XOC24SMUA

XOC30SMUA

XOC36S

XOC30S

NEED HELP?

Call our ventilation experts toll free al 800-966-8300

AVEZ-VOUS BESOIN D’AIDE ?

Contactez nos experts au numéro gratuit 800-966-8300

¿NECESITA AYUDA?

Póngase en contacto con nuestros expertos a través del número gratis 800-966-8300

USA

F

E

RANGE HOOD - User instructions

HOTTE DE CUISINE - Notice d’utilisation

CAMPANA EXTRACTORA - Manual de utilización

XO Hood Warranty

Proof of original purchase date and invoice is needed to obtain

service under warranty.

What is covered

What is not covered

Limited 2 Year Warranty.

For 2 years from the original date of purchase, we will provide,

free of charge, parts and service labor in your home to repair or

replace any part of the hood that fails because of a manufacturing defect.

The warranty is extended to the original purchaser for products

purchased for ordinary home use in North America.

Should you require service for your XO product call a product

service specialist at 800.966.8300

Improper Installation.

Service trips to the home to teach you how to use the product.

Resetting circuit breakers.

Damage caused after delivery.

EXPECT MORE FROM XO

When buying any XO appliance

you can be condent

you have purchased a high quality,

innovative, and stylish product,

from a company who cares about you

ENGLISH

IMPORTANT SAFETY INSTRUCTIONS

FOR RESIDENTIAL USE ONLY

USA

READ AND SAVE THESE INSTRUCTIONS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

IMPORTANT: Save these Instructions for the Local Electrical Inspectors use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

Take care when using cleaning agents or detergents.

Suitable for use in household cooking area.

WARNING - To reduce the risk of re or electric shock, do not use this fan with any

Solid-State Speed Control Device.

CAUTION - To reduce risk of re and to properly exhaust air, be sure to duct air out-

side – Do not vent exhaust air into spaces within walls or ceilings or into attics, crawl

spaces, or garages.

CAUTION - For general ventilating use only. Do not use to exhaust hazardous or ex-

plosive materials and vapors.

CAUTION - To avoid motor bearing damage and noisy and/or unbalanced impellers,

keep drywall spray, construction dust, etc. o power unit.

CAUTION - Please read specication label on product for further information and

requirements.

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer. If you have questions,

contact the manufacturer.

B. Before servicing or cleaning unit, switch power o at service panel and lock the ser-

vice disconnecting means to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

WARNING - TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause smoking and

greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

B. Always turn hood ON when cooking at high heat or when ambeing foods ( i.e.

- 3 -

Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambè ).

C. Clean ventilating fans frequently. Grease should not be allowed to accumulate on

fan or lter.

D. Use proper pan size. Always use cookware appropriate for the size of the surface

element.

E. Keep fan, lters and grease laden surface clean.

F. Use high range setting on range only when necessary.Heat oil slowly on low to me-

dium setting.

G. Don’ t leave range unattended when cooking.

H. Always use cookware and utensils appropriate for the type and amount o food be-

ing prepared.

WARNING – TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE

TOP GREASE FIRE, OBSERVE THE FOLLOWINGa:

A. SMOTHER FLAMES with a close-tting lid, cookie sheet, or metal tray, then turn o

the burner. BE CAREFUL TO PREVENT BURNS. If the ames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

B. NEVER PICK UP A FLAMING PAN – You may be burned.

C. DO NOT USE WATER, including wet dishcloths or towels – a violent steam explosion

will result.

D. Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher, and you already know how to operate it.

2. The re is small and contained in the area where it started.

3. The re department is being called.

4. You can ght the re with your back to an exit.

a

Based on “kitchen resafety tips” published by NFPA

Proper maintenance of the Range Hood will assure proper performance of the

unit.

INSTALLATION INSTRUCTIONS

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

A. Installation work and electrical wiring must be done by qualied person(s) in accord-

ance with all applicable codes and standards, including re-rated construction.

B. Sucient air is needed for proper combustion and exhausting of gases through the

ue (chimney) of fuel burning equipment to prevent back drafting. Follow the heating equipment manufacturer’s guideline and safety standards such as those published by the National Fire Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local

code authorities.

C. When cutting or drilling into wall or ceiling, do not damage electrical wiring and

other hidden utilities.

D. Ducted fans must always be vented to the outdoors.

- 4 -

E. This unit must be grounded.

WARNING - TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

WARNING - UNDER CERTAIN CIRCUMSTANCES DOMESTIC APPLIANCES MAY BE DAN-

GEROUS.

A. Do not check lters with hood working.

B. Do not touch the lamps after a prolonged use of the appliance.

C. No food must be cooked ambè underneath the hood.

D. The use of an unprotected ame is dangerous for the lters and could cause res.

E. Watch constantly the fried food in order to avoid the cooking oil ares up.

F. Before performing any mainteinance operation, disconnect the hood from the elec-

trical service.

The manufacturers will not to accept any responsability for eventual damages, be-

cause of failure to observe the above instructions.

- 5 -

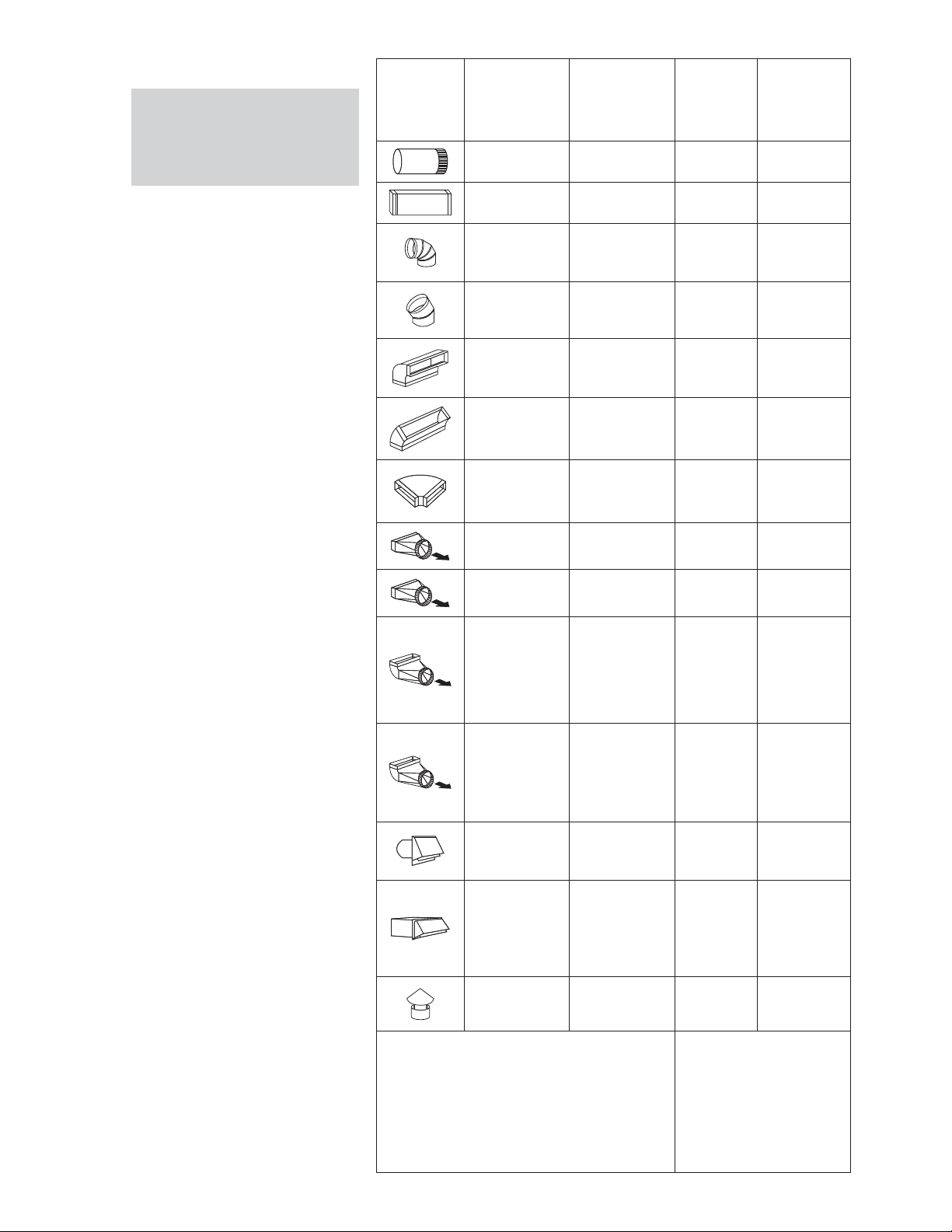

DUCT FITTINGS:

This Hood Must Use an

6" Round Duct. It Can

Transition to 3-1/4" x

10" or 3-1/4" x 12" Duct.

Use this chart to compute maximum permissible

lengths for duct runs to

outdoors.

Duct

Piece:

Equivalent

Dimensions:

Round, straight

3-1/4" x 10"

straight

90° elbow 12 ft.

Number

Length*:

1 ft. (per foot

lenhgth)

1 ft. (per foot

lenhgth)

Quantity

Used:

Total

Equivalent

Length:

NOTE: Do not exceed maxi-

Installation Preparation

mum permissible equivalent

lengths!

Maximum duct length:

100 feet for range ho-

ods.

Flexible ducting:

If flexible metal ducting

is used, all the equivalent

feet values in the table

should be doubled. The

flexible metal duct should

be straight and smooth

and extended as much as

possible.

DO NOT use flexible plastic

ducting.

NOTE: Any home ventilation

system, such as a ventilation

hood, may interrupt the

proper flow of combustion

air and exhaust required

by fireplaces, gas furnaces,

gas water heaters and other

naturally vented systems. To

minimize the chance of interruption of such naturally

vented systems, follow the

heating equipment manufacturer’s guidelines and

safety standards such as

those published by NFPA.

45° elbow 7 ft.

3-1/4" x 10"

3-1/4" x 12"

90° elbow

3-1/4" x 10"

3-1/4" x 12"

45° elbow

3-1/4" x 10"

3-1/4" x 12"

90° elbow

6" round to

rectangular

Rectangular to

8" round

3-1/4" x 10"

3-1/4" x 12"

6" round to

rectangular

transition 90°

elbow

3-1/4" x 10"

3-1/4" x 12"

Rectangular to

6" transition

90° elbow

Round wall

cap with

dramper

3-1/4" x 10"

3-1/4" x 12"

Rectangular

wall cap with

dramper

Round roof

cap

14 ft.

10 ft.

8 ft.

6 ft.

33 ft.

24 ft.

2 ft.

2 ft.

4 ft.

4 ft.

4 ft.

4 ft.

24 ft.

24 ft.

18 ft.

33 ft.

*Actual length of straight duct plus duct

fitting equivalent. Equivalent length of duct

pieces reflect requirements for good venting

performance with any ventilation hood.

- 6 -

Total Duct Run =

WARNING FIRE HAZARD

NEVER exhaust air or terminate duct work into spaces between walls, crawl spaces,

ceiling, attics or garages.

All exhaust must be ducted to the outside, unless using the recirculating option.

Use single wall rigid Metal ductwork only.

Fasten all connections with sheet metal screws and tape all joints w/ certied Silver

Tape or Duct Tape.

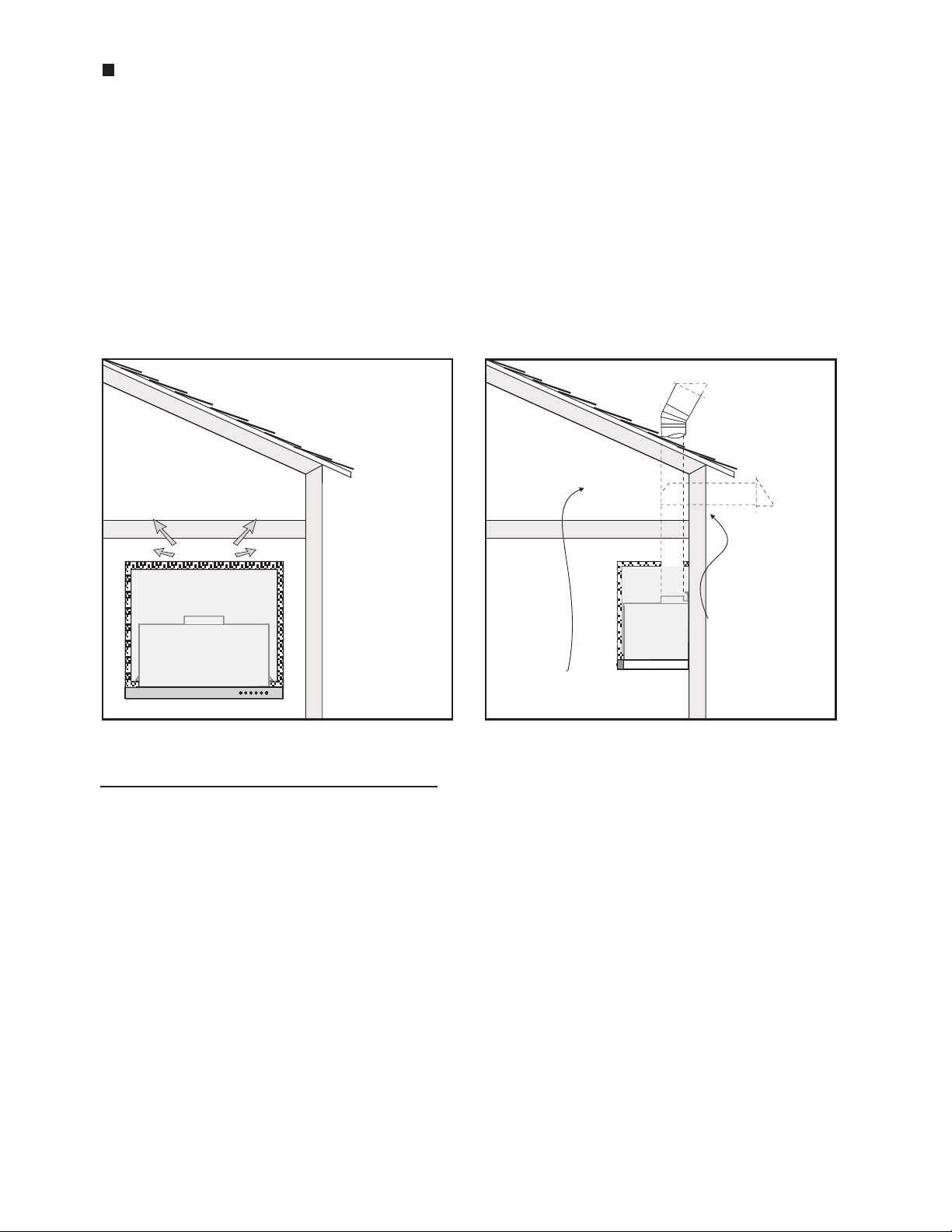

Installation - Ducting Options

INSTALL THE DUCTWORK:

NOTE: To reduce the risk of re, use only metal ductwork.

1. Decide where the ductwork will run between the hood and the outside.

2. A straight, short duct run will allow the hood to perform most eciently.

3. Long duct runs, elbows, and transitions will reduce the performance of the

hood. Use as few of them as possible.

4. Install a roof or wall cap. Connect 6" round metal ductwork to cap and work

back towards hood location. Use duct tape to seal the joints between ductwork

sections.

- 7 -

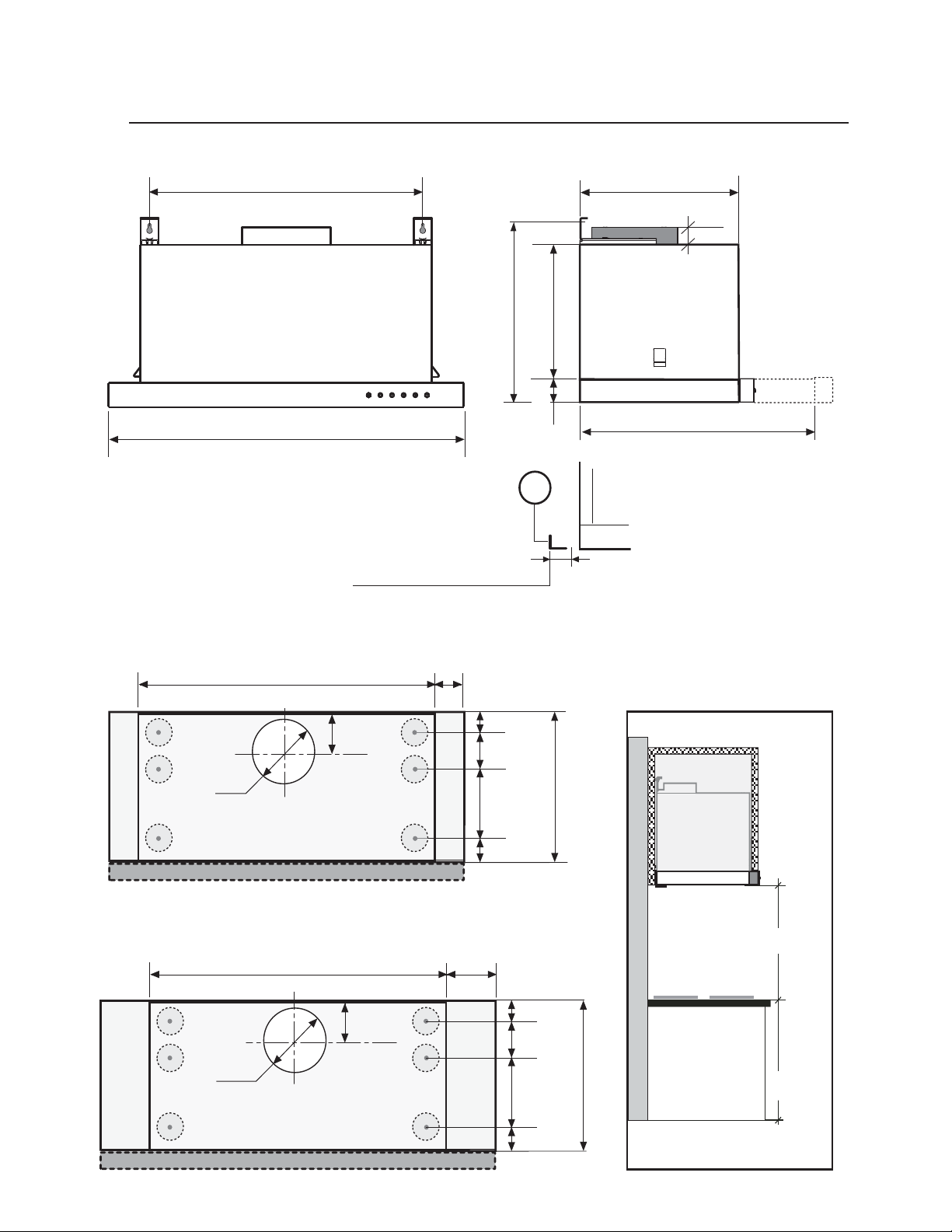

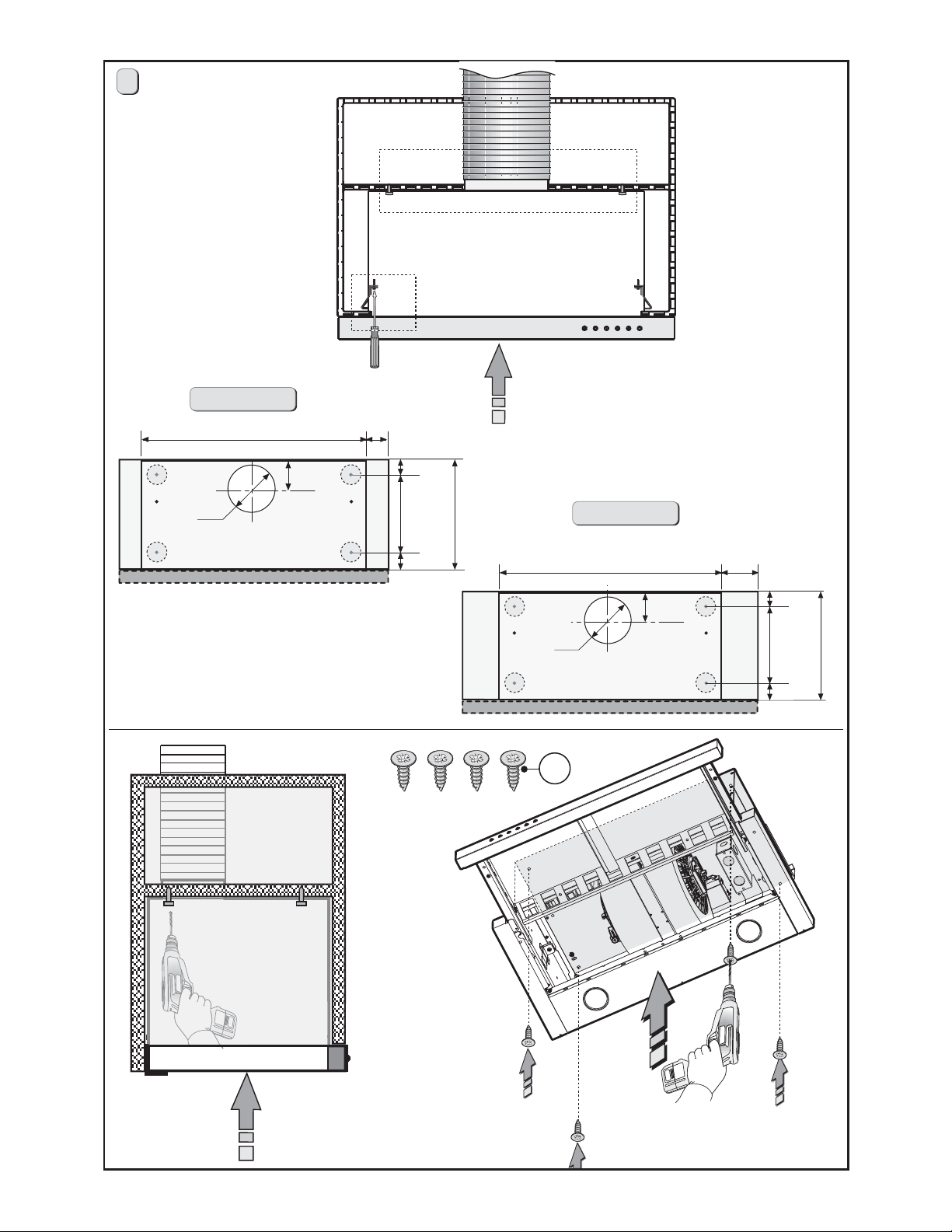

PRODUCT DIMENSIONS AND CLEARANCE

XOC24SMUA - XOC30SMUA - XOC36S - XOC30S:

Front of hood

18-5/8" (24" - 30")

30-7/16" (36")

Side of hood

11-1/16"

1-3/16"

Hood Specications

9"

12-1/8"

23-9/16" (24") - 29-15/16" (30") - 35-3/8" (36")

1-9/16"

L

min 0 - 0/16" - max 1 - 4/16"

min 0 - 0/16" - max 1 - /4"

Top of hood Mounting height and

clearance:

19-11/16" (24")

1-15/16" (24"-36")

16-15/16"

31-1/2" (36")

Ø 6"

Ø 6"

3-13/16"

19-11/16" (30")

3-13/16"

1-11/16"

2-9/16"

5-1/8"

1-11/16"

5-1/8" (30")

1-11/16"

2-9/16"

5-1/8"

1-11/16"

11-1/16"

Min 27" - Max 32"

36"

11-1/16"

Fig.1

- 8 -

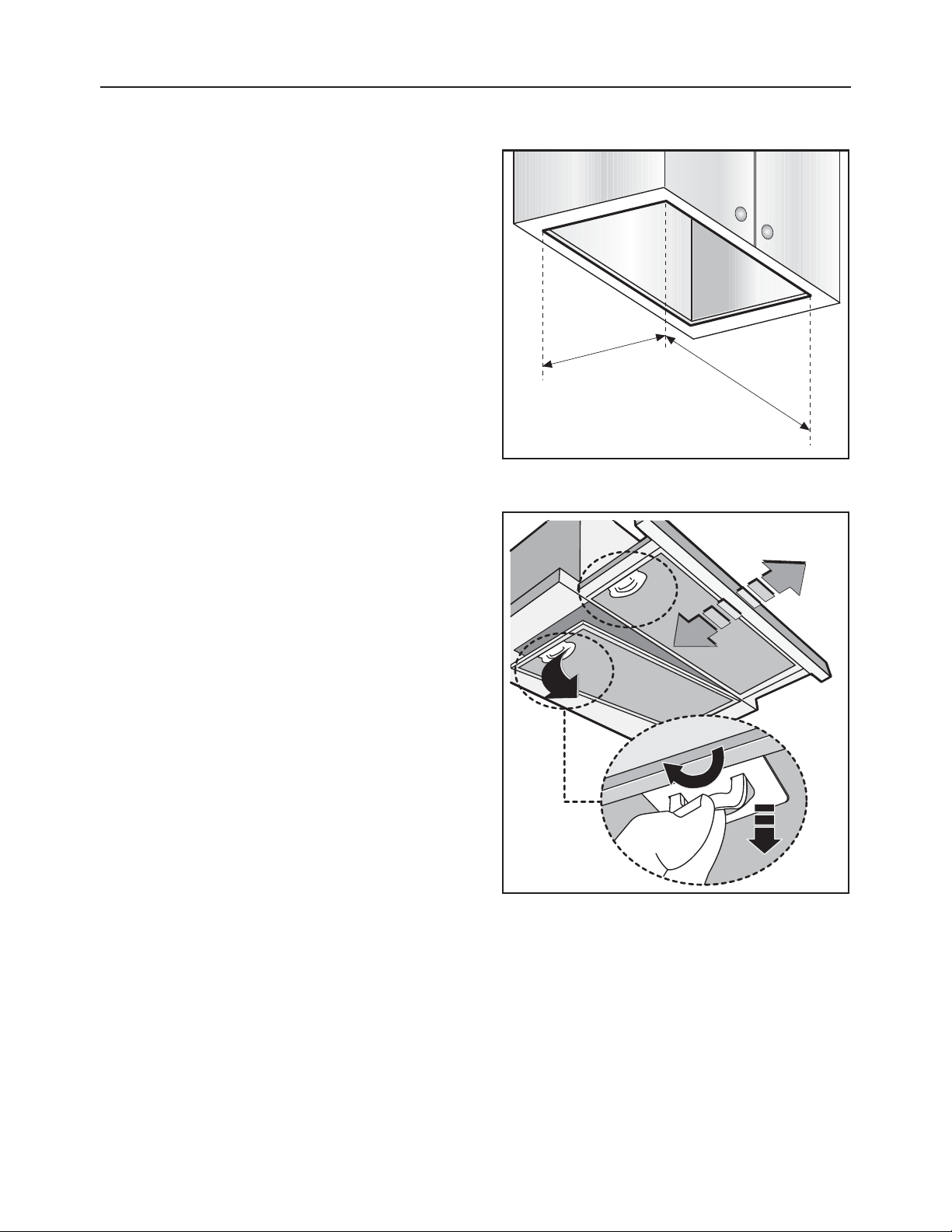

INSTALLATION INSTRUCTIONS

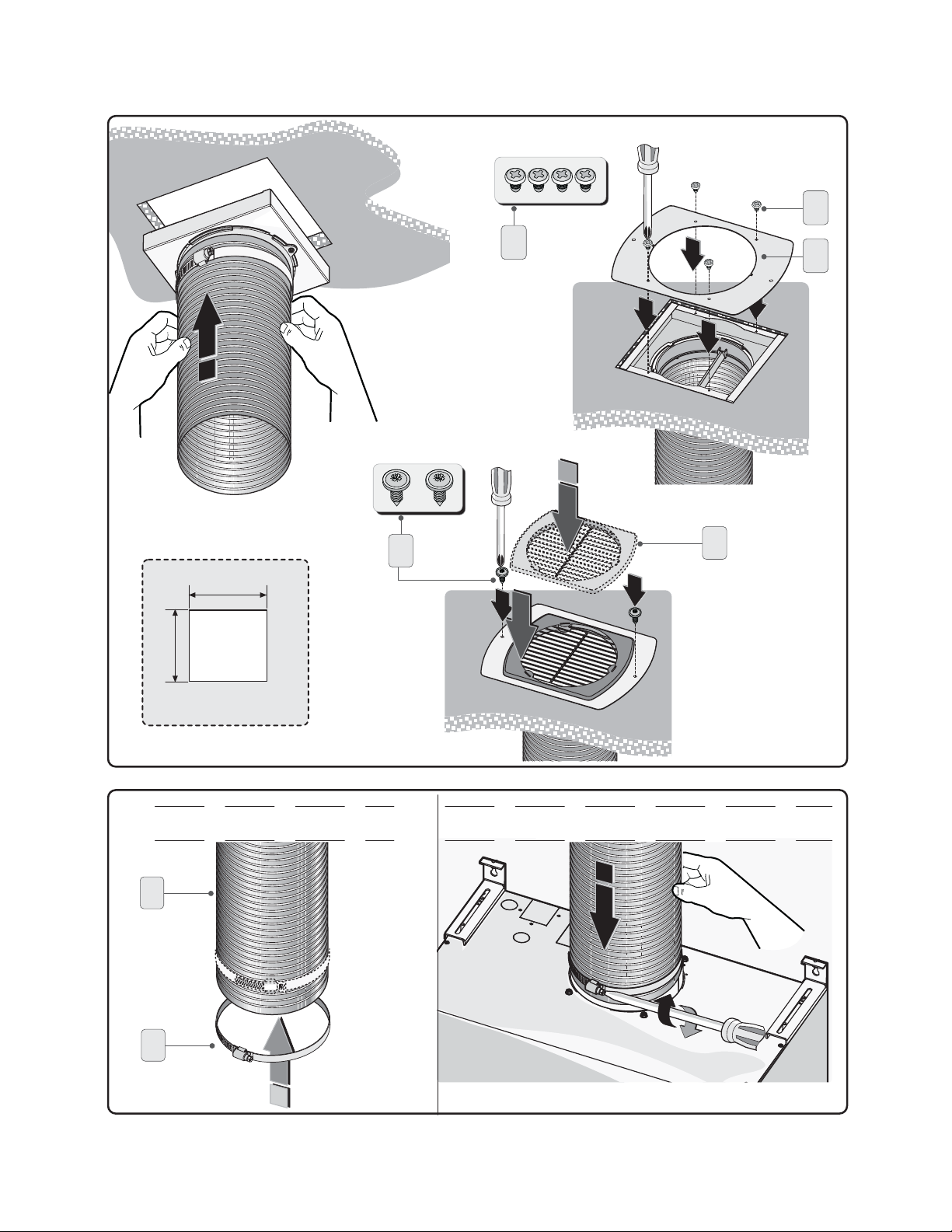

INSTALLATION VENTED TO THE OUTSIDE

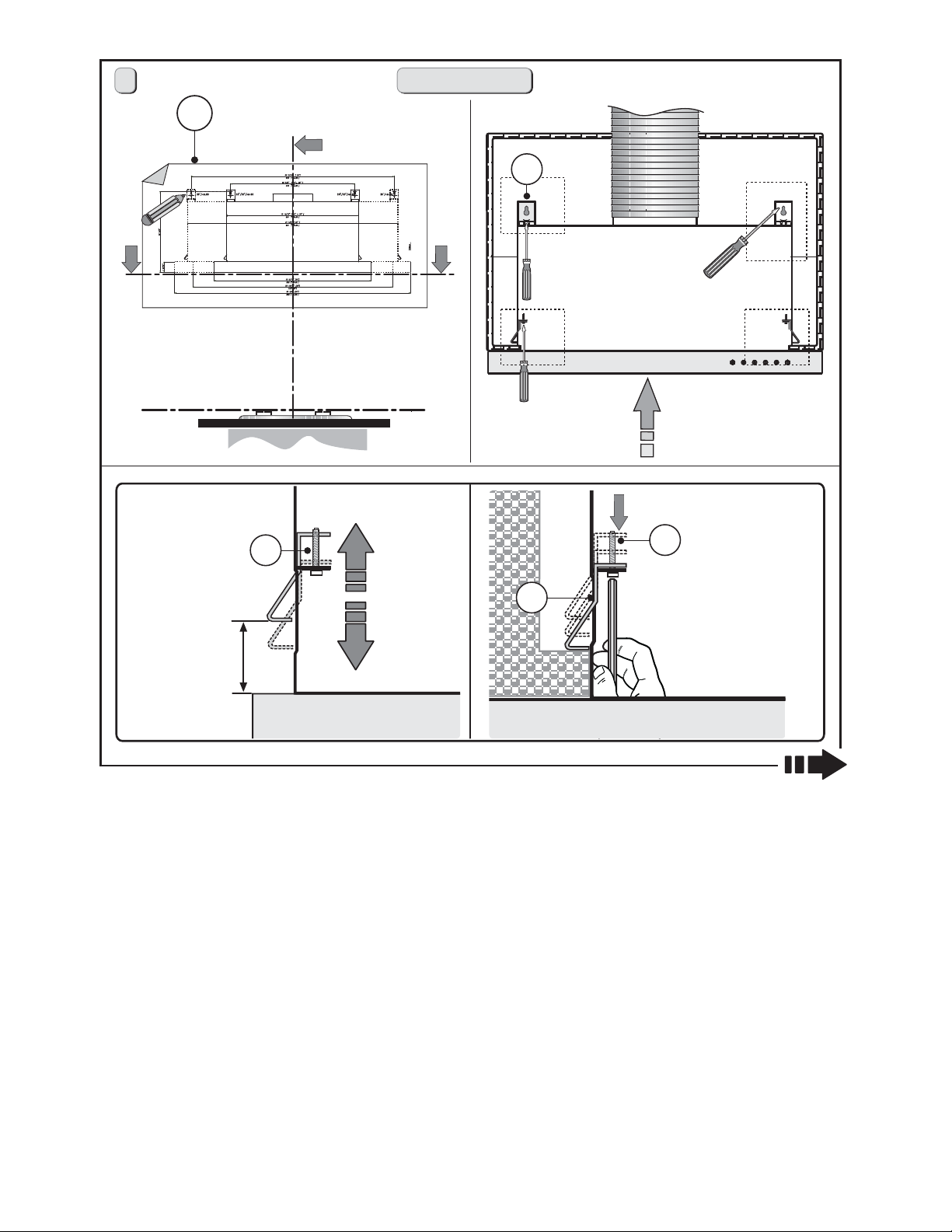

Before proceeding with installation operations, remove the anti-grease filters (Fig.3)

in order to make handling the device

easier.

This product can be installed in 3 different

ways, depending on the model and on

your requirements:

1- installation of the hood on the lower

part of the wall unit.

2- installation of the hood on the lower

part of the wall unit on a divider support.

3- Installation of the hood on the lower

part of the wall unit only for 30".

Fig.2

11-1/4"

19-15/16"

31-3/4"

Fig.3

1

2

- 9 -

1

24" - 36" - 30"

B

A

3

4

2

Min 0-1/2"

Max 1/016"

2

2

1

F

F

M

Fig.4

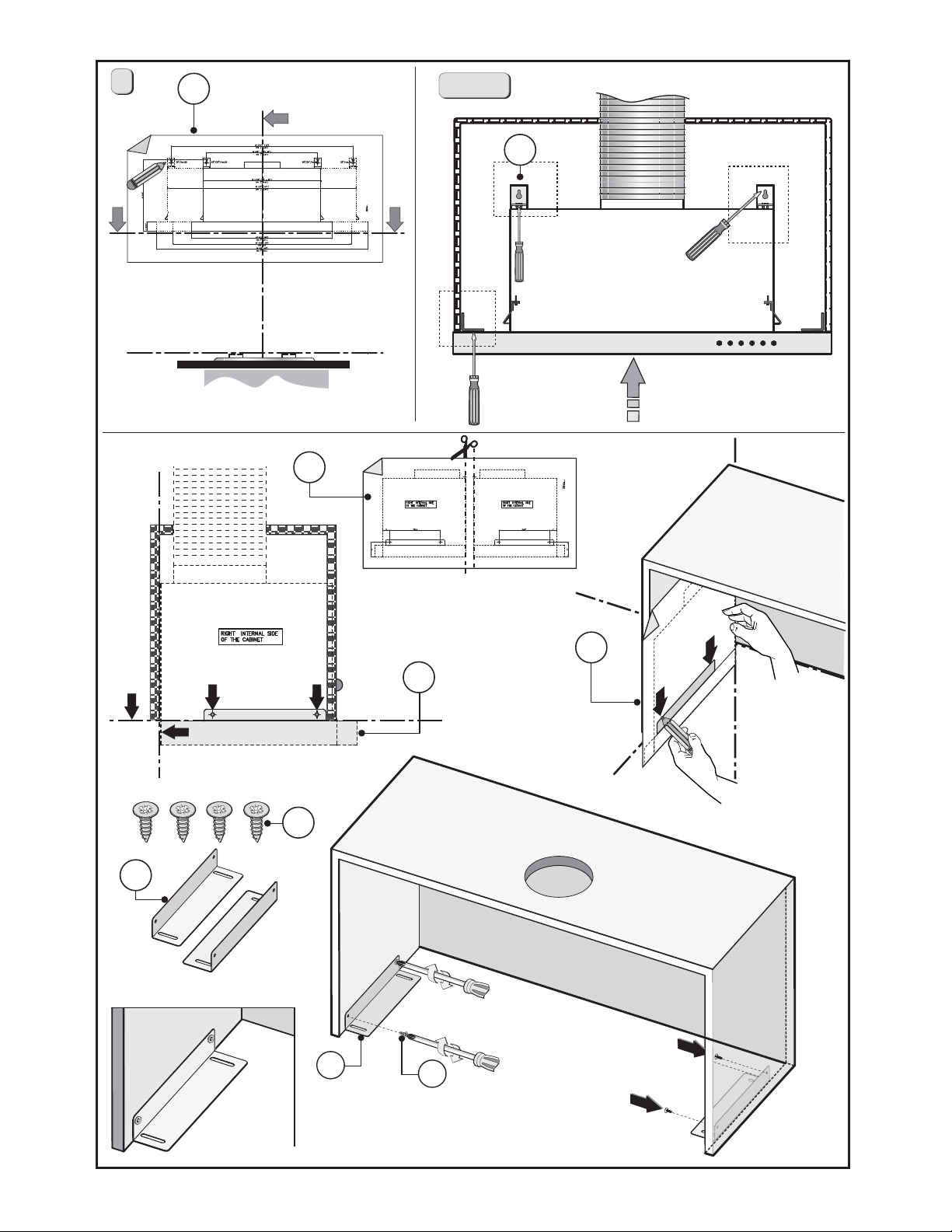

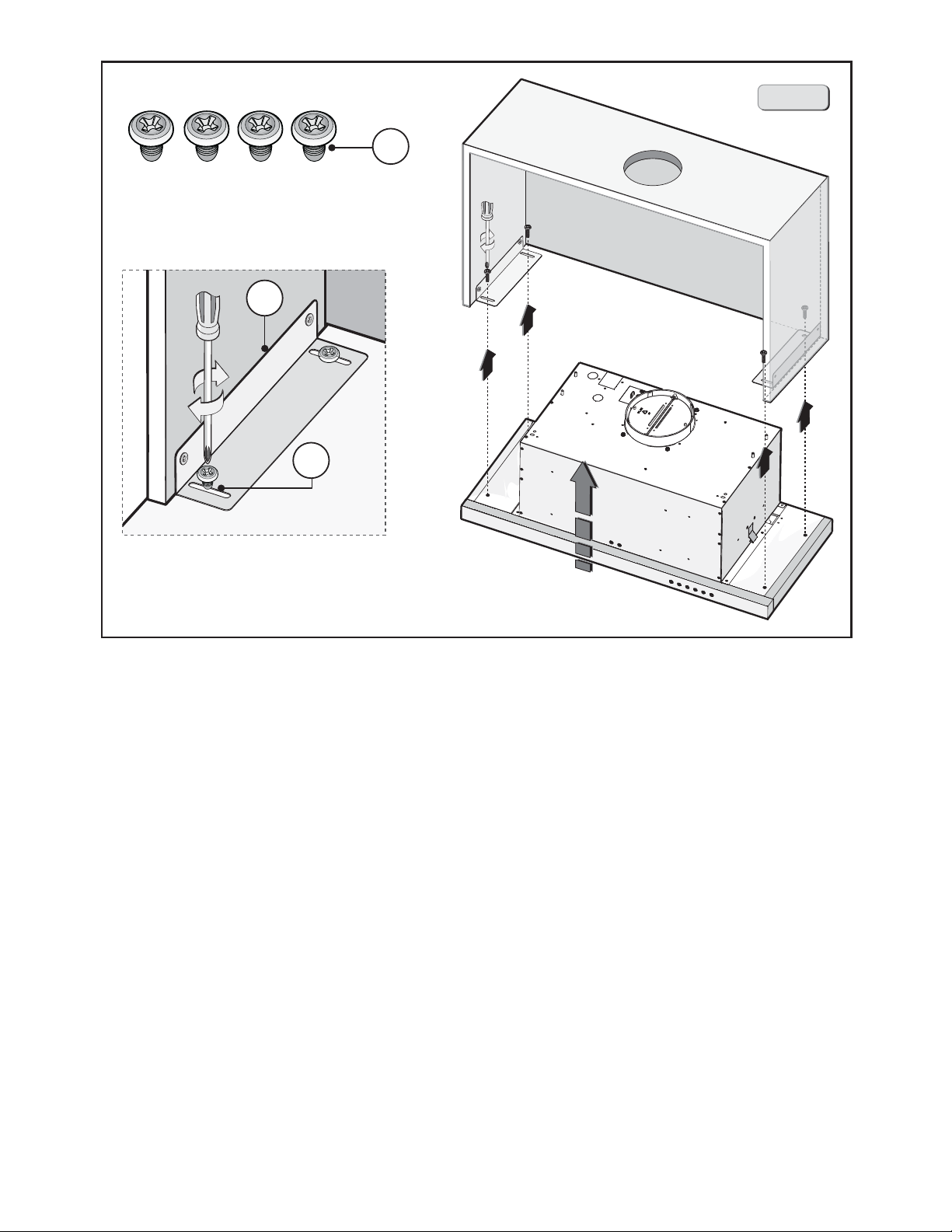

1. FIXING THE HOOD TO THE LOWER PART OF THE WALL CABINET:

Follow the steps below:

1- Position template B on the wall unit, bearing in mind the measurements indicated in

g. 1-2 and the minimum distance from the hob.

- Mark the references to x brackets A to the wall unit, as indicated in gure 4.

2- Make sure the thickness of the wall unit is within the parameters indicated in gure

4 - step 2.

3- Build the hood in the wall unit and make sure the 2 side springs F are connected correctly. Fasten the hood to the wall unit using the screwdriver and the relative screws M

and tighten until the device is rmly against the wall unit (gure 4 - step 2).

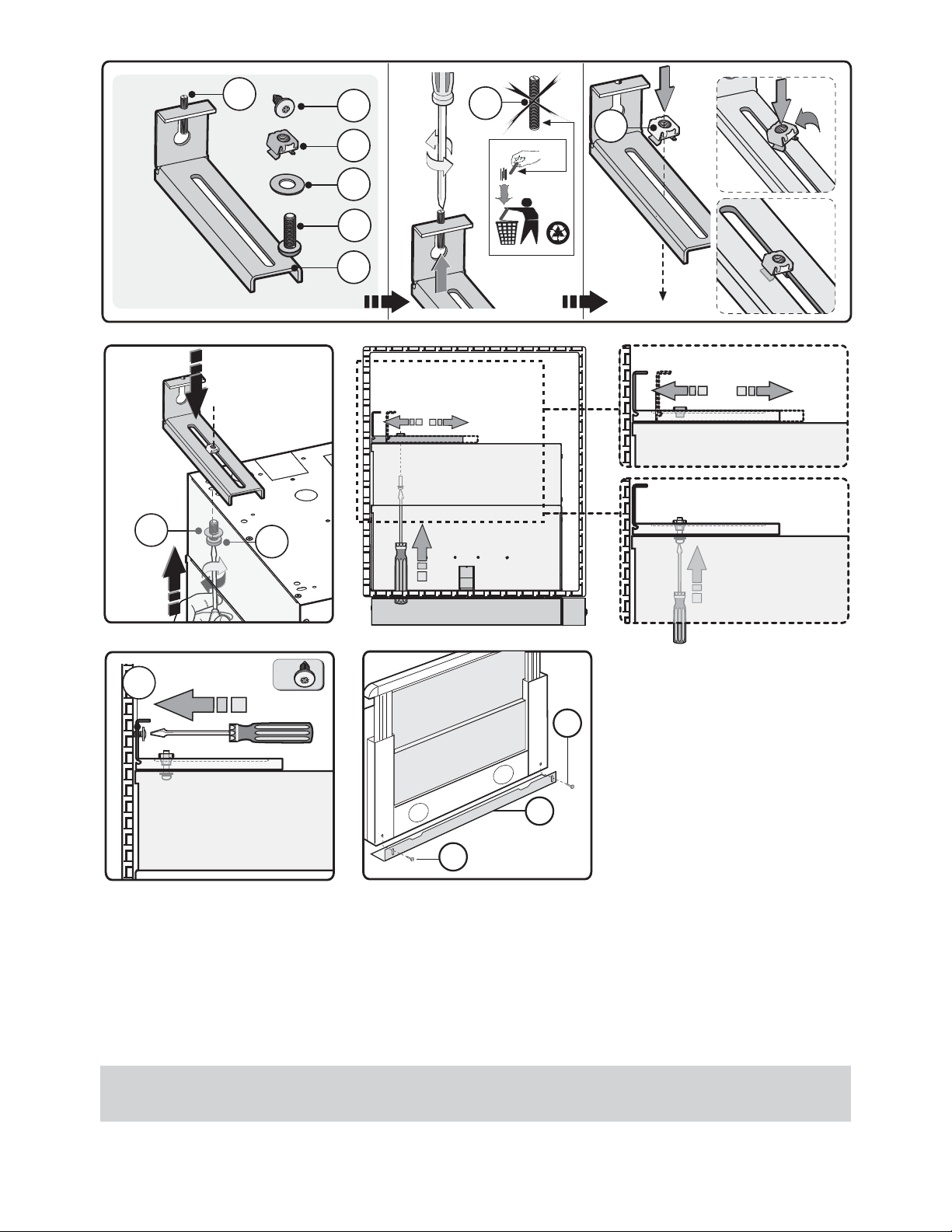

4- Remove pin Y from bracket A. Then place the insert X on the slot of the bracket A, as

indicated in gure 4 - step 3.

- Match the C screws with the L wascher and x the A bracket to the cabinet as indicated

in gure 4 - step 3.1. Pay attention not to completely tighten screws C before the bracket

- 10 -

3

3.3

C

L

3.1

C

Y

D

X

L

C

A

Y

X

3.2

3.2

3.3

3.3

D

rmly reaches the wall unit (gure 4 - step 3.2). After any adjusting, tighten the bracket

to the body (gure 4 - step 3.3).

- Fasten screw D to the wall unit as indicated in gure 4 - step 4.

- Once you have fastened the hood to the wall unit, adjust the spacer L, with the screws

P, to make the device line up with the rear wall unit (gure 4 - step 5).

IMPORTANT - The range hood must be secured to wall studs or use drywall

anchors capable of supporting 75 lbs.

4

D

P

L

P

5

- 11 -

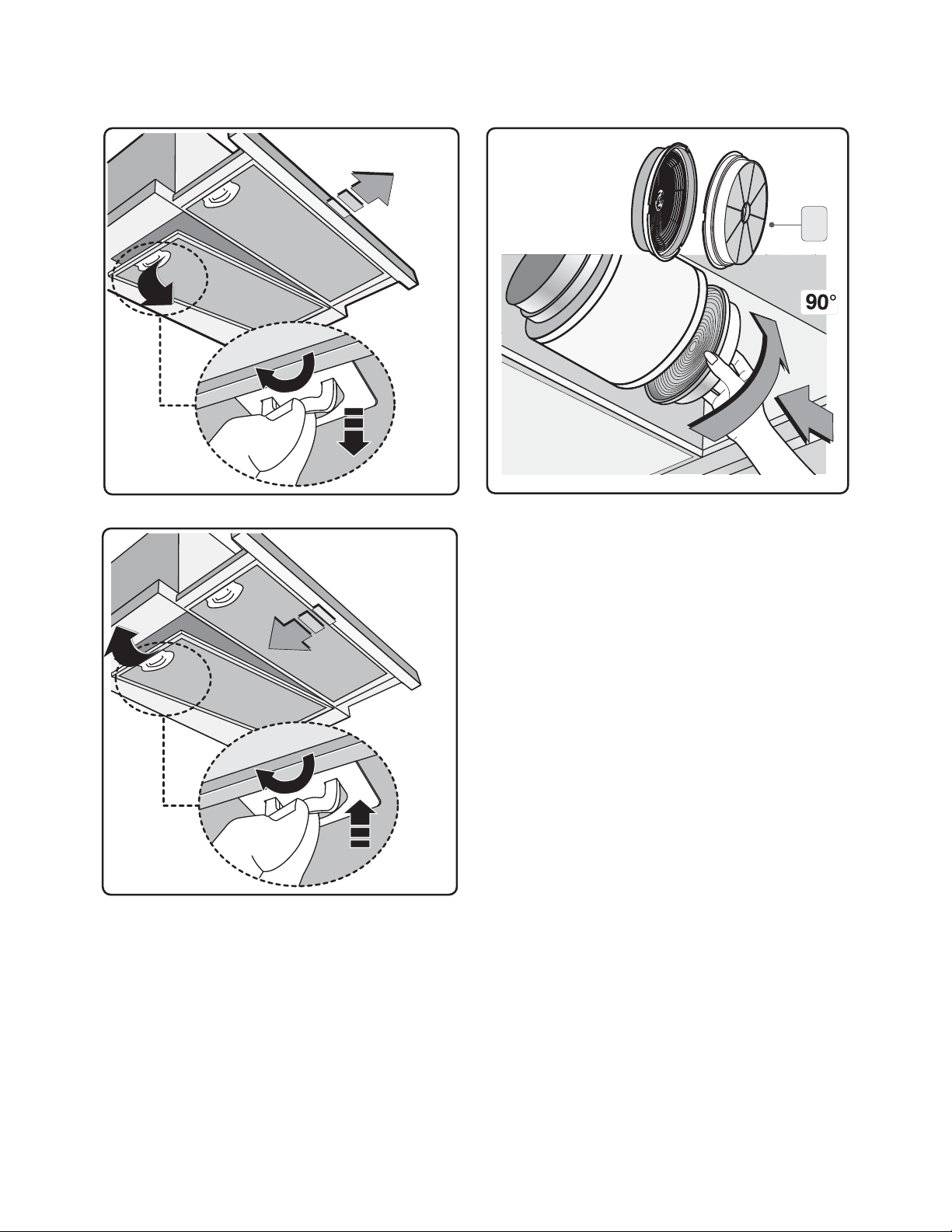

2. INSTALLATION OF THE HOOD ON THE LOWER PART OF THE WALL UNIT ON THE

DIVIDING PANEL.

Follow the steps below:

1 -Check the measurements indicated in fig.1-2 and the minimum distance from the hob,

before installing the hood on the dividing panel.

3- Make sure the thickness of the wall unit is within the parameters indicated in figure

4 - step 2.

4- Build the hood in the wall unit and make sure the 2 side springs F are connected

correctly. Fasten the hood to the wall unit using the screwdriver and the relative screws

M and tighten until the device is firmly against the wall unit (figure 4 - step 2).

5- Fasten the hood to the upper wall unit as indicated in figure 5 - step 6.

- Once you have fastened the hood to the wall unit, adjust the spacer L, with screws P, to

make the device line up with the rear wall unit (figure 4 - step 5).

IMPORTANT - The range hood must be secured to wall studs or use drywall

anchors capable of supporting 75 lbs.

- 12 -

2

6

2

1

24" - 36"

19-11/16" (24")

31-1/2" (36")

3-13/16"

1-15/16" (24"-36")

1-11/16"

Ø 6"

7-11/16"

1-11/16"

11-1/16"

19-11/16" (30")

Ø 6"

30"

3-13/16"

5-1/8" (30")

1-11/16"

7-11/16"

11-1/16"

1-11/16"

D

6

Fig.5

6

- 13 -

3

B

30"

A

3

4

7

1

E

G

1

D

G

E

E

2

D

3

Fig.6

- 14 -

G

30"

E

E

5

4

3. INSTALLATION OF THE HOOD ON THE LOWER PART OF THE WALL UNIT ONLY FOR

30".

This model includes side installation to the wall unit by using 2 brackets B (figure 6 besides

steps 3-4, indicated in figure 4).

1- Position template B on the wall unit, bearing in mind the measurements indicated in

fig. 1-2 and the minimum distance from the hob.

- Mark the references to fix brackets A to the wall unit, as indicated in figure 6.

2 - Position the second template E on the side of the wall unit and make sure that the line

matches up with that traced in figure 6 - step 1.

3 - Mark and drill the 4 fixing holes (figure 6 - step 2).

- Fasten the 2 brackets G to the wall unit using the 4 screws D (figure 6 - step 3).

- Fasten the hood to bracket G using the 4 screws E (figure 6 - step 4-5).

4- Remove pin Y from bracket A. Then place the insert X on the slot of the bracket A, as

indicated in figure 4 - step 3.

- Match the C screws with the L wascher and x the A bracket to the cabinet as indicated

in gure 4 - step 3.1. Pay attention not to completely tighten screws C before the bracket

firmly reaches the wall unit (figure 4 - step 3.2). After any adjusting, tighten the bracket

to the body (figure 4 - step 3.3).

- Fasten screw D to the wall unit as indicated in figure 4 - step 4.

- 15 -

- Once you have fastened the hood to the wall unit, adjust the spacer L, with screws P, to

make the device line up the rear wall unit (figure 4 - step 5).

IMPORTANT - The range hood must be secured to wall studs or use drywall

anchors capable of supporting 75 lbs.

- 16 -

POWER SUPPLY:

IMPORTANT – (Please read carefully)

WARNING:

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE PROPERLY GROUNDED.

Remove house fuse or open circuit breaker before beginning installation. Do not use an

extension cord or adapter plug with this appliance. Follow National electrical codes or

prevailing local codes and ordinances.

Electrical supply:

These vent hoods must be supplied with 120V, 60Hz, and connected to an individual,

properly grounded branch circuit, and protected by a 15 or 20 amp circuit breaker or

time delay fuse.

t 8JSJOHNVTUCFXJSFXJUIHSPVOE

t *G UIF FMFDUSJDBM TVQQMZ EPFT OPU NFFU UIF BCPWF SFRVJSFNFOUT DBMM B MJDFOTFE

electrician before proceeding.

t 3PVUFIPVTFXJSJOHBTDMPTFUPUIFJOTUBMMBUJPOMPDBUJPOBTQPTTJCMFJOUIFDFJMJOHPS

back wall. Refer to Wiring Locations on page 18.

t $POOFDUUIFIPPEXJSJOHUPUIFIPVTFXJSJOHJOBDDPSEBODFXJUIMPDBMDPEFT

WARNING: The improper connection of the equipment-grounding conductor

can result in a risk of electric shock. Check with a qualied electrician or service representative if you are in doubt whether the appliance is properly grounded.

- 17 -

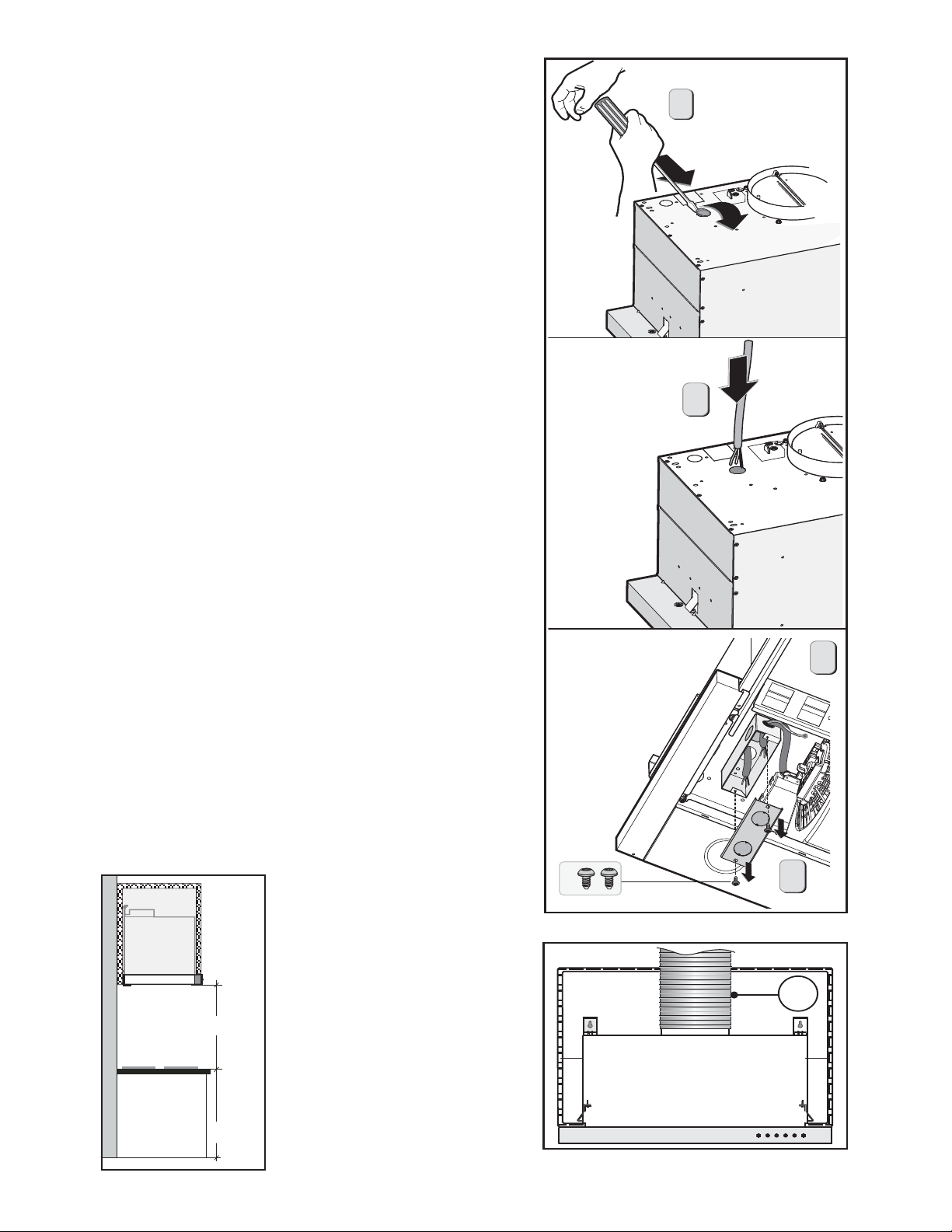

2. CONNECT ELECTRICAL:

t 1PXFS4VQQMZ$POOFDUJPO

For connection to the power supply refer to the

follows Fig.7:

BLACK = L line

WHITE = N neutral

GREEN/YELLOW = G ground

- A double-pole switch properly rated must be

installed to provide the range hood power supply

disconnection.

- Connect the electrical conduit to the Field Wiring

Compartment using listed conduit ttings.

- Carry out the power supply connection in accordance with the national electric code, ANSI/NFPA

70-1999.

5. Insert the wires into the box, then close the box

cover, securing it using the s cr ew s th a t we re

previously removed.

The appliance should be installed at a minimum

height of 27" up to a maximum height of 32" for optimal performance. If a connection ductwork composed of two parts is used, the upper part must be

placed outside the lower part. Do not connect the

range hood exhaust duct air to the same duct air

used to exhaust hot air or fumes from other appliances other than electrical.

tIn the FILTERING version it is necessary to apply a

metal air exhaust tube M (Fig.8), with a minimum

length of 15", connected to the ange of the collector. It must be positioned vertically and fastened

to a specic opening made on the top part of the

cabinet.

1

2

4

3. CONNECT THE DUCTWORK:

Min 27" - Max 32"

36"

- 18 -

A

Fig.7

Fig.8

3

M

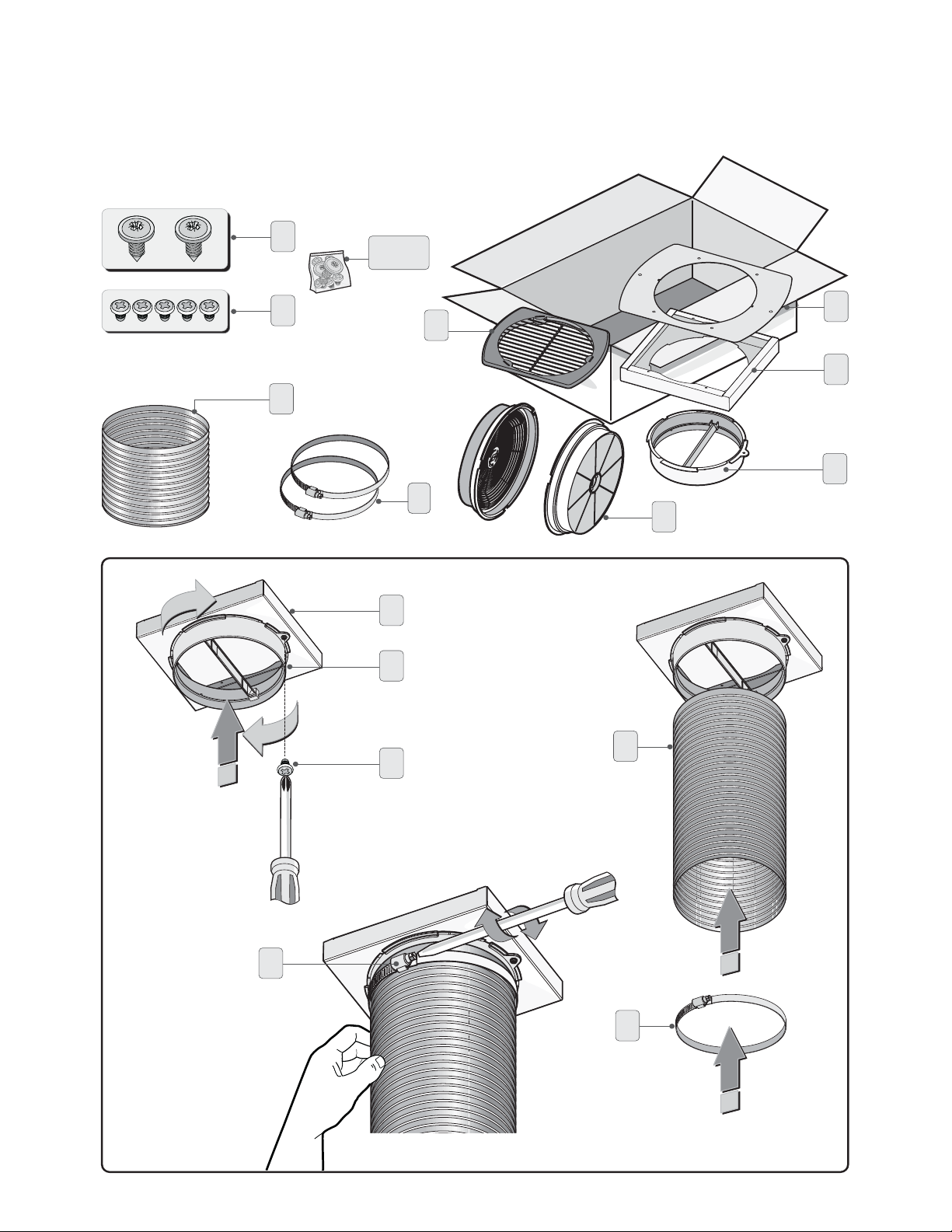

DUCTLESS RECIRCULATING OPTION:

CARBON FILTER KIT XOC24SMUA - XOC30SMUA - XOC36S - XOC30S : follow the indi-

cations described in the additional sheet to install the kit.

a

a-b

2

1

b

h

c

f

d

e

g

i

d

e

h

b

3

g

6

4

g

5

- 19 -

8

b

7-9/16"

6-3/4"

7

a

9

b

c

10

f

h

g

12

13

11

- 20 -

i

14

16

1

1

2

15

2

- 21 -

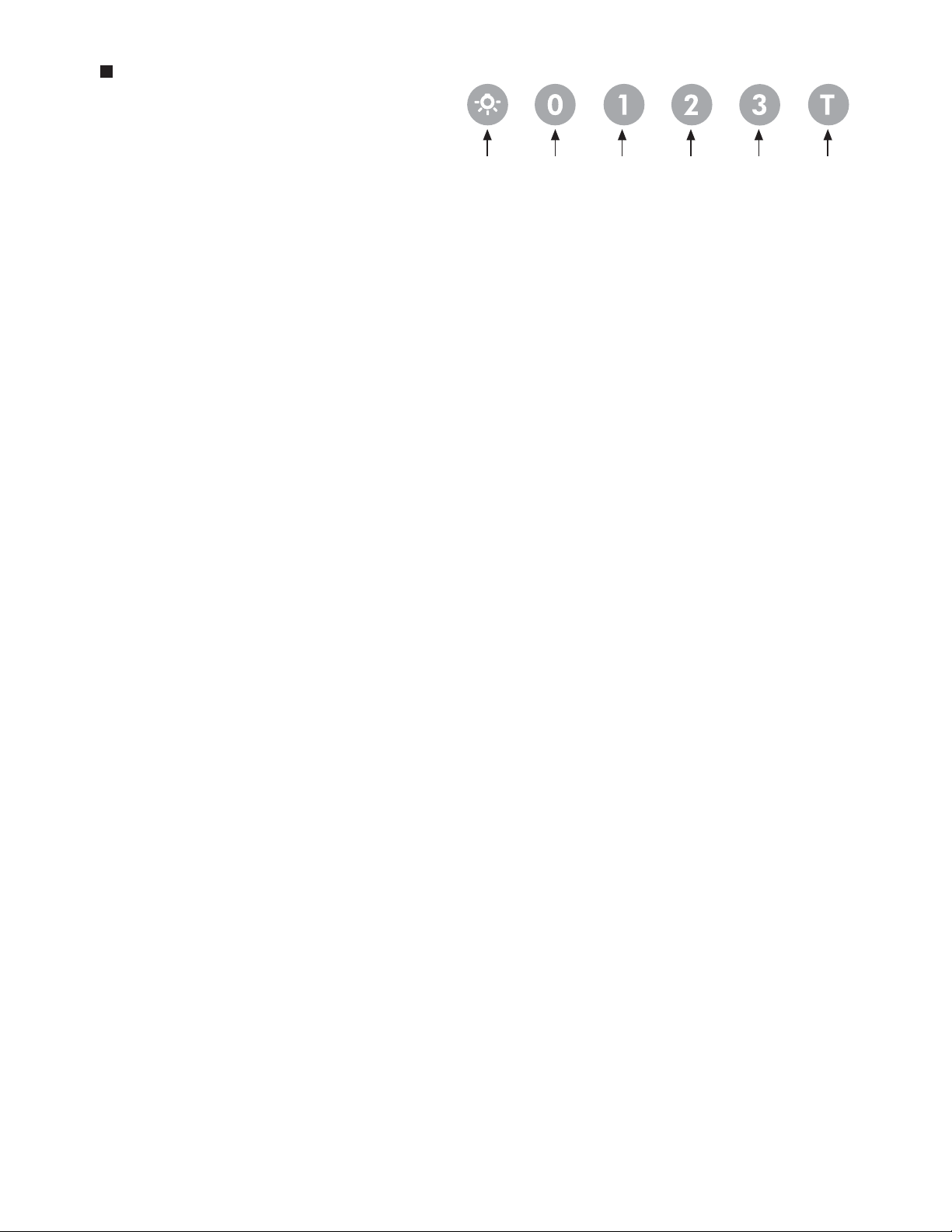

USE

t*GUIFBQQBSBUVTJTFRVJQQFEXJUIUIF

following controls luminous:

A = LIGHT

B = OFF

C = SPEED I

D = SPEED II

E = SPEED III

F =

AUTOMATIC STOP TIMER - 15 minutes (*)

tThe appliance has the INTENSIVE speed function, press key E for two seconds and it will

be activated for 10 minutes after which it will return to the previously set speed. When

the function is active the LED ashes. To interrupt it before the 10 minutes have expired

press key E again.

IMPORTANT: Intensive function is available only for model XOC36S - XOC30S

t By pressing key F for two seconds (with the hood switched o) the “clean air” function

is activated. This function switches the appliance on for ten minutes every hour at the

rst speed. As soon as this function is activated the motor starts up at the rst speed for

ten minutes. During this time key F and key C must ash at the same time.

After ten minutes the motor switches o and the LED of key F remains switched on with

a xed light until the motor starts up again at the rst speed after fty minutes and keys

F and C start to ash again for ten minutes and so on.

By pressing any key for the exclusion of the hood light the hood will return immediately

to its normal functioning (e.g. if key D is pressed the “clean air” function is deactivated

and the motor moves to the 2nd speed straight away. By pressing key B the function is

deactivated).

A

B

C

D

E

F

(*) The “automatic stop timer” delays stopping of the hood, which will continue functioning for 15 minutes at the operating speed set at the time this

t"DUJWFDBSCPOHSFBTFöMUFSTBUVSBUJPO

- When button A ashes at a frequency of 2 seconds, the grease lters must be cleaned.

- When button A ashes at a frequency of 0.5 seconds, the carbon lters must be replaced.

After the clean lter has been replaced, the electronic memory must be reset by pressing

button A for approximately 5 seconds, until the light on the button stops ashing.

- 22 -

function is activated.

MAINTENANCE

tWe recommend that the cooker hood is

switched on before any food is cooked.

We also recommend that the appliance is

left running for 15 minutes after the food

is cooked, in order to thoroughly eliminate

all contaminated air. The eective performance of the cooker hood depends on

constant maintenance; the anti-grease lter and the active carbon lter both require

special attention.

t5IFBOUJHSFBTFGJMUFS is used to trap

any grease particles suspended in the air,

therefore is subject to saturation (the time

it takes for the lter to become saturated

depends on the way in which the appliance is used). The grease lters should be

cleaned frequently. Use a warm detergent solution. Grease lters are a dishwasher safe.

- To prevent potential re hazards, the anti-grease lters should be washed a minimum

of every 2 months (it is possible to use the dishwasher for this task).

- After a few washes, the colour of the lters may change. This does not mean they have

to be replaced. If the replacement and washing instructions are not followed, the antigrease lters may present a re hazard.

t5IFBDUJWFDBSCPOöMUFST are used to purify the air which is released back into the room.

The lters are not washable or re-usable and must be replaced at least once every four

months. The active carbon lter saturation level depends on the frequency with which

the appliance is used, the type of cooking performed and the regularity with which the

anti-grease lters are cleaned.

tClean the cooker hood frequently, both inside and outside, using a cloth which has been

dampened with denatured alcohol or neutral, non-abrasive liquid detergents.

tThe light on the cooker hood is designed for use during cooking and not for general

room illumination. Extended use of the light reduces the average duration of the bulb.

Hood Cleaning:

Stainless steel is one of the easiest materilas to keep clean. Occasional care will help

preserve its ne appearance.

Cleaning tips:

- Hot water with soap or detergent is all that is usually needed.

- Follow all cleaningby rising with clear water. Wipe dry with a clean, soft cloth to avoid

water marks.

- For discolorations or deposit that persist, use a non-scratching household cleanser or

stainless steel polishing powder with a little water and a soft cloth.

- For stubborn cases, use a plastic scouring pad or soft bristle brush together with cleaser

and water. Rub lightly in direction of polishing lines or "grain" of the stainless finish. Avoid

using too much pressure wich may mar the surface.

- DO NOT allow deposit to remain for long periods of time.

Fig.9

1

2

G

- 23 -

- DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere to the

surface causing rust.

- DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to remain

in contact with stainless steel for extended periods. Many of these compounds contain

chemicals with may be harmful. Rinse with water after exposure and wipe dry with a

clean cloth.

Painted surfaces should be cleaned with warm water and mild detergent only.

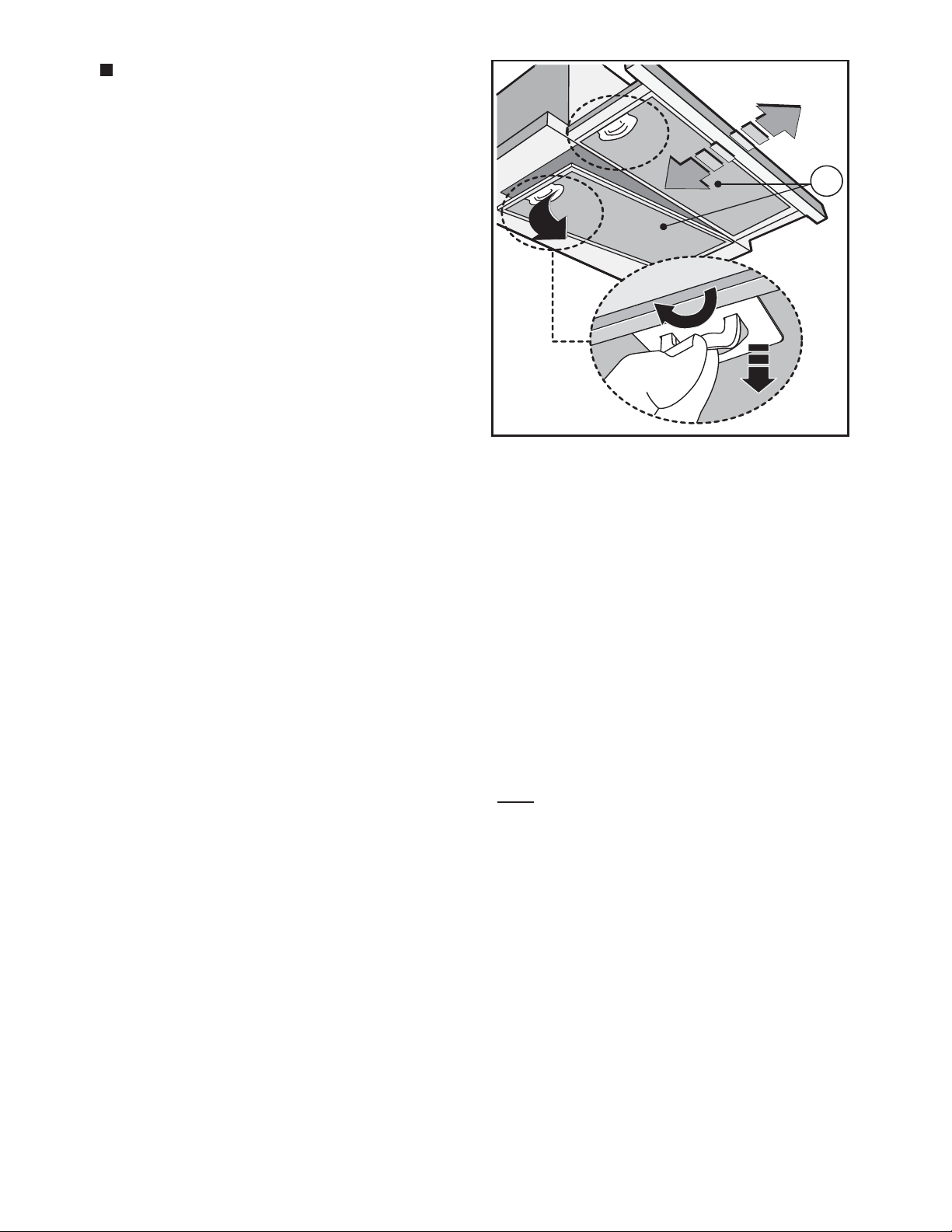

t 3FQMBDJOHUIFBMVNJOVNQBOFMT

To replace the aluminium panels, simply pull handle G as shown in Fig.9.

- 24 -

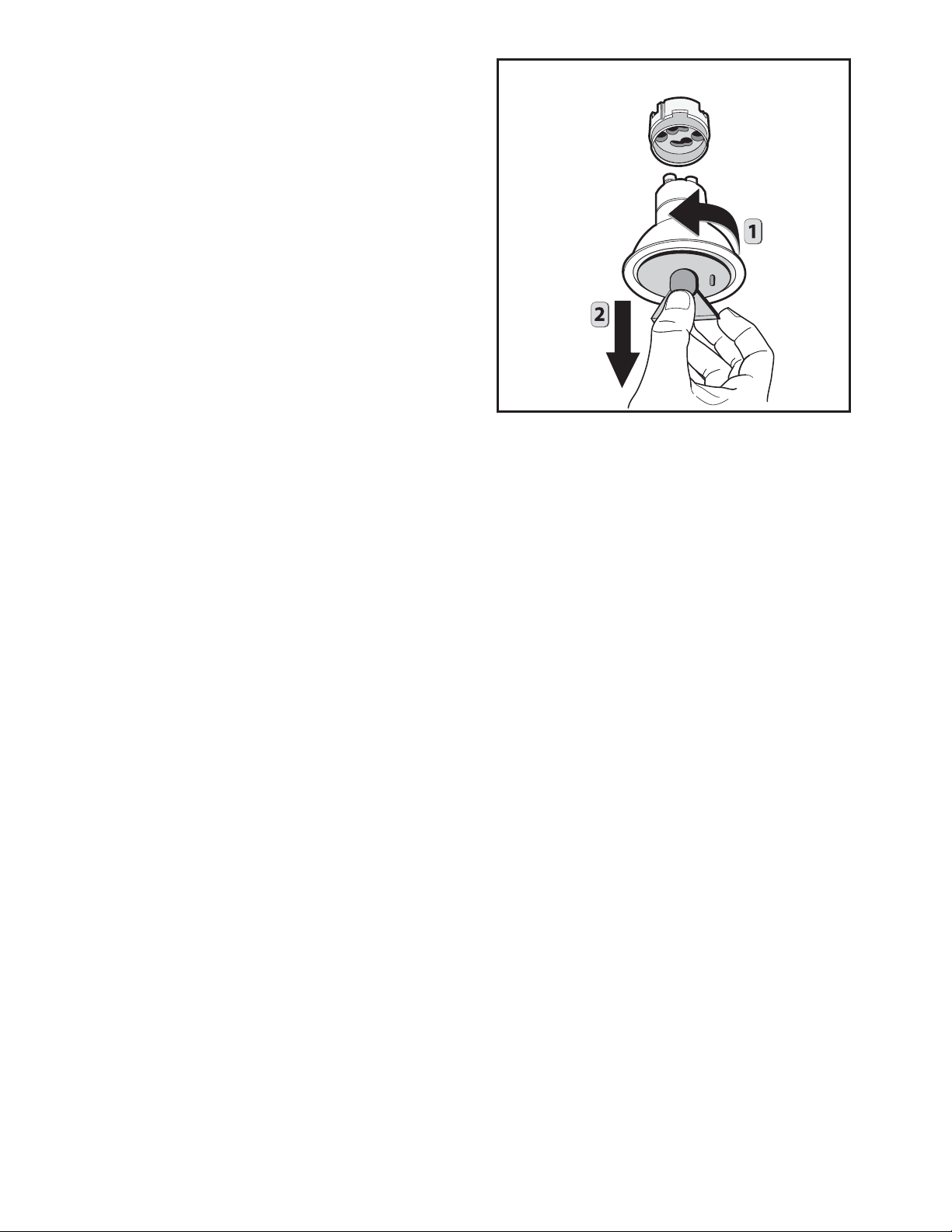

t3FQMBDJOHIBMPHFOMJHIUCVMCT

To replace the dichroic lamps, rotate the

lamp anticlockwise by means of a suction

cup as shown in gure.

Replace the bulbs with new ones of the

same type.

- 25 -

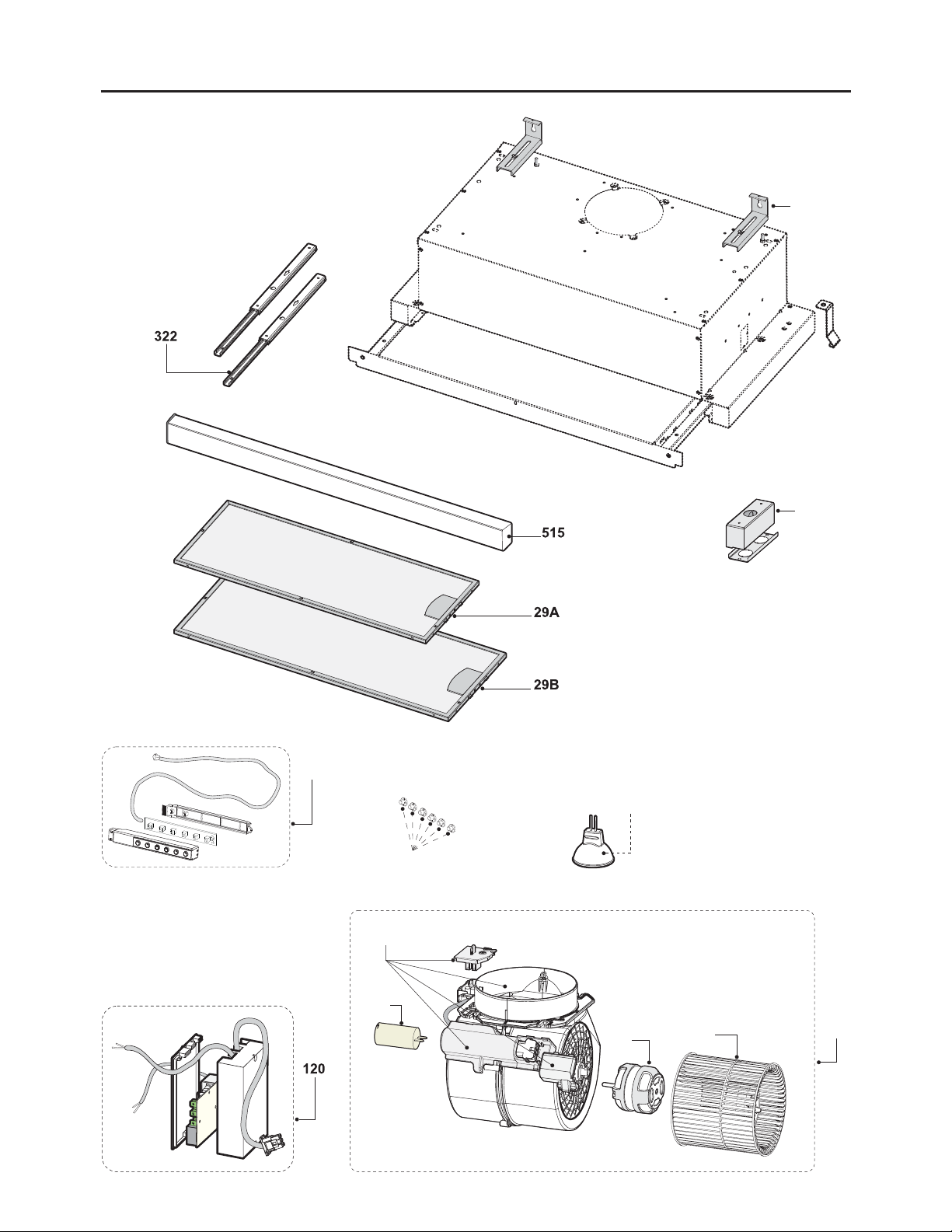

XOC24SMUA - XOC30SMUA - XOC36S - XOC30S:

530

173

110

261

39

160

- 26 -

70

609

40

140

OPTIONS AND ACCESSORIES:

Model XORFRND Ductless Recirculating Filter Kit.

Model XORFK12 Ductless Recirculating Filter Kit.

- 27 -

INSTALLATION PREPARATION:

Check installation hardware:

Locate the hardware package packed with the hood and check contents.

TYPE DESCRIPTION N°

1/4"

A

1/8" x 1/4" 3

6/16"

B

3/16" x 9/16" 4

Adjusting brackets Aluminum lter

Supply of side xing brackets on wall unit only for 30"

1/8" x 1/4" N°4

3/16" x 9/16" N°4

1/4"

6/16"

Side fixing brackets on wall unit

no. 2.

- 28 -

XOC Spec Sheet

Model: XOC24SMUA - XOC30SMUA - XOC36S -

XOC30S

Sizes: 24" - 30" - 36" Depth: 11-1/16"

Features and Benets:

Model: XOC24SMUA - XOC30SMUA

- 395 CFM high velocity blower optimally removes

Smoke, Grease and Odors.

- 3 speed electronic illuminated controls.

Model: XOC36S - XOC30S

- 600 CFM high velocity blower optimally removes

Smoke, Grease and Odors.

- 3+1 speed electronic illuminated controls.

- Two 50W Halogen Lights - Provide brilliant

illumination over the cooking surface.

- Aluminum Mesh Filters - Trap airborne smoke and

grease particles. They can be easily be removed

for dishwasher-safe cleaning.

- Mounting Height from cooking surface 27”-32”

10-9/16"

11-1/16"

16-15/16"

19-11/16" - 31-1/2"

18-5/8" - 30-7/16"

Ø6"

11-1/16"

9-0/16"

Duct Options and Electrical Requirements:

- 6 inch duct required.

- Ductless Option for applications where no

ducting in available.

Model: XOC24SMUA - XOC30SMUA

- AC 120v-60Hz (3.5amp).

Model: XOC36S - XOC30S

- AC 120v-60Hz (4.35amp).

Options:

- Optional recirculating kit if outside venting is

unavailable.

Model: XORFRND - XORFK12

XO is Exclusively Distributed by:

Eastern Marketing Corp 24 Eisenhower Parkway Roseland,

New Jersey 07068 800-966-8300

www.easternmarketing.com

1-0/16"

1-9/16"

23-9/16" - 29-15/16" - 35-3/8"

www.xoappliace.com

- 29 -

Garantie hotte XO

Pour demander une intervention en garantie, la facture d’achat

est nécessaire.

Que couvre-t-elle ?

Que ne couvre-t-elle

pas ?

Garantie de deux ans.

La garantie couvre la réparation et le remplacement gratuitement

à votre domicile de pièces de la hotte avec des défauts dérivant

d’une erreur de fabrication, pour une période de deux ans à

compter de la date d’achat.

La garantie couvre les achats effectués pour un usage domestique

en Amérique du Nord.

Si vous avez besoin d’assistance pour votre produit XO, téléphonez

au numéro 800.966.8300

Installation incorrecte.

Visites à votre domicile pour vous conseiller sur comment utiliser

le produit.

Réinitialisation des interrupteurs.

Dommages causés après la livraison.

VOUS DEVEZ VOUS ATTENDRE QUELQUE CHOSE DE PLUS

D’UN XO

En achetant un produit XO

vous pouvez être certain

d’avoir acheté un produit de grande qualité,

innovant et agréable à regarder

d’une entreprise qui reste à vos côtés.

- 30 -

FRANÇAIS

INSTRUCTIONS DE SECURITE IMPORTANTES

POUR UN USAGE DOMESTIQUE EXCLUSIVEMENT

LIRE ET CONSERVER LES INSTRUCTIONS

COMMENCER PAR LIRE ENTIEREMENT LES INSTRUCTIONS.

IMPORTANT: Conserver les Instructions à usage des Inspecteurs Electriques

Locaux.

A L’ATTENTION DE L’INSTALLATEUR: Laisser les Instructions dans l’unité à usage du

propriétaire.

A L’AT TENTION DU PROPRIETAIRE: Conserver les Instructions pour des consultations

ultérieures.

N’utiliser des produits de nettoyage ou des détergents qu’avec la plus grande

prudence.

Cet appareil est propre à une utilisation domestique et culinaire.

F

AVERTISSEMENT – An de réduire les risques d’incendie ou d’électrocution, ne pas

utiliser le moteur avec un Dispositif de Contrôle de la Vitesse à Semi-conducteurs

quel qu’il soit.

ATTENTION – An de réduire les risques d’incendie et de permettre une aspiration

correcte de l’air, s’assurer que celui-ci est bien transporté à l’extérieur à travers un

conduit d’évacuation. – Ne pas évacuer l’air dans des interstices tels qu’entre des

cloisons ou des plafonds, dans des greniers, des espaces connés ou des garages.

ATTENTION – N’utiliser que pour une ventilation générique. Cet appareil n’est pas

propre à l’aspiration de matières ou de vapeurs dangereuses ou explosives.

ATTENTION – An d’éviter des bruits et des dommages au niveau du moteur, et/ou

un déséquilibre au niveau des hélices, veiller à ce que l’unité d’alimentation n’entre

pas en contact avec du spray, de la poussière etc.

ATTENTION – Pour obtenir des compléments d’informations, consulter l’étiquette

de spécication sur le produit.

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES D’INCENDIE, D’ÉLECTROCUTION

OU DE DOMMAGES AUX PERSONNES, RESPECTER LES REGLES SUIVANTES :

A. N’utiliser l’unité que pour les opérations prévues par le fabricant. Pour toute question

éventuelle, contacter le fabricant.

B. Avant d’eectuer des opérations de maintenance ou de nettoyage sur l’unité,

- 31 -

débrancher le panneau de service et fermer à clef les commandes de déconnection

an d’éviter toute mise sous tension accidentelle.

Au cas où les commandes de déconnection ne pourraient être fermées à clef, xer sur

lepanneau de service un message avertissant du danger, par exemple une plaque.

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES D’INCENDIE PAR

INFLAMMATION DES GRAISSES PRESENTES SUR LA GAZINIERE :

A. Ne jamais laisser de casseroles sur feu vif sans surveillance. D’éventuels débordements

dus à une forte ébullition peuvent provoquer de la fumée et des dépôts de graisses

susceptibles de prendre feu. Réchauer l’huile lentement, à petit feu ou moyen.

B. ALLUMER systématiquement la hotte pour cuisiner à des températures élevées ou

pour amber des aliments (ex. : Crêpes Suzette, Cherries Jubilee – cerises ambées au

brandy et glace -, Boeuf ambé au poivre).

C. Nettoyer souvent le moteur. Eviter que les graisses ne s’accumulent sur le moteur ou

sur le ltre.

D. Utiliser des plats aux dimensions adaptées. Toujours utiliser des ustensiles de cuisine

adaptés à la taille de la casserole qui se trouve sur la cuisinière.

E. Veiller à ce que le moteur, les ltres et la surface où viennent s’accumuler les graisses

restent propres.

F. N’utiliser une amme élevée que lorsque cela est nécessaire. Réchauer l’huile

lentement, à faible ou moyenne température.

G. Ne jamais laisser la cuisinière sans surveillance pendant la cuisson.

H. Utiliser systématiquement des ustensiles de cuisine adaptés au type et à la quantité

d’aliments que l’on prépare.

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES DE DOMMAGES AUX PERSONNES

EN CAS D’INCENDIE PAR INFLAMMATION DES GRAISSES PRESENTES SUR LA CUISINIERE,

RESPECTER LES REGLES SUIVANTESa:

A. ETOUFFER LA FLAMME à l’aide d’un couvercle hermétique, une plaque à four ou un

plateau en métal et éteindre le brûleur. PROCEDER AVEC LA PLUS GRANDE PRUDENCE

AFIN D’EVITER TOUTE BRULURE. Si les ammes ne s’éteignent pas immédiatement,

EVACUER LA PIECE ET APPELER LES POMPIERS.

B. NE JAMAIS TOUCHER UN PLAT EN FEU – on risque de se brûler.

C. NE PAS UTILISER D’EAU, ni de chions ou de serviettes humides – cela pourrait

provoquer une violente explosion de vapeur.

D. Utiliser un extincteur UNIQUEMENT dans les cas suivants:

1. On dispose d’un extincteur de Classe ABC que l’on sait faire fonctionner.

2. L’incendie est peu important et il est conné à la zone où il a éclaté.

3. On a déjà appelé les pompiers.

4. On peut aronter les ammes tout en ayant une issue de secours derrière soi.

aBasé sur les « mesures de sécurité incendie dans la cuisine « publiées par l’organisme

NFPA.

Une bonne maintenance de la hotte garantit le parfait fonctionnement de l’unité.

- 32 -

INSTRUCTIONS D’INSTALLATION

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES D’INCENDIE, D’ÉLECTROCUTION

OU DE DOMMAGES AUX PERSONNES, RESPECTER LES REGLES SUIVANTES :

A. Les opérations d’installation et de branchement électrique doivent être eectuées

par du personnel qualié, conformément aux lois et aux normes en vigueur, y

compris celles relatives aux appareils à feu.

B. Il est nécessaire de disposer d’une quantité d’air susante pour une bonne

combustion et aspiration des gaz à travers le conduit de fumée de l’installation

de combustion du carburant, an d’éviter un appel d’air de l’arrière. Suivre les

indications du fabricant de l’installation de chauage et les normes de sécurité

correspondantes telles que celles émises par l’Association Nationale de Protection

contre les Incendies (National Fire Protection Association - NFPA), la Société

Américaine des Techniciens de Chauage, Réfrigération et Climatisation de l’Air

(American Society for Heating, Refrigeration and Air Conditioning Engineers -

ASHRAE), et par les autorités locales préposées.

C. Au cours des opérations de découpage ou de perforation du mur ou du plafond,

veiller à ne pas endommager les câbles électriques ou d’autres canalisations

cachées.

D. L’appareil doit toujours être relié à un trou d’évacuation vers l’extérieur.

E. L’unité doit être reliée à la terre.

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES D’INCENDIE, N’UTILISER QUE

DESCONDUITS METALLIQUES

AVERTISSEMENT – LES APPAREILS ELECTROMENAGERS PEUVENT PARFOIS S’AVERER

DANGEREUX.

A. Ne pas contrôler les ltres lorsque la hotte est en état de marche.

B. Ne pas toucher les lampes après une utilisation prolongée de l’appareil.

C. Ne jamais faire amber d’aliments sous la hotte.

D. L’usage de ammes libres est dangereux pour les ltres et peut générer des incendies.

E. Contrôler constamment les fritures pour éviter que des éclaboussures d’huile ne

prennent feu.

F. Avant d’eectuer toute opération de maintenance, débrancher la hotte du réseau

d’alimentation électrique.

Le fabricant ne pourra être retenu responsable d’éventuels dommages causés par le

non respect des instructions susmentionnées.

- 33 -

RACCORDS DE

CANALISATION:

Cette hotte doit utiliser

un conduit rond de 20

cm (8 po) raccordan

à un tuyau 8 cm x 30

cm (3-1/4" po x 12 po).

Reportez-vous au tableau

pour calculer les longueurs maximales autorisées

pour les conduits vers l’extérieur.

Préparation à l'installation

REMARQUE: Ne dépassez

pas les longueurs maximales

autorisées!

Longueur maximale de

conduit: 30 m (100 pi)

pour les hottes de cuisinière.

Conduit: Dimensions:

Rond droit

Droit 8 cm x 30

cm (3-1/4 po x

12 po)

Coude 90°

Coude 45°

Coude 90° 8 cm

x 30 cm (3-1⁄4

po x 12 po)

Coude 45° 8 cm

x 30 cm (3-1/4

po x 12 po)

Coude plat 90°

8 cm x 30 cm

(3-1/4 po x 12

po)

Longueur

équivalente*:

30 cm (1 pied)

(par longueur

en pied)

30 cm (1 pied)

(par longueur

en pied)

5 m (17

pieds)

3 m (10

pieds)

13 m (43

pieds)

7,90 m (26

pieds)

32 m (102

pieds)

Quantité

utilisée:

Longueur

total

équivalente:

Conduit flexible:

En cas d’utilisation de conduits métalliques flexibles,

les valeurs en pieds figurant

dans le tableau doivent

être doublées. Le conduit

métallique flexible doit

être droit et lisse et étiré au

maximum.

N’utilisez PAS de conduit en

plastique flexible.

REMARQUE: Tout système

de ventilation domestique

tel qu’une hotte aspirante,

est susceptible d’interrompre

le débit d’air et de fumées

de combustion requis pour

les cheminées, fours à gaz,

les chauffe-eau à gaz et autres systèmes naturellement

ventilés. Afin de réduire les

probabilités d’interruption

de ces systèmes naturellement ventilés, nous vous

recommandons de suivre

les consignes du fabricant de

l’équipement de chauffage

et les normes de sécurité

telles que celles publiées par

la NFPA.

Rond 20 cm

(8 po) pour

raccord 8 cm x

30 cm (3-1/4 po

x 12 po)

8 cm x 30 cm

(3-1/4 po x

12 po) pour

raccord rond 20

cm (8 po)

Rond 20 cm

(8 po) pour

raccord en

coude 90° 8 cm

x 30 cm (3-1/4

po x 12 po)

8 cm x 30 cm

(3-1/4 po x

12 po) pour

raccord rond 20

cm (8 po) en

coude 90°

Cache mur rond

avec registre

Cache mur 9

cm x 30 cm (31/4 po x 12 po)

avec registre

Cache rond

pour toiture

*Longueur réelle du conduit droit plus le raccord

de conduit équivalent. Longueur équivalente des

conduits satisfait aux exigences pour de bonnes

performances en termes de ventilation de toute

hotte aspirante.

60 cm (2

pieds)

1,5 m (5

pieds)

1,8 m (6

pieds)

3,96 m (13

pieds)

9,7 m (32

pieds)

22,9 m (75

pieds)

13 m (44

pieds)

Parcours total

des conduits =

- 34 -

AVERTISSEMENT: DANGER D’INCENDIE

N’installez JAMAIS le conduit d’évacuation de l’air dans les interstices des murs,

vides sanitaires, attiques ou garages.

L’air doit toujours être évacué à l’extérieur sauf si on opte pour l’option de la

recirculation.

Utilisez exclusivement des conduits en métal rigide à simple paroi.

Procédez à toutes les connexions en vous servant des vis auto-taraudeuses et

appliquez du ruban adhésif américain certié sur toutes les jonctions.

Installation – Options D’aspiration

INSTALLATION DES TUYAUX:

NOTE: pour diminuer le risque d’incendie, utiliser uniquement des tuyaux en

métal.

1. Décider la position du tuyau entre la hotte et l’extérieur.

2. Un tuyau court et droit améliore les performances de la hotte.

3. De longs tuyaux, des coudes et des raccords en diminuent les performances.

Utiliser ces éléments le moins possible.

4. Installer une cheminée au toit ou au mur. Raccorder un tuyau en métal circulaire

à la cheminée et procéder vers la hotte (de haut en bas). Utiliser du ruban isolant

pour les tuyaux pour sceller les jonctions entre les diérentes sections.

- 35 -

DIMENSIONS DU PRODUIT ET DISTANCES

XOI27S:

Partie avant de la hotte Partie latérale de la hotte

18-5/8" (24" - 30")

30-7/16" (36")

Specications Techniques

23-9/16" (24") - 29-15/16" (30") - 35-3/8" (36")

9"

12-1/8"

1-9/16"

11-1/16"

1-3/16"

16-15/16"

L

min 0 - 0/16" - max 1 - 4/16"

min 0 - 0/16" - max 1 - /4"

Partie supérieure de la hotte Hauteur de montage

19-11/16" (24")

1-15/16" (24"-36")

et distances :

31-1/2" (36")

Ø 6"

Ø 6"

3-13/16"

19-11/16" (30")

3-13/16"

1-11/16"

2-9/16"

5-1/8"

1-11/16"

5-1/8" (30")

1-11/16"

2-9/16"

5-1/8"

1-11/16"

11-1/16"

Min 27" - Max 32"

36"

11-1/16"

Fig.1

- 36 -

INSTRUCTIONS POUR L’INSTALLATION

INSTALLATION AVEC ÉVACUATION VERS L’EXTÉRIEUR

Avant de procéder aux opérations de montage, pour facilité la manœuvrabilité de

l'appareil, retirer le(s) filtre(s) anti-graisse

(Fig.3).

Ce produit peut être installé de 3 façons

différentes selon le modèle et vos besoins :

1- montage de la hotte dans la partie inférieure du meuble suspendu.

2- Montage de la hotte dans la partie inférieure du meuble suspendu sur support

de séparation.

3- Montage de la hotte dans la partie inférieure du meuble suspendu uniquement

pour le 30".

11-1/4"

Fig.2

19-15/16"

31-3/4"

- 37 -

1

2

Fig.3

1

24" - 36" - 30"

B

A

3

4

2

Min 0-1/2"

Max 1/016"

2

2

1

F

F

M

Fig.4

1. FIXATION DE LA HOTTE SOUS UN ÉLÉMENT HAUT:

Pour un bon montage, suivre les étapes suivantes :

1 - Positionner le gabarit B au meuble suspendu en tenant compte des mesures indiquées

sur la fig. 1-2 et de la distance minimale du plan de cuisson.

- Marquer les références pour la fixation des étriers A au meuble suspendu comme indiqué

sur la figure 4.

2 - Faire attention à ce que l'épaisseur du meuble suspendu soit comprise dans les valeurs

indiquées sur la figure 4 - étape 2.

3 - Encastrer la hotte dans le meuble suspendu et faire attention à ce que les 2 ressorts

latéraux F soient bien accrochés, fixer définitivement la hotte au meuble suspendu en

vissant les vis M à l'aide d'un tournevis jusqu'à porter l'appareil en butée avec le meuble

suspendu figure 4 - étape 2.

4 - Prendre l'étrier A et retirer le pivot Y, prendre ensuite l'insert X et le positionner sur la

fente de l'étrier A comme indiqué sur la figure 4 - étape 3.

- 38 -

3

3.3

C

L

3.1

C

Y

D

X

L

C

A

Y

X

3.2

3.2

3.3

3.3

D

- Apparier la vis C avec la rondelle L et fixer l'étrier à la coque comme indiqué sur la figure

4 - étape 3.1. Faire attention à ne pas serrer complètement la vis C, avant il faut porter

l'étrier en butée avec le meuble suspendu figure 4 - étape 3.2, lorsque le réglage a été

effectué, serrer définitivement l'étrier à la coque figure 4 - étape 3.3.

- Prendre la vis D, l'incliner et la fixer au meuble suspendu comme indiqué sur la figure

4 - étape 4.

- Une fois fixée la hotte au meuble suspendu, régler l'entretoise L, à l'aide des vis P, pour

faire coïncider à l'arrière l'appareil au meuble suspendu figure 4 - étape 5.

4

D

P

L

P

5

IMPORTANT: La hotte doit être xée au mur avec des pivots de support letés

ou des chevilles d’une capacité de 75 lbs.

- 39 -

2. MONTAGE DE LA HOTTE DANS LA PARTIE INFÉRIEURE DU MEUBLE SUSPENDU

SUR PANNEAU DE SEPARATION.

Pour un bon montage, suivre les étapes suivantes :

1 - Avant de monter la hotte au panneau de séparation, contrôler les mesures indiquées

sur la fig. 1-2 et la distance minimale du plan de cuisson.

3 - Faire attention à ce que l'épaisseur du meuble suspendu soit comprise dans les valeurs

indiquées sur la figure 4 - étape 2.

4 - Encastrer la hotte dans le meuble suspendu et faire attention à ce que les 2 ressorts

latéraux F soient bien accrochés, fixer définitivement la hotte au meuble suspendu en

vissant les vis M à l'aide d'un tournevis jusqu'à porter l'appareil en butée avec le meuble

suspendu figure 4 - étape 2.

5 - Fixer la hotte au meuble suspendu supérieur comme indiqué sur la figure 5 - étape 6.

- Une fois fixée la hotte au meuble suspendu, régler l'entretoise L, à l'aide des vis P, pour

faire coïncider à l'arrière l'appareil au meuble suspendu figure 4 - étape 5.

IMPORTANT: La hotte doit être xée au mur avec des pivots de support letés

ou des chevilles d’une capacité de 75 lbs.

- 40 -

2

6

2

1

24" - 36"

19-11/16" (24")

31-1/2" (36")

3-13/16"

1-15/16" (24"-36")

1-11/16"

Ø 6"

7-11/16"

1-11/16"

11-1/16"

19-11/16" (30")

Ø 6"

30"

3-13/16"

5-1/8" (30")

1-11/16"

7-11/16"

11-1/16"

1-11/16"

D

6

Fig.5

6

- 41 -

3

B

30"

A

3

4

7

1

E

G

1

D

G

E

E

2

D

3

Fig.6

- 42 -

G

30"

E

E

5

4

3. MONTAGE DE LA HOTTE DANS LA PARTIE INFÉRIEURE DU MEUBLE SUSPENDU

UNIQUEMENT POUR LE 30".

Le montage latéral au meuble suspendu est prévu pour ce modèle, au moyen des 2 étriers

figure 6, en plus des étapes 3-4 indiquées sur la figure 4.

1 - Positionner le gabarit B au meuble suspendu en tenant compte des mesures indiquées

sur la fig. 1-2 et de la distance minimale du plan de cuisson.

- Marquer les références pour la fixation des étriers A au meuble suspendu comme indiqué

sur la figure 6.

2 - Prendre le second gabarit E et le positionner sur le coté du meuble suspendu en faisant

attention à ce que la ligne coïncide avec celle tracée sur la figure 6 - étape 1.

3 - Marquer et effectuer les 4 trous de fixation figure 6 - étape 2.

- Fixer les 2 étriers G au meuble suspendu à l'aide des 4 vis D figure 6 - étape 3.

- Prendre la hotte et la fixer définitivement à l'étrier G à l'aide des 4 vis E figure 6 - étape 4-5.

4 - Prendre l'étrier A et retirer le pivot Y, prendre ensuite l'insert X et le positionner sur la

fente de l'étrier A comme indiqué sur la figure 4 - étape 3.

- Apparier la vis C avec la rondelle L et fixer l'étrier à la coque comme indiqué sur la figure

4 - étape 3.1. Faire attention à ne pas serrer complètement la vis C, avant il faut porter

l'étrier en butée avec le meuble suspendu figure 4 - étape 3.2, lorsque le réglage a été

effectué, serrer définitivement l'étrier à la coque figure 4 - étape 3.3.

- 43 -

- Prendre la vis D et la fixer au meuble suspendu comme indiqué sur la figure 4 - étape 4.

- Une fois fixée la hotte au meuble suspendu, régler l'entretoise L, à l'aide des vis P, pour

faire coïncider à l'arrière l'appareil au meuble suspendu figure 4 - étape 5.

IMPORTANT: La hotte doit être xée au mur avec des pivots de support letés

ou des chevilles d’une capacité de 75 lbs.

- 44 -

ALIMENTATION:

IMPORTANT (veuillez lire attentivement)

MISE EN GARDE:

POUR VOTRE SECURITE, L’APPAREIL DOIT ETRE MIS SUR LE SOL.

Avant de commencer l’installation, éliminer le fusible ou ouvrir l’interrupteur du circuit.

Ne pas utiliser de rallonges et de prises d’adaptation avec cet appareil. Veuillez vous en

tenir aux codes nationaux sur la sécurité électrique ou aux codes et règlements locaux

en matière.

Alimentation électrique:

cette hotte de ventilation doit être alimentée avec du courant 120V, 60 Hz et raccordée à

un seul réseau, avec une mise à la terre, protégée par des interrupteurs automatiques à

15 ou 20 ampères ou des fusibles retardés.

t $ÉCMFËEFVYöMTBWFDNJTFËMBUFSSF

t 4JMBMJNFOUBUJPOÏMFDUSJRVFOFTUQBTDPOGPSNFBVY TQÏDJöDBUJPOT TVTNFOUJPOOÏFT

appelez un électricien avant de continuer.

t 1PTFSMFTDÉCMBHFTEPNFTUJRVFTMFQMVTQSÒTQPTTJCMFEFMJOTUBMMBUJPOBVQMBGPOEPV

sur le mur de support. Veuillez consulter les positions des câblages à la page 46.

t 3BDDPSEFS MFT DÉCMBHFT EFMB IPUUF BVY DÉCMBHFT EPNFTUJRVFT DPOGPSNÏNFOU BVY

codes locaux.

Instructions pour la mise à la terre:

Le conducteur pour la mise à la terre doit être connecté à un système de câblage xe

avec mise à la terre, ou à une borne ou conducteur de terre dans la hotte.

MISE EN GARDE: une mauvaise connexion du conducteur de terre des équi-

pements peut causer des risques de secousse électrique. En cas de doute sur la mise à la

terre correcte de la hotte, consulter un électricien ou un préposé à l’assistance.

- 45 -

2. RACCORDEMENT ELECTRIQUE:

t#SBODIFNFOUÏMFDUSJRVF

Pour brancher l’appareil au réseau d’alimentation

électrique, suivre les indications reportées sur la

gure 7:

NOIR = L ligne

BLANC = N neutre

VERT/JAUNE = G terre

- Un interrupteur bipolaire approprié doit être installé an de permettre à la hotte de se débrancher

du réseau électrique.

- Raccordez le conduit électrique au boîtier de

connexion en n’utilisant que des composants homologués.

- Réalisez la connexion électrique conformément

aux dispositions de la norme nationale (ANSI/NFPA

70-1999).

5. Insérez les câbles à l’intérieur de la boîte et ensuite fermez-la en xant le couvercle avec les vis

précédemment enlevées. L’appareil doit être installé à une hauteur minimum de 27" par rapport à une

cuisinière électrique, et de 32" s’il s’agit d’une cuisinière à gaz ou combinée. Si l’on utilise un conduit

composé de deux éléments, la partie supérieure

doit alors être reliée à l’extérieur de la partie inférieure. Ne pas relier le conduit d’aspiration d’air de

la hotte à celui utilisé pour aspirer l’air chaud ou les

fumées provenant de d’autres appareils électroménagers non électriques.

t Pour la version FILTRANTE il faut appliquer un

tuyau métallique pour l’évacuation de l’air M

(Fig.8), de minimum 15" de longueur, relié à la

bride du convoyeur. Celui-ci devra être positionné

verticalement et xé à une ouverture eectuée sur

la partie supérieure du meuble suspendu.

1

2

4

3. RACCORDEMENT DES TUYAUX:

Min 27" - Max 32"

36"

- 46 -

A

Fig.7

Fig.8

3

M

OPTION DE RECIRCULATION SANS TUYAU:

KIT FILTRE A CHARBON XOC24SMUA - XOC30SMUA - XOC36S - XOC30S: pour l'ins-

tallation du kit, suivre les étapes indiquées dans le livret complémentaire.

a

a-b

2

1

b

h

c

f

d

e

g

i

d

e

h

b

3

g

6

4

g

5

- 47 -

8

b

7-9/16"

6-3/4"

7

a

9

b

c

10

f

h

g

12

13

11

- 48 -

i

14

16

1

1

2

15

2

- 49 -

UTILISATION

t4JMBQQBSFJMEJTQPTFEFTDPNNBOEFT

suivantes:

A = Touche ECLAIRAGE

B = Touche OFF

C = Touche PREMIERE VITESSE

D = Touche DEUXIEME VITESSE

E = Touche TROISIEME VITESSE

F = Touche MINUTEUR ARRET AUTOMATIQUE 15 minutes (*)

Si votre appareil possède la fonction vitesse INTENSE, maintenir appuyé pendant environ 2 secondes le bouton E pour activer la fonction pendant 10 minutes, après quoi elle

retournera à la vitesse établie en précédence. Quand la fonction est active, la LED clignote.

Pour l’interrompre avant les 10 minutes, presser de nouveau sur la touche E.

IMPORTANT: la fonction intensive est uniquement disponible pour le modèle XOC36S

- XOC30S

En appuyant sur le bouton F pendant 2 secondes (lorsque la hotte est allumée), la fonction “clean air” s’active. Cette fonction démarre le moteur pour 10 minutes par heure à la

première vitesse. Dès que la fonction est activée, le moteur démarre en 1

10 minutes pendant lesquelles les boutons F et C doivent clignoter en même temps. A

la n de ce temps, le moteur s’arrête et la diode électroluminescente du bouton F reste

allumée sans clignoter jusqu’à ce que le moteur reparte en 1

Les diodes électroluminescentes F et C recommencent à clignoter pendant 10 minutes

et ainsi de suite. En appuyant sur n’importe quelle touche à l’exception des touches de

lumière, la hotte retourne immédiatement à son fonctionnement normal (ex. en appuyant

sur le bouton D la fonction “clean air” se désactive et le moteur passe directement à la

ème

2

vitesse; en appuyant sur le bouton B la fonction se désactive).

A

B

C

ère

vitesse 50 minutes plus tard.

D

E

ère

vitesse pour

F

(*) La fonction “minuter arrêt automatique” retarde l’arrêt de la hotte, qui continuera de

fonctionner à la vitesse de service en cours au moment de l’activation de cette fonction,

pendant 15 minutes.

t 4BUVSBUJPOöMUSFTBOUJHSBTDIBSCPOBDUJG

- Quand la touche A se met à clignoter par intervalles de 2 secondes, il est temps de laver

les ltres anti-gras.

- Quand la touche A se met à clignoter par intervalles de 0,5 secondes, il est temps de

changer les ltres à charbon.

Après avoir remis le ltre propre à sa place, procéder à une remise à zéro la mémoire électronique en appuyant 5 secondes de suite sur la touche A jusqu’à ce que cette dernière

cesse de clignoter.

- 50 -

MANTENANCE

tIl est conseillé de mettre en service la hotte

quelques minutes avant de commencer à

cuisiner. De même il est conseillé de l’arrêter 15 minutes après avoir terminé la cuisson pour éliminer au maximum les odeurs

et évacuer l’air vicié.Le bon fonctionnement

de la hotte est lié à la fréquence des opérations d’entretien et, plus particulièrement,

à l’entretien du ltre anti-graisse et du ltre

à charbon actif.

t-FöMUSFBOUJHSBJTTFa pour rôle de retenir

les particules grasses en suspension dans

l’air. Il peut donc se boucher plus ou moins

rapidement selon la fréquence d’utilisation

de la hotte. Nettoyer fréquemment les

ltres de la graisse à l’aide d’une solution

détergente. Les ltres de la graisse peuvent être lavés dans le lave-vaisselle.

t-PTöMUSPTEFDBSCØ

- Pour prévenir tout risque d’incendie, il faut laver les ltres anti-graisse au moins tous

les 2 mois, ces derniers son lavables même au lave-vaisselle.

- Après plusieurs lavages, ils peuvent changer de couleur. Ceci ne donne pas droit à

réclamation ni droit, par conséquent, à leur remplacement.

Le non-respect des consignes de remplacement et de lavage peut entraîner un risque

d’incendie des ltres anti-graisse.

t-FTöMUSFTËDIBSCPOBDUJG servent à ltrer l’air qui est ensuite renvoyé dans la pièce.

Les ltres ne sont ni lavables ni régénérables, il faut par conséquent les changer au moins

tous les quatre mois.

La saturation du charbon actif dépend de l’utilisation plus ou moins prolongée de l’appareil, du type de cuisine pratiquée et de la régularité du nettoyage du ltre anti-graisse.

tNettoyez fréquemment la hotte, à l’intérieur et à l’extérieur, à l’aide d’un chion imbibé

d’alcool dénaturé ou de détergents liquides neutres non abrasifs.

tN’utiliser l’éclairage de la hotte que pendant la cuisson, ce dernier n’est en eet pas conçu

pour un éclairage général prolongé de la pièce. Une utilisation prolongée de l’éclairage

diminue considérablement la durée de vie moyenne des lampes.

t/FUUPZBHFEFMBIPUUF

l’acier inox est l’un des matériaux les plus faciles à nettoyer. Un entretien régulier permettra

de garder l’acier inox en bon état.

Suggestions pour le nettoyage :

- il suffit d’utiliser de l’eau chaude avec du savon ou du détergent.

- Après avoir nettoyé, rincer avec de l’eau. Essuyer avec un chiffon sec et propre pour le

rendre brillant.

- En cas de décolorations ou de graisse, utiliser un détergent domestique non abrasif ou

une poudre pour l’acier avec un peu d’eau et un chiffon doux.

- En cas de saleté incrustée, utiliser un racloir en plastique ou une brosse souple avec du

Fig.9

1

2

G

- 51 -

détergent et de l’eau. Frotter légèrement en direction des lignes du poli ou du “grain” de

la finition en acier inox. Ne pas trop gratter pour ne pas endommager la surface.

- NE PAS laisser les dépôts pendant trop longtemps sur la hotte.

- NE PAS utiliser de tampons à récurer ou de brosse en acier. Sur la surface des particules

en acier pourraient adhérer et former, par conséquent, de la rouille.

- NE PAS laisser des solutions salines, des désinfectants, de la javelle ou des détergents

en contact avec l’acier inox pendant une durée excessivement longue. Certains de ces

produits contiennent des substances chimiques qui pourraient être nuisibles. Rincer avec

de l’eau et essuyer avec un chiffon propre.

Les surfaces vernies doivent être nettoyées avec de l’eau chaude et un détergent neutre.

t3FNQMBDFNFOUEFTQBOOFBVYBMVNJOJVN

Pour remplacer les panneaux aluminium, il sut de tirer sur la poignée G comme illustré

Fig.9.

- 52 -

t3FNQMBDFNFOUEFTMBNQFTIBMPHÒOFT

Pour le remplacement des lampes dichroiques, tourner la lampe dans le sens

antihoiraire à l'aide d' une ventouse

comme représenté sur la gure.

Remplacez-les par des ampoules de même

type.

- 53 -

XOC24SMUA - XOC30SMUA - XOC36S - XOC30S:

530

173

110

261

39

160

- 54 -

70

609

40

140

OPTIONS ET ACCESSOIRES:

Kit filtre de recirculation sans tuyaux modèle XORFRND

Kit filtre de recirculation sans tuyaux modèle XORFK12

- 55 -

INSTALLATION PREPARATION:

Vérification du matériel d’installation:

Inspectez le paquet de l’appareil emballé avec la hotte et vérifiez le contenu.

TYPE DESCRIPTION N°

1/4"

A

1/8" x 1/4" 3

6/16"

B

3/16" x 9/16" 4

Étriers de réglage Filtre en aluminium

Équipement étriers de xation latéraux au meuble suspendu uniquement pour le

30"

1/4"

1/8" x 1/4" N°4

étriers de fixation

6/16"

latéraux au meuble suspendu N°2

3/16" x 9/16" N°4

- 56 -

Spécifications XOC

Modèle: XOC24SMUA - XOC30SMUA - XOC36S -

XOC30S

Dimensions: 24" - 30" - 36" Profondeur: 11-1/16"

Fonctions et avantages:

Modèle: XOC24SMUA - XOC30SMUA

- La grande vitesse de 395 CFM du souffleur élimine

de façon optimale la fumée, la graisse et les odeurs.

- Commandes électroniques éclairées à 3 vitesses.

Modèle: XOC36S - XOC30S

- La grande vitesse de 395 CFM du souffleur élimine

de façon optimale la fumée, la graisse et les odeurs.

- Commandes électroniques éclairées à 3+1 vitesses.

- Deux lampes halogènes à 50W éclairent très bien

la superficie de cuisson.

- Les filtres d’aluminium résille capturent la fumée

et les particules de graisse dans l’air. Faciles à

démonter, ils peuvent être lavés dans le lavevaisselle.

- Hauteur de montage de la superficie de cuisson

27”-32”.

10-9/16"

11-1/16"

16-15/16"

19-11/16" - 31-1/2"

18-5/8" - 30-7/16"

Ø6"

11-1/16"

9-0/16"

1-9/16"

Tuyaux en option et conditions électriques requises:

- Utiliser des tuyaux de 6 pouces.

- Option sans tuyau pour les applications où les

tuyaux ne sont pas disponibles.

Modèle: XOC24SMUA - XOC30SMUA

- AC 120v-60Hz (3.5 amp).

Modèle: XOC36S - XOC30S

- AC 120v-60Hz (4.35amp).

Options:

- Kit de recirculation en option si la ventilation vers

l’extérieur n’est pas disponible.

Modèle: XORFRND - XORFK12

XO est Exclusivement Distribué par:

Eastern Marketing Corp 24 Eisenhower Parkway Roseland,

New Jersey 07068 800-966-8300

www.easternmarketing.com

1-0/16"

23-9/16" - 29-15/16" - 35-3/8"

www.xoappliace.com

- 57 -

XO Hood Warranty

Para solicitar una intervención en garantía, es necesaria la factura

de compra.

What is covered

What is not covered

Garantía de dos años.

La garantía cubre la reparación y la sustitución gratuita, en su

domicilio, de partes de la campana con defectos que puedan

derivarse de errores de fabricación, durante un período de dos

años a partir de la fecha de compra.

La garantía cubre las compras realizadas para uso doméstico en

América del Norte.

Si necesita asistencia para su producto XO, llame al número

800.966.8300

Instalación incorrecta.

Visitas a domicilio para recomendaciones sobre el uso del

producto.

Reset de interruptores.

Daños causados después de la entrega.

¿SE ESPERABA MÁS DE UN XO?

Cuando compra un producto XO puede estar seguro de que ha

comprado un producto de alta calidad, innovador y agradable

desde el punto de vista estético, realizado por una empresa

que está siempre cerca de usted.

- 58 -

ESPAÑOL

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

RELATIVAS SOLO AL USO DOMESTICO

E

LEA LAS INSTRUCCIONES COMPLETAMENTE ANTES DE PROCEDER.

IMPORTANTE: Guarde las Instrucciones de uso de los Inspectores Eléctricos Locales.

PARA EL INSTALADOR: Deje las Instrucciones en la unidad de uso del proprietario.

PARA EL PROPIETARIO: Guarde las instrucciones para consultas futuras.

Preste máxima atención durante el uso de productos de limpieza o detergentes.

Aparato adapto para uso doméstico y culinario.

ADVERTENCIA – Para reducir el riesgo de incendio o de sacudida eléctrica, no use el

motor junto con ningún Dispositivo de Control de Velocidad con Semiconductores.

ATENCION – Para reducir el riesgo de incendio y aspirar correctamente el aire,

asegúrese que esta última sea transportada al externo a través de un conducto de

evacuación. – No descargue el aire en paredes dobles entre paredes o techos o en

desvanes, espacios angostos o garajes.

ATENCION – Usar sólo para una ventilación general. No es adapto para aspirar

materiales o vapores peligrosos o explosivos.

ATENCION – Para evitar daños al motor y rumores, y/o hélices desbalanceadas, evite

que la unidad de alimentación llegue a contacto con esprays, polvo, etc.

ATENCION – Para ulterior información y pedidos, lea la etiqueta de especicación del

producto.

ADVERTENCIA – PARA REDUCIR EL RIESGO DE INCENDIO, SACUDIDA ELECTRICA O

SDAÑOS A PERSONAS, SIGA LAS SIGUIENTES PAUTAS:

A. Use la unidad sólo para nalidades previstas por el fabricante. Para eventuales

preguntas, contacte el fabricante.

B. Antes de efectuar operaciones de mantención o limpieza a la unidad, desconecte la

corriente del panel de servicio y cierre con llave los comandos de desconexión para

evitar que se encienda accidentalmente la corriente de alimentación.

Si los comandos de desconexión no pueden ser cerrados con llave, je rmemente

un aviso de peligro que sea evidente al panel de servicio, como una placa por ejemplo.

ADVERTENCIA – PARA REDUCIR EL RIESGO QUE LA GRASA DE LA SUPERFICIE

DEL HORNO SE INCENDIE:

A. Nunca deje ollas en la supercie del horno en posición alta sin supervisión. Eventua

les desbordamientos por el hervor pueden causar humo y rebalses de grasa que pue

den encenderse. Caliente el aceite lentamente en posición baja o media.

- 59 -

B. ENCIENDA siempre la campana cuando cocine a temperaturas elevadas o cuando

amee los alimentos (ej. Crêpes Suzette, Cherries Jubilee, cerezas ameadas con

brandy y helado -, Carne de buey ameada a la pimienta).

C. Encienda frecuentemente el motor. Evite que la grasa se acumule en el motor o en el

ltro.

D. Use cazuelas de dimensiones adaptas. Siempre utilize utensilios de cocina idóneos a

la dimensión de la olla que se encuentra sobre la supercie del horno.

E. Mantenga limpio el motor, los ltros y la supercie donde se acumula la grasa.

F. Use el horno en posición alta sólo cuando sea necesario. Caliente el aceite lentamen-

te en posición baja o media.

G. No deje nunca el horno sin supervisión durante la cocción.

H. Use siempre utensilios y herramientas de cocina adaptos al tipo y a la cantidad de

comida que esté preparando.

ADVERTENCIA – PARA REDUCIR EL RIESGO DE DAÑOS A PERSONAS EN CASO QUE SE

ENCIENDA LA GRASA DE LA SUPERFICIE DEL HORNO, SIGA LAS SIGUIENTES PAUTASa:

A. SOFOQUE LAS LLAMAS con una tapa hermética, una losa de horno o una bandeja

metálica y luego apague el quemador. PRESTE MUCHA ATENCION DURANTE

ESTA OPERACION PARA EVITAR QUEMADURAS. Si las llamas no se extinguen

inmediatamente, EVACUE EL LUGAR Y LLAME A LOS BOMBEROS.

B. NO TOQUE NUNCA UNA CAZUELA HIRVIENTE – se puede quemar.

C. NO USE AGUA, inclusive estropajos o toallas húmedas – se produciría una violenta

explosión de vapor.

D. Use un extinguidor SOLO en caso que:

1. Se tenga un extinguidor de Clase ABC y sepa utilizarlo.

2. Sea un incendio de dimensiones pequeñas y contenido en el área en la cual ha

estallado.

3. Ya hayan sido llamados los bomberos.

4. Se puedan afrontar las llamas con la espalda dirigida hacia una salida.

aBasado en las “medidas sobre seguridad antiincendio en la cocina” publicadas por el

NFPA.

Una correcta mantención de la campana garantiza un funcionamiento perfecto de

la unidad.

INSTRUCCIONES PARA LA INSTALACION

ADVERTENCIA – PARA REDUCIR EL RIESGO DE INCENDIO, SACUDIDA ELECTRICA O

DAÑOS A PERSONAS, SIGA LAS SIGUIENTES PAUTAS:

A. Las operaciones de instalación y conexión eléctrica deben ser efectuadas por

personal calicado, conforme con las leyes y normativas en vigor, incluyendo las de

aparatos de fuego.

B. Es necesario tener una cantidad de aire suciente para obtener una combustión

y aspiración del gas correcta a través del humero de la planta de combustión del

carburante, para evitar un tiro del del aire en la parte posterior. Sega las indicaciones

- 60 -

del fabricante de la planta de calefacción y las relativas normas de seguridad, como

las emitidas por la Asociación Nacional de Protección contra Incendios (National Fire

Protection Association - NFPA), por la Sociedad Americana de Técnicos de Calefacción,

Refrigeración y Aire Acondicionado (American Society for Heating, Refrigeration and

Air Conditioning Engineers - ASHRAE) y por las autoridades de códigos locales.

C. Cuando corte o taladre en la pared o el techo, no dañe el cableado eléctrico ni otras

utilidades escondidas.

D. El aparato debe estar siempre conectado a un agujero de evacuación hacia el exterior.

E. La unidad deber ser conectada al suelo.

ADVERTENCIA – PARA REDUCIR EL RIESGO DE INCENDIO, USE SOLO TUBERIAS

METALICAS.

ADVERTENCIA – EN CIERTOS CASOS LOS ELECTRODOMESTICOS PUEDEN REVELARSE

PELIGROSOS.

A. No controle los ltros mientras la campana se encuentre en función.

B. No toque las luces después de un uso prolungado del aparato.

C. Nunca amee un alimento bajo la campana.

D. El uso de llamas libres es peligroso para los ltros y puede generar incendios.

E. Controle constantemente los alimentos fritos para evitar que los chorros del aceite

de la fritura puedan incendiarse.

F. Antes de efectuar cualquier operación de mantención, desconecte la campana de la

red eléctrica.

El fabricante no será responsable por eventuales daños causados por la falta de

observación de las instrucciones citadas arriba.

- 61 -

ACCESORIOS

PAR

CONDUCTOS:

Esta campana debe

usar un conducto

redondo de 8". Puede

cambiar a un conducto

de 3-1/4" x 12".

Utilice esta tabla para calcular las longitudes máximas permitidas para recorridos de conductos hacia el

exterior.

Pieza del

ducto:

Dimensiones:

Circular, recta.

3-1/4" x 12"

recta.

Codo de 90° 17 pies

Codo de 45° 10 pies

Longitud

Equivalente*:

1 pie recto

(por longitud

de pie)

1 pie recto

(por longitud

de pie)

Cantidad

utilizada:

Longitud

Equivalente

Total:

NOTA: ¡No supere las longi-

Preparación para la instalación

tudes equivalentes máxima

permitidas!

Longitud máxima del

ducto: 100 pies para cam-

panas para estufas.

Conductos flexibles:

Si se utilizan conductos

flexibles de metal, todos

los valores equivalentes

en pies de la tabla deben

duplicarse. El conducto

flexible de metal debe ser

recto y liso y debe exten-

derse lo máximo posible.

NO USE conductos flexibles

de plástico.

NOTA: Cualquier sistema

de ventilación doméstico,

como una campana de ventilación, puede interrumpir

el flujo adecuado de aire

de combustión y de escape

requerido para chimeneas,

hornos a gas, calentadores

de agua a gas y otros sistemas de ventilación natural.

Para minimizar las posibilidades de interrupción de

tales sistemas de ventilación

natural, siga las pautas y

normas de seguridad del

fabricante del equipamiento

de calefacción, tales como

las publicadas por NFPA.

Codo de 90°

de 3-1/4" x 12"

Codo de 45°

de 3-1/4" x 12"

Codo plano de

90° de 3-1/4"

x 12"

Circular de 8"

a 3-1/4" x 12"

nsición

Transición

3-1/4" x 12"

a circular de 8”

Codo de 90°

de transición

circular 8" a

3-1/4" x 12"

Codo de 90°

de transición

de 3-1/4" x

12" a circular

de 8"

Tapa de pared

circular con

regulador de

tiro

Tapa de pared

de 3-1/4" x 12"

con regulador

de tiro

Tapa de techo

circular

*Longitud real del conducto recto más

equivalente de accesorio del conducto. La

longitud equivalente de los conductos se

encuentra basada en pruebas reales lasque

reflejan los requisitos para un buen desempeño

de ventilación con cualquier campana de

ventilación.

43 pies

26 pies

102 pies

2 pies

5 pies

6 pies

13 pies

32 pies

75 pies

44 pies

Recorrido total de los

conductos =

- 62 -

ADVERTENCIA: PELIGRO DE INCENDIO

NO instale NUNCA el conducto con la descarga de aire colocada en la escotadura

de paredes, en pavimentos ventilados, áticos o garajes.

El aire se debe descargar hacia afuera salvo cuando se utiliza la opción de la

recirculación.

Utilice exclusivamente los conductos de metal rígido de pared simple.

Realice todas las conexiones utilizando los tornillos autorroscantes y aplique una

cinta americana certicada en todas las juntas.

Instalación – Opciones De Aspiración

INSTALACIÓN DE LA TUBERÍA:

NOTA: para reducir el riesgo de incendio, utilice solo tuberías de metal.

1. Decida la posición del tubo entre la campana y el exterior.

2. Un tubo corto y recto mejora los rendimientos de la campana.

3. Los tubos largos, codos y racores reducen los rendimientos. Utilice el menor

número posible de estos elementos.

4. Instale un sombrerete de techo o de pared. Conecte un tubo circular metálico

en el sombrerete y continúe hacia la campana (desde arriba hacia abajo). Utilice

una cinta aislante para tubos para sellar las junturas entre las varias secciones.

- 63 -

DIMENSIONES DEL PRODUCTO Y DISTANCIAS

XOC24SMUA - XOC30SMUA - XOC36S - XOC30S

:

Parte frontal de la campana Parte lateral de la campana

18-5/8" (24" - 30")

30-7/16" (36")

Especicaciones Técnicas

23-9/16" (24") - 29-15/16" (30") - 35-3/8" (36")

9"

12-1/8"

1-9/16"

11-1/16"

1-3/16"

16-15/16"

L

min 0 - 0/16" - max 1 - 4/16"

min 0 - 0/16" - max 1 - /4"

Parte superior de la campana Altura de montaje

19-11/16" (24")

31-1/2" (36")

Ø 6"

19-11/16" (30")

3-13/16"

3-13/16"

1-15/16" (24"-36")

1-11/16"

2-9/16"

5-1/8"

1-11/16"

5-1/8" (30")

1-11/16"

2-9/16"

11-1/16"

y distancias:

Min 27" - Max 32"

Fig.1

Ø 6"

- 64 -

5-1/8"

1-11/16"

36"

11-1/16"

INSTRUCCIONES PARA LA INSTALACIÓN

INSTALACIÓN CON DESCARGA AL AIRE LIBRE

Antes de efectuar las operaciones de montaje y para que sea más fácil maniobrar

el aparato, quite el/los filtro/s antigrasa

(Fig.3).

Este producto se puede instalar de 3 maneras diferentes según sea el modelo o

sus exigencias:

1- montaje de la campana en la parte

inferior del mueble de pared.

2- Montaje de la campana en la parte

inferior del mueble de pared, sobre un

soporte divisorio.

3- Montaje de la campana en la parte inferior del mueble de pared sólo para el 30".

Fig.2

11-1/4"

19-15/16"

31-3/4"

Fig.3

1

2

- 65 -

1

24" - 36" - 30"

B

A

3

4

2

Min 0-1/2"

Max 1/016"

2

2

1

F

F

M

Fig.4

1. MONTAJE DE LA CAMPANA EN LA PARTE INFERIOR DEL MUEBLE COLGANTE:

Para realizar un montaje correcto, efectúe las siguientes fases:

1 - Coloque la plantilla B sobre el mueble de pared, teniendo en cuenta las medidas

indicadas en la fig. 1-2 y la distancia mínima desde la encimera de cocción.

- Marque las referencias para la fijación de los estribos A en el mueble, tal como se indica

en la figura 4.

2 - Preste atención en que el grosor del mueble no supere las cotas indicadas en la figura

4 -fase 2.

3 - Empotre la campana en el mueble y asegúrese de que los 2 muelles laterales F estén

bien enganchados, fije definitivamente la campana al mueble, usando un destornillador

para atornillar los correspondientes tornillos M hasta que el aparato se acople totalmente

al mueble, figura 4 -fase 2.

4 - Tome el estribo A y quite el perno Y, a continuación, tome el inserto X y colóquelo en

el orificio alargado del estribo A tal como se indica en la figura 4 - fase 3.

- 66 -

3

3.3

C

L

3.1

C

Y

D

X

L

C

A

Y

X

3.2

3.2

3.3

3.3

D

- Acoplar el tornillo C con la arandela L j fijar el estribo A al cuerpo como se indica en

la figura 4 - fase 3.1. Ponga atención en no apretar completamente el tornillo C, antes

habrá que apoyar completamente el estribo al mueble, figura 4 - fase 3.2, tras lo cual fije

definitivamente el estribo al bastidor, figura 4 - fase 3.3.

- Tome el tornillo D y fíjelo al mueble, tal como se indica en la figura 4.

- Una vez fijada la campana al mueble, regule el separador L, mediante los tornillos P, para

que el aparato se alinee con el mueble por la parte trasera, figura 4 - fase 5.

4

D

P

L

P

5

IMPORTANTE: la campana se debe jar a la pared con pernos roscados o tacos

con capacidad para 75 libras.

- 67 -

2. MONTAJE DE LA CAMPANA EN LA PARTE INFERIOR DEL MUEBLE SOBRE EL PANEL

DIVISORIO.