Page 1

XO FLEX

INSTRUCTIONS

FOR USE

Page 2

XO FLEX – Instructions for use

2

Page 3

XO FLEX – Instructions for use Table of contents

CONTENTS

1 EXTRAORDINARY DENTISTRY ....................................................................................................... 7

2 Installation ........................................................................................................................................ 8

3 Operation ....................................................................................................................................... 11

3.1 General .................................................................................................................................... 11

3.2 Switch the unit on ................................................................................................................... 12

3.3 Instrument bridge in parking position ..................................................................................... 13

3.4 Foot control ............................................................................................................................. 13

Function ............................................................................................................................ 13

Position the foot control ................................................................................................... 14

3.5 XO SMART LINK ..................................................................................................................... 15

3.6 Patient chair ............................................................................................................................ 15

Foot control of patient chair ............................................................................................. 15

Smaller adjustments of patient chair ................................................................................ 15

Safety ............................................................................................................................... 16

Supine patient position ..................................................................................................... 16

Neck rest .......................................................................................................................... 16

Child cushion .................................................................................................................... 17

3.7 Instrument bridge in working position ..................................................................................... 17

Balanced instruments ....................................................................................................... 17

Four-handed or solo work ................................................................................................ 18

Working positions ............................................................................................................. 18

3.8 Instrument control ................................................................................................................... 21

Foot control of instruments .............................................................................................. 21

Instruments on the instrument bridge .............................................................................. 21

Instrument bridge display ................................................................................................. 21

3.9 Syringe – Luzzani .................................................................................................................... 22

3.10 Micromotor – Bien-Air MC3 / Bien-Air MX2 .......................................................................... 22

3.11 XO OSSEO motor ................................................................................................................. 23

Set-up ............................................................................................................................. 23

Operation ........................................................................................................................ 24

Implant surgery - operation with XO Smart Link ............................................................ 25

3.12 Air instrument ........................................................................................................................ 25

3.13 Ultrasonic scalers .................................................................................................................. 26

3.14 XO ODONTOSON 360 ultrasonic scaler ............................................................................... 27

How to use XO ODONTOSON 360 ................................................................................ 28

Changing the instrument ................................................................................................ 29

XO ODONTOSON 360 with antimicrobials and sterile saline ......................................... 30

3.15 XO ODONTOCURE curing light ............................................................................................ 30

3.16 XO Peristaltic Pump .............................................................................................................. 32

Disposable irrigation kit .................................................................................................. 32

Attaching the pump module ........................................................................................... 33

Attaching the irrigation tube ........................................................................................... 33

3

Page 4

XO FLEX – Instructions for use Table of contents

Irrigation bag .................................................................................................................. 35

Irrigation reservoir ........................................................................................................... 35

Designation of instrument .............................................................................................. 36

Adjusting the flow level ................................................................................................... 37

3.17 Intraoral HD video camera .................................................................................................... 37

3.18 Operating Light ..................................................................................................................... 38

Position the light ............................................................................................................. 38

Switch the light on and adjust the light intensity ............................................................ 39

Automatic functions ....................................................................................................... 40

3.19 XO HD Display ...................................................................................................................... 40

3.20 Hand instruments .................................................................................................................. 41

3.21 Suction .................................................................................................................................. 42

3.22 Cuspidor and cup filler .......................................................................................................... 42

Automatic function ......................................................................................................... 43

3.23 Assistant call ......................................................................................................................... 43

3.24 Sound generator and sounds ............................................................................................... 44

3.25 System messages ................................................................................................................. 44

3.26 XO SEAT and XO STOOL ...................................................................................................... 44

XO SEAT ......................................................................................................................... 45

XO STOOL ...................................................................................................................... 46

4 Configuration ................................................................................................................................. 48

4.1 Configuration of patient chair positions .................................................................................. 48

4.2 Configuration of general unit and patient chair functions ....................................................... 48

4.3 Configuration of unit instruments ............................................................................................ 49

5 Cleaning and infection control ....................................................................................................... 53

5.1 Cleaning, disinfection and sterilization procedures ................................................................ 53

5.2 Detergents and disinfectants for cleaning and/or disinfection of the unit .............................. 53

5.3 General cleaning of unit and patient chair surfaces ................................................................ 53

5.4 Cleaning of Comfort and skai fabric ....................................................................................... 54

5.5 General disinfection of unit surfaces ....................................................................................... 54

5.6 Infection control instrument and bridge protection pad ......................................................... 54

5.7 Autoclaving handles ................................................................................................................ 54

5.8 Disinfection of instrument hoses and suspensions................................................................. 55

5.9 Infection control Luzzani syringe ............................................................................................ 56

5.10 Infection control Bien-Air micromotors ................................................................................. 56

5.11 Autoclaving of XO OSSEO motor.......................................................................................... 56

5.12 Infection control XO ODONTOSON 360 ............................................................................... 57

5.13 Infection control XO ODONTOCURE curing light ................................................................. 57

5.14 Infection control other instruments ....................................................................................... 58

5.15 Infection control XO Peristaltic Pump ................................................................................... 58

5.16 Disinfection of light................................................................................................................ 58

5.17 Infection control XO HD Display ........................................................................................... 59

Front panel ..................................................................................................................... 59

5.18 Disinfection of cuspidor bowl and cup holder ...................................................................... 59

5.19 Disinfection of suction lines .................................................................................................. 60

General ........................................................................................................................... 60

4

Page 5

XO FLEX – Instructions for use Table of contents

Suction filters .................................................................................................................. 61

Replacement of XO Suction Disinfection cartridge ........................................................ 62

5.20 Disinfection of unit water lines .............................................................................................. 63

Overnight water treatment .............................................................................................. 63

Intensive water treatment ............................................................................................... 64

Replacement of XO Water Clean cartridge .................................................................... 64

6 Maintenance and repairs ............................................................................................................... 66

6.1 Foot control ............................................................................................................................. 66

6.2 XO OSSEO motor ................................................................................................................... 66

Motor repair ...................................................................................................................... 66

6.3 XO ODONTOSON ................................................................................................................... 66

Handpiece repair .............................................................................................................. 66

Tightening / exchanging the ferrite rod ............................................................................ 66

6.4 XO ODONTOCURE ................................................................................................................. 67

Handpiece repair .............................................................................................................. 67

Manual measurement of curing effectiveness .................................................................. 67

6.5 XO Peristaltic Pump ................................................................................................................ 69

6.6 Adjustment of the hand instrument table ................................................................................ 69

6.7 Control of the water disinfection system ................................................................................ 69

6.8 Maintenance and replacement of main filter for water supply ................................................ 70

6.9 Cuspidor valve – cleaning the course filter ............................................................................. 70

6.10 Flushing of cuspidor drain..................................................................................................... 70

6.11 Suction hoses ....................................................................................................................... 70

6.12 Air and Amalgam separator .................................................................................................. 71

Dürr CS1 Combi-Sepamatic – Air separator .................................................................. 71

Dürr CAS 1 Combi-Separator – Air and amalgam separator ......................................... 71

7 Unit messages and remedial actions ............................................................................................. 72

7.1 Error messages ....................................................................................................................... 72

7.2 Service messages and remedial actions ................................................................................. 73

8 Preventive service, safety inspections and repairs ........................................................................ 74

8.1 General .................................................................................................................................... 74

8.2 Preventive service and safety inspection ................................................................................ 74

Preventive service and safety inspection A – 12, 36 etc. months after installation .......... 74

Preventive service and safety inspection B – 24, 48 etc. months after installation ......... 74

Service notification ........................................................................................................... 74

8.3 Adjustment of the arm systems .............................................................................................. 75

8.4 Adjustment of balanced instrument suspension arms ............................................................ 75

8.5 Replacement of operating light source ................................................................................... 75

8.6 XO HD Display ........................................................................................................................ 75

9 Infection control and maintenance checklist ................................................................................. 76

10 Accessories, detachable parts and consumables ....................................................................... 78

10.1 Accessories ........................................................................................................................... 78

10.2 Detachable parts ................................................................................................................... 78

10.3 Consumables ........................................................................................................................ 79

5

Page 6

XO FLEX – Instructions for use Table of contents

10.4 Suggested retail prices ......................................................................................................... 80

11 Legal ............................................................................................................................................ 81

11.1 Modification of the equipment .............................................................................................. 81

11.2 Warrantee .............................................................................................................................. 81

11.3 Expected Service Life ........................................................................................................... 81

11.4 3

rd

Party instruments and accessories .................................................................................. 82

11.5 Product updates ................................................................................................................... 82

11.6 Firmware version ................................................................................................................... 82

11.7 Applicable standards ............................................................................................................ 82

11.8 Electromagnetic emission ..................................................................................................... 82

11.9 Interference Immunity ........................................................................................................... 83

11.10 Classification ....................................................................................................................... 84

11.11 Applied parts ....................................................................................................................... 84

11.12 Marking plate ...................................................................................................................... 84

11.13 Other labels ......................................................................................................................... 85

11.14 Product disposal information .............................................................................................. 85

12 Symbols ....................................................................................................................................... 86

13 Dimensions and technical data ................................................................................................... 89

13.1 Dimensions and range of movement .................................................................................... 89

13.2 Technical specifications ........................................................................................................ 90

14 XO FLEX Quick Guide .................................................................................................................. 93

6

Page 7

XO FLEX – Instructions for use EXTRAORDINARY DENTISTRY

XO FLEX must be inspected and serviced every 12 months by an XO authorized

XO CARE and the XO authorized service provider offer 36 months warranty on XO

1 EXTRAORDINARY DENTISTRY

Dear XO user,

Please read this manual carefully and explore all the equipment’s extraordinary features:

• The unit shall be installed as described in section 2

• In section 3 we describe how you use the equipment for performing extraordinary dentistry

• You may configure the unit to your own personal needs – see details in section 4

• Read details about infection control and cleaning in section 5

• Maintain the unit as described in section 6

• XO FLEX must be inspected and serviced every 12 months by an XO authorized service

provider to ensure safe operation and high uptime – see details in section 8

• In section 9 you find a checklist containing all infection control and maintenance

procedures that must be observed

• Section 10 contains a complete list of accessories, detachable parts and consumables that

you should be aware of

• In section 0 we list important legal information

• Please see section 12 for a list of symbols used and section 13 for technical product details

• Finally, in section 14 you see XO FLEX Quick Guide

Find more information at xo-care.com or contact XO customer service at info@xo-care.com.

Best regards

Kim Sørensen

CEO XO CARE A/S

service provider to ensure safe operation and high uptime.

Authorized service providers are listed under “Distributors” at xo-care.com.

FLEX provided that the unit is serviced as prescribed.

7

Page 8

XO FLEX – Instructions for use Installation

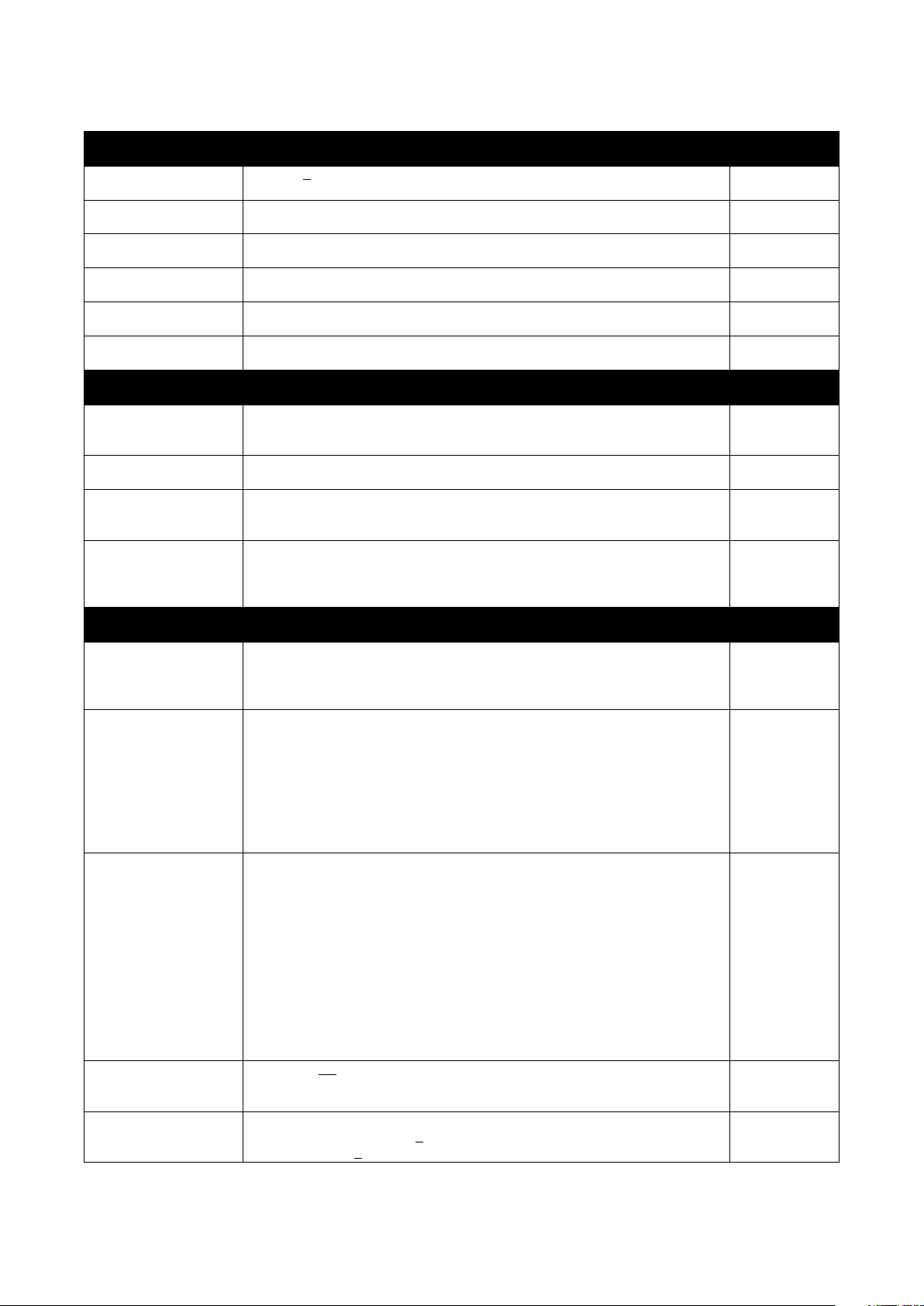

Condition

Operation

Transport and storage

Temperature:

+15oC – +40oC

-40oC – +60oC

Relative humidity:

20% – 85%

10% – 95%

Air pressure:

800 hPa – 1060 hPa

700 hPa – 1060 hPa

Installation altitude

Max. 2,000 meters above sea level

-

2 INSTALLATION

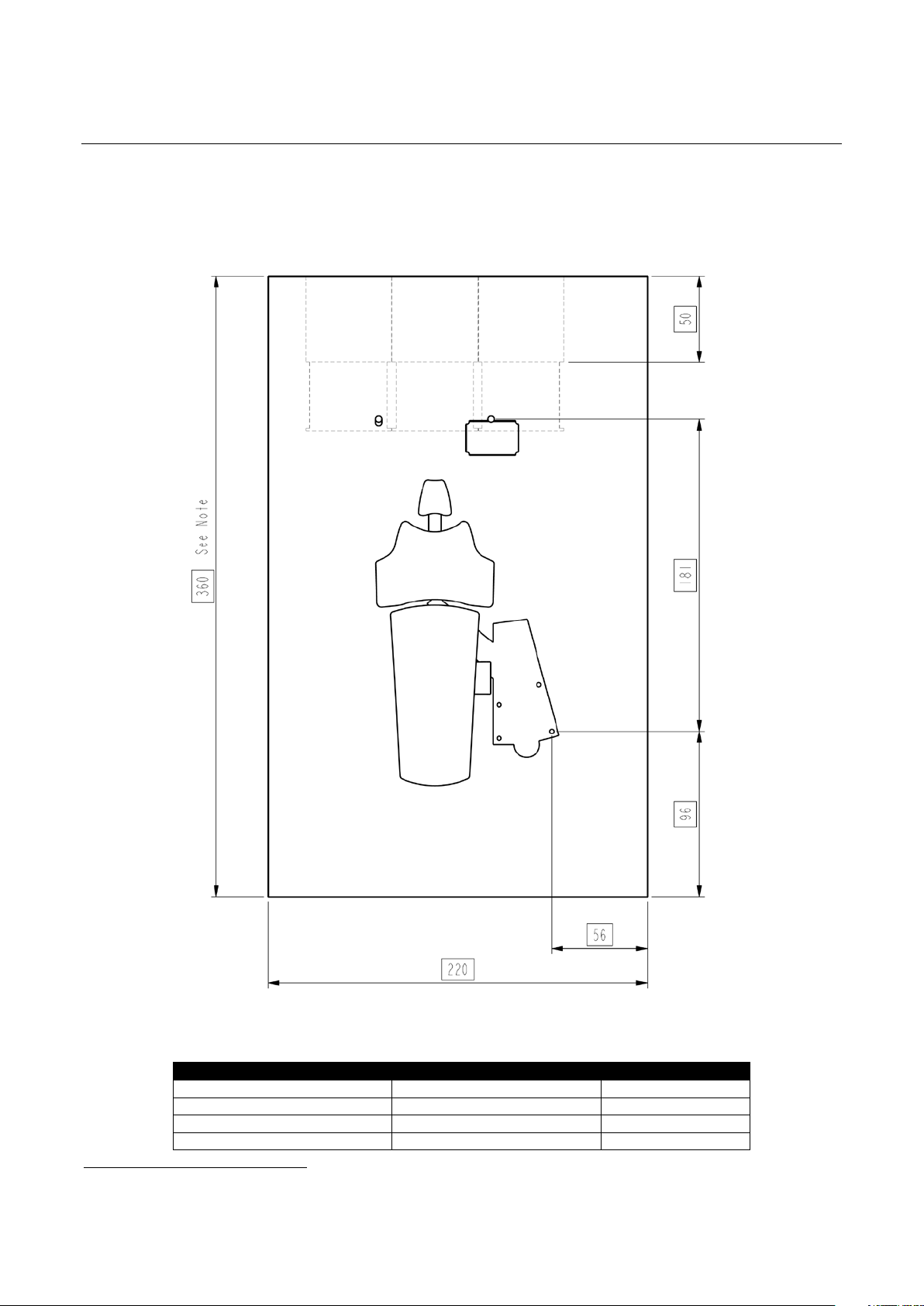

XO FLEX is intended to be permanently installed in a dental operatory at least 220 cm wide and

1

360 cm long

For transport and storage conditions see Table 1 and in Table 2 the installation requirements are

given.

– see Figure 1 and see the required operation conditions in Table 1.

1

Note: This dimension depends on the depth of the cabinets – in the example shown in Figure 1 the cabinets are 50 cm deep

Figure 1 – Plan of installation – XO FLEX

Table 1 – Operating and transport/storage conditions

8

Page 9

XO FLEX – Instructions for use Installation

Electrical

Requirement

Length above

Mains supply

230 VAC + 10%, 50 – 60 Hz with earth min. 3 x 1,5 mm2

75 cm

Equipotential earth (if

1 x 4.0 mm2

Assistant call control

Min. 2 x 0.1 mm2 and max. 2 x 1.25 mm2

75 cm

X-ray unit attached to the

Cable for X-Ray must have its own installations pipe. Cable shall be connected to an

Suction motor control

Min. 2 x 0.1 mm2 and max. 2 x 1.25 mm2

75 cm

Positioning of cables in

See installation drawing YB-235.

Data

Requirement

Length above

Isolation transformer

When connecting the external PC to the unit, the external PC must be equipped with

RS-232 cable

Connect unit and external PC through a RS-232 cable, male/female. The cable’s

70 cm

XO HD Display

Connect XO HD Display and an external PC through a HDMI cable.

10 cm

Intraoral video camera

Connect the intraoral video camera to an external PC through a USB A cable

USB extension

Suction, air and water

Requirement

Height above

Suction

Suction machine power >600 l/min.

Incoming (compressed)

Pipe 3/8” female internal thread – preferably fitted with a ball valve – see YB-235.

7 cm max.

Incoming water

Pipe 3/8” female internal thread – preferably fitted with a ball valve – see YB-235

7 cm max.

Backflow prevention

If the unit is not supplied with “unit backflow water prevention” it must have an

Drain

Plastic pipe Ø 32 mm with socket – see YB-235.

6 cm max.

Table 2 – Installation requirements

floor surface

Main fuse 10 A

required by national law)

cable

XO unit

cable

the floor

Max. 2 A / 60 VDC or 2 A / 25 VAC

installation box in the floor.

Max. 2 A / 60 VDC or 2 A / 25 VAC

a medical grade power supply or be powered via a medical grade isolating

transformer! XO part number: XO-620

male connector to the unit end.

Depending on the environment it might be necessary to use an HDMI amplifier with

the HDMI cable.

male/female. The cable’s female connector is in the unit end.

It is recommended to use a USB Extension 10 m cable with Repeater from Dürr

Dental - part number: 2106-155-60.

Vacuum pressure at the connection point under static conditions: Min = 35 mbar,

Max = 150 mbar.

Plastic pipe Ø 32 mm with socket – see YB-235.

floor surface

cable: 20 cm

floor surface

6 cm max.

air

Incoming air:

• Air pressure 5.5 – 7,5 bar

• Air flow rate > 55 l/min

• Humidity dew point < -20°C at atmospheric pressure

• Oil contamination max. 0.5 mg/m

• Particulate contamination < 100 particles/m

If the incoming air pressure exceeds 7,5 bar a reduction valve must be fitted.

Air quality must be in accordance to local quality of air regulations.

Incoming water:

• Inlet pressure 2.5 – 6 bar

• Water flow rate > 5 l/min

• Water hardness < 2.14 mmol/l (< 12

In case of poorer water quality, water softener should be replaced more often than

the normal recommendation, for example twice a year

• pH: 6.5 – 8.5

• Maximum particle size < 100µm

If the incoming water pressure exceeds 6 bar a reduction valve must be mounted

before the unit.

Water quality must be in accordance to local drinking water regulations.

external backflow prevention device at the connection point with the water supply,

or an air gab of at least 20 mm.

Gradient of waste water lines > 1%

Drainage capacity > 10 l/min

3

3

(particle size 1 – 5 µm

o

dH)

9

Page 10

XO FLEX – Instructions for use Installation

XO FLEX unit must be installed by an XO authorized service provider.

WARNING: To avoid the risk of electric shock, this equipment must be connected to a

When connecting an external PC (including monitor) to the XO FLEX unit, the

Installation instructions for XO FLEX can be downloaded from xo-care.com.

Authorized service providers are listed under “Distributors” at xo-care.com.

supply mains with protective earth.

external equipment must be powered by a medical grade isolating transformer (e.g.

XO part number: XO-620).

The external equipment must also comply with the applicable standards, e.g.:

• IEC 60950-1 (information technology equipment) or IEC 62368-1 (electronic

equipment within the field of audio, video, information and communication

technology), and

• IEC 60601-1 (medical electrical equipment)

When external equipment is connected to the XO FLEX unit to create a medical

electrical system, the requirements of IEC 60601-1, 3

with.

It is the responsibility of the person/organization installing and/or modifying the

equipment to ensure that the system conforms to applicable legislation, e.g.

Directive 93/42/EEC, or Regulation (EU) 2017/745, and the requirements of IEC

60601-1, 3

rd

edition.

rd

edition, must be complied

10

Page 11

XO FLEX – Instructions for use Operation

A complete technical description of XO FLEX is available at xo-care.com.

3 OPERATION

3.1 GENERAL

XO FLEX is a combined dental unit and patient chair which is to be used by skilled dental

operators for prevention and treatment of diseases in the oral cavity of humans.

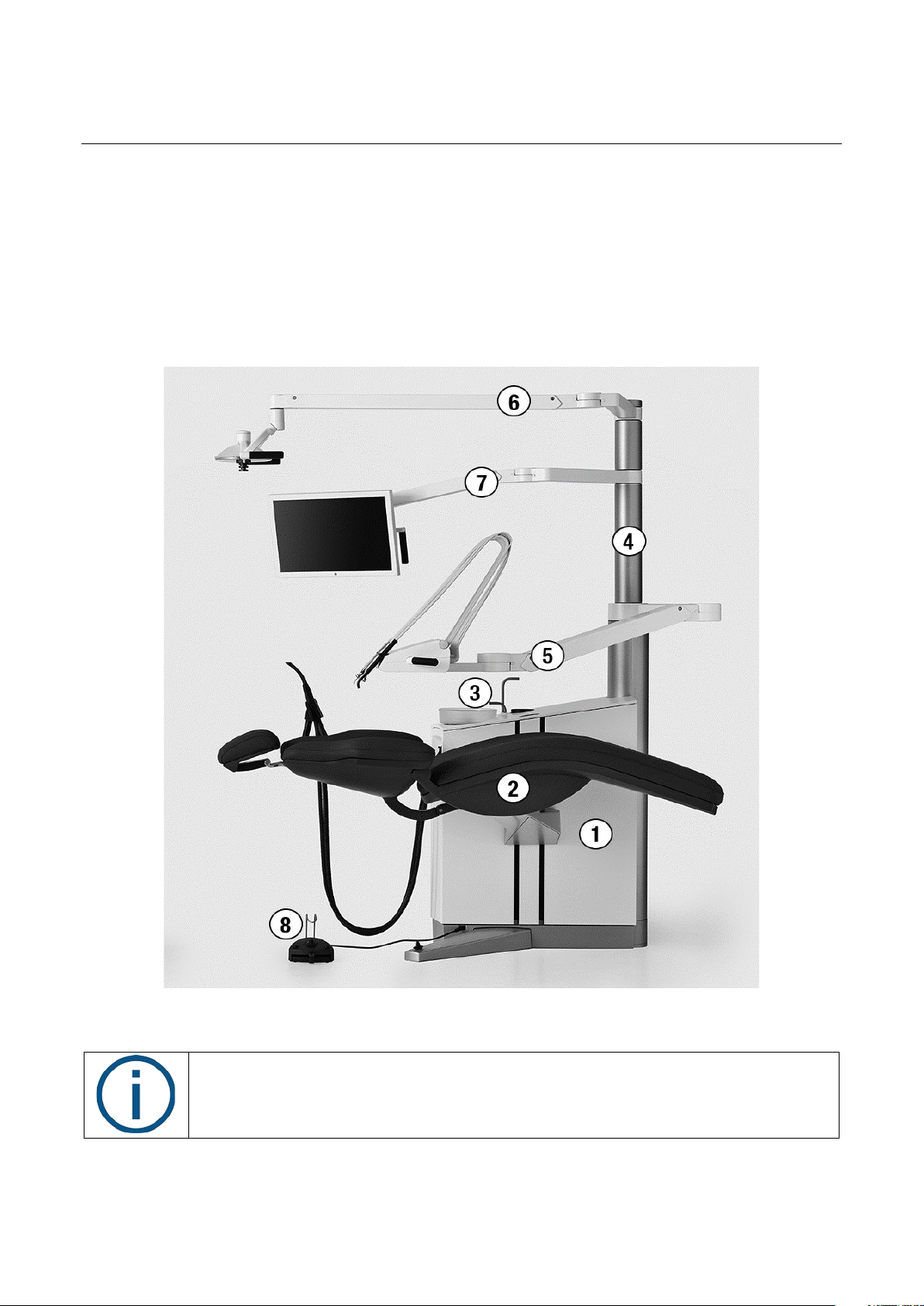

The unit has a compact floor-mounted stand fitted with a patient chair, a cuspidor and singlecolumn pivoting articulated balanced arms for the instrument bridge, operating light and display –

see Figure 2.

Figure 2 – Main XO FLEX elements: (1) unit stand, (2) patient chair, (3) cuspidor and cup filler,

(4) unit column, (5) instrument bridge, (6) operating light, (7) HD Display and (8) foot control

11

Page 12

XO FLEX – Instructions for use Operation

Please note that XO FLEX must be operated in accordance with this manual and by

To avoid injury to persons or material, do not use XO FLEX or its accessories if signs

Do not use XO FLEX in oxygen-rich environments!

Use of other equipment adjacent to or stacked on this equipment should be avoided

Do not simultaneously touch the patient and any external electrical equipment such

Do not simultaneously touch the patient and the connector for peristaltic pump on

dental professionals only!

of operational, electrical or mechanical defects are found.

This equipment does not have a gas sealed electronic enclosure and could ignite any

flammable or explosive gases in its environment.

because it could result in improper operation.

as PCs, monitors, etc.

the rear panel of the unit.

3.2 SWITCH THE UNIT ON

Switch the unit on (and off) using the main switch – see Figure 3.

The unit is ready for use after a few seconds when the text “XO FLEX” is shown on the instrument

bridge display and you hear the welcome tune.

Figure 3 – Main switch (1)

12

Page 13

XO FLEX – Instructions for use Operation

In case of emergency, use this switch to turn off the unit.

Always place the instrument bridge to the left of the unit when the patient is

X

O

3.3 INSTRUMENT BRIDGE IN PARKING POSITION

accessing the chair as shown in Figure 4.

In this position, the patient does not see the instruments when getting in and out of the chair and

the bridge will be easily accessible for cleaning and disinfection.

Figure 4 – Position of instrument bridge for optimal patient access to chair

3.4 FOOT CONTROL

FUNCTION

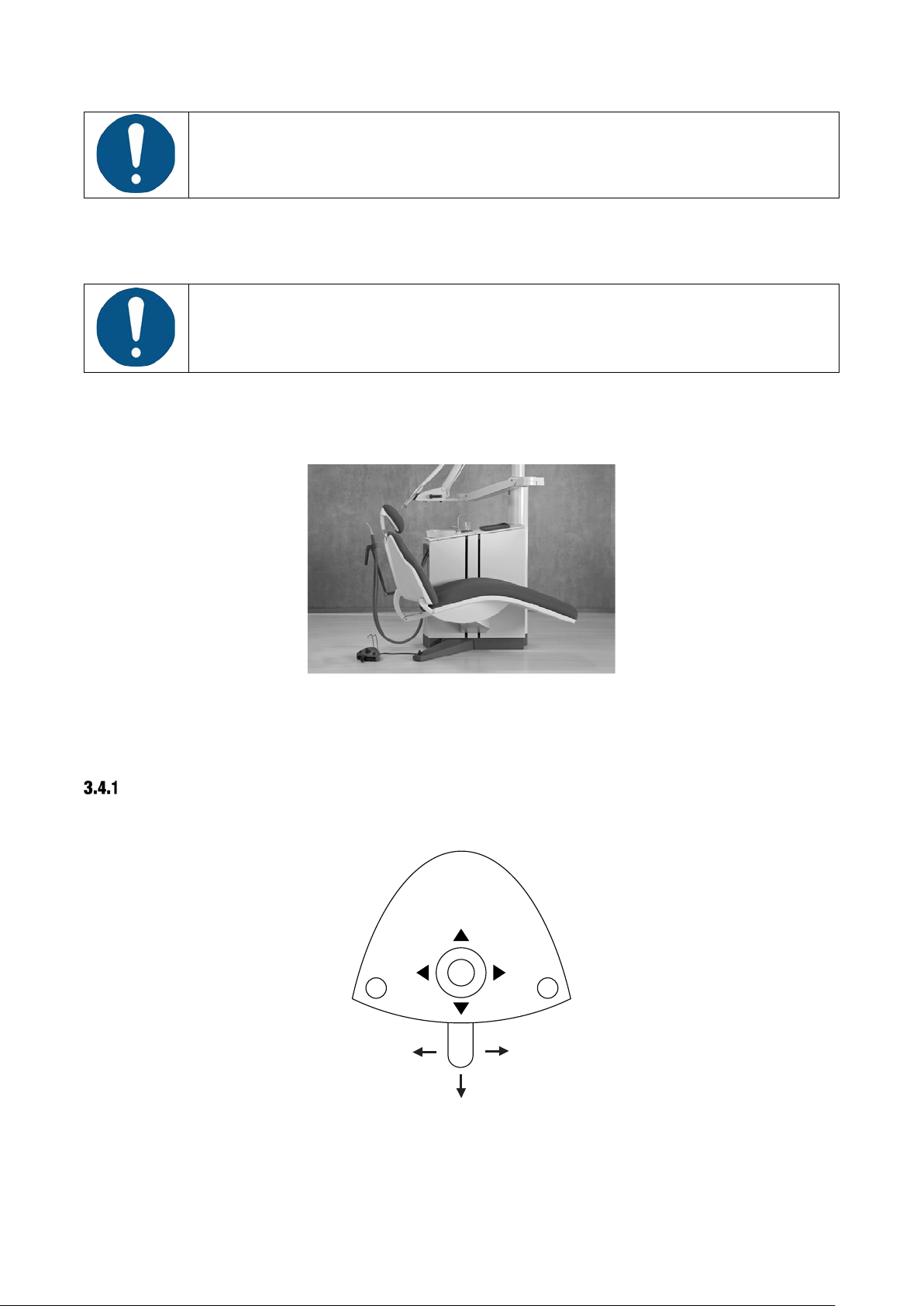

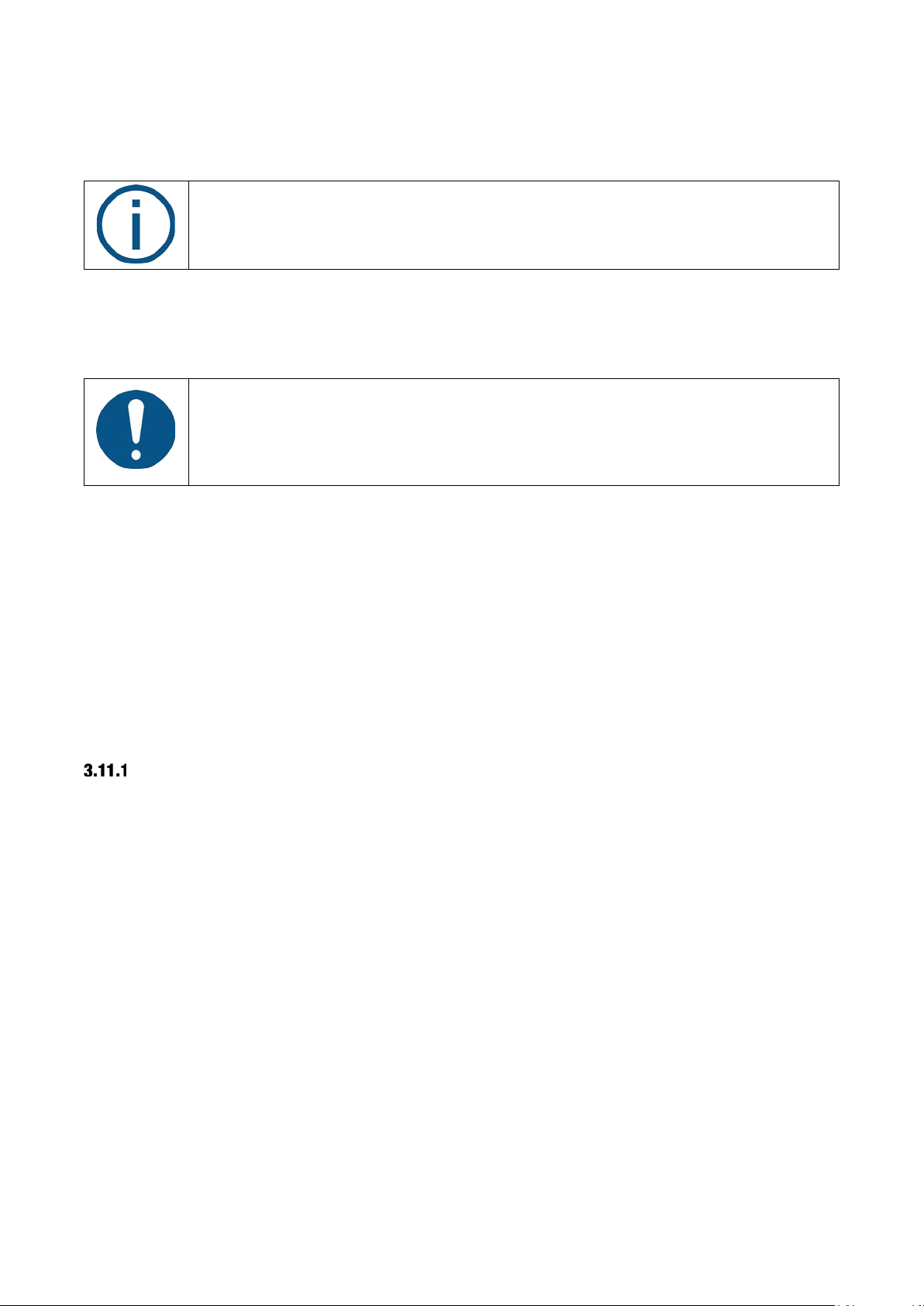

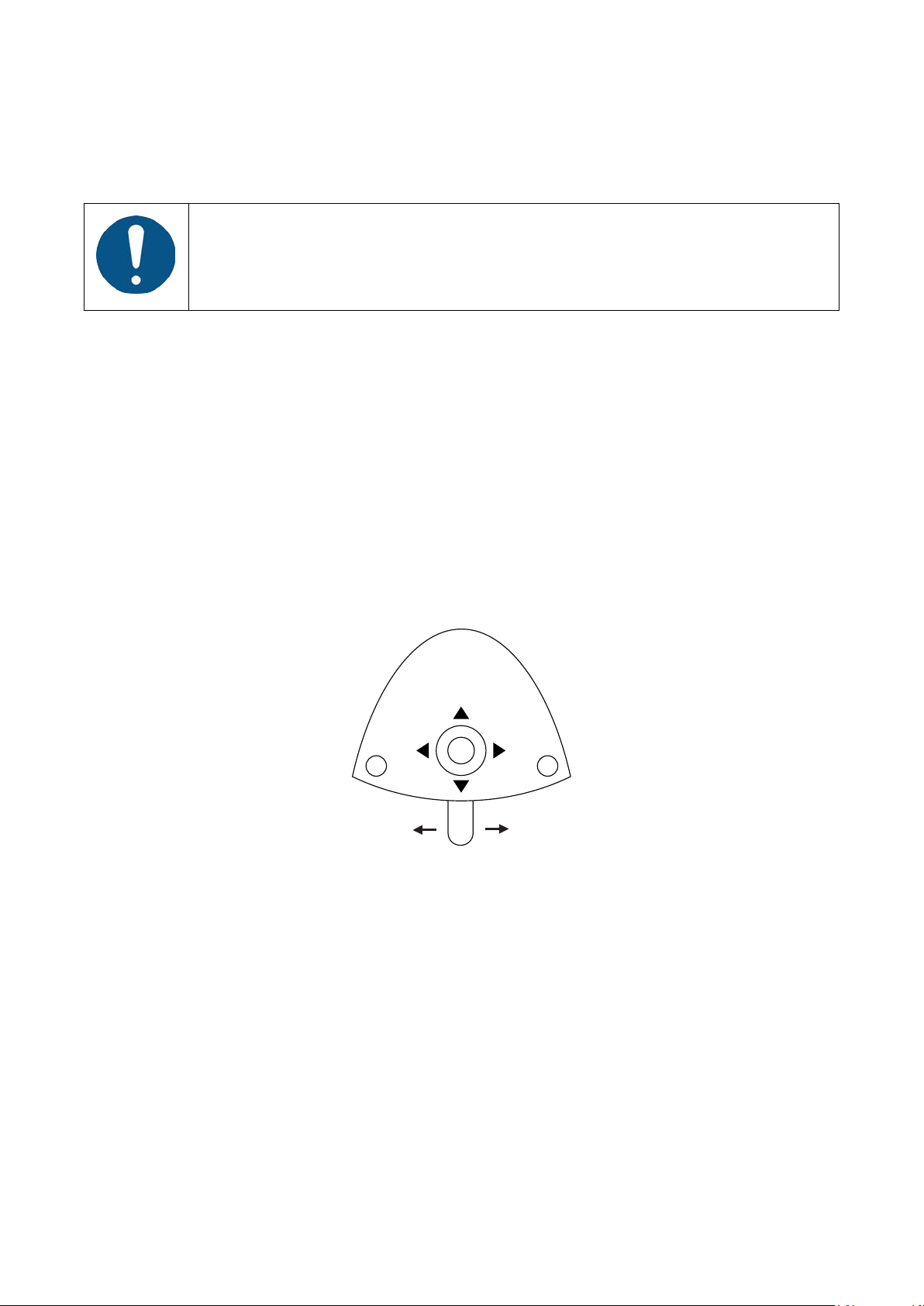

XO FLEX is controlled hands free by using the foot control – see Figure 5 – and the chair base

joystick – see Figure 6.

Figure 5 – Foot control

The foot control has:

• a pedal that can be moved to the right (⮕), to the left (⬅) and pressed down (⬇)

13

Page 14

XO FLEX – Instructions for use Operation

In this manual, the above-presented terminology (e.g. ▲ = move joystick to north) will

See section 14 for an overview of the foot control and chair base joystick functions.

• an X button

• an O button

• a joystick that can be moved north (▲), west (◄), south (▼) and east (►)

When all unit instruments are at rest, the foot control manages functions related to the unit and

chair etc.

When a unit instrument is lifted forward, the foot control manages the active instrument.

The chair base joystick is used to position the patient chair.

The chair base joystick can be moved north ( ), west ( ), south ( ) and east ( ) – see Figure 6.

Figure 6 – Chair base joystick

be used to explain the functions of XO FLEX.

POSITION THE FOOT CONTROL

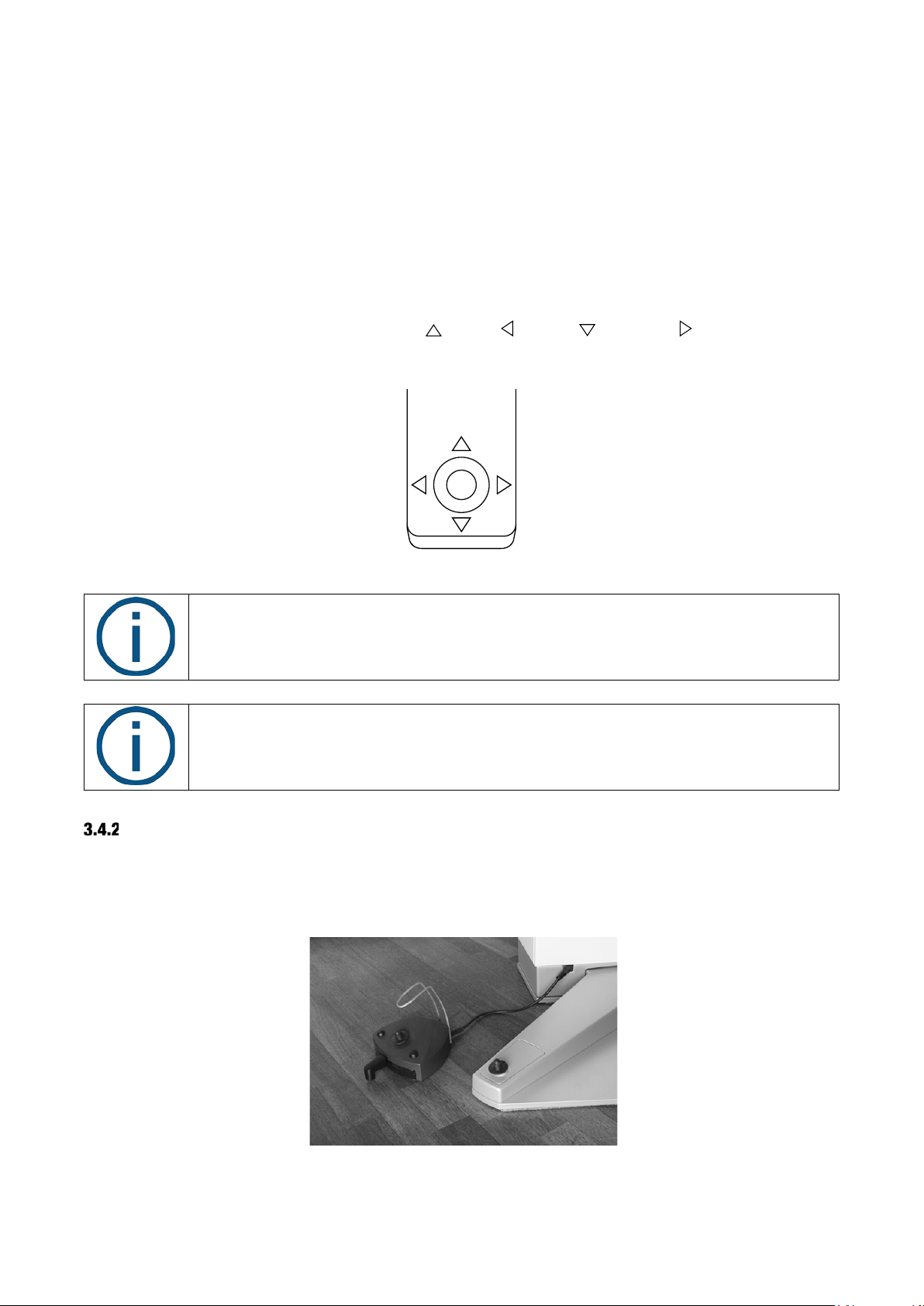

Place the foot control close to the unit’s supporting leg and operate it with your right foot when

working in positions 9 – 11 o’clock (see Figure 7). In working position 12 o’clock you may find it

easier to use the left foot (right-handed operator).

Figure 7 – Optimal position of foot control

14

Page 15

XO FLEX – Instructions for use Operation

3.5 XO SMART LINK

XO SMART LINK is an optional software running on an external PC connected to FLEX.

With XO SMART LINK you can configure the function of the foot control and you can work with

instrument programs.

Please see “XO SMART LINK instructions for use”.

3.6 PATIENT CHAIR

FOOT CONTROL OF PATIENT CHAIR

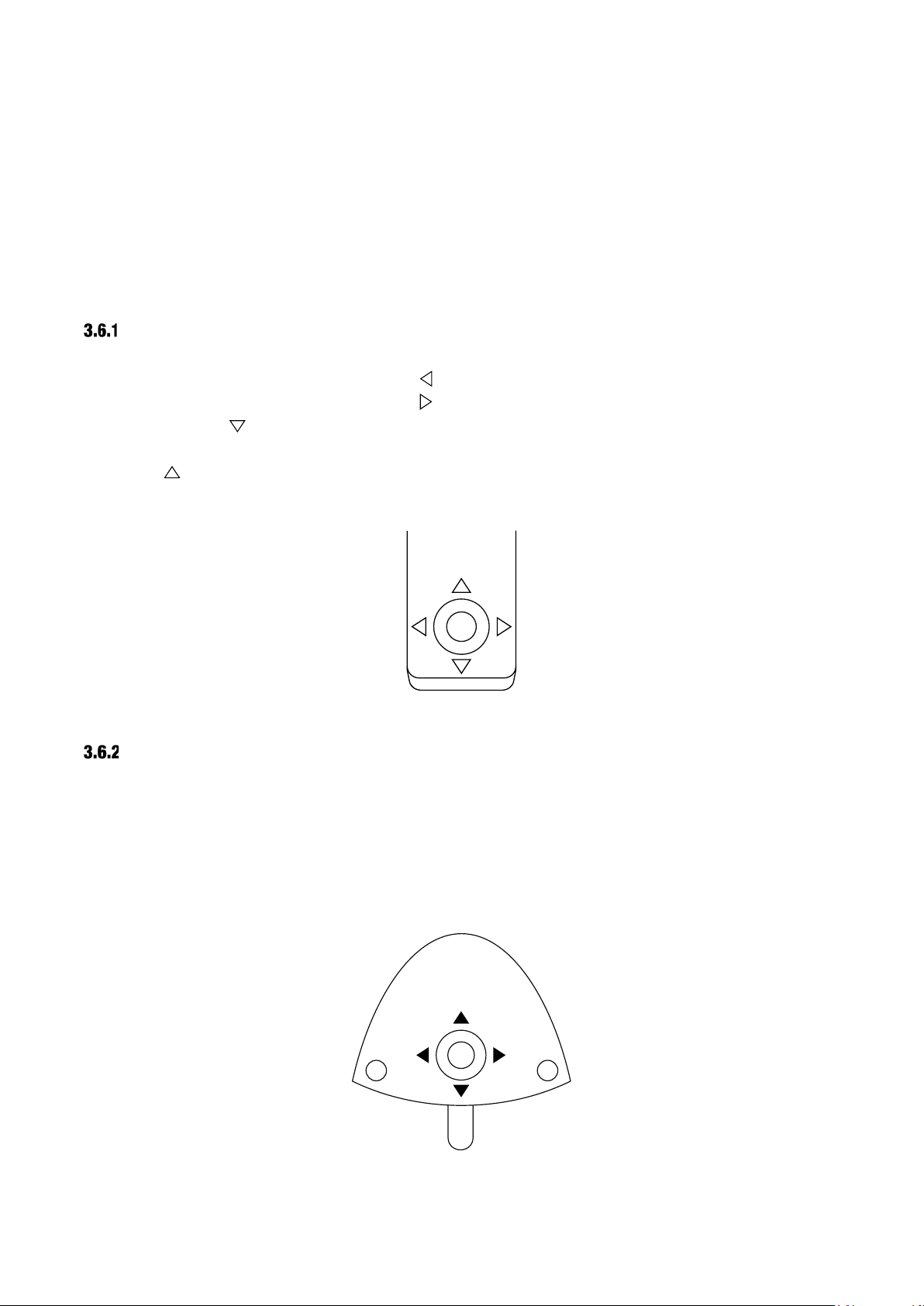

Use the foot control to position the patient chair.

Position the chair in working position 1 with .

Position the chair in working position 2 with .

When you activate the chair moves to the entry position – the position used to enter the chair

and for rinsing.

Activating brings the chair to the previous position – the last “still” position prior to the present.

See Figure 8.

Figure 8 – Position the patient chair using the chair base joystick

SMALLER ADJUSTMENTS OF PATIENT CHAIR

You make smaller adjustments of the chair with the foot control joystick:

• Lift the chair with ▲ (north)

• Lower the chair with ▼ (south)

• Increase the backrest inclination with ►(east)

• Decrease the backrest inclination with ◄ (west)

See Figure 9.

Figure 9 – Smaller adjustments of the patient chair using the foot control joystick

15

Page 16

XO FLEX – Instructions for use Operation

The patient chair is equipped with a function stop:

To avoid damage never place any objects, including operators’ seats, under the

The patient chair is dimensioned to carry a patient with a weight of up to 150 kg!

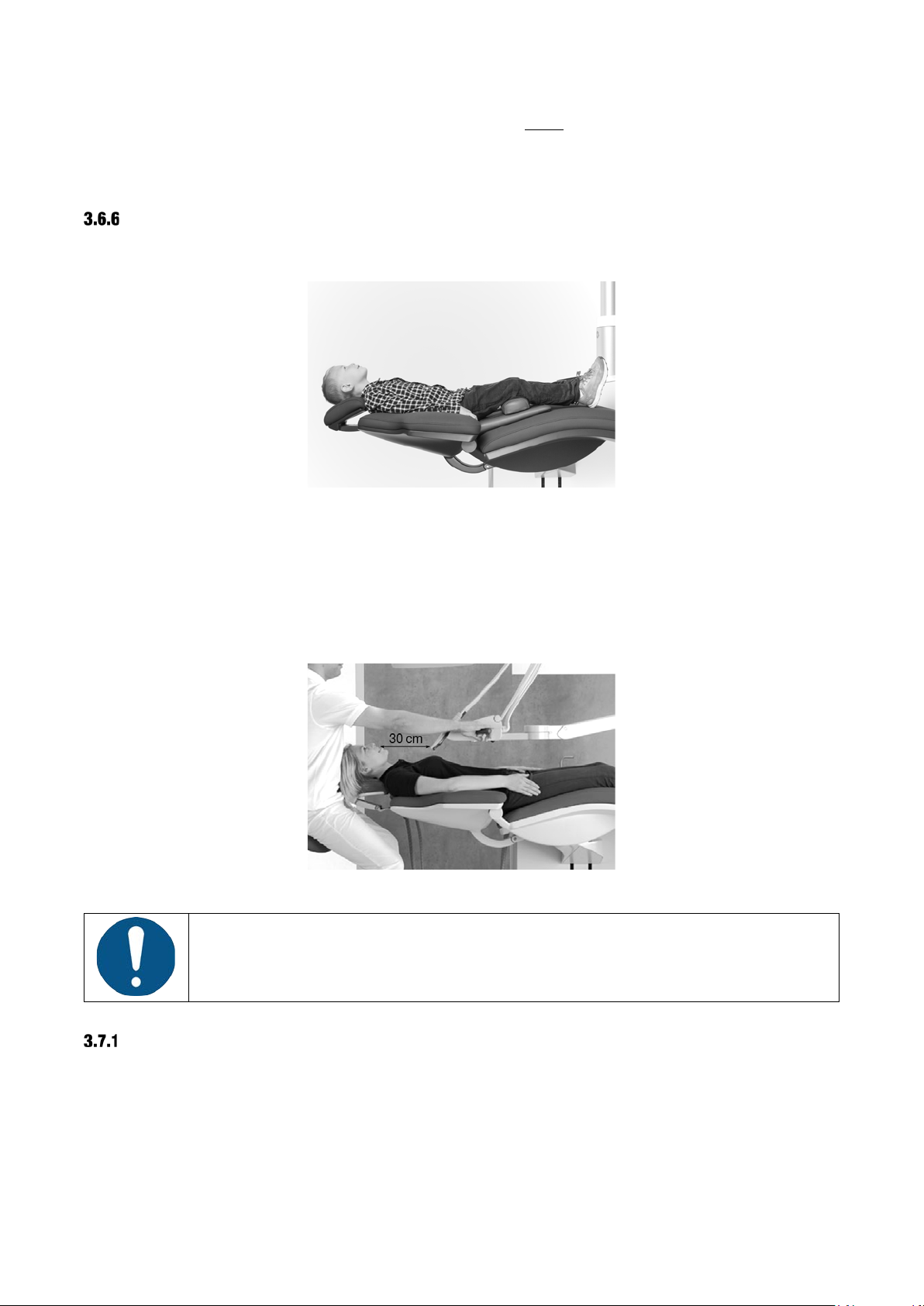

XO FLEX is intended to be used primarily with supine patients!

SAFETY

The chair has been designed with a hinged backrest and is shaped so that the legs of the

operators will not be trapped below the chair when moving downwards.

You interrupt all automatic chair movements immediately by touching any button on

the foot control or by lifting an instrument forward.

patient chair.

Exceeding the maximum allowed weight will compromise the structural stability of

the unit and the patient chair.

SUPINE PATIENT POSITION

The unit is designed with over-the-patient delivery of instruments for working primarily on supine

patients. That allows you to see all tooth surfaces in good working postures – see details in section

3.7.

NECK REST

The patient chair is equipped with an adjustable neck rest, supporting the patient’s neck and head.

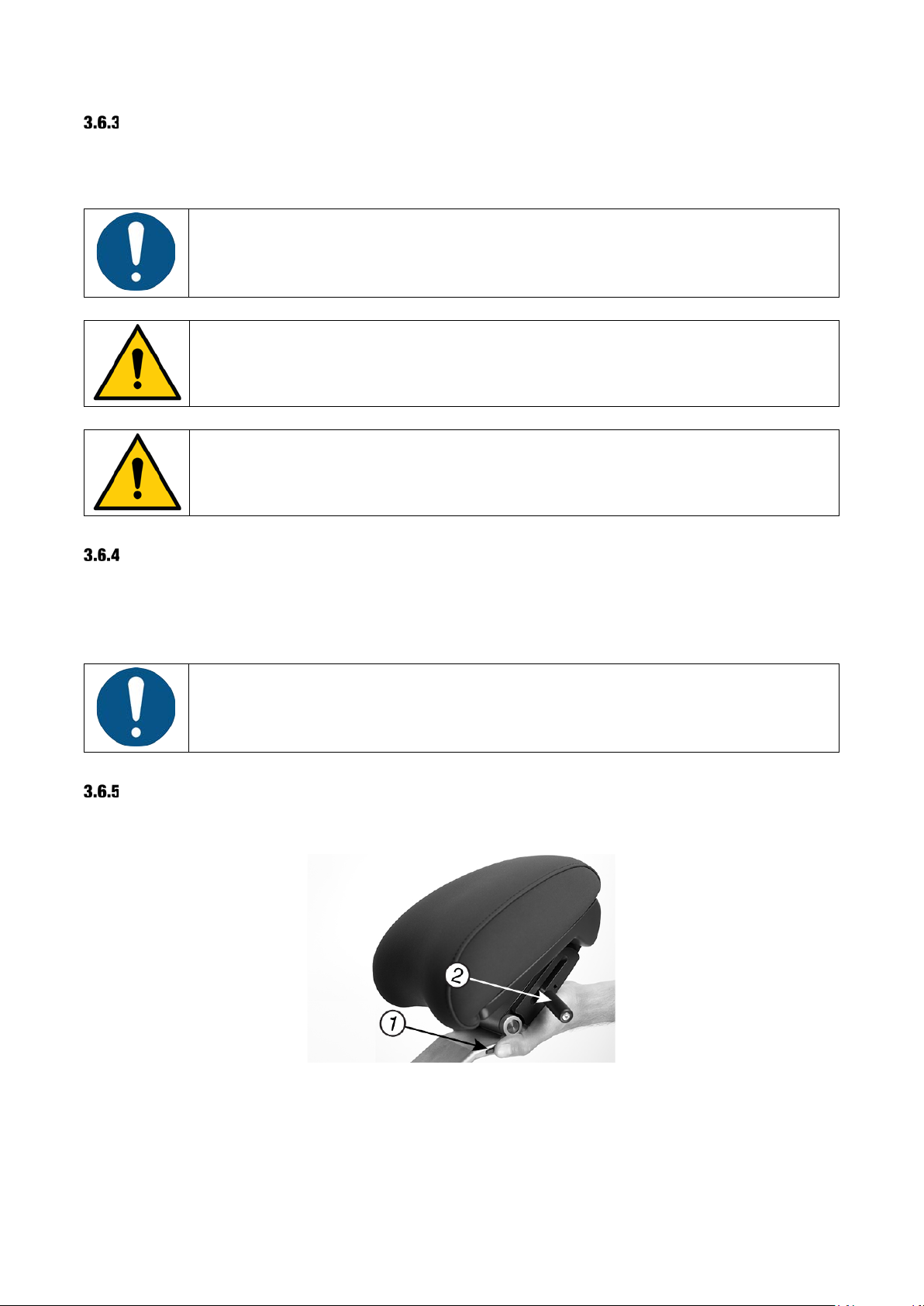

Figure 10 – Neck rest with (1) longitudinal lock and (2) release handle

To obtain the best patient experience, please follow these instructions when bringing the patient

into a working position:

1. Start positioning the chair

16

Page 17

XO FLEX – Instructions for use Operation

Always use the handles to position the instrument bridge.

2. Release the longitudinal lock (1) – see Figure 10

– while the chair is moving

3. When in the desired working position, adjust the angular position of the neck rest using the

release handle (2)

CHILD CUSHION

For treatment of children, a child cushion is available.

Figure 11 – Child cushion

3.7 INSTRUMENT BRIDGE IN WORKING POSITION

To obtain easy access to and optimal balancing of the instruments, place the instrument bridge

close to the center of the patient’s chest – with a distance from the tips of the instruments to the

oral cavity of 30 cm – see Figure 12.

Figure 12 – Position of instrument bridge while working

Never pull the instrument bridge using an instrument – this may damage the

instrument suspension.

BALANCED INSTRUMENTS

Grab an instrument as shown in Figure 13.

17

Page 18

XO FLEX – Instructions for use Operation

Figure 13 – Lifting an instrument forward

Each instrument suspension is fitted with a spring that can be adjusted so that the instrument is

perfectly balanced - see section 8.4.

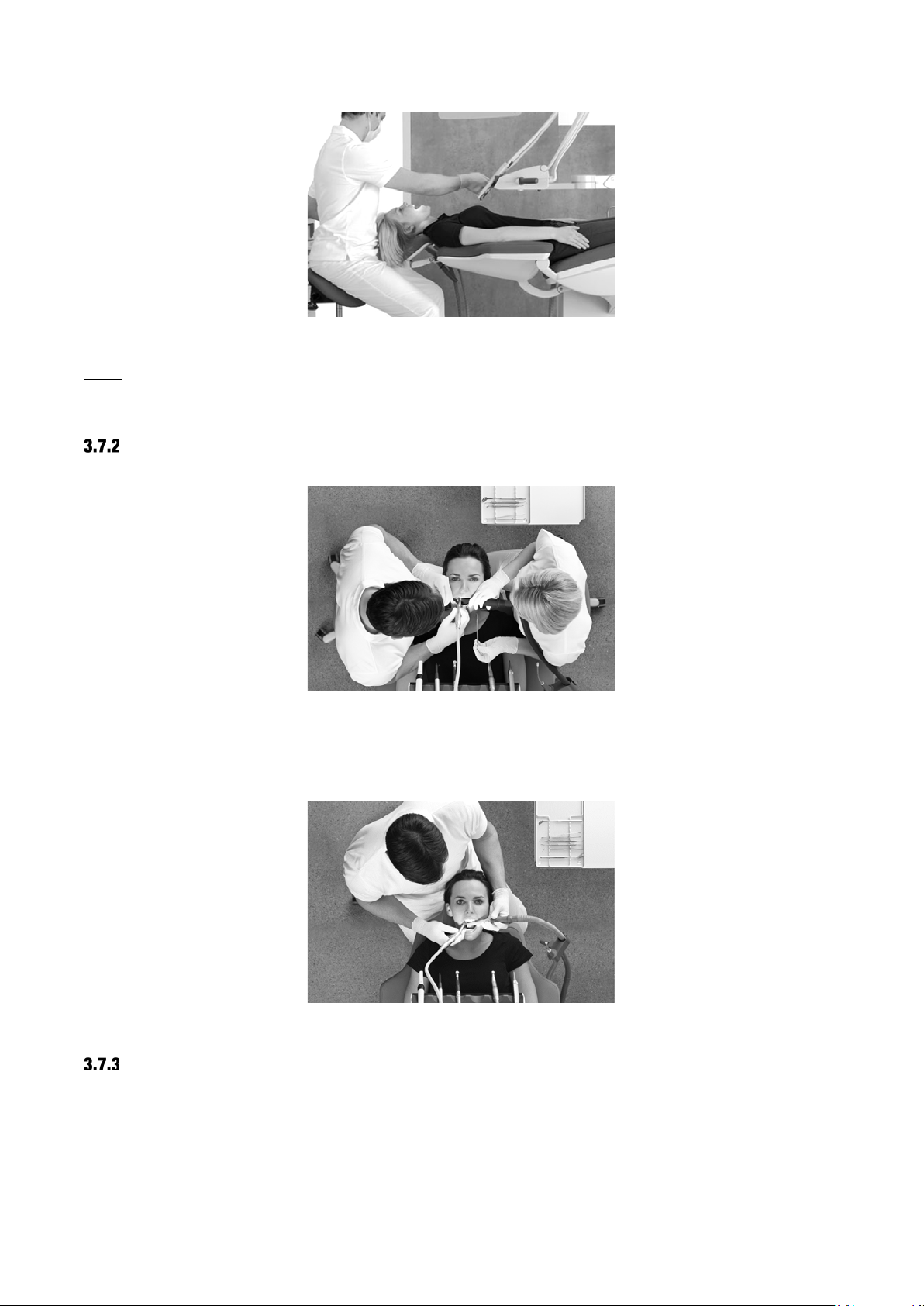

FOUR-HANDED OR SOLO WORK

Figure 14 – Four-handed operation – here the operator is working in the 9 o’clock position, the chairside

assistant in the 3 o’clock position and the hand instruments are positioned near the patient’s temple

XO FLEX is equally suited for four-handed (Figure 14) and two-handed operation (Figure 15).

Figure 15 – Two-handed operation – here the operator is working in the 11 o’clock position

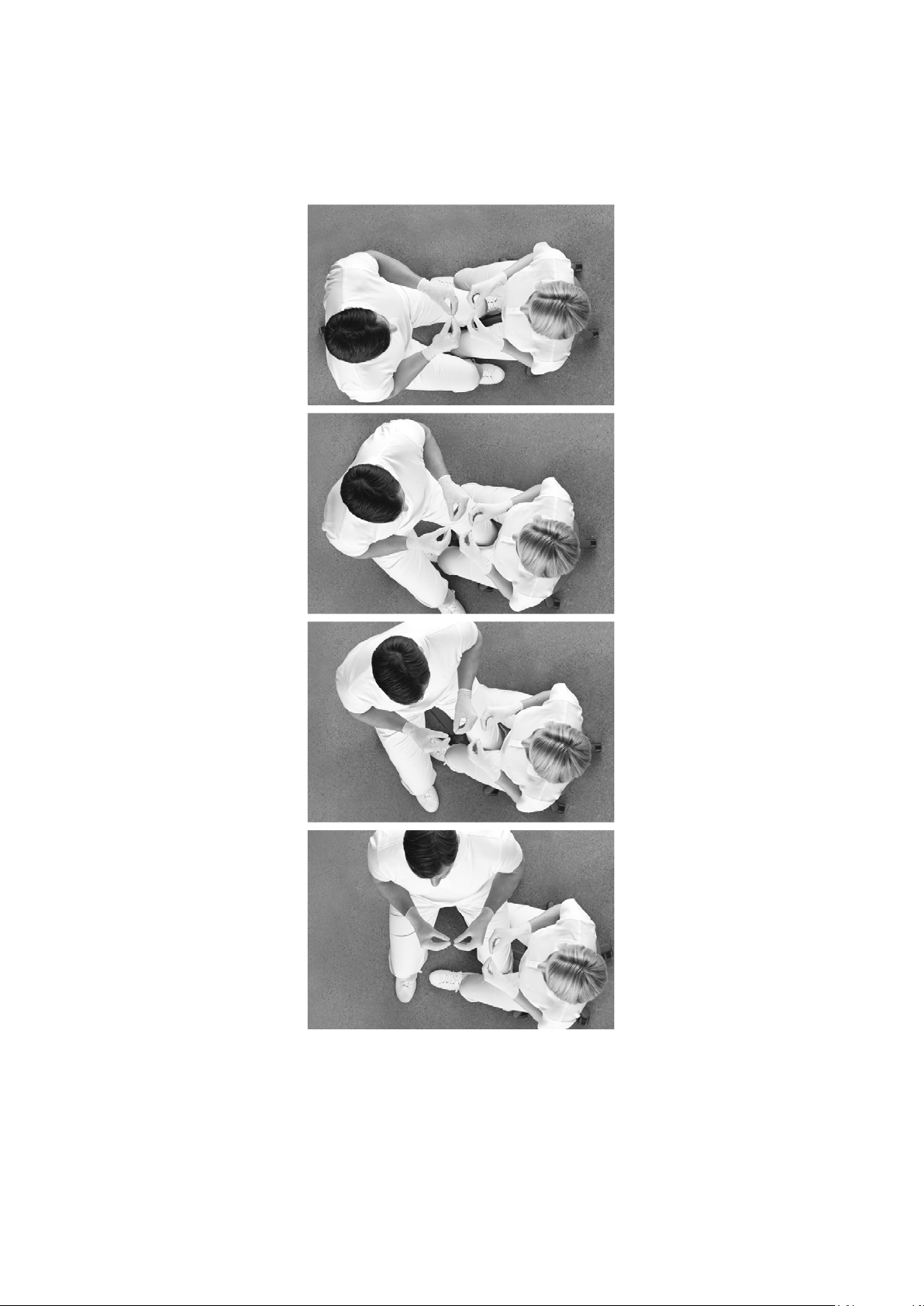

WORKING POSITIONS

With the patient in the supine position you may work in positions between 9 o’clock to 12 o’clock

(see Figure 16) to obtain the best possible vision while maintaining a healthy sitting position (see

section 3.24.)

The patient chair neck rest allows you to place the patient’s head in six different positions (see

18

Page 19

XO FLEX – Instructions for use Operation

Figure 17). This, combined with the flexibility of working in positions between 9 and 12 o’clock (see

Figure 16), provides you with the best possible view of each tooth surface without bending or

straining your neck, spine or upper body.

Figure 16 – Four operator’s positions

19

Page 20

XO FLEX – Instructions for use Operation

Figure 17 – Six different patient positions

20

Page 21

XO FLEX – Instructions for use Operation

3.8 INSTRUMENT CONTROL

FOOT CONTROL OF INSTRUMENTS

You activate the first instrument lifted forward with the foot control pedal. To avoid unintentional

activation of a second instrument lifted forward you will only be able to activate the second

instrument when the first instrument is laid back and the foot control has been released.

The syringe may be used even though another instrument is lifted forward.

The intraoral video camera may be used simultaneously with another activated instrument – but

control of camera functions via the foot control is only possible when the video camera is the only

instrument lifted forward.

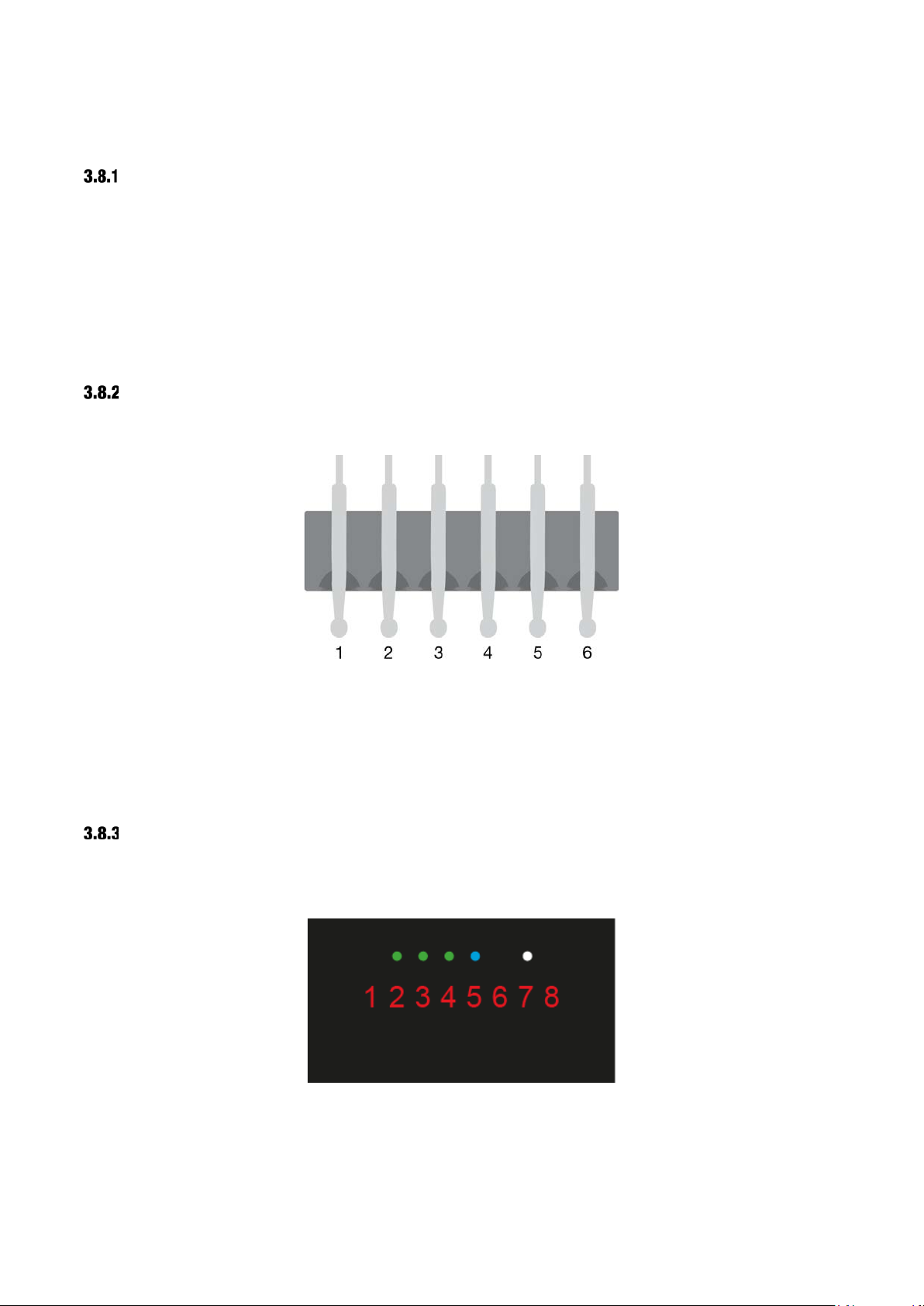

INSTRUMENTS ON THE INSTRUMENT BRIDGE

Up to 6 instruments may be fitted to the instrument bridge.

Figure 18 – Numbering of unit instruments

The instruments are numbered 1 – 6 starting from the left.

Your XO authorized service provider may add instruments or change the order of the instruments –

the multifunction syringe, however, must always be placed to the left (right-handed operator) or to

the right (left-handed operator).

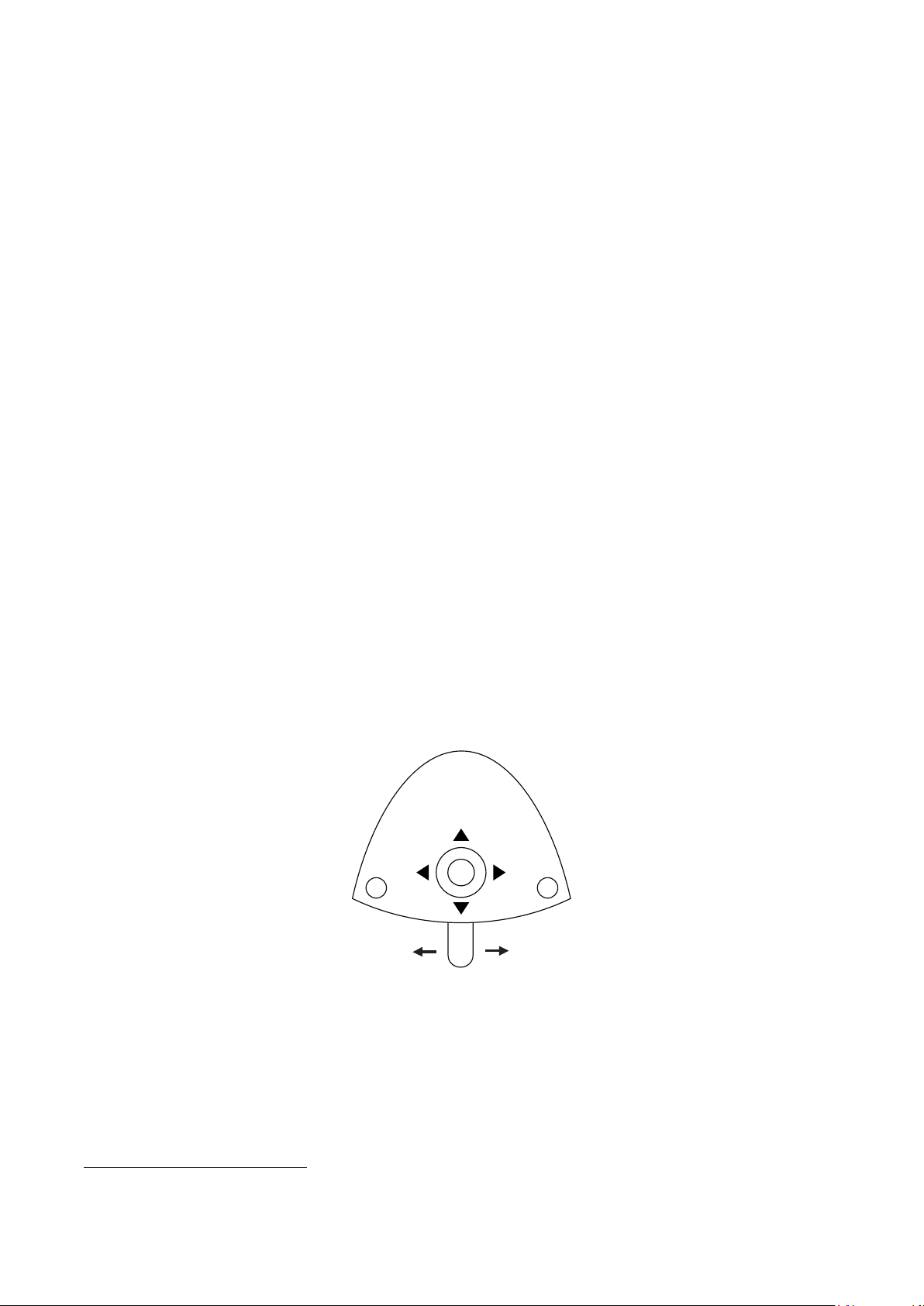

INSTRUMENT BRIDGE DISPLAY

Data concerning the selected instrument is shown on the instrument bridge display – see Figure 19

– and the instrument may be controlled using the foot control.

Figure 19 – Instrument bridge display

21

Page 22

XO FLEX – Instructions for use Operation

X

O

The display consists of:

• One red 8-digit text field mostly used for indication of the primary instrument parameter (for

example, speed of a micro motor)

• Three green LEDs for indication of selected amount (three levels) of spray water or for spray

water off (all LEDs off)

• One blue LED for indication of spray air on/off

• One white LED for indication of automatic chip blow enabled/disabled

3.9 SYRINGE – LUZZANI

The syringe is used as described in the manual supplied by Luzzani – or visit luzzani.com.

Lift the syringe forward and control it with the two buttons.

The syringe can be used at the same time as the other instruments.

3.10 MICROMOTOR – BIEN-AIR MC3 / BIEN-AIR MX2

The micromotor is used as described in the manual supplied by Bien-Air – or visit bienair.com.

The micromotor is intended to be used with contra-angles and handpieces with couplings as

specified in ISO 3964, type 2 or type 3

Lift the micromotor forward and control it with the foot control.

Activate the motor clockwise in the range 100 RPM – select maximum speed

2

(see below) with ⮕

or counterclockwise with ⬅.

Figure 20 – Foot control of micromotor

See the maximum speed on the display when the foot control is not activated.

See the actual speed on the display when the motor is running.

Change spray selection (water & air, air only or no spray) with X.

2

Please note that this is the speed of the micro motor itself. When you fit a contra-angle the speed of the bur may be changed!

22

Page 23

XO FLEX – Instructions for use Operation

When the automatic chip blow is enabled a short burst of high-pressure air dries the

To avoid necrosis, it is generally recommended to work with a “wet” spray that gives

Enable/disable automatic chip blow with O.

preparation each time an instrument with spray water stops.

Using the automatic chip blow function significantly reduces the number of shifts

between rotation instrument and syringe.

Choose between three levels of spray water:

Increase amount of water with ►.

Decrease amount of water with ◄.

at least 50 ml spray water per minute measured with the contra-angle fitted!

In some cases – e.g. when preparing a cavity that is not close to the pulp – and you

want to minimize the spray aerosol – it may be acceptable to use less water in the

spray.

Choose between three maximum speed levels:

Increase maximum speed with ▲.

Decrease maximum speed with ▼.

3.11 XO OSSEO MOTOR

XO OSSEO motor is intended for bone surgery in general and for dental implantology.

XO OSSEO motor is intended to be used with surgical contra-angles and handpieces with

couplings as specified in ISO 3964, type 1.

SET-UP

Appropriate sterile handling procedures must be observed to ensure and maintain sterile

conditions:

1. Remove the sterilized motor and hose from the autoclave bag – or wrap motor and hose

immediately before use.

2. Connect the motor hose to the matching connector at the rear of the instrument bridge –

see section 5.8. The instrument suspension shall be configured as MOTOR.

3. Prepare the peristaltic pump as described in section 3.16.

4. Remove the sterilized contra-angle from the autoclave bag just prior to surgery.

5. Slide the contra-angle firmly in place on the motor shaft.

6. Attach the sterile irrigation tube to the contra-angle using one of the two supplied outlets –

See Figure 21. The choice of outlet depends on the contra-angle.

23

Page 24

XO FLEX – Instructions for use Operation

To avoid necrosis, it is generally recommended to work with an amount of irrigation

X

Figure 21 Attaching the irrigation tube

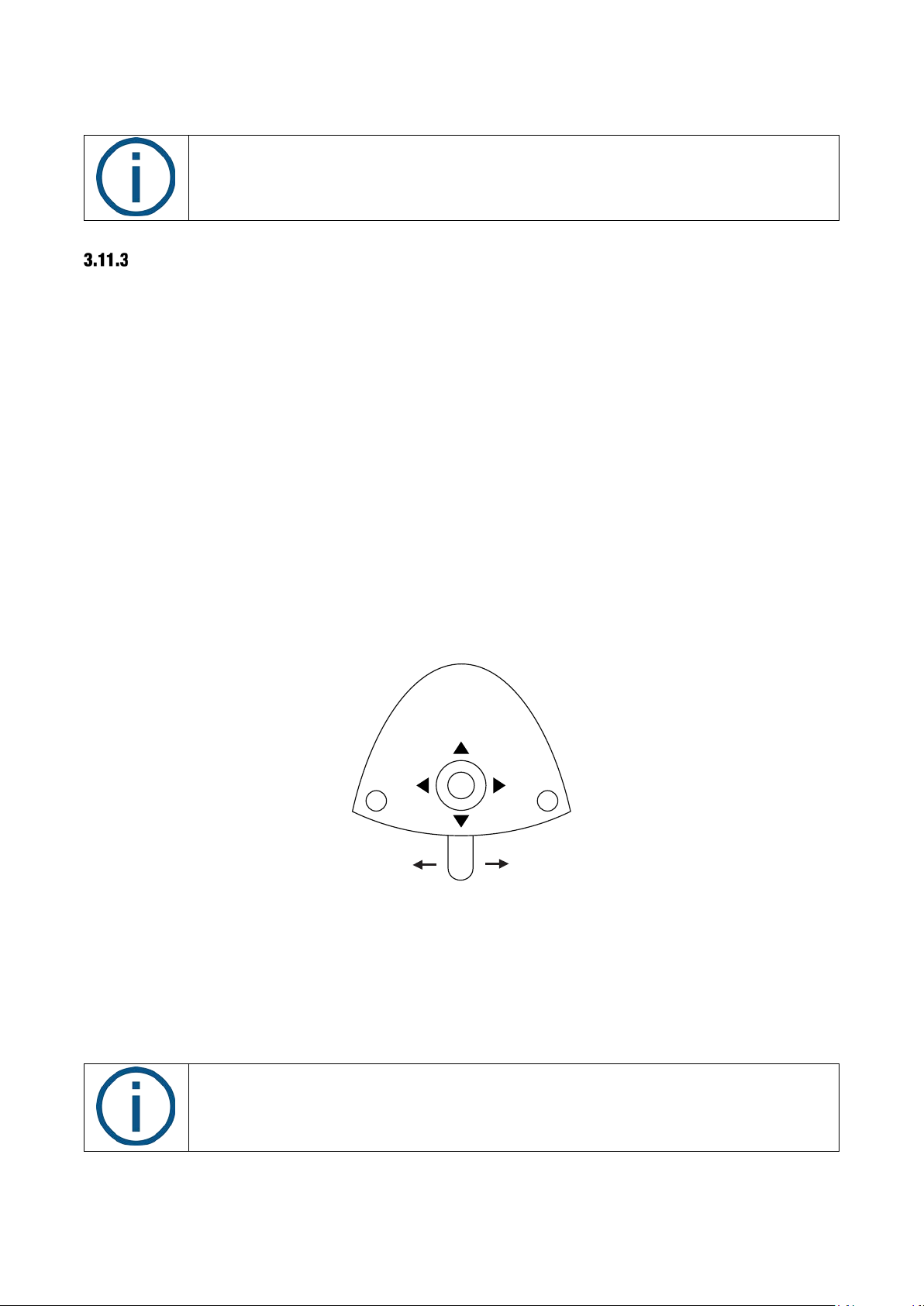

OPERATION

Lift the motor forward and control it with the foot control.

Activate the motor clockwise in the range 100 RPM – select maximum speed

3

(see below) with ⮕

or counterclockwise with ⬅.

See the maximum speed on the display when the foot control is not activated. See the actual

speed on the display when the motor is running.

Figure 22 – Foot control of XO OSSEO motor

Switch irrigation on/off with X.

Choose between three levels of irrigation:

Increase amount of irrigation with ►.

Decrease amount of irrigation with ◄.

of at least 50 ml per minute measured with the contra-angle fitted!

Choose between three maximum speed levels:

Increase maximum speed with ▲.

Decrease maximum speed with ▼.

3

Please note that this is the speed of the motor itself. When you fit a contra-angle the speed of the bur may be changed!

24

Page 25

XO FLEX – Instructions for use Operation

The motor operates at maximum torque.

When the automatic chip blow is enabled a short burst of high-pressure air dries the

X

O

Please see section 3.11.3 if you need to control the maximum torque!

IMPLANT SURGERY - OPERATION WITH XO SMART LINK

In combination with XO Smart Link you can work with instrument programs and implant

treatments.

Please see “XO Smart Link – Instructions for use”.

3.12 AIR INSTRUMENT

An air turbine or an air scaler may be attached to the hose – in the following called “the air

instrument”.

The air instrument is used as described by the supplier.

Air instruments with a type 3 coupling as specified in ISO 9168 shall be used.

Lift the air instrument forward and control it with the foot control.

Activate the air instrument (one step) with ⮕ or ⬅.

Figure 23 – Foot control of turbine

See drive air (in % of maximum) on the display.

Change spray selection (water & air, air only or no spray) with X.

Enable/disable automatic chip blow with O.

preparation each time an instrument with spray water stops.

Using the automatic chip blow function significantly reduces the number of shifts

between rotation instrument and syringe.

25

Page 26

XO FLEX – Instructions for use Operation

To avoid necrosis, it is generally recommended to work with a “wet” spray that gives

X

Choose between three levels of spray water:

Increase amount of water with ►.

Decrease amount of water with ◄.

at least 50 ml spray water per minute measured with the turbine hand-piece fitted!

In some cases – e.g. when preparing a cavity that is not close to the pulp – and you

want to minimize the spray aerosol – it may be acceptable to use less water in the

spray.

Choose between three drive air levels:

Increase drive air with ▲.

Decrease drive air with ▼.

3.13 ULTRASONIC SCALERS

The ultrasonic scaler is used as described by the supplier.

For XO ODONTOSON scalers see below in section 3.14.

Lift the scaler forward and control it with the foot control.

Switch on the power (one step) with ⮕ or ⬅.

Figure 24 – Foot control of scaler

See the power (in % of maximum) on the display.

Enable/disable irrigation water with X.

Choose between three levels of irrigation water:

Increase amount of water with ►.

Decrease amount of water with ◄.

Choose between three power levels:

• Increase maximum power with ▲.

• Decrease maximum power with ▼.

For details about XO ODONTOSON 360 scaler see below.

26

Page 27

XO FLEX – Instructions for use Operation

For Thin Line instruments please observe:

For details about other scalers – see user manuals supplied by the manufacturer.

3.14 XO ODONTOSON 360 ULTRASONIC SCALER

XO ODONTOSON 360 is intended to be used for treatment in the oral cavity of humans. XO

ODONTOSON 360 is a multi-purpose dental scaler for periodontology, endodontics and

prophylaxis.

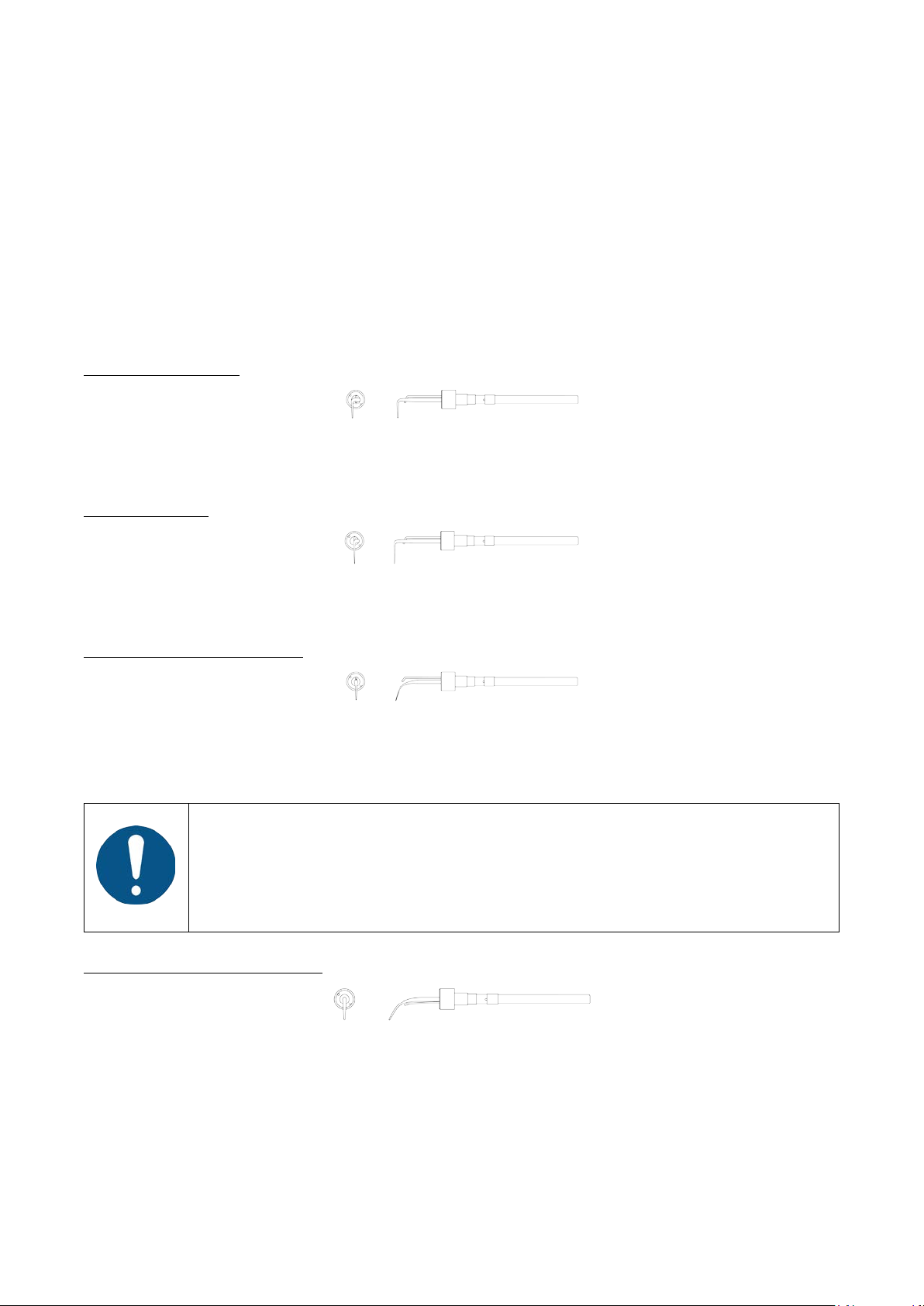

XO ODONTOSON 360 is supplied with one handpiece and six instruments (consisting of a titanium

tip fitted with an exchangeable ferrite rod) fitted into two autoclavable instrument holders in Teflon:

Universal instrument (209080) – 2 pieces

For removal of supra- and subgingival stain and calculus in all areas and for general scaling on

patients with moderate plaque or calculus.

Perio instrument (209030)

Removes supra- and subgingival stain and calculus in all areas. Particularly useful for removal of

subgingival calculus in pockets as deep as 13 mm. Use the tip as if using a periodontal probe.

Thin Line Straight instrument (209034) – 2 pieces

Useful for fine planning after gross scaling with other XO ODONTOSON 360 instruments. Provides

good furcation access. Is also useful for root planning, but only after gross debridement with a

Perio instrument.

Use only for fine scaling or debridement after gross scaling with other instruments.

Repeated use of Thin Line instruments for gross scaling can result in damage to the

titanium tip.

Thin Line instruments should never be used at power level settings more than 50 %

of maximum power.

Heavy Duty Straight Instrument (209010)

Particularly useful for removal of supra- and subgingival calculus labially and lingually. Can be

applied interproximally, using the rounded tip to remove calculus and other heavy deposits and

stains.

27

Page 28

XO FLEX – Instructions for use Operation

Do not attempt to sharpen, bend or otherwise re-shape the instrument tips!

When working with XO ODONTOSON 360:

Increasing the contact pressure will neither increase the efficiency nor improve the

Doing so may seriously degrade the performance of the instrument.

For a complete list of available instruments – including instruments for endo procedures – please

visit xo-care.com.

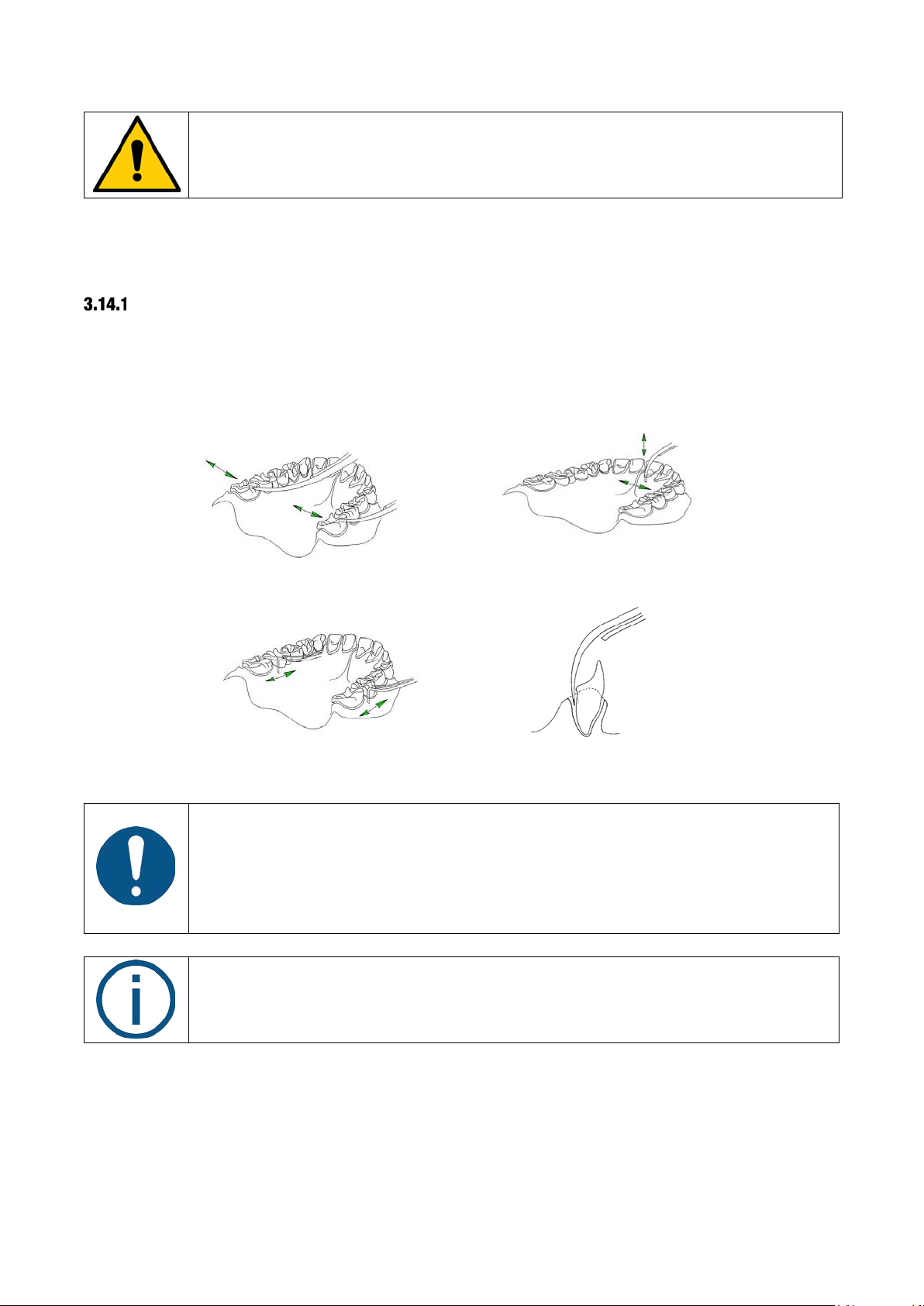

HOW TO USE XO ODONTOSON 360

To fully benefit from the rotational titanium tip movement and high frequency, it is important that

the instrument is properly handled and applied – see Figure 25.

Use short, sweeping, paintbrush-like, back and forth strokes over the surface being treated.

Keep the tip moving back and forth with the end of the tip probing the pocket when necessary.

Figure 25 – Using XO ODONTOSON 360

• Always use the instrument parallel to the tooth surface with the sides of the

tip applied to the tooth surface

• Do not apply the tip at right angles to the tooth surface

• Do not use the tip as a pick – this will scratch the tooth surface

• Always apply very little pressure to the tooth surface

quality or speed of the treatment!

If you use XO ODONTOSON 360 instrument in this way you will achieve:

• Easy access to any tooth surface without awkward positioning of the hand-piece and hand.

As the tip rotates and is "active" on all sides, you have a 360° highly efficient working

surface without “dead zones”.

28

Page 29

XO FLEX – Instructions for use Operation

Only use XO ODONTOSON 360 on teeth and root surfaces.

Risk of thermal injury!

Handle the instruments carefully as the attached ferrite rod is fragile!

Always use as much irrigation water as practically possible to avoid unnecessary

Always empty the hand-piece of any water before applying a new instrument.

It is important that the instrument is always firmly seated in the hand-piece!

• The rotational motion brushes rather than “hammers” the tooth. This has a gentle polishing

effect on the tooth. It is generally much less painful for the patient and less tiring for the

operator.

Use the mirror to hold lips and tongue away from the instrument tip.

Avoid touching patient lips, tongue or other soft tissue with the non-cooled part of

the instrument tip!

wear of the instrument.

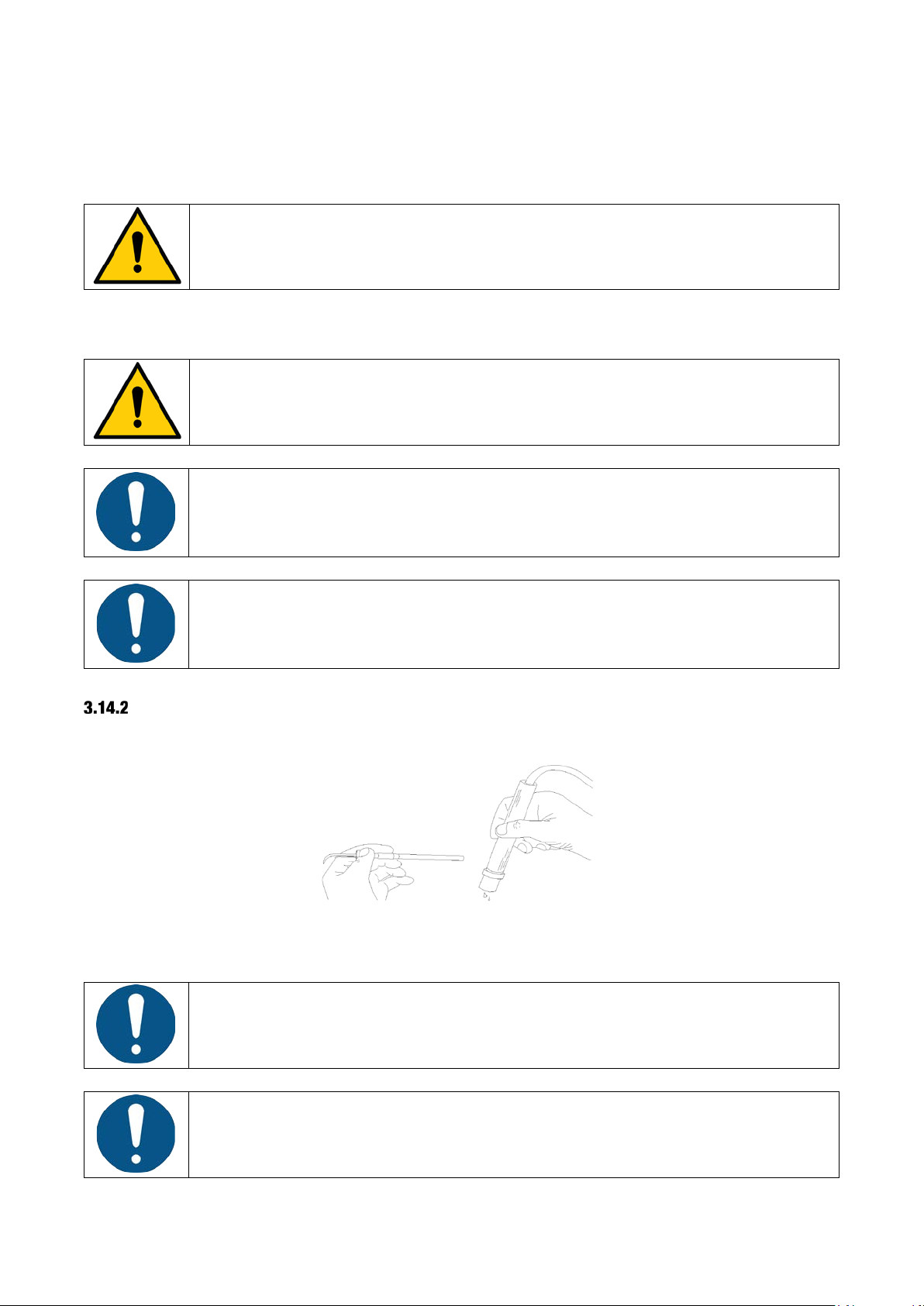

CHANGING THE INSTRUMENT

Detach the instrument from the hand-piece just by pulling it out.

Figure 26 – Changing instrument

Wipe off any drops of water before applying an instrument.

29

Page 30

XO FLEX – Instructions for use Operation

As a matter of course, the titanium tips will become worn down with time due to use. The efficiency

of an instrument will therefore be gradually reduced.

Several factors contribute to wear of instruments:

• Time used

• The type and consistency of calculus deposits in patients

• The quantity of irrigation being used

The lifetime may therefore vary considerably from instrument to instrument.

XO ODONTOSON 360 WITH ANTIMICROBIALS AND STERILE SALINE

In combination with XO Peristaltic Pump, XO ODONTOSON 360 can be used with antimicrobials or

sterile saline.

Prepare the peristaltic pump as described in section 3.16.

Insert the connector piece (XO-069) between the hose and the handpiece – as shown in Figure 27.

Figure 27 – Connector piece for external irrigation of XO ODONTOSON 360

Attach the irrigation tube to the connector piece using the appropriate outlet – see Figure 28.

Figure 28 – XO ODONTOSON 360 connected to external irrigation

3.15 XO ODONTOCURE CURING LIGHT

The intended use of XO ODONTOCURE is polymerization of light cure resin based composites

used for fillings in human teeth.

Lift the curing light forward and control it with the foot control.

See the current exposure time on the display before the foot control is activated.

Choose between three different exposure times with ▲ and ▼ and see the selected time on the

instrument bridge display.

Start the curing process with ⮕ or ⬅.

30

Page 31

XO FLEX – Instructions for use Operation

Never look directly into the light or direct it at the eyes of others!

CAUTION! The high light intensity of XO ODONTOCURE is accompanied by heat

O

Figure 29 – Foot control of XO ODONTOCURE

See elapsed exposure time on the display during the process.

Hear a beep at intervals of 5 seconds.

XO ODONTOCURE emits thermal radiation, and blue light and ultraviolet light in the

range 385 – 515 nm at an intensity that requires protection of the eyes. Protect eyes

with light shield and/or protective eyewear that removes light in the previously

mentioned wavelengths.

generation on the exposed surface! Uninterrupted exposure of more than 20 seconds

to the same surface shall be avoided. Curing at intermitted intervals is

recommended.

Switch soft-start on and off with O while the light is not activated.

Soft-start is a feature that can help reduce shrinkage. When enabled, the light will emit light at a

reduced intensity for a manually preset number of seconds before going to full intensity.

For curing of posterior teeth use a protection cap:

Figure 30 Protection cap

For curing of anterior teeth use the light shield:

31

Page 32

XO FLEX – Instructions for use Operation

XO ODONTOCURE is intended for intermittent use. If activated continuously the

Use of peristaltic pumps requires that the unit be prepared for it (i.e. unit must be

Figure 31 Light Shield

message “TOO HOT” is displayed and the instrument is turned off.

After some seconds, depending on the temperature, the light is ready for reactivation.

3.16 XO PERISTALTIC PUMP

XO Peristaltic Pump is intended for supplying sterile saline or antimicrobials when using XO

ODONTOSON 360 or XO OSSEO motor.

Irrigation liquid is carried by means of the pump and an irrigation tube, from a reservoir or a bag

located at the rear of the unit to an instrument of the operator’s choosing. The irrigation tube is part

of a disposable irrigation kit that contains the different tube parts needed for connecting a reservoir

or bag with the different supported instrument types.

The pump is detachable and can be shared among multiple XO units.

The pump is automatically detected by the unit when attached.

equipped with option XO-051).

DISPOSABLE IRRIGATION KIT

The irrigation kit is manufactured for XO CARE A/S as an accessory for XO Peristaltic Pump.

The kit consists of a main tubing part and two alternative outlet parts. The main tube is equipped

with a bag inlet cannula and an insert piece for the pump. Two alternative outlet parts are provided:

one for connecting hand-pieces with a single inlet and one for connecting hand-pieces with two

inlets.

32

Page 33

XO FLEX – Instructions for use Operation

Risk of contamination!

The disposable irrigation kit package has been sterilized by ethylene oxide gas. Sterility

cannot be relied upon if 1) the package has been opened or damaged or 2) the expiration

date stamped on the package has passed.

Appropriate sterile handling procedures must be observed to ensure and maintain sterile

conditions.

The disposable irrigation kits are for one-time use only. Do not re-sterilize!

XO Peristaltic Pump is delivered with two sample disposable irrigation kits. Additional kits can be

ordered from your XO distributor:

• Pre-sterilized, disposable irrigation kit, 50 pcs (XO-055)

• Pre-sterilized, disposable irrigation kit, 10 pcs (XO-056)

ATTACHING THE PUMP MODULE

Attach the pump module as shown in Figure 32.

After use, the pump module can be safely removed from the unit. It is not necessary to switch off

the unit before detaching the pump.

ATTACHING THE IRRIGATION TUBE

Release the pump head by turning the handle (1) counter-clockwise – see Figure 33.

Attach the irrigation tubing to the pump head as shown in Figure 34.

Make sure the tube is held in place by the two plastic connectors.

Figure 32 – Attaching the pump module to the unit

Figure 33 – Releasing the pump head

33

Page 34

XO FLEX – Instructions for use Operation

Figure 34 – Attaching the irrigation tubing

Lock the pump head by turning the handle (1) clockwise – see Figure 35.

Figure 35 – Locking the pump head

Place the irrigation tube into the tube guide and attach it to the instrument bridge arm, as shown in

Figure 36.

Figure 36 – Placing the irrigation tube

Attach the irrigation tube to the hose of the instrument to be used using the stainless steel clips –

see Figure 37.

34

Page 35

XO FLEX – Instructions for use Operation

Figure 37 – Attaching the irrigation tube to the instrument hose

IRRIGATION BAG

Insert the bag inlet cannula into the irrigation bag and hang the bag containing the irrigation liquid

from the knob at the bottom of the pump module – see Figure 38.

Figure 38 – Irrigation bag

IRRIGATION RESERVOIR

Place the reservoir containing the irrigation liquid into the holder below the pump – see Figure 39.

Figure 39 – Placing the reservoir

Using an appropriate sterile tool (e.g. a pair of scissors), cut the inlet cannula off the irrigation

tubing. Attach the irrigation tubing to the spear and place the spear in the reservoir.

See Figure 40.

35

Page 36

XO FLEX – Instructions for use Operation

Figure 40 - Cutting the irrigation tubing bag inlet cannula

DESIGNATION OF INSTRUMENT

Figure 41 – Initiating selection of instrument to be used with XO Peristaltic Pump

Before the pump can be used, a designated instrument must be selected.

With all instruments at rest, press the button (1) once – see Figure 41.

The unit enters configuration mode and a menu will be shown on the display.

Activate ▲ and ▼ of the foot control joystick to navigate to the menu item labeled “PUMP”.

Figure 42 – Foot control configuration of peristaltic pump

Activate ► to access configuration of the pump – see Figure 43.

36

Page 37

XO FLEX – Instructions for use Operation

Figure 43 – Display

Use ▲ and ▼ to select the designated suspension that should be used with the pump – see

numbers in Figure 18, page 21.

Figure 44 – Displaying instrument suspension

Use ◄ to confirm the choice of suspension.

Press the configuration button (1) on Figure 41 once to exit configuration mode.

When the designated instrument has been selected, the green LED will blink.

If you want to use the designated instrument without peristaltic pump, select “NONE” in the PUMP

menu.

ADJUSTING THE FLOW LEVEL

Choose between three levels of irrigation:

Increase irrigation with ►

Decrease irrigation with ◄

3.17 INTRAORAL HD VIDEO CAMERA

Unlike all other unit instruments, you may use the video camera also when another instrument is

active.

Lift the camera forward and display a video image on a screen.

Control the video camera with the foot control when no other instruments are lifted forward.

Toggle between “still” and “live” mode with ⬅.

Save the active video image to the connected PC with ⮕.

37

Page 38

XO FLEX – Instructions for use Operation

The intraoral camera must be connected to an external PC!

To use the foot control for controlling the camera, the PC must be appropriately

To ensure a stable connection, we highly recommend that the connection be made

Place the light head 70 cm from the patient’s lips and position the light head so that

Figure 45 – Foot control of intraoral video camera

This is done during installation of the unit and shall be done by an XO authorized

service provider.

configured and a compatible imaging program must be used. Furthermore, the PC

must be connected to the unit by means of a serial cable for carrying the control

signals from the foot control to the imaging program. This is in addition to the USB

cable carrying the video signal.

Please consult your XO authorized service provider for further details.

using a special USB cable supplied by Dürr Dental.

For other information please see the enclosed information from Dürr Dental.

3.18 OPERATING LIGHT

POSITION THE LIGHT

the direction of the light is parallel to your viewing direction. See Figure 46.

This position of the light head also prevents the instrument suspensions from touching the light

head while working.

38

Page 39

XO FLEX – Instructions for use Operation

Figure 46 – Correct position of light

SWITCH THE LIGHT ON AND ADJUST THE LIGHT INTENSITY

Manage the light manually by activating the no-touch sensor under the light head – see Figure 47

(1).

Hold your hand within activation distance for less than one second and the lamp switches on/off.

Change the light intensity (3 levels) by activating the sensor for more than one second.

Figure 47 – No-touch sensor

Optionally, you may configure the operating light to be switched on/off using the foot control while

the instruments rest:

• Switch the light on/off with a short activation of ⬇

• You change light intensity by holding ⬇ down

Figure 48 – Optional foot control of light

39

Page 40

XO FLEX – Instructions for use Operation

When working with light-curing composites please note that the operating light may

Please note that XO HD Display must be connected to an external PC!

The best image quality is obtained using the native resolution of 1920 * 1080 pixels.

Please do not press the sensor buttons too hard or you may damage the buttons!

MENU AU TO

BUTTON

DESCRIPTION

MENU

Menu Button. Press this button to show the on-screen-display (OSD). This button is also used to exit

influence the curing process.

Switch to a lower light intensity or switch the light off if necessary!

AUTOMATIC FUNCTIONS

The light switches on automatically when the patient chair reaches working positions 1, 2 or

previous position.

The light switches off automatically when the patient chair is moved towards the entry position.

3.19 XO HD DISPLAY

The display contains 6 sensor buttons at the bottom right (see Figure 49). The meanings of the

buttons are described in Table 3. Note that some buttons have different functionality depending on

whether the on-screen-display (OSD) is shown or not.

Figure 49 – Control panel sensor buttons – HD display

Table 3 Control panel sensor buttons – HD display

the OSD or to return to a higher-level OSD menu.

40

Page 41

XO FLEX – Instructions for use Operation

BUTTON

DESCRIPTION

If held pressed for 10 seconds, this button will lock the OSD. When locked, it is not possible to

seconds.

Game mode button (not relevant for dental use).

Up/down buttons. These buttons are used for navigating the menu or to adjust values in the OSD.

Brightness button. This button is used to control the brightness of the display.

Switch input button. Use this button to switch between analogue and digital input.

Select button. Used for selecting functions in the OSD.

AUTO

Auto button. Use this button to automatically adjust the display settings when using an analog input.

ON/OFF button. Switches the display on and off.

automatically be switched on as well.

change the OSD settings. The lock can be disabled by holding the menu button pressed for 10

Note: Switching off the unit will also switch off the display. When the unit is on again, the display will

3.20 HAND INSTRUMENTS

The optimal place for hand-instruments is near the patient’s temple – see Figure 50 – where both

you and your chairside assistant can reach the instruments in healthy postures.

Figure 50 – Hand-instrument table near the patient’s temple

Alternatively, the unit may be configured with a hand-instrument table fitted under the instrument

bridge – see Figure 51.

Figure 51 – Hand-instrument table attached to XO FLEX

41

Page 42

XO FLEX – Instructions for use Operation

Maximum load on hand instrument table attached to XO FLEX unit is 1.5 kg!

Please note that the brake and the balance spring of the arm system should be adjusted by an XO

authorized service provider in accordance with the load of the hand instrument table.

Exceeding the limit may compromise the balance of the instrument bridge and could

cause the bridge suspension arm to fail altogether exposing the patient to a risk.

3.21 SUCTION

Activate each suction hose individually by lifting it from the holder. When working solo, move the

suction hose holder forward to facilitate easy access to the suction hoses.

Figure 52 – Suction – (1) DUO position / (2) SOLO position

Relieve the suction hose by pressing it into the slot in the suction hose holder.

Figure 53 – Relieving the suction hose

3.22 CUSPIDOR AND CUP FILLER

Start the cuspidor flush manually with (1) – see Figure 54 – it will stop automatically after the preset

rinsing time.

Abort the cuspidor flush by activating (1) while rinsing.

42

Page 43

XO FLEX – Instructions for use Operation

X

Figure 54 – Manual start of (1) cuspidor and (2) cup filler

Activate (2) – see Figure 54 – for less than one second and the glass fills with the pre-configured

amount of water.

Activate (2) again for less than one second to stop automatic filling.

If (2) is activated for more than one second, water fills the cup while the button is activated.

The cup filler may alternatively be activated/deactivated using X while all unit instruments rest.

Figure 55 – Foot control of cup filler

AUTOMATIC FUNCTION

The cuspidor flush starts automatically after the cup filler has been activated and when the patient

chair reaches the entry-position.

3.23 ASSISTANT CALL

Activating O while all unit instruments are at rest will activate a relay contact that may be

connected to a bell or other external signaling devices.

43

Page 44

XO FLEX – Instructions for use Operation

Sound

Meaning

Welcome

The unit is turned on and ready to use

Wrong

You try to do something that does not make sense

Setting saved

Setting saved successfully

Notification

A non-urgent event occurred

Connection lost

Computer connection is disconnected

To maintain a healthy sitting position, it is extremely important to individually adjust

O

Figure 56 – Foot control of assistant call

3.24 SOUND GENERATOR AND SOUNDS

The instrument bridge is fitted with a sound generator that indicates events as described below:

Table 4 - Sounds

3.25 SYSTEM MESSAGES

The unit generates messages that can be seen from the instrument bridge display.

See details in section 7.

3.26 XO SEAT AND XO STOOL

We recommend you sit in an upright, balanced position with an angle between thighs and upper

body of about 120

XO SEAT and XO STOOL are available in two heights: 1) for operators up to about 180 cm tall and

2) for operators who are taller. If your XO SEAT/XO STOOL is too low or too high, it is possible to

replace the gas spring with a shorter or longer version. Please contact your XO authorized service

provider.

If the height difference between the operator and the chairside assistant is more than 10 cm, a

foot-ring may be fitted.

o

– see Figure 57.

the height and seat angle of the operator’s stool as described in this section!

44

Page 45

XO FLEX – Instructions for use Operation

Figure 57 – Upright, balanced position

XO SEAT

Adjust the seat height using the left handle as shown in Figure 58.

Figure 58 – Adjustment of seat height

Adjust the seat angle with the right handle as shown in Figure 59.

45

Page 46

XO FLEX – Instructions for use Operation

Figure 59 – Adjusting the seat angle

XO STOOL

Adjust the seat height as shown in Figure 60 and the seat angle as shown in Figure 61.

Figure 60 – Adjusting the seat height

Figure 61 – Adjusting the seat angle

Adjust the backrest as shown in Figure 62 and Figure 63.

46

Page 47

XO FLEX – Instructions for use Operation

Figure 62 – Adjusting the backrest angle

Figure 63 – Adjusting the backrest height

47

Page 48

XO FLEX – Instructions for use Configuration

4 CONFIGURATION

This section describes the many aspects of XO FLEX that can be customized to fit your personal

needs.

4.1 CONFIGURATION OF PATIENT CHAIR POSITIONS

1. Adjust the chair to the required position using the foot control joystick as described in

section 3.6.2

2. Press the configuration button – see Figure 64 – within 8 seconds

3. The display will show “CHAIR”

4. Activate the chair base joystick – see Figure 65 – according to the position being

configured:

: Working position 1

: Working position 2

: Rinse position

(twice within one second): Entry position

5. Subsequently, an “OK” sound is heard

6. The display will show the configured position shortly afterwards

Figure 64 – Configuration button (1) under the instrument bridge

Figure 65 – Chair base joystick

4.2 CONFIGURATION OF GENERAL UNIT AND PATIENT CHAIR FUNCTIONS

1. Activate the configuration button (1) while all instruments are resting – see Figure 64.

2. Activate ▲ / ▼ or ⬇ – see Figure 66 – to browse the parameter to change (see Table 5)

3. Activate ► to select the parameter to change

4. Use ▲ / ▼ to change the value of the selected parameter or ⬇ to increase the value

5. Activate ◄ to save the new value

6. Press the configuration button again

48

Page 49

XO FLEX – Instructions for use Configuration

Parameter

Display text

Factory default

Possible settings

Enabling XO Peristaltic

PUMP

None

None, POS. 1 – 6

Cuspidor flush stops

FLUSH/S

15 s

10 – 600

Cup filler stops after

CUP/S

10 s

5 – 15 s

Cuspidor flush starts

FLUSH/CH

Enabled

Disabled, enabled

Cuspidor flush starts

FLUSH/CF

Enabled

Disabled, enabled

Light on when patient

LAMP/CH

Disabled

Disabled, enabled

Light on/off with foot

LAMP/PD

Disabled

Disabled, enabled

Reset unit and patient

RESET

-

Yes, No

Rinse position = entry

RINSE = 0

Disabled

Disabled, enabled

Figure 66 – Configuration using the foot control

Table 5 – Unit and patient chair parameters that can be configured

configuration

Pump

after

automatically when chair

reaches entry position

automatically when cup

filler stops

chair reaches a working

position or previous

position.

Light off when chair

moves towards entry, 0position or working

positions 1 or 2.

control

chair functions to

“factory standard”

position (0-position)

4.3 CONFIGURATION OF UNIT INSTRUMENTS

1. Lift the instrument to be programmed forward

2. Activate the configuration button (1) until the display shows the instrument setting – see

Figure 64

3. Activate ▲ / ▼ or ⬇ – see Figure 66 – to browse the parameter to change (see Table 6)

49

Page 50

XO FLEX – Instructions for use Configuration

Parameter

Display text

Factory default

Possible settings

Bien-Air MC3 / MX2 micro motor

LEVEL 3

40,000 RPM

100 – 40,000 + 10% RPM

Maximum speed – Level

LEVEL 2

10,000 RPM

100 – 40,000 + 10% RPM

Maximum speed – Level

LEVEL 1

4.000 RPM

100 – 40,000 + 10% RPM

Amount of spray water –

W LEVEL 3

Without contra-

Without contra-angle: 10 –

Amount of spray water –

W LEVEL 2

Without contra-

Without contra-angle: 10 –

Amount of spray water –

W LEVEL 1

Without contra-

Without contra-angle: 10 –

Amount of spray air

AIR

70%

0 – 100%

Automatic chip blow

CHIP

Enabled

Enabled, Disabled

Spray selection

4 STATES

Disabled

Enabled, Disabled

XO OSSEO motor

LEVEL 3

40,000 RPM

100 – 40,000 + 10% RPM

Maximum speed – Level

LEVEL 2

16,000 RPM

100 – 40,000 + 10% RPM

Maximum speed – Level

LEVEL 1

300 RPM

100 – 40,000 + 10% RPM

4. Activate ► to select the parameter to change

5. Use ▲ / ▼ to change the value of the selected parameter or ⬇ to increase the value

6. Activate ◄ to save the new parameter

7. If an additional instrument parameter is to be configured, use ▲ / ▼ until the display shows

the parameter in question

8. Place the instrument on the bridge again

Table 6 – Unit instrument parameters that can be configured

configuration

Maximum speed4 –

Level 3

2

1

Level 3

Level 2

Level 1

angle (what you see

on the display): 100

ml/min

With contra-angle:

approximately 70

ml/min

angle (what you see

on the display): 50

ml/min

With contra-angle:

approximately 50

ml/min

angle (what you see

on the display): 35

ml/min

With contra-angle:

approximately 35

ml/min

100 ml/min

100 ml/min

100 ml/min

Maximum speed5 –

Level 3

2

1

4

Please note that it is the speed of the micromotor itself. When you fit a contra-angle the speed of the bur may be changed!

5

Please note that it is the speed of the micromotor itself. When you fit a contra-angle the speed of the bur may be changed!

50

Page 51

XO FLEX – Instructions for use Configuration

Parameter

Display text

Factory default

Possible settings

Amount of spray water –

W LEVEL 3

50 ml/min

rrigation

Amount of spray water –

W LEVEL 2

30 ml/min

rrigation

Amount of spray water –

W LEVEL 1

10 ml/min

rrigation

Turbine (Air instrument)

Drive air – Level 3

LEVEL 3

100%

0 – 100%

Drive air – Level 2

LEVEL 2

90%

0 – 100%

Drive air – Level 1

LEVEL 1

70%

0 – 100%

Amount of spray water –

W LEVEL 3

Without turbine

Without turbine hand-piece:

Amount of spray water –

W LEVEL 2

Without turbine

Without turbine hand-piece:

Amount of spray water –

W LEVEL 1

Without turbine

Without turbine hand-piece:

Amount of spray air

AIR

70%

0 – 100%

Automatic chip blow

CHIP

Enabled

Enabled, Disabled

XO ODONTOSON 360 or other ultrasonic scaler

Power – Level 3

LEVEL 3

100%

0 – 100%

Power – Level 2

LEVEL 2

70%

0 – 100%

Power – Level 1

LEVEL 1

40%

0 – 100%

Amount of irrigation

W LEVEL 3

40 ml/min

10 – 90 + 10% ml/min

Amount of irrigation

W LEVEL 2

30 ml/min

10 – 90 + 10% ml/min

configuration

Peristaltic pump i

Level 3

Level 2

Level 1

flow rate: 10 – 90 ml/min ±

20%

Peristaltic pump i

flow rate: 10 – 90 ml/min ±

20%

Peristaltic pump i

flow rate: 10 – 90 ml/min ±

20%

Level 3

Level 2

Level 1

hand-piece (what

you see on the

display): 100 ml/min

With turbine handpiece:

approximately 70

ml/min

hand-piece (what

you see on the

display): 50 ml/min

With turbine handpiece:

approximately 50

ml/min

hand-piece (what