Page 1

LCD TELEVISION

LC-52R36

Page 2

CONTENTS

Safety precautions………………………………………………………………………..…

Alignment instructions …………………………….…….…………………………………

Working principle analysis of the unit……………………………………………………………..

Block diagram…………………………………..………………………………….…………

IC block diagram………………………………………………………………………..……

Wiring diagram …………………………………………………………………………….

Troubleshooting guide ………………………………………………………………..……

Schematic diagram…………………………………………………………………………

APPENDIX-A: Assembly list

APPENDIX-B: Exploded View

1

2

6

7

8

20

21

27

Page 3

Attention: This service manual is only for service personnel to take reference with. Before

servicing please read the following points carefully.

Safety precautions

1. Instructions

Be sure to switch off the power supply before replacing or welding any components or

inserting/plugging in connection wire Anti static measures to be taken (throughout the entire

production process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety requirements.

Do not change the specs and type at will.

2. Points for attention in servicing of LCD

2.1 Screens are different from one model to another and therefore not interchangeable. Be sure to

use the screen of the original model for replacement.

2.2 The operation voltage of LCD screen is 700-825V. Be sure to take proper measures in

protecting yourself and the machine when testing the system in the course of normal operation or

right after the power is switched off. Please do not touch the circuit or the metal part of the module

that is in operation mode. Relevant operation is possible only one minute after the power is

switched off.

2.3 Do not use any adapter that is not identical with the TV set. Otherwise it will cause fire or

damage to the set.

2.4 Never operate the set or do any installation work in bad environment such as wet bathroom,

laundry, kitchen, or nearby fire source, heating equipment and devices or exposure to sunlight etc.

Otherwise bad effect will result.

2.5 If any foreign substance such as water, liquid, metal slices or other matters happens to fall into

the module, be sure to cut the power off immediately and do not move anything on the module lest it

should cause fire or electric shock due to contact with the high voltage or short circuit.

2.6 Should there be smoke, abnormal smell or sound from the module, please shut the power off at

once. Likewise, if the screen is not working after the power is on or in the course of operation, the

power must be cut off immediately and no more operation is allowed under the same condition.

2.7 Do not pull out or plug in the connection wire when the module is in operation or just after the

power is off because in this case relatively high voltage still remains in the capacitor of the driving

circuit. Please wait at least one minute before the pulling out or plugging in the connection wire.

2.8 When operating or installing LCD please don’t subject the LCD components to bending, twisting

or extrusion, collision lest mishap should result.

2.9 As most of the circuitry in LCD TV set is composed of CMOS integrated circuits, it’s necessary

to pay attention to anti statics. Before servicing LCD TV make sure to take anti static measure and

ensure full grounding for all the parts that have to be grounded.

2.10 There are lots of connection wires between parts behind the LCD screen. When servicing or

moving the set please take care not to touch or scratch them. Once they are damaged the screen

1

Page 4

would be unable to work and no way to get it repaired.

If the connection wires, connectors or components fixed by the thermotropic glue need to disengage

when service, please soak the thermotropic glue into the alcohol and then pull them out in case of

damage.

2.11 Special care must be taken in transporting or handling it. Exquisite shock vibration may lead to

breakage of screen glass or damage to driving circuit. Therefore it must be packed in a strong case

before the transportation or handling.

2.12 For the storage make sure to put it in a place where the environment can be controlled so as to

prevent the temperature and humidity from exceeding the limits as specified in the manual. For

prolonged storage, it is necessary to house it in an anti-moisture bag and put them altogether in one

place. The ambient conditions are tabulated as follows:

Temperature Scope for operation 0 ~ +50 oC

Scope for storage -20 ~ +60 oC

Humidity Scope for operation 20% ~ 85%

Scope for storage 10% ~ 90%

2.13 Display of a fixed picture for a long time may result in appearance of picture residue on the

screen, as commonly called “ghost shadow”. The extent of the residual picture varies with the

maker of LCD screen. This phenomenon doesn’t represent failure. This “ghost shadow” may remain

in the picture for a period of time (several minutes). But when operating it please avoid displaying

still picture in high brightness for a long time.

3. Points for attention during installation

3.1 The front panel of LCD screen is of glass. When installing it please make sure to put it in place.

3.2 For service or installation it’s necessary to use specified screw lest it should damage the screen.

3.3 Be sure to take anti dust measures. Any foreign substance that happens to fall down between

the screen and the glass will affect the receiving and viewing effect

3.4 When dismantling or mounting the protective partition plate that is used for anti vibration and

insulation please take care to keep it in intactness so as to avoid hidden trouble.

3.5 Be sure to protect the cabinet from damage or scratch during service, dismantling or mounting.

Alignment instructions

1. Test equipment

PM5518 (Video signal generator)

VG-848 (Signal generator)

CA210 (White balancer)

2

Page 5

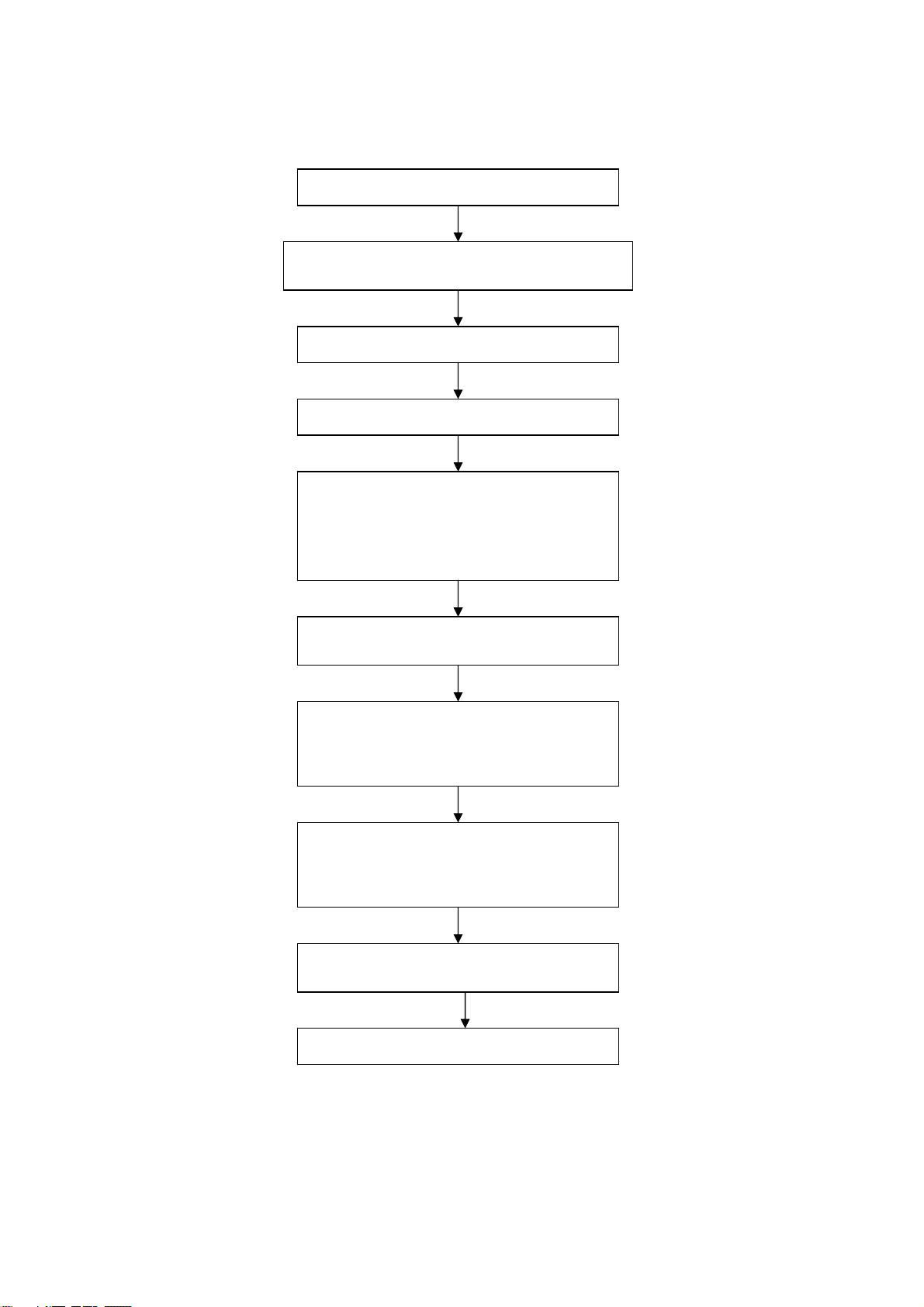

2. The alignment flow chart (see below figure)

Production of main board and analog board on the line.

Check DDC, HDCP KEY and FLASH

Check CPU board and analog board

Combined test for general assembly

Connect to central signal source; check if various

TV functions (station skipping, modulate quantity

control etc), check if the output of earphone and

speaker are normal.

Input AV/S signal and HDTV signal; check various

functions under AV/S terminal

Input VGA signal and check if display is normal in

the state of PC and various functions (analog

quantity control, line/field center etc.)

Input HDMI signal and check if display is normal in

the state of HDMI and various functions (sound

and analog quantity control).

Preset ex-factory

Check accessories and then packing

3

Page 6

3. Adjustment illustration

3.1 The unit adjustment

Connect all the boards according the wiring diagram, then power on and check the display.

3.2 The method for entering factory menu

Enter factory menu method: press the SOURCE→ 2→ 5→8→0 buttons one by one on the remote

control to enter factory menu. When the first line of the adjustment item is light, press the MENU

button to select item and press the DSP button to exit the factory menu.

3.3 EEPROM initialization

Enter the firs page of factory menu, adjust item OPTION-1 to 25, OPTION-2 to 5, select the

EEPROM Initial after, press the VOL+ button, then display the DOING, still the DOING disappear

and turn off the unit.

Note: option-1 and option-2 function as follows:

Option-1 Option-2

Bit4 0: RS232 can’t be controlled by the external unit

1: RS232 can be controlled by the external unit

Bit3 0: No memory function after power off for 10s

1: memory function after power off for 10s

Bit2,1 00: STANDBY

01: turn on

10: memory function of turn on

Bit0 0: without LOGO

1: With LOGO

0: Gammar On

1: Gammar Off

0:no signal noise wave of TV

1:no signal blue screen of TV

hold

0: Video and Graphic channel white balance no share

1: Video and Graphic channel white balance share

3.2 HDMI channel adjustment

Input the VG-848 TIME854(800X600/60Hz) and PATTERN920 8-LEVEL gray signal, enter the

factory menu2(white balance adjustment menu), adjust the third step and the seventh step.

Adjust R-offset, G-offset and B-offset item, still the third step color coordinate to (275, 285). Adjust

R-gain, G-gain and B-gain item, still the seventh step color coordinate to (275, 285). Repeat

adjustment R-offset, G- offset and B- offset item and R-gain, G-gain and B-gain item, still two step

gray to (275, 285).

Note: R-offset, G-offset, B-offset values must be an item value to 128 at least; R-gain, G-gain,

B-gain values must be an item value to 255 at least.

3.3 VGA channel adjustment

3.3.1 mode pre-set

Input the VGA signal of VG-848 (PATTERN 980:1 dot ON/OFF), select the TIME877 (720x400/70Hz)

signal, press auto-adjust button to all screen or adjust PC settings menu to auto correction.

Separate auto adjust for TIME885 (640x480/60Hz) and TIME854 (800x600/60Hz).

3.3.2 VGA channel auto color adjustment

Input the VG-848 TIME854(800x600/60Hz) and PATTERN920(GRAY 8 STEP(H)), enter the factory

menu1, select the AUTO COLOR after, press the VOL+ button to select AUTO COLOR.

3.4 YPBPR channel adjustment

Input the VG-848 TIME972(1080i/60Hz) and PATTERN976(64 GRAY & Color), enter the factory

menu1, select the AUTO COLOR after, press the VOL+ button to select AUTO COLOR.

4

Page 7

4. Performance check

4.1 TV function

Input center source signal to RF-TV terminal, enter search menu→auto search, check if the channel

is leak for auto searching.

4.2 AV/S and YPbPr terminal

Input AV/S and HDTV signal, check if the signal is normal.

4.3 VGA terminal

Input 640 x 480 @60Hz VGA format signal, check if the signal is normal.

4.4 HDMI terminal

Separate input HDMI and DVI signal; check the picture and sound is normal, check if the HDCP

function is normal.

4.5 check the sound channel

Check the speaker and headphone of each channel.

4.6 check the clock

Enter user’s clock setting menu, set the clock and calendar and power off, then power on and check

if the clock and calendar settings are stored.

4.7 light sensor function

Enter user’s picture menu, set “light sensor” to On and check if the brightness of picture changes

according to the ambient room light conditions

4.6 ex-factory setting

Enter the first page of factory menu, select the factory out after, press the VOL+ button to display

“doing”, then “doing” disappear while it can auto ex-factory setting.

5

Page 8

Working principle analysis of the unit

The RF1 via integrative tuner TUNER1 after, the FBAS VIDEO1 and SIF is generated. The RF2 via

integrative tuner TUNER2 after, the FBAS VIDEO2 and AUDIO is generated. Video signal and

audio signal of VIDEO1,VIDEO2,AV1/SVHS1,AV2,AV3 and audio signal of VGA and so on, its sent

NA3 (CXA2089Q) to switch selection. The output video signal of main picture (Y/V, C) sent N7

(TVP5160) to decode. The signal via N7 decode after, it sent 8-bit ITU-R656 format signal to N10

(FLI2310) non-interlaced processing. It sent 24bit YUV signal to main processing control chip

N15(GM1501/1601).

The sub-picture video signal via CXA2089Q select after, it sent N8 (TVP5147) to decode. The signal

via N8 decode after, it sent 8-bit ITU-R656 format signal to N15 (GM1501/1601). Therein, the signal

of TUNER2 is sub-picture only.

The main-picture video signal from CXA2089Q is sent to decoder and also AV OUTPUT.

USB signal via A/V decoder AML278 to output RGB and digital audio signal, the audio signal via

CS4334 D/A convert then output L/R-USB.

Two ways YPBPR signal via HDTV switch NA1(PI5V330W) selection after, it sent to HDTV switch

device NA15(PI5V330W) switch selection together with USB signal, then sent RGB switch

N4(PI5V330W) select with RGB from VGA port of PC , then it sent to GM1501/1601.

Another two ways HDMI via HDMI switch (FSHDMI04) selecting after, it sent to HDMI receiver

N34(MST3383MB), then output RGB signal of 24bit to GM1501/1601.

They sent to GM1501/1601 picture processing, therein YPBYP or RGB to A/D conversion after, it

and other two signals are switched selection and digital display processing, it include OSD, GAMMA

correction, brightness and contrast processing, then LVDS conversion to signal acceptable for LCD

panel, namely four pairs of differential signal and one pair of clock signal, then it is sent to image

enhancer PW9702 to improve the image, and then to LCD panel for picture display.

The SIF of tuner output signal to audio processing NA4(MSP3420),The audio of main-picture and

sub-picture via switch conversion CXA2089Q to MSP3410; the audio of two YPBPR and USB

processed by AML3278 via switch conversion NA2(HEF4052) to MSP3410, the HDMI via

MST3383MB decode to audio, it audio via N26(CS4334) D/A conversion to MSP3410 too.

The stereo of the SIF with other four ways audio switch conversion selection to volume control and

audio processing. One way output right/left channel audio of main-picture, the signal sent SRS

processing NA5 (M62494) to SRS sound stereo processing. It via sound amplifier NA20, NA21

(TPA3001D1) to speaker; one way output right/left channel audio of sub-picture, it sent to earphone,

another way is AV OUT R/L output.

The work of whole unit is controlled by MCU, which includes GM1501/1601.

6

Page 9

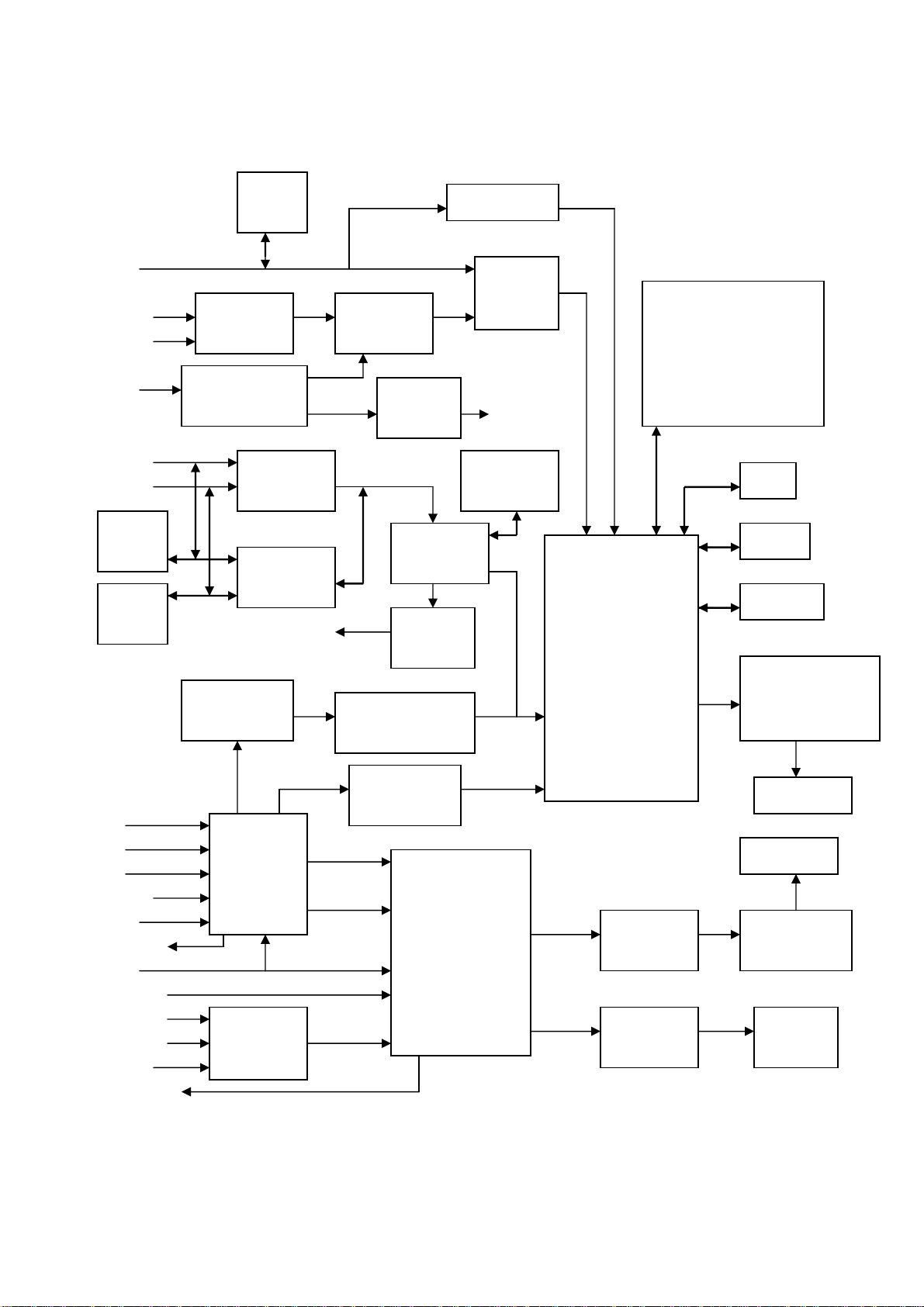

Black diagram

Hs,Vs

RGB

VGA

YPbPr1

YPbPr2

USB

A/V Processor

AML3278

HDMI1

HDMI2

EDID

24C02

EDID

24C02

L/R-HDMI

Y Main/C Main V-PIP

AV1

AV2 L/R-PIP

AV3

L/R-VGA L/R-Main

Tuner2

V-AVOUT SIF

Tuner1

L/R-HDMI

L/R-YPbPr1

L/R-YPbPr2

L/R-USB

L/R-AVOUT

VIDEO DEC.

TVP5160

EDID

24C02

HDTV SW.

PI5V330

HDMI SW.

FSHDMI04

LOGIC SW.

CBT3257

AV SW.

CXA2089Q

AUDIO SW.

HEF4052

HDTV SW.

PI5V330

D/A

CS4334

HDMI RX

MST3383

D/A

CS4334

DEINTERLACER

FLI2310

VIDEO DEC.

TVP5147

AUDIO

PROCESSOR

MSP3410/MSP3420

SN74AHC14

RGB SW.

PI5V330

L/R-USB

HDCP KEY

24C04

Power-ON,IR,KeyA,

KeyB,Led1,Led2,Mute,

HP-SW,VGA-CAB,DV

I-CAB,YUV/VGA,YU

V-SW,YUV/USB

LCD TV

CONTROLLER

GM1501/GM1601

SRS

M62494

HP AMP

TDA7053

DDR

FLASH

EEPROM

IMAGE QUALITY

ENHANCER

PW9702

PANEL

SPEAKER

AUDIO AMP .

TPA3001 x2

HEAD

PHONE

7

Page 10

IC block diagram

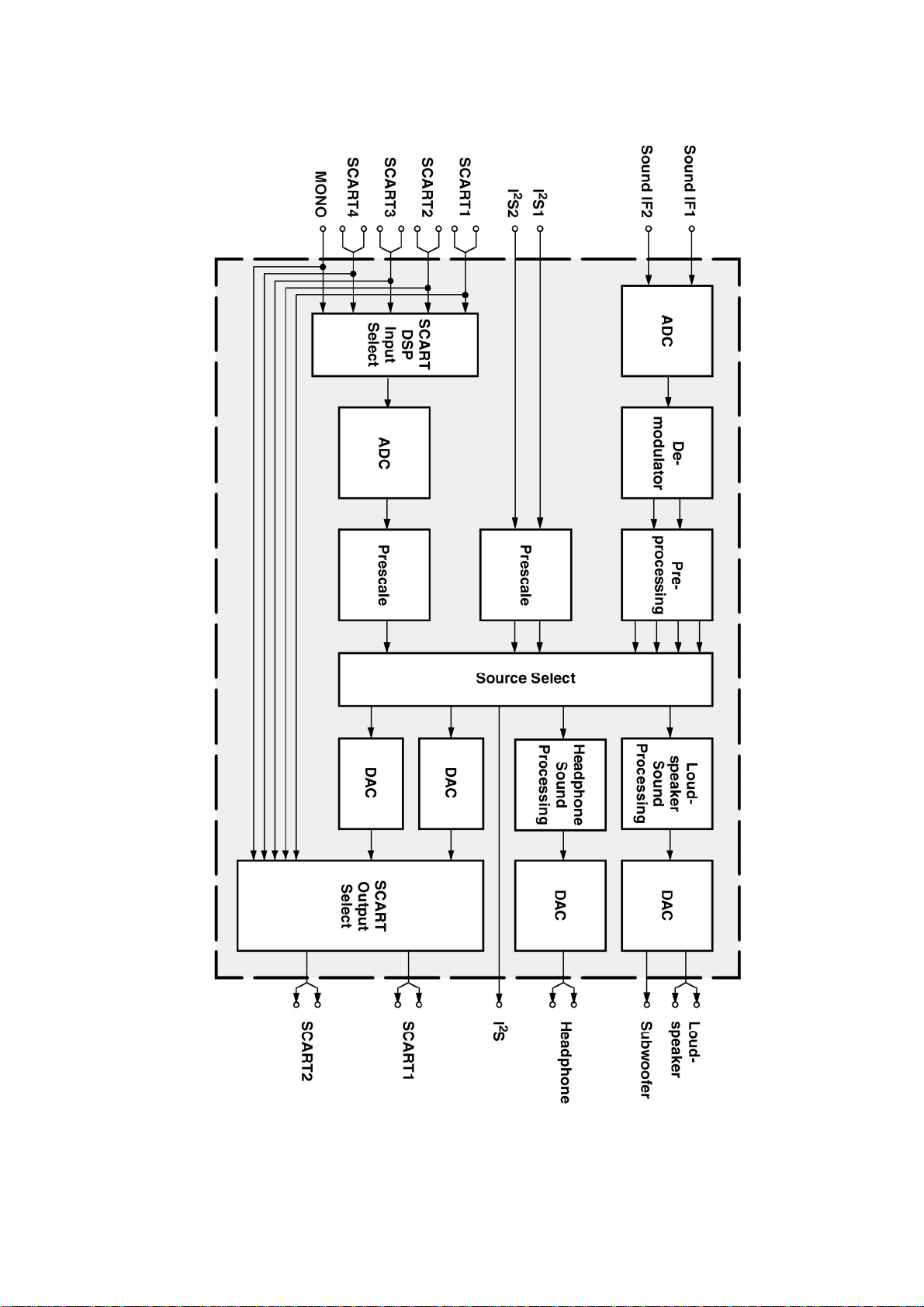

1.MSP34X0G

The MSP 34x0G family of single-chip Multistandard Sound Processors covers the sound

processing of all analog TV-Standards worldwide, as well as the NICAM digital sound standards.

The full TV sound processing, starting with analog sound IF signal-in, down to processed analog

AF-out, is performed on a single chip. Figure 1–1 shows a simplified functional block diagram of the

MSP 34x0G.

This new generation of TV sound processing ICs now includes versions for processing the

multichannel television sound (MTS) signal conforming to the standard recommended by the

Broadcast Television Systems Committee (BTSC). The DBX noise reduction, or alternatively,

Micronas Noise Reduction (MNR) is performed alignment free.

Other processed standards are the Japanese FM-FM multiplex standard (EIA-J) and the FM Stereo

Radio standard.

Current ICs have to perform adjustment procedures in order to achieve good stereo separation for

BTSC and EIA-J. The MSP 34x0G has optimum stereo performance without any adjustments.

All MSP 34xxG versions are pin compatible to the MSP 34xxD. Only minor modifications are

necessary to adapt a MSP34xxD controlling software to the MSP 34xxG. The MSP 34x0G further

simplifies controlling software. Standard selection requires a single I2C transmission only.

The MSP 34x0G has built-in automatic functions: The IC is able to detect the actual sound standard

automatically (Automatic Standard Detection). Furthermore, pilot levels and identification signals

can be evaluated internally with subsequent switching between mono/ stereo/bilingual; no I2C

interaction is necessary (Automatic Sound Selection).

The MSP 34x0G can handle very high FM deviations even in conjunction with NICAM processing.

This is especially important for the introduction of NICAM in China.

The ICs are produced in submicron CMOS technology. The MSP 34x0G is available in the following

packages: PLCC68 (not intended for new design), PSDIP64, PSDIP52, PQFP80, and PLQFP64.

8

Page 11

Fig. 1–1: Simplified functional block diagram of the MSP 34x0G

9

Page 12

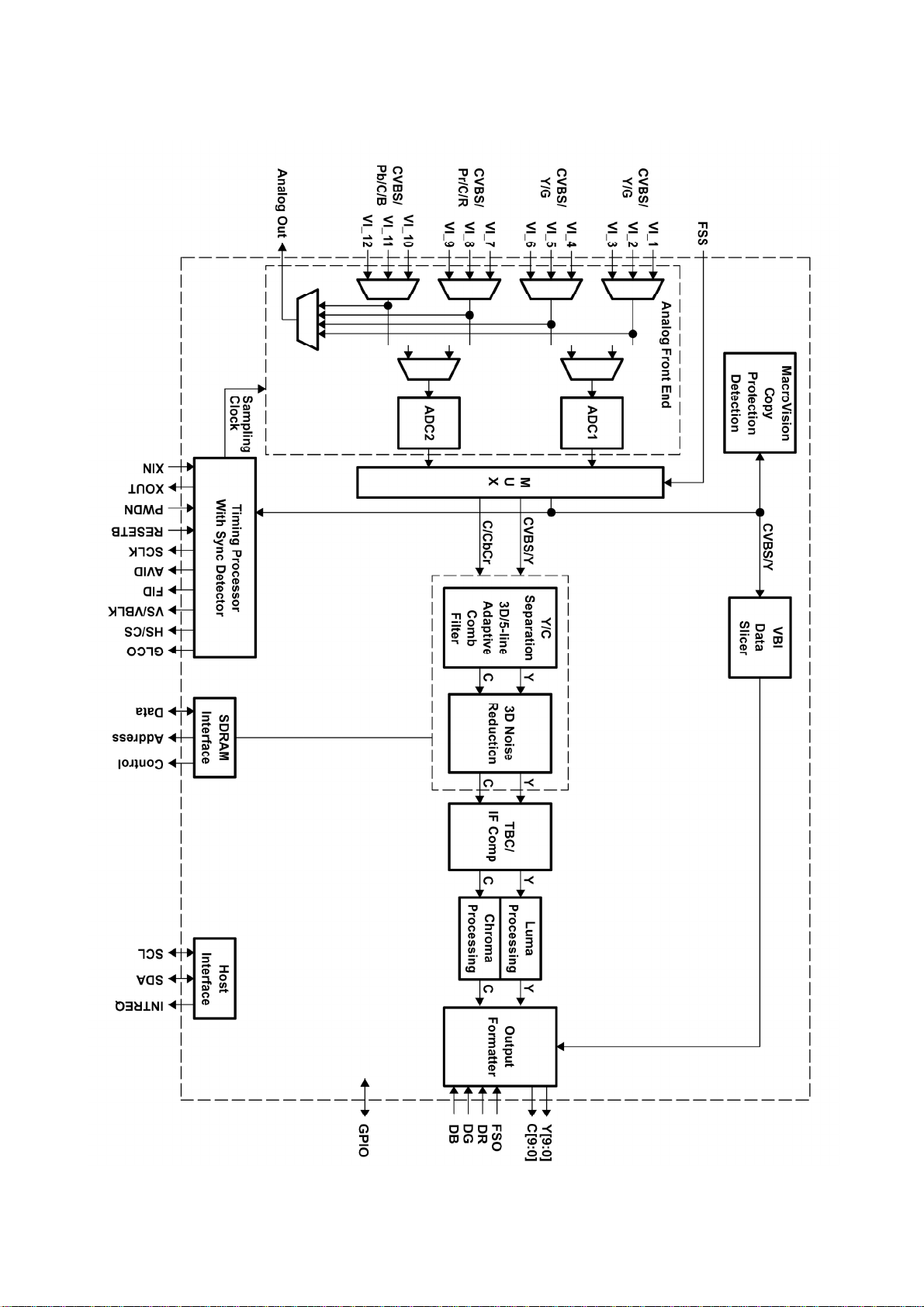

2. TVP5160

The TVP5160 device is a high quality; digital video decoder that digitizes and decodes all popular

baseband analog video formats into digital component video. The TVP5160 decoder supports the

A/D conversion of component YPbPr and RGB (SCART) signals, as well as the A/D conversion and

decoding of NTSC, PAL, and SECAM composite and S-Video into component YCbCr. Additionally,

component progressive signals can be digitized. The chip includes two 11-bit, 60-MSPS, A/D

converters (ADCs). Prior to each ADC, each analog channel contains an analog circuit, which

clamps the input to a reference voltage and applies a programmable gain and offset. A total of 12

video input terminals can be configured to a combination of YPbPr, RGB, CVBS,

and S-Video video inputs. Progressive component signals are sampled at 2x clock frequency (54

MHz) and are then decimated to the 1x rate. In SCART mode the component inputs and the CVBS

inputs are sampled at 54 MHz alternately, then decimated to the 1x rate. Composite or S-Video

signals are sampled at 4x the ITU-R BT.601 clock frequency (54 MHz), line-locked for correct pixel

alignment, and are then decimated to the 1x rate. CVBS decoding utilizes advanced 3D Y/C filtering

and 2-dimensional complementary 5-line adaptive comb filtering for both the luma and chroma data

paths to reduce both cross-luma and cross-chroma artifacts. 3D Y/C color separation may be used

on both PAL and NTSC video signals. A chroma trap filter is also available. On CVBS and Y/C

inputs, the user can control video characteristics such as hue, contrast, brightness, and saturation

via an I2C host port interface. Furthermore, luma peaking with programmable gain is included, as

well as a patented color transient improvement (CTI) circuit. Attenuation at higher frequencies or

asymmetrical color subcarrier sidebands are compensated using the IF compensation block. Frame

adaptive noise reduction may be applied to reduce temporal noise on CVBS, S-Video, or

component inputs. 3D noise reduction and 3D Y/C separation may be used at the same time or

independently. The TVP5160 decoder utilizes Texas Instruments’ patented technology for locking

to weak, noisy, or unstable signals and can auto-detect between broadcast quality and VCR-style

(nonstandard) video sources. The TVP5160 decoder generates synchronization, blanking, field,

active video window, horizontal and vertical syncs, clock, genlock (for downstream video encoder

synchronization), host CPU interrupt and programmable logic I/O signals, in addition to digital video

outputs. The TVP5160 decoder includes methods for advanced vertical blanking interval (VBI) data

retrieval. The VBI data processor (VDP) slices and performs error checking on teletext, closed

caption, and other VBI data. A built-in FIFO stores up to 11 lines of teletext data, and, with proper

host port synchronization, full-screen teletext retrieval is possible. The TVP5160 decoder can pass

through the output formatter 2x sampled raw Luma data for host-based VBI processing. Digital RGB

overlay can be synchronously switched with any video input, with all signals being oversampled at

4x the pixel rate.

10

Page 13

INTERNAL BLOCK DIAGRAM:

11

Page 14

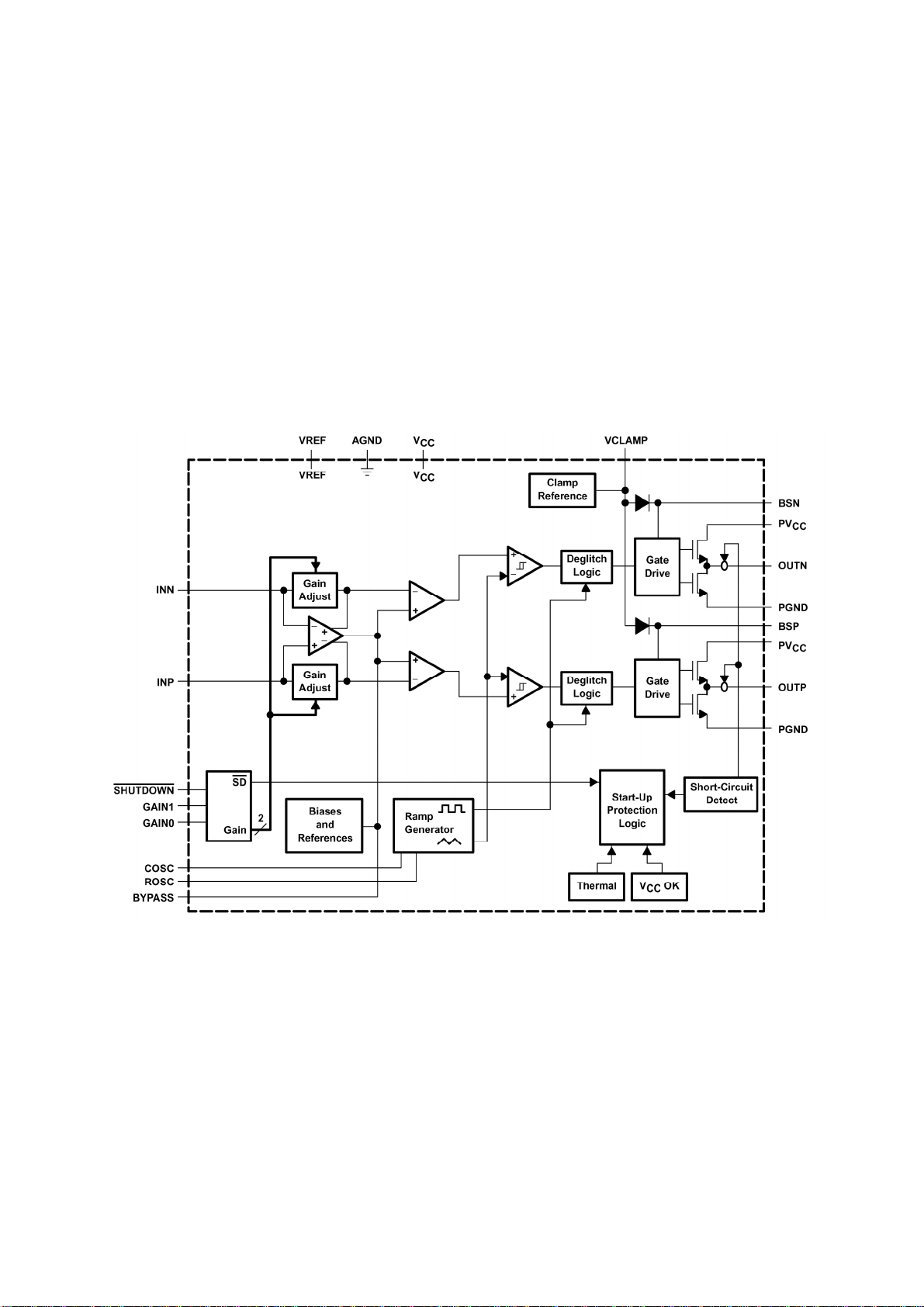

3. TPA3001D1

The TPA3001D1 is a 20-W mono bridge-tied load (BTL) class-D audio power amplifier with high

efficiency, eliminating the need for heat sinks. The TPA3001D1 can drive 4-Ω or 8-Ω speakers with

only a ferrite bead filter required to reduce EMI.

The gain of the amplifier is controlled by two input terminals,GAIN1 and GAIN0. This allows the

amplifier to be configured for a gain of 12, 18, 23.6, and 36 dB. The differential input stage provides

high common mode rejection and improved power supply rejection.

The amplifier also includes depop circuitry to reduce the amount of pop at power-up and when

cycling SHUTDOWN.

The TPA3001D1 is available in the 24-pin thermally enhanced TSSOP package (PWP) which

eliminates the need for an external heat sink.

INTERNAL BLOCK DIAGRAM:

12

Page 15

4. MST3383MB

The MST3383MB integrates the HDMI compliant receiver for enabling advanced digital display

devices such as digital TVs, plasma displays, LCD TVs and projectors to receive and display.

Compliant with the HDMI 1.0 specification, the MST3383MB enables consumer electronic devices

to receive uncompressed, high quality, digital audio and video HD content over a single, low-cost

HDMI cable. The MST3383MB is available in a 128-pin PQFP package.

FUNCTIONAL DESCRIPTION

DVI/HDMI Interface

The MST3383MB integrates an HDMI compliant receiver and enables a high quality and secure

delivery of digital video and audio. The HDMI link input supports up to 170 MHz pixel rate. With the

HDMI input and signal detection, the MST3383MB provides a high-performance solution for up to

1080p for video and 1600x1200 (UXGA) for monitor applications. The MST3383MB’s HDMI

receiver is fully backward compatible to DVI 1.0 and HDCP 1.0.

MCU Interface

The MST3383MB provides 2-wire serial bus for interfacing with an MCU. It detects active inputs for

both on-line and off-line operations. During on-line operation, the MST3383MB also provides

polarity and period count information of active input’s DE signals. The MCU can easily adjust the

input mode and switch to active input properly.

Color Space Conversion

The MST3383MB supports all general color space conversions such as RGB to YUV or RGB to

YCbCr using parameters programmable by 2-wire serial bus.

Digital Video Output Formatting

The MST3383MB can output digital data in the following configurations:

. 24-bit 4:4:4 YCbCr/RGB output formats

. 16-bit 4:2:2 YCbCr output formats (ITU.601)

. 8-bit 4:2:2 YCbCr output formats (ITU.656)

. Channel swap

. MSB/LSB swap

Audio Stream

S/PDIF port output is supported to enable PCM, Dolby Digital, DTS with sample rates of 32~48 kHz

and a sample size of 16~24 bits.

Audio Serial bus is supported to enable 2-channel PCM audio with sample rates of 32~192 kHz and

a sample size of 16~24 bits.

13

Page 16

5.GM1601/GM1501

The gm1601H is a dual channel graphics and video processing IC for Liquid Crystal Display (LCD)

monitors and televisions incorporating Picture in Picture, up to WUXGA output resolutions. The

gm1601H provides all key IC functions required for image capture, processing and display timing

control. On-chip functions include a high-speed triple-ADC and PLL, Ultra-Reliable DVI® receiver,

high quality zoom and shrink scaling engines, Motion Adaptive De-Interlacing (MADI), Low Angle

Diagonal Interpolation (LADI), an on-screen display (OSD) controller, a 100MHz on-chip X186

micro-controller (OCM), and a selectable double wide TTL or dual channel LVDS transmitter for

interface to displays. With all these functions integrated onto a single device, the gm1601H

eliminates the need for several system components, simplifying the design and reducing the cost of

high-end multimedia LCD monitors and televisions while maintaining a high degree of flexibility and

quality. The gm1601H is available in two silicon revisions – “BD” and “CF”. GM1601H-CF is a

backwards-compatible addition that incorporates some functional and quality improvements.

Applliicattiions

z Multi-media LCD monitors up to WUXGA resolutions

z LCD, PDP and Rear Projection TV at WXGA, UXGA, WUXGA and HD(720P & 1080P)

resolutions

GM1601H Systtem Desiign Examplle

Figure 2 below shows a typical high-resolution multi-media LCD monitor/TV system based on the

gm1601H. Designs based on the gm1601H have reduced system cost, simplified hardware and

firmware design and increased reliability because only a minimal number of components are

required in the system.

Figure 2. gm1601H System Design Example

14

Page 17

6. FLI2310

The FLI230x and FLI2310 are highly integrated digital video format converters for DTV and DVD

applications using patented deinterlacing and post processing algorithms from Faroudja

Laboratories, coupled with highly flexible scaling, a wide variety of aspect ratio conversions, and

other special video enhancing features to produce the highest quality image.

6.1 Inputs

z Input all industry standard and non-standard video resolutions, including 480i (NTSC), 576i

(PAL/SECAM), 480p, 720p, 1080i, and VGA to XGA

z Digital input, 8-bit Y/Cr/Cb (ITU-R BT656), 8-bit Y/Pr/Pb, 16-bit Y Cr/Cb (ITU-R BT601), 24-bit

RGB, YCrCb, YPrPb

z Input pixel rate up to 75MHz maximum

6.2 Outputs

z Output resolutions include 480p, 576i, 576p, 720p, 1080i, 1080p, and VGA to SXGA

z Interlaced or Progressive output

z In the FLI230x, the output can be either analog YUV/RGB (through the integrated 10-bit DAC),

or digital 24-bit RGB, YCrCb, YPrPb (4:4:4), or digital 16/20-bit Y Cr/Cb (4:2:2)

z The FLI2301 can provide 525P/625P Macrovision compliant analog output

z In the FLI2310, digital output of 24-bit RGB, YCrCb, YPrPb (4:4:4), or 16/20-bit Y Cr/Cb (4:2:2)

are available

z Output pixel rate up to 150 MHz maximum

6.3 Formats

z Input color manipulation matrix supports all color spaces: RGB, YPrPb, 4:4:4 YCrCb, 4:2:2

YCr/Cb, ITU-R BT656, ITU-R BT601

z Output supports analog RGB, YPrPb, and YCrCb in the FLI230x; and digital RGB, YPrPb, 4:4:4

YCrCb and 4:2:2 YCr/Cb in FLI230x/FLI2310

6.4 Frame Rate Conversion

Tearless Frame Rate Conversion 50/60/72/75/100/120 Hz

6.5 Front End Processing

z Motion Adaptive Noise Reduction – Improves picture quality for off-air material.

z Cross Color Suppressor (CCS) - Removes cross color artifacts in composite video signals due

to poor Y/C separation in standard 2-D video decoders, eliminating the need for expensive 3-D

video decoders.

6.6 Deinterlacing

z Per-pixel Motion Adaptive Deinterlacing

z Patented FilmMode Processing - Used for proper de-interlacing of 3:2 and 2:2 pulldown

material.

z Edit Correction - Film content is continuously monitored for any break in sequence caused by

“bad edits” and quickly compensates for the most effective reduction in artifacts.

z DCDi™ - Video is analyzed on a single pixel granularity to detect presence or absence of

angled lines and edges, which are then processed to produce a smooth and natural looking

image without visible artifacts or “jaggies”.

6.7 Scaling

z High Quality Fully Programmable Two Dimensional Scaler

z Aspect Ratio Conversion for “Anamorphic” or “Panoramic” (non-linear)

z Display 4:3 images on 16:9 displays and vice versa, including Letterbox to Fullscreen, Pillarbox,

15

Page 18

and Subtitle Display Modes

6.8 TrueLife™ Enhancer

Two dimensional, non-linear, luma and chroma video enhancer brings out details in the picture,

producing a more life-like image.

6.9 Memory

32-bit wide SDRAM (i.e. one 2M x 32-bit, or two 1M x 16-bit) controller, up to 166 MHz operation, for

external SDRAM

INTERNAL BLOCK DIAGRAM:

7. TVP5147

Functional Block Diagram

16

Page 19

8. CXA2089Q

17

Page 20

9. AML3278

The AML3478 is a highly integrated device that provides cost-effective solutions for portable players,

media players and integrated entertainment centers.

10. PW9720

The PW9702 is a highly-integrated, 10-bit processing, advanced image quality enhancer. It is used

to improve the detail, color, and contrast performance for the existing platform of various

applications.

18

Page 21

19

Page 22

Wiring diagram

To key board

T

o

I

R o

b r

a

d

Speaker

or

or

Power board

Board

board

board

CPU board

or

Analog board

20

Page 23

Trouble shooting

1. Fault clearance

Before servicing please check to find the possible causes of the troubles according to the table

below.

1.1 Antenna (signal):

Picture is out of focus or jumping z Bad status in signal receiving

z Poor signal

z Check if there are failures with the electrical connector or

the antenna.

z Check if the antenna is properly connected.

Fringe in picture z Check if the antenna is correctly oriented.

z Maybe there is electric wave reflected from hilltop or

building.

Picture is interfered by stripe shaped

bright spots

There appear streaks or light color

on the screen

1.2 TV set:

Symptoms Possible cause

Unable to switch the power on z Check to see if the power plug has been inserted properly

No picture and sound z Check to see if the power supply of liquid crystal TV has

Deterioration of color phase or color

tone

Screen position or size is not proper z Check is the screen position and size is correctly set up.

Picture is twisted and deformed z Check to see if the picture-frame ratio is properly set up.

Picture color changed or colorless z Check the “Component” or “RGB” settings of the liquid

z Possibly due to interference from automobile, train, high

voltage transmission line, neon lamp etc.

z Maybe there is interference between antenna and power

supply line. Please try to separate them in a longer

distance.

z Maybe the shielded-layer of signal wire is not connected

properly to the connector.

z Check if interfered by other equipment and if interfered

possibly by the equipment like transmitting antenna,

non-professional radio station and cellular phone.

into the socket.

been switched on. (As can be indicated by the red LED at

the front of the TV set)

z See if it’s receiving the signal that is transmitted from other

source than the station

z Check if it’s connected to the wrong terminal or if the input

mode is correct.

z Check if the signal cable connection between video

frequency source and the liquid crystal TV set is correct.

z Check if all the picture setups have been corrected.

crystal TV set and make proper adjustment according to the

21

Page 24

signal types.

Picture too bright and there is

distortion in the brightest area

Picture is whitish or too bright in the

darkest area of the picture

No picture or signal produced from

the displayer if “XXX in search”

appears.

There appears an indication -

“outside the receivable scope)

Remote control cannot work

properly

No picture and sound, but only

hash.

Blur picture z Check if the antenna cable is correctly connected.

No sound z Check if the “mute” audio frequency setting is selected.

When playing VHS picture search

tape, there are lines at the top or

bottom of the picture.

z Check if the contrast setting is too high.

z Possibly the output quality of DVD broadcaster is set too

high.

z It maybe also due to improper terminal connection of the

video frequency signal in a certain position of the system.

z Check if the setting for the brightness is too high

z Possibly the brightness grade of DVD player (broadcaster)

is set too high.

z Check if the cable is disconnected.

z Check if it’s connected to the proper terminal or if the input

mode is correct.

z Check if the TV set can receive input signal. The signal is

not correctly identified and VGA format is beyond the

specified scope.

z Check if the batteries are installed in the reverse order.

z Check if the battery is effective.

z Check the distance or angle from the monitor.

z Check if there is any obstruct between the remote control

and the TV set.

z Check if the remote control signal- receiving window is

exposed to strong fluorescence.

z Check if the antenna cable is correctly connected, or if it

has received the video signal correctly.

z Of if it has received the right video signal.

z Check if the sound volume is set to minimum.

z Make sure the earphone is not connected.

z Check if the cable connection is loose.

z When being played or in pause VHS picture search tape

sometimes can’t provide stable picture, which may lead to

incorrect display of the liquid crystal TV, In this case please

press “auto” key on the remote control so as to enable the

liquid crystal TV set to recheck the signal and then to

display correct picture signal

22

Page 25

2. Troubleshooting guide

Make sure that the IR board, key board and their connection wires are good then judge below:

2.1 Without backlight

In STANDBY, does

LED red light

No

Check if the pin3 of X505 has

+5V output

No

Is the FUSE

melted?

No

Ye s

Press POWER button

to turn on the unit,

then check the LED

Ye s

Replace CPU board

Check power

board

No change color

Blue

No

Press any key on the RC,

Does LED flicker?

Yes

Check if the X506

(pin6-7) of the power

board has 18V, pin1-5

has 18V.

If N21 pin4 is 18V?

No

Replace N21

Replace CPU board

No

LCD screen has problem

Yes

Replace CPU.

Yes

Low High

Check if FU1 of CPU

No

board is melted?

Replace the fuse.

Check if L43, L44 have

+3.3V?

No

Check if base of V15

is 3.3V

Ye s

Yes

No

Is it 18V for pin1-5 of

X16 of CPU ?

Check if the back light

socket is well insert?

Ye s

Replace N22

Yes

23

Page 26

2.2 With backlight, without picture

p

Does remote control

and key of the unit

operate?

Does not picture

of all channel

No Yes

No

Ye s

Enter the factory

menu, the CLEAR

EEPROM

adjustment after,

turn off the unit,

and check if the

picture is normal

when turn on.

No

Replacing

N21

If R335 R334 R325

R324 has signal

Yes

Ye s

Display OSD?

No

Is LVDS

cord

loose?

Does N21

(pin5-8)

output

18V?

Ye s

Check FU1

HDMI

Does R223 and

R216-R219

output signal?

No Ye s No

Replace

CPU

assy

DoesR252

,R251 has

output

Replace

N38

Which no picture

VGA

Check the

pin4 and

pin8 of

N24 has

H-V sync?

Replace

N34

YPBPR

TV/VIDEO

Check if C16

has SOG

signal

Sub

picture

No Yes Yes No

Main

picture or

sub

picture?

Main

picture

If N41

No

output

1.9V

Yes

Replace

N40

Replacing CPU

Replacing N7

Replacing

N24

Replacing N4

Replacing N8

Yes

No

Does

R70-R73

input signal

Ye s

Check if the pin1 and pin5

of N24 has input signal

Ye s

Check if the pin2 and pin3

of N4 has input signal

No

Check if R74, R75 has

output signal

Ye s

Ye s

No

Check the

N10 input

and output

Replacing

CPU assy

Yes

Check the N35

No

and N36 input

and out

ut

24

Page 27

2.3 No sound

Check if the pin2 of

XA15 is 18V?

No Yes

Check if the

pin1 and pin2 of

XA17 is 18V?

Check if XA14

pin3 is low

level?

Yes

Is high level of

NA20 NA21 pin5?

No

High

Low

Check CPU board

Check if VA21 VA22

break down

No

Check the

supply power

Ye s

Is the signal

output from NA5

(pin5 and pin8)

Ye s

Replacing NA20 NA21

Is the signal output from

NA4 (pin27 and pin28)

Does NA4 (pin67) input

signal?

Is the signal output from

TUNA1 (pin12)

No

Ye s

Replacing NA5

No

Ye s

Replacing NA4

No

No

Replacing TUNA2

25

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

APPENDIX-A: Main assembly 9252LR3611

NAME NO.

Analog board

CPU board

IR receive board

Key board

Side AV board

USB board

Power board

Remote control

Panel

MAIN COMPONENT AND IT'S NO.

NA4

6LR0375310

6LR0385610

6LR0380910

6LR03805A0

6LR0382910

6LR02316A0 NU4 AML3278 (5273278001)

6LR0372010

6010L01601

5203528501

NA5

NA20, NA21

N15

N10

N7

N8

N34

N40

RC-L16-0A

V520H1- L03

MSP3410 (5273410001)

M62494FP (5276249401)

TPA3001D1 (5273001001)

GM1601 (5271601001)

FLI2310 (5272310002)

TVP5160 (5275160001)

TVP5147 (5275147001)

MST3383MB (5273383001)

PW9702 (5279702001)

Page 42

APPENDIX-B: Exploded view (LC-52X36)

Page 43

PART LIST OF EXPLODED VIEW

NO. DESCRIPTION

1 Front cabinet

2 decorative board

3 speaker net

4 side AV board

5 push bar

6 push bar

7 push bar

8 push bar

9 key board

10 speaker assy

11 panel

12 power bracket

13 panel fixed bracket

14 panel fixed bracket

15 panel fixed bracket

16 panel fixed bracket

17 conncetion bracket

18 panel fixed bracket

19 conncetion bracket

20 stand fixed bracket

21 wall mount bracket

22 main board frame

23 digital board

24 main board frame

25 analog board

26 power board

27 back cabinet

28 stand

Note: design and specifications are subject to change without notice.

Page 44

9252LR3611

Ver.1.0

Loading...

Loading...