Page 1

Transceiver

Installation Manual

Exciter

Page 2

Warranty

Xmark's products are warranted against defects in materials and workmanship and shall

perform in accordance with published specifications for 1 year.

Xmark's warranty is limited solely to the repair or replacement of the defective part or

product. Xmark reserves the right to change product specifications without notice.

Regulatory Statements

United States - Federal Communication Commission (FCC)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

War ning: Any changes or modifications not expressly approved by Xmark could void the

user's authority to operate the equipment.

Canada - Industry Canada

The term "IC:" before the certification/registration number only signifies that Industry

Canada technical specifications were met.

Important Recommendation

Xmark’s systems are designed to assist staff in providing a high degree of safety for people

and assets and therefore should be used as a component of a comprehensive security

program of policies, procedures, and processes. As with every security system, Xmark

highly recommends regular system operational checks to verify functional integrity.

Page 3

Introduction

The exciter is an additional Low Frequency (LF) antenna for a Transceiver. By

using exciters, additional LF Fields can be created and the tag detection zones

can be extended.

Each Transceiver supports a maximum of three transceiver exciters. The

LF Fields of the Transceiver and all exciters will be in phase.

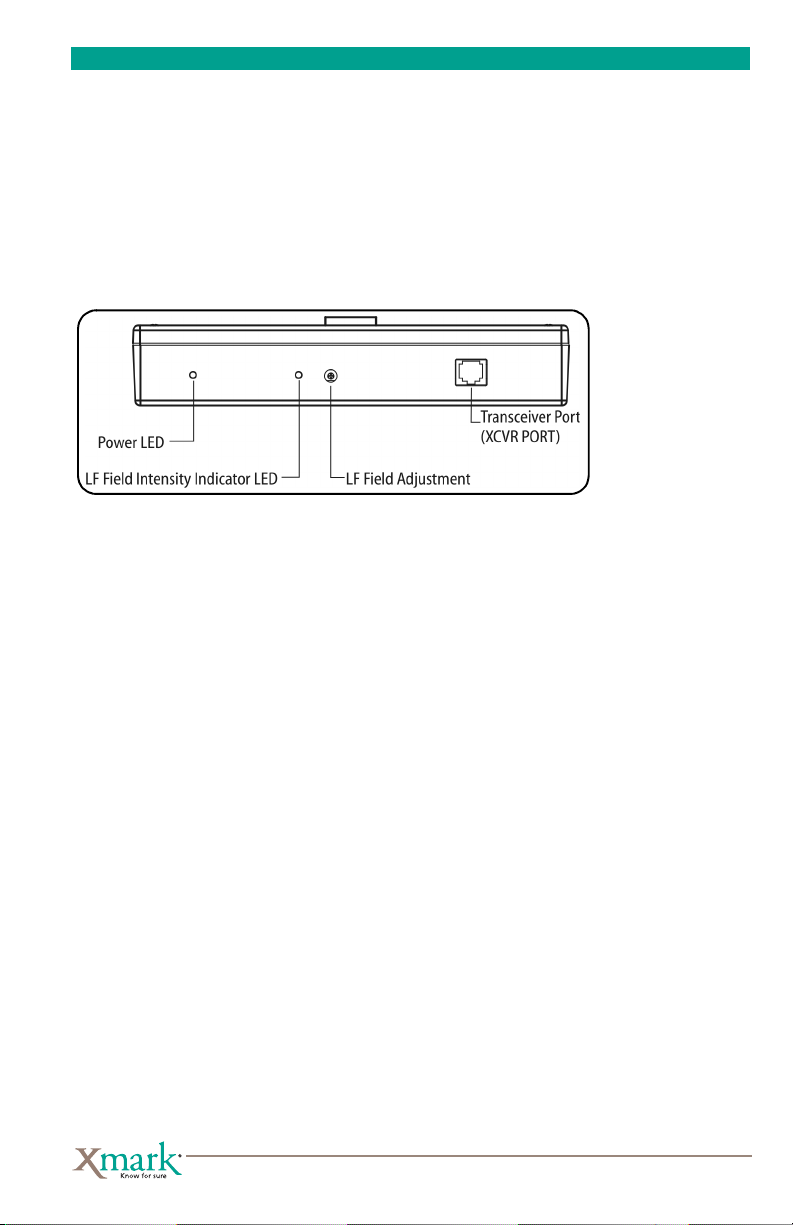

Figure 1: Exciter Front Panel

The exciter is connected to a transceiver (Part Number SR4TX01) from the

exciter’s XCVR PORT to any one of the transceiver’s three SATELLITE

EXCITERS ports using a standard ethernet cable (CAT5, EIA 568A termination). The exciter also draws its power from this connection.

1

Firmware Updates

The exciter does not contain firmware. Its operating features are dependent on

the Transceiver.

Installation Tips

When installing the exciter:

• Use both mounting holes to ensure that the exciter is secure.

• Mount the exciter so that the front panel is easily accessible and visible from the

floor. If mounting above a ceiling, place the exciter so that the front panel is visible

from the floor when a ceiling tile is removed.

• Check that the LF Field radiated by the exciter(s) and the Transceiver is continuous

(no dead spots) and that it covers the correct area. See “Configuration” on page 4.

Location Selection

Any of the following are suitable locations for an exciter:

Transceiver Exciter Installation Guide

Page 4

2

• On the wall above the egress point or monitored area.

•Inside a wall cavity.

• On the sidewall along the hallway mounted flat against the wall.

Location Considerations

When planning the exciter location, consider the following:

• Ceiling Height and Corridor Width — The exciter LF Field should extend to the

floor and from one wall of the corridor to the other. Tags must not be able to pass

under or around the LF Field.

• Any Nearby Metal — Large metal surfaces close to the exciter can distort the

LF Field in unpredictable ways. This effect can increase or decrease the LF Field

strength and even extend the LF Field shape. At times this effect can be used to

advantage but the desired result can only be obtained experimentally. Metal plate,

foil, or mesh must not come between the exciter and the tags to be queried and read.

The exciter top, bottom, and rear panels must be at least 3 in. (7.6 cm) from any

metallic surfaces.

• LF Field Shape — In the absence of large metal objects the LF Field is a sphere with

a 15 ft. (4.5 m) maximum radius centered around the exciter. As a result, the

LF Field range is unaffected by rotating the exciter, or by placing the exciter vertically or horizontally.

• Adjacent Floors — If the LF Field extends into adjacent floors, it will cause tags on

the adjacent floors to be reported as if on the exciter floor.

LF Field Coverage

When the exciter is used to monitor an egress point, such as a door or elevator,

the LF Field(s) should cover all possible approaches. As many as three exciters

can be used with a single Transceiver to modify the LF Field for this application.

Tags must be detected at least 8 ft. (2.4 m) before the door when the Transceiver

is part of a door locking system. This ensures adequate time for the lock to energize before the tag reaches the doorway.

The LF Field should not extend into adjacent areas, including adjacent floors,

containing tags. These tags could cause the Transceiver to activate the lock even

though tags are not approaching the exit.

Exciter Installation

To install the exciter:

1 Mount the exciter with #8 hardware using the two mounting holes.

2 Record the exciter location for later consideration.

3 Route the cable (not supplied) from the exciter to the Transceiver.

Transceiver Exciter Installation Guide

Page 5

3

4 Disconnect the Transceiver from its power supply.

5 Plug the cable into the Transceiver and the exciter.

6 Reconnect the Transceiver power supply.

7 Verify that the exciter power LED and the field intensity LED are on. See

Figure 1 for the location of these indicators. If they are not lit, check that the

Transceiver has power, and that the cable plug is properly inserted.

8 Adjust the exciter LF Field as described in “Configuration” below.

Configuration

The exciter is configured by adjusting the LF Field strength and size.

Before you set the LF Field Strength

Ensure that the Transceiver UHF Threshold is properly set: That is, the red

UHF Rx LED on the Transceiver is lit most of the time but continues to flicker

occasionally. If this is not true, set the UHF Threshold as described in the Transceiver Installation Manual.

The LF Field causes a tag to transmit a UHF message to the Transceiver. When

in test mode, the Transceiver beeps when a tag message is successfully received.

The beeping sound allows you to estimate the LF Field size.

The LF Field should be:

• Strong enough to make the tag respond throughout the desired area. That is, the

Transceiver beeps continually while the tag is anywhere within the desired area.

• Not strong enough to make the tag respond outside of the desired area. That is, the

Transceiver does not beep when the tag is outside of the desired area.

• Not strong enough to bleed onto adjacent floors. That is, the Transceiver does not

beep when the tag is on an adjacent floor.

To s et the LF Fi eld:

1 Set test mode by moving switch 1 down on the transceiver’s MODE DIP swtich

block.

2 Confirm tag operation by holding the tag close to the Transceiver. The Trans-

ceiver should beep continuously.

3 Using the tag, explore the desired coverage area while constantly re-orienting

the tag with respect to the exciter. The Transceiver should beep continuously.

Within the desired coverage area there may be locations with low LF Field

strength called dead spots. The Transceiver will stop beeping when the tag

enters a dead spot. The size and number of dead spots should be minimized.

However, a small number of dead spots may be acceptable.

Transceiver Exciter Installation Guide

Page 6

4

Some dead spots are less important than others. For example, if the aim is to

record the movement of tags through a door, a dead spot far from the door

may be less important than one near the door.

4 If the dead spot size and number is unacceptable, or if the LF field coverage

area is too small, increase the strength of the LF field by turning the LF FIELD

ADJ screw on the exciter clockwise.

The exciter adjustments are delicate. Do not turn the adjustments forcefully

to the limits. Do not needlessly wiggle or turn the adjustments.

As you turn the LF FIELD ADJ screw, the LF FIELD INTENSITY Indicator becomes:

w Brighter as you turn the ADJ screw clockwise and increase the LF Field strength;

—or—

w Dimmer as you turn the ADJ screw counterclockwise and decrease the LF Field strength.

5 If the tag is detected outside of the desired area, decrease the LF Field strength

by turning the adjustment counterclockwise until detection is limited to the

desired area.

Be aware that if the LF field reaches into adjacent floors it may cause tags on

those floors to be reported as if on the exciter floor.

6 Continue moving between steps 4 and 5 to achieve the best compromise

between a minimum number of dead spots, and limited detection.

7 If a suitable compromise cannot be achieved, consider relocating the exciter

and repeating the procedure.

8 When you have successfully set the LF Field strength, turn off test mode on the

transceiver and fix the exciter cables permanently in place.

Tip: If the exciter is above a suspended ceiling, place a colored adhesive dot on the

ceiling tile to mark the exciter location. Consult facility management before placing

the dots.

Transceiver Exciter Installation Guide

Page 7

Specifications

Part Number . . . . . . . . . . . . . . . . . . . . . . . . SR4EX01

Physical Specifications

Operating Temperature . . . . . . . . . . . . . . . . 32º F to 131º F (0º C to 55º C)

Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 – 90% RH non-condensing

Size including mounting bracket

(W x H x D) . . . . . . . . . . . . . . . . . . . . . . . . 8.62 in. x 1.5 in. x 6.5 in.

(21.9 cm x 3.81 cm x 16.5 cm)

Maximum Cable Length . . . . . . . . . . . . . . . 20 ft. (6 m)

Weight including mounting bracket . . . . . . 19.4 oz. (551 g)

Electrical Specifications

Maximum Power . . . . . . . . . . . . . . . . . . . . . 150 mA @ 24 VDC —

by the Transceiver.

Transmit Frequency . . . . . . . . . . . . . . . . . . 307.2 kHz

LF Detection Zone . . . . . . . . . . . . . . . . . . . . 5 ft. – 15 ft. (1.5 m – 4.6 m), adjustable

The

exciter

is powered

5

Transceiver Exciter Installation Guide

Page 8

© 2005–2007 Xmark Corporation. All Rights Reserved. Xmark is a registered trademark of

309 Legget Drive Ottawa, ON Canada K2K 3A3

Telephone:1.866.55.XMARK

International:+1 (613) 592.6997

Facsimile:(613) 592.4296

Web site:www.xmark.com

E-mail:support@xmark.com

Xmark Corporation in North America. All other company and product names may be

trademarks of their respective companies.

Printed in Canada. October 2007. 981-000305-000 R02.

Loading...

Loading...