Page 1

COLOR TELEVISION

PS-42D8 B

PS-42D8 S

PH-42D8

Page 2

CONTENT

Safety instructions………………………………………………………………………..…

Method of Debugging ……………….…………………………….…….…………………

Method of software upgrading ………………………………………….…………………

Briefing on the operation principle of the plasma TV series PS and PH …………….

Wiring diagram……………………………………………………………..……………....

Distribution of the Circuit Board of Different Screens and their Functions ……….…

PCB parts and number …………………………………………………………………….

Diagnosis for Plasma Screen of PS and PH ………………………………………..….

Troubleshooting guide………………………………………………………………..……

Schematic diagram…………………………………………………………………………..…

Exploded views………………………………………………………………..……….…..

1

4

5

7

15

18

19

20

23

28

43

Page 3

Note: This maintenance manual is intended only for t he reference of the maintenance people.

Please pay attention to the following points bef or e car rying out the maintenance work.

Safety Instructions

Please read the “Points for attention for the Maintenance & Repair of PDP”and “Criterion for

Identifying the Defects on Screen” as below, before inspecting and adjusting the TV set.

1. “Points for attention for t he M ai nt enance & Repair of PDP”

To avoid possible danger, damage or jeopardy to health and to prevent PDP screen from new

damage, the maintenance people must read the following carefully. If they ignore the following

warnings, there will be deathful risks:

1.1 Screens vary from one model to another and therefore not interchangeable. Be sure to use the

same type of screen in the replacement.

1.2 The operation voltage is approximately 350v for PDP module (including screen, driving circuit,

logic circuit and power module). If you want to conduct maintenance w ork on PDP module whe n

the set is in normal operation or just after the power is off, you must take proper measures to

avoid electric shock and never have direct contact or touch w ith t he circuit r y of the working

module or metal parts. That’s because within a short time relatively high voltage st ill remains on

the capacitor of the driving part even after the power is off. Make sure to begin relevant

maintenance operation at least one minute after the power is off.

1.3 Don’t apply on the module any power supply that is higher than the specification.If the power supply

used deviates from the value given in the specification, there might be a possibility of leading to fire or

damage to the module.

1.4 Never have operation or mounting work under unsuitable environment such as areas in the

vicinity of water – bath room, laundry, water chute of kitchen – sources of fire,

heat-radiation parts or direct exposure to sunlight . O therwise there will be kickbacks.

1.5 In case foreign substances such as water, liquid, metal slices or others fall into the module

carelessly power must be cut off immediately. Keep the module as it is and do not move

anything on the module. Otherwise it might be possible to contact t he high voltage or cause

shock short circuit so that it may lead to fire or electric shock.

1.6 If there is smoke, abnormal smell or sound from the module, please cut the power off

immediately. Likewise in case the screen doesn’t work when the power is on or during the

operation, please also cut off the power at once. No more operation in this case.

1.7 Do not remove or plug its connection wire when the module is in operation or right after the

power is off. That’s because there remains a relatively high voltage on the capacitor of the

driving circuit. If there is a need to remove or plug in the connection wire, please wait at least

one minute after the power is off.

1.8 Considering the module has a glass faceplate, please avoid extrusion by external force lest it

1

Page 4

should cause glass breakage that may get people injured. Two people are needed in

cooperation to move this module lest contingency takes place.

1.9 The complete TV set is designed on the basis of full consideration of thermal dissipation by

convection, with the round hole on the top for heat emission. To avoid overheat, please do not

have any covering on the hole during normal operation and never put it in the place where the

space is narrow and in bad ventilation.

1.10 There are quite a number of circuits in PDP that are integrated ones. Please be on guard

against static electric ity. During maintenance operation be sure to cover yours el f with ant i-static

bag and before operation make sure to have it sufficiently grounded.

1.11 There are a big number of connection wires distributed around the screen. Please take care

not to touch or scuff them during maintenance or removing the screen, because

once they are damaged the screen will fail to work and it’s not possible to repair it.

1.12 Connector for the circuit board of the screen part is relatively fine and delicate. Please take

care in the replacement operation lest it should get damaged.

1.13 Special care must be taken during transportation and handling because strenuous vibration

could lead to screen glass breakage or damage on the drivi ng circuitry. Be sure to use a strong

outer case to pack it up before transportation or handling.

1.14 Please put it for storage in an environment in which the conditions are under control so as to

prevent the temperature and humidity from exceeding the scope stipulated in the specification.

For prolonged storage please cover it w ith anti-mois ture bag and hav e the m piled an d stored in

one place. The environmental conditions are tabulated as below:

Temperature Scope for

operation

Scope for storage -15~60centigrade

Humidity Scope for

operation

Scope for storage 20%~80%

1.15 If a fixed picture is displayed for a long time, difference in its brightness and color may occur

compared with movable pictures. But it doesn’t show any problem and the reason is t hat t here

0~50centigrade

20%~80%

is reduced density of f luorescent pow der in t he for mer. On the other hand, even if ch anges t ake

place in the picture, it can keep its brightness for a period of time (several minutes). It’s a

feature inherent with plasma and it’s not abnormal. Howev er please try as much as possible to

avoid showing a still picture of high brightness for a long time during operat ion.

1.16 As a digit alized display devise, this module is provided with error diffusion technology and the

gray scale and false enhancement of contour can be displayed by reusing of sub-field. As

2

Page 5

H

compared with cathode ray tube, it can be found in the moving picture that at the brim of the

face of a person there are some wrong colors.

1.17 During the display of graph (indicating the gradual change in brightness horizontally or

vertically) resulting from gray scale test it can be found that t he bright ness for the t wo adjacent

levels is uneven. This is caused by t he reuse of sub-field, the display of load rectification and

the eletrolyzation.

1.18 The screen front plate is of glass. Please make sure that the screen has been put in place

during erection. If it is not in place before the erection begins it may lead to screen crack or

breakage.

1.19 Make sure the screw used in the mounting of the screen is of the original specs lest it should

cause damage to the screen due to mismatch. Special care sh ould be taken not t o use too long

or too big screw.

1.20 Care must be taken to guard aga inst dust durin g assembling or dismantl ing, espe cially to avoid

dirt from falling in between the screen and the glass lest it should harm the receiving and

viewing effect.

1.21 There is piece of insulator stuck on the rear chassis corresponding to the power supply board.

It is used to isolate the cool part from the hot part. Please ta ke care to keep it intact lest it

should become a potential safety trouble.

1.22 In addition to plasma screen, the glass is a part of high value. It has such functions as

anti-radiation, adjustment of color temperature etc. Please handle it carefully.

2.“Criterion for Identifying the Defects on Screen”

The PDP produced by our Company at present uses the following criterion for identifying the

defective points:

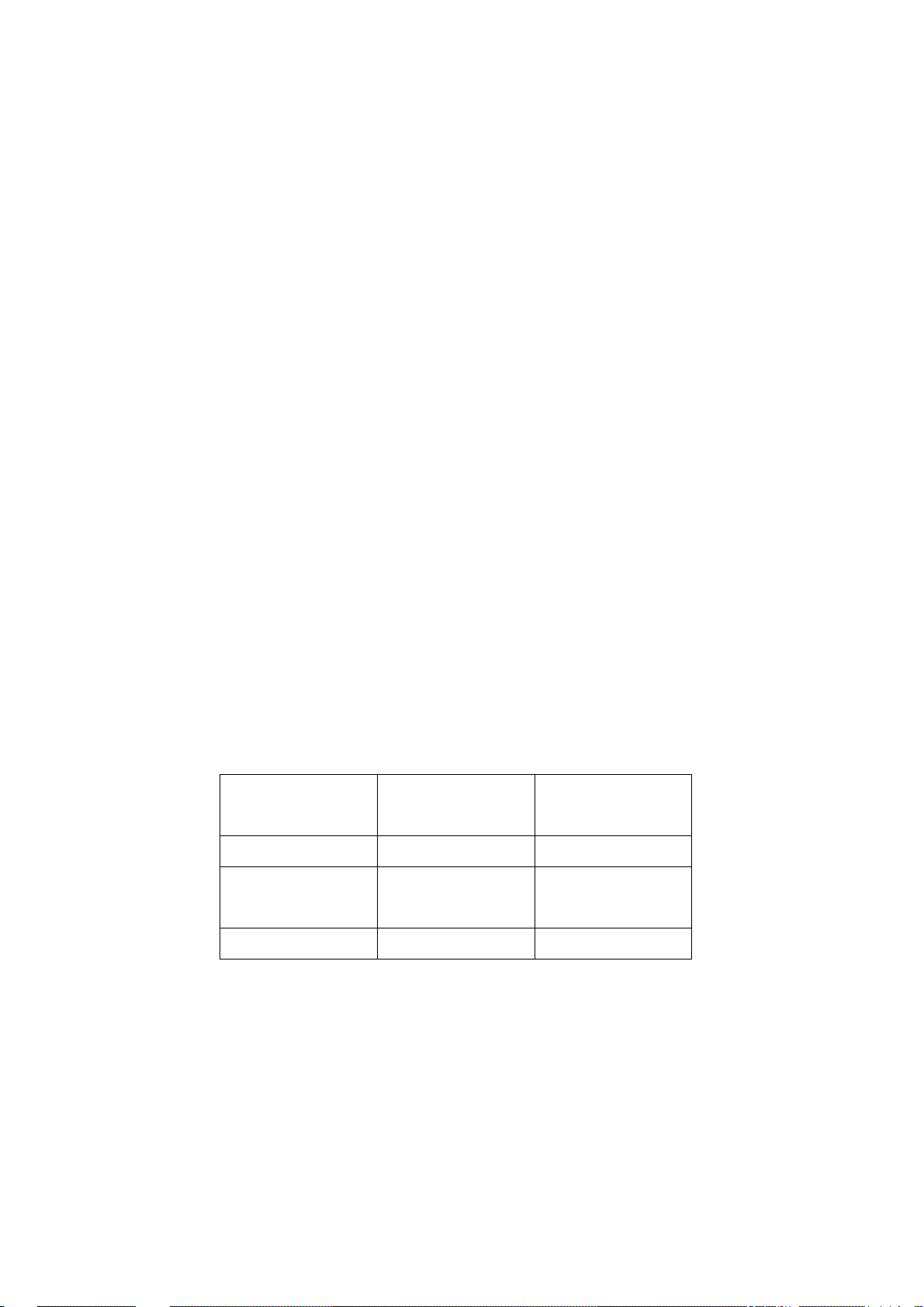

MODEL PS-42D8 B/S,PH-42D8:

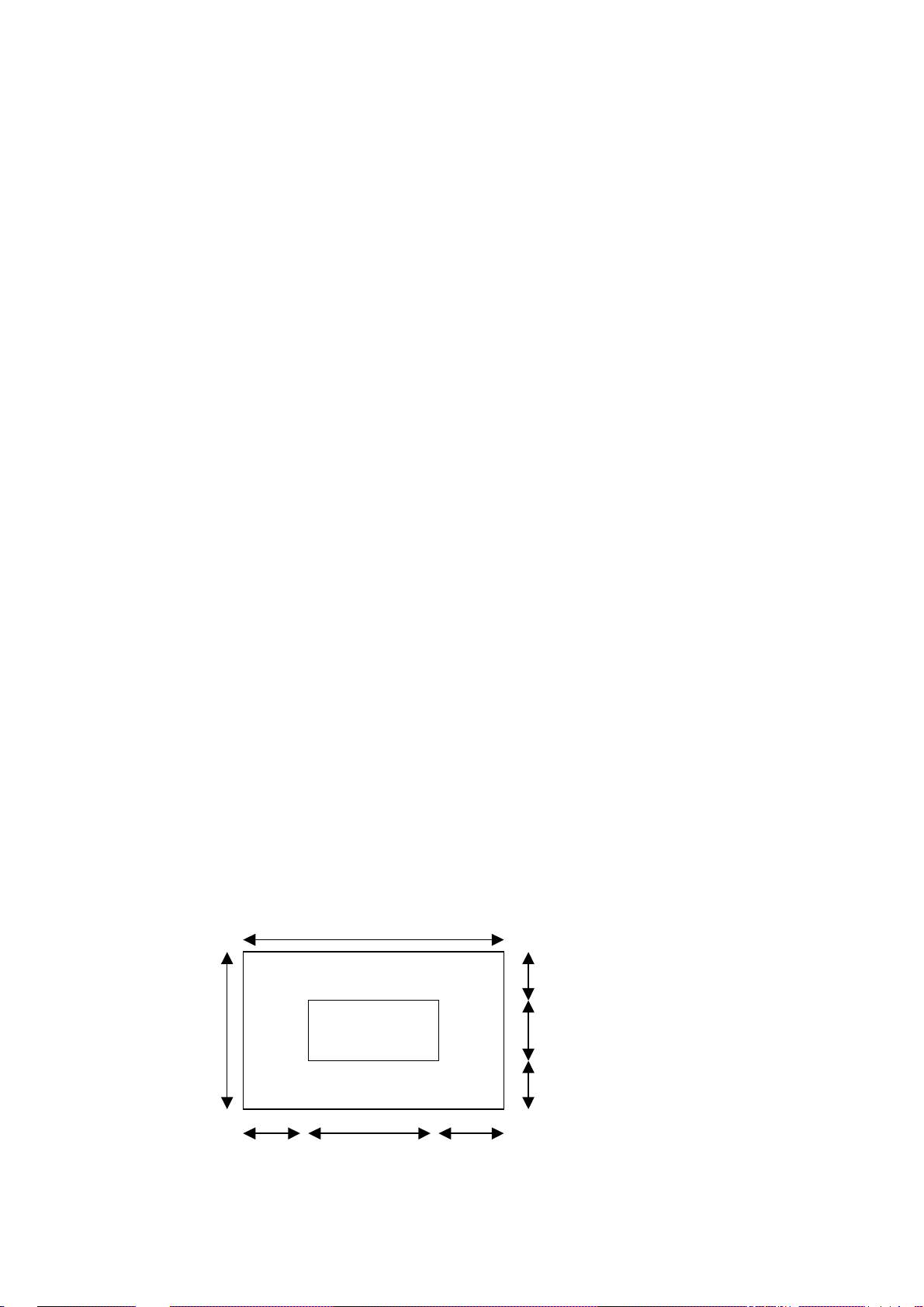

There may appear three kinds of defective points for this m odel as shown in Fig.1, i.e.bright spot

(remain bright); dark spot (non-illuminating) ; flickering spot (cont inuously flickering).

However they should not exceed the specification as in table 1. O t herw ise t he product shall

be deemed as sub-standard.

Figure 1 Defective Points

Zone B

Zone A

W/4 W/2

W

H/4

H/2

H/4

W/4

3

Page 6

Table 1 Criterion for Three Kinds of Defective Points

Kind Area A Area B Remark

Dark spots No more than 2 No more than 8

Bright spot No more than 1 No more than 2

Flickering spot No more than 1 No more than 2

Total number of

defective points in A

and B shall not exceed

8. The distance

between two defective

points shall not be

shorter than 15mm.

Method of Debugging

For Models PS-42D8 B/S PH-42D8, the debugging part lies only in the white balance adjustment.

Nothing else should be adjusted and the maintenance software supplied for after-sale purpose has

normally shielded the value of white balance i.e., no more adjustment is needed when upgrading the

software. In case of special circumstances where the main board is replaced f ollowing method can be

adopted:

1.The white balance ad ju st ment is made resp ectiv ely in t hree way s - TV/AV,VGA,Y pbPr. First adjust

TV/AV, then VGA and YpbPr at the last.

2. Select corresponding channels respectively. After successively press the keys on the production

plant’s remote control (the key at the right hand lower corner doesn’t show up), go on to press the left

key, right key, confirmation key on the small keyboard one by one and then it’s possible to enter the

menu set up in the plant.

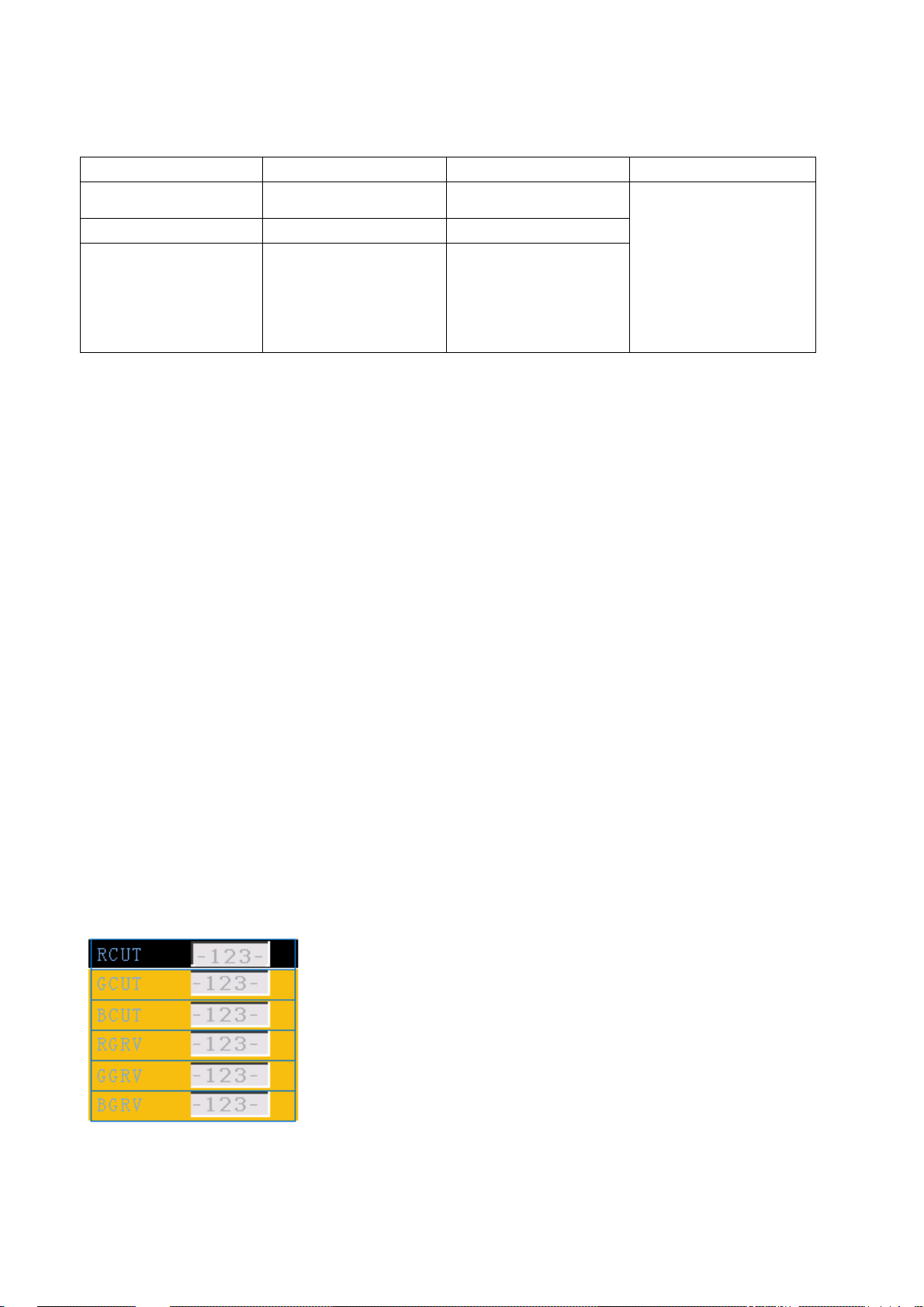

3. Use the right key to select and calibrate the menu. The white balance adjustment and YpbPr

white balance adjustment are for the purpose of white balance adjustment. For the white balance

adjustment of TV/AV and VGA it’s OK just directly adjust the first item whereas for YpbPr adjust the

second item.For the white balance adjustment of TV/AV and VGA: select the item of “white balance

adjustment” from the menu. W hen it’s entered (as shown in the fig. Below), keep RCUI immovable and

adjust GCUT and BCUT so as to adjust the white balance of the dark area. For the adjustment of white

balance of the bright area, keep RGR immovable and then adjust GGRV and BGRV. Repeat the above

steps several times until the picture is normal in white balance.

4. For the white balance a djustment of YpbPr: select the item of “white bala nce adjust ment” from th e

menu. When it’s entered (as shown in the fig. Below), adjust RCUT and BCUT and it’s done.

4

Page 7

5. Note: Except for the two items in the plant setup menu as above used f or the white balance

adjustment and the items 5,6,7 (for test of pattern, color collocation and degree of pure gray) in the

calibrated menu that can be used to shoot trouble, no adjustment should be made for the other items.

Otherwise it may cause abnormality to the set. The internal test signal of PW181 can be used for

troubleshooting.

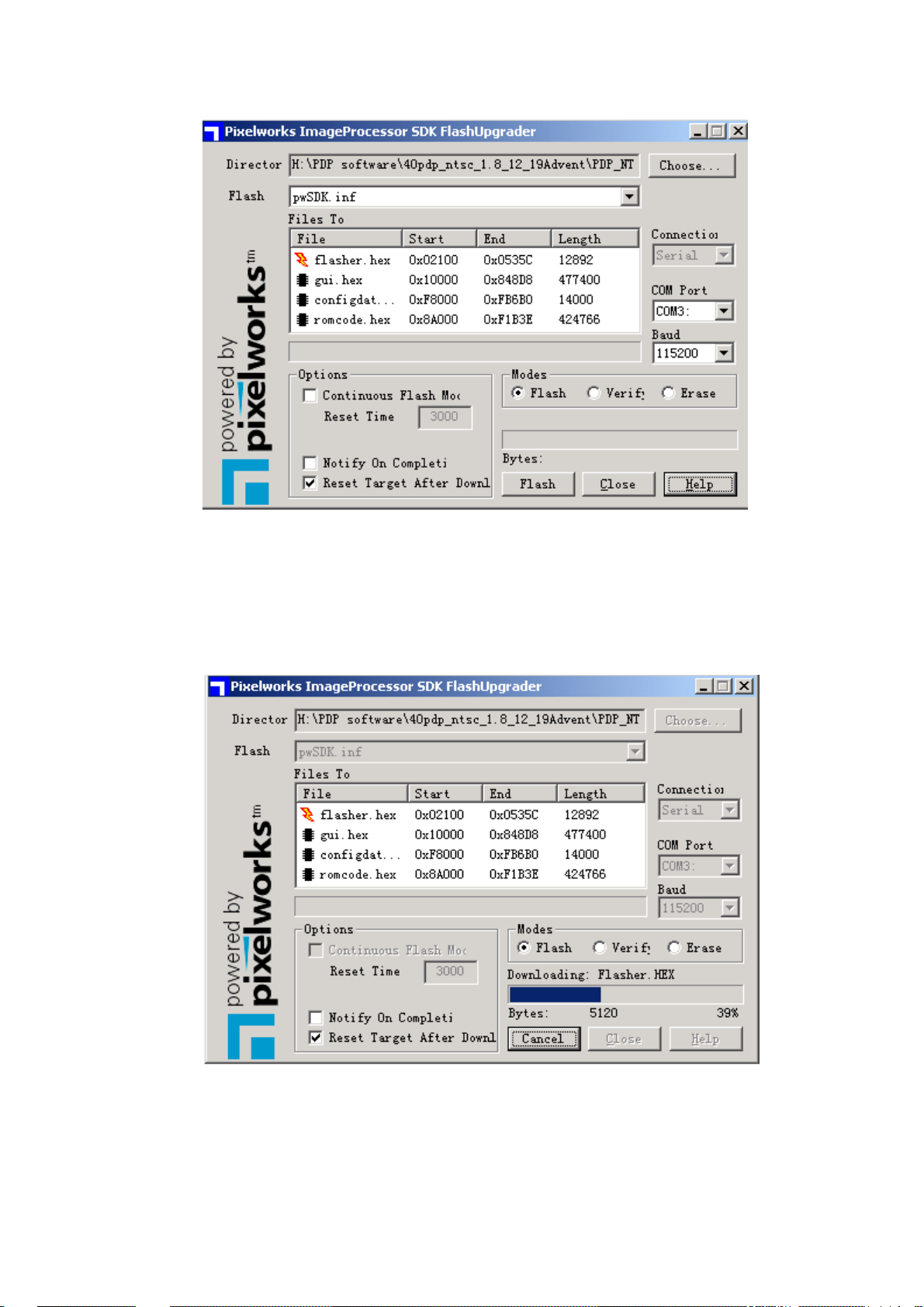

Method of softwar e upgrading

The plasma TV models PS -42D8 B/S and PH-42D8 launched by our company are equipped with

RS-232 interface for upgrading that is carried in the steps below:

Select a connection wire o f serial port (see the figure below) w hich i s required t o hav e a notch o n its

both ends and also the pins 2 and 3 on the two ends are cross-connected.

1.Use the serial port connection wire to connect PC with PDP and set PDP to the off position.

2.Open the folder of the upgrading software and double click the FlashUpgraderNT (on condition of

window 2000/XP/NT)

or the FlashUpgrader (on condition of window 98)

After running the programs the following interfaces w ill appear :

5

Page 8

Based on the features of computer set up the serial port (COM Port) and select corresponding

serial port (if it’s not possible to burnt-write other serial port can be used instead). Baud-select

115200 and then select Reset Target After Download. Hit flash press button and it’s ready to

operate. For the setup of other items please refer to the figure above (already defaulted by the

system so it’s normally unnecessary to alter)

1. Switch on PDP and it begins to run the burnt -w rit e program;

2.Once it’s over with burnt-write, the cancel pushbutton will become flash. Switch off the

main power and then to switch on the TV set again.

Note: Do not switch the power or t he set off in the course of burnt-writing. Otherwise it

may result in the inability of the flash to burnt-write again.

6

Page 9

Briefing on the operation princi ple of the plasma TV series PS and PH

Plasma plane screen technology represents the state-of-the-art and it’s also the best choice for

high quality picture and large purely place screen. Plasma display screen PDP is a display unit

employing gas discharge. This screen uses plasma tube as its light emission component. The faceplate

(panel)of PDP consists of many image elements (plasma tubes) for example, the series PS ,PH pdp

now on the market consists of 852*480 image elements. Each image element in turn consists of three

kinds of image sub-elements. Each image element is actually a plasma tube. These tubes are present

respectively in red, green and blue colors, as shown in fig. I. Each small chamber that corresponds to

each plasma tube is filled with neon and xenon gases. After applying high voltage between the plasma

electrodes, the gases in the small chambers of the plasma tubes sealed in the two layers of glass will

produce ultraviolet so as to excite the three basic co lor (red, green and blue) fluorescent powder to emit

visible light. Each plasma tube acts as an image element. From the composition of these image

elements in different brightness, darkness and colors result the pictures and images of various grays

and colors, which is very similar to the light emission of display tube. Plasma technology is obviously

different form other display methods and is more advanced in structure and formation. Its working

principle is similar to normal daylight lamp. The TV color picture is composed of the light emitted from

various independent fluorescent powder image elements and therefore the picture is fresh and gaily

colored, bright, clean and clear. Furthermore the most outstanding feat ure of plasma TV is that it can be

made super thin and it’s easy to make TV sets of more than 40” with completely plane big screen but in

thickness less than 100 mm (Our Model PS-42D 8 is only 79mm thick and it’s the thinnest in the m arket

at present.)

Plasma TV model PS-42 D8 B/ S and PH-42 D8 serie s of XO CECO is des igned and dev elope d by

XOCECO itself. In terms of the main CMOS chip this series of TV set employs PW181 made by

Pixelworks Company.

7

Page 10

Page 11

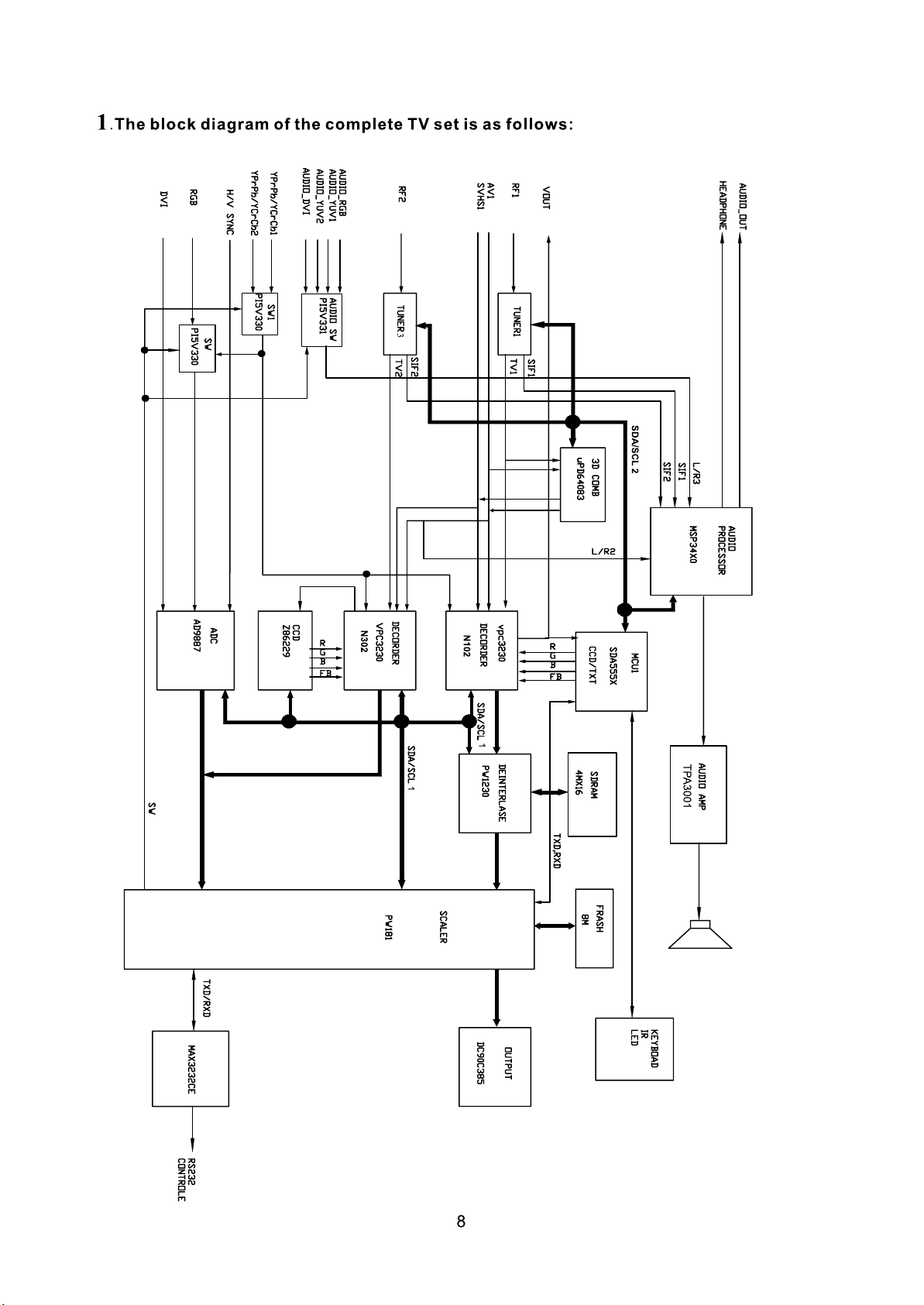

Among which:video decoder:VPC3230 Non-interlace conversion:PW1230

Ad conversion and DVI interface :AD9887 Audio treatment:MSP3440

Sound power amplification:D type power amplification of TI : Tpa3001

3D Y/C separation:uPD64083

CCD/V-CHIPdecoder:Z86229(For North America only)

2. the basic work process flow of model PS and PH series:

2.1. control part

This TV model is based on dual MCU control of which the main MCU is PW181(N501, taking care

of the operation of various chips (includin g image treatment , channel sw itching, image display etc.), infra

red remote control receiving, the standby control, the control of auxiliary CPU, menu display, debugging

of picture effects and other major functions. The auxiliary CPU is SDA555X(NM5, which is responsible

for sound treatment (includin g v olu me adjust ment, cont rol of a lt and base sou nd, st ereo decod e), st atio n

searching control, push button, separation of 3D Y/C (valid only for system N) as well as the

CCD/V-CHIP decoding for the text for oversea sale TV sets etc. Connection between two MCU is made

by means of three pins of X708, i.e., INT (int errupt ion) , S1(RX D), S2(TXD)

2.2. Volume of sound

This model employs double integrated tuner (including high frequency and m edium amplification

circuits). The signal received by antenna is fed to the main tuner, TUNER1, which contains a high

frequency distributor, from which RF signal is shunt to supply to TUNER3 for use. Pin 14 of TUNER1 is

for the power supply of high frequency distributor (+5v). Tuners are controlled by auxiliary MCU NM5

(SDA and SCL)to select proper channel and carry out correct switching of systems. After high

amplification and medium amplification decoding, video signal and audio signal are output. The output

signal of TUNER1 is fed into decoder N102 as the display of main picture whereas the output signal of

TUNER3 is fed into decoder N302 as the display of the auxiliary picture for dual picture. Audio signal is

directly fed into audio frequency processor NM2 MSP3440. At the same time dual way tuners all send

their medium frequency signal of the seco nd soun d to NM2 for treat ment (used for decoding o f stereo or

automatic sound volume control). NM2 is provided with the switching over device for audio frequency

channels. Audio input of VGA/DVI/YprPb of the main board, after the switching-over as selected by N3,

is fed together with the audio signal of TV and AV into NM2, where switching over is selected. The

selected audio frequency signal is made use of in the following three ways. One way is, after being

subjected to the control of volume and alt and base sound, fed separately through left and right sound

channels into sound power amplifier TPA3001 for amplification. Then it is fed into the loudspeaker for

sound reproduction. Another way is also fed separately through left and right sound channels into

earphone power amplifier NM9 TDA7053 for amplification before being output to earphone socket for

listening, of which the volume is controlled by PWM signal produced by pin 50 of NM5.The remaining

way is output through video board as AV out.

9

Page 12

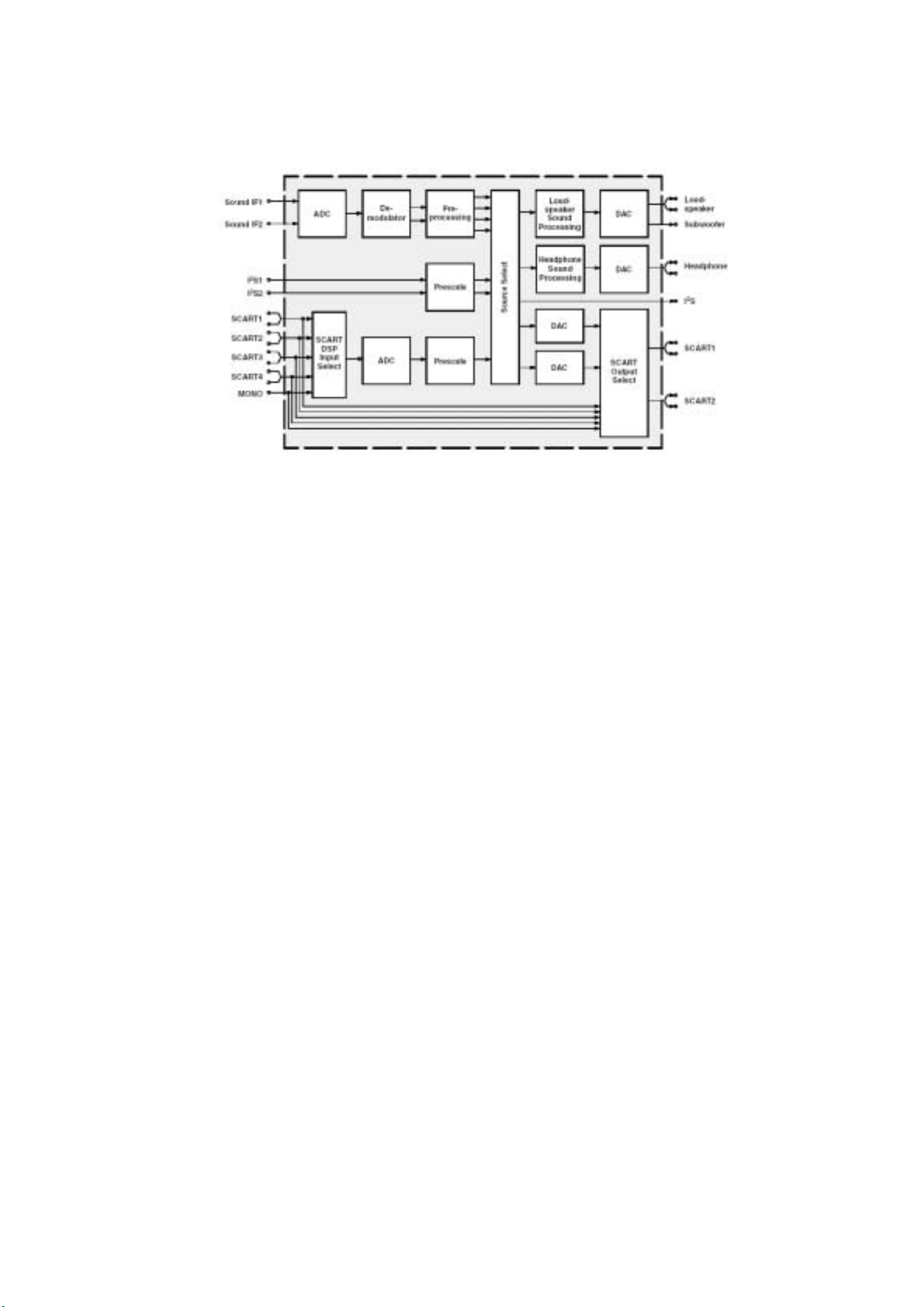

The block diagram of MSP3440 is as follows:

2, 3:SCL and SDA for the control of IC operation;

27,28:output to the right and left channel of sound power amplifier;

33,34:right and left channel of earphone sound;

36,37:AV OUT right and left channel of sound;

47,48:right and left channel of sound fed from main board;

50,51:AV IN right and left channel of sound;

53,54:right and left sound channel of sub-channel TV ;

56,57:right and left sound channel of main channel TV ;

67,69:SIF input of main and sub channel TV

Sound power amplifier TPA3001 is an amplification of mono-channel high efficiency D type power.

Under the condition of no heat dissip atio n its output power can be as hi gh as 20 w. It has the functions of

over current and overheating protection. Automatic protection comes in when the input to the ground is

short-circuited. Then output is stopped. After the removal of short circuit, switch the set again and it

restores to normal. Therefore if the set becomes soundless due to the short circuit caused in carelessly

pulling out or plugging in the audio frequency wire (it is certainly not recommendable to do so), just

switch it on again and no big deal.

2.3.Picture and image:

Y signal of AV and SVHS shares the same chann el. SVHS has pr iorit y. Identification of termin al S is

determined by electric level SID fed from SVHS socket to NM5. When the electric level of SID is of hi gh

value, the system is identified as SVHS. Signals from TV or AV and YCRCB are altogether fed into

digital decoder VPC3230 (sent separately in two ways to N102 and N302). Channel switching is carried

out. They are decoded int o 16b it C CIR601 signa l to be fed i nto t he process or of lower l ev el for treat ment .

VPC3230 mainly functions to switch over channels, separate Y/C of 4 lines, decoding of colors and

adjustment of picture effect.

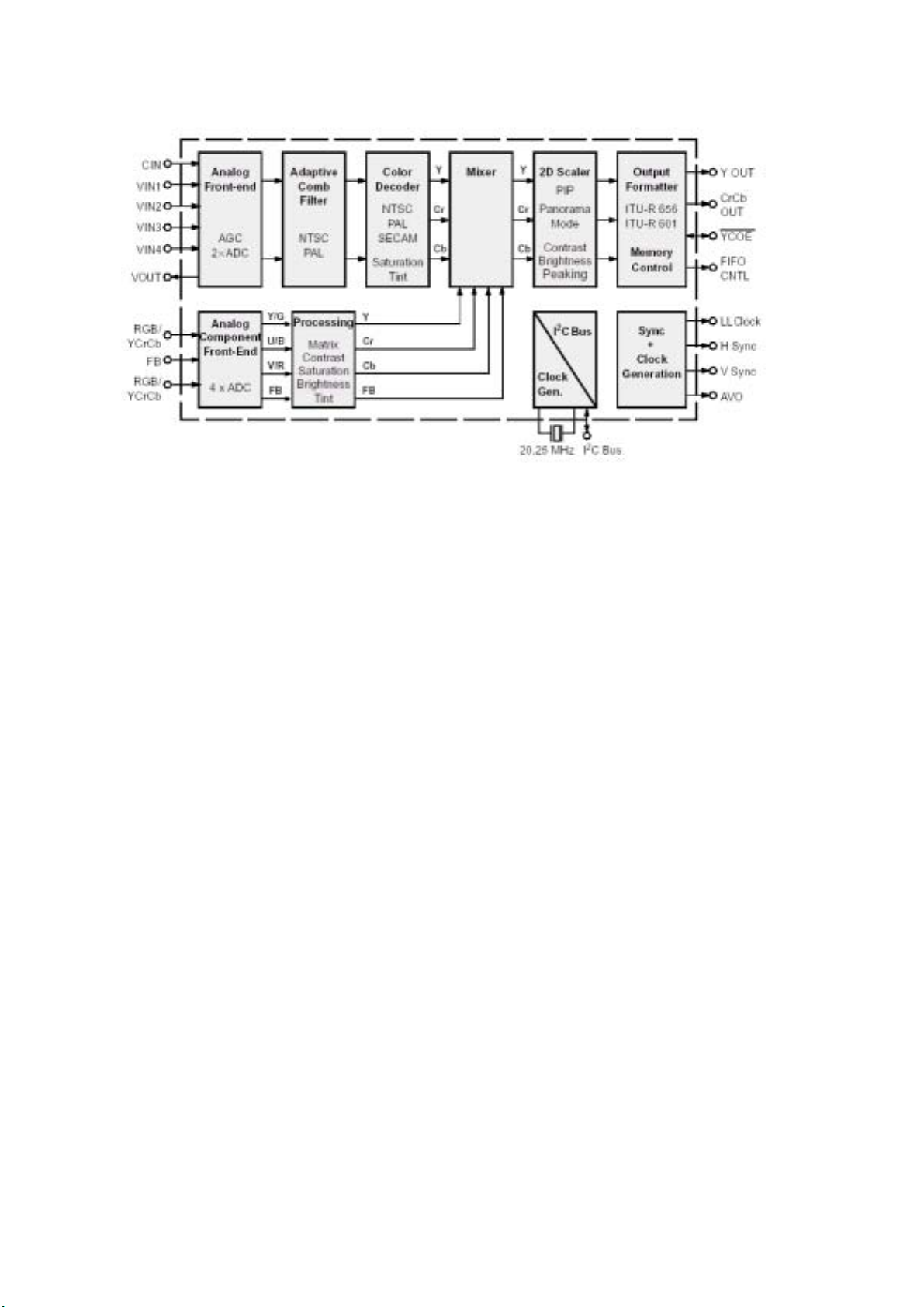

2.3.1The block diagram of VPC3230 is shown below:

10

Page 13

In which: Pin 71 is used for the input of C signal of SVHS;

Pin 72 VIN1 is used for the input of Y signal of CVBS or SVHS of AV;

Pin 73 VIN2 is used for the input of TV signal;

Pin 75 VIN4 is used for the input of Y signal of YCRCB to synchronously identify YCRCB.

Main channel: The digital YCRCB signal in the form at of CCIR601 after being decoded in N102 is

fed into non-interlace processor N204 PW1230 for treatment from alternate-line into non-interlace.

VD1_CLK,VD1_HSYNC VD1_VSY N C, VD1_ACTIVE and VD1_ FI ELD sent from VPC3230 is used as a

key signal to identify modes. If certain channels become abnormal the corresponding pictures will also

become abnormal. In addition to the function PW1230 has to process the signal from alternate-line into

non-interlace, it can also function to enhance the picture and convert the movie modes 3:2/2:2. The

adjustment of brightness and contrast of the main channel is performed by this chip whereas the

adjustment of chroma and definition is performed by N102. The digital 24 bit RGB signal output from

PW1230 after treatment is fed into V PORT of N5 01 P W181 for further processing. The signa ls of VCLK

(clock) and VVS(field synchronization) and VHS(line synchronization) and VPEN(enable signal)are the

basic reference for the image processing of lower level.

For TV set of mono N system, this series has an additional 3D Y/C separation function in the main

channel, which is performed by ND02 Upd64083 so as to enhance the quality of the image.

In this case the signal flow process of the main channel is different. Video signal and AV/SVHS signal

sent from TUNER1 first undergo switching in the switch circuit ND01, then are fed into ND 02 for

separation of brightness from col or and outp ut as sig nal Y and C. For N102, no matter whether it’s TV or

AV/SVHS, finally the signals are all fed in the form of Y/C into the input port of VIN1and CIN. Yet the

setup for the software is somewhat different.

The decoding for the text of main channel or CCD/V-CHIP is performed by auxiliary CPU. Video

signal is directly fed to pi n 12 of NM5 for decoding. The decoded text or CCD/V-CHIP signal is output in

the form of R, G, B, FB and fed into N102 for character superposing.

Sub-channel:

Signal CCIR601 after being decoded in VPC3230 is directly fed into PW 181 G PORT where direct

processing is carried out by PW181. The non-interlace conversion in this channel is performed by the

non-interlace processor inside PW181. Relatively speaking, the efficiency of the internal non-interlace

processor of PW181 is lower than that of PW1230. Therefore when displaying dual picture the main

11

Page 14

picture effect is better than that of sub-picture. The adjustment of brightness, contrast, definition and

chroma is performed by N302.

The decoding of CCD/V-CHIP in this channel is specially performed by 21 line decoder N301

Z86229. The deco ded information is superposed onto the image in N302 a lso i n t he form of R, G, B and

FB.

For VGA and YPRPB, after the selection in N1 YPRPB1 and YPRPB2 are fed together with N402

for channel selection. The selected signal is fed into the ADC part of N403 AD9887 for A/D conversi on

so as to produce 24 bit digital RGB signal to be fed into the G PORT of PW181. The line and field

synchronous signal of VGA is directly fed into N403 whereas The line and field synchronous signal of

YPRPB is obtained after synchronous separation of Y signal of SOGIN

in AD9887 (This signal is input t o N403 pin 108).

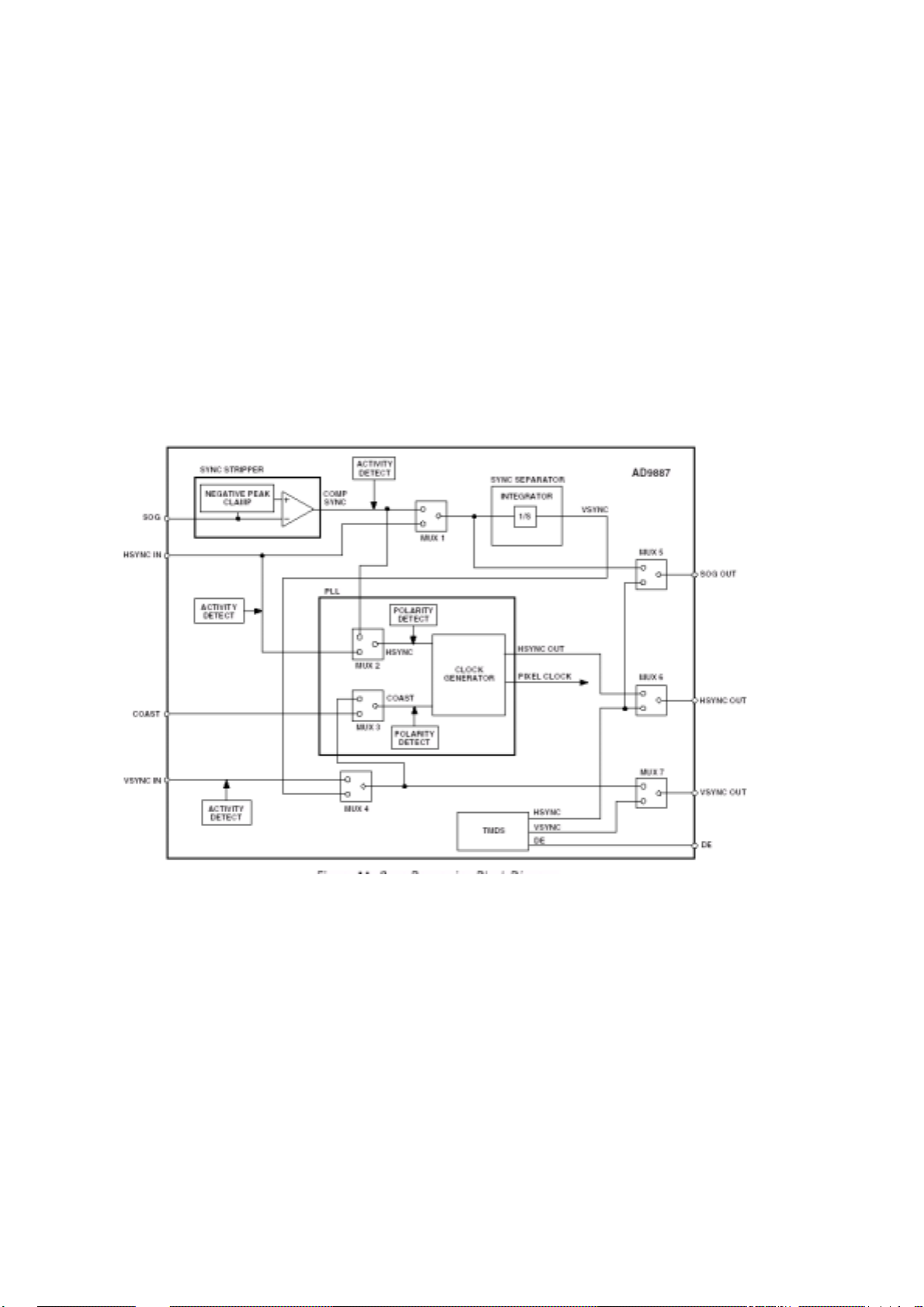

Synchronous switching device is shown in the f ol l owing fi gur e:

AD9887 is also provided with DVI input port. The DVI input signal is converted into 48 bit digital

RGB signal and sent to G PORT of PW181 for processing. The selection from DVI and VGA/YPRPB is

performed by AD9887.Certain organizations for the oversea sales of this TV series h ave been equipped

with the capabili ty to decode HDCP. PORTA4 and PORTA5 of PW181 verify the password (cip her key)

through bus line with broadcast equipment. Each TV set has its own independent password, which is

stored in EEPROM.

The mode identification of VGA or YPRPB is performed by PW181. The identification process is :

When selecting channel si gnal input P W181 preset s t he synchronou s select ion of AD9887 so that it

can directly output the required synchronous si gnal for direct feed ing to P W181. The synchronou s signal

format is identified inside PW 181. By making cross-reference with the format table pre-stored inside a

most similar format is obtained. Then the parameters of this format are called for use in setting up the

parameters for modular conversion so t hat it is optimized. At the same time the conversion coefficient of

SCALER is confirmed.

12

Page 15

2.3.2 Block diagram of A D9887 i s shown below

Finally the video signals o f dif f erent cha nnels are se nt respectively t o V POR T and G PORT of main

processing chip PW181 for processing. PW181 has such processing capabilities as “picture out of

picture”, “picture in picture”, “multiple pictures”. So long as the signals come respecti vely from V PORT

and G PORT, they automatically become “picture out of picture”, “picture in picture”. PW181 has the

function of SCALER, which means it can conduct format conversion for the input signals of different

format to enable it to meet the requirement of the screen for format and finally output the signal in the

form of 24 bit RGB.

The standard of interface f or PDP screen is LVDS (low voltage differential signal). So the digital

RGB signal output from PW181 still needs to be converted into LVDS signal by the conversion interface

chip of LVDS - N602 DS90C385 (This chip may vary with the manufacturer of the screen). This

converted signal is in turn fed to the screen for driving purpose. The output of N602 is four pairs of

differential signa l and one pair of c lock sign al. If any pair of signal is abnor mal t hen the i mage is affected

to be abnormal for example, a certain color may become abnormal. The PWRDOWN signal output from

PW181 is used to control the operation of N602, which works under low electric level.

13

Page 16

PW181 is also the main CPU. Its program is stored in the externally connected flash N601. The

software upgrading of RS-232 is actually the upgrading of the stored memory in N601 by PW181. The

interface of menu is also produced by PW181. PW181 can automatically produce self check signal for

trouble shooting.

2.3.3 Block diagram of PW181 is shown below:

The above is a short account of the s ignal flow pro cess o f the TV series . Plea se note HS (Horiz ontal

Synchronous), VS (V ert ical Sy nchronou s) and CLK ( Cloc k), PEN (Enab le) between i ndividua l stages ar e

invariably the basic reference for the mode identification of lower level chip. Make sure that they are in

normal working condition.

PW181 controls the standby of the complete TV set. The POWER-ON signal output from

PORTB3 of P W181 is used t o control the operat ion of the pow er sup ply board . When it is PO WER_O N ,

the TV set is switched on with low electric level and is in standby wi th high electric level. When it’s in

standby the remaining power supply is only 5VSTBY.

The voltage VS required by the operation of screen is also controlled by VS_ON output from logic

board. It is in operation when the electric level is high. Only when the logic board receives correct sign a l

(clock, synchronous, enable et c.) can VS_O N be correctly output. The oper atio n of PDP scr een has v ery

high demand for the time sequence of power supply. If the time sequence is wrong it might make the

screen unable to work normally.

14

Page 17

1.PS-42D8 B

WIRING DIAGRAM

CN8002

POWER BOARD(1)

CN4001

CN8007

CN9006

CN9007

CN8004

CN9003

X-DRIVER

BOARD

BOARD

POWER FILTER

VIDEO BOARD

VIDEO PROCESSOR

BOARD

SOUND POWER

AMP. BOARD

CN4002

3

3

POWER BOARD(2)

CN8009

CN5008

CN9005

CN9004

CN8008

CN8006 CN8003

BUFFER

KEYSETS

MAIN BOARD

LOGIC CIRCUIT BOARD

CN5001

Y-DRIVER

BOARD

BUFFER

KEY BOARD

15

Page 18

2.PS-42D8 S

CN8002

POWER BOARD(1)

CN4001

X-DRIVER

BOARD

CN4002

BOARD

POWER FILTER

06

M07

CN8007

CN9006

CN9007

CN8004

10

CN9003

02

VIDEO PROCESSOR

BOARD

05

M09

03

VIDEO BOARD

3

3

POWER BOARD(2)

CN8009

CN5008

CN9005

CN9004

CN8008

CN8006 CN8003

BUFFER

KEYSETS

MAIN BOARD

LOGIC CIRCUIT BOARD

CN5001

Y-DRIVER

BOARD

BUFFER

KEY BOARD

16

Page 19

3.PH-42D8

CN4001

X-DRIVER

BOARD

CN4002

BOARD

POWER FILTER

CN401

CN8002

6

D02

CN8007

CN9006

CN9007

CN8004

7

CN9003

2

VIDEO PROCESSOR

BOARD

D01

5

3

VIDEO BOARD

SOUND POWER

AMP. BOARD

CN2006

CN402

CN2003

POWER BOARD(2)

POWER BOARD(1)

CN2001

CN8009

CN9005

CN9004

KEYSETS

CN2004 CN2005

CN8008

MAIN BOARD

CN8005

CN8006 CN8003

CN807 CN402

CN5008

Y-DRIVER

BOARD

BUFFER

BUFFER

LA01

CN2007

CN5001

LOGIC CIRCUIT BOARD

CN2002

KEY BOARD

17

Page 20

Distribution of the Circuit Board of Different Screens and their Functions

42SD-V3(Type: S42 SD-YB03,Code No: 335-42001-00)

Power board(2)

Power board(1)

Y driving

Logic board

logic BUFFERY BUFFER

COF

Xdriving

42HD-V3 (Type:S42AX-XB01,Code No:335-42002-00)

Ydriving

logic BUFFER

Power board(2)

COF

Power board(1)

X driving

Y BUFFER

Logic board

logic BUFFER

COF

18

Page 21

* Power supply board: to supply power for the screen, other functional modules on the screen,

our own main board, and video frequency processing board.

* X driving board: to produce and provide driving signal for X electrode according to the time

sequence signal sent from logic board.

* Y driving board: to produce and provide driving signal for Y electrode according to the time

sequence signal sent from logic board.

*Logic board: to process the image signal sent from the main board, to produce addressing

signal and to provide driving signal for X and Y driving boards.

*Logic BUFFER board: To convert the data signal and control signal sent from the logic board

into the signals required by COF

*Y BUFFER board: to transmit the scanning signal from th e Y driving board to the screen, which

is divided into upper and lower parts.

*COF:to convert the signal sent from the logic BUFFER board into the address signal used by

the screen.

PCB parts and number

Singal processor boards:

Main board video frequency processor boards

video frequency boards parts

video frequency boards

Switch parts

19

Page 22

Parts name

Main board

PS-42D8

B

667-PHID8

-01 C

Parts number

PH-42D8 PS-42D8S

667-PHID8

-01 U

667-PSID8

-01S

Main parts and number

N501 PW181-20 (353-01810-00)

N204 PW1230 (353-12300-00)

N403 AD9887-140 (353-98870-30)

N102/N302 VPC3230D (353-32300-80)

N602 DS90C385MTD (353-03850-20)

N601 AM29L V800BT -90E(353-29800-10)

video frequency

processor boards

video frequency

boards

Sound

amplification

boards

Transformer board 667-PS42D8-46

Remote parts

key-press board

parts

power supply filter

parTs

667-PS42

D8-40 C

667-PS42

D8-70

301-UPS4

2D8-09

667-PS42D8-51 C

667-PH42

667-PS42

667-PS42D8-24

301-UPS4

667-PH42D8-05

D8-40 U

D8-70 U

2D8-06R

PS42D8-4

0S

667-PS42

D8-70S

667-PS42

D8-46S

301-UP42

D8-25R

667-PS42

D8-51

NM5 SDA555XFL (352-05550-20)

NM2 MSP3440G (353-34400-00)

NM9 TDA7053A T (353-70530-70)

TUNER1

JS-6B1/112A2-A2(590-40425-00)

TUNER3 JS-6B1/111C6 (590-40422-00)

NA01/NA02 TP A3001D (353-30010-10)

Diagnosis for Plasma Screen of PS and PH

Trouble diagnosis: Trouble diagnosis:

1.The screen is not bright:

a. Check to see if the power supply plug from the power filter board to the power supply board is

well inserted into the socket. If not, plug it in.

b. Check if the fuse on the power supply board is blown up. If yes, replace it for a good one.

c. Remove our main board and the video frequency processing board, ground the pin 4

POWER_ON/OFF of socket CN802 of the power supply board, and then push the slide switch

SW2001 on the logic board to the internal modes (1, 3 up and 2, 4 down) from external modes (1, 2,

4 up and 3down) Switch the power on and see if the screen is lit. If the screen can give a normal

and completely white field signal, then the problem lies in our main board or video frequency

processing board, which will be dealt with separat ely.

d. If the screen is not lit, then first replace the power supply board to see if the problem is solved.

e. If the problem remains after the power s upply board is replace d, then the pr oblem lies i n the screen.

Replace the entire screen for treatment.

2.There appears on the screen a line or several unlit lines.

20

Page 23

Check if the socket between Y driving board and Y BUFFER is plugged well. If not, plug it well. If yes

then replace Y BUFFER (upper, lower) in respect to the upper , lower part of the dark line on the

screen.

3.There appear on the screen one or several horizontal lines that are much brighter than the remaining

horizontal lines at the edge:

Check if the socket between Y driving board and Y BUFFER is plugged well. If not, plug it well. If yes

then replace Y BUFFER (upper, lower) in respect to the upper , lower part of the dark line on the

screen.

4.There appear on the screen one vertical unlit line or a vertical entirely unlit block

a. If it’s one vertical unlit line, then COF has problem.

b. If it’s a vertical entirely unlit block, then first check if the connection socket between COF and

logic BUFFER has problem. If not, check if the connection socket between the logic BUFFER

and the logic board is normal. If yes, replace the logic BUFFER. Finally, if the problem still

remains when the replacement is over, then replace the logic board.

5.There appears on the screen a mono color signal and one or several vertical bright lines of other

colors:

21

Page 24

a. If it’s a vertical bright line of other colors, then the problem lies with COF or the screen.

b. If it’s an entire vertical block of other colors, then first check to see if the connection socket

between COF and logice BUFFER has problem. If no problem, check if the connection socket

between the logic BUFFER and the logic board is normal. If it’s normal, then replace the logic

BUFFER. If the problem still remains after the replacement, then replace the logic board. Finally if

the problem is still there, then the problem lies w it h COF.

6.There appear on the screen abnormal bright spots or blocks that are different from what’s described

above:

a. Check if the connection socket between COF and logic BUFFER board has been well plugged.

b. Replace the lo gic BUFFER board. If i t’s not solved then repla ce logic board. If the problem still

remains, then it’s the problem with COF.

22

Page 25

Troubleshooting guide

p

n

pply

p

d

b

b

y

p

1.no raster and not sound

yes no

Turn off the set ,unplug

VGA cable,disconnect

power board(2) and

signal process

board,connect X709

pin8 to GND,set panel

yes no

to self-check status,turn

abnormal

on the set again,check

no

whether the panel

yes

Check signal

abnormal normal

rocess board

normal abnormal

power supply

normal abnormal

normal

abnormal

normal abnormal

Check signal channel

connection status

ok

normal

lights up.

Check logic

power supply

Disconnect

ower board an

signal process

oard

Replacing power

su

board

Load short

circuit,replacing

singal processing

Replacing main board

Replace

video process

board

board’s

oard

Check if the red

indicator

LED8004

onpower board

lights up

Replacing power

supply board

Screen

problem

Disconnect

ower board

and signal

process board

Replacing

power supply

board

If power

indication

lamp is lit

Cut off connect

X2between main

board and video

processing,which

the board is

abnormit

Power ope

circuit

Check 5V-STBY

Cutoff the connection

between power board

and signal process,

check5V-STB

Replacing

power supply

board

23

Page 26

2.no picture and have sound:

N

N

N

N

N

N

N

N

N

N

t

d

N

N

no

Check

501 Check N302

yes

yes no B no

TV no

Test R342-345

A DVI

YC signal

yes

yes AV

Test n302

VGA normal

pin72 signal

YPBPR/YCBCR abnormal

Test N102

pin72 signal

no yes

yes

Test R145-148

YC signal

YCBCR both YPBPR

abnormal normal

Check

102

nomar

abnormal

abnormal normal

Check

204

sub C

main

Test

R207-213

and N204

In which signal

channel ther is no

Both YPBPR to

YCBCR no picture

Check N1

Check

501

Check if there’s

initial screen with

logo appearing

o picture

picture

yes

Check

302

Turn of power board

board,X709 pin8,check

if the screen light up?

Check

501

Check n601

601 bad

Judge if the troble is

YPBPR and YCBCR

Check

501

Check N402

and signal process

Screnn bad

Check N501

Check

signal

VGA

Check

403

A

VGA work’s

normal

Check socke

X401 an

403

connection

Check

403

Check R414

24

Page 27

B

V

N

N

n

A

N

N

normal abnormal

Call out double screen,set the two

screen’s signal source to

TV,confirm if the split screen is

normal

Check if the input A

signal is normal

normal abnormal

Check if input

double scree

signal is normal

normal abnormal

Check TUNER1

normal

工作 D D

Check

normal abnormal normal

Check N204

output signal

102

Check N102

output signal

Check

102

Check

TUNER

Check VG

signal

abnormal

Check N702

abnormal normal normal

Check N204 Check N501

Check if every part’s

connection is credibility

C

D

normal abnormal

yes no

normal abnormal

Check

403

Check YPBPR

Check

402

Check if it can identify

VGA format

Check double screen TV

pictures are normal

Check N403 Check N501

25

Page 28

Setting up for the self check of the screen:

d

t

For 42”SD-v3 screen (S42SD-YB04):Push down 2 and 4 and push up 3 of

SW2001on the logic board;

For 42”HD-V3 screen (S42AX-XB01): Push down 2 and 4 and push up 3 of

SW2001on the logic board

Please make sure resume it to the original status when the check is over.

3.There is picture but not sound:

yes

no

yes

no

no

yes

Sound power AMP. or other peripheral

circuit have problem. Check power

supply,if SHUTDOWN pin control is

normal and if output short circuited or

other problems that cause protection to

normal abnormality

4.Abnormal pictur e :

Peculiar color, which may be caused by the following phenomena:

Turn off the set and then turn on,check if

the sound is restored to normal

Sound output is

short

Check if XA04 soun

on power AMP.board

Measure if there is signal in pin 2

of sound power AMP.

Measure if the sound input

of the present channel

corresponding to NM2 is

normal

work.

MSP3440 or other peripheral

circuit have problem

A certain different i al wire pair of LVDS(RX0+/-,RX1+/-,RX2+/-,RX3+/-)

is abnormal, which may lead to lack of color ( it’s not a complete loss of

color);

Failure with resistor rows R550~R555 , which may lead to loss of

corresponding color from the gray degree corresponding to the picture of all

channels. Through self signal check by PW181, the failure is still there.

Failure with resistor rows R419, R421, R425, R427, R431, R432,which may

lead to loss of corresponding color from the gray degree corresponding to

the picture of channels VGA/YPRPB/DVI.

Sound box damaged

Check different levels of circui

following input audio signal channel

26

Page 29

Failure with resistor rows R415, R418, R422, R424, R429, R430,which may

lead to loss of corresponding color from the gray degree corresponding to

the picture of channel DVI.

Failure with resistor rows R342, R343, R344, R345,which may lead to loss

of corresponding color from the gray degree corresponding to the picture of

sub-channels TV/AV/YCRCB, or lead to abnormal brightness.

Failure with resistor rows R207, R208, R209, R210, R211, R212 or R145,

R146, R147, R148,which may lead to loss of corresponding color from the

gray degree corresponding to the picture of main channels TV/AV, or lead to

abnormal brightness.

Bad connection between N203 and N204, which may also lead to abnormal

picture (column bar like) in main channel TV/AV.

Abnormal picture vertically or horizontally (bar like): Abnormal in complete line

extending all the way from up downward on the screen of stand definition TV setr;

abnormal vertically on half screen of high definition TV set. They may be caused

by the damage of the address BUFFER module that directly corresponds to its

position, or may be caused by the damage of the connection wire that directly

corresponds to the position of the screen. The horizontal bar like abnormality is

also related to the Y driving circuit that corresponds directly to its position. To

judge these phenomena, It’s possible to check it by setting the screen to the

status of self check as explained above

No brightness in the square block area: Normally it’s caused by the damage of

the address BUFFER module that directly corresponds to its position, or may be

caused by the damage of the connection wire that directly corresponds to the

position of the screen. To judge these phenomena, It’s possible to check it by

setting the screen to the state of self check as explained above

27

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Loading...

Loading...