Xitron 2551, 2551E User Manual

X

ITRON TECHNOLOGIES

USER'S GUIDE

2551/2551E

Single-Phase

P

ower Analyzer

Warranty 3

Warranty

The Xitron Technologies instrument is warranted against defects in material and

workmanship for a period of two years after the date of purchase. Xitron Technologies

agrees to repair or replace any assembly or component (except batteries) found to be

defective, under normal use, during the warranty period. Xitron Technologies’ obligation

under this warranty is limited solely to repairing any such instrument which in Xitron

Technologies’ sole opinion proves to be defective within the scope of the warranty, when

returned to the factory or to an authorized service center. Transportation to the factory or

service center is to be prepaid by the purchaser. Shipment should not be made without

prior authorization by Xitron Technologies.

The warranty does not apply to any products repaired or alt ered by persons not authorized

by Xitron Technologies, or not in accordance with instructions provided by Xitron

Technologies. If the instrument is defective as a result of misuse, improper repair, or

abnormal conditions or operations, repairs will be billed at cost.

Xitron Technologies assumes no responsibility for its product being used in a hazardous

or dangerous manner, either alone or in conjunction with other equipment. Special

disclaimers apply to this instrument. Xitron Technologies assumes no liability for

secondary charges or consequential damages, and, in any event, Xitron Technologies'

liability for breach of warranty under any contract or otherwise, shall not exceed the

original purchase price of the specific instrument shipped and against which a claim is

made.

Any recommendations made by Xitron Technologies or its Representatives, for use of its

products are based upon tests believed to be reliable, but Xitr on Technologies makes no

warranties of the results to be obtained. This warranty is in lieu of all other warranties,

expressed or implied, and no representative or person is authorized to represent or assume

for Xitron Technologies any liability in connection with the sale of our produc ts other

than set forth herein.

Instrument Serial Number: ___________________________ _______

4 2551 User's Guide

T

Document Part Number: MO-2551/2551E-M Revision E

Print date: January 31, 2006

Copyright

Copyright© 1998 - 2000 Xitron All rights reserved.

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any form

without prior written consent from Xitron Technologies. This product manual is

copyrighted and contains proprietary information, which is subject to change without

notice. The product's displays and manual text may be used or copied only in accordance

with the terms of the license agreement.

iTRON

or registered trademarks are acknowledged as the exclusive property of their respective

owners.

In the interest of continued product development, Xitron Technologies Inc., reserves the

right to make changes in this guide and the product it describes at an y time, without

notice or obligation.

ECHNOLOGIES

is a trademark of Xitron Technologies. All other trademarks

Xitron Technologies Incorporated

9770-A Carroll Centre Rd

San Diego, California 92126

Telephone: (858) 530-8099

Fax: (858) 530-8077

E-mail: sales@xitrontech.com

E-mail: support@xitrontech.com

ISO-9001: 2000

Cert. No. A0001474-1

Contents 5

Contents

INTRODUCTION _________________________________________________ 11

Scope ________________________________________________________ 11

Features ______________________________________________________ 12

FUNCTIONAL DESCRIPTION _____________________________________ 13

Theory of Operation____________________________________________ 13

Interfaces_____________________________________________________ 15

Front Panel_________________________________________________ 15

Parallel Printer______________________________________________ 15

IEEE488___________________________________________________ 16

USING THE POWER ANALYZER __________________________________17

Setting Up ____________________________________________________ 17

Front Panel ___________________________________________________ 18

Rear Panel Connections_________________________________________ 19

Starting the Power Analyzer _____________________________________ 20

Configuring the Power Analyzer__________________________________ 20

Measurement Connections_______________________________________ 24

Using the Internal Current Transducer ___________________________ 25

Using an External Current Transducer ___________________________ 26

SEQUENCE OF DISPLAY SCREENS________________________________29

Using the Diagrams_____________________________________________ 29

Diagrams _____________________________________________________ 30

VIEWING RESULTS ______________________________________________ 35

Display Screens ________________________________________________ 35

6 2551 User's Guide

PRINTING RESULTS _____________________________________________ 49

CALIBRATION___________________________________________________ 63

APPENDIX A - PHYSICAL SPECIFICATIONS _______________________ 73

Basics Group _______________________________________________ 36

Rectified___________________________________________________ 38

Harmonics Group____________________________________________ 40

Waveforms Group ___________________________________________ 43

History Group ______________________________________________ 45

Sample Printouts_______________________________________________ 49

Removing DC Current Offsets____________________________________63

Calibrating the Power Analyzer __________________________________ 65

Calibration Procedures _________________________________________ 65

Voltage Calibration __________________________________________ 67

Current Calibration __________________________________________ 69

Calibration Faults______________________________________________ 71

Temperature & Humidity______________________________________73

Size & Weight ______________________________________________ 73

Power Input ________________________________________________ 73

APPENDIX B – MEASUREMENT SPECIFICATIONS__________________ 75

Power Source Capabilities (Option E only)________________________ 75

Input Signal Capabilities ______________________________________ 75

Input Burden _______________________________________________ 76

Measurement Accuracy_______________________________________ 76

Figures 7

Figures

Figure 1. Bench Type Power Analyzer__________________________________ 17

Figure 2. Front Panel detail___________________________________________ 18

Figure 3. Rear Panel detail ___________________________________________ 19

Figure 4. Startup screen _____________________________________________ 20

Figure 5. Setup Index screen with INTERFAC ES/ D ATE/TIME selected _______ 21

Figure 6. The Interface Setup screen____________________________________ 21

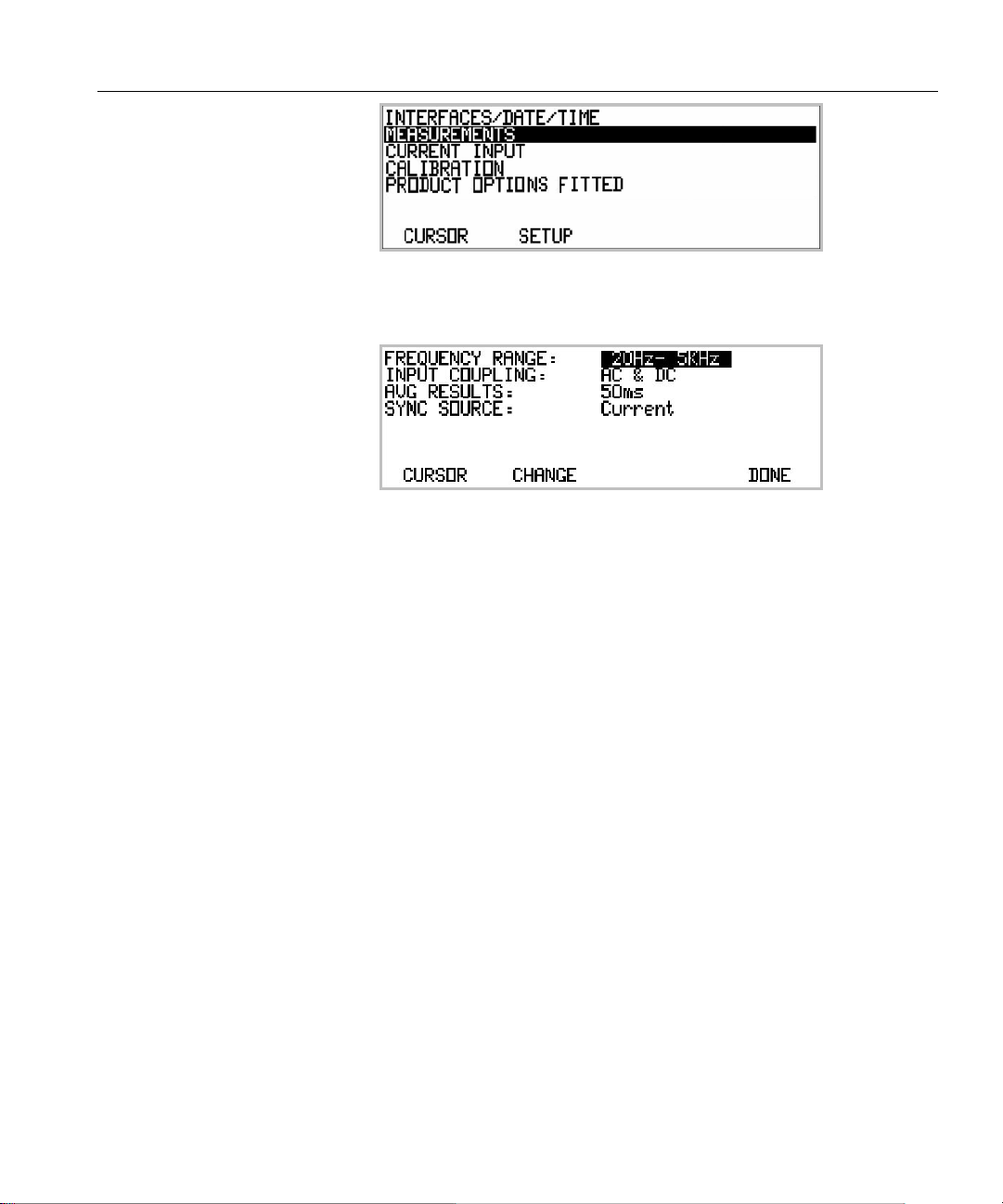

Figure 7. Setup Index screen with MEASUREMENTS selected ______________ 22

Figure 8. The Measurement Setup screen________________________________ 22

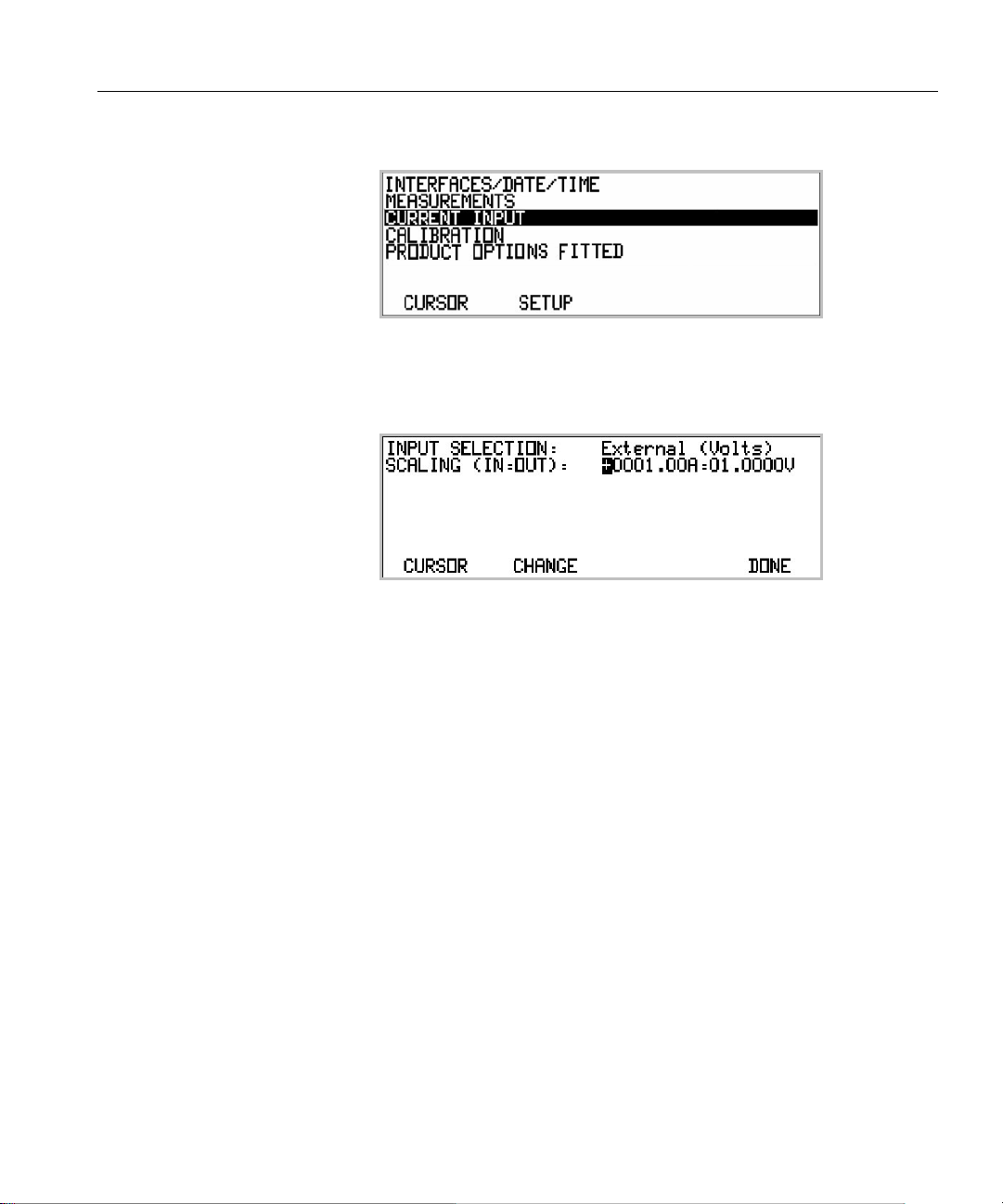

Figure 9. Setup Index screen with CURRENT INPUT selected_______________ 23

Figure 10. The Current Input Setup screen_______________________________ 23

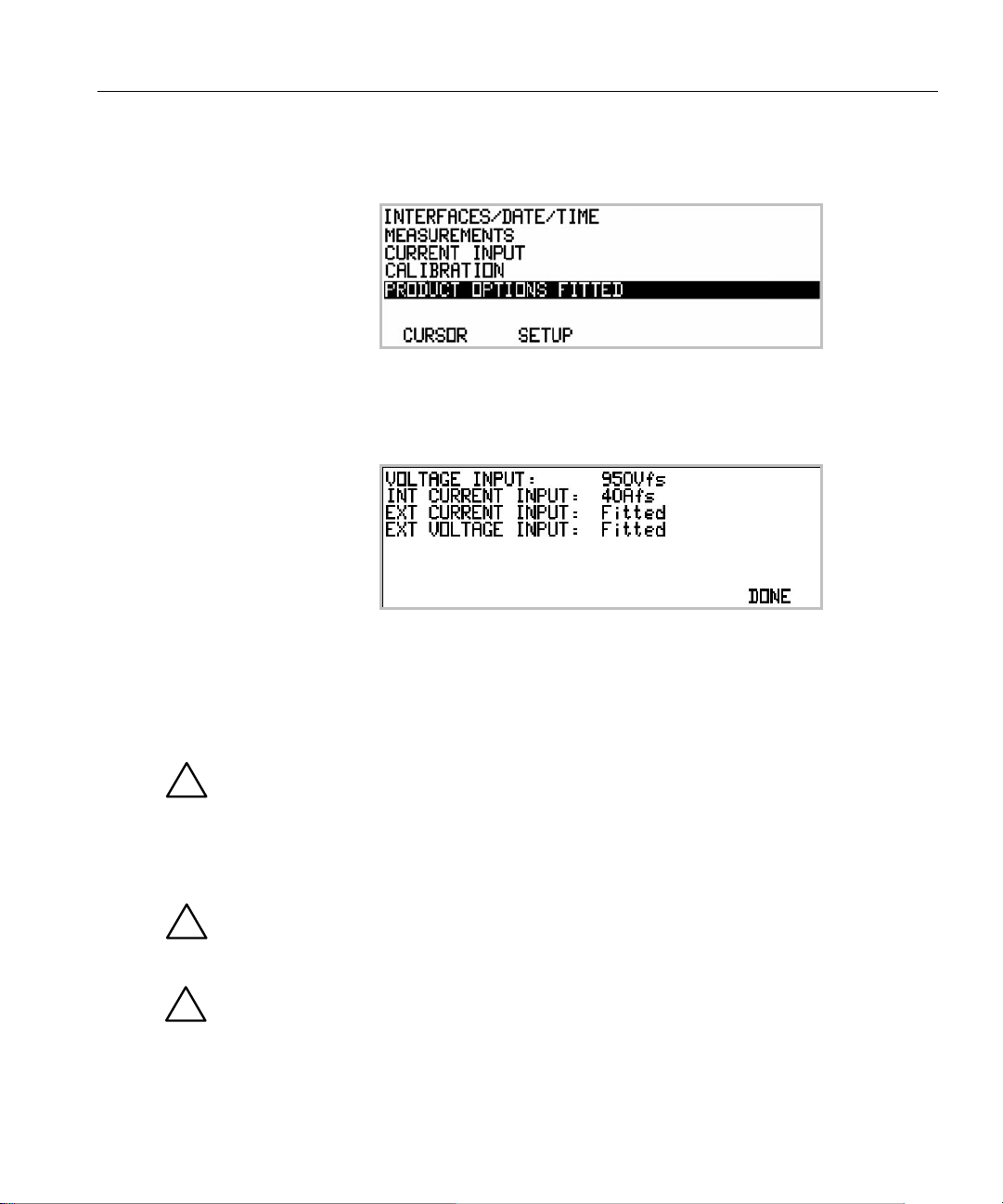

Figure 11. Setup Index screen with PRODUCT OPTIONS FITTED selected____ 24

Figure 12. The Options Fitted screen ___________________________________ 24

Figure 13. Test Device Connections____________________________________ 25

Figure 14. 2551/2551E Internal Effective Circuit (shown for reference)________ 25

Figure 15. External Transducer Test Connections _________________________ 26

Figure 16. Sample Basics display screen ________________________________ 29

Figure 17. Basic ∑RMS sample _______________________________________ 30

Figure 18. Harmonics Listing and Bargraph samples_______________________ 31

Figure 19. Waveforms V&A DIST sample_______________________________ 32

Figure 20. History VOLTS PEAK sampl e _______________________________ 33

Figure 21. ∑RMS MEAS display with callouts ___________________________ 36

Figure 22. ∑RMS INRUSH display ____________________________________ 36

Figure 23. ∑RMS INTEGRATED display with callouts ____________________ 36

8 2551 User's Guide

Figure 24. ∑RMS INTEG AVG display_________________________________ 37

Figure 25. Basics DC MEAS display ___________________________________ 37

Figure 26. Basics DC INRUSH display _________________________________ 37

Figure 27. Basics DC INTEGRATED displ ay ____________________________ 37

Figure 28. Basics DC INTEG AVG display _____________________________ 38

Figure 29. Basics DC LOAD display with cal louts ________________________ 38

Figure 30. Basics RECTIFIED MEAS display with callouts _________________ 38

Figure 31. RECTIFIED INRUS H di spl ay________________________________38

Figure 32. Basics FUND MEAS display wit h call o ut s______________________ 39

Figure 33. Basics FUND LOAD display ________________________________ 39

Figure 34. ∑HARMS display with callouts ______________________________ 39

Figure 35. Harmonics LISTING ABS display ____________________________ 40

Figure 36. Harmonics LISTING PCT display_____________________________ 40

Figure 37. Harmonics LISTING PHASE display__________________________ 40

Figure 38. Harmonics AMPS ABS Lin display with callouts_________________ 41

Figure 39. Harmonics AMPS ABS Log displ a y___________________________ 41

Figure 40. Harmonics AMPS % Lin display______________________________41

Figure 41. Harmonics AMPS % Log display _____________________________ 41

Figure 42. Harmonics VOLTS ABS Lin display __________________________ 42

Figure 43. Harmonics VOLTS ABS Log display__________________________ 42

Figure 44. Harmonics VOLTS % Lin display_____________________________ 42

Figure 45. Harmonics VOLTS % Log display ____________________________ 42

Figure 46. Waveforms V&A CONT display wi t h call o ut s___________________ 43

Figure 47. Waveforms V&W CONT displa y _____________________________ 43

Figure 48. Waveforms V&A DIST display wi th callout_____________________ 43

Figure 49. Waveforms V PEAK display with callout_______________________ 44

Figure 50. Waveforms A PEAK display with callouts ______________________ 44

Figure 51. Waveforms V GLITCH displa y_______________________________ 44

Figure 52. Waveforms A GLITCH displa y_______________________________ 44

Figure 53. History VOLTS RMS display with callouts _____________________ 45

Figure 54. History VOLTS PEAK dis pl a y _______________________________ 45

Figures 9

Figure 55. History VOLTS ENVELOPE dis pl ay__________________________ 45

Figure 56. History VOLTS % THD display______________________________ 45

Figure 57. History AMPS RMS display _________________________________ 46

Figure 58. History AMPS PEAK displ ay ________________________________ 46

Figure 59. History AMPS ENVELOPE dis pla y___________________________ 46

Figure 60. History AMPS % THD display_______________________________ 46

Figure 61. History WATTS displa y ____________________________________ 46

Figure 62. History VAR display ______________________________________ 47

Figure 63. History PF display_________________________________________ 47

Figure 64. Basic Measurement sample printout ___________________________ 51

Figure 65. Harmonics Data List sample printout __________________________ 52

Figure 66. Current Harmonics Barchart sample printout ____________________ 53

Figure 67. Current Harmonics Barchart sample printout ____________________ 54

Figure 68. Volts, Amps, Power Waveforms sample printout _________________ 55

Figure 69. Volts and Amps Waveforms nongraphic sample printout___________ 56

Figure 70. Volts Glitch Capture sample printout __________________________ 57

Figure 71. Amps Peak Capture sample printout ___________________________ 58

Figure 72. Distortion Waveforms sample printout _________________________ 59

Figure 73. Voltage Level History sample printout _________________________ 60

Figure 74. Voltage Level History nongraphic sample printout________________ 61

Figure 75. . Setup Index screen with Current In puts selected_________________ 63

Figure 76. INPUT SELECTION selected________________________________ 64

Figure 77. CALIBRATION selected ___________________________________ 64

Figure 78. DC ZERO Date selected ____________________________________ 64

Figure 79. Calibration selected________________________________________ 66

Figure 80. Calibration Date selected____________________________________ 66

Figure 81. Open Circuit Point prompt___________________________________ 66

Figure 82. Voltage Point Initial display _________________________________ 67

Figure 83. External Voltage Point dis pla y _______________________________ 68

Figure 84. Voltage Point Zero Readings _________________________________ 68

Figure 85. Internal Current Cal Point display_____________________________ 69

10 2551 User's Guide

Figure 86. Load L Current Cal Point display _____________________________ 69

Figure 88. External Transducer Current Cal Point display ___________________ 70

Figure 87. Calibrations Successful display_______________________________ 70

Introduction 11

Introduction

The purpose of this user guide is to describe the use and capabilities of the 2551 and

2551E (External Current) Single-Phase Power Analyzers.

Scope

The single-phase 2551/2551E is an easy-to-use, general purpose power analyzer.

Overall, the 2551/2551E analyzes the electrical power delivered to or by a device. The

unit can be quickly set up on your bench top. You can adjust the viewi n g angl e using the

handle and adjust the contrast from the configuration screen.

The 2551E provides support for an external current transducer of the current:current or

current:voltage type. This option also provides receptacles at the rear panel allowing the

user to power external circuitry from the 2551’s internal DC power supplies (positive and

negative 15V).

Both the 2551 and 2551E analyzers display voltage, current and wattage results in

numeric and graphic waveform formats. Results include voltage, current and wattage,

high and low peaks and harmonic frequencies in absolute, percentage and phase. You

may display the harmonics in a bargraph format through the 40

format through the 50

glitches graphically and chart historical results in divisions of time from seconds to days.

Additional screens display voltage and current envelopes, harmonics, averages, reactive

power, integrated results, K-factor, power factor and crest factor of the voltage or current

signal.

All of the data that can be displayed on the 2551/2551E screens can be printed in fullpage printout formats. Refer to Printing Results page 49. Note that both bargraph and

listing fundamental printouts contain the 2

Note: For further information on Xitron Technologies’ measurement techniques and

formulas used please refer to the Methods Guide. Please contact Xitron Technologies for

a copy or visit our support page at www.xitrontech.com

th

harmonic. You may examine power waveform distortion and

nd

through the 50th harmonics.

th

harmonic or in a listing

12 2551 User's Guide

Features

The 2551/2551E Power Analyzers’ features include the following—

• A simple interface.

• Display basic measurements of ∑RMS, DC, fundamental (harmonic), and

• Displays harmonics in bargraph or a list format.

• Continuously updated display s of vol ta ge, current and wattage waveform s.

• Displays waveforms of voltage and current distortion, peaks and glitches.

• Displays historic results for voltage and current, watts, reactive power and power

• Allowances for scaling of all current readings by a numerical factor.

• Provides adjustable display contrast.

• All measurements are performed and updated on each measurement cycle all of the

∑Harmonics for any single phase.

factor.

time, this ensures that you are testing your product in real-time.

Functional Description 13

Functional Description

This chapter describes the circuitry and interfaces of the 2551/2551E.

Theory of Operation

The 2551/2551E are high performance test equipment. Within the analyzer, voltage and

current signals are converted to digital data where the signals are sampled automatically

and periodically. A/D converters scale and sample data. The DSP components analyze

voltage and current input samples for harmonic content.

The following is a list of the significant components and a description of their function

within the analyzer.

Voltage Attenuators—Resistively attenuate the voltages present on the SOURCE L (A)

and N terminals to a 2.5V peak amplitude maximum voltage signal.

Hall Effect Transducer—Converts the current flowing from SOURCE to LOAD into an

isolated voltage of the 2551/2551E.

Analog Anti-Alias Filters—Reduce the bandwidth of the signals applied to the inputs of

the ADCs to less than the sampling frequency.

Each of the attenuator’s outputs and the output of the Hall Effect transducer are

passed through identical analog anti-alias filters.

16-Bit A to D converters (ADC) and First In/First Out memory (FIFO)—

The ADCs digitize each signal with 16-bit resolution at the DSP generated

Sample Clock frequency. The FIFOs store each digital sample in memory to be

read by the DSP in blocks of 32 samples per converter.

Digital Signal Processor (DSP)—Processes the tasks required to compute the multiple

voltage, current, and power results. Also processes the tasks required to format

the results for display, printout and interrogation via the IEEE488 interface.

Computed results are independent of the selected display and IEEE488 interface

requirements.

14 2551 User's Guide

The DSP generates a sample-clock signal from the compute d fre quency of the

user-selected synchronization source. The sample-clock signal clocks the ADCs

at a suitable frequency to ensure exact synchronization of the overall

measurements to the applied signals. The sampling frequency may be up to

220kHz and is slightly "dithered" to ensure that individual samples cannot be

exactly at the same phase of the applied signals, while maintaining exact

synchronization for the overall measurement period.

The samples read from the FIFOs are passed through one to three stages of 6pole elliptical filters. (The stage of filtering is dependent on user-selected

configuration and bandwidth of harmonics measurements.) The first stage

filters the samples for all nonharmonic measurements. The second stage is antialias filtering of the samples for the DFT and waveform collection. The third

stage filters the samples for waveform period measurements to display the

synchronized results.

All measurements are made nominally over four cycles of the applied signal and

then two-pole filtered with a user-selected averaging filter to produce fast, yet

stable, measurement results. (Note that there are more cycles at very high

frequencies and less at very low frequencies.)

Historical results are maintained by the DSP from the unfiltered measurement

results. Harmonics results, both amplitude and phase, are computed by the DSP

by means of a variable length Discrete Fourier Transform (DFT). Nominally

400 equally spaced samples per cycle are also collected for waveform display

purposes.

At nominal line frequencies and below, all measurements are continuous, there

being no missed portions of the signal in any of the resultant measurements. At

very high frequencies "gaps" can only result in the harmonics measurements.

The DSP also contains 4Kx24 of internal RAM for working memory, 3Kx24 of

program memory and a 1Kx24 level 1 cache memory.

The DSP can perform one arithmetic operation and two data movements per

12.5ns, yielding 80MIPs for arithmetic operations and 240MIPs overall

capability.

IEEE488 Interface—Performs the majority of the bus interface details for the IEEE488

protocol. All IEEE448 interfacing is done with data output from the DSP, or

data and commands input to the DSP. This interface is controlled using a

commercially available IC (National Instruments TNT488).

Parallel Printer Interface—This IC performs the majority of the bus interface details

for the parallel printer protocol. The data to be output over the interface comes

from the DSP. This interface is controlled using a commercially available IC.

Functional Description 15

Graphical Display Module—Allows a visual reading of the results in alphanumeric

and/or graphical format. The display screen is a commercially available LCD

with 240x64 pixels and a CCFL backlight. All graphical information for the

screens is generated by the DSP.

Keyboard—Allows for changing and bringing up the various displays of results. The

keyboard is formed by six key switches, each individually readable by the DSP.

All actions taken as a result of a key being pressed are generated by the DSP.

Real Time Clock (RTC) and Non-Volatile Memory (NVRAM)—Generates the date

and time of day information, and also stores the user display configuration, the

IEEE488 address, and the calibration data for each input. Both clock and

memory are within a single commercially available IC.

Random Access Memory (RAM)—A total of 256Kx24, 15ns access time memory is

available to the DSP to store all "working" information, all computed results,

formatted printout data and display pixels. This memory also contains the

software program for the DSP, copied from the Flash memory.

Flash Program Memory—This memory is rewritable Flash memory used for DSP

program storage. The program is copied into RAM following application of

power and is CRC checked for integrity. After being copied into RAM, the

Flash memory is not used during normal operation.

Interfaces

Note: Specifications are subject to change without notice.

Front Panel

Liquid Crystal Display—

Keyboard—Two fixed-purpose keys + four softkeys

Parallel Printer

Printer Interface—Parallel IEEE1284

Format—Unformatted text or PCL (user selectable)

Data Rate—Up to 1000 characters per second (limited by printer)

240 x 64 High-speed graphics LCD with CC FL Backli g ht ( 5" x 1.35" viewing

area)

16 2551 User's Guide

Compatible Printers—

IEEE488

Interface—

Addressing—

Capabilities—

Max. Talk Data Rate—

Max. Listen Data Rate—

Command Set—

Text: any 80 character wide (or more) by 66 character long (or more) ASCII

parallel text printer

PCL: Hewlett-Packard DeskJet family, Hewlett-Packard LaserJet family, other

PCL level two (or higher) compatible parallel printer with 75dpi or greater raster

graphics print resolution

IEEE488.1 (Certain commands conform to IEEE488.2)

Single address, user selectable via front panel between 0 and 29 inclusive

SH1 AH1 T6 L4 SR1 RL1 PP0 DC1 DT1 C0 E2 (350ns min. T1)

>300,000 bytes per second

>100,000 bytes per second

All front panel capabilities are provided via ASCII textual command sequences.

Results—

Any results may be obtained at any time from the interface as ASCII textual

numerical data. Additionally, status and state interrogatives are provided for onthe-fly determination of product status.

Using the Power Analyzer 17

Using the Power Analyzer

The purpose of this chapter is to describe how to set up and use the 2551/2551E. This

chapter covers—

• Setting Up

• Using the Front Panel Buttons

• Rear Panel Connections

• Power Testing

Setting Up

The Power Analyzer is made to sit on your bench. You can optimize the viewing angle

by adjusting the handle and optimize the viewing brightness by adjusting the DISPLAY

CONTRAST. (See Configuring the Power Analyzer page 20.)

Figure 1. Bench Type Power Analyzer

♦ To adjust the handle—

1. Press and hold the buttons located on the rear side where the handle attaches to the

case sides.

2. Rotate the handle until it clicks into place.

18 2551 User's Guide

S

WARNING: IF THE POWER ANALYZER IS USED IN A MANNER NOT SPECIFIED BY

!

XITRON TECHNOLOGIES INC., THE PROTECTION PROVIDED BY THE EQUIPMENT

MAY BE IMPAIRED.

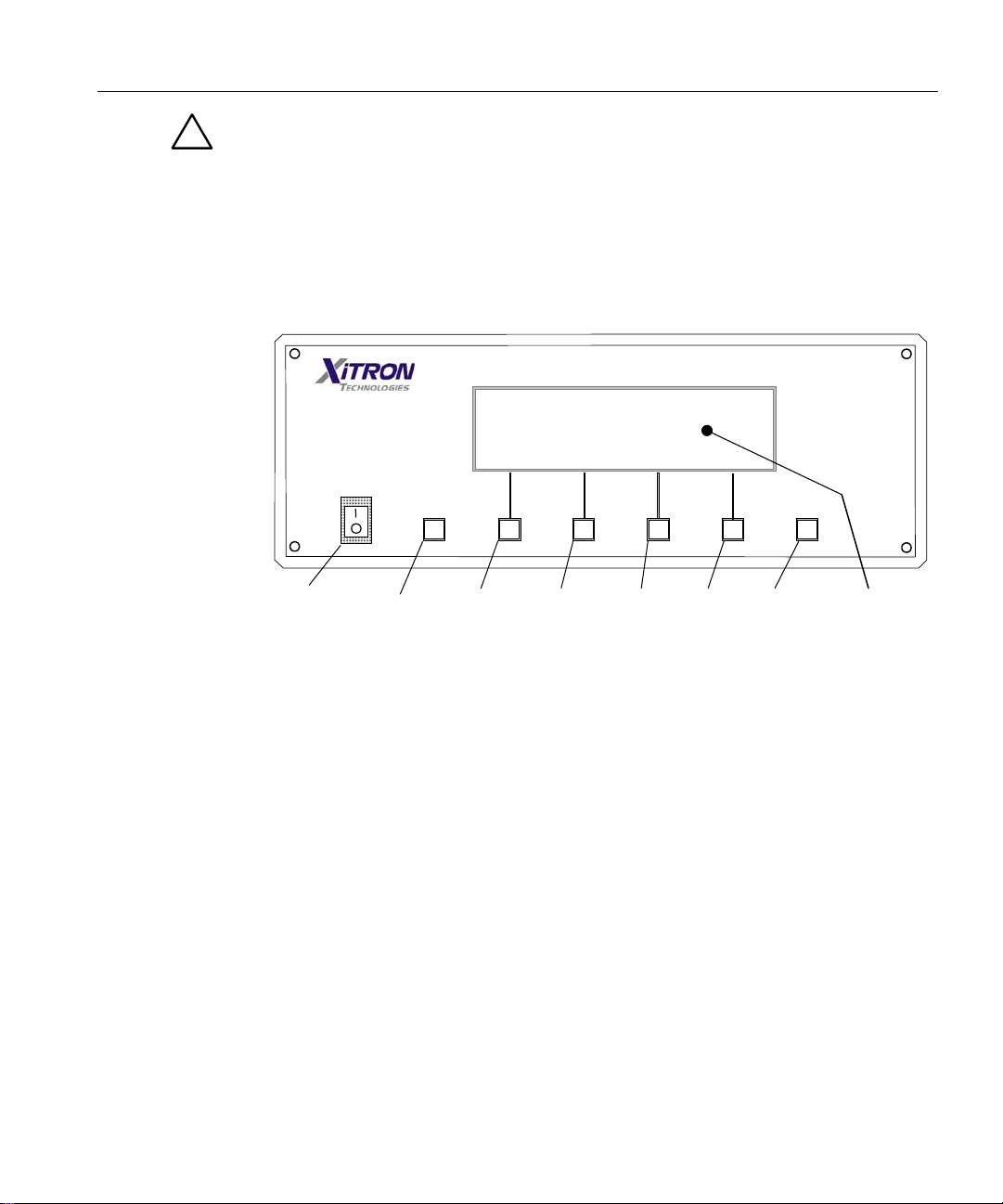

Front Panel

The front panel on the 2551 and 2551E includes a LCD display screen, power switch and

buttons. The buttons are from left to right: NEXT, F1, F2, F3, F4 and PRINT. See

below.

ON

OFF

Power switch

NEXT

2551

NEXT

F1

INGLE PHASE POWER ANALYZER

F2

F3

F4

PRINT

LCD display

Figure 2. Front Panel detail

The screen shows the power measurement results numerically and graphically. Refer to

Viewing Results, page 35.

The ON/OFF button powers the 2551/2551E on or off.

The NEXT button allows you to toggle through the five main display groups. Refer to

Sequence of Display Screens, page 29.

The F1 through F4 buttons (functional softkeys) allow you to select menu choices and

options. For more information, refer to Configuring the Power Analyzer page 20 and

Viewing Results page 35.

The PRINT button allows you to print a full page of data reflecting the display results. A

printout is formatted either graphically or by tabulation.

Using the Power Analyzer 19

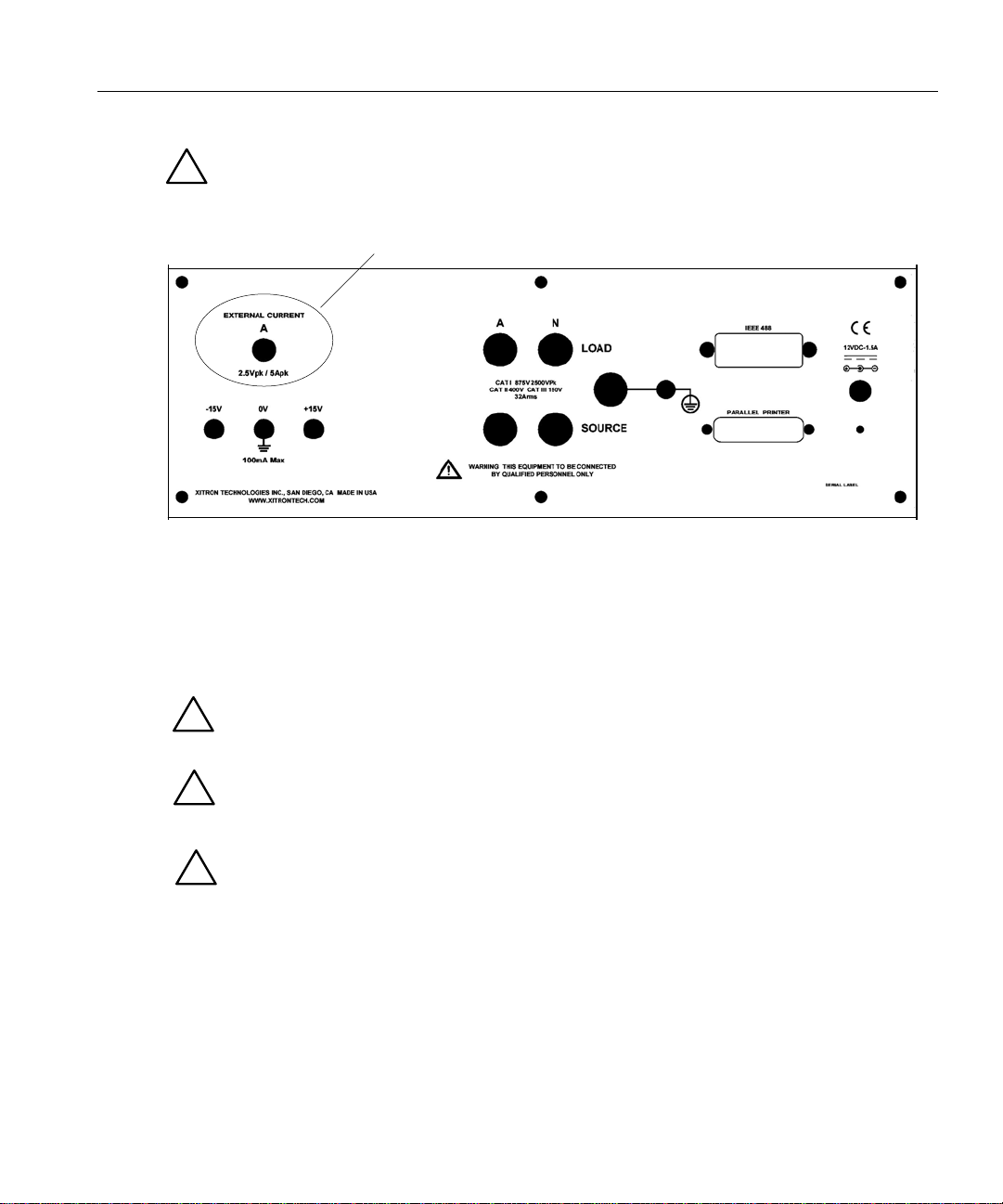

Rear Panel Connections

!

Figure 3. Rear Panel detail

The 2551/2551E rear panels provide connectors for a DC power jack, parallel printer

cable and computer interface cable. The 2551E additionally provides an external current

(BNC) connector and three transducer voltage receptacles. See below.

Available on 2551E only

♦ To power the 2551/2551E—

• Insert the 2.5mm DC power jack’s socket end of the power cord through the supplied

strain relief and into the rear panel’s 2.5mm connector. Insert the plug end of the

external power supply into an 85-265 volt AC, 47 - 400 Hz outlet.

WARNING: SHOCK HAZARD. LETHAL VOLTAGES OR CURRENT MAY BE

!

!

!

PRESENT. ENSURE NO VOLTAGE OR CURRENT EXISTS ON THESE CONNECTIONS

PRIOR TO ATTEMPTING TO CONNECT TO THESE INPUT TERMINALS.

WARNING: IT IS RECOMMENDED THAT THE PROTECTIVE CONDUCTOR

TERMINAL IS CONNECTED TO EARTH GROUND WHEN THE SIGNALS BEING

MEASURED ARE REFERENCED TO EARTH GROUND.

THE USE OF THE T5 CHARGER FROM XITRON TECHNOLOGIES OR A XITRON

TECHNOLOGIES RECOMMENDED REPLACEMENT MUST BE USED TO ENSURE

THAT THE UNIT GROUND IS NOT COMPROMISED.

♦ To connect a printer to the 2551/2551E—

• For printer interface, connect one end of your printer's cable to the PARALLEL

PRINTER port and the other to the printer.

♦ To connect a PC to the 2551/2551E—

1. Attach the computer's IEEE488 cable connector to the 24-pin socket marked

IEEE488 on the rear panel.

20 2551 User's Guide

2. On the front panel, press the NEXT button until you see the main Setup Index

3. Press CURSOR until INTERFACES/DATE/TIME is highlighted.

4. Press the SETUP button. The screen changes to the Interface Setup display.

5. Press CURSOR until the IEEE ADDRESS option is selected.

6. Press the CHANGE button until the appropriate address number displays and press

Starting the Power Analyzer

♦ To start the 2551/2551E, click the ON/OFF button to the ON position.

A startup screen will display for a few seconds. This screen lists the model number,

current and voltage input options, software revision number, and firmware installation

date and time.

display.

DONE.

Xitron 2551/2551E

Internal Current

External Current = CURRENT & VOLTAGE

Voltage Input = 950Vpk

= 8Apk

V2.6 Jun 25 2003 09:10:38

Figure 4. Startup screen

Note: If your unit is not calibrated, a WARNING statement will display along the top of

the Startup screen stating either: “ UNCALIBRATED INSTRUMENT” or

“CALIBRATION DATA HAS BEEN LOST.”

The next display you will see is the same screen that displayed when the analyzer was

last turned off.

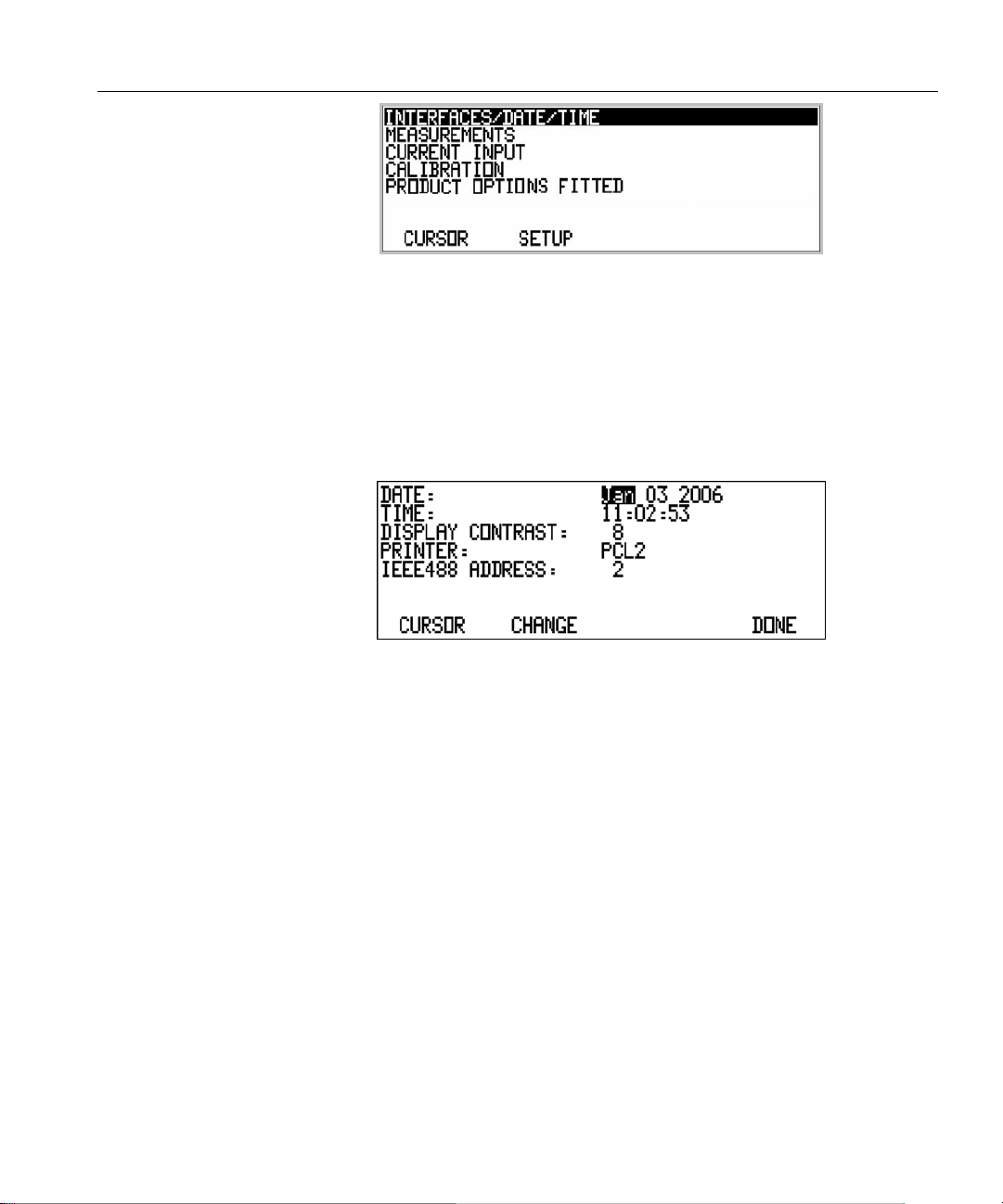

Configuring the Power Analyzer

The Setup Index screen gives you access to separate interface configuration screens.

There is a screen for Interfaces/Date/Time; Measurements; Current Input (selection and

scaling); Calibration and one to view Product Options. Refer to Figure 5, Figure 7,

Figure 9, and Figure 11.

♦ To reconfigure the power analyzer —

1. Press the NEXT button until you see the main Setup Index screen display, as shown

below.

Using the Power Analyzer 21

Figure 5. Setup Index screen with INTERFACES/DATE/TIME selected

2. Press the CURSOR button to highlight the configuration item of choice and press

SETUP. The screen will change to display the selected item’s configuration screen.

♦ To setup the Printer and IEEE488 address interfaces and set the date and

time—

1. With INTERFACES/DATE/TIME highlighted, press the SETUP button. The

display changes to the Interface Setup display.

Figure 6. The Interface Setup screen

2. Use the CURSOR key to highlight any portion of the display that you desire to

modify. Press the CHANGE key to change the highlighted portion of the display to

the next available option for that data.

DATE = month, day, year.

TIME = (24) hours:minutes:seconds.

DISPLAY CONTRAST = 0 to 15 (default is 8)

PRINTER = PCL2; None; Text. Note that selecting None for the printer type

disables the PRINT button in all screens.

IEEE488 ADDRESS = 1 through 29

Note: If you pass an option you desire, you can come back to it by continuing to press

CURSOR.

3. Press the DONE key to save any changes made, and to return to the Setup Index

screen.

♦ To configure the measurements —

1. From the main Setup Index display, press the CURSOR button to highlight

MEASUREMENTS.

22 2551 User's Guide

Figure 7. Setup Index screen with MEASUREMENTS selected

2. Press the SETUP button. The display changes to the Measurements Setup display.

Figure 8. The Measurement Setup screen

3. Use the CURSOR key to highlight any portion of the display that you desire to

modify. Press the CHANGE key to change the highlighted portion of the display to

the next available option for that data. The defaults are shown in bold.

FREQUENCY RANGE = .02Hz- 20Hz; 20Hz- 100KHz; 20Hz- 5KHz;

INPUT COUPLING =

AVG RESULTS =

SYNC SOURCE =

2Hz- 2KHz; 0.2Hz- 200Hz

AC & DC; AC only

50ms; 250ms; 1s; 2.5s; 5s; 10s; 20s; 1min

Voltage; Current; 50Hz; 60Hz; 400Hz; No Harmonics

4. Press the DONE key to save any changes made, and to return to the main Setup

Index screen.

♦ To configure the Current Input

The Current Input configuration screen includes selection and scaling. The current scale

allows you to scale all current readings by a numerical factor. Separate scale factors are

stored for each current input option, and are entered as transducer input:output ratio. This

scale factor may also be negative, effectively reversing the polarity of current flow.

Using the Power Analyzer 23

1. From the Setup Index display, press the CURSOR button twice. The CURRENT

INPUT choice is now highlighted as shown below.

Figure 9. Setup Index screen with CURRENT INPUT selected

2. Press the SETUP button. The display changes to the Current Input Setup display.

See example shown below.

Figure 10. The Current Input Setup screen

3. Use the CURSOR key to highlight any portion of the display that you desire to

modify. Press the CHANGE key to change the highlighted portion of the display to

the next available option for that data.

INPUT SELECTION = External (Volts); Internal: External (Amps)

The scaling limits for current are within:

SCALING (IN=OUT) = +0000 .00A = 00.0000A through -9999 .99A = 99.9999A

The scaling limits for voltage are within:

SCALING (IN=OUT) = +0000 .00V = 00.0000V through -9999 .99V = 99.9999V

4. Press the DONE key to save any changes made, and to return to the Setup Index

screen. Note that the scale factor for each available current input is stored

separately.

Note: To remove DC offset and calibrate the power analyzer, refer to the Calibration

section on page 63.

24 2551 User's Guide

♦ To view the Option Content of your Power Analyzer

1. From the Setup Index display, press the CURSOR button four times. The

Figure 11. Setup Index screen with PRODUCT OPTIONS FITTED selected

2. Press the SETUP button. The display will show the Product Options screen. See

Figure 12. The Options Fitted screen

PRODUCT OPTIONS FITTED choice is now highlighted as shown below.

an example shown below.

3. Press the DONE k ey to return to the Setup Index screen.

Measurement Connections

WARNING: IF THE POWER ANALYZER IS USED IN A MANNER NOT SPECIFIED BY

!

!

!

XITRON TECHNOLOGIES INC., THE PROTECTION PROVIDED BY THE EQUIPMENT

MAY BE IMPAIRED.

CAUTION:

SEPARATED.

WARNING: IT IS RECOMMENDED THAT THE PROTECTIVE CONDUCTOR

TERMINAL IS CONNECTED TO EARTH GROUND WHEN THE SIGNALS BEING

MEASURED ARE REFERENCED TO EARTH GROUND.

THE USE OF THE T5 CHARGER FROM XITRON TECHNOLOGIES OR A XITRON

TECHNOLOGIES RECOMMENDED REPLACEMENT MUST BE USED TO ENSURE

THAT THE UNIT GROUND IS NOT COMPROMISED.

FOR ALL CONNECTIONS, KEEP INPUT AND OUTPUT WIRING

Using the Power Analyzer 25

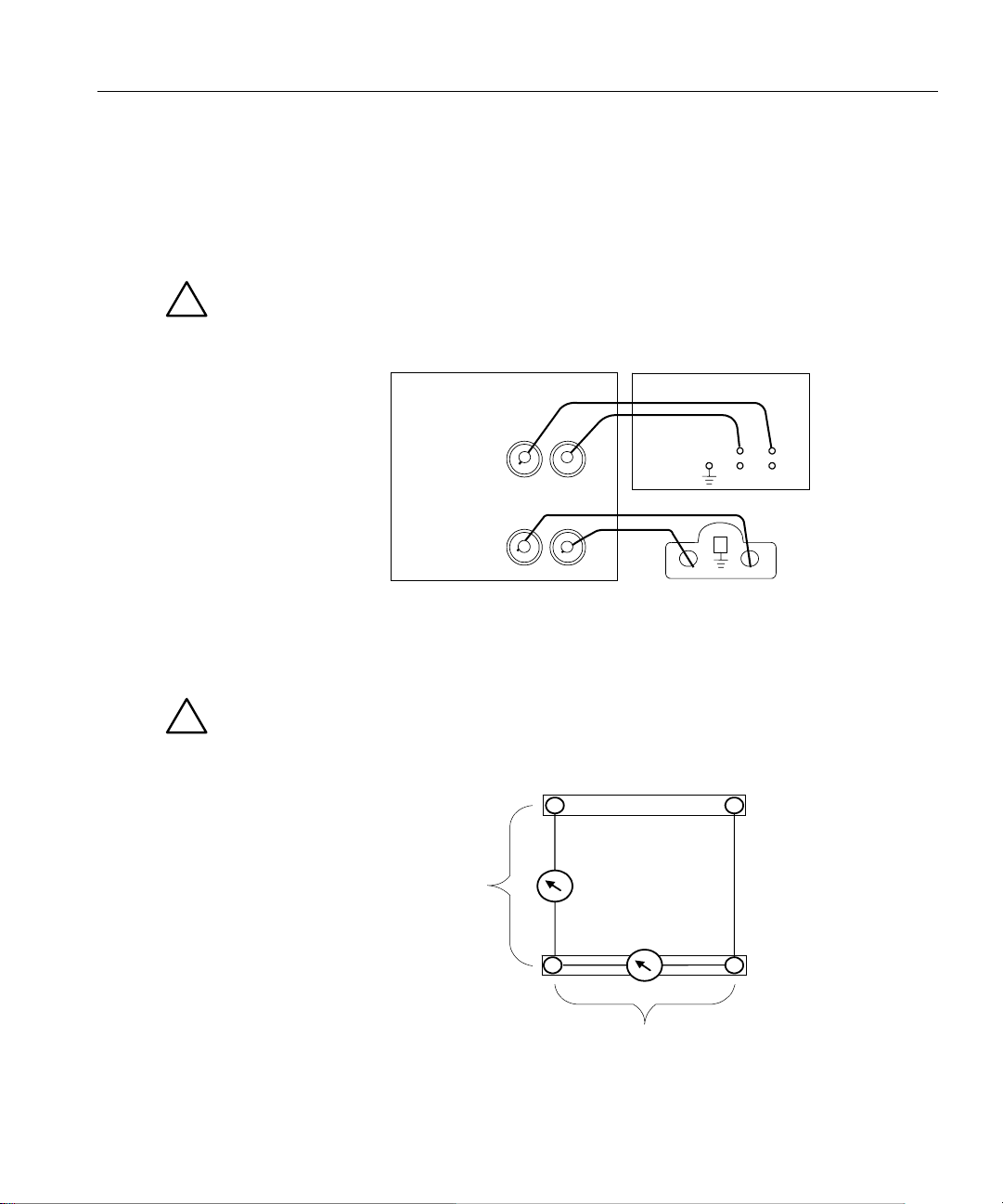

Using the Internal Current Transducer

When using the internal current transducer of the power Analyzer, access the Current

Input Setup screen. Set the INPUT SELECTION to Internal and +1.0:1.0 for Scaling.

Refer to the connections shown in Figure 13.

Internal Transducer Connections for Test

Turn the source power off for the device-under-test before making each connection.

!

Attach the test device to the input terminals on the analyzer's rear panel.

Refer to the following illustration when attaching the test device.

2551

A N

LOAD

SOURCE

TEST DEVICE

USER LOAD

LINE NEUTRAL

POWER SOURCE

Figure 13. Test Device Connections

WARNING:

!

PRESENT. ENSURE NO VOLTAGE OR CURRENT EXISTS ON THESE CONNECTIONS

PRIOR TO ATTEMPTING TO CONNECT TO THESE INPUT TERMINALS.

SHOCK HAZARD. LETHAL VOLTAGES OR CURRENT MAY BE

LOAD

To measure

current

LINE (A)

A

NEUTRAL (N)

V

SOURCE

To measure

voltage

Figure 14. 2551/2551E Internal Effective Circuit (shown for reference)

Loading...

Loading...