Xlerator XL Installation Instructions Manual

XL

INSTALLATION INSTRUCTIONS FOR XLERATOR® HAND DRYER

FOR PROPER ELECTRICAL CONNECTIONS, CHECK YOUR LOCAL BUILDING CODES.

YOUR UNIT MUST BE INSTALLED BY A QUALIFIED, LICENSED ELECTRICIAN.

IF MOUNTING OVER COUNTERTOP, DISTANCE FROM

COUNTER TO DRYER MUST BE 15” (381mm) MINIMUM

1. Remove cover of dryer by unscrewing two tamper-proof bolts from the sides of the cover with the special wrench provided with each unit.

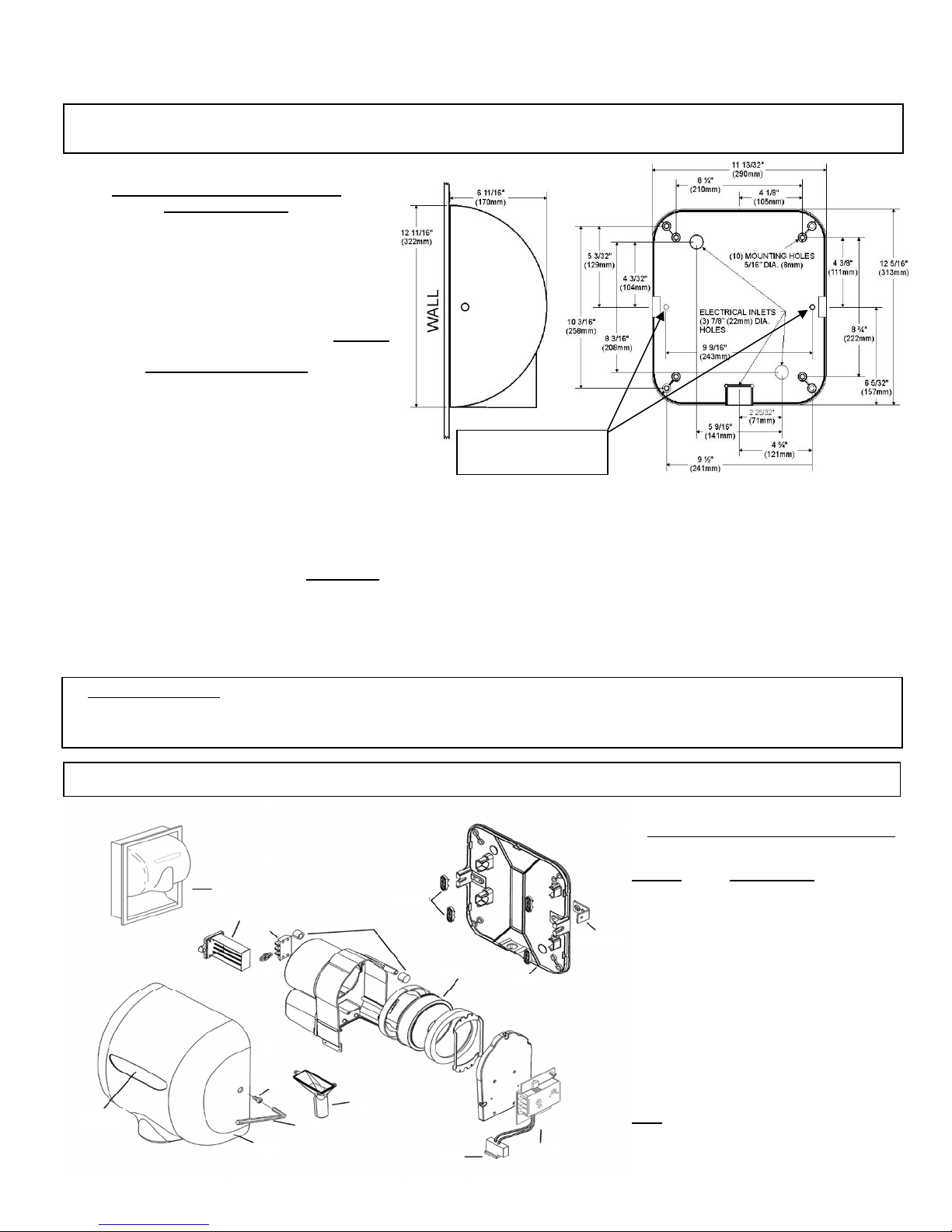

2. Attach wall plate at the four corners to smooth wall. In locations where vandalism is a concern, use the two additional mounting holes shown.

Remove control assembly to access right side mounting hole. Attach with the recommended type of fastener (see above).

Suggested Mtg. Heights from floor

to bottom of dryer

Men’s 45“ (1143 mm)

Ladies’ 43“ (1092 mm)

Teenagers’ 41“ (1041 mm)

Sm. Children 35“ (889 mm)

Handicapped 37“ (940 mm)

Recommended Fastener

Masonry Wall ½” expansion sleeve with ¼” lag bolt

Hollow Wall ¼” wing type through bolt

Wooden Wall ¼” lag screw with washer

LOCATION OF ADDED MTG

HOLES FOR MORE SECURE

INSTALLATION

3. Connect a 110/120V dryer to a 15 Amp. dedicated branch circuit using at least #12 GA copper wire. (Do not exceed a 20 Amp. branch circuit)

Connect a 208, 220/240V or 277V dryer to no more than a 15 Amp. dedicated branch circuit using at least a #14 GA copper wire.

Attach lines to terminals as indicated by the schematic inside dryer cover. Be sure that an equipment ground wire is securely fastened to green

ground screw on base plate. Dryers should be installed per local code requirements.

4. In multiple installations, before replacing cover, check the Serial Number marked inside the dryer to be sure it matches the Serial Number marked

on the label at the bottom of cover. PLEASE DO NOT SWITCH COVERS. Do not forget to leave the special TAMPER PROOF WRENCH with

the owner.

INSTALLATION NOTE: If the dryer will not turn on, stays on or stops working, it may be mounted too close to a counter or object. Turn off the

power to dryer for 10 seconds and then reapply power. If dryer will start, then turn off again, relocate the object or remount dryer. If this is not

possible, adjust the range of the sensor by turning the range adjustment on the control board, counterclockwise to decrease sensor range.

Please call the factory at 1-800-255-9235 and one of our trained technicians will be happy to assist you.

NOTE: Upon completing installation and checking for proper operation, it is highly recommended that a bead of silicone sealant be placed around

the outside of the cover at the wall to protect dryer from internal corrosion caused by wash water and cleaning solutions

PARTS LIST FOR XLERATOR DRYER

XL2

(Location)

XL14

XL8

XL6

XL3

XL1

XL4

XL12 (4)

XL5

XL13 (4)

XL9

XL15

REF NO.

XL11 (2)

XL10

NOTE

dryer MUST BE included when or dering parts.

XL7

DESCRIPTION

XL 1 Cover (includes Nameplate)

XL 2 Nameplate

XL 3 Tamper-proof Bolt

XL 4 Tamper-proof Wrench

XL 5 Air Outlet (includes gasket)

XL 6 Terminal Block (includes screws)

XL 7 Control Assembly & Sensor

XL 8 Heating Element Assembly

XL 9 Motor Assembly

XL 10 Wall Plate Assembly

XL 11 Cover Mounting Brackets

XL 12 Housing Grommet

XL 13 Housing Retainer

XL 14 Recess Kit (for ADA)

XL 15 Optics Assembly (Sensor)

: Model, Serial Number and Voltage of the

XleratorManual3-11.doc

OUTSIDE

Gently wash cover (including air Inlet holes) using a soft cloth or sponge and a mild soap or detergent with lukewarm water to loosen dirt and grime.

INSIDE - CLEANING SHOULD BE PERFORMED BY QUALIFIED SERVICE PERSONNEL

With normal use, dryer will require cleaning once a year. Heavier usage requires more frequent cleaning. Lint on the air inlet or other internal

parts of dryer will reduce efficiency and shorten the life of the working parts. To clean, remove cover by unscrewing the tamper-proof bolts from cover

with the special wrench provided with each dryer. Use a small, soft brush to gently clean all parts.

DISCONNECT ELECTRICAL SUPPLY TO DRYER PRIOR TO SERVICING

CLEANING INSTRUCTIONS

TROUBLESHOOTING YOUR DRYER

As with any electrical appliance, repairs to be performed by qualified service personnel

If your dryer does not turn on

1. Verify that the dryer is receiving power by checking electrical

service, circuit breaker or fuse to the dryer.

2. Check voltage to dryer terminal block.

3. Check RED service LED light for the following:

Light is ON – Place hands under sensor. If light stays on, then

replace sensor. If light goes off, check to make sure wiring is

correct at dryer control. If OK, check motor fuse if so equipped,

and wire connecting to motor. If both are OK, replace motor.

Light is OFF – Check for loose, disconnected or improper wiring

at dryer control (See wiring schematic inside dryer cover), or

replace dryer control.

Light is FLASHING – Dryer is in lockout mode. (See installation

note.)

If your dryer does not shut off

1. May be mounted too close to a counter or object

(See installation note).

2. Check for loose, disconnected or improper wiring at dryer control.

(See wiring schematic inside dryer cover)

3. Replace dryer control.

If your dryer heats up but no air comes out

1. Check motor fuse if so equipped.

2. Check wire connection to motor

3. Replace motor.

If your dryer does not always turn on, or turns on by itself

1. May be mounted too close to a counter or object

(See installation note).

2. Check for foreign material on optical sensor next to air outlet.

3. Check for loose wires on dryer control.

4. Replace dryer control.

If your dryer blows only cold air

1. Check for loose connections to heating element.

2. Replace heating element.

If your dryer has a loss of air volume

1. Check for air leaks at the heating element or nozzle. If leaking,

replace heating element or nozzle.

2. Check for slow running motor or burning smell. If so, replace

motor.

If the problem cannot be resolved with the above, please call

Note:

the factory at 1-800-255-9235 and one of our trained technicians will

be happy to assist you.

XL

1. This product is warranted to be free from defects for a period of five (5) years from the date of shipment from the Manufacturer's factory at

357 Chestnut St., East Longmeadow, Massachusetts 01028. In the event of a breach of the warranty described above, the Owner

shall have either one of the following remedies:

a. The Owner shall return the defective product to the Manufacturer, postage prepaid, and the Manufacturer shall repair said product

within a reasonable time and free of charge, provided that said product is returned within five (5) years from the date of original shipment

from the Manufacturer's factory in East Longmeadow, Massachusetts; and, provided further that said defect is not due to faulty

installation, accident, misuse, or vandalism; or

b. The Owner may notify the Manufacturer by telephone or in writing of the defect and, within a reasonable time, the Manufacturer shall

send a suitable replacement part to remedy said defect, and Owner shall be charged for said part at the current price level. The Owner

may return the defective part to the Manufacturer, postage prepaid, along with the serial number of the defective product and the

Manufacturer will then issue to the Owner a full credit for the repair part, including outgoing postage. Said remedy is available only within

five (5) years from the date of original shipment of the product from the Manufacturer's factory in East Longmeadow, Massachusetts, and

provided further that said defect is not due to faulty installation, accident, misuse, or vandalism.

2. Any implied warranties of merchantability or fitness for a particular purpose are hereby limited to the duration of the express written

warranty contained in paragraph one (1); namely, five (5) years from the date of shipment from the Manufacturer's factory in East

Longmeadow, Massachusetts.

3. There are no other warranties and remedies except as contained herein. This warranty shall inure to the benefit of the Owners,

Successors and Assigns.

5-YEAR LIMITED WARRANTY

XleratorManual3-11.doc

Loading...

Loading...