Xinje VB3, VB5, V5 User Manual

Xinje Electronic Co.,Ltd.

VB3/VB5/V5 frequency inverter

User manual

No. INV C 01 20081130 204

VB3/VB5/V5 seires inverter

2

VB3/VB5/V5

Series Inverter

User Manual

Table of Contents

Preface

———————————————

Safty Precautions

———————————————

Product Introductions

———————————————

Installation and Wiring

———————————————

Operation Descriptions

———————————————

Function Parameters

———————————————

Fault Diagnosis and Disposal

———————————————

Maintenance

———————————————

Communication Protocol

———————————————

VB3/VB5/V5 series inverter

This manual includes the basic caution items that you should obey to ensure your personal safety, as well as to protect the

product and the connected equipments. These items are highlighted in the manual by a warning triangle. Please comply

with the essential electric operation `rules that are not indicated in this manual.

Please comply with these items, incorrect operation may cause the system error working even abnormal.

More serious would cause possession loss.

The device and its components can only be used in the applications described in the catalog and the

technical manuals, can only be connected with devices or components from other manufacturers which

have been approved or recommended by Xinje.

The products will run normally in the condition of been transported, stored, configured and installed

correctly, been operated and maintained as recommended.

Xinje Electronic Co., Ltd. Copyright reserved

Without written authority, please do not copy, transfer or use this document and its content. Anyone who disobeys this

should take responsibility for the loss.

Obligation Declare

We have checked and confirmed that the contents in this manual were compatible with the hardware and software described. Since mistakes are hard to avoid, we cannot promise total accordant. This manual is subject to change without notices.

2010.01

Correct Applications

Installing Precautions

VB3/VB5/V5 series inverter

i

CATALOG

PREFACE .......................................................................................................................................1

SAFETY PRECAUTIONS ...............................................................................................................2

1 PRODUCT INSTRUCTION ..........................................................................................................6

1-1. Product overview .............................................................................................................................................................. 6

1-2. Product technical specification ......................................................................................................................................... 7

1-3. Product appearance .......................................................................................................................................................... 9

1-4. Product dimension .......................................................................................................................................................... 12

2 INSTALLATION AND WIRING ..................................................................................................15

2-1. Installation environment ................................................................................................................................................ 15

2-1-1. Environment requirement .......................................................................................................................................... 15

2-1-2. Mounting location and space ..................................................................................................................................... 15

2-1-3. Mounting and removing............................................................................................................................................. 15

2-2. Wiring ............................................................................................................................................................................. 16

2-3. Wiring of main circuit terminals .................................................................................................................................... 16

2-3-1. Wiring diagram ......................................................................................................................................................... 16

2-3-2. Terminal assignment and description .......................................................................................................................... 17

2-4. Basic running wiring ...................................................................................................................................................... 18

2-5. Setting and wiring of control circuit ............................................................................................................................... 18

2-5-1.Position and function of terminals and jumpers on control panel .................................................................................. 18

2-5-2.Terminals on control panel .......................................................................................................................................... 20

2-5-3. Analog I/O terminal wiring ........................................................................................................................................ 22

2-5-4. Connection of communication terminals .................................................................................................................... 23

2-6. Mounting guide according with EMC ............................................................................................................................ 24

2-6-1. Control the noise ....................................................................................................................................................... 24

2-6-2. Local wiring and grounding ....................................................................................................................................... 25

3 OPERATING INSTRUCTIONS ..................................................................................................26

3-1. Run the inverter.............................................................................................................................................................. 26

3-1-1. Command channel of inverter .................................................................................................................................... 26

3-1-2. Frequency setting channel .......................................................................................................................................... 26

3-1-3. Running state ............................................................................................................................................................ 26

3-1-4. Running modes ......................................................................................................................................................... 27

3-2. Use the keyboard ............................................................................................................................................................ 28

VB3/VB5/V5 seires inverter

ii

3-2-1. Keyboard layout ........................................................................................................................................................ 28

3-2-2. Keyboard function ..................................................................................................................................................... 28

3-2-3. Fucntion description of LED and indicator ................................................................................................................. 29

3-2-4. Display of the operation panel.................................................................................................................................... 29

3-2-5. Panel operation method ............................................................................................................................................. 31

3-3. Power on the inverter ..................................................................................................................................................... 33

3-3-1. Checking after power on ............................................................................................................................................ 33

3-3-2. Power on the inverter for the first time ....................................................................................................................... 33

4 FUNCTION PARAMETERS .......................................................................................................35

4-1. Function code .................................................................................................................................................................. 35

4-2. Function code description ............................................................................................................................................... 51

4-2-1. Basic operating function parameters (Group P0) ........................................................................................................ 51

4-2-2. Parameters of frequency setting (Group P1) ............................................................................................................... 56

4-2-3. Starting and braking parameters (Group P2) ............................................................................................................... 57

4-2-4. Auxiliary running parameters (Group P3) ................................................................................................................... 59

4-2-5. Function parameters of terminal (Group P4)............................................................................................................... 64

4-2-6. Protection function parameters (Group P5)................................................................................................................. 73

4-2-7. Fault recording parameters (Group P6) ...................................................................................................................... 75

4-2-8. Close-loop control parameters (Group P7) ................................................................................................................. 75

4-2-9. Simple PLC operation parameters (Group P8) ............................................................................................................ 78

4-2-10. Swing frequency function parameters (Group P9) .................................................................................................... 81

4-2-11. Vector control parameters (Group PA) ...................................................................................................................... 83

4-2-12. Special application function parameters (Group PB) ................................................................................................. 84

4-2-13. Default setting and password (Group PF) ................................................................................................................. 85

5 FAULT DIAGNOSIS AND SOLUTION.......................................................................................86

5-1. Fault diagnosis and solution ........................................................................................................................................... 86

5-2. Check the fault records ................................................................................................................................................... 88

5-3. Fault reset ....................................................................................................................................................................... 88

6 MAINTENANCE ........................................................................................................................89

6-1. Maintenance ................................................................................................................................................................... 89

6-1-1. Routine maintenance ................................................................................................................................................. 89

6-2. Periodical care and maintenance .................................................................................................................................... 89

6-2-1.Periodical care ............................................................................................................................................................ 89

6-2-2. Periodical maintenance .............................................................................................................................................. 89

6-3. Warranty of the inverter................................................................................................................................................. 90

7 COMMUNICATION PROTOCOL ...............................................................................................91

7-1. Overview of communication protocol............................................................................................................................. 91

VB3/VB5/V5 series inverter

iii

7-2. Communication protocal ................................................................................................................................................ 91

7-2-1. Communication networking mode ............................................................................................................................. 91

7-2-2. Communication protocol modes................................................................................................................................. 92

7-2-3. Communication port .................................................................................................................................................. 92

7-3.Modbus-RTU communication protocol ........................................................................................................................... 92

7-3-1. Character structure .................................................................................................................................................... 92

7-3-2. Communication information ...................................................................................................................................... 92

7-3-3.Communication parameter .......................................................................................................................................... 95

APPENDIX A ACCESSORIES .....................................................................................................97

A-1. Brake resistor ................................................................................................................................................................. 97

A-2. Operate panel ................................................................................................................................................................. 98

A-3. Extension cable of operate panel ................................................................................................................................... 98

APPENDIX B FUNCTION CONFIGURATION LIST .....................................................................99

1

——Essential introduction for this manual

Preface

Thank you for purchasing Xinje inverter, this manual should be read and understood before attempting relevant operations.

1. Purpose of this manual

This manual offers guidance and introductions about how to use and maintains the inverter correctly, including functions,

usages, installation, maintenance, etc.

2. Qualified personnel

This manual is intent for the following personnel:

Inverter installation personnel

Project technical personnel(electric engineer, electrician)

Design personnel

The above personnel should read and understand this manual carefully before operating and debugging.

3. Validity of this manual

This manual may only be used for inverters made by Xinje.

4. Electronic Documents

In addition to our written manuals, we offer electronic documentations of our products by the following ways.

User CD

There are software, user manual and application tip of relevant products.

Website

Please visit www.xinje.com to obtain all variable electronic documents.

VB3/V5/VB5 series inverter

2

——Essential introduction about product operation

Safety Precautions

Upon unpacking, please confirm that: Check whether the model and the rated values on the nameplate of the inverter are in

accordance with your order. Check if there is any damage occurred during transportation; pleases contact us or the distributor if you find any missing or damage of the products.

In order to use this product correctly, the user who uses the product for the first time must read this manual carefully and

pay close attention to the safety precautions.

Please keep this manual properly, hand it to the terminal user and lay it on the place where the operators can read it easily.

Confirmations Upon Delivery

Notice

1. Never install an inverter that is damaged or missing components. Doing so can result in injury.

Installation

Notice

1. Always hold the bottom of the inverter when carrying it. If the inverter is held by the front cover, the main body

of the inverter may fall, possible resulting in injury.

2. Attach the inverter to metal or other noncombustible materials. Fire can result if the inverter is attached to a

combustible material.

3. Install a cooling fan or other cooling device when installing more than one inverter in the same enclosure so that

the temperature of the air entering the inverters is below 45℃. Overheating can result in fires or other accidents.

Wiring

Danger

1. Always turn off the input power supply before wiring. Otherwise, an electric shock or fire may occur.

2. Wiring must be operated by an authorized person qualified in electrical work. Otherwise, an electric shock or

fire may occur.

3. Make sure to ground the ground terminals. Otherwise, an electric shock or fire may occur.

4. Always check the operation of any emergency stop circuits after they are wired. Otherwise, possibly result in

injury ( user responsibility for the wiring).

5. Never touch the output terminal directly by your hands or let the output terminals to come into contact with the

inverter case. Never short the output terminals. Otherwise, an electric short or ground short may occur.

6. Never touch the internal circuit or the zero-component until power off and the charge indicator is off as

there may still be high voltage inside the AC motor dirver.

Notice

◎ Safty Precautions ◎

VB3/V5/VB5 series inverter

3

1. Confirm that the voltage of the main AC power supply satisfies the rated voltage of the Inverter. Injury and fire

may occur if the voltage is not right.

2. Do not perform voltage withstand tests on the Inverter. Otherwise, semiconductor elements and other devices

can be damaged.

3. Connect braking resistors, Braking Resistor Units, and Braking Units as shown in the I/O wiring examples.

Otherwise, a fire may occur.

4. Tighten all terminal screws to the specified tightening torque.

Otherwise, a fire may occur.

5. Do not connect AC power to output terminals U, V, and W.

The interior parts of the Inverter will be damaged if voltage is applied to the output terminals.

6. Do not connect phase-advancing capacitors or LC/RC noise filters to the output circuits.The Inverter may be

damaged or internal parts burnt if these devices are connected.

7. Do not connect electromagnetism switch, electromagnetism contactor to output circuit. When the inverter is

running with load, the electromagnetism switch and electromagnetism contactor will generate inrush current

which will cause inverter’s over current protection.

8. Do not disassemble the whole front cover as disassembling the top front while wiring is ok. Otherwise, inverter

internal parts may be damaged.

Maintenance and Inspection

Danger

1. Do not touch the inverter terminals, as they may carry high voltage.

Otherwise, an electric short may occur.

2. Make sure to have protective cover .Always have the protective cover in place when power is being supplied to

the Inverter. When attaching the cover, please with the power turns off.

Otherwise, an electric short may occur.

3. Maintenance, inspection, must be performed only by authorized personnel.

Otherwise, an electric short may occur.

Notice

1. A CMOS IC is used in the control board. Handle the control board and CMOS IC carefully. The CMOS IC can

be destroyed by static electricity if touched directly.

2.Do not change the wiring, or remove connectors or the Digital Operator, during operation.

Otherwise, The devices may be damaged.

Constant torque low speed running

When the inverter outputs to a common motor at low speed for a long term, the output rated torque should be derated due

to the worsening radiating effect. If low speed constant torque long term running is required, then a special variable frequency motor is needed.

Motor insulation

When using the V5/F5 series inverter, make sure to confirm the insulation of the motor which will be used to avoid device

damage. Besides, do the periodic check for the insulation condition of the motor located in the bad environment to guarantee the system can operate safely.

Negative torque load

If in the case of improving load, negative torque may occur. Braking units should be connected with the inverter, or over

current and over voltage fault may happen.

◎ Usage Precautions ◎

VB3/V5/VB5 series inverter

4

Mechanical resonance point of load

The inverter may encounter the mechanical resonance point of load within certain output frequency range. Jump frequencies have to be set to avoid it.

Capacitor and resistor

Because the inverter output pulse wave, capacitor and resistors shouldn't be connected with the output terminals of the inverter, or the inverter may trip or components may be damaged; Besides, don’t connect switch components such as air

switch and contactor with the output terminals is recommended, as shown in Fig.0-1(If switch components need to be

connected with the output terminals, make sure output current of the inverter is zero when switch is acting).

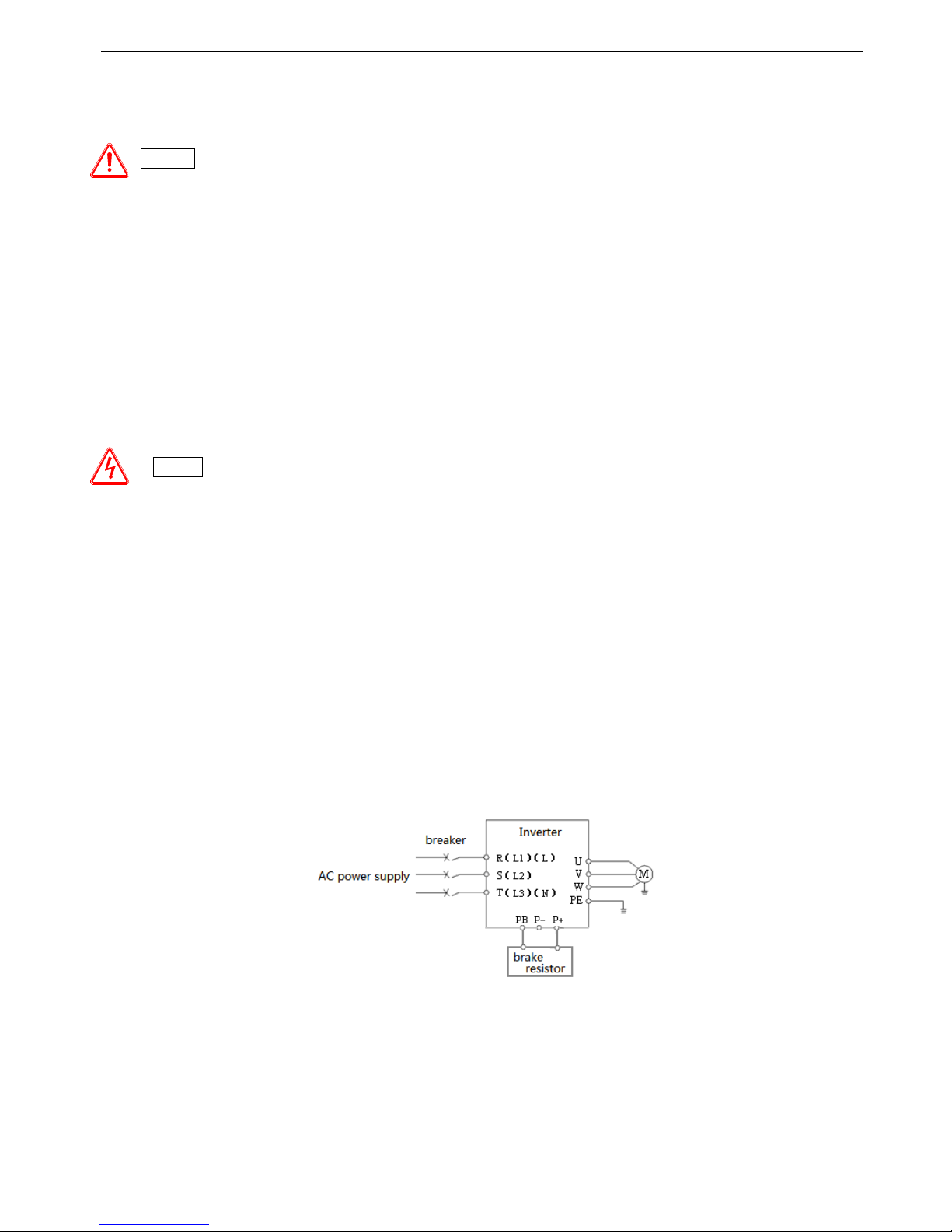

Fig.0-1 Capacitor is prohibited to be connected with

output terminals of inverter

Derate according to basic frequency setting

When the basic frequency is lower than the reference frequency, please consider duration for the motor so as to avoid motor’s damage caused by overheating.

Running at frequency above 50Hz

If running at frequency above 50Hz, besides the increment of vibration and noise, the ranges of running speed of motor

shaft and mechanical device have to be guaranteed. Be sure to make an enquiry first.

The electro-thermal protective value of motor

If the applicable motor is selected as per requirements, the inverter can perform the thermal protection to the motor. If the

ratings of applied motor are not in compliance with the inverter, be sure to adjust the protective value or adopt other protective measures to guarantee the safe running of motor.

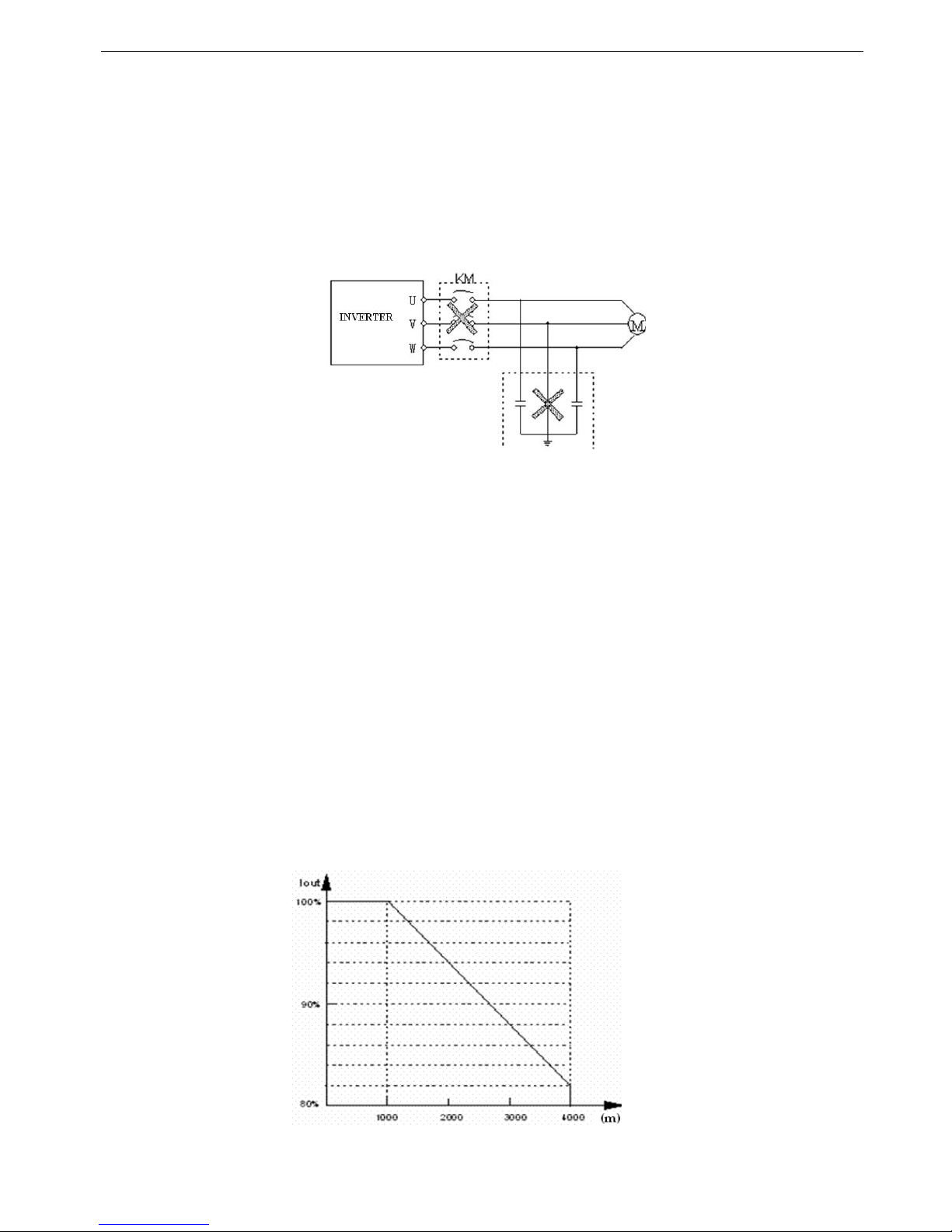

Altitude and derate

When the altitude is higher than 1000m, the cooling effect of inverter is deteriorated because of the rareness of air, deration

must be considered, shown in Fig.0-2 which indicates the relationship between the altitude and rated current of frequency

inverter.

Fig. 0-2 The relationship between the altitude and rated

current of frequency inverter

VB3/V5/VB5 series inverter

5

About protection classes

The protection class of V5/F5 series inverter IP20 is reached in the case of status display unit or keyboard.

When you scrap the inverter, please pay attention to:

Explosion risk of capacitor: The capacitors in the main circuits may explode when they are burned.

Waste gas when plastic parts are burned: Poisonous gas may be generated when front panel is burned.

Dispose method: Please dispose as industrial rubbish.

◎ Note For Scrap ◎

VB3/V5/VB5 series inverter

6

1 Product Instruction

1-1. Product overview

VB3/VB5/V5 series inverter is produced by Xinje Co., Ltd with high performance, easy operating and low noise. It is a

innovative product with a series advanced and practical running and control functions such as practical PI, flexible input

and output terminals, parameter modification online, fixed length control, traverse operation, RS485 control, bus-mastering.

It provides OEM customers with high integrated, reliable, cost-effective solution.

V5 only has 380V level types; VB3/VB5 series frequency inverter has 220V and 380V voltage levels. Suitable motor capability is from 0.4KW to 55KW.

Please note 220V level types have no vector control.

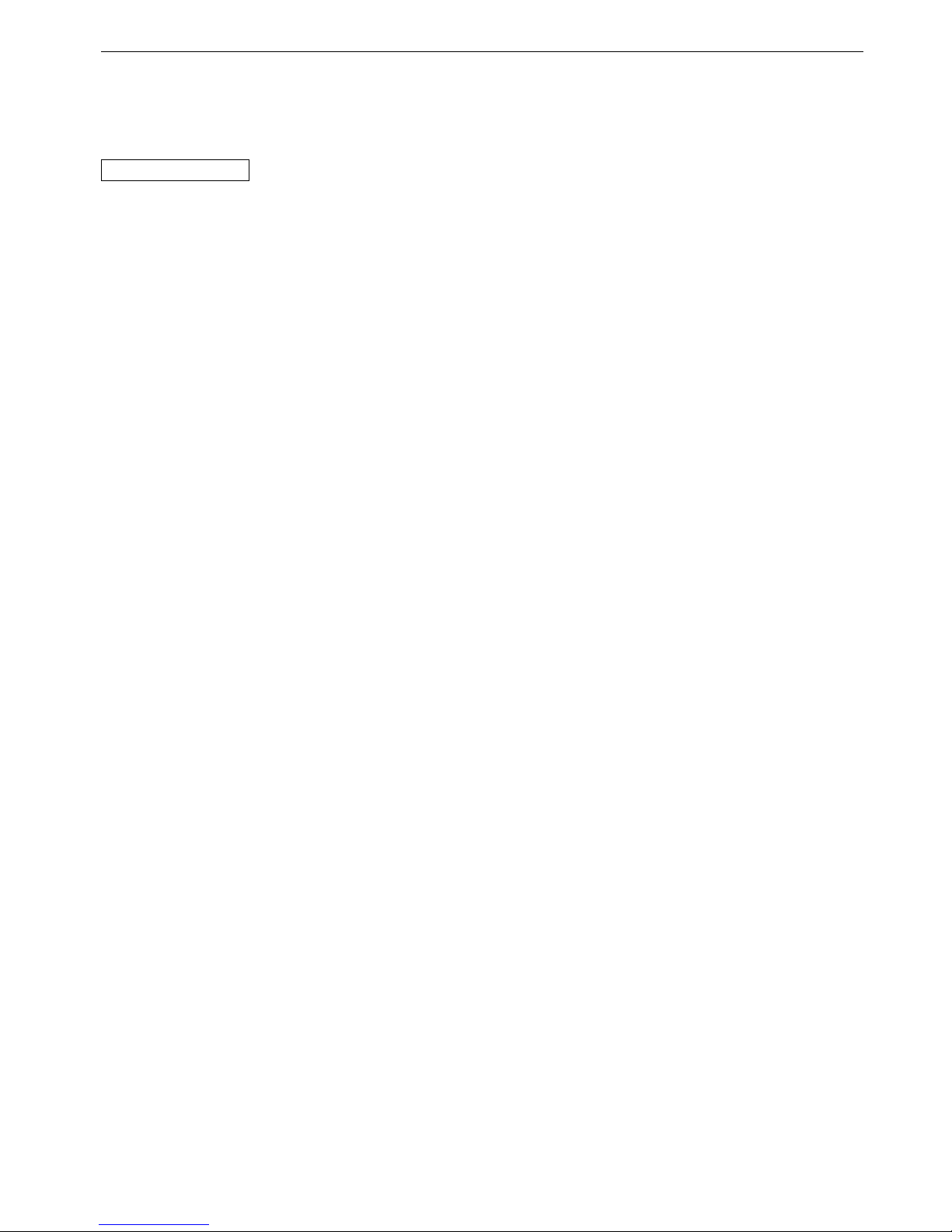

Voltage level Type Rated capacity (KVA) Rated output current (A) Match motor (kW)

220V

Single-phase

VB3-20P7 1.5 4.7 0.75

VB5-20P7 1.5 4.7 0.75

VB5-21P5 2.8 7.5 1.5

VB5-22P2 4.5 10.0 2.2

380V

3-phase

VB3-40P7 2.1 2.5 0.75

VB3-41P5 2.5 4.0 1.5

VB3-42P2 3.0 6.0 2.2

VB3-43P7 5.9 9.6 3.7

VB5-40P7 2.1 2.5 0.75

VB5-41P5 2.5 4.5 1.5

VB5-42P2 3.0 6.0 2.2

VB5-43P7 5.9 9.6 3.7

VB5-45P5

8.5 14.0 5.5

VB5-47P5 11 17.0 7.5

V5-4011 15 25 11

V5-4015 20 33 15

V5-4018 25 38 18.5

Name Designation Rules

VB 5

-

4 3 P 7

Max Suitable Motor's Capacity

011: 11KW

1P5: 1.5KW

And so on

( P: Stands for radix Point)

Voltage Level

2:220V

4:380V

Type

Inverter Series

V5: VVVF/vector control

VB5: VVVF/vector control

VB3: VVVF control, mini type

VB3/V5/VB5 series inverter

7

1-2. Product technical specification

1. Technical specification

220V

Type VB3-20P4 VB3-20P7 VB5-20P7 VB5-21P5 VB5-22P2

Output Match Motor (kW) 0.4 0.75 0.75 1.5 2.2

Output Current (A) 3.0 4.7 4.7 7.5 10.0

Voltage (V) AC 200

Frequency Range (Hz) 0~500

Frequency Resolution (Hz) 0.01

Overload Ability 150%Rated Current for 1 minutes,180% Rated Current for 1 second

Input Rated Voltage/Frequency Single-phase 220V,50/60Hz

AC voltage permit fluctuate range Voltage: -20% ~ +20%

Voltage Unbalance Rate: < 3%

Frequency fluctuate Range Frequency:±5%

Power Capacity (kVA) 0.9 1.5 1.5 2.8 4.5

380V

V5-4022 30 46 22

V5-4030 40 60 30

V5-4037 50 75 37

V5-4045 60 90 45

V5-4055 75 110 55

VB3-4_ _ _ 0P7 1P5 2P2 3P7

output

Suitable motor (kW) 0.75 1.5 2.2 3.7

Rated current (A) 2.5 4.0 6.0 9.6

Rated voltage ( V) AC 380

frequency range (Hz) 0~500

frequency accuracy (Hz) 0.01

Overload Ability 150% Rated Current for 1 minute, 180% Rated Current for 1 second

Input

Rated voltage

/Frequency

Three phase 380V; 50Hz/60Hz

AC voltage fluctuate range Voltage:-20% ~ +20%

Voltage Unbalance Rate:<3%

Frequency fluctuate range

Frequency: ±5%

Power Capacity (kVA) 2.1 2.5 3.0 5.9

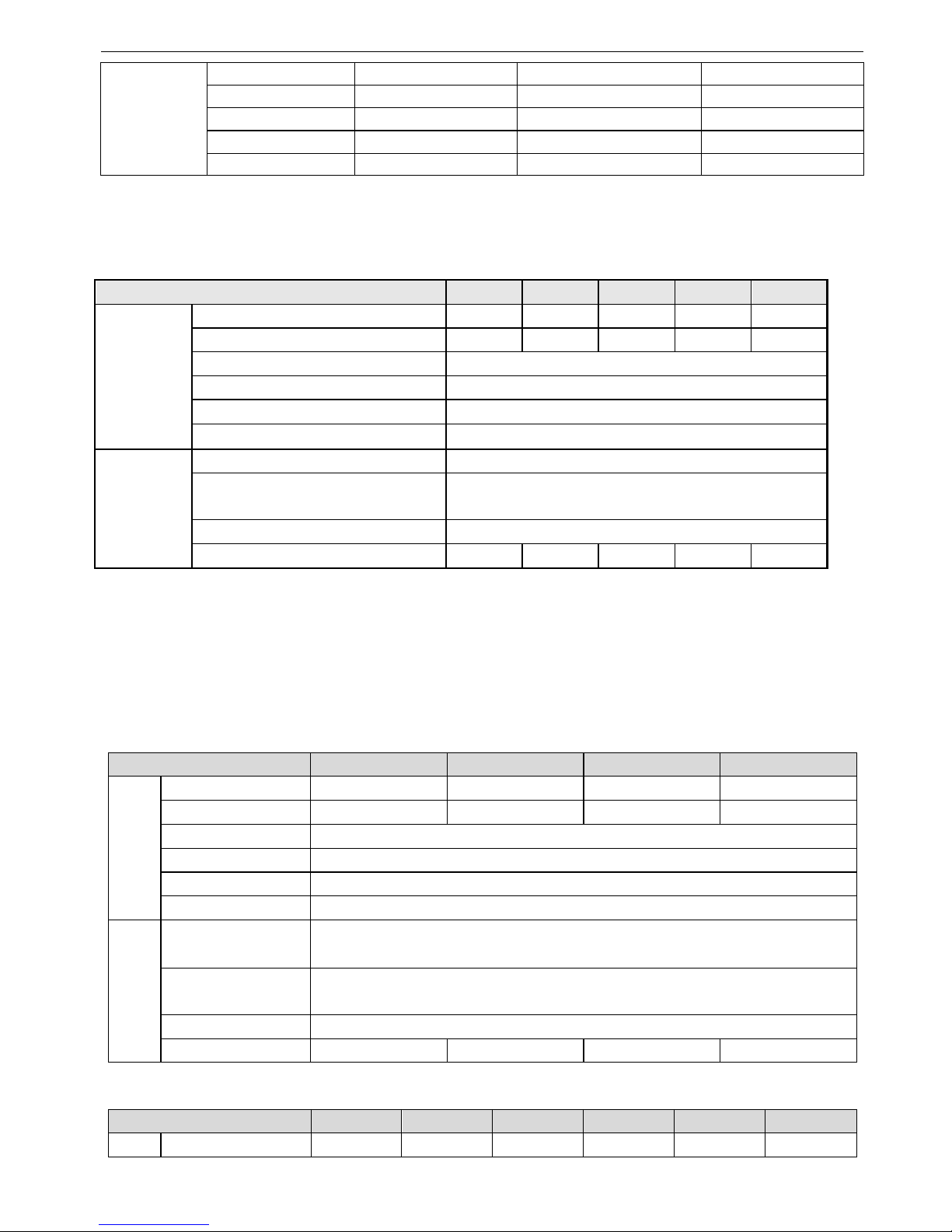

VB5-4_ _ _ 0P7 1P5 2P2 3P7 5P5 7P5

Suitable motor (kW) 0.75 1.5 2.2 3.7 5.5 7.5

VB3/V5/VB5 series inverter

8

Common characteristics

Environment Application environment In-door, free from direct sunlight, dust, corrosive gas, oil mist, steam, water drop etc

Elevation Lower than 1000m (The inverter should be derated when the elevation is higher than

1000m )

Ambient Temperature -10

℃

~ +40℃

Humidity Less than 90% RH, No condensation

Vibration Less than 5.9 m/s2 (0.6M)

Storage Temperature -20

℃

~ +60℃

Structure Protect Configuration IP20 (In the state of state display units or keyboard)

Cooling Manner Fan cooling

Installation Wall mounted or install inside cabinet

2. General Specification

Modulation mode

Optimized space voltage vector SVPWM modulation

Control mode SVPWM control (dead zone compensation for optimized low-frequency)

Frequency precision

Digital Setting: max frequency × ±0. 01%;

Analog Setting: max frequency × ±0.2%

output Rated current (A) 2.5 4.0 6.0 9.6 14.0 17.0

Rated voltage ( V) AC 380

frequency range (Hz) 0~500

frequency accuracy (Hz) 0.01

Overload Ability 150% Rated Current for 1 minute, 180% Rated Current for 1 second

Input

Rated voltage

/Frequency

Three phase 380V; 50Hz/60Hz

AC voltage fluctuate range Voltage:-20% ~ +20%

Voltage Unbalance Rate:<3%

Frequency fluctuate range

Frequency: ±5%

Power Capacity (kVA) 2.1 2.5 3.0 5.9 8.5 11

V5-4_ _ _ 011 015 018 022 030 037 045 055

output

Suitable motor (kW) 11 15 18.5 22 30 37 45 55

Rated current (A) 25 33 38 46 60 75 90 110

Rated voltage ( V) AC 380

frequency range (Hz) 0~500

frequency accuracy (Hz) 0.01

Overload Ability 150% Rated Current for 1 minute, 180% Rated Current for 1 second

Input

Rated voltage

/Frequency

Three phase 380V; 50Hz/60Hz

AC voltage fluctuate range Voltage:-20% ~ +20%

Voltage Unbalance Rate:<3%

Frequency fluctuate range

Frequency: ±5%

Power Capacity (kVA) 15 20 25 30 40 50 60 75

VB3/V5/VB5 series inverter

9

Main Control

Function

Frequency resolution Digital Setting: 0.01Hz; Analog Setting: max frequency × 0.1%

Start frequency 0.40Hz ~ 20.00Hz

Torque boost Auto torque boost, manual torque boost 0.1% ~ 30.0%

V/F curve

Five modes: constant torque V/F curve, 1 V/F curve mode by user and 3 kinds of

torque-derating modes (2nd power, 1.7th power, 1.2nd power)

Accelerate/Decelerate curve

Two modes: linear Acc/Dec, S curve Acc/Dec; seven kinds of Acc/Dec time,

Maximum: 6000 minutes, the time unit (minute or second) is selectable

DC brake

Initial frequency of DC braking: 0~15.00Hz

Braking time: 0~60.0 s

Braking current: 0~80%

Power consumption brake Built-in brake unit, can connect external brake resistor

Jog Range of jog frequendy: 0.1Hz~50.00Hz, Acc/Dec time of jog 0.1~60.0s

Built-in PI Easy to form close loop control system

Multi-step speed running Multi-step speed work through built-in PLC or control terminals

Textile wobble frequency Adjustable preset frequency and center frequency

Auto voltage regulation

(AVR)

When the power system voltage changes, maintain the constant of output voltage

Auto energy saving running

Auto-optimize V/F curve according to the load condition to realize energy saving

operation

Auto current limit Auto-limit running current to avoid trip caused by overcurrent

Fix-length control The frequency inverter will stop running when reaching the fixed length

Communication

function

With RS485 port, support Modbus-RTU protocol. Be with master-slave mul-

ti-device linkage function

Operate function

Command channel

Operation panel setting;control terminals setting;serial port setting; three modes

are exchangeable

Frequency channel

Keyboard analog potentiometer setting; , keys setting;function code

digital setting; serial port setting;UP/DOWN terminal setting;analog voltage

setting;analog current setting; pulse setting;combination setting; different setting

modes can be switched

Digital input channel

Forward/Reverse running command;6 channels programmable digital input,can

set 35 kinds of function,X6 support 0~20KHz pulse input

Analog input channel 2 channels analog input , 4~20mA and 0~10V can be selected

Analog output channel

1 channel analog output: 0~10V/4~20mA, can output setting frequency, output

frequency

Digital/pulse output channel

1 channel programmable open-collector output; 1 channel relay output; 1 channel

0~20KHz pulse output

Operation panel

LED Display Can display setting frequency, output voltage, output current and other parameters

External meter Display

Display output frequency, output current, output voltage and other physical quan-

tities

Button Lock

Lock all the buttons

Protection Function

Over current protection;over voltage protection;under voltage protection;over

heat protection;over load protection

Optional parts

Brake parts, operation panel, extension cable of operation panel

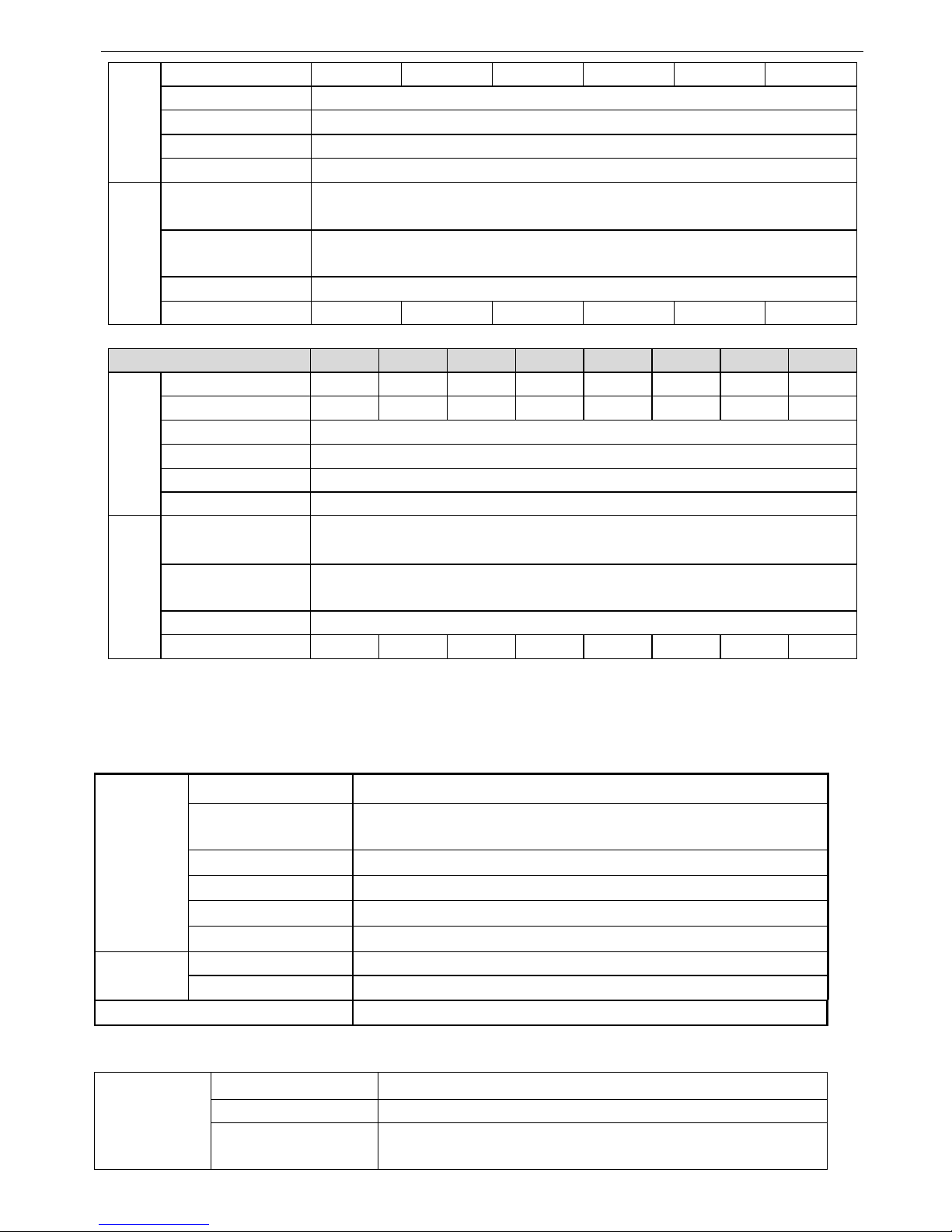

1-3. Product appearance

VB3 series 0.4~0.75KW

VB3/V5/VB5 series inverter

10

MENU

ESC

JOG

REV

ENT

DATA

FWD

STOP

RESET

FWD REV ALM HZ V A

LED

Control

terminals

Power

terminals

Mounting hole

4 bits LED display

Buttons

Analog potentiometer

VB3/V5/VB5 series inverter

11

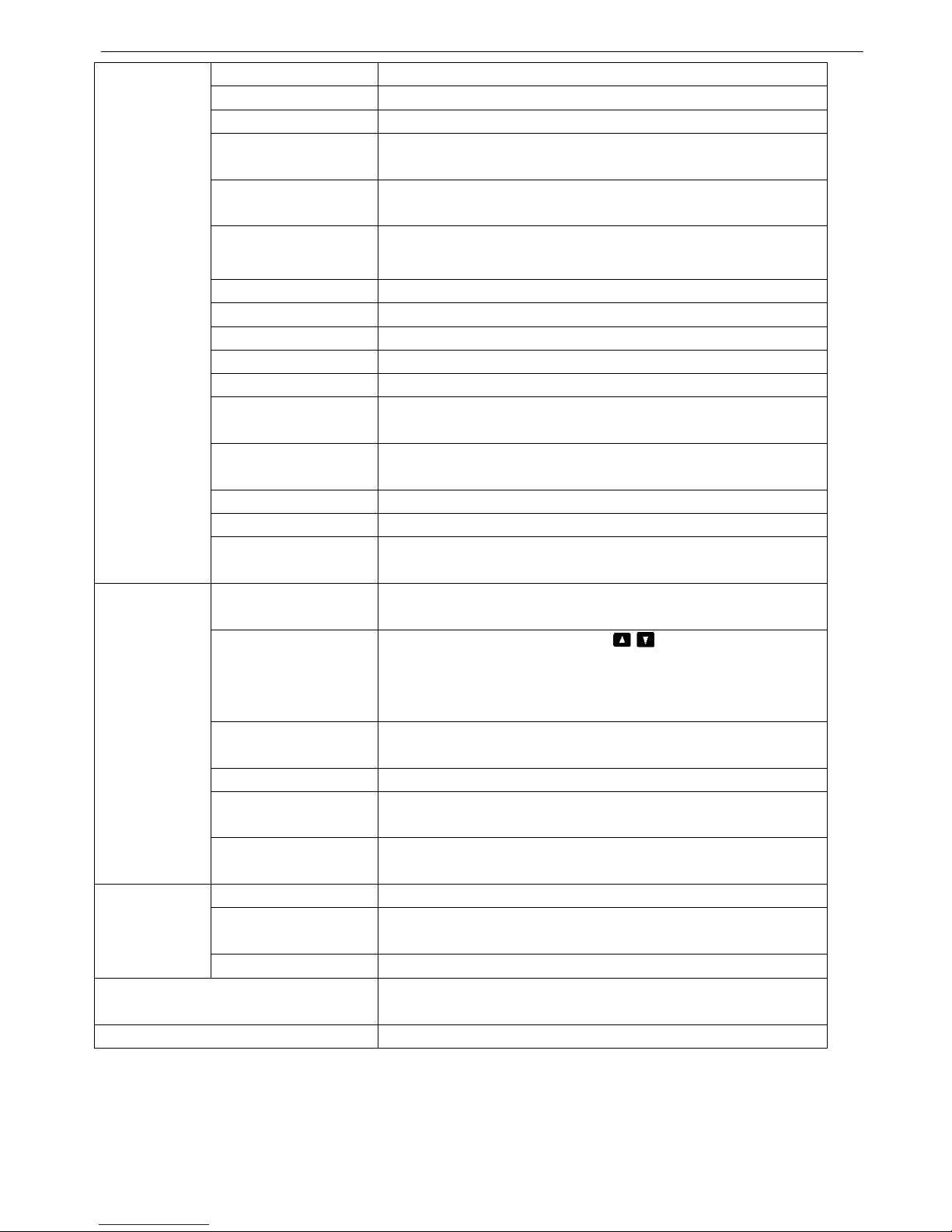

VB5 series single-phase 0.75~2.2KW

VB3/VB5 series 3-phase 0.75~3.7KW

VB5 series 5.5KW~7.5KW

V5 series 11~18.5KW V5 series 22~55KW

MENU

ESC

FWD

ENT

DATA

JOG

REV

STOP

RESET

FWD REV ALM HZ V A

WARNING

!

* STORED CHARGE DO NOT TOUCH

UNTIL 10 MIN. AFTER DISCO-

* RISK OF ELECTRIC SHOCK-DUAL

SUPPLY DISCONNECT MAINS AND

* DO NOT CONNECT AC POWER TO

OUTPUT TERMINALS OF "U V W"

LOADSHARING BEFORE SERVICE

NNECTION

MENU

ESC

FWD

ENT

DATA

JOG

REV

STOP

RESET

FWD REV ALM HZ V A

MENU

ESC

ENTER

DATA

FWD

JOG

REV

STOP

RESET

FWD REV ALM HZ V A

MENU

ESC

ENTER

DATA

FWD

JOG

REV

STOP

RESET

FWD REV ALM HZ V A

VB3/V5/VB5 series inverter

12

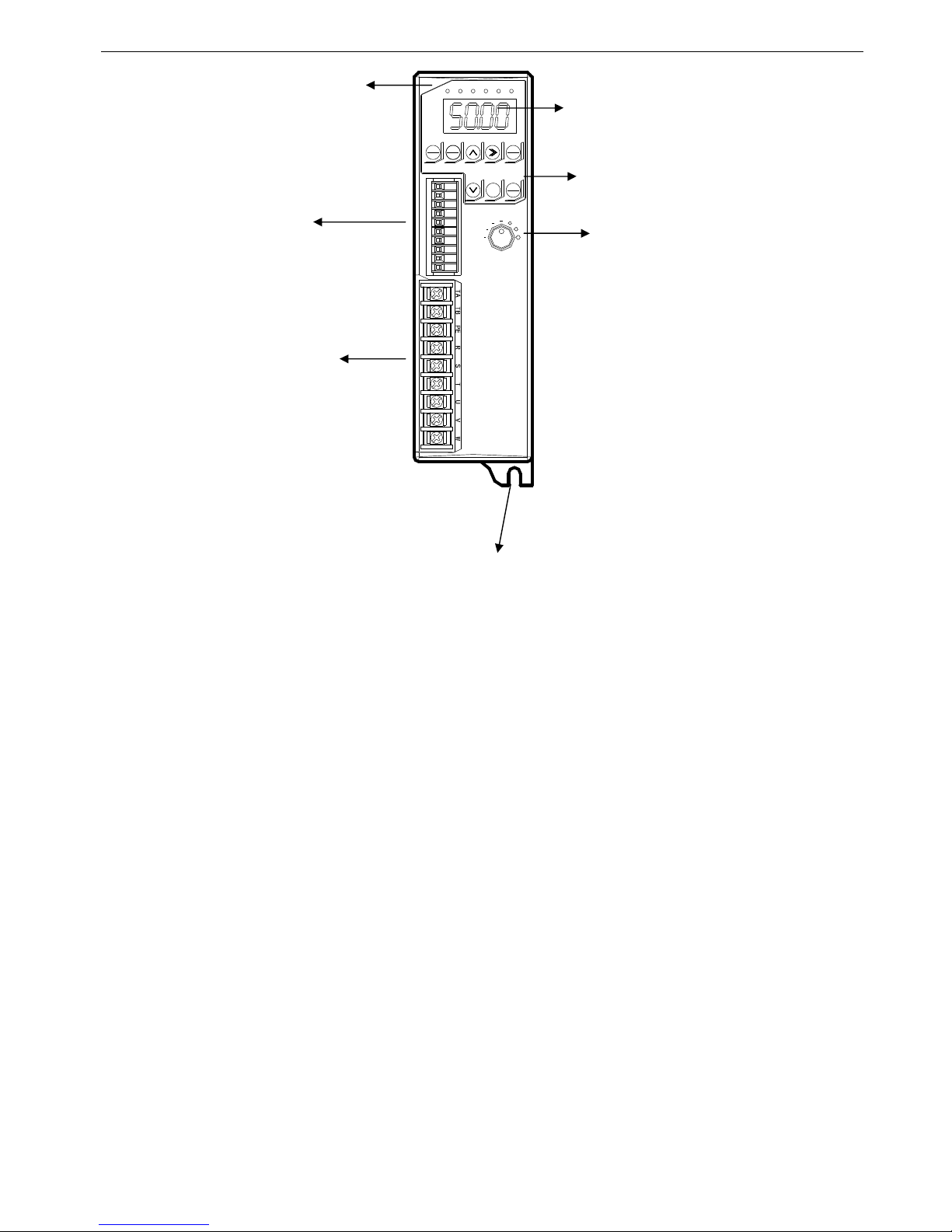

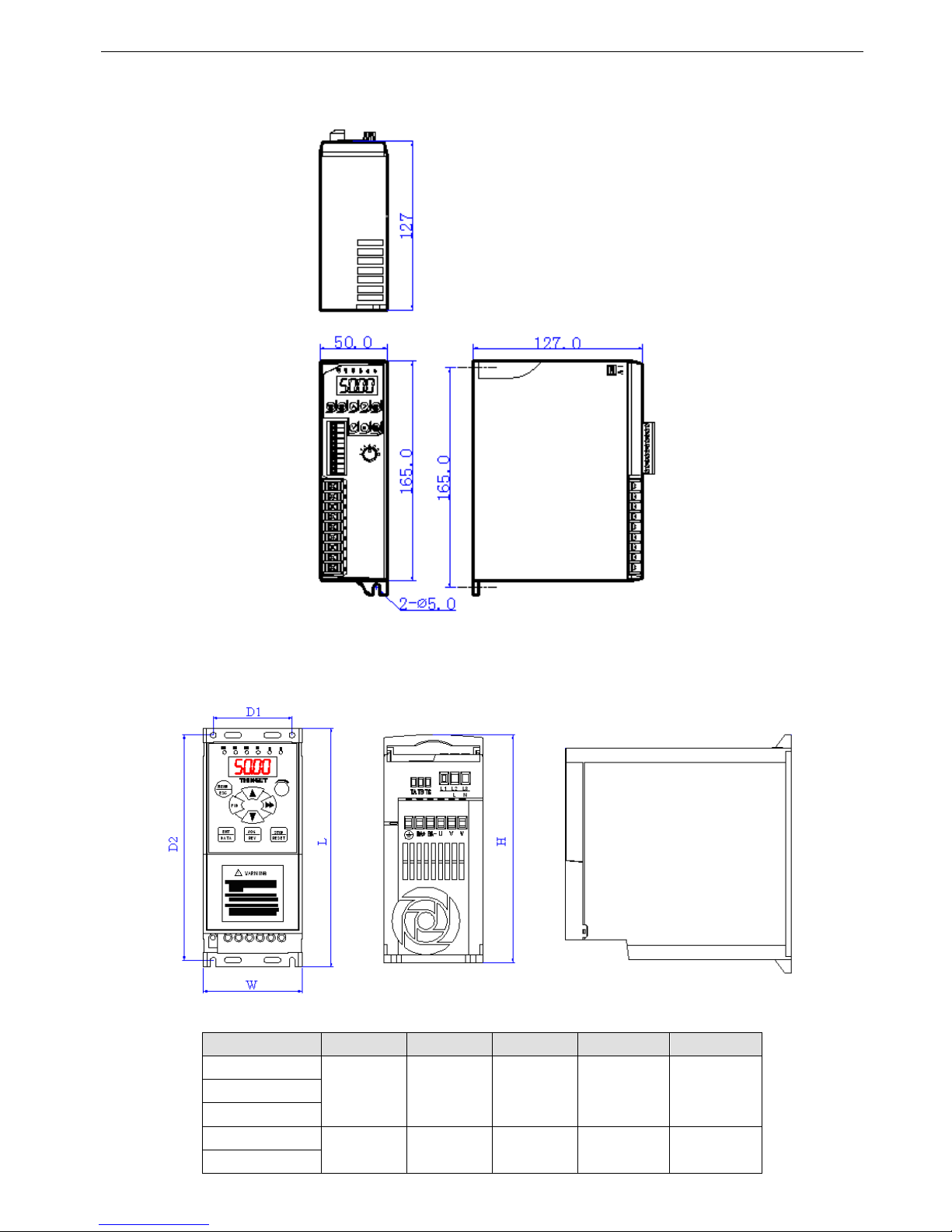

1-4. Product dimension

VB3 series 0.4~0.75KW (Unit: mm)

VB3, VB5 series 0.75~3.7KW (Unit: mm)

The details of the dimension:

Type W D1 L D2 H

VB5-20P7

70 56 170 160 162 VB5-21P5

VB5-22P2

VB3/VB5-40P7

80 56 200 190 162

VB3/VB5-41P5

VB3/V5/VB5 series inverter

13

VB3/VB5-42P2

VB3/VB5-43P7

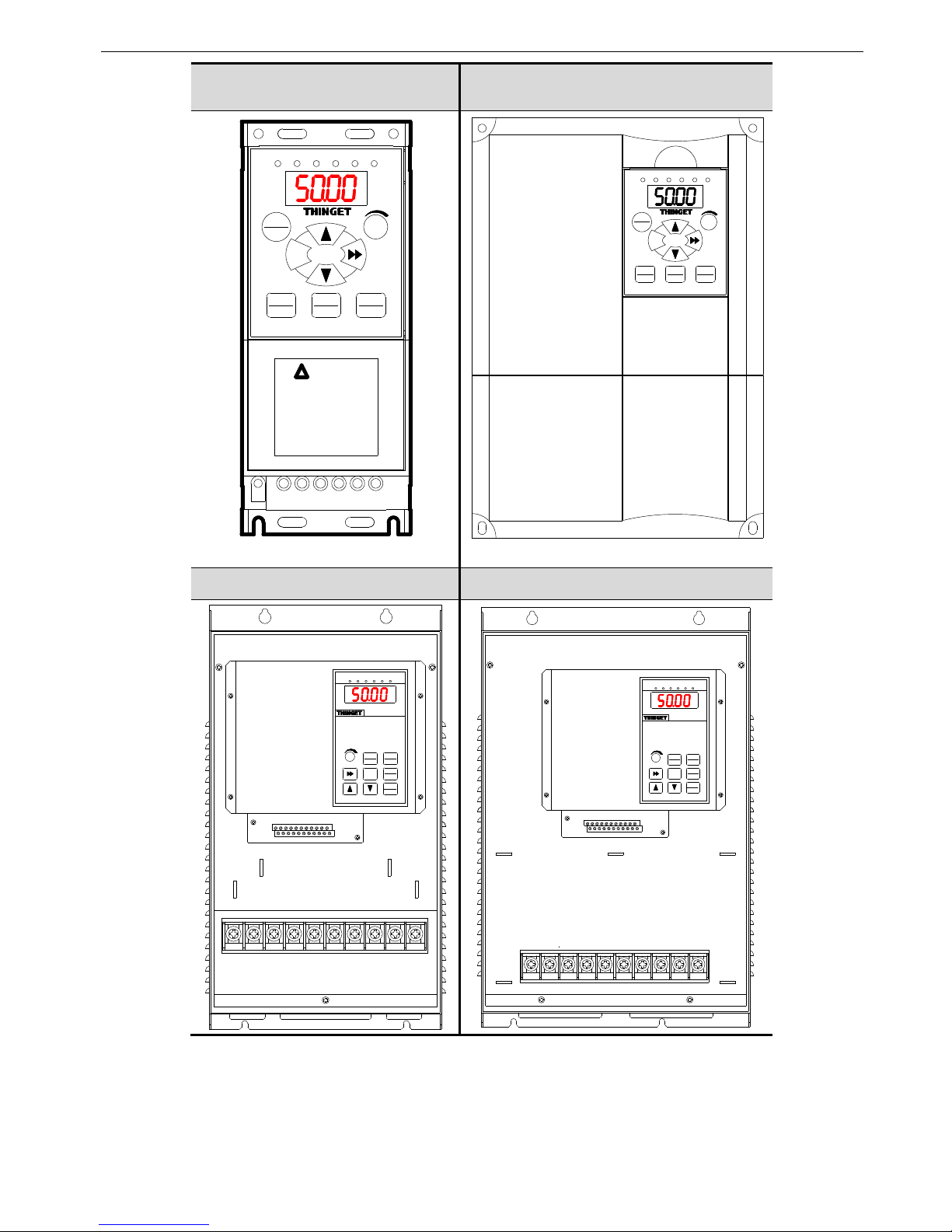

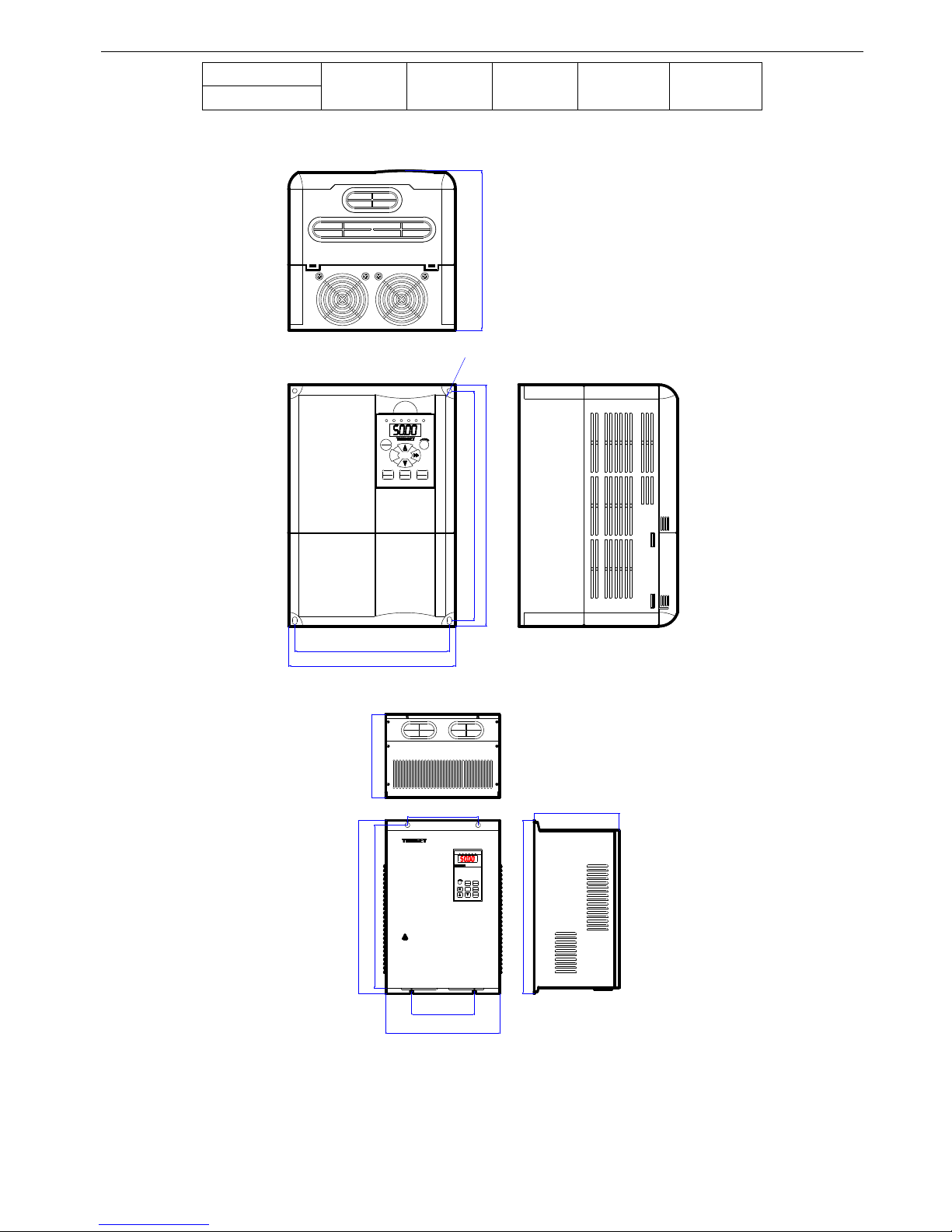

VB5 series 3-phase 5.5~7.5KW (Unit: mm)

V5 series 3-phase 11~55KW (Unit: mm)

MENU

ESC

FWD

ENT

DATA

JOG

REV

STOP

RESET

FWD REV ALM HZ V A

180.0

167.0

260.0

247.5

171.8

?5.0

MENU

ESC

ENTER

DATA

FWD

JOG

REV

STOP

RESET

FWD REV AL M HZ V A

L

W

D2

D3

D1

L

H

* STORED CHARGE DO NOT TOUCH UNTIL

10 MIN. AFTER DISCONNECTION

* RISK OF ELECTRIC SHOCK-DUAL SUPPLY

DISCONNECT MAINS AND LOADSHARING

WARNING

!

* DO NOT CONNECT AC POWER TO OUTPUT

TERMINALS OF "U V W"

BEFORE SERVICE

H

VB3/V5/VB5 series inverter

14

The details of the dimension:

Type W D1 L D2 H D3

V5-4011

230 120 420 160 218 400 V5-4015

V5-4018

V5-4022

290 180 450 210 217 430

V5-4030

V5-4037

375 230 581 230 261 551 V5-4045

V5-4055

V5 series inverter

15

2 Installation and Wiring

2-1. Installation environment

2-1-1. Environment requirement

Ambient tempeature: -10ºC~40ºC. The inverter should be derated when the temperature over 40ºC, at the same time

ventilation and heat dissipation should be enhanced.

Far away from the location with direct sunlight, dust, floating fiber or metal powder.

Mount in the location free of corrosive gas and combustible gas.

Mount in the location free of condensation, and the humidity should less then 95%RH.

Mount in the location where vibration less than 5.9m/s²(0.6G)

Far away from electramagnetism interfere source and other electric instruments sensitive with electramagnetism in-

terfere.

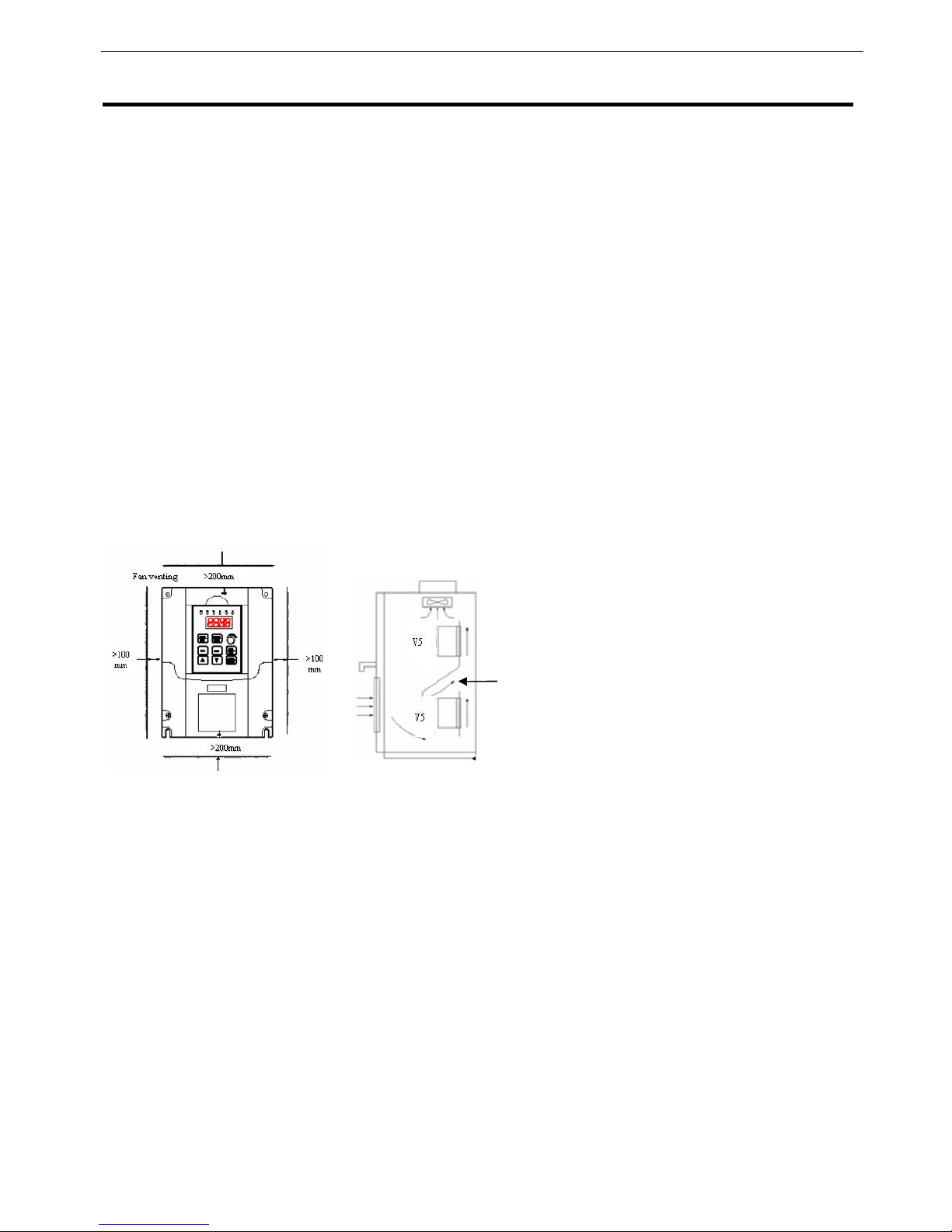

2-1-2. Mounting location and space

Mount the inverter vertically under general condition.

The mounting space and distance are shown in Fig. 2-1.

When several inverters are mounted up and down, air diversion plate should be fixed in the middle as shown in Fig.

2-2.

Fig. 2-1 Mounting Space Fig.2-2 Mounting of Multi-Inverters

2-1-3. Mounting and removing

Removing: Romove the four screws on the cover with phillips screwdriver

Mounting: Allign the mounting holes and then fix the screws.

Air diverting

plate

V5 series inverter

16

2-2. Wiring

Wiring after power off for at least 10 minutes, otherwise, an electronic short may occur.

Do not connect AC power to output terminals U, V and W.

Both the inverter and the motor should be safety grounded as there is leakage current inside the inverter.The diameter

of grounding copper cable must be more than 3.5mm², grounding resistor must be less than 10ohm.

Withstand voltage test of the inverter has been done in the factory, users would better not do it again.

Do not install electromagnetic contactor, absorption capacitor or other resistance-capacitance absorption devices, as

shown in Fig2-3.

In order to make the input over-current protection and power off maintenance easily, the inverters should connect

power supply via braker.

The connection cable of relay I/O circuit (X1~X6, FWD, REV, OC, DO) should select the twisted-pair or shield cable

with diameter over 0.75 mm². One terminal of the shield layer should be hung in the air and the other terminal should

be connected with the inverter’s grounding terminal E, the cable length should be less than 50m.

2-3. Wiring of main circuit terminals

2-3-1. Wiring diagram

Fig. 2-3 Wiring of main circuit

Caution

Danger

Before layout operation, make sure the power supply of inverter is cut off, all the LED on the operate panel is black out

and delay for more than 10 minutes.

Wiring work can be performed after the voltage between internal electrolesis capacity “+” and “–” is below DC36V.

Wiring work can only be done by trained and professional personnel.

Before power on, please check if the power supply voltage is consistent with the inverter voltage level, otherwise

device damage, human injuries and deaths may occur.

V5 series inverter

17

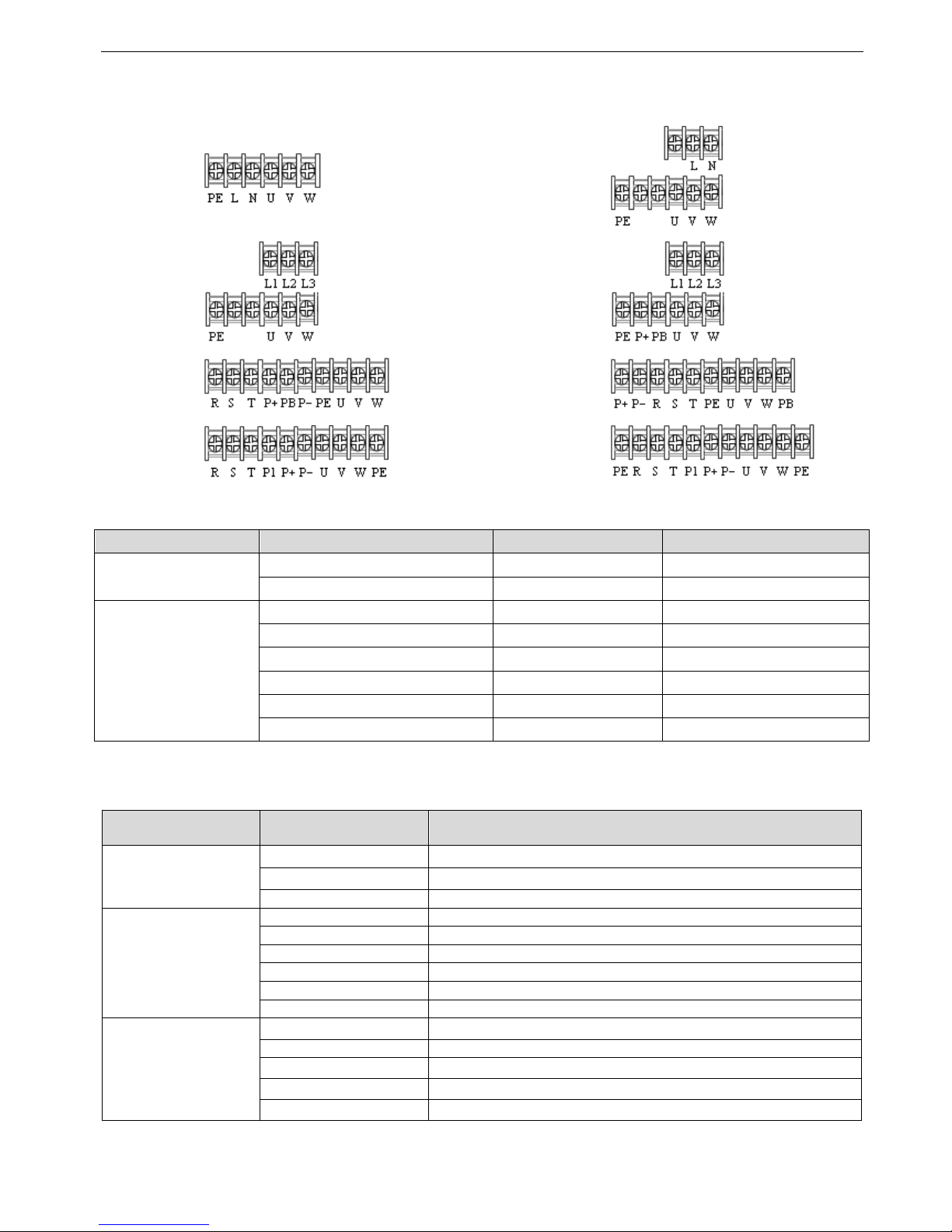

2-3-2. Terminal assignment and description

Fig. A

Fig. B

Fig. C

Fig. D

Fig. E

Fig. F

Fig. G

Fig.H

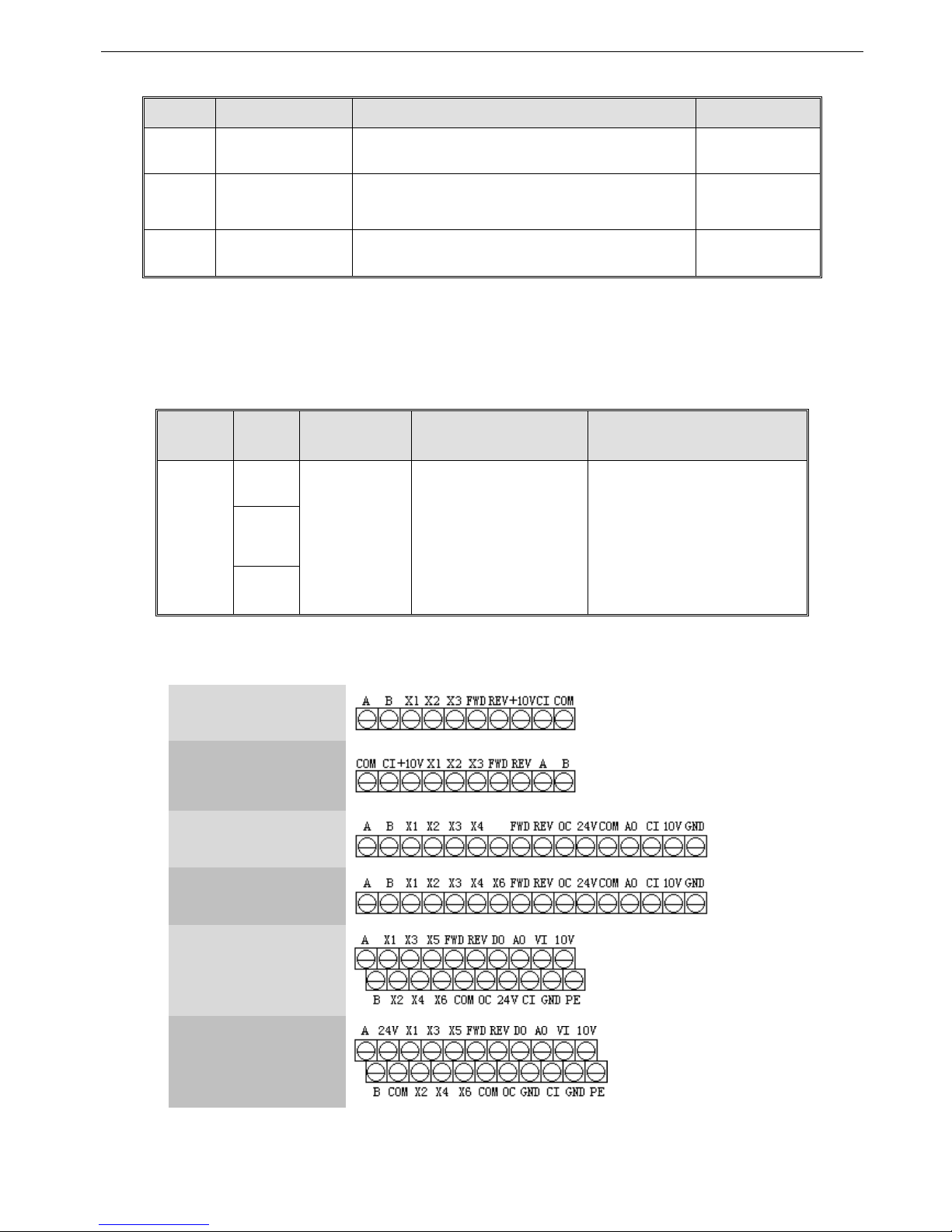

The relationship between main circuit terminals and product types:

Voltage level Power (KW) Figure Series

220V

0.4~0.75 Fig. A VB3

0.75~2.2 Fig. B VB5

380V

0.75~3.7 Fig. C VB3

0.75~3.7 Fig. D VB5

5.5~7.5 Fig. E VB5

11~18.5 Fig. F V5

22~30 Fig. G V5

37~55 Fig. H V5

I/O terminals of main circuit:

Table 2-1 main circuit I/O terminals

Voltage

Terminal Function

VB3, VB5 series

Single phase 220V

L, N Single phase AC 220V input

U, V, W Three phases AC output

PE G

round

VB3, VB5 series

Three phases 380V

L1, L2, L3 T

hree phase

s AC 380V input

(fit for power below 3.7KW )

R, S, T Three phase

s AC 380V input

(fit for power below 3.7KW )

P+, PB Brake

resistor

(some types don’t have brake unit)

P+, P- G

eneratrix + and

- U, V, W T

hree phase

s AC output

PE Ground

V5 series

Three phases 380V

R, S, T Three phases AC 380V input

U, V, W T

hree phase

s AC output

P+, P- Generatrix + and -

P1, PB Brake resistor

PE Ground

V5 series inverter

18

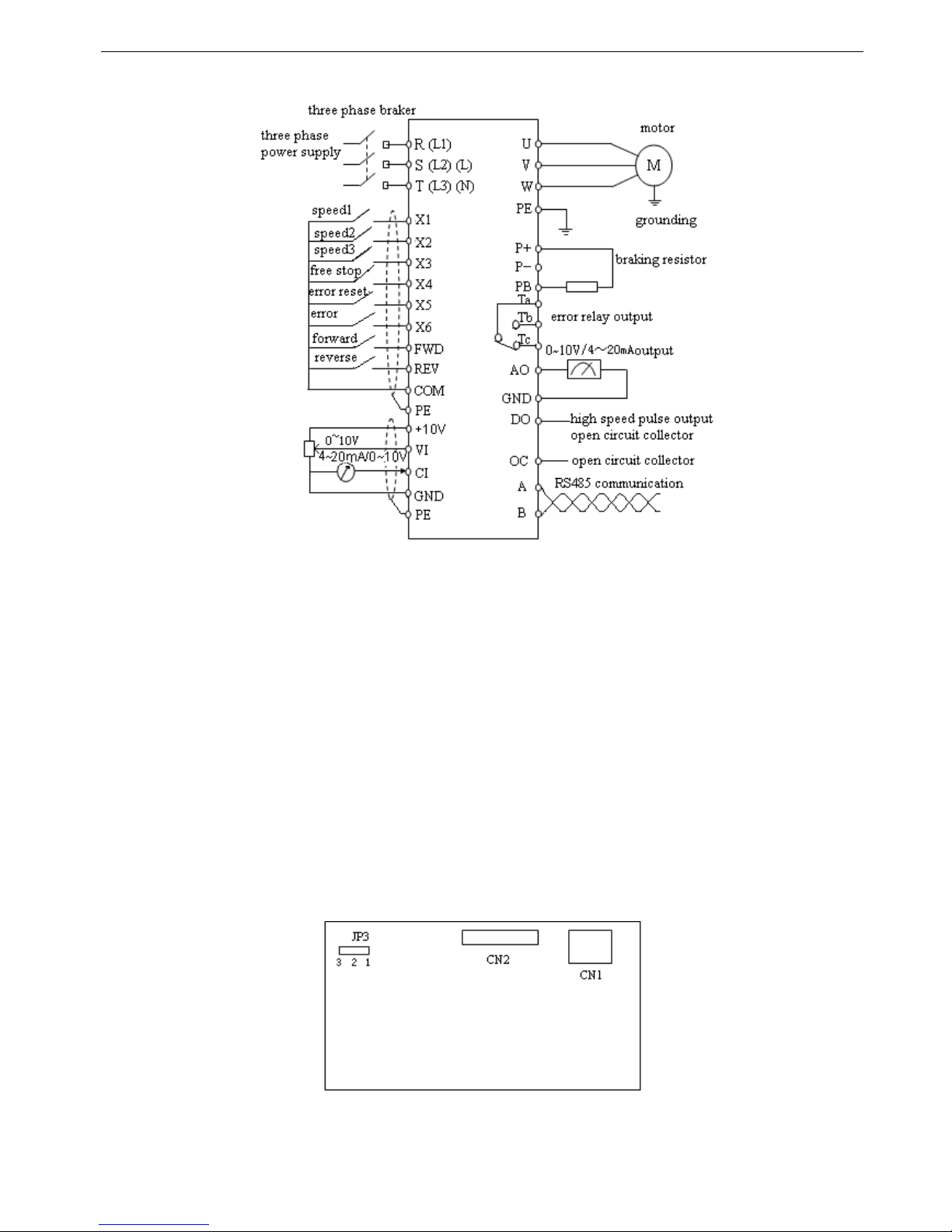

2-4. Basic running wiring

Note:

(1) P- terminal is only used in 5.5KW and larger inverters.

(2) L, N terminals are suitable for 220V single phase inverters.

(3) L1, L2, L3 terminals are suitable for VB5 series 0.75~3.7KW three phases types.

(4) VB5 series 0.75~3.7KW three phases have no digital input X5, analog input VI and digital output DO.

(5) VB3/VB5 series single phase have no X4~X6, VI, AO, DO, OC, P+, P-, PB.

(6) VB3 series 0.75~3.7KW three phases have no terminal X5, X6 and VI, DO, P+, P-, PB.

2-5. Setting and wiring of control circuit

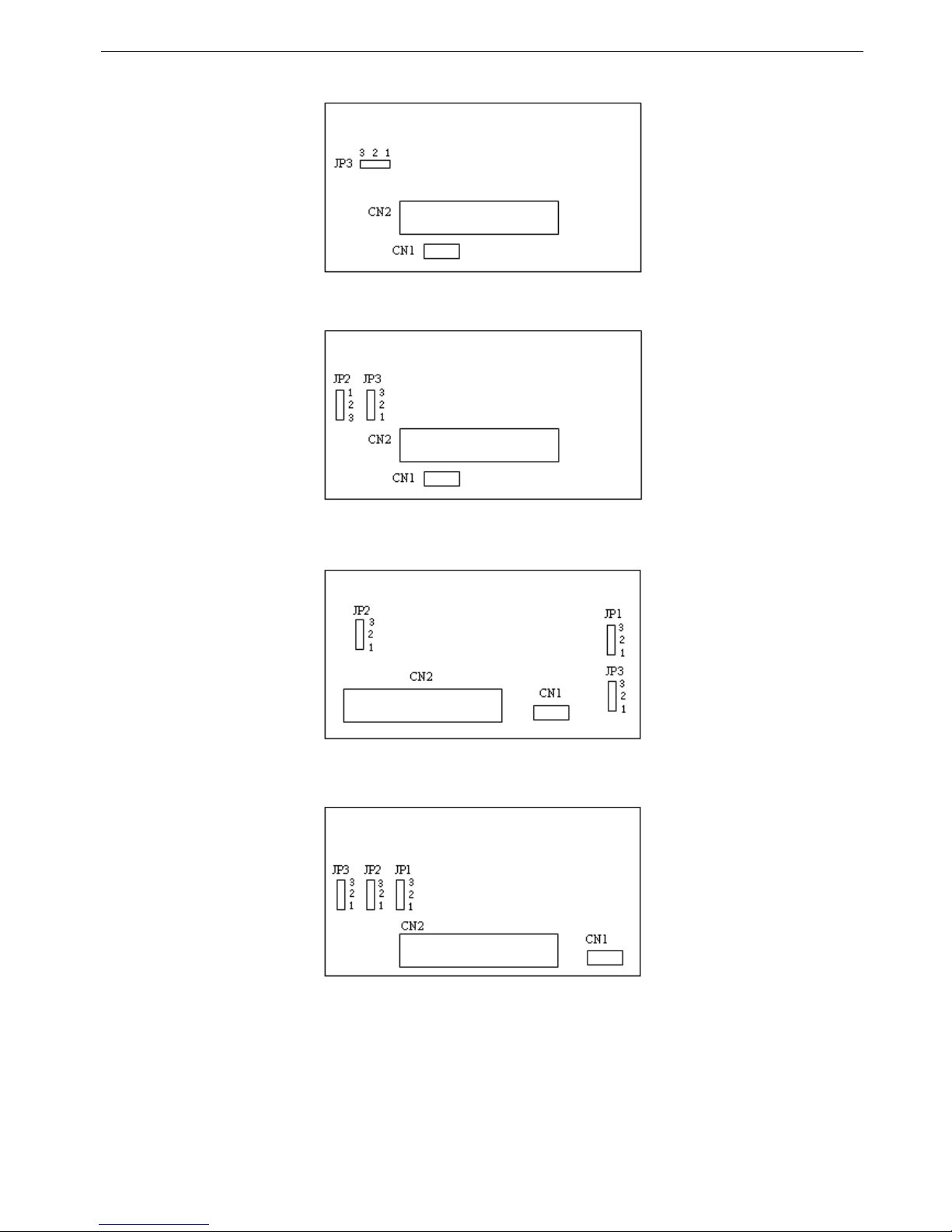

2-5-1.Position and function of terminals and jumpers on control panel

Please open the front cover of inverter, there is the PCB board inside. The jumper is on the board.

0.4 ~0.75KW VB3 series inverter jumper position

Fig 2-4(a) jumper position on control board

V5 series inverter

19

0.75~2.2KW VB5 series single phase inverter jumper position

Fig 2-4 (b) jumper position

0.75~3.7KW VB3, VB5 series three phases inverter jumper position

Fig 2-4 (c) jumper position

5.5~7.5KW VB5 series three phases inverter jumper position

Fig 2-4 (d) jumper position

11~55KW V5 series inverter jumper position

Fig 2-4 (e) jumper position

The position of jumpers are shown in Fig. 2-4, the function of jumper terminals are shown in Table 2-3 and the function descriptions of jumpers and their setting method are shown in Table2-2. Before running the inverter, make sure terminals wiring

and jumpers setting have been done, more than 1mm2 cables are recommended to use.

V5 series inverter

20

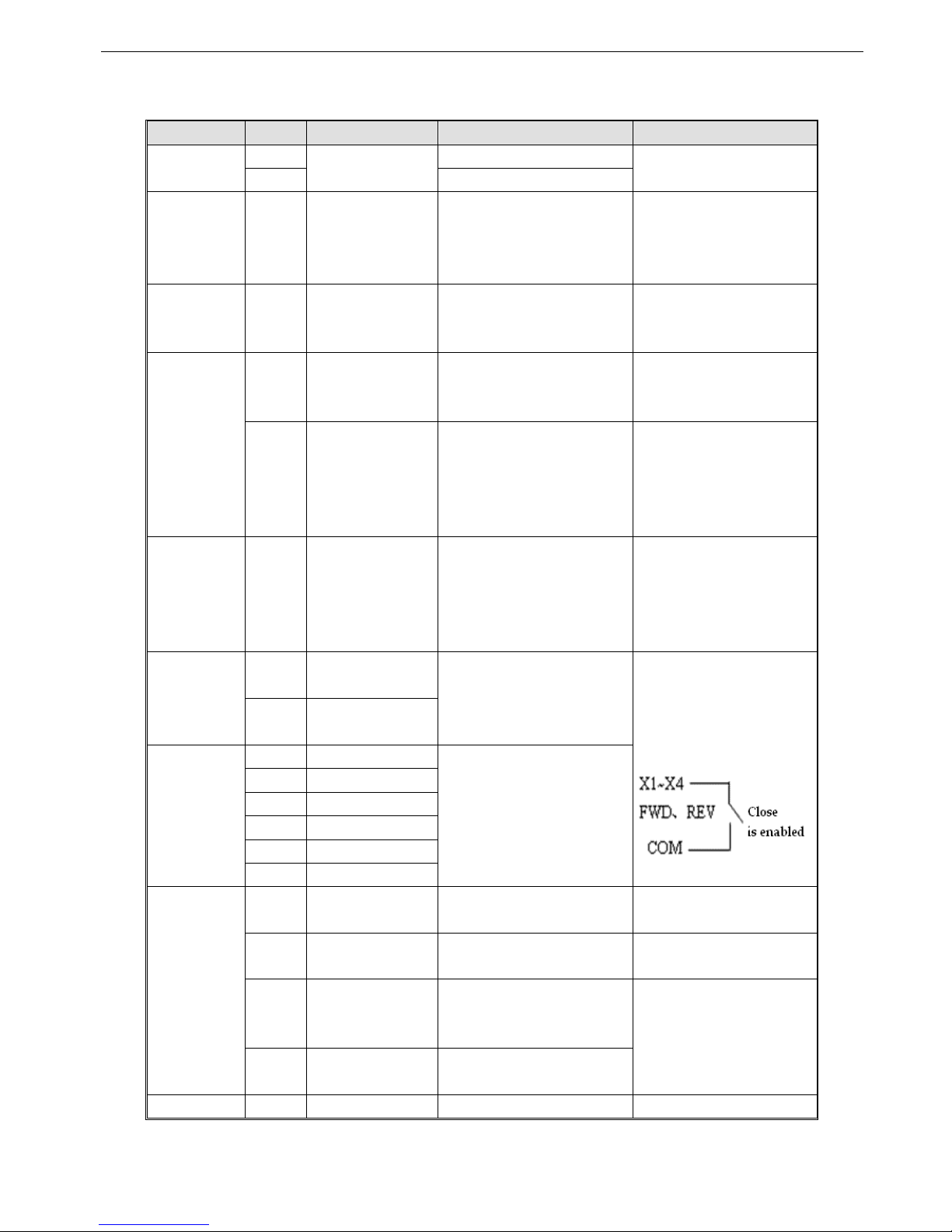

Table 2-2 Function of jumpers

Jumper Function Setup Default Setup

JP1

Pulse output terminal

DO power selection

1-2 connect: External power supply

2-3 connect: Inverter’s internal 24V power supply

External power

supply

JP2

Analog output terminal

AO output

1-2 connect: 4~20mA, AO terminal outputs current signal

2-3 connect: 0~10V, AO terminal outputs voltage signal

0~10V

JP3

CI current/voltage input

modes selection

1-2 connect : V side: 0~10V voltage signal

2-3 connect : I side: 4~20mA current signal

4~20mA

2-5-2.Terminals on control panel

1. Functions of CN1 terminal are shown in Table 2-3:

Table 2-3 Function of CN1

Type

Terminal

Mark

Name Function Description Specification

Relay output

terminal

TA

Multi-function

relay output

terminals

Multi-functional relay output

terminals. Please refer to function parameters P4.11 and description of output terminals

TA-TC: normal close

TA-TB: normal open

Contactor Capacity:

AC250V/2A (COSΦ=1)

AC250V/1A (COSΦ=0.4)

DC30V/1A

TB

TC

2. Control circuit terminals CN2

VB3 3-phase

0.4~0.75KW

VB5 1-phase

0.75~2.2KW

VB3 3-phase

0.75~3.7KW

VB5 3-phase

0.75~3.7KW

VB5 3-phase

5.5~7.5KW

V5 3-phase

11~55KW

Fig. 2-5 Terminals on control panel

V5 series inverter

21

3. CN2 terminals’ function description are shown as below:

Table 2-4 CN2 terminals’ function description

Type Terminal Name Terminal Function Description Specification

Communication

A

RS485 port

RS485 difference signal +

standard RS485 port, please use

twisted cable or shielded cable

B RS485 difference signal -

Multifunction

output terminal

OC

Open collector output

terminal 1

Multi-function digital

output terminal,

refer to P4.10 for details

(common

terminals: COM)

optical coupling isolation output

voltage range: 9~30V

max output current: 50mA

please refer to P4.10 for details

Pulse output

terminal

DO

Open collector pulse

output terminal

Multi-functional pulse output terminal, refer to P4.20, P4.21 for details

(common terminals: COM)

Output frequency range: set

P4.21, the max is 20KHz

Analog input

VI Analog input VI

analog voltage input

(reference ground: GND)

Input voltage range:

0~10V (input

resistance:47KΩ)

Resolution: 1/1000

CI Analog input CI

Analog current/voltage input, vol-

tage and current are selected by

jumper JP3 and the default is current.

(reference ground: GND)

Input voltage range:

0~10V (input

resistance: 47KΩ)

Input current range:

4~20mA

(input resistance: 500Ω)

Resolution: 1/1000

Analog output AO Analog output AO

Analog voltage/current ouput, they

are selected by jumper JP2 and the

default is voltage which can indicate 7 values. (reference ground:

GND)

Voltage output range: 0~10V

Current output range: 4~20mA

Running control

terminal

FWD

Forward running com-

mand

Forware/reverse digital command.

Refer to P4.08 for details (instruction about 2-wire and 3-wire control function).

Optical coupling isolation input

Input resistance: R=2KΩ

Highest input frequency: 200Hz

Input voltage range: 9~30V

REV

Reverse running com-

mand

Multifunction

input terminal

X1 Multifunction input 1

Multi-function digital input terminals, refer to parameter P4.

(common terminal: COM)

X2 Multifunction input 2

X3 Multifunction input 3

X4 Multifunction input 4

X5 Multifunction input 5

X6 Multifunction input 6

Power supply

24V +24V power supply

Supply +24V power supply

(negative terminal: COM)

-

10V +10V power supply

Supply +10V power supply

(negative terminal: GND)

Max output current: 50mA

GND

+10V

power supply common

terminal

Reference ground of analog signal and

+10V power supply

COM is isolated with GND

inside

inverter

COM

+24V power supply

common terminal

Digital signal I/O common terminal

Shield PE Shield terminal

V5 series inverter

22

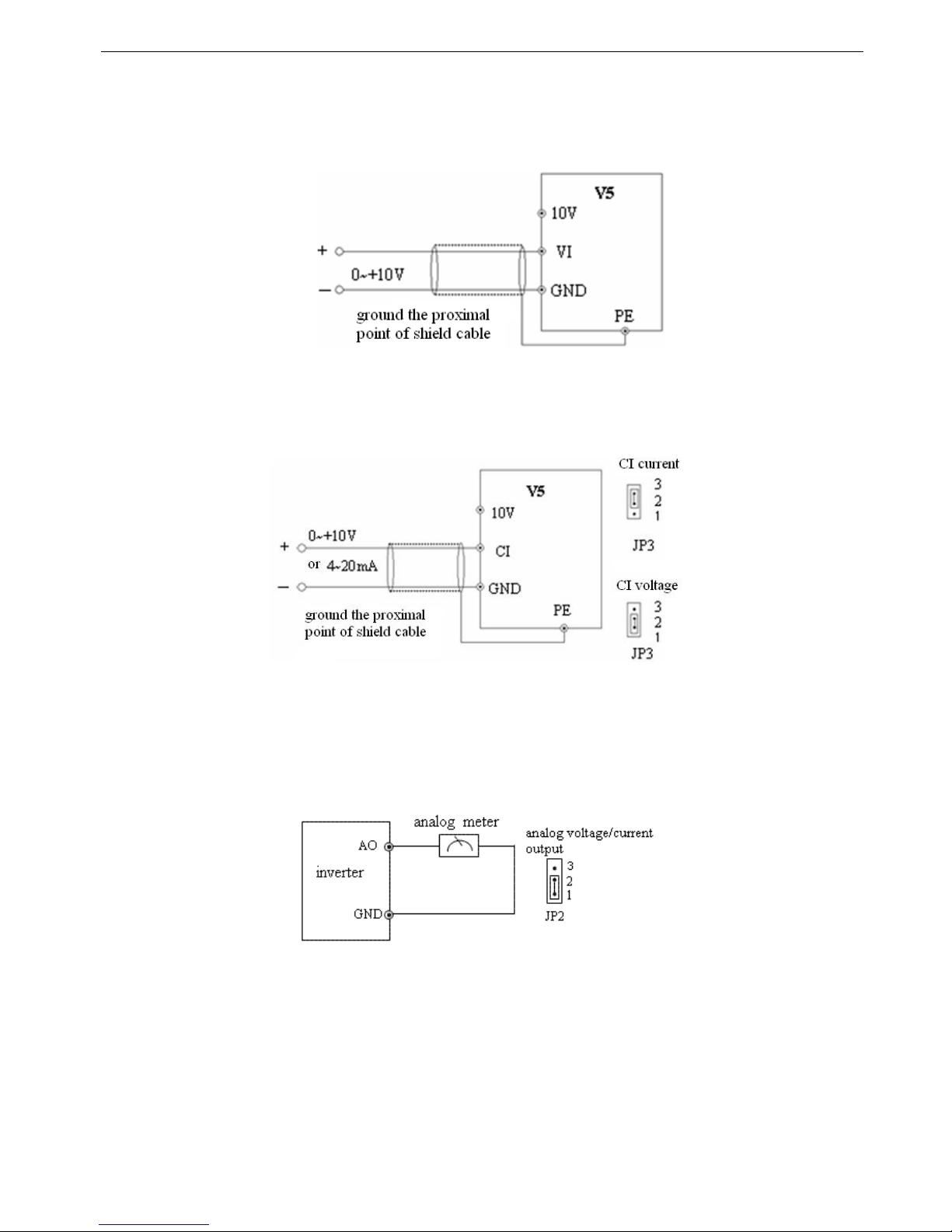

2-5-3. Analog I/O terminal wiring

1. The wiring of VI terminal voltage signal input

Fig. 2-6 VI terminal wiring diagram

2. CI terminal analog input, jumper select voltage input(0~10V) or current input(4~20mA):

Fig. 2-7 CI terminal wiring

3. Wiring for analog ouput terminal AO

Analog output terminal AO can display various physical quantities. The output voltage is 0~10V, output current is

4~20mA.

Fig. 2-8 Analog output wiring

Note:

(1) When using analog input, you can connect filter capacitor or common mode choke between VI and GND, or CI and GND.

(2) Because analog input signal is easily interfered by outside, the shield cable is required, the cable length must be short

and the shield layer must be grounded well.

Loading...

Loading...