XP3-BD User Manual Page 2 of 30 MANUL008R2V1

XP3-BD User Manual

Index Page

Chapter 1 Configuration of the BD-Board

1-1 Configuration 3

Chapter 2 AI and temperature sampling board XP3-2AD2PT-BD

2-1 General 5

2-2 Specs 6

2-3 External installations and connections 7

3-4 Assignment of input ID 8

2-5 Working Mode settings 9

2-6 Control settings 10

2-7 Application of PID output value 10

2-8 Programs 11

Chapter 3 K type thermo coupling temperature PID board XP3-2TC-P-3D

3-1 General 13

3-2 Specs 14

3-3 External installations and connections 15

3-4 Assignment of input ID 17

3-5 Working Mode settings 18

3-6 Control Speciality 19

3-7 Programs 20

Chapter 4 Analogue AI/AO temperature sampling board XP3-2PT2ADIDA-

BD

4-1 General 21

4-2 Specs 22

4-3 External installations and connections 23

4-4 Assignment of input ID 24

4-5 Working Mode settings 25

4-6 Control Speciality 26

4-7 Programs 27

XP3-BD User Manual Page 3 of 30 MANUL008R2V1

1 Configuration of the BD-Board

1. Install BD correctly on the main unit;

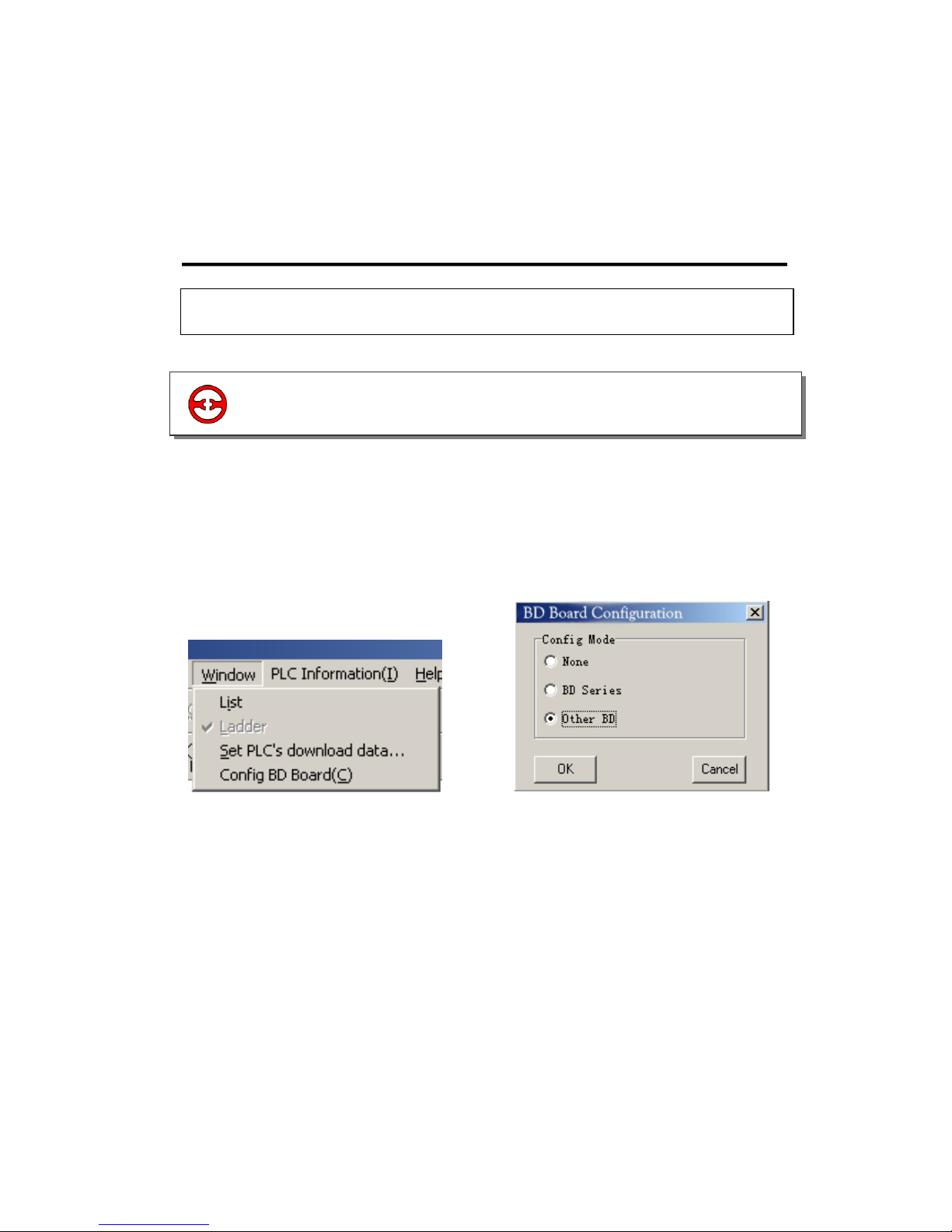

2. Then connect the model online via XCP edit tool, in the “Window” menu, choose “Config

BD Board(C)” (Image 1).

3. Click it, in the “Config BD Board(C)” dialog box, choose “Other BD” (Just as shown in graph

and click “OK” to download the program.

Image 1 Image 2

1-1 Configuration

1-1.Configuration

XP3-BD User Manual Page 4 of 30 MANUL008R2V1

2 AI and temperature sampling board XP3-

2AD2PT-BD

2-2.Specs

2-3.External installations and connections

2-1.General

2-5.Working Mode settings

2-6.Control settings

2-4.Assignment of input ID

2-7.Application of PID output value

XP3-BD User Manual Page 5 of 30 MANUL008R2V1

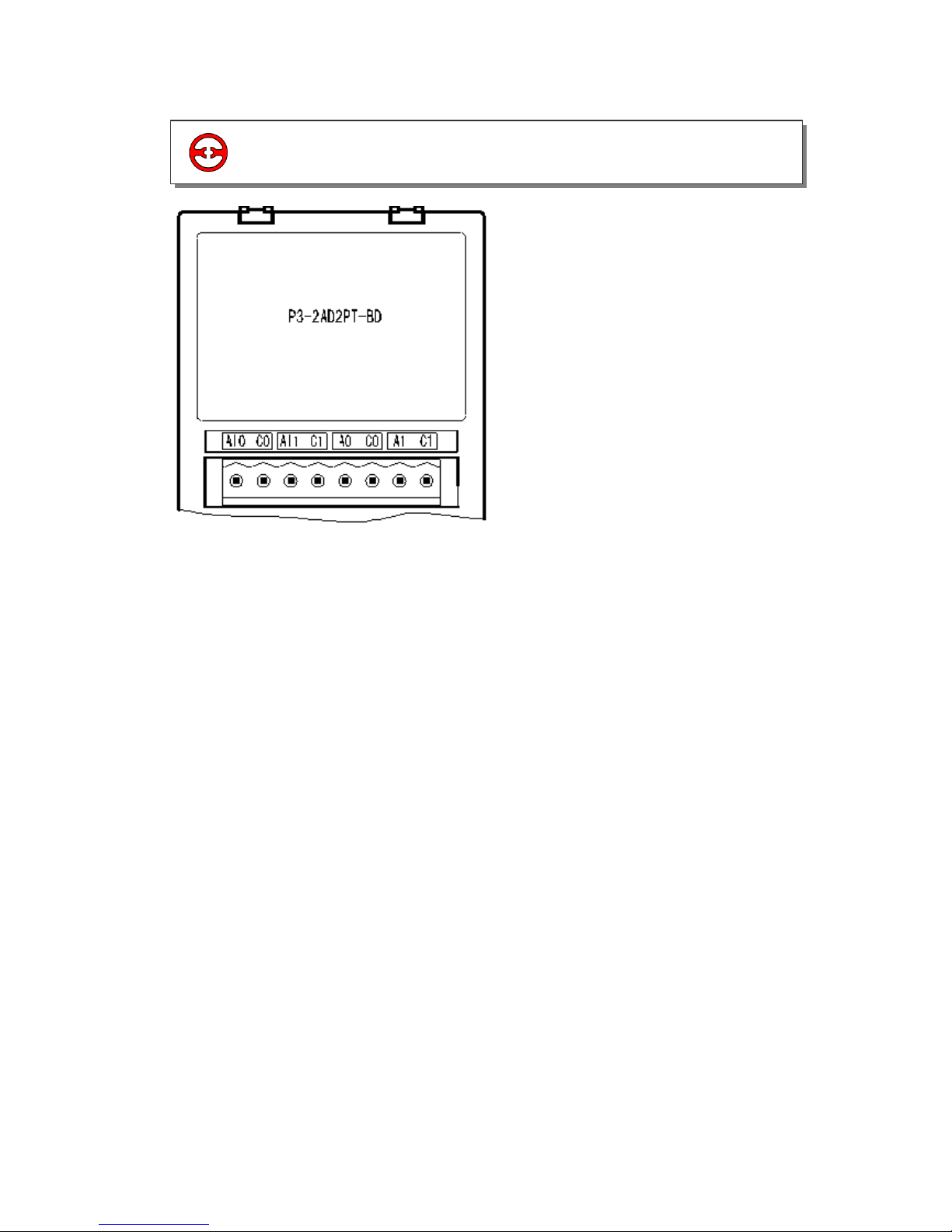

2-1 General

14 bits high precision analogue input.

2 Channel voltage 0/10V, 0/5V

(selectable) analogue input.

2 channels PT temperature testing.

resistor (PT100 two-wire format)

temperature sensor analogue input.

XP3-BD User Manual Page 6 of 30 MANUL008R2V1

Item

Voltage Input

Temperature Input

Analogue Input

Signal

DC: 0 to 5V, 0 to 10V

(Input resistor 300kΩ)

Platinum Resistor PT100

(2-wire format)

Temperature

Testing band

-

-100 to 350 degrees C

Resolution

0.15mV 10/16383

0.1

Digital Output

band

0 to 16383

-1000 to 3500

Integrate

Precision

±0.8% of full scale

Convert Time

15ms × 4 channels

PID Output

Value

0 to K4095

Vacant

Defaulted

Value

0

3500

Input

Specialty

Isolation

No isolation between each channel of PLC

Used points

0 point (As operated via data register, so the used points are not limited

by PLC’s max control points)

2-2 Specs

XP3-BD User Manual Page 7 of 30 MANUL008R2V1

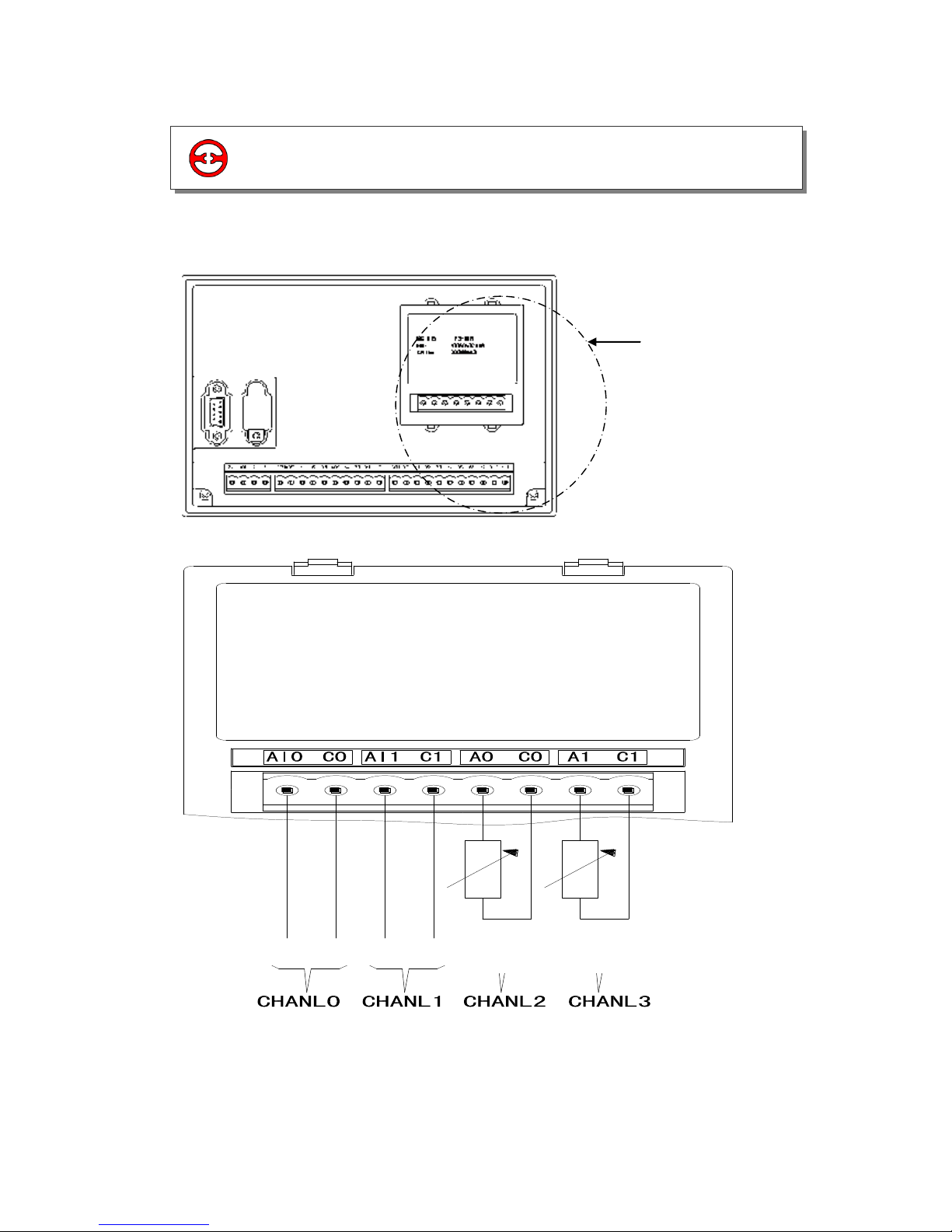

Board’s install

position

1) The Installation of Board:

Open the board’s cover at the back of XP3 (As shown in the following image); install it according

to the pin arrangement. Then fix it with screws, close the cover.

2) Connection: See the following diagram

PT100

PT100

V-

V+

V-

V+

2-3 External installations and connections

XP3-BD User Manual Page 8 of 30 MANUL008R2V1

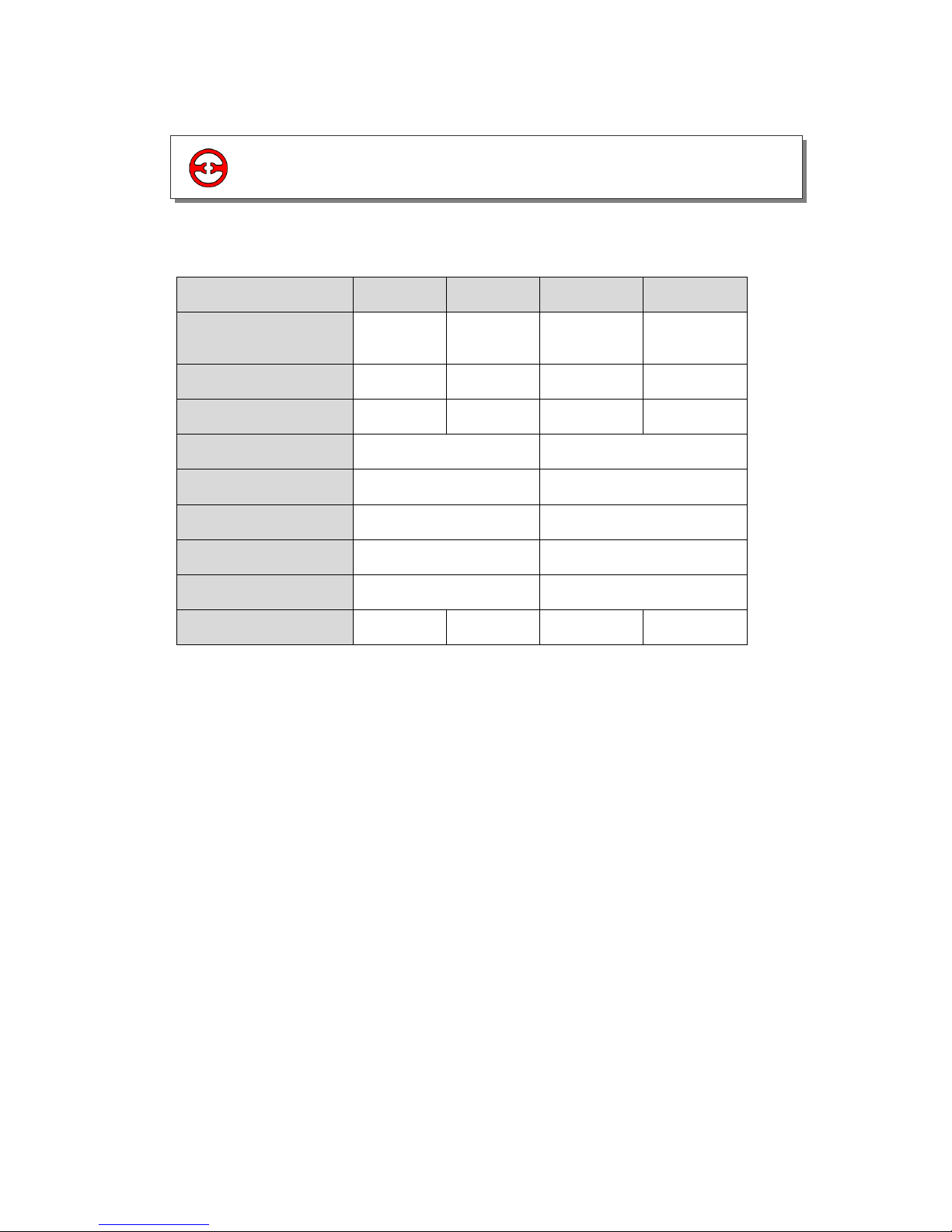

This BD board does not use standard I/O units memory addresses, the converted data will be

directly sent into PLC register. The channels correspond to the PLC register ID:

Channel

0CH

1CH

2CH

3CH

AD signal/Temperature

value

ID1000

ID1001

ID1002

ID1003

PID output value

ID1004

ID1005

ID1006

ID1007

Set the target value

QD1000

QD1001

QD1002

QD1003

Kp

QD1004

QD1009

Ki

QD1005

QD1010

Kd

QD1006

QD1011

Diff

QD1007

QD1012

Dead Band

QD1008

-

Start/Stop

Y1000

Y1001

Y1002

Y1003

Note:

1. PID value: PID output value:0 to 4095.

2. Kp: proportion parameter

3. Ki: Integral parameter.

4. Kd: Differential parameter.

5. Diff: Control proportion band.

6. Control coil’s status: Y1000/Y1001 (0 = means stop PID control, 1 = means run PID control

Description:

0CH and 1CH are AD input channels.

2CH and 3CH are PT100 input channels.

Kp: proportion parameter.

Ki: Integral parameter.

Kd: Differential parameter.

Diff: Control band.

Control Band Diff: Carry on PID control in the assigned band, beyond the band, don’t carry

on PID control

Start Signal (Y): PID control is closed when Y is 0, open PID control when Y is 1.

Dead Band “Dead Band”: Compare the current PID output value with the preceding PID

output value. If their difference is less than the set Dead Band, the module will abandon the

current PID output value; still transferring the preceding PID output value to PLC main unit.

2-4 Assignment of input ID

XP3-BD User Manual Page 9 of 30 MANUL008R2V1

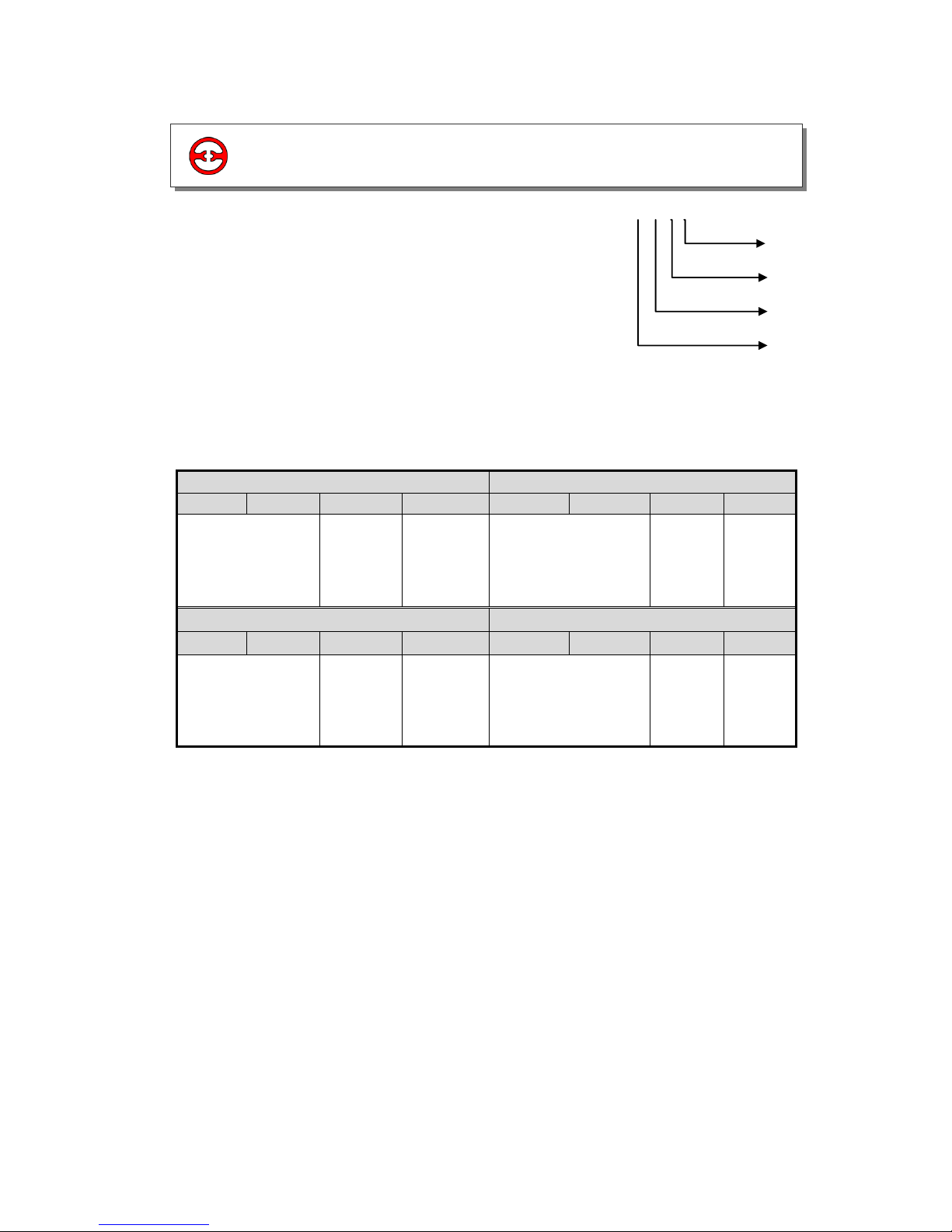

2) Each channel’s working mode is assigned by the four bits of the corresponding register, each

bits definition is shown below:

Register FD8306:

1. Usage of four parameters: Proportion parameter (Kp), integral parameter (Ki), differential

parameter (Kd), control proportion band (Diff).

2. Parameter P is proportion parameter, mainly reflect system’s wrap, when system wrap

appears, carry on control immediately to decrease the wrap.

3. Parameter I is integral parameter, mainly used to remove net difference, improve the systems

no-difference degree

4. Parameter D is differential parameter; mainly used to control the signal’s change trend,

decrease system’s shake.

5. Temperature control proportion band means: in the assigned band, carry on PID control,

beyond the band, do not carry on PID control.

CH1

CH 0

Bit7

Bit6

Bit5

Bit4

Bit3

Bit2

Bit1

Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~10V

1:0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0/10V

1:0/5V

CH3

CH 2

Bit15

Bit14

Bit13

Bit12

Bit11

Bit10

Bit9

Bit8

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

-

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

-

2-5 Working Mode settings

1) Expansion’s input has voltage 0/5V and 0/10V. These

two modes and filter form to select. Set via special

FLASH data register FD8306 in PLC.

Refer to the graph (right) each register set the 4

channels’ modes, each register has 16 bits. From low bit

to high bit, each 4 bits set one channel mode.

FD8306 H O O O O

0CH

1CH

2CH

3CH

XP3-BD User Manual Page 10 of 30 MANUL008R2V1

1. Usage of four parameters: Proportion parameter (Kp), integral parameter (Ki), differential

parameter (Kd), control proportion band (Diff)

Parameter P is the proportion parameter.

Parameter I is the integral parameter.

Parameter D is differential parameter

Temperature Control Band Means: in the assigned band, to carry out PID control.

PID Temperature Control Curve is Shown Below:

Note:

Each parameter’s reference value: Kp=20/100, Ki=5/20, Kd=200~500, DIFF=100/200.

This reference value only for normal condition, according to the locale detail condition, each

reference value could be beyond the band.

When using PID, the BD board will perform heating control with a cycle of 2 Seconds.

This modifies the output value based on the PID control.

2-6 Control settings

2-7 Application of PID output values

XP3-BD User Manual Page 11 of 30 MANUL008R2V1

E.g.1: Real time readings of the AD value of CH0, and then carries on PID parameters setting

with CH0, then read the PID output value.

MOV K800 QD1000

MOV ID1000 D10

M8000

END

MOV K30 QD1004

MOV K5 QD1005

MOV K500 QD1006

MOV K150 QD1007

MOV K200 QD1008

MOV ID1004 D1000

Y1000

M8

2-8 Programs

Write CH0’s input value into D10

Set CH0’s value as 800

Set CH0’s Kp as 30

Set CH0’s Ki as 5

Set CH0’s Kd as 500

Set CH0’s Diff as 150

Set CH0’s Death as 200

Write CH0’s PID output value into

D1000

Start/stop PID adjustment of CH0

XP3-BD User Manual Page 12 of 30 MANUL008R2V1

E.g.2. PID temperature control example

MOV K800 QD1002

MOV ID1006 D1000

MUL D1000 K200

DDIV D1100 K4095

D1100

D1200

M8000

M8000

T200 K200

T200

T200 D1200

≤

Y3

Y1000

M10

END

MOV K30 QD1009

MOV K5 QD1010

MOV K500 QD1011

MOV K150 QD1012

D1100>K0

T200 is 10ms timer

Convert PID output value (0/4095) to be

value of 0/200

Via ON/OFF of Y3, carry on PID

temperature adjustment

Stop/start CH2

Set CH2’s value as 800 (80 degrees)

Set CH2’s Kp as 30

Set CH2’s Ki as 5

Set CH2’s Kd as 500

Set CH2’s Diff as 150

XP3-BD User Manual Page 13 of 30 MANUL008R2V1

3 K Type thermo coupling temperature PID

board XP3-2TC-P-3D

3-1. General

3-2.Specs

3-3.External installations and connections

3-4.Assign input/output ID

3-5.Working Mode settings

3-6.Control speciality

3-7.Programs

3-1 General

Analogue input used by thermocouple (K type) temperature sensor

2 channels input, 2 channels output

2 groups PID parameters

Cold terminal compensate circuit inside

Resolution is 0.1

XP3-BD User Manual Page 14 of 30 MANUL008R2V1

Item

Content

Analogue Input Signal

Thermocouple K type

Input Points

2 points

Temperature Testing Band

0 to 970°C

Digital Output Band

0~9700, 16 bits binary

Output Points

2 points

Output Format

NPN collector open circuit transistor output

Control Precision

0.4°C

Resolution

0.1°C

Synthesis Precision

±0.8% (Relative max value)

Conversion Speed

45ms × 2 channels

Analogue Power

DC24V±10%, 50mA

3-2 Specs

XP3-BD User Manual Page 15 of 30 MANUL008R2V1

Install Position of

Expansion Board

Installation Method of Expand Board:

1. Open the expansion cover behind XP3 (See the following diagram), then install according to

the pin and fix with screws.

2. Connection Method

3-3 External installations and connections

XP3-BD User Manual Page 16 of 30 MANUL008R2V1

Output terminals:

Transistor output terminals - please choose DC5V to 30V-regulated power.

Circuit insulation:

Between programmable controller’s interior circuit and output transistor, use optical coupling

device to insulate. Each public module is divided separately

Response time:

The time from PLC drive optical coupling device to transistor ON/OFF is not more than 0.2ms.

Output current:

Each point’s current could be 0.8A, but to restrict temperature increasing, please use as 1.2A

per 4

Open circuit leakage current:

Below 0.1mA

The Output Current is Shown Below:

XP3-BD User Manual Page 17 of 30 MANUL008R2V1

This BD expansion does not use I/O unit, the converted data is directly sent into PLC register,

also add two extra output points. Extra outputs do not include normal system’s I/O output.

Channels correspond to the PLC register ID:

Channel

Current

Temperature

Set

Temperature

Kp

Ki

Kd

Diff

Start/stop

0CH

ID1000

QD1000

QD1

001

QD1

002

QD1

003

QD1

004

Y1000

1CH

ID1001

QD1005

QD1

006

QD1

007

QD1

008

QD1

009

Y1001

Note:

1. Kp: proportion parameter, Ki: integral parameter, Kd: differential parameter; Diff: control

proportion band.

2. Control coil’s status (Y1000/Y1001): 0 = means close PID control, 1 = means start PID

control.

3. Expansion’s input has voltage 0/5V or 0/10V these two modes and filter form to select. Set

via set the 4 channels’ mode, each register has 16 bits. From low bit to high bit, each 4 bits set

one channel’s mode

3-4 Assign input/output ID

XP3-BD User Manual Page 18 of 30 MANUL008R2V1

2) Temperature Control Cycle

Temperature Control Cycle: When carry on PID adjustment, the output terminals carry on

heating according to the duty cycle got by PID output value, this period is called Temperature.

Control Cycle

CH1

CH0

Bit7

Bit6

Bit5

Bit4

Bit3

Bit2

Bit1

Bit0

- - -

0:2 Sec.

- - -

0:2 Sec.

1:20 Sec.

1:20 Sec.

FD8306 H O O O O

0CH

1CH

3-5 Working Mode settings

1) Set the expansion’s working mode via special FLASH

data register FD8306 in PLC. Refer to the graph by the

right, each register has 16 bits, from low bit to high bit,

every 4 bits confirm 1 channel’s mode.

XP3-BD User Manual Page 19 of 30 MANUL008R2V1

1. Usage of Four Parameters:

Proportion parameter (Kp), integral parameter (Ki), differential

parameter (Kd), control proportion band (Diff)

Parameter P is the proportion parameter:

Parameter I is the integral parameter, mainly used to remove net difference.

Parameter D is the differential parameter, mainly used to control signal’s change trend.

Temperature Control Band Means: in the assigned band, to carry out PID control,beyond

the band does not carry out PID control.

2. Temperature Control Cycle:

When carrying out PID adjustment, the output will carry on

heating according to the duty cycle got by PID output value, this period is called

Temperature Control Cycle.

3. Control Specialties:

The band of the PID adjustment is: (QD-Diff QD + Diff), when the temperature is lower

than QD-Diff, controller goes on heating, when temperature is higher than QD + Diff, the

controller will stop heating.

The Control Curve of PID is Shown Below:

Each parameter’s reference value: Kp=20/100, Ki=5/20, Kd=200/500. DIFF=100~200

This reference value only for normal condition,according to the locale detail condition, each

reference value could be beyond the band.

3-6 Control specialities

XP3-BD User Manual Page 20 of 30 MANUL008R2V1

Program with CH0

K800MOV QD1000

K500MOV QD1003

K5MOV QD1002

K30MOV QD1001

M8000

END

K150MOV QD1004

Y1000

M0

3-7 Programs

Set value in CH0 as 800 (80 degrees)

Set CH0’s Kp as 30

Start/stop CH0

Set CH0’s Ki as 5

Set CH0’s Kd as 500

Set CH0’s Diff as 150

(i.e., carry on PID operation at

650)

XP3-BD User Manual Page 21 of 30 MANUL008R2V1

4 Analogue AI/AO temperature sampling

board XP3-2PT2ADIDA-BD

4-1. General

4-2.Specs

4-3.External installations and connections

4-4.Assignment of input ID

4-5.Working Mode settings

4-6.Control settings

4-7.Programs

XP3-BD User Manual Page 22 of 30 MANUL008R2V1

4-1 General

14 bits high precision analog input

10 bits high precision analog output

2 channels voltage 0/10V or 0/5V (selectable)

analog input

2 channels PT temperature testing resistor

(PT100 2-wire format) temperature sensor

analog input

XP3-BD User Manual Page 23 of 30 MANUL008R2V1

Item

Voltage Input

Temperature Input

D/A output

Analogue

Input Signal

DC: 0to 5V, 0 to 10V

(Input Resistance

300kΩ)

Platinum resistor PT100

(2-wire format)

Digital Input

band

10 bits Binary

(0/1023)

Analogue

Output band

0/20mA, 4/20mA

Temperature

Testing

band

-100 to 350°C

Distinguish

Ratio

0.15mV 10/16383

0.1ºC

1/1023

Digital Output

band

0 to 16383

-1000 to 3500

Integrate

Precision

±0.8% of the full scale

Conversion

Time

15ms × 4 channels

PID output

value

0 to K4095

Vacant

defaulted

value

0

3500

-

Input/output

Specialty

Isolation

No isolation among PLC’s each channel

Used I/O

0 point (because it is operated via data register, so it is not limited by

master PLC’s standard I/O control points)

4-2 Specs

XP3-BD User Manual Page 24 of 30 MANUL008R2V1

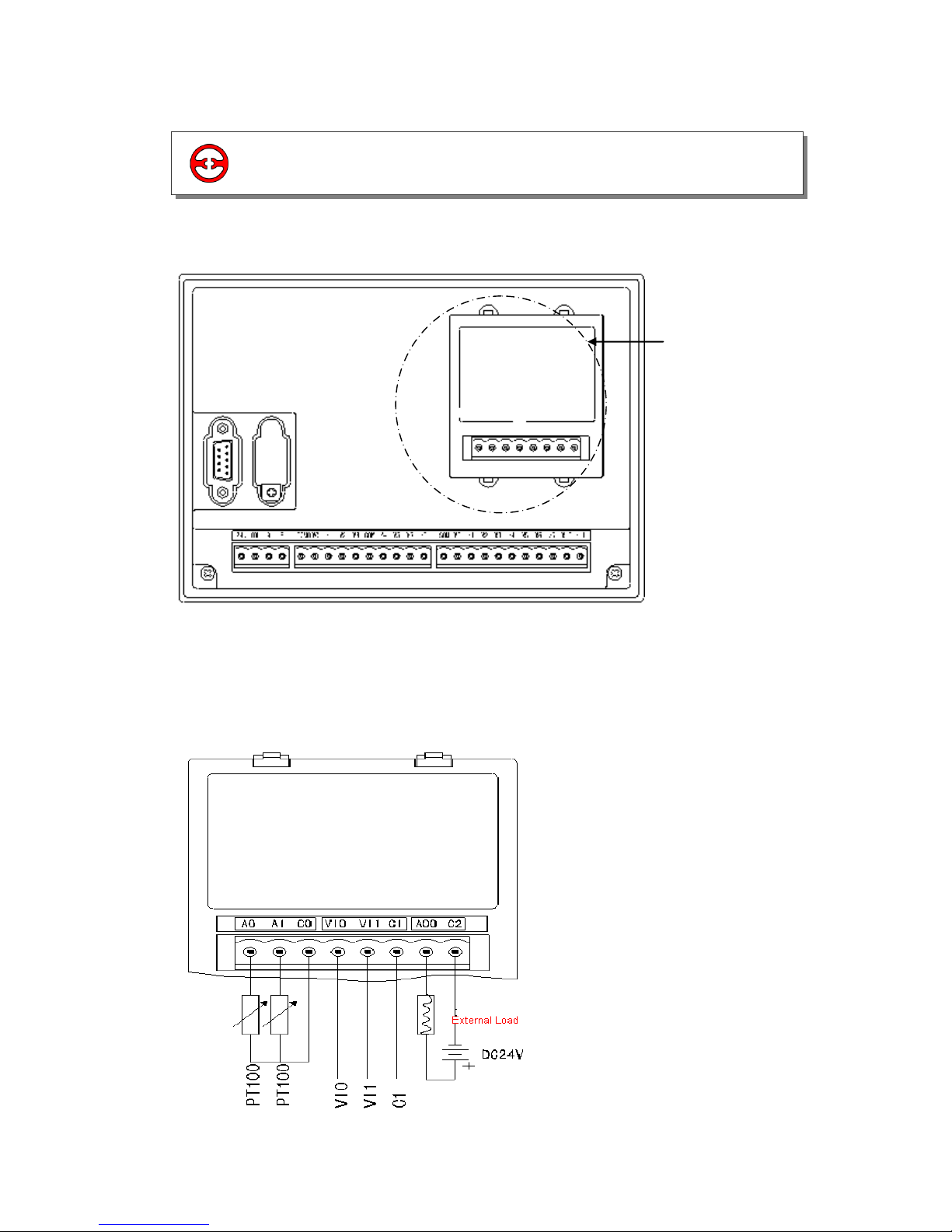

Board’s install

position

1. Installation method of the expansion board:

Open the board’s cover at the back of XP3 (As shown in the following graph), and then

install it according to the pin arrangement. Then fix it with screws, close the cover.

2. Connection format: As shown in the following graph:

Note:

Module’s 0/20mA or 4/20mA output needs 24V power supplier from outside. According to

the QD value, the module adjusts the signal’s current. However, the model itself doesn’t

generate current.

4-3 Extension installations and connections

XP3-BD User Manual Page 25 of 30 MANUL008R2V1

This BD board does not use I/O units, the converted data will be sent directly into the PLC

register. The channel’s corresponding PLC register ID is:

Channel

0CH

1CH

2CH

3CH

AD signal/Temperature

value

ID1000

ID1001

ID1002

ID1003

PID output value

ID1004

ID1005

ID1006

ID1007

Set the target value

QD1001

QD1002

QD1003

QD1004

D/A Output Value

QD1000

Kp

QD1005

QD1009

Ki

QD1006

QD1010

Kd

QD1007

QD1011

Diff

QD1008

QD1012

Dead Band

--

QD1013

Start/Stop

Y1000

Y1001

Y1002

Y1003

Note:

1. Both 0CH and 1CH are PT input channels; 2CH and 3CH are AD input channels

2. Kp: proportion parameter

3. Ki: Integral parameter

4. Kd: Differential parameter

5. Diff: Control band

Control band

6. (Diff): Carry on PID control in the assigned band;

7. Start Signal (Y): Close PID control when Y is 0, open PID control when Y is 1

8. Dead Band (Dead Band): Compare the current PID output value with the preceding PID

output value. If their difference is less than the set Dead Band, the module will not use the

current

PID output value and will transfer the preceding PID output.

4-4 Assignment of input ID

XP3-BD User Manual Page 26 of 30 MANUL008R2V1

Register FD8306:

2) Output channel’s mode setting value is stored in register FD8307 (Low bit); its definition is

CH 1

CH 0

Bit7

Bit6

Bit5

Bit4

Bit3

Bit2

Bit1

Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

-

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

-

CH 3

CH 2

Bit15

Bit14

Bit13

Bit12

Bit11

Bit10

Bit9

Bit8

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~10V

1:0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~10V

1:0~5V

4-5 Working mode settings

FD8306 H O O O O

0CH

1CH

2CH

3CH

1) Expansion’s input cards have voltage 0/5V,

0/10V these two modes and filter form to

select. Set via special FLASH data register

FD8306 in PLC. Refer to the graph by the

right; each register set the 4 channels’ modes,

each register has 16 bits. From low bit to high

bit, each 4 bits set one channel’s mode

XP3-BD User Manual Page 27 of 30 MANUL008R2V1

shown below:

Register FD8307:

P

a

r

a

m

e

t

e

r

D

i

s

Parameter D is the differential parameter.

Temperature control proportion band: in the assigned band, and will carry on PID

control.

-

D/A channel

Bit7

Bit6

Bit5

Bit4

Bit3

Bit2

Bit1

Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

-

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~20m

A

1:4~20m

A

-

-

Bit15

Bit14

Bit13

Bit12

Bit11

Bit10

Bit9

Bit8

-

- - -

-

-

XP3-BD User Manual Page 28 of 30 MANUL008R2V1

1. Usage of Four Parameters: Proportion parameter (Kp), integral parameter (Ki), differential

parameter (Kd), control proportion band (Diff).

Parameter P is the proportion parameter.

Parameter I is the integral parameter, mainly used to remove net difference.

Parameter D is the differential parameter, mainly used to control signal’s change trend.

Temperature Control Band Means: in the assigned band, to carry out PID control, beyond the

band does not carry out PID control.

2. Temperature Control Cycle: When carrying out PID adjustment, the output will carry on

heating according to the duty cycle got by PID output value, this period is called Temperature

Control Cycle

3. Control Specialties: The band of the PID adjustment is: (QD-Diff QD + Diff), when the

temperature is lower than QD-Diff, controller goes on heating, when temperature is higher than

QD + Diff, the controller will stop heating.

The Control Curve of PID is Shown Below:

Each parameter’s reference value: Kp=20/100, Ki=5/20, Kd=200/500. DIFF=100~200

This reference value only for normal condition,according to the locale detail condition, each

reference value could be beyond the band.

4-6 Control specialities

XP3-BD User Manual Page 29 of 30 MANUL008R2V1

The following example is a sample Program & corresponding description:

MOV ID1000 D0

MOV K5 QD1010

M8000

END

MOV ID1001 D2

MOV ID1002 QD1004

MOV ID1003 D4

MOV K30 QD1009

MOV K500 QD1011

Y1003

M8

MOV K150 QD1012

MOV K200 QD1013

MOV ID1007 D10

M8000

DIV D10 D12K4

MOV D12 QD1000

4-7 Programs

Write channel 0 (input temperature) into D0

Write channel 1 (output temperature) into D2

Treat CH2 (Pressure setting 0/10V) as the

set value in CH3

Write CH3 (Pressure Feedback) into D4

Set AD Channel’s Kp as 30

Set AD Channel’s Ki as 5

Set AD Channel’s Kd as 500

Set AD Channel’s Diff as 150

Set AD Channel’s Dead band as 200

Start/stop PID adjustment of CH3

Write PID output value of CH3 into D10

Change PID output range from 0/4095 as

0/1023

Convert PID output to be 0/10V output, to

control the inverter’s rotation speed

XP3-BD User Manual Page 30 of 30 MANUL008R2V1

Documentation Reference

Document Number

Revision Date

MANU

L008

R2

V1

05/07/2011

XINJE IS A REGISTERED TRADEMARK OF XINJE ELECTRICAL CO.LTD.

REPLICATION OF THE INFORMATION CONTAINED WITHIN THIS DOCUMENT

WITHOUT PRIOR NOTIFICATION AND AGREEMENT IS PROHIBITED.

Engineered and supplied by:

International partners with:

Web: www.listo-ltd.com

www.xinje-support-centre-listo.com

E-mail: support@listo-ltd.com

Please consider the environment before printing

this document

Loading...

Loading...