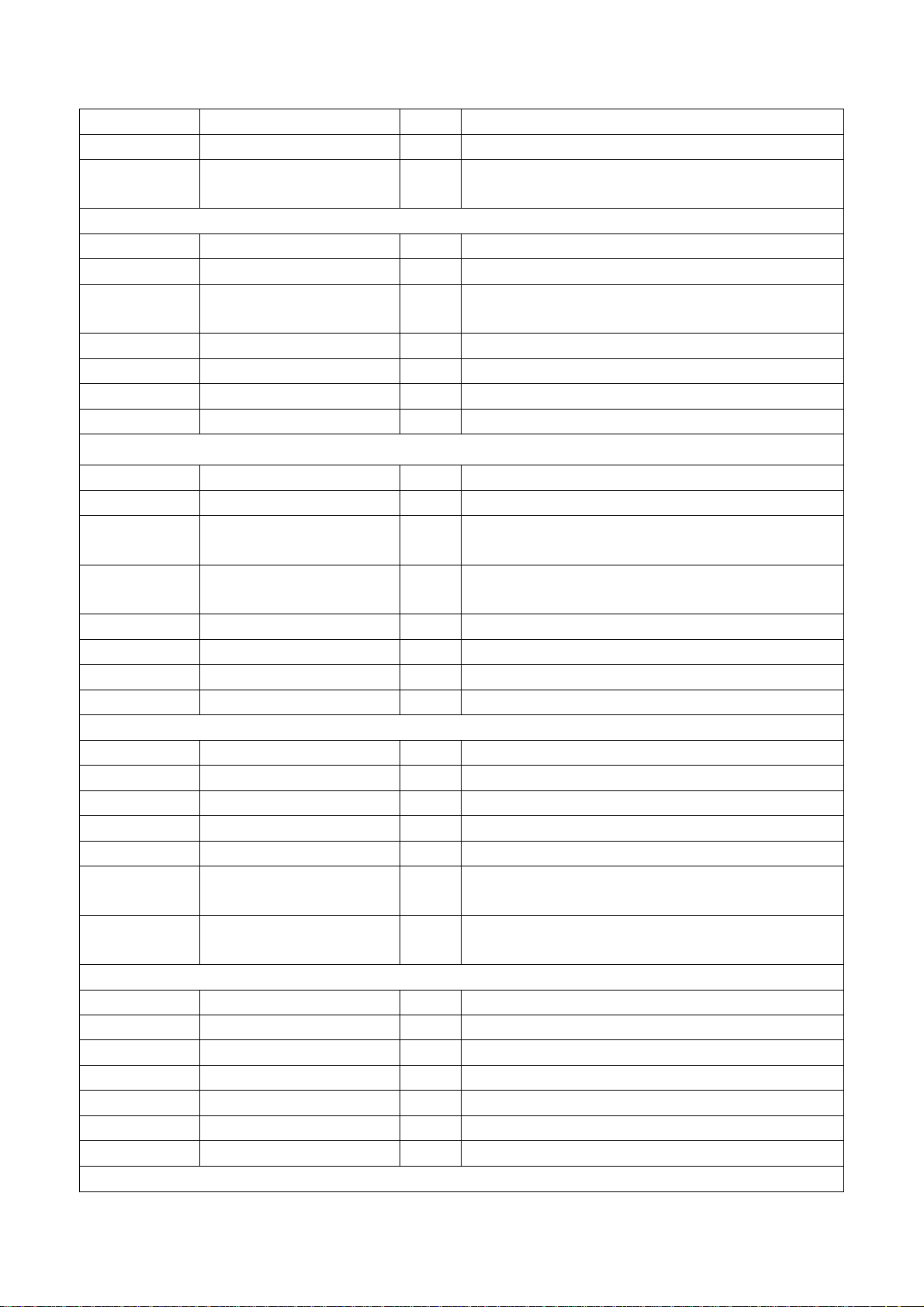

Function introduction to pin

pin function Reference

voltage

(V)

1 SIF output 2.28 64 PIF input1 2.86

2 PIF AGC 2.61 63 PIF input 2 2.86

3 SIF input 3.11 62 IF GND 0

4 FM filter 2.64 61 RF AGC output 4.55

5 FM filter/sound output 2.25 60 Video output 2.30

6 Sound output 2.24 59 AFT filter 2.50

7 SIF APC filter 2.24 58 APC filter 2.60

8 IF VCC(5V) 4.92 57 Black level detection

9 Expanded sound input 2.25 56 Internal video input and

10 ABL 3.21 55 Video, colour and

11 RGB VCC(8V/18Ma) 8.00 54 Expanded video input

12 R ouput 2.65 53 Colour APC filter 3.40

13 G ouput 2.65 52 Selection video output

14 B ouput 2.67 51 Cr input 2.50

15 AKB (undo) 2.31 50 4.43 MHZ crystal 2.73

16 Field sawtooth filter to

capacitance

17 Field output 2.34 48 Fast blank-out input 0

18 VCO Reference voltage 1.65 47 R input 1.89

19 H/BUS VCC(5V/27mA) 6.81 46 G input 1.90

20 H/APC filter 2.54 45 B input 1.90

21 H-output 0.28 44 Retrace impulse input 1.20

22 Video,colour and

deflexion ground

23 x -ray protection, low

2.16 49 Cb input 2.50

0 43 CCD VCC 4.50

5.00 42 CPU GND 0

level availability

24 S input detection, high

3.50 41 PLL 3.50

Level availability

25 DVD detection, high

6.50 40 reset 4.00

Level availability

26 IR control input 4.90 39 Button input 0.32

27 AV1/AV2 H=AV1

0 38 TV/AV H=TV L=AV 0

L=AV2

pin function Reference

2.50

filter

2.70

S-C input

4.90

deflexion power VCC

2.50

and Y input

2.40

and FSC output

voltage

(V)

11

Page 14

28 POWER H=OFF

0 37 BL 5.00

L=ON

29 Turn voltage PWM

1.73 36 BH 5.00

output

30 Mute, high

0 35 VDD 5.00

Level availability

31 I2C DATA 5.00 34 x T2 4.50

32 I2C CLOCK 5.00 33 x T1 2.70

AN7522

Pins function

pin function pin function

1

2

3

4

5

6

power

CH1+ output

GND

CH1- output

Stand-by

CH1 input

7

8

9

10

11

12

GND input

CH2 input

volume

CH1+ output

GND (CH2 output)

CH1+ output

12

Page 15

FSCQ1265RT

13

Page 16

WIRING DIAGRAM

14

Page 17

1

2

3

4

5

6

7

C323

VD306

S5295G

VD305

FR103

VD304

C312

(1500)

1110987654321

N701

10

C734

C722

10n

1u/16V

C735

10n

R401

C401

100

100p

12

R CRT

R407

4K7

R410

C402

R402

100p

13

100

G CRT

R408

4K7

C403

14

100p

B CRT

R409

4K7

R410

1K2

R CRT

G CRT

C407

10u 16V

B CRT

R412

12K

C408

0.01

R319

VD309

22K

HZ5B3

R320

22K

C328

0.1

680p

R309

10

1

R308

1 1/2W

R307

1W 3.6

C315

680p

1

R306

FR103

1W 2.4

R304

R301

10 1W

9K1 2W

1

C339

1W

400V 0.39

VD313

S5295G

1

VD301

S5295J

C303

C302

33u 250V

220p

XS604

GVGRL

C606

10u/16A

21

R615

4.7K

R730

10K

R731

10K

C732

10u/16V

VIN

9V

R231

560

R230

R229

24K

24K

L202

22uH

C235

C243

50V 1u

C232

C233

R247

2M2

0.01

10V 470u

C231

680K

0.047

53

54

55

565758

C APC

V IN/Y IN

V/C/D VCC

V IN/S-C IN

A IN

ABL

RGB VCC

R OUT

10

11121314151617

R206

10K

RGB

R208

51

C211

C212

C210

0.01

22u 16V

10V 100u

R207

390K

R522

3K9

1

N503

7805

2

680

C519

1000u 25V

C518

103p

R512

C527

10n

2K

R513

200K 1/4W

2

N504

R511

TL431

4K7 1/4W

PIN6

C604

10u/16v

43521

6

R744

100K

15

16

1Y1141Y2

VCC

TC4052

N702

2Y222Y012Z32Y342Y15E6VEE7GND

R733

100K

L-OUT

C234

10V4700u

V202

A1015

C229

0.47

18p

C228

G202

0.1

C230

0.1

*

R232

100

505152

CB

CR

4.43M

V OUT/FSC

LA76932

*

AKB

V RAMPOSC

G OUT

B OUT

C214

0.47

R210

4K7

C246

15n

C215

0.47u

5V-2

5V-1

V507

C1815

R515

R616

4.7K

A_Lout

13

12

1Z

R-OUT

R244

F B IN

V OUT

1/4W 5K1

R213

R514

10K

5K6

R743

100K

AV/TV

10

1Y3111Y0

R737

100K

C226

47pF

1K8

46

474849

R IN

G IN

N201

LA76932

VCO IREF

H VCC

18

192021

C216

0.015

68K

R242

C218

R211

10V 100u

220

C522

R523

*

10K

V506

C1815

R524

5K6

R528

5K6

5V-2

R227

VD201

HZ5C2

AV1/AV2

S19S0

8

GND

20K

C225

10V 100u

B IN

FBP INH OUT

H AFC

C217

R212

3K

C241

R701

C717

C719

C716

1M

4.7uF

1uF/16V

0.068

C718

1uF

21

24

23

22

ST-2

HPFC

Lch-in

DET OUT

GND1Rch-in2R-DC13ST-14LPFC5R-TC16R-BC7R-BC8R_DC29R-VROUT10VREF11VCC

C703

5600pF

1u /25V

4.7u/50V

C701

C702

KEY

AV1/AV2(A)

FBP

C223

R228

R223

C224

100

0.01

R224

100

C222

0.033

42

434445

CPU GND

CCD VCC

P00 X-RAY

GND

2223242526

1u

0.01

C530

330u/16V

R241

50V 2.2

1M

15K

C245

C227

1u

R225

R221

47K

C244

10k

0.01

383940

41

PLL

KEY

RESET

TV/AV

AV1/AV2

PO7/AN7

PO6/AN6

PO1/INT1

S-DET

PO3/INT3

P14 AV1/AV2

REM

P15 POW

PO2 DVD-DET

27

DVD

R243

N505

7805

2

REM

10K

POWER

OFF

R245

10K

ON

2829303132

R216

4K7

R217

4K7

1

C520

330u/16V

R215

4K7

R214

4K7

R220

4K7

S-DET

VD302

R343

R344

68K

68K

ABL

C715

0.1uF

20

C704

2700pF

4.7uF

0.1uF

0.1uF

2700p

18

L-TC119L-TC1

LV1115N703

C705

C706

0.1u

0.1u

GND

KEY1

R712

R711

220

220

15

16

13

14

VD703

IN4148

*

1

CLK

L-BC17L-BC

C728

0.1u

DATA

L-DC2

L-VROUT

C709

4.7uf

4.7u

C720

R708

1K

R709

V701

10K

A1015

9V

12

C710

1000u/35V

VIN

S-C

AV/TV

AV1/AV2(A)

SCL1

SDA1

C711

C712

C713

C714

TVO

C221

C220

15p

15p

0.1

G201

R222

*

390K

L204

68uH

33

34

353637

XT2

XT1

VDD

PO5/AN5

PO4/AN4

POWER KEY

1

VD704

IN4148

VCC1OUT1(+)2GND3OUT1(-)4STB5GND7IN28VOL9OUT2(-)

10K

C721

R716

2200u/16V

R707

C708

R715

560K

16V 220u

10K

1K

R710

R706

VD702

10K

1

4.7u/16V

1N4148

10K

C707

R703

N601

TC4053

9v

1

16

2

15

C602

3

14

1u/16V

4

13

5

12

6

11

7

10

89

C608

100k

R617

R618

100k

R613

R

G

B

6K8

N301

P17

VOL

P16 PWM3

IC BUS CON

P12/SDA1

P13/SCK1

SDA1

SCL1

CON

C240

SDA1

0.01

SCL1

R219

100

N202

24C08

1

8VCC

A0

R218

2

7

TEST

A1

100

3

6

SCL

A2

45

SDA GND

X-RAY

9V

TP9

R520

1W

15 1W

5V2

R352

*

TP6

6

V301

2SC2383

R349

C314

100

100u/16V

R348

3K

V305

C1815

R351

1K

R350

1K

1

470u 16V C321

C322

R329

C309

100u/16V

10K

C306

C305

390p

820

341

C307

R302

160V 4u7

2K7

3W

R332

3K3 3W

V304

A562

R347

2.7K

140V

C335

35V 100u

R330

5K6

V303

C1815Y

*

R314

1/2W 56

N201

7809

2

R322

1.5K

VD303

18V

C308

T302

XR0961

2

R346

3.3K

1

1N4148

VD315

INV IN1VCC2PUMP3GND4OUTPUT5OUT VCC6NON IN

1

VD308

IN4002

C333

1000

R327

12K

TP1

TP2

TP2

TP2

VD307

HZ7C2

R313

4K7

R312

C325

4K3

100u 16V

12

12V

1000u 16V

27V

V302

C2539

7

R303

2n2

33

VD317

ERD07-15

L307

R345

LH133

1

1W

C340

V306

10u/160V

C5248

AN7522

IN1

6

C723

1u/16V

9V

10K

R714

10u/16V

10uf/16V

3k

C733

C736

R717

10K

R713

C605

5V-2

16V 10u

R612

100K

75

R620

10u 16V

R614

XS201

XS401

15K

1

2

5C1

3

VD202

5C1

4

VD203

5

VD204

HZ5C1

6

*

LA78041

C327

10u 16V

C332

C331

100U 35V

R321

R325

10p

10K

1 1/2W

R326

R328

C329

330

33K

2200u 25V

1W

C330

R324

4u7 25V

0.68 1W

TP1

TP1

R311

C324

8K2

10u 50V

C318

C319

C320

680p

10n

470u 16V

1

C317

C316

1000u 35V

27V

10n

C311

8n2

C310

8n2

1

C350

22n/400V

*

1

VD318

ERC20M-04

C338

250V 4u7

D

L601

56uH

*

C101

4u7 50V

C601

3

R601

0.01uF

82

4

C609

0.01

T101

AGCBMSCL

BM

1

3

R101

C105

100K

100u

XS602

C113

R104

4

R611

75

10

5

9

6

8

7

4

0.01

100

SCL1 SDA1

XS601

113

2

2

7

10

6

9

8

SDA

BM

5

6

R103

100

L102

68uH

IN OUT

CbYCr

14

13

12

11

14

8

10

13

12

7119

C102

VT

0.22

R603

R602

75

75

R105

IF1

5K6

R108

560

R110

100

C106

0.01

R106

1K2

V101

C2717

5

S-DET

15

16

R6071KR608

C610

100u/16V

LRV

191817

20

1K

R610

75

C611

10u 16V

V703

C1815

R7501KR751

1k

DVD

9V

V704

C1815

R

LV

1

3

9

2

4

R604

R606

4.7K

4.7K

C613

C612

10u/16V

10u/16V

R107

L101

150

56uH

9V

C107

0.01

C108

0.01

R109

27

S-C

TVO

C239

V203

50V 1u

A1015

Z201

*

C201

10pF

R507

10

VD505

IN4148

VD502

IN4148

R239

R235

680

3215

R240

0.01

4

C237

63

64

IF GND

RF AGC

PIF IN 1

PIF IN 2

SIF IN

SIF OUT

PIF AGC

FM FIL

1

234

C205

0.022

C204

1u

C202

C203

0.022

39pF

R201

39K

L201

15uH

T501

SD4929A

9

20

*

*

8

19

7

18

*

6

*

17

15

3

*

2

*

13

N502

1

4

3

2

*

R509

8M2

C523

2n2 400V~

R236

10K

0.1u

R237

47K

R238

47K

C247

C236

560

0.47

606162

59

V OUT

AFT FIL

A OUT

FM/A OUT

56789

C207

0.01

R204

10K

C206

0.022

C209

100u

A_OUT

FM_OUT

C515

680

1

VD507

FR103

C521

470u 16V

1W

1W

R531

C514

1n 1KV

1

VD509

TBY56J

C517

R510

3K9

R508

VD511

R525

220

HZ7A2

C242

560

50V 1u

R246

180K

1K

R234

C238

50V 2.2u

R233

APC FIL

B L D FIL

SIF APC FIL

IF VCC

R205

C208

2K2

1500

L203

68uH

5V-2

V501

1015

R521

10K

C513

1

VD508

FR103

R527

100K

100u 160V

3 1

1K

V505

C1815

R526

5K6

5K6

R516

R517

R518

10K

C505

XS202

*

XS203

*

X201

10K

C528

10u/16V

VD501

VD501

4

4n7

X202

*

PIN4

4

3

2

1

2

1

4

3

2

1

C506

4n7

N101

upc574

5V-1

1

2

3

CON

SCL

SDA

C504

4n7

N501

12345

C508

1000 1KV

2W

R116

12K 2W

C112

4u7 50V

REM

KEY1

KEY

R504

1/2W 110K

1 2

R503

C507

1/2W 110K

150uF 400V

1 2

VD504

FR103

VD510

1

1

R506

680

1

C511

3300

C531

10uf/50V

C510

R505

0.022

330

HZ12B2

FSCQ1265RT

VD503

C509

HZ5B1

47u 50V

C512

0.047

R

9

FSC

R-OUT

8

R-OUT

L-OUT

7

L-OUT

6

GND

C

B

XS502

XS502

A

5

SCL

9V

4

SDA

3

9V

2

GND

FM-OUT

1

SIF

MTS

C902

XS902

33u

KEY

VOL-

VOL+

CH-

CH+

MENU

AV/TV

POWER

RL01

3

2

1 5

NPN2

PTC

C526

0.1

1

XS501

1

2

SW901

3

R902

PIN3

1K

SW902

R903

2K2

SW903

R904

3K3

R905

SW904

4K7

R906

SW905

8K2

SW906

R907

12K

R908

SW907

33K

R909

150K

RT501

C524

470pF 250V~

L501

1

2

1 2 3 4 5 6 7 8 9 10 11 12

3

2

4

t

2

R501

FU501

T4A 250V~

12V

V503

C1815

GND

C503

4n7

C502

0.1

213

R502

R502

C525

470pF 250V~

341

C501

0.1

2.2M

C741

C742

100p

100p

GND

OUT2(+)

11

12

V401

2SC2688

VD401

IN4148

1

C401

390p

R404

390

330

V402

2SC2688

VD402

IN4148

1

C402

390p

R405

R411

330

390

CRT R

V403

R403

2SC2688

100

VD403

IN4148

1

C403

R406

390p

R412

390

330

V404

C1815

R411

1K8

XS403

CRT

R419

R318

1K5

3.3 1W

241

3

XS402

PIN4

10

XS301

6

C326

100n

5

1 2

R317

R315

R316

1W 1K

1W 1K

330 1/2W

3

1W

1W

1

L302 L303

*

T301

*

10

9

4

7

6

1

3

2

L301

L2

R305

C304

*

C301

33u 250V

5n6 400V

200V

Title

Number RevisionSize

A1

Date: 13-Jan-2005 Sheet of

File: E:\PROTEL\LHL.Ddb Drawn By:

12

C743

C744

100p

100p

1

R+

2

R-

3

L+

4

L-

X728

D

2W

R419

15K

R413

2.7K

R420

15K

2W

R414

2.7K

R421

15K

2W

R415

2.7K

CRT G

CRT B

C

C409

250V 10u

6

2

G

3

CRT G

5

R

CRT R

B

CRT B

*

8

HV

7

4

C410

1n 2KV

B

HV

*

FOCUS

SCREEN

A

XS302

4

3

2

1

*

Page 18

15

16

17

18

19

20

21

22

23

14

13

12

11

10

9

8

24

25

7

26

6

5

27

4

28

29

3

30

31

2

1

32

Page 19

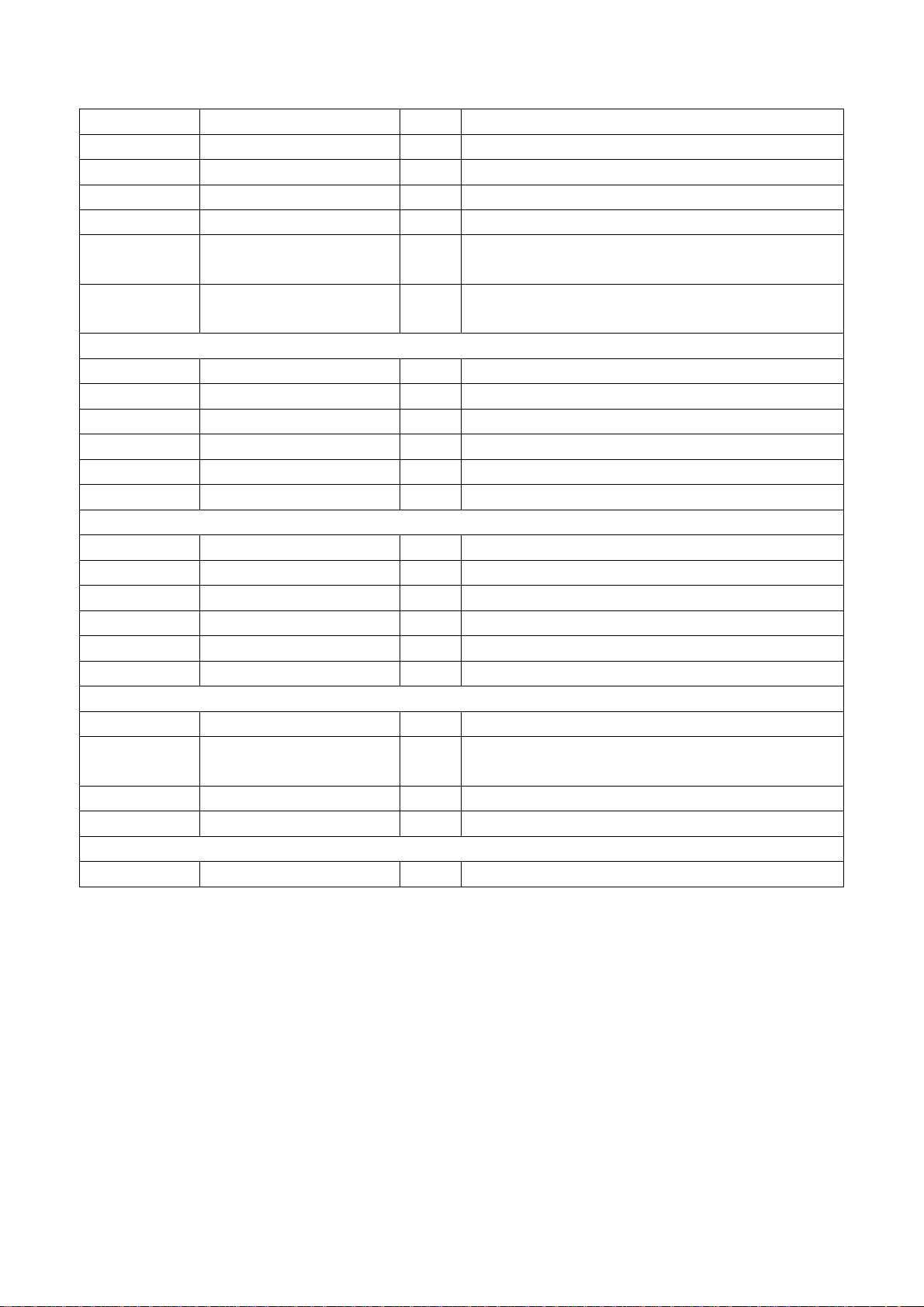

PART LIST OF EXPLODED VIEW

No. DESCRIPTION PART NO.

1 SCREW 851-24016-14

2 SCREW 851-23012-14

3 REAR CABINET 780-10641-J02A

4 BRAIDED WIRE 123-30001-04

5 LINE CLASP 742-30032-00

6 DEGAUSSING COIL 477-12904-00

7 BRAIDED PULLING SPRING 838-10401-00

8 SCREW 851-24016-14

9 LINE CLASP 742-30038-00

10 REAR PANEL 808-10521-020

11 MAIN BOARD ASSY 667-TSX16-01A

12 FRONT CABINET 611-E16Y1-AR1

13 BUTTON BOARD 667-TSE16-05A

14 BUTTON 877-50316-6C0

15 SCREW 851-24016-14

16 FRONT NAMEPLATE 880-10391-00

17 LED COLUMN 700-60099-00

18 POWER INDICATOR LIGHT 700-60100-00

19 POWER BUTTON

20 SPEAKER BRACKET 870-20664-00

21 SPEAKER 384-40908-B0

22 SCREW 855-85020-31

23 CRT BRACKET 870-20666-00

24 POWER SWITCH

25 SCREW 851-53008-31

26 SCREW 851-24016-14

27 CRT 335-2942Q-60

28 CRT FIXER 868-20337-00

29 CUSHION 868-10089-00

30 NUT 893-10600-11

31 CRT BOARD 667-TSE30-02

32 REAR NAMEPLATE 880-10205-936

Page 20

PART LIST

PART# DESCRIPTION LOCA.NO.

203-TS27160-10 TK2716D, PRIMA BRAND DIGISTAR,

100-TS27160-01 TS2716

123-30001-04 TWIST WIRE

602-TS2750-01 SCHEMATIC DIAGRAM

615-10105-00 CRT FIXER ASS'Y

648-30001-00 COMPOSE NUTS SJ2843-87M6

655-63101-09 (6-PINS) LEAD WITH HOUSING

700-60099-00 LED COLUMN

700-60100-00 LED COLUMN

741-10001-02 WIRE FIXED BLADE

742-30005-09 LINE TIE

742-30005-09 LINE TIE

742-30006-09 GRADING TIE

742-30032-00 TIE

742-30038-00 TIE

770-40151-40 IMITATEUL1672 22# 400mm BLACK

780-10641-J02A BACK CABINET (HIPS V0 MOLD BLACK )

808-70239-00 EVA GLUE 150X50X1

838-10401-00 BRAIDED WIARE SPRING

851-23012-14 SCREW SJ2824 ST3X12C-Y

851-24014-11 SCREW SJ2824 ST4X14C-D.Zn

851-24016-14 SCREW SJ2824 ST4X16C-Y

851-24016-14 SCREW SJ2824 ST4X16C-Y

851-24020-14 SCREW SJ2824 ST4X20C-Y

851-24030-11 SCREW SJ2824 ST4X30C-D.Zn

851-53008-31 SCREW SJ2825 ST3X8FT D.Zn

851-53008-31 SCREW SJ2825 ST3X8FT D.Zn

855-85020-31 COMPOSE SCREW ST5X20FT-D.Zn

857-10002-09 COTTON FLANNEL

857-10004-00 COTTON FLANNEL

857-10004-00 COTTON FLANNEL

862-20028-00 POWER CORD CLAMPE

863-80727-00 POLY FOAM (TOP ) ( SMALL )

863-80728-00 POLY FOAM (BOTTOM ) ( SMALL )

868-20007-00 SLEEVE

868-20175-00 SUPPORT CUSHION

868-20271-00 RUBBER WASHER

868-20271-00 RUBBER WASHER

868-20337-00 CRT FIXER

868-20548-00 CUSHION

Page 21

868-20553-00 CABINET BOTTOM CUSHION

870-20666-00 CRT BRACKET

881-60085 BLANK WARNING LABEL

887-20044-01 POWER CORD COVER

887-20047-00 ACCESSORY PALSTIC BAG

887-21114-P0 PE/PEARL COTTONPALSTIC BAG 1300X1250

893-10600-11 NUT GB6170-86-M6 D.Zn

335-2942Q-60 CRT NA MAGNETIC FIELD !

477-12904-00 DEGAUSS COIL DX-29!

488-10012-00 BATTERY 7# ENGLISH

604-TS27167-00 OWNER'S MANUAL(DIGISTAR/MTS)

611-E16Y1-AR1 FRONT CABINET ASS'Y ( BLACK ,SILK-SCREEN )

880-10205-936 BACK PLATE (TK2716D,DIGISTAR)

880-10391-00 FRONT LOGO (DIGITAR)

881-TS27167-00 OPERATION CARD

881-63329-00 LABEL (FPE2000,AUDIOVOX)

881-63840-00 POWER SYMBOL LABEL

881-64087-00 TRANSPORTATION LABEL (TK2716D,DIGISTAR)

881-80811-00 ACKNOWLEDGEMENT CARD ((DIGISTAR)

881-80812-00 EXTENDED CARD (DIGISTAR 27 inch CRT)

886-31115-270W CARTON BOX (TK2716D,DIGISTAR)

301-ATS3235-27D RC-A27-0DREMOTE CONTROL UNIT (DIGISTAR)

615-20382-00 SPEAKER ASS'Y

384-40908-B0 SPEAKER ST613-04

655-41201-317 (4-PINS) LEAD WITH HOUSING

851-53008-31 SCREW SJ2825 ST3X8FT D.Zn

868-20217-00 WASHER

870-20664-00 SPEAKER BRACKET

667-Q32351-05 STANDBY KEY BOARD ASS'Y

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B S1

665-21201-28 ( 2-PINS ) LEAD WITH HOUSING X1

782-13Y90-050A BUTTON PCB

667-TSE16-05A KEY BOARD ASS'Y

340-10055-90 LED HFT505M VD901

352-03810-50 IC AT138A (M) N901

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B SW901

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B SW902

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B SW903

Page 22

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B SW904

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B SW905

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B SW906

464-6D622-M0 ELECTROLYTIC CAPACITOR CD110-16V-22uF-M C901

464-6D633-M0 ELECTROLYTIC CAPACITOR CD110-16V-33uF-M C801

467-1C110-H0 CARBON RESISTOR 1/6W-100Ω-J R908

467-1C210-H0 CARBON RESISTOR 1/6W-1K-J R901

467-1C210-H0 CARBON RESISTOR 1/6W-1K-J R902

467-1C220-H0 CARBON RESISTOR 1/6W-2K-J R801

467-1C222-H0 CARBON RESISTOR 1/6W-2.2K-J R903

467-1C233-H0 CARBON RESISTOR 1/6W-3.3K-J R904

467-1C247-H0 CARBON RESISTOR 1/6W-4.7K-J R905

467-1C282-H0 CARBON RESISTOR 1/6W-8.2K-J R906

467-1C312-H0 CARBON RESISTOR 1/6W-12K-J R909

467-1C418-H0 CARBON RESISTOR 1/6W-180K-J R907

655-71201-79 (7-PINS) LEAD WITH HOUSING XS901

782-E2916-050A BUTTON PCB

870-20374-00 IR RECEIVER HOLDER

877-50316-6C0 KEY (PLATE BLACK )

998 JUMPER WIRE J901

667-TSE30-02 CRT PCB ASS'Y

340-00001-00 DIODE 1N4148 VD401

340-00001-00 DIODE 1N4148 VD402

340-00001-00 DIODE 1N4148 VD403

343-18150-10 TRANSISTOR 2SC1815-Y V404

343-26880-20 TRANSISTOR 2SC2688L V401

343-26880-20 TRANSISTOR 2SC2688L V402

343-26880-20 TRANSISTOR 2SC2688L V403

364-58210-00 CRT SOCKET GZS10-2-102G ! X403

459-2147H-90 CERAMIC CAPACITOR CC1-12-SL-63V-471J C401

459-2147H-90 CERAMIC CAPACITOR CC1-12-SL-63V-471J C402

459-2147H-90 CERAMIC CAPACITOR CC1-12-SL-63V-471J C403

459-8222K-00 CERAMIC CAPACITOR DE1005B222K2K C407

464-6D722-M0 ELECTROLYTIC CAPACITOR CD110-16V-220uF-M C411

464-65610-M0 ELECTROLYTIC CAPACITOR CD288-250V-10uF-M C409

467-1C110-H0 CARBON RESISTOR 1/6W-100Ω-J R401

467-1C110-H0 CARBON RESISTOR 1/6W-100Ω-J R402

467-1C110-H0 CARBON RESISTOR 1/6W-100Ω-J R403

467-1C130-H0 CARBON RESISTOR 1/6W-300Ω-J R404

467-1C130-H0 CARBON RESISTOR 1/6W-300Ω-J R405

467-1C130-H0 CARBON RESISTOR 1/6W-300Ω-J R406

Page 23

467-1C224-H0 CARBON RESISTOR 1/6W-2.4K-J R407

467-1C224-H0 CARBON RESISTOR 1/6W-2.4K-J R408

467-1C224-H0 CARBON RESISTOR 1/6W-2.4K-J R409

467-1C310-H0 CARBON RESISTOR 1/6W-10K-J R422

467-1C310-H0 CARBON RESISTOR 1/6W-10K-J R423

467-2G315-H0 METAL RESISTOR 2W-15kΩ-JL R419

467-2G315-H0 METAL RESISTOR 2W-15kΩ-JL R420

467-2G315-H0 METAL RESISTOR 2W-15kΩ-JL R421

467-8E227-H0A SOLID RESISTOR 1/2W-2.7KΩ-J ! R413

467-8E227-H0A SOLID RESISTOR 1/2W-2.7KΩ-J ! R414

467-8E227-H0A SOLID RESISTOR 1/2W-2.7KΩ-J ! R415

471-2068K-10 PEAKING COIL LGA0410-68uH-K L402

655-41201-240 ( 4-PINS ) LEAD WITH HOUSING X302

655-61201-173 ( 6-PINS ) LEAD WITH HOUSING X401

782-TS2735-0200 CRT PCB

998 JUMPER WIRE L401

998 JUMPER WIRE R416

998 JUMPER WIRE R410

998 JUMPER WIRE R411

998 JUMPER WIRE R412

998 JUMPER WIRE J401

998 JUMPER WIRE J402

998 JUMPER WIRE R424

998 JUMPER WIRE J404

998 JUMPER WIRE R426

667-TSX16-01A MAIN PCB ASS'Y

364-99208-00 AV JACK AV901-5 XS601

462-88282-H0 POLYESTER CAPACITOR CBB81-1600V-8200PF-J C310

462-88282-H0 POLYESTER CAPACITOR CBB81-1600V-8200PF-J C311

467-4FA15-H0 FUSIBLE RESISTOR 1W-1.5Ω-JL R308

472-2710H-00U FBT BSC29-3718 ! T301

477-00054-00 HORIZONTAL LINEARITY COIL HL1835H-X06 L302

491-7521D-02 POWER CORD UL !

329-33204-00 CRYSTAL 32.768K G201

329-54401-00 CRYSTAL JA18 4.433619MHZ G202

340-00079-00 DIODE FR103 VD304

340-00079-00 DIODE FR103 VD305

340-00079-00 DIODE FR103 VD306

340-00079-00 DIODE FR103 VD504

340-00079-00 DIODE FR103 VD505

340-00079-00 DIODE FR103 VD507

Page 24

340-00163-00 DIODE RGP10G VD318

340-00297-00 DIODE ERD07-15 VD317

340-00426-00 DIODE TRU4C VD509

340-52840-0G ZENER DIODE RD30E-B3 N101

340-80019-00 RECTIFIER T3SB60 VD501

343-20090-80 TRANSISTOR ST2009DHI V302

343-52480-30 TRANSISTOR 2SC5248E V306

352-04310-00 IC LM431A (M) N504

352-06210-70U IC TLP621-GB(UL) (O)! N502

352-12650-90 IC FSCQ1265RT N501

352-24080-50 IC M24C08BN6 N202

352-40520-60 IC TC4052BP (M) N702

352-40530-00 IC TC4053BP (M) N601

352-75220-00 IC AN7522N (M) N701

352-76932-30 IC LA76932N-7N56P7-E

352-78041-00 IC LA78041 (M) N301

352-78050-00 IC KA7805 (M) N505

352-78050-00 IC KA7805 (M) N503

352-78090-40 IC TA78M09P (D) N201

364-32101-00 2-PINS CONNECTORS TJC3-02A X202

364-32108-00 2-PINS CONNECTORS TJC1-2A XS502

364-33101-00 3-PINS CONNECTORS TJC3-03A XS203

364-34101-00 4-PINS CONNECTORS TJC3-04A XS202

364-34101-00 4-PINS CONNECTORS TJC3-04A XS604(2,5)

364-34101-00 4-PINS CONNECTORS TJC3-04A X728

364-36102-00 6-PINS CONNECTORS TJC2-6A XS301

364-77511-00 FUSE HOLDER FU501

364-91202-00 S-VIDEO TERMINAL CKX5-2K-2 XS602

457-12003-90U RELAY JQX-115F-012-1H1 ! RL01

458-07009-00 ACOUSTIC SURFACE-WAVE COMPONENT FILTER M1859M Z201

459-B147M-20 CERAMIC CAPACITOR ECK-DNS471MBX ! C524

459-B147M-20 CERAMIC CAPACITOR ECK-DNS471MBX ! C525

459-B222M-20 CERAMIC CAPACITOR ECK-DNS222MEX ! C523

459-6147K-00 CERAMIC CAPACITOR DE0705B471K1k C514

459-6210K-00 CERAMIC CAPACITOR DE0705B102K1K C508

459-6210K-00 CERAMIC CAPACITOR DE0705B102K1K C503

459-6210K-00 CERAMIC CAPACITOR DE0705B102K1K C504

459-6210K-00 CERAMIC CAPACITOR DE0705B102K1K C505

459-6210K-00 CERAMIC CAPACITOR DE0705B102K1K C506

462-00333-H0 POLYESTER CAPACITOR CL11-100V-0.033uF-J

462-2B410-M0V POLYESTER CAPACITOR 250VAC-0.1uF-M ! C501

462-2B410-M0V POLYESTER CAPACITOR 250VAC-0.1uF-M ! C502

Page 25

462-83356-H0 POLYESTER CAPACITOR CBB21-200V-0.056uF-J C304

462-83439-H0 POLYESTER CAPACITOR CBB21-200V-0.39uF-J C339

462-85318-H0 POLYESTER CAPACITOR CBB21-400V-0.018uF-J C350

464-04747-M0R ELECTROLYTIC CAPACITOR 200USP470MA35 C507

464-6D747-M0 ELECTROLYTIC CAPACITOR CD110-16V-470uF-M C240

464-6D822-M0 ELECTROLYTIC CAPACITOR CD110-16V-2200uF-M C721

464-6E822-M0 ELECTROLYTIC CAPACITOR CD110-25V-2200uF-M C329

464-6F747-M0 ELECTROLYTIC CAPACITOR CD110-35V-470uF-M C335

464-6F810-M0 ELECTROLYTIC CAPACITOR CD110-35V-1000uF-M C317

464-62547-M0 ELECTROLYTIC CAPACITOR CD288-160V-4.7uF-M C340

464-62633-M0 ELECTROLYTIC CAPACITOR CD288-160V-33uF-M C301

464-62710-M0 ELECTROLYTIC CAPACITOR CD288-160V-100uF-M C517

464-65633-M0 ELECTROLYTIC CAPACITOR CD288-250V-33uF-M C303

467-1C075-H0 CARBON RESISTOR 1/6W-75Ω-J R610

467-1C247-H0 CARBON RESISTOR 1/6W-4.7K-J R202

467-2D247-F0 METAL RESISTOR 1/4W-4.7K-F R511

467-2E001-H0 METAL RESISTOR 1/2W-1Ω-JL R321

467-2E133-H0 METAL RESISTOR 1/2W-330Ω-JL R317

467-2FB82-H0 METAL RESISTOR 1W-0.82Ω-JL R324

467-2F001-H0 METAL RESISTOR 1W-1Ω-JL R345

467-2F210-H0 METAL RESISTOR 1W-1KΩ-JL R315

467-2G012-H0 METAL RESISTOR 2W-12Ω-JL R520

467-2G312-H0 METAL RESISTOR 2W-12kΩ-JL R116

467-2G312-H0 METAL RESISTOR 2W-12kΩ-JL R301

467-2H239-H0D METAL RESISTOR 3W-3.9kΩ-JL R332

467-4FB33-H0 FUSIBLE RESISTOR 1W-0.33Ω-JL R306

467-4FB33-H0 FUSIBLE RESISTOR 1W-0.33Ω-JL R531

467-4F001-H0 FUSIBLE RESISTOR 1W-1Ω-JL R307

467-4F010-H0 FUSIBLE RESISTOR 1W-10Ω-JL R304

467-8E422-H0 SOLID RESISTOR 1/2W-220KΩ-JL ! R504

467-8E522-H0A SOLID RESISTOR 1/2W-2.2M-J ! R501

467-8E582-H0A SOLID RESISTOR 1/2W-8.2MΩ-J ! R509

468-33207-00 POTENTIOMETER EVND8A-20K VR501

469-10023-00 THERMISTOR 96708 (9Ω) RT501

469-40004-00 THERMISTOR 5D2-14LC ! R502

470-00376-00U *SWITCHING TRANSFORMERSD4929A ! T501

471-2056H-60 PEAKING COIL LGA0307-56uH-J L601

472-10001-00 HORIZONTAL DRIVE TRANSFORMER XR0961 T302

477-20005-00 POWER FILTER LF21061 ! L502

477-20031-00 POWER FILTER LCL-21 ! L501

477-40031-00 FIXED INDUCTANCE LG750 L301

477-40031-00 FIXED INDUCTANCE LG750 L503

Page 26

477-40111-00 FIXED INDUCTANCE LH133 L307

569-18101-00U FUSE 51S 5A/125V ! FU501

590-40707-00 TUNER 115-B-8035AZ TUNER

681-40003-00 OK LABEL

706-T3003-01 RADIATOR PIECE N701

706-T5004-01 RADIATOR PIECE V302

706-T7501-01 RADIATOR PIECE N301

706-20173-00 RADIATOR PIECE N505

706-20231-00 RADIATOR PIECE V306

706-46006-01 RADIATOR PIECE N501

741-10001-02 WIRE FIXED BLADE

742-30005-09 LINE TIE

775-10054-00 SOLDERING BLADE A1

775-10054-00 SOLDERING BLADE A2

775-60044-00 SOCKET PIN RT-01T-1.3B TP1

775-60044-00 SOCKET PIN RT-01T-1.3B TP2

775-60137-00 HOLLOW PILLAR φ2.36×14B R332

775-60137-00 HOLLOW PILLAR φ2.36×14B VD509

775-60137-00 HOLLOW PILLAR φ2.36×14B VD318

808-10521-020 BLACK PLATE ( MOLD BLACK )

808-60748-02 INTERFACE SPACE PLATE (SILK-SCREEN )

851-13008-56 SCREW P(+) T3X8S-R N701

851-13008-56 SCREW P(+) T3X8S-R N301

851-13008-56 SCREW P(+) T3X8S-R N501

851-13008-56 SCREW P(+) T3X8S-R V302

851-23010-14 SCREW SJ2824 ST3X10C-Y

851-24014-31 SCREW SJ2824 ST4X14C-D.Zn

851-53010-31 SCREW SJ2825 ST3X10FT-D.Zn

851-53012-31 SCREW SJ2825ST3X12FT-DZn

851-53016-31 SCREW ST2825 ST3X16FT-D.Zn

852-13008-81 SCREW P(+) M3X8-D.Zn N505

852-13008-81 SCREW P(+) M3X8-D.Zn V306

863-60122-U00H MAIN BOARD FRAME (HIPS V0)

870-20357-00 WIRE FIXED HOLDER

870-20690-U00A FBT BRACKET (HIPS V0)

881-60074-00 HIGH VOLTAGE WARNING LABEL

893-10300-11 NUT GB6170-86-M3-D.Zn N505

893-10300-11 NUT GB6170-86-M3-D.Zn V306

894-40030-11 WASHER GB859-87,3-DZn N505

894-40030-11 WASHER GB859-87,3-DZn V306

998 JUMPER WIRE X301

998 JUMPER WIRE L303

Page 27

998 JUMPER WIRE V702(BC)

998 JUMPER WIRE J31

741-10001-02 WIRE FIXED BLADE

851-53016-31 SCREW ST2825 ST3X16FT-D.Zn

998 JUMPER WIRE N703

467-2D347-F03 METAL RESISTOR 1/4W-47K-F R513

340-00001-003 DIODE 1N4148 VD502

340-00001-003 DIODE 1N4148 VD512

340-00001-003 DIODE 1N4148 VD315

340-00001-003 DIODE 1N4148 VD202

340-00001-003 DIODE 1N4148 VD203

340-00001-003 DIODE 1N4148 VD204

340-00001-003 DIODE 1N4148 VD703

340-00005-003 DIODE S5295J VD301

340-00005-003 DIODE S5295J VD313

340-00011-003 DIODE 1N4002 VD308

340-00291-003 DIODE TEU2YX VD508

340-50470-003 ZENER DIODE HZ5B1 VD503

340-50610-003 ZENER DIODE HZ6C2 VD511

340-50750-003 ZENER DIODE HZ7C2 VD307

343-10150-104 TRANSISTOR 2SA1015Y Pr2.5 V202

343-10150-104 TRANSISTOR 2SA1015Y Pr2.5 V203

343-10150-104 TRANSISTOR 2SA1015Y Pr2.5 V304

343-10150-104 TRANSISTOR 2SA1015Y Pr2.5 V501

343-10150-104 TRANSISTOR 2SA1015Y Pr2.5 V701

343-18150-104 TRANSISTOR 2SC1815-Y V704

343-18150-104 TRANSISTOR 2SC1815-Y V703

343-18150-104 TRANSISTOR 2SC1815-Y V303

343-18150-104 TRANSISTOR 2SC1815-Y V505

343-18150-104 TRANSISTOR 2SC1815-Y V506

343-18150-104 TRANSISTOR 2SC1815-Y V507

343-18150-104 TRANSISTOR 2SC1815-Y V503

343-18150-104 TRANSISTOR 2SC1815-Y V305

343-23830-604 *TRANSISTOR 2SC2383-0 V301

343-27170-004 TRANSISTOR 2SC2717 V101

459-2015H-102 CERAMIC CAPACITOR CC45-CH1H150JYR C201

459-2015H-102 CERAMIC CAPACITOR CC45-CH1H150JYR C220

459-2015H-102 CERAMIC CAPACITOR CC45-CH1H150JYR C221

459-2022H-102 CERAMIC CAPACITOR CC45-CH1H220JYR C229

459-2039H-102 CERAMIC CAPACITOR CC45-CH1H390JYR C203A

459-2047H-102 CERAMIC CAPACITOR CC45-CH1H470JYR C226

459-2122H-102 CERAMIC CAPACITOR CC45-CH1H221JYR C219

Page 28

459-2210K-002 CERAMIC CAPACITOR CK45-B1H102KYR C333

459-2215K-002 CERAMIC CAPACITOR CT1-06-2B4-63V-152K C208

459-2233K-002 CERAMIC CAPACITOR CT1-08-2B4-63V-332K C511

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C106

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C107

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C108

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C207

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C210

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C224

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C232

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C237

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C241

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C244

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C601

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C609

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C215

459-2322R-002 CERAMIC CAPACITOR CT1-10-2F4-63V-223Z C202

459-2347R-002 CERAMIC CAPACITOR CT1-14b-2E-63V-473Z C231

459-2410R-002 CERAMIC CAPACITOR DD308-63F104Z50 C228

459-2410R-002 CERAMIC CAPACITOR DD308-63F104Z50 C230

459-5122K-002 CERAMIC CAPACITOR RQC05B221K-6H46UA C302

459-5139K-002 CERAMIC CAPACITOR CK45-B2H391KYR C306

459-5168K-002 CERAMIC CAPACITOR RQC06B681K-6H46UA C315

459-5168K-002 CERAMIC CAPACITOR RQC06B681K-6H46UA C318

459-5168K-002 CERAMIC CAPACITOR RQC06B681K-6H46UA C323

459-5168K-002 CERAMIC CAPACITOR RQC06B681K-6H46UA C513

459-5168K-002 CERAMIC CAPACITOR RQC06B681K-6H46UA C515

459-5182K-002 CERAMIC CAPACITOR DD06-999B812K500 C305

462-B0410-H02 POLYESTER CAPACITOR CL21X-50V-0.1uF-J C527

462-B0447-H02 POLYESTER CAPACITOR CL21X-50V-0.47uF-J C214

462-00256-H02 POLYESTER CAPACITOR CL11-100V-5600PF-J C734

462-00256-H02 POLYESTER CAPACITOR CL11-100V-5600PF-J C735

462-00315-H02 POLYESTER CAPACITOR CL11-100V-0.015uF-J C216

462-00315-H02 POLYESTER CAPACITOR CL11-100V-0.015uF-J C205

462-00322-H02 POLYESTER CAPACITOR CL11-100V-0.022uF-J C510

462-00333-H02 POLYESTER CAPACITOR CL11-100V-0.033uF-J C222

462-00347-K02 POLYESTER CAPACITOR CL11-100V-0.047uF-K C512

462-00410-K02 POLYESTER CAPACITOR CL11-100V-0.1uF-K C326

462-00410-K02 POLYESTER CAPACITOR CL11-100V-0.1uF-K C328

464-30447-M02 ELECTROLYTIC CAPACITOR CD11W-50V-0.47uF-M C235

464-6C710-M02 ELECTROLYTIC CAPACITOR CD110-10V-100uF-M C105

464-6C710-M02 ELECTROLYTIC CAPACITOR CD110-10V-100uF-M C209

Page 29

464-6C710-M02 ELECTROLYTIC CAPACITOR CD110-10V-100uF-M C225

464-6C747-M02 ELECTROLYTIC CAPACITOR CD110-10V-470uF-M C218

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C325

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C327

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C604

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C605

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C606

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C611

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C612

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C613

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C732

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C733

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C245

464-6D622-M02 ELECTROLYTIC CAPACITOR CD110-16V-22uF-M C211

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C212

464-6D710-M02 ELECTROLYTIC CAPACITOR CD110-16V-100uF-M C314

464-6D710-M02 ELECTROLYTIC CAPACITOR CD110-16V-100uF-M C322

464-6D710-M02 ELECTROLYTIC CAPACITOR CD110-16V-100uF-M C610

464-6D710-M02 ELECTROLYTIC CAPACITOR CD110-16V-100uF-M C528

464-6D722-M02 ELECTROLYTIC CAPACITOR CD110-16V-220uF-M C234

464-6D722-M02 ELECTROLYTIC CAPACITOR CD110-16V-220uF-M C521

464-6D722-M02 ELECTROLYTIC CAPACITOR CD110-16V-220uF-M C708

464-6D733-M02 ELECTROLYTIC CAPACITOR CD110-16V-330uF-M C233

464-6D733-M02 ELECTROLYTIC CAPACITOR CD110-16V-330uF-M C530

464-6D747-M02 ELECTROLYTIC CAPACITOR CD110-16V-470uF-M C319

464-6D747-M02 ELECTROLYTIC CAPACITOR CD110-16V-470uF-M C519

464-6F710-M02 ELECTROLYTIC CAPACITOR CD110-35V-100uF-M C332

464-60433-M02 ELECTROLYTIC CAPACITOR CD110-50V-0.33uF-M C227

464-60447-M02 ELECTROLYTIC CAPACITOR CD110-50V-0.47uF-M C102

464-60447-M02 ELECTROLYTIC CAPACITOR CD110-50V-0.47uF-M C236

464-60447-M02 ELECTROLYTIC CAPACITOR CD110-50V-0.47uF-M C736

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C204

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C217

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C239

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C242

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C243

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C701

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C718

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C719

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C722

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C723

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C602

Page 30

464-60522-M02 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M C223

464-60522-M02 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M C238

464-60522-M02 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M C707

464-60547-M02 ELECTROLYTIC CAPACITOR CD110-50V-4.7uF-M C101

464-60547-M02 ELECTROLYTIC CAPACITOR CD110-50V-4.7uF-M C112

464-60547-M02 ELECTROLYTIC CAPACITOR CD110-50V-4.7uF-M C330

464-60547-M02 ELECTROLYTIC CAPACITOR CD110-50V-4.7uF-M C520

464-60610-M02 ELECTROLYTIC CAPACITOR CD110-50V-10uF-M C324

464-60647-M02 ELECTROLYTIC CAPACITOR CD110-50V-47uF-M C509

464-62547-M02 ELECTROLYTIC CAPACITOR CD288-160V-4.7uF-M C307

464-62547-M02 ELECTROLYTIC CAPACITOR CD288-160V-4.7uF-M C338

467-1C010-H03 CARBON RESISTOR 1/6W-10Ω-J R309

467-1C010-H03 CARBON RESISTOR 1/6W-10Ω-J R507

467-1C027-H03 CARBON RESISTOR 1/6W-27Ω-J R109

467-1C033-H03 CARBON RESISTOR 1/6W-33Ω-J R303

467-1C051-H03 CARBON RESISTOR 1/6W-51Ω-J R208

467-1C075-H03 CARBON RESISTOR 1/6W-75Ω-J R602

467-1C075-H03 CARBON RESISTOR 1/6W-75Ω-J R603

467-1C075-H03 CARBON RESISTOR 1/6W-75Ω-J R611

467-1C075-H03 CARBON RESISTOR 1/6W-75Ω-J R620

467-1C082-H03 CARBON RESISTOR 1/6W-82Ω-J R601

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R103

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R104

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R110

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R218

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R219

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R224

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R228

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R232

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R108

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J J216

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R708

467-1C115-H03 CARBON RESISTOR 1/6W-150Ω-J R107

467-1C120-H03 CARBON RESISTOR 1/6W-200Ω-J R211

467-1C122-H03 CARBON RESISTOR 1/6W-220Ω-J R525

467-1C133-H03 CARBON RESISTOR 1/6W-330Ω-J R326

467-1C139-H03 CARBON RESISTOR 1/6W-390Ω-J R234

467-1C147-H03 CARBON RESISTOR 1/6W-470Ω-J R349

467-1C147-H03 CARBON RESISTOR 1/6W-470Ω-J R505

467-1C156-H03 CARBON RESISTOR 1/6W-560Ω-J R231

467-1C156-H03 CARBON RESISTOR 1/6W-560Ω-J R235

467-1C156-H03 CARBON RESISTOR 1/6W-560Ω-J R239

Page 31

467-1C156-H03 CARBON RESISTOR 1/6W-560Ω-J R240

467-1C168-H03 CARBON RESISTOR 1/6W-680Ω-J R506

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R750

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R751

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R350

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R351

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R607

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R710

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R347

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R305

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R508

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R604

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R606

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R608

467-1C212-H03 CARBON RESISTOR 1/6W-1.2K-J R106

467-1C212-H03 CARBON RESISTOR 1/6W-1.2K-J R717

467-1C215-H03 CARBON RESISTOR 1/6W-1.5K-J R318

467-1C218-H03 CARBON RESISTOR 1/6W-1.8K-J R244

467-1C218-H03 CARBON RESISTOR 1/6W-1.8K-J R704

467-1C220-H03 CARBON RESISTOR 1/6W-2K-J R348

467-1C222-H03 CARBON RESISTOR 1/6W-2.2K-J R205

467-1C230-H03 CARBON RESISTOR 1/6W-3K-J R212

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J R346

467-1C239-H03 CARBON RESISTOR 1/6W-3.9K-J R510

467-1C239-H03 CARBON RESISTOR 1/6W-3.9K-J R522

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R214

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R615

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R616

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R210

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R215

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R216

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R220

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R313

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R217

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R243

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R312

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R329

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R720

467-1C251-H03 CARBON RESISTOR 1/6W-5.1K-J R516

467-1C251-H03 CARBON RESISTOR 1/6W-5.1K-J R524

467-1C251-H03 CARBON RESISTOR 1/6W-5.1K-J R526

467-1C251-H03 CARBON RESISTOR 1/6W-5.1K-J R528

Page 32

467-1C256-H03 CARBON RESISTOR 1/6W-5.6K-J R105

467-1C256-H03 CARBON RESISTOR 1/6W-5.6K-J R330

467-1C282-H03 CARBON RESISTOR 1/6W-8.2K-J R320

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R730

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R204

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R206

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R236

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R325

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R514

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R515

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R521

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R523

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R221

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R714

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R731

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R735

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R736

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R715

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R716

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R713

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R709

467-1C312-H03 CARBON RESISTOR 1/6W-12K-J R327

467-1C315-H03 CARBON RESISTOR 1/6W-15K-J R241

467-1C320-H03 CARBON RESISTOR 1/6W-20K-J R227

467-1C322-H03 CARBON RESISTOR 1/6W-22K-J R319

467-1C322-H03 CARBON RESISTOR 1/6W-22K-J R517

467-1C324-H03 CARBON RESISTOR 1/6W-24K-J R229

467-1C324-H03 CARBON RESISTOR 1/6W-24K-J R230

467-1C333-H03 CARBON RESISTOR 1/6W-33K-J R328

467-1C333-H03 CARBON RESISTOR 1/6W-33K-J R518

467-1C339-H03 CARBON RESISTOR 1/6W-39K-J R201

467-1C347-H03 CARBON RESISTOR 1/6W-47K-J R237

467-1C347-H03 CARBON RESISTOR 1/6W-47K-J R238

467-1C368-H03 CARBON RESISTOR 1/6W-68K-J R242

467-1C368-H03 CARBON RESISTOR 1/6W-68K-J R344

467-1C410-H03 CARBON RESISTOR 1/6W-100K-J R101

467-1C410-H03 CARBON RESISTOR 1/6W-100K-J R527

467-1C410-H03 CARBON RESISTOR 1/6W-100K-J R733

467-1C410-H03 CARBON RESISTOR 1/6W-100K-J R737

467-1C410-H03 CARBON RESISTOR 1/6W-100K-J R743

467-1C410-H03 CARBON RESISTOR 1/6W-100K-J R744

467-1C415-H03 CARBON RESISTOR 1/6W-150K-J R225

Page 33

467-1C439-H03 CARBON RESISTOR 1/6W-390K-J R207

467-1C439-H03 CARBON RESISTOR 1/6W-390K-J R222

467-1C468-H03 CARBON RESISTOR 1/6W-680K-J R233

467-1C510-H03 CARBON RESISTOR 1/6W-1M-J R223

467-1D227-H03 CARBON RESISTOR RT14-1/4W-2.7K-J R302

467-1E415-H03 CARBON RESISTOR 1/2W-150K-J R343

467-2D251-F03 METAL RESISTOR 1/4W-5.1K-F R213

467-2D282-G03 METAL RESISTOR 1/4W-8.2K-G R311

467-2D418-H03 METAL RESISTOR 1/4W-180K-J R512

471-2B68K-003 PEAKING COIL SPT0305-R68K-5 L101

471-2022K-003 PEAKING COIL SPT0305-220K-5 L201

471-2022K-003 PEAKING COIL SPT0305-220K-5 L202

471-2027K-003 PEAKING COIL SPT0305-270K-5 L203

471-2027K-003 PEAKING COIL SPT0305-270K-5 L204

471-2068K-103 PEAKING COIL LGA0410-68uH-K L102

782-TS2730-010C MAIN PCB

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M01

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M02

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M03

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M04

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M05

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M06

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M09

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M10

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M11

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M12

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M15

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M16

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M17

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M18

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M19

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M20

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M21

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M22

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M23

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M24

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M25

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M26

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M27

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M28

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M29

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M30

Page 34

895-6020025-50 RIVET GB876-86-2X2.5-COPPER M31

895-6020025-50 RIVET GB876-86-2X2.5-COPPER V302(S)

895-6020025-50 RIVET GB876-86-2X2.5-COPPER T301

895-6025030-50 RIVET GB876-86-2.5X3 COPPER M07

895-6025030-50 RIVET GB876-86-2.5X3 COPPER M08

895-6025030-50 RIVET GB876-86-2.5X3 COPPER M13

895-6025030-50 RIVET GB876-86-2.5X3 COPPER M14

998 JUMPER WIRE J521

998 JUMPER WIRE R503

998 JUMPER WIRE J101

998 JUMPER WIRE J102

998 JUMPER WIRE J103

998 JUMPER WIRE J201

998 JUMPER WIRE J202

998 JUMPER WIRE J203

998 JUMPER WIRE J204

998 JUMPER WIRE J205

998 JUMPER WIRE J206

998 JUMPER WIRE J207

998 JUMPER WIRE J208

998 JUMPER WIRE J209

998 JUMPER WIRE J210

998 JUMPER WIRE J212

998 JUMPER WIRE J213

998 JUMPER WIRE J214

998 JUMPER WIRE J215

998 JUMPER WIRE J217

998 JUMPER WIRE J218

998 JUMPER WIRE J219

998 JUMPER WIRE J220

998 JUMPER WIRE J221

998 JUMPER WIRE J222

998 JUMPER WIRE J223

998 JUMPER WIRE J224

998 JUMPER WIRE J225

998 JUMPER WIRE J226

998 JUMPER WIRE J227

998 JUMPER WIRE J228

998 JUMPER WIRE J229

998 JUMPER WIRE J230

998 JUMPER WIRE J231

998 JUMPER WIRE J232

Page 35

998 JUMPER WIRE J233

998 JUMPER WIRE J301

998 JUMPER WIRE J302

998 JUMPER WIRE J303

998 JUMPER WIRE J304

998 JUMPER WIRE J305

998 JUMPER WIRE J306

998 JUMPER WIRE J307

998 JUMPER WIRE J308

998 JUMPER WIRE J309

998 JUMPER WIRE J310

998 JUMPER WIRE J501

998 JUMPER WIRE J502

998 JUMPER WIRE J503

998 JUMPER WIRE J505

998 JUMPER WIRE J506

998 JUMPER WIRE J508

998 JUMPER WIRE J509

998 JUMPER WIRE J510

998 JUMPER WIRE J511

998 JUMPER WIRE J512

998 JUMPER WIRE J513

998 JUMPER WIRE J514

998 JUMPER WIRE J515

998 JUMPER WIRE J516

998 JUMPER WIRE J517

998 JUMPER WIRE J518

998 JUMPER WIRE J519

998 JUMPER WIRE J601

998 JUMPER WIRE J602

998 JUMPER WIRE J603

998 JUMPER WIRE J604

998 JUMPER WIRE J605

998 JUMPER WIRE J701

998 JUMPER WIRE J702

998 JUMPER WIRE J703

998 JUMPER WIRE J704

998 JUMPER WIRE J705

998 JUMPER WIRE J706

998 JUMPER WIRE J708

998 JUMPER WIRE J709

998 JUMPER WIRE J710

Page 36

998 JUMPER WIRE J712

998 JUMPER WIRE J713

998 JUMPER WIRE J714

998 JUMPER WIRE J715

998 JUMPER WIRE J716

998 JUMPER WIRE J719

998 JUMPER WIRE J231

998 JUMPER WIRE J236

998 JUMPER WIRE J234

998 JUMPER WIRE J104

998 JUMPER WIRE J107

998 JUMPER WIRE J106

998 JUMPER WIRE J108

998 JUMPER WIRE J109

998 JUMPER WIRE R322

998 JUMPER WIRE J312

998 JUMPER WIRE R703

998 JUMPER WIRE R530

998 JUMPER WIRE J10

998 JUMPER WIRE J311

998 JUMPER WIRE J237

998 JUMPER WIRE J235

998 JUMPER WIRE J507

998 JUMPER WIRE J110

998 JUMPER WIRE R314

998 JUMPER WIRE VD704

667-TS2755-31 MTS BOARD ASS'Y

353-58320-50 SMD ICAN5832SA (D) NS01

782-Q2735-310B STEREO PCB

475-15451-00 CERAMIC FILTER LT4.5MH CS12

343-18150-104 TRANSISTOR 2SC1815-Y VS01

343-18150-104 TRANSISTOR 2SC1815-Y VS02

364-3E123-00 40-PINS CONNECTORS L40P XS01

459-2410R-00 CERAMIC CAPACITOR DD308-63F104Z50 CS04

459-2410R-00 CERAMIC CAPACITOR DD308-63F104Z50 CS06

459-2410R-00 CERAMIC CAPACITOR DD308-63F104Z50 CS10

459-2410R-00 CERAMIC CAPACITOR DD308-63F104Z50 CS21

462-B0322-H02 POLYESTER CAPACITOR CL21X-50V-0.022uF-J CS05

462-B0333-H02 POLYESTER CAPACITOR CL21X-50V-0.033uF CS07

462-B0422-H02 POLYESTER CAPACITOR CL21X-50V-0.22uF-J CS11

464-6D710-M0 ELECTROLYTIC CAPACITOR CD110-16V-100uF-M CS19

Page 37

464-6E547-M0 ELECTROLYTIC CAPACITOR CD110-25V-4.7uF-M CS14

464-60433-M0 ELECTROLYTIC CAPACITOR CD110-50V-0.33uF-M CS02

464-60433-M0 ELECTROLYTIC CAPACITOR CD110-50V-0.33uF-M CS09

464-60522-M0 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M CS08

464-60522-M0 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M CS15

464-60522-M0 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M CS16

464-60522-M0 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M CS18

464-60533-M0 ELECTROLYTIC CAPACITOR CD110-50V-3.3uF-M CS03

464-60610-M0 ELECTROLYTIC CAPACITOR CD110-50V-10uF-M CS01

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J RS06

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J RS07

467-1C115-H03 CARBON RESISTOR 1/6W-150Ω-J RS04

467-1C115-H03 CARBON RESISTOR 1/6W-150Ω-J RS09

467-1C168-H03 CARBON RESISTOR 1/6W-680Ω-J RS05

467-1C168-H03 CARBON RESISTOR 1/6W-680Ω-J RS10

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J RS03

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J RS08

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J RS01

467-1C418-H03 CARBON RESISTOR 1/6W-180K-J RS02

471-2068K-103 PEAKING COIL LGA0410-68uH-K LS01

998 JUMPER WIRE WS01

998 JUMPER WIRE CS17

998 JUMPER WIRE CS20

667-TS2916-29 SIDE AV BOARD ASS'Y

364-92216-00 AV JACK AV205-1 XC04

364-92219-00 AV JACK CKG-3-3 XC06

655-4A501-08 * (4-PINS ) LEAD WITH HOUSING XC03

782-R2935-2900 SIDE AV PCB

851-53012-11 SCREW SJ2825 ST3X12C-D.Zn

868-10089-00 CUSHION

870-20707-022 SIDE AV BRACKET ( MOLD BLACK SILK-SCREEN )

998 JUMPER WIRE RC06

998 JUMPER WIRE LC01

998 JUMPER WIRE LC02

Loading...

Loading...