TP/TH/TG series HMI

manual【Hardware】

WUXI XINJE ELECTRIC CO., LTD.

Data No. : HC 01 20120105 2C6

I

CATALOG

1 TP SERIES HMI ................................................................................................................................................. 1

1-1 Features ............................................................................................................................ 1

1-1-1 Product features .................................................................................................... 1

1-1-2 Model naming rule ................................................................................................ 1

1-1-3 Product models...................................................................................................... 2

1-2 General specifications .................................................................................................... 2

1-3 Hardware .......................................................................................................................... 3

1-3-1 Hardware structure ............................................................................................... 3

1-3-2 Port introduction .................................................................................................... 3

1-4 Dimension and installation ............................................................................................. 7

1-4-1 Product dimensions .............................................................................................. 7

1-4-2 Installation and using environment ..................................................................... 8

2 TH SERIES HMI .............................................................................................................................................. 10

2-1 Features ........................................................................................................................... 10

2-1-1 Product features .................................................................................................. 10

2-1-2 Model naming rule .............................................................................................. 11

2-1-3 Model form ........................................................................................................... 11

2-2 General specifications.................................................................................................... 12

2-3 Hardware ......................................................................................................................... 14

2-3-1 Hardware structure ............................................................................................. 14

2-3-2 Port introduction .................................................................................................. 14

2-4 Dimensions and installation .......................................................................................... 20

2-4-1 Product dimensions ............................................................................................ 20

2-4-2 Installation and using environment ................................................................... 22

3 TG SERIES HMI .............................................................................................................................................. 24

3-1 Features ........................................................................................................................... 24

3-1-1 Product features .................................................................................................. 24

3-1-2 Module naming rule ............................................................................................ 25

3-1-3 Product models.................................................................................................... 25

3-2 General specifications.................................................................................................... 26

3-3 Hardware ......................................................................................................................... 27

3-3-1 Hardware structure ............................................................................................. 27

3-3-2 Ports introduction ................................................................................................ 28

3-4 Dimensions and installation .......................................................................................... 31

3-4-1 Product dimensions ............................................................................................ 31

3-4-2 Installation and using environment ................................................................... 34

1

1 TP series HMI

1-1 Features

Xinje TP series HMI have strong functions. It supports multi-language, any font and size of

characters. The basic functions include data display and monitoring, alarm, recipe. It can

communicate with most brands of PLC, two ports can communicate individually. The

programming software Touchwin has friendly interface and easy to operate. The software

can simulate online and offline (SCADA function).

1-1-1 Product features

Display

Monochrome or 256 colors LCD, support BMP, JPG pictures display

Support multi-language: Chinese, English, Japanese, Korean, German, French,

Arabic, etc. The fonts support any size, artistic effect, bold, italic, etc.

Large program capacity support more program screens and data.

Control

Dynamic data displaying and monitoring, bar map, real-time/historical trend map,

discrete/continuous histogram, switching control;

Real-time/historical alarm records;

Sample and save the data at certain time or conditions;

Nine levels password protection;

On/off line simulation, SCADA function

Communication

Two ports can communicate independently, enable to connect many devices at the

same time;

Support micro-printer

Support free format communication, user can make the communication protocol

freely.

1-1-2 Model naming rule

□□○○○—□

1 2 3

1:Series name TP

2:LCD size 460:4.7’’

760:7.0’’

3:LCD display L:Monochrome LCD

T:256 colors TFT LCD

2

1-1-3 Product models

TP series HMI can connect to PLC, inverter, meters and other devices. As the interface of

machine and user, it can monitor data, control the machine operation. It is fit for small and

medium control systems.

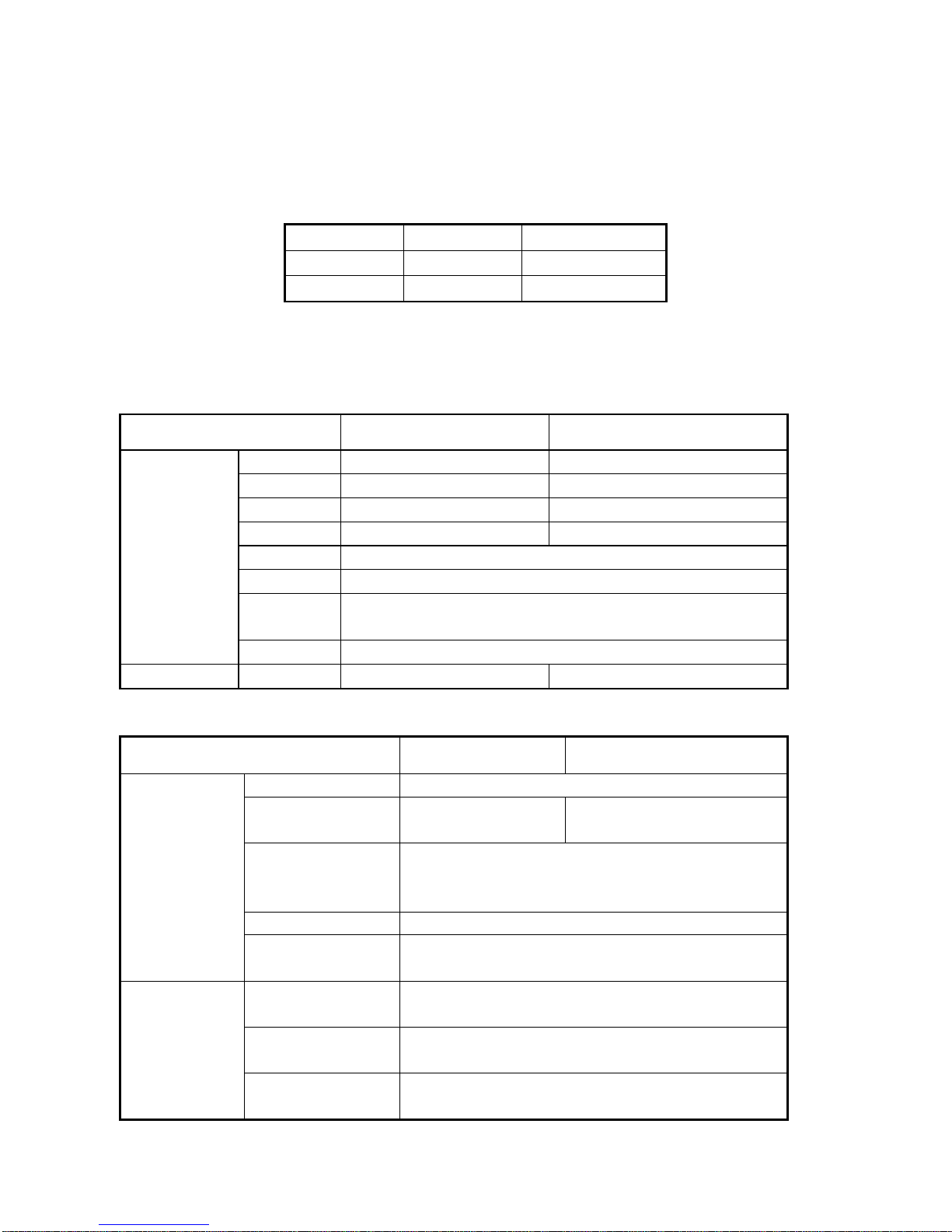

1-2 General specifications

HMI specifications

Item

TP460-L

TP760-T

Screen

Size

4.7″

7.0″

Type

Monochrome

256 colors

Resolution

240*128

480*234

Brightness

Adjust by potentiometer

/

Touch panel

Matrix digital touch panel

Using life

More than 50000 hours, temperature 25℃,running for 24 hours

Language

Chinese, English, Japanese, Korean, German, French,

Arabic…

Character

Any font and size

Memory

Capacity

2MB

4MB

Electric specifications

Item

TP460-L

TP760-T

Electric

Input voltage

DC24V (voltage range: DC22V-DC26V)

Consumption

current

200mA

280mA

Allowable

momentary power

failure

Below 10ms (Actual power failure<1s)

Withstand voltage

AC1000V,10mA,less than 1 minute (signal and ground)

Insulated

impedance

DC500V, above 10MΩ (signal and ground)

Environment

Operation

temperature

0-50℃

Reserve

temperature

-20-60℃

Environment

humidity

10%RH-90%RH (no condensation)

Model

LCD size

LCD type

TP460-L

4.7 inch

Monochrome LCD

TP760-T

7.0 inch

256 colors TFT

3

Withstand oscillation

10-25HZ(X,Y,Z each direction 30 minutes 2G)

Anti-jamming

Voltage noise:1500Vp-p,pulse 1us,1 minute

Surrounding air

No corrosive gas

Protection

construction

IP65

Construction

Cooling method

Natural air cooling

Exterior dimension

(mm)

173.2*121.4*45.1

200.0*148.0*45.0

Mounting dimension

(mm)

165.2*113.4

182.4*134.4

Ports

PLC port

Support RS232/RS485/RS422

Download port

Support RS232/RS485

1-3 Hardware

1-3-1 Hardware structure

The hardware structure of TP series touch screen includes front and back side. Take

TP460-L as an example to explain the structure.

1-3-2 Port introduction

Xinje TP series HMI have two communication ports: Download port and PLC port, below is

the feature and function of TP series, take the ports of TP460-L as an example:

Power supply

Download port

PLC port

Nameplate

4

1. Download communication port

The main functions of the port:

Download: Connect with PC to download program;

Communication: Connect with PLC, printer, frequency converter etc, as a

communication port.

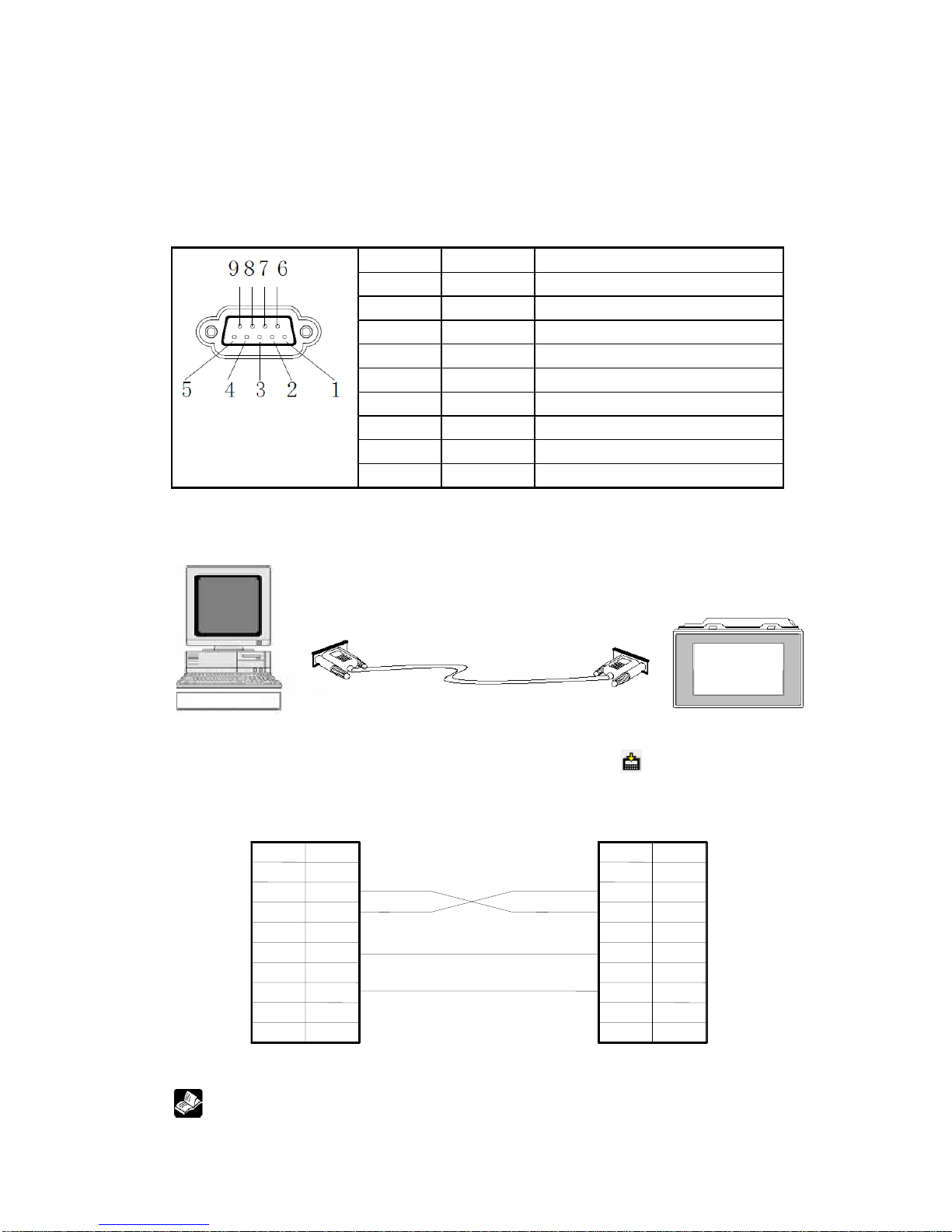

Pins of download port:

Pin

Name

Meaning

1

NC

Unused terminal

2

RXD

RS232 receive

3

TXD

RS232 send

4

A

RS485 communication “+” signal

5

GND

Signal ground

6

BUSY

Busy signal

7

B

RS485 communication “-” signal

8

NC

Unused terminal

9

NC

Unused terminal

(1) Download function

When you use download function of TP series, please use Xinje special download cable:

Before user download a program, please make sure your PC has installed multiport serial

card or USB-RS232 convertor, and connect cable correctly, click “ ” button in Touchwin

software, then you could download data successfully, below are the pin definitions:

PC serial Port (COM) Download Port (TP series)

Connection diagram (Normal download)

If the connection between PC and HMI is correct, but still can’t download, user

Pin 1 2 3 4

5

6 7 8

9

RXD

TXD

GND

RTS

NC

NC B BUSY

GND

A

TXD

RXD

NC

9

8 7 6

5

4 3 2 1 Name

Pin

Name

5

can try “Forced Download” function. The connection diagram of this function as

below shows:

Download Port (TP series)

pin5&8 shorted forced download mode

Steps:

a. Cut the power of TP, shorted the Pin 5 and 8;

b. Power on, move away the shorted line;

c. Start to download the program with special download cable.

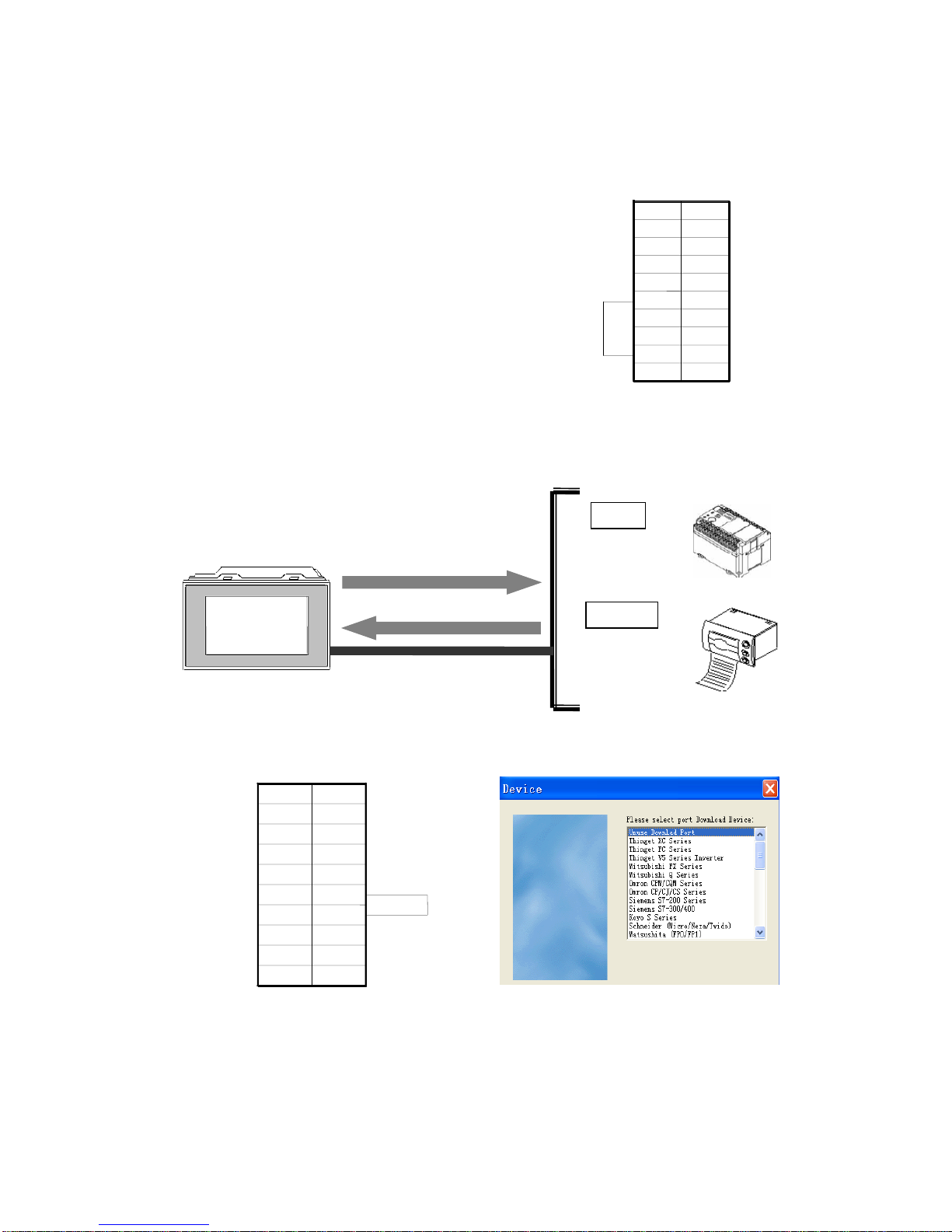

(2) Communication function

The download port of TP series not only has the download function, but also has the

powerful communication function.

When use the communication function of download port, please shorted the pin 5 and pin

6, select the corresponding communication equipment in software settings.

Download port communication mode transformation Select communication device of download port

Receive data

Send data

Printer

PLC

TP Series HMI

Download communication port

Pin

Name 1 2 3 4 5 6 7 8 9 NC

RXD

TXD A GND

BUSY B NC

NC

NC

NC

B

BUSY

GND A TXD

RXD

NC

9

8

7

6 5 4

3 2 1

Name

PIN

6

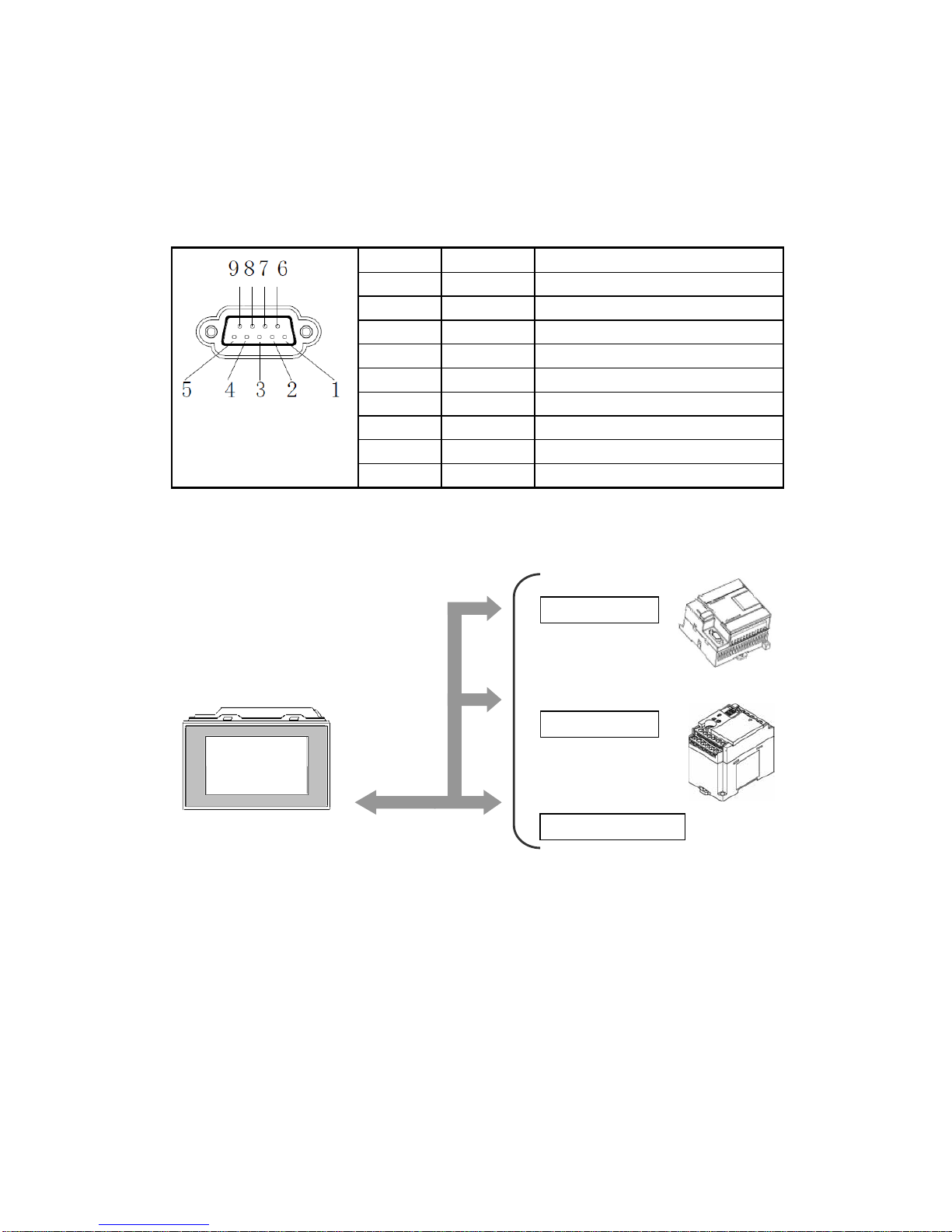

2. Communication interface of PLC

The PLC communication port of TP series has below function:

Connect and communication with industrial control equipments: PLC, inverter,

meter etc.

The pins definition of PLC communication port:

Pin

Definition

Description

1

TD+

RS422 send “+”

2

RXD

RS232 receive

3

TXD

RS232 send

4

A

RS485 “+”

5

GND

Signal ground

6

TD-

RS422 send “—”

7

B

RS485 “—”

8

RDD-

RS422 receive “—”

9

RDD+

RS422 receive “+”

(1) Communicate with PLC

TP series HMI can communicate with most of popular PLCs

Please select correct PLC port device and communication parameters:

Data transfer

TP Series

PLC com port

SIEMENS PLC

Panasonic PLC

Other PLCs

7

(2) Communicate with inverter

TP can communicate with various brands of frequency inverters. For the brands which are

not in the list, user can select Modbus protocol or user-defined protocol.

(3) Communicate with meters

About the communication between TP and meters, users can select user-defined protocol

or Modbus protocol.

1-4 Dimension and installation

1-4-1 Product dimensions

TP460-L (Unit: mm)

0.0

+0.5

0.0

+0.5

40.6

165.0

113.0

163.2

45.1

111.4

121.4

173.2

PLC com port

TP series

Mitsubishi FR series inverter

Inovance MD series inverter

Bosch Rexroth FE series

inverter

8

TP760-T (Unit: mm)

180.4

200.0

148.0

134.4

182.4

0.0

+0.5

0.0

+0.5

132.4

44.4

40.0

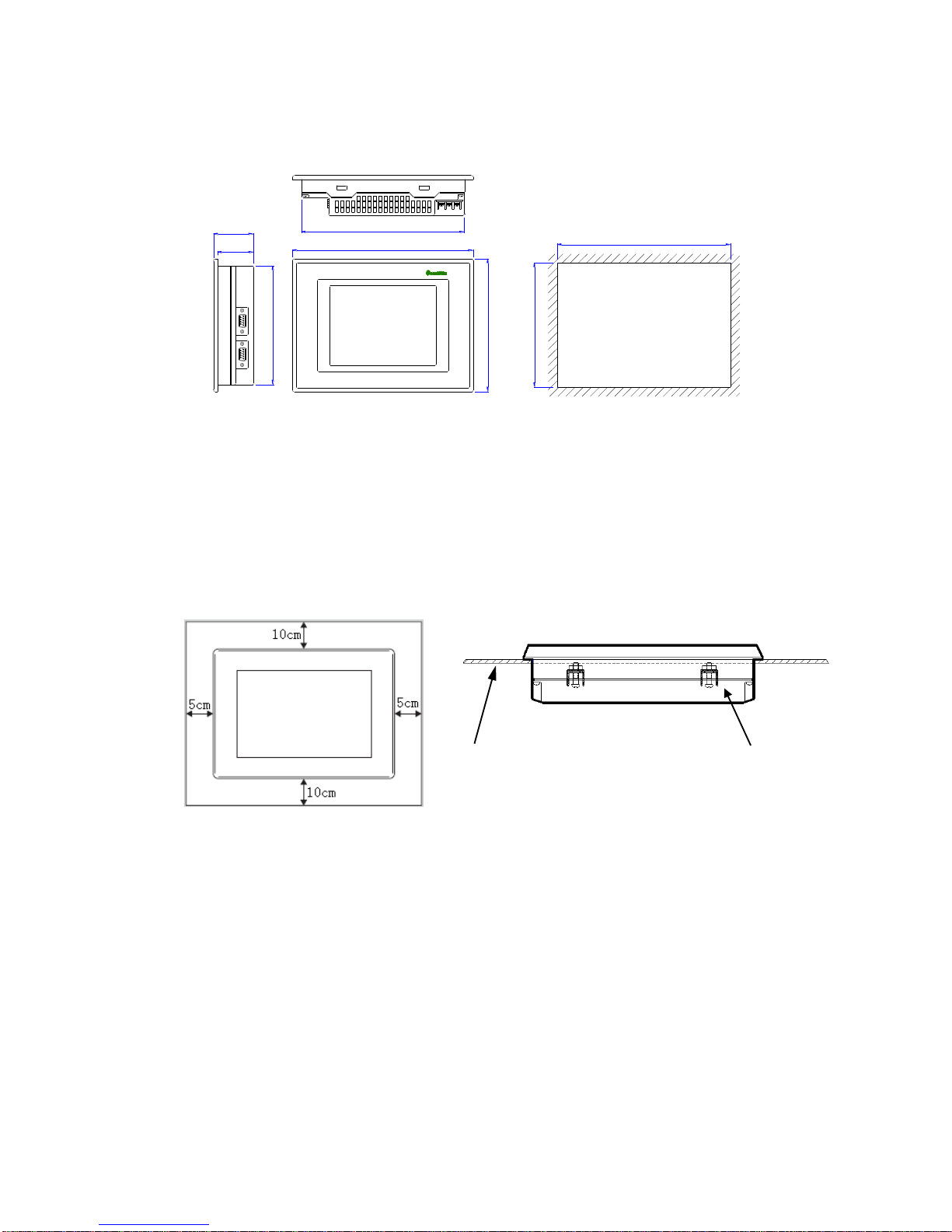

1-4-2 Installation and using environment

Install requirements:

TP has four ferric mounting racks when out of factory, there are two square holes on the

top, bottom side of TP, use mounting rack to fix the TP with control cabinet.

In order to avoid TP temperature too high after long time working, please keep 10cm

space on the up/down and 5cm on the left/right side of the TP when installing.

Install steps:

1. Refer to the dimension in the former chapter to open a rectangle mounting hole in

the control cabinet

2. Add airproof circles in the airproof slot when installing

3. Insert the bottom of TP into the mounting hole of control cabinet

4. Insert the install rack into the fix hole of TP then tighten the screw

5. Connect TP and PLC with communication cable

Notice: The communication cable can be offered by the supplier or made by user

according to the connection diagram, input +24V DC power to start working.

Environment:

Please use TP series touch screen indoor.

Fixed bracket

Install panel

9

Do not use TP in below environment:

Inflammable gas, steam, dust, fast vary temperature, high humidity (it may cause moisture

inside TP).

Power supply requirements:

TP series touch screen use DC +24V power supply only. The permitted voltage range is

20V~26V. The connection is as below:

+24V

0 V

+DC-

+DC-

0 V

+24V

Terminal type Pin type

Besides, if connect high voltage or AC power supply with TP, the TP may be damaged and

cause electric shock to human body.

NOTE: if use the DC +24V output of PLC to drive the TP, make sure the PLC

has enough current to drive the TP.

Loading...

Loading...