Page 1

COLOR TELEVISION

TK2450

Page 2

CONTENTS

Safety instruction………………………………………………………………………1

General instruction……………………………… ……………………………………… .1

Alignment instruction……………………………………………………………………2

Alignment flow ..……………………………………………………………………..2

Alignment method…………………………………………………………………..3

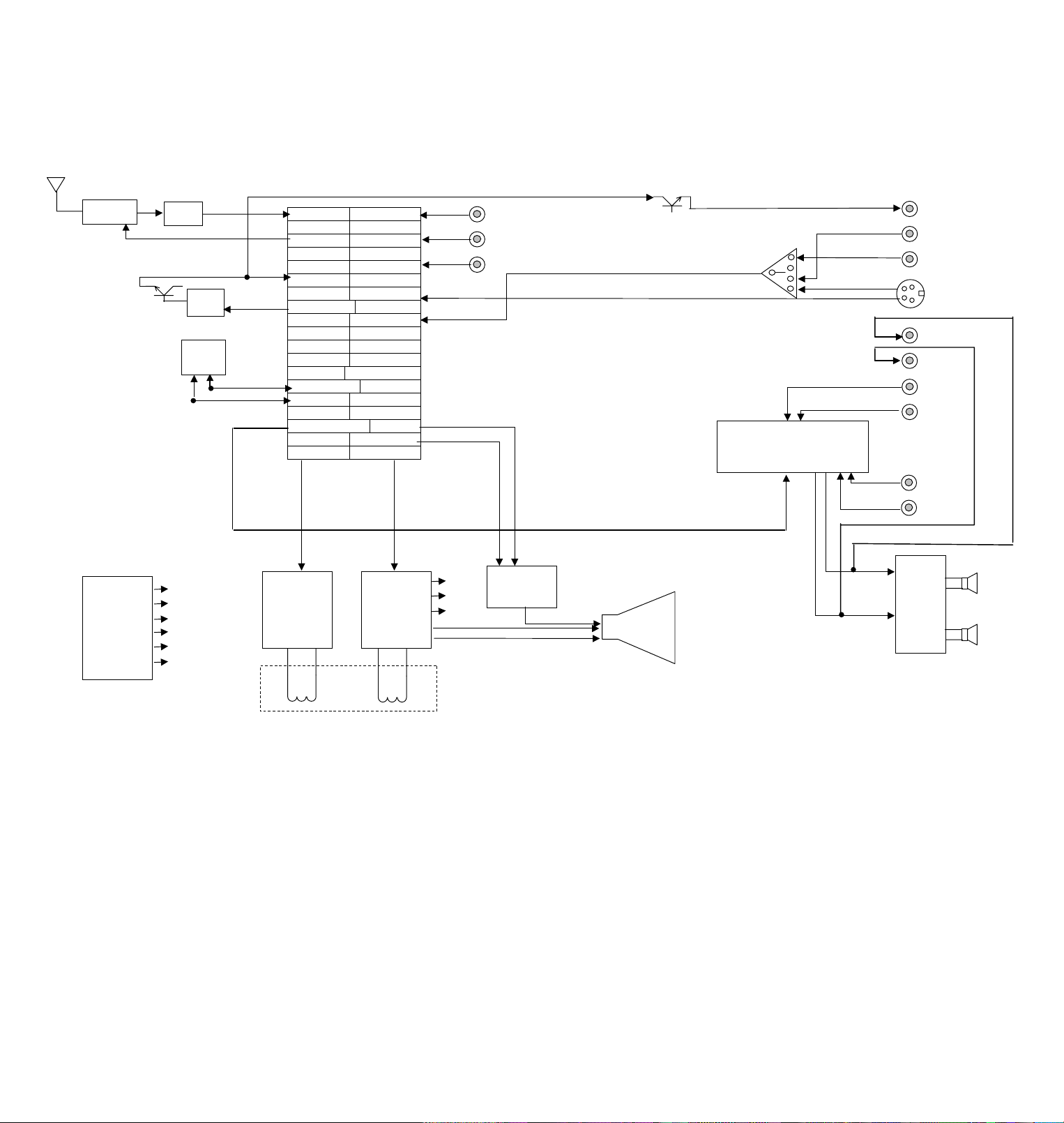

BLOCK DIAGRAM………………………………………………………………………... 8

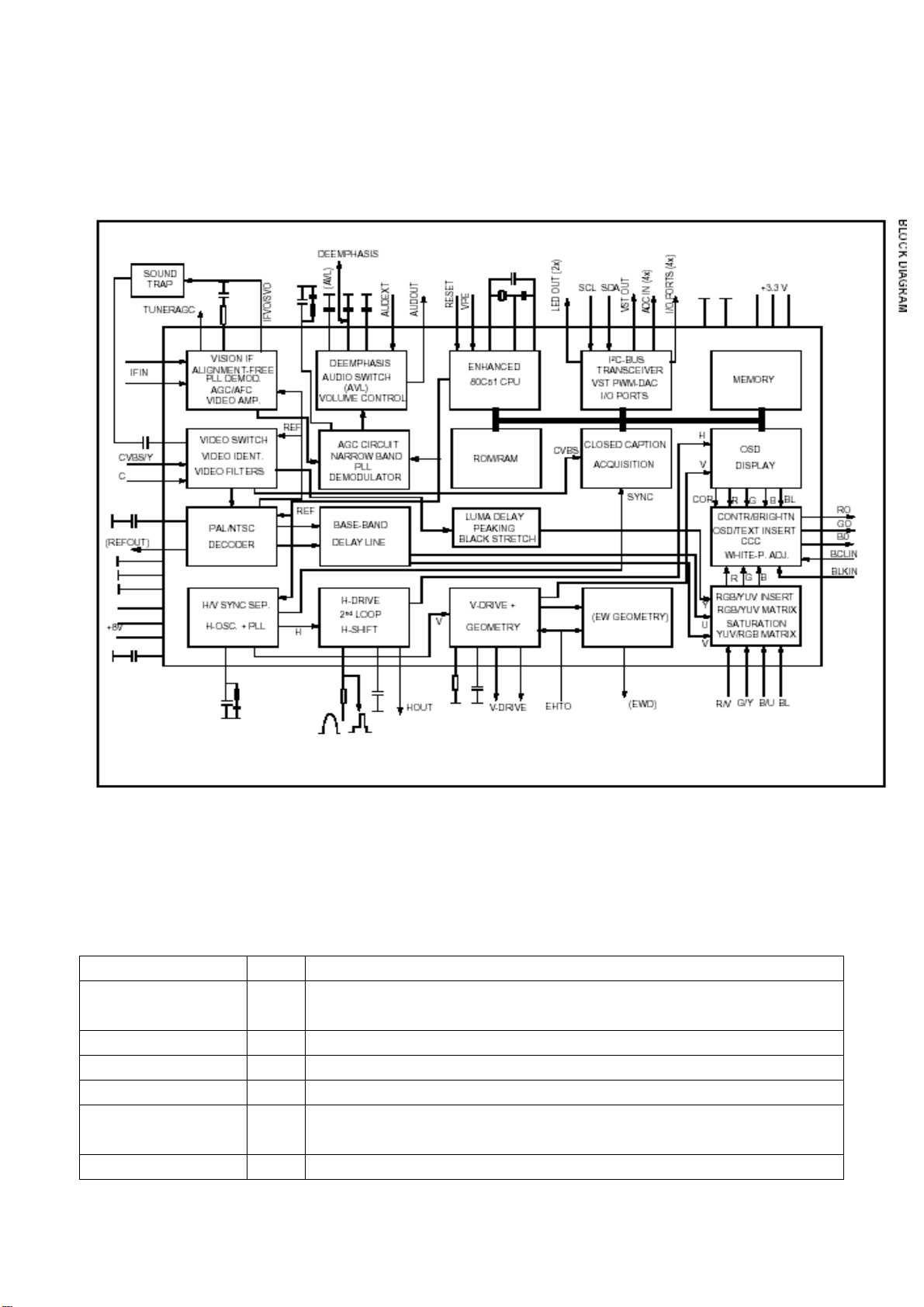

MAIN IC……………………………………………………………………………….. 9

Parts list………………………………………………………………................13

Exploded view …………………….………………………………………………31

Schematic diagram…………………………………………………………………. 33

Page 3

Note: This service manual is only for professional service personnel’s reference. Before

servicing the unit, please read the following items carefully.

1 safety instruction

1.1 X-RAY radiation precaution

1.1.1 Excessive voltage will cause harmful X-ray. To avoid this radiation hazard, the high voltage should

fall within the limitation. The appliance works at AC 120V, 60Hz. The high voltage of zero beam current

should be within 29.0kV on condition that the main power (B+) voltage is AC135V. And it should not

exceed 30kV in any condition.

* Keep the main power voltage at 135V when checking the high voltage.

1.1.2 The primary source of X-RAY RADIATION is the CRT. The CRT of this TV set have gotten the

approval of safety authenticat ion i nspect ion. The rep lacem ent CR T should be exactly the same type and

specification CRT which has gotten a similar safety approval, and check the high voltage according to

the HIGH VOLTAGE CHECK procedure.

1.2 safety precaution

a. Since the power supply circuit of this receiver is directly connected to the AC power line, an isolation

transformer is necessary during dynamic service to avoid possible shock hazard.

b. Always discharge the graphite layer conductor when moving the CRT.

c. Disconnect the power cord before replacing parts.

d. When replacing high-power resistor, keep the resistor 10 mm away from the circuit board.

1.3 Component safety precaution

Many electrical and mechanical parts in the chassis have special safety-related characteristics. These

characteristics are often passed unnoticed by a visual inspection. Replacement parts which have these

special safety characteristics are identified in this manual and its supplement electrical components

having such features are shaded or marked by on the schematic diagram and the parts list. Before

replacing any of these components, read the parts list in this m anual carefully. The use of substitute

replacement parts which do not have the same characteristic as specified in the parts list may create

shock, fire, X-RAY RADIA TI O N or other hazards.

2.General instruction

2.1 Copy the standard model dat a t o let EEPROM of the chassis have those d ata bef ore placing it on the

unit, do “factory adjustment” if necessary. If use a blank EEPROM directly, you should preset IIC data

and then do other common adjustment. Refer to TABLE1 to preset EEPROM.

2.2 the adjustment should be done under following circumstances without additional instruction

a) Alternating current 120V/60Hz

b) Preheat at least 30 min

2.3The unit has auto degaussi ng circuit , the auto de gaussing proce ss can be finishe d within 1s w hen the

main power. only when turn on the unit at least 30min after last time turn off TV does the auto

degaussing circuit work.

2.4 If the CRT with magnetism affects color purity and convergence, when t he aut o degaussing

eraser . if the color purity and convergence are st ill not very good, then corresponding adjustment

should be done. Refer to picture tube adjustment method for adjustment.

Alignment instruction

3

1

Page 4

3.1 Debugging item

N

a)adjust mode instruction

b)B+ voltage adjustment

c)RFAG C voltage adjustment

d)focus adjustment

e)Screen-grid voltage white balance, sub brightness adjust ment

f)filed scan center , line , amplitude adjustment

g)H-scan center adjustment

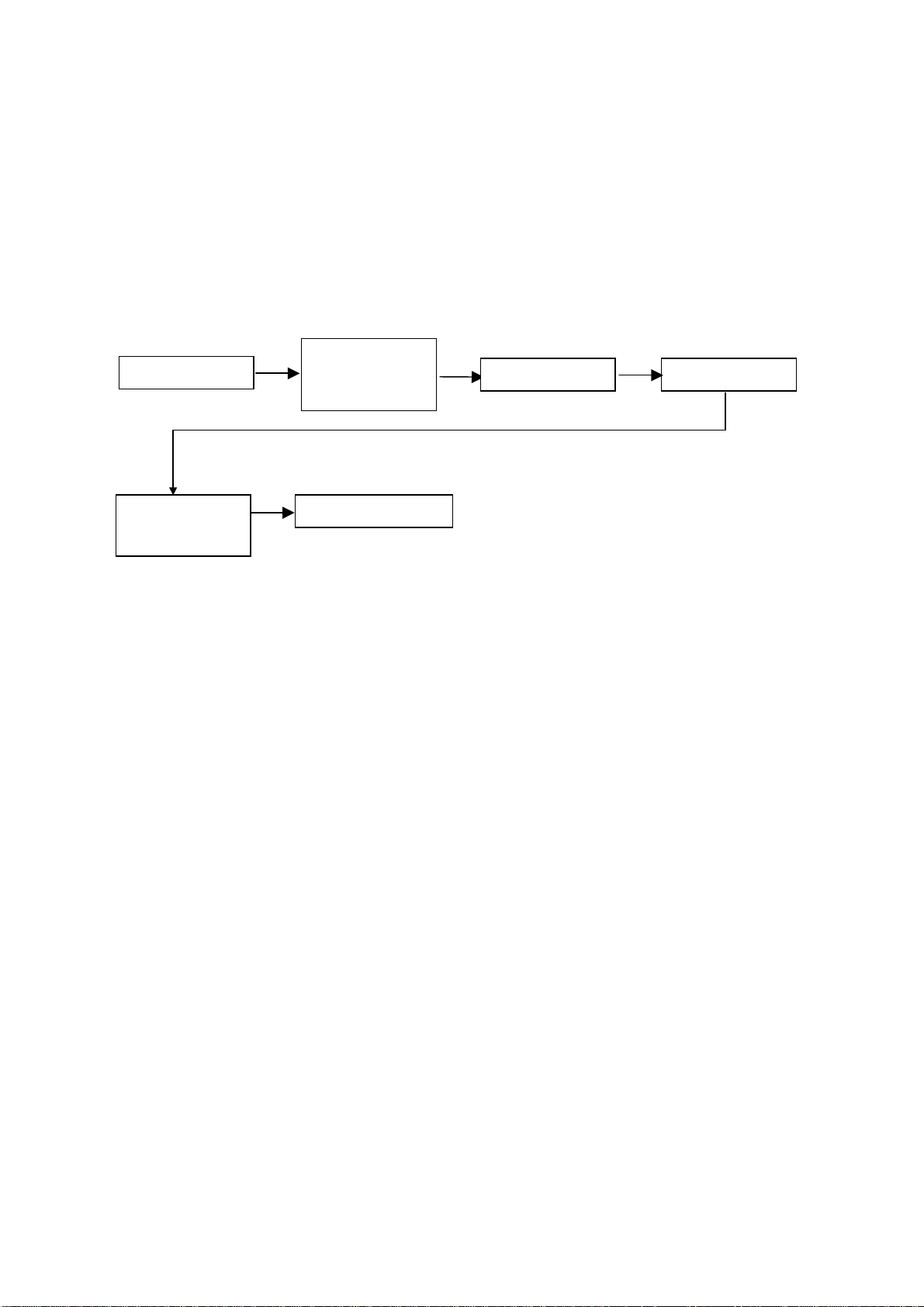

3.2 Alignment flow

+B adjustment

ormal

temperature aging

Focus adjustment

AGC adjustment

White balance

adjustment

Picture adjustment

Fig-1 alignment flow

3.3 Enter/exit factory adjustment method

Use remote control, press “MENU” button, then press 6483,”M”will appear on screen to show that you

have entered the factory adjustment method, press “STANDBY” to exit it.

3.4 Select adjustment item and adjust data

After entering factory adjustme nt mode, press 1-4 n umber button s to select menu1- menu4; To enter into

MENU0~MENU5, press “CHILD LOCK” button and then the number button (5~0) to enter into relative

menus. Press “P+” and “P-” to select and “V+” and “V-”to adjust.

4 Alignment method

4.1 B+ voltage adjustment

a) connect B+ point with a digital voltmeter to measure the negative pole of VD524

b) receive PHILIPS test pattern signal and set the picture to standard.

c) Adjust VR501 to let the value of B+ voltage be 135 V ±0.5 V (yongxin super pure flat)

4.2 AGC adjustment

a) receive VHF-H band,60 dB RF signal.

b) Select factory menu2 of “AGC”.

c) Press “V+”,”V-”to let voltage value of tuner pin AGC be 3.8 V ± 0.1 V(DC).(if the selected tuner

is changed, then the voltage of AGC should be measured again: receive VHF-H band and 60

dB RF signal, adjust AGC-TOP to let the picture just without noisy, then the voltage of tuner

AGC is the required value for adjustment.)

d) exit factory menu

4.3 Normal temperature aging

a) do not receive signals.

2

Page 5

b) under ”M” condition, set the accelerator to an appropriate point for aging.

4.4 Accelerator adjustment

a) do not receive signals;

b) select “SC” of factory menu3 to let the field scanning stop working.

c) adjust acceleration potentiometer to let bright lines just appears on screen.

d) exit SC menu.

4.5 High voltage check

Note: the main power voltage (B+=135 V)can affect the high voltage directly, so be sure to let the B+

power voltage accurate. Under any state, the high voltage should not exceed 30 kV.

a) connect an accurate high voltage meter between the second anode cap of picture tube and

ground.

b) turn on TV and receive testing card signal.

c) set picture to standard, the high voltage should be 27 kV± 1 kV.

d) the high voltage should not exceed 30KV with minimum brightness and contrast.

4.6 Focus adjustment

a) receive PHILIPS signal

b) adjust focus electrode potentiometer on FBT to optimize B area focus of screen.

4.7 White balance adjustment (color temperature 12000°K± 8MPCD,X=0.270± 0.008,Y=0.283± 0.008)

a) receive full white signal

b) select factory menu3

c) on the basis of blue, adjustment RD,GD of M3, let to white balance coincide with standard.

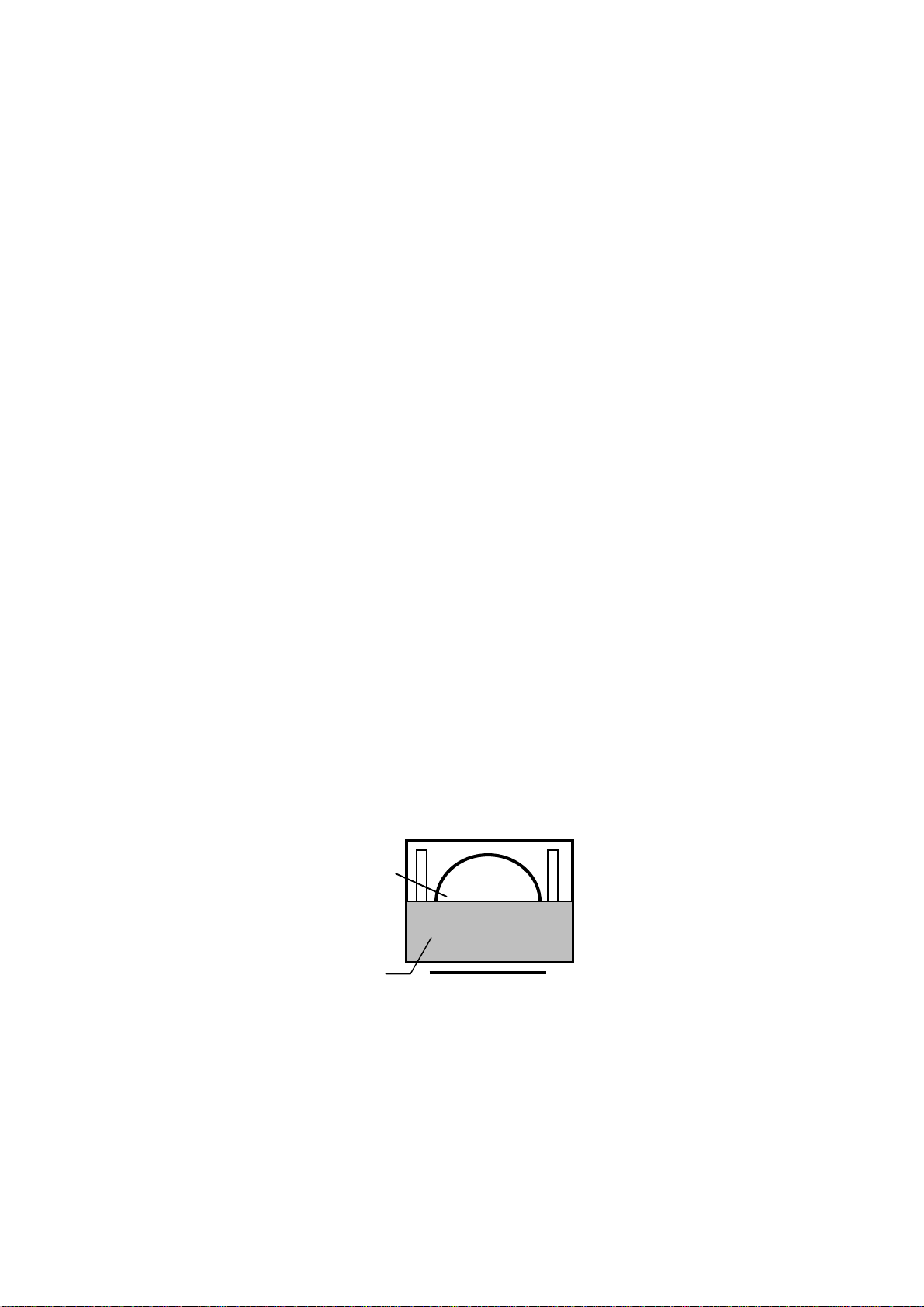

4.8 Filed scanning adjustment (fig-2)

a) receive PAL of PHILIPS test pattern signal.

b) select factory menu1

c) adjust V- SLO PE menu to let the horizontal center line of test pattern above blanking.

d) select V- SHI FT menu and adjust to let the vertical center of picture coincide with

vertical center of picture tube.

e) Select V-SIZE menu and adjust to let the vert ical reproduct ion ratio of picture acceptable.

f) Adjust V.SC to optimise the vertical S correction of picture.

g) Receive NTSC PHILIPS test pattern and readjust the above items.

4.9 Horizontal scanning adjustment (Fig-3)

a) Receive PAL PHILIPS signal

b) Select factory menu1

c) Select H.SHIFT menu and adjust to let the scanning horizontal center coincide with mechanical

center of picture tube

d) Exit M3 menu

e) Adjust VR433 to let horizontal reproduction ration of picture acceptable

f) Adjust VR432 to minimize left-right edge pincushion distortion of picture

Horizontal line

Under part banking

Fig-2 field scan adjustment

3

Page 6

g) Adjust VR431 to minimize trapezoidal distortion

h) Exit factory menu

a

4.10 Sub-brightness adjustment

a) Receive PAL-D/K PHILIPS signal

b) Select “SB” of factory menu3

c) Adjust “SB” to let things between the sixth and seventh grey scale clear

4.11 OSD adjustment

a) Receive PAL-D/K PHILIPS signal

b) Select OSD H and OSD V of factory menu4. Adjust OSD H and OSD V to let OSD at a specified

place.

c) Exit factory menu

4.12 Degaussing

a) The unit has and auto degauss ing circuit, the degaussing circuit works several seconds after turning

on TV

b) If you want to move TV or change the direction, turn off TV and ten minutes later the degaussing

circuit will work

c) For better degaussing effect, you can use magnetic eraser

d) Move the magnetic eraser clockwise before your TV, when it is 2m away from your TV, turn off the

magnetic eraser. If the effect is still not very good, you can adjust “color pur it y” and “convergence”

4.13 Color purity correction

a) Turn on your TV

b) At least 15 minutes later, use anti-magnetized coil for degaussing

c) Obtain maximum brightness and contrast

d) Select factory menu3 and adjust to let R and B be zero, then let only green raster appear on the

screen at the moment

e) Loosen screws of deflection yoke frame to let vertical green belt appear on screen only

f) Move the rubber wedge

g) Rotate along neck of picture tube and slide color-purity magnets until the green belt at the middle of

screen and is vertical at the same time

h) Slowly move the deflectio n y oke backw ard of forwar d until the w h ole gre en rast er appears on scree n,

tighten the screws of the deflection yoke

i) Check the color purity of red raster and blue raster

j) Adjust white balance again to obtain white raster

4.14 Convergence correction

4.14.1 Central convergence correction

a) Turn on your TV

Fig-3 line scan adjustment

4

Page 7

b) At least 15 minutes later, receive square test pattern signal

c) Adjust brightness and contrast to get the best picture

d) Adjust the angle of two tetrode magnetic rings to let the red vertical line coincide with the blue

vertical line at middle of screen

e) Keep the angle unchanged, move the two tetrode magnetic rings at the same time to let t he red and

blue horizontal lines coincide at middle of screen

f) Adjust two hexode magnetic rings to let the green line coincide with the mixed line of red and blue.

Adjust the angle between them will affect the vertical line, move them together will affect the

horizontal line.

g) Repeat d), e), f) and observe the movement of red, green and blue.

4.14.2 Ambient convergence correction

a) Turn on your TV

b) At least 15 minutes later, loosen the screws of the deflection yoke

c) Fixate the rubber wedge temporarily under the deflection yoke

d) Move the deflection yoke upward or downward to get best convergence, push the rubber wedge into

space between picture tube and deflection yoke to fixate the deflection yoke temporarily

e) Place the rubber wedge whose overlay paper has been removed at t he bot tom space

f) Move the deflection yoke left and right to get best convergence

g) Keep the condition unchanged, place another rubber wedge whose overlay paper has been

removed also at the upper space at the same time

h) Remove the interim rubber wedge, adhere it to picture tube and deflection yoke

i) After placing three rubber wedges, check all the convergence again

j) Stick three transparent viscous belts to the rubber w edge

2

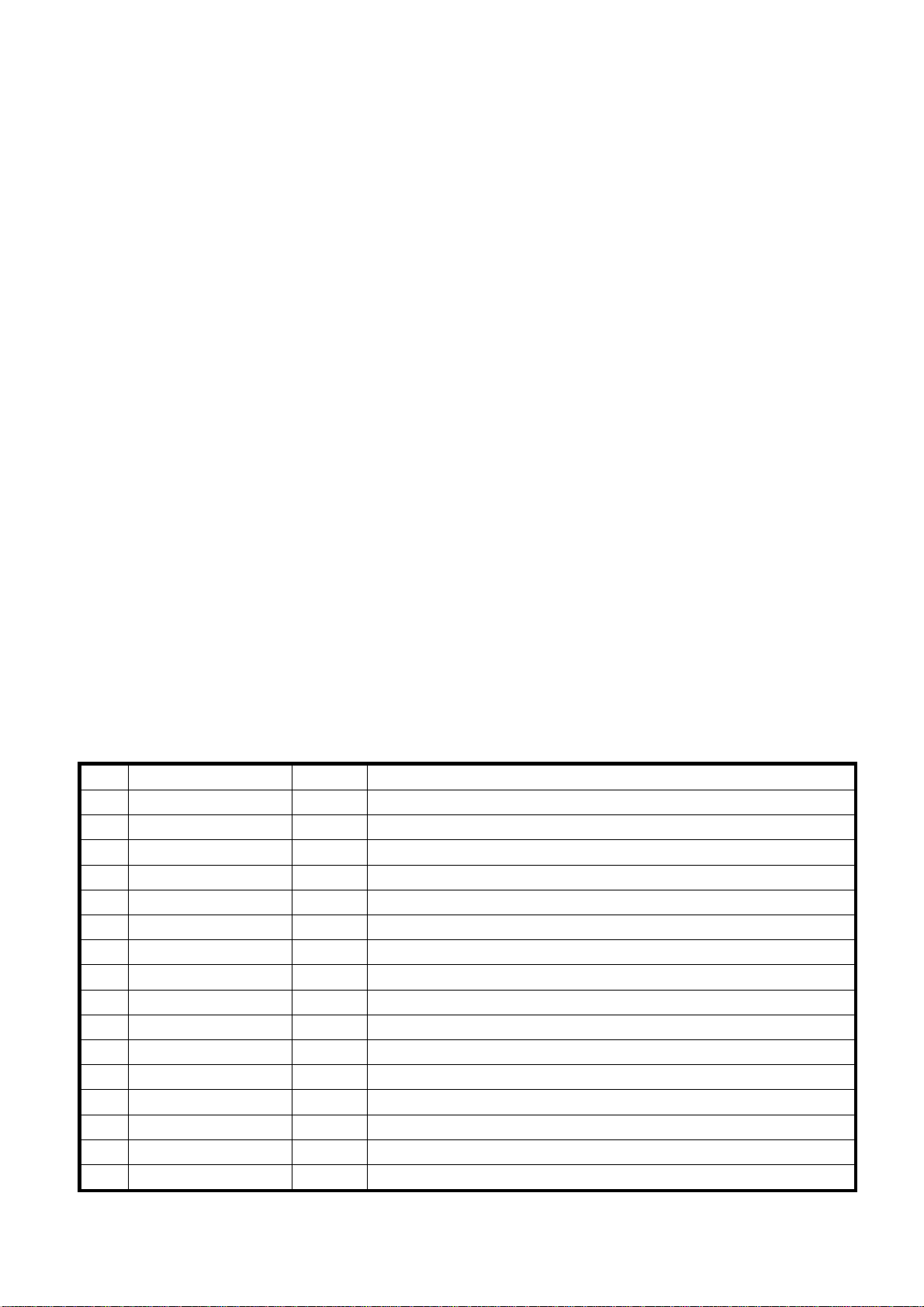

Chart 1 I

2

C standard UOC for export bus control adjustment i tem default setting

I

C TDA (NOM)8377-B-6NA E2PROM pre-set data

MI Items Variable Preset

M0 SUBCON 56(sub-contrast)

SUBCOL 56(sub-chroma)

SUBSHP 48(sub-acutance)

SUBTINT 31(sub-hue)

M1 V.SLOPE 34(field center adjustment)

V.SHIFT 27(field point adjustment)

V.SIZE 36(field amplitude adjustment)

V.SC 32(field line )

HSHIFT 32(line point adjustment)

PROGRAMA.NO 2(channel)

M2 AGCTAKEOVER 24(AGC adjustment)

SHIPPING 0(leav e fact ory set)

M3 BT 75(adjust white balance of brightness)

5

Page 8

CT 75(adjust white balance of brightness contrast)

SC OFF

RB 32(red cut off level adjustment)

GB 32(green cut off level adjustment)

RD 32(red cut off level adjustment)

GD 32(green cut off level adjustment)

BD 32(blue cut off level adjustment)

SB 40(sub brightness adjustment)

M4 OSD.V.POSITION 10(OSD position)

OSD.H.POSITION 5(OSD H-position)

BTSC-MODE MONO(STEORO,SAP )

BTSC-ST 13

BTSC-SP 12

BTSC-L1 1

BTSC-A1 15

BTSC-A2 0

BTSC-TC 0

BTSC-STS

BTSC-ADJ

MI Items Variable Preset

M5 MODE STANADARD(standard, soft, floweriness)

BRIGHT 75

COLOR 50

SCBRIGHT 20

YDELAYTV 12

YDELAYAV 12

M6 OSO 1(field over-scan switch)

AGCSPEED 1(AGC of speed)

FFI 0(IF PLL SPEED)

FMWS 1(frequency range of sound OFF=225KHZ,ON=450KHZ)

RP0 0(pre-shock and over-shock scale)

NTSCMATRIX USA

VOLPIN 0(1:push-pull output; 0: OC gate output.)

SOFT CLIP 3(white level limit)

PEAK WHITE 15(peak white limit)

CORING 0(coring noise reduction)

M7 AV2 1

SVHS 1

YUV 1

CONTRAST

0

75

6

Page 9

VOLADJPOING 1(volume value have:1,25,50,75)

VOLVALUE 20(volume curve value:20,60,75,90)

M8 CATHOOELEVEL 7(cathode level)

UOCVOLUME 0(0:PWM terminal control; 1:UOC sound amplitude control of

inside)

FMATT 45(UOC sound output of amplitude) BTSC : 38

COMBFILTRE 0(N comb filter)

HEADPHONE 0(earphone function selection)

VM OPTION 0(VM function selection)

FRANCE 1 French

SPANISH 1 Spaish

POTUGUES 1 Portuguese

M9 NOM8377-B-6NA

STARTON 2(turn on)

STARTTIME 8(turn on time)

IF OFFSET 32(IF compensate)

TUNER OPTION 0(BXATB01 1F---X/ BXATB108F---K) 1 (BXATB017F---K) 2(XXX)

7

Page 10

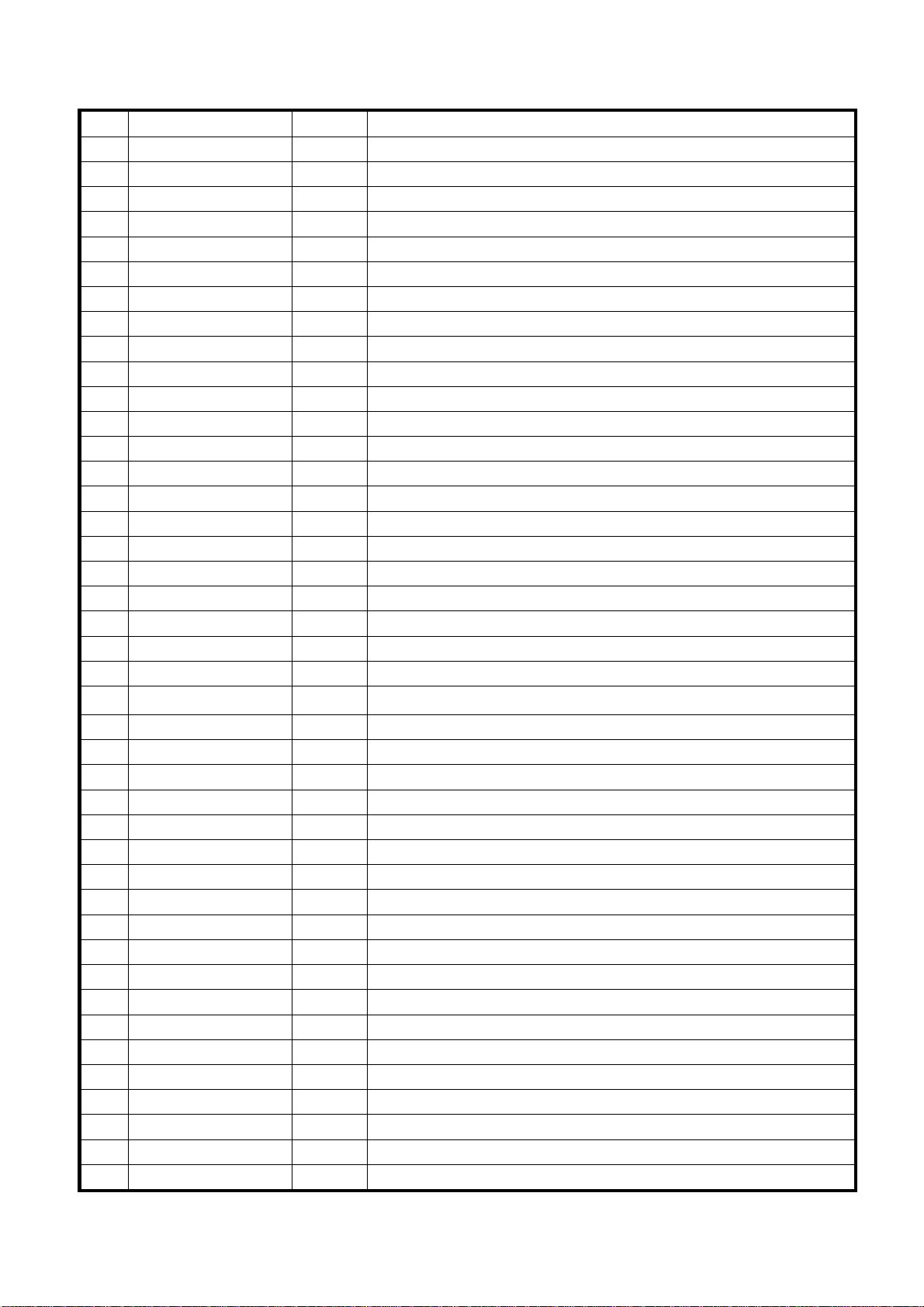

Block diagram

rCb

L

DY

S

F

S

TUNER

POWER

UNIT

SAW

135V

24V

16V

8V

5V

3.3V

S

TRAP

24C08

video

bus

TDA8377

IF IN Y IN

RF AGC V IN

U IN

CVBSINT

CHROMA

IFVO OUT

CVBS/Y IN

SDA

SCL

AUDIO OUT IK

RGB OUT

V OUT H OUT

V IN

TDA8177

V OUT

H IN

H OUT

H OUT

video

200V

+15V

-15V

Y

C

CRT PCB

CREEN

OCU

audio

video

CRT

video

4052

audio

N801

video

audio

Y

C

BU4052

V1i

ARo

ALo

ARi2

ARi1

A

ALi1

AN7522

Vi1

OUT1-

OUT1+

Vi2

OUT2-

OUT2+

Vo

V2i

S-VHS

i2

8

Page 11

MAIN IC 8377:

ICs functional description

UOC TDA8377

SYMBOL PIN DESCRIPTION

STAND BY output. 1 In STAND BY mode, high level (Power OFF).

For Power ON this pin will be reduced to low.

SCL 2 I2C-bus clock line

SDA 3 I2C-bus data line

TUNING 4 tuning V o ltage (Vt) PWM output

P3.0/NTSC SW 5 Port 3.0 or NTSC output/SCART SW input, Forced NTSC selection,

Low-level output, otherwise High output.

KEY 6 Control keys input *3

9

Page 12

VOL 7 Sound Volume control PWM output

MUTE 8 Sound mute output

VSSC/P 9 Digit ground for µ-controller core and periphery

BAND1 10 Tuner Band selection output

BAND2 11 Tuner Band selection output

VSSA 12 Analog ground of teletext decoder and digital ground of TV-processor

SECPLL 13 SECAM PLL decoupling

VP2 14 2nd supply voltage TV-processor(+8V)

DECDIG 15 decoupling digital supply of TV-processor

PH2LF 16 Phase-2 filter

PH1LF 17 Phase-1 filter

GND3 18 Ground 3 for TV-processor

DECBG 19 Band gap decoupling

AVL/EWD 20 Automatic volume leveling /EAST - WEST drive output

VDRB 21 Vertical drive B output

VDRA 22 Vertical drive A output

IFIN1 23 IF input 1

IFIN2 24 IF input 2

IREF 25 Reference current input

VSC 26 Vertical sawtooth capacitor

TUNER AGC 27 Tuner AGC output

AUDEEM/SIFIN1 *1 28 Audio deemphasis or SIF input

DECSDEM/SIFIN2 29 decoupling sound demodulator or SIF input 2

GND2 30 ground 2 for TV processor

SNDPLL/SIFAGC *1 31 narrow band PLL filter or AGC sound IF

AVL/SNDIF/REF0/

AMOUT *1

HOUT 33 horizontal output

FBISO 34 flyback input/sandcastle output

AUDEXT/QSSO/

AMOUT *1

EHTO 36 EHT/overvoltage protection input

PLL IF 37 IF-PLL loop filter

IFVO/SVO 38 IF video output / selected CVBS output

VP1 39 supply voltage TV processor

CVBS INT 40 internal CVBS input

GND1 41 ground for TV processor

CVBS/Y 42 CVBS/Y input

CHROMA 43 C input

AUDOUT/AMOUT

*1

INSSW2 45 2nd RGB / YUV insertion input

32 Automatic V olume L evellin g / sound I F input / subc arrier ref erence outp ut

/ audio

deemphasis

35 external audio output / QSS intercarrier out

44 audio output /AM audio output (volume controlled)

10

Page 13

R2/VIN 46 2nd R input / V (R-Y) input / PR input

G2/YIN 47 2nd G input / Y input

B2/UIN 48 2nd B input / U (B-Y) input / PB input

BCLIN 49 beam current limiter input

BLKIN 50 black current input / V-guard input

RO 51 Red output

GO 52 Green output

BO 53 Blue output

VDDA 54 analog supply of Closed Caption decoder and digital supply of

TV-processor (3.3 V)

VPE 55 OTP Programming Voltage

VDDC 56 digital supply to core ( 3.3 V)

OSCGND 57 oscillator ground supply

XTALIN 58 cryst a l oscillat or input

XTALOUT 59 crystal oscillator out put

RESET 60 reset

VDDP 61 digital supply to periphery (+3.3 V)

P1.0/INT1 62 TV/AV (AV1) / AV2 /S-VHS mode Output.

P1.1/T0 63 TV/AV (AV1) / AV2 /S-VHS mode Output.

P1.2/INT0 64 Remote control signal input.

AN7522 Function : audio output

Symbol PIN Function Symbol PIN Function

Vcc 1 Power supply GND 7 ground

Out 1 (+) 2 Ch 1 output (+) In 2 8 Ch 2 input

GND(out 1) 3 Ch 1Ground VOL 9 Volume Control

Out 1 (-) 4 Ch 1 output (-) Out 2 (-) 10 Ch 2 output (-)

Standby 5 Mute input GND(out 2) 11 Ch 2 Ground

In 1 6 Ch 1 input Out 2 (+) 12 Ch 2 output (+)

TDA8177 Function : vertical output

Symbol PIN Function Symbol PIN Function

INV IN 1 Input V OUT 5 Vertical output

VCC1 2 Power VCC2 6 Out put pow er supply

PUMP UP 3 Pump up power NON INV IN 7 Negative feedback

GND 4 Ground

11

Page 14

Test point Waveforms

2.6Vpp

H

TDA8377

95Vpp

H

1Vpp

TDA8377

V

H H

1.2Vpp

H

TDA8377

95Vpp

H H

CRT KG CRT KR

0.8Vpp

V

TDA8377

300Vpp 22Vpp

T511 PIN7

3.8Vpp

H

TDA8377

95Vpp

CRT KB

TDA8377

2.5Vpp

H H

TDA8377

0.9Vpp

H

TDA8377

2.7Vpp

H

V451 B

2.5Vpp

TDA8377 PIN51

5Vpp

H

TDA8377 PIN34

1000Vpp

H

V451 C

IC voltages

TDA8377

PIN 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

V 2.8 3.8 3.6 3.3 3.5 3.5 0.1 0.1 0 5.4 0.1 0 2.3 8 5 3

PIN 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

V 4 0 4 0.9 0.7 0.8 1.9 1.9 3.9 3.8 1.6 3.2 3.4 0 2.4 0.1

PIN 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

V 0.6 0.5 3.7 1.7 2.4 3.1 8 3.8 0 3.4 1.5 3.6 2.3 2.6 2.6 2.6

PIN 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

V 2.3 7.2 2.7 2.7 2.7 3.5 0 3.5 0.1 1.7 1.8 0 3.5 0.1 0.1 5

TDA8177

PIN 1 2 3 4 5 6 7

V 0.7 15 -12 -15 0.3 15.9 -0.07

AN 7522

PIN 1 2 3 4 5 6 7 8 9 10 11 12

V 12 7 0 7 3.3 1.4 0 1.4 0 7 0 7

12

Page 15

PART LIST

PART# DESCRIPTION LOCA.NO.

100-TK24500-11 TK2450

100-TK24500-01 TK2450

838-10012-00 BRAIDED WIARE SPRING

887-20171-00 PALSTIC BAG 70-500-0.06

615-10223-00 CRT HOLDER ASS'Y

648-30001-00 COMPOSE NUTS SJ2843-87M6

881-60085 BLANK WARNING LABEL

700-60151-00 LED LED COLUMN

700-60152-00 LED LED COLUMN

742-30005-09 LINE TIE

742-30006-09 GRADING TIE

742-30032-00 TIE

742-30038-00 TIE

808-70239-00 EVA GLUE 150X50X1

851-24012-14 SCREW SJ2824 ST4X12C-Y

851-24012-14 SCREW SJ2824 ST4X12C-Y

851-24020-11 SCREW SJ2824 ST4X20C-D.Zn

851-24020-11 SCREW SJ2824 ST4X20C-D.Zn

851-24020-14 SCREW SJ2824 ST4X20C-Y

851-24020-14 SCREW SJ2824 ST4X20C-Y

851-53010-11 SCREW SJ2825 ST3X10C-D.Zn

851-53010-11 SCREW SJ2825 ST3X10C-D.Zn

851-53010-11 SCREW SJ2825 ST3X10C-D.Zn

851-53010-11 SCREW SJ2825 ST3X10C-D.Zn

851-53010-11 SCREW SJ2825 ST3X10C-D.Zn

851-53010-11 SCREW SJ2825 ST3X10C-D.Zn

855-A0029-00 SCREW ST4X14

855-A0029-00 SCREW ST4X14

742-30029-00 POWER CORD CLASPER

868-10107-00 CUSHION

868-2E557-00 FIXER

868-2E557-00 FIXER

868-2F557-00 FIXER

868-2H558-00 FIXER (HIPS)

868-2H558-00 FIXER (HIPS)

868-20007-00 SLEEVE

868-20007-00 SLEEVE

868-20142-00 RUBBER WASHER(δ1.5)

868-20142-00 RUBBER WASHER(δ1.5)

868-20175-00 SUPPORT CUSHION

868-20175-00 SUPPORT CUSHION

887-20044-01 POWER CORD COVER

335-2512D-00U CRT 64SX505Y22-DC02 !

611-D50X2J0H1 FRONT CABINET ASS'Y (HIPS V0 SILVERY WHITE 03

886-31207-00

780-10966J040A

863-80801-00

863-80802-00

887-21097-P0 PE/PEARL COTTONPALSTIC BAG 1200X1050

CARTON BOX ( BLANK , small )

BACK CABINET (HIPS V0 MOLD GREY )

POLY FOAM (TOP )( small )

POLY FOAM (BOTTOM )( small )

13

Page 16

123-30001-04 TWIST WIRE

770-40151-40 IMITATEUL1672 22# 400mm BLACK

887-21135-00 CLASPER PALSTIC BAG 230X330X0.1

880-10633-A1 FRONT LOGO (PRIMA SILVERY GREY 10C

880-10205-790A BACK PLATE (TK2450,PRIMA)

881-63016-00A

881-63899-03

881-61341-00 CUL LABEL

881-63899-01

881-63899-02

886-31207-34A CARTON BOX (TK2450,PRIMA)

881-TK24507-00 OPERATION CARD

881-80671-00

604-TK24507-00

488-10007-01

615-20416-00 SPEAK ASS'Y

384-40908-B0 SPEAKER ST613-04

655-41201-322 (4-PINS) LEAD WITH HOUSING

851-53008-31 SCREW SJ2825 ST3X8FT D.Zn

857-10002-09 COTTON FLANNEL

868-20217-00 WASHER

870-20700-00A SPEAK BRACKET

POWER SYMBOL LABEL (T2751)

LABEL (PRIMA )

LABEL (PRIMA )

LABEL (PRIMA )

SERVICE CARD (20-24 CRT)

OWNER'S MANUAL(PRIMA加MTS)

BATTERY (5# NO CHINESE , IRON CASE )

667-TKD50-01A MAIN PCB ASS'Y

667-TKD50-01A\

467-8E522-H0U SOLID RESISTOR 1/2W-2.2MΩ-JL ! R501

535-TK2550-00W OUTSOURCING ASS'Y

535-TK2953-00W OUTSOURCING ASS'Y

BT-0329B---CH REMOTE CONTROL UNIT ZZ010

BXATB017F---K TUNER(ET-5T5E-AF108) A101

CED101M1ACBFP ELECTROLYTIC CAPACITOR 25V 100u C471,C471A

CEF471M1ACHNP ELECTROLYTIC CAPACITOR 50V 470u C2001

CKF221K1BA-FN CERAMIC CAPACITOR 50V 220P C321

CKMX471K301ND CERAMIC CAPACITOR AC 400V 470P C598,C598B

CMM334J8-H-NL POLYESTER CAPACITOR 400V 0.33u C467

CMNX224M801NP POLYESTER CAPACITOR AC 275V 0.22u C502

CNM393J7-H-NE POLYESTER CAPACITOR CBB12 400V 0.039u C457

DH24R5M001-NC THERMISTOR PTC 4.5ohm(3 END) PS501

DN15R0M001-NH NTC 5ohm R502

DRRGP10D---TD DIODE RGP10D VD2002

GABV2001----A 2S SOCKET(MIDDLE) XS2002

GACV2001----A 2S SOCKET( small XH) KTa XS2001

GBAVL007----A CRT SOCKET(THICK GZS10-2-108 XS901

HAA0004-----G SMIT-SS-112DM(27ohm) CN2001

JS2451-B002-A 2P LINE(450mm) XS2003

JS4501-B251-A DY LINE(500mm) KDY

JW2301-E001-P 2P LINE(300mm XH-D2) XS201

LBB5R6K----TC 5.6uH-K L351

LEA001-5---NJ M-COIL L505

LG-003-----NL LINE FILTER(4MH) L502

MAIN PCB ASS'Y (MANUAL INSERTION )

Page 17

LG-040-----NL LINE FILTER L501

LM-068-----NG DEGAUS COIL(110V 9ohm)25

MB1X0234---BF RADIATOR H-V451

MG1X0013---B6 8-PINSSOCKET PIN XS3101

NOM8377-B-9NA OM8377 PS/N3 N301

PX20030A---8S MAIN+CRT PCB zz060

PYF0001----2S RELAY CIRCUIT BOARD ZZ63

Q2PA1015-GNF- TRANSISTOR 2PA1015G V2001

RSF151J7ACDND METAL RESISTOR 2W 150 R545

RGDX126K-03NA SOLID RESISTOR 1/2W 12M(PMSR34015126) R519

RSF3R9J7ACDND METAL RESISTOR 2W 3.9 R480

TF-0116----0U F.B.T T451

TM-0112U---0L CON.TRANS(BCK-180-34B UL T501

XFS031-----NB SAWF M1967 Z301

CAF223J1-H-FC POLYESTER CAPACITOR 50V 0.022u C05

DZHZ5C1----TQ ZENER TUBE HZ5C1 VD01

PE80002----1S BTSC PCB

Q2PC1815-GNF- TRANSISTOR 2PC1815 G V01,V02

NAN5832SA--N- AN5832SA N01

569-18101-00U FUSE 51S 5A/125V !

667-TKE53-01\

MAIN PCB ASS'Y (MANUAL INSERTION )

364-32101-00 2-PINS CONNECTORS TJC3-02A XS702

364-33101-00 3-PINS CONNECTORS TJC3-03A U701

364-36101-00 6-PINS CONNECTORS TJC3-06A XS895

459-2156K-00 CERAMIC CAPACITOR CT1-06-2B4-63V-561K C381

459-2310R-00 CERAMIC CAPACITOR CT1-08-2F4-63V-103Z C472

464-60510-M0 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C827

464-60522-M0 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M C339

464-60547-M0 ELECTROLYTIC CAPACITOR CD110-50V-4.7uF-M C340

464-62610-M0 ELECTROLYTIC CAPACITOR CD288-160V-10uF-M C458

467-1DA82-H0 CARBON RESISTOR RT14-1/4W-8.2Ω-J R513

467-1E433-H0 CARBON RESISTOR 1/2W-330K-J R942

467-2D218-G0 METAL RESISTOR 1/4W-1.8K-G R403

467-2D218-G0 METAL RESISTOR 1/4W-1.8K-G R405

535-TK2953-00W OUTSOURCING ASS'Y

RDD683J-NACTD CARBON RESISTOR 1/2W 68K R507 R508

RFD1R0J4ACCNF FUSIBLE RESISTOR 1/2W 1.0 R430 R473B

RFER27J5ACDNF FUSIBLE RESISTOR 1W 0.27 R555 R565 R566

RFER47J5ACDNF FUSIBLE RESISTOR 1W 0.47 R165 R470 R472

RGDX152K-03NZ 1/2W 1.5K R918 R928 R938

RGDX246K-03NZ 1/2W 24M R519

RJB393F-NAATD METAL RESISTOR 1/6W 39K R411

RSE102J4ACCND METAL RESISTOR 1W 1K R466

RSE1R5J5DCCND METAL RESISTOR 1W 1.5 R406

RSE1R8J5DCCND METAL RESISTOR 1W 1.8 R408

RSE220J5ACCND METAL RESISTOR 1W 22 R300A

RSF101J5ACDND METAL RESISTOR 2W 100 R407

RSF103J5ACDND METAL RESISTOR 2W 10K

R467 R703 R915 R925 R935

Page 18

RSF223J7ACDND METAL RESISTOR 2W 22K R556

)

RSF271J7ACDND METAL RESISTOR 2W 270 R454 R546

RSF4R7J7ACDND METAL RESISTOR 2W 4.7 R445

RSF560J5ACDND METAL RESISTOR 2W 56 R446 R530

RSF5R6J5ACDND METAL RESISTOR 2W 5.6 R941 R480

RSG473J7ACEND METAL RESISTOR 3W 47K R504

RWH3R9K3AK-NR 5W 3.9 R458

VDAAA104A001C POTENTIOMETER 100KB VR431 VR432

VDAAA203A001C POTENTIOMETER 20KB VR433 VR501

CCF330J1CA-FC CERAMIC CAPACITOR 50V 33P C761 C762

CKF331K1BA-FC CERAMIC CAPACITOR 50V 330P C911 C921 C931

CKF471K1BA-FC CERAMIC CAPACITOR 50V 470P

C513 C732 C803 C805

C812 C814 C824 C826

CKF472K1BA-FC CERAMIC CAPACITOR 50V 4700P C324 C336

CKMX102M301ND CERAMIC CAPACITOR AC 400V 1000P C515

CKMX471K301ND CERAMIC CAPACITOR AC 400V 470P C515A

CKP101K1BA-FC CERAMIC CAPACITOR 500V 100P C482

CKW102K2BJ-ND CERAMIC CAPACITOR 1KV 1000P C503 C504 C505 C506

CKW471K2RA-ND CERAMIC CAPACITOR 1KV 470P C529

CKX102P2EJ-ND CERAMIC CAPACITOR 2KV 1000P C512 C943

CKX221K2RA-ND CERAMIC CAPACITOR 2KV 220P C509

CKX471K2RA-ND CERAMIC CAPACITOR 2KV 470P C543

CKX681K2RA-ND CERAMIC CAPACITOR 2KV 680P C527

CED101M1ACBNP ELECTROLYTIC CAPACITOR 25V 100u C471 C471A

CED102M1ACHNP ELECTROLYTIC CAPACITOR 25V 1000u C522

CED222M2ACKNP ELECTROLYTIC CAPACITOR 25V 2200u C524

CED471M1ACENP ELECTROLYTIC CAPACITOR 25V 470u C161 C474 C474A

CEE101M1ACCFP ELECTROLYTIC CAPACITOR 35V 100u C406

CEE331M1ACFNP ELECTROLYTIC CAPACITOR 35V 330u C530

CEE470M1ACCFP ELECTROLYTIC CAPACITOR 35V 47u C430 C453 C490

CEH471M3AEBNM ELECTROLYTIC CAPACITOR 160V 470u C528B

CEH4R7M1BCCFP ELECTROLYTIC CAPACITOR 160V 4.7u C466

CEK100M1ACHNP ELECTROLYTIC CAPACITOR 250V 10u C477 C941

CEM331M3AEPNM ELECTROLYTIC CAPACITOR 400V 330u(30*40) C507

CPFX6R8MY01NP

LECTROLYTIC CAPACITOR 50V 6.8u( NO POLARITY

C446

CAF104K1-H-FC POLYESTER CAPACITOR 50V 0.1u

C326 C338 C365 C411 C431 C511

CAF224K1-H-FC POLYESTER CAPACITOR 50V 0.22u C331 C334

CAF474K1-H-FC POLYESTER CAPACITOR 50V 0.47u C404 C461

CMNX224M801NE POLYESTER CAPACITOR AC 275V 0.22u C501

CMM434J8-H-NL POLYESTER CAPACITOR 400V 0.43u C467

CMR103J5-H-NE POLYESTER CAPACITOR 630V 0.01u C508

CMZ822J7-H-NE POLYESTER CAPACITOR 1.6KV 8200p C456

CMZ912J7-H-NE POLYESTER CAPACITOR 1.6KV 9100P C455

CNM333J7-H-NE POLYESTER CAPACITOR 400V 0.033u C457

LAD601K2---NJ STAND INDUCTANCE LGB-600uH(1.5A) L441

LBB820K----TG 82uH-K L911 L912 L913

LEA001-3---NJ M-COIL L505

LEA001-5---NJ M-COIL L450

LEE004-----NJ MAGNETISM PEARL(6*5*1.5mm) ZD524A ZD524B

Page 19

LF-026-3---NJ LINE COIL L452

LG-013-----NL LINE FILTER 10*12.5 L501

LM-040-----NG DEGAUS COIL(E7X 12ohm) L901

DH2090M003-NC MZ73BL-9ohm PS501

DN14R7M001-NC NTC 4.7ohm R502

DRBAV21----NJ DIODE BAV21 VD912 VD922 VD932

DRTVR4J----ND DIODE TVR4J

DRRGP10D---TD DIODE RGP10D

VD503 VD504 VD505 VD506

VD401 VD470 VD471 VD510

VD512 VD522 VD525 VD490

DRRGP10J---TD DIODE RGP10J VD436 VD472 VD513

DRRGP15D---ND DIODE RGP15D VD543

DRRGP30D---ND DIODE RGP30D VD521

DRTRGP30J---NZ DIODE TRGP30J VD524

DRTRU4C----NZ DIODE TRU4C VD452

DRTRU4DS---NZ DIODE TRU4DS VD451

DRTVR4J----ND DIODE TVR4J VD508

DZHZ22-2---TQ ZENER TUBE HZ22-2 VD432 VD481

DZHZ3C3----TQ ZENER TUBE HZ3C3 VD564

DZHZ4A2----TQ ZENER TUBE HZ4A2 VD509

DZHZ5C1----TQ ZENER TUBE HZ5C1 VD300A

DZHZ7C1----TQ ZENER TUBE HZ7C1 VD381 VD382 VD383

DZHZ9A3----TQ ZENER TUBE HZ9A3

VD460 VD483 VD822 VD941 VD861A

NAN7522N---N- AN7522N N161

NAT24C08---N- AT24C08 N702

NCD8145CP--N- CD8145CP N431

NCW574CS---N- CW574CS N703

NHEF4052---BP HEF4052 N121 N801

NK1010B----N- K1010B N504

NKA431AZ---N- KA431AZ V540

NKA5Q1265RFN- KA5Q1265RF N501

NMC7805CT--N- MC7805CT N505

NMC7808CT--N- MC7808CT N503

NTDA8177---N- TDA8177 N401

NTDA9381B39NE TDA9381PS/NB/2 1831 N301

Q2PA1015-GNF- TRANSISTOR 2PA1015G V171 V491

Q2PC1815-GNF- TRANSISTOR 2PC1815 G

V121 V122 V173 V351

V352 V395 V504 V801 V490

Q2SB1443--NN- TRANSISTOR 2SB1443 TV2 Q V542

QBF421----NN- TRANSISTOR BF421 V913 V923 V933

QBF422----NN- TRANSISTOR BF422 V912 V922 V932

QFJAF6810-NN- TRANSISTOR FJAF6810 V451

QKSA940----N- TRANSISTOR KSA940 V432

QKSC1674C-NN- TRANSISTOR KSC1674C V308

QKSC2383-ONN- TRANSISTOR KSC2383O V450

QKSC2688--NN- TRANSISTOR KSC2688 V911 V921 V931

QPH2369---NN- TRANSISTOR PH2369 V701

FBA3154S02C-A FUSE 3.15A 250V(FUSE ) F501

XFS043-----NB SAW FILTER(K2966M D2901C Z301

XTC006-----ND T 6.5M Z351

XTC008-----ND T 5.5M Z354

XX-021-----NV CR.OSC(12M 18P) X761

Page 20

GAAV2001----A 2S SOCKET(BIG) XR502 XS501A

GABV2001----N 2S SOCKET(MIDDLE) XS502

GABV5001----A DY SOCKET(MIDDLE) DYa XS403

GACV4001----A 4S SOCKET( small XH) XS161

GBAVL005----A CRT SOCKET(GZS8-6-4CE) XS901

GBBB9-06----8 AV SOCKET XS801

GBCH5001----Y S END XS861

JD2261-A010-A POWER CORD(260mm KF'

JS4501-B001-A DY LINE(500mm) KDY

JW4451-J001-A 4P LINE(450mm D2-D2) XP402

JW5501-E001-A 5P LINE(500mm XH-D2) XS903

TD-0042----0L H-DRIVER BCH-13 T450

TF-0090----2U F.B.T T451

TM-0108----OL CON.TRANS(BCK-1254-108) T501

BT-0308A---CH ZZ010

BXATB138----S TUNER 38.9MHZ A101

M90X0003---91 INSULATING CUSHION 18*13 D4.8 Z1

MB0X0011---G8 FUSE SOCKET(FUSE HOLDER ) F501A F501B

MB1X0040---BF 12V RADIATOR H-N505

MB1X0114---BF 5V RADIATOR (CUBA) H-N503

MB1X0163---BG RADIATOR (BLACK ) H-V432

MB1X0179---BF RADIATOR (AN7522N) H-N161

MB1X0204---BF POWER RADIATOR H-N501

MB1X0208---BF FRAME,ROW RADIATOR H-V451

MG3X0036---D7 INSULATING WASHER (D9) Z2

MG3X0037---D7 INSULATING WASHER (D9) Z3

PX20030----9S MAIN+CRT PCB zz060

SCA-25016FE-H GB818 M2.5*16 SN 401

SFAC30010FE1H SJ2836-87(M3*10.I)

SN 503 SN161A SN161B

SFAC30012FE1H SJ2836-87(M3*12.I) S-N501 S-V451

SKA-308R0FE-H GB845-78 ST3*8 S-N505 S-V432

SXN1A25--FF-H M2.5NUT zz360

SXN1A30--FF-H M3(NUT )

N-N501 N-N503 N-V451

NN161A NN161B

SXW1A25--FE-H GB97.1 D2.5 WASHER ZN401

GACV5001----A

5S SOCKET( small XH)

XS301

MG3X0073----G7 FIXED CARD

998 JUMPER WIRE W343

998 JUMPER WIRE W844A

998 JUMPER WIRE W861

998 JUMPER WIRE VD1561

471-2001K-00 PEAKING COIL SPT0305-1R0K-5 L302

471-2A39K-00 PEAKING COIL SPT0305-3R9K-5K L351

464-6D747-M0 ELECTROLYTIC CAPACITOR CD110-16V-470uF-M C801

459-5239K-00 CERAMIC CAPACITOR RQC12B392K-H46CA C451

467-1E210-H0 CARBON RESISTOR 1/2W-1K-J R453

464-6D647-M0 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C804

666-12301-00 FERRITE BEAD TY23X13.5X6

851-24012-11 SCREW SJ2824 ST4X12C-D.Zn

851-53012-11 SCREW SJ2825 ST3X12C-D.Zn

851-53012-11 SCREW SJ2825 ST3X12C-D.Zn

Page 21

851-53012-11 SCREW SJ2825 ST3X12C-D.Zn

851-53012-14 SCREW SJ2825 ST3X12C-D.Zn

851-53012-14 SCREW SJ2825 ST3X12C-D.Zn

851-53016-11 SCREW SJ2825 ST3X16C-D.Zn

851-53016-11 SCREW SJ2825 ST3X16C-D.Zn

851-53016-11 SCREW SJ2825 ST3X16C-D.Zn

863-60172U000 MAIN BOARD FRAME (HIPS V0)

870-20357-00B WIRE FIXED HOLDER

870-30150U000 FBT BRACKET (HIPS V0)

881-60074-00 HIGH VOLTAGE WARNING LABEL

681-40003-00 OK LABEL

741-10001-02 WIRE FIXED BLADE

666-12301-00 FERRITE BEAD TY23X13.5X6

808-10760-020

808-60895-01

364-32101-00 2-PINS CONNECTORS TJC3-02A XS701

475-25451-00 CERAMIC TRAPE FILTER XT4.5MB Z351

998 JUMPER WIRE N502

863-60175U000A MAIN BOARD FRAME (HIPS,V0)

851-24014-31 SCREW SJ2824 ST4X14C-D.Zn

851-24014-31 SCREW SJ2824 ST4X14C-D.Zn

491-752H0-02 POWER CORD UL !

808-1B814-040

808-60907-01

BLACK PLATE ( MOLD BLACK )

INTERFACE SPACE PLATE (SILK-SCREEN )

BLACK PLATE ( MOLD GREY )

INTERFACE SPACE PLATE (SILK-SCREEN )

667-TKD50-01A*

340-51240-003 ZENER DIODE HZ12A3 VD588

464-6D710-M02 ELECTROLYTIC CAPACITOR CD110-16V-100uF-M C536

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R301A

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R302A

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R723A

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R724A

467-1C168-H03 CARBON RESISTOR 1/6W-680Ω-J R463

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R380

895-6016030-50 RIVET GB876-86 1.6X3 COPPER L502

895-6016030-50 RIVET GB876-86 1.6X3 COPPER

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J R702

459-2182K-002 CERAMIC CAPACITOR RPU05B821K-H46CA C323

667-TKE53-01*

340-00001-003 DIODE 1N4148 VD171

340-00001-003 DIODE 1N4148 VD431

340-00001-003 DIODE 1N4148 VD461

340-00001-003 DIODE 1N4148 VD462

340-00001-003 DIODE 1N4148 VD511

340-00001-003 DIODE 1N4148 VD544

340-00001-003 DIODE 1N4148 VD561

340-00001-003 DIODE 1N4148 VD562

340-00001-003 DIODE 1N4148 VD734

340-00001-003 DIODE 1N4148 VD911

340-00001-003 DIODE 1N4148 VD921

340-00001-003 DIODE 1N4148 VD931

MAIN PCB ASS'Y (AUTOMATIC INSERTION )

MAIN PCB ASS'Y (AUTOMATIC INSERTION )

Page 22

459-2133K-902 CERAMIC CAPACITOR RBU07SL331K-H46CA C323

459-2210K-002 CERAMIC CAPACITOR CK45-B1H102KYR C308

459-2210K-002 CERAMIC CAPACITOR CK45-B1H102KYR C311

459-2210K-002 CERAMIC CAPACITOR CK45-B1H102KYR C401

459-2210K-002 CERAMIC CAPACITOR CK45-B1H102KYR C402

459-2210K-002 CERAMIC CAPACITOR CK45-B1H102KYR C721

459-2210K-002 CERAMIC CAPACITOR CK45-B1H102KYR C861

459-2222K-002 CERAMIC CAPACITOR CT1-08-2B4-63V-222K C335

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C162

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C302

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C309

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C313

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C332

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C362

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C475

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C535

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C703A

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C723

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C744

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C752

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C756

459-5122K-002 CERAMIC CAPACITOR RQC05B221K-6H46UA C405

459-5210K-002 CERAMIC CAPACITOR CK45-B2H102KYR C452

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R351

462-00233-K02 POLYESTER CAPACITOR CL11-100V-3300PF-K C321

462-00256-H02 POLYESTER CAPACITOR CL11-100V-5600PF-J C154

462-00256-H02 POLYESTER CAPACITOR CL11-100V-5600PF-J C158

462-00333-K02 POLYESTER CAPACITOR CL11-100V-0.033uF-K C403

462-00333-K02 POLYESTER CAPACITOR CL11-100V-0.033uF-K C510

462-00333-K02 POLYESTER CAPACITOR CL11-100V-0.033uF-K C544

462-00347-K02 POLYESTER CAPACITOR CL11-100V-0.047uF-K C427

462-00410-K02 POLYESTER CAPACITOR CL11-100V-0.1uF-K C460

462-00410-K02 POLYESTER CAPACITOR CL11-100V-0.1uF-K C705

462-00410-K02 POLYESTER CAPACITOR CL11-100V-0.1uF-K C706

462-00410-K02 POLYESTER CAPACITOR CL11-100V-0.1uF-K C707

464-6C710-M02 ELECTROLYTIC CAPACITOR CD110-10V-100uF-M C548

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C163A

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C172

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C301

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C307

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C322

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C363

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C364

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C367

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C751

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C807

464-6D610-M02 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C871

464-6D622-M02 ELECTROLYTIC CAPACITOR CD110-16V-22uF-M C745

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C116

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C171

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C333

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C352

Page 23

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C561

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C723A

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C811

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C823

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C121

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C123

464-6D647-M02 ELECTROLYTIC CAPACITOR CD110-16V-47uF-M C806

464-6D710-M02 ELECTROLYTIC CAPACITOR CD110-16V-100uF-M C361

464-6D710-M02 ELECTROLYTIC CAPACITOR CD110-16V-100uF-M C743

464-6D747-M02 ELECTROLYTIC CAPACITOR CD110-16V-470uF-M C525

464-6D747-M02 ELECTROLYTIC CAPACITOR CD110-16V-470uF-M C532

464-60447-M02 ELECTROLYTIC CAPACITOR CD110-50V-0.47uF-M C372

464-60447-M02 ELECTROLYTIC CAPACITOR CD110-50V-0.47uF-M C374

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C153

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C157

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C163

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C337

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C813

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C815

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C825

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C862

464-60522-M02 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M C755

464-60547-M02 ELECTROLYTIC CAPACITOR CD110-50V-4.7uF-M C303

464-60547-M02 ELECTROLYTIC CAPACITOR CD110-50V-4.7uF-M C304

464-60547-M02 ELECTROLYTIC CAPACITOR CD110-50V-4.7uF-M C325

464-60547-M02 ELECTROLYTIC CAPACITOR CD110-50V-4.7uF-M C464

464-60622-M02 ELECTROLYTIC CAPACITOR CD110-50V-22uF-M C703

464-60647-M02 ELECTROLYTIC CAPACITOR CD110-50V-47uF-M C462

464-60647-M02 ELECTROLYTIC CAPACITOR CD110-50V-47uF-M C517

467-1C010-H03 CARBON RESISTOR 1/6W-10Ω-J R312

467-1C010-H03 CARBON RESISTOR 1/6W-10Ω-J R871

467-1C022-H03 CARBON RESISTOR 1/6W-22Ω-J R914

467-1C022-H03 CARBON RESISTOR 1/6W-22Ω-J R924

467-1C022-H03 CARBON RESISTOR 1/6W-22Ω-J R934

467-1C033-H03 CARBON RESISTOR 1/6W-33Ω-J R398

467-1C033-H03 CARBON RESISTOR 1/6W-33Ω-J R806

467-1C047-H03 CARBON RESISTOR 1/6W-47Ω-J R368

467-1C047-H03 CARBON RESISTOR 1/6W-47Ω-J R708

467-1C047-H03 CARBON RESISTOR 1/6W-47Ω-J R911

467-1C047-H03 CARBON RESISTOR 1/6W-47Ω-J R921

467-1C047-H03 CARBON RESISTOR 1/6W-47Ω-J R931

467-1C056-H03 CARBON RESISTOR 1/6W-56Ω-J R355

467-1C068-H03 CARBON RESISTOR 1/6W-68Ω-J R304

467-1C068-H03 CARBON RESISTOR 1/6W-68Ω-J R801

467-1C082-H03 CARBON RESISTOR 1/6W-82Ω-J R313

467-1C082-H03 CARBON RESISTOR 1/6W-82Ω-J R815

467-1C082-H03 CARBON RESISTOR 1/6W-82Ω-J R824

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R301

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R302

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R363

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R365

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R381

Page 24

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R382

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R383

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R401

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R402

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R452

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R463

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R723

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R724

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R743

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R861

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R862

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R366

467-1C115-H03 CARBON RESISTOR 1/6W-150Ω-J R815A

467-1C115-H03 CARBON RESISTOR 1/6W-150Ω-J R848

467-1C115-H03 CARBON RESISTOR 1/6W-150Ω-J R852

467-1C118-H03 CARBON RESISTOR 1/6W-180Ω-J R353

467-1C122-H03 CARBON RESISTOR 1/6W-220Ω-J R311

467-1C122-H03 CARBON RESISTOR 1/6W-220Ω-J R442

467-1C122-H03 CARBON RESISTOR 1/6W-220Ω-J R917

467-1C122-H03 CARBON RESISTOR 1/6W-220Ω-J R927

467-1C122-H03 CARBON RESISTOR 1/6W-220Ω-J R937

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R481

467-1C130-H03 CARBON RESISTOR 1/6W-300Ω-J R913

467-1C130-H03 CARBON RESISTOR 1/6W-300Ω-J R923

467-1C130-H03 CARBON RESISTOR 1/6W-300Ω-J R933

467-1C133-H03 CARBON RESISTOR 1/6W-330Ω-J R916

467-1C133-H03 CARBON RESISTOR 1/6W-330Ω-J R926

467-1C133-H03 CARBON RESISTOR 1/6W-330Ω-J R936

467-1C139-H03 CARBON RESISTOR 1/6W-390Ω-J R322

467-1C147-H03 CARBON RESISTOR 1/6W-470Ω-J R308

467-1C168-H03 CARBON RESISTOR 1/6W-680Ω-J R316

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R128

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R129

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R369

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R460

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R464

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R531

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R541

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R544

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R701

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R734

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R802

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R803

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R816

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R818

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R825

467-1C210-H03 CARBON RESISTOR 1/6W-1K-J R827

467-1C212-H03 CARBON RESISTOR 1/6W-1.2K-J R305

467-1C212-H03 CARBON RESISTOR 1/6W-1.2K-J R560

467-1C215-H03 CARBON RESISTOR 1/6W-1.5K-J R397

467-1C215-H03 CARBON RESISTOR 1/6W-1.5K-J R732

467-1C222-H03 CARBON RESISTOR 1/6W-2.2K-J R371

Page 25

467-1C222-H03 CARBON RESISTOR 1/6W-2.2K-J R451

467-1C222-H03 CARBON RESISTOR 1/6W-2.2K-J R540

467-1C224-H03 CARBON RESISTOR 1/6W-2.4K-J R515

467-1C239-H03 CARBON RESISTOR 1/6W-3.9K-J R321

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J R721

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J R722

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J R728

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J R735

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J R736

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J R737

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J R741

467-1C233-H03 CARBON RESISTOR 1/6W-3.3K-J R742

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R131

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R133

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R154

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R158

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R306

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R462

467-1C247-H03 CARBON RESISTOR 1/6W-4.7K-J R733

467-1C256-H03 CARBON RESISTOR 1/6W-5.6K-J R370

467-1C268-H03 CARBON RESISTOR 1/6W-6.8K-J R426

467-1C282-H03 CARBON RESISTOR 1/6W-8.2K-J R153A

467-1C282-H03 CARBON RESISTOR 1/6W-8.2K-J R157A

467-1C282-H03 CARBON RESISTOR 1/6W-8.2K-J R562

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R126

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R127

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R163

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R395

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R396

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R427

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R461

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R543

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R548

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R551

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R704

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R705

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R706

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R707

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R709

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R816A

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R818A

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R825A

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R827A

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R851A

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R852A

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R912

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R922

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R932

467-1C312-H03 CARBON RESISTOR 1/6W-12K-J R425

467-1C315-H03 CARBON RESISTOR 1/6W-15K-J R331

467-1C322-H03 CARBON RESISTOR 1/6W-22K-J R162

467-1C322-H03 CARBON RESISTOR 1/6W-22K-J R384

Page 26

467-1C322-H03 CARBON RESISTOR 1/6W-22K-J R422

467-1C322-H03 CARBON RESISTOR 1/6W-22K-J R455

467-1C327-H03 CARBON RESISTOR 1/6W-27K-J R484

467-1C327-H03 CARBON RESISTOR 1/6W-27K-J R487

467-1C333-H03 CARBON RESISTOR 1/6W-33K-J R171

467-1C333-H03 CARBON RESISTOR 1/6W-33K-J R175

467-1C333-H03 CARBON RESISTOR 1/6W-33K-J R317

467-1C333-H03 CARBON RESISTOR 1/6W-33K-J R385

467-1C333-H03 CARBON RESISTOR 1/6W-33K-J R431

467-1C333-H03 CARBON RESISTOR 1/6W-33K-J R434

467-1C347-H03 CARBON RESISTOR 1/6W-47K-J R172

467-1C347-H03 CARBON RESISTOR 1/6W-47K-J R732A

467-1C347-H03 CARBON RESISTOR 1/6W-47K-J R745

467-1C356-H03 CARBON RESISTOR 1/6W-56K-J R424

467-1C368-H03 CARBON RESISTOR 1/6W-68K-J R173

467-1C410-H03 CARBON RESISTOR 1/6W-100K-J R429

467-1C410-H03 CARBON RESISTOR 1/6W-100K-J R483

467-1C410-H03 CARBON RESISTOR 1/6W-100K-J R802A

467-1C410-H03 CARBON RESISTOR 1/6W-100K-J R803A

467-1C415-H03 CARBON RESISTOR 1/6W-150K-J R318

467-1C427-H03 CARBON RESISTOR 1/6W-270K-J R174

467-1C456-H03 CARBON RESISTOR 1/6W-560K-J R465

467-1DA27-H03 CARBON RESISTOR RT14-1/4W-2.7Ω-J R468

467-1D001-H03 CARBON RESISTOR RT14-1/4W-1Ω-J R404

467-1D027-H03 CARBON RESISTOR RT14-1/4W-27Ω-J R561

467-1D110-H03 CARBON RESISTOR RT14-1/4W-100Ω-J R486

467-1D222-H03 CARBON RESISTOR RT14-1/4W-2.2K-J R161

467-1D310-H03 CARBON RESISTOR RT14-1/4W-10K-J R485

467-1D351-H03 CARBON RESISTOR RT14-1/4M-51K-J R539

467-1D351-H03 CARBON RESISTOR RT14-1/4M-51K-J R539A

998 JUMPER WIRE W930

467-1C310-H03 CARBON RESISTOR 1/6W-10K-J R380

471-2010K-003 PEAKING COIL SPT0305-100K-5 L331

471-2010K-003 PEAKING COIL SPT0305-100K-5 L361

471-2010K-003 PEAKING COIL SPT0305-100K-5 L751

471-2010K-003 PEAKING COIL SPT0305-100K-5 L752

471-2010K-003 PEAKING COIL SPT0305-100K-5 L753

998 JUMPER WIRE W011

998 JUMPER WIRE W265

998 JUMPER WIRE W266

998 JUMPER WIRE W391

998 JUMPER WIRE W486

998 JUMPER WIRE W791

998 JUMPER WIRE W901

998 JUMPER WIRE W852

998 JUMPER WIRE W851A

998 JUMPER WIRE W582

998 JUMPER WIRE W684

998 JUMPER WIRE W021

998 JUMPER WIRE W051

998 JUMPER WIRE W122

998 JUMPER WIRE W131

Page 27

998 JUMPER WIRE W168

998 JUMPER WIRE W264

998 JUMPER WIRE W311

998 JUMPER WIRE W356

998 JUMPER WIRE W368

998 JUMPER WIRE W373

998 JUMPER WIRE W381

998 JUMPER WIRE W385

998 JUMPER WIRE W442

998 JUMPER WIRE W443

998 JUMPER WIRE W466

998 JUMPER WIRE W467

998 JUMPER WIRE W471

998 JUMPER WIRE W493

998 JUMPER WIRE W531

998 JUMPER WIRE W532

998 JUMPER WIRE W554

998 JUMPER WIRE W555

998 JUMPER WIRE W562

998 JUMPER WIRE W563

998 JUMPER WIRE W564

998 JUMPER WIRE W581

998 JUMPER WIRE W652

998 JUMPER WIRE W721

998 JUMPER WIRE W763

998 JUMPER WIRE W764

998 JUMPER WIRE W771

998 JUMPER WIRE W773

998 JUMPER WIRE W774

998 JUMPER WIRE W841

998 JUMPER WIRE W862

998 JUMPER WIRE W863

998 JUMPER WIRE W881

998 JUMPER WIRE W843

998 JUMPER WIRE W844

998 JUMPER WIRE W231

998 JUMPER WIRE W243

998 JUMPER WIRE W358

998 JUMPER WIRE W762

998 JUMPER WIRE W875

998 JUMPER WIRE W876

998 JUMPER WIRE W401

998 JUMPER WIRE W786

998 JUMPER WIRE W675

998 JUMPER WIRE W242

998 JUMPER WIRE W552

998 JUMPER WIRE W553

998 JUMPER WIRE W662

998 JUMPER WIRE W663

998 JUMPER WIRE W244

998 JUMPER WIRE W245

998 JUMPER WIRE W148

Page 28

998 JUMPER WIRE W152

998 JUMPER WIRE W154

998 JUMPER WIRE W166

998 JUMPER WIRE W171

998 JUMPER WIRE W241

998 JUMPER WIRE W263

998 JUMPER WIRE W421

998 JUMPER WIRE W435

998 JUMPER WIRE W472

998 JUMPER WIRE W342

998 JUMPER WIRE W484

998 JUMPER WIRE W485

998 JUMPER WIRE W643

998 JUMPER WIRE W653

998 JUMPER WIRE W655

998 JUMPER WIRE W741

998 JUMPER WIRE W921

998 JUMPER WIRE W922

998 JUMPER WIRE W650

998 JUMPER WIRE W900

998 JUMPER WIRE W341

998 JUMPER WIRE W752

998 JUMPER WIRE W420

998 JUMPER WIRE W651

998 JUMPER WIRE W213

998 JUMPER WIRE W214

998 JUMPER WIRE W313

998 JUMPER WIRE W312

998 JUMPER WIRE W411A

998 JUMPER WIRE W153

998 JUMPER WIRE W251

998 JUMPER WIRE W159

998 JUMPER WIRE W571

998 JUMPER WIRE W432

998 JUMPER WIRE W454

998 JUMPER WIRE W551

998 JUMPER WIRE W665

998 JUMPER WIRE W621

998 JUMPER WIRE W674

998 JUMPER WIRE W681

998 JUMPER WIRE W682

998 JUMPER WIRE W673

998 JUMPER WIRE W731

998 JUMPER WIRE W873

998 JUMPER WIRE W872

998 JUMPER WIRE W781

998 JUMPER WIRE W142

998 JUMPER WIRE W253

998 JUMPER WIRE W162

998 JUMPER WIRE W355

998 JUMPER WIRE W451

998 JUMPER WIRE W331

Page 29

998 JUMPER WIRE W163

998 JUMPER WIRE W164

998 JUMPER WIRE W369

998 JUMPER WIRE W412

998 JUMPER WIRE W434

998 JUMPER WIRE W452

998 JUMPER WIRE W453

998 JUMPER WIRE W463

998 JUMPER WIRE W464

998 JUMPER WIRE W465

998 JUMPER WIRE W641

998 JUMPER WIRE W642

998 JUMPER WIRE W644

998 JUMPER WIRE W656

998 JUMPER WIRE W672

998 JUMPER WIRE W840

998 JUMPER WIRE R520

998 JUMPER WIRE W221

998 JUMPER WIRE W362

998 JUMPER WIRE W363

998 JUMPER WIRE W364

998 JUMPER WIRE W365

998 JUMPER WIRE W366

998 JUMPER WIRE W367

998 JUMPER WIRE W461

998 JUMPER WIRE W462

998 JUMPER WIRE W671

998 JUMPER WIRE W761

998 JUMPER WIRE W156

998 JUMPER WIRE W561

998 JUMPER WIRE W661

998 JUMPER WIRE W664

998 JUMPER WIRE W494

998 JUMPER WIRE L401

998 JUMPER WIRE W903

998 JUMPER WIRE W904

340-00001-003 DIODE 1N4148 VD491

467-1C322-H03 CARBON RESISTOR 1/6W-22K-J R482

467-1C315-H03 CARBON RESISTOR 1/6W-15K-J R491

467-1C315-H03 CARBON RESISTOR 1/6W-15K-J R453A

464-60547-M02 ELECTROLYTIC CAPACITOR CD110-50V-4.7uF-M C481

464-60510-M02 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C841

895-6016030-50 RIVET GB876-86 1.6X3 COPPER L501

895-6016030-50 RIVET GB876-86 1.6X3 COPPER PS501

895-6016030-50 RIVET GB876-86 1.6X3 COPPER T501

895-6016030-50 RIVET GB876-86 1.6X3 COPPER T451

895-6016030-50 RIVET GB876-86 1.6X3 COPPER L452

895-6016030-50 RIVET GB876-86 1.6X3 COPPER

895-6025030-50 RIVET GB876-86-2.5X3 COPPER C507

895-6025030-50 RIVET GB876-86-2.5X3 COPPER VD451

895-6025030-50 RIVET GB876-86-2.5X3 COPPER VD452

895-6025030-50 RIVET GB876-86-2.5X3 COPPER V451

Page 30

895-6025030-50 RIVET GB876-86-2.5X3 COPPER V432

895-6025030-50 RIVET GB876-86-2.5X3 COPPER

459-2310R-002 CERAMIC CAPACITOR CK45-F1H103ZYR C399

467-1D227-H03 CARBON RESISTOR RT14-1/4W-2.7K-J R512

467-1C318-H03 CARBON RESISTOR 1/6W-18K-J R804

467-1C347-H03 CARBON RESISTOR 1/6W-47K-J R807

467-1C118-H03 CARBON RESISTOR 1/6W-180Ω-J R805

467-1C110-H03 CARBON RESISTOR 1/6W-100Ω-J R354

895-6016030-50 RIVET GB876-86 1.6X3 COPPER C467

895-6016030-50 RIVET GB876-86 1.6X3 COPPER

998 JUMPER WIRE W371

998 JUMPER WIRE W261

998 JUMPER WIRE W262

998 JUMPER WIRE W252

998 JUMPER WIRE W441

998 JUMPER WIRE W271

998 JUMPER WIRE W272

998 JUMPER WIRE W122A

998 JUMPER WIRE W882

998 JUMPER WIRE W883

998 JUMPER WIRE W884

998 JUMPER WIRE R737A

462-00268-H02 POLYESTER CAPACITOR CL11-100V-6800PF-J C154

462-00268-H02 POLYESTER CAPACITOR CL11-100V-6800PF-J C158

667-TK2525-29B SIDE AV BOARD ASS'Y

364-93202-00 AV JACK AV306-2 XAA1

655-6E301-24 (6-PINS) LEAD WITH HOUSING XAA3

782-Q2455-2900 SIDE AV PCB

808-6B786-07

851-53010-31 SCREW SJ2825 ST3X10FT-D.Zn

868-10043-00 WASHER (14X4X1 METAL )

870-30233-040

998 JUMPER WIRE LAA1

998 JUMPER WIRE LAA2

667-TK2450-05 KEY BOARD ASS'Y

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B S901

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B S902

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B S903

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B S904

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B S905

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B S906

467-1C215-H0 CARBON RESISTOR 1/6W-1.5K-J R902

467-1C218-H0 CARBON RESISTOR 1/6W-1.8K-J R903

467-1C230-H0 CARBON RESISTOR 1/6W-3K-J R904

467-1C230-H0 CARBON RESISTOR 1/6W-3K-J R905

467-1C262-H0 CARBON RESISTOR 1/6W-6.2K-J R906

467-1C318-H0 CARBON RESISTOR 1/6W-18K-J R907

352-03810-80 *IC AT138B-T12 N901

340-10039-20

AV挡 BOARD (SILK-SCREEN )

SIDE AV BRACKET ( MOLD GREY )

LED HFR205 (RED )

VD901

Page 31

655-21201-16

998 JUMPER WIRE R911

782-TS2150-0500 BUTTON PCB

467-1C139-H0 CARBON RESISTOR 1/6W-390Ω-J R913

655-31201-30 (3-PINS) LEAD WITH HOUSING XS901

877-50411-00 KEY

877-60563-T0

667-TK2953-31 MTS BOARD ASS'Y

467-1C310-H0 CARBON RESISTOR 1/6W-10K-J R04

467-1C310-H0 CARBON RESISTOR 1/6W-10K-J R08

467-1C247-H0 CARBON RESISTOR 1/6W-4.7K-J R05

467-1C247-H0 CARBON RESISTOR 1/6W-4.7K-J R09

467-1C147-H0 CARBON RESISTOR 1/6W-470Ω-J R06

467-1C147-H0 CARBON RESISTOR 1/6W-470Ω-J R10

467-1C115-H0 CARBON RESISTOR 1/6W-150Ω-J R07

467-1C115-H0 CARBON RESISTOR 1/6W-150Ω-J R11

467-1C418-H0 CARBON RESISTOR 1/6W-180K-J R01

467-1C233-H0 CARBON RESISTOR 1/6W-3.3K-J R02

467-1C327-H0 CARBON RESISTOR 1/6W-27K-J R03

464-6D610-M0 ELECTROLYTIC CAPACITOR CD110-16V-10uF-M C01

464-60433-M0 ELECTROLYTIC CAPACITOR CD110-50V-0.33uF-M C02

464-60433-M0 ELECTROLYTIC CAPACITOR CD110-50V-0.33uF-M C08

464-60533-M0 ELECTROLYTIC CAPACITOR CD110-50V-3.3uF-M C03

464-60522-M0 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M C11

464-60522-M0 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M C12

464-60522-M0 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M C13

464-60522-M0 ELECTROLYTIC CAPACITOR CD110-50V-2.2uF-M C14

464-60510-M0 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C16

464-60510-M0 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C17

464-60510-M0 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C18

464-60510-M0 ELECTROLYTIC CAPACITOR CD110-50V-1uF-M C19

462-00410-K02 POLYESTER CAPACITOR CL11-100V-0.1uF-K C04

462-00410-K02 POLYESTER CAPACITOR CL11-100V-0.1uF-K C06

462-00333-K02 POLYESTER CAPACITOR CL11-100V-0.033uF-K C07

462-00322-K02 POLYESTER CAPACITOR CL11-100V-0.022uF-K C05

998 JUMPER WIRE W01

998 JUMPER WIRE W02

462-00410-K02 POLYESTER CAPACITOR CL11-100V-0.1uF-K C09

462-00422-K0 POLYESTER CAPACITOR CL11-100V-0.22uF-K C10

464-6D710-M0 ELECTROLYTIC CAPACITOR CD110-16V-100uF-M C15

(2-PINS) LEAD WITH HOUSING

BUTTON COVER (PLATE )

667-TK2950-17 RELAY BOARD ASS'Y

340-00001-00 DIODE 1N4148 VD2003

467-1C310-H0 CARBON RESISTOR 1/6W-10K-J R2001

467-1C247-H0 CARBON RESISTOR 1/6W-4.7K-J R2002

464-6F710-M0 ELECTROLYTIC CAPACITOR CD110-35V-100uF-M C2002

667-Q27351-05 Stand By KEY BOARD ASS'Y

360-10001-00 TACT SWITCH KFC-A06-4X4.5X5B S1

665-21201-16

782-13Y90-050A BUTTON PCB

(2-PINS) LEAD WITH HOUSING

X1

Page 32

31

Page 33

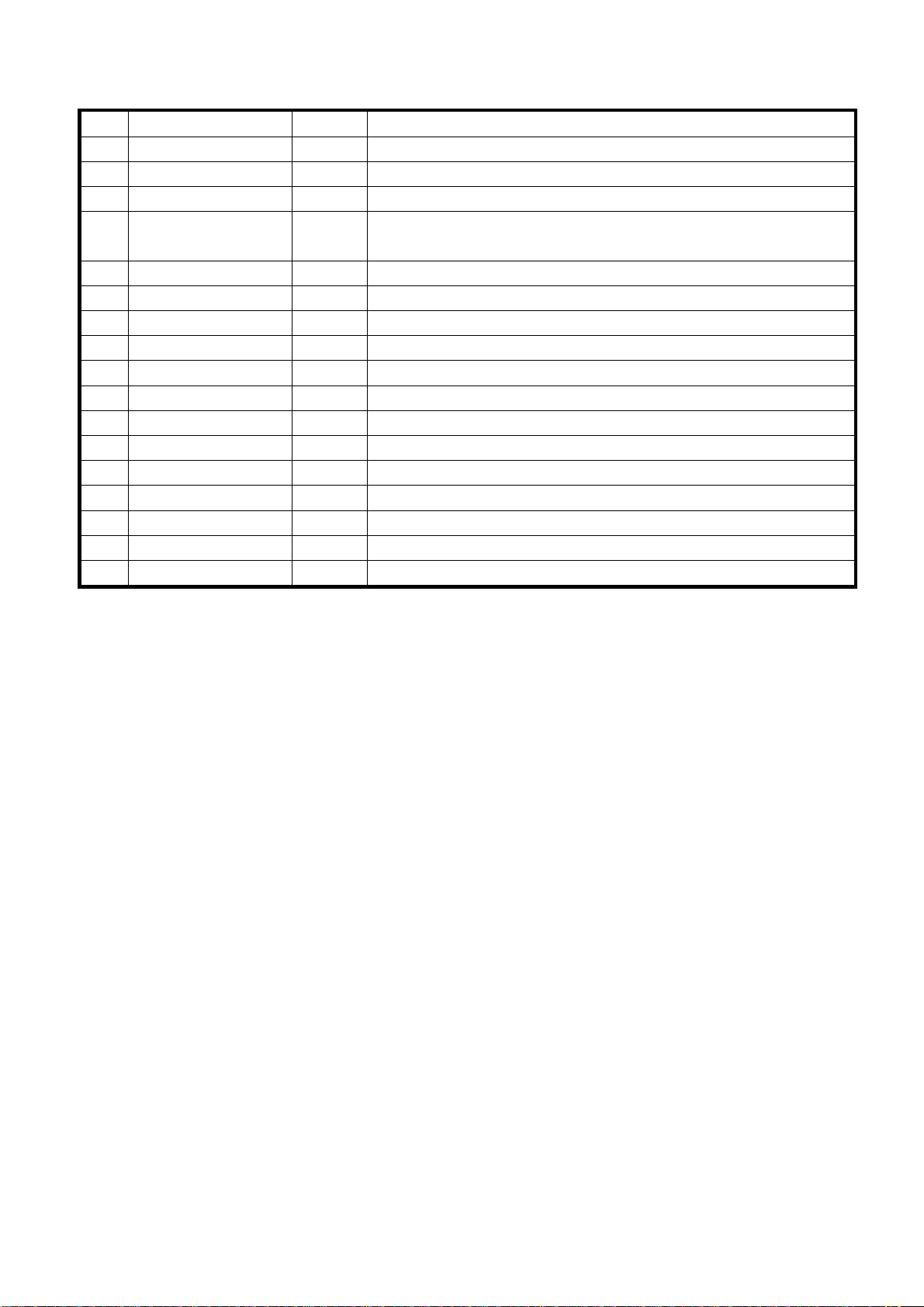

TK2450

PART LIST OF EXPLODED VIEW

NO. DESCRIPTION PART#

1 BACK CABINET 780-10966J040A

2 POWER CORD CLAMPE 742-30029-00

3 REAR PANEL 808-1B814-040

4 MAIN BORD 667-TKD50-01A

5 CRT 335-2512D-00U

6 CRT FIXER 615-10223-00

7 SPEAKER BRACKET 870-20700-00A

8 SIDE AV BRACKET 870-30233-040

9 WASHER 868-20217-00

10 SPEAKER 384-40908-B0

11 FRONT CABINET 611-D50X2J0H1

12 BUTTON 877-50411-00

13 SCREW 855-A0029-00

14 BUTTON BOARD 782-TS2150-0500

15 LED COLUMN 700-60151-00

16 SCREW 851-24020-11

17 COMPONENT NUT 648-30001-00

18 DEGAUSSING COIL 477-12503-00

19 CRT BOARD No number

20 SCREW 851-24020-14

21 LABLE 880-10205-790A

Page 34

SCHEMATIC DIAGRAM

CAUTION:all the parts in the schematic diagram marked with shodows and the signs of

are extremely

important for safety. In case of replacement of any part of components. Be sure to consult the service manual

carefully.

1. the schematic diagram is characteristic. The various valus in the electric circuits are basic data, which are

changeable according to the various basic circuits.

2. testing waves are abtained by inputing the standard color bar of the signed.

6

)

3. resistance unit is in Ohm, namely: K=1000; M=1000K; Capacitance unit is in µF; P=µµF(µ=10

4. Unless othervise noted inside, all resistors are 1/6W, the withstand voltage of all capacitor are 50V.

5. Inductance unit is in µH.

6. The mark

in the diagram means Ferrite ring

7. The symbols of various types of resistors and capacitors are listed as follows:

Carbon film resistor

Metal film resistor

M

Potentiometer resistor

1/2w resistor

1w resistor

2w resistor

3w resistor

Ceramic capacitor

AC Ceramic capacitor

Terylene capacitor

Polypropylene capacitor

Metal Terylene capacitor

Aluminium electrolyse capacitor

Tantalum electrolyse capacitor

AC

1

2

3

T

33

Page 35

Loading...

Loading...