Page 1

COLOR TELEVISION

TJ# series

TJ2768

TJ2778

TJ306

America

Page 2

CONTENTS

Safety precautions………………………………………………………………………..…

Alignment instructions. ………………………………….………..…………………….…

Working principle analysis of the unit……………………………….………….………….

Block diagram………………………………….. ……………………………………….…………

IC block diagram………………………………………………………………………..……

Wiring diagram ……………………………………………………………..……………...

Troubleshooting……………………………………………………………………………..……

Schematic diagram. ………………………………………………………………………..

1

3

10

11

12

18

19

21

Page 3

Attention: This service manual is only for service personnel to take reference with. Before

servicing please read the following points caref ully.

Safety precautions

After the original service problem has been cor rected, a check should be made of the f ollowing:

FIRE & SHOCK HAZARD

1. Be sure that all components are positioned in such a way as to avoid possibility of adjacent

component shorts. This is especially important on those chassis, which are transported to and from

the repair shop.

2. Never release a repair unless all protective devices such as insulators, barriers, covers, shields,

strain reliefs, and other hardware have been reinstalled per original design.

3. Soldering must be inspected to discover possible cold solder joints, frayed leads, damaged

insulation (including A.C. cord), solder splashes or sharp solder points. Be certain to remove all

loose foreign particles.

4. Check for physical evidence of damage or deterioration to parts and components, and replace if

necessary follow original layout, lead length and dress.

5. No leads or components should touch a receiving tube or a resistor rated at 1 watt or more. Lead

tension around protruding metal surfaces must be avoided.

6. All critical components such as fuses, flameproof resistors, capacitors, etc. must be replaced with

exact factory types. Do not use replacement components other than those specified or make

unrecompensed circuit modifications.

7. After re-assembly of the set always perform an A.C. leakage test on all exposed metallic parts of

the cabinet, (the channel selector knob, antenna terminals, handle and screws) to be sure the set is

safe to operate without danger of electrical shock. Do not use a line isolation transformer during

this test. Use an A.C. voltmeter, having 5000 ohms per volt or more sensitivity, in the following

manner: connect a 1500ohm 10watt resistor, paralleled by a 0.15uF. 150V A.C. type capacitor

between a known good earth ground 9water pipe, conduit, etc. and the exposed metallic parts, one

at a time. Measure the A.C. voltage across the combination of 1500ohm resistor and 0.15uF

capacitor. Reverse the A.C. plug and repeat A.C. voltage measurements for each exposed metallic

part. Voltage measured must not exceed 0.75 volts R.M.S. This corresponds to 0.5 milliamp A.C.

Any value exceeding this limit constitutes a potential shock hazard and must be corrected

immediately.

GRAPHIC SYMBOLS:

It is intended to alert the service personnel to the presence of uninsulated dangerous

voltage that may be of sufficiently magnitude to constitute a risk of electric shock.

It is intended to alert the service personnel to the presence of important safety

information in service literatur e.

X-RADIATION

Too excessive voltage will cause harmful X-ray. To avoid this radiation hazard, the high voltage

should fall within the limitation. The appliance works at AC 120V, 60Hz. The high voltage of zero

1

Page 4

beam current should be within 35KV on condition that the main power(B+) voltage is DC140V . And it

should not exceed 36KV in any condition.

1. Be sure procedures and instructions to all service personnel cover the su bject of X-rays in current

TV is the picture tube. However, this tube does not emit X-rays when the high voltage is at the

factory specified level. The proper value is given in the applicable schematic. Operation at higher

voltages may cause a failure of the picture tube or high voltage supply and, under certain

circumstances, may produce radiation in excess of desirable levels.

2. Only factory specified C.R.T. anode connectors must be used. Degaussing shields also serve as

X-ray shield in color sets. Always re-install them.

3. It is essential that the serviceman has available an accurate and reliable high voltage meter. The

calibration of the meter should be checked periodically against a reference standard. Such as the

one available at your distributor.

4. When the high voltage circuitry is operating properly there is no possibility of an X-radiation

problem. Every time a color chassis is serviced, the brightness should be run up and down while

monitoring the high voltage with a meter to be certain that the high voltage does not exceed the

specified value and that it is regulating correctly. We suggest that you and your service or ganization

review test procedures so that voltage regulation is always checked as a standard servicing

procedure. And that the high voltage r eading be recorded on each customer s invoice.

5. When troubleshooting and making test measurements in a receiver with a problem of excessive

high voltage, avoid being unnecessarily close to the picture tube and the h i gh v oltage compartment.

Do not operate the chassis longer than is necessary to locate t he cause of excessive voltage.

6. Refer to HV, B+ and Shutdown adjustment procedures described in the appropriate schematic

and diagrams. Too excessive voltage will cause harmful X- r ay.

IMPLOSION

1. All direct viewed picture tubes are equipped with an integral implosion protection system, but

care should be taken to avoid damage during installation. Avoid scratching the tube. If scratched,

replace it.

2. Use only recommended factory replacement tubes.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in closed-in recess, cubbyhole or closely fitting shelf space over, or

close to heat duct, or in the path of heated airflow.

2. Avoid conditions of high humidity such as: Outdoor patio installations where dew is a factor. Near

steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct rear venting. The customer should also avoid the

use of decorative scarves or other coverings which might obstruct ventilat ion.

4. Wall and shelf mounted installations using a commercial mounting kit, must follow the factory

approved mounting instructions. A receiver mounted to a shelf or platform must retain its original

feet(or the equivalent thickness in spacers) to provide adequate are flow across the bottom, blots or

screws used for fasteners must not touch and parts or wiring. Perform leakage test on customized

installations.

5. Caution customers against the mounting of a receiver on sloping shelf or a tilted position, unless

the receiver is properly secured.

6. A receiver on a roll-about cart should be stable on its mounting to the cart. Caution the customer

on the hazards of trying to roll a cart with small caster s acr oss t hresholds or deep pile carpets.

2

Page 5

Alignment instructions

1. General instructions

1.1 The program data should be copied into the EEPROM (N802 M24C16) in this set according to

Standard Sample program data, then execute “Factory Adjustment”. If adopt empty EEPROM,

please preset I2C datum before any debugging.

1.2 If ther e is no special not ice, the unit adjustment should be done on the following conditions:

a. AC power 120V/60Hz.

b. Pre-heat the set for above 30 minutes.

1.3 There is a auto-degaussing circuit inside which could degauss the set automatically within one

second after turn on the power. The auto-degaussing circuit effects on condition that every interval

of turning on the set is longer than 30 minutes at least.

1.4 The magnetized CRT will influence the colour purity and focus. When the inside degaussing

circuit can’t degauss thoroughly then an outside degausser is necessary. Colour purity and focus

adjustment should be executed according to the colour purity and focus adjusts procedures if the

colour purity and focus is not good.

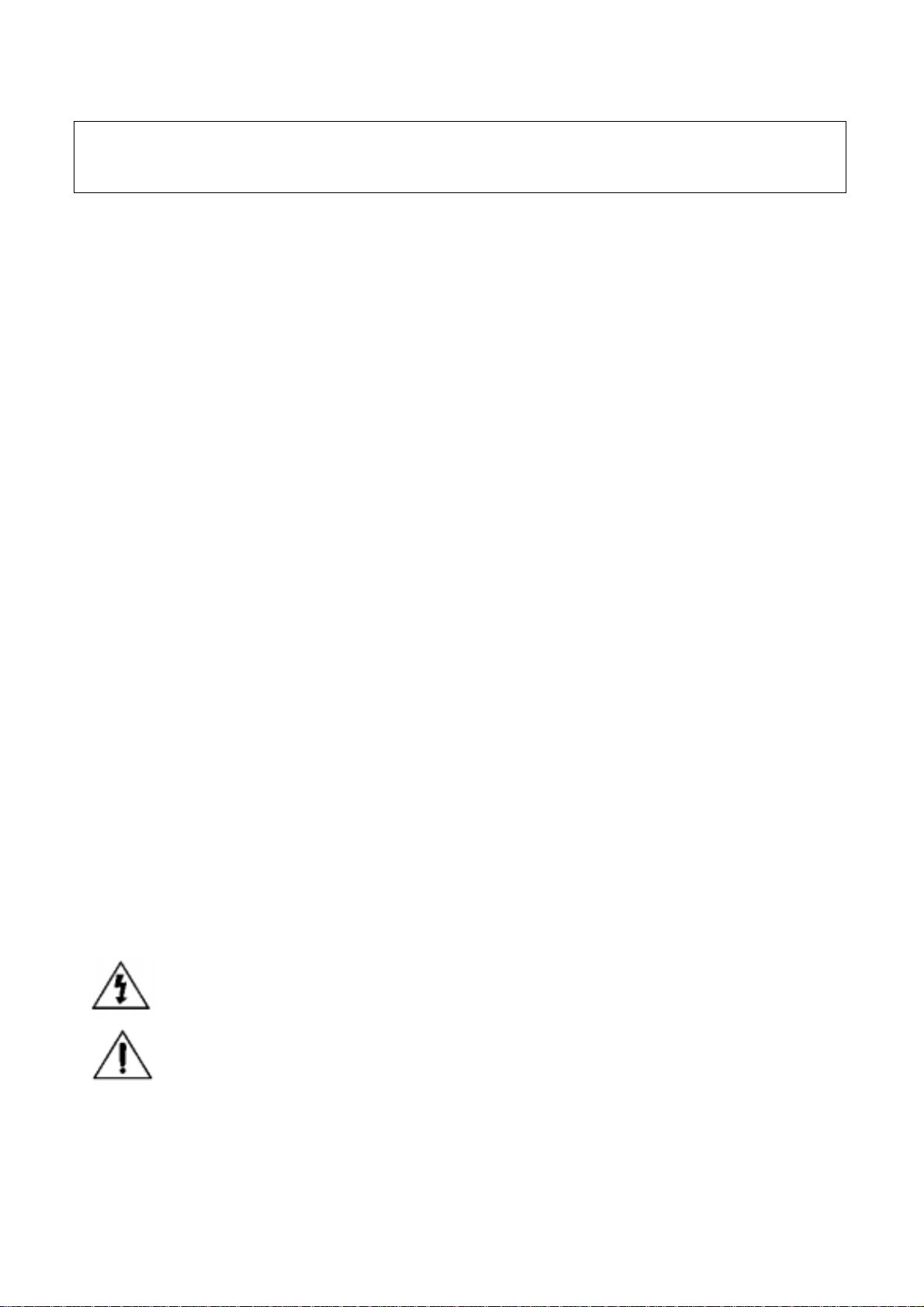

2. Alignment items and procedure

a) B+ voltage check

b) OSD character center adjustment

c) AFT and RFAGC voltage adjustment

d) Focus adjustment

e) Screen-grid voltage adjustment

f) White balance adj ust ment

g) Horizontal and vertical scanning centre and amplitude adjustment

h) Raster correction adjustment

i) HDTV white balance adjustment

j) HDTV Horizontal and vertical scanning centre and amplitude adjustment

k) HDT V raster correction adjustment

Adjustment flow-chat is shown as Fig-1

3

Page 6

E2PROM copy

High voltage check

B+ voltage

OSD position

AFT adjustment

AGC adjustment

Focus

Screen-grid voltage and w hite

balance adjustment

Centre of scanning amplitude and

raster adjustment

X-ray protection check

Filament voltage

SELF CHECK

Picture parts

Sub-brightness

White balance

Colour purity and convergence

Stereo check

Video/S-VHS/DVD

Check

Auto adjustment

The unit and remote

Control function

Fig-1 Adjustment flow-chart

3. Factory mode adjustment

3.1 Enter factory mode adjustm ent

Press the “factory menu” butt on on t he r emote control, the screen display the factory menu.

3.2 factory menu operation method

Press the channel +/- button to selection the sub menu of factory menu, and press the vol+/- to

enter the sub menu or setting the value.

3.3 exit the factory menu

Press the MENU button again and again; it can exit the factory menu.

4

Page 7

4. Adjustment methods

4.1 B+ voltage adjustment

a. Be sure the voltage AC 120V/60Hz.

b. Connect the digital voltmeter to TP3 and GND of B+ test point, input the US-7 signal, set the

picture control to “standard”, adjust RP501 to let the B+(test point) voltage 140V+/ - 0.3V

c. In the STAND BY t urn off, B+ voltage about 20V

4.2 OSD position adjustment

In the factory menu, select SYS SETTING sub menu, adjust OSD H-POS item, let the character

position to screen display center.

4.3 AFT adjustment

a. IF of tuner (TUNER101) output and TP6 are separate.

b. Input 45.75MHz of frequency and 90db of amplitude signals to TP6

c. Adjust the tunable inductance L110, and measure between the TP4 and GND voltage, until the

TP4 voltage to be 2.5V.

d. Output pin IF of TUNER101 and TP6 bonding pad is normal.

4.4 AGC voltage adjustment

a. Receive 60db split field signal

b. Adjust the potentiometer RP101, and measure the TP5 to GND voltage, until the voltage of TP5

to be 3.5V, t hen noise wave of t he pict ur e point disappears.

4.5 focus adjustment

a. Receive A28 signal, set the picture mode to standar d.

b. Adjust focus potentiometer of FBT, until the B area display best.

4.6 Screen-grid voltage and white balance adjustment

a. Receive US-7 split field signal, the picture mode to “warm”.

b. In the factory menu, select the W HITE BALANCE SETTING menu, fixed the CUT OFF R and

adjust the CUT OFF G and the CUT OFF B, until the white balance is norm al.

c. Select t he color and contrast to 0, select the brightness to 50 in the user menu. In the factory

menu, select the LUMINANCE SETTING menu; adjust the Brightness min, until the back level

voltage about 180V. Adjust the SCREEN potentiometer, until rightmost of gray of the US-7

picture up and down separate.

d. Select the color to 0, the brightness to 50 and the contrast to 100 in the user menu, adjust the

Contrast max, until the eight level g r ay amplitude Vp-p to 100V.

e. Select the color to 0, the brightness and the contrast to 100 in the user menu, adjust the

BRIGHTNESS max, until low right back color of the D-8 picture does not white.

f. In the factory menu, select the WHITE BALANCE SETTING sub menu; adjust the white balance

(color temperature to 12000K+/- 8MPCD, the color coor dinat e to 0.270+/-0.008, 0.283+/-0.008).

4.7 Horizontal and vertical scanning centre adjustment of TV

4.7.1 Horizontal center adjustment

Receive A6 signal, the picture mode to “STANDARD” in the factor y menu, select Horizontal

setting menu, adjust the H PO S, until the picture H-center and screen center accord.

4.7.2 Vertical center adjustment

Receive A6 signal, the picture mode to “STANDARD” in the factory menu, select Vertical

setting menu, adjust the V PO S, until the picture V-center and screen center accord.

4.8 Vertical scanning adjustment

Receive A12 signal, the picture mode to “STANDARD” in the factory menu, select Vertical setting

5

Page 8

menu, adjust the V SIZE, until up and down over scanning of the picture to 8% of the all screen.

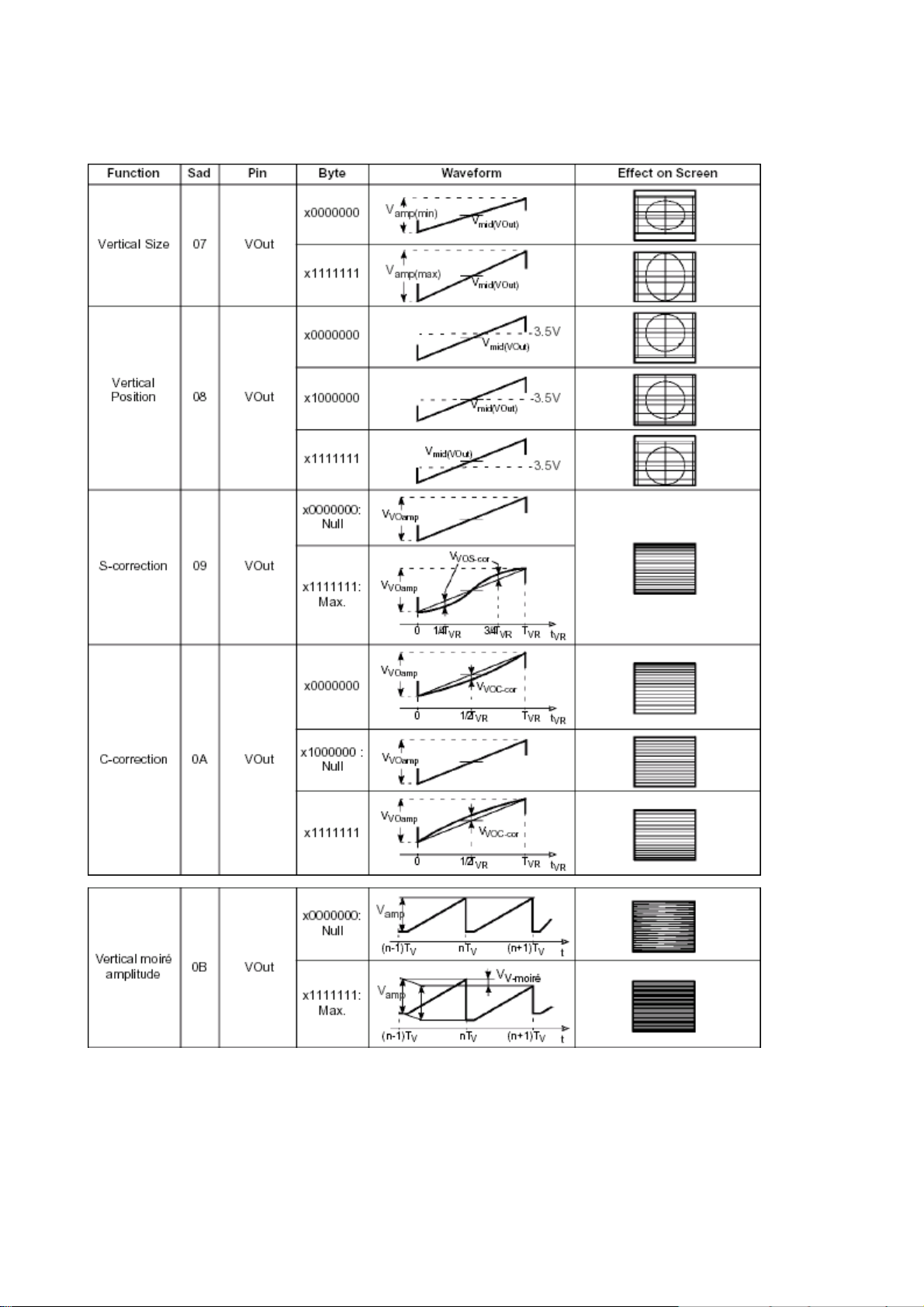

4.9 Raster correction and horizontal amplitude adjust ment of TV

Receive white grid of NTSC signal, the picture mode to “STANDARD” in the factory menu, select

horizontal setting menu, adjust the PCC, until the raster distort least, adjust the H SIZE, until r ight

and left over scanning of the picture t o 8% of the all screen.

4.10 If the scanning line distortion and raster geometric distortion dissatisfy condition, you can

adjust the factory menu item

SCOR

CCOR

PCAC

PCC

KEYST

PARAL

TCC

BCC

4.11 O utput the max sound of power

Receive the US-7 signal; adjust the volume to max, check the sound power output no less than 2 x

6W.

4.12 White balance and Horizontal and vertical scanning centre and amplitude adjustment of HDTV

The unit has the YPBPR terminal; it can display the HDTV sig nal

Support the HDTV and TIMING of the VG 848 format.

When th e whit e bal an ce ad ju stm ent , t he p ict ur e mod e to STANDARD i n the us er m ode. W hen The

H-V scanning adjustment, set the H-CENTER, H-amplitude, V-CENTER and V-amplitude to 0 in the

user menu.

4.12.1 YPbPr input (480p signal)

a. Whit e balance adj ustment

Input eight level gray of 480p format signal to HDTV YPbPr terminal, the picture mode to

ST ANDARD.

In the factory menu, select the WHITE BALANCE SETTING menu; adjust the white balance (color

temperature to 12000K+/-8MPCD, the color coordinat e t o 0. 270+/-0.008, 0.283+/-0.008).

b. H-CENTER adjustment

Input white grid of 480p format signal to HDTV YPbPr terminal, t he picture mode to STANDARD.

In the factory menu, select Horizontal setting menu, adjust the H POS, until the picture H-center and

screen center accord.

c. V-CENTER adjustment

S-Correction

C-Correction

Pin C ushion Asymmetry Correction

Pin Cushion Correction

Keystone Correction

Parallelogram Correction

Top Corner Correction

Bottom Corner Correction

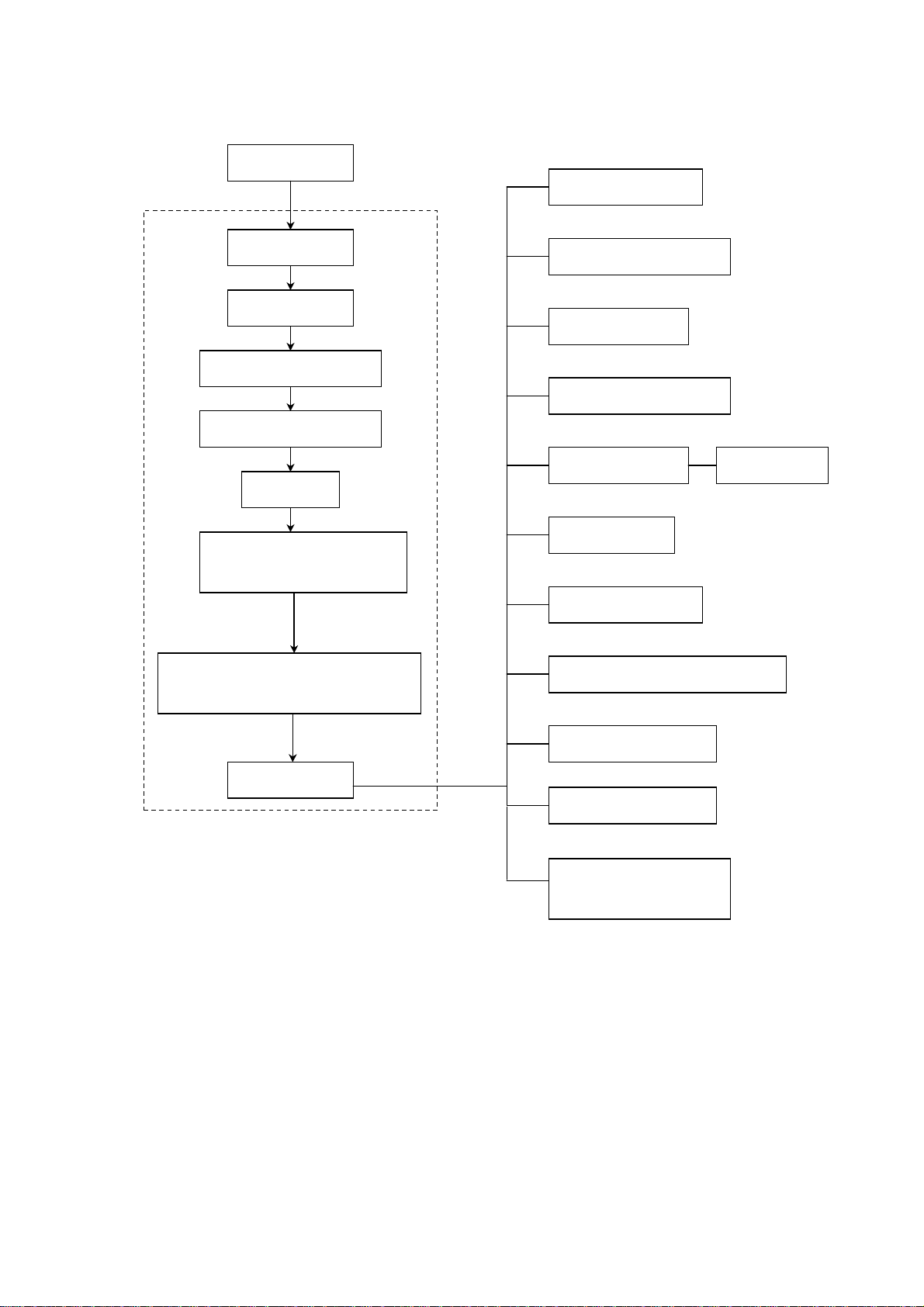

Support input signal of YPbPr

Signal form at TIMING of the VG848 format

480I 950

480P 978

576I 969

576P 979

1080I/60Hz 972

720P/60Hz 976

1080P/60Hz 970

6

Page 9

In the factory menu, select Vert ical setting menu, adjust the V POS, until the picture V-center and

screen center accord.

d. V-SCANNING adjustment

In the factory menu, select Vertical setting menu, adjust the V SIZE, until up and down over

scanning of the picture to 8% of the all screen.

e. Raster correction and horizontal amplitude adjustment

Receive white grid of NTSC signal, the picture mode to “STANDARD” in the factory menu, select

horizontal setting menu, adjust the PCC, until the raster distort least, adjust the H SIZE, until right

and left over scanning of the picture t o 8% of the all screen.

f. If the scanning line distortion and raster geometric distortion dissatisfy condition, you can adjust

the factory menu item

SCOR

CCOR

PCAC

PCC

KEYST

PARAL

TCC

BCC

4.12.2 YPbPr input (1080I/60Hz format signal)

Adjustment mode to 4.12.1

5. Check point

5.1 check the high voltage

a. Check the second anode and GND connect to the high voltmeter

b. Receive US-7 signal, the picture mode to STANDARD, measure the high voltage to

30.0KV+/-1KV.

c. The brightness and contrast t o m in value, while measure the high voltage no more than 35KV.

5.2 check the CRT Filament voltage

Receive the US-7 signal, the picture mode to STANDARD item, measure the CRT filament voltage

to be 6.3+/-0.2Vrms.

5.3 Check the X-ray protection

a. Receive the US-7 signal, the picture to STANDARD item.

b. Connect TP1 to TP2 point of short circuit; X-ray protection cir cuit must be operation.

5.4 Check the picture part

5.5 Check the sub-brightness

5.6 Check chromatic purity and converge

5.7 Check the VIDEO and audio input/out put

5.8 Check the unit and the remote control function

6. Ex-factory pre-setting

7. Check the supply power (AC 100V-140V/60Hz)

S-Correction

C-Correction

Pin Cushion Asymmetry Correction

Pin Cushion Correction

Keystone Correction

Parallelogram Correction

Top Corner Correction

Bottom Corner Correction

7

Page 10

APPX: horizontal and vertical scanning adjustment diagram

8

Page 11

9

Page 12

Working principle analysis of the unit

The unit is digital frequency conversion processing of 16bit bus control color television, it adopt high

integrity digital processing chip EX-11 of TRIDENT, this chip has a A/D conversion, decoder and

scaler. The MCU is 16bit parallel processor M16C of RENESAS.

The unit adopt frequency composition tuner, it can direct display frequency point of every channel.

The decoder chip have digital comb filter, Y/C processing clean separation, chroma signal and

non-crosstalk brightness signal. It adopts three 10bit A/D and D/A conversion to reality of the picture.

The unit working a singles horizontal frequency, it has two YPBPR terminal inputs and support

multi-high definition format (1080i60, 720p, 1080p and so on), it have picture freeze, dynamic digital

code noise reduction, picture edge enhance, PULL-DOWN, 16:9 mode, timing turn off, rotate, CCD

and V-CHIP functions and so on,

The audio processing adopt application specific IC M61519 of MITSUBISHI, it supports stereo,

treble-bass volume control, volume balance, surround sound and over-bass sound functions and so

on. The unit has two AV inputs, an S terminal input, two YCRCB/YPBPR terminal inputs and a video

output.

The RF signal send to compose tuner TUNER101, its pin11 output 38M of IF signal. After the signal

via pre-intermediate frequency amplifier circuit V101, it sends to the picture SAWF Z102 and sound

SAWF Z101, their are co ntain two filter of single PAL and NTSC, i t be contr olled high-low level of the

pin 75 of MCU output (the pin59 of main board X701). The Z101 output sends to the pin8 of

N101(LA7566) and Z102 output sends to the pin5 and pin6 of N101. The N101 supports PAL and

NTSC system, it be controlled high-low level of MCU (N707, M16C/30620SPGP) output. The level

define as follow:

System X701-pin55 X701-pin53 X701-pin51 X701-pin49

DK (6.5M) 0 1 1 0

I (6M) 1 0 0 1

BG (5.5M) 1 1 0 1

M(4.5M) 0 0 0 0

Note: 1-high level, 0-low level

The pin13 of tuner output video, the video send to the digital chip N700(EX-11). It have VIDEO, two

AV input, S terminal input and two YCRCB/YPBPR input, it through matching circuit to N700. After it

via bus control and digital processing to pin37, pin39 and pin41 of X701 socket output R, G and B

signal (peak value to 0.8V) and the pin 48 and pin48 output V-SYNC and H-SYNC. The V-SYNC

and H-SYNC send to deflection chip N302(STV9118), the pin26 of N302 output H-signal drive the

V301(2SC5422) and H-deflection coil of picture tube. The pin24 of N302 output EW signal for raster

geometry adjustment. After the R, G and B signal of digital board send to the pin1, pin3 and pin5 of

pre-video amplifier N801(STV9211) form pin14, pin16 and pin18 output to CRT board. The N401 of

CRT board to R,G,B signal amplify to peak value(about 100V), it send to c athode of the pictu re tube.

The SIF of the SAWF output send to stereo decoder NS01(LA72700), then it output L/R of audio.

The L/R audio of TV, AV/S input and YCRCB/YPBPR input send to sound processor N601(M61519).

Through BUS control of N707 to select processing of N601 signal channel, the pin25 and pin18 of

N601 output L/R audio send to N602 (TA8256BH), the pin8 and pin12 of N602 output L/R audio

drive speaker. In the mute state, the N707 send high level to the pin5 of N602, but the power

amplifier without signal.

10

Page 13

0

bPr1YPbPr2

t

R

N

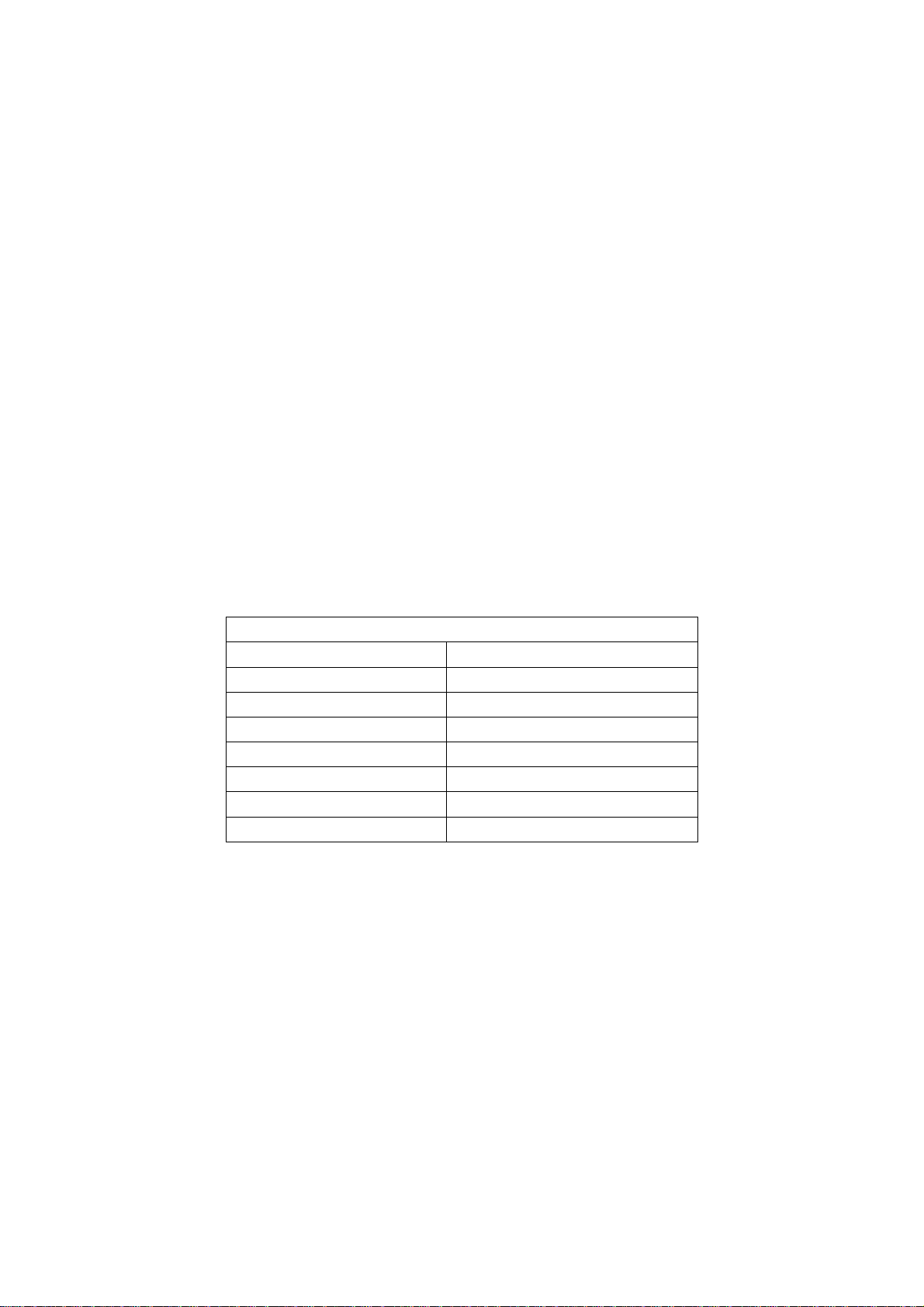

Block diagram

LA72700

I2C

NS01

SIF

N101

IF

LA7566

Clamp

Blanking

R

G

B

I2C

L/R

N801

PRE-VIDEO

AMP.

STV9211

I2C

N707

CPU

M16c/30620SPGP

AV ou

AV2

L

L

I2C

2

I

R

C

L

SOUND PROCESSING

R

G

B

R

N601

M61519

BOARD

LM2423

DDY

STV9118

ROM

24C16

L

CRT

302

YP

R

AV1/S

L

STEREO DECODER

AVOUT-V

TUNER

AV1(video)/Y

C

AV2(video)

YPbP

r1

SOUND SAWF

PICTUR SAWF

Z1

N700

ND decodor, scaler

Trident

EX-11

2

CVBS

YPbP

r2

I2C

EMST

16161

EMST

16161

R

L

R

R

G

B

SOUND

AMP.

TA8256

CRT

H-AMP

2SC5422

V-AMP

LA78041

L

11

Page 14

IC block diagram

1. LA7566

10: AFT output 19: SIF output

9: AGC output 1: TV audio output

5, 6: picture IF input 13: TV video output

8: sound IF input 3: 9V

12

Page 15

2. EX-11

185: S-C input 187: Pb2 input

196: AV1-V/S-Y input 180: Pr2 input

197: AV2-V input 14: SCL

198: TV-V input 16: SDA

200: Y1(PbPr) input 190, 191: AVOUT-V output

186: Pb1 input 28: B output

179: Pr1 input 29: G output

202: Y2(PbPr) input 30: R output

34: H-SYNC output 31: VM output

37: V-SYNC output 9, 168 and so on: 1.8V

36: CLAMP output 15: 5V-1

13

Page 16

3. M61519FP

39: AV2 audio-L input 7: AV1/Saudio-R input

4: AV2aduion-R input 35: AVOUT audio-L output

6, 37: TV audio input 8: AVOUT audio-R output

38: YPbPr1audio-L input 11: audio- L output

5: YPbPr1audio-R input 19: audio-R output

40: YPbPr2audio-L input 22: CLOCK

3: YPbPr2audio-R input 21: DATA

36: AV1/Saudio-L input 20: 9V

14

Page 17

4. STV9118

2: V-SYNC input 24: pincushion correction output

1;V-SYNC input 25: X-ray protection input

18: Vertical high voltage compensation input 31: SDA

17:Horizontal high voltage compensation input 30: SCL

26: horizontal signal output 29: 12V

23: vertical signal output

15

Page 18

5. STV9211

1: R input 1: ABL

3: G input 5: B input

13: SDA 16: G output

19: CLAMP 14: B output

20: BLANK 7, 17: 5V

18: R output 12: SCL

16

Page 19

6. LA72700V

5: SIF input 25: R output

11: SDA 26: L output

12: SCL 31: 9V

17

Page 20

Wiring diagram

18

Page 21

Trouble shooting

f

y

n

y

l

N

N

f

N

No N

1. No raster, No picture and No sound

Check the indicator

Press the power button

o signal

Check if the pin10 o

CPU has low-level

output

Check if it has X-ra

protection

Check if it has

vertical protectio

circuit

Light

Turn on

Check if the N802 is

normal

o-light

Check the FU501

Measure if the C516 is

about 150V

Check the N501, N502

and peripheral circuit

Check the suppl

power

Check the D501

and periphera

circuit

2. Picture, but w i t hout sound

Check if the N602 output

Check if the pin2 and pin4 o

sound amplifier output

Check the supply power, the

pin5 of mute is low level

Yes

Yes

Speaker damage

o

Check if sound-processing

601 is normal.

19

Page 22

3. Sound, but wit hout pi cture

p

p

p

d

N

No N

Without raster Raster

It has sound, but without picture

Check if the

in26 of N302

has H-frequency

Check if the

V301 is damage

Abnormal

Check B+

Check if the H-V

circuit is normal

ormal

Check the FBT

Check the filament

voltage of CRT

board

Check if the digital

rocessing board has

RGB and H-V sync

output

Check if the digital

rocessing board has

RGB output

Check the N801 an

peripheral circuit

Check the N700

and peripheral

circuit

o

Check the digital

20

Page 23

Schematic diagram

21

Page 24

Page 25

Page 26

5

SC1

SD1

5V-1_DPTV

D D

C783

0.1uF

0

R729

C C

B B

MD[0..31]

DQM[0..3]

A A

MA[0..10]

NKL

CS0#

RAS#

CAS#

R774 68

R770 68 RN702

C770

68pF

RST

N700A

MD0

53

MD1

MD2

MD3

MD4

MD5

MD6

MD7

MD8

MD9

MD10

MD11

MD12

MD13

MD14

MD15

MD16

MD17

MD18

MD19

MD20

MD21

MD22

MD23

MD24

MD25

MD26

MD27

MD28

MD29

MD30

MD31

DQM0

DQM1

DQM2

DQM3

5

MD0

55

MD1

56

MD2

58

MD3

62

MD4

64

MD5

66

MD6

68

MD7

69

MD8

71

MD9

72

MD10

74

MD11

78

MD12

80

MD13

82

MD14

84

MD15

124

MD16

126

MD17

128

MD18

130

MD19

134

MD20

136

MD21

137

MD22

139

MD23

140

MD24

142

MD25

144

MD26

146

MD27

150

MD28

152

MD29

153

MD30

155

MD31

59

DQM0

75

DQM1

133

DQM2

149

DQM3

SVP-EX_208

NKL

C772

68pF

12

13

15

V5SF

RESET

TESTMODE

SVP-EX [208]

DQS060DQS176DQS2

DQS3

132

148

NKL

4

A4

A5

16

SDA

A7A1A6

RN701

22x4

7 8

14

165

SCL

5 6

164

A_D7

A_D6

3 4

163

A_D5

1 2

162

A_D4

161

A3

7 8

160

A_D3

A_D2

A2

5 6

159

A_D1

A0

3 4

158

A_D0

22x4

1 2

(1 of 2)

MA1185MA1087MA988MA890MA791MA693MA594MA496MA398MA299MA1

MA7

MA8

MA9

MA6

MA5

MA10

4

MA4

MA3

101

MA1

MA2

TP_C30

MA0

102

MA0

TP1

170

171

RD#

MCK0

106

107

172

ALE

WR#

MCK0#

CS0#

CS1#

109

111

3

RN703

1 2

3 4

5 6

7 8

173

174

INT#

MPUCS0N

RAS#

CAS#

MVREF

113

114

116

TP2

TP_C30

3

22x4

MPUCS0N

R711 0_DNS

18

17

P_17

FLD/IO

MPUGPIO0

MPUGPIO1

VDDR

VSSR

VDDM

VDDM

VDDM

VDDM

VDDM

VDDM

VDDM

VDDM

VDDM

VDDM

VDDM

VDDM

VSSM

VSSM

VSSM

VSSM

VSSM

VSSM

VSSM

VSSM

VSSM

VSSM

VSSM

VSSM

WE#

CLKE

BA0

BA1

118

R710 0_DNS

120

121

123

A[0..7]

Option

157

156

115

117

151

145

135

129

112

110

100

95

79

73

63

57

147

143

131

127

108

105

97

92

81

77

65

61

Option

BA

CLKE

WE#

2

VCC_3

I2C Address:

10K

7E/7F

I2C

Address:

7C/7D

Not

Populated

CS

1K_DNS

VCC_3

R732

10K

R731

INPUT

MPUGPIO0

01

OUTPUT

MPUCS0N

0

RD

WR

ALE

INT

10K_DNS

MPUGPIO0

MPUGPIO1

R781

R782

VDDM

110

*CS1N is not a input or output pin

CS1N=0: SVP-EX CPU access enabled

CS1N=1: SVP-EX CPU access disabled

VDDM VDDM

C767

0.1uF

C764

0.1uF

Title

Schematict Name Rev

A

Size

2

10K

R769

R768

1K

SVP-EX 1 of 2

FB420 G

16

of

Date:Sheet

Tuesday, Apr il 0 5, 2005

1

CS1N

1

Page 27

5

MLF1

PLF2

C794

0.1uF

C786

0.1uF

AGND

67

83

89

119

125

141

168

54

70

86

122

138

154

169

208

SVP-EX_208

C795

20pF

R702 10K_DNS

N700B

3

MLF1

6

PLF2

9

VDDC

VDDC

VDDC

VDDC

VDDC

VDDC

VDDC

VDDC

8

VSSC

VSSC

VSSC

VSSC

VSSC

VSSC

VSSC

VSSC

1

XTALO

XTALI

C793 2700pF

C785 2700pF

PDVDD

C7A3

0.1uF

PDVSS

PAVDD

C7B0

0.1uF

PAVSS

5

Option

52

EX11/12 USE

EX32 USE

R704

10K_DNS

Option

R706

10K

VDDC

VDDH

VSSH

VSSC

41

43

P_4444P_4545P_4646P_4747P_4848P_4949P_5050P_5151P_52

P_3737P_3838P_3939P_4040P_41

P_4242P_43

SVP-EX [208]

(2 of 2)

PAVSS

PDVSS

AVSS_ADC1

AVSS3_BG_ASS

AVSS_ADC2

AVSS_ADC3

VSSH

VSSL

189

182

176

AVSS_ADC3

AVSS3_BG_ASS

AVDD_ADC3

AVSS_ADC3

167

20

VSSH

103

VSSL

VSSH

AVDD_ADC1

AVSS_ADC1

AVDD_ADC2

AVSS_ADC2

L710

C7A1

0.1uF

C7A9

0.1uF

C7A7

0.1uF

PAVSS2

4

7

PAVSS2

PAVSS1

PAVSS1

207

205

PDVSS

PAVSS

PAVDD1

PAVSS1

PAVDD2

PAVSS2

193

AVSS_ADC1

MLF1

PLF2

AVSS_ADC2

R708 10

36

PAVDD2

2

5

PAVDD2

PAVDD1

C732

10uF/16V

PAVDD

PAVDD1

206

PAVDD

1 2

VD3_3

D D

VD1_8

C C

G700

14.318MHz

C796

20pF

VL1_8

L704 150_Ohm_600mA

B B

1 2

C729

10uF/16V

L707 150_Ohm_600mA

1 2

C727

10uF/16V

L711 150_Ohm_600mA

1 2

C734

A A

10uF/16V

L713 150_Ohm_600mA

1 2

C743

10uF/16V

4

ADVDD33

AVSS33_1

PDVDD

AVDD_ADC1

AVDD3_AVSP2

AVDD_ADC2

AVDD_ADC3

204

192

188

181

175

PDVDD

AVDD_ADC2

AVDD_ADC1

AVDD_ADC3

AVDD3_AVSP2

L705

1 2

C742

150_Ohm_600mA

10uF/16V

L708

1 2

C740

150_Ohm_600mA

10uF/16V

VA1_8

150_Ohm_600mA

4

166

VDDH

19

AGND

R775

AVDD33

VDDH

AVSS33_3

VDDL

104

VDDL

VDDH

VA1_8

VA1_8

560

AGND

AIN_HS

AIN_VS

P_2121P_2222P_2323P_2424P_2525P_2626P_2727P_2828P_2929P_3030P_3131P_3232P_3333P_3434P_3535P_36

Y_G1

PB_B1

PR_R1

Y_G2

PB_B2

PR_R2

CVBS_OUTP

CVBS_OUTN

CVBS1

CVBS2

CVBS3

AIN_N1

AIN_N2

AIN_N3

VREFP_1

VREFN_1

VREFP_2

VREFN_2

VREFP_3

195

194

184

183

178

VDDL

C760

0.1uF

VSSL

AGNDAGND

VDDC

VSSC

AVDD3_AVSP2

C7A8

0.1uF

AVSS3_BG_ASS

C

VREFN_3

177

VREFN_3

VREFP_3

VREFN_2

VREFP_2

VREFN_1

VREFP_1

VD1_8

10

11

200

186

179

202

187

180

190

191

196

197

198

185

199

201

203

PRELIMINARY

V-sync

CLAMP

H-sync

VM

R_

G_

B_

R773

0/10K

When use EX12,use 0ohm;

When use EX22,use 10Kohm.

H-DSUB

V-DSUB

Y

Pb

Pr

Y_G2

PB_B2

PR_R2

CVBS_OUTP

CVBS_OUTN

CVBS1_

CVBS2_

CVBS3_

C_

AIN_N1

C766

0.1uF

AIN_N2

AIN_N3

L706

1 2

C704

10uF/16V

L712

1 2

C741

10uF/16V

AIN_N2

AIN_N3

VD1_8

150_Ohm_600mA

VD3_3

150_Ohm_600mA

3

C749 0.1uF

CVBS1_

R759

75

CVBS1_G

C750 0.1uF

CVBS2_

R760

75

CVBS2_G PB_B2_G

C751 0.1uF

CVBS3_

R761

75

CVBS3_G

C746 0.1uF

C_

R756

75

C_G

AVDD33

ADVDD33

AVSS33_3

AVSS33_2

AVSS33_1

AIN_N1

CVBS_OUTP

CVBS_OUTN

AGND

3

C712

0.1uF

CVBS1_G

CVBS2_G

CVBS3_G

C_G PR_R2_G

Place this

R790

resistor close to

EX chip

1K

AGND

10uF/16V

C7A2

30pF

C799 0.1uF

TV Y G-DSUB

TV_G

VIDEO1

VIDEO1_G

VIDEO2/Y-YC Pr

VIDEO2/Y_G

C-YC

VD3_3

C718

0.1uF

C733

VIDEO_OUT

R789

75

VIDEO_OUT_G

2

Y

Pb

Pb

Pr

C780

B

C720

10uF/16V

VREFP_2

0.1uF_DNS

AVSS_ADC2

C761

0.1uF

L709

1 2

C788

Title

VDDH

C710

VREFP_1

0.1uF_DNS

AVSS_ADC1

2

C719

0.1uF

C789

AIN_N2

R791

1K

AGND

C774

0.1uF

VSSH

C782

0.1uF

AIN_N2 AIN_N3

C791

0.1uF

0.1uF

VREFN_1

C781

0.1uF

0.1uF

Y_G1_G

PB_B1_G

PR_R1_G

Place this

resistor close to

EX chip

C763

C762

0.1uF

0.1uF

Schematict Name Re v

Size

1

C753 0.1uF

Y_G2

R763

75

Y_G2_G

C748 0.1uF

PB_B2

R758

75

C745 0.1uF

PR_R2

R755

75

PR_R2_G

VD3_3

150_Ohm_600mA

VREFN_2

C779

0.1uF

AIN_N3

R793

1K

AGND

C765

C768

0.1uF

0.1uF

SVP-EX 2 of 2

FB420 G

26

of

VREFP_3

0.1uF_DNS

C778

0.1uF

AVSS_ADC3

Y_G2_G

PB_B2_G

Place this

resistor close to

EX chip

C776

C792

0.1uF

0.1uF

Tuesday, April 05, 2005

Date:Sheet

1

B-DSUB

R-DSUB

C787

C784

0.1uF

VREFN_3

VD1_8

C777

0.1uF

Page 28

5

4

3

2

1

BA

WE#

CAS#

D D

RAS#

NKL

R709 33

R705 33

R703 33

R701 33

R700 33

BA_

WE_

CAS_

RAS_

NKL_

MA[0..10]

CLKE

C C

VCC3_M

B B

R707 33

35

15

16

17

MD0

MD1

MD2

MD3

MD4

MD5

MD6 MD17

MD7

MD8

MD9

MD10

MD11

MD12

MD13

MD14

MD15

11

12

39

40

42

43

45

46

48

49

13

38

44

25

2

DQ0

3

DQ1

5

DQ2

6

DQ3

8

DQ4

9

DQ5

CLK

RAS

CAS

WE

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

VDDQ

7

VDDQ

VDDQ

VDDQ

VDD

1

VDD

CS

18

CLKE_

19

KM416S1020B

MA10

BA

MA9

MA8

MA7

MA6

MA5

MA4

MA3

MA2

MA1

MA0

CKE

UDQM

LDQM

N.C.

N.C./RFU

VSSQ

VSSQ

VSSQ

VSSQ

VSS

VSS

N701

20

32

31

30

29

28

27

24

23

22

21

34

36

14

33

37

10

4

47

41

50

26

MA10

MA9

MA8

MA7

MA6

MA5

MA4

MA3

MA2

MA1

MA0

DQM1

DQM0

VCC3_M

MD23

MD22

MD21

MD20

MD19

MD18

MD16

MD24

MD25

MD26

MD27

MD28

MD29

MD30

MD31

11

12

39

40

42

43

45

46

48

49

13

38

44

25

2

3

5

6

8

9

7

1

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

VDDQ

VDDQ

VDDQ

VDDQ

VDD

VDD

35

17

CLK

16

RAS

15

CAS

18

19

WE

CS

KM416S1020B

MA10

BA

MA9

MA8

MA7

MA6

MA5

MA4

MA3

MA2

MA1

MA0

CKE

UDQM

LDQM

N.C.

N.C./RFU

VSSQ

VSSQ

VSSQ

VSSQ

VSS

VSS

N702

20

32

31

30

29

28

27

24

23

22

21

34

36

14

33

37

10

4

47

41

50

26

MA10

MA9

MA8

MA7

MA6

MA5

MA4

MA3

MA2

MA1

MA0

DQM3

DQM2

VCC3_M

VCC3_M

VCC3_M

VCC3_M

C722

1000pF

C702

0.1uF

C701

1000pF

C726

0.1uF

C775

1000pF

C700

0.1uF

1000pF

C790

0.1uF

C709

C773

1000pF

C707

0.1uF

C711

0.1uF

C723

100uF/16V

C708

1000pF

C703

100uF/16V

CS0#

MD[0..31]

DQM[0..3]

MD[0..31]

DQM[0..3]

SDRAM

DECOUPLING

VCC3_MVCC3

CAPACITORS

L700

C728

A A

22uF/16V

C797

0.1uF

Title

SDRAM 1MX16

Schematict Name Rev

FB420 G

A

Size

5

4

3

36

2

of

Date:Sheet

Thursday, March 31, 2005

1

Page 29

5

4

3

2

1

3.3V POWER FOR SDRAM

3.3V_1

D D

L714

C757

C7B5

100uF/16V

0.1uF

N703

SS6117A-1.8

3

IN

GND

OUT

2

L720

VA1_8

C7A6

0.1uF

C739

22uF/16V

1

3.3V_2

L717

C7B1

0.1uF

L716

C755

22uF/16V

3.3V POWER FOR SVP-EX

VL1_8

N704

SS6117A-1.8

3

IN

C C

OUT

2

GND

1

L721

C737

0.1uF

C735

22uF/16V

L718

C769

0.1uF

VD3_33.3V

C713

22uF/16V

VCC3

C7A0

0.1uF

VDDM

C736

22uF/16V

VD1_8

N705

SS6085-1.8

3

IN

B B

4

GND

GND

1

OUT

2

C705

0.1uF

C706

22uF/16V

3.3V_3

L719

3.3V POWER FOR SVP-EX

L715

C7C0

0.1uF

C759

22uF/16V

C758

22uF/16V

VCC_3

C7B9

0.1uF

L722

5V-1 5V-1_DPTV

D702 1N4148

A A

Title

POWER

Schematict Name Rev

FB420 G

A

Size

5

4

3

46

2

of

Date:Sheet

Tuesday, Apr il 0 5, 2005

1

Page 30

5

4

3

2

1

LR-MUTE

X700 HEADER_24X2

W-MUTE

SDA-EEP

D D

SCL-EEP

PAGE-EEP

CNVSS

RESET-CPU

TX

RX

5V-1

CLK1

CTX1/RTX1

HOLD

WR_

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

27 28

29

C C

SDA

SCL

31 32

33 34

35 36

R-OUT

G-OUT

B-OUT

37 38

39 40

41 42

21

SCL_CPU

SDA_CPU

3.3V

ON-TIMER

REMOTE

KEY

5V-1

Power

FLASH

26

30

V_Protect

X_Ray

5V-1_CPU

SDA

R7A5

SCL

10K

S-TRAP4

S-TRAP3

S-TRAP2

S-TRAP1

PAL/N

AFT

TV_G

VIDEO1_G

VIDEO1

AIN_N3

V-DSUB

H-DSUB

B-DSUB

G-DSUB

R-DSUB

TV_G

TV

TV

VIDEO1_G

VIDEO1

AIN_N3

Rotation

SVM

X701 HEADER_17X2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

27 28

29

31 32

33 34

21

VIDEO OUT_G

VIDEO2/Y_G

26

AIN_N2

30

Pr_1

Pb_1

Y_1

R762

75

R757

75

C744 0.1uF

C747 0.1uF

C752 0.1uF

R754

75

TV-Hsync

3.3V_1

3.3V_2

3.3V_3

VIDEO_OUT_G

VIDEO_OUT

YC/VIDEO

C-YC

VIDEO2/Y_G

VIDEO2/Y-YC

AIN_N2

Pr_1#

Pb_1#

Y_1#

43 44

BLANKING

CLAMP

45 46

47 48

GND_CPU

B B

R764

R765

R766

75

75

75

C7B4

10pF

L701

L702

L703

10pF

C7B6

10pF

C7B7

C7B8

10pF

G-OUT

B-OUT

R_

R_ R-OUT

G_

G_

B_

B_

C7B2

C7B3

10pF

10pF

A A

GND_CPU

5

V-sync

H-sync

SDA

SCL

0

R798

0

R7A1

VM

R7A6

100

5V-1

R7A0

4.7K

5V-1

R7A2

4.7K

R771

2.2K

V700

MMBT3906

(PNP)

R799

R7A3

R772

1K

C7Y3 0.1uF

C7Y4 0.1uF

Pr_1#

PR_2

R7Y3

5V-1

C7Y2

47uF/16V

0_DNS

C7Y5 0.1uF

NY01

1

2

3

4

5

R7Y4 100

5V-1

C7Y1

1000pF

R7Y1

R7Y2

0_DNS

0_DNS

0

SD1

0

SC1

SELECT

TJC3_5

X702

SVM

Y_1#

Y_2

Pb_1#

PB_2

1

IN

2

S1A

3

S2A

4

DA

5

S1B

6

S2B

7

DB

GND8DC

FSAV330

VCC

S1D

S2D

S1C

S2C

/EN

16

15

14

13

12

DD

11

10

9

Y

Pb

Pr

Title

INTERFACE CONNECTOR

Schematict Name Re v

B

Size

4

3

2

FB420 G

Wednesday, April 06, 2005

56

Date:Sheet

of

1

Page 31

5

4

3

2

1

5V-1_CPU

R78510K

V701

MMBT3904_DNS

R787

1K_DNS

Optional

GND_CPU

E C

Power

D D

100

LR-Mute

W-Mute

PAL/N

R784

100

R743

R783 100_DNS

R780 100

OPTION

75

100

R7A4

10K

GND_CPU

PAGE-EEP

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

GND_CPU

R779

R778

47

R777 100

100

R720

100_DNS

R718

OPTION

R719 10K

SELECT

100

R717

R726 100

R725 100

R724 100

5V-1_CPU

100_DNS

R723

R721 100_DNS

OPTION

PAGE-EEP

ON-Timer

BLANKING

D701

C C

B B

GND_CPU

V_Protect

5V-1_CPU

R716

10K

KEY

100pF

GND_CPU

C725

YC/VIDEO

X_Ray

AFT

5V-1_CPU

C724

100pF

Key_IN_LED

GND_CPU

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

P1_2

P1_1

P1_0

P0_7/AN0_7

P0_6/AN0_6

P0_5/AN0_5

P0_4/AN0_4

P0_3/AN0_3

P0_2/AN0_2

P0_1/AN0_1

P0_0/AN0_0

P10_7/AN7

P10_6/AN6

P10_5/AN5

P10_4/AN4

P10_3/AN3

P10_2/AN2

P10_1/AN1

Avss

P10_0/AN0

Vref

Avcc

P9_7/ADTRG

P9_6

P9_5

P9_4/DA11P9_2/TB2in3P9_1/TB1in4BYTE6CNVss7P8_6/Xcout9Reset10Vss12Xin

Rotation

S-TRAP1

S-TRAP2

S-TRAP3

S-TRAP4

R722 100

Option

R727 0_DNS

R728 0_DNS

R730 0_DNS

R733 0_DNS

5V-1_CPU

R715 220

D700 HZ4A2

R713 1K

C721 1000pF

C714 10uF/16V

A A

GND_CPU

R714

8.2K

C715

47uF/16V

MMBT3906

B

C E

B

P1_474P1_3

P9_3/DA0

2

V702

RESET-CPU

TP3

AD0

R78610K

73

P1_7/INT571P1_6/INT472P1_5/INT3

P9_0/TB0in

5

R734

4.7K

5V-1_CPU

TP4

AD1

TP8

TP5

AD2

A1A3A0

TP9

TP6

TP7

AD5

AD6

AD3

AD4

A4A4A3A1A2

A5A5A7

A6

P2_0/A0/D070P2_1/A1/D169P2_2/A2/D268P2_3/A3/D367P2_4/A4/D466P2_5/A5/D565P2_6/A6/D664P2_7/A7/D7

M30620SPGP

P8_7/Xcin

Xout

8

11

CNVSS

R735

GND_CPU

GND_CPU

G701

10MHz

C798

15pF

4.7K

TP10

AD7

63

N707

13

5V-1_CPU

62

Vss

Vcc114P8_5/NIM

C7A4

15pF

RESET-CPU

5V-1_CPU

GND_CPU

61

P3_0/A8

15

R788

4.7K

A[0..7]

60

59

Vcc2

P3_1/A9

P8_3/INT117P8_2/INT018P8_0/TA4out20P7_7/TA3in

P8_4/INT216P8_1/TA4in

P3_2/A1058P3_3/A1157P3_4/A1256P3_5/A1355P3_6/A1454P3_7/A1553P4_0/A1652P4_1/A17

P6_0/CTS0/RTS0

P6_4/CTS1/RTS1

P7_5/TA2in

P7_6/TA3out

P7_4/TA2out

23

22

21

19

24

H-sync

51

P4_2/A18

P4_3/A19

P4_4/CS0

P4_5/CS1

P4_6/CS2

P4_7/CS3

P5_0/WR

P5_1/BHE

P5_2/RD

P5_3/BCLK

P5_4/HLDA

P5_5/HOLD

P5_6/ALE

P5_7/RDY

P6_1/CLK0

P6_2/SCL0

P6_3/SDA0

P6_5/CLK1

P6_6/RXD1

P6_7/TXD1

P7_0/SDA2

P7_1/SCL2

P7_2/TA1out

P7_3/TA1in

25

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

5V-1_CPU

R741

R740

R739

R738

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

C731

33pF

R742

R737

10K

RX

TX

SDA-EEP

SCL-EEP

100_DNS

100

100

100

GND_CPUGND_CPU

R753 100

R752 4.7K

R751 4.7K

R749 100

R747 100

R746 4.7K

R745 100

100_DNS

OPTION

OPTION

C730

100pF

A[8..17]

A[0..7]

R712

0

12

11

10

27

26

23

25

28

29

30

31

9

8

7

6

5

4

3

2

N708

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

WE

A290021

(W29C020)

A0

A2

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

5V-1_CPU

TP12

RD

TP13

ALE

ALE

FLASH

INT

Rotation

SCL_CPU

SDA_CPU

GND_CPU

TV-Hsync

REMOTE

13

I/Q0

14

I/Q1

15

I/Q2

17

I/Q3

18

I/Q4

19

I/Q5

20

I/Q6

21

I/Q7

22

CE

24

OE

32

VCC

1

RESET

16

GND

R748 47K

R736

1K_DNS

Option

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

PS

GND_CPU

CS_

R750 0

RD_

5V-1_CPU

R796

4.7K

CTX1/RTX1

CLK1

RX

WR_

HOLD

TX

CNVSS

5V-1_CPU

C717

0.01uF

10uF/16V

R795

4.7K

R744

10K

C754

100pF

GND_CPUGND_CPU

C716

5V-1_CPU

R767

10K

100pF

C756

CS

R794 100

B

C7C1

100pF

GND_CPUGND_CPU

GND_CPU

5V-1_CPU

E C

GND_CPU

100pF

TP14

R797

10K

V703

MMBT3904_DNS

SCL

SDA

C7C2

SDA-EEP

SCL-EEP

N706

1

2

3

4

5

6

7

14

1Y

VCC

13

1A

4Y

12

1B

4A

11

2Y

4B

10

2A

3Y

9

2B

3A

8

3B

GND

74HC02

TP11

WR

C738

10uF/16V

GND_CPU

5V-1_CPU

C7A5

0.01uF

RD

WR

RST

5V-1

5

R792 0

5V-1_CPU

Title

Schematict Name Rev

C

4

3

2

Size

M30620SPGP

FB420 G

66

of

Date:Sheet

1

Tuesday, April 05, 2005

Page 32

603-TJ27680-01

603-TJ27780-01

603-TJ3060-01

Ver.1.0

Loading...

Loading...