Xnexus NXT200, NXT250 Instruction Manual

INSTRUCTION MANUAL

NXT200/250 AC/DC

Valid from 0426 50113125

CONTENTS

- Warning/Electromagnetic emissions............................................................... 3

- Initial operation ............................................................................................... 4

- Maintenance / Technical data......................................................................... 5

- Initial instructions............................................................................................6

-

Circuit diagram ........................................................................................ 10-11

- Spare parts list

Instruction manual NXT200/250 AC/DC page 3

ENGLISH

Electromagnetic emissions and the radiation of electromagnetic disturbances

This welding equipment for industrial and professional use is in

conformity with the European Standard EN60974-10. The

purpose of this standard is to prevent the occurrence of situations

where the equipment is disturbed or is itself the source of

disturbance in other electrical equipment or appliances. The arc

radiates disturbances, and therefore, a trouble-free performance

without disturbances or disruption, requires that certain measures

are taken when installing and using the welding equipment. The

user must ensure that the operation of the machine does not

occasion disturbances of the above mentioned nature.

The following shall be taken into account in the surrounding area:

1. Supply and signalling cables in the welding area which are

connected to other electrical equipment.

2. Radio or television transmitters and receivers.

3. Computers and any electrical control equipment.

4. Critical safety equipment e.g. electrically or electronically controlled guards or protective systems.

5. Users of pacemakers and hearing aids etc.

6. Equipment used for calibration and measurement.

7. The time of day that welding and other activities are to be

carried out.

8. The structure and use of buildings.

If the welding equipment is used in a domestic establishment it

may be necessary to take special and additional precautions in

order to prevent problems of emission (e.g. information of temporary welding work).

Methods of reducing electromagnetic emissions:

1. Avoid using equipment which is able to be disturbed.

2. Use short welding cables.

3. Place the positive and the negative cables close together.

4. Place the welding cables at or close to floor level.

5. Remove signalling cables in the welding area from the supply

cables.

6. Protect signalling cables in the welding area, e.g. with

selective screening.

7. Use separately-insulated mains supply cables for sensitive

electronic equipment.

8. Screening of the entire welding installation may be considered under special circumstances and for special applications.

WARNING

Arc welding and cutting can be dangerous to the user, people working nearby, and the surroundings if the equipment

is handled or used incorrectly. Therefore, the equipment must only be used under the strict observance of all relevant

safety instructions. In particular, your attention is drawn to the following:

Electricity

- The welding equipment must be installed according to safety regulations and by a properly trained and qualified

person.

- Avoid all contact with live components in the welding circuit and with electrodes and wires if you have bare hands.

Always use dry welding gloves without holes.

- Make sure that you are properly and safely earthed (e.g use shoes with rubber sole).

- Use a safe and stable working position (e.g. avoid any risk of accidents by falling).

- Make sure that the welding equipment is correctly maintained. In the case of damaged cables or insulation work

must be stopped immediately in order to carry out repairs.

- Repairs and maintenance of the equipment must be carried out by a properly trained and qualified person.

Light and heat emissions

- Protect the eyes as even a short-term exposure can cause lasting damage to the eyes. Use a welding helmet with

suitable radiation protection glass.

- Protect the body against the light from the arc as the skin can be damaged by welding radiation. Use protective

clothes, covering all parts of the body.

- The place of work should be screened, if possible, and other persons in the area warned against the light from the

arc.

Welding smoke and gases

- The breathing in of the smoke and gases emitted during welding is damaging to health. Make sure that any

exhaust systems are working properly and that there is sufficient ventilation.

Fire hazard

- Radiation and sparks from the arc represent a fire hazard. As a consequence, combustible materials must be

removed from the place of welding.

- Working clothing should also be secure against sparks from the arc (e.g. use a fire-resistant material and watch out

for folds and open pockets).

Noise

- The arc generates surface noise according to welding task. In some cases, use of hearing aids is necessary.

Use of the machine for other purposes than it is designed for (e.g. to unfreeze water pipes) is strongly deprecrated. If

occasion should arise this will be carried out without responsibility on our part.

Read this instruction manual carefully

before the equipment is installed and in operation

Instruction manual NXT200/250 AC/DC page 4

INITIAL OPERATION

Mains connection

The machine should be connected to a mains supply

and must be correctly earthed. After the mains plug

has been connected to the mains the machine is

ready for use. Please note that all cable connections

must be made by authorised and qualified staff.

Switch on and off the machine by means of the

breaker on the rear of the machine.

Configuration

The manufacturer and supplier disclaim all

responsibility for any damage caused or related to

welding with undersized welding torches and/or

welding cables. If in doubt contact your NEXUS

distributor for recommended sizes and types.

Gas connection

Connect the machine to the gas system by means of

a gas regulator with flow control. Fit and secure the

gas hose to the gas connection on the rear of the

machine

Important!

In order to avoid damage to

plugs and cables, good electric

contact is required when

connecting earth cable and

welding torch to the machine.

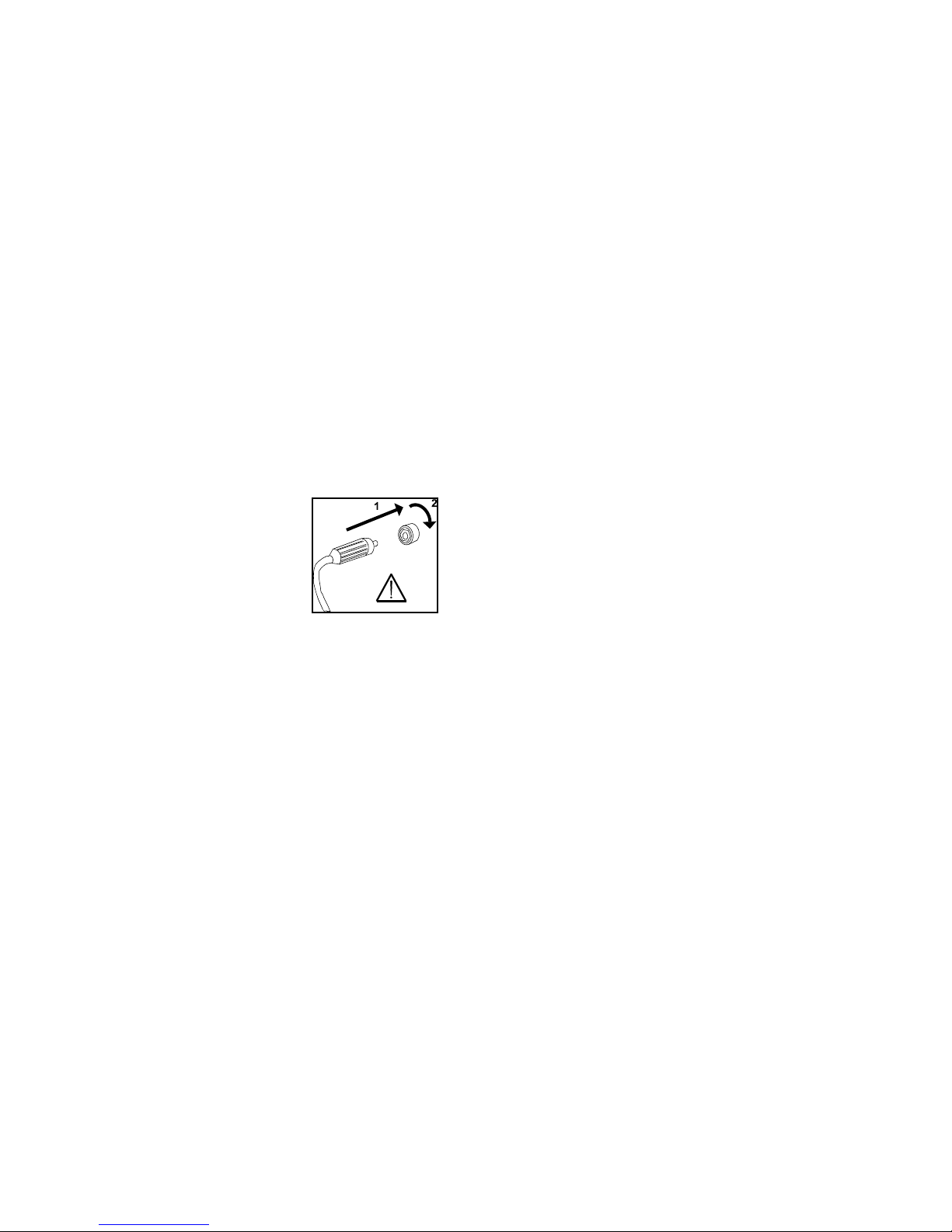

Connection of welding cables

Connect the welding cables and the return current

cable to the front of the machine.

Please note that the plug must be turned 45 degrees

after insertion into the socket - otherwise the plug

can be damaged due to excessive contact

resistance.

Connect always the TIG connection in the minus (-)

socket and the return current cable in the plus (+)

socket.

The control signals from the TIG torch are transformed to the machine through the circularly 7-pin

plug. When the plug has been assembled please

secure it by turning the "circulator" clockwise.

Connect the gas hose to the quick connection.

COATED ELECTRODES: Electrodes are marked

with a polarity on the packing. Connect the electrode

holder in accordance with this marking to the plus or

minus sockets of the machine.

Connection of remote control

Connect the remote control unit on the 7-ways plug

in the front of the machine. (OPTIONAL)

Usage of the machine

When welding, a heating of various components of

the machine takes place and during breaks these

components will cool down again. It must be ensured

that the air flow is not reduced or stopped.

When the machine is set for higher welding currents,

there will be a need for periods during which the

machine can cool down.

The length of these periods depends on the current

setting, and the machine should not be switched off

in the meantime. If the periods for cooling down

during use of the machine are not sufficiently long,

the overheating protection will automatically stop the

welding process and the yellow LED in the front

panel will come on. The yellow LED switches off

when the machine has cooled down sufficiently and

is ready for welding.

Instruction manual NXT200/250 AC/DC page 5

MAINTENANCE

Insufficient maintenance may result in reduced

operational reliability and could invalidate guarantee.

The NXT welding machines require virtually no

maintenance. However, exposure to extremely

dusty, damp or corrosive air can be damaging to

welding equipment.

Periodically maintenance

In order to prevent problems arising, the following

procedure should be observed at least once a year

or as required.

- Disconnect the machine from the mains supply

and wait 2 minutes before removing the covers.

- Clean the fan blades and the internal components

in the machine with clean, dry, low pressure

compressed air.

Calibration

The machine has been calibrated at the factory. The

certificate is valid for one year. If further

maintenance, or re-calibration is required, please

contact your NEXUS distributor or service department.

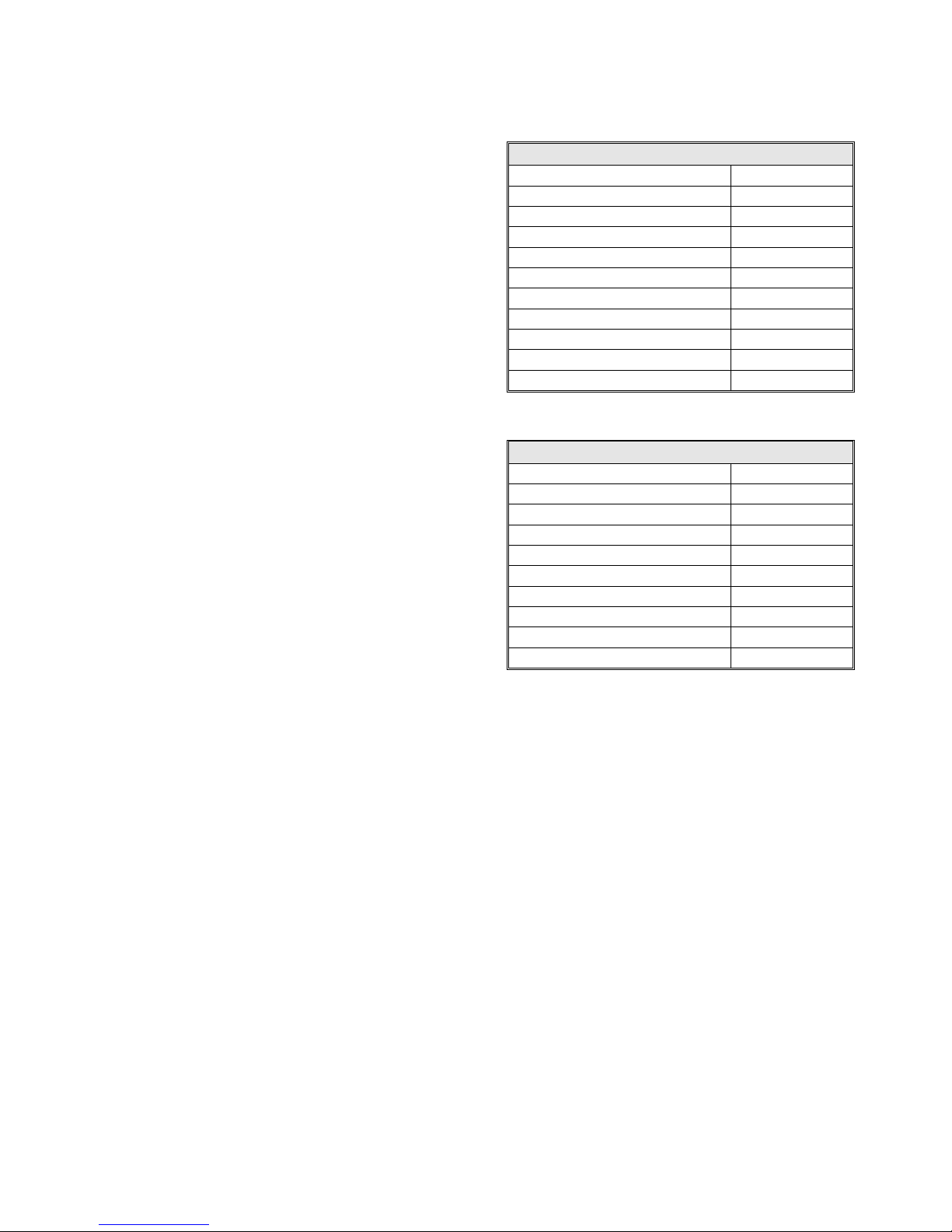

7 pin Plug connections

The functions of the 7 pin remote plug are as follows:

Pin 1 = red, water cooling

Pin 2 = black, torch switch

Pin 3 = not connected

Pin 4 = brown, water cooling

Pin 5 = not connected

Pin 6 = grey, torch switch

Pin 7 = not connected

TECHNICAL DATA

NXT200 AC/DC

Mains voltage 1x230 V

PFC (power factor correction) Yes

Duty cycle 100 % TIG 140 A 40°C

Duty cycle 100 % MMA 130 A 40°C

Duty cycle 40 % TIG 200 A 40°C

Duty cycle 40 % MMA 170 A 40°C

Open circuit voltage 60 V

Current range TIG 7 – 200 A

Current range MMA 7 – 170 A

Dimensions (LxWxH) mm 205x345x475

Weight 20 kg

NXT250 AC/DC

Mains voltage 3x400 V

Duty cycle 100 % TIG 150 A 40°C

Duty cycle 100 % MMA 150 A 40°C

Duty cycle 35 % TIG 250 A 40°C

Duty cycle 35 % MMA 200 A 40°C

Open circuit voltage 65 V

Current range TIG 7 – 250 A

Current range MMA 7 – 200 A

Dimensions (LxWxH) mm 205x345x475

Weight 20 kg

Instruction manual NXT200/250 AC/DC page 6

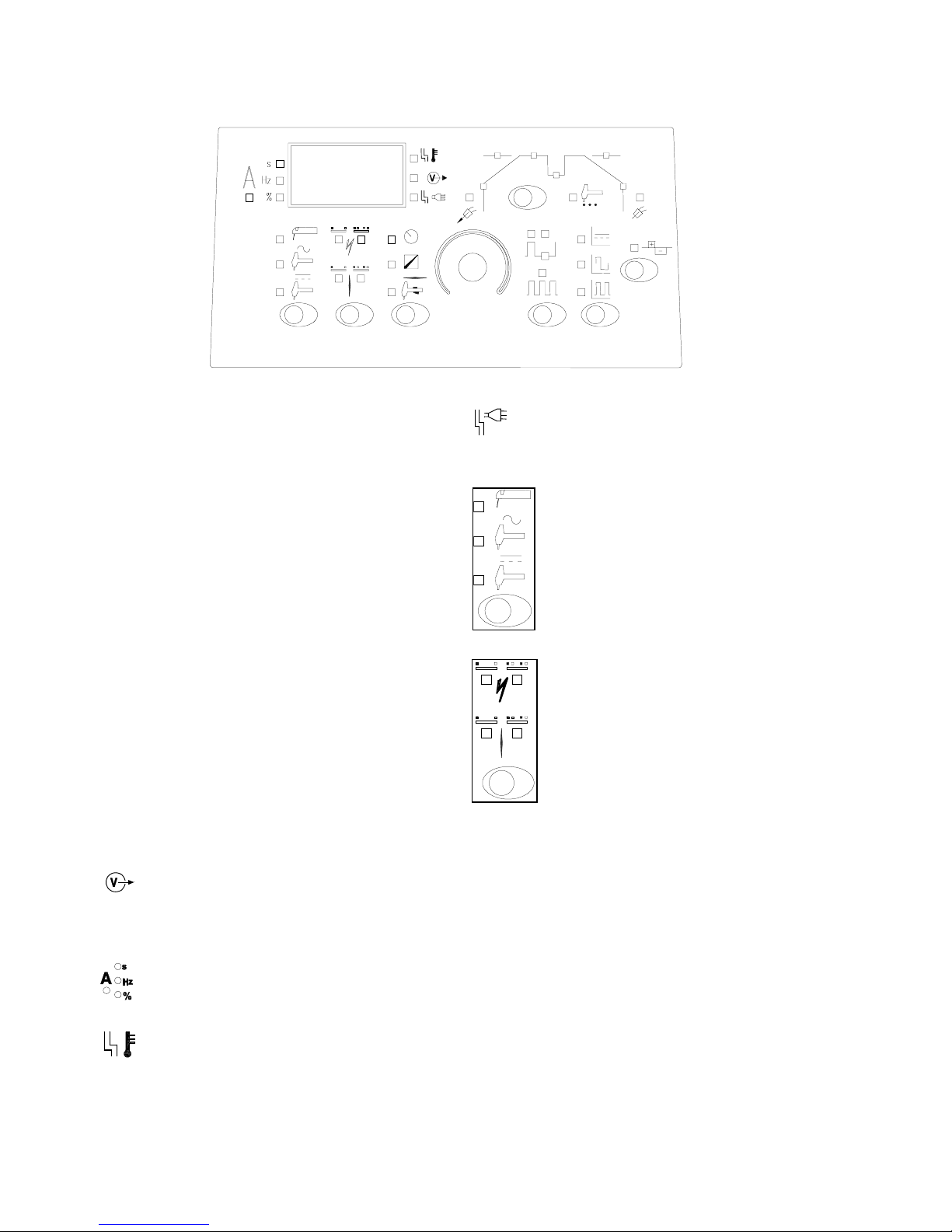

INITIAL INSTRUCTIONS

All "parameters" are set by the use of only one

control knob. These parameters include current,

pulse time, slope-up time, etc.

This control knob is positioned in the middle of the

control panel. The digital display shows the value of

the parameter being set. The unit of measurement of

the parameter is shown at the left hand side of the

digital display.

Selection of a parameter is by means of the relative

keypad in the relevant section. The parameter

selected is indicated by a bright indication light. Then

turn the control knob to set the new value.

Storage of parameters

The machine memorises all settings also when the

mains voltage is switched off, thus ensuring that the

same machine settings are available when the

machine is switched on again.

Independent adjustments in the two welding

processes (MMA and TIG) are stored as well, so that

switching from one welding process to another does

not require a new setting of parameters.

Setting of the machine

The following describes in detail the operation of the

machine.

Welding voltage

The welding voltage indicator is illuminated for

reasons of safety and in order to show if there is

voltage at the output connectors.

Units of measurement of the parameter

Units of measurement of the selected

parameter.

Overheating

The overheating indicator is illuminated if

welding is interrupted due to overheating of the

machine.

Input voltage variations

The mains error indicator is illuminated if the

mains voltage is more than 15% lower or higher than

the rated voltage.

Welding process

In this section it is possible to choose

the welding process:

• MMA electrode

• TIG AC/DC

• TIG DC

It is not possible to change welding

process during welding.

Torch switch functions

It is possible to choose between to

different methods of ignition for TIG

welding: High-Frequency (HF) and

LIFTIG ignition. Moreover, it is possible

to adjust the following parameters:

slope-up, slope-down and second

current level. It is not possible to

change setting during welding.

HF-ignition:

In HF-TIG ignition the TIG arc is ignited without

contact. A high-frequency (HF) impulse initiates the

arc when the torch trigger is activated.

The HF will not arise and the machine will stop if the

electrode is in contact with the workpiece. Detach

the electrode and start again.

LIFTIG-ignition:

In LIFTIG ignition the TIG arc is ignited after making

contact between the workpiece and the tungsten

electrode, after which the trigger is activated and the

arc is established by lifting the electrode from the

workpiece.

Two-times:

The welding process begins by pressing the torch

trigger. Welding continues until the trigger is

released again which effects the slope-down period.

Loading...

Loading...