XLT Ovens AVI Hood, AVI-1832B-S, XLT-1832C-S, XLT-1832C-W, AVI-1832B-W Installation & Operation Manual

...

XD-9004A

GA-SWC-HB

04/09/2012

XLT Gas Oven & AVI Hood

Installation & Operation Manual

This appliance is for professional use by qualified personnel. This appliance must be installed

by qualified persons in accordance with the regulations in force. This appliance must be installed with

sufficient ventilation to prevent the occurrence of unacceptable concentrations of substances harmful

to health in the room in which it is installed. This appliance needs an unobstructed flow of fresh air for

CAUTION

Current versions of this manual, Rough-In Specifications, Parts & Service Manual, Architectural Drawings,

For use with the following XLT GAS Oven Versions:

Standard (S) C

World (W) C

satisfactory operation & must be installed in a suitably ventilated room in accordance with current

regulations. This appliance should be serviced by qualified personnel at least every 12 months or

sooner if heavy use is expected.

& a list of International Authorized Distributors are available at: www.xltovens.com

For use with the following AVI Gas Hood Versions:

Standard (S) B

World (W) B

2000887

US: 888-443-2751 FAX: 316-943-2769 INTL: 316-943-2751 WEB: www.xltovens.com

XLT Ovens

PO Box 9090

Wichita, Kansas 67277

2

WARNING & SAFETY INFORMATION

SAFETY DEPENDS ON YOU

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury, or death. Read the installation, operating and maintenance in-

WARNING

Post in a prominent location instructions to be followed in the event you smell gas. This infor-

mation can be obtained by consulting your local gas supplier.

WARNING

In the event a gas odor is detected, shut off the gas at the main shutoff valve immediately.

Contact your local Gas Company or supplier.

Do not restrict the flow of combustion and/or ventilation air to the unit. Provide adequate

clearance for operating, cleaning, & maintaining the unit & adequate clearance for operating

the gas shutoff valve when the unit is in the installed position.

Keep the area free & clear of combustible material. DO NOT SPRAY AEROSOLS IN THE

VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

Ovens are certified for installation on combustible floors.

Electrical schematics are located inside the control box of the oven & and in this manual. Dis-

connect input power to the unit before performing any maintenance.

This unit requires a ventilation hood. The installation must conform to local codes.

This unit may be operated with either natural gas or LP fuel as designated on the nameplate

label located on the side of the unit.

This unit must be operated by the same voltage, phase, & frequency of electrical power as des-

ignated on the nameplate label located on the side of the unit.

Minimum clearances must be maintained from combustible & non-combustible construction

materials.

Follow all local codes when installing this unit.

Follow all local codes to electrically ground the unit.

Appliance is not to be cleaned with high pressure water.

XLT ovens are certified for use in stacks of up to three (3) units of XLT products. Integration

of other manufacturer’s products into an oven stack is not recommended, & will void any war-

ranties. XLT Ovens assumes no liability for mixed product applications.

Failure to call XLT Customer Service at 1-888-443-2751 prior to contacting a repair company

voids any & all warranties.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

structions thoroughly before installing, using, or servicing this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable liquids or vapors in

the vicinity of this or any other appliance.

XLT Ovens has spent millions of dollars designing and testing our products as well as de-

veloping Installation & Operation Manuals. These manuals are the most complete and easiest to

understand in the industry. However, they are worthless if they are not followed.

We have witnessed store operators and building owners lose many thousands of dollars in

lost revenue due to incorrect installations. We highly recommend you follow all instructions given

in this manual as well as follow best practices in plumbing, electrical, and HVAC building codes.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

WARNING & SAFETY INFORMATION

Definitions & Symbols

A safety instruction (message) includes a “Safety Alert Symbol” & a signal word or phrase

such as WARNING or CAUTION. Each signal word has the following meaning:

This symbol indicates high voltage. It calls your attention to items or operations

that could be dangerous to you & other persons operating this equipment. Read the

HIGH

VOLTAGE

WARNING

CAUTION

message & follow the instructions carefully.

Indicates a potentially hazardous situation that, if not avoided, can result in serious

injury or death.

Indicates a potentially hazardous situation, that if not avoided, can result in minor to

moderate injury or serious damage to the product. The situation described in the

CAUTION may, if not avoided, lead to serious results. Important safety measures are

described in CAUTION (as well as WARNING), so be sure to observe them.

3

NOTE

TIP

Notes indicates an area or subject of special merit, emphasizing either the product’s

capability or common errors in operation or maintenance.

Tips give a special instruction that can save time or provide other benefits while installing

or using the product. The tip calls attention to an idea that may not be obvious to first-time

users of the product.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

4

WARRANTY - US & Canada

XLT warrants gas ovens manufactured after April 1, 2009 utilizing quietFIRE™ burners

and all electric ovens manufactured after April 1, 2011 to be free from any defect in material and

workmanship under normal use for five (5) years from the date of original purchase by the end

user, and further warrants main fan blades, conveyor shafts, and conveyor bearings for ten (10)

years. XLT further warrants all ovens to be free from rust for ten (10) years from the date the

equipment is originally purchased. XLT warrants AVI hoods to be free from any defect in material and workmanship under normal use for two (2) years from the date of original purchase by the

end user. In the event of a part failure, XLT will furnish a replacement part and pay for all labor

associated with the replacement of the part if, upon inspection, XLT determines that the part is defective. This warranty is extended to the original end user purchaser and is not transferable without prior written consent of XLT. Damages are limited to the original purchase price.

DUTIES OF THE OWNER:

The owner must inspect the equipment and crates at time of receipt. Damage during shipment

is to be immediately reported to the carrier and also to XLT.

The equipment must be installed and operated in accordance with the written instructions fur-

nished with the unit.

This warranty shall not excuse the owner from properly maintaining the equipment in accor-

dance with the written instructions furnished with the unit.

A copy of the “Initial Start-Up Checklist” must be filled out and returned to XLT Ovens and

the Authorized Distributor when the unit is initially installed, and/or when the unit is removed

and installed in another location.

The gas, electric, and HVAC utilities must be connected to the oven and installed by locally

licensed contractors.

Failure to contact XLT Ovens prior to contacting a repair company for warranty work voids

any and all warranties.

WHAT IS NOT COVERED:

The following items are not covered by this warranty:

Freight damage

Any part that becomes defective because of utility services (power surges, high or low volt-

ages, high or low gas pressure or volume, contaminated fuel, or improper utility connections)

Conveyor belts

Filters

Exhaust Fans

Light Bulbs

Normal maintenance or adjustments

This warranty shall not apply if the equipment or any part is damaged as a result of accident,

casualty, alteration, misuse, abuse, improper cleaning, improper installation, improper operation, natural disasters, or man-made disasters.

CLAIMS HANDLED AS FOLLOWS:

Should any such defect be discovered, XLT must be notified. Upon notification, XLT will arrange

for necessary repairs to be made by an authorized service agent. Denial of services upon the arrival of an authorized service agent will release XLT of any and all warranty obligations.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

LIMITED WARRANTY - INTERNATIONAL

5

XLT warrants gas ovens manufactured after January 1, 2011 utilizing quietFIRE™ burners

and all electric ovens manufactured after April 1, 2011 to be free from any defect in material and

workmanship under normal use for two (2) years from the date of original purchase by the end

user. XLT warrants AVI hoods to be free from any defect in material and workmanship under normal use for one (1) year from the date of original purchase by the end user. In the event of a part

failure, XLT will furnish a replacement part to the Authorized Dealer if, upon inspection, XLT determines that the part is defective. The Authorized Dealer will pay for all labor associated with the

replacement of the part. This warranty is extended to the original end user purchaser and is not

transferable without prior written consent of XLT. Damages are limited to the original purchase

price.

DUTIES OF THE OWNER:

The owner must inspect the equipment and crates at time of receipt. Damage during shipment

is to be immediately reported to the carrier and also to XLT.

The equipment must be installed and operated in accordance with the written instructions fur-

nished with the unit.

This warranty shall not excuse the owner from properly maintaining the equipment in accor-

dance with the written instructions furnished with the unit.

A copy of the “Initial Start-Up Checklist” must be filled out and returned to XLT Ovens and

the Authorized Dealer when the unit is initially installed, and/or when the unit is removed and

installed in another location.

The gas, electric, and HVAC utilities must be connected to the oven and installed by locally

licensed contractors.

Failure to contact the Authorized Dealer prior to contacting a repair company for warranty

work voids any and all warranties.

WHAT IS NOT COVERED:

The following items are not covered by this warranty:

Freight damage

Any part that becomes defective because of utility services (power surges, high or low volt-

ages, high or low gas pressure or volume, contaminated fuel, or improper utility connections)

Conveyor belts

Filters

Exhaust Fans

Light Bulbs

Normal maintenance or adjustments

This warranty shall not apply if the equipment or any part is damaged as a result of accident,

casualty, alteration, misuse, abuse, improper cleaning, improper installation, improper operation, natural disasters, or man-made disasters.

CLAIMS HANDLED AS FOLLOWS:

Should any such defect be discovered, the Authorized Dealer must be notified. Upon notification,

the Authorized Dealer will arrange for necessary repairs to be made by an authorized service

agent. The Authorized Dealer will notify XLT Ovens of all discovered defects.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

6

RECEIVING & INSPECTION

NOTIFY CARRIER OF DAMAGE AT ONCE

Upon receiving of all goods shipped by a Common Carrier, check for any exterior damage

that may indicate interior damage. If conditions permit, open all crates & do a full inspection for

any damage while the delivery driver is still there. If there is damage, please note on the delivery

receipt & call the carrier to make a freight damage claim within 24 hours of receipt. Failure to

make a damage claim within the first 24 hours may void the opportunity to have the claim resolved.

XLT Ovens wants you to be totally satisfied with every aspect of owning & using your

oven & hood. Your feedback, both positive & negative, is very important to us as it helps us understand how to improve our products & our company. Our goal is to provide you with equipment

that we can be proud to build & you can be proud to own.

To receive technical support for the oven or hood you purchased, XLT has qualified customer service personnel that can provide assistance on any type of XLT oven problem you may

experience. Customer Service is available 24/7/365 or visit www.xltovens.com.

Installation of all gas appliances & ventilation exhaust hoods should only be performed by a qualified professional who has read & understands these instructions &

is familiar with proper safety precautions. Read this manual thoroughly before in-

WARNING

stalling or servicing this equipment.

Save this Manual

This document is the property of the owner of this equipment.

XLT Ovens reserves the right to make changes in design & specifications, and/or make additions to or improvements to its product without imposing any obligations upon itself to install

them in products previously manufactured.

All Right Hand & Left Hand designations in this manual are from the point of view as if

standing directly in front of the glass sandwich door.

Revision History Table

Revision Comments Date

A New Release 04/09/2012

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

TABLE OF CONTENTS

Warning & Safety Information..................................................................................................... 2

Warranty ....................................................................................................................................... 4

Oven & Hood Descriptions .......................................................................................................... 8

Oven Dimensions & Weights ..................................................................................................... 10

Oven Gas Requirements ............................................................................................................. 12

Oven Electrical Requirements .................................................................................................... 16

Oven Only Rough-In Specifications .......................................................................................... 17

Oven Assembly .......................................................................................................................... 18

Oven Installation ........................................................................................................................ 23

Oven Fire Suppression ............................................................................................................... 25

Oven Ventilation Requirements & Guidelines ........................................................................... 27

Oven Initial Start-Up .................................................................................................................. 28

Oven Operation .......................................................................................................................... 29

Oven Operator Controls ............................................................................................................. 30

Oven Cleaning ............................................................................................................................ 31

Oven Maintenance ...................................................................................................................... 35

Oven Troubleshooting ................................................................................................................ 36

Hood Description ....................................................................................................................... 39

Hood Dimensions & Weights..................................................................................................... 40

Hood Electrical Requirements.................................................................................................... 42

Hood Electrical Connections ...................................................................................................... 44

Hood Rough-In Specifications ................................................................................................... 57

Hood Exhaust Flow Rates .......................................................................................................... 58

Hood Installation ........................................................................................................................ 60

Hood Initial Start-Up .................................................................................................................. 79

Hood Operator Controls ............................................................................................................. 80

Hood Valance Kit ....................................................................................................................... 81

Hood Duct Wrap Kit .................................................................................................................. 84

Hood Cleaning ............................................................................................................................ 85

Hood Troubleshooting ................................................................................................................ 86

Variable Frequency Drive Manual Mode ................................................................................... 87

Electrical Schematics ................................................................................................................. 88

Certifications .............................................................................................................................. 97

Oven Start-Up Checklist ............................................................................................................ 99

Hood Start-Up Checklist .......................................................................................................... 101

7

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

8

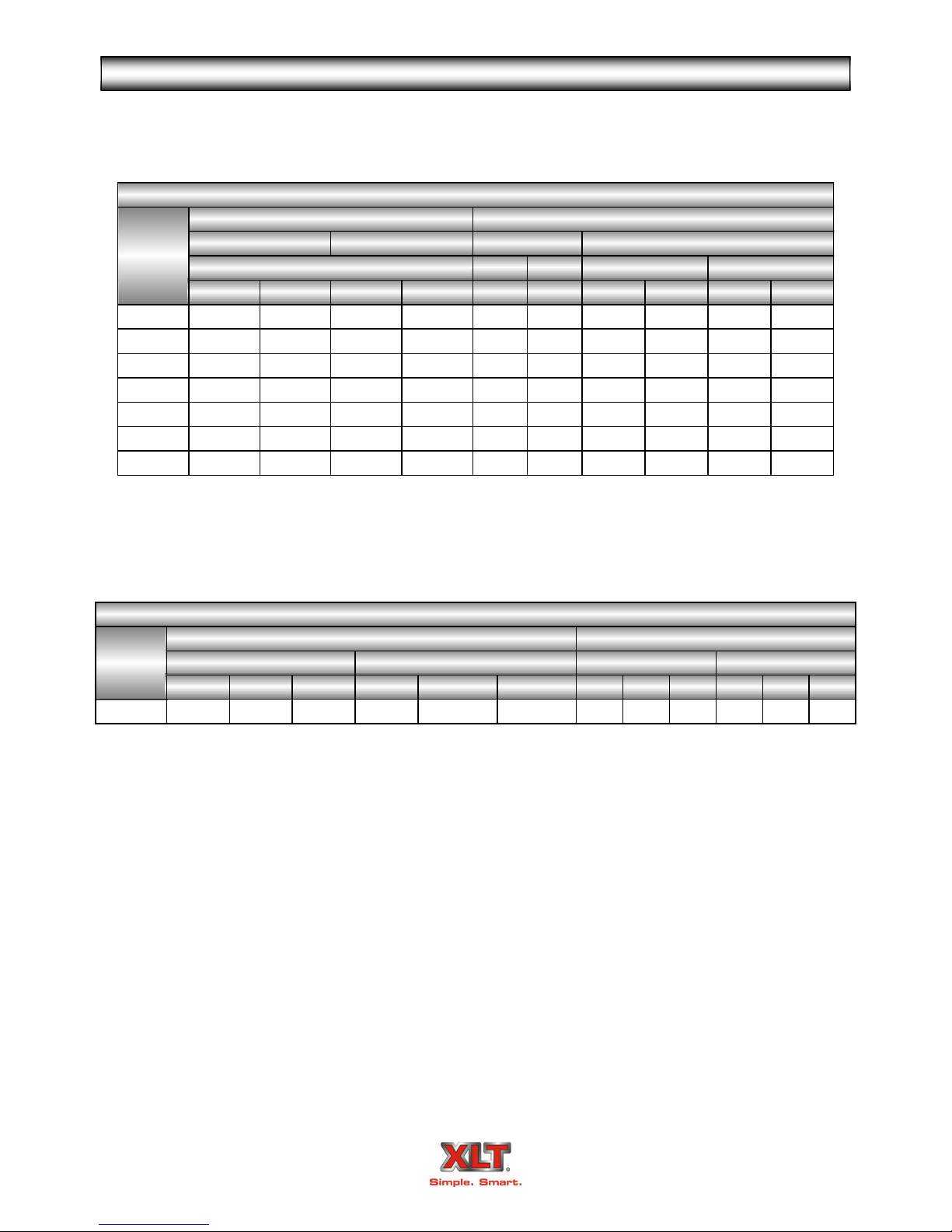

Standard World Standard World

XLT-1832C-S XLT-1832C-W AVI-1832B-S AVI-1832B-W

XLT-2440C-S XLT-2440C-W AVI-2440B-S AVI-2440B-W

XLT-3240C-S XLT-3240C-W AVI-3240B-S AVI-3240B-W

XLT-3255C-S XLT-3255C-W AVI-3255B-S AVI-3255B-W

XLT-3270C-S XLT-3270C-W AVI-3270B-S AVI-3270B-W

XLT-3855C-S XLT-3855C-W AVI-3855B-S AVI-3855B-W

XLT-3870C-S XLT-3870C-W AVI-3870B-S AVI-3870B-W

Hoods

Ovens

This manual covers the following XLT Oven & AVI Hood models:

The first 2 digits of the model number represent the conveyor width and the last two digits

indicate the bake chamber length. The ovens may be used in a single, double, or triple oven stack

configuration. All ovens are gas-fired & are available in Natural gas or LP gas models (Electric

ovens are also available). The 3270 & 3870 models have two burners, one on each side, & have

two control boxes. All other models have only a single burner with a single control box that can

be supplied on either end. All models can be configured for a split belt conveyor.

DESCRIPTIONS

OVEN DESCRIPTION

Food product is placed on the stainless steel wire conveyor belt on one side of the oven.

The conveyor then transports the food through the bake chamber at a user-controlled speed. This

provides repeatable and uniform food cooking. The conveyors can be easily configured to move

either left-to-right or right-to-left. A large center sandwich door allows the introduction or removal of food items for cooking at shorter times. Precise temperatures are user adjustable and

maintained by a digital control.

An easily removable front panel allows the full cleaning of the oven interior. All exposed

oven surfaces both exterior and interior are stainless steel. The conveyor is a one piece design and

is removed from the side which has the control box. No tools are required for disassembly and

cleaning of the conveyor or oven interior. The oven itself is mounted on lockable swivel casters

for easy moving and maintenance.

Accessories such as extended conveyor shelves, base shelves, cool fronts, fire suppression

components, and perforated crumb trays are available from XLT. In addition, moving equipment

such as carts and lifting jacks are available to help install and move ovens. Please contact XLT

Ovens or your Authorized Distributor for more information.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

OVEN DESCRIPTION

9

Conveyor

Crumb Tray

Front Panel Knob

Sandwich Door

Front Panel

Oven Lid

Control Box

Product Stop

Locking

Swivel Caster

Data Plate

Control Box Lid

Control Switch

Control Panel

Chain Guard

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

10

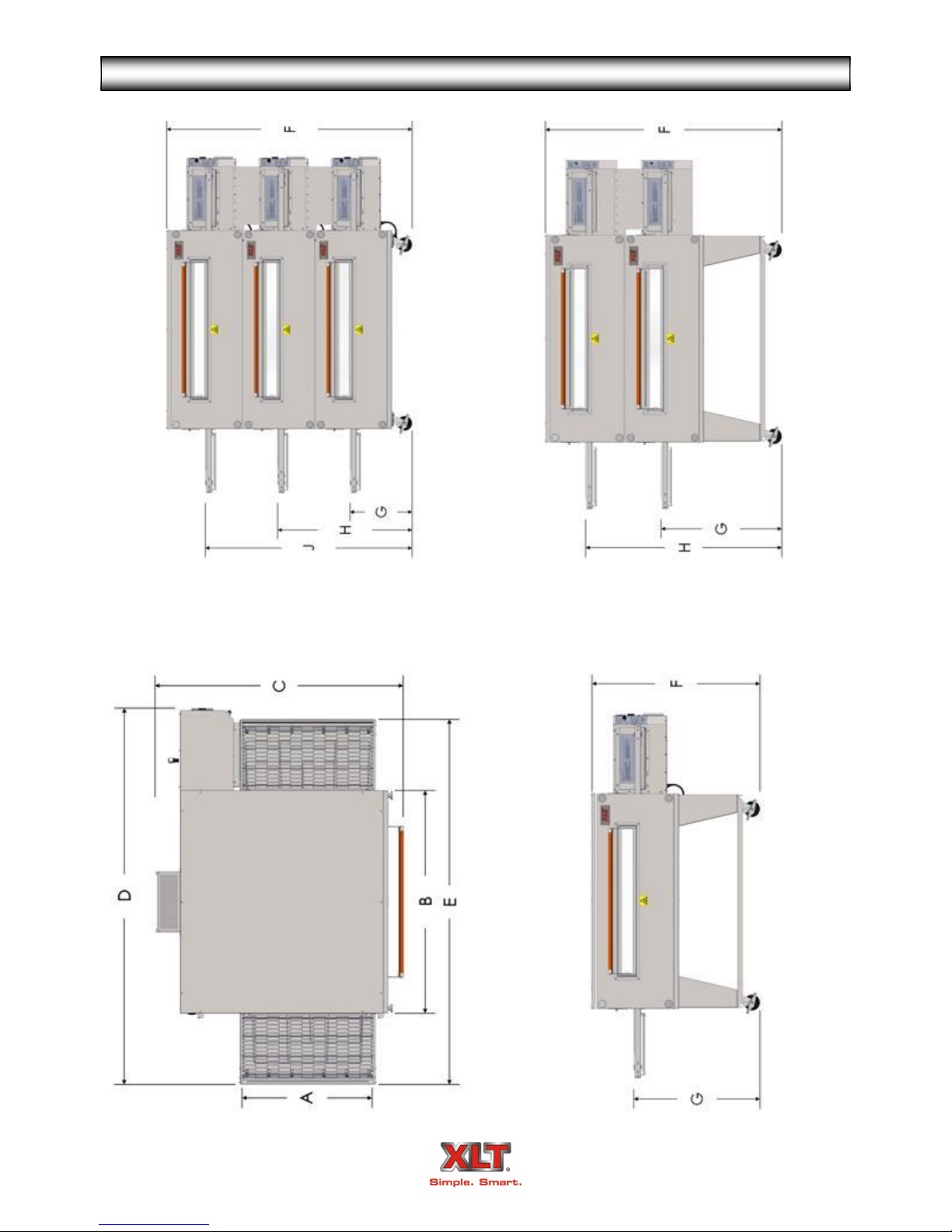

OVEN DIMENSIONS

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

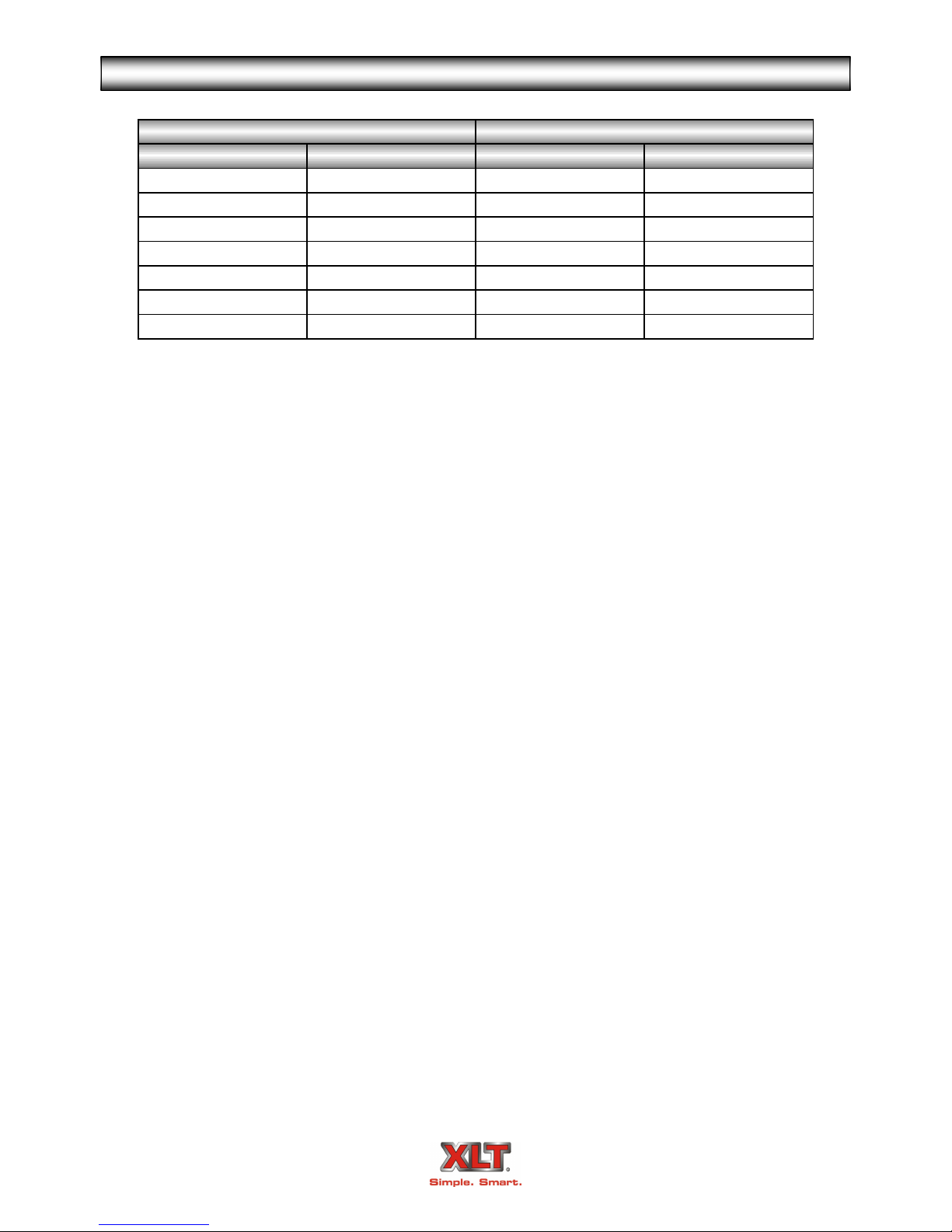

OVEN DIMENSIONS & WEIGHTS

18

32 47 1/4 70 67 1/4 42 3/4 32

477

[457] [813] [1200] [1778] [1708] [1086] [813] [216]

24 40 53 1/4 78 75 1/4 42 3/4 32

543

[610] [1016] [1353] [1981] [1911] [1086] [813] [246]

32 40 61 1/4 78 75 1/4 42 3/4 32

629

[813] [1016] [1556] [1981] [1911] [1086] [813] [285]

32 55 61 1/4 93 90 1/4 42 3/4 32

757

[813] [1397] [1556] [2362] [2292] [1086] [813] [343]

32 70 61 1/4 110 3/4 105 1/4 42 3/4 32

985

[813] [1778] [1556] [2813] [2673] [1086] [813] [447]

38 55 67 1/4 93 90 1/4 42 3/4 32

829

[965] [1397] [1708] [2362] [2292] [1086] [813] [376]

38 70 67 1/4 110 3/4 105 1/4 42 3/4 32

1077

[965] [1778] [1708] [2813] [2673] [1086] [813] [489]

18

32 47 1/4 70 67 1/4 62 3/4 32 52

863

[457] [813] [1200] [1778] [1708] [1594] [813] [1321] [391]

24 40 53 1/4 78 75 1/4 62 3/4 32 52

981

[610] [1016] [1353] [1981] [1911] [1594] [813] [1321] [445]

32 40 61 1/4 78 75 1/4 62 3/4 32 52

1142

[813] [1016] [1556] [1981] [1911] [1594] [813] [1321] [518]

32 55 61 1/4 93 90 1/4 62 3/4 32 52

1380

[813] [1397] [1556] [2362] [2292] [1594] [813] [1321] [626]

32 70 61 1/4 110 3/4 105 1/4 62 3/4 32 52

1817

[813] [1778] [1556] [2813] [2673] [1594] [813] [1321] [824]

38 55 67 1/4 93 90 1/4 62 3/4 32 52

1513

[965] [1397] [1708] [2362] [2292] [1594] [813] [1321] [686]

38 70 67 1/4 110 3/4 105 1/4 62 3/4 32 52

1984

[965] [1778] [1708] [2813] [2673] [1594] [813] [1321] [900]

18

32 47 1/4 70 67 1/4 67 3/4 17 37 57

1216

[457] [813] [1200] [1778] [1708] [1721] [432] [940] [1448] [552]

24 40 53 1/4 78 75 1/4 67 3/4 17 37 57

1386

[610] [1016] [1353] [1981] [1911] [1721] [432] [940] [1448] [629]

32 40 61 1/4 78 75 1/4 67 3/4 17 37 57

1617

[813] [1016] [1556] [1981] [1911] [1721] [432] [940] [1448] [733]

32 55 61 1/4 93 90 1/4 67 3/4 17 37 57

1964

[813] [1397] [1556] [2362] [2292] [1721] [433] [941] [1448] [891]

32 70 61 1/4 110 3/4 105 1/4 67 3/4 17 37 57

2610

[813] [1778] [1556] [2813] [2673] [1721] [433] [941] [1448] [1184]

38 55 67 1/4 93 90 1/4 67 3/4 17 37 57

2156

[965] [1397] [1708] [2362] [2292] [1721] [433] [941] [1448] [978]

38 70 67 1/4 110 3/4 105 1/4 67 3/4 17 37 57

2846

[965] [1778] [1708] [2813] [2673] [1721] [433] [941] [1448] [1291]

WEIGHT

1832

2440

3240

3255

3270

3855

3870

3270

N/A

3855

N/A

3870

N/A

TRIPLE

STACK

ABCDEFGHJ

WEIGHT

1832

N/A

2440

N/A

3240

N/A

3255

N/A

3855

N/A

N/A

3270

N/A

N/A

DOUBLE

STACK

ABCDEFGHJ

N/A

3240

N/A

N/A

3255

N/A

N/A

3270

N/A

N/A

NOTE: All dimensions in inches [millimeters], ± 1/4 [6], unless otherwise noted. All weights in pounds [kilograms] unless otherwise noted.

SINGLE

STACK

ABCDEFGHJ

WEIGHT

1832

N/A

N/A

2440

N/A

11

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

12

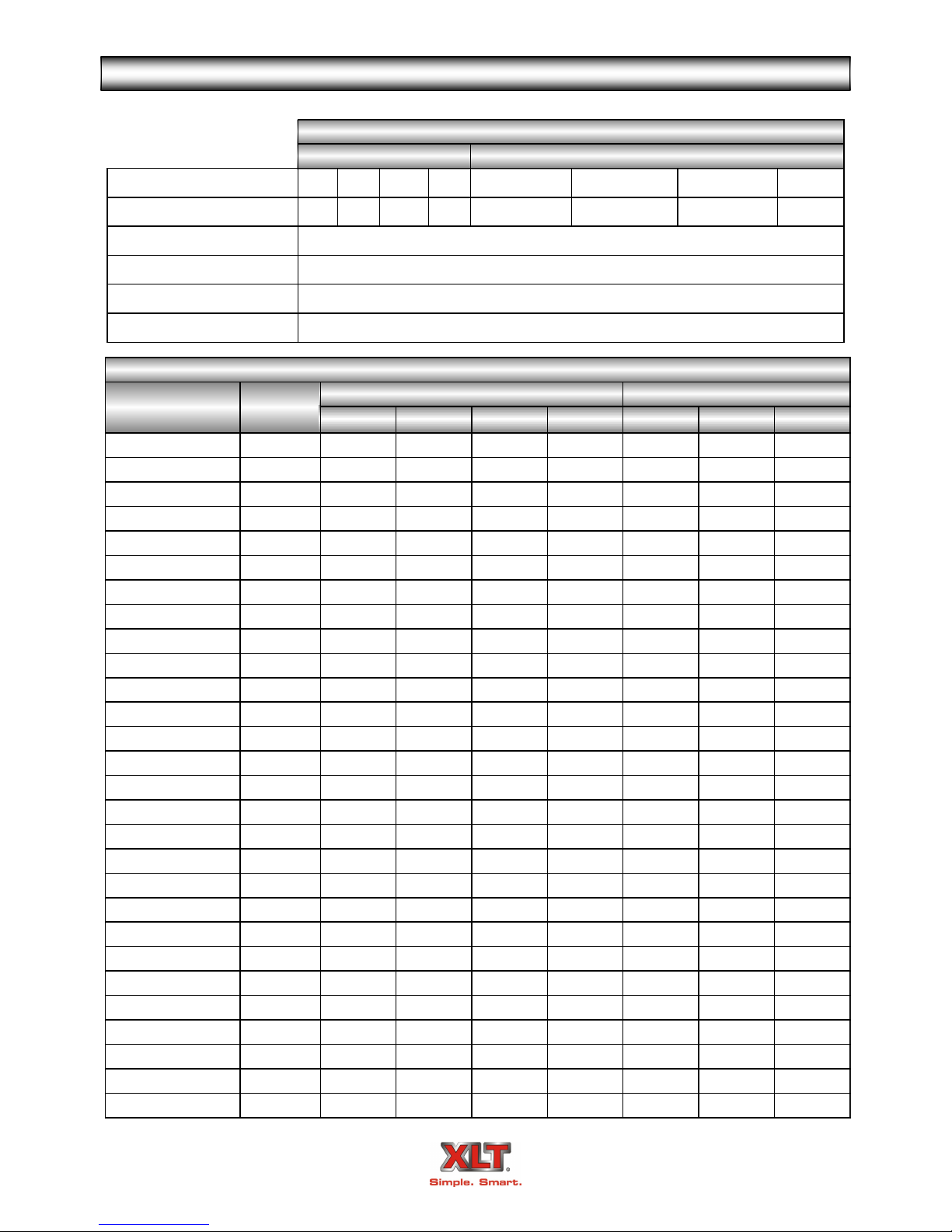

NAT LP

MJ/HR KW/HR

BTU/HR

KW/HR MM MM Inches MM Inches MM

1832 63 17.5 47,700 13.97 3.56 2.24 0.125 3.18 0.081 2.06

2440 79 22.0 67,200 19.68 3.96 2.44 0.144 3.66 0.089 2.26

3240 105 29.2 96,100 28.14 4.62 2.79 0.170 4.32 0.113 2.87

3255 169 47.0 119,900 35.11 5.94 3.66 0.191 4.85 0.116 2.95

3270 190 52.8 140,800 41.23 4.39 2.64 0.144 3.66 0.096 2.44

3855 169 47.0 142,200 41.64 5.94 3.66 0.209 5.31 0.125 3.18

3870 190 52.8 137,900 40.38 4.39 2.64 0.144 3.66 0.096 2.44

Australian

Standard & World

Standard & World

Australian

Gas Oven Heating Values & Orifice Sizes

Oven

Model

All Fuels

NAT

LP

Heating Values

Orifice Sizes

W/C mbar kPa W/C mbar kPa W/C mbar kPa W/C mbar kPa

All 6-14 15-35 1.5-3.5 11.5-14 27.5-35.0 2.75-3.50 3.5 8.75 0.875 10 25 2.5

Natural Gas

LP Gas

Natural Gas

LP Gas

Oven

Models

Gas Oven Fuel Pressure Requirements

Inlet Pressure Range

Manifold Pressure

OVEN GAS REQUIREMENTS

All values shown this page are per each oven

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

OVEN GAS REQUIREMENTS

I

2H

I

2L

I

2E

I

2E+

I

3B/P

I

3+

I

3P

Austria AT X X

Belgium BE X X

Cyprus CY X X X

Czech Republic CZ X X

Denmark DK X X

Estonia EE X

Finland FI X X

France FR X X X X

Germany DE X X X

Greece GR X

Hungary HU X X

Iceland IS

Ireland IE X X X

Italy IT X X

Latvia LT X

Lithuania LV

Luxembourg LU

Malta MT X X

Netherlands NL X X X

Norway NO X

Poland PL X

Portugal PT X X X

Slovakia SK X

Slovenia SI X

Spain ES X X X

Sweden SE X X

Switzerland CH X X X X

United Kingdom GB X X X

Natural Gas (8.75 mbar manifold)

Country

Symbol

Gas Matrix by Country

LP Gas (25 mbar manifold)

Gas Group I2H I2E I

2E+

I2L I3+ I

3B/P (30)

I

3P (30/37/50)

I

3B (37)

Inlet pressure (mbar) 20 20 20/25 25 28/30/37/50 28-30/37/50 30/37/50 37

Number of injectors

Main burner opening size

Ignition

Inlet connection

Fixed

Electric Direct Spark Igniter

BSP 3/4" male thread

World Oven Gas Group

(1) per burner

Natural Gas

Propane Gas

13

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

14

OVEN GAS REQUIREMENTS

Gas Supply Requirements for Australian, Standard. & World Ovens

All installations must conform to local building & mechanical codes.

NOTE

1. The gas supply shall have a gas meter & regulator large enough to handle ALL of the gas ap-

pliances, such as the furnace, water heater, & ovens in operation at the same time. Add up all

of the Btu/kw/MJ ratings to determine the total load.

2. The gas supply shall have a separate gas meter and gas pressure regulator for each occupant.

Installations in multiple occupancy buildings, (strip malls) shall not share gas meters and regulators with other occupants.

3. Gas hose assemblies with quick disconnects for each oven deck will be installed at each valve.

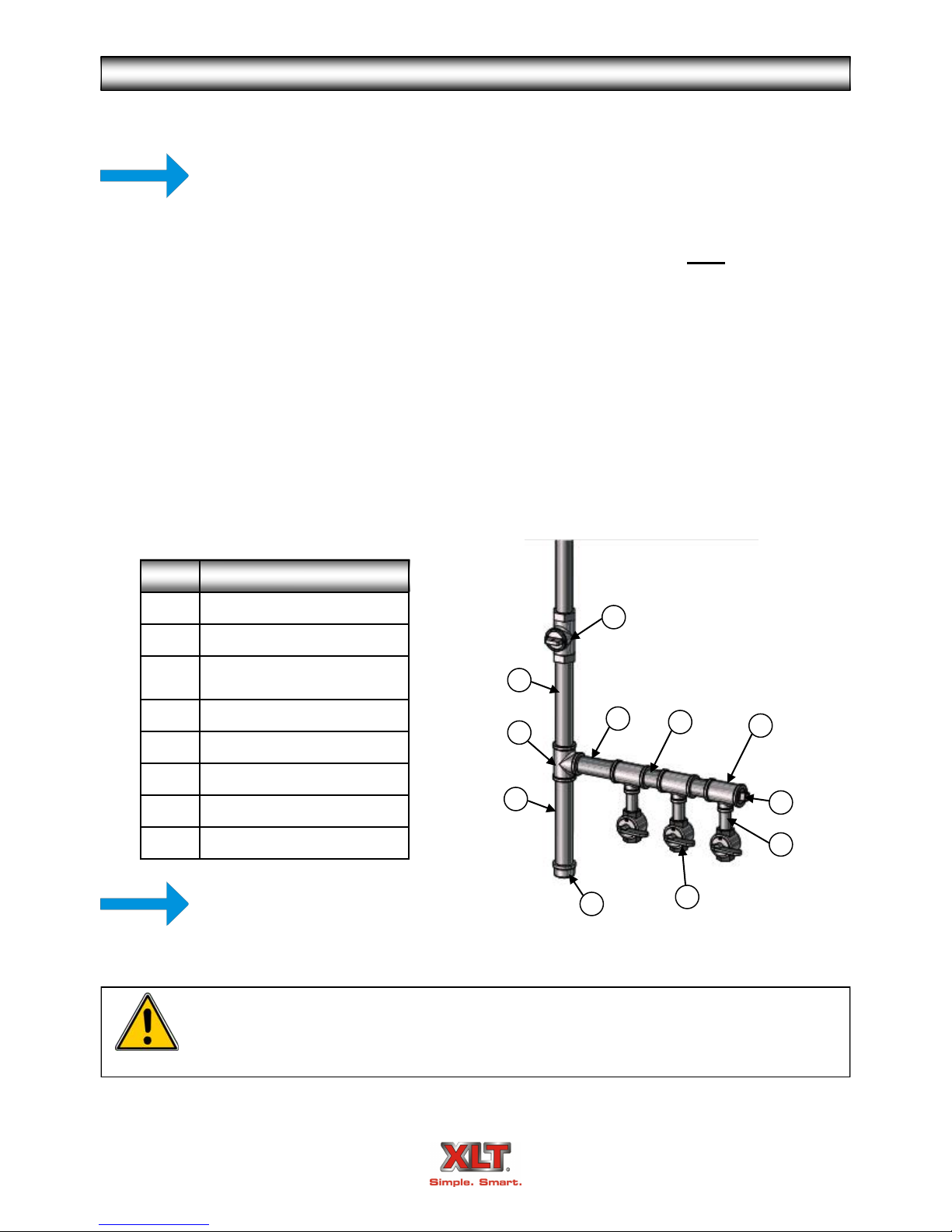

4. A sediment trap shall be installed downstream of the equipment shutoff valve as close to the

inlet of the appliance as practical atr the tiume of appliance installation. The sediment trap

shall be either a tee fitting with a capped nipple in the bottom outlet as illustrated, and in accordance with ANSI Z223.1-2012 and NFPA 54-2012 National Fuel Gas Code, section 9.6.7.

Item # Description

1 1-½ [40] Shut-Off Valve

2 ¾ [20] Shut-Off Valve

3 6 [150] Nipple

4 ¾ [20] Nipple

5 Reducing Tee

6 Tee

7 Cap

8 Plug

All pipe fittings to be 1-½ [40] minimum

unless noted. NPT & BSP

NOTE

CAUTION

1

3

6

3

3

7

Do not use Teflon tape on gas line connections as this can possibly cause gas valve

malfunction or plugging of orifices from shreds of tape. Use of Teflon tape may affect warranty.

4

5

8

4

2

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

OVEN GAS REQUIREMENTS

15

Gas Supply Testing Requirements

1. The appliance & its individual shutoff valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 3.5 kPa or ½psi.

2. The appliance must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 3.45 kPa or ½-psi.

Gas Hose Requirements

For Australia, if installing with a flexible hose assembly, the assembly must be certified to

AS/NZS 1869, & be Class B or D.

For Standard Ovens, if installing with a flexible gas hose, the installation must comply with

either ANSI Z21.69 or CAN/CGA-6.16 & a disconnect device complying with either ANSI

Z21.41 or CAN-6.9.

The installation must conform with local building codes, or in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1, latest version, Natural Gas Installation Code, CAN/

CGA-B149.1, or the Propane Installation Code, CAN/CGA-B149.2, as applicable.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

16

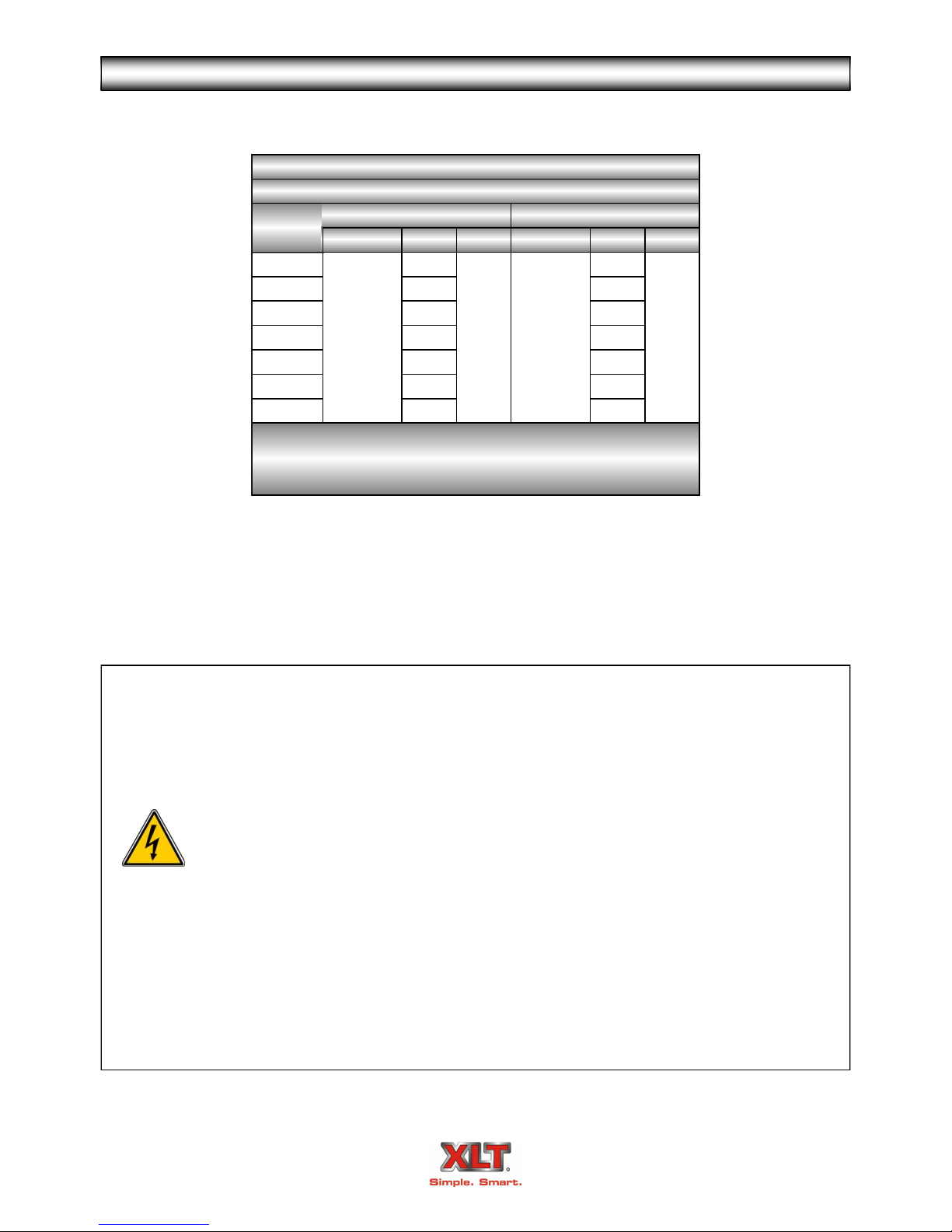

Volts AC Amps Hertz Volts AC Amps Hertz

1832 6 3

2440 6 3

3240 6 3

3255 6 3

3270 12 6

3855 6 3

3870 12 6

50

120 VAC

1Φ

60

220/230/

240 VAC

1Φ

Gas Oven Electrical Requirements

Per EACH Oven

Oven

Model

STANDARD

WORLD

OVEN ELECTRICAL REQUIREMENTS

All values shown this page are per each oven

FOR EACH OVEN:

A separate circuit breaker must be provided for each oven deck.

Electrical connections must be accessible when the ovens are in the installed position.

Electrical connections must meet all local code requirements.

Standard Ovens

Electrical Grounding Instructions

This appliance is equipped with a three-prong (grounding) plug for your protection against shock hazard & should be plugged into a properly grounded

three-prong receptacle. Do not cut or remove the grounding prong from this

plug.

When installed, the appliance must be electrically grounded in accordance with lo-

HIGH

VOLTAGE

cal codes, or in the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.2, as applicable.

World Ovens

This appliance is equipped with a ground lug for your protection against shock

hazard & must be properly grounded.

When installed, the appliance must be electrically grounded in accordance with

local codes.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

NOTE

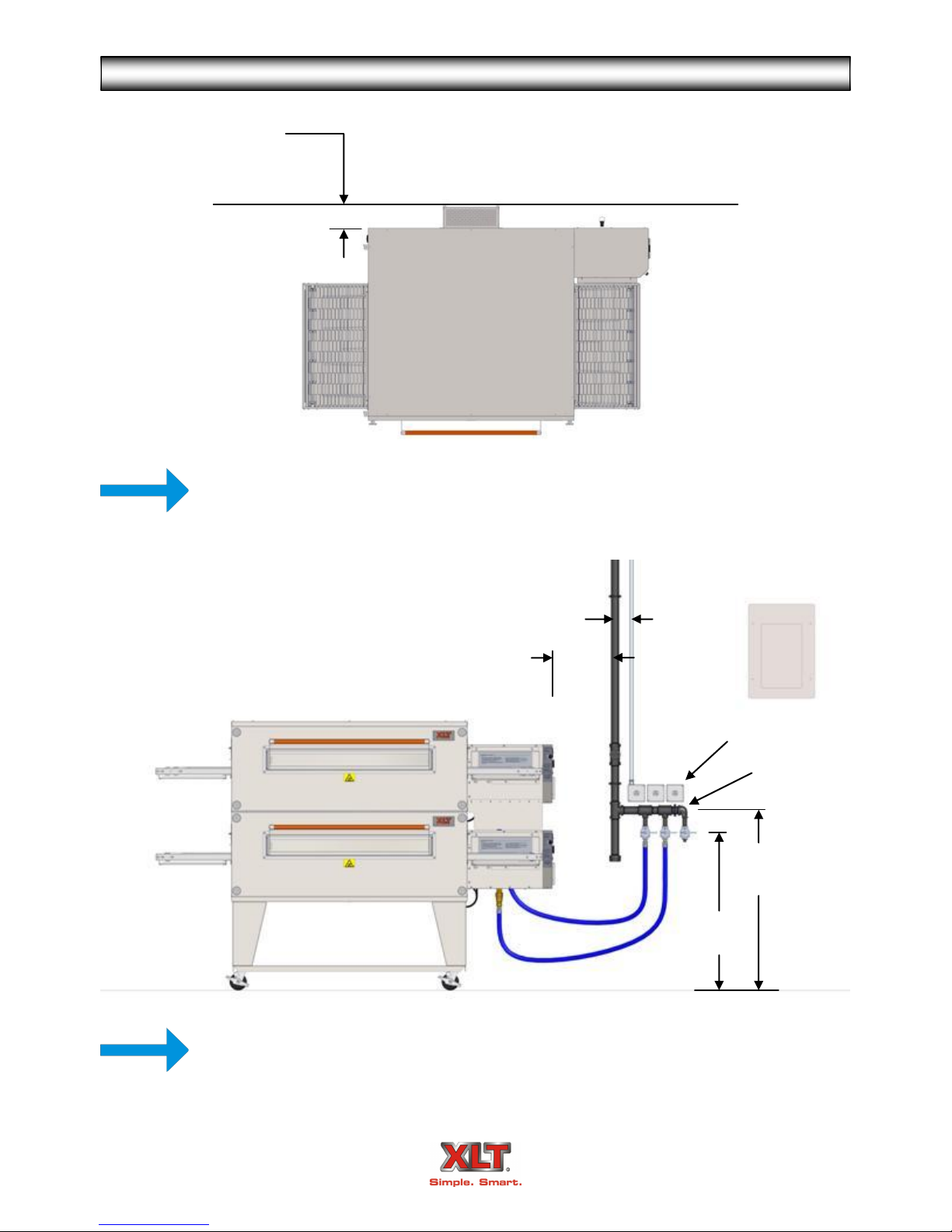

OVEN ONLY ROUGH-IN SPECIFICATIONS

6.00 [152]

From back of

oven to wall

17

Utilities must be easily accessible when the ovens are in the installed position. Do not

install utilities behind the ovens.

NOTE

3.00

[76]

6.00

[152]

Electrical Supply

Gas Manifold

48.00

[1219]

42.00

[1067]

All installations must conform to local building and mechanical codes. It is required

that the ovens be placed under a ventilation hood to provide exhaust ventilation and

adequate air supply.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

18

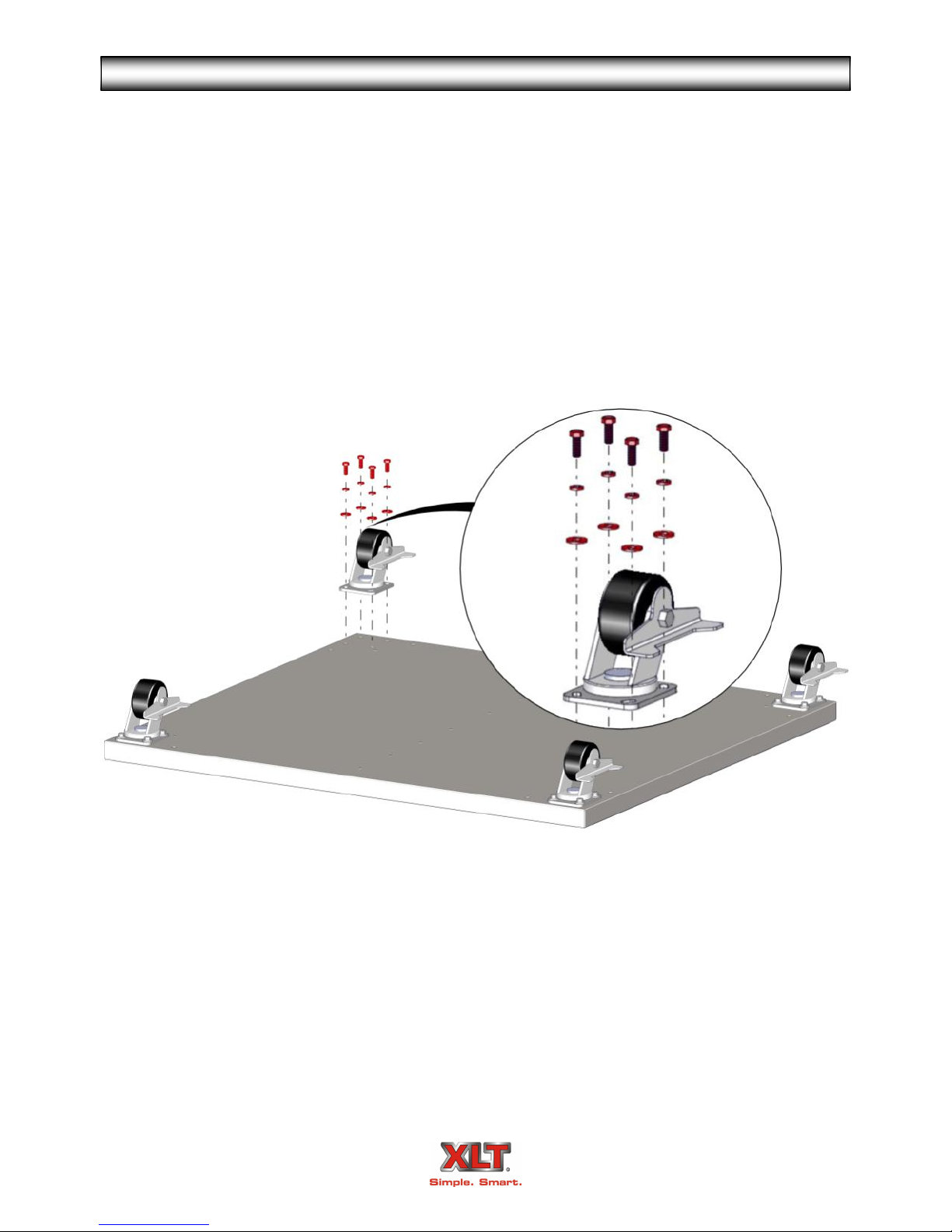

OVEN ASSEMBLY

Base Assembly - Triple Stack

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

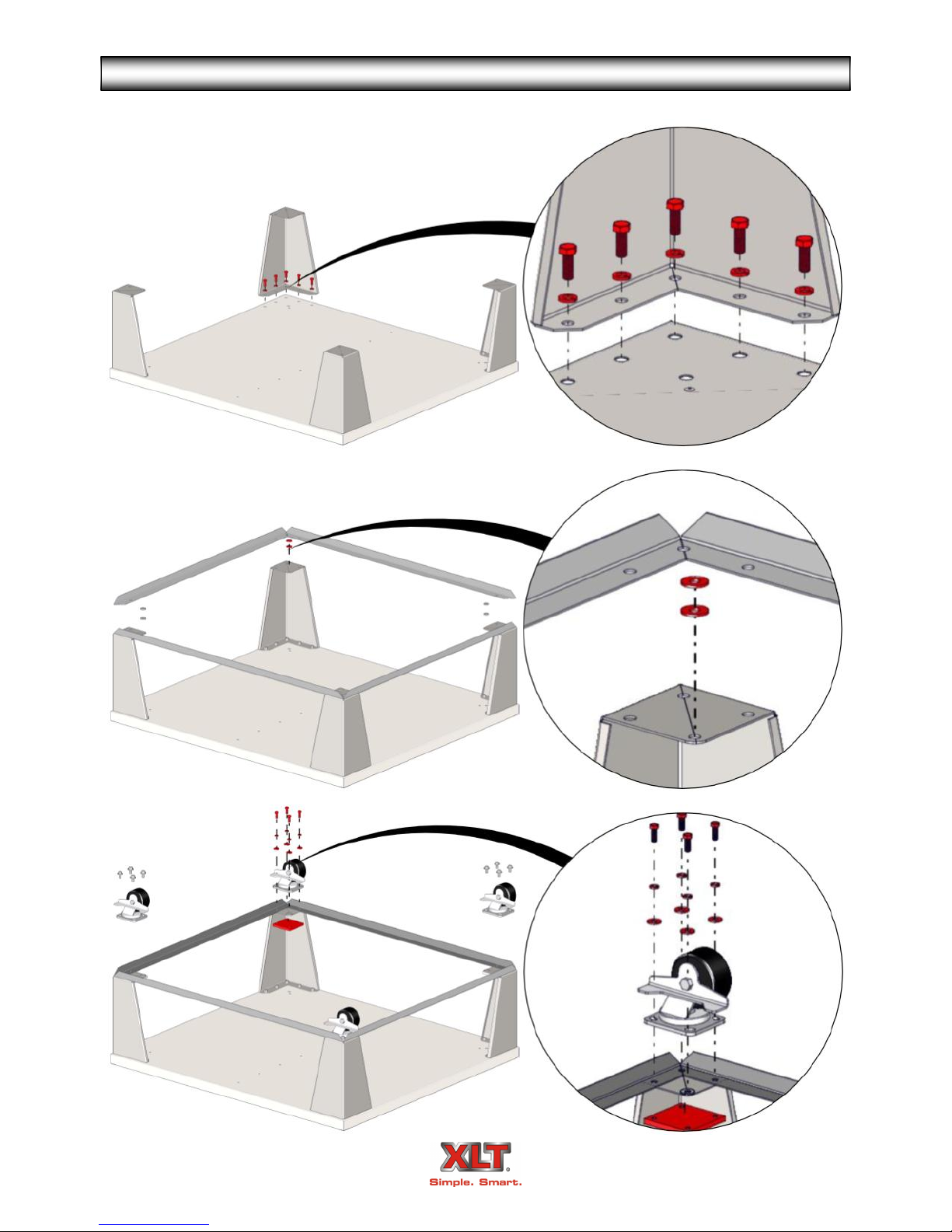

OVEN ASSEMBLY

Base Assembly - Single & Double Stack

19

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

20

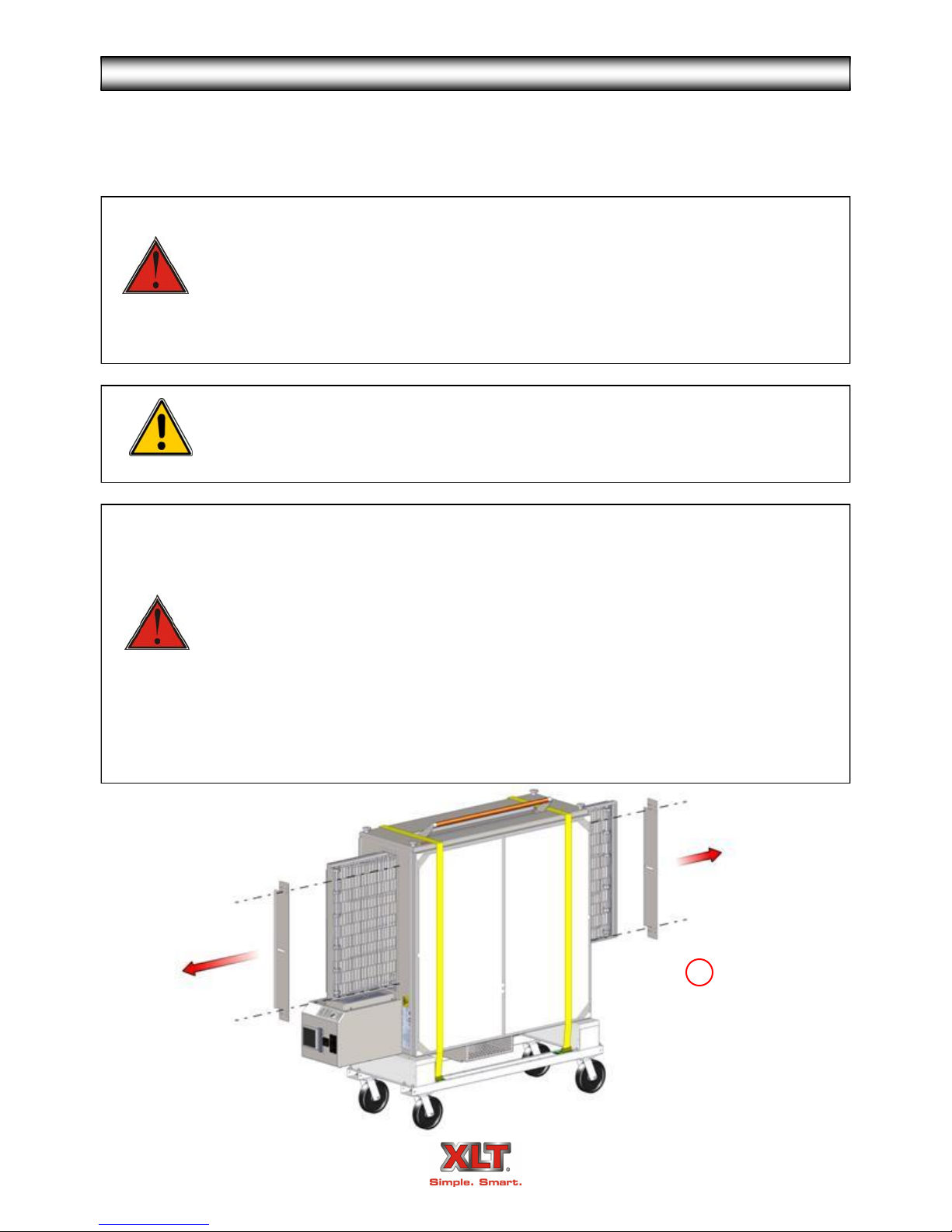

OVEN ASSEMBLY

WARNING & SAFETY INFORMATION

XLT ovens can easily be moved and stacked with the proper lifting equipment. The use of

XLT approved lifting equipment is highly recommended. Contact XLT for more information.

These ovens are heavy & can tip or fall causing bodily injury.

NEVER place any part of your body beneath any oven that is suspended by the

lifting jacks. A crush hazard exists if the oven falls or slips.

DO NOT place your hands on the lifting jack vertical pole beneath the jack’s

WARNING

CAUTION

WARNING

winch. As the jack’s winch descends when you turn the jack handle, a pinch

point is created between the winch & the pole.

BE CAREFUL when rolling the oven on the cart, especially when going up or

down ramps & over bumps. Leave the straps/banding on until the oven is near

the assembly area.

Make sure that the notch on tube of the winch assembly is aligned with the pin

in the tripod base as shown. These alignments are important and keep the jack

aligned properly.

Check for smooth operation. The cable should not be pinched and should pass

smoothly over the pulley on top of the pole assembly.

Inspect cable prior to each use.

If cable is frayed or shows signs of excessive wear and tear, DO NOT USE until

cable is replaced.

At a minimum replace the cable annually with wire rope that meets or exceeds

the jack manufacturer’s specifications.

Do not exceed the stated capacity of the jack.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

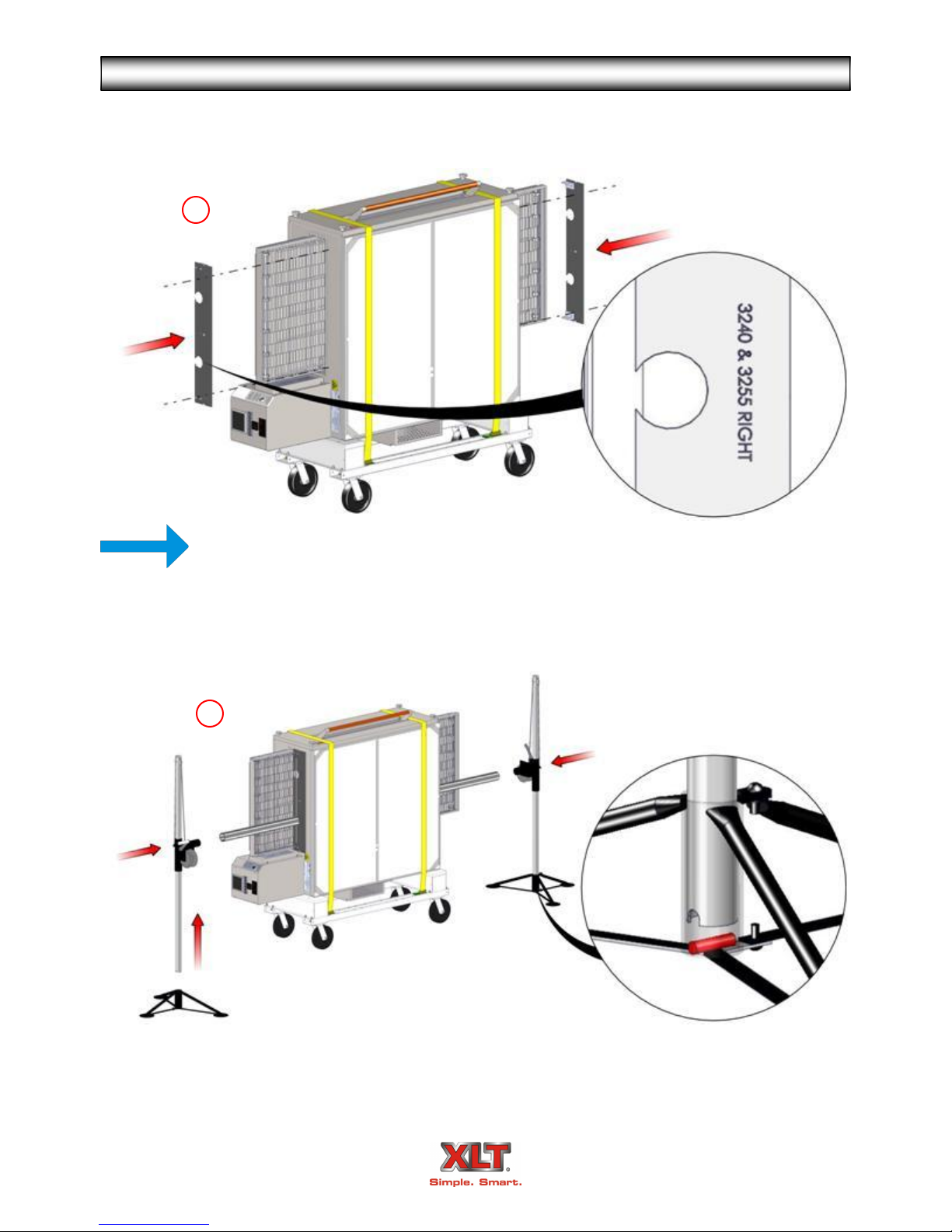

1

2

OVEN ASSEMBLY

21

NOTE

The Lifting Pipe hole, marked for the appropriate oven size, must be installed closest

to the control box.

3

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

22

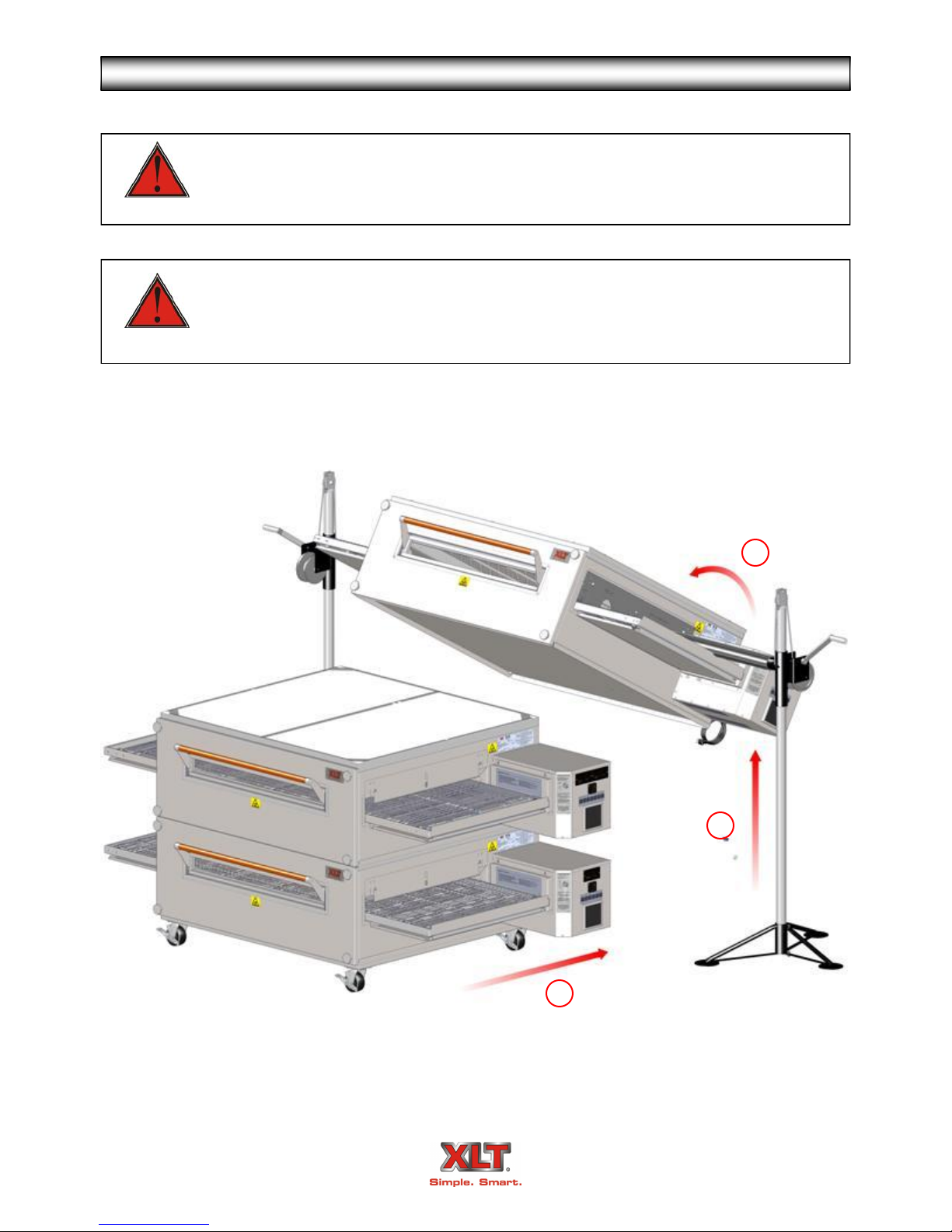

WARNING

WARNING

OVEN ASSEMBLY

Stacking the Ovens

Failure to engage the Lifting Jacks into the Lifting Pipe properly and completely

will result in damage, injury, or death from a falling oven.

Both jacks should be raised in unison, otherwise they may bind and a dangerous

situation will develop.

Do not put any part of yourself under the oven at any time.

The Oven is top heavy. Be careful.

6

5

4

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

OVEN ASSEMBLY

Stacking the Ovens

23

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

24

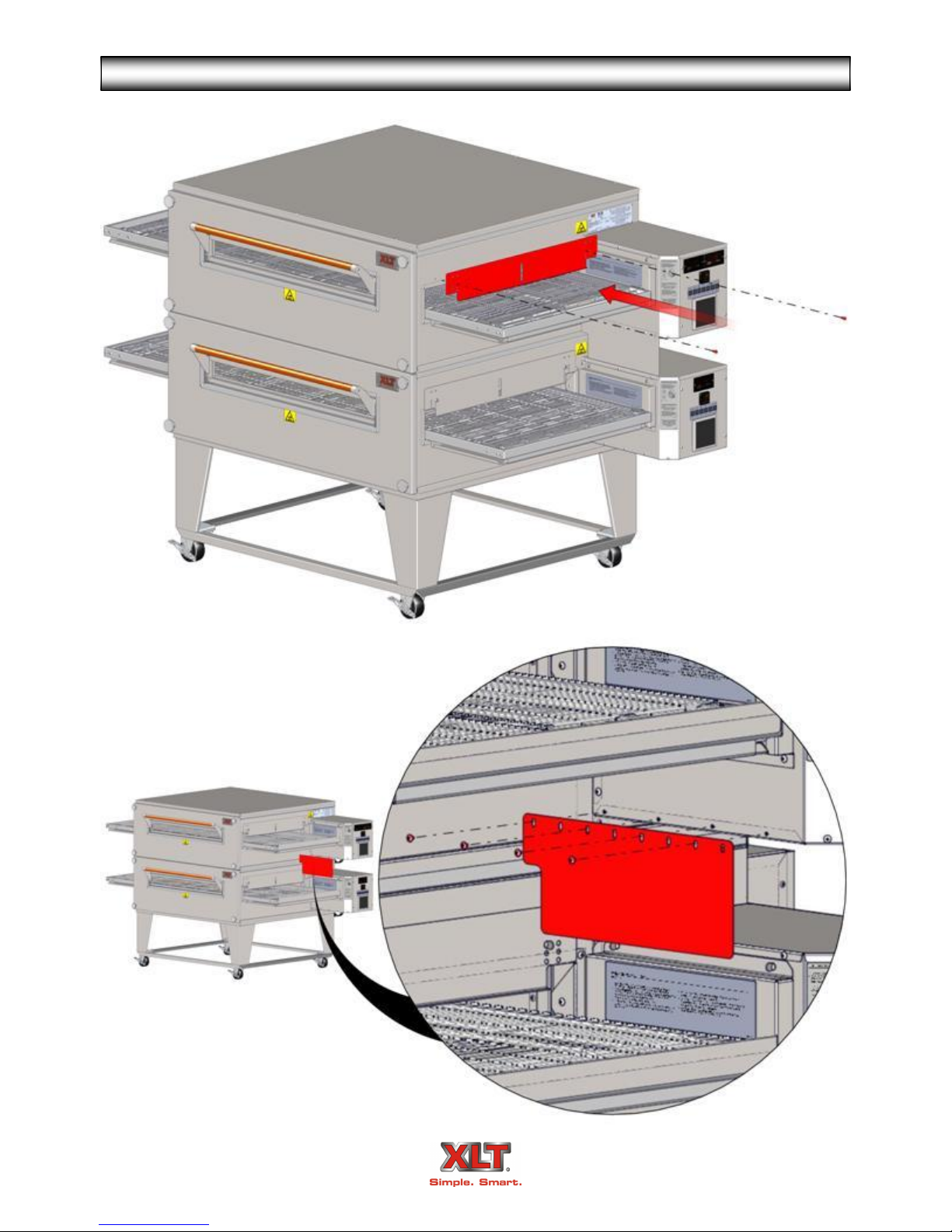

OVEN INSTALLATION

Physical Location & Spacing Requirements

These ovens are suitable for installation on either combustible or non-combustible floors,

and adjacent to either combustible or non-combustible walls. The motor cover is designed to provide the proper clearance to the back of the oven. The minimum side clearances are 6in. / 150mm,

measured from the end of the conveyor.

All installations must conform to local building and mechanical codes.

NOTE

Restraint

Because all ovens are equipped with casters, all installations must be configured with a restraint to limit the movement of the oven without depending on the electric power supply cord or

gas hose to limit the oven movement. One (1) restraint kit, which includes one (1) eye bolt, (1)

stainless steel clip & a cable, is required for each oven stack, regardless if used on a single, double,

or triple configuration. The clip should be installed in the lowest hole of the back wall on the control end of the lowest oven in the stack. The lag eye bolt must be installed into a structural mem-

ber of a wall or the floor. It is the owner’s responsibility to ensure the restraint is installed cor-

rectly.

Upon completion of performing any service or cleaning functions that require removal of

the restraint, insure that it is correctly re-attached to the oven.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

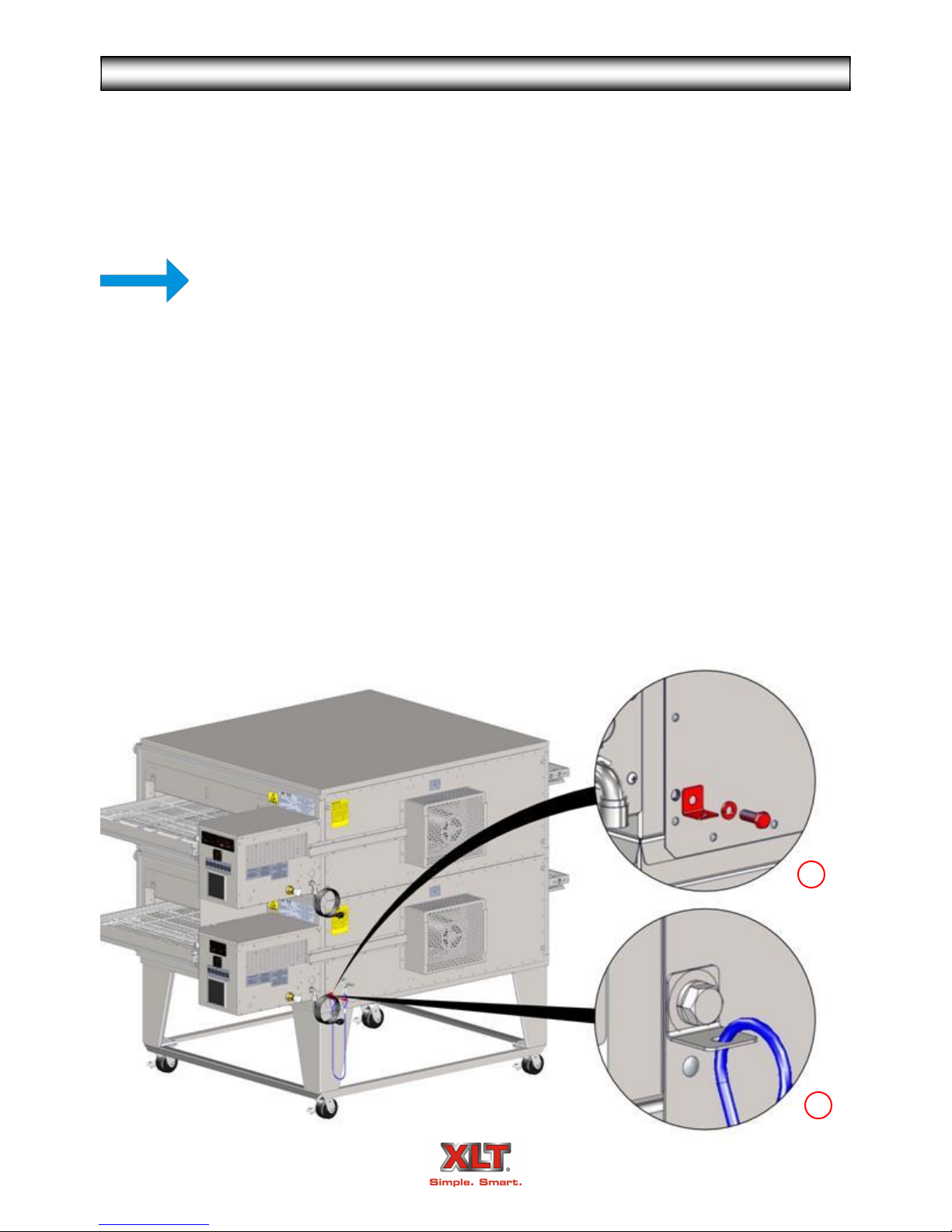

1

2

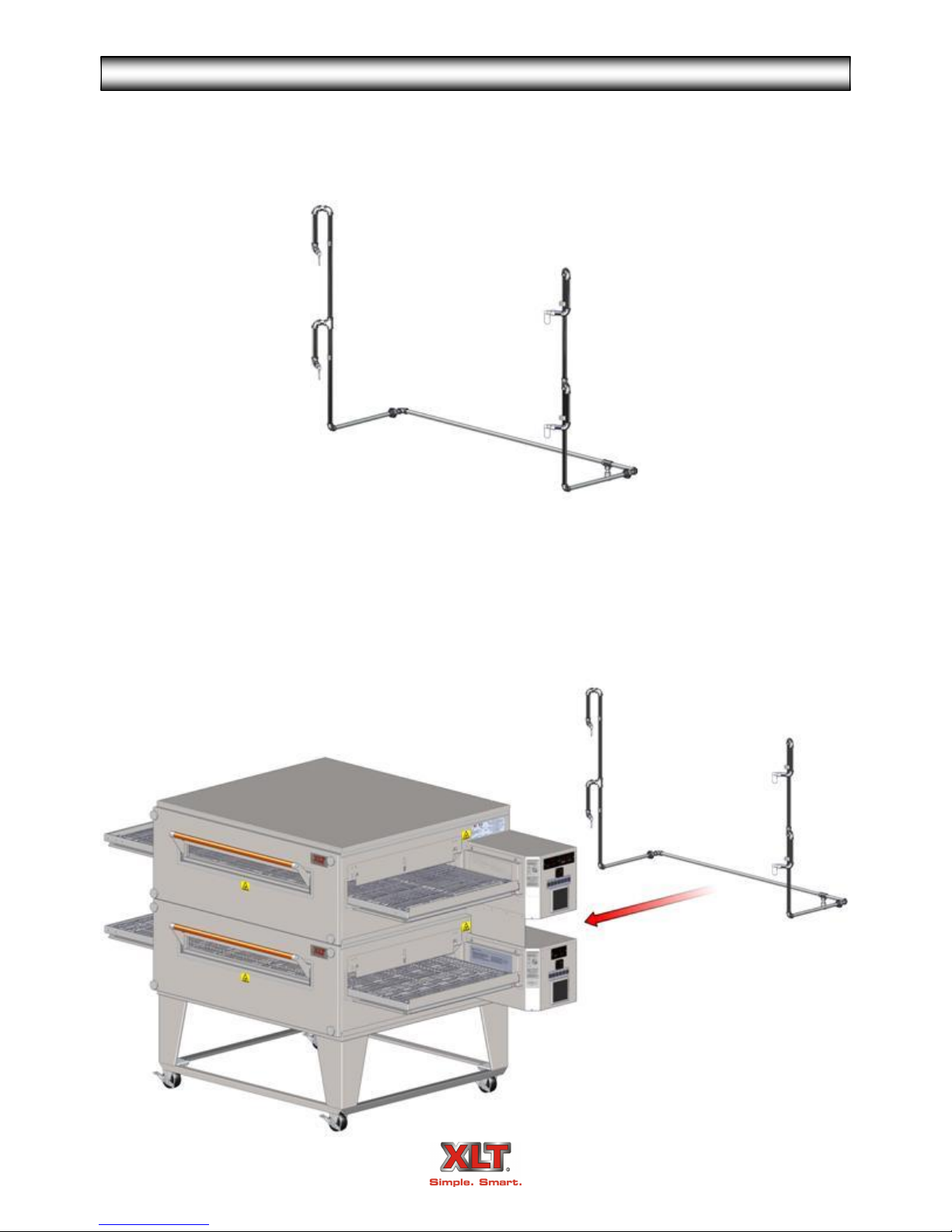

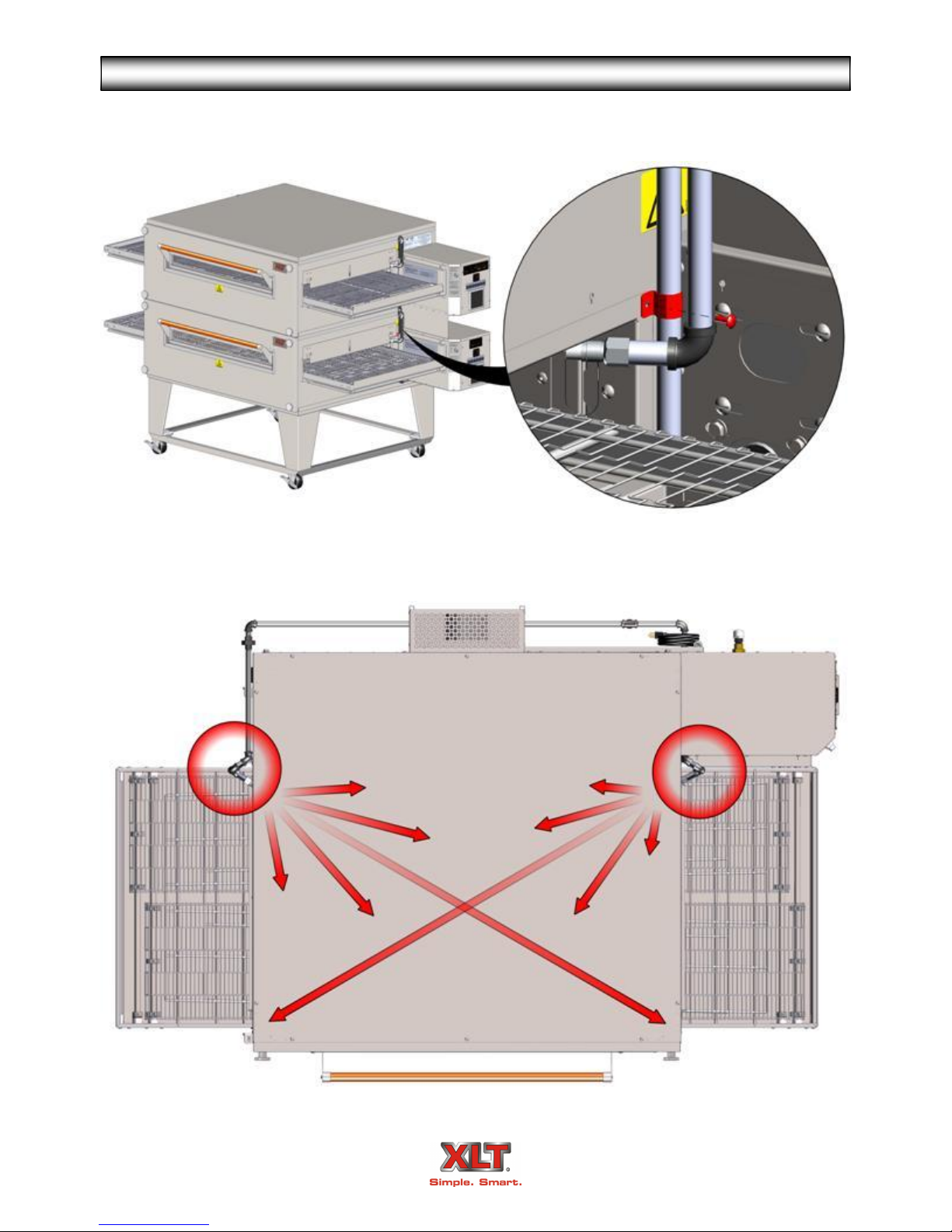

OVEN FIRE SUPPRESSION

The requirement for fire suppression systems vary by location and the authority having jurisdiction. If you are required to install fire suppression on your oven, a pre-assembled piping kit

is available that utilizes pre-existing holes that simplify installation and future service.

25

This design has been tested and approved to successfully comply with fire suppression

codes. It uses only two (2) nozzles per bake chamber, and allows crumb trays, chain guards, and

all other accessories to be easily removed. The kit does not interfere with any operations or maintenance.

A flexible hose that connects the oven to the rest of the fire suppression system is also

available. This allows easy movement of the oven(s) for cleaning and maintenance.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

26

OVEN FIRE SUPPRESSION

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

OVEN VENTILATION REQUIREMENTS & GUIDELINES

27

Ventilation Requirements

A powered ventilation hood is required to remove heat and vapors. Some provision must

be made to replenish the amount of air that is extracted from the building. The hood and HVAC

installation must meet local building and mechanical codes. Requirements vary throughout the

country depending upon location. Proper ventilation is the oven owner’s responsibility. The AVI

Hood system is designed to meet all requirements for XLT ovens and it is our recommendation

that this system be used.

Ventilation Guidelines

Obtain information from the authority having jurisdiction to determine the requirements for

your installation. Your ventilation hood supplier and HVAC contractor should be contacted to

provide guidance. An air balance test is highly recommended, performed by a licensed contractor.

A properly engineered and installed ventilation hood and HVAC system will expedite approval,

reduce all maintenance costs, and provide a more comfortable working environment. XLT also

recommends that the operator switches for the ovens and the operator switch for the exhaust fan be

interlocked so that the exhaust fan gets energized whenever the ovens are turned on. For more information, see the following links at xltovens.com:

Kitchen Ventilation Design Guide 1

Kitchen Ventilation Design Guide 2

Kitchen Ventilation Design Guide 3

Kitchen Ventilation Design Guide 4

Ventilation Performance Test

After the oven and ventilation hood have been installed and are operating, a smoke candle

can be used to “see” if the heat and vapors are being completely extracted. The test procedure is

outlined below:

The oven must be operating at 450º-500ºF / 232º-260ºC.

The conveyor must be turned off.

The ventilation hood exhaust fan must be turned on.

Put a smoke candle in a pan on the conveyor belt at the center of the oven.

Observe the smoke pattern coming out of the oven.

Repeat the smoke candle test for each oven, as well as when all ovens are operating.

The ventilation hood must capture all of the smoke from the oven.

After the exhaust fan has been adjusted to completely capture and contain the heat, there

needs to be a corresponding amount of make up air (MUA) introduced into the building to offset

the amount of air volume being removed. An air balance test can determine the proper amount of

make-up air flow rates.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

28

OVEN INITIAL START-UP

All ovens are tested at the factory for functional operation. Operation is verified and adjustments are made to ensure proper function. However, field conditions are sometimes different

than factory conditions. It is necessary to have an authorized service technician verify operation

and make field adjustments if needed.

The Oven Initial Start-Up Checklist, found at the end of this manual, must be completed

(both sides) at time of installation, signed by the Customer and returned to XLT Ovens and the Authorized Distributor to initiate Warranty Policy.

If the Start-Up Checklist is not filled out completely and returned to XLT Ovens, then the

Warranty will not be honored.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

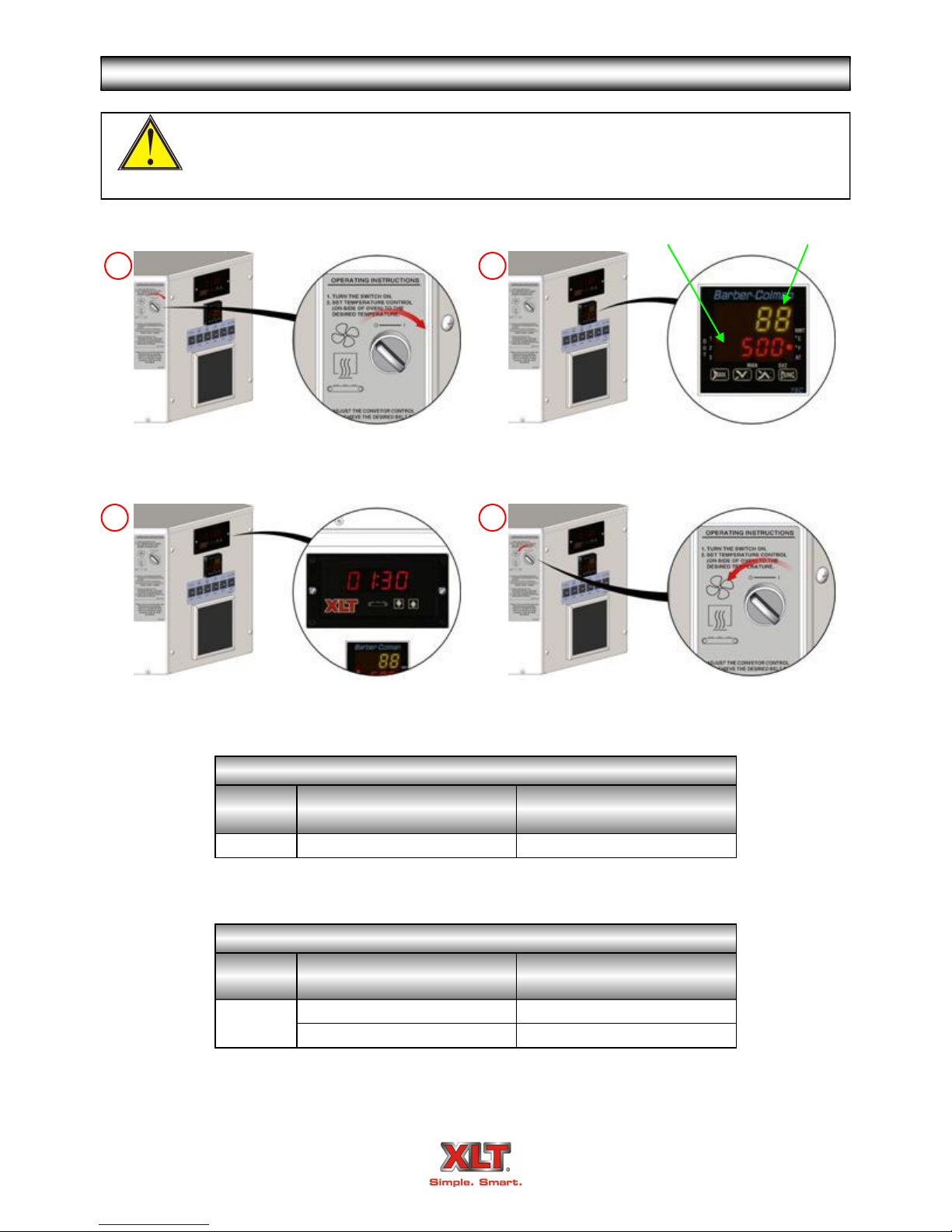

CAUTION

Oven Operating Temperature Range

Oven

Models

MINIMUM

MAXIMUM

All

400° F

590° F

205° C

310° C

All

Conveyor Belt Times (Min:Sec)

Oven

Models

MINIMUM

MAXIMUM

1:30

17:00

OVEN OPERATION

This oven is not capable of being safely placed in operation in the event of a

power failure. No attempt should be made to operate this oven during power

failure.

Actual Set Point

29

3

1

2

Temperature Control

Push and Hold

4

Conveyor Control

Push and Hold

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

30

OVEN OPERATOR CONTROLS

Conveyor

Speed

Controls

Control Panel Split Belt

Temperature

Control

Circuit

Breakers

Fan &

Filter

Control Panel Standard Belt

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

OVEN CLEANING

31

Your XLT oven is constructed of stainless steel. Most commercial cleaning agents may be

used safely on all stainless steel surfaces. Check application restrictions on product label prior to

usage. Observe recommended precautionary and safety measures as dictated by the product manufacturer. Do not use caustic cleaner on the conveyor bearings.

Do not use abrasive cleaners or abrasive pads as they can scratch stainless steel surfaces.

Areas with heavy buildup should be sprayed and allowed to soak for up to 5 minutes prior to wiping clean. Always wipe with the “grain” of the surface to maintain appearance.

The most critical item to be cleaned is the filter on the fan. The filter is held in place by the

stainless steel fan guard/filter mount & can be washed several times. Regular cleaning of the filter

is important to maintain air circulation within the control box. Depending upon store conditions,

this filter should be cleaned weekly or as it gets clogged with dust. Please contact XLT Ovens for

replacement parts.

Fan Guard/Filter

Holder

Fan Filter

Oven must be cool and the electric cord unplugged before any cleaning or

maintenance is done.

WARNING

If the oven is to be removed from its installed location for cleaning or servicing,

the following procedure is to be followed:

CAUTION

1. Shut off main manual gas valve.

2. Unplug electric cord.

3. Unplug gas line.

4. Unlock casters.

5. Disconnect restraint.

6. When servicing or cleaning is complete, move oven to original location.

7. Connect restraint.

8. Lock casters.

9. Plug in electric cord.

10. Plug in gas line.

11. Turn manual gas valve on.

12. Follow normal lighting instructions.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

32

OVEN CLEANING

2

1

Opening the Sandwich Door will provide a grip location for removing the Front Panel.

TIP

CAUTION

4

1

Front Panels can weigh up to 75 lbs. [34 kg]. Use caution when lifting.

3

5

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

OVEN CLEANING

33

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

34

OVEN CLEANING

DO NOT spray liquid cleaning agents in the slots and holes in the following locations:

Rear of Control Box

CAUTION

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Underneath Control Box

Main Fan Motor Cover

Cleaning

Empty Crumb Trays

□

Wipe down Front, Sides, & Top

□

Wipe down Control Box & Control Panel

□

Clean or Replace Fan Filters

□

Remove large debris from Conveyor

□

Wipe down Motor Cover

□

Clean Sandwich Window

□

Remove debris from Finger Outers

□

Remove debris from inside Bake Chamber

□

Remove debris from Main Fan Motor

□

Clean Finger Outers

□

Clean inside Bake Chamber

□

Clean Conveyor Assembly

□

Inspection

Check Fan Filters for dirt

□

Check Conveyor Wire Belt for Stretch

□

Check Conveyor Drive Roller Chain for Stretch

□

Adjust

Conveyor Wire Belt

□

Lubricate

Conveyor Drive Roller Chain

□

Replace

Fan Filters

□

Oven Maintenance Schedule

Daily

Weekly

Monthly

Semi-

Annual

OVEN MAINTENANCE

35

As with any appliance, periodic maintenance is required. Many factors affect this schedule

such as product mix and hours of usage. An example schedule is included.

Contact a factory representative or a local service company to perform all other maintenance and repairs.

Oven must be cool and the electric cord unplugged before any cleaning or

maintenance is done.

WARNING

Contact a factory representative or a local service company to perform all other maintenance & repairs.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

36

OVEN TROUBLESHOOTING

Proper Cooking

Experimentation is about the only way to determine proper time and temperature settings.

While a pizza may look perfectly cooked on the outside, the inside may be undercooked. A thermometer is necessary to determine if food items are being properly cooked. Most health departments have rules and regulations that establish minimum temperatures for internal food temperatures. Most operators want to cook foods as fast as possible in order to serve more customers per

hour. However, cooking foods slower is the only way to achieve a proper internal temperature. If

your food products look acceptable on the outside, but have an internal temperature that is too low,

then lowering the temperature and decreasing the belt speed (thereby increasing the cook time),

will be necessary.

Several factors may affect the cooking performance and characteristics:

1. Oven temperature (generally affects color)

2. Conveyor speed (generally affects doneness)

3. Finger arrangement

4. Altitude

5. Pans versus screens

6. Dough thickness

7. Cheese type

8. Raw ingredient temperature (frozen?)

9. Quantity of toppings

XLT ovens can be configured to cook a wide variety of food items. This is accomplished

by arranging the fingers to control the baking characteristics. Generally speaking, most cooking is

a “bottom up” process. The hot air from the bottom row of fingers has to go through the conveyor

(a distance of about 2” / 50.8mm), heat the pan or screen, and then actually cook raw dough. The

hot air from the top, on the other hand, basically only has to melt cheese and re-heat precooked

toppings. Consequently, most operators will use the oven with the fingers arranged so that a lot

more air is directed to the bottom of the pizza than to the top. There are places for an equal number of fingers above and below the conveyor. Available are finger cover plates that have six rows

of holes, four rows of holes, two rows of holes, and no holes (or blank cover plates). A typical fin-

ger arrangement might have most or even all fingers on the bottom “full open”, that is fingers with

all six rows of holes, and only two or three fingers on top with four or six rows of holes. The top

fingers can be arranged in a symmetrical pattern or can be shifted asymmetrically to either the entrance or exit end of the conveyor. We encourage you to experiment by trying different finger arrangements, temperatures and belt speeds. XLT Ovens can assist you with your oven/product configurations.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

OVEN TROUBLESHOOTING

Mechanical Function

If your oven does not function properly, please verify the following conditions:

1. Verify that the power cord to the oven is connected and/or plugged in if equipped with a plug

and receptacle.

2. Check to see that the circuit breakers in the building electrical service panel have not been

tripped or turned off.

3. Check all circuit breakers on the oven control panel to ensure they have not been tripped.

4. Gas line size and pressure must be adequate to support total BTU requirements with all appliances in store turned on. Refer to the “Oven Gas Requirements” section of this manual.

5. Check the quick-disconnect on the gas hose to verify that it is fully and completely engaged.

6. Check the Manual gas valve to verify that it is turned on completely. The handle on the valve

should be parallel with the gas piping when the valve is turned on, and the handle will be perpendicular with the gas piping when the valve is turned off. Also remember that anytime the

gas hose has been disconnected it will take time to purge the air from the gas train.

37

7. Check to see that the oven is fully assembled. All of the fingers must be properly installed.

Incorrect or incomplete finger placement can cause a “windy” condition that can cause the

burner not to light.

If your oven still does not function properly, XLT has qualified customer service personnel

that can provide assistance on any type of XLT oven problem you may experience. Customer Service is available 24/7/365 at 888-443-2751, or visit www.xltovens.com. An interactive troubleshooting guide is available on the website.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

38

AVI HOOD INSTALLATION

Check all local codes prior to installation. Special requirements may be necessary

depending upon building material construction. It is the installing contractor’s re-

sponsibly to ensure that the structure the hood is to be hung from meets all codes

WARNING

and can carry the hood weight.

Purchaser’s Responsibility

It is the responsibility of the purchaser:

Thoroughly review the floor plans and specifications. The exact location of the oven must be

determined before installing the hood.

To unload, uncrate, assemble, and install the hood to it’s intended location.

To ensure that electric utilities are installed on site in accordance with local building codes and

with the specifications in this manual.

To see that electric utilities are connected properly by a qualified installer using the proper

hardware.

To ensure a qualified installer has performed an initial start-up procedure.

Location should minimize long and twisted duct runs. Make efforts to have a straight clear path

to the roof fan curb.

All hood supporting structures must be strong enough to support the weight of the hood and

shrouds. Refer to the Hood Dimensions & Weights page for weight.

Maintain the proper clearances from combustible materials according to International Me-

chanical code (IMC), and National Fire Protection Agency (NFPA) 96, and local mechanical

codes.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Main Canopy

AVI EXHAUST HOOD

HOOD DESCRIPTION

39

VFD Exhaust Fan

Controller

Front

Shroud

Panel

End Shroud Panel

The AVI Hood System consists of three (3) major parts; the Main Canopy, the Shrouds,

and the Variable Frequency Drive (VFD) exhaust fan controller.

The Main Canopy serves to collect and transmit heat to the exhaust fan. It houses filters,

lights, and switches. The switches control both the hood and ovens. The main canopy size is dependent upon oven size.

The Shrouds assist the efficiency of the main canopy by entrapping heat. They are configurable for either side or end loading or unloading, and are easily removable for cleaning and maintenance.

The VFD converts input power to variable frequency three-phase output power to control

the speed of the exhaust fan. All electric utilities for the hood and exhaust fan connect through the

electrical box located on the rear of main canopy. The operator switches are located on the control

panel on the front of main canopy, and interlock the function of the hood and oven(s). There are

optional relays that provide interlocks for equipment such as, fire suppression, HVAC dampers,

and/or dedicated MUA units.

All AVI hoods are available pre-piped for fire suppression, allowing for simple, in-field

installations.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

40

AVI HOOD DIMENSIONS

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

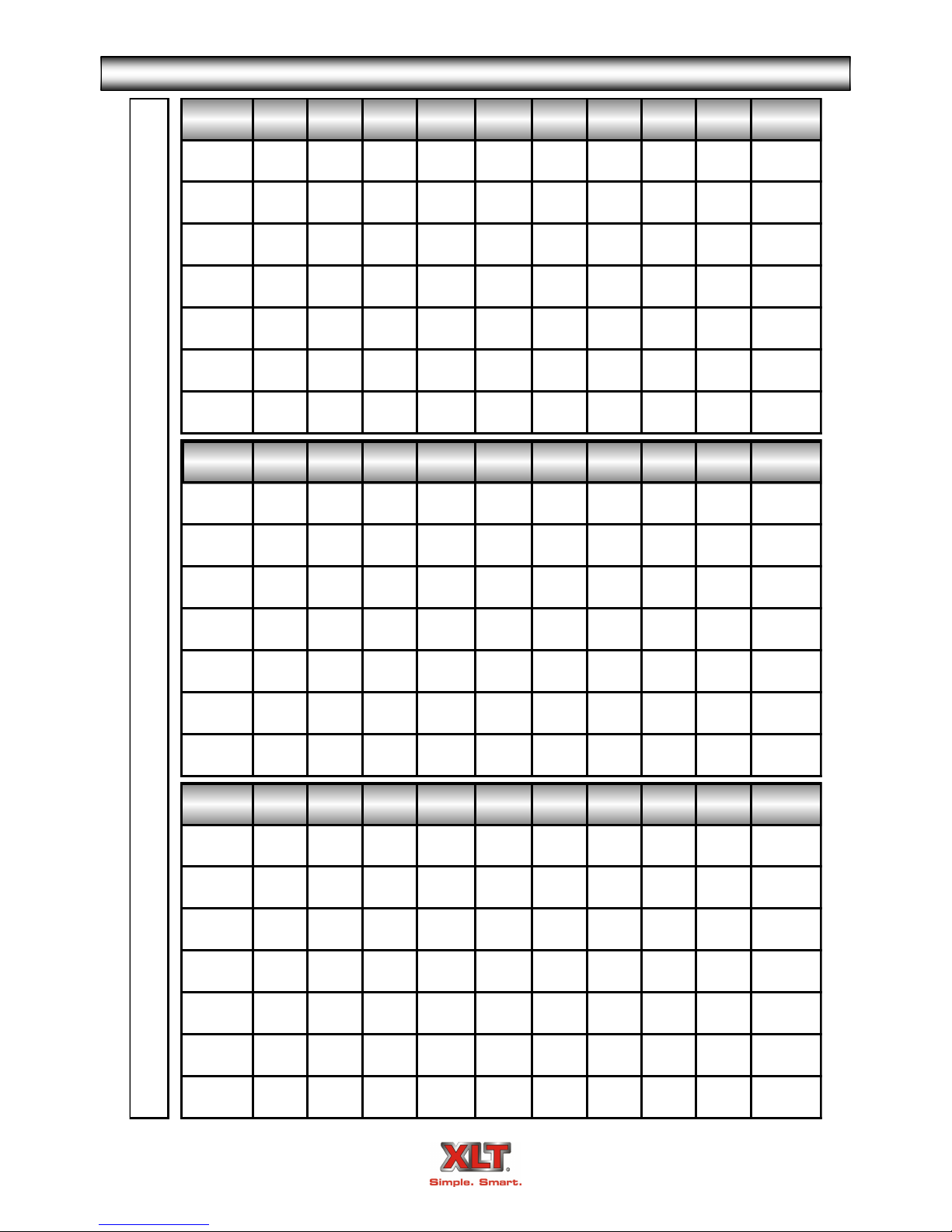

A B C D E F G H J K Single Double Triple

34 3/8 88 5/8 18 32 30 5/8 540 500 525

[873] [2251] [457] [813] [778]

[245] [227] [238]

40 3/8 96 5/8 24 40 33 5/8 620 570 595

[1026] [2454] [610] [1016] [854]

[281] [259] [270]

48 3/8 96 5/8 32 40 37 5/8 680 630 655

[1229] [2454] [813] [1016] [956]

[308] [286] [297]

48 3/8 111 5/8 32 55 37 5/8 740 670 695

[1229] [2835] [813] [1397] [956]

[336] [304] [315]

48 3/8 126 5/8 32 70 37 5/8 780 705 720

[1229] [3216] [813] [1778] [956]

[354] [320] [327]

54 3/8 111 5/8 38 55 40 5/8 795 720 745

[1381] [2835] [965] [1397] [1032]

[361] [327] [338]

54 3/8 126 5/8 38 70 40 5/8 825 750 770

[1381] [3216] [965] [1778] [1032]

[374] [340] [349]

Hood Dimensions

13 1/2

[343]

12

[305]

NOTE: All dimensions in inches [millimeters], ± 1/4 [6], unless otherwise noted.

All weights in pounds [kilograms] unless otherwise noted.

Hood Weights

69 5/8

89 7/8

91 3/4

[1768]

[2283]

[2330]

3870

Oven

Model

1832

2440

3240

3255

3270

3855

AVI HOOD DIMENSIONS & WEIGHTS

41

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

42

# of Circuits Rating Purpose

1 230 VAC, 1 Phase, 50 Hz, 3 Amp VFD Controller

1 230 VAC, 1 Phase, 50 Hz, 1 Amp Lights

1 208/240 VAC, 3 Phase, 60 Hz, 3 Amp VFD Controller

1 120 VAC, 1 Phase, 60 Hz, 1 Amp Lights

1 230 VAC, 1 Phase, 50 Hz, 3 Amp VFD Controller

1 230 VAC, 1 Phase, 50 Hz, 1 Amp Lights

Australian

Standard

World

AVI Hood Electric Utility Specifications

AVI HOOD ELECTRICAL REQUIREMENTS

Inputs into VFD Box

Outputs from VFD Box

The AVI Hood system provides:

Three (3) switching outputs for HVAC dampers and dedicated units

One (1) 230 VAC, 10 Amp, variable frequency, three phase power output for the ventilation

exhaust fan.

Three (3) receptacles for ovens.

One (1) 120 VAC fire alarm signal for Standard hoods, or one (1) 24 VAC fire alarm signal for

World Hoods

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD ELECTRICAL DESCRIPTION

VFD Control Box - Standard

43

MUA Damper Relay

(R1)

MUA Damper Relay

(R2)

MUA Damper Relay

(R3)

Fire Suppression Relay

(R4)

Grounding Block Terminal Strip (TS1)

Terminal Strip (TS2)

Manual Mode

Relay (R5)

Manual Mode

Relay (R6)

Manual Mode

Relay (R7)

Fire Suppression

Relay (R8)

Circuit Breaker

VFD Controller

Manual Mode Switch #1

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Manual Mode Switch #2

Oven/hood interface

VFD Control Box (Cover removed)

44

AVI HOOD ELECTRICAL CONNECTIONS

Input Power to VFD Controller - Standard Voltage & Frequency

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD ELECTRICAL CONNECTIONS

Input Power to Lights with VFD- Standard Voltage & Frequency

45

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

46

AVI HOOD ELECTRICAL CONNECTIONS

Power from VFD to Exhaust Fan - Standard Voltage & Frequency

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD ELECTRICAL CONNECTIONS

Fire Alarm Relay - Standard Voltage & Frequency

47

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

48

AVI HOOD ELECTRICAL CONNECTIONS

MUA Damper Relays - Single Output - Standard Voltage & Frequency

MUA Unit Relay

Power Power

A1 A2

Neutral

Supply from Breaker Panel

10 Amperes Maximum

TS 1

Some wiring removed for clarity. See schematic for details.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

TS 2

R3 R2 R1

AVI HOOD ELECTRICAL CONNECTIONS

MUA Damper Relays - Multiple Output - Standard Voltage & Frequency

MUA Unit Relay MUA Unit Relay MUA Unit Relay

49

Power Power

A1 A2

Power Power

A1 A2

Power Power

A1 A2

Neutral

Supply from Breaker Panel

10 Amperes Maximum

TS 1

Some wiring removed for clarity. See schematic for details.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

TS 2

R2 R1

R3

50

AVI HOOD ELECTRICAL CONNECTIONS

VFD Control Box - World

Oven Fire Suppression

Relay (R5)

Grounding Block Terminal Strip (TS1)

Terminal Strip (TS2)

Hood Fire Suppression

Relay (R4)

MUA Damper Relay

(R1)

Oven Fire Suppression

Relay (R6)

Oven Fire Suppression

Relay (R7)

VFD Controller

MUA Damper Relay

(R2)

MUA Damper Relay

(R3)

Circuit Breaker

Oven/hood interface

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

VFD Control Box (Cover removed)

AVI HOOD ELECTRICAL CONNECTIONS

Input Power to VFD Controller - World Voltage & Frequency

51

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

52

AVI HOOD ELECTRICAL CONNECTIONS

Output Power from VFD to Exhaust Fan - World

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD ELECTRICAL CONNECTIONS

Fire Alarm Relay - World (optional)

53

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

54

AVI HOOD ELECTRICAL CONNECTIONS

MUA Damper Relays - Single Output - World Voltage & Frequency

MUA Unit Relay

Power Power

A1 A2

Neutral

Supply from Breaker Panel

10 Amperes Maximum

TS 1

Some wiring removed for clarity. See schematic for details.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

TS 2

R2 R1

R3

AVI HOOD ELECTRICAL CONNECTIONS

MUA Damper Relays - Multiple Output - World Voltage & Frequency

MUA Unit Relay MUA Unit Relay MUA Unit Relay

55

Power Power

A1 A2

Power Power

A1 A2

Power Power

A1 A2

Neutral

Supply from Breaker Panel

10 Amperes Maximum

TS 1

Some wiring removed for clarity. See schematic for details.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

TS 2

R2 R1

R3

56

AVI HOOD ELECTRICAL CONNECTIONS

Input Power to Lights - Without VFD Controller

Terminal Strip (TS1) Grounding Block

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Oven/hood interface

Non-VFD Control Box (Cover removed)

AVI HOOD ROUGH-IN SPECIFICATIONS

Roof

57

Ceiling Joist

HVAC Unit

Drop Ceiling

Hood Electrical

3 Phase Power to

Three Phase

Finished Floor

Power to Oven

Exhaust Fan

Duct Wrap

Fan Curb

Welded Duct

(optional)

by Unistrut (4 Locations)

1/2” All-thread Supported

Service Panel

Fire Suppression

All structural members, electrical & fire suppression equipment shown for reference only.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

58

Top Middle Bottom

500 500 500 500

[14.16] [14.16] [14.16] [14.16]

500 500 500 500

[14.16] [14.16] [14.16] [14.16]

506 644 828 966

[14.33] [18.24] [23.45] [27.35]

506 644 828 966

[14.33] [18.24] [23.45] [27.35]

500 500 500 500

[14.16] [14.16] [14.16] [14.16]

506 644 828 966

[14.33] [18.24] [23.45] [27.35]

766 975 1254 1463

[21.69] [27.61] [35.51] [41.43]

506 644 828 966

[14.33] [18.24] [23.45] [27.35]

766 975 1254 1463

[21.69] [27.61] [35.51] [41.43]

766 975 1254 1463

[21.69] [27.61] [35.51] [41.43]

766 975 1254 1463

[21.69] [27.61] [35.51] [41.43]

Exhaust Flow Rates VOLUME (min. recommended)

Switches On

18xx

32xx

38xx

24xx

Double

Triple

X

Single

XXX

X

XXXXXXX

XXXXX

NOTE: All values are CFM [M3/Min] unless otherwise noted.

NOTE: Figures represent TOTAL VOLUME measured at the duct.

AVI RECOMMENDED EXHAUST FLOW RATES

In accordance with mechanical codes, make up air must be supplied. For commercial

kitchen make up air, the amount is determined by the exhaust hood flow rate requirements & all

other exhaust flow rate requirements in the kitchen.

At a minimum, smoke candles must be used for a Capture & Containment (C&C) test. Refer to the Ventilation Requirements disclosed in the Oven section in this manual.

A Test & Balance (TAB) report is recommended after installation has been completed.

Below are the minimum items to be included is this report:

Total airflow on all A/C, Make-Up Air (MUA), & exhaust systems.

Airflow on each supply & exhaust grille.

Airflows on exhaust hoods compared to design specifications.

A final air balance report, with any corrections of issues found in the report, will help to

insure that your building systems are functioning properly & efficiently.

Refer to “Oven Ventilation Requirements & Guidelines”

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Top Middle Bottom

187.5 187.5 93.75 93.75

[57.15] [57.15] [28.58] [28.58]

187.5 187.5 93.75 93.75

[57.15] [57.15] [28.58] [28.58]

189.75 241.5 155.25 181.125

[57.84] [73.61] [47.32] [55.21]

189.75 241.5 155.25 181.125

[57.84] [73.61] [47.32] [55.21]

187.5 187.5 93.75 93.75

[57.15] [57.15] [28.58] [28.58]

189.75 241.5 155.25 181.125

[57.84] [73.61] [47.32] [55.21]

287.25 365.625 235.125 274.3125

[87.55] [111.44] [71.67] [83.61]

189.75 241.5 155.25 181.125

[57.84] [73.61] [47.32] [55.21]

287.25 365.625 235.125 274.3125

[87.55] [111.44] [71.67] [83.61]

287.25 365.625 235.125 274.3125

[87.55] [111.44] [71.67] [83.61]

287.25 365.625 235.125 274.3125

[87.55] [111.44] [71.67] [83.61]

Single

X

Double

X

Switches On

18xx

24xx

32xx

38xx

Exhaust Flow Rates VELOCITY (min. recommended)

X

Triple

XXXXX

X

X

X

X

NOTE: Figures represent VELOCITY measured at the Grease Filter.

XXX

NOTE: All values are FPM [M/Min] unless otherwise noted.

X

X

AVI RECOMMENDED EXHAUST FLOW RATES

59

NOTE: Most building codes require 500 Feet per Minute velocity. Exhaust duct is 1 ft2. Check

with your local building official for requirements.

The VELOCITY readings above are obtained by holding an anemometer 3” away from the Grease

Filter. Take several readings in different locations across the filters and average the results.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

60

AVI HOOD INSTALLATION

Prepare Ovens - Remove Lid Screws - Two (2) Only

Prepare Ovens - Control Box Closeout Bracket

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Conveyors have been removed for clarity

AVI HOOD INSTALLATION

Prepare Ovens - Front Shroud Brackets

61

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

62

AVI HOOD INSTALLATION

Prepare Ovens - Bottom Rail Bracket

Prepare Ovens - Control Box Side Closeout

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD INSTALLATION

Prepare Ovens - Rear Shroud Brackets

63

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

64

AVI HOOD INSTALLATION

Prepare Hood

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD INSTALLATION

65

Lifting Gear Setup

AVI hoods can easily be moved and stacked with the proper lifting equipment. The use of

XLT approved lifting equipment is highly recommended. Contact XLT for more information.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

66

WARNING

AVI HOOD INSTALLATION

Lifting Jack Setup

Check for smooth operation. The cable should not be pinched & should pass

smoothly over the pulley on top of the pole assembly.

Inspect cable prior to each use.

If cable is frayed or shows signs of excessive wear & tear, DO NOT USE until

cable is replaced.

At a minimum replace the cable annually with wire rope that meets or exceeds

the jack manufacturer’s specifications.

Do not exceed the stated capacity of the jack.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

WARNING

WARNING

AVI HOOD INSTALLATION

67

Stacking Hood on the Ovens

Failure to engage the Lifting Jacks into the Lifting Pipe properly and completely

will result in damage, injury, or death from a falling hood.

Both jacks should be raised in unison, otherwise they may bind and a dangerous

situation will develop.

Do not put any part of yourself under the hood at any time.

The hood is top heavy. Be careful.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

68

AVI HOOD INSTALLATION

Hang Hood From Ceiling Joists

All thread provided by others

69 5/8 ±1/8

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD INSTALLATION

Install Grease Trays, Light Bulbs & Covers, and Grease Filters

1 2

3 4

69

5 6

Filler Panel to be

Grease Filters

Grease Tray

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

70

AVI HOOD INSTALLATION

Install Shroud Hanging Brackets

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD INSTALLATION

Install Corner Posts

71

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

72

AVI HOOD INSTALLATION

Install Bottom Rails

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD INSTALLATION

Install Bottom Rails

73

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

74

AVI HOOD INSTALLATION

Install Control Box Upper Closeout

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD INSTALLATION

Install Shroud Panels - Front and Ends

75

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

76

AVI HOOD INSTALLATION

Install Back Shroud Panel

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

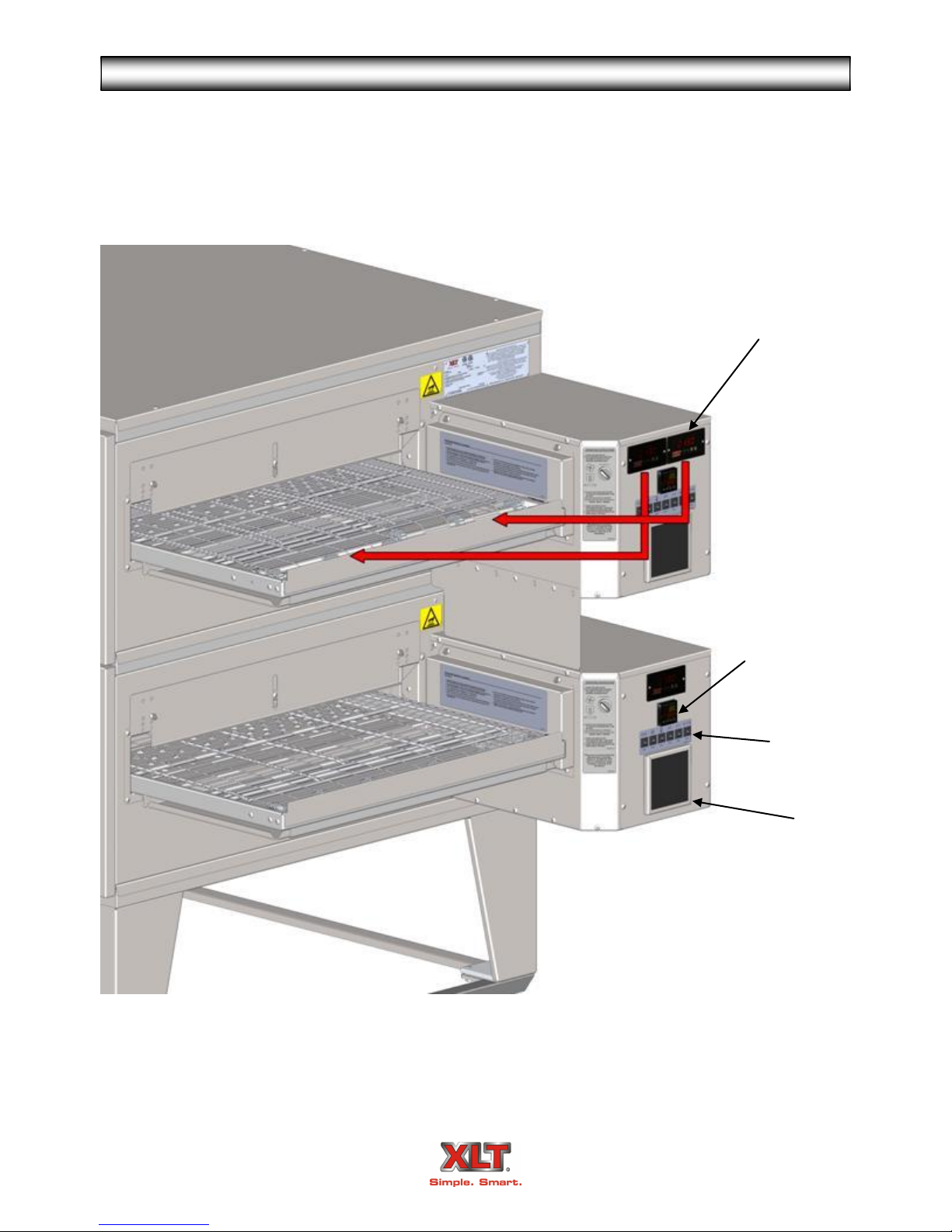

AVI HOOD INSTALLATION

Install Hood Control Cord Assembly

77

All hoods are outfitted with three (3) control cord outlets, regardless of how many XLT

Ovens are installed. For a single oven use “Top” location. For a double stack use “Top” location

for upper oven and “Bottom” location for lower oven, leaving “Middle” location open.

Insert and lock each oven control cord into the designated location on the bottom of the

hood control box.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

78

AVI HOOD INSTALLATION

Connect Hood Control Cord Assembly

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Top Middle Bottom

Single X 20 Hz 25 Hz 30Hz

X 20 Hz 25 Hz 30Hz

X 35 Hz 40 Hz 45 Hz

X X 35 Hz 40 Hz 45 Hz

X 20 Hz 25 Hz 30Hz

X 30 Hz 35 Hz 40 Hz

X 40 Hz 45 Hz 50 Hz

X X 30 Hz 35 Hz 40 Hz

X X 40 Hz 45 Hz 50 Hz

X X 40 Hz 45 Hz 50 Hz

X X X 45 Hz 50 Hz 55 Hz

Fire Suppression

60 Hz

Triple

Double

VFD Controller Settings

Switches On

1832, 1855 & 2440

3240, 3255 & 3270

3855 & 3870

AVI HOOD INITIAL START-UP

79

Variable Frequency Drive Adjustments

All AVI Hoods are functionally tested at the factory. Operation is verified, and adjustments are made to ensure proper operation. However, field conditions are sometimes different

than factory conditions. These variables make it necessary to have an authorized service technician verify operation and make field adjustments if needed. The following items must be checked

and verified to meet the specifications and requirements stated in this manual prior to the hood being commissioned:

Correct fan rotation.

Balanced make-up air.

The Initial Start-Up Checklist must be completed at time of installation, signed by the Customer and returned to XLT Ovens to initiate Warranty Policy.

The VFD controller is adjusted at the factory to the values displayed in the chart below.

If you require either more or less air flow, follow these steps:

1. Turn at least one (1) oven switch ON. The VFD display should show the POWER and RUN

LED lamps lit up, and a numeric value should appear in the window display.

Window Display

Function

VFD Controller Display

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Store

80

2. Press & hold the function key until <d001> displays.

3. Use the up / down arrows to reach <F001>.

4. Press the function key one (1) time. A frequency will display according to the switches that

are ON per the chart below.

5. Turn all oven switches OFF. The display should read <0.0>.

6. Turn ON the oven switches to be set. For example, both Top and Bottom ovens, or Top oven

only, or Bottom oven only, etc.

7. Press the Up/Down arrows until you reach the desired initial settings.

8. Press the store button once to store the new setting.

9. Repeat steps 6-8 for additional settings as needed.

10. When finished, turn all of the oven switches to the OFF position.

11. Press the <FUNC> key until <d001> appears in the display.

12. Press the <FUNC> one more time. The actual frequency will appear in the window display.

13. Press the <STR> button one time to store the values.

The control switches are located on the front of the hood.

AVI HOOD OPERATOR CONTROLS

When XLT Ovens are outfitted with AVI Hoods, the main switch on the oven is disabled and no longer operates. The switch on the AVI Hood overrides the oven switch.

NOTE

1. Turn the light switch on.

2. Turn the desired oven switch on. Refer to the Oven start-up section for instructions on how to

adjust temperature and conveyor speed. The oven(s), exhaust fan, and make-up air unit will be

activated by this switch if the AVI Hood is installed according to this manual.

3. When additional oven switches are turned on, the VFD will automatically increase the exhaust

fan speed.

4. When shutting down the ovens, turn the desired oven switch off. The make-up air unit will

shut off. The ovens and exhaust fan will shut off after about 30 minutes. Refer to the Oven

shutdown section for instructions.

5. Do not press the <STOP/RESET> switch on the Variable Frequency Drive itself. The RUN

and POWER LED should stay lit all of the time.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Hood Operation

AVI HOOD VALANCE KIT (OPTIONAL)

81

The valance kit size is determined by AVI Hood size & distance from the finished floor to

the installed drop ceiling height. The valance kit screws directly to the AVI Hood & does not require any structural support. All kits have provisions for hood fire suppression piping to pass

through without modification. The plastic coating must be removed from all parts prior to installation.

AVI Hood valance kits are available for different floor to ceiling heights. Contact XLT

Ovens or your designated representative for more information.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

82

AVI HOOD VALANCE KIT (OPTIONAL)

Install Valance Brackets

Install Front & Back Panels

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD VALANCE KIT (OPTIONAL)

Install Corner Panels

83

Install End Panels

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

84

AVI DUCT WRAP KIT (OPTIONAL)

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

AVI HOOD CLEANING

Cleaning

Wipe down Front, Sides, & Top

?

Clean Light Globes

?

Empty & Clean Grease Trays

? ?

Clean Grease Filters

? ?

Clean Duct and Exhaust Fan

? ?

Inspection

Check Indicator Lamp

?

Check Grease Trays

?

Check Grease Filters

?

Adjust

No Adjustments Necessary

Lubricate

No Lubrication Required

Replace

Light Bulbs

?

Hood Cleaning & Maintenance Schedule

Daily

Weekly

Monthly

Semi-

Annual

As Required

85

Your AVI hood is constructed of stainless and aluminized steel. Check application restrictions on product label prior to usage. Observe recommended precautionary and safety measures as

dictated by the product manufacturer.

Do not use abrasive or caustic cleaners. Abrasive pads will scratch stainless steel surfaces.

Areas with heavy buildup should be sprayed and allowed to soak for up to 5 minutes prior to wip-

ing clean. Always wipe with the “grain” of the surface to maintain appearance.

Schedule provided as a guide only. Frequency of cleaning may vary as needed.

Oven must be cool and the electric cord unplugged before any cleaning is done.

WARNING

Shroud Panels can weigh up to 60 lbs [27 kg]. Use caution when lifting.

CAUTION

DO NOT spray liquid cleaning agents in the slots & holes of the following locations:

CAUTION

Refer to the Hood Installation Section for disassembly and reassembly.

Technical Support US: 888-443-2751 Technical Support INTL: 316-943-2751

Hood electrical box (located on back of upper portion)