OP operate panel

User manual

Xinje Electric Co., Ltd.

Data No. HOC01 20110705 8.0

Basic instructions

Thanks for buying OP series operate panel.

This manual will introduce the hardware features and wiring of OP.

Please read the manual carefully before wiring.

For OP software, please refer to OP software manual.

Please pass the manual to the final user.

User notes

Only the operator who has electrical knowledge can use the OP. Please consult us if there

is anything unclear.

The examples in the manual are only for reference, we are not sure they can work.

Please confirm the product is accord with related specifications when use with other

products.

Please confirm the product is accord with safety requirements when using. Please set the

safety function for the machine.

Responsibility

We can not ensure the manual contents are accord with the product totally though we have

checked the manual carefully.

We are glad to accept customers’ advice. We will often check the manual contents and

modify them in the next version.

Please note that we will not inform customers if the manual has been modified.

Contact us

Telephone: +86-0510-85134136

Fax: +86-0510-85111290

Address: 4th floor, building 7, originality industrial city, JiangSu province, Wuxi, China

Post code: 214072

Xinje Electronic Co., Ltd. All rights reserved

Without written permission, copy, transfer or use the contents in the manual are forbidden.

July, 2011

Catalog

1 HARDWARE ............................................................................................................................... 3

1-1.INTRODUCTION ................................................................................................................................................... 3

1-2.GENERAL SPECIFICATIONS .................................................................................................................................. 3

1-3.FUNCTION SPECIFICATIONS................................................................................................................................. 4

1-3-1.OP320/OP320-S ........................................................................................................... 4

1-3-2.OP320-A/OP320-A-N/OP320-A-S .............................................................................. 4

1-3-3.OP325-A/OP325-A-S ................................................................................................... 5

1-3-4.OP330/OP330-S ........................................................................................................... 5

1-4.PART ................................................................................................................................................................... 6

1-5.BUTTON FUNCTION ............................................................................................................................................. 7

1-6.PORT AND DOWNLOAD CONNECTION .................................................................................................................. 8

1-6-1.Port ............................................................................................................................... 8

1-6-2.Download connection ................................................................................................... 8

1-7.DIMENSION AND INSTALLATION ......................................................................................................................... 9

1-7-1.Dimension..................................................................................................................... 9

1-7-2.Installation .................................................................................................................. 10

2 Q&A ............................................................................................................................................ 11

2-1.CANNOT DOWNLOAD PROGRAM ....................................................................................................................... 11

2-2.COMMUNICATION PROBLEM ABOUT OP AND PLC ............................................................................................ 11

2-3.PROGRAM SECURITY ........................................................................................................................................ 12

2-4.INTERACTIVE CONTROL .................................................................................................................................... 12

2-5.SET DATA IN SEQUENCE .................................................................................................................................... 13

2-6.OTHERS ............................................................................................................................................................ 13

3 PLC CONNECTION ................................................................................................................. 14

3-1.XINJE XC SERIES PLC ...................................................................................................................................... 14

3-1-1.Connection unit .......................................................................................................... 14

3-1-2.Communication parameter ......................................................................................... 14

3-1-3.Cable connection ........................................................................................................ 15

3-2.MITSUBISHI FX SERIES PLC ............................................................................................................................. 17

3-2-1.Connection unit .......................................................................................................... 17

3-2-2.Communication parameters ........................................................................................ 17

3-2-3.Cable connection ........................................................................................................ 18

3-3.SIEMENS S7-200 SERIES PLC ........................................................................................................................... 19

3-3-1.Connection unit .......................................................................................................... 19

3-3-2.Communication parameters ........................................................................................ 19

3-3-3.Cable connection ........................................................................................................ 20

3-4.OMRON C SERIES PLC ...................................................................................................................................... 20

3-4-1.Connection unit .......................................................................................................... 20

3-4-2.Communication parameters ........................................................................................ 21

3-4-3.Cable connection ........................................................................................................ 22

1

3-5.KOYO S SERIES PLC ......................................................................................................................................... 23

3-5-1.Connection unit .......................................................................................................... 23

3-5-2.Communication parameters ........................................................................................ 24

3-5-3.Cable connection ........................................................................................................ 25

3-6.DELTA DVP SERIES PLC ................................................................................................................................... 26

3-6-1.Connection unit .......................................................................................................... 26

3-6-2.Communication parameters ........................................................................................ 26

3-6-3.Cable connection ........................................................................................................ 27

3-7.LG MASTER-K (PROGRAMMING PORT) SERIES PLC ......................................................................................... 27

3-7-1.Connection unit .......................................................................................................... 28

3-7-2.Communication parameters ........................................................................................ 28

3-7-3.Cable connection ........................................................................................................ 29

3-8.LG MASTER-K (MODBUS) SERIES PLC (MULTI-FUNCTION PORT) .................................................................... 29

3-8-1.Connection unit .......................................................................................................... 29

3-8-2.Communication parameters ........................................................................................ 29

3-8-3.Cable connection ........................................................................................................ 30

3-9.LG MASTER-K (CNET) SERIES PLC (MULTI-FUNCTION PORT) ......................................................................... 31

3-9-1.Connection unit .......................................................................................................... 31

3-9-2.Communication parameters ........................................................................................ 31

3-9-3.Cable connection ........................................................................................................ 33

3-10.MATSUSHITA FP SERIES PLC .......................................................................................................................... 34

3-10-1.Connection unit ........................................................................................................ 34

3-10-2.Communication parameters ...................................................................................... 34

3-10-3.Cable connection ...................................................................................................... 35

3-11.SCHNEIDER NEZA SERIES PLC ...................................................................................................................... 37

3-11-1.Connection unit ......................................................................................................... 37

3-11-2.Communication parameters ...................................................................................... 37

3-11-3.Cable connection ...................................................................................................... 39

3-12.FATEK FB SERIES PLC .................................................................................................................................... 39

3-12-1.Connection unit ........................................................................................................ 39

3-12-2.Communication parameters ...................................................................................... 40

3-12-3.Cable connection ...................................................................................................... 40

3-13.VIGOR VB SERIES PLC ................................................................................................................................... 42

3-13-1.Connection unit ........................................................................................................ 42

3-13-2.Communication parameters ...................................................................................... 43

3-13-3.Cable connection ...................................................................................................... 43

3-14.EMERSON EC20 SERIES PLC .......................................................................................................................... 44

3-14-1.Connected unit .......................................................................................................... 44

3-14-2.Communication parameters ...................................................................................... 45

3-14-3.Cable connection ...................................................................................................... 45

3-15.IDEC MICRO SMART SERIES PLC .................................................................................................................. 46

3-16.KEYENCE KV SERIES PLC .............................................................................................................................. 47

3-17.SAIA-BURGESS PCD SERIES PLC.................................................................................................................. 48

2

Power

-

off permission

< 20ms

Voltage endurance

AC1000V

-

10MA 1minute (signal and ground)

Air No corrosive gas

Protection

IP65 for front cover

Cooling method

Natural cooling

1 Hardware

1-1.Introduction

OP series operate panel can control the PLC through buttons, texts, lamps.

Characteristics:

Edit the program in OP20 software, download program via PC serial port

Can communicate with various PLCs. Such as Mitsubishi FX series, Omron C series,

Siemens S7 series, Koyo SG series and so on

Password function

Built-in RTC

OP can display dynamic text

Alarm function

All the buttons can be defined as multi-function

STN LCD with backlight

Protection level is up to IP65

Support bmp picture displaying

1-2.General specifications

1. Electrical spec

Input voltage DC24V

Input voltage range DC20V-DC28V

Power < 4W(TYPE2.0W)

Insulated resistance DC500V- about 10MΩ (signal and ground)

2.Environment

Operate temperature

Storage temperature

Humidity 20~85% (no condensation)

Vibration endurance 10~25Hz(X, Y, Z direction 30 minutes 2G)

Noise immunity Voltage noise: 1000Vp-p, pulse width is 1

0~50℃, no condensation

–20~60℃

3

OP320

-A

RS232/RS422

OP320

-A-N

RS232

Button

7

Program

64KB FalshROM

Data

1KB SRAM

Display area

192

*64

Memory

Data

1KB SRAM

Download

RS232

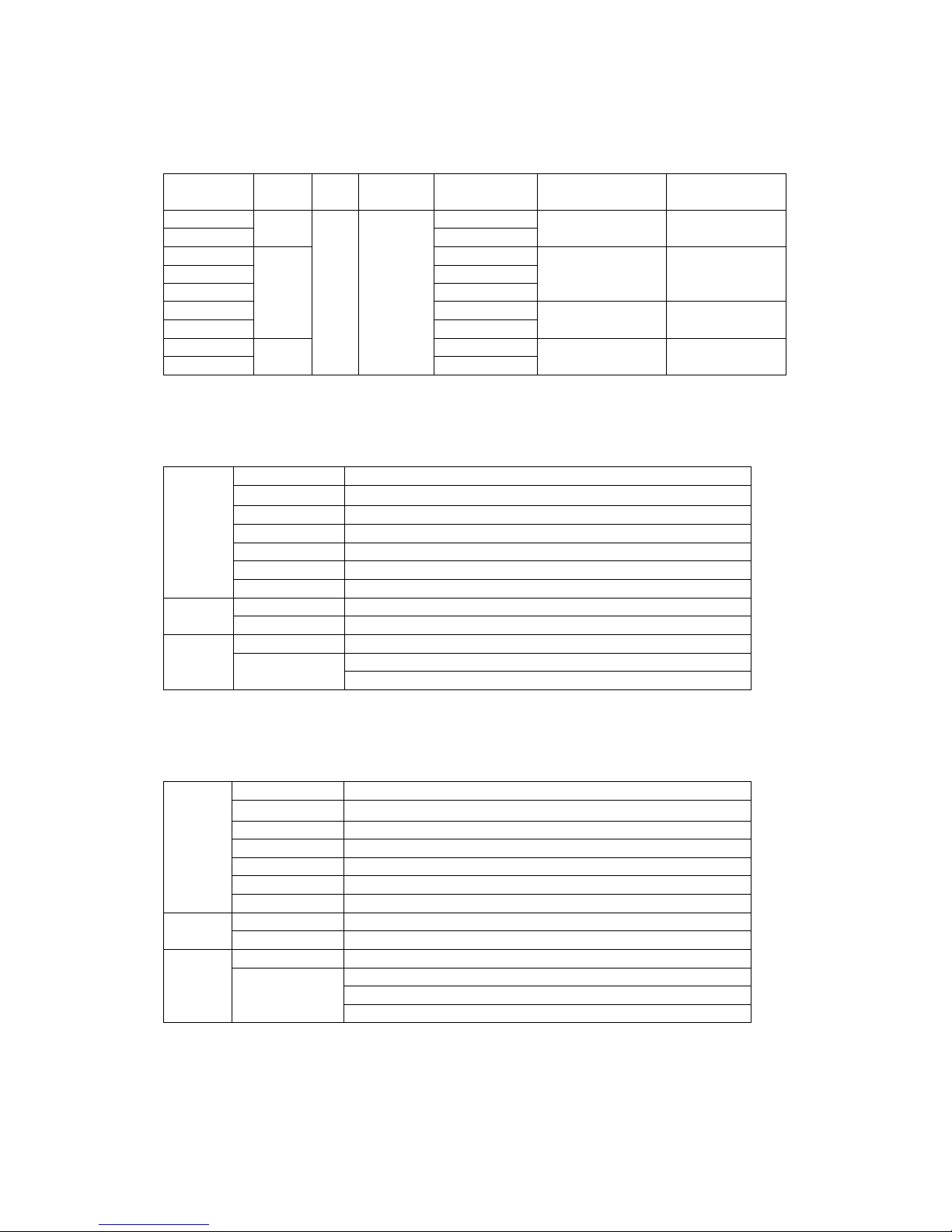

1-3.Function specifications

OP series:

Type Button LCD Backlight Port Dimension (mm)

OP320

OP320-S RS232/RS485

7

RS232/RS422

162.0×102.0×38.0 156.5×94.0

Mounting

dimension (mm)

STN

OP320-A-S RS232/RS485

20

3.7”

OP325-A RS232/RS422

LCD

OP325-A-S RS232/RS485

OP330

OP330-S RS232/RS485

26

RS232/RS422

1-3-1.OP320/OP320-S

Type Blue LCD

Use life

Above 20000 hours, temperature 25℃, 24-hour running

Display area 192*64

Display

Brightness Adjust by potentiometer

Text English (24 words×4 rows)

Font Lattice, vector

Memory

Download RS232

Port

communication

OP320: RS232/RS422

OP320-S: RS232/RS485

1-3-2.OP320-A/OP320-A-N/OP320-A-S

Type Blue LCD

Use life

Above 20000 hours, temperature 25℃, 24-hour running

172.0×94.0×30.0 163.0×85.0

172.0×94.0×38.3 164.2×86.8

172.0×121.0×56.5 164.0×113.0

Display

Brightness Adjust by potentiometer

Text English (24 words×4 rows)

Font Lattice, vector

Button 20

Program 64KB FalshROM

Port

communication

OP320-A: RS232/RS422

OP320-A-N: RS232

OP320-S: RS232/RS485

4

Display area

192*64

Memory

Prog

ram 64KB FalshROM

Data

1KB SRAM

Download

RS232

Display area

192*64

Brightness

Adjust by

potentiometer

Memory

Download

RS232

OP330: RS232/RS422

1-3-3.OP325-A/OP325-A-S

Type Blue LCD

Use life

Above 20000 hours, temperature 25℃, 24-hour running

Display

Brightness Adjust by potentiometer

Text English (24 words×4 rows)

Font Lattice, vector

Button 20

Port

communication

1-3-4.OP330/OP330-S

Type Blue LCD

Use life

Display

Text English (24 words×4 rows)

Font Lattice, vector

Button 7

Program 64KB FalshROM

Data 1KB SRAM

Port

communication

OP325-A: RS232/RS422

OP325-A-S: RS232/RS485

Above 20000 hours, temperature 25℃, 24-hour running

OP330-S: RS232/RS485

5

Buttons

Power

DC24V

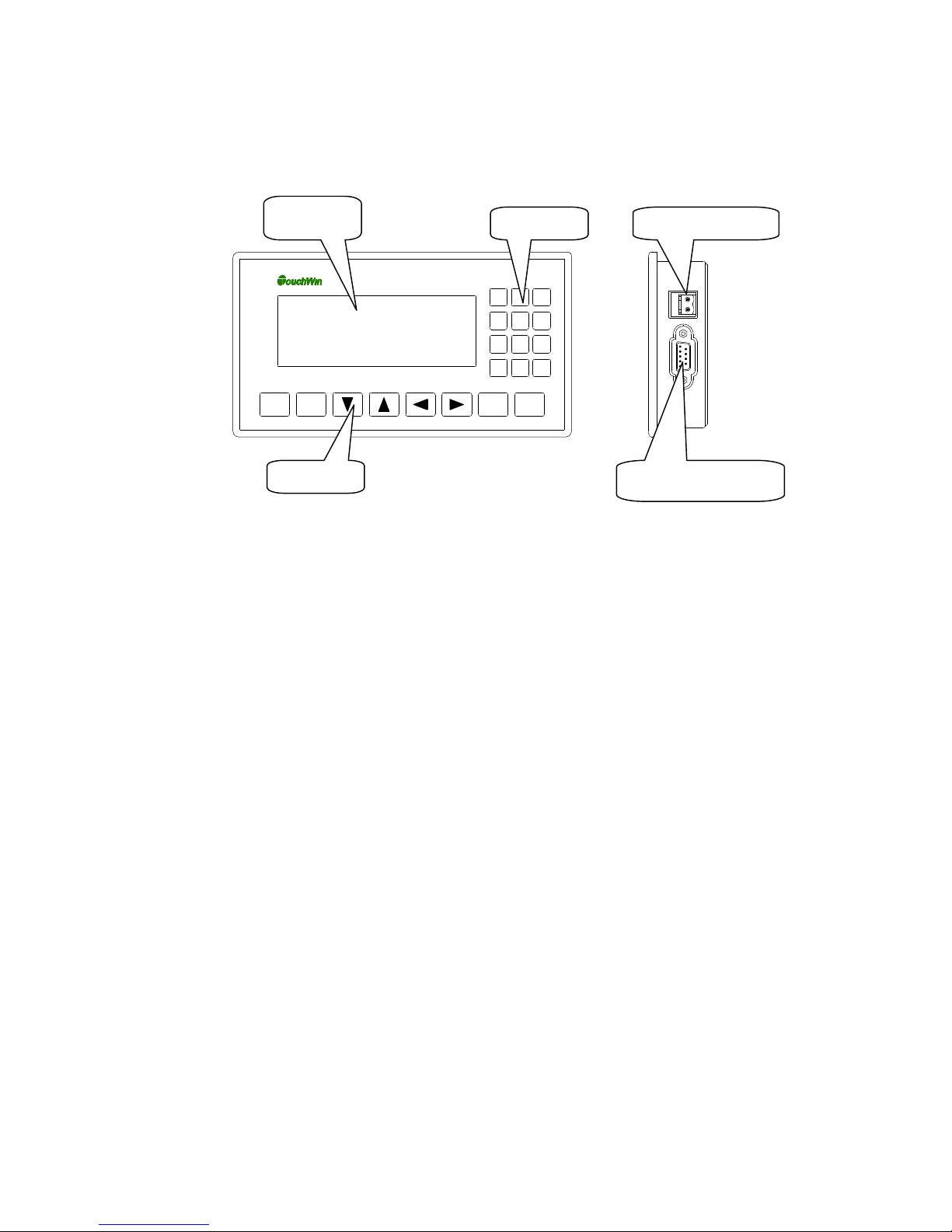

1-4.Part

Take OP320-A for example:

Note:

(1) There is a potentiometer at the reverse side of OP cover. It can adjust the LCD brightness.

Please rotate it with the screw. The LCD backlight will be OFF if there are no any

operations for 3 mintues.

(2) The diagram is only for your reference, each type please see the real product.

Display

Buttons

987

654

321

CLR+/-0

SET ENTALMESC

Download/COM port

6

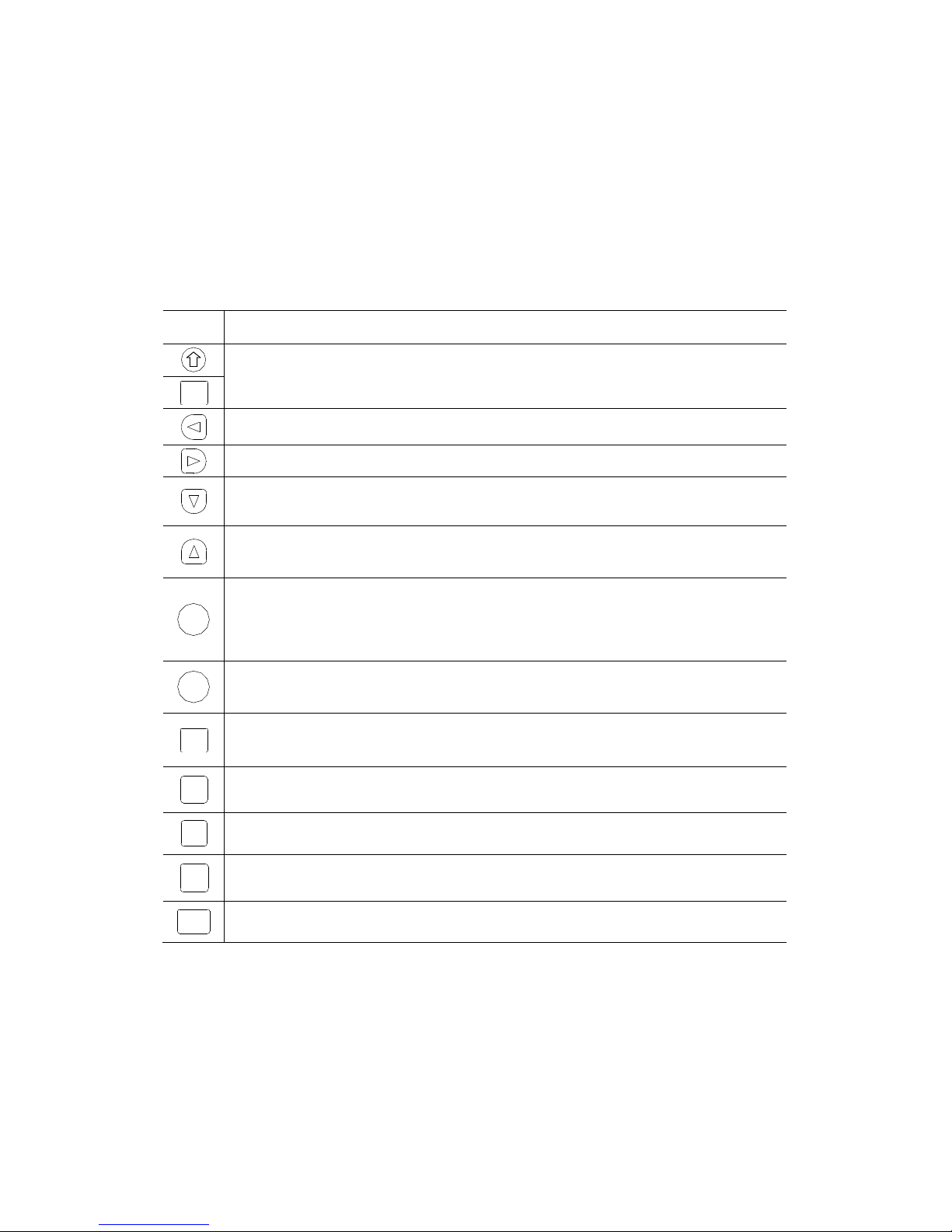

1-5.Button function

The buttons on the OP panel can be defined as many functions. They can instead of the buttons

on the control machine which has long using life and better touch feeling.

Besides, these buttons can be defined to special function such as set on /off bit, screen jump. If

no need special functions, the buttons will execute basic functions: set the value of register, reset

original screen, page up/down.

Buttons functions:

Button

ESC

SET

ENT

ALM

CLR

+/-

Basic function

Return to the original screen (default is screen no.1). The main menu or frequenct-used

screen can be set to original screen

Left shift data bit when changing the register

Right shift data bit when changing the register

Page down, the default value = current page -1.

Minus one for the data being changed, the range is 0 -> 9 -> 0

Page up, the default value = current page +1.

Plus one for the data being changed, the range is 9 -> 0 -> 9

Press this button to change the register value, the changed bit is shining. If there is no

register in the program, this button executes do-nothing operation.

Press this button before pressing ENT to cancel the current modification and continue to

change the next register.

Confirm the modification and continue the next one

After setting alarm list function, press this button to enter alarm screen

Used as function button

Clear the register value

Used as function button

Set the negative or positive of value

Used as function button

Numeric button (range: 0~9)

n

Used as function button

Fn

Overall function button or normal function button

7

4 5

GND

6 TD-

4 5

GND

6

4 5

GND

6 TD-

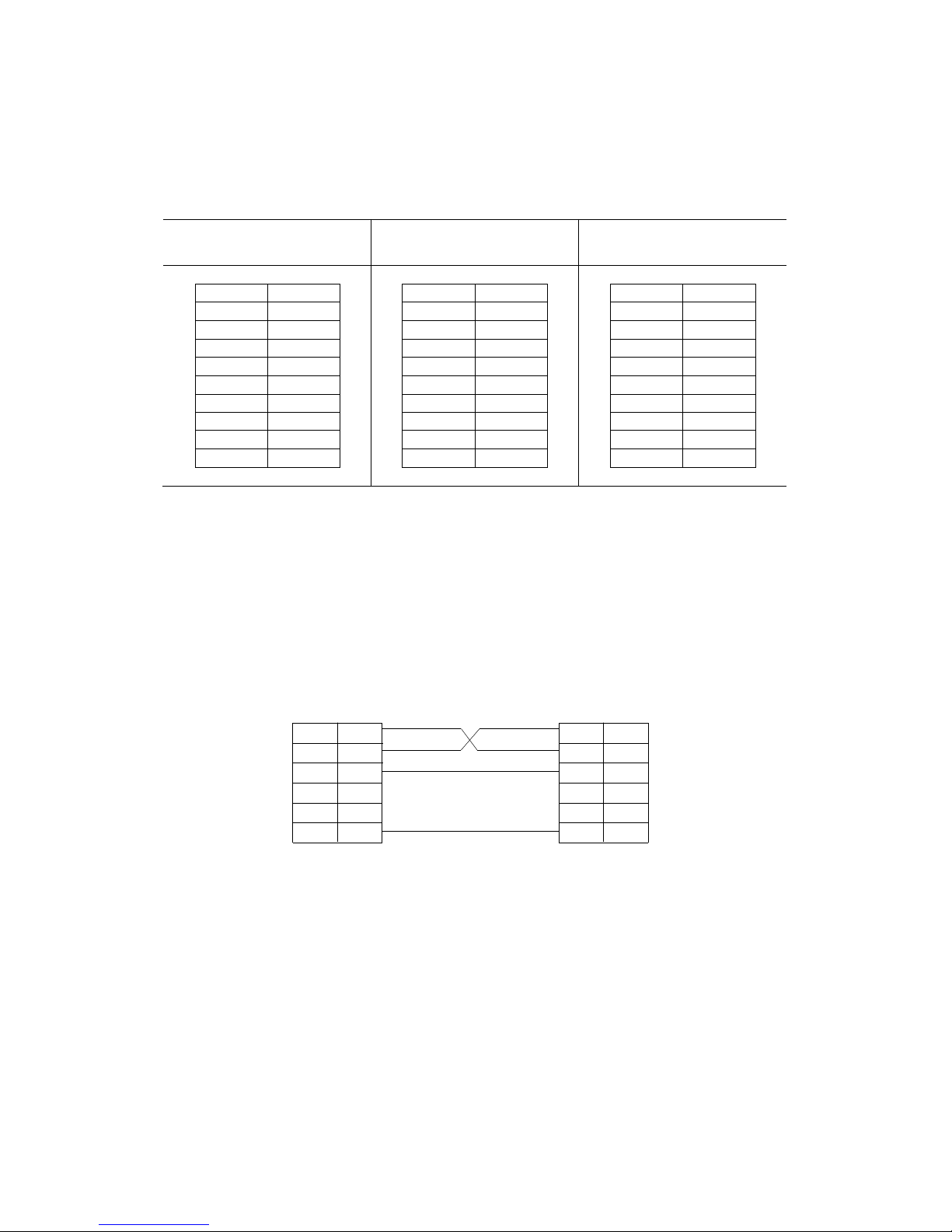

1-6.Port and download connection

1-6-1.Port

OP series has a DB9 port. It can download program and communicate with other devices.

OP320, OP320-A,

OP325-A, OP330

OP320-A-N

OP320-S, OP320-A-S,

OP325-A-S, OP330-S

Pin Name

1 TD+

2 RXD

3 TXD

7

8 RD9 RD+

Pin Name

2 RXD

3 TXD

7

8

9

Pin Name

1 TD+

2 RXD

3 TXD

7

8 B

9 A

1-6-2.Download connection

Please use OP cable to connect OP 9-pin port and PC serial port. The cable can be also used to

connect OP and PLC.

OP and PC connection diagram:

OP (9-pin port) PC (9-pin port)

RXD

TXD

2

3

7

2

RXD

3

TXD

7

CTS

GND

5

8

5

GND

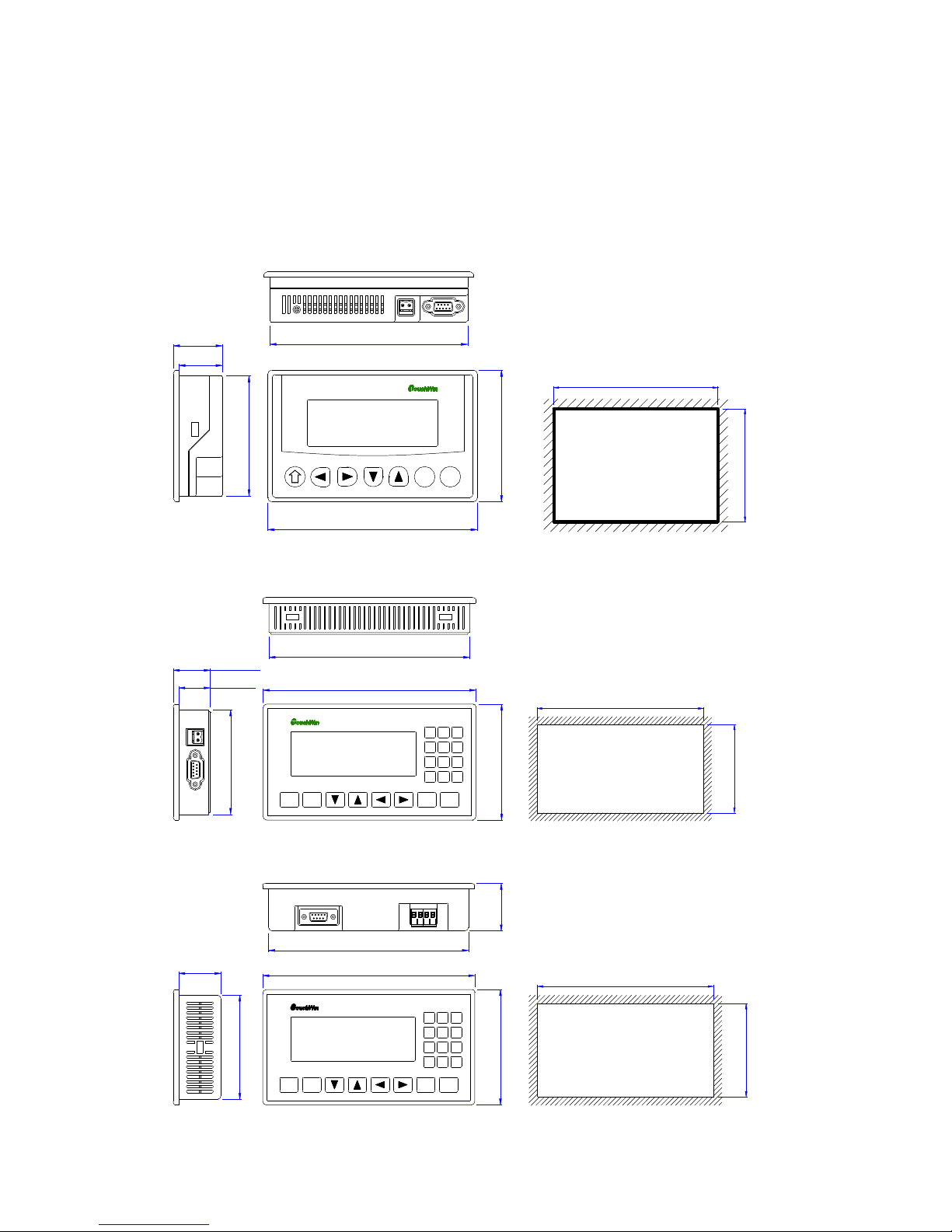

1-7.Dimension and installation

1-7-1.Dimension

Unit: mm

OP320, OP320-S

38.0

153.0

33.7

93.0

SET ENT

162.0

OP320-A, OP320-A-N, OP320-A-S

162.2

30.0

25.5

84.8

172.0

987

654

321

CLR+/-0

SET ENTALMESC

OP325-A, OP325-A-S

102.0

94.0

156.5

94.0

163.0

85.0

34.3

84.8

162.1

172.0

38.8

164.2

987

654

321

CLR+/-0

94.0

SET ENTALMESC

9

86.8

Mounting panel

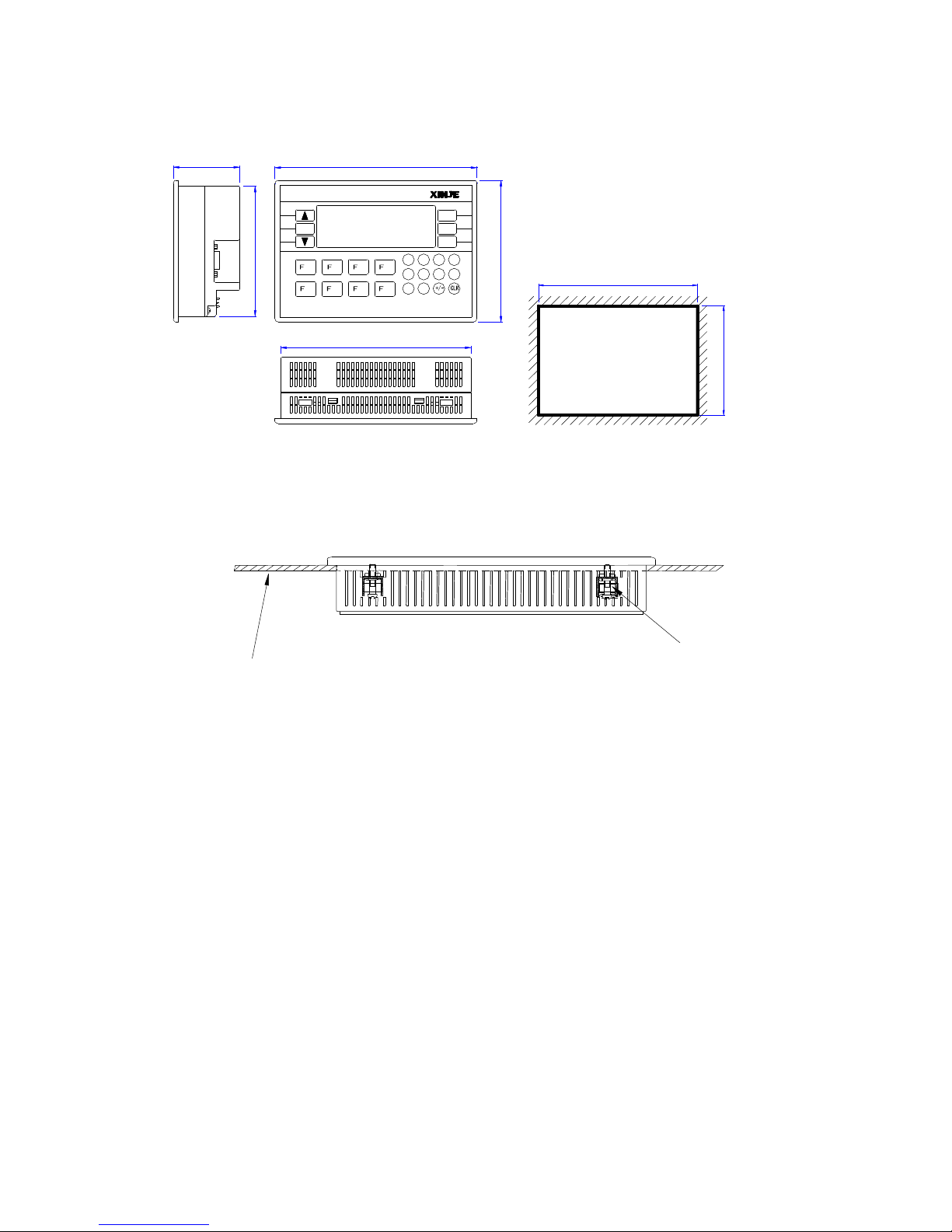

OP330, OP330-S

56.5

ALM SET

111.0

1-7-2.Installation

OP installation diagram:

1 2 3 4

172.0

8765

162.0

ESC

ENT

6 7 8 9

1 0

121.0

5432

164.0

113.0

Mounting stand

Mounting steps:

(1) Make a mounting hole on the mounting panel

(2) Put the bottom of OP into the hole

(3) Mount the mounting stand into the fixing hole

(4) Tighten the 4 screws in the fixing hole

Note:

1. Make sure the mounting hole will not hurt the OP surface. Please leave some space

between hole and OP.

2. Don’t make the screw too tight to avoid cover damage.

3. Please add seal ring in the hole

10

V7.0—V8.0 V8.0n

2 Q&A

OP program is edited in OP20 software; please refer to OP software manual. This chapter will

explain some general questions about using OP.

2-1.Cannot download program

1. The version of hardware and software must be matched. Please see the following table.

Hardware version Software version

V3.6 V3.6

V4.0—V7.0 (not include 7.0) V6.5z

Hardware version: Please see the label at the reverse side of OP product.

Software version: please see the item Help/about…. in OP20 software.

2. Check the download cable

OP (9-pin port) PC (9-pin port)

RXD

TXD

GND

3. Try to download program via PC serial port.

4. If download program via USB-RS232 converter, it will be error sometime. Because some

converter doesn’t connect pin7, but OP need to connect pin7.

5. Open the OP20 software, click file/com port… to choose the PC serial port.

2

3

7

5

2

RXD

3

TXD

7

CTS

5

GND

2-2.Communication problem about OP and PLC

1. PLC and OP is all powered on, and the cable connection is well; the PLC device choice is

correct in the OP20 software. Please refer to chapter 3 for the cable connection diagram.

2. Check the communication parameters of PLC and OP, they must be the same.

3. Check the station no. especially the station no. of alarm list, register and relay.

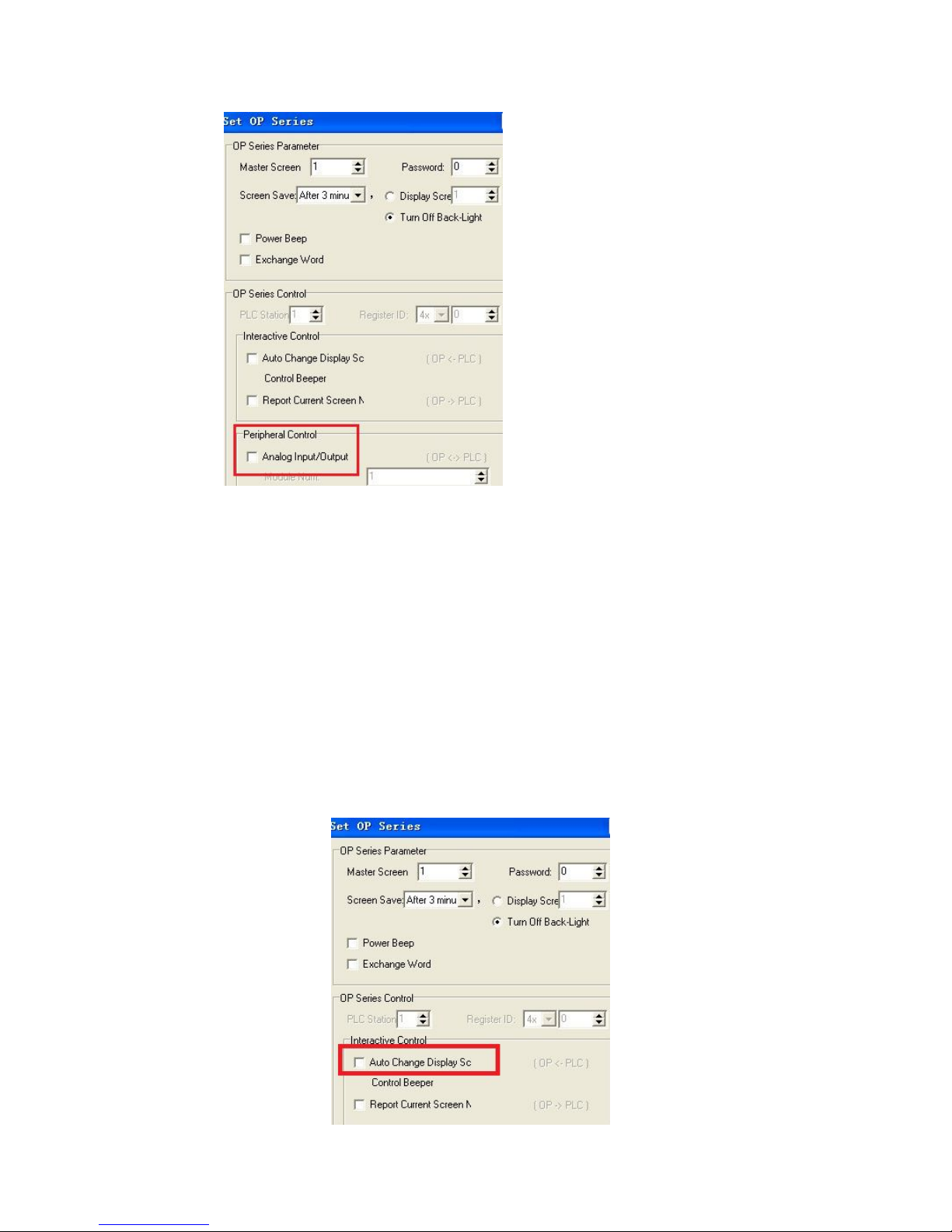

4. Don’t choose analog input/output in Tool/Set OP series...

11

5. Contact us if they still cannot communicate.

2-3.Program security

OP program cannot be uploaded for security reason.

2-4.Interactive control

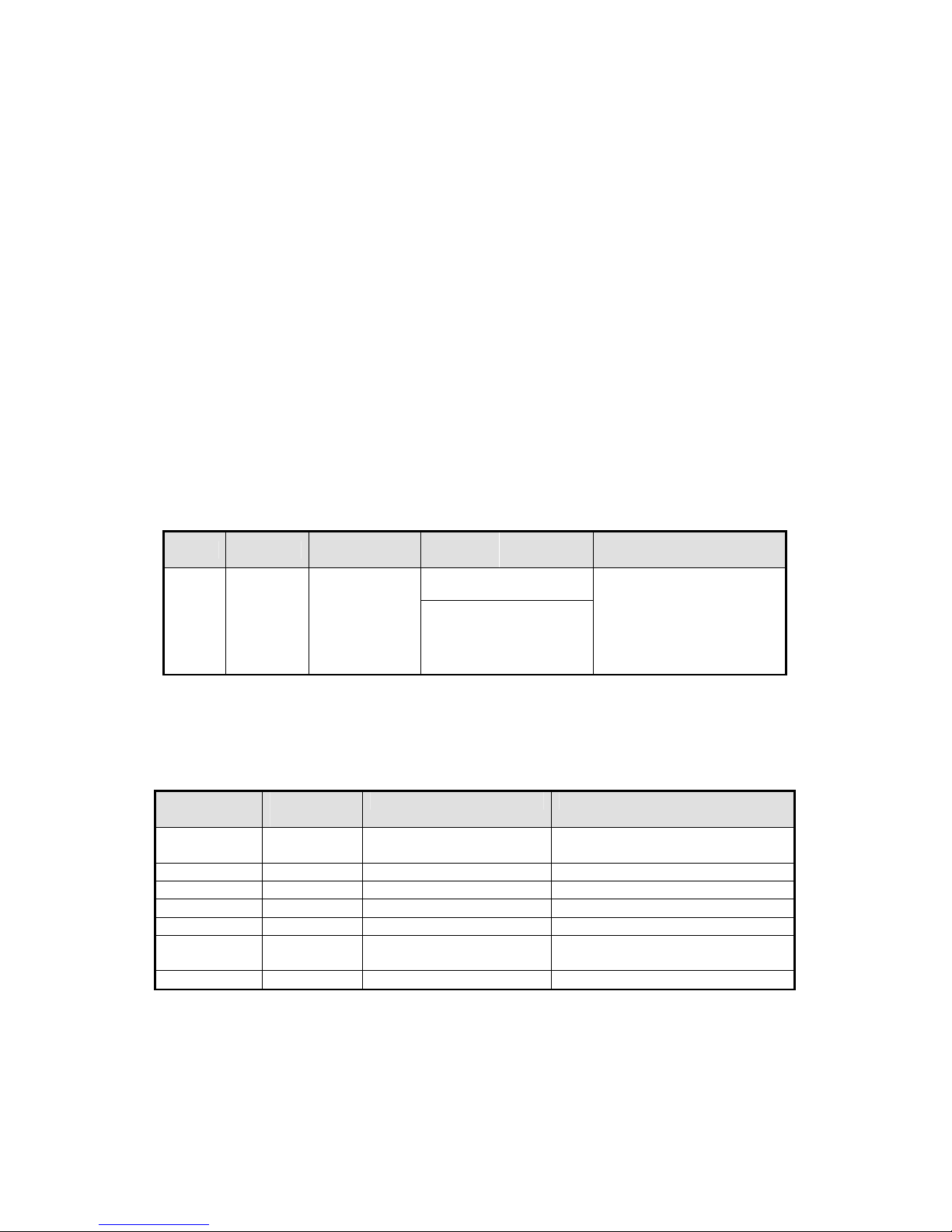

Please choose “auto change display Screen” and set register address in Tool/Set OP series…

Set the register to n, OP will jump to screen No.n when power on. Then the register value will be

cleared.

12

2-5.Set data in sequence

If there are many values need to set in one screen, please click each of them in sequence before

downloading. Then you can set these values in sequence.

2-6.Others

1. When choosing Modbus or free format protocol, OP20 will have register 4x, 3x, 1x, 0x.

1x and 3x mean read only.

0x and 4x mean read and write.

2. OP320/OP320-A/OP325/OP330 cannot support RS485.

13

3 PLC connection

This chapter will introduce the connection method of OP and PLC.

The communication steps of PLC and OP:

1. Choose the PLC type communicating with OP. Check if the communication parameters of

OP and PLC are the same. The station no. of each part in the OP program should be same to

PLC.

2. Please disconnect the OP cable with PC after finish the downloading.

3. Connect OP and PLC with PLC cable, power on them, OP starts to work.

3-1.Xinje XC series PLC

3-1-1.Connection unit

Series

XC

3-1-2.Communication parameter

OP software default settings:

Parameter Recommend

PLC model XC series FC/XC series Choose correct PLC model

Port RS232 RS232/RS485

Data bit 8 7/8 Accord with PLC port settings

Stop bit 1 1/2 Accord with PLC port settings

Parity Even parity Even /odd/no parity Accord with PLC port settings

Baud rate 19200 4800/38400/9600/115200

Station no. 1 0~255

Default communication parameters of Xinje XC series PLC: 19200, 8, 1, even parity, station

no.1.

CPU

XC1

XC2

XC3

XC5

XCM

XCC

Connected

Settings

module

CPU

/19200/187500

Port Cable Choose PLC type in OP20

RS232

RS485

Choices of settings Note

Diagram 1

Xinje XC series

Diagram 2

communicating with OP

Accord with PLC port settings

14

Loading...

Loading...