Page 1

PDP TELEVISION

PH-63FB8

Page 2

CONTENTS

Safety precautions………………………………………………………………………..…

Alignment instructions …………………………….…….…………………………………

Method of software upgrading……………….…….……………………………………….…….

Working principle analysis of the unit……………………………….………….………….

Block diagram…………………………………..………………………………….…………

IC block diagram………………………………………………………………………..……

Wiring diagram …………………………………………………………………………….

Diagnosis for plasma screen……………………………………………………….……..

Troubleshooting guide ………………………………………………………………..……

Schematic diagram…………………………………………………………………………

APPENDIX: Exploded View

1

6

11

17

18

19

27

28

31

43

Page 3

Note: This maintenance manual is intended only for the reference of the maintenance people.

Please pay attention to the following points before carrying out the maintenance work.

Safety Precautions

Please read the “Points for attention for the Maintenance & Repair of PDP” and “Criterion for

Identifying the Defects on Screen” as below, before inspecting and adjusting the TV set.

1. “Points for attention for the Maintenance & Repair of PDP”

To avoid possible danger, damage or jeopardy to health and to prevent PDP screen from new

damage, the maintenance people must read the following carefully. If they ignore the following

warnings, there will be deathful risks:

1.1 Screens vary from one model to another and therefore not interchangeable. Be sure to use the

same type of screen in the replacement.

1.2 The operation voltage is approximately 350V for PDP module (including screen, driving circuit,

logic circuit and power module). If you want to conduct maintenance work on PDP module when the

set is in normal operation or just after the power is off, you must take proper measures to avoid

electric shock and never have direct contact or touch with the circuitry of the working module or

metal parts. That’s because within a short time relatively high voltage still remains on the capacitor

of the driving part even after the power is off. Make sure to begin relevant maintenance operation at

least one minute after the power is off.

1.3 Don’t apply on the module any power supply that is higher than the specification. If the power

supply used deviates from the value given in the specification, there might be a possibility of leading

to fire or damage to the module.

1.4 Never have operation or mounting work under unsuitable environment such as areas in the

vicinity of water – bathroom, laundry, water chute of kitchen – sources of fire, heat-radiation parts or

direct exposure to sunlight. Otherwise there will be kickbacks.

1.5 In case foreign substances such as water, liquid, metal slices or others fall into the module

carelessly power must be cut off immediately. Keep the module as it is and do not move anything on

the module. Otherwise it might be possible to contact the high voltage or cause shock short circuit

so that it may lead to fire or electric shock.

1.6 If there is smoke, abnormal smell or sound from the module, please cut the power off

immediately. Likewise in case the screen doesn’t work when the power is on or during the operation,

please also cut off the power at once. No more operation in this case.

1.7 Do not remove or plug its connection wire when the module is in operation or right after the

power is off. That’s because there remains a relatively high voltage on the capacitor of the driving

circuit. If there is a need to remove or plug in the connection wire, please wait at least one minute

after the power is off.

1.8 Considering the module has a glass faceplate, please avoid extrusion by external force lest it

should cause glass breakage that may get people injured. Two people are needed in cooperation to

move this module lest contingency takes place.

1.9 The complete TV set is designed on the basis of full consideration of thermal dissipation by

convection, with the round hole on the top for heat emission. To avoid overheat, please do not have

any covering on the hole during normal operation and never put it in the place where the space is

narrow and in bad ventilation.

1.10 There is quite a number of circuits in PDP that are integrated ones. Please be on guard against

1

Page 4

static electricity. During maintenance operation be sure to cover yourself with anti-static bag and

before operation make sure to have it sufficiently grounded.

1.11 There are a big number of connection wires distributed around the screen. Please take care

not to touch or scuff them during maintenance or removing the screen, because once they are

damaged the screen will fail to work and it’s not possible to repair it.

If the connection wires, connectors or components fixed by the thermotropic glue need to disengage

when service, please soak the thermotropic glue into the alcohol and then pull them out in case of

damage.

1.12 Connector for the circuit board of the screen part is relatively fine and delicate. Please take

care in the replacement operation lest it should get damaged.

1.13 Special care must be taken during transportation and handling because strenuous vibration

could lead to screen glass breakage or damage on the driving circuitry. Be sure to use a strong

outer case to pack it up before transportation or handling.

1.14 Please put it for storage in an environment in which the conditions are under control so as to

prevent the temperature and humidity from exceeding the scope stipulated in the specification. For

prolonged storage please cover it with anti-moisture bag and have them piled and stored in one

place. The environmental conditions are tabulated as below:

Temperature Scope for operation 0~50centigrade

Scope for storage -15~60centigrade

Humidity Scope for operation 20%~80%

Scope for storage 20%~80%

1.15 If a fixed picture is displayed for a long time, difference in its brightness and color may occur

compared with movable pictures. But it doesn’t show any problem and the reason is that there is

reduced density of fluorescent powder in the former. On the other hand, even if changes take place

in the picture, it can keep its brightness for a period of time (several minutes). It’s a feature inherent

with plasma and it’s not abnormal. However please try as much as possible to avoid showing a still

picture of high brightness for a long time during operation.

1.16 As a digitalized display devise, this module is provided with error diffusion technology and the

gray scale and false enhancement of contour can be displayed by reusing of sub-field. As compared

with cathode ray tube, it can be found in the moving picture that at the brim of the face of a person

there are some wrong colors.

1.17 During the display of graph (indicating the gradual change in brightness horizontally or

vertically) resulting from gray scale test it can be found that the brightness for the two adjacent

levels is uneven. This is caused by the reuse of sub-field, the display of load rectification and the

electrolysis.

1.18 The screen front plate is of glass. Please make sure that the screen has been put in place

during erection. If it is not in place before the erection begins it may lead to screen crack or

breakage.

1.19 Make sure the screw used in the mounting of the screen is of the original specs lest it should

cause damage to the screen due to mismatch. Special care should be taken not to use too long or

too big screw.

1.20 Care must be taken to guard against dust during assembling or dismantling, especially to avoid

dirt from falling in between the screen and the glass lest it should harm the receiving and viewing

2

Page 5

effect.

1.21 There is piece of insulator stuck on the rear chassis corresponding to the power supply board.

It is used to isolate the cool part from the hot part. Please take care to keep it intact lest it should

become a potential safety trouble.

1.22 In addition to plasma screen, the glass is a part of high value. It has such functions as

anti-radiation, adjustment of color temperature etc. Please handle it carefully.

2. “Criterion for Identifying the Defects on Screen”

The PDP produced by our Company at present uses the following criterion for identifying the defective

points:

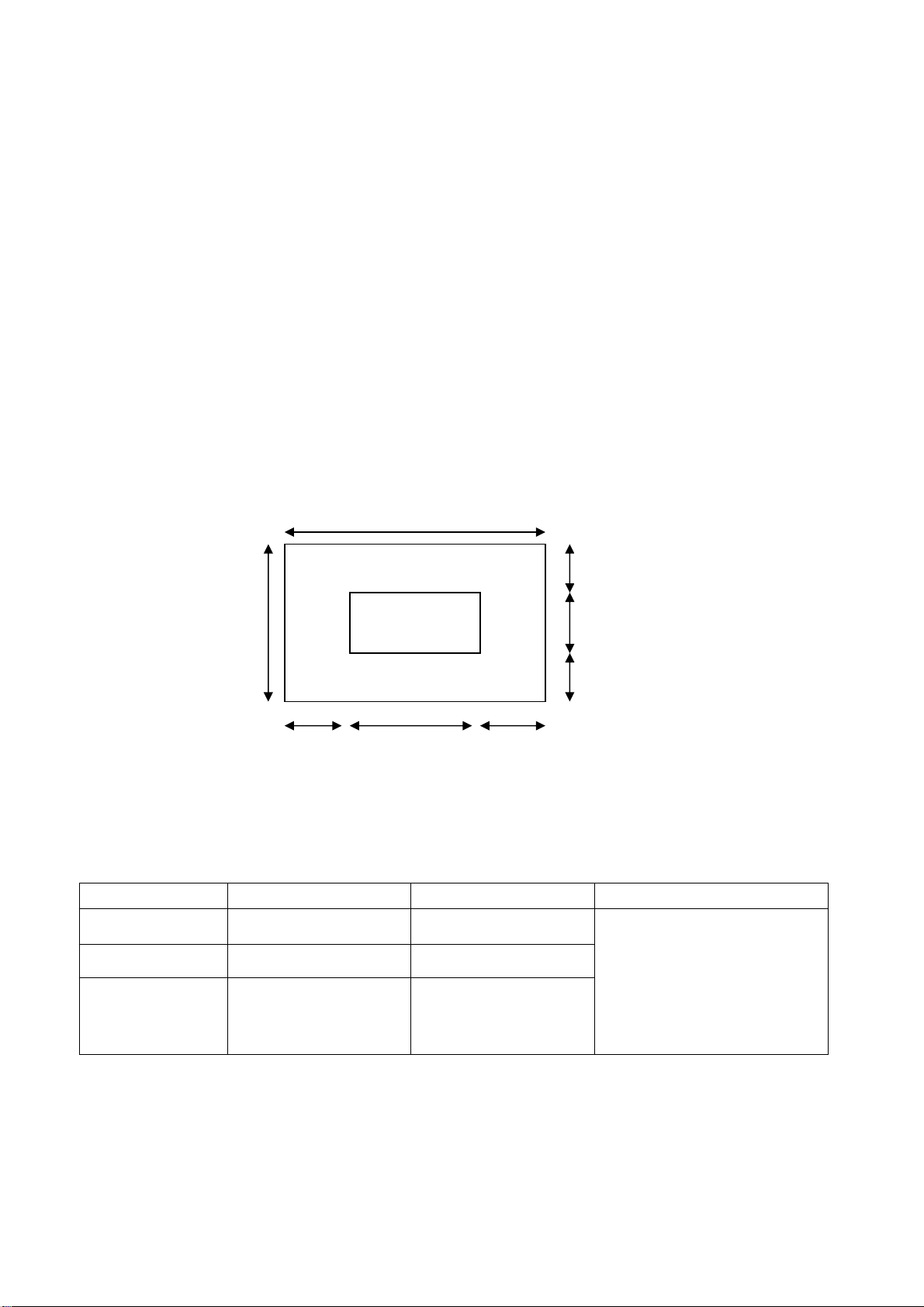

2.1 Model PS-42XX:

There may appear three kinds of defective points for this model as shown in Fig.1, i.e., bright spot

(remain bright); dark spot (non-illuminating); flickering spot (continuously flickering).

However they should not exceed the specification as in table 1. Otherwise the product shall be deemed

as sub-standard.

H

Zone B

W/4 W/2 W/4

Figure 1 Defective Points

Zone A

W

H/4

H/2

H/4

Table 1 Criterion for Three Kinds of Defective Points

Kind Area A Area B Remark

Dark spots No more than 2 No more than 8

Bright spot No more than 1 No more than 2

Total number of defective

points in A and B shall not

exceed 8. The distance

Flickering spot No more than 1 No more than 2

between two defective

points shall not be shorter

than 15mm.

2.2 Model PH-42XX:

3

Page 6

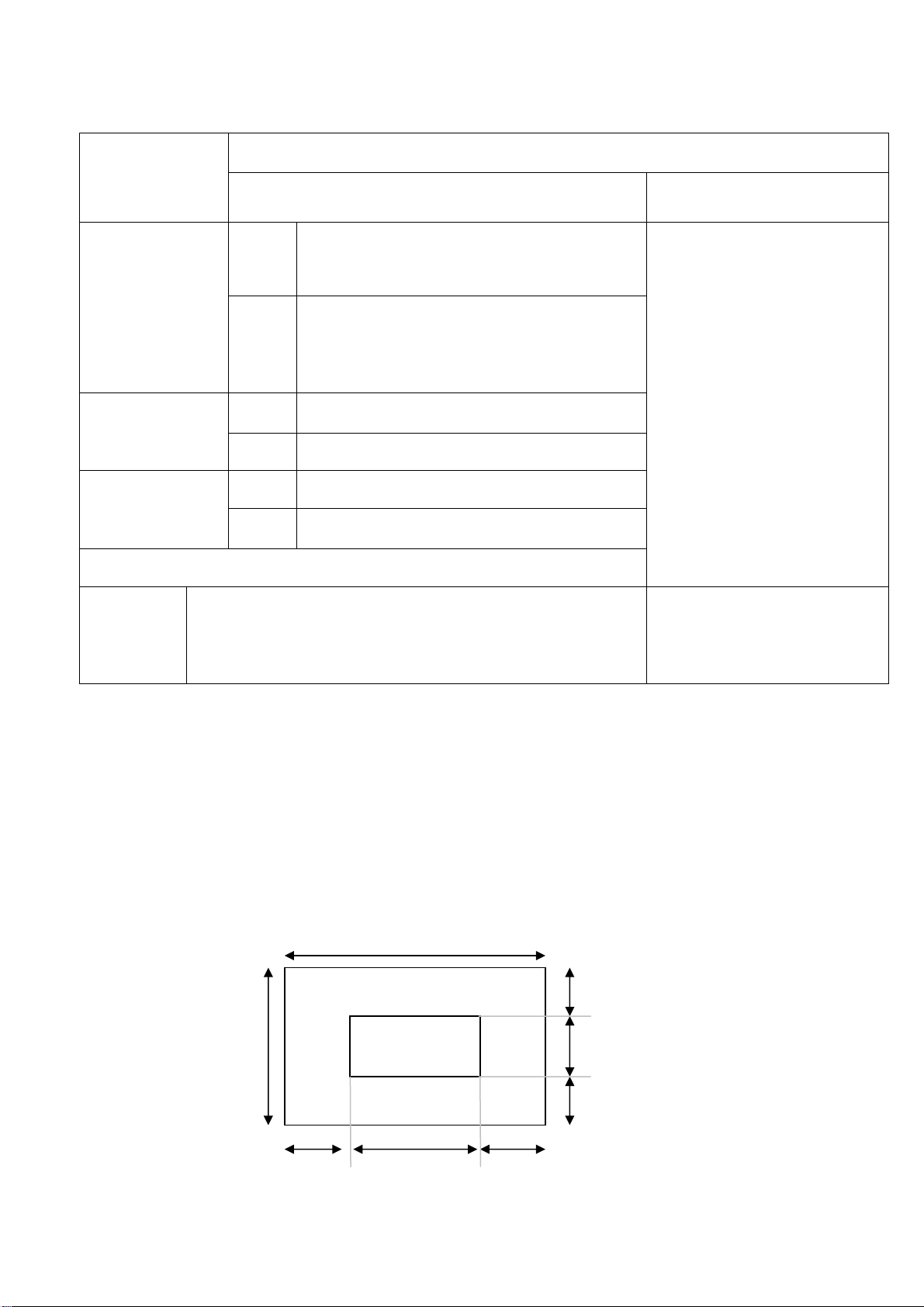

Table 2 Cell Defect Specifications

Defect

Number of Cell Defects (N)

►Total N≤4 [cells/full screen]

Non-Ignition

1)

Dot*

+Unstable Dot*2)

A-zone

B-zone

►N≤2 [cells/each R,G,B screen]

►N=0 [adjacency of 2-cells/full-white screen]

►Total N≤11 [cells/full screen]

►N≤5 [cells/each R,G,B screen]

►N≤5 [adjacency of 2-cells/full-white screen]

=0[adjacency of 3-cells/full-white screen]

Uncontrollable

3)

Dot*

Non-Extinguishing

4)

Dot*

A-zone ►N≤1 [cells/each R,G,B screen]

B-zone ►Total N≤3 [cells/ full screen]

A-zone ►N=0

B-zone ►N=0

►Total sum of all defects N≤17 [cells/full-white screen]

Specification

Distance between two defects

(D)

►A-Zone:≥100mm

►B-Zone: N≤2

(100mm circle/screen: 2points

allowed)

►A, B Zone overlap: N≤2

(100mm circle/screen: 2points

allowed)

►N≤6, for the stain of which longer-axis length is 5mm or

Stain*

5)

►N=0, for the stain of which longer-axis length is longer than

shorter.

►D≥50mm

5mm.

1) Non-Ignition Dot (Dark Defect) is defined as “A cell of which more than 50% area is not ignited”

2) Unstable Dot (Flickering) is defined as “A cell which repeats On and Off”

3) Uncontrollable Dot is defined as “A cell which is distinctly brighter or darker than other cells around it”

and/or “A cell of which color is distinctly different from that of other cells around it”

4) Non-Extinguishing Dot (brightness defect) is defined as “A cell of which more than 50% area is

always ON”

5) Stain is defined as “A blob due to local color contamination in white or simple color pattern”

●The decision distance is 3H away from the panel, intensity of illumination is between 100 Lux and 200

Lux.

H

V/4

V

A -Zone

(25% of display area)

B -Zone

(75% of display area)

V/2

V/4

H/4 H/2 H/4

4

Page 7

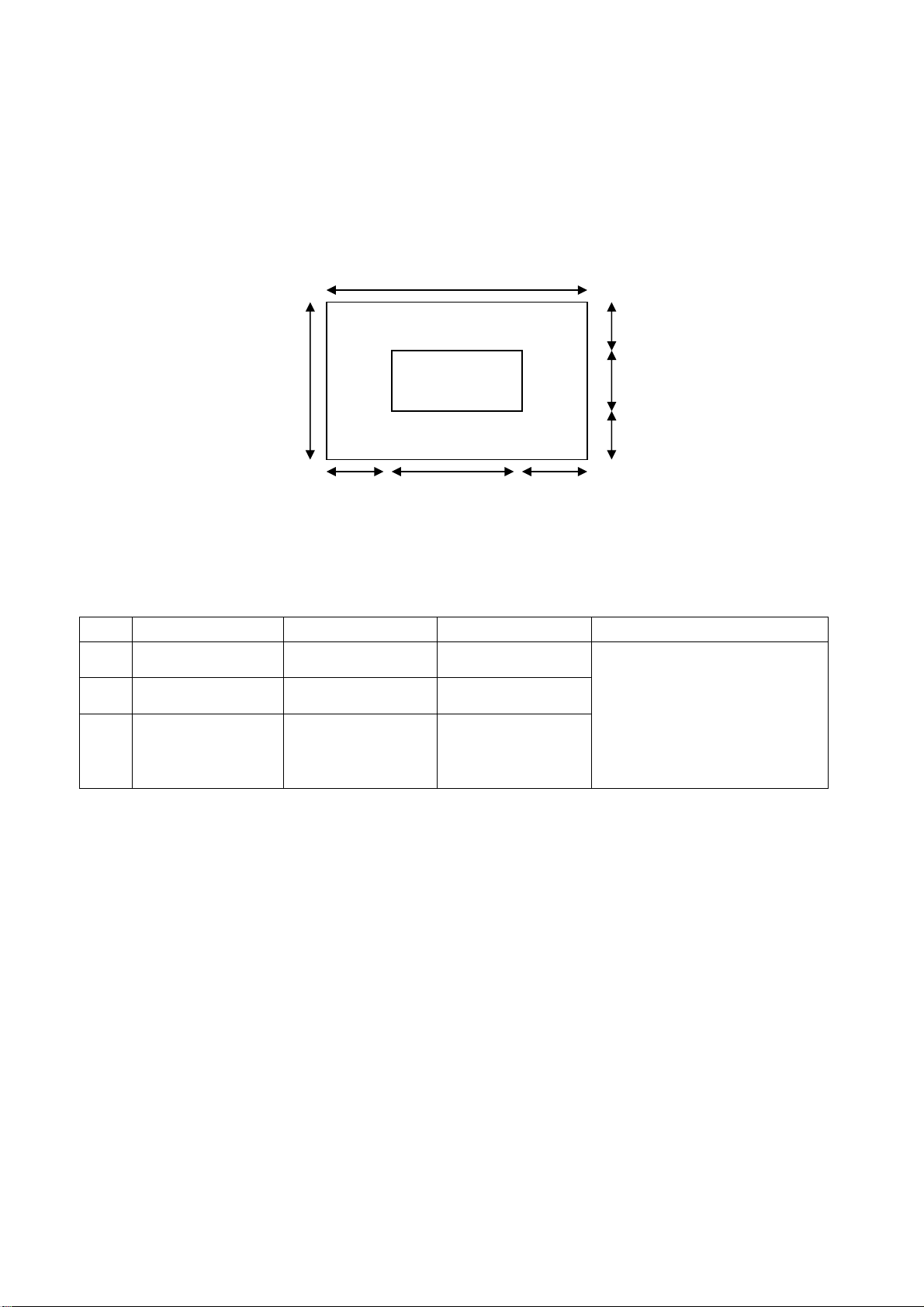

2.3 Model PH-50XX:

There may appear three kinds of defective points for this model as shown in Fig.3 i.e., bright spot

(remain bright); dark spot (non-illuminating); flickering spot (remain flickering).

However they should not exceed the specification as in table 3. Otherwise the product shall be deemed

as sub-standard.

Table 3 Criterion for Three Kinds of Defective Points

H

Zone B

Figure 2 Defective Points

Zone A

W

H/4

H/2

H/4

W/4 W/2 W/4

Item Kind Area A Area B Remark

1 Dark spots No more than 4 No more than 10

2 Bright spot No more than 1 No more than 3

Total number of defective

points in A and B shall not

exceed 14. The distance

3 Flickering spots No more than 1 No more than 3

between two defective

points shall not be shorter

than 10mm.

5

Page 8

Alignment instructions

1. Test equipment

PM5515 (video signal generator)

VG-849 (YUV, VGA, HDMI signal generator)

CA100 (white balancer)

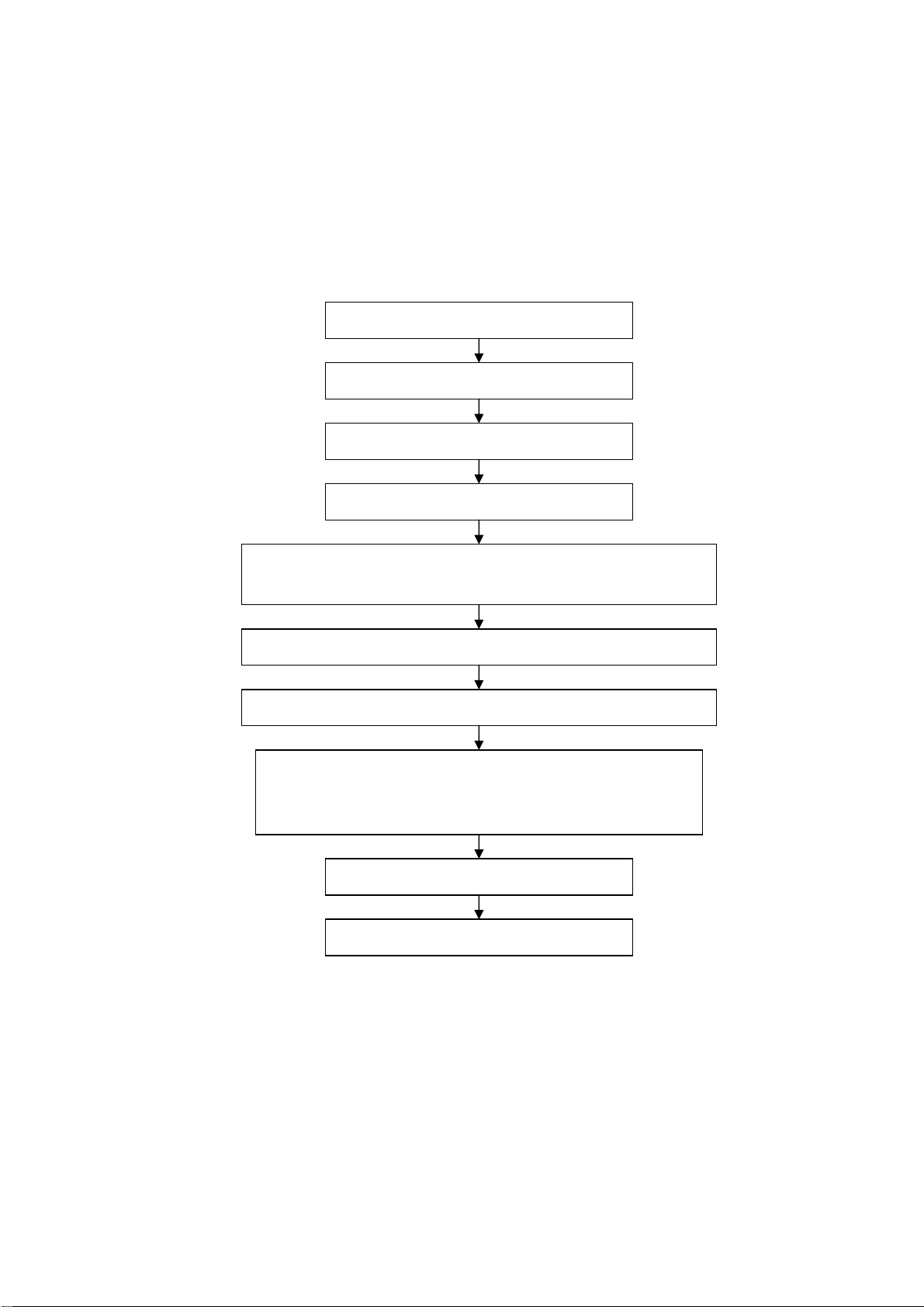

2. The alignment flow chart (see below figure)

Connect with central signal source, then check each function of TV such as

station missing, analog control etc., check the output of headphone and speaker

Input AV/SVIDEO signal, then check each function of all the terminals

Input HD signal (format), then check each function of the terminal

Input VGA, HDMI signal, check if the display is normal, check each

function such as analog control etc., check horizontal /vertical center etc.

3. Description of adjustment

3.1 Unit adjustment

To produce digital board and analog board

Check the accessories and pack them in box

Check DDC and FLASH

All testing

Adjust white balance

Preset ex-factory

Fig-1 adjustment flow-chart

Connect the digital processing board, analog board, power board, power filter board and button

board according to the wiring diagram 203-PH42FB8-01JL. Connect with power and observe the

display.

Method for using factory menu: press ”INPUT” button, then press”2580” to enter level one factory

menu. Press ”CH+” and “CH-“ to select adjustment page, then press “OK” to access. Press “CH+”

6

Page 9

and “CH-“ to move cursor up and down, when the cursor stays on a certain adjustment item, press

“VOL-“ and “VOL+” to adjust. Press “MENU” exit to the level one factory menu; press “EXIT” to exit

from the factory menu at any situation.

Note: channel switch isn’t available at adjustment menu, only after return to level one factory menu,

you can switch channel.

3.2 adjustment of white balance

3.2.1 input 16 level gray-scale signal from VG849 to HDMI channel (TMIING: select a support

format of HDMI), enter white balance adjustment page of factory menu, select cool color

temperature of item, fixed WBGG_HDMI to 50H, adjust WBRG_HDMI, WBBG_HDMI, let the color

coordinate of third level on the right be (270,283) at 120nits; fixed WBBO_HDMI to 50H, adjust

WBRO_HDMI, WBGO_HDMI, let the color coordinate of third level on the left be (270,283) at 5nits.

The brightness of 120nits and 5nits may obtain by adjusting the contrast and brightness of menu.

3.2.2 input 16 level gray-scale signal from VG849 to AV channel (TMIING:968), enter white balance

adjustment page of factory menu, select cool color temperature of item, fixed WBGG_NTSC to 50H,

adjust WBRG_NTSC, WBBG_ NTSC, let the color coordinate of third level on the right be (270,283)

at 120nits; fixed WBBO_ NTSC to 50H, adjust WBRO_ NTSC, WBGO_ NTSC, let the color

coordinate of third level on the left be (270,283) at 5nits. The brightness of 120nits and 5nits may

obtain by adjusting the contrast and brightness of menu.

3.2.3 input 16 level gray-scale signal from VG849 to VGA channel (TMIING: select a support format

of VGA), enter white balance adjustment page of factory menu, select cool color temperature of

item, fixed WBGG_VGA to 128, adjust WBRG_ VGA, WBBG_VGA, let the color coordinate of third

level on the right be (270,283) at 120nits; fixed WBGO_VGA to 128, adjust WBRO_VGA,

WBBO_VGA, let the color coordinate of third level on the left be (270,283) at 5nits. The brightness

of 120nits and 5nits may obtain by adjusting the contrast and brightness of menu.

3.2.4 input 16 level gray-scale signal of 480I from VG849 to YPbPr channel, enter white balance

adjustment page of factory menu, select cool color temperature of item, fixed WBRG_YPbPr480I,

WBGG_YPbPr480I, WBBG_YPbPr480I to 128, and WBRO_YPbPr480I to 128, adjust

WBRO_YPbPr480I, WBBO_YPbPr480I, let the color coordinate of third level on the left be (270,283)

at 5nits. The brightness of 5nits may obtain by adjusting the contrast and brightness of menu.

Input format signals separately list on table 1, repeat the operation above until the white balance

pass muster.

Note: the white balance adjustment of VGA and YPBPR must be done at the situation that the white

balance adjustment of HDMI is accurate.

4 Performance check

4.1 TV function

Connect RF-TV terminal to the central signal source, enter the setup menu→ auto search, check if

there is station skipping, the output of earphone and speaker, the picture are normal.

4.2 AV/S-VIDEO terminal

Input AV/S signal, check if the picture and sound are normal.

4.3 YPbPr/YCbCr terminal

Input YUV signal (VG-849 signal generator), separate input YUV format signal of table 1 and check

if the picture and sound are normal.

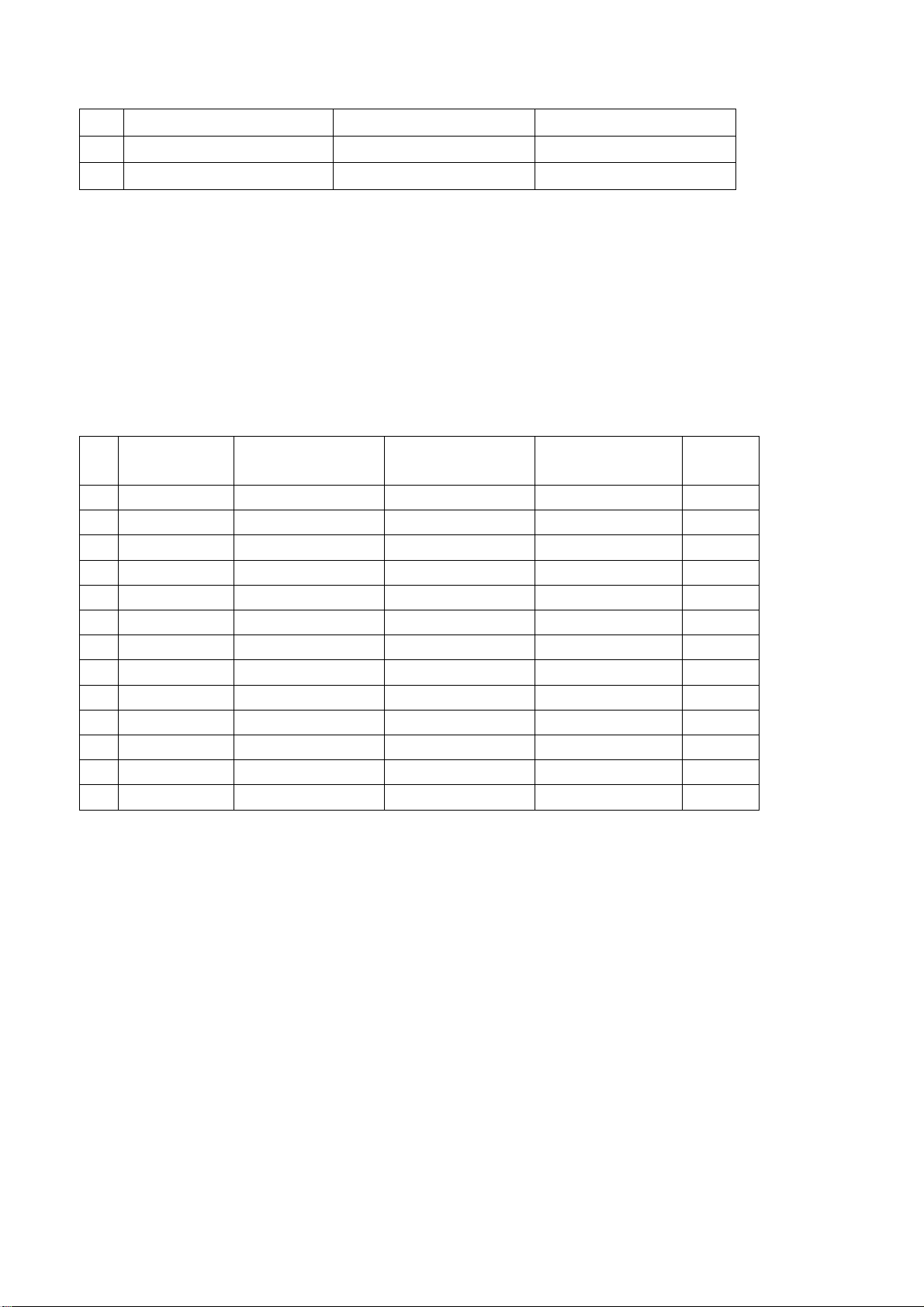

Table 1 YUV signal format

No H-frequency (KHz) V-frequency (KHz) Signal

1 15.734 59.94 SDTV 480i

7

Page 10

2 31.469 59.94 HDTV 480p

3 44.955 59.94 HDTV 720p

4 33.716 59.94 HDTV 1080i

4.4 VGA terminal

Input VGA signal (VG-849 signal generator), separate input VGA format signal of table 2 and check

if the picture and sound are normal. If the image is deflection of the H-field, select manual correction

of Advanced Video Menu.

4.5 HDMI terminal

HDMI signal format receives the three high-definition signals: 480I, 480P, 720P/60Hz, 1080I/60Hz,

except for the table 2 signal. Check if the image (contain HDCP ON and OFF) and sound are

normal.

Table 2 VGA signal format

No Resolution H-frequency(kHz) V-frenquency(Hz)

1 720 X 400 31.469 70.086 28.322 IBM

2 640 X 480 31.469 59.94 25.175 IBM

3 640 X 480 37.861 72.809 31.5 VESA

4 640 X 480 37.5 75 31.5 VESA

5 640 X 480 43.269 85.008 36 VESA

6 800 X 600 35.156 56.25 36 VESA

7 800 X 600 37.879 60.317 40 VESA

8 800 X 600 48.077 72.188 50 VESA

9 800 X 600 46.875 75 49.5 VESA

10 800 X 600 53.674 85.061 56.25 VESA

11 1024 X 768 48.363 60.004 65 VESA

12 1024 X 768 56.476 70.069 75 VESA

13 1024 X 768 60.023 75.029 78.75 VESA

Point clock pulse

frenquency(MHz)

Remark

5 Ex-factory setting of user menu

1) Select TV channel, volume: 25

2) Video menu, Picture Mode: Nature, Aspect Ratio: Wide

3) Video menu, Advanced Video Menu:

Noise Reduction——Spatial: On

Noise Reduction——Speckle: Off

Noise Reduction——Temporal: On

Sharpness: 0

Tint: 50

Color Temperature: Cool

3D Y/C: On

4) Audio menu, Sound Mode: News, Balance: 31, Earphone Vo1:31

Digital Audio Output: AC-3, MTS: Mono

5) Setup menu, Tuning Band: Air

8

Page 11

6) Feature menu, Sleep Timer: Off, Menu Language: English

Note: Except for Color Temperature of Cool, the Advanced Video Menu of YPbPr/YCbCr and VGA

channels sets according to the adjustment of factory.

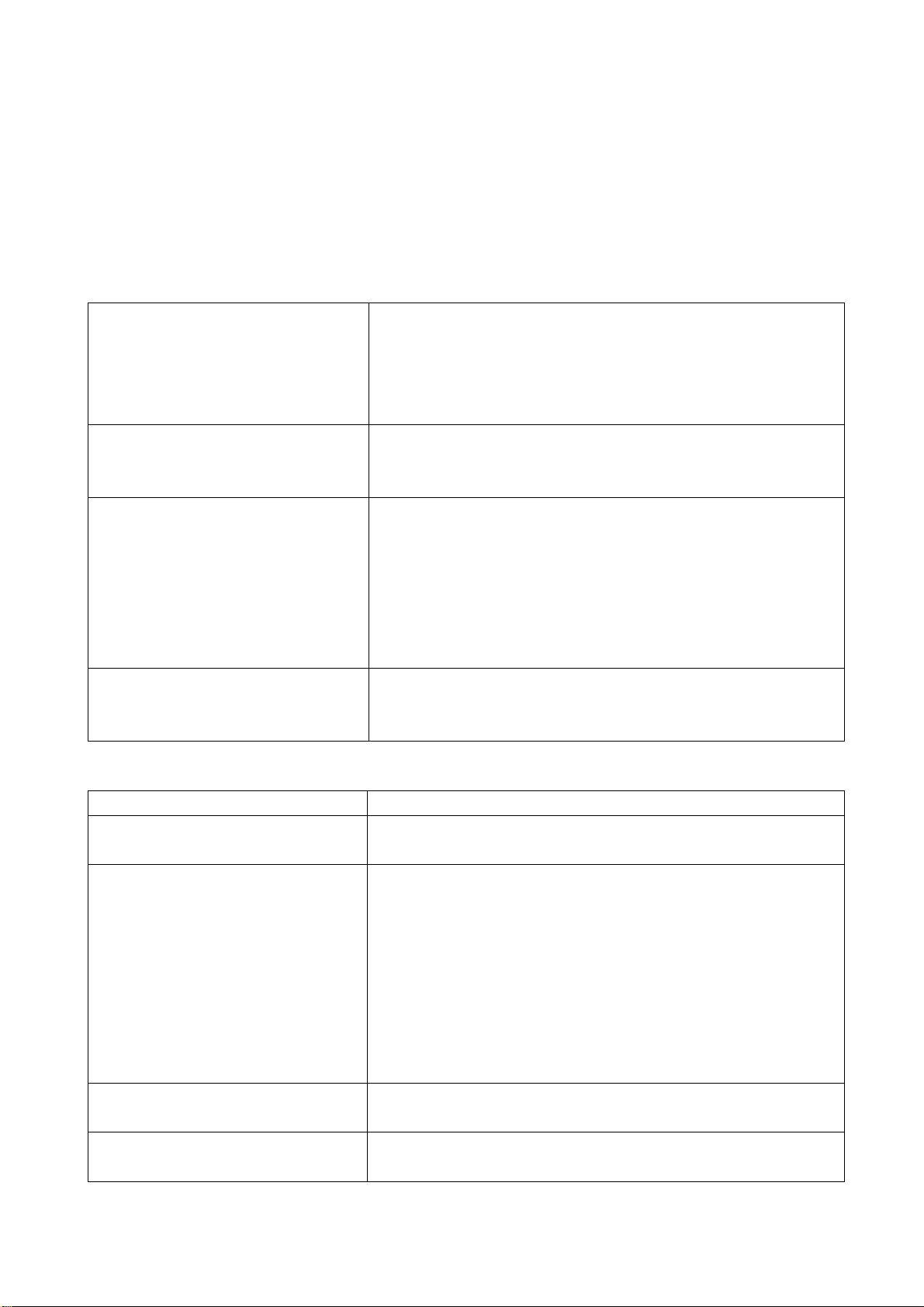

Trouble shooting

Before servicing please check to find the possible causes of the troubles according to the table

below.

1.Antenna(signal):

Picture is out of focus or jumping z Bad status in signal receiving

z Poor signal

z Check if there are failures with the electrical connector or

the antenna.

z Check if the antenna is properly connected.

Fringe in picture z Check if the antenna is correctly oriented.

z Maybe there is electric wave reflected from hilltop or

building.

Picture is interfered by stripe

shaped bright spots

There appear streaks or light color

on the screen

2.TV set:

Symptoms Possible cause

Unable to switch the power on z Check to see if the power plug has been inserted

No picture and sound z Check to see if the power supply of liquid crystal TV has

Deterioration of color phase or

color tone

Screen position or size is not

proper

z Possibly due to interference from automobile, train, high

voltage transmission line, neon lamp etc.

z Maybe there is interference between antenna and power

supply line. Please try to separate them in a longer

distance.

z Maybe the shielded-layer of signal wire is not connected

properly to the connector.

z Check if interfered by other equipment and if interfered

possibly by the equipment like transmitting antenna, non

professional radio station and cellular phone.

properly into the socket.

been switched on. ( as can be indicated by the red LED

at the front of the TV set)

z See if it’s receiving the signal that is transmitted from

other source than the station

z Check if it’s connected to the wrong terminal or if the

input mode is correct.

z Check if the signal cable connection between video

frequency source and the liquid crystal TV set is correct.

z Check if all the picture setups have been corrected.

z Check is the screen position and size is correctly set up.

9

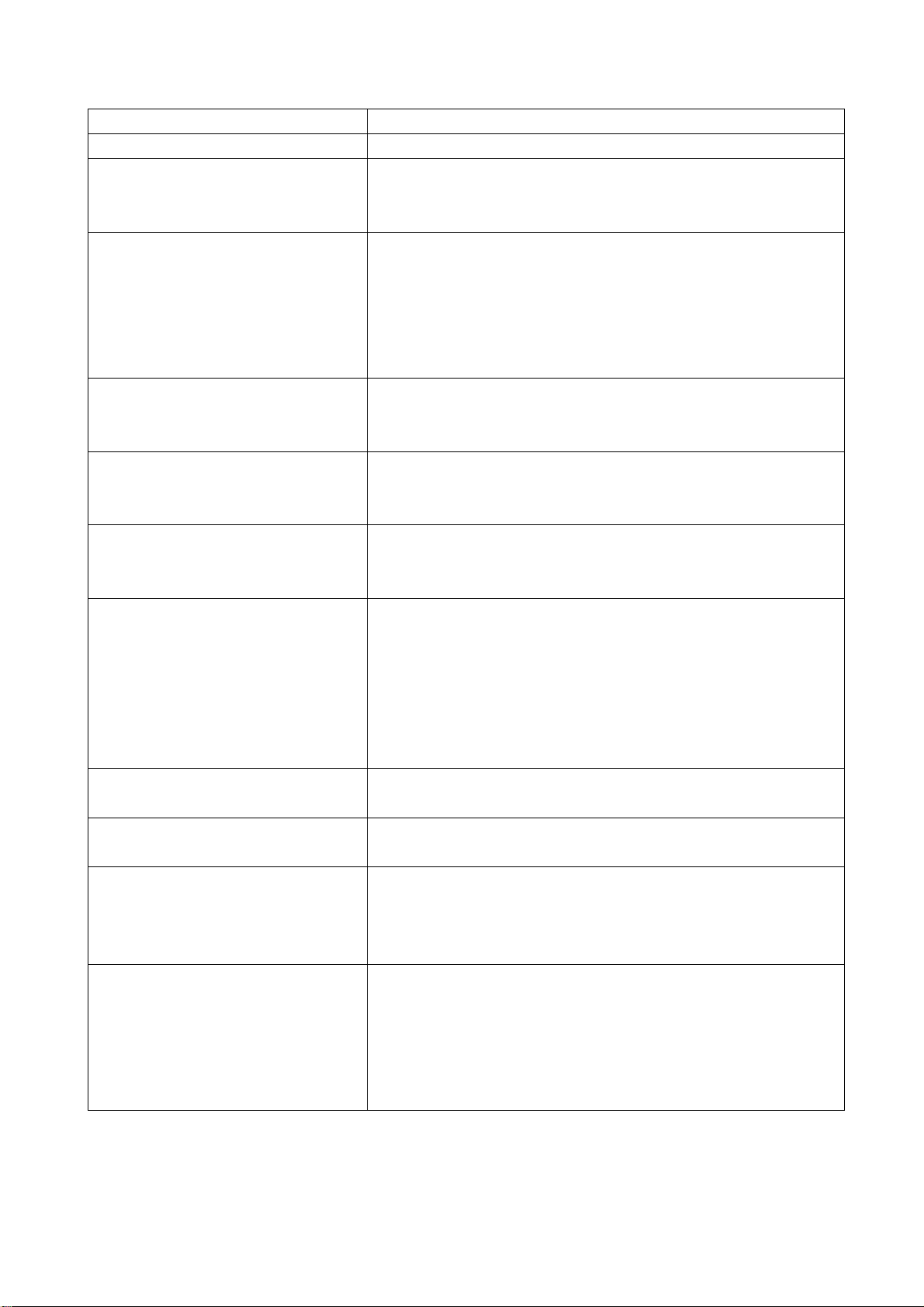

Page 12

Symptoms Possible cause

Picture is twisted and deformed z Check to see if the picture-frame ratio is properly set up.

Picture color changed or colorless z Check the “Component” or “RGB” settings of the liquid

crystal TV set and make proper adjustment according to

the signal types.

Picture too bright and there is

distortion in the brightest area

Picture is whitish or too bright in

the darkest area of the picture

No picture or signal produced from

the displayer if “XXX in search”

appears.

There appears an indication “outside the receivable scope)

Remote control cannot work

properly

No picture and sound, but only

hash.

Blur picture z Check if the antenna cable is correctly connected.

No sound z Check if the “mute” audio frequency setting is selected.

When playing VHS picture search

tape, there are lines at the top or

bottom of the picture.

z Check if the contrast setting is too high.

z Possibly the output quality of DVD broadcaster is set too

high.

z It maybe also due to improper terminal connection of the

video frequency signal in a certain position of the

system.

z Check if the setting for the brightness is too high

z Possibly the brightness grade of DVD player

(broadcaster) is set too high.

z Check if the cable is disconnected.

z Check if it’s connected to the proper terminal or if the

input mode is correct.

z Check if the TV set can receive input signal. The signal is

not correctly identified and VGA format is beyond the

specified scope.

z Check if the batteries are installed in the reverse order.

z Check if the battery is effective.

z Check the distance or angle from the monitor.

z Check if there is any obstruct between the remote control

and the TV set.

z Check if the remote control signal- receiving window is

exposed to strong fluorescence.

z Check if the antenna cable is correctly connected, or if it

has received the video signal correctly.

z Of if it has received the right video signal.

z Check if the sound volume is set to minimum.

z Make sure the earphone is not connected.

z Check if the cable connection is loose.

z When being played or in pause VHS picture search tape

sometimes can’t provide stable picture, which may lead

to incorrect display of the liquid crystal TV, In this case

please press “auto” key on the remote control so as to

enable the liquid crystal TV set to recheck the signal and

then to display correct picture signal

10

Page 13

Method of software upgrading

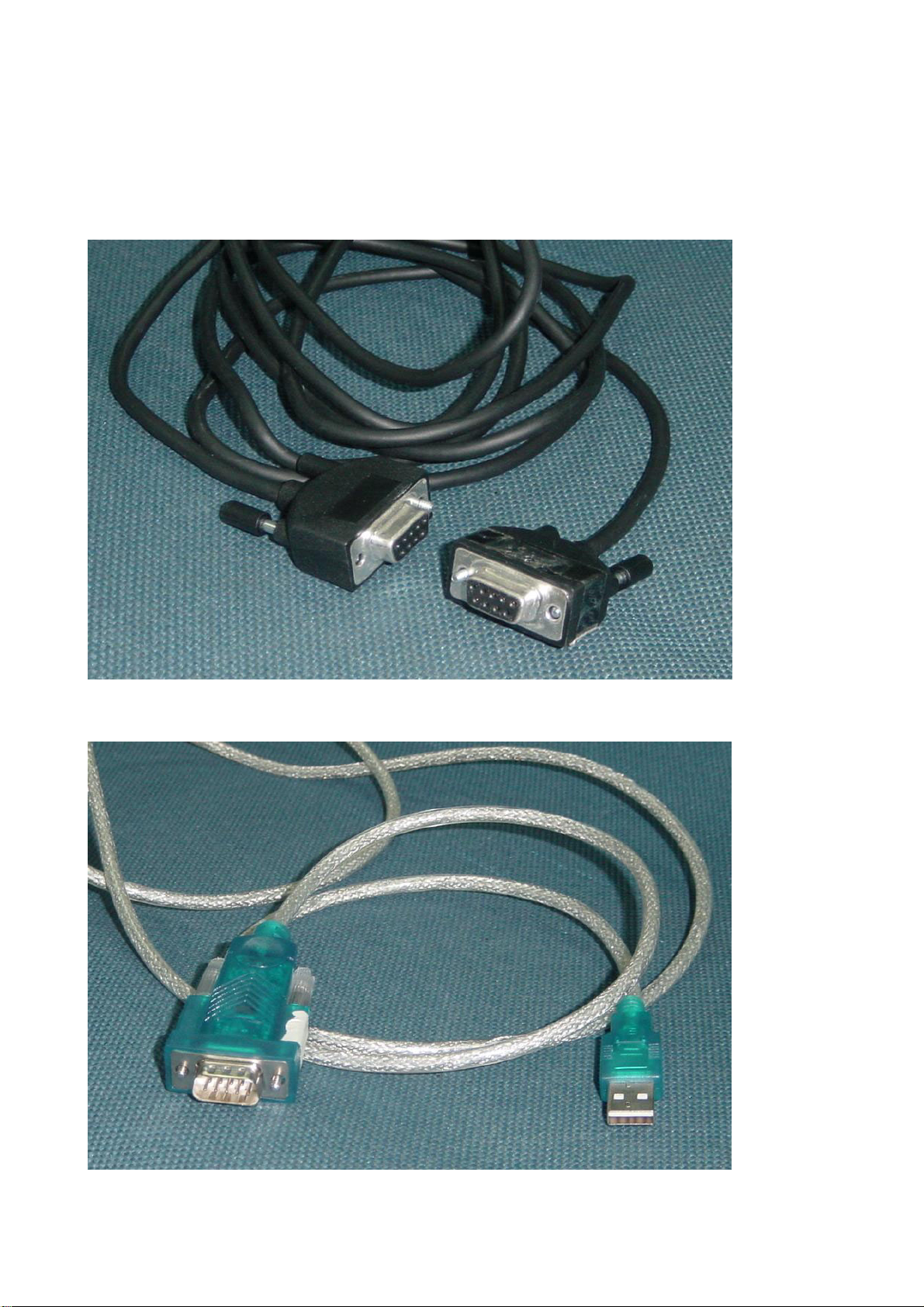

1. Connect RS-232 cable to computer and TV set. The cable must be a female to female RS-232

cable, and the line is TXD to RXD and RXD to TXD cross-link. It’s popular for PC to PC

connection.

2. If the computer has no RS-232 serial port(e.g. Notebook PC),you needs a additional USB to serial

port cable.

11

Page 14

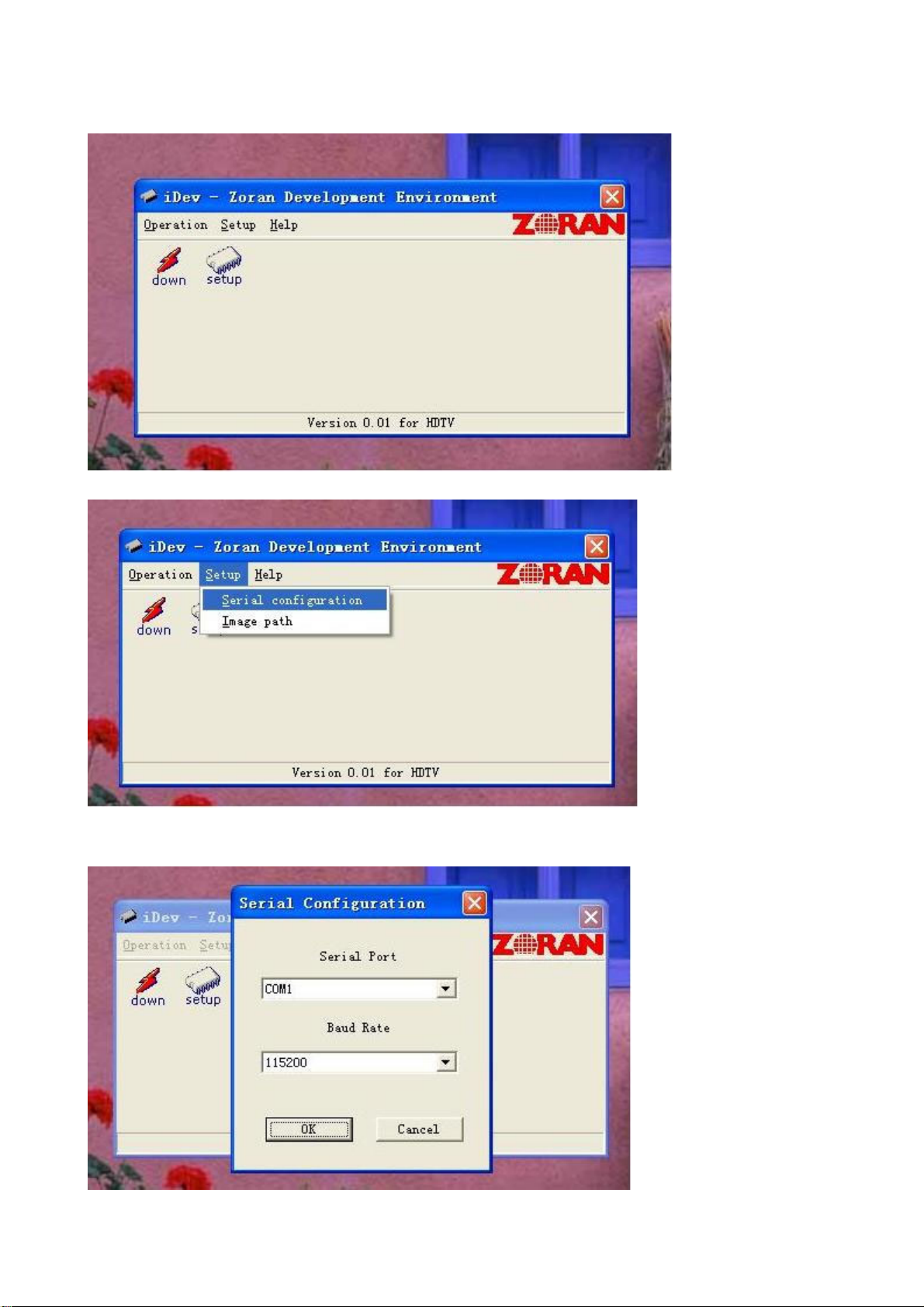

3. Copy the update tools (iDev.exe) to the path you want to do it, and double click it.

4. Select “setup” menu.

5. Confirm the Serial port is right. Base on the port which using for update. And set the band rate to

115200 (default).

12

Page 15

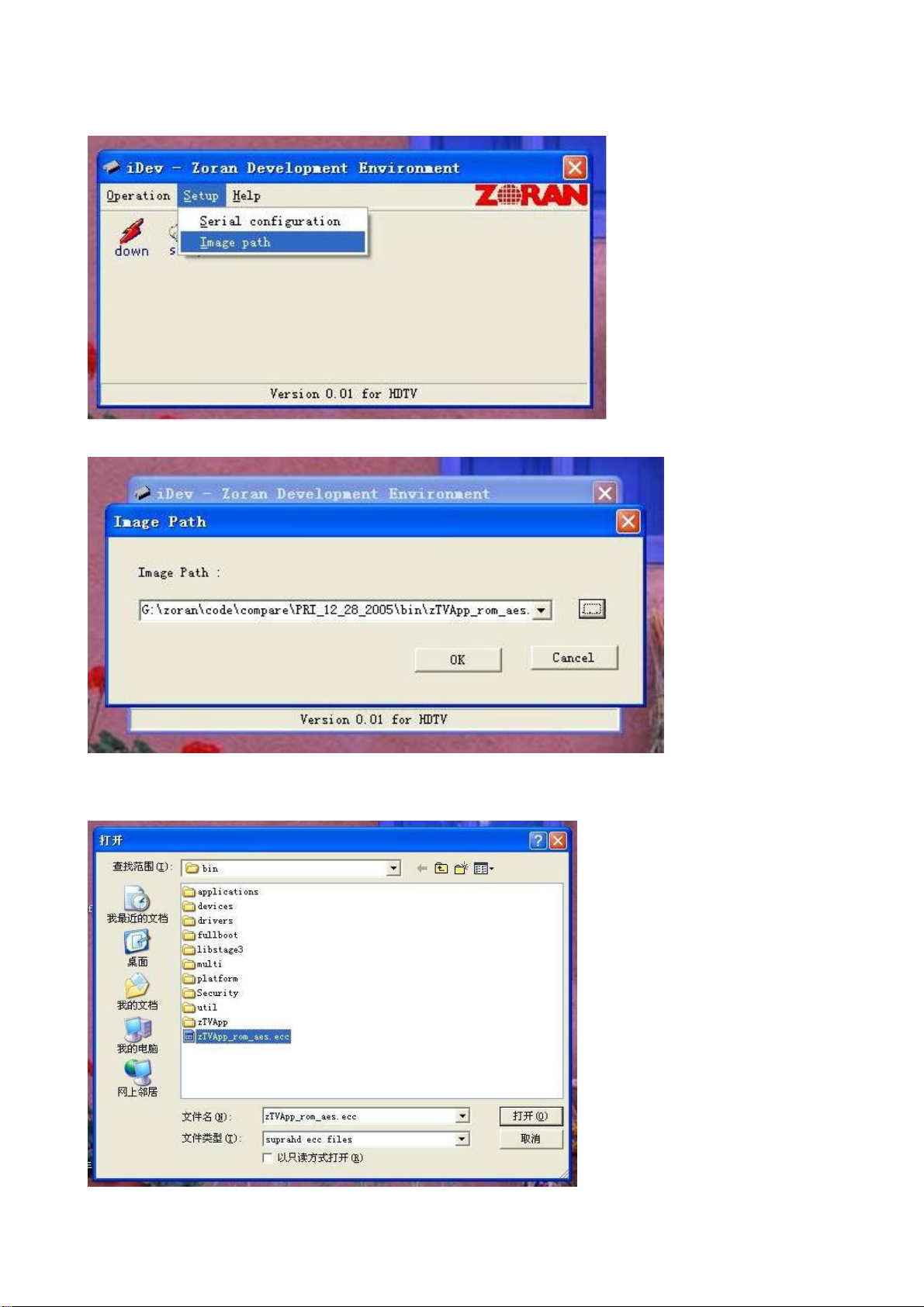

6. Select the “Image path” menu.

7. Confirm it’s the right file.

8. If it’s not right(Maybe you didn’t select it before),click the “…”button to select “*.ecc” file. Sometimes

the image file you got it will be “*.rar ”or “*.zip” zip file, needs unzip it first.

13

Page 16

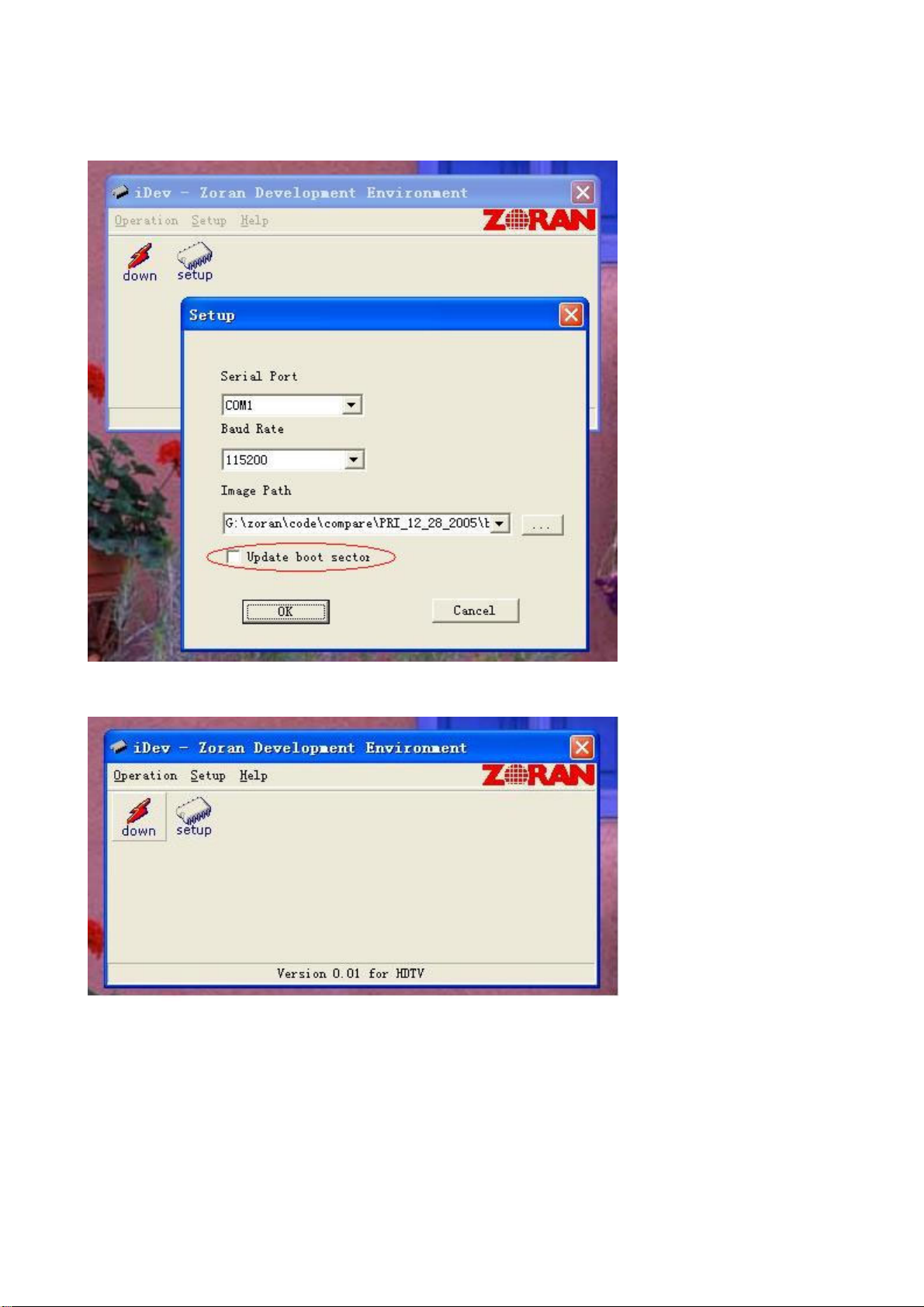

9. You also can click the setup button to select and config, but please don’t select the red

one(update boot sector).

10. Then click the “down” button.

14

Page 17

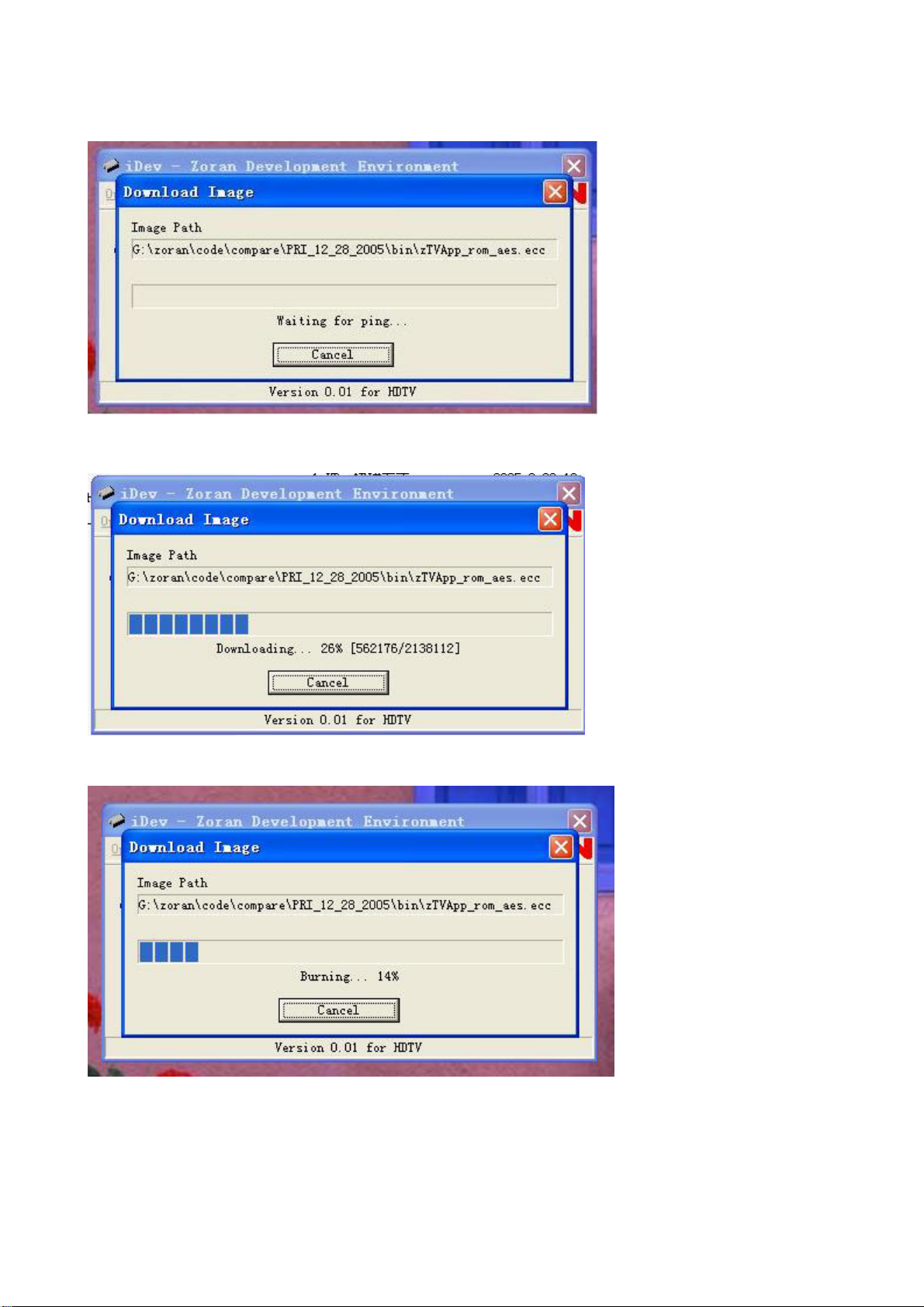

11. You can see the “waiting” window.

12. Then power (off then) on the TV set.

13. After download, it will be burning.

15

Page 18

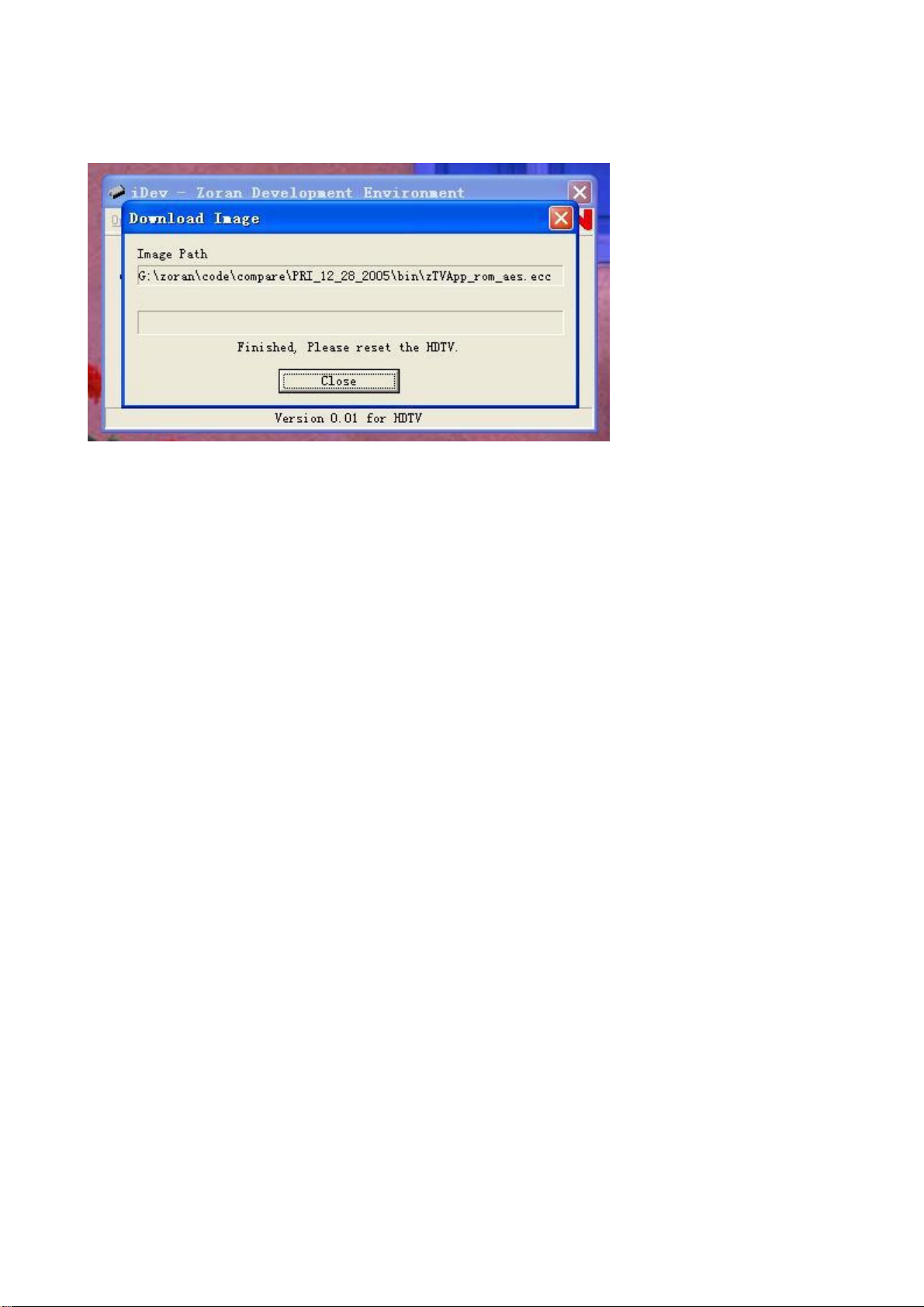

14. Last it will be finished

15. Press the (IR/ locate keypad) power key and holding for several second to force power off TV set,

then power on again. It would be ok now. If it’s failure you can try once again.

16

Page 19

Working principle analysis of the unit

1. NTSC signal flow:

Antenna reception NTSC signal send to the integrative tuner FQD1236, which contains HF and IF

amplifier circuit and video decoding circuit. It is controlled by main IC ZR39660 (inside CPU)

through I2C bus. The NTSC signal via frequency tuning, HF amplification, IF amplification, system

switching and decoding, output video signal TV-CVBS of 1Vpp and sound IF signal (SIF).

TV-CVBS and AV1-CVBS, AV2-CVBS input from AV terminal, via switch IC HEF4052 to output

signal, one way send to ZR39660 for VEDIO DECODER, DEINTERLACE and SCALER, then send

to LVDS level drive for LCD screen, another way is output through AV output socket as AV OUT.

The sound IF (SIF) is fed into demodulation IC CAS220, via decoding and A/D conversion, it is fed

into ZR39660 for analog control in the format of I2S. ZR39660 outputs audio data of I2S format, it is

fed into audio D/A converter IC CS4344, output analog L/R signal. The L/R signal and sound signal

of PC/YPRPB via diverter switch HEF4052BT, send to R2S15900SP (sound processing and volume

control). Select right/left sound channel, their send to digital sound amplifier TPA3001 amplify, then

send to speaker.

2. ATSC signal flow:

Antenna reception ATSC signal send to tuner FQD1236, after frequency tuning, HF amplification, IF

amplification and SAW FILTER, output IF signal to demodulation chip CAS220, via VSB or QAM

demodulation, Sound stereo decoder, fed to ZR39660 for information source decoding in the format

of standard serial TS stream.

HD video signal via decoding to A/D conversion and OSD superposition, at last send to LVDS drive

level for PDP panel.

HD audio signal, via decoder built-in ZR39660, resumed to multi- channel sound of Dolby AC-3, at

the same time output data stream of I2S format and S/PDIF data stream. Audio data of I2S format is

fed to audio D/A conversion chip CS4344 to output analog L/R signal. S/PDIF data stream directly

output from optical fiber interface.

3. PC/YPrPb signal flow

PC and two YPBPR signal via matched resistance, it a-c couple to video switch SN74CBT3257CDR,

via switching to selected signal to Triple Video A/D Converter MST9883 A/D conversion. Send

B/G/B of 24 bit to main IC ZR39660 digital decode, image scale and OSD superposition, then send

to LVDS level drive for LCD screen.

Sound signal (PC, YPrPb) via switch diverter HEF4052BT to output signal, it send to R2S15900SP

(sound processing and volume control) switch of audio. Select right/left sound channel, their send to

digital sound amplifier TPA3001 amplify, then send to speaker.

4. HDMI signal flow

HDMI video signal is directly fed to main IC ZR39660 (with HDCP function of HDMI) digital decode,

image scale and OSD superposition, then output LVDS drive level for screen.

HDMI audio signal, via decoder built-in ZR39660,output data stream of I2S format and S/PDIF data

stream at the same time. Audio data of I2S format is fed to audio D/A conversion chip CS4344 to

output analog L/R signal. S/PDIF data stream directly output from optical fiber interface.

17

Page 20

Block diagram

1

VGA

D

DVI AUDIO

YPBPR1 AUDIO

YPBPR2 AUDIO

YPBPR1

YPBPR2

2

SN3257C

SN3257C

YPbPr

3

MST9883

HDMI1

HDMI2

4

M29W320E

HDMI Switch

FLASH

5

6

2X16MX16

DDRAM

D

LVDS

HS,VS,CLK

24-BIT Data

Panel

SN3253C

TUNER

C

FQD1236 MK5

Digital IF

CAS220CS

Analog SIF

ZR39660

BGA400

AV_OUT

C

B

AV1 AUDIO

A

AV2 AUDIO

CVBS1

CVBS2

S_Y

S_C

HEF4052BT

R2S15903SP

CVBS_TV

D/A CS4344

TPA3001

NJW1109

Loudspeaker

Earphone

IIS IN

TS

CVBS,Y/C

IIS OUT

B

A

PH-63FB8 D_HDMI

V1.0

1 2 3 4 56

18

Page 21

IC block diagram

1. ZR39140

19

Page 22

Pin descriptions of ZR39660:

(1) Serial Transport Input Port

T4: MPEG Transport Port Input Clock

T3: MPEG Transport Input Data

U3: MPEG Transport Input Frame

Y1: MPEG Transport Input Valid

(2) HDMI Input

D1,E3,F3,E2,F2,E1: HDMI Differential Data Pairs

D2,C1: HDMI Differential Clock Pair

C3: HDMI Serial Clock

B2: HDMI Serial Data

A1: HDMI Hot Plug Detect

D3: HDMI Current Set

(3) NTSC/PAL Analog Input Port

W2: Video Front End Luminance In

Y3: Video Front End Chroma In

W3: Video Front End Common Mode Reference

(4) Analog Video Output

K18: Composite Data Output (CVBS)

J20: Blue/Pb Pixel Data Output

J18: Green/Y Pixel Data Output

J19: Red/Pr Pixel Data Output

(5) Audio I/O

R2: Audio Clock

R3: Bit Clock

P3: Left/Right Channel Selector

U2: Serial Audio Data Input

T2: Serial Audio Data Output

V1: IEC958 Format Out

(6) LVDS Panel Interface

B20,C19: Output Clock Pair

E18,F17: Output Data Pairs 0

C20,D19: Output Data Pairs 1

F18,G17: Output Data Pairs 2

D20,E19: Output Data Pairs 3

E20,F19: Output Data Pairs 4

H18,G18: Output Data Pairs 5

F20,G19: Output Data Pairs 6

G20,H19: Output Data Pairs 7

D18 : External Resistor Connection

20

Page 23

(7) UART and I2C Interface

N1: UART 0 Transmit

P1: UART 0 Receive

R1:I2C Compatible Clock 0

P2:I2C Compatible Data 0

M3:I2C Compatible Clock 1

M2:I2C Compatible Data 1

(8) Miscellaneous

M4, N3: Two pins required to support the 24.576 MHz crystal

N5: Power On Reset

L4: Infrared Receive

2. CAS220/CS

The CAS-220/CSO is a multi-standard demodulator and decoder for terrestrial and digital cable TV

reception. It is designed to support 8-VSB (Vestigial Side Band) in full compliance with ATSC Digital

Television Standards, ITU-T J.83 Annex B, and OpenCable™ Out-of-Band Signaling. The

CAS-220/CSO also demodulates analog BTSC and Korea A2 sound.

Its basic function is to recover the digital data encoded into the broadcast signal, which includes

video and sound program information and ancillary data service.

21

Page 24

Pin configuration of CAS220/CS:

Pin descriptions of CAS220/CS:

61: RESET_N

79, 80 oscillator

13 Select I2C address

16: I2C data for host communication with the tuner

18: I2C clock to the tuner

19: I2C clock from host

20: I2C data from/to host

93,94: Differential input for IF

96,97: Differential input for SIF

63: Digital Sound Word select (L/R select)

65: Digital Sound Serial data output

66: Digital Sound Serial clock.

17,30,46,62,74,82,84: Power Supply 3.3V

5,9,22,37,53,69,75,78,86,87,99: Power Supply 1.8V

6,7,15,23,33,35,45,55,60,70,73,76,77,81,83,85,88,91,92,95,98: Ground

22

Page 25

3. MST9883

MST9883 is a Triple Video A/D Converter with Clamps & Pixel Clock Synthesizer. The triple ADC

support 12 - 110 MHz Sampling Rate. It integrated 5-bit pixel clock phase adjustment for precise

sample timing control. It’s Output support 4:2:2 Format Mode and it can Pin Compatible with

AD9883A.

Block diagram of MST9883 is flow:

23

Page 26

Pin configuration of MST9883:

Pin descriptions of MST9883:

54: Red analog input

48: Green analog input

43: Blue analog input

49: Sync on Green analog input

38: External Clamp Input

30: Horizontal SYNC Input

31: Vertical SYNC Input

29: Hold PLL Frequency, do not track HSYNC

56: Serial Interface clock

57: Serial Interface data pin

55: Serial interface address pin

70-77: Red output data

2-9: Green output data

12-19: Blue output data

67: Output data clock

66: HSYNC output

64: VSYNC output

39,42,45,46,51,52,59,62: Analog Power

24

Page 27

26,27,34,35: PLL Power

11,22, 23, 69,78,79: Digital Output Power

1,10,20,21,24,25,28,32,36,40,41,44,47,50,53,60,61,63,68,80:Ground

4. R2S15900SP

R2S15900SP is an audio signal processor. It has MUTE and Volume/Tone control. It can support 5

input selector.

Pin descriptions of R2S15900SP:

2,27: AV1 AUDIO INPUT L/R

3,26: AV2 AUDIO INPUT L/R

4,25: DTV AUDIO INPUT L/R

5,24: EAR PHONE L/R

6,23: AV OUT L/R

11,19: AUDIO OUTPUT L/R

17,18:I2C SDA/SCL

28: Power Supply

12: Ground

25

Page 28

5. TPA3001

The sound power amplifier TPA3001 Class D AMP is the high effective D type of power amplifier of

the single track. The output power can reach 20W with 8-Ω speakers, +18V power supply,

eliminating the need for heat sinks. The TPA3001D1 is available in the 24-pin thermally enhanced

TSSOP package.

Pin configuration of TPA3001:

Pin description of TPA3001:

1: Negative differential input

2: Positive differential input

3,4: gain control

10,11: Negative BTL output

14,15: Positive BTL output

9,16,24: Power Supply

6,12,13,18,19: Power Ground

5: Shutdown terminal

26

Page 29

Wiring diagram

Butt on bo ar d

(667 -PH42F B6 -05)

XB01

X103

XC01

X232

Digital processing board

667 -P S42FB 6 -69

XB03

X231

X801

X101

`

XA50

31 6 12 11 4 6

X802

X602

Logica l board

LA03

335-42012-00

Powe r boa rd

X603

Panel

(667

-

PS42D8

X608

X601

-

20)

X606

X603

5

X226

X501

RS-232

S/PDIF

HDMI

VGA

YpbPr 1

YpbPr 2

XC02

5 6 5 5 9

X102

AV o ut

Earp hone

X105

2

S-Video

Analog board

667-PS42FB6-53

X106

Speaker assy

Power filter board

AV1 in

AV2 in

RF

X104

4

27

Page 30

Diagnosis for Plasma Screen of PH42/50FBXX

)

And Maintenance of the Functions of Various Modules on Screen

1. Functions of Various Modules on Screen

As shown in the figure below, PDP screen can be divided into power supply board, X driving board, Y

driving board, logic board, logic BUFFER board (E, F, G), Y BUFFER board (upper and lower), COF etc.:

Y BUFFER(up)

Y driver board

Y BUFFER(down)

Logic

BUFFER(E)

Logic

BUFFER(F

Power supply board

Logic board

X driver board

Logic

BUFFER(G)

* Power supply board: to supply power for the screen, other functional modules on the screen, our own

main board, and video frequency processing board.

* X driving board: to produce and provide driving signal for X electrode according to the time sequence

signal sent from logic board.

* Y driving board: to produce and provide driving signal for Y electrode according to the time sequence

signal sent from logic board.

*Logic board: to process the image signal sent from the main board, to produce addressing signal and

to provide driving signal for X and Y driving boards.

*Logic BUFFER board (E, F): To convert the data signal and control signal sent from the logic board

into the signals required by COF

*Y BUFFER board(Upper,Lower): to transmit the scanning signal from the Y driving board to the

screen, which is divided into upper and lower parts.

*COF: to convert the signal sent from the logic BUFFER board into the address signal used by the

screen.

COF(7 blocks)

28

Page 31

2. Trouble diagnosis:

1) The screen is not bright:

a. Check to see if the power supply plug from the power filter board to the power supply board is

well inserted into the socket. If not, plug it in.

b. Check if the fuse on the power supply board is blown up. If yes, replace it for a good one.

c. Remove digital processing board and analog board, ground socket X601 of the power supply

board to the AUTO mode.

Switch the power on and check if the output voltages of the power board are normal. If

normal, then the problem lies in digital processing board and analog board, which will be

dealt with separately. If abnormal, then first replace the power supply board to see if the

problem is solved.

2) There appears on the screen a line or several unlit lines.

Check if the socket between Y driving board and Y BUFFER is plugged well. If not, plug it well. If

yes then replace Y BUFFER (upper, lower) in respect to the upper , lower part of the dark line on

the screen.

3) There appear on the screen one or several horizontal lines that are much brighter than the

remaining horizontal lines at the edge:

Check if the socket between Y driving board and Y BUFFER is plugged well. If not, plug it well. If

yes then replace Y BUFFER (upper, lower) in respect to the upper , lower part of the dark line on

the screen.

4) There appear on the screen one vertical unlit line or a vertical entirely unlit block

29

Page 32

a. If it’s one vertical unlit line, then COF has problem.

b. If it’s a vertical entirely unlit block, then first check if the connection socket between COF and

logic BUFFER has problem. If not, check if the connection socket between the logic BUFFER

and the logic board is normal. If yes, replace the logic BUFFER. Finally, if the problem still

remains when the replacement is over, then replace the logic board.

5) There appears on the screen a mono color signal and one or several vertical bright lines of other

colors:

a. If it’s a vertical bright line of other colors, then the problem lies with COF or the screen.

b. If it’s an entire vertical block of other colors, then first check to see if the connection socket

between COF and logice BUFFER has problem. If no problem, check if the connection

socket between the logic BUFFER and the logic board is normal. If it’s normal, then

replace the logic BUFFER. If the problem still remains after the replacement, then replace

the logic board. Finally if the problem is still there, then the problem lies with COF.

6) There appear on the screen abnormal bright spots or blocks that are different from what’s

described above:

a. Check if the connection socket between COF and logic BUFFER board has been well

plugged.

b. Replace the logic BUFFER board. If it’s not solved then replace logic board. If the problem

still remains, then it’s the problem with COF.

30

Page 33

Troubleshooting guide

Yes, turn the unit on

If the picture of each channel

is normal?

If the sound of each channel is

normal?

(1) abnormal picture

a) Failure with resistor rows R839~R844 of image processing board, which may lead to lack of

b) Failure with resistor rows R825~R830 of image processing board, which may lead to lack of

c) A certain differential wire pair of LVDS of XA50 or X803(RX0+/-, RX1+/-, RX2+/-, RX3+/-)is

d) Failure with resistor rows RA18~RA25, which may lead to loss of corresponding color from

e) Failure with NB07,NA51 and their peripheral circuit, which may lead to picture abnormal of

f) Failure with N104, which may lead to picture abnormal of TV, AV1, AV2, S-VIDEO.

g) Failure with N803/N805/N806, which may lead to picture abnormal in all channels.

Begin

A red indicator

lights?

A blue indicator

lights?

Ye s

Display picture?

Ye s

color or color splash.

color or color splash.

abnormal, which may lead to lack of color or color splash.,

the gray degree corresponding to the picture of channel HDMI.

PC, YPrPb and YCrCb.

No

No

No

No

No

Check power board , button board and power

cord

Check if the pin1 of X602 in data processing

board is high level(+5V)? check V660/V661.

Check if the crystal in data processing board

starts, DDR clock is correct?

Check the signal inputted from the channel to

pin IC or IC and its peripheral circuit or the

output of LVDS is normal

Check the signal inputted from the channel to

pin IC is normal or IC(R2S15900/TPA3001)

and its periphery is normal

31

Page 34

g

b

p

p

(2) no picture, no sound

No picture, no sound

Red

Check the color of indicator

li

Check the power

oard

No sound No picture

Refer to (3) checking

rocedure

(3) with picture but no sound

With picture but no sound

Check if the voltage of sound amplifier

of X106 in analog board is normal?

Check if the pin2 of N112/N113

inputs signals

Ye s

Check N112/N113 and

their peripheral circuit

ht

Blue

Check the output voltage of

sockets X601~X603/X606/X608

Ye s

No

Power board problem

Refer to (4) checking

rocedure

No

Ye s

Check the power board

No

Check N103/NB05 and

their peripheral circuit

32

Page 35

(4) with sound but no picture

Yes N o

If there is no picture

in all channels?

Ye s

Check N108 and

its peripheral circuit

With sound but no picture

Display OSD MENU?

Ye s

Display LOGO? If pin5 of X602 (IRR) has signal?

Check if the crystal in data processing board starts,

DDR clock and DDR SDRAM are normal?

No

Refer to (6), (7), (8), (9), (10),

(11), (12) checking procedure

Refer to (5) checking

procedure

No

Yes N o

Check N801, N802, DDR

and their peripheral circuit

and power supply

33

Page 36

(5) Check image processing board

Check the power supply

of N803

Ye s

No

Check if pin20, 21, 27,

30 of X801is high level

Check if the power supply of

L801/L802 are normal

Ye s

No

Check if pin3, 5, 26 of N806

output H/V-SYNC and clock

Check the peripheral and power supply of

N801, N802, DDR of data board

Ye s No

Check the peripheral and power

supply of N806

Check if pin34, 65, 66 of N803 output

H/V-SYNC and clock

Ye s No

Check the peripheral and

power supply of N803

Check the peripheral and

power supply of N805

Note: please make sure that the data of FLASH N804 is correct before checking the image

processing board.

34

Page 37

(6) AV no picture

Check if pin13 of N104

outputs signals?

Ye s

Check the periphery circuit

from XC02 to N801

(7) S-terminal no picture

Check if pin13/3 of N104

outputs signals?

Ye s

Check the periphery circuit

from XC02 to N801

Check if C136 and C137

input signals?

Ye s

No

Check if C105 and C138

input signals?

Ye s

No

No

Check N105/N106 and the circuit

from AV terminal to N104

Check N104 and its

periphery circuit

No

Check N108 and the circuit

from S-terminal to N104

Check N104 and its

periphery circuit

35

Page 38

(8) NTSC channel no picture

Check if pin11 of TUNER226

output signals?

Ye s

No

Check if pin13 of N104

outputs signals?

Check TUNER226 power supply

and the peripheral circuit.

Ye s

No

Check the periphery circuit

from XC02 to N801

Check N104 and its

periphery circuit

(9) ATSC channel no picture

Check if pin6/7 of TUNER226

output signals?

Ye s

No

Check if the crystal of

N228 (20MHz) is normal?

Check TUNER226 power supply

and the peripheral circuit.

Ye s

No

Check the clock signal of

each pin of XC01

Check G226, N228 and

periphery circuit

Note :

The I2C bus line control of TUNER is switch through the bus line of N228, so after checking the power

supply and peripheral circuit of TUNER226, it is still no picture in NTSC and ATSC channel, please

check N228 emphatically.

36

Page 39

(10) YprPb or Ycrcb channel no picture

Check if pin4/7/9 of NB07

output signals?

Ye s

Check if pin64/66/67 of

NA51 are normal?

Yes N o Yes N o

Check resistor

rows RA63~

RA68

Check NA51

and peripheral

circuit.

(11) D-sub channel no picture

Check if pin4/7/9 of NB07

output signals?

Ye s

Check if pin64/66/67 of

NA51 are normal?

Yes N o

Check resistor

rows RA63~

RA68

Check NA51

and peripheral

circuit.

No

Check if pin4/7/9 of NB08 output

signals?

Check NB01/NB02

and the circuit from

X807/X808 to N808

No

Check NB03/NB04

and the circuit from

X807/X808 to N808

Check NB07

and peripheral

circuit.

37

Page 40

p

(12) HDMI channel no picture

Check DETECT NA04 and its

peripheral circuit?

Ye s

No

Check if signals of

RA18~RA25 are normal?

Ye s

Check N801 and its

eripheral circuit

Check the connection to HDMI

socket, NA04 and its peripheral

circuit

Note: N801 embeds FLASH, which stores DDC and HDCP information of HDMI, so make sure the

connection between HDMI socket/interface and the bus line is well- going, the picture will display.

38

Page 41

Block diagram of LG 42” power board

IIC

IR

KEY

VGA_H∕V

LED

RESET

5VCTRL Va.Vs.

Overvo ltag e und ervol tgae t est.

ATMEGA8L

Input AC v olta ge test

MCU

Output v olta ge control ON /OFF

Va,Vs active d ischage con trol

PFC OUT 400V

AC IN

EMI

Rectify

PFC

STR

–E1565

DC/DC

Isol ati on

18V

STR X6769–

DC/DC

Isolat ion

Vs

DC/DC

STR F6468–

Isolat ion

Va

STR A6159M

DC/DC

–

Isolat ion

AP1501

Fliter

DC/DC

AP1501A

DC/DC

AP1501

DC/DC

AP1501

DC/DC

5VSB

18VSC

12VSC

5VCTRL

5VSC

3V3SC

39

Page 42

Block diagram of LG 50” power board

IIC

IR

KEY

VGA_H∕V

LED

RESET

5VCTRL.Va.Vs

Overvo ltag e.undervol tgae t est

ATMEGA8L

Input AC v olta ge test

MCU

Output v olta ge control ON /OFF

Va,Vs active d ischage con trol

PFC OUT 400V

AC IN

EMI

Rectify

L4981BD

PFC

DC/DC

STR–F6467

Isolat ion

18V

STR–X6769

DC/DC

Isolat ion

DC/DC

STR–F6468

Isolat ion

Vs

Va

STR

DC/DC

–A6159M

Isolat ion

AP1501

Fliter

DC/DC

AP1501A

DC/DC

AP1501

DC/DC

AP1501

DC/DC

5VSB

18VSC

12VSC

5VCTRL

5VSC

3V3SC

40

Page 43

Troubleshooting of LG 42” power board

Instruction of system and time sequence control

The whole system is composed of EMI, rectify, PFC, DC/DC and MCU. Therein MCU is the control

core of the whole system. On the one hand, it controls ON/OFF time sequence of each voltage and

the main, AC voltage test. On the other hand, it performs the standby CPU function with IIC bus to

the main CPU.

Time sequence

The system has two working modes: AUTO and NORMAL, AUTO mode is used for adjustment and

service, while NORMAL mode is used for TV at normal time. At AUTO mode(short X610), connect

5VCTRL with load of about 2A, turn on power, then output several low-voltage power supplies,

delay 1.5s or so and output Va, Vs. First stop the output of Va, Vs at power-down, and active

discharge to output-capacitor of Va,Vs. on condition that the voltage Va,Vs each is lower than 10

percent (if unsatisfied, then wait), then delay 0.5s and stop all the low-voltage power supplies

except for 5VSB into Standby mode.

At NORMAL mode, MCU receives power-on control of IR or button board, outputs several

low-voltage power supplies, after main CPU sending Va,Vs start-control through IIC bus, outputs

Va,Vs. at the status of turn on, MCU receives power-down control from main CPU and performs

power-down time sequence (power-down time sequence is the same at AUTO mode).

At the two modes, when detect the lower input AC voltage, it will not perform power-on. At the status

of turn on, when detect the lower input AC voltage or 5VCTRL,Va,Vs beyond normal scope value, it

will perform the power-down time sequence above and enter into Standby mode.

Trouble diagnosis

The voltage 5VSB is normal, while the voltages of other circuits are zero, in this case, it may switch

power on at AUTO mode and check if 5VCTRL delay 1.5s or so, if NO, check 5VCTRL and its

fore-circuit; if YES, check LED (LED601), if LED lights, check the circuit of Va, jf not, check the

circuit of Vs (note: premise N608 and its periphery circuit are normal). If the voltages of other circuits

are abnormal, check the corresponding circuits.

Trouble phenomenon (premise the voltage 5VSB is normal)

The main voltage of power board is abnormal, which is commonly detected to enter into Standby

mode, the phenomenon is that switch power off immediately after switching power on.

AC detect circuit or IR, button circuit is abnormal, which will lead to unable to switch power on.

The low-voltage power supplies are normal, while the voltage Va, Vs is zero, it maybe

communication abnormal of IIC bus between MCU and main CPU.

41

Page 44

Troubleshooting of LG 50” power board

Instruction of system and time sequence control

The whole system is composed of EMI, rectify, PFC, DC/DC and MCU. Therein MCU is the control

core of the whole system. On the one hand, it controls ON/OFF time sequence of each voltage and

the main, AC voltage test. On the other hand, it performs the standby CPU function with IIC bus to

the main CPU.

Time sequence

The system has two working modes: AUTO and NORMAL, AUTO mode is used for adjustment and

service, while NORMAL mode is used for TV at normal time. At AUTO mode(short X5201), connect

5VCTRL with load of about 2A, turn on power, then output several low-voltage power supplies,

delay 1.5s or so and output Va, Vs. First stop the output of Va, Vs at power-down, and active

discharge to output-capacitor of Va,Vs. on condition that the voltage Va,Vs each is lower than 10

percent (if unsatisfied, then wait), then delay 0.5s and stop all the low-voltage power supplies

except for 5VSB into Standby mode.

At NORMAL mode, MCU receives power-on control of IR or button board, outputs several

low-voltage power supplies, after main CPU sending Va,Vs start-control through IIC bus, outputs

Va,Vs. at the status of turn on, MCU receives power-down control from main CPU and performs

power-down time sequence (power-down time sequence is the same at AUTO mode).

At the two modes, when detect the lower input AC voltage, it will not perform power-on. At the status

of turn on, when detect the lower input AC voltage or 5VCTRL,Va,Vs beyond normal scope value, it

will perform the power-down time sequence above and enter into Standby mode.

Trouble diagnosis

The voltage 5VSB is normal, while the voltages of other circuits are zero, in this case, it may switch

power on at AUTO mode and check if 5VCTRL delay 1.5s or so, if NO, check 5VCTRL and its

fore-circuit; if YES, check LED (LED5201), if LED lights, check the circuit of Va, jf not, check the

circuit of Vs (note: premise N608 and its periphery circuit are normal). If the voltages of other circuits

are abnormal, check the corresponding circuits.

Trouble phenomenon (premise the voltage 5VSB is normal)

The main voltage of power board is abnormal, which is commonly detected to enter into Standby

mode, the phenomenon is that switch power off immediately after switching power on.

AC detect circuit or IR, button circuit is abnormal, which will lead to unable to switch power on.

The low-voltage power supplies are normal, while the voltage Va, Vs is zero, it maybe

communication abnormal of IIC bus between MCU and main CPU.

42

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

APPENDIX-A: Main assembly

Model Part name No.

PH-63FB8 Key board 667.PH63FB8-05

IR receiver board 667.PH63FB8-09

Analog board 667.PH63FB8-53

Digital processing board 667.PH63FB8-69

Remote control 301.D42FB6-06E

Panel 335.63003-00

Page 57

603-PH63FB8-11

Ver.1.0

Loading...

Loading...