XLT Ovens 3240-AE-B, 3255-AE-B, 3270-AE-B, 3270S-AE-B, 3855-AE-B Installation & Operation Manual

...

XD-9010B-GA

Rev 03 04/07/2011

XLT Oven & AVI Hood

Installation & Operation Manual

This appliance is for professional use by qualified personnel. This appliance must be installed

by qualified persons in accordance with the regulations in force. This appliance must be installed with

sufficient ventilation to prevent the occurrence of unacceptable concentrations of substances harmful

to health in the room in which it is installed. This appliance needs an unobstructed flow of fresh air for

CAUTION

An electronic copy of this manual & warranty policy is available at: www.xltovens.com

For use with the following XLT GAS Oven Versions:

Australian (AE) B

Standard (S) B

World (W) B

satisfactory combustion and must be installed in a suitably ventilated room in accordance with current

regulations. This appliance should be serviced by qualified personnel at least every 12 months or

sooner if heavy use is expected.

For use with the following AVI Hood Versions:

Standard (S) A

World (W) A

2000887

TEL: 888-443-2751 FAX: 316-943-2769 WEB SITE: www.xltovens.com

XLT Ovens

PO Box 9090

Wichita, Kansas 67277

2

WARNING & SAFETY INFORMATION

SAFETY DEPENDS ON YOU

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury, or death. Read the installation, operating and maintenance in-

WARNING

Post in a prominent location instructions to be followed in the event you smell gas. This infor-

mation can be obtained by consulting your local gas supplier.

WARNING

In the event a gas odor is detected, shut off the gas at the main shutoff valve immediately.

Contact your local Gas Company or supplier.

Do not restrict the flow of combustion and/or ventilation air to the unit. Provide adequate

clearance for operating, cleaning, and maintaining the unit and adequate clearance for operating the gas shutoff valve when the unit is in the installed position.

structions thoroughly before installing, using, or servicing this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable

liquids or vapors in the vicinity of this or any other appliance.

Keep the area free and clear of combustible material. DO NOT SPRAY AEROSOLS IN THE

VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

Ovens are certified for installation on combustible floors.

Electrical schematics are located inside the control box of the oven and at the end of this man-

ual. Disconnect input power to the unit before performing any maintenance.

This unit requires a Type I ventilation hood, which requires make-up and exhaust air to ensure

adequate air supply. The installation should conform to local codes.

This unit may be operated with either natural gas or LP fuel as designated on the nameplate

label located on the side of the unit.

This unit must be operated by the same voltage, phase, and frequency of electrical power as

designated on the nameplate label located on the side of the unit.

Minimum clearances must be maintained from combustible and non-combustible construction

materials.

Follow all local codes when installing this unit.

Follow all local codes to electrically ground the unit.

Appliance is not to be cleaned with high pressure water.

Ovens are certified for use in stacks of up to three (3) units of XLT products. Integration of

other manufacturer’s products into an oven stack is not recommended, and will void any war-

ranties. XLT Ovens assumes no liability for mixed product applications.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

SAFETY MESSAGES

For the best results with the XLT Oven and AVI Hood, carefully read this manual and all

of the warning labels attached to the products before installing and operating them, and follow the

instructions exactly. Keep this manual handy for quick reference.

Definitions and Symbols

A safety instruction (message) includes a “Safety Alert Symbol” and a signal word or

phrase such as WARNING or CAUTION. Each signal word has the following meaning:

This symbol indicates high voltage. It calls your attention to items or operations

that could be dangerous to you and other persons operating this equipment. Read

HIGH

VOLTAGE

WARNING

the message and follow the instructions carefully.

Indicates a potentially hazardous situation that, if not avoided, can result in serious

injury or death.

3

Indicates a potentially hazardous situation, that if not avoided, can result in minor to

moderate injury or serious damage to the product. The situation described in the

CAUTION may, if not avoided, lead to serious results. Important safety measures are

CAUTION

described in CAUTION (as well as WARNING), so be sure to observe them.

Notes indicates an area or subject of special merit, emphasizing either the product’s

NOTE

capability or common errors in operation or maintenance.

Tips give a special instruction that can save time or provide other benefits while installing or

using the product. The tip calls attention to an idea that may not be obvious to first-time users of the product.

TIP

Purchaser’s Responsibility

It is the responsibility of the purchaser:

To unload, uncrate, assemble, and move the ovens to their intended location.

To ensure that the gas and electric utilities are installed on site in accordance with local build-

ing codes and with the specifications in this manual.

To see that the gas and electric utilities are connected properly by a qualified installer using the

proper hardware.

To ensure a qualified installer has performed an initial start-up procedure.

In Australia, install oven in accordance with the latest version of AS5601 Gas Installation.

4

Your new oven and hood system is the result of our dedication to help you produce the finest quality baked goods. XLT Ovens has made a substantial and growing investment in capital

equipment and facilities, including state of the art CAD/CAM designing and fabricating software

and machine tools. The company has also developed ways to build quality into its products at each

stage of the manufacturing process, both through extensive use of automation and, most importantly, through an awareness that people are the central element in quality control.

XLT Ovens wants you to be totally satisfied with every aspect of owning and using your

oven and hood. Your feedback, both positive and negative, is very important to us as it helps us

understand how to improve our products and our company. Our goal is to provide you, our customer, with equipment that we can be proud to build and you can be proud to own.

To receive technical support for the oven or hood you purchased, contact the designated

representative from whom you purchased the unit, or XLT Ovens at 888-443-2751 anytime day or

night, 365 days per year. Please be prepared to provide the Model and Serial Number.

Receiving and Inspection

NOTIFY CARRIER OF DAMAGE AT ONCE

Upon receiving of all goods shipped by a Common Carrier, check for any exterior damage

that may indicate interior damage. If conditions permit, open all crates and do a full inspection for

any damage while the delivery driver is still there. If there is damage please note on the delivery

receipt and call the carrier to make a freight damage claim within 24 hours of receipt. Failure to

make a damage claim within the first 24 hours may void the opportunity to have the claim resolved.

Installation of all gas appliances and ventilation exhaust hoods should only be performed by a qualified professional who has read and understands these instructions

WARNING

and is familiar with proper safety precautions. Read this manual thoroughly before

installing or servicing this equipment.

Save this Manual

This document is the property of the owner of this equipment. Please make sure to leave

this copy with the store owner or “on site” manager, so it can be incorporated in the owners “on

site” book of manuals for future use.

XLT Ovens reserves the right to make changes in design and specifications, and/or make

additions to or improvements to its product without imposing any obligations upon itself to install

them in products previously manufactured.

All Right and Left Hand designations in this manual are from the point of view as if standing directly in front of the ovens.

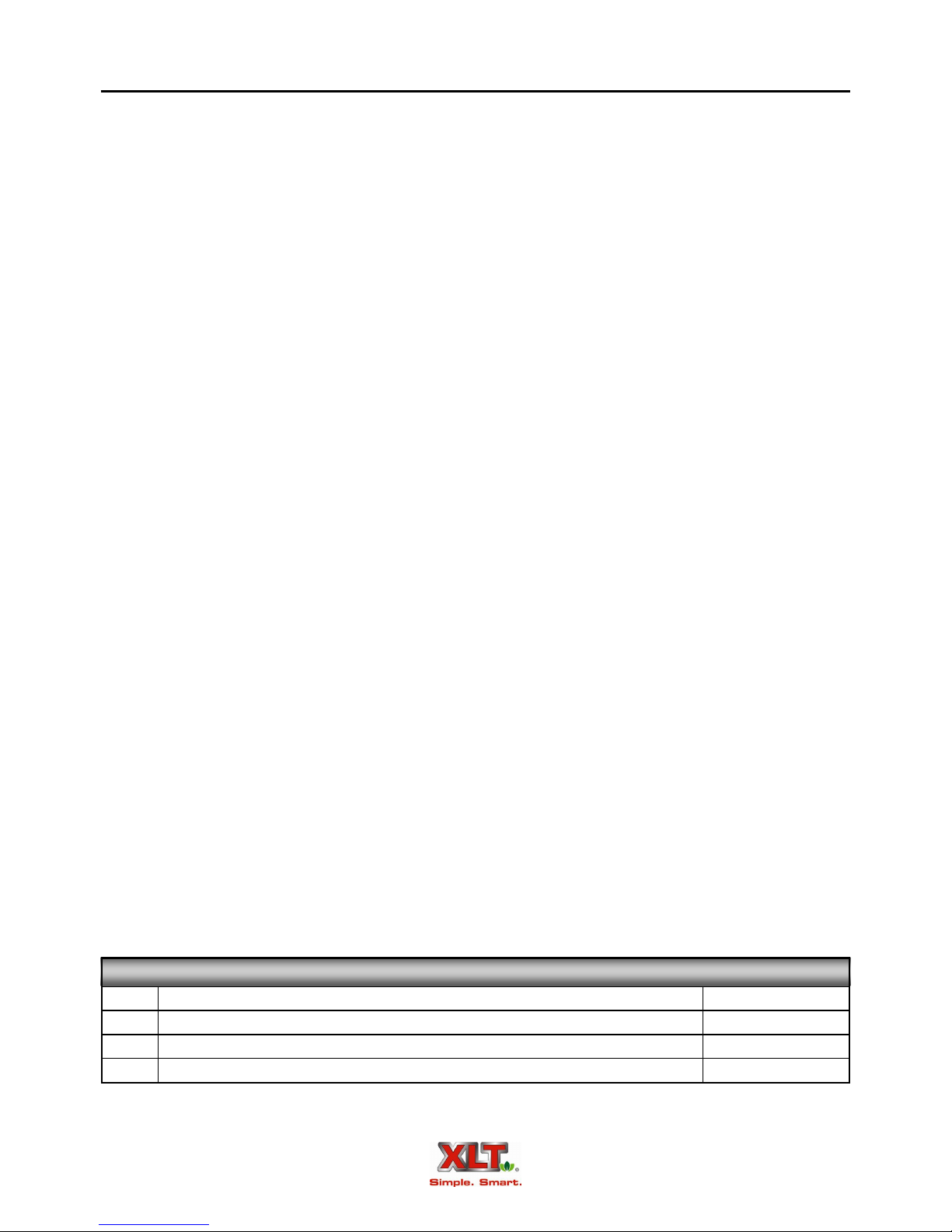

TABLE OF CONTENTS

Warning & Safety Information..................................................................................................... 2

Safety Messages ........................................................................................................................... 3

Oven Description .......................................................................................................................... 6

Oven Dimensions ......................................................................................................................... 8

Gas & Electrical Connection Dimensions .................................................................................. 10

Oven Electrical Requirements .................................................................................................... 12

Oven Gas Requirements ............................................................................................................. 13

Oven Only Rough-In Specifications .......................................................................................... 15

Oven Assembly .......................................................................................................................... 17

Oven Installation ........................................................................................................................ 23

Oven Ventilation Requirements & Guidelines ........................................................................... 27

Oven Initial Start-Up .................................................................................................................. 29

Oven Operator Controls ............................................................................................................. 33

Oven Operation .......................................................................................................................... 35

Oven Cleaning ............................................................................................................................ 36

Oven Maintenance ...................................................................................................................... 40

Oven Troubleshooting ................................................................................................................ 41

Hood Description ....................................................................................................................... 44

Hood Dimensions ....................................................................................................................... 45

Hood Electrical Requirements................................................................................................... 47

Hood Ventilation Requirements ................................................................................................. 64

Hood Rough-In Specifications ................................................................................................... 65

Hood Installation ........................................................................................................................ 66

Variable Frequency Drive Adjustments ..................................................................................... 85

Hood Operator Controls ............................................................................................................. 86

Hood Initial Start-Up .................................................................................................................. 87

Hood Valance Kit ....................................................................................................................... 89

Hood Cleaning ............................................................................................................................ 92

Hood Troubleshooting ................................................................................................................ 94

International Distributors ........................................................................................................... 94

Electrical Schematics ................................................................................................................. 95

5

Revision History Table

Revision Comments Date

01 Initial Release 1/19/2011

02 Updated Hood Installation Dimensions page 45 3/8/2011

03 Revised MJ/hr 04/07/2011

6

Oven Description

This manual covers the following XLT Series Ovens and AVI Hood models:

1832-AE-B

2440-AE-B

3240-AE-B

3255-AE-B

3270-AE-B

3270S-AE-B

3855-AE-B

3870-AE-B

1832B-S

2440B-S

3240B-S

3255B-S

3270B-S

3270SB-S

3855B-S

3870B-S

1832B-W

2440B-W

3240B-W

3255B-W

3270B-W

3270SB-W

3855B-W

3870B-W

AVI-1832A-S AVI-1832A-W

AVI-2440A-S AVI-2440A-W

AVI-3240A-S AVI-3240A-W

AVI-3255A-S AVI-3255A-W

AVI-3270A-S AVI-3270A-W

AVI-3855A-S AVI-3855A-W

AVI-3870A-S AVI-3870A-W

XLT Ovens are certified to the following Standards:

“-AE” indicates Australian Export configuration, certified to AGA AS 4563.

“-S” indicates Standard configuration, certified to ANSI Z83.11/CSA 1.8 & ANSI/NSF 4.

“-W” indicates World configuration, certified to CE GAD 90/396/EEC & BS EN 203-1.

AVI Hoods are certified to the following Standards:

“-S” indicates Standard configuration, certified to UL 710, ULC-S646, NFPA 96, and ANSI/NSF 2.

“-W” indicates World configuration, certified to UL 710, ULC-S646, NFPA 96, and ANSI/NSF 2.

The first 2 digits of the model number represent the conveyor width and the last two digits

indicate the bake chamber length. The ovens may be used in a single, double, or triple oven stack

configuration. A single or double configuration can be upgraded by adding additional decks up to

the maximum of three. All ovens are gas-fired and are available in Natural gas or LP gas models

(Electric ovens are also available). The 3270 and 3870 models have two burners, one on each side,

and have two control boxes. All other models have only a single burner with a single control box

that can be supplied on either end. All models can be configured for a split belt conveyor.

Food product is placed on the stainless steel wire conveyor belt on one side of the oven.

The conveyor then transports the food through the bake chamber at a user-controlled speed. This

provides repeatable and uniform food cooking. The conveyors can be easily configured to move

either left-to-right or right-to-left. A large center sandwich door allows the introduction or removal of food items for cooking at shorter times. Temperatures up to 550º F or 288º C inside the

oven are achieved by means of a user-adjustable digital control.

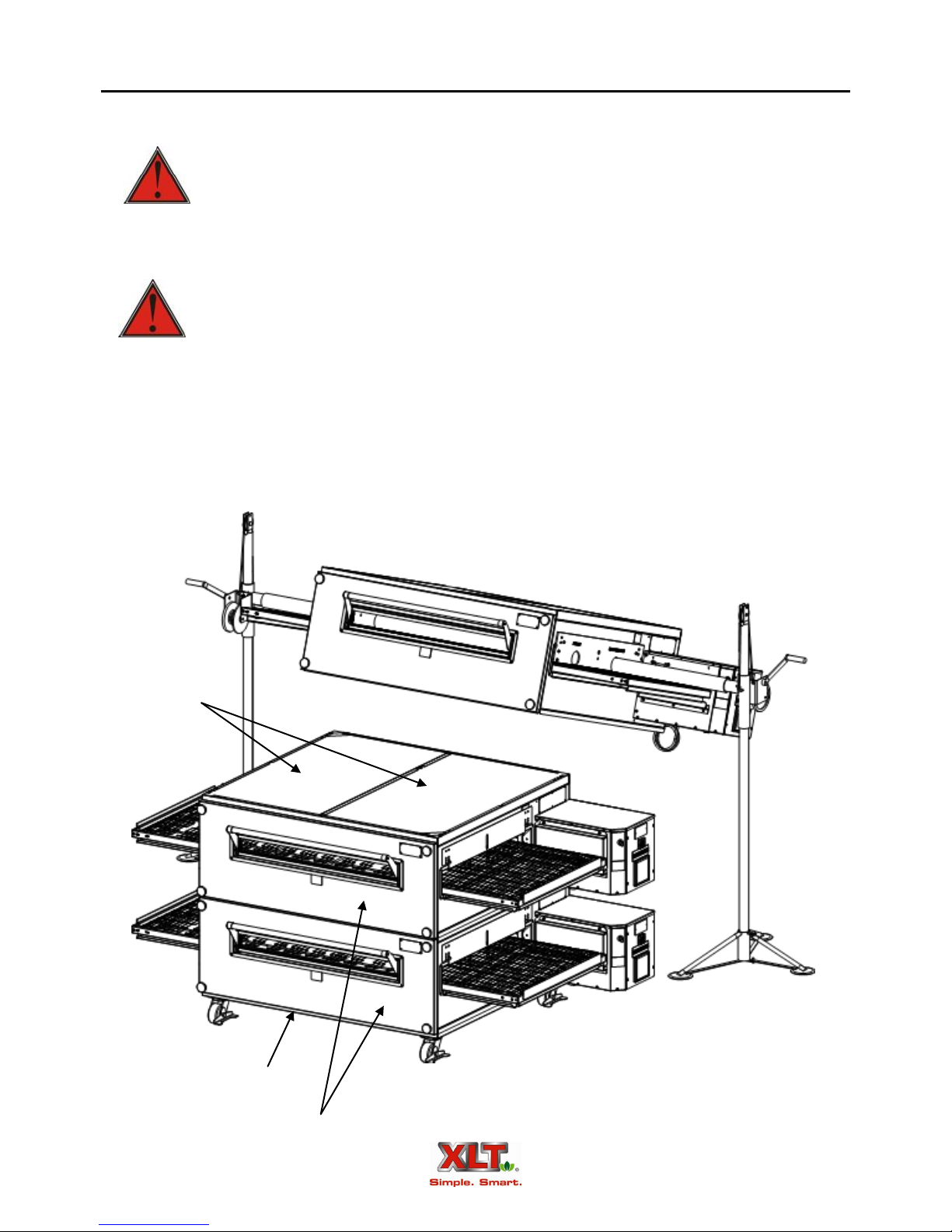

Oven Description

An easily removable front panel allows the full cleaning of the oven interior. All exposed

oven surfaces both exterior and interior are stainless steel. The conveyor is a one piece design and

is removed from the side which has the control box. No tools are required for disassembly and

cleaning of the conveyor or oven interior. The oven itself is mounted on lockable swivel casters

for easy moving and maintenance.

Accessories such as extended conveyor shelves and perforated crumb trays are available

from XLT. In addition, moving equipment such as carts and lifting jacks are available to help install and move ovens and hoods. Please contact XLT or your designated representative for more

information.

Control Box (LH)

(3270/3870 Only)

Sandwich Door

Oven Lid

Control Box (RH)

7

Crumb Tray

Front Panel Knob

Single/Double Stack

Base Assembly

Control Box Lid

Control

Panel

(LH)

Front Panel

Product Stop

Conveyor

Swivel Caster

Data Plate

Chain Guard

Control

Box Lid

Control

Panel

(RH)

Switch Control

Models 3270 & 3870

All Models

8

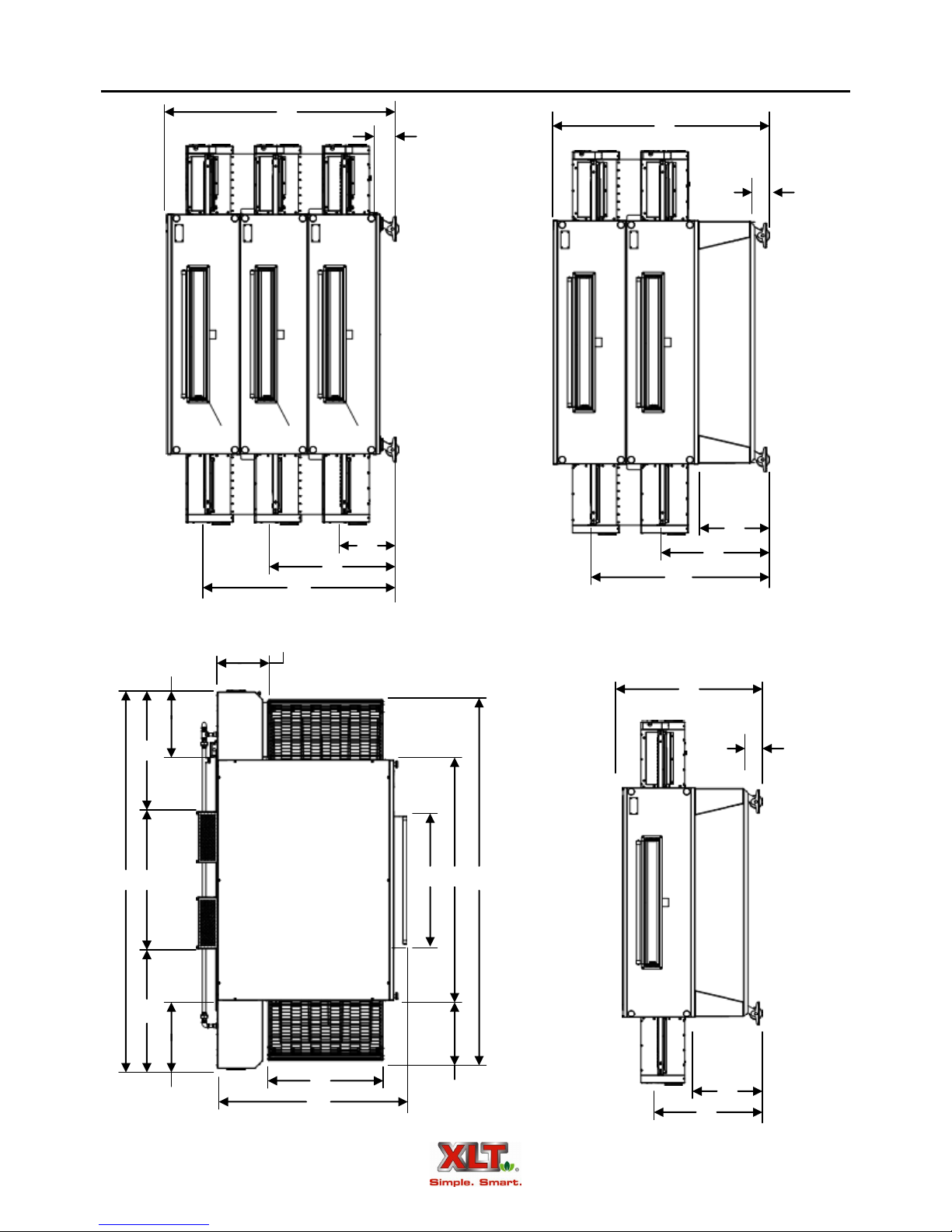

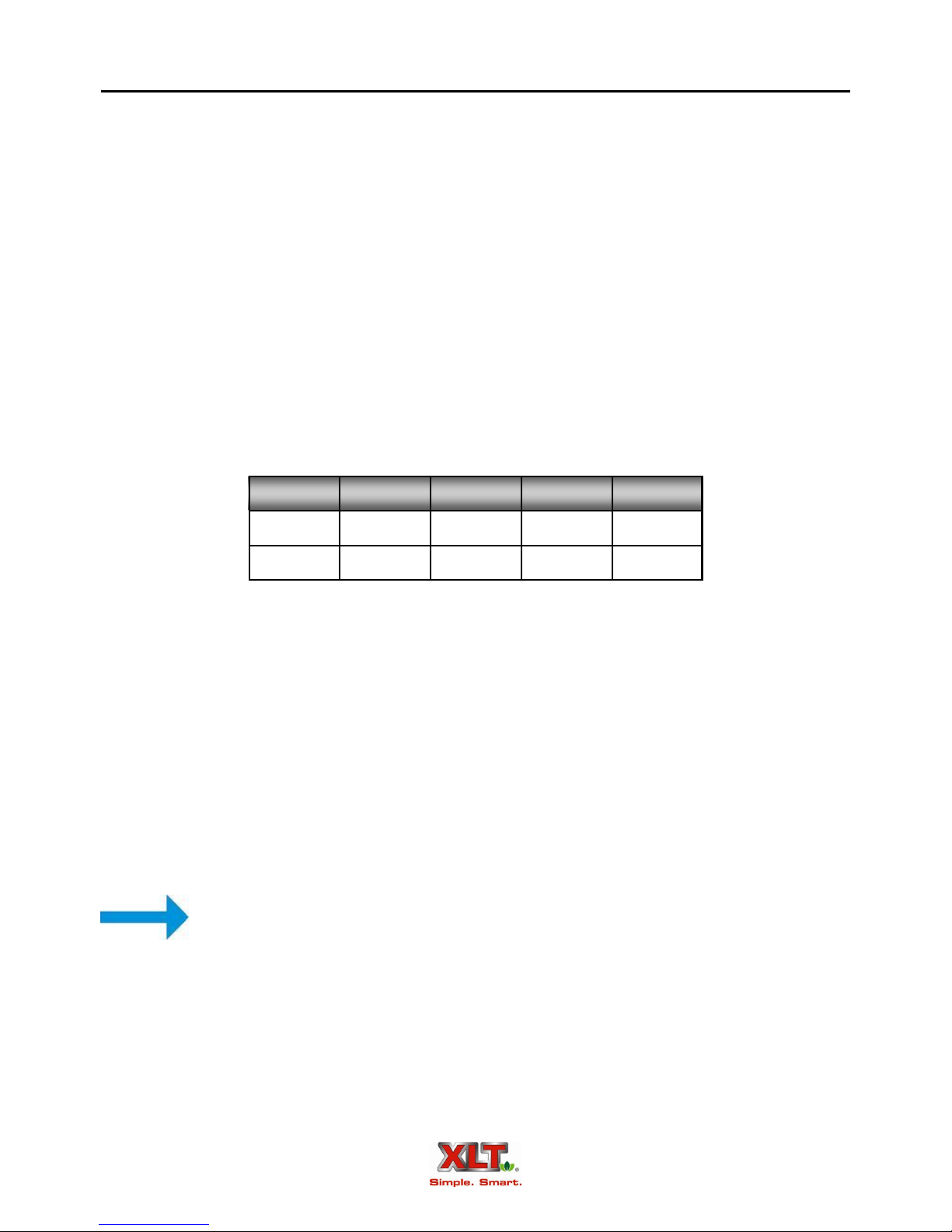

Oven Dimensions

L

K

L

K

M

N

P

Q

[530]

20.87

[502]

19.77

H

J G F

B C D

N

P

L

NOTE: All dimensions in inches [mm].

K

[502]

* 19.77

A

E

[446]

17.55

M

N

SINGLE

STACK

1832

2440

3240

3255

3270

3855

3870

DOUBLE

STACK

1832

2440

3240

3255

3270

3855

3870

Oven Dimensions

A B C D E F G H J K L M N P Q WEIGHT

19.41

32.13

67.25

19.72

47.23

[493]

[816]

[1708]

[501]

25.41

40.13

75.25

[645]

[1019]

33.41

40.13

[849]

[1019]

33.41

55.13

[849]

[1400]

33.41

70.13

[849]

[1781]

39.41

[1001]

[1001]

[1001]

[1001]

55.13

[1400]

39.41

70.13

[1781]

A B C D E F G H J K L M N P Q WEIGHT

19.41

32.13

[493]

[816]

25.41

40.13

[645]

[1019]

33.41

40.13

[849]

[1019]

33.41

55.13

[849]

[1400]

33.41

70.13

[849]

[1781]

39.41

55.13

[1400]

39.41

70.13

[1781]

[1911]

75.25

[1911]

90.25

[2292]

105.25

[2673]

90.25

[2292]

105.25

[2673]

67.25

[1708]

75.25

[1911]

75.25

[1911]

90.25

[2292]

105.25

[2673]

90.25

[2292]

105.25

[2673]

19.72

[501]

19.72

[501]

37.72

[958]

37.72

[958]

37.72

[958]

37.72

[958]

19.72

[501]

19.72

[501]

19.72

[501]

37.72

[958]

37.72

[958]

37.72

[958]

37.72

[958]

[1200]

53.23

[1352]

61.23

[1555]

61.23

[1555]

61.23

[1555]

67.23

[1708]

67.23

[1708]

47.23

[1200]

53.23

[1352]

61.23

[1555]

61.23

[1555]

61.23

[1555]

67.23

[1708]

67.23

[1708]

N/A* N/A*

N/A* N/A*

N/A* N/A*

N/A* N/A*

109.72

[2787]

N/A* N/A*

109.72

[2787]

N/A* N/A*

N/A* N/A*

N/A* N/A*

N/A* N/A*

109.72

[2787]

N/A* N/A*

109.72

[2787]

34.94

[887]

34.94

[887]

34.94

[887]

34.94

[887]

39.92

[1014]

39.92

[1014]

39.92

[1014]

39.92

[1014]

34.94

[887]

39.92

[1014]

34.94

[887]

39.92

[1014]

39.92

[1014]

39.92

[1014]

39.92

[1014]

34.94

[887]

39.92

[1014]

34.94

[887]

14.85

[377]

14.85

[377]

14.85

[377]

14.85

[377]

39.85

[1012]

14.85

[377]

39.85

[1012]

14.85

[377]

14.85

[377]

14.85

[377]

14.85

[377]

39.85

[1012]

14.85

[377]

39.85

[1012]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

5.70

[145]

42.73

[1085]

42.73

[1085]

42.73

[1085]

42.73

[1085]

42.73

[1085]

42.73

[1085]

42.73

[1085]

62.72

[1593]

62.72

[1593]

62.72

[1593]

62.72

[1593]

62.72

[1593]

62.72

[1593]

62.72

[1593]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

31.78

[807]

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

51.77

[1315]

51.77

[1315]

51.77

[1315]

51.77

[1315]

51.77

[1315]

51.77

[1315]

51.77

[1315]

N/A

N/A

N/A

N/A

N/A

N/A

N/A

[227]

[272]

[327]

[386]

1100

[500]

1050

[476]

1300

[590]

[404]

1060

[481]

1300

[590]

1500

[680]

2000

[907]

1800

[816]

2300

[1043]

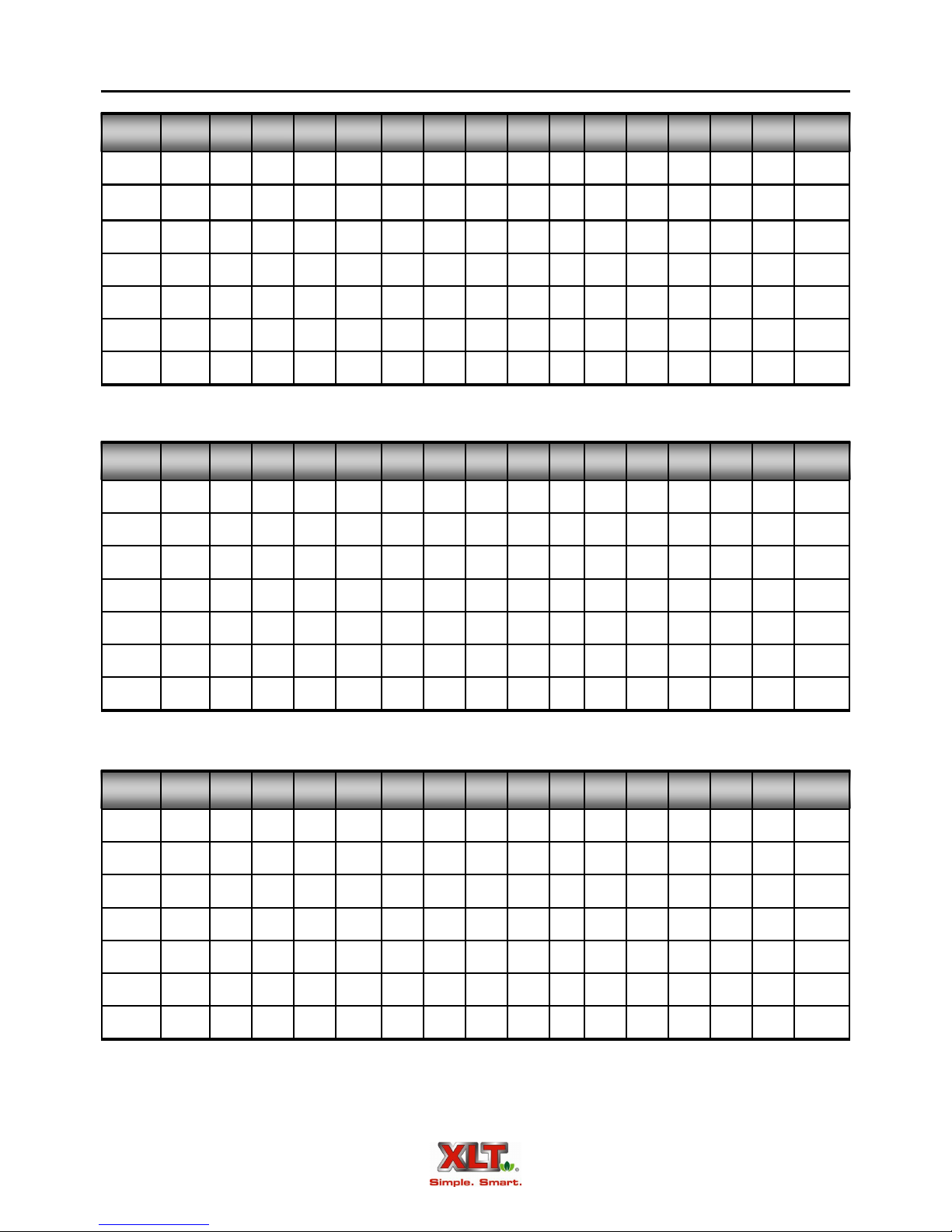

9

500

600

720

850

890

TRIPLE

STACK

1832

2440

3240

3255

3270

3855

3870

A B C D E F G H J K L M N P Q WEIGHT

19.41

32.13

67.25

[493]

25.41

[645]

33.41

[849]

33.41

[849]

33.41

[849]

39.41

[1001]

39.41

[1001]

[816]

40.13

[1019]

40.13

[1019]

55.13

[1400]

70.13

[1781]

55.13

[1400]

70.13

[1781]

[1708]

75.25

[1911]

75.25

[1911]

90.25

[2292]

105.25

[2673]

90.25

[2292]

105.25

[2673]

19.72

[501]

19.72

[501]

19.72

[501]

37.72

[958]

37.72

[958]

37.72

[958]

37.72

[958]

* Oven does not have left hand control box.

NOTE: All dimensions in inches [mm]. All weights in pounds [kg].

47.23

[1200]

53.23

[1352]

61.23

[1555]

61.23

[1555]

61.23

[1555]

67.23

[1708]

67.23

[1708]

N/A* N/A*

N/A* N/A*

N/A* N/A*

N/A* N/A*

109.72

34.94

[2787]

[887]

N/A* N/A*

109.72

34.94

[2787]

[887]

39.92

[1014]

39.92

[1014]

39.92

[1014]

39.92

[1014]

34.94

[887]

39.92

[1014]

34.94

[887]

14.85

[377]

14.85

[377]

14.85

[377]

14.85

[377]

39.85

[1012]

14.85

[377]

39.85

[1012]

5.63

67.69

20.66

16.75

36.73

[143]

5.63

[143]

5.63

[143]

5.63

[143]

5.63

[143]

5.63

[143]

5.63

[143]

[1726]

67.69

[1726]

67.69

[1726]

67.69

[1726]

67.69

[1726]

67.69

[1726]

67.69

[1726]

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

20.66

[525]

[425]

16.75

[425]

16.75

[425]

16.75

[425]

16.75

[425]

16.75

[425]

16.75

[425]

[933]

36.73

[933]

36.73

[933]

36.73

[933]

36.73

[933]

36.73

[933]

36.73

[933]

56.72

[1441]

56.72

[1441]

56.72

[1441]

56.72

[1441]

56.72

[1441]

56.72

[1441]

56.72

[1441]

1240

[562]

1500

[680]

1830

[830]

2100

[953]

2850

[1293]

2550

[1157]

3300

[1497]

10

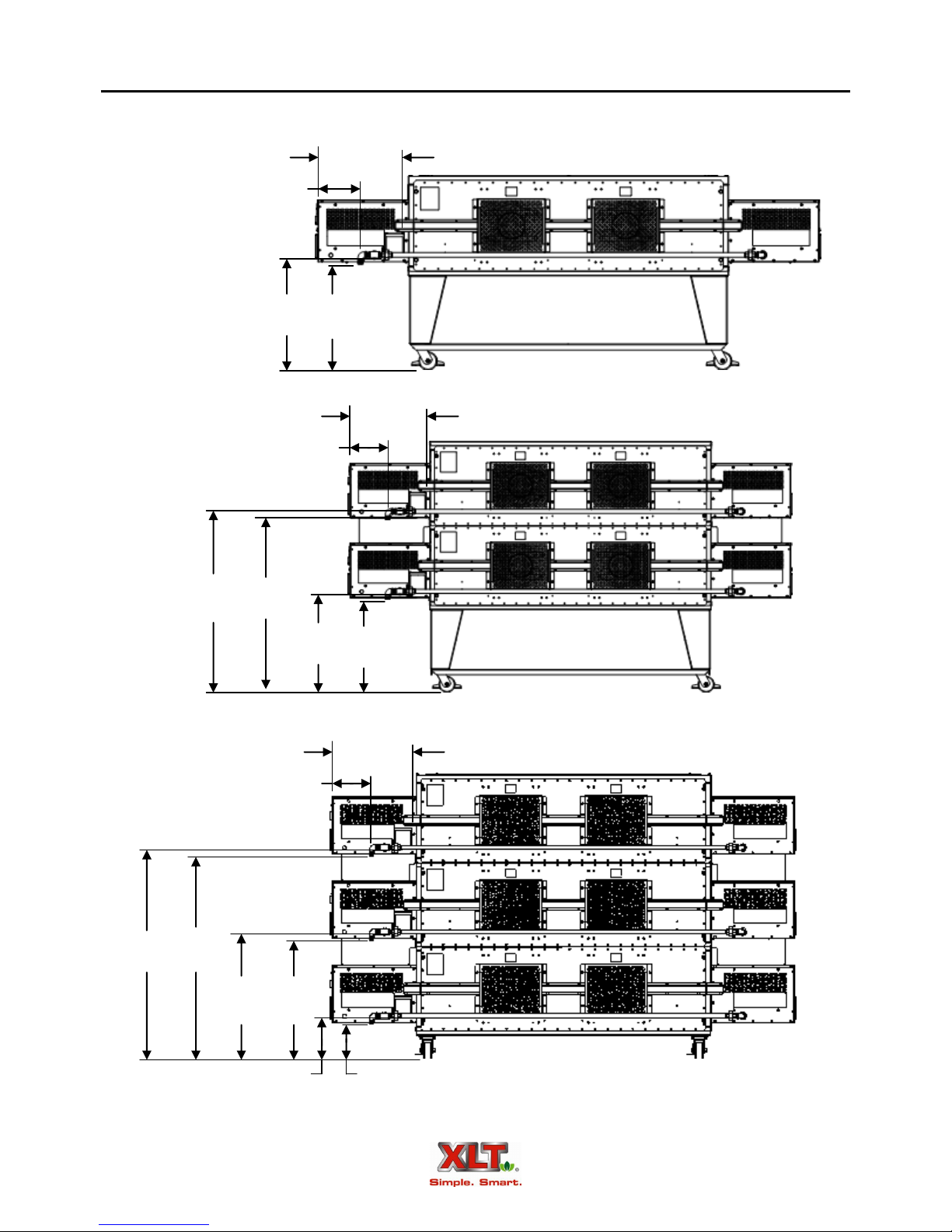

Gas & Electrical Connection Dimensions - Australian & World Ovens

For Models 3270 & 3870

18.91

[480]

9.30

[236]

44.87

[1140]

24.88

[632]

43.23

[1098]

9.30

[236]

24.88

[632]

9.30

[236]

23.24

[590]

18.91

[480]

23.24

[590]

18.91

[480]

49.82

[1265]

48.18

[1224]

29.83

[758]

28.19

[716]

9.85

[250]

8.21

[208]

NOTE: All dimensions in inches [mm].

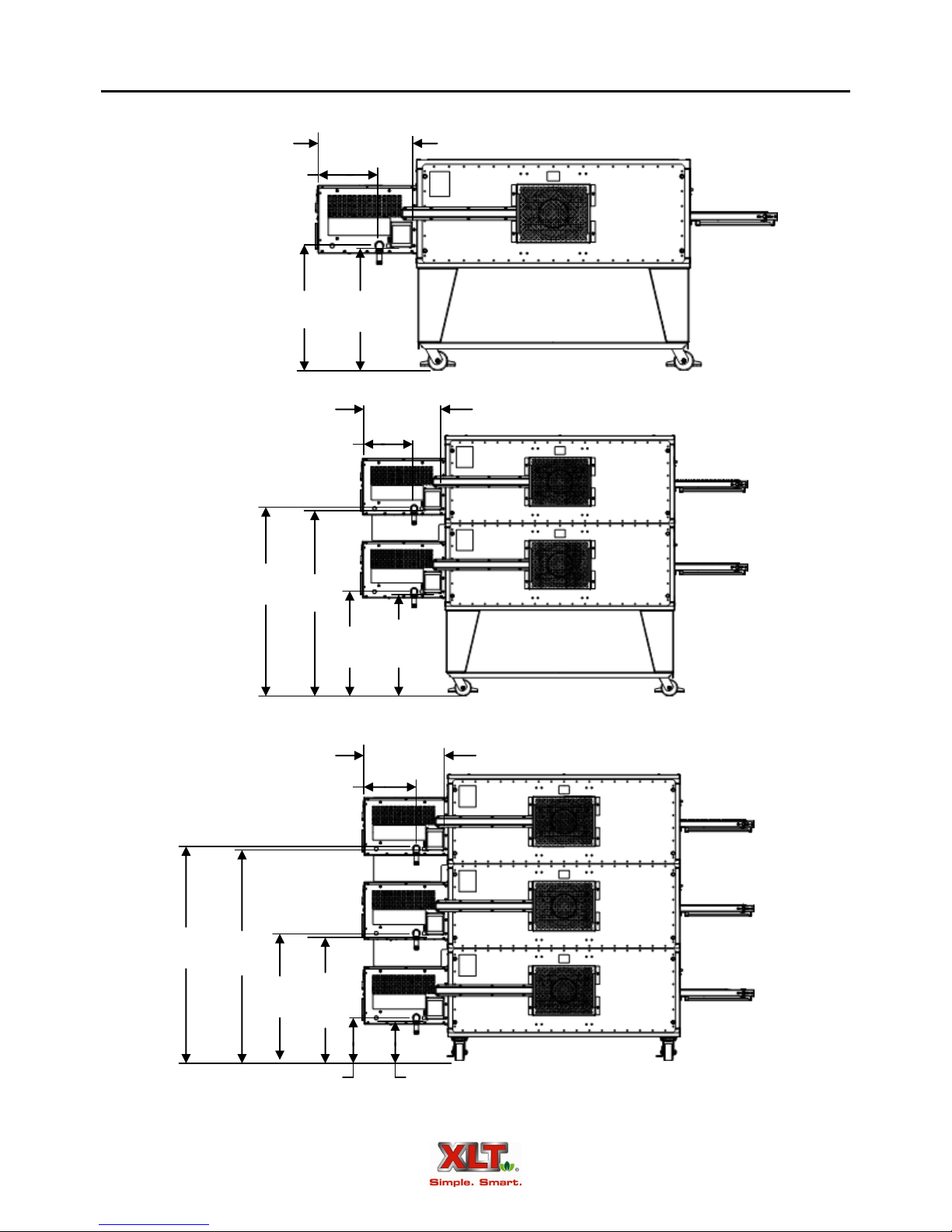

Gas & Electrical Connection Dimensions - Australian & World Ovens

For Models 1832, 2440, 3240, 3255 & 3855

18.91

[480]

12.35

[314]

24.88

[632]

25.24

[641]

18.91

[480]

12.35

[314]

11

49.82

[1265]

44.87

[1140]

50.18

[1275]

29.83

[758]

45.23

[1149]

12.35

[314]

30.19

[767]

24.88

[632]

25.24

[641]

18.91

[480]

9.85

[250]

10.21

[259]

NOTE: All dimensions in inches [mm].

12

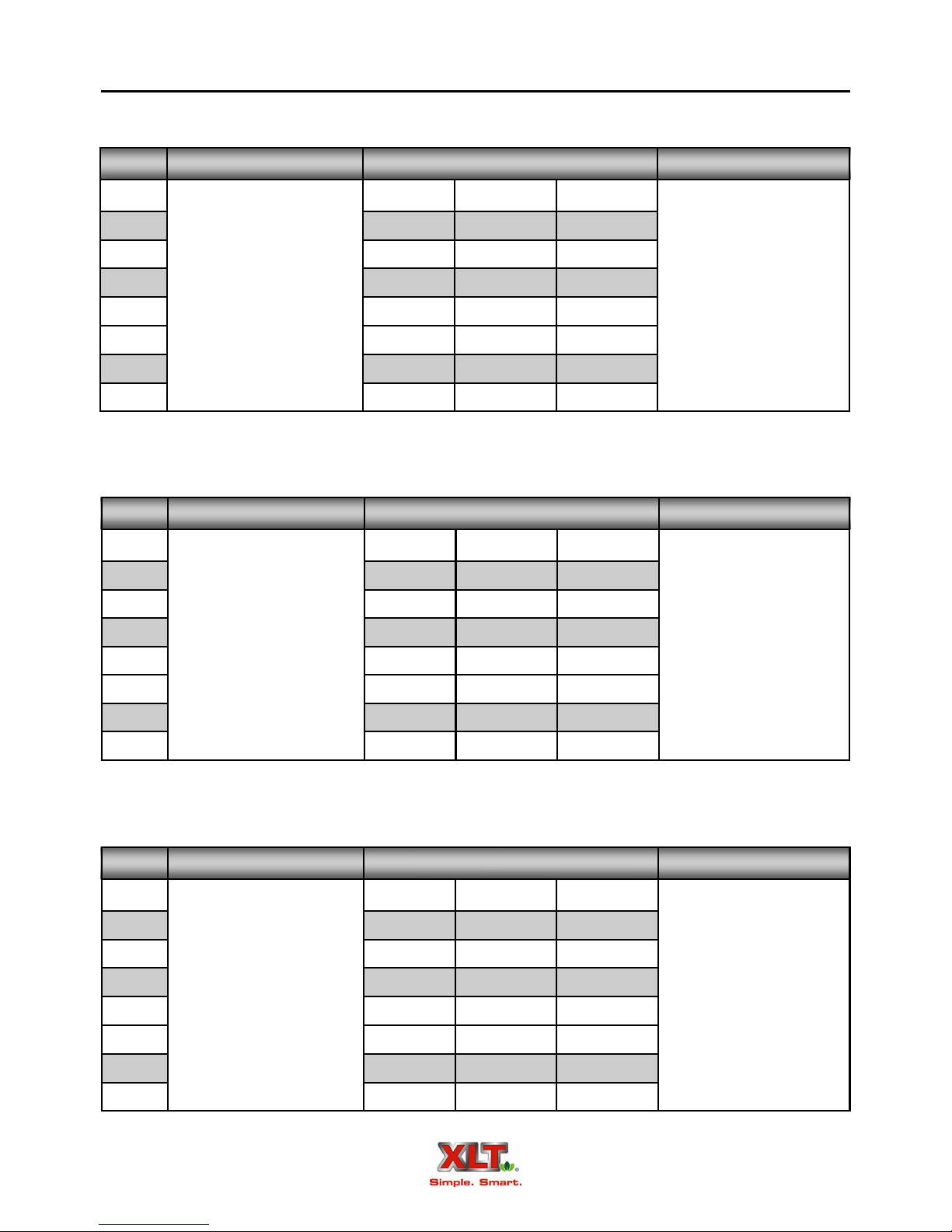

Oven Electrical Requirements

Australian Ovens

OVEN VOLTS AMPS FREQUENCY

Size

1832 3 6 9

2440 3 6 9

3240 3 6 9

220/230/240 VAC

3255 3 6 9

3270 6 12 18

3855 3 6 9

3870 6 12 18

Single Double Triple

50 Hz

Standard Ovens

OVEN VOLTS AMPS FREQUENCY

Size

1832 6 12 18

2440 6 12 18

3240 6 12 18

120 VAC

3255 6 12 18

3270 12 24 36

3855 6 12 18

3870 12 24 36

Single Double Triple

60 Hz

World Ovens

OVEN VOLTS AMPS FREQUENCY

Size

1832 3 6 9

2440 3 6 9

3240 3 6 9

220/230/240 VAC

3255 3 6 9

Single Double Triple

50 / 60 Hz

3270 6 12 18

3855 3 6 9

3870 6 12 18

Gas Requirements Australian, Standard. & World

Oven Burner Max. Capacity NAT Gas LP Gas

Size BTU/HR KW/HR MJ/HR W/C mbar kPa W/C mbar kPa

1832 52,000 15.24 63 6-14 15-35 1.5-3.5 11.5-14 27.5-35 2.75-3.5

2440 65,000 19.05 79 6-14 15-35 1.5-3.5 11.5-14 27.5-35 2.75-3.5

3240 90,000 26.37 105 6-14 15-35 1.5-3.5 11.5-14 27.5-35 2.75-3.5

3255 150,000 43.95 169 6-14 15-35 1.5-3.5 11.5-14 27.5-35 2.75-3.5

3270 160,000 46.88 190 6-14 15-35 1.5-3.5 11.5-14 27.5-35 2.75-3.5

3855 150,000 43.95 169 6-14 15-35 1.5-3.5 11.5-14 27.5-35 2.75-3.5

3870 160,000 46.88 190 6-14 15-35 1.5-3.5 11.5-14 27.5-35 2.75-3.5

Inlet Pressure

13

Manifold Pressure

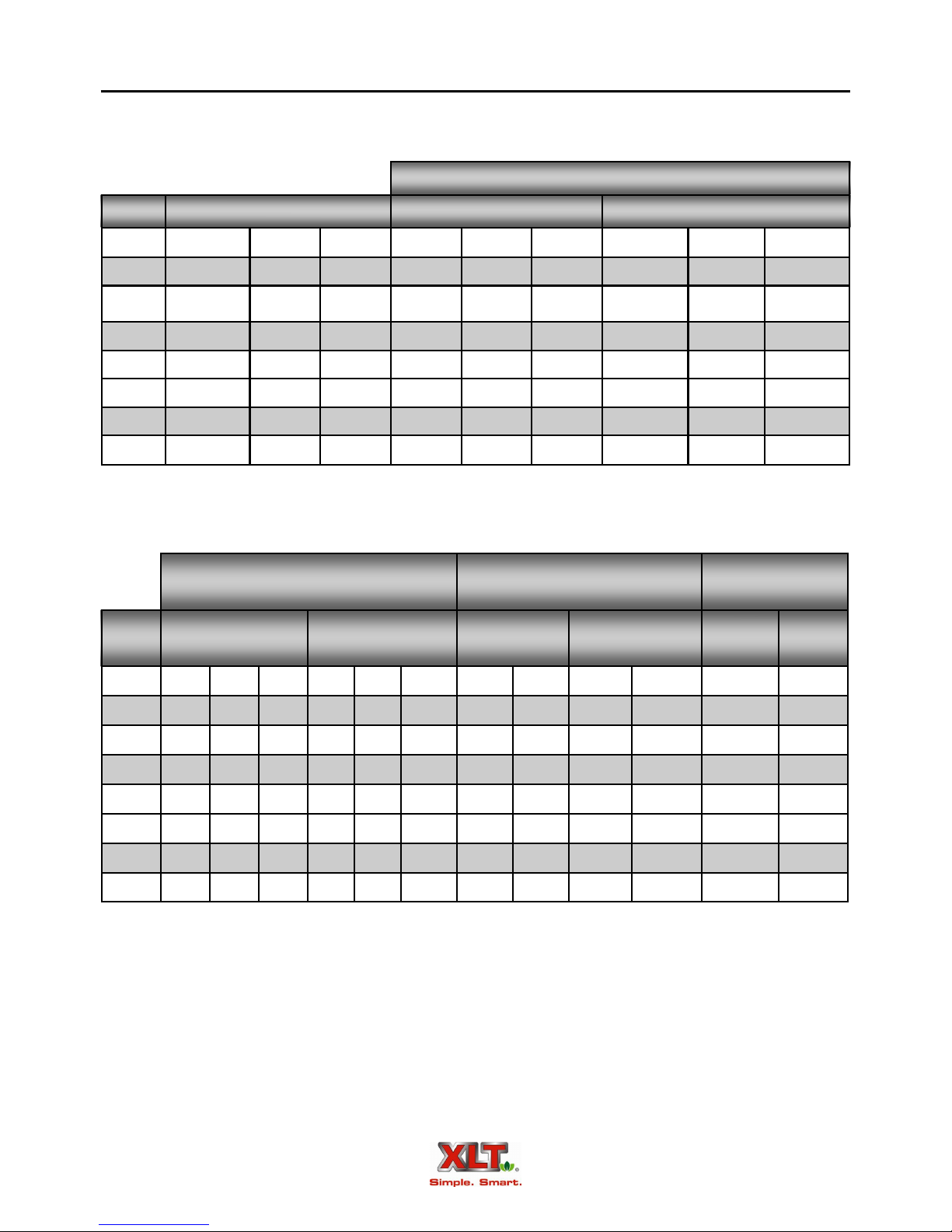

Orifice Sizes

Standard & World

Oven Natural Gas LP Gas Natural Gas LP Gas Natural

Size W/C mbar kPa W/C mbar kPa Inches MM Inches MM MM MM

1832 3.5 8.75 .875 10 25 2.5 .1285 3.26 .0820 2.08 3.56 2.24

2440 3.5 8.75 .875 10 25 2.5 .144 3.66 .0890 2.26 3.96 2.44

3240 3.5 8.75 .875 10 25 2.5 .1695 4.3 .1040 2.64 4.62 2.79

3255 3.5 8.75 .875 10 25 2.5 .219 5.56 .1285 3.26 5.94 3.66

3270 3.5 8.75 .875 10 25 2.5 .147 3.73 .0980 2.49 4.39 2.64

3855 3.5 8.75 .875 10 25 2.5 .219 5.56 .1285 3.26 5.94 3.66

3870 3.5 8.75 .875 10 25 2.5 .147 3.73 .0980 2.49 4.39 2.64

Orifice Size

Australia

LP

Gas

Gas

All values shown this page are per each oven

14

Gas Group I2H I2E I

World Oven Gas Group

Natural Gas Propane Gas

I2L I3+ I

2E+

3B/P (30)

I

3P

(30/37/50)

I

Inlet pressure (mbar) 20 20 20/25 25 28/30/37/50 28-30/37/50 30/37/50 37

Number of injectors (1) per burner

Main burner opening size Fixed

Ignition Electric Direct Spark Igniter

Inlet connection

BSP 3/4" male thread

Gas Matrix by Country

Natural Gas (8.75 mbar manifold) LP Gas (25 mbar manifold)

3B (37)

Country Symbol

I2H I2L I2E I

I

2E+

I3+ I3P

3B/P

Germany DE X X X

Austria AT X X

Belgium BE X X

Denmark DK X X

Spain ES X X X

Finland FI X X

France FR X X X X

Greece GR X

Ireland IE X X X

Iceland IS

Italy IT X X

Luxembourg LU

Norway NO X

Netherlands NL X X X

Portugal PT X X X

United Kingdom GB X X X

Sweden SE X X

Switzerland CH X X X X

Slovenia SI X

Slovakia SK X

Cyprus CY X X X

Estonia EE X

Latvia LT X

Lithuania LV

Malta MT X X

Hungary HU X X

Poland PL X

Czech Republic CZ X X

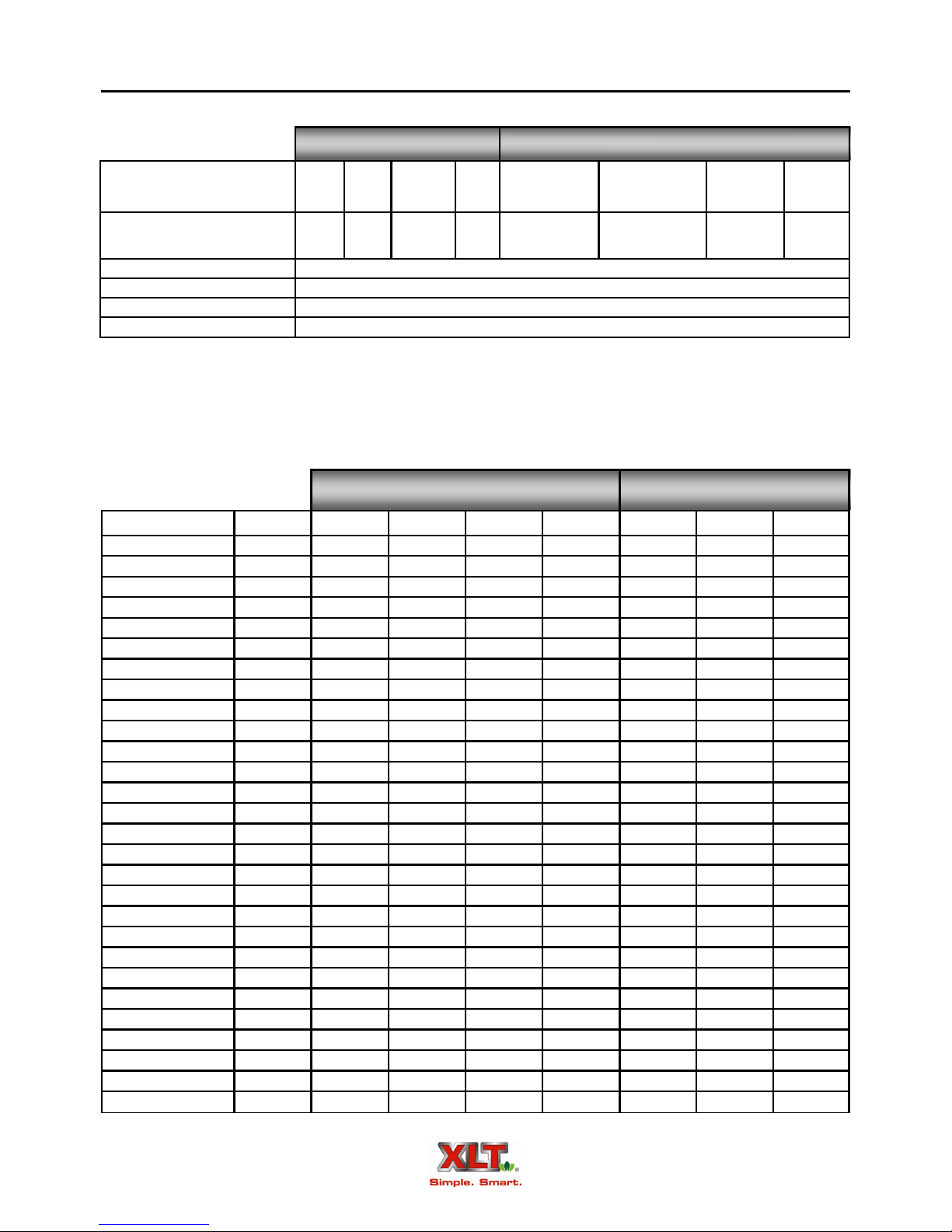

Oven Only Rough-In Specifications

The gas supply and the electrical supply are to be provided by the customer prior to installation. The picture shows a typical utility rough-in for a triple stack oven. Preparing the utilities

this way allows for an easy third deck addition if a double stack oven is initially installed.

6.00 [152]

From back of oven to wall

Utilities must be easily accessible when the ovens are in the installed position. Do not install utilities

behind the ovens.

NOTE

15

3.00

6.00

[76]

[152]

1. All dimensions in inches [mm].

2. All dimensions on this page are recommended.

Electrical Supply

Gas Manifold

48.00

[1219]

42.00

[1067]

NOTE

All installations must conform to local building and mechanical codes. It is required that

the ovens be placed under a ventilation hood. The gas supply should have a gas meter and regulator large enough to handle all of the gas appliances, such as the furnace, hot water heater, and ovens, in operation at the same time. Add up all of the BTU / kw / MJ ratings to determine the total

load. (See Oven Specifications page for supply requirements).

16

Oven Only Rough-In Specifications

FOR EACH OVEN:

Electrical service for Standard Ovens must be 120VAC, 20 A, 60 Hz single phase circuits

with ground.

Electrical service for World Ovens must be 220/230/240VAC, 10 A, 50/60 Hz single phase

circuits with ground.

Electrical service for Australian Ovens must be 220/230/240 VAC, 10 A, 50Hz single

phase and installed in accordance with the latest version of AS/NZS 3000 wiring rules.

A separate circuit breaker must be provided for each oven deck.

Gas and electric connections must be accessible when the ovens are in the installed position.

Electrical plugs and cords must meet all local code requirements.

Do not use Teflon tape on gas line connections as this can possibly cause gas valve

malfunction or plugging of orifices from shreds of tape. Use of Teflon tape may af-

CAUTION

fect warranty.

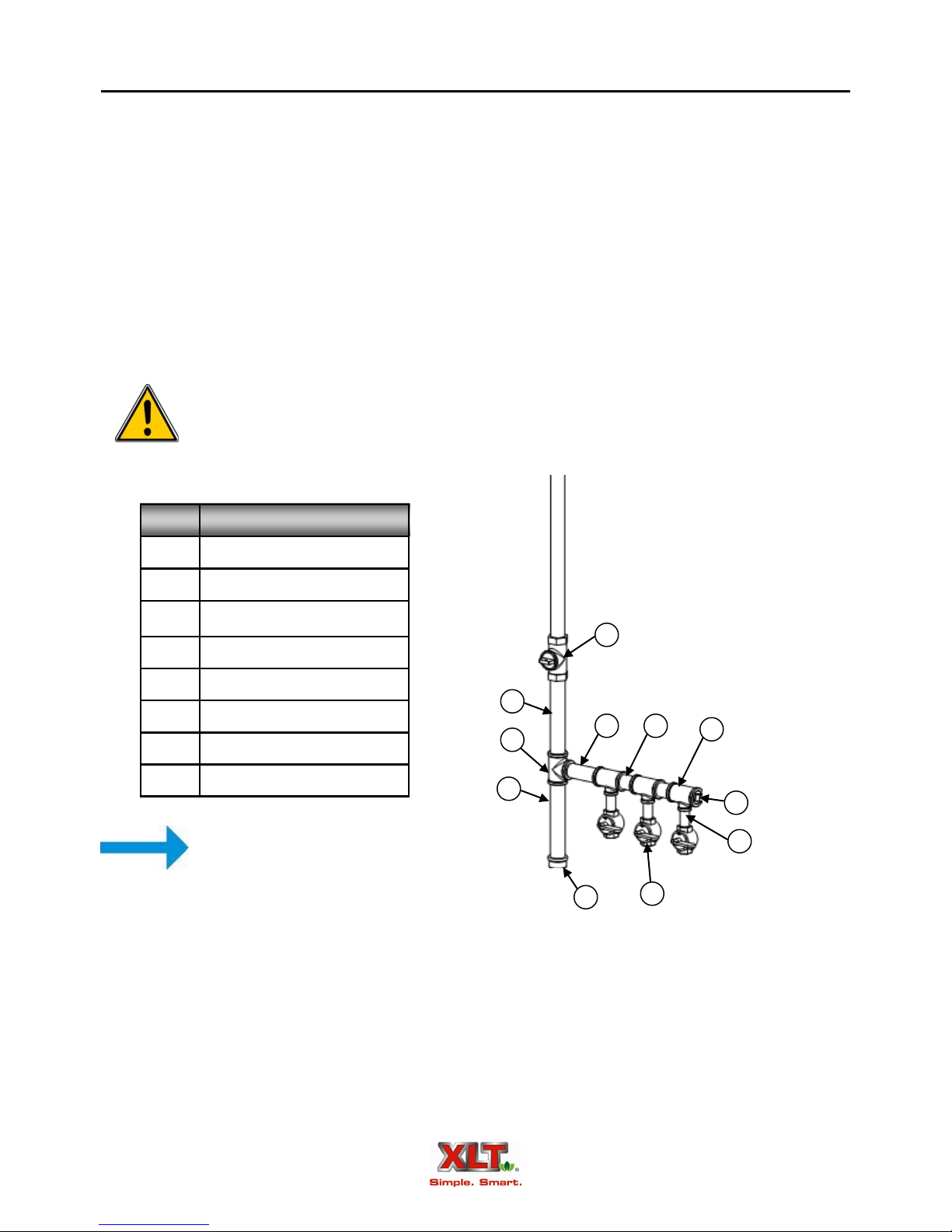

Item # Description

1 1-½ [40] Shut-Off Valve

2 ¾ [20] Shut-Off Valve

3 6 [150] Nipple

1

4 ¾ [20] Nipple

5 Reducing Tee

3

6 Tee

7 Cap

8 Plug

6

3

3

4

5

8

All pipe fittings to be 1-½ [40] minimum

4

unless noted. NPT & BSP

NOTE

7

2

Gas hose assemblies with quick disconnects for each oven deck will be installed at each valve.

NOTE: All dimensions in inches [mm].

Oven Assembly

17

WARNING & SAFETY INFORMATION

XLT ovens can easily be moved and stacked with the proper lifting equipment. The use of

lifting equipment is highly recommended.

These ovens are heavy and can tip or fall causing bodily injury.

NEVER place any part of your body beneath any oven that is suspended by the

lifting jacks. A crush hazard exists if the oven falls or slips.

DO NOT place your hands on the lifting jack vertical pole beneath the jack’s

WARNING

CAUTION

winch. As the jack’s winch descends when you turn the jack handle, a pinch

point is created between the winch and the pole.

BE CAREFUL when rolling the oven on the cart, especially when going up or down

ramps and over bumps. Leave the straps/banding on until the oven is near the assembly area.

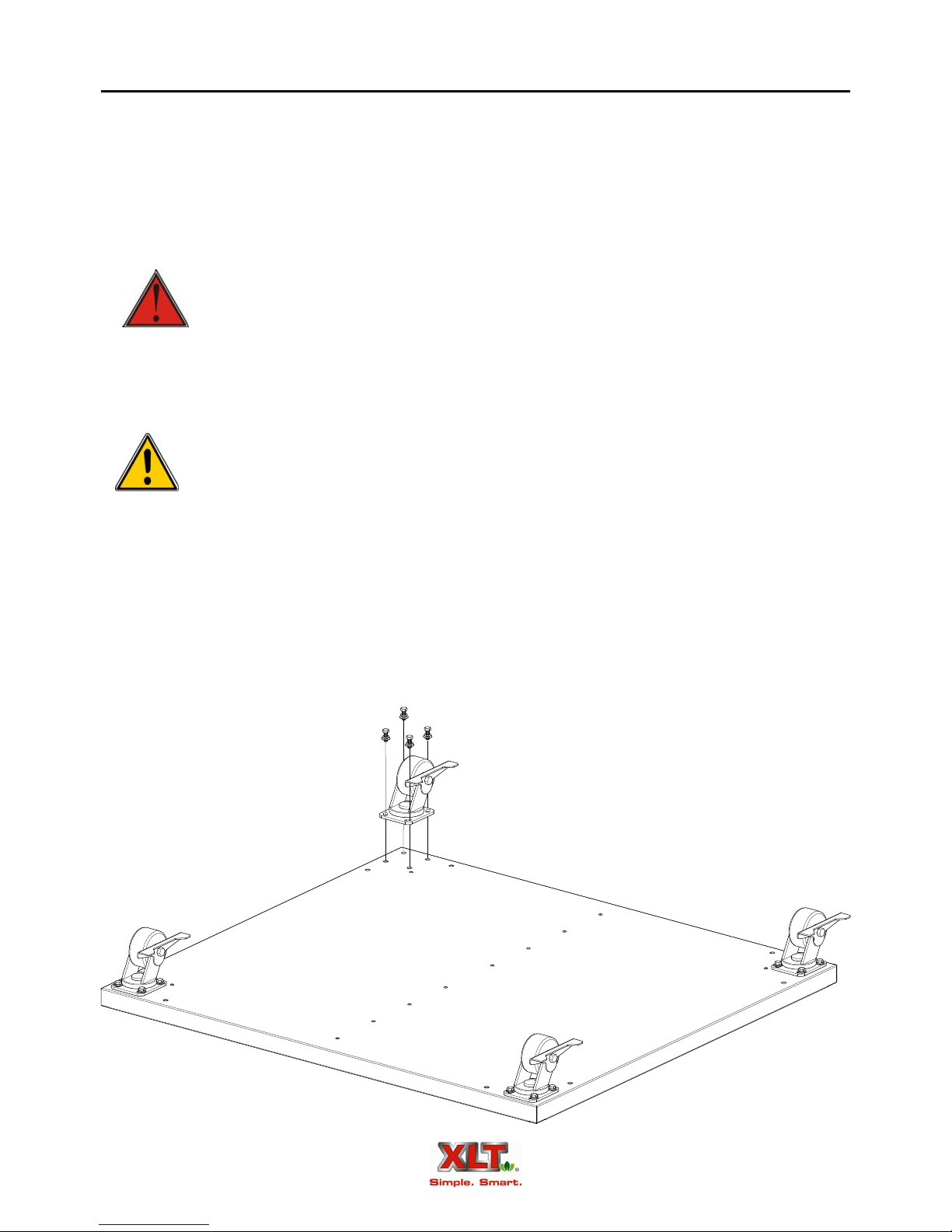

Base Assembly - Triple Stack

1. Flip the oven base upside down on the floor.

2. For triple-stack configurations, attach the four casters directly to the base with the supplied

3/8" x 1" hex bolts, washers, and lock-washers.

3. Flip the base assembly over and ensure the insulation is placed properly.

18

Oven Assembly

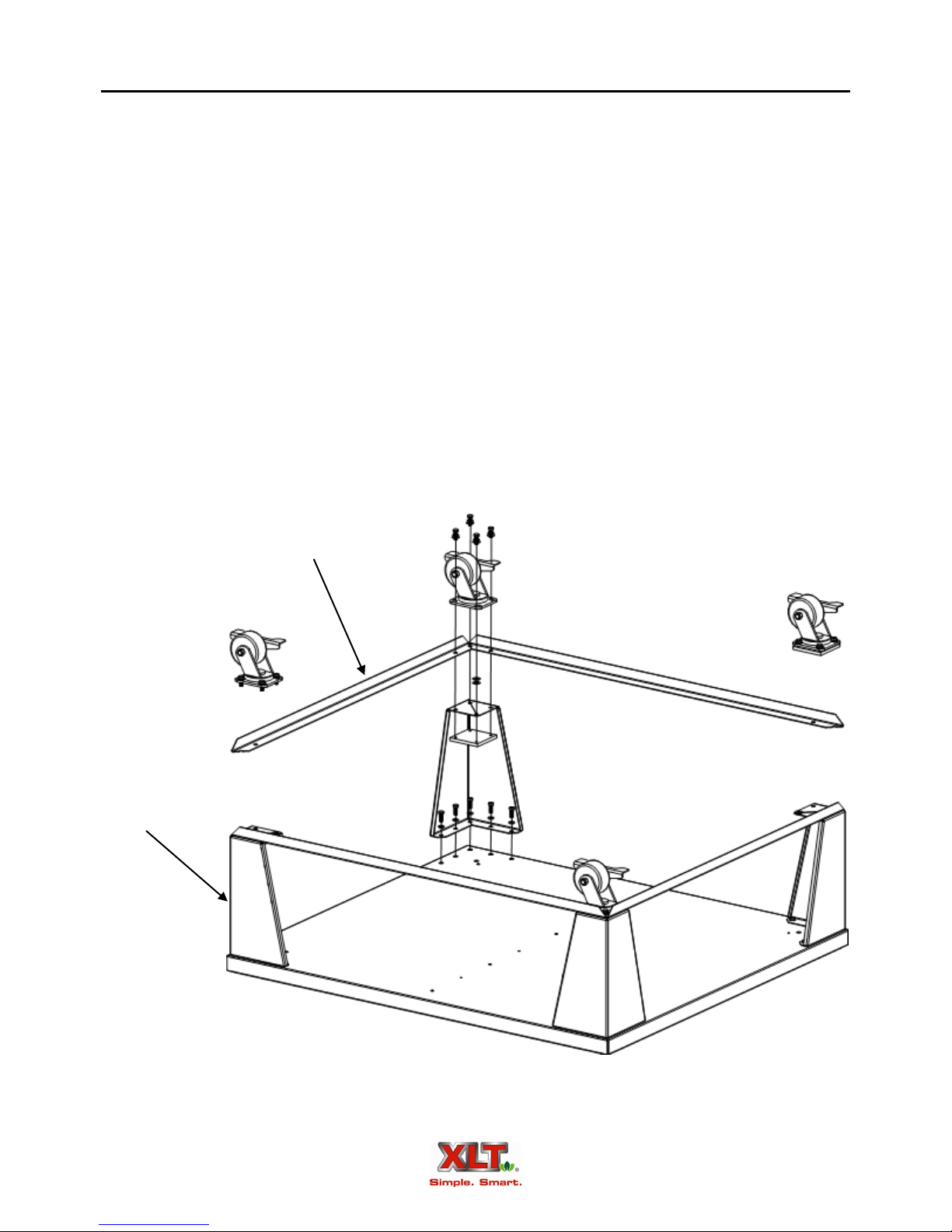

Base Assembly - Single & Double Stack

1. Flip the oven base upside down on the floor.

2. For single and double-stack configurations, attach the four legs to the bottom of the base with

the supplied 3/8" x 1" hex bolts, washers, and lock-washers. Do not fully tighten them at this

time. Leave them slightly loose so that the rest of the components can be more easily assembled.

3. Place the four leg angles on top of the legs as shown. All of the leg angle holes should line up

with the holes in the bottom of the legs. Place two (2) washers on each leg at the inner corner

holes. These 2 washers are approximately the same thickness as the leg angles, and will keep

the caster level.

4. Attach the four casters to the legs as shown. The leg angles and washers are sandwiched between the casters and the leg base plates.

5. Tighten all fasteners.

6. Flip the base assembly over and ensure the insulation is placed properly.

Leg

Leg Angle

Oven Assembly

Prepare the Oven for Lifting

1. Remove the two conveyor opening flaps and thumbscrews from the oven. Set them aside for

reinstallation later.

2. Install the lifting plates in place of the conveyor opening flaps using the same thumbscrews.

If using an AVI Hood System, conveyor flaps are not needed.

NOTE

Conveyor

Opening Flap

Thumb

Screws

Thumb

Screws

Conveyor

Opening Flap

19

NOTE

Right Hand

Lifting Plate

Thumb

Screws

Top of Oven

The Lifting Pipe hole, marked for the appropriate oven size, must be installed closest

to the control box.

Thumb

Screws

Left Hand

Lifting Plate

Top of Oven

20

Oven Assembly

Lifting Jack Setup

Each lifting jack consists of two (2) parts; the pole/winch assembly, and the tripod base.

1. Place the bottom of the pole into the socket of the tripod base.

Make sure that the notch on tube of the winch assembly is aligned with the pin

in the tripod base as shown. These alignments are important and keep the jack

aligned properly.

WARNING

2. Insert the lifting pipe through the oven bake chamber. Make sure the pipe is centered.

Check for smooth operation. The cable should not be pinched and should pass

smoothly over the pulley on top of the pole assembly.

Inspect cable prior to each use.

If cable is frayed or shows signs of excessive wear and tear, DO NO USE until

cable is replaced.

At a minimum replace the cable annually with wire rope that meets or exceeds

the jack manufacturer’s specifications.

Do not exceed the stated capacity of the jack.

Jack

Top of Oven

Front of Oven

Lifting Pipe

Cart

Bands

Illustrations shown with XLT Oven on Cart, instructions also apply when oven is crate shipped.

Oven Assembly

Stacking the Ovens

1. Fully insert the lifting jacks into the lifting pipe.

Failure to engage properly can result in damage, injury, or death from a falling

oven.

WARNING

2. Raise the oven high enough to clear the cart or the skid.

Both jacks should be raised in unison, otherwise they may bind and a dangerous

situation may develop.

Do not put any part of yourself under the oven at any time.

WARNING

3. Remove the cart or skid.

4. Rotate the oven as shown.

5. Roll the appropriate oven base underneath the oven.

6. Lower the oven onto the base.

7. Repeat as necessary

The oven is top heavy. Be careful!

21

Insulation

Base Assembly

Installed Oven Decks

22

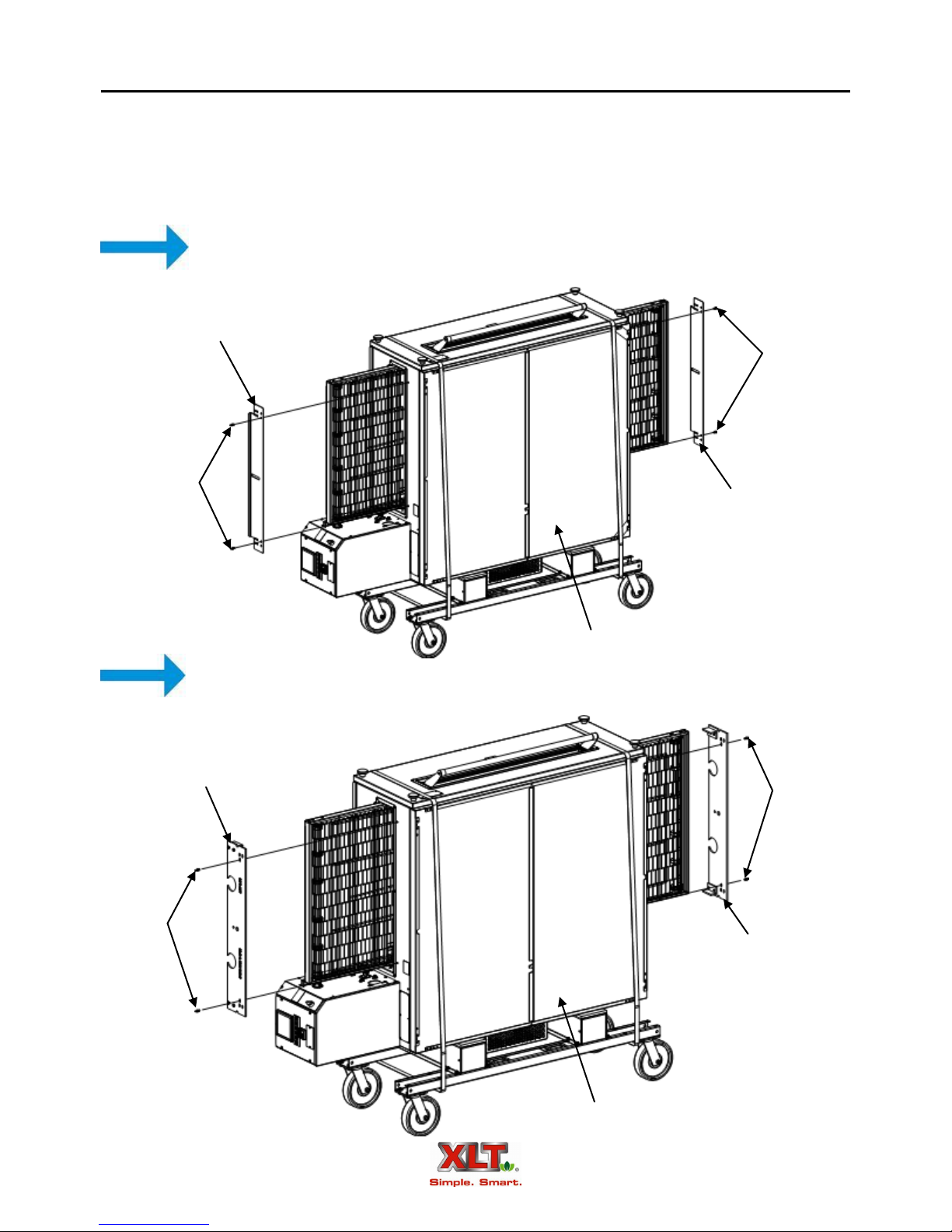

Oven Assembly

Stacking the Ovens

8. Reinstall the conveyor opening flaps in each oven deck. A series of holes in the flaps allow

adjustment for different heights of food product.

9. Control box heat shields need to be installed on any multi-deck installation. For xx70 models,

they are required on both ends. To install, remove the four (4) control box screws under the

conveyor. Place the panel with the notch towards the bake chamber. Line up the slots with the

existing holes and replace the screws.

Conveyor Opening Flap

Thumb Screws

Lower Control Box Plate Notch

Lower Control Box Plate

Control Box Screws

Oven Installation

Electric Supply Requirements for Australian, Standard. & World Ovens

Australian Ovens

In Australia, the electrical service must be installed in accordance with the latest

CAUTION

HIGH

VOLTAGE

version of AS/NZS 3000 wiring rules.

Standard Ovens

Electrical Grounding Instructions

This appliance is equipped with a three-prong (grounding) plug for your protection against shock hazard and should be plugged into a properly grounded

three-prong receptacle. Do not cut or remove the grounding prong from this

plug.

When installed, the appliance must be electrically grounded in accordance with

local codes, or in the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.2, as applicable.

World Ovens

23

This appliance is equipped with a ground lug for your protection against shock

hazard and must be properly grounded.

When installed, the appliance must be electrically grounded in accordance with

local codes.

Physical Location & Spacing Requirements

XLT Ovens are suitable for installation on either combustible or non-combustible floors,

and adjacent to either combustible or non-combustible walls. The motor cover is designed to provide the proper clearance to the back of the oven. The minimum side clearances are 6in. / 150mm,

measured from the end of the conveyor.

All installations must conform to local building and mechanical codes.

NOTE

24

Oven Installation

Gas Supply Requirements for Australian, Standard. & World Ovens

The gas supply shall have a gas meter and regulator large enough to handle all of the gas

appliances, such as the furnace, water heater, and ovens in operation at the same time. Add up all

of the Btu/kw/MJ ratings to determine the total load. The installation must conform to local building codes.

1. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 3.5 kPa or

½-psi.

2. The appliance must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 3.45 kPa or ½-psi.

Minimum and maximum inlet pressures are as follows:

Gas Type Min kPa Max kPa Min “WC Max “WC

Natural 1.5 3.5 6.0 14

LP 2.75 3.5 11.5 14

For Australia, if installing with a flexible hose assembly, the assembly must be certified to

AS/NZS 1869, and be Class B or D.

For Standard Ovens, if installing with a flexible gas hose, the installation must comply with

either ANSI Z21.69 or CAN/CGA-6.16 and a disconnect device complying with either ANSI

Z21.41 or CAN-6.9.

The installation must conform with local building codes, or in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1, latest version, Natural Gas Installation Code, CAN/

CGA-B149.1, or the Propane Installation Code, CAN/CGA-B149.2, as applicable.

All installations must conform to local building and mechanical codes.

NOTE

Oven Installation

25

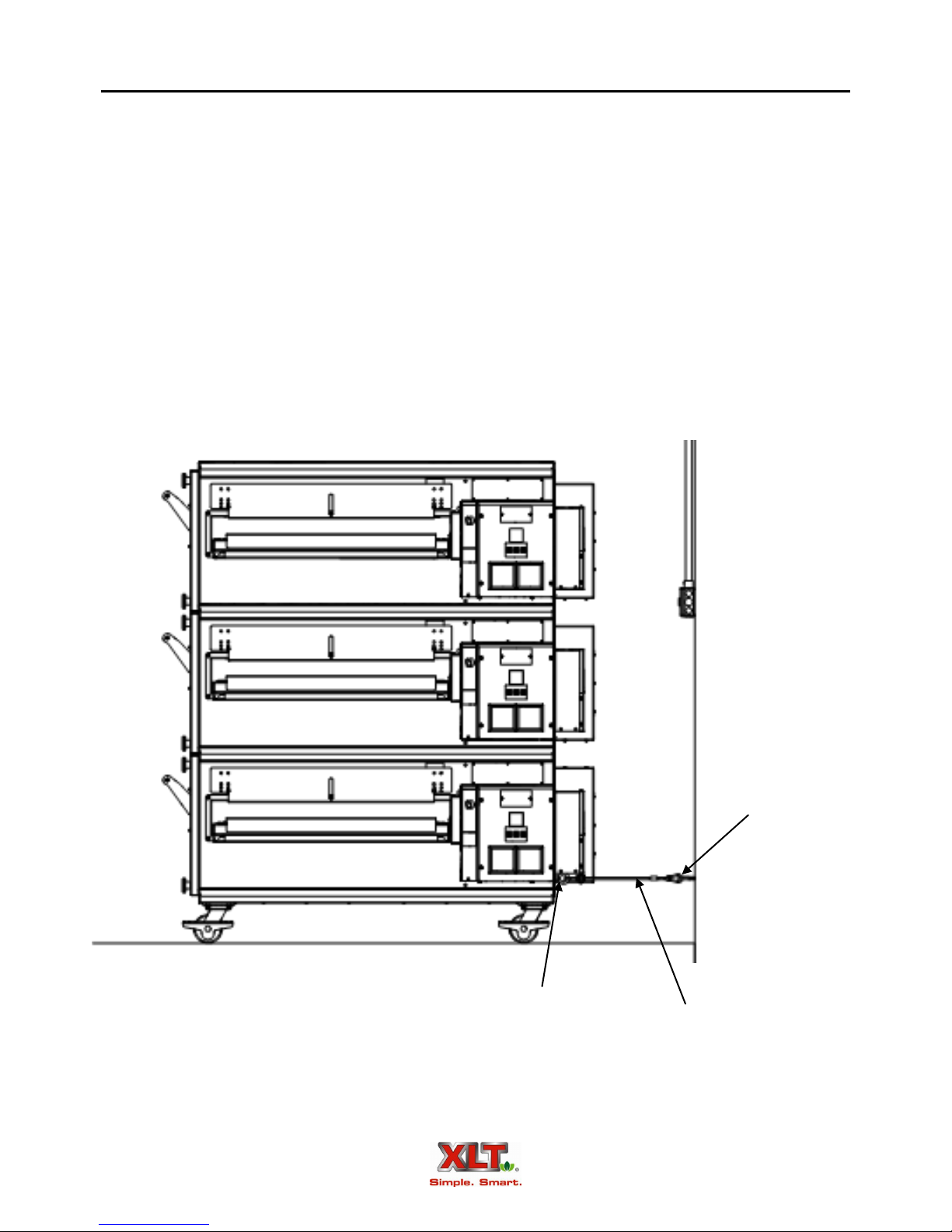

Restraint

Because all ovens are equipped with casters, all installations must be configured with a restraint to limit the movement of the oven without depending on the gas connector and quickdisconnect device or its associated piping, and the electric power supply cord to limit the oven

movement. One (1) restraint kit, which includes two (2) eye bolts and a cable, is required for each

oven stack, regardless if used on a single, double, or triple configuration. The machine eye bolt

should be installed in the lowest hole of the back wall on the control end of the lowest oven in the

stack. The lag eye bolt must be installed into a structural member of a wall.

Upon completion of performing any service or cleaning functions that require removal of

the restraint, insure that it is correctly re-attached to the oven. In Australia, install the restraint cable in accordance with AS 5601, latest version.

Lag Eye Bolt

Machine Eye Bolt

Restraint Cable

(shown fully extended)

26

Oven Installation

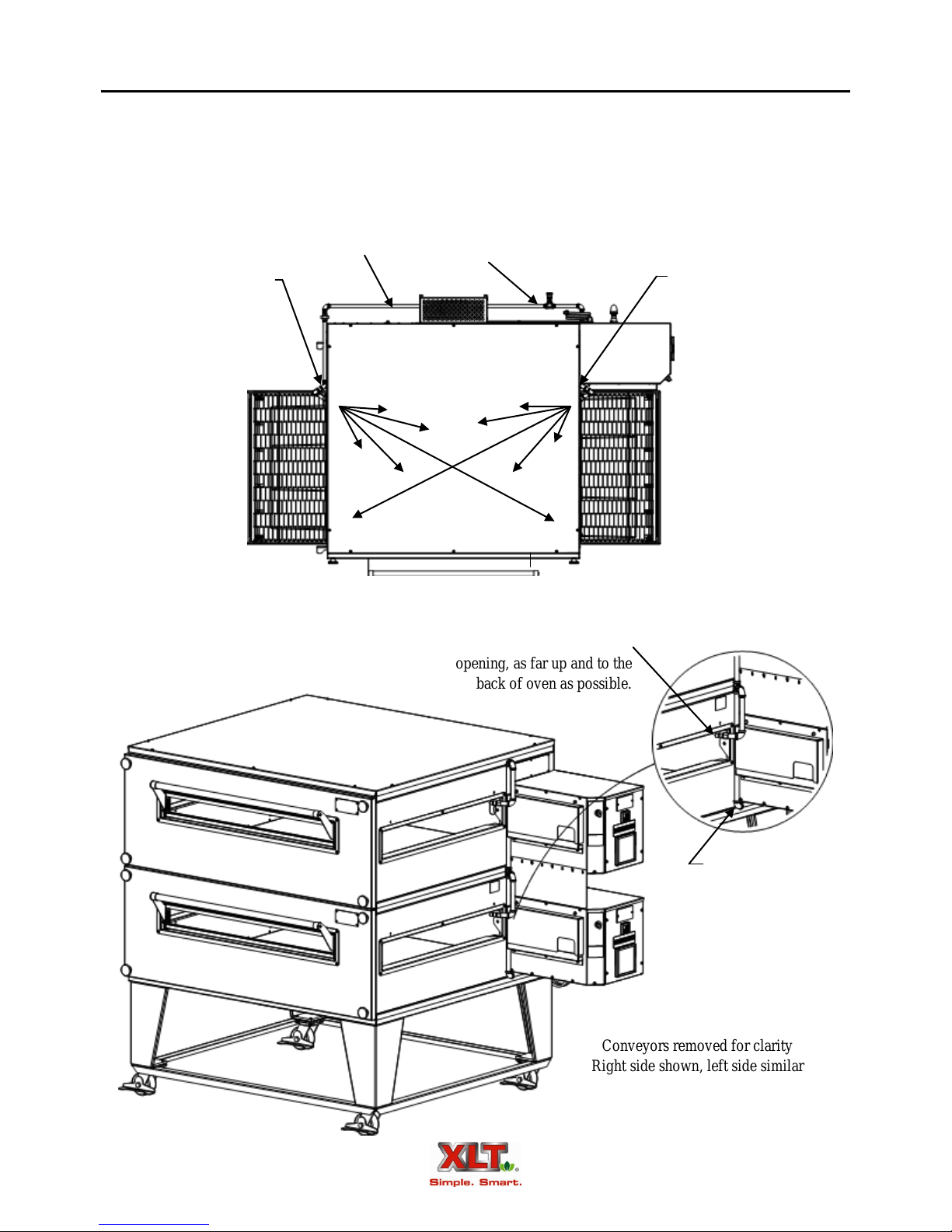

Fire Suppression

The requirement for fire suppression systems vary by location and the authority having jurisdiction. Contact XLT Ovens for fire suppression kit availability. Crumb trays and chain guards

must be removable without disturbing fire suppression piping.

Supply Line

Aim nozzles at

center of oven

Supply Inlet

Aim nozzles at

center of oven

Place nozzles into conveyor

opening, as far up and to the

back of oven as possible.

Conveyors removed for clarity

Right side shown, left side similar

Connect supply lines

under lower control

box and across back

of ovens

Ventilation Requirements & Guidelines

27

Ventilation Requirements

Most gas burning appliances produce CO (carbon monoxide), a poison. CO and heat must

be vented to the outside. A powered ventilation hood is required to remove these. The hood and

HVAC installation must meet local building and mechanical codes. In Australia, a ventilation

hood should be installed in accordance with AS5601 Gas Installation. Requirements vary through-

out the country depending on the location by city. Proper ventilation is the oven owner’s responsi-

bility. The AVI Hood system is designed to meet all requirements on XLT ovens and it is our recommendation that this system be used.

Ventilation Guidelines

Obtain information from the authority having jurisdiction to determine the requirements for

your installation. Your ventilation hood supplier and HVAC contractor should be contacted to

provide guidance. An air balance test is highly recommended, performed by a licensed contractor.

A properly engineered and installed ventilation hood and HVAC system will expedite approval,

reduce oven maintenance cost, and provide a more comfortable working environment.

Ventilation Performance Test

After the oven and ventilation hood have been installed and are operating, a smoke candle

can be used to “see” if the heat and products of combustion are being properly exhausted. Smoke

candles can be purchased through HVAC contractors. The test procedure is outlined below.

The oven must be operating at 450º-500ºF / 232º-260ºC.

The conveyor must be turned off.

The ventilation hood exhaust fan must be turned on.

Put a smoke candle in a pan on the conveyor belt at the center of the oven.

Observe the smoke pattern coming out of the oven.

The ventilation hood must capture all of the smoke from the oven. An air balance test can

help determine the proper amount of exhaust and make-up air flow rates.

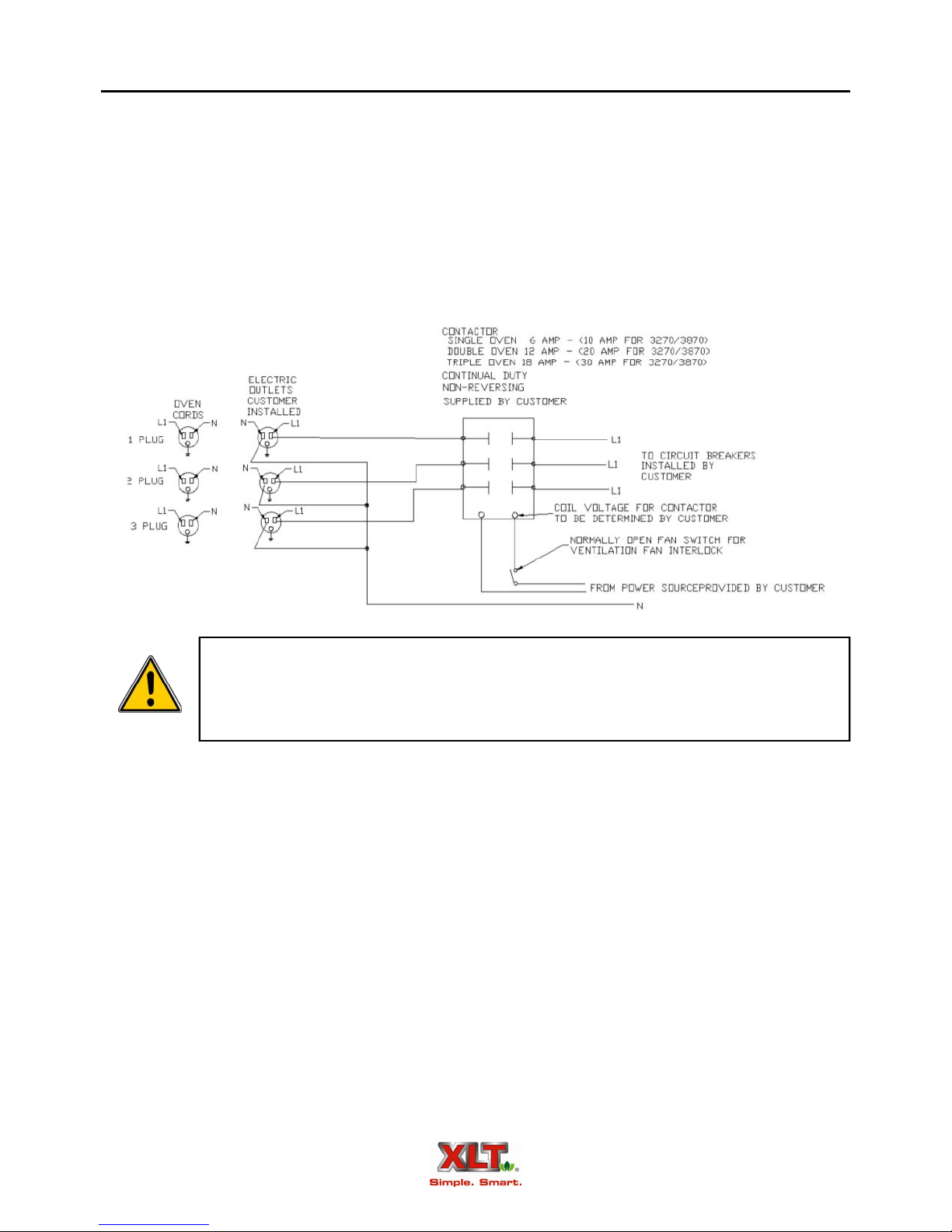

Oven & Hood Interlock

An interlock system between the oven and hood is highly recommended and is required in

some jurisdictions. AVI hoods have this feature.

28

Ventilation Requirements & Guidelines

Non-AVI Hood Interlock

The following is a recommended method of providing an interlock system (if required),

between the exhaust fan and ovens. The circuit shown will stop the ovens from operating if the

exhaust fan fails and also prevent the ovens from starting if the exhaust fan is not first operating. It

is recommended that the fan interlock switch be located on the exhaust fan itself rather than the

motor to prevent a false run signal in the case of a broken fan drive belt. It is the customer’s re-

sponsibility to have the interlock system installed by a licensed electrician and that it meets all required local codes.

Always use the proper oven shut down procedure for turning ovens off. Do not

turn off the exhaust fan until cool down sequence on oven is completed. The use

of the exhaust fan control to shut off ovens manually may void the warranty on

CAUTION

ovens.

Oven Initial Start-Up

All XLT ovens are test-fired at the factory. Operation is verified, and adjustments are

made to ensure proper function. However, field conditions are sometimes different than factory

conditions, such as voltage and fuel pressure. These variables make it necessary to have an authorized service technician verify operation and make field adjustments if needed. The following

items must be checked and verified to meet the specifications and requirements stated in this manual prior to the oven being commissioned:

Fuel line pipe size

Fuel pressure (static)

Fuel pressure (dynamic)

Proper electrical connections

Proper ventilation

The following Initial Start-Up Checklist must be completed (both sides) at time of installation,

signed by the Customer and returned to XLT Ovens to initiate Warranty Policy.

Oven Initial Start-up Checklist - Remove & Return to XLT Ovens

Date of installation: ______________________________

Installed by: XLT installer: ______________________

Other: Company:____________________

Installer: ____________________

Phone #: ____________________

Facility Information

Store Name: ___________________________________

Physical Address: ______________________________

City: ____________________ State: _____ Zip:_______

Phone #: ______________________________________

E-mail: _______________________________________

Contact Person: ________________________________

Freestanding Strip Mall New construction

Electrical

Electrical supply accessible after installation: YesNo

Separate electrical circuit per oven: Yes No

Electrical Supply (per oven): _______ Volt _____ Amp

_______Hz _____ Phase

Gas N/A

Inlet Pressures: Static: _________________ ” W/C

Dynamic (full burn): _________________ ” W/C

Existing location Remodel

Gas Line Size: ___________ Teflon Tape: Yes No

Oven Location: Against wall In corner Island

I&O Manual presented to store operator: Yes No

Utilities present at installation: Electric Gas

On-Site dough prep: Yes No

Air-born contaminates: Flour Cornmeal Grease

Other _________________________________

HVAC/Contractor Contact:_______________________

Address: ______________________________________

City: ____________________ State: _____ Zip:_______

Phone #: _______________ Cell: __________________

E-mail: _______________________________________

Restraint Cable Installed (bottom oven): Yes No

Customer or store operator shown how to disassemble and

clean ovens and hood: Yes No ________________

Test cook performed: Yes No ________________

Ovens ran for 20 min. Yes No ________________

All features explained: Yes No ________________

Damage to ovens or hood during shipment or installation:

______________________________________________

Missing parts: __________________________________

Customer Signature: _____________________________

List all gas appliances in store (with gas requirements)

XLT Oven #1 __________________________________

XLT Oven #2 __________________________________

XLT Oven #3 __________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

Total gas requirements for store: ___________________

Regulator Capacity: _____________________________

Meter Capacity: ________________________________

Shut off valve accessible after installation: Yes No

One shut off valve per oven: Yes No

Gas line purged of air prior to installation: Yes No

Fittings tested for gas leaks: Yes No

Results: _______________________________________

Ventilation

Hood manufacturerAVI Other (specify)

_____________________________________________

Interlock system for non-AVI hood: Yes No

Air balance test performed: Yes No

Smoke test preformed: Yes No

Return to: XLT Ovens

PO Box 9090

Wichita, KS 67277

FAX: 316-943-2769

Oven Size: 1832 2440 3240 3255

3270 3855 3870

Heat Source: Natural Gas LP Electric

Oven Initial Start-up Checklist - Remove & Return to XLT Ovens

Bottom Oven N/A

Model #: __________________________________

Serial #: __________________________________

Thin Crust Thick Crust Pan Screen

Other Product: ____________________________

Front Belt Speed: _______min ______sec

Back Belt Speed: _______min ______sec N/A

Good Belt Tension: Yes No

Conveyor Belt Direction: L to R R to L

Set Point Temp: Left ________ Right _________

Fingers in proper location: Yes No

Crumb Trays: Solid Perforated None

Fire Suppression Installed: Yes No

Right Burner: Square Round

Main Shutter Setting: _______________________

Secondary Shutter Setting: ___________________

Low flame after temperature drop: Yes No

Was Combination Valve adjusted: Yes No

High Bias: ___________ Low Bias: ___________

Left Burner: N/A

Main Shutter Setting: _______________________

Secondary Shutter Setting: ___________________

Low flame after temperature drop: Yes No

Was Combination Valve adjusted: Yes No

High Bias: ___________ Low Bias: ___________

Middle Oven N/A

Model #: __________________________________

Serial #: __________________________________

Thin Crust Thick Crust Pan Screen

Other Product: ____________________________

Front Belt Speed: _______min ______sec

Back Belt Speed: _______min ______sec N/A

Top Oven

Model #: __________________________________

Serial #: __________________________________

Thin Crust Thick Crust Pan Screen

Other Product: ____________________________

Front Belt Speed: _______min ______sec

Back Belt Speed: _______min ______sec N/A

Good Belt Tension: Yes No

Conveyor Belt Direction: L to R R to L

Set Point Temp: Left ________ Right _________

Fingers in proper location: Yes No

Crumb Trays: Solid Perforated None

Fire Suppression Installed: Yes No

Right Burner: Square Round

Main Shutter Setting: _______________________

Secondary Shutter Setting: ___________________

Low flame after temperature drop: Yes No

Was Combination Valve adjusted: Yes No

High Bias: ___________ Low Bias: ___________

Left Burner: N/A

Main Shutter Setting: _______________________

Secondary Shutter Setting: ___________________

Low flame after temperature drop: Yes No

Was Combination Valve adjusted: Yes No

High Bias: ___________ Low Bias: ___________

Good Belt Tension: Yes No

Conveyor Belt Direction: L to R R to L

Set Point Temp: Left ________ Right _________

Fingers in proper location: Yes No

Crumb Trays: Solid Perforated None

Fire Suppression Installed: Yes No

Right Burner: Square Round

Main Shutter Setting: _______________________

Secondary Shutter Setting: ___________________

Low flame after temperature drop: Yes No

Was Combination Valve adjusted: Yes No

High Bias: ___________ Low Bias: ___________

Left Burner: N/A

Main Shutter Setting: _______________________

Secondary Shutter Setting: ___________________

Low flame after temperature drop: Yes No

Was Combination Valve adjusted: Yes No

High Bias: ___________ Low Bias: ___________

Low Flame Bias

Adjustment (5mm)

Combination Gas Valve

Manifold Pressure

Adjustment (High

Flame Bias Screw

(Brass Nut– 8mm)

Oven Initial Start-Up

Inlet Pressure Tap

Manifold

Pressure Tap

31

Secondary

Shutter

Main Shutter

Low Flame Bias

Adjustment (5mm)

Manifold Pressure Adjustment High

Flame Bias Screw (Brass Nut 8mm)

Combination

Gas Valve

Quiet Fire

Direct Ignition Burner

Inlet Pressure Tap

Manifold

Pressure Tap

Contact XLT Ovens or your designated representative to make all gas pressure adjustments.

Direct Ignition Burner

32

Manifold Pressure

Regulator (under

cap screw)

Oven Initial Start-Up

Manifold

Pressure Tap

Combination

Gas Valve

Inlet Pressure Tap

Direct Ignition Burner - Australia

Contact XLT Ovens or your designated representative to make all gas pressure adjustments.

Left

Oven Operator Controls

Models 1832, 2440, 3240, 3255 & 3855

Single oven shown, Double and Triple Stack similar

Right

Front

Conveyor Speed

Control

33

Oven

Switch

Circuit Breakers

Fan & Filter

Control Panel

Standard Belt

Back

Left Right

Temperature

Control

Back Conveyor

Speed Control

Front

Conveyor

Speed

Control

Front

Control Panel

Split Belt

34

Left

Oven Operator Controls

Models 3270 & 3870

Single oven shown, Double and Triple Stack similar

Right

Front

Circuit Breakers

Oven

Switch

Fan & Filter

Left Side Control Panel

(Standard & Split Belt)

Back

Left Right

Front

Left Side

Temperature

Control

Front

Conveyor

Speed

Control

Right Side

Temperature

Control

Right Side Control Panel

Standard Belt

Back

Conveyor

Speed

Control

Right Side Control Panel

Split Belt

Oven Operation

35

This oven is not capable of being safely placed in operation in the event of a

power failure. No attempt should be made to operate this oven during power

failure.

CAUTION

1. Turn the switch on. The fan(s) will energize, the temperature and conveyor control will light

up, and the conveyor will start to move.

2. Adjust the temperature controller set-point to the desired temperature. To change the oven setpoint temperature, press and hold either the UP or DOWN key. The keys needs to be depressed for at least 2 seconds. After UP or DOWN key inactivity, the display will blink once

indicating that the set point temperature has been set. The FUNC and MAN keys are used at

the factory to program the variables in the controller. It is recommended that the FUNC and

MAN keys be left alone. If either of these keys has been pressed, simply press them again until the display matches the Figure shown. It may take several key-presses to cycle through all

the variables.

3. Adjust the conveyor control to the desired belt time. To change the belt time, press and hold

either the UP or DOWN key.

4. To turn the conveyor ON or OFF, push both arrow keys simultaneously.

5. Allow about 30-45 seconds for the burner to ignite. You should hear combustion and see the

indicated temperature rise.

6. If the burner does not ignite, turn the switch off, wait five (5) minutes, and repeat step 1. If it

does not light after three (3) attempts, please see the troubleshooting section of this manual.

7. Allow about 30 minutes for the oven to reach the desired temperature.

8. To turn the oven off, turn the switch to the off position. Do not unplug the oven from electrical

power. The oven is equipped with an automatic cool down feature that allows the fan to run

until the oven is cooled to a safe level (approximately 30 minutes).

NOTE

Belt Time

(MIN: SEC)

Up and Down

Arrow Buttons

Up Key

Down Key

Temperature Control

Actual

Temperature

Set Point

Temperature

6:30

Conveyor Control

The Conveyor Control is factory preset at 1:30 minute minimum and 17:00 minutes

maximum. If a belt time is desired that is outside these limits, contact XLT Ovens for

proper service procedures.

36

Oven Cleaning

As with any appliance, periodic cleaning and maintenance is required. Many factors affect

this schedule such as product mix and hours of usage. An example schedule is included.

Your XLT oven is constructed of stainless steel. Most commercial cleaning agents may be

used safely on all stainless steel surfaces. Check application restrictions on product label prior to

usage. Observe recommended precautionary and safety measures as dictated by the product manufacturer.

Do not use abrasive cleaners or abrasive pads as they can scratch stainless steel surfaces.

Example Cleaning Schedule for XLT Ovens

Task Daily Weekly Monthly Semi- annual

Wipe down front

Clean sandwich window

Wipe down sides

Wipe down top

Wipe down control box

Wipe down motor cover

Empty Crumb Trays

Remove large debris from conveyor

Clean / replace cooling fan filters

Clean finger covers

Clean bake chamber floor

Clean bake chamber walls

Clean bake chamber top

Clean inside of face panel

Clean control box sides and top

Clean control box face and switches

Clean conveyor

Clean finger bodies

Deep clean oven chamber

Clean Main Fan Motor/Motor Cover

Oven must be cool and the electric cord unplugged before any cleaning is done.

WARNING

Oven Cleaning

37

1. Remove and clean crumb trays, product stops, and conveyor opening flaps.

Product Stop

Conveyor

Opening

Flap

Crumb Tray

Thumb Screws

2. Hold the front panel in place while removing the four (4) front panel knobs. Then remove and

clean the front panel.

TIP

CAUTION

Opening the sandwich door will provide a grip location for removing the front panel.

Front panels can weigh up to 75 lbs. or 34 kg. Use caution when lifting.

Front Panel Knob

DO NOT immerse front panel as it contains insulation that could become saturated.

NOTE

38

Oven Cleaning

3. To remove and clean the lower finger outer panels and lower finger body assemblies, raise the

front of the conveyor and insert two (2) front panel knobs, one (1) each side, as shown.

Front Panel Knobs

4. Raise the front of the lower finger bodies, one at a time, approximately one inch, [25 cm], and

slide the finger outer panels out towards the front.

Finger Bodies

Prior to the removal of the finger covers, note the location and configuration to ensure

proper reassembly. Typically, upper finger bodies are approximately 2” [50 mm] thin-

NOTE

ner than lower finger bodies. The finger outer panels are the same dimensions.

Oven Cleaning

Finger Covers

5. Raise the front of the upper finger bodies, one at a time, approximately 1” [25 cm], and slide

the finger assembly out towards the front.

39

Upper Finger Bodies

Lower Finger Bodies

6. Wipe down and clean all interior and exterior surfaces.

DO NOT spray liquid cleaning agents in the slots and holes in the following locations:

Back of Control Box

CAUTION

Underneath Control Box

Main Fan Motor Cover

7. After all components are clean and dry, re-assemble the oven in the reverse order.

40

Oven Maintenance

The most critical item to be maintained is the filter on the Flow Path Pressure Generating

fan. The filter is held in place by the stainless steel fan guard/filter mount and can be washed several times. Regular cleaning of the Flow Path Pressure Generating Fan filter is important to provide combustion air and to maintain air circulation within the control box. Depending upon store

conditions, this filter should be cleaned weekly or as it gets clogged with dust. After several cleanings the filter will need to be replaced.

Filter

Filter Holder

Contact a factory representative or a local service company to perform all other maintenance and repairs.

NOTICE: If the oven is to be removed from its installed location for cleaning or

servicing, the following procedure is to be implemented:

1. Shut off main manual gas valve.

2. Unplug electric cord.

3. Unplug gas line.

4. Unlock casters.

5. Disconnect restraint.

6. When servicing or cleaning is complete, move oven to original location.

7. Connect restraint.

8. Lock casters.

9. Plug in electric cord.

10. Plug in gas line.

11. Turn manual gas valve on.

12. Follow normal lighting instructions.

Oven Troubleshooting

Oven Problems

Before trouble-shooting the oven;

1. Make sure that the oven is connected to the proper voltage.

2. Check to see that the breaker in the service panel is not disengaged.

3. Check to see that all circuit breakers on the oven are not disengaged.

4. Check to see if the gas supply is adequate.

5. The gas hose must be connected to the oven and the manual shutoff valve fully opened.

6. Check to see that the oven is fully assembled. All of the fingers must be properly installed.

XLT Ovens has qualified customer service personnel that can provide assistance on any

type of issue that you may experience. Customer Service can be contacted at 888-443-2751, 24

hours per day, 7 days per week. For Australian and World Ovens, contact your designated representative.

41

42

Oven Troubleshooting

Proper Cooking

Experimentation is about the only way to determine proper time and temperature settings.

While a pizza may look perfectly cooked on the outside, the inside may be undercooked. A thermometer is necessary to determine if food items are being properly cooked. Most health departments have rules and regulations that establish minimum temperatures for internal food temperatures. Most operators want to cook foods as fast as possible in order to serve more customers per

hour. However, cooking foods slower is the only way to achieve a proper internal temperature. If

your food product look acceptable on the outside, but has an internal temperature that is too low,

then lowering the temperature and decreasing the belt speed (thereby increasing the cook time),

will be necessary.

Several factors may affect the cooking performance and characteristics:

1. Oven temperature (generally affects color)

2. Conveyor speed (generally affects doneness)

3. Finger arrangement

4. Altitude

5. Pans versus screens

6. Dough thickness

7. Cheese type

8. Raw ingredient temperature (frozen?)

9. Quantity of toppings

XLT ovens can be configured to cook a wide variety of food items. This is accomplished

by arranging the fingers to control the baking characteristics. Generally speaking, most cooking is

a “bottom up” process. The hot air from the bottom row of fingers has to go through the conveyor

(a distance of about 2” / 50.8mm), heat the pan or screen, and then actually cook raw dough. The

hot air from the top, on the other hand, basically only has to melt cheese and re-heat precooked

toppings. Consequently, most operators will use the oven with the fingers arranged so that a lot

more air is directed to the bottom of the pizza than to the top. There are places for an equal number of fingers above and below the conveyor. Available are finger cover plates that have six rows

of holes, four rows of holes, two rows of holes, and no holes (or blank cover plates). A typical fin-

ger arrangement might have most or all fingers on the bottom “full open”, that is fingers with all

six rows of holes, and only two or three fingers on top with four or six rows of holes. The top fingers can be arranged in a symmetrical pattern or can be shifted asymmetrically to either the entrance or exit end of the conveyor. We encourage you to experiment by trying different finger arrangements, temperatures and belt speeds. XLT Ovens can assist you with your oven/product configurations.

This page intentionally left blank.

43

44

Main Canopy

End Shroud Panel

(size specific)

AVI Exhaust Hood

Hood Description

Duct Collar

Oven & Hood

Switches

VFD Control Box

Product Take-Off

Front Shroud Panel

Shelves (optional)

The AVI Hood System consists of three (3) major parts, the main canopy, the shrouds, and

the Variable Frequency Drive (VFD) exhaust fan controller.

The main canopy serves to collect heat and products of combustion and transmits the effluents to the exhaust fan. It houses filters, lights, and switches. The switches control both the hood

and ovens. The main canopy size is dependent upon oven size.

The shrouds assist the efficiency of the main canopy by entrapping heat and products of

combustion. They are configurable for either side or end loading or unloading, and are easily removable for cleaning and maintenance.

The VFD control box operates at 208/230 VAC single phase, 50/60 Hz. All electric utilities for the hood, oven(s), and exhaust fan connect to the VFD control box. The control box

houses a variable frequency drive, fuses, receptacles, and relays. The VFD converts the singlephase input power to adjustable three-phase output power to vary the speed of the exhaust fan.

The oven(s) plug in to the receptacles to provide a safety interlock. The optional relays provide

fire suppression interlocks and interlocks for up to three (3) HVAC dampers.

All AVI hoods are available pre-piped for fire suppression, allowing for simple, in-field

installations..

Most illustrations in this manual show the ovens and hood in a double stack configuration. All instructions apply to single and triple stack configurations unless noted other-

NOTE

wise.

C

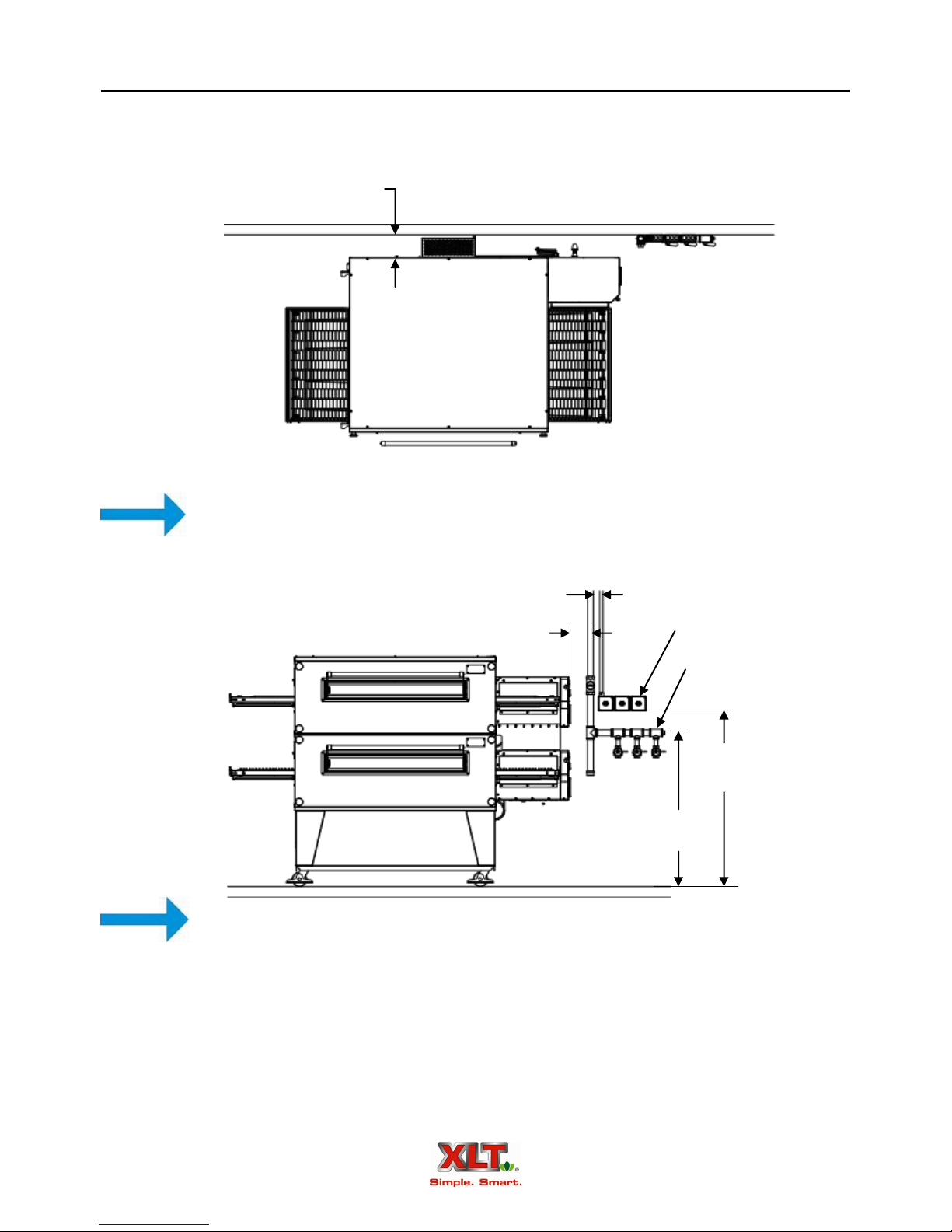

Hood Dimensions

+1/2 +13

13 1/2 [343 ]

-0 -0

Critical Dimension needed to maintain

proper clearances for installed ovens

F

12 [305]

28 7/8

[733]

E

12 [305]

(24 [610])

45

B

A

D

“A”

“B”

“C”

“D”

“E”

“F”

AVI 1832 AVI 2440 AVI 3240 AVI 3255 AVI 3270 AVI 3855 AVI 3870

34-11/32

[872]

18-11/16

[474]

30-11/16

[779]

88-19/32

[2250]

44-5/16

[1125]

30

[762]

40-11/32

[1025]

21-11/16

[550]

33-11/16

[856]

96-19/32

[2454]

48-5/16

[1227]

38

[965]

Model Numbers

48-11/32

[1228]

25-11/16

[652]

37-11/16

[957]

96-19/32

[2454]

48-5/16

[1227]

38

[965]

48-11/32

[1228]

25-11/16

[652]

37-11/16

[957]

111-19/32

[2835]

55-13/16

[1417]

53

[1346]

48-11/32

[1228]

25-11/16

[652]

37-11/16

[957]

126-19/32

[3216]

63-5/16

[1608]

68

[1727]

54-11/32

[1380]

28-11/16

[728]

40-11/16

[1033]

111-19/32

[2454]

55-13/16

[1417]

53

[1346]

54-11/32

[1380]

28-11/16

[728]

40-11/16

[1033]

126-19/32

[3216]

63-5/16

[1608]

68

[1727]

NOTE: All dimensions in inches [mm] unless otherwise noted.

46

(90 [2286])

Hood Dimensions

Front of Hood Canopy

Switches to be on

Front of the Hood

69 1/2 ±1/8

[1765 ±3.2]

Single Stack

Double Stack

Finished Floor

NOTE: All dimensions in inches [mm] unless otherwise noted.

Hood Weight (Does not include ovens)

AVI

1832

560.39

[254]

513.78

[233]

AVI

2440

644.84

[292]

576.72

[262]

AVI

3240

708.73

[321]

640.25

[290]

AVI

3255

757.05

[343]

681.29

[309]

AVI

3270

790.12

[358]

704.08

[319]

AVI

3855

812.03

[368]

728.01

[330]

AVI

3870

845.32

[383]

750.23

[340]

Triple Stack

594.64

[270]

593.48

[269]

657.82

[298]

698.99

[317]

709.52

[322]

NOTE: All weights in pounds [kg].

840.39

[381]

754.55

[342]

Hood Electrical Requirements

47

Inputs into VFD Box

The AVI Hood system requires two (2) separate electrical inputs and has provision for one

(1) optional input. All inputs and input connection points are located on the top of the VFD control box, as well as the connection to the exhaust fan. All optional outputs (fire suppression,

HVAC dampers), are also located on the top of the VFD control box. Inputs are:

One (1), 230 VAC, 10 Amp, 50/60 Hz, single phase connection to power the VFD (Variable

Frequency Drive), which powers the ventilation fan.

Standard - Three (3), 120 VAC, 20 Amp, 60 Hz, single phase connections to power each indi-

vidual XLT oven.

World - Three (3), 230 VAC, 10 Amp, 50/60 Hz, single phase connections to power each indi-

vidual XLT oven.

One (1) optional Normally Closed (N/C) input from the fire suppression system.

VFD Box

Oven Control Cords

Double Stack configuration shown, Single and Triple stack configurations wire similarly.

Oven Power Cords

Outputs from VFD Box

The AVI Hood system provides three (3) power and signal outputs. The power outputs for

the ovens are on the bottom of the box, while the signal outputs for fire suppression and HVAC

dampers are on the top of the box. Outputs are:

One (1) 230 VAC, 10 Amp, variable frequency, three phase output for the ventilation exhaust

fan.

Standard - Three (3), 120 VAC, 20 Amp, 60 Hz, single phase power outputs for each individ-

ual XLT oven.

World - Three (3), 230 VAC, 10 Amp, 50/60 Hz, single phase connections to power each indi-

vidual XLT oven.

Three (3) optional Normally Open (N/O) outputs for HVAC dampers.

48

Hood Electrical Requirements

VFD Control Box - Standard

Electrical supply, MUA and fire

suppression controls are wired

through top of VFD control box

Terminal Block (TB)

Grounding Block

Fuses

VFD Controller

MUA Damper

Relays (optional)

Fire Suppression

Relay (optional)

Oven/hood interface and power cords

connect to bottom of VFD control box

Wiring removed for clarity. See schematic for wiring details.

Hot

TB Positions 1&2

Neutral

TB Position 3

Hood Electrical Requirements

Power to VFD Controller - Standard

230V 1 Phase 10 Amp

Ground

49

Conduit and breaker panel shown for reference only

Terminal Block (TB)

Top of Variable Frequency Drive (VFD) Box

50

Hood Electrical Requirements

Power for Ovens - Standard

Three (3) 120V 1 Phase 20 Amp Circuits

Hot

TB Positions 7, 9 & 11

Neutral

TB Positions 8, 10 & 12

Conduit and breaker panel shown for reference only

Hood Electrical Requirements

Power from VFD to Exhaust Fan - Standard

Exhaust Fan (not to scale)

51

All wiring below the terminal

block to be done by XLT Ovens

and is removed for clarity. See

schematic for wiring details.

Red TB Position 4

Blue TB Position 5

Black TB Position 6

Conduit shown for reference only

Ground (green)

52

Hood Electrical Requirements

Fire Alarm Relay - Standard (optional)

120VAC

Supply

Fire

Alarm

Switch

Oven power in

Signal in from fire suppression panel

TB Position 17

All wiring below the terminal

block to be done by XLT Ovens

and is shown for reference only.

See schematic for wiring details.

Neutral

A1

A2

T3

L3

T2

L2

T1

L1

Oven power out

Conduit, breaker panel and fire suppression panel shown for reference only.

MUA Damper Relays - Single Output Configuration - Standard (optional)

All wiring below the terminal

block to be done by XLT Ovens

and is shown for reference only.

Some wiring removed for clarity.

See schematic for wiring details.

(Up to 10Amps - Determined by MUA)

Hood Electrical Requirements

MUA Unit Relay

(shown for reference only)

Power In

A1 A2

Supply from Breaker Panel

53

Power Out

Neutral

R3 R2 R1

Relays located in VFD box

54

MUA Damper Relays - Multiple Output Configuration - Standard (optional)

MUA Unit 3 Relay

Power

In

A1

Hood Electrical Requirements

MUA Unit 2 Relay

Power

Out

A2

Neutral

(Up to 10 Amps - Determined by MUA)

Power

In

A1

Supply from Breaker Panel

A2

Neutral

Power

Out

MUA Unit 1 Relay

Power

In

A1

All wiring below the terminal block to be done by XLT

Ovens and is shown for reference only. Some wiring

removed for clarity. See

schematic for wiring details.

Power

Out

A2

Neutral

R3 R2 R1

Relays located in VFD box

Terminal Block (TB)

Fuses

Hood Electrical Requirements

VFD Control Box - World

Grounding Block

55

Electrical supply, MUA and fire

suppression controls are wired

through top of VFD control box

Terminal Block (TB)

24V Transformer

VFD Controller

MUA Damper

Relays (optional)

Fire Suppression

Relays (optional)

Oven/hood interface and power cords

connect to bottom of VFD control box

Wiring removed for clarity. See schematic for wiring details.

56

Hood Electrical Requirements

Power to VFD Controller - World

230V 1 Phase 10 Amp

Hot TB Positions 1&2

Ground

Conduit and breaker panel shown for reference only

Terminal Block (TB)

Terminal Block (TB)

Top of Variable Frequency Drive (VFD) Box

Hood Electrical Requirements

Power for Ovens - World

Three (3) 230V 1 Phase 20 Amp Circuits

Hot TB Positions 7 &8

Hot TB Positions 9 &10

Hot TB Positions 10 & 11

57

Conduit and breaker panel shown for reference only

58

Hood Electrical Requirements

Power from VFD to Exhaust Fan - World

Exhaust Fan (not to scale)

Red TB Position 4

Blue TB Position 5