Xinje DS3-20P2-PQA, DS3E-20P2-PFA, DS3L-20P2-PFA, DS3-20P2-PTA, DS3-20P4-PQA User Manual

...

DS3/DS3E/DS3L series servo drive

User manual

Serial No. SC3 02 20171010 1.0

WUXI XINJE ELECTRIC CO., LTD.

All copyrights reserved by WUXI XINJE ELECTRIC CO., LTD.

Any copying, transferring or any other usage is pro hibited. Otherwise Xinje will have the right to

pursue legal responsibilities. All rights including patent and pemission of modules and designs are

reserved.

January, 2010

a

CAUTION

Indicates a potentially hazardous situation, which, if not heeded, could

result in death or serious injury

WARNING

Indicates a potentially hazardous situation, which, if not avoided, may result

in minor or moderate injury.

CAUTION

1. DO NOT install any drive which is damaged, lack of accessories or not the same with the model

ordered.

Doing so may result in electric shock.

WARNING

1. Cut off external power supply before installation.

Not doing so may result in electric shock.

CAUTION

1. Always use the servomotor and servo amplifier in one of the specified combinations.

Never use the products in an environment subject to water, corrosive gases, inflammable gases, or

combustibles.

Doing so may result in electric shock, fire or malfunction.

2. DO NOT touch any metallic part.

Doing so may result in malfunction.

WARNING

1. Cut off external power supply before wiring.

Not doing so may result in electric shock.

2. Connect AC power supply to the corresponding terminals.

Faulty wiring may result in fire.

CAUTION

Be sure to review this section carefully before use this product. In precondition of security, wire

the product correctly.

Safety Precautions

The following defines the symbols used in this manual to indicate varying degrees of safety precautions

and to identify the corresponding level of hazard inherent to each. Failure to follow precautions

provided in this manual can result in serious, possibly even fatal, injury, and/or damage to the persons,

products, or related equipment and systems.

Checking Products upon Delivery

Installation

Wiring

b

1. Do not connect a three-phase power supply to the U, V, or W output terminals.

Doing so may result in injury or fire.

2. Use 2mm2 wire to grounding the groud terminals.

Not doing so may result in electric shock.

3. Securely fasten the power supply terminal screws and motor output terminal screws.

Not doing so may result in fire.

Operation

WARNING

1. Never touch any rotating motor parts while the motor is running.

Doing so may result in injury.

2. DO NOT touch the inside the drive.

Doing so may result in electric shock.

3. Do not remove the panel cover while the power is ON.

Doing so may result in electric shock.

4. Do not touch terminals for five minutes after the power has been turned OFF.

Residual voltage may cause electric shock.

CAUTION

1. Conduct trial operation on the servomotor alone with the motor shaft disconnected from machine to

avoid any unexpected accidents.

Not doing so may result in injury.

2. Before starting operation with a machine connected, change the settings to match the parameters of

the machine.

Starting operation without matching the proper settings may cause the machine to run out of control

or malfunction.

3. Before starting operation with a machine connected, make sure that an emergency stop can be

applied at any time.

Not doing so may result in injury.

4. Do not touch the heat sinks during operation.

Not doing so may result in burns due to high temperatures.

5. Do not attempt to change wiring while the power is ON.

Doing so may result in electric shock or injury

3

Catalog

1 Checking Product and Part Names ....................................................................................................... 7

1-1.Checking Products on Delivery ............................................................................................. 7

1-2.Product appearance and name rule ........................................................................................ 7

2 Installations ........................................................................................................................................ 11

2-1.Servo motor ......................................................................................................................... 11

2-1-1.Storage Temperature ................................................................................................ 11

2-1-2.Installation Site ......................................................................................................... 11

2-1-3.Concentricity ............................................................................................................ 11

2-1-4.Orientation ................................................................................................................ 12

2-1-5.Handling Oil and Water ............................................................................................ 12

2-1-6.Cable Stress .............................................................................................................. 12

2-2.Servo Drive .......................................................................................................................... 12

2-2-1.Storage Conditions ................................................................................................... 12

2-2-2.Installation Site ......................................................................................................... 12

2-2-3.Orientation ................................................................................................................ 13

2-2-4.Installation ................................................................................................................ 13

3 Wiring ................................................................................................................................................ 15

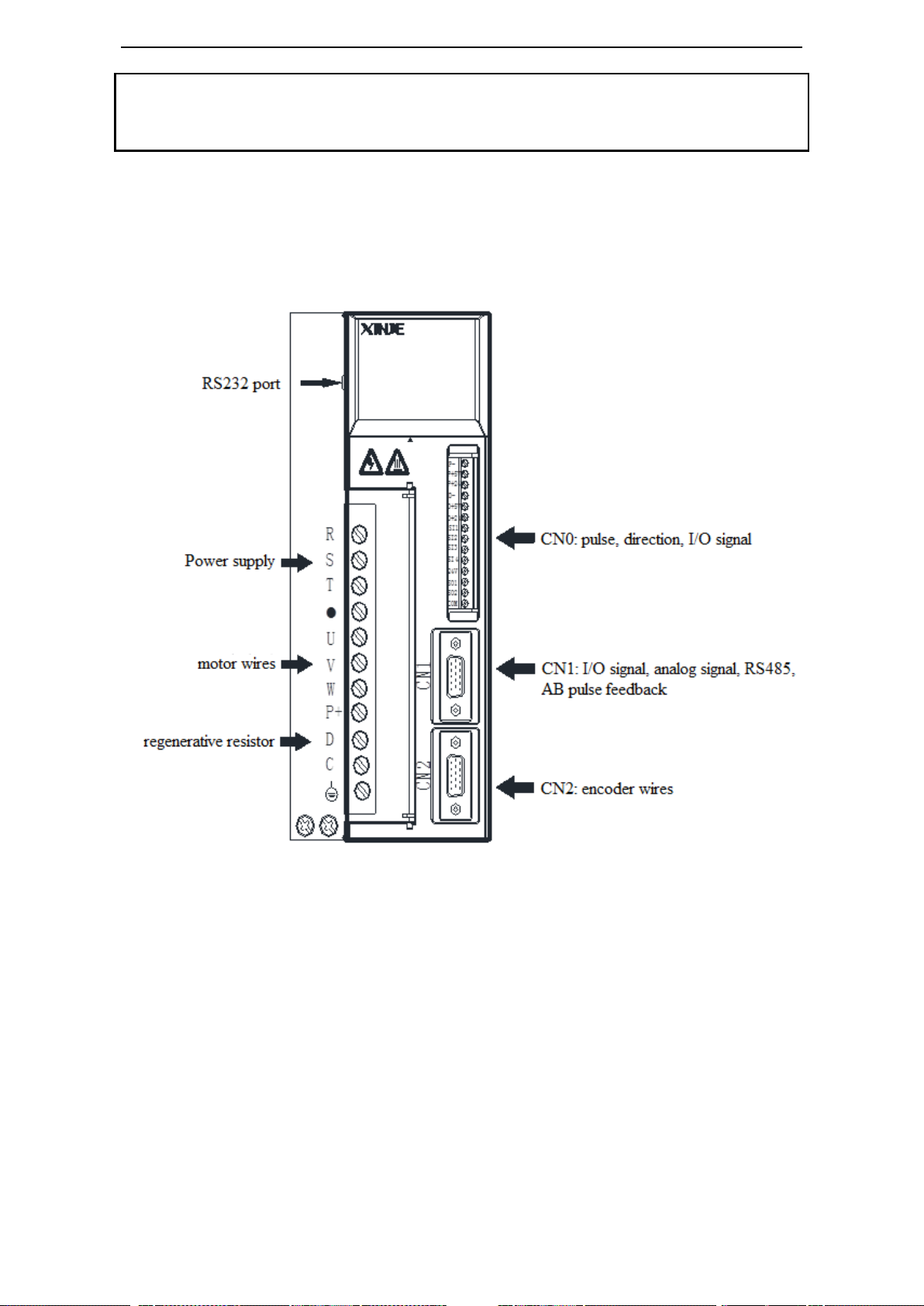

3-1.DS3-PQA series ................................................................................................................... 16

3-1-1.Main circuit wiring ................................................................................................... 16

3-1-1-1. Servo drive terminal arrangement ........................................................................... 16

3-1-1-2. Main circuit terminals ............................................................................................. 17

3-1-1-3.Winding Terminals on Servo motor ...................................................................... 18

3-1-1-4.CN0, CN1, CN2 terminals .................................................................................... 18

3-1-1-5. Communication port ................................................................................................ 20

3-1-2.Signal terminals ........................................................................................................ 22

3-1-2-1. Pulse signal ............................................................................................................. 22

3-1-2-2.SI input signal ....................................................................................................... 23

3-1-2-3. SO output signal ...................................................................................................... 23

3-1-2-4. Analog input circuit ................................................................................................. 24

3-1-2-5. Encoder feedback signal ......................................................................................... 25

3-1-3. Standard wiring example .................................................................................................... 25

3-1-3-1.Position Control Mode .......................................................................................... 25

3-1-4.Regenerative Resistor ....................................................................................................... 27

3-2. DS3E/DS3L-PFA .................................................................................................................. 28

3-2-1. Main circuit wiring ..................................................................................................... 28

3-2-1-1. The terminal arrangement ....................................................................................... 28

3-2-1-2. Main circuit terminals ............................................................................................. 29

3-2-1-3.Winding Terminals on Servo motor ...................................................................... 30

3-2-1-4.CN0, CN1, CN2 terminals .................................................................................... 30

3-2-1-5. Communication port ................................................................................................ 32

3-2-2.Signal terminals ................................................................................................................ 34

3-2-2-1. Pulse signal ............................................................................................................. 34

3-2-2-2.SI input signal ....................................................................................................... 35

3-2-2-3. SO output signal ...................................................................................................... 35

3-2-2-4. Analog input circuit ................................................................................................. 36

3-2-2-5. Encoder feedback signal ......................................................................................... 36

3-2-3. Standard wiring example .................................................................................................... 36

3-2-3-1. Position mode .......................................................................................................... 36

3-2-4. Regenerative resistor .................................................................................................. 36

3-3. DS3-PTA series ..................................................................................................................... 37

3-3-1. Main circuit wiring ..................................................................................................... 37

3-3-1-1. The terminal arrangement ....................................................................................... 37

3-3-1-2. Main circuit terminals ............................................................................................. 37

4

3-3-1-3.Winding Terminals on Servo motor ...................................................................... 39

3-3-1-4.CN0, CN1, CN2 terminals .................................................................................... 39

3-3-1-5. Communication port ................................................................................................ 40

3-3-2.Signal terminals ................................................................................................................ 42

3-3-2-1. Pulse signal ............................................................................................................. 42

3-3-2-2.SI input signal ....................................................................................................... 43

3-3-2-3. SO output signal ...................................................................................................... 44

3-3-2-4. Analog input circuit ................................................................................................. 45

3-3-2-5. Encoder feedback signal ......................................................................................... 45

3-3-3. Standard wiring example .................................................................................................... 45

3-3-4. Regenerative resistor .................................................................................................. 45

4 Use the operate panel ......................................................................................................................... 45

4-1.Basic Operation ................................................................................................................... 45

4-1-1. Functions of operate panel .......................................................................................... 45

4-1-2. Basic Mode Switching ................................................................................................ 45

4-2.Running status mode ............................................................................................................ 46

4-3.Monitoring Mode ................................................................................................................. 47

4-4.Auxiliary Function ............................................................................................................... 52

4-4-1.F0-XX ....................................................................................................................... 52

4-4-2. F1-XX ......................................................................................................................... 53

4-5.Alarm (E-XXX) ................................................................................................................... 54

4-6.Example ............................................................................................................................... 54

4-7.Change the motor code ........................................................................................................ 55

5 Run the servo system ......................................................................................................................... 56

5-1.Control mode selection ........................................................................................................ 56

5-2.Basic function setting........................................................................................................... 56

5-2-1. Servo ON setting ........................................................................................................ 57

5-2-2. Switch the motor rotate direction ............................................................................... 57

5-2-3. Stop mode ................................................................................................................... 57

5-2-4. Overtravel Limit (P-OT & N-OT) .............................................................................. 58

5-2-5. Power-off Brake (BK) ................................................................................................ 59

5-2-6. Alarm output ............................................................................................................... 61

5-2-7. Anti-block run alarm .................................................................................................. 61

5-3.Position mode (external pulse command) ............................................................................ 61

5-3-1. External position mode ............................................................................................... 62

5-3-2. Pulse command and pulse form .................................................................................. 62

5-3-3. Electronic gear ratio ................................................................................................... 63

5-3-4. Position command filter ............................................................................................. 66

5-3-5. Pulse deviation clear (/CLR) ...................................................................................... 67

5-3-6. Positioning complete (/COIN, /COIN_HD) ............................................................... 67

5-3-7. Positioning near (/NEAR) .......................................................................................... 70

5-3-8. Command pulse prohibition (/INHIBIT) .................................................................... 71

5-3-9. Positoin pulse difference ............................................................................................ 71

5-4.Speed control (analog voltage command) (Only for DS3-PQA) ......................................... 71

5-4-1. Control mode selection ............................................................................................... 72

5-4-2. Analog value of rated speed ....................................................................................... 72

5-4-3. Speed command difference auto-adjustment (F1-03) ................................................. 73

5-4-4. Proportion action command (/P-CON) ....................................................................... 73

5-4-5. Zero clamp (/ZCLAMP) ............................................................................................. 74

5-4-6. Speed coincidence checking (/V-CMP)...................................................................... 74

5-4-7. Torque limit ................................................................................................................ 75

5-4-8. Soft start ..................................................................................................................... 76

5-4-9. Filter ........................................................................................................................... 77

5-4-10. Speed reach signal (/V-RDY) ................................................................................... 77

5-4-11. Alarm speed .............................................................................................................. 78

5-4-12. Speed command input dead area voltage.................................................................. 78

5-5.Speed control (internal speed) ............................................................................................. 78

5-5-1. Control mode selection ............................................................................................... 79

5

5-5-2. Internal speed setting .................................................................................................. 79

5-5-3. Input signal setting ..................................................................................................... 79

5-6.Speed control (pulse frequency command) .......................................................................... 81

5-6-1. Control mode selection ............................................................................................... 81

5-6-2. Pulse frequency command .......................................................................................... 81

5-6-3. Command pulse frequency at rated speed .................................................................. 81

5-6-4. Speed command pulse filter time ............................................................................... 82

5-7.Torque control (analog voltage command) (only for DS3-PQA) ........................................ 82

5-7-1. Control mode selection ............................................................................................... 82

5-7-2. The analog value of rated torque ................................................................................ 82

5-7-3. Torque command offset autoadjustment (F1-04) ....................................................... 83

5-7-4. Torque command filter time ....................................................................................... 83

5-7-5. Torque limit ................................................................................................................ 83

5-7-5-1. Internal speed limit .................................................................................................. 83

5-7-5-2. External speed limit ................................................................................................. 84

5-7-5-3. Speed up to limit value output ................................................................................. 84

5-8.Torque control (internal setting) .......................................................................................... 84

5-8-1. Control mode selection ............................................................................................... 85

5-8-2. Internal torque command ............................................................................................ 85

5-9.Motion fieldbus control (position mode) (only for DS3E) .................................................. 85

5-10. Absolute encoder servo drive .............................................................................................. 86

5-10-1. Absolute enocder servo encoder cable ..................................................................... 87

5-10-2. Read the absolute encoder servo position ................................................................. 87

5-10-3. The use and replacement of battery .......................................................................... 88

5-11.Other output signals ........................................................................................................... 88

5-11-1. /ALM and /ALM-RST .............................................................................................. 88

5-11-2. /WARN ..................................................................................................................... 89

5-11-3. Rotation checking (/TGON) ..................................................................................... 89

5-11-4. Hysteresis loop ......................................................................................................... 90

5-11-5. Servo ready (/S-RDY) .............................................................................................. 90

5-11-6. Encoder Z phase output (/Z) (only for DS3-PQA/DS3-PTA) .................................. 90

5-11-7. ABZ phase feedback signal of encoder (CN1 15-pin support) ................................. 91

5-11-8. User-defined output signal........................................................................................ 92

5-11-9. IO filter time ............................................................................................................. 93

5-11-10.Switch the control mode ....................................................................................... 93

5-12. I/O signal distribution .......................................................................................................... 94

5-12-1. Input signal distribution ............................................................................................ 94

5-12-2. Default setting of input terminal ............................................................................... 95

5-12-3. Output terminal distribution ..................................................................................... 95

5-12-4. Default setting of output terminal ............................................................................. 95

5-13. DS3-PTA series absolute encoder servo drive ..................................................................... 95

5-13-1. Read the absolute encoder position .......................................................................... 96

5-13-2. Battery using and changing ...................................................................................... 97

5-14.Internal position mode (only for DS3E/DS3L) .................................................................. 97

5-14-1. Control mode selection ............................................................................................. 98

5-14-2. Internal position mode .............................................................................................. 98

5-14-3. Position parameters from segment 1 to 35 ............................................................. 101

5-14-4. Change step (/CHGSTP) ........................................................................................ 102

5-14-5. Pause current segment signal (/INHIBIT) .............................................................. 102

5-14-6. Skip current segment signal (/ZCLAMP) ............................................................... 102

5-14-7. Reference origin ..................................................................................................... 102

5-14-8. Set segment through communication...................................................................... 104

5-14-9. Motion start signal (/MRUN) ................................................................................. 104

6 Servo gain adjustment ...................................................................................................................... 105

6-1.Gain parameter adjustment ................................................................................................ 105

6-1-1. Gain parameters ........................................................................................................ 105

6-1-2. Other parameters ...................................................................................................... 106

6-2.Parameter switching ........................................................................................................... 107

6-2-1. G-SEL signal input ................................................................................................... 108

6

6-3.The experience of gain adjustment .................................................................................... 108

7 Specification and dimension ............................................................................................................ 109

7-1.Servo motor ....................................................................................................................... 109

7-1-1.Servo motor specification ....................................................................................... 109

7-1-2.Torque-Speed Feature ............................................................................................ 113

7-1-3.Servo motor dimensions ......................................................................................... 115

7-2.Servo drives ....................................................................................................................... 119

7-2-1.DS3E, DS3L, DS3-PTA, DS2 comparison table .................................................... 119

7-2-2.Servo drive dimensions .......................................................................................... 121

8 Alarm Information ........................................................................................................................... 124

Appendix 1 Parameter list ................................................................................................................... 130

Appendix 2 UX-XX monitoring parameters ....................................................................................... 139

Appendix 3 FX-XX auxiliary function ............................................................................................... 142

Appendix 4 Modbus address ............................................................................................................... 142

Appendix 5 General debug steps......................................................................................................... 145

Appendix 6 Application ...................................................................................................................... 146

Appendix 7 Compatible table of servo and motor .............................................................................. 148

7

Items

Comments

Are the delivered products the ones

that were ordered?

Check the model numbers marked on the nameplates of the

servomotor and servo drive.

Does the servomotor shaft rotate

smoothly?

The servomotor shaft is normal if it can be turned smoothly

by hand. Servomotors with brakes, however, cannot be

turned manually.

Is there any damage?

Check the overall appearance, and check for damage or

scratches that may have occurred during shipping.

Are there any loose screws?

Check screws for looseness using a screwdrive.

Is the motor code the same with the

code in drive?

Check the motor code marked on the nameplates of the

servomotor and the parameter P0-33 on the servo drive.

1 Checking Product and Part Names

1-1.Checking Products on Delivery

Use the following checklist when products are delivered.

If any of the above is faulty or incorrect, contact Xinje or an authorized distributor.

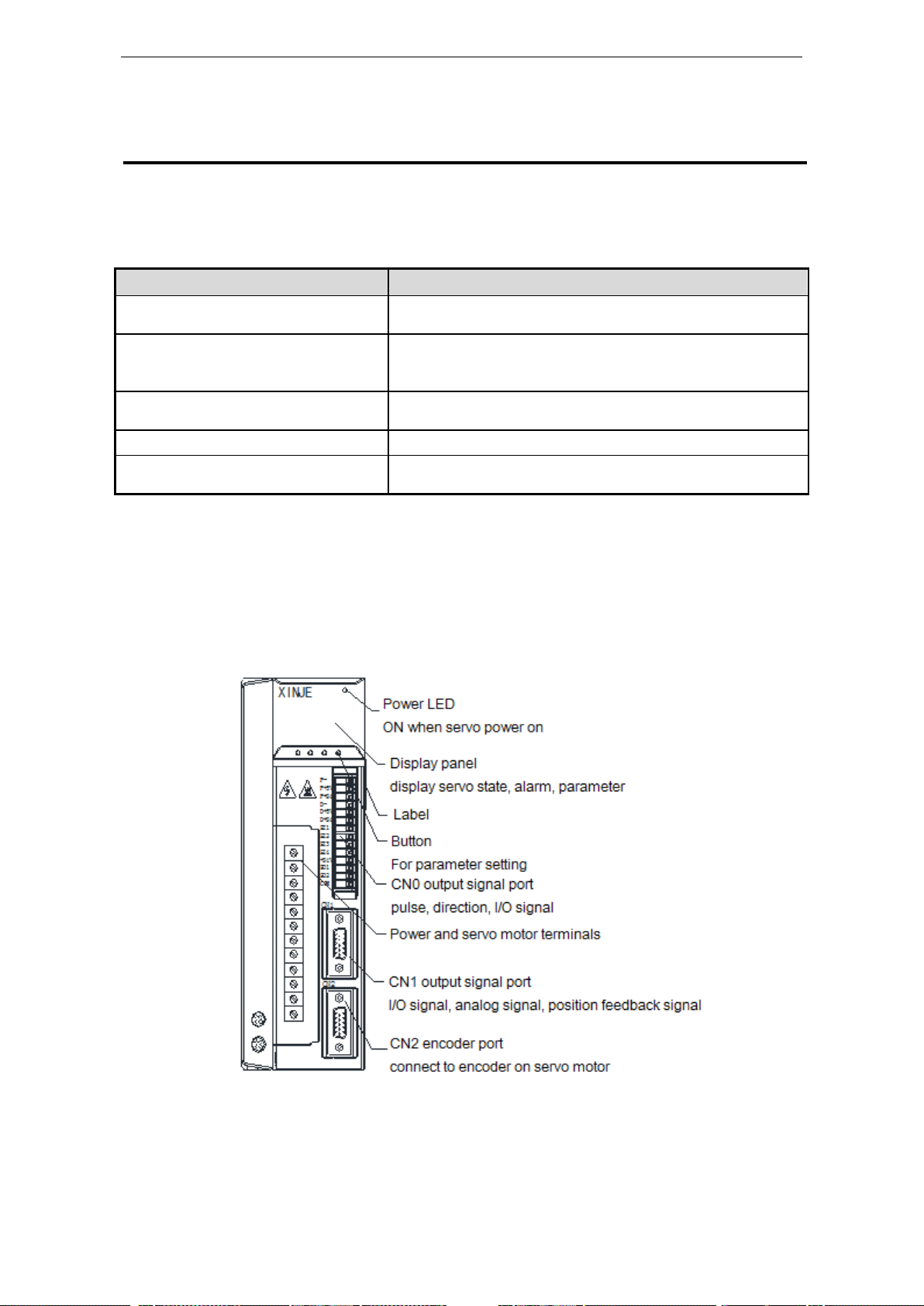

1-2.Product appearance and name rule

DS3-2□P□-PQA/ DS3-4□P□-PQA/ DS3E-2□P□-PFA/ DS3E-4□P□-PFA

Appearance and nameplate

8

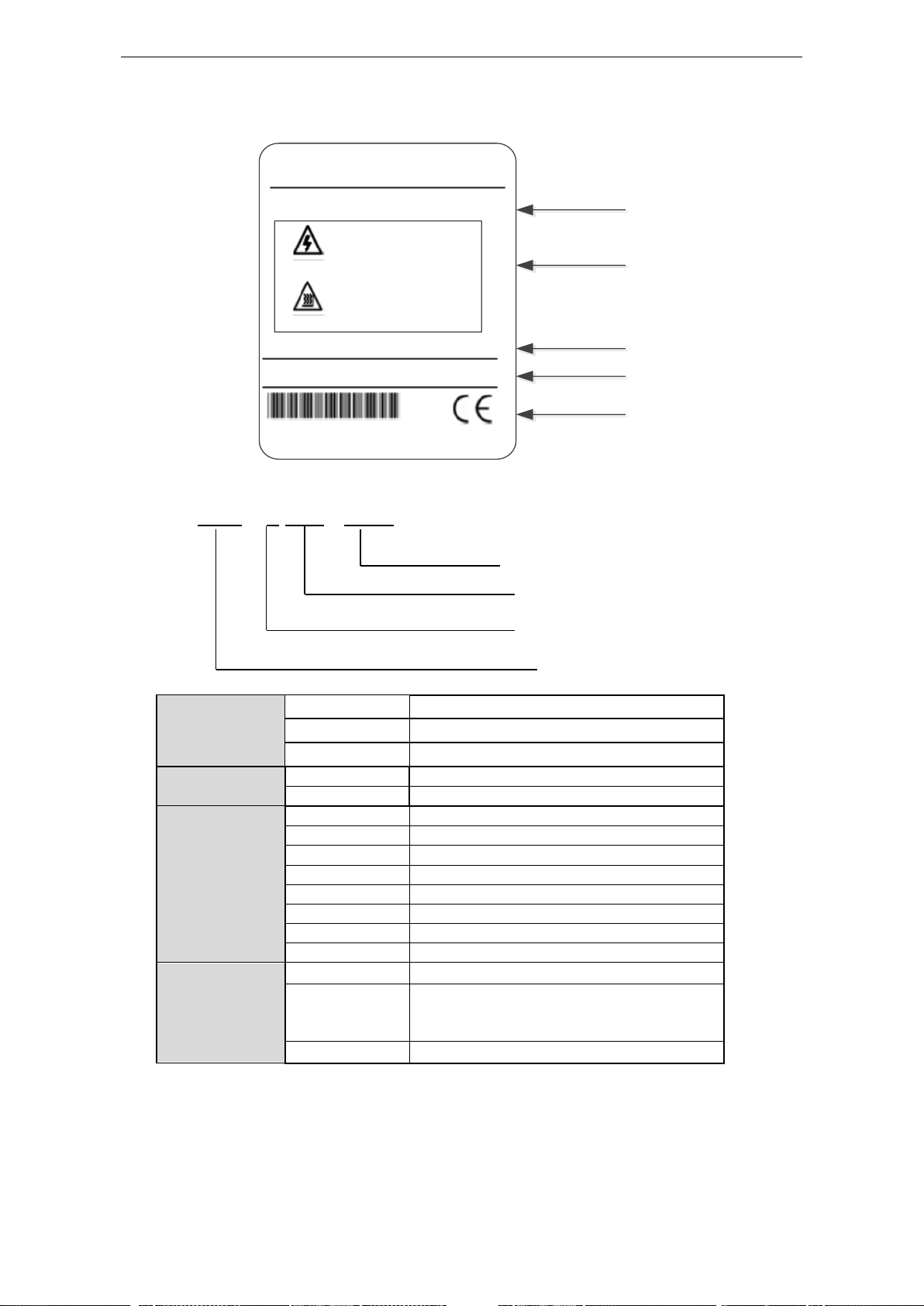

Servo drive nameplate

Series

DS3

DS3 series high precision servo drive

DS3E

DS3E series filedbus servo drive

DS3L series pulse-type servo drive

Voltage level

2

220V

4

380V

Suitable motor

capacity

0P2

0.2 KW

0P4

0.4KW

0P7

0.75KW

1P5

1.5KW

2P3

2.3KW

3P0

3.0KW

5P5

5.5KW

7P5

7.5KW

Configuration

type

P

Input command type: pulse

Encoder type

Q-quadrature encoder

F-compatible quadrature encoder

T-17 bits absolute value encoder

A

Design order: A

Configure type

Series name

Suitable motor capacity

Voltage level

XINJE

SERVO DRIVER

DS3-20P7-PQA

WARNING

CAUTION

AC INPUT:1PH/3PH 200-240V 50/60Hz 3.5A

AC OUTPUT:3PH 0-200V 3.5A 0.75KW

12052013

WUXI XINJE ELECTRIC CO.,LTD

Drive model

Caution

Input power supply

Output power supply

Serial no.

(1) Naming rule

DS3 – 2 0P7 - PQA

9

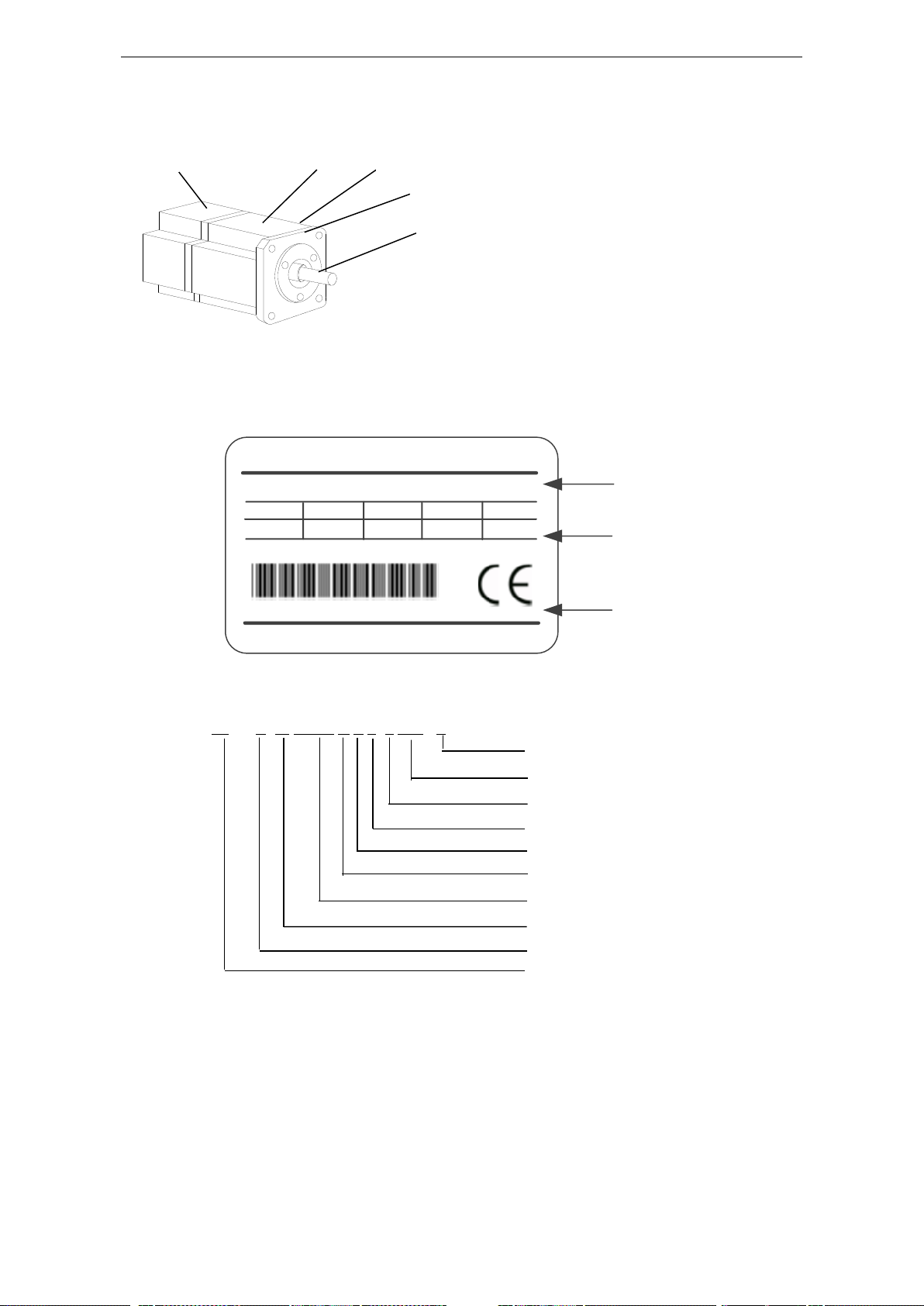

Servo motor

Encoder part

Frame

Flange

Output (transmission) shaft

Motor label

XINJE

AS SERVO MOTOR

MS- 80ST- M02403B -20P7

0.75

XJY1410714180480701

Motor model

Motor

specification

Serial no.

KW

IP

65

MOTOR CODE:1011

WUXI XINJE ELECTRIC CO.,LTD

N M

A

rpm

30003.2

2.39

Shaft length

power

voltage level

body length

power-loss brake

shaft specification

performance parameter code

feedback component code

oil seal

base no.

(1) Appearance and nameplate

Motor label

(2) Naming rule

MS -80 ST E- M 02430 B Z S- 2 0P7 - S

10

Base number

40, 60, 80, 90, 110, 130, 180, 220

Oil seal

Empty

Without oil seal (130ST and above models all

have oil seal, so the model without E)

E

With oil seal (60ST, 80ST model name has

differences)

Feedback

component no.

M

Incremental encoder (2500ppr optical pulse

encoder)

F

Line-saving incremental encoder (2500ppr

optical pulse encoder)

T

17 bits absolute value encoder

N

20 bits absolute value encoder

Performance

parameter no.

First 3 bits mean rated torque, last 2 bits mean rated speed

Such as: 00630: rated torque 0.6N.m, rated speed 3000rpm

06025: rated torque 6.0N.m, rated speed 2500rpm

19015: rated torque 19.0N.m, rated speed 1500rpm

Shaft spec

A

No bond

B

With bond

Power-loss

brake

Vacant

No

Z

With power-off brake

Body length

Vacant

Normal models

S

Short body

Voltage level

2

220V

4

380V

Power

Such as: 0P4: 0.4kW

0P7: 0.75kW

1P5: 1.5KW

Motor shaft

length

Note: only

180ST has

differences

vacant

Normal models

S

Short shaft

11

2 Installations

CAUTION

1. The end of the motor shaft is coated with antirust. Before installing, carefully remove all of the

paint using a cloth moistened with paint thinner.

2. Avoid getting thinner on other parts of the servomotor.

Antirust

2-1.Servo motor

MS series servomotors can be installed either horizontally or vertically. The service life of the

servomotor can be shortened or unexpected problems might occur if it is installed incorrectly or in an

inappropriate location. Follow these installation instructions carefully.

2-1-1.Storage Temperature

Store the servomotor within -20~+60 ℃ as long as it is stored with the power cable disconnected.

2-1-2.Installation Site

MS series servomotors are designed for indoor use. Install the servomotor in environments that satisfy

the following conditions.

Free of corrosive or explosive gases.

Well-ventilated and free of dust and moisture.

Ambient temperature of 0° to 50°C.

Relative humidity (r.h.) of 20 to 90% with no condensation.

Accessible for inspection and cleaning.

2-1-3.Concentricity

Please use coupling when connecting to machine; keep the shaft center of servo motor and machine at

the same line. It should be accord to the following diagram when installing the servo motor.

12

Situation

Installation Precaution

Installation in a Control

Panel

Design the control panel size, unit layout, and cooling method so the

temperature around the servo drives does not exceed 50°C.

Through part of the shaft

Measure it at 4 places of the circle, the difference should be below

0.03mm. (Rotate with the shaft coupler)

Measure it at 4 places of the circle, the difference should be below 0.03mm.

(Rotate with the shaft coupler)

Note: (1) If the concentricity is not enough, it will cause the vibration and bearing damage.

(2) When installing the coupler, prevent direct impact to the shaft. This can damage the encoder

mounted on the shaft end at the opposite side of the load.

2-1-4.Orientation

MS series servomotors can be installed either horizontally or vertically.

2-1-5.Handling Oil and Water

Install a protective cover over the servomotor if it is used in a location that is subject to water or oil

mist. Also use a servomotor with an oil seal when needed to seal the through-shaft section.

2-1-6.Cable Stress

Make sure that the power lines are free from bends and tension. Be especially careful to wire signal line

cables so that they are not subject to stress because the core wires are very thin, measuring only 0.2 to

0.3mm2.

2-2.Servo Drive

The DS3 series PQA servo drives are base-type servo drive. Incorrect installation will cause problems.

Follow the installation instructions below

2-2-1.Storage Conditions

Store the servo drive within -20~+60℃, as long as it is stored with the power cable disconnected.

2-2-2.Installation Site

The following precautions apply to the installation site.

13

Installation Near a

Heating Unit

Minimize heat radiated from the heating unit as well as any temperature

rise caused by natural convection so the temperature around the servo

drives does not exceed 50°C.

Installation Near a Source

of Vibration

Install a vibration isolator beneath the servo drive to avoid subjecting it to

vibration.

Installation at a Site

Exposed to Corrosive Gas

Corrosive gas does not have an immediate effect on the servo drives, but

will eventually cause electronic components and terminals to malfunction.

Take appropriate action to avoid corrosive gas.

Other Situations

Do not install the servo drive in hot and humid locations or locations

subject to excessive dust or iron powder in the air.

2-2-3.Orientation

Install the servo drive perpendicular to the wall as shown in the figure. The servo drive must be

oriented this way because it is designed to be cooled by natural convection or by a cooling fan.

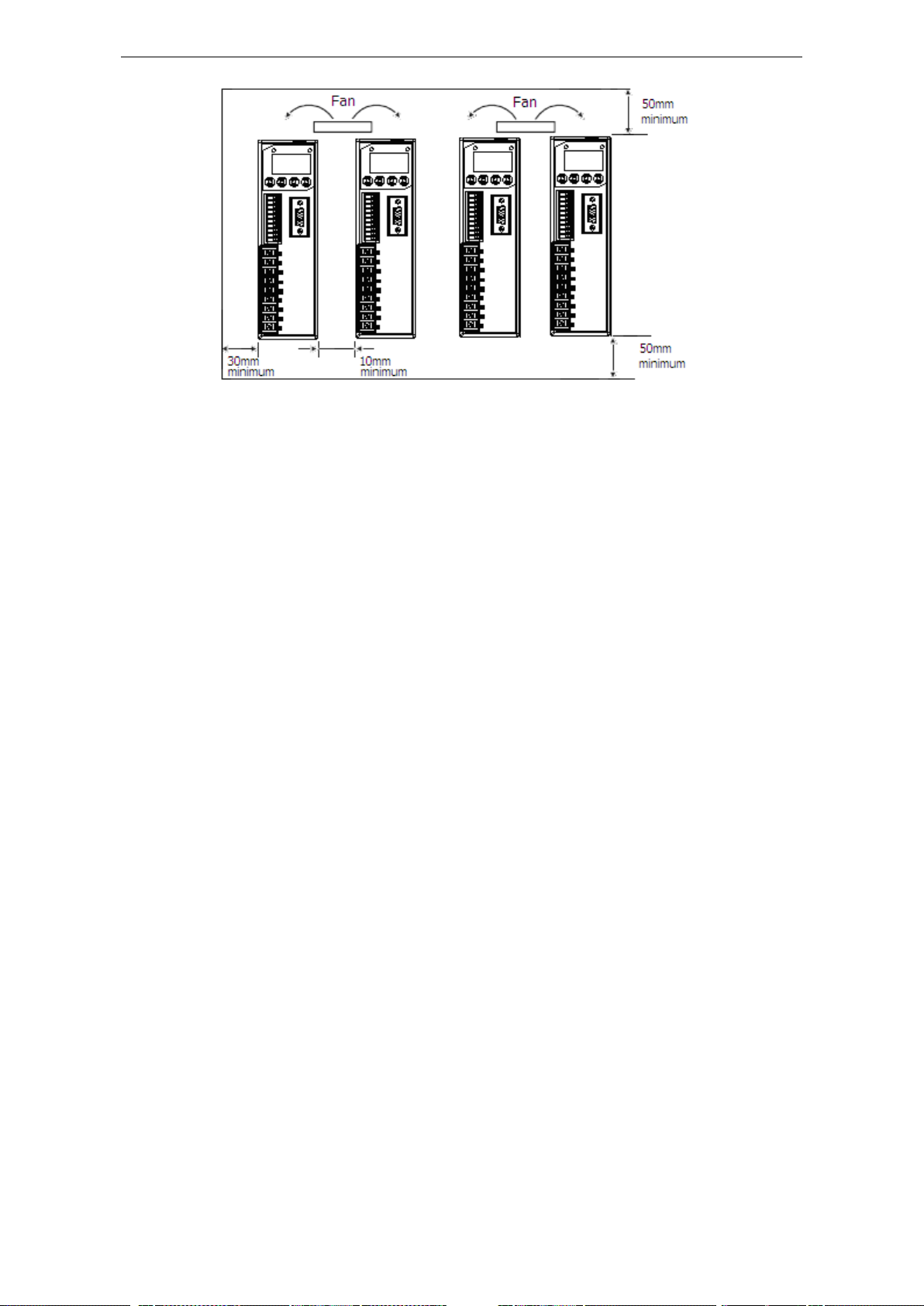

2-2-4.Installation

Follow the procedure below to install multiple servo drives side by side in a control panel.

14

Servo Drive Orientation

Install the servo drive perpendicular to the wall so the front panel containing connectors faces outward.

Cooling

As shown in the figure above, allow sufficient space around each servo drive for cooling by cooling

fans or natural convection.

Side-by-side Installation

When install servo drives side by side as shown in the figure above, make at least 10mm between and

at least 50mm above and below each servo drive. Install cooling fans above the servo drives to avoid

excessive temperature rise and to maintain even temperature inside the control panel.

Environmental Conditions in the Control Panel

Ambient Temperature: 0~50 ℃

Humidity: 90%RH or less

Vibration: 4.9m/s2

Condensation and Freezing: None

Ambient Temperature for Long-term Reliability: 50°C maximum

15

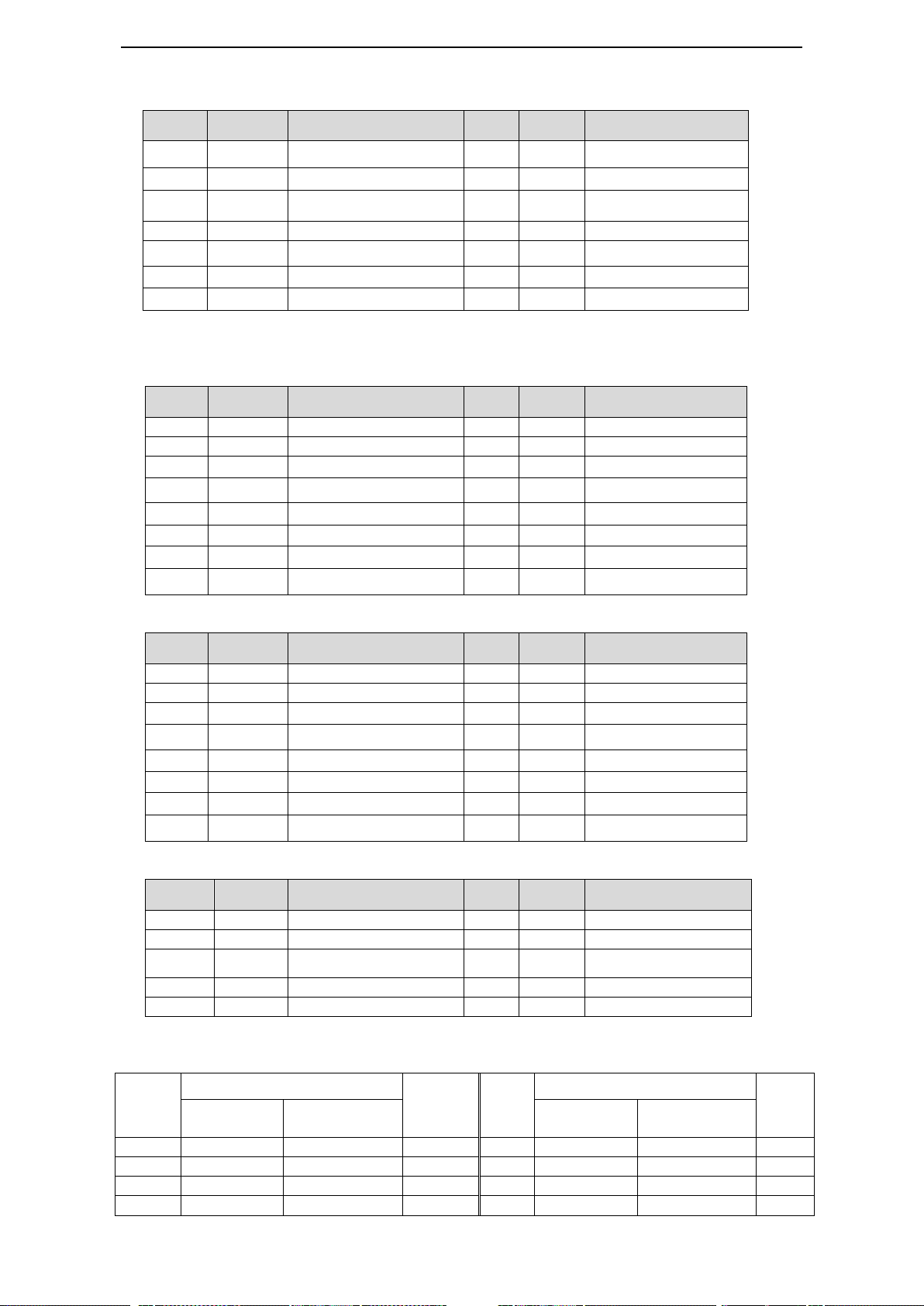

3 Wiring

Servo drive

Power supply

cable diameter

mm²

UVW power cable

diameter mm²

Encoder cable

diameter mm²

Ground cable

diameter mm²

DS3-20P2-PQA

DS3E-20P2-PFA

DS3L-20P2-PFA

DS3-20P2-PTA

2.0

0.75

0.2 (14 cores)

2.0

DS3-20P4-PQA

DS3E-20P4-PFA

DS3L-20P4-PFA

DS3-20P4-PTA

2.0

0.75

0.2 (14 cores)

2.0

DS3-20P7-PQA

DS3E-20P7-PFA

DS3L-20P7-PFA

DS3-20P7-PTA

2.0

0.75

0.2 (14 cores)

2.0

DS3-21P5-PQA

DS3E-21P5-PFA

DS3L-21P5-PFA

DS3-21P5-PTA

2.0

1.5

0.2 (14 cores)

2.0

DS3-22P3-PQA

DS3E-22P3-PFA

DS3L-22P3-PFA

DS3-22P3-PTA

2.0

1.5

0.2 (14 cores)

2.0

DS3E-22P6-PFA

DS3L-22P6-PFA

2.0

1.5

0.2 (14 cores)

2.0

DS3-41P5-PQA

DS3E-41P5-PFA

DS3L-41P5-PFA

DS3-41P5-PTA

2.0

1.5

0.2 (14 cores)

2.0

DS3-43P0-PQA

DS3E-43P0-PFA

DS3L-43P0-PFA

DS3-43P0-PTA

2.0

2.5

0.2 (14 cores)

2.0

DS3-45P5-PQA

DS3L-45P5-PQA

DS3-47P5-PQA

DS3L-47P5-PQA

6.0

6.0

0.2 (14 cores)

6.0

DS3-411P0-PQA

DS3-415P0-PQA

10.0

10.0

0.2 (9 cores)

10.0

Caution

1. Do not bundle or run power and signal lines together in the same duct. Keep power and signal

lines separated by at least 11.81inch(30cm)

2. Use twisted pair wires or multi-core shielded-pair wires for signal and encoder (PG) feedback

lines.

The maximum length is 118.11 inch (3m) for reference input lines and is 787.40 inch (20m) for

encoder (PG) feedback lines.

3. Do not touch the power terminals for 5 minutes after turning power OFF because high voltage

may still remain in the servo amplifier.

Please make sure to check the wiring after the CHARGE light is going off.

4. Avoid frequently turning power ON and OFF. Do not turn power ON or OFF more than once per

Servo drive cable table:

16

minute.

Since the servo amplifier has a capacitor in the power supply, a high charging current flows for

0.2s when power is turned ON. Frequently turning power ON and OFF causes main power devices

like capacitors and fuses to deteriorate, resulting in unexpected problems.

3-1.DS3-PQA series

3-1-1.Main circuit wiring

3-1-1-1. Servo drive terminal arrangement

17

3-1-1-2. Main circuit terminals

DS3-20P2-PQA, DS3-20P4-PQA, DS3-20P7-PQA

Terminal

Function

Explanation

L1/L2/L3

Power supply input of

main circuit

Single or 3 phase AC 200 ~ 240V,

50/60Hz

Note: for single phase 220V, connect

power supply to L1, L3, otherwise it will

affect the power-off retentive function

●

Vacant terminal

-

U, V, W

Motor terminals

Connect the motor

Terminal

Color

U

brown

V

black

W

blue

PE

Yellow green

Note: the ground line is on the cooling

fin, please check it before power on! Do

not connect to P+ or P-!

P+, D, C

Internal regenerative

resistor

Short P+ and D, disconnect P+ and C, set

P0-24=0

External regenerative

resistor

Connect regenerative resistor between P+

and C, disconnect P+ and D, set P0-24=1,

P0-25= power value, P0-26= resistor

value (see chapter 3-4)

P+/P-

Bus terminal

Real-time check the bus voltage, please

take attention of this terminal

DS3-21P5-PQA, DS3-22P3-PQA, DS3-41P5-PQA

Terminal

Function

Explanation

R/S/T

Power supply input of

main circuit

DS3-21P5/22P3-PQA

3 phase AC 200~240V, 50/60Hz

Note: for single phase 220V, connect

power supply to terminal R, T, otherwise

it will affect the power-off retentive

function.

DS3-41P5-PQA

3 phase AC 360~400V, 50/60Hz

●

Vacant

-

U, V, W

Motor terminals

Connect the motor

Terminal

Color

U

brown

V

black

W

blue

PE

Yellow green

P+, D, C

Internal regenerative

resistor

Short P+ and D, disconnect P+ and C,

set P0-24=0

External regenerative

resistor

Connect regenerative resistor between

P+ and C, disconnect P+ and D, set

P0-24=1, P0-25=power value,

P0-26=resistor value (see chapter 3-1-4)

Ground

Connect to ground terminal of motor,

then connect to the ground

L1

L2

.

U

V

W

P+

D

C

P-

L3

R

S

T

.

U

V

W

P+

D

C

18

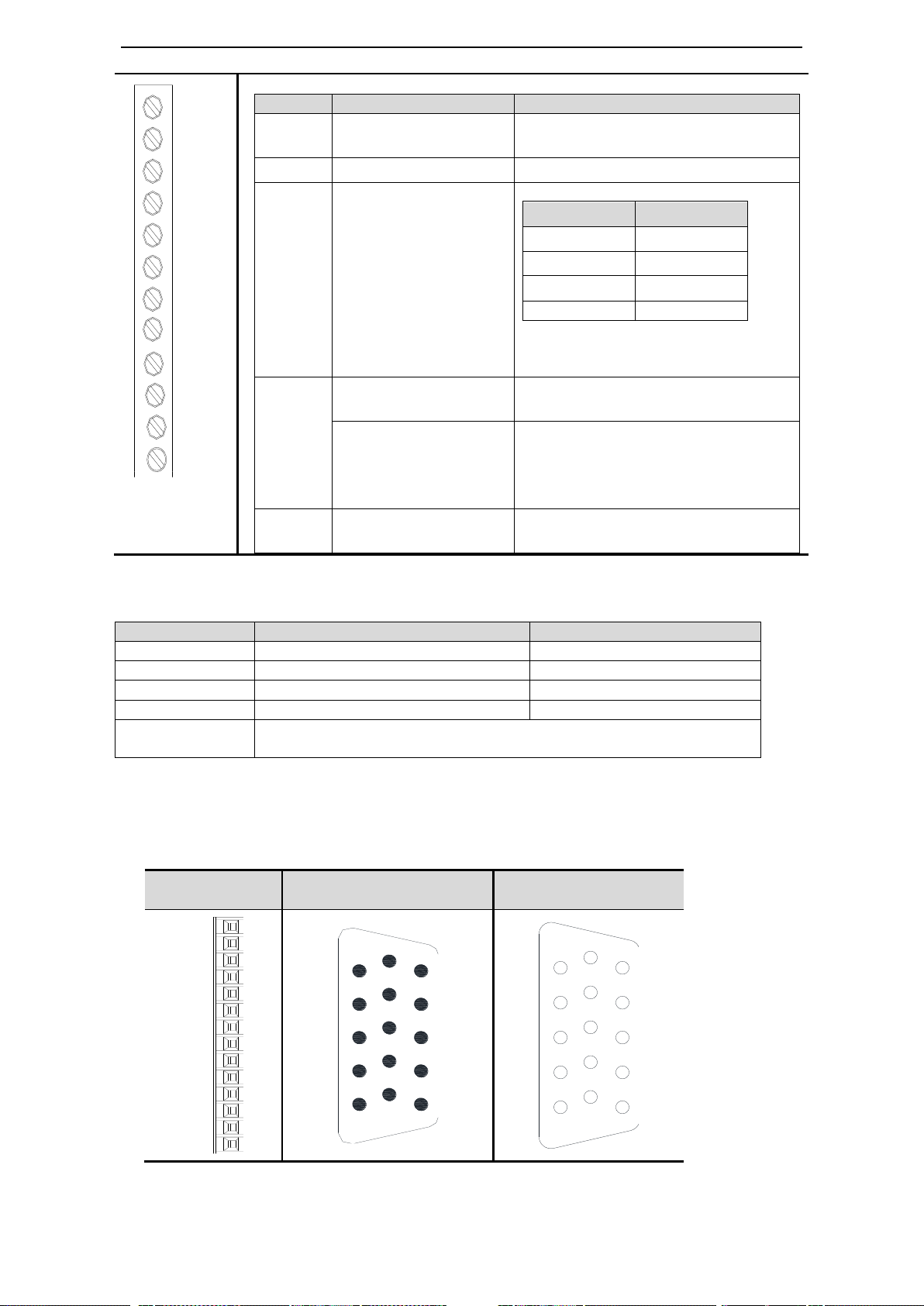

DS3-43P0-PQA

Terminal

Function

Explanation

R/S/T

Power supply input of

main circuit

3 phase AC 360~400V, 50/60Hz

●

Vacant

U、V、

W

Motor terminals

Connect the motor

Terminal

Color

U

brown

V

black

W

blue

PE

Yellow green

Note: the ground line is on the cooling

fin, please check it before power on! Do

not connect to P+ or P-!

P+、D、

C

Internal regenerative

resistor

Short P+ and D, disconnect P+ and C,

set P0-24=0

External regenerative

resistor

Connect regenerative resistor between

P+ and C, disconnect P+ and D, set

P0-24=1, P0-25=power value,

P0-26=resistor value (see chapter 3-1-4)

P+/P-

Bus terminal

Real-time check the bus voltage, please

take attention of this terminal

Symbol

40, 60, 80, 90 Series

110, 130, 180 Series

PE

4-yellow green (yellow green)

1-yellow green

U

1-brown (red)

2-brown

V

3-black (blue)

3-black

W

2-blue (yellow)

4-blue

Terminal for brake

1: +24V

2: GND

CN0

CN1(DB15 male port) drive

side

CN2(DB15 female port)

drive side

R

S

T

.

U

V

W

P+

D

C

P-

.

PP+5V

P+24V

DD+5V

D+24V

SI1

SI2

SI3

SI4

+24V

SO1

SO2

COM

1

5

6

10

11

15

5

1

10

6

15

11

3-1-1-3.Winding Terminals on Servo motor

3-1-1-4.CN0, CN1, CN2 terminals

19

No.

Name

Explanation

No.

Name

Explanation

1

P-

Pulse input PUL-

8

SI2

Input 2

2

P+5V

5V difference input

9

SI3

Input 3

3

P+24V

Open collector input

10

SI4

Input 4

4

D-

Direction input DIR-

11

+24V

Input +24V

5

D+5V

5V difference input

12

SO1

Output 1

6

D+24V

Open collector input

13

SO2

Output 2

7

SI1

Input 1

14

COM

Ground of output

No.

Name

Explanation

No.

Name

Explanation

1

GND

GND-485

9

Z-

Encoder output Z-

2

A1

RS485+

10

B+

Encoder output B+

3

B1

RS485-

11

T-REF

Torque analog input

4

VCC

VCC-RS485

12

V-REF

Speed analog input

5

B-

Encoder output B-

13

GND

GND for analog input

6

A+

Encoder output A+

14

A2

RS485+

7

A-

Encoder output A-

15

B2

RS485-

8

Z+

Encoder output Z+

No.

Name

Explanation

No.

Name

Explanation

1

NC

Reserved

9

Z-

Encoder output Z-

2

NC

Reserved

10

B+

Encoder output B+

3

SI5

Input 5

11

T-REF

Torque analog input

4

SO3

Output 3

12

V-REF

Speed analog input

5

B-

Encoder output B-

13

GND

GND for analog input

6

A+

Encoder output A+

14

A

RS485+

7

A-

Encoder output A-

15

B

RS485-

8

Z+

Encoder output Z+

No.

Name

Explanation

No.

Name

Explanation

1

GND

GND-485

2

A1

RS485+

3

B1

RS485-

4

A2

RS485+

5

B2

RS485-

6

GND

GND-485

7

NC

Reserved

8

NC

Reserved

9

NC

Reserved

Drive

port

Motor encoder port

Name

Drive

port

Motor encoder port

Name

60, 80, 90

series

110, 130, 180

series

60, 80, 90

series

110, 130, 180

series

1 9 4

A+ 2 4

5

B+

3 7 6

Z+ 4 6

10

U+ 5 11

12

W+ 6 13

7

A- 7 14

8

B- 8 5

9

Z-

CN0 terminals

CN1 (DB15) terminals

DS3 series 750W and below servo drive (hardware version v3.1.20)

DS3 series above 750W servo drive

DS3 series 5.5KW and 7.5KW servo drive (only these two models use 9-pin port)

CN2 terminals

20

9 8 13

U-

10

15

15

W-

11 1 1

Connect

to shield

layer

12 3 3

GND

13 2 2

5V

14

10

11

V+

15

12

14

V-

(5-pin port)

Pin no.

Name

Explanation

1

TXD

RS232 send

2

RXD

RS232 receive

3

GND

RS232 ground

Parameter

Function

Default

setting

Range

Modify

Effective

P7-10

Modbus station no.

1

1~255

Servo OFF

At once

Parameter

no.

Function

Default

value

Range

Effective

time

n.xx□□

Baud rate

06

00~10

00:300

01:600

02:1200

03:2400

04:4800

05:9600

06:19200

07:38400

08:57600

09:115200

At once

1

5

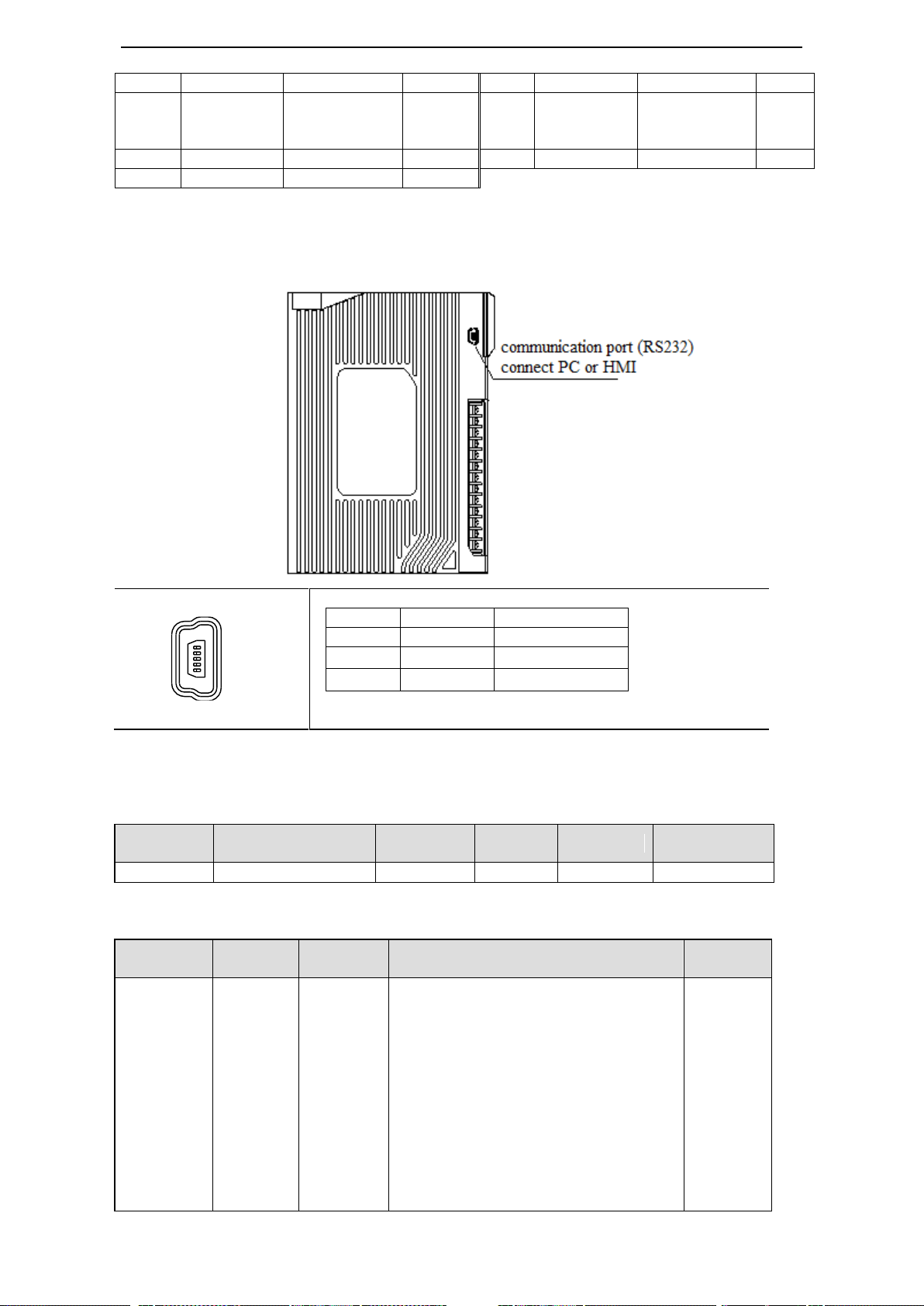

3-1-1-5. Communication port

RS-232 communication

Note: please use the cable supplied by XINJE Company

Communication parameters:

RS232 default communication parameters: baud rate 19200bps, data bit 8, stop bit 1, even parity.

Modbus station no. setting:

Please set the following parameters through P7-11:

21

0A:192000

0B:256000

0C:288000

0D:384000

0E:512000

0F:576000

10:768000

n.x□xx

Stop bit

2

0:2 bits, 2:1 bit

At once

n.□xxx

Parity bit

2

0~2

0:no parity, 1: odd parity, 2: even parity

At once

Note: data bit cannot be changed, it is 8 bits.

Pin no.

Name

CN1-14

A

CN1-15

B

Parameter

Function

Default value

Range

Effective time

P7-00

Modbus station no.

1

0~255

At once

Parameter

Function

Default value

Range

Effective

time

n.xx□□

Baud rate

06

00~10

00:300

01:600

02:1200

03:2400

04:4800

05:9600

06:19200

07:38400

08:57600

09:115200

0A:192000

0B:256000

0C:288000

0D:384000

0E:512000

0F:576000

10:768000

11:1M

12:2M

13:3M

14:4M

15:5M

At once

910

15 14 13

12

11

1

2

345

6

7

8

RS-485 port

Communication parameters:

RS485 default communication parameters: baud rate 19200bps, data bit 8, stop bit 1, even parity,

Modbus station no.1.

The Modbus station no. can be set through P7-00:

The communication parameters can be set through P7-01:

22

16:6M

n.x□xx

Stop bit

2

0:2 bits, 2:1 bit

At once

n.□xxx

Parity bit

2

0~2

0:no parity, 1: odd parity, 2: even

parity

At once

Note: data bit cannot be changed, it is 8 bits.

Parameter

Function

Default

setting

Range

Modify

Effective

P7-02

RS485

communication

protocol

1

1: Modbus Rtu protocol

2: Xnet filedbus protocol

Servo OFF

At once

Command

Choice

Meaning

P-input signal

D-input signal

Chapter

P0-10

xxx□

0

CW, CCW double pulse

mode

CW

CCW

5-3-2

1

AB phase mode

A phase

B phase

2

Pulse + direction mode

Pulse

Direction

Collector open circuit (24V) input positive signal: P+24V/D+24V

Differential mode (5V) input positive signal: P+5V/D+5V

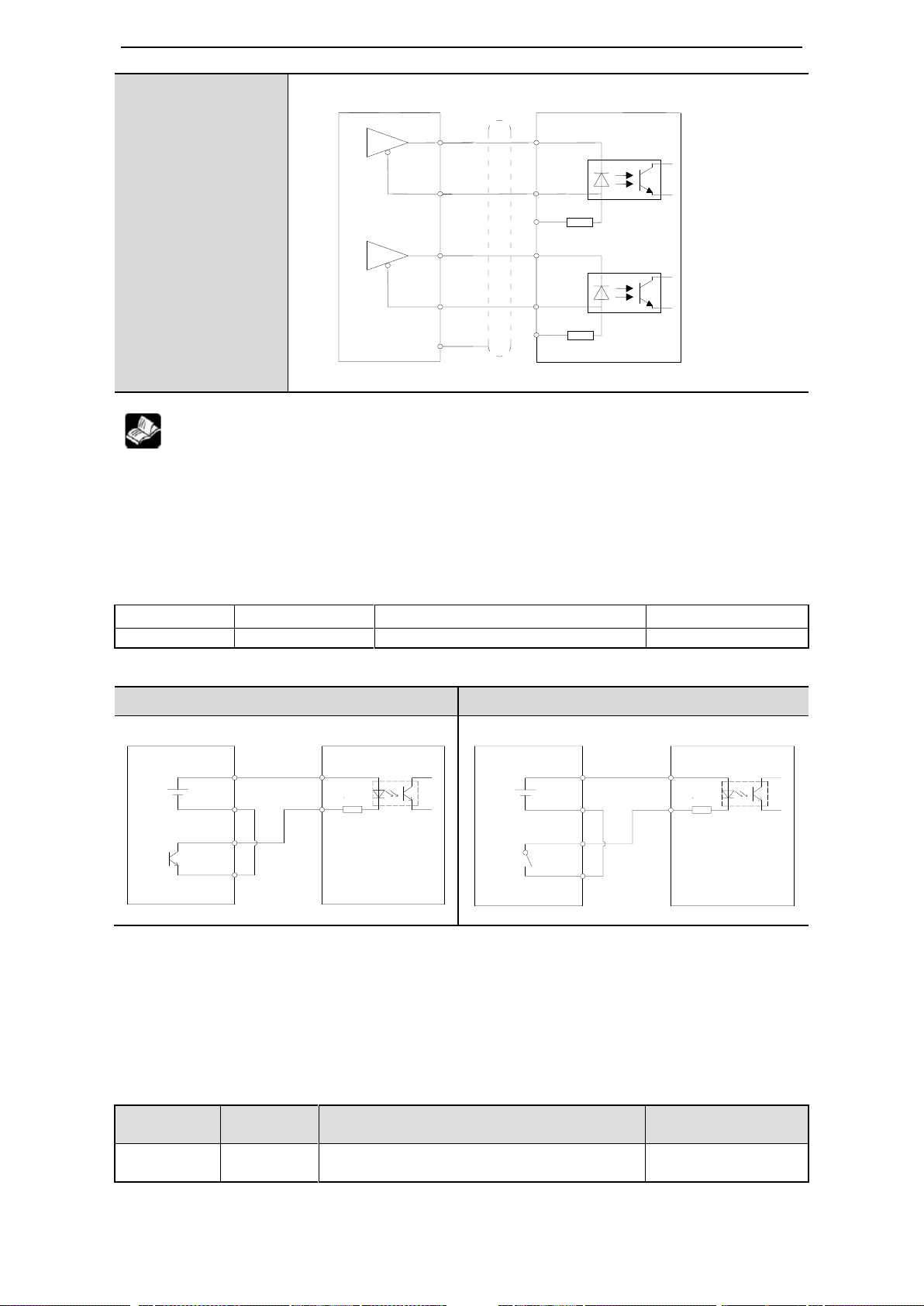

DS3-2□P□-PQA

DS3-4□P□-PQA

Open collector (24V)

PLC, SCM, etc servo drive

Note:

(1) P-/P+24V, D-/D+24V power supply range is 18~25V. if the voltage

is lower than 18V, the pulse and direction will be error.

(2) To avoid the interference, please use shielded twisted-pair cable.

DS3-2□P□-PQA

Differential mode (5V)

COM0

Y0

+24V

P-

R=3.3K

COM1

Y1

D-

R=3.3K

P+5V

D+5V

Shield layer

0V

D+24V

P+24V

When upper

device is open

collector output,

please use this

wiring diagram.

Please note:

P+5V and

D+5V must be

vacant.

P7-02 RS485 communication protocol setting:

1. Support standard Modbus RTU protocol, it is used as Modbus slave device.

2. RS232 port and RS485 port can be used at the same time.

3-1-2.Signal terminals

3-1-2-1. Pulse signal

The interface circuit of Pulse + direction and CW, CCW mode:

23

DS3-4□P□-PQA

PLC, SCM, etc servo drive

To avoid the interference, please use shielded twisted-pair cable.

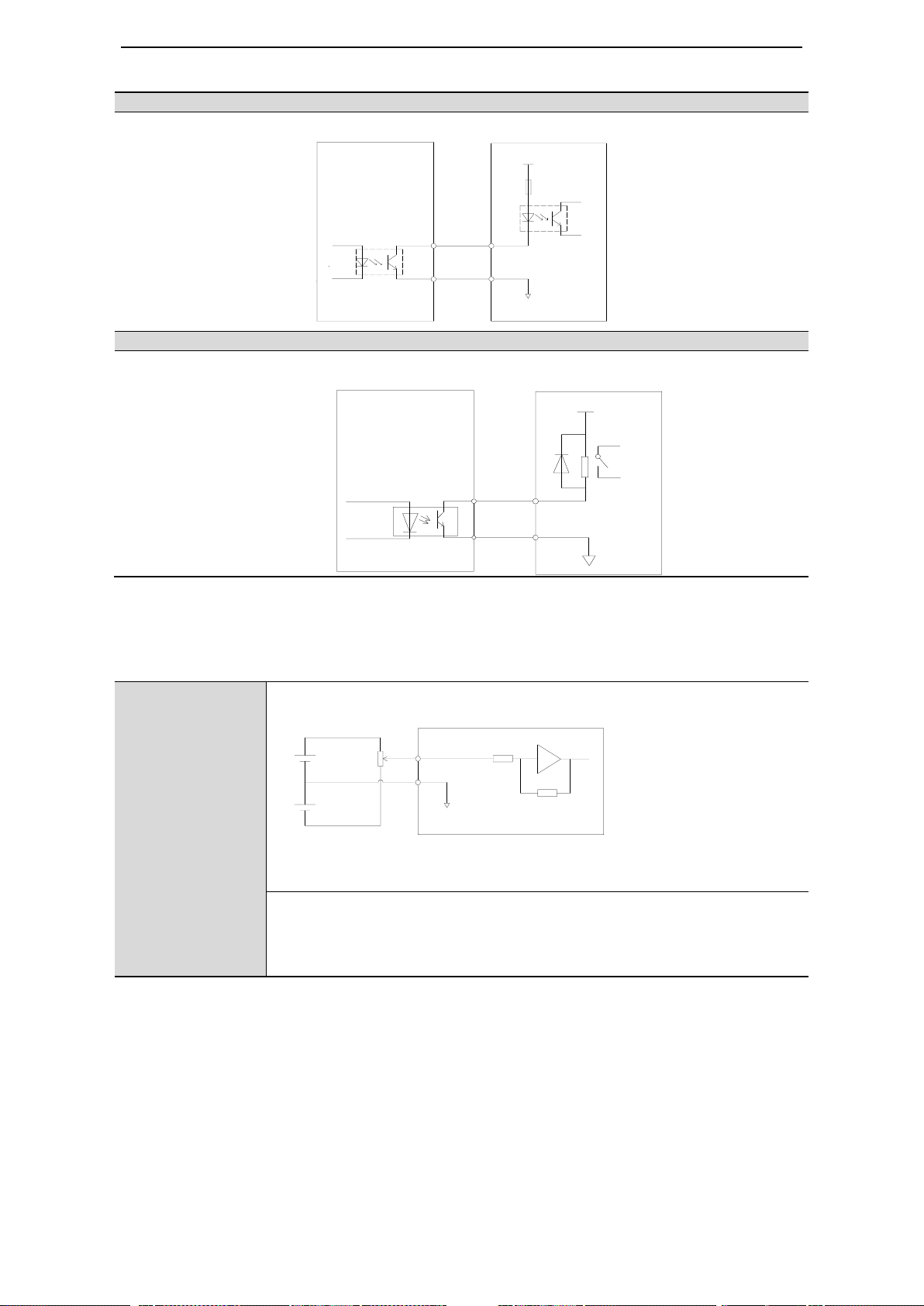

Type

Input terminal

Function

Reference chapter

Digital input

SI1~SI5

Multi-functional input

5-12-1

Open collector (24V power supply)

Relay (24V power supply)

Upper device servo drive

Upper device servo drive

Type

Output

terminal

Function

Reference chapter

Optocoupler

output

SO1~SO3

Multiple functions output terminal

5-12-3

SI

+24V

+

COM2

Y2

0V

+24V

R=2.2KΩ

R=2.2KΩ

+24V

0V

Y2

COM2

+

+24V

SI

P+24V

PUL+

PUL-

P-

R=3.3K

DIR-

D-

R=3.3K

P+5V

D+5V

Shield layer

0V

D+24V

DIR+

When upper

device is 5V

differential

output, please

use this wiring

diagram. Please

note: P+24V

and D+24V

must be vacant.

(1) Servo pulse input will be ON at 10mA.

(2) If the controller is XINJE PLC, pulse output rated current is 50mA, so 1 channel of pulse can

connect 5 servo drives. We suggest not over 3 servo drives.

3-1-2-2.SI input signal

Please use relay or open collector transistor to connect. When using relay, please choose micro-current

relay. Otherwise, the contact will be not good.

Note: the max allowable voltage and current of open collector output circuit:

Voltage: max DC30V

Current: max DC50mA

3-1-2-3. SO output signal

24

Optocoupler type

Servo drive upper device

Relay type

Servo drive upper device

DS3-2□P□-PQA

DS3-4□P□-PQA

Upper device servo drive

Note: analog terminal 11 (T-REF analog torque), 12(T-REF analog speed),

13(analog GND) come from CN1 DB15, refer to chapter 3-1-1-4.

Analog signal is speed command or torque command. Input impedance:

• speed command input: about 13KΩ

• torque command input: about 13KΩ

• max allowable voltage of input signal is ±10V

COM

SO

X3

COM

0V

+24V

+10V

-10V

11 T-REF

12 V-REF

13 GND

0V

R=13KΩ

2KΩ

1W

Note: max load current 400mA (if control the brake motor by SO signal, please confirm the

brake current, if it is larger than 400mA, please use intermediate relay)

3-1-2-4. Analog input circuit

25

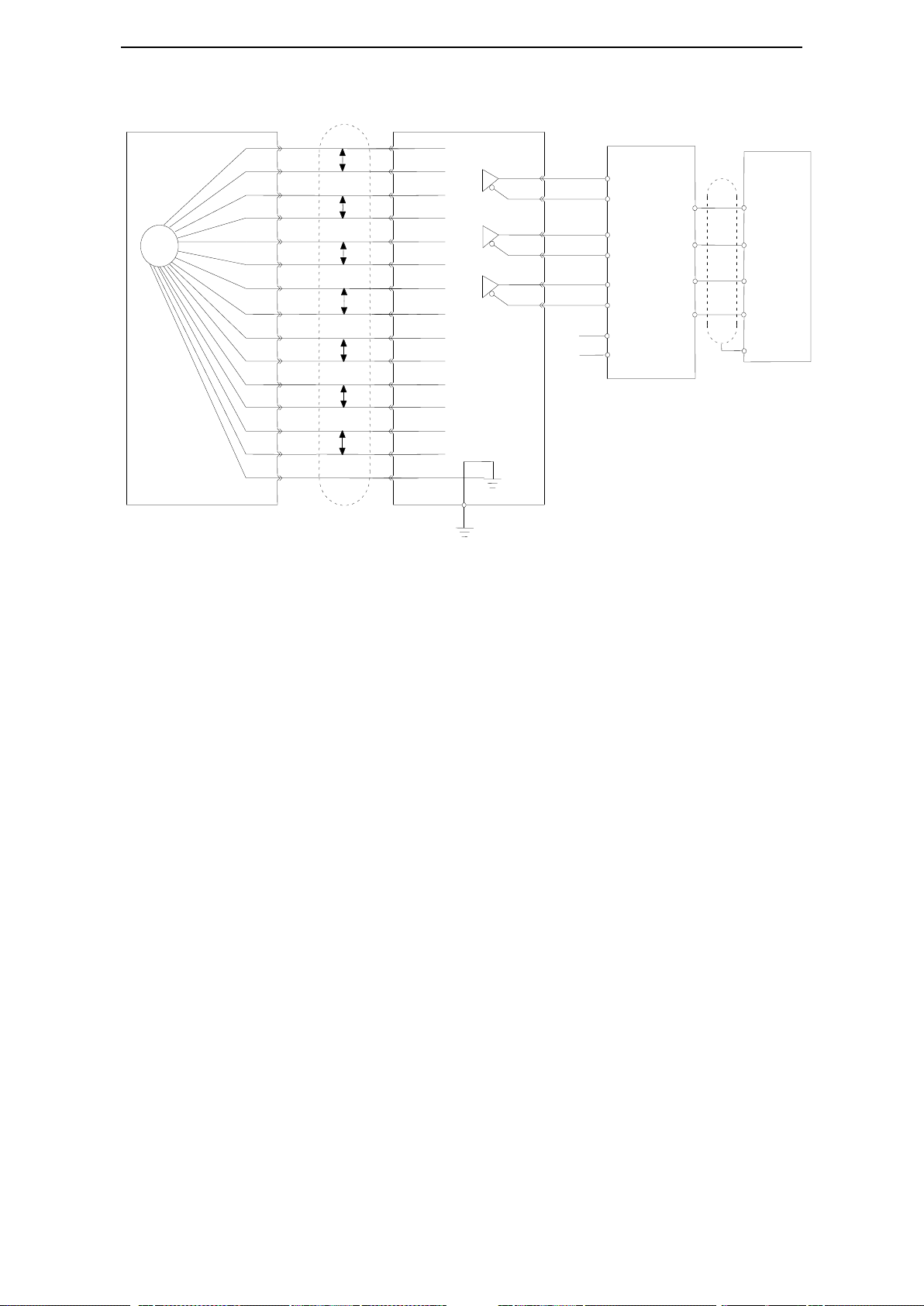

3-1-2-5. Encoder feedback signal

PG

A+

A-

B+

B-

Z+

Z-

U+

U-

V+

V-

W+

W-

+5V

GND

SHIELD

cover

A+

A-

B+

B-

Z+

Z-

U+

U-

V+

V-

W+

W-

+5V

GND

Connector cover

CN2

AO+

AO-

BO+

BO-

ZO+

ZO-

0V

24V

AO+

AO-

BO+

BO-

ZO+

ZO-

X0

X1

X2

COM

Incremental encoder

Upper device

0V

Shield cable

Shiled layer

COM

Z B A

Servo unit

Differential to collector

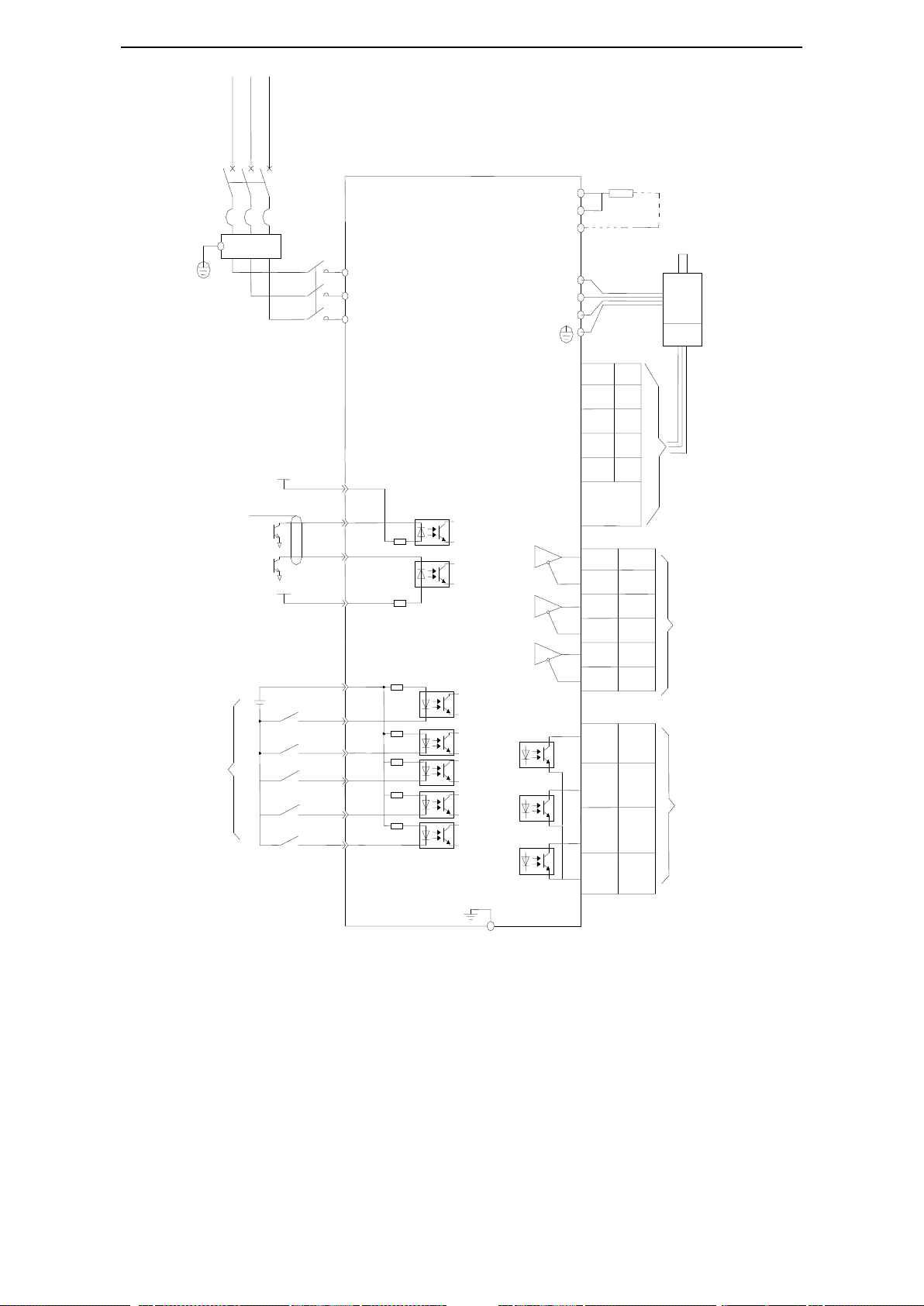

3-1-3. Standard wiring example

For the following wiring diagram, the input and output terminal function is out of factory settings. The

setting can be changed, please see chapter 5-12.

3-1-3-1.Position Control Mode

DS3-21P5-PQA

26

CN0-11

A0-

AO+

COM

Shield layer connect

0V at signal side

Be vacant at

Drive side

Vcc

CN0-1

2.2

Ω

W

V

DS3-21P5-PQA,DS3-22P3-PQA: 3-phase AC220V (50/60Hz)

DS3-4□P□-PQA: 3-phase AC380V (50/60Hz)

CN2

R

S-RDY

ALM

COIN

FIL

Self-define the

Terminals function

CN0-8

CN0-7

/S-ON

+24VIN

U

S

T

CN0-10

/N-OT

/ALM-RST

3.3KΩ

P+24V

CN0-3

Vcc

2.2

Ω

CN1-5

CN1-10

B0-

BO+

CN1-9

CN1-8

Z0-

ZO+

C

D

P+

Servo motor

Encoder

CN2-5

W+

CN2-4

CN2-3

U+

Z+

CN2-2

CN2-1

B+

A+

.

. . .

.

.

Differential encoder

feedback

Self-define

the terminals

function

D+24V

D-

P-

CN0-6

CN0-4

CN1-7

CN1-6

CN0-14

CN1-4

CN0-13

CN0-12

CN1-3

CN0-9

/P-OT

/SPD-A

Regenerative resistor

27

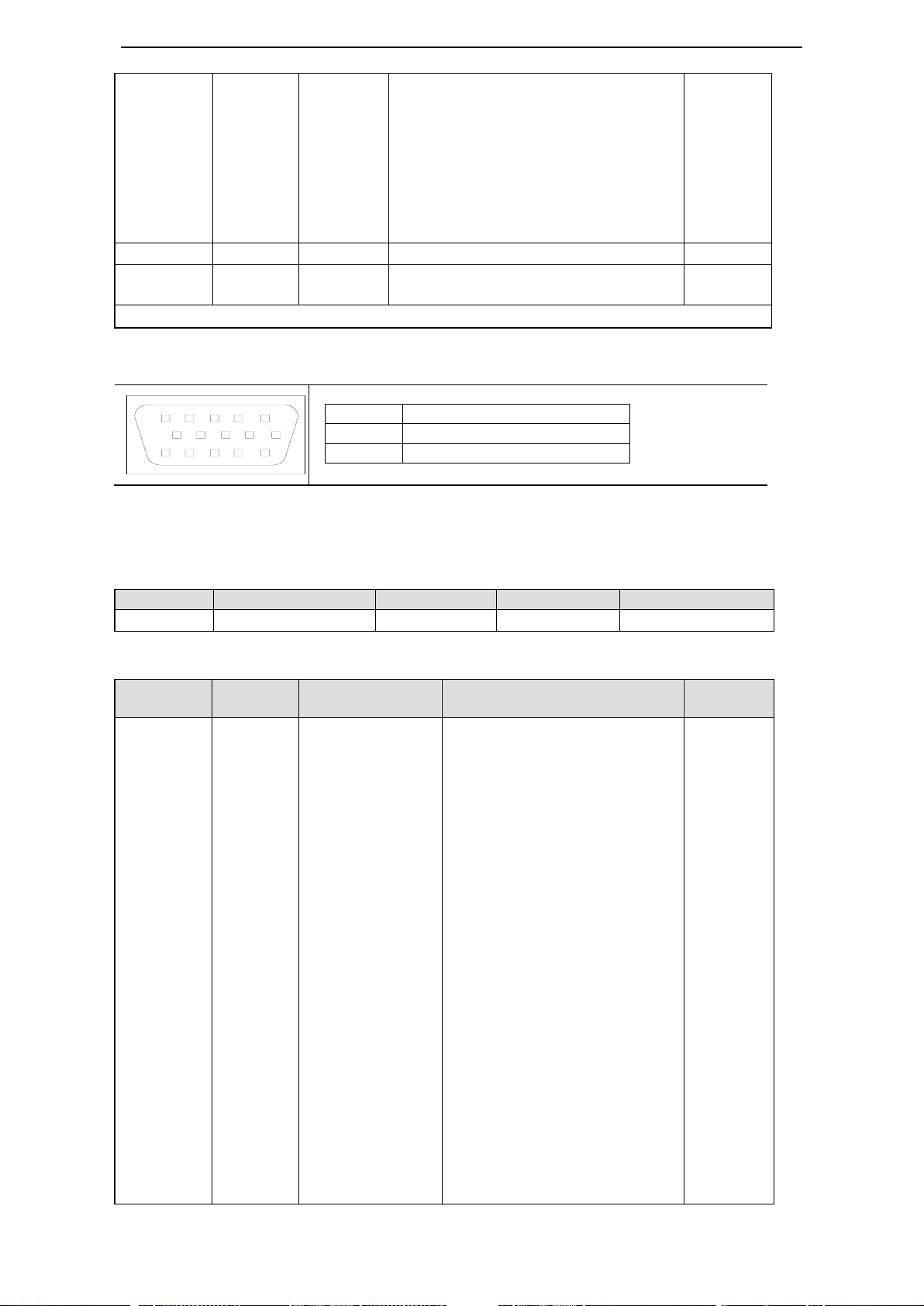

3-1-4.Regenerative Resistor

Servo drive

Regenerative resistor connection terminals

DS3-2□P□-PQA

DS3-4□P□-PQA

DS3E-2□P□-PFA

DS3E-4□P□-PFA

DS3L-2□P□-PFA

DS3L-4□P□-PFA

DS3-2□P□-PTA

DS3-4□P□-PTA

for internal regenerative resistor: short P+ and D, disconnect P+ and C,

P0-24=0.

for external regenerative resistor: connect resistor between P+ and C,

disconnect P+ and D, P0-24=1, P0-25=power value, P0-26=resistor value.

Parameter

Signal name

Setting

Meaning

Effective

Modify

P0-24

Choose

regenerative

resistor

0

Use internal regenerative resistor

At once

Servo OFF

1

Use external regenerative resistor

(resistor type please refer to the

following table)

Parameter

Signal name

Setting

Unit

Effective

P0-25

Discharge

resistor power

1. self-cooling mode (natural convection cooling):

below 20% of regenerative resistor capacity (W)

2. forced air cooling: below 50% of regenerative

resistor capacity (W)

W

At once

P0-26

Discharge

resistor value

Resistor value

Ω

At once

Servo drive

Min resistor

(cannot smaller than

this value)

External regenerative

resistor (recommend

value)

External regenerative

resistor (recommend

power)

DS3-20P2-PQA

DS3E-20P2-PFA

DS3L-20P2-PFA

DS3-20P2-PTA

50Ω

50Ω—100Ω

Above 200W

DS3-20P4-PQA

DS3E-20P4-PFA

DS3L-20P4-PFA

DS3-20P4-PTA

40Ω

40Ω—100Ω

Above 500W

DS3-20P7-PQA

DS3E-20P7-PFA

DS3L-20P7-PFA

DS3-20P7-PTA

40Ω

40Ω—100Ω

Above 500W

DS3-21P5-PQA

DS3E-21P5-PFA

DS3L-21P5-PFA

DS3-21P5-PTA

25Ω

25Ω—50Ω

Above 1000W

DS3-22P3-PQA

DS3E-22P3-PFA

DS3L-22P3-PFA

25Ω

25Ω—50Ω

Above 1000W

When the servo motor operates in generator mode, power is returned to the servo drive side. This is

called regenerative power. The regenerative power is absorbed by charging the smoothing capacitor,

but when the capacitor’s charging limit is exceeded, the regenerative power needs to be reduced by the

regenerative resistor.

The servomotor is driven in regeneration (generator) mode in the following conditions:

From decelerating to stop for acceleration/deceleration operation.

Move down on the vertical axis.

The external load drives the motor running

The type of regenerative resistor:

28

DS3-22P3-PTA

DS3-41P5-PQA

DS3E-41P5-PFA

DS3L-41P5-PFA

DS3-41P5-PTA

55Ω

55Ω—100Ω

Above 1000W

DS3-43P0-PQA

DS3E-43P0-PFA

DS3L-43P0-PFA

DS3-43P0-PTA

55Ω

55Ω—75Ω

Above 1000W

DS3-45P5-PQA

DS3L-45P5-PQA

25 Ω

25 Ω —65 Ω

Above 2000W

DS3-47P5-PQA

DS3L-47P5-PQA

25 Ω

25 Ω —50 Ω

Above 2000W

DS3-411P0-PQA

DS3-415P0-PQA

18 Ω

18 Ω —45 Ω

Above 3000W

1. The temperature will be very high when the regenerative resistor is discharging, please using

heat-resistant non-flammable wire. Don’t touch the regenerative resistor when wiring.

2. When you choose the regenerative resistor, please make the resistor value close to the min value of

recommend value. The resistor power is decided by the actual consition specially the heat.

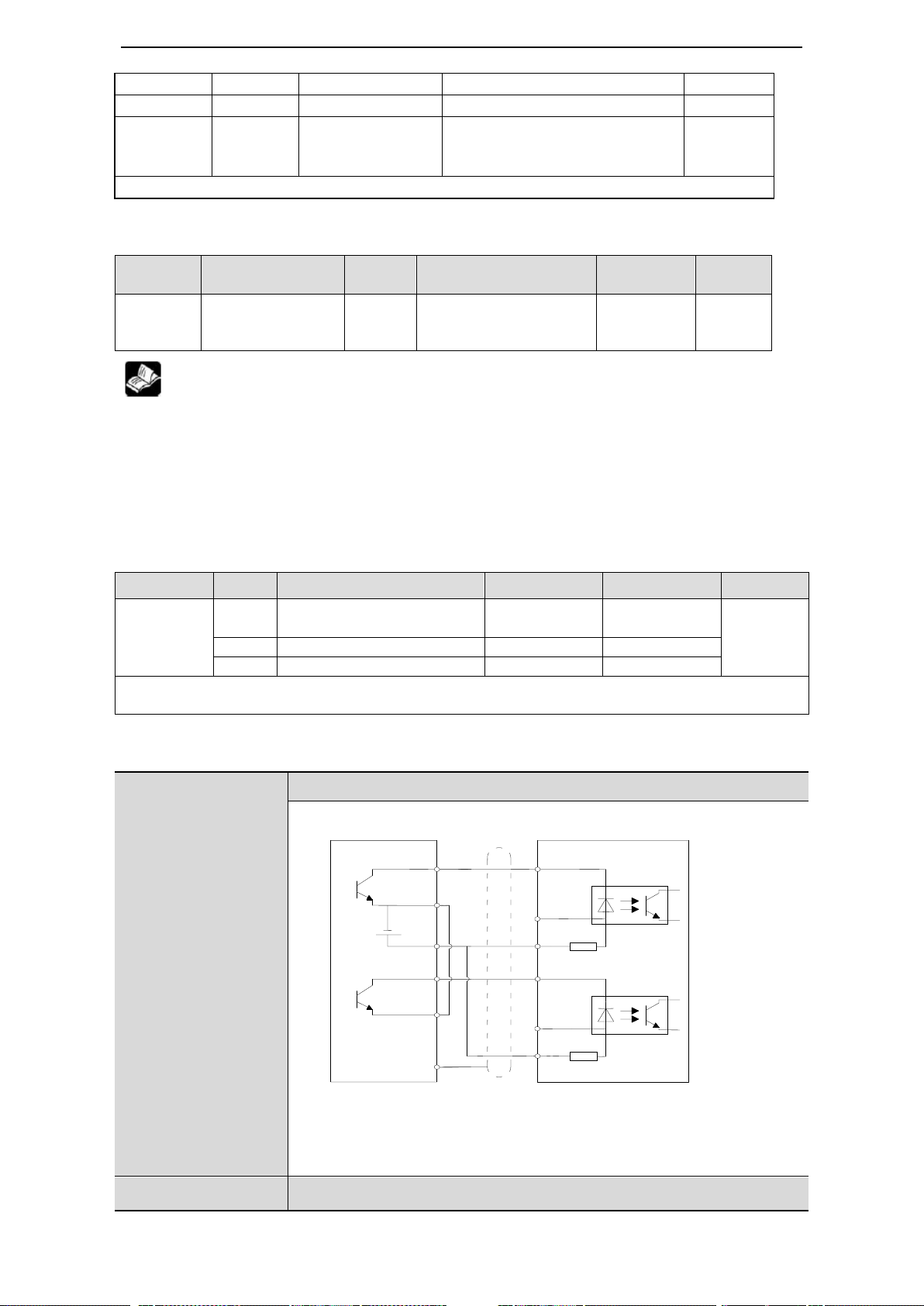

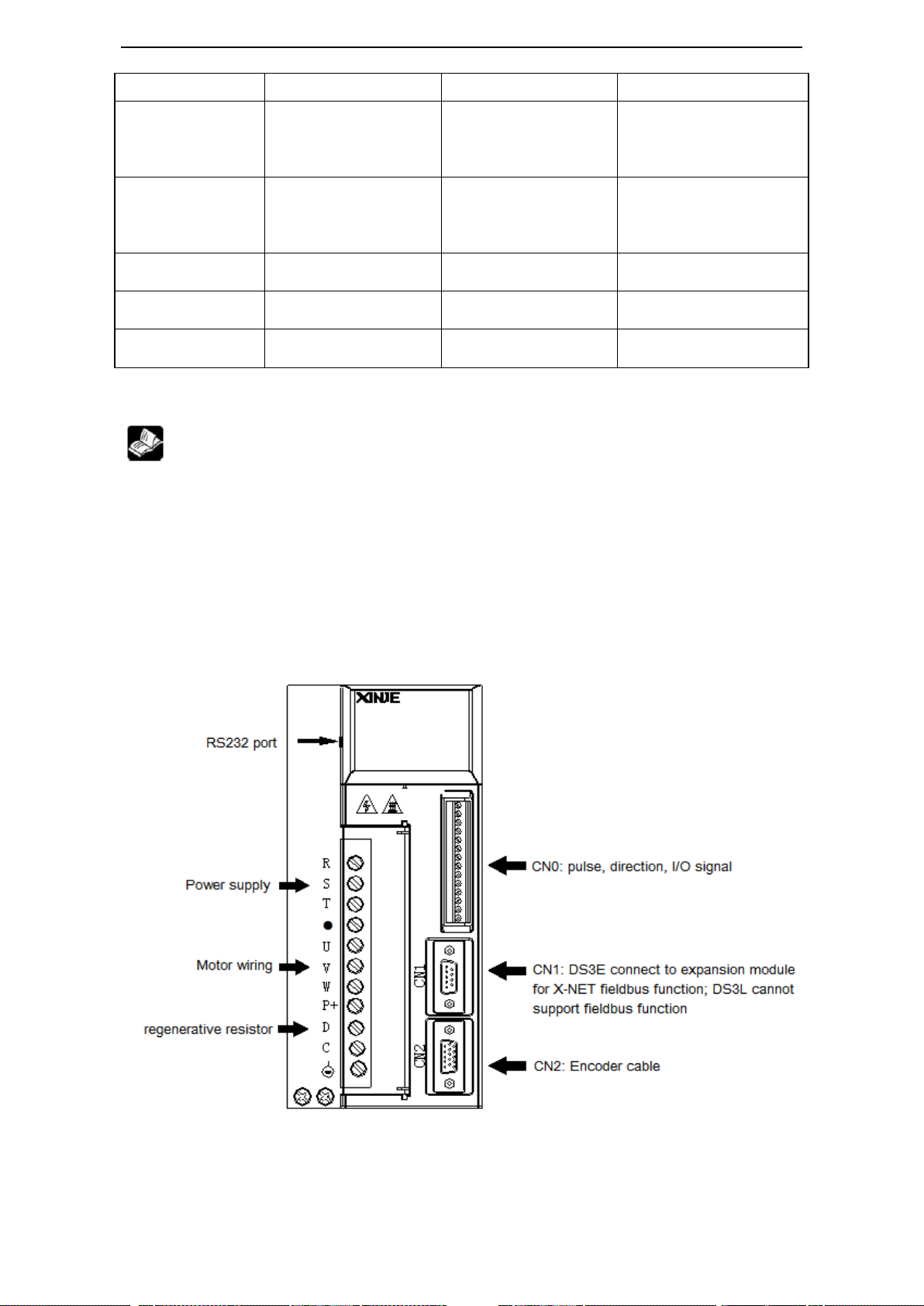

3-2. DS3E/DS3L-PFA

3-2-1. Main circuit wiring

3-2-1-1. The terminal arrangement

Loading...

Loading...