XP3-BD User Manual Page 2 of 30 MANUL008R2V1

XP3-BD User Manual

Index Page

Chapter 1 Configuration of the BD-Board

1-1 Configuration 3

Chapter 2 AI and temperature sampling board XP3-2AD2PT-BD

2-1 General 5

2-2 Specs 6

2-3 External installations and connections 7

3-4 Assignment of input ID 8

2-5 Working Mode settings 9

2-6 Control settings 10

2-7 Application of PID output value 10

2-8 Programs 11

Chapter 3 K type thermo coupling temperature PID board XP3-2TC-P-3D

3-1 General 13

3-2 Specs 14

3-3 External installations and connections 15

3-4 Assignment of input ID 17

3-5 Working Mode settings 18

3-6 Control Speciality 19

3-7 Programs 20

Chapter 4 Analogue AI/AO temperature sampling board XP3-2PT2ADIDA-

BD

4-1 General 21

4-2 Specs 22

4-3 External installations and connections 23

4-4 Assignment of input ID 24

4-5 Working Mode settings 25

4-6 Control Speciality 26

4-7 Programs 27

XP3-BD User Manual Page 3 of 30 MANUL008R2V1

1 Configuration of the BD-Board

1. Install BD correctly on the main unit;

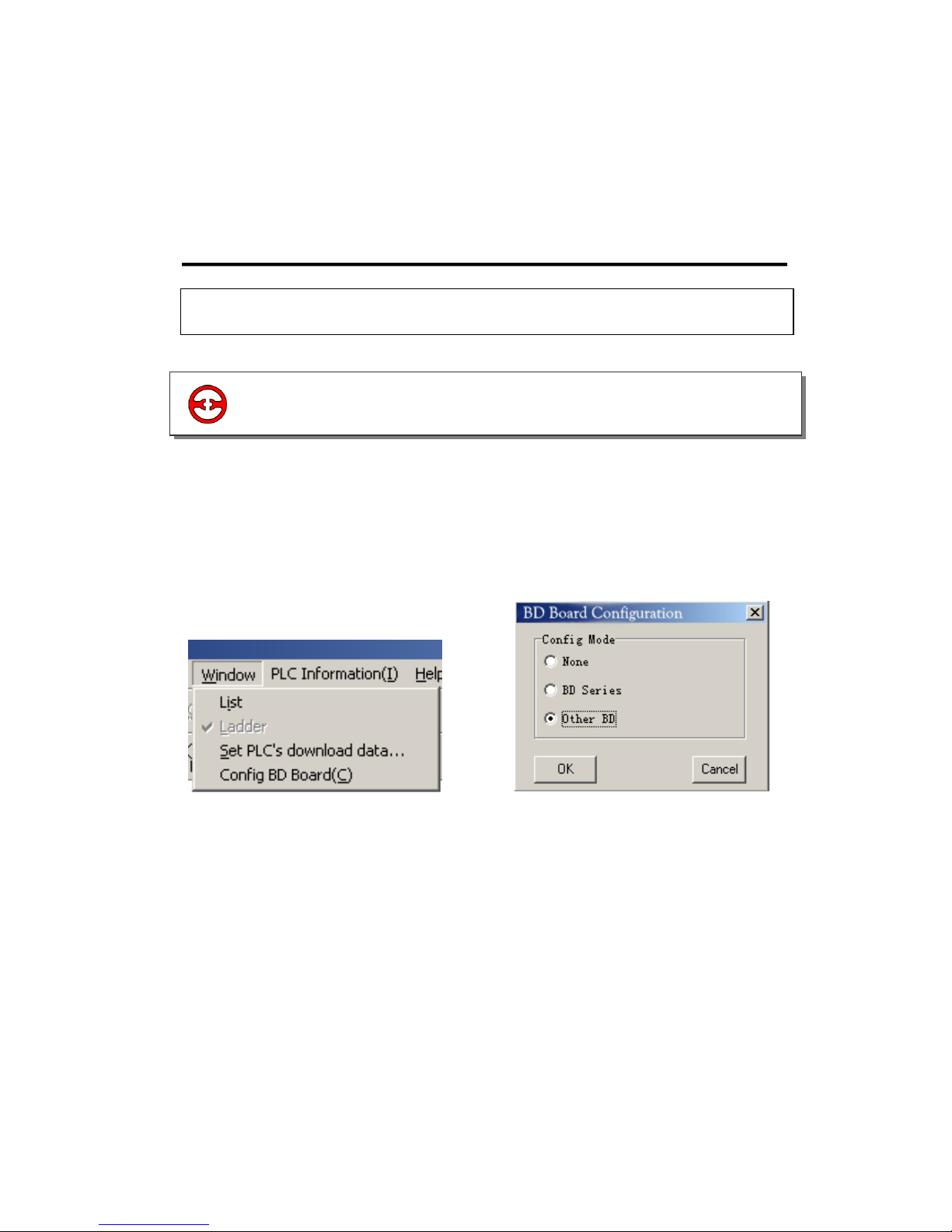

2. Then connect the model online via XCP edit tool, in the “Window” menu, choose “Config

BD Board(C)” (Image 1).

3. Click it, in the “Config BD Board(C)” dialog box, choose “Other BD” (Just as shown in graph

and click “OK” to download the program.

Image 1 Image 2

1-1 Configuration

1-1.Configuration

XP3-BD User Manual Page 4 of 30 MANUL008R2V1

2 AI and temperature sampling board XP3-

2AD2PT-BD

2-2.Specs

2-3.External installations and connections

2-1.General

2-5.Working Mode settings

2-6.Control settings

2-4.Assignment of input ID

2-7.Application of PID output value

XP3-BD User Manual Page 5 of 30 MANUL008R2V1

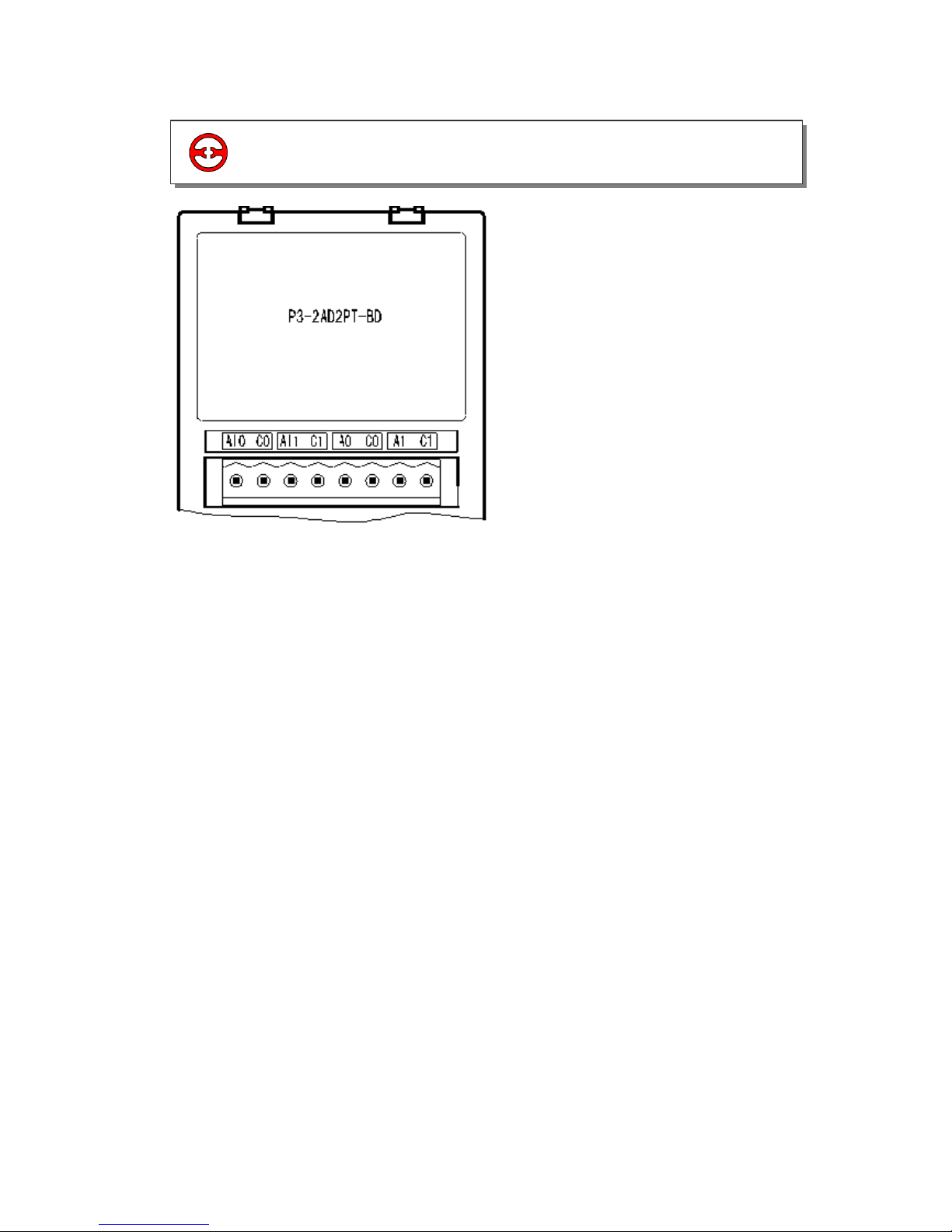

2-1 General

14 bits high precision analogue input.

2 Channel voltage 0/10V, 0/5V

(selectable) analogue input.

2 channels PT temperature testing.

resistor (PT100 two-wire format)

temperature sensor analogue input.

XP3-BD User Manual Page 6 of 30 MANUL008R2V1

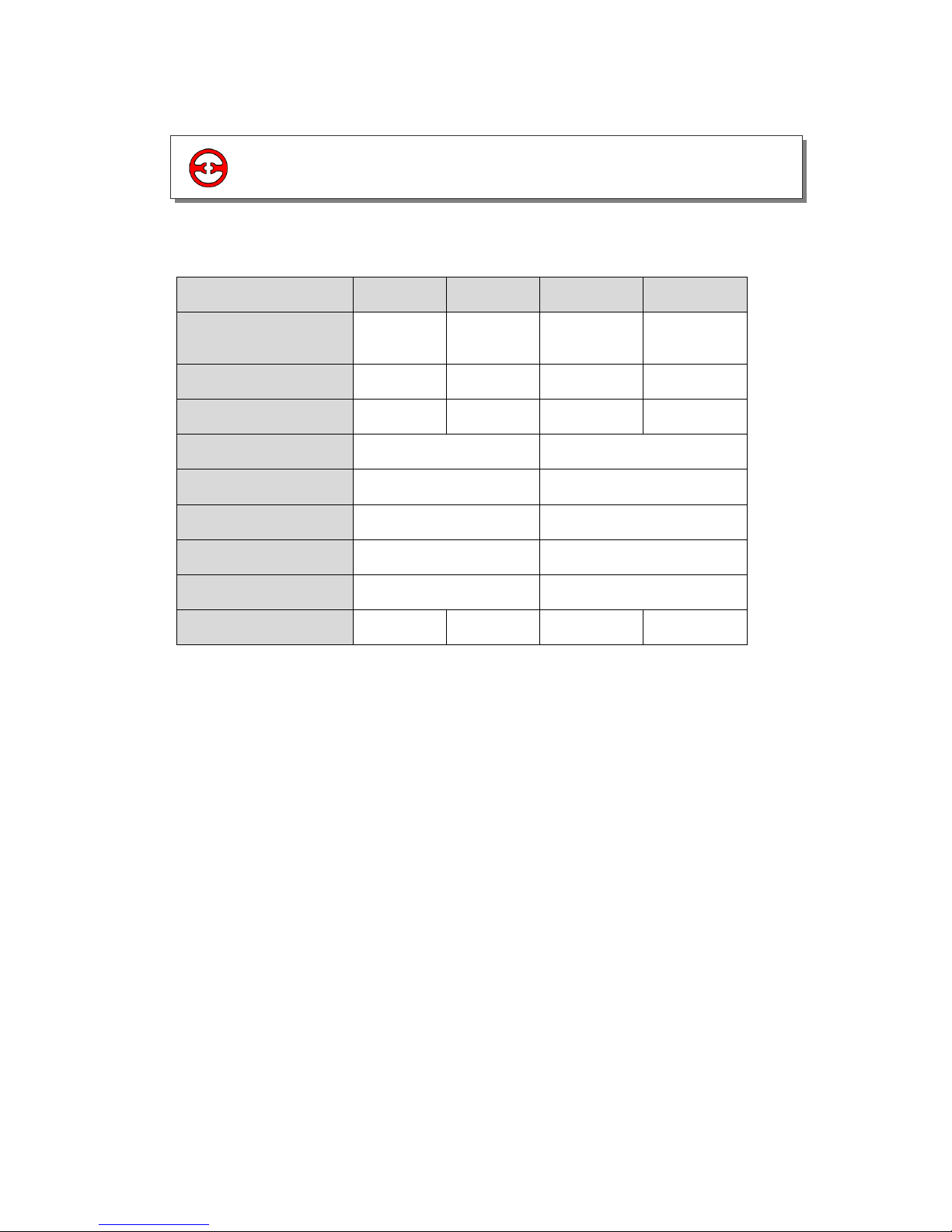

Item

Voltage Input

Temperature Input

Analogue Input

Signal

DC: 0 to 5V, 0 to 10V

(Input resistor 300kΩ)

Platinum Resistor PT100

(2-wire format)

Temperature

Testing band

-

-100 to 350 degrees C

Resolution

0.15mV 10/16383

0.1

Digital Output

band

0 to 16383

-1000 to 3500

Integrate

Precision

±0.8% of full scale

Convert Time

15ms × 4 channels

PID Output

Value

0 to K4095

Vacant

Defaulted

Value

0

3500

Input

Specialty

Isolation

No isolation between each channel of PLC

Used points

0 point (As operated via data register, so the used points are not limited

by PLC’s max control points)

2-2 Specs

XP3-BD User Manual Page 7 of 30 MANUL008R2V1

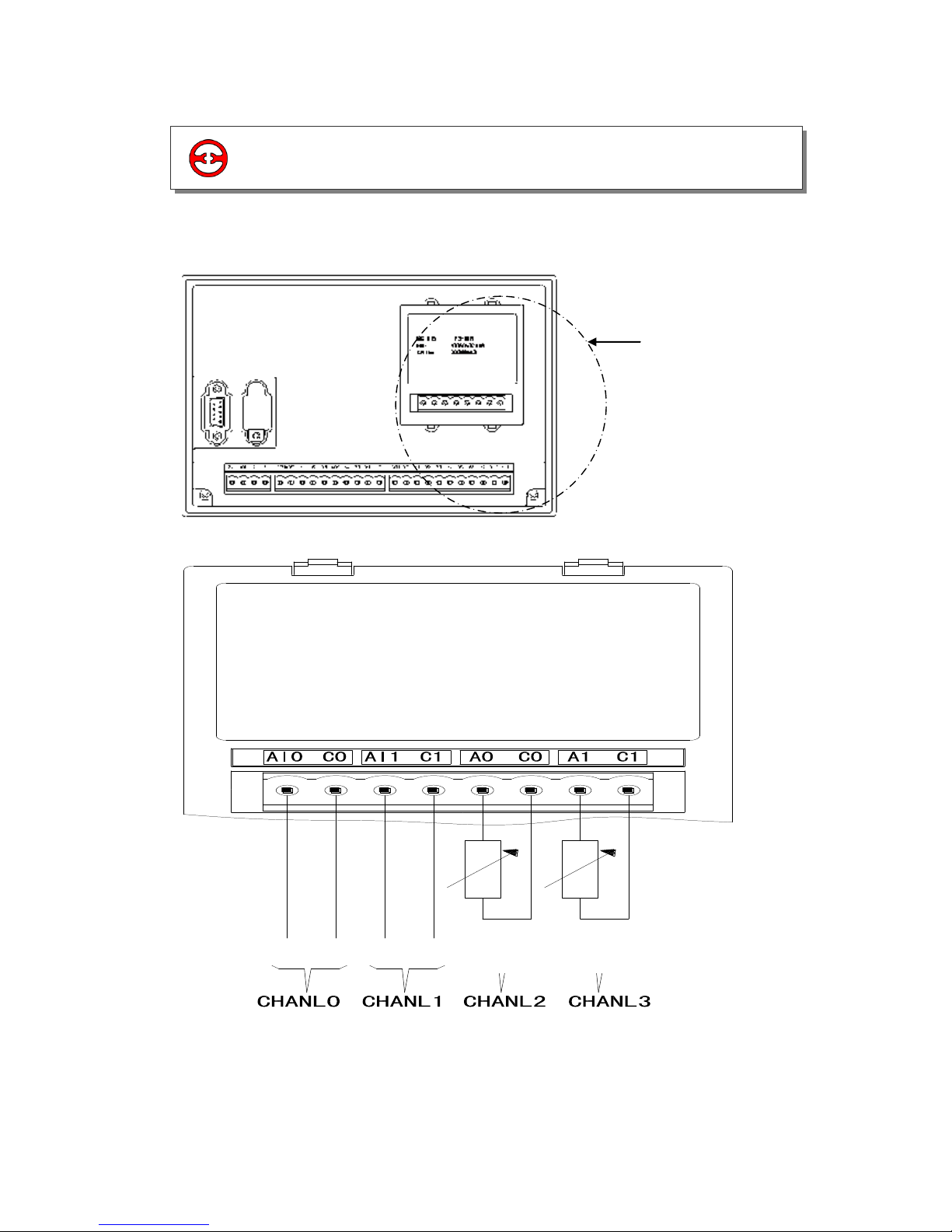

Board’s install

position

1) The Installation of Board:

Open the board’s cover at the back of XP3 (As shown in the following image); install it according

to the pin arrangement. Then fix it with screws, close the cover.

2) Connection: See the following diagram

PT100

PT100

V-

V+

V-

V+

2-3 External installations and connections

XP3-BD User Manual Page 8 of 30 MANUL008R2V1

This BD board does not use standard I/O units memory addresses, the converted data will be

directly sent into PLC register. The channels correspond to the PLC register ID:

Channel

0CH

1CH

2CH

3CH

AD signal/Temperature

value

ID1000

ID1001

ID1002

ID1003

PID output value

ID1004

ID1005

ID1006

ID1007

Set the target value

QD1000

QD1001

QD1002

QD1003

Kp

QD1004

QD1009

Ki

QD1005

QD1010

Kd

QD1006

QD1011

Diff

QD1007

QD1012

Dead Band

QD1008

-

Start/Stop

Y1000

Y1001

Y1002

Y1003

Note:

1. PID value: PID output value:0 to 4095.

2. Kp: proportion parameter

3. Ki: Integral parameter.

4. Kd: Differential parameter.

5. Diff: Control proportion band.

6. Control coil’s status: Y1000/Y1001 (0 = means stop PID control, 1 = means run PID control

Description:

0CH and 1CH are AD input channels.

2CH and 3CH are PT100 input channels.

Kp: proportion parameter.

Ki: Integral parameter.

Kd: Differential parameter.

Diff: Control band.

Control Band Diff: Carry on PID control in the assigned band, beyond the band, don’t carry

on PID control

Start Signal (Y): PID control is closed when Y is 0, open PID control when Y is 1.

Dead Band “Dead Band”: Compare the current PID output value with the preceding PID

output value. If their difference is less than the set Dead Band, the module will abandon the

current PID output value; still transferring the preceding PID output value to PLC main unit.

2-4 Assignment of input ID

XP3-BD User Manual Page 9 of 30 MANUL008R2V1

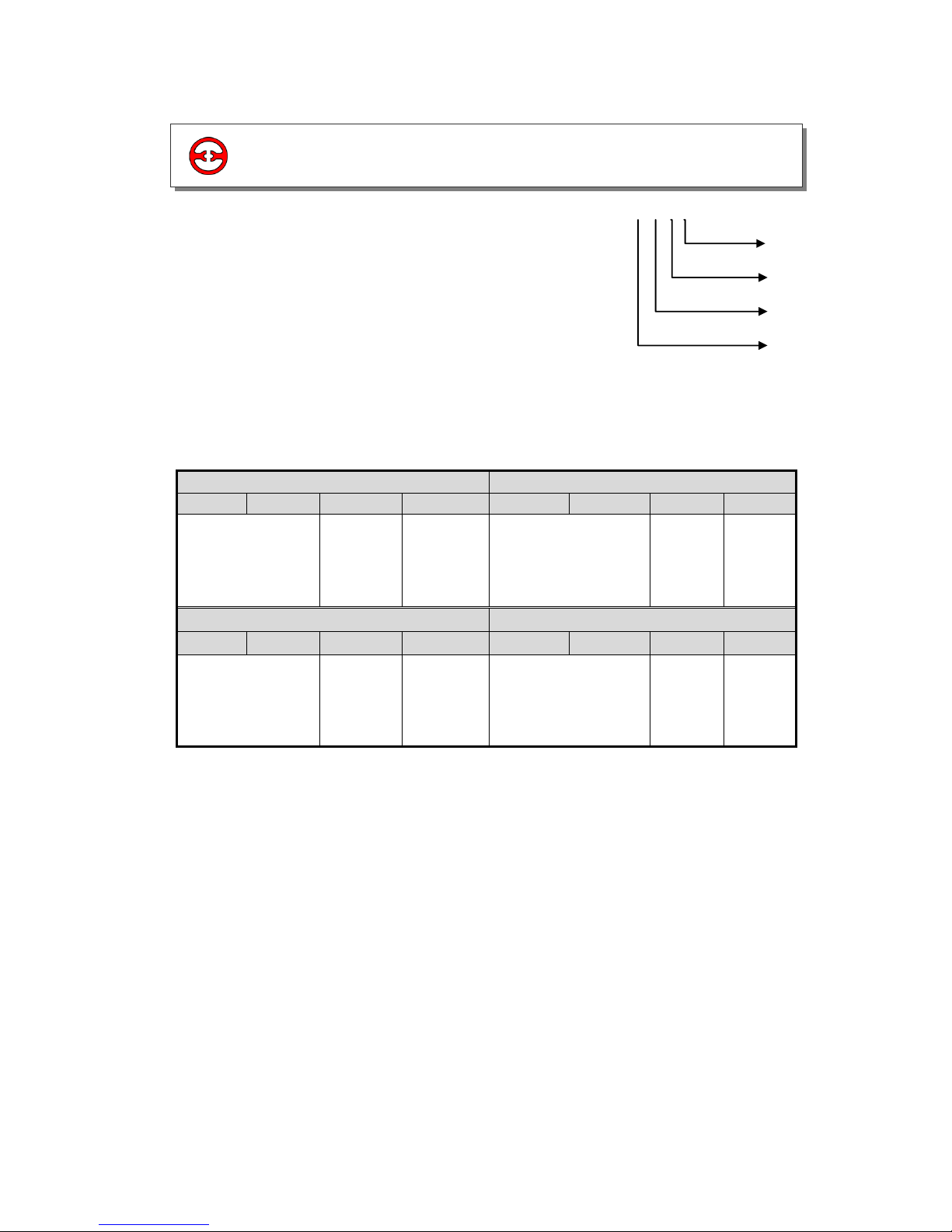

2) Each channel’s working mode is assigned by the four bits of the corresponding register, each

bits definition is shown below:

Register FD8306:

1. Usage of four parameters: Proportion parameter (Kp), integral parameter (Ki), differential

parameter (Kd), control proportion band (Diff).

2. Parameter P is proportion parameter, mainly reflect system’s wrap, when system wrap

appears, carry on control immediately to decrease the wrap.

3. Parameter I is integral parameter, mainly used to remove net difference, improve the systems

no-difference degree

4. Parameter D is differential parameter; mainly used to control the signal’s change trend,

decrease system’s shake.

5. Temperature control proportion band means: in the assigned band, carry on PID control,

beyond the band, do not carry on PID control.

CH1

CH 0

Bit7

Bit6

Bit5

Bit4

Bit3

Bit2

Bit1

Bit0

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0~10V

1:0~5V

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

0:0/10V

1:0/5V

CH3

CH 2

Bit15

Bit14

Bit13

Bit12

Bit11

Bit10

Bit9

Bit8

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

-

00: 1/2 filter

01: not filter

10: 1/3 filter

11: 1/4 filter

-

-

2-5 Working Mode settings

1) Expansion’s input has voltage 0/5V and 0/10V. These

two modes and filter form to select. Set via special

FLASH data register FD8306 in PLC.

Refer to the graph (right) each register set the 4

channels’ modes, each register has 16 bits. From low bit

to high bit, each 4 bits set one channel mode.

FD8306 H O O O O

0CH

1CH

2CH

3CH

Loading...

Loading...